Metal solder-microwave welded and strip frame-edge-sealed convex low vacuum glass and manufacturing method thereof

A low-altitude glass and welding surface technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve the problems of hollow glass failure, slow cooling speed, long heating time, etc., to increase the contact area and reduce the tension. Stress, the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

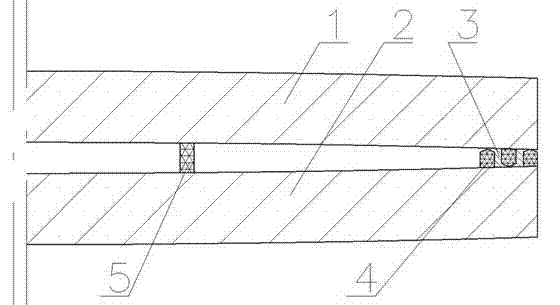

[0068] Embodiment 1: see figure 1 The low-altitude glass is composed of two pieces of glass, one of which is low-emissivity glass, and its production method is as follows: first, cut a piece of flat glass and a piece of low-emission glass of the required size according to the shape and size of the low-altitude glass to be produced, and perform edge grinding, After chamfering, film removal, cleaning and drying, the low-temperature glass powder paste is printed on the glass to form an edge banding frame by printing technology. The upper glass has one edge banding frame, and the lower glass has two edge banding frames. The size of the upper glass edge seal frame is between the lower glass edge seal frames. After the upper and lower glass are combined, the edge seal frame of the upper glass can be embedded between the edge seal frames of the lower glass; the upper and lower glass are dried Finally, print or spray commercially available silver paste on the position of the edge band...

Embodiment 2

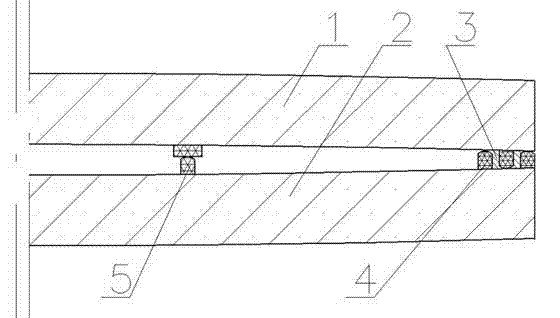

[0071] Example 2: see figure 2 , one of the two pieces of low-altitude glass is low-emissivity glass, and the other is tempered glass or semi-tempered glass. Radiation glass, after grinding, chamfering, removing film, after cleaning and drying, use a spray gun to spray low-temperature glass powder paste on two pieces of glass to make an edge banding frame, in which the upper glass has an edge banding frame, the lower glass There are two edge sealing frames, the size of the upper glass edge sealing frame is between the two edge sealing frames of the lower glass, after the upper and lower glass are combined, the edge sealing frame of the upper glass can be embedded Between two edge banding frames; after the upper and lower glass are dried, print or spray a layer of paste containing low-temperature glass powder on the position of the edge banding frame, and then print or spray a layer of commercially available silver paste as a transition layer Next, put the upper glass into th...

Embodiment 3

[0076] Embodiment 3: see image 3 , the two pieces of glass of the low-altitude glass are tempered glass or semi-tempered glass, one of which is low-emissivity glass, and its production method is as follows: first, a piece of flat glass and a piece of low-emissivity glass are cut according to the shape and size of the low-altitude glass to be produced. , carry out edge grinding, chamfering, film removal, after cleaning and drying, use nylon screen to print low-temperature glass powder paste on two pieces of glass to form an edge banding frame, in which the upper glass has an edge banding frame and the lower glass There are two edge sealing frames, the size of the upper glass edge sealing frame is between the two edge sealing frames of the lower glass, after the upper and lower glass are combined, the edge sealing frame of the upper glass can be embedded Between two edge banding strip frames; secondly, put two pieces of glass into two forming molds respectively, the forming mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com