Mending method and production method of colorful filtering substrate

A technology of color filter substrate and manufacturing method, which is applied in the field of repair, can solve problems such as increased production costs, failure to ship, scrapped glass substrates, etc., and achieve the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

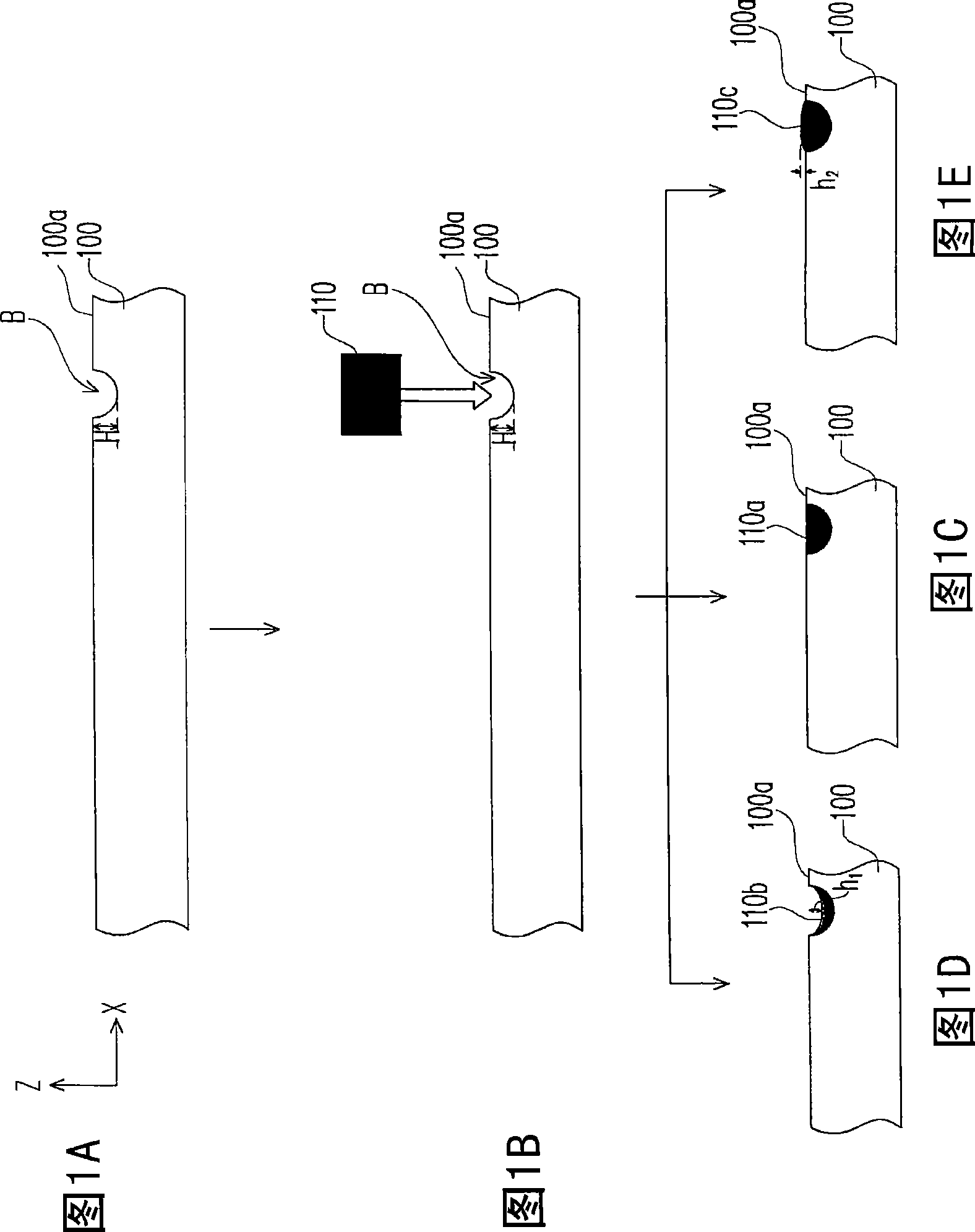

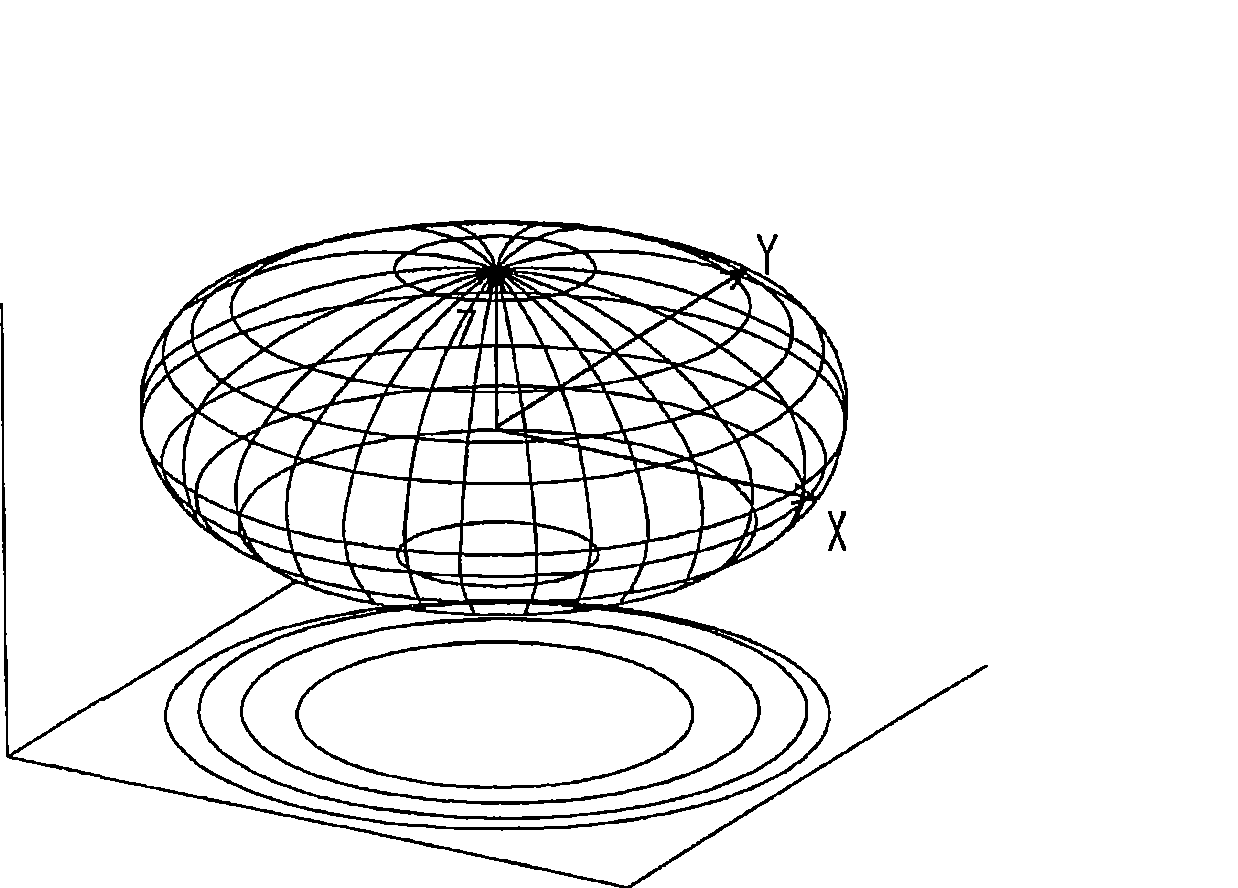

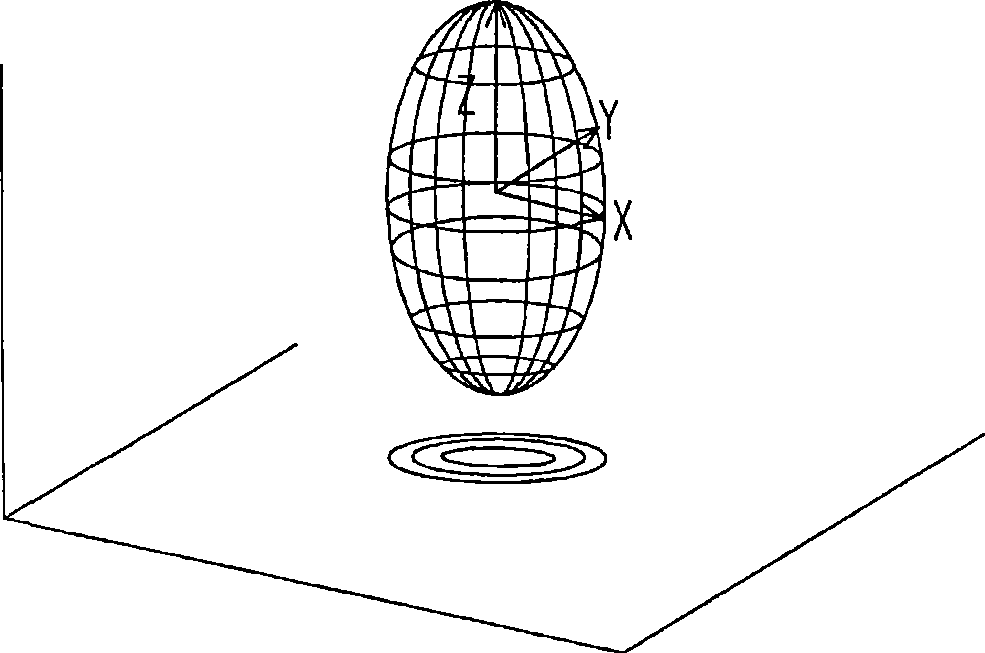

[0033] 1A to 1E are schematic flow charts of the repair method of the first embodiment of the present invention, and Figure 2A ~ Figure 2B It is a schematic side view of an ellipsoid in this embodiment. First, please refer to FIG. 1A , the repairing method of this embodiment is suitable for repairing the bubble defect B on the surface 100 a of the glass substrate 100 . Before repairing, firstly, it is necessary to estimate the depth H of the depression caused by the bubble defect B on the surface 100 a of the glass substrate 100 . In the present invention, there are many ways to calculate the depth H of the depression. In this embodiment, since the bubble defect B can be approximately a semi-ellipsoid depression, as shown in FIG. 1A, the present embodiment The sag depth H caused by the bubble defect B can be calculated by using the ellipsoid equation. The following will match Figure 2A and Figure 2B The method of estimating the depth H of the dent will be described.

[...

no. 2 example

[0040] Figure 3A ~ Figure 3E It is a schematic diagram of the manufacturing method of the color filter substrate according to the second embodiment of the present invention. Please refer to Figure 3A Firstly, a glass substrate 300 is provided, and it is determined whether there is a bubble defect B on a surface 300 a of the glass substrate 300 .

[0041] Next, before repairing, it is necessary to estimate the depth H of the depression caused by the bubble defect B. In the present invention, there are many ways to calculate the depth H of the depression. In this embodiment, since the bubble defect B can be roughly a semi-ellipsoid depression, the present embodiment can use the ellipsoid equation to calculate the result of the bubble defect B. The depth H of the depression. The following will match Figure 2A and Figure 2B The method of estimating the depth H of the dent will be described.

[0042] Please refer to Figure 3A and Figure 2A ~ Figure 2B , similar to the ...

no. 3 example

[0049] Figure 4A ~ Figure 4D It is a schematic diagram of the manufacturing method of the color filter substrate according to the third embodiment of the present invention. Please refer to Figure 4A Firstly, a glass substrate 400 is provided, and a color filter layer 420 is formed on the glass substrate 400 . In detail, the color filter layer 420 may include a red filter film 420a, a green filter film 420b, and a blue filter film 420c. In this embodiment, the color filter layer 420 may further include a black matrix 420d.

[0050] After that, it is determined whether there is a depression C caused by a bubble defect B on a surface 400 a of the glass substrate 400 in the color filter layer 420 . In detail, in this embodiment, the depression C caused by the bubble defect B is located on the glass substrate 400 corresponding to the red filter film 420a, as shown in Figure 4A shown.

[0051] Next, please refer to Figure 4B , removing part of the color filter layer 420 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com