Manufacturing process of automobile half shaft

An automobile half shaft and manufacturing process technology, which is applied in the field of shaft parts manufacturing process, can solve the problems of workpiece length, large volume, large volume of half shaft blank, easy deviation handling process, etc., achieves accurate precision, solves position deviation, The effect of improving production efficiency and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] A manufacturing process for automobile half shafts, which is characterized in that it comprises the following steps:

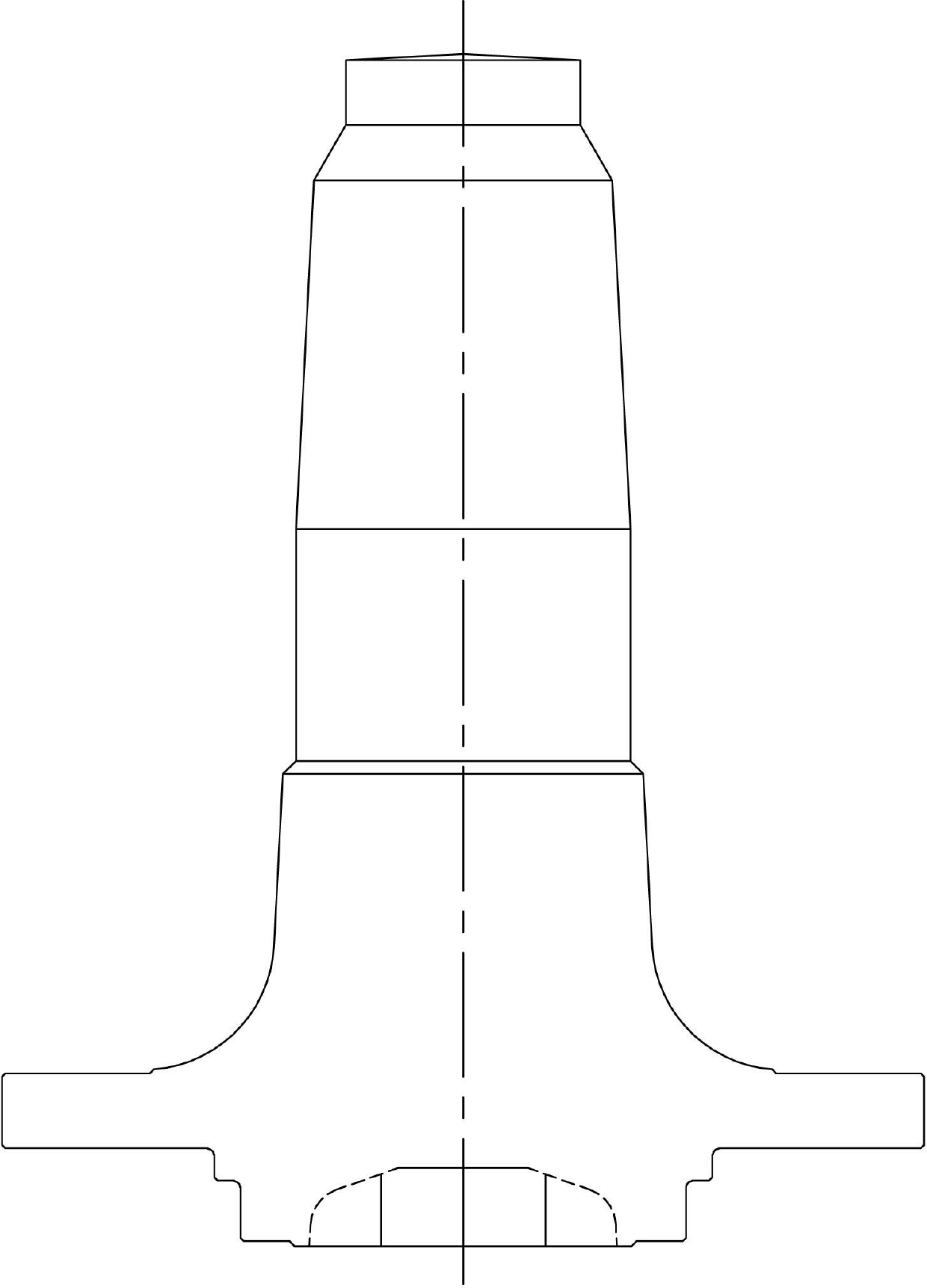

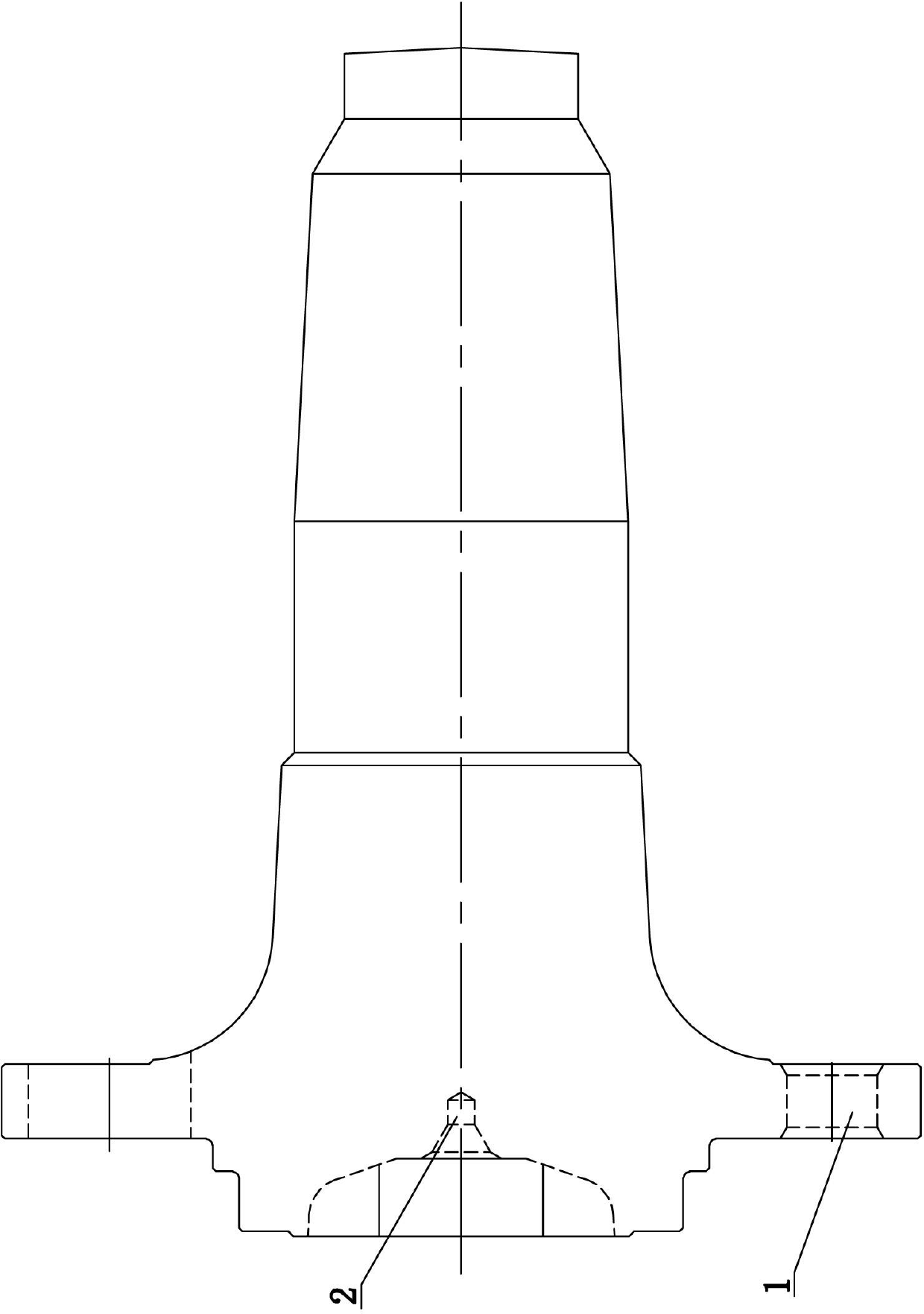

[0019] (1) Raw material: cut a certain length of steel rod with the same thickness as the half shaft as the raw material for the half shaft (such as figure 1 Shown); select flange blanks as the raw material of the flange (such as figure 2 Shown);

[0020] (2) Flange finishing: turning the flange blank, processing the positioning reference surface and clamping position required for precision drilling of the flange surface, and then drilling 1, chamfering and drilling center hole 2 (such as image 3 Shown);

[0021] (3) Friction crimping: the finished flange and the semi-shaft raw materials are crimped into the whole automobile semi-shaft (such as Figure 4 Shown);

[0022] (4) Half-shaft processing: Turn the whole half-shaft, rub the spline, heat it to 750-890℃ by the intermediate frequency equipment, and then spray water to cool it to reach the required hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com