Planar toughened vacuum glass welded by using glass solder with edges being sealed by strip borders and groove

A technology of vacuum glass and glass solder, applied in glass forming, glass re-forming, glass production and other directions, can solve the problems of unbearable, difficult and difficult automatic production for users, to eliminate the influence of flatness and improve qualified efficiency and longevity, good thermal and sound insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

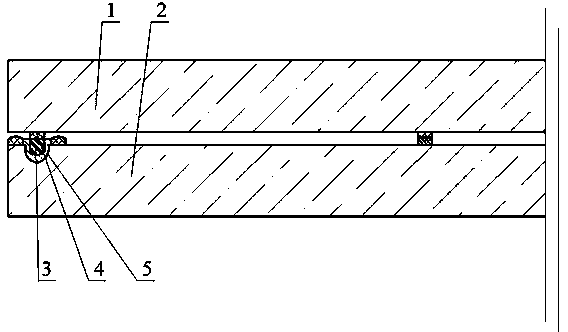

[0042] Embodiment 1: see figure 1 , Tempered vacuum glass is composed of two pieces of tempered glass or semi-tempered glass, one of which is low-emissivity glass, and its production method is as follows: First, cut a flat glass and a piece of low-emission For glass, edge sealing grooves are set at the peripheral welding of the lower glass, and edge grinding, chamfering, and film removal are performed. After cleaning and drying, tempered glass ink is used to make edge sealing strips on the two pieces of glass by screen printing, of which There is one edge banding frame for the upper glass, and two edge banding frames for the lower glass. The size of the edge banding frame of the upper glass is between the two edge banding frames of the lower glass. The side strip frame can be fitted in the edge sealing groove between the two edge strip frames of the lower glass; secondly, the two pieces of glass are sent into the tempering furnace and tempered under the same conditions, and th...

Embodiment 2

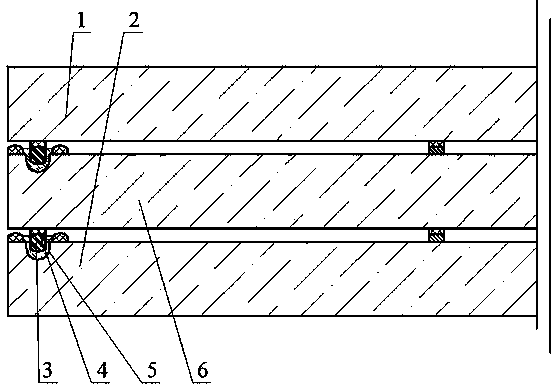

[0043] Example 2: see figure 2 , the upper and lower glass of the double vacuum layer tempered vacuum glass is tempered glass or semi-tempered glass, and the middle glass is low-emissivity glass. The production method is as follows: first cut two pieces of flat glass of the required size according to the shape and size of the vacuum glass to be produced and For a piece of low-emissivity glass, set up edge sealing grooves at the upper surface of the middle glass and the lower glass, and perform edge grinding, chamfering, and film removal. After cleaning and drying, use printing technology to print The tempered glass ink is printed into the edge banding frame, and the support is printed on the upper and lower glass at the same time. The upper glass has an edge banding frame, and the upper surface of the middle glass has two edge banding bars. The lower surface of the frame has an edge banding strip The frame and the lower glass have two edge-seal frames, the size of the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com