Double-machine double-layer continuous slip-form concrete paving construction application

A slip-form paver and concrete technology, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of insufficient filling, affecting the flatness of the paving forming surface, and poor flatness of cement concrete pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

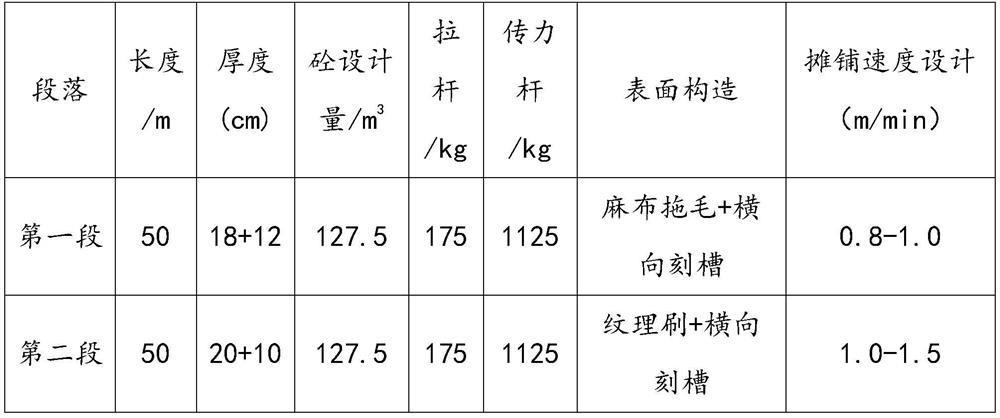

Embodiment 1

[0023] 1. Preparation

[0024] 2 sets of slip-form paver: Gaomaco 4000 and Gaomaco 2800, 1 excavator, 5 transport vehicles, 1 water truck, 1 core pulling machine, 1 three-meter ruler, slump detection 1 bucket, a batch of aluminum alloy, 1 set of measuring instruments, 80 meters of single-side line piles, 1 set of engraving machines, several brushes, 10m templates, and 1 mop. The main equipment is provided by the company, and other small items required for cooperation The machines and tools are brought by the labor coordinating workers.

[0025] Materials: gravel, sand, cement, water reducing agent, water, tie rod steel bar, dowel bar steel bar, health-preserving agent, retarder, geotextile, cloth-pressing sandbag, etc.

[0026] Ordinary portland cement is used for the cement, the steel bar of the tie rod is Φ16mm, the length is 80cm, and the spacing is 50cm.

[0027] Site preparation: The underlayment of the test pavement section is asphalt concrete, which is similar in stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com