Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Easy to uncover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

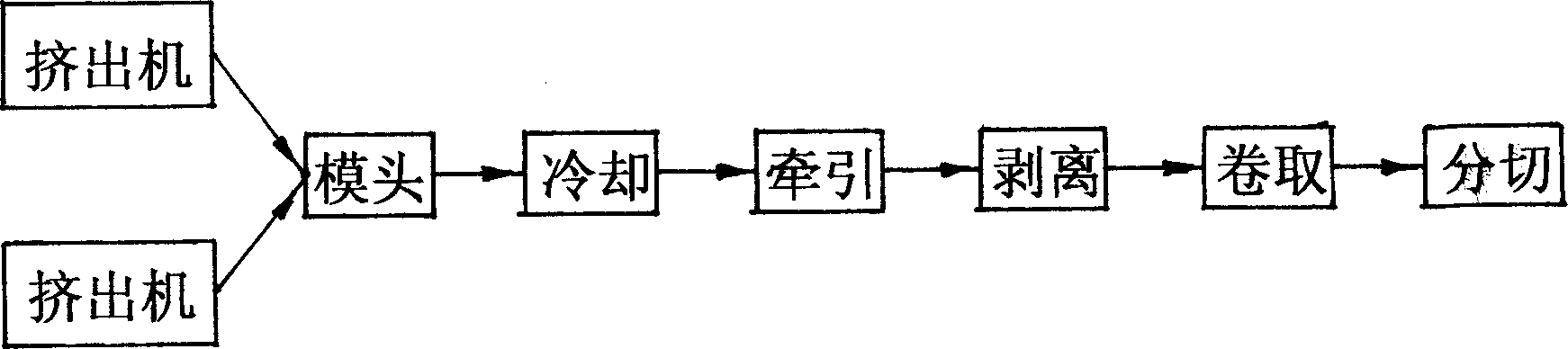

Method for preparing new protective film without incohesion

A non-adhesive protecting film for stainless steel, plastics, etc is prepared from high-pressure polyethylene LDPE, linear high-pressure polyethylene LLDPE, and self-adhesive high-molecular polymer PIB, EVA, or MLLDPE through mixing, coextruding out, blowing film cooling, drawing, stripping, winding and cutting. Its advantages are no volatile solvent, easy sticking and tearing off, and no residual on the protected surface.

Owner:HONGDA XINGYE CO LTD

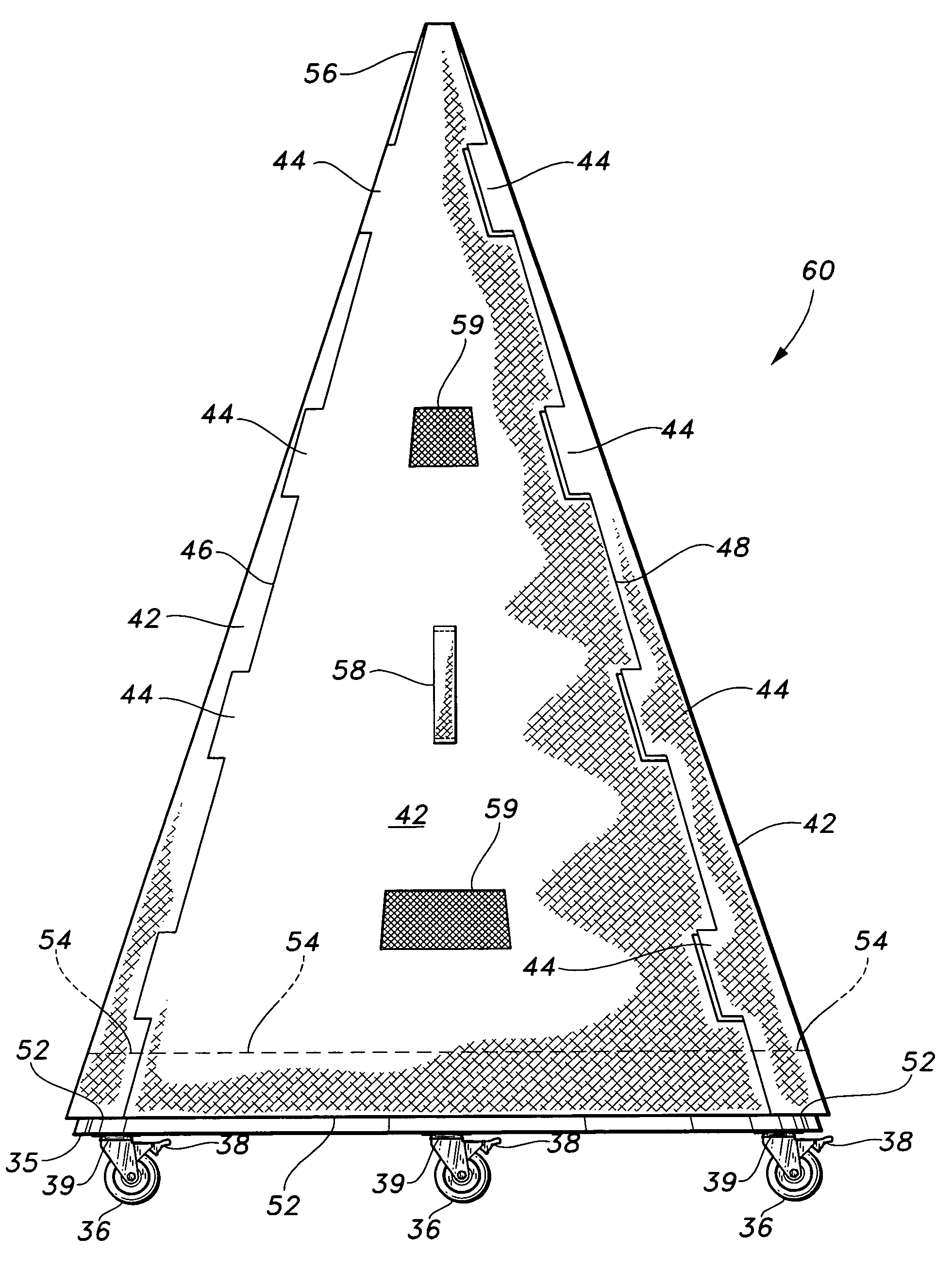

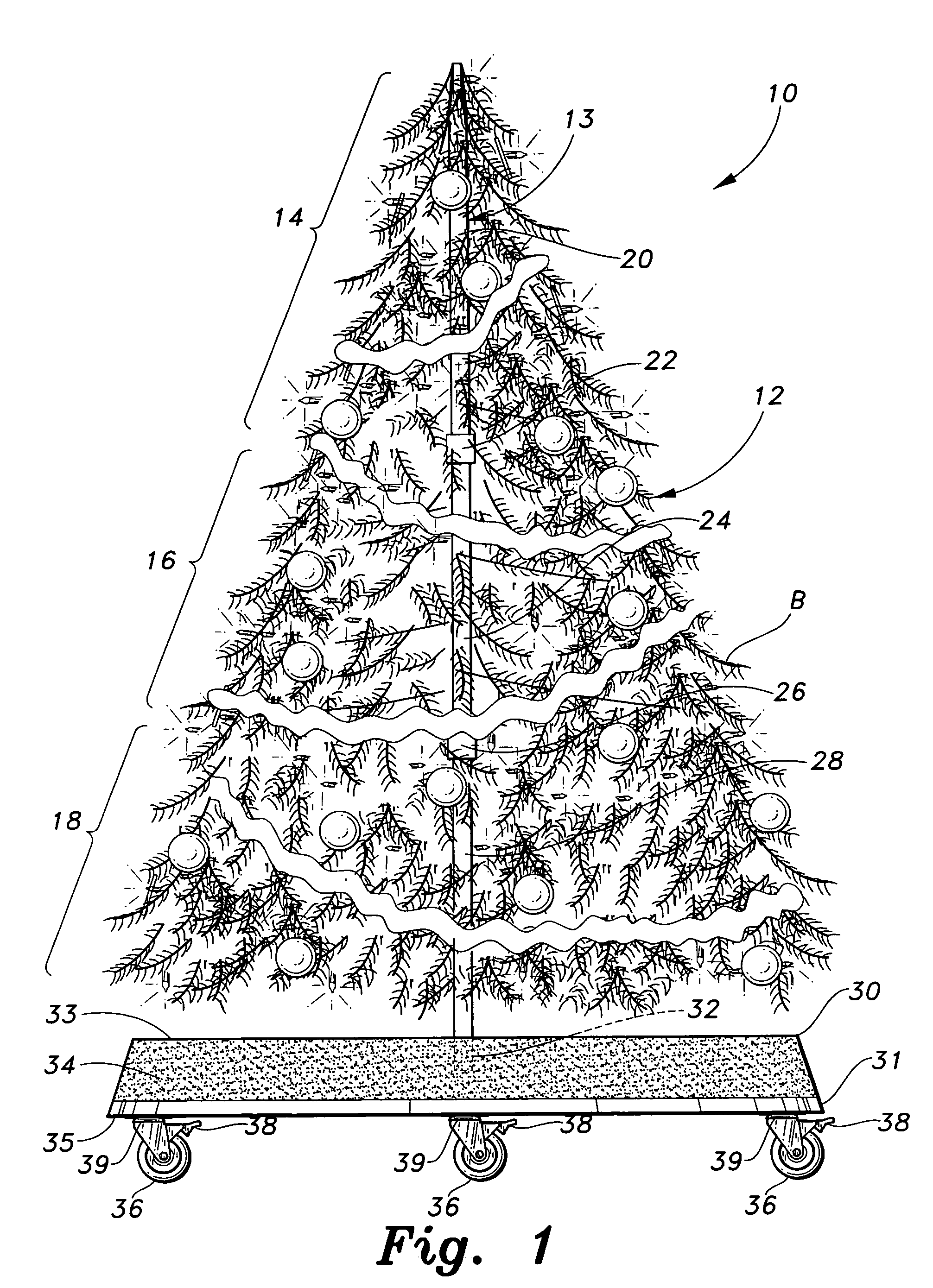

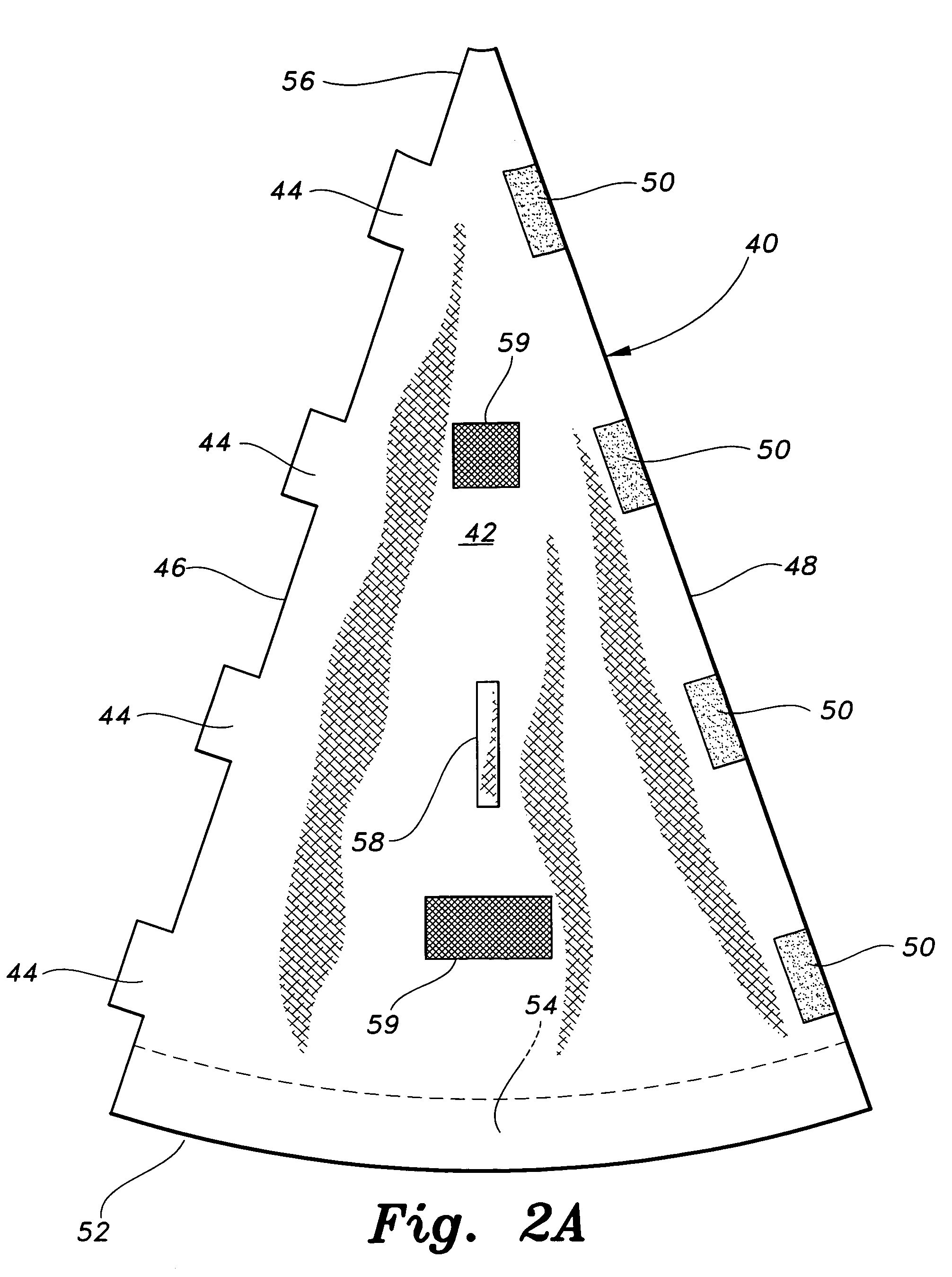

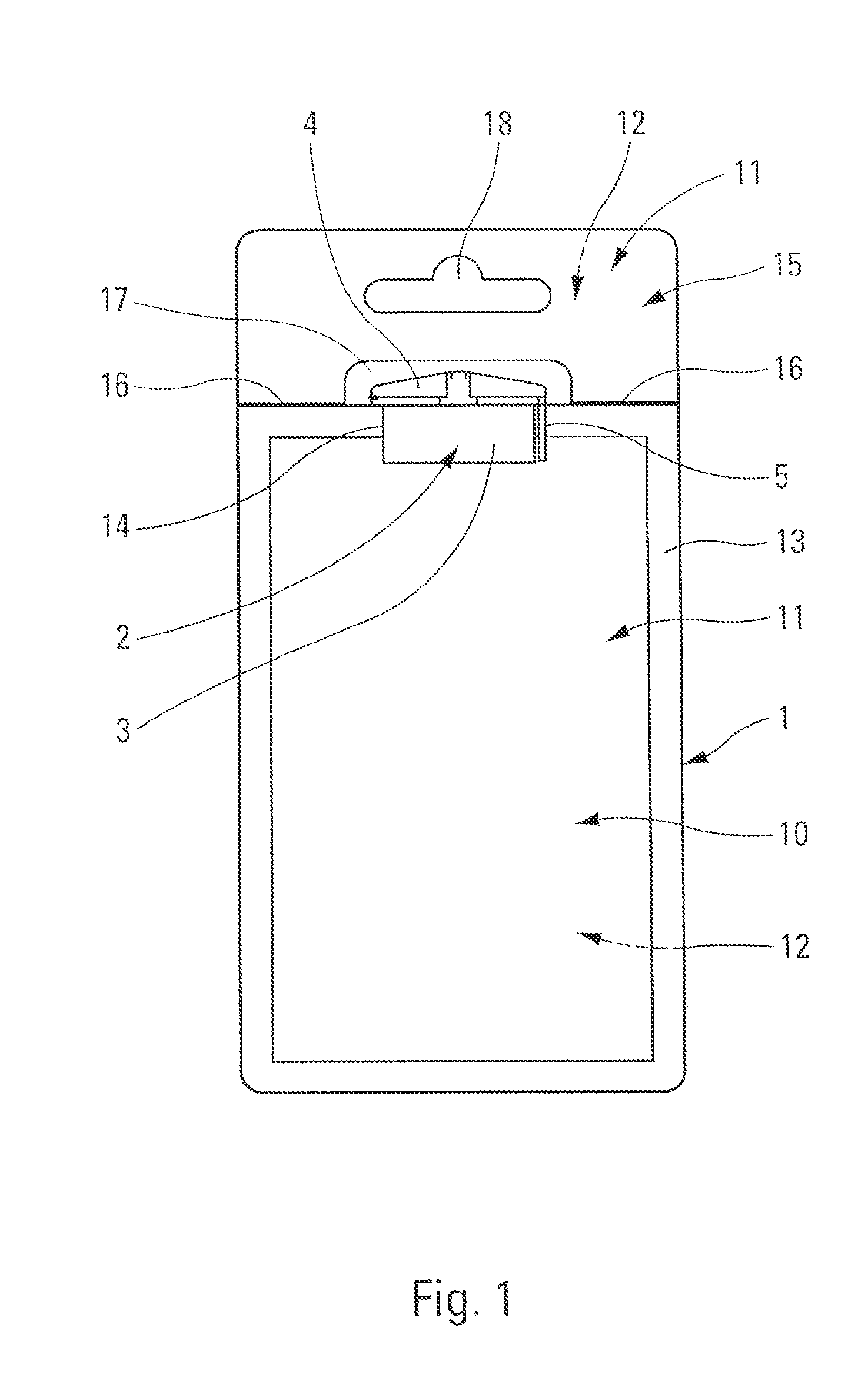

Artificial Christmas tree and cover system

InactiveUS7160588B2Easy to uncoverTravelling carriersLiving organism packagingTree trunkVertical edge

An artificial Christmas tree and storage cover a trunk and progressively larger branches from the top to near the base of the tree. The tree trunk rests in a central bore of a frustoconical base and has at least three swivel castor wheels mounted on the lower wall, providing movable support for the tree assembly. At least one castor wheel has a foot-operated brake. A conical cover covers the standing, decorated tree and attaches to the base. The cover has flaps spaced along one vertical edge of the cover and receiving mating patches spaced along an opposite edge the flaps and mating patches having VELCRO, hook and loop material on the mating surfaces thereof. The cover has three triangular portions each having mating flaps and patches in turn. The base and the lower end of the cover have mating strips of hook and loop material.

Owner:SANFORD JUDITH L +1

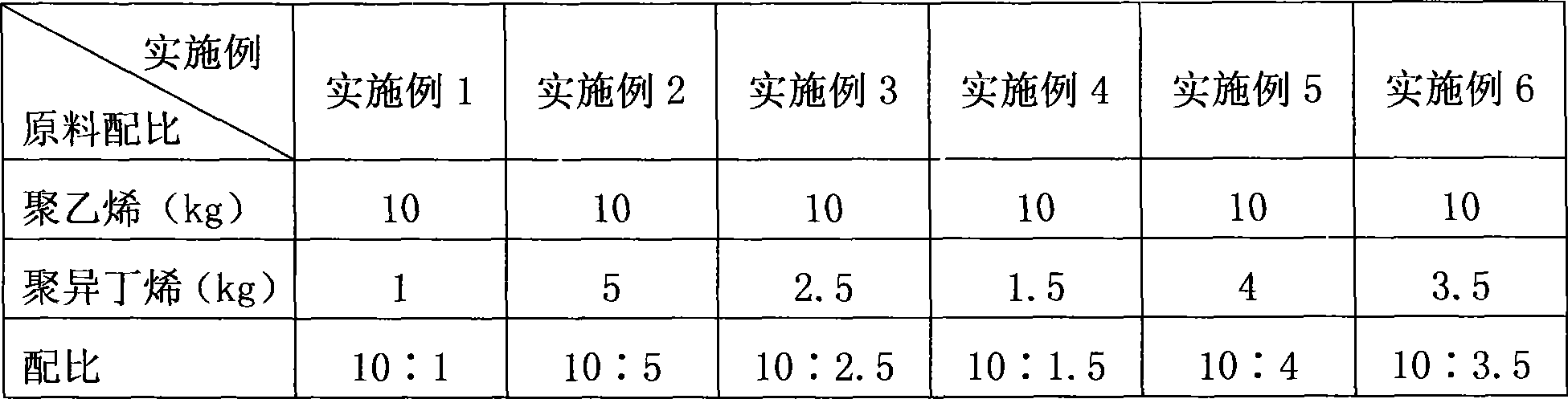

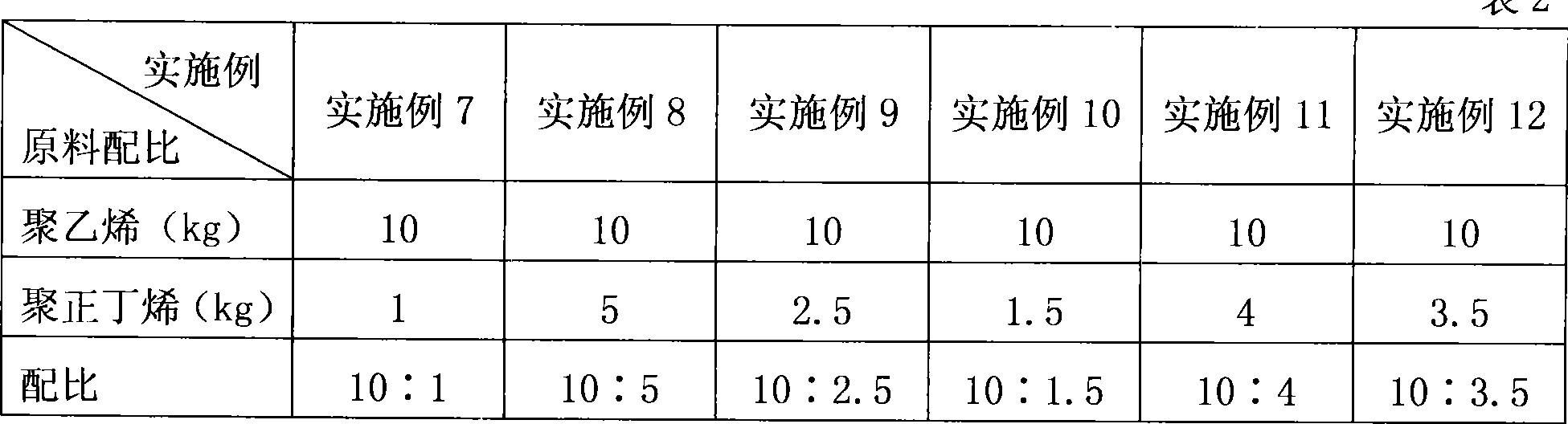

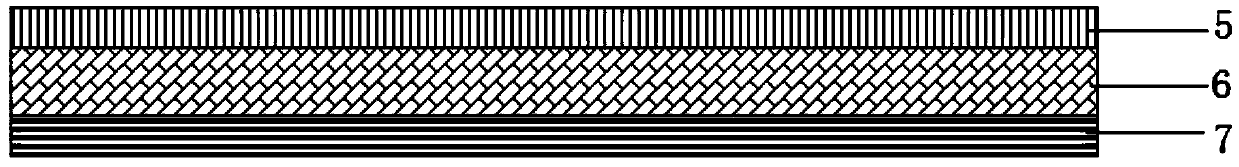

Modified polyethylene and easy-to-uncover suppositorium packaging film

ActiveCN101463157AGood barrier propertiesGood processing performanceFlexible coversWrappersChemistrySuppository

The invention discloses modified polyethylene and an easy removing suppository packaging film. The raw materials of the modified polyethylene comprise according to the parts by weight: 100 parts of polyethylene and 5-40 parts of polybutene or modified polybutene. The easy removing suppository packaging film comprises a barrier layer and a heat-sealing layer. The barrier layer is an aluminum foil layer and a polyvinyl chloride layer. The barrier layer and a heat-sealing layer are compounded together by a gluing mode. The heat-sealing layer is composite layer structure and sequentially one to two-layer polyethylene layer and one-layer modified polyethylene layer along the direction far away the barrier layer. Raw materials used by the modified polyethylene layer are 100 parts of polyethylene, and 5-40 parts of polybutene or modified polybutene according to the parts by weight. The heat-sealing layer has good easy removing performance after lap piling and heat-sealing.

Owner:ZHEJIANG GOLDSTONE PACKING

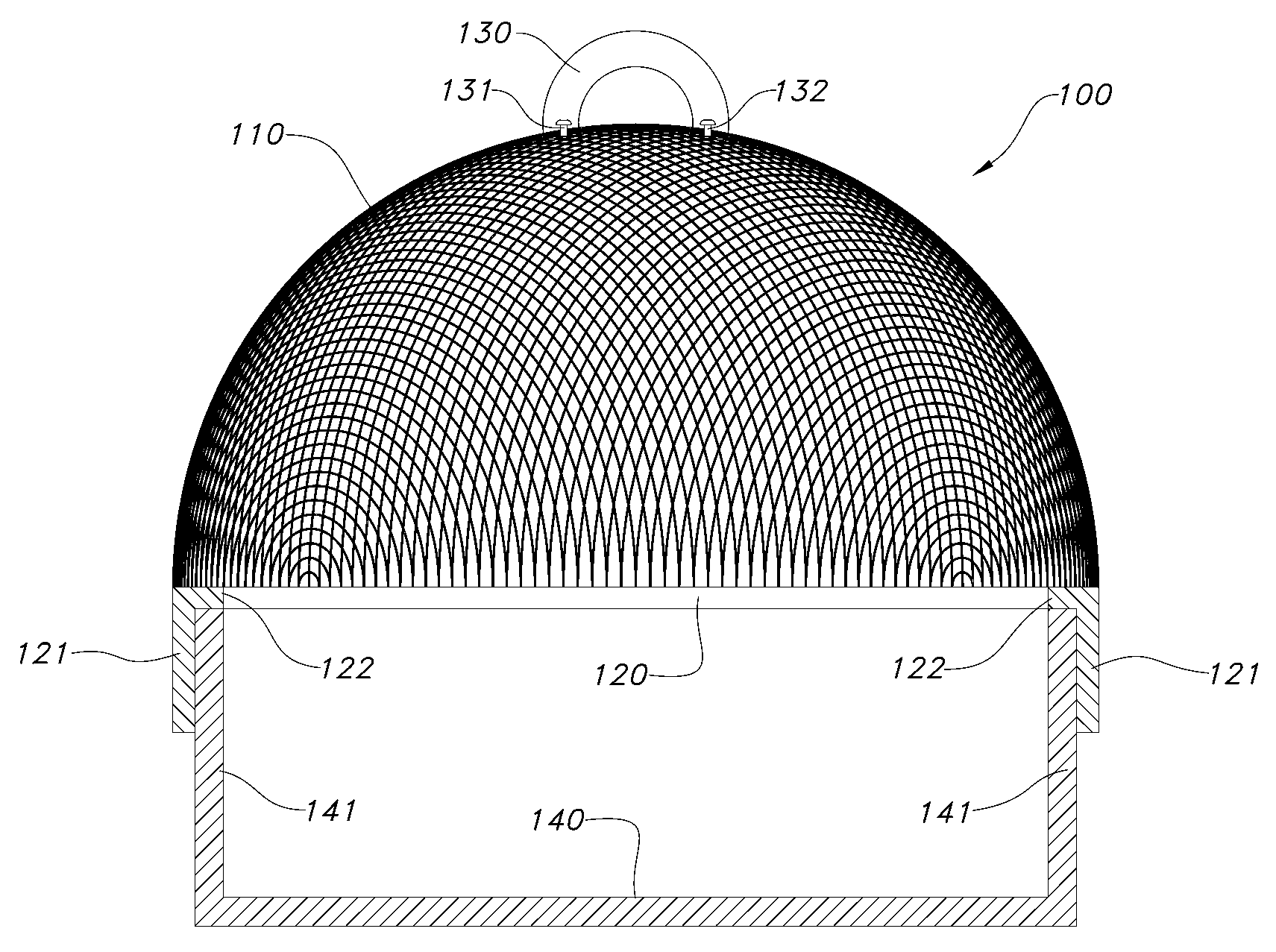

Domed splatter screen with a fitted rim

InactiveUS20080296303A1Easy to uncoverPrevent lateral movementCooking vesselsSealingEngineeringDome shape

A domed splatter screen with a fitted rim. The domed splatter screen is placed over a pan used for frying a food item. The splatter screen includes a handle, a body, and a rim. The body is constructed of metal mesh and is dome shaped. The mesh catches and prevents oil droplets from splattering onto the stovetop. The dome shape allows the splatter screen to cover a pan with a food item that extends above the pan wall. The rim encircles the edge of the body and is fitted to securely attach to the pan wall. The handle is attached to the body to enable the splatter to screen to be placed over and removed from the pan.

Owner:LIFETIME BRANDS

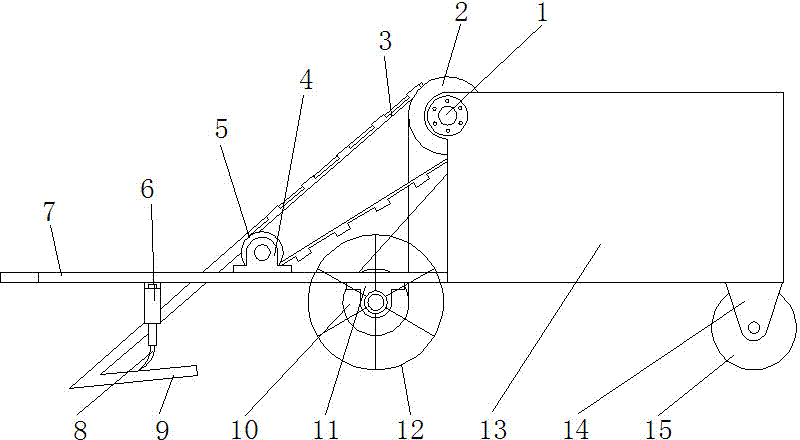

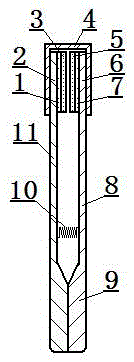

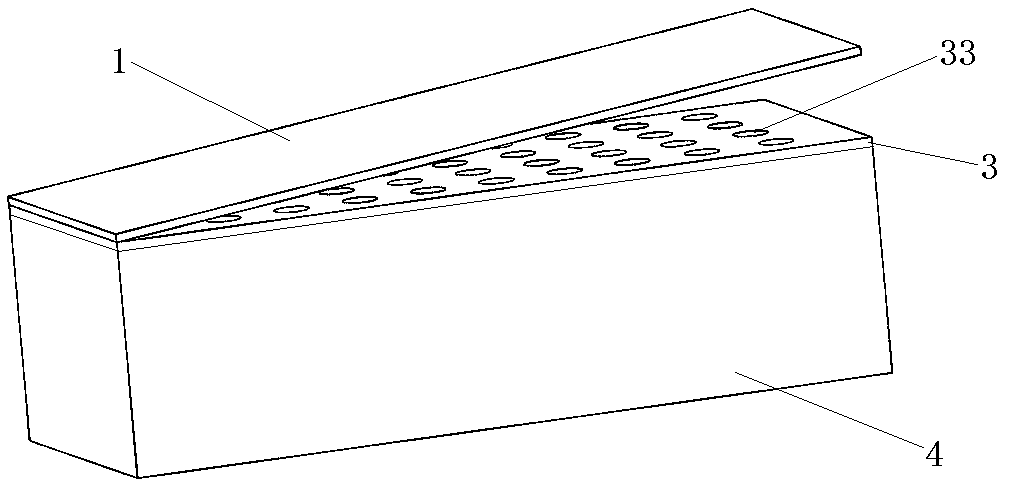

Film residue recycling machine

The invention relates to agricultural equipment, in particular to a film residue recycling machine. A traction frame is installed at the front end of a machine frame of the film residue recycling machine. A film residue collecting box is installed at the rear end of the machine frame. Walking wheels are installed on the two sides of the machine frame and fixedly installed at the two ends of a shaft, and the shaft is fixedly installed on the machine frame through bearing pedestals (11). A transmission chain is fixedly installed on one side of the shaft. A conveying device is installed at the portion, between the film residue collecting box and the traction frame, of the machine frame. Three or more triangular film lifting devices are fixed below the portion, at the front end of the conveying device, of the machine frame in parallel, and the upper edges the film lifting devices are respectively arranged between two adjacent strip-shaped conveying belts. Soil spades or film cutters are installed at the portions, on the two sides of the film lifting devices, of the machine frame. The film residue recycling machine can recycle film residues remaining after whole-film mulching or half-film mulching and has the advantages of being simple in structure, small in mating power, low in recycling cost, high in one-time completely-recycling rate and the like.

Owner:单思诚

Anti-pollution low-temperature heat-sealing polyethylene film easy to tear off

The invention discloses an anti-pollution low-temperature heat-sealing polyethylene film easy to tear off. The polyethylene film consists of the following components in part by weight: 45 to 65 parts of polyethylene resin, 15 to 30 parts of EVA (ethylene-vinyl acetate) and 3 to 5 parts of an additive. According to the invention, the polyethylene resin is modified by matching of EVA and the additive; when the prepared polyethylene film is made into a plastic package, a sealing temperature is low, so that the phenomenon of false sealing is effectively avoided; after the plastic package is sealed, the polyethylene film is still easy to tear off, so that the use convenience is improved.

Owner:SICHUAN HUILI IND

Easy-to-uncover heat sealable films special for sanitary bag

The invention discloses a special easy-peel heat sealable film for a Tyvek sanitary bag. The film is made from 100 parts of polyethylene and 10-50 parts of polybutene or modified polybutene by weight. When the film is subject to thermal sealing with Tyvek material, two layers of materials have proper cohesive force therebetween, can bear articles, be easily torn, and convenient for use.

Owner:ZHEJIANG GOLDSTONE PACKING

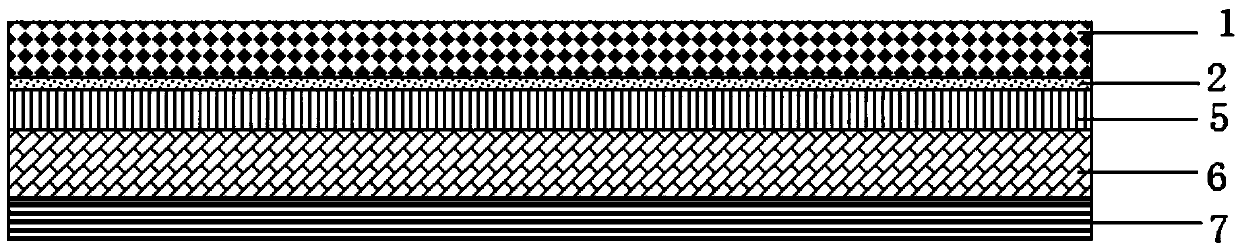

Uncovering type anti-shifting digital anti-counterfeiting mark paster and manufacturing method thereof

InactiveCN105321423AImprove anti-counterfeiting functionPlay an anti-counterfeiting roleStampsIdentification meansWater basedBiochemical engineering

The invention discloses an uncovering type anti-shifting digital anti-counterfeiting mark paster and a manufacturing method thereof. The uncovering type anti-shifting digital anti-counterfeiting mark paster comprises a black ink layer, a backing paper layer, a second glue layer, a white ink layer, a second data printing layer, a second water-based polishing oil layer, a silicone oil separation layer, an uncovering layer, a first glue layer, a paper layer, a surface printing layer, a first water-based polishing oil layer, a first data printing layer, an oil-based polishing oil layer, a covering layer and a caption layer which are compounded in sequence. The paster is characterized in that the paper layer is provided with a safety line and comprises a first paper layer, a printing layer, an aluminum layer, a fluorescent layer, a PET layer and a second paper layer which are sequentially compounded together. According to the uncovering type anti-shifting digital anti-counterfeiting mark paster, the uncovering layer can be completely uncovered, a large amount of anti-counterfeiting information is provided, and the anti-counterfeiting effect is achieved. The uncovering type anti-shifting digital anti-counterfeiting mark paster is particularly suitable for top-grade wine, top-grade cigarettes and the like.

Owner:无锡新光印防伪技术有限公司

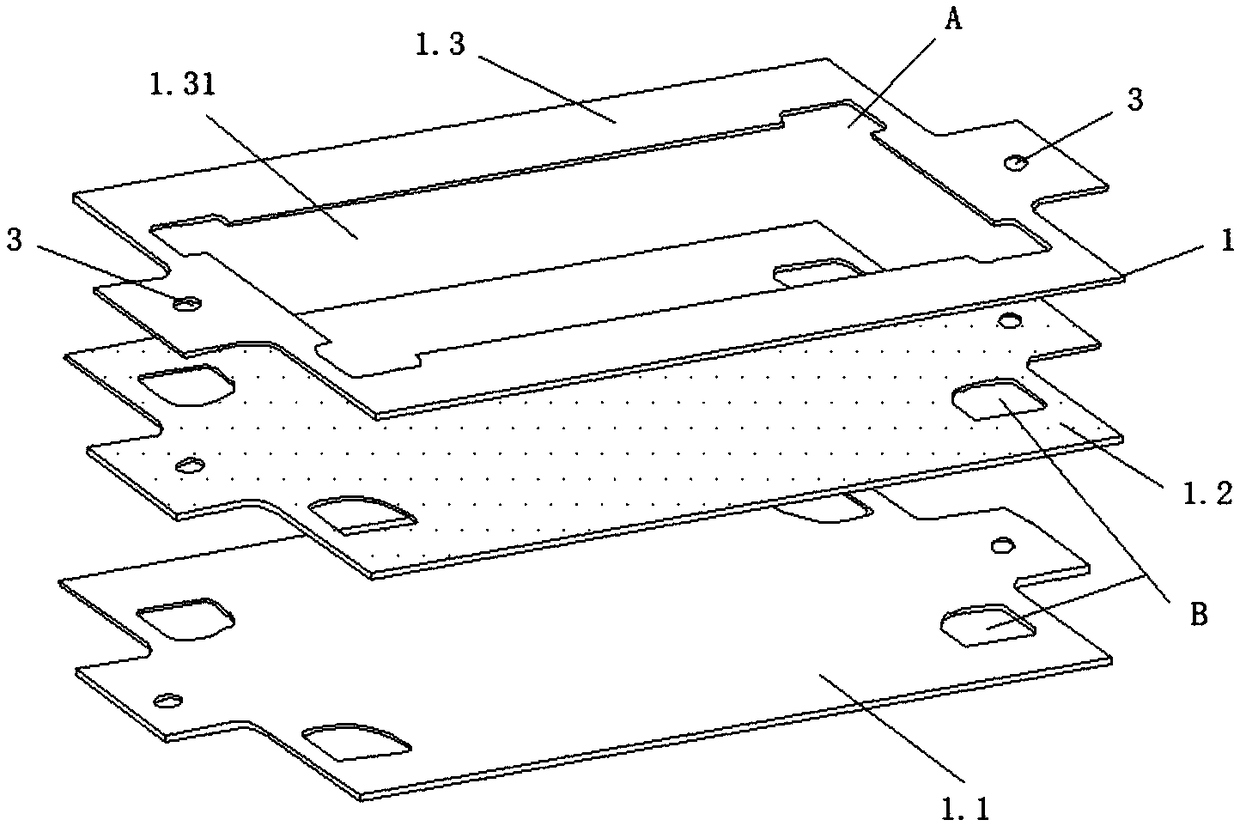

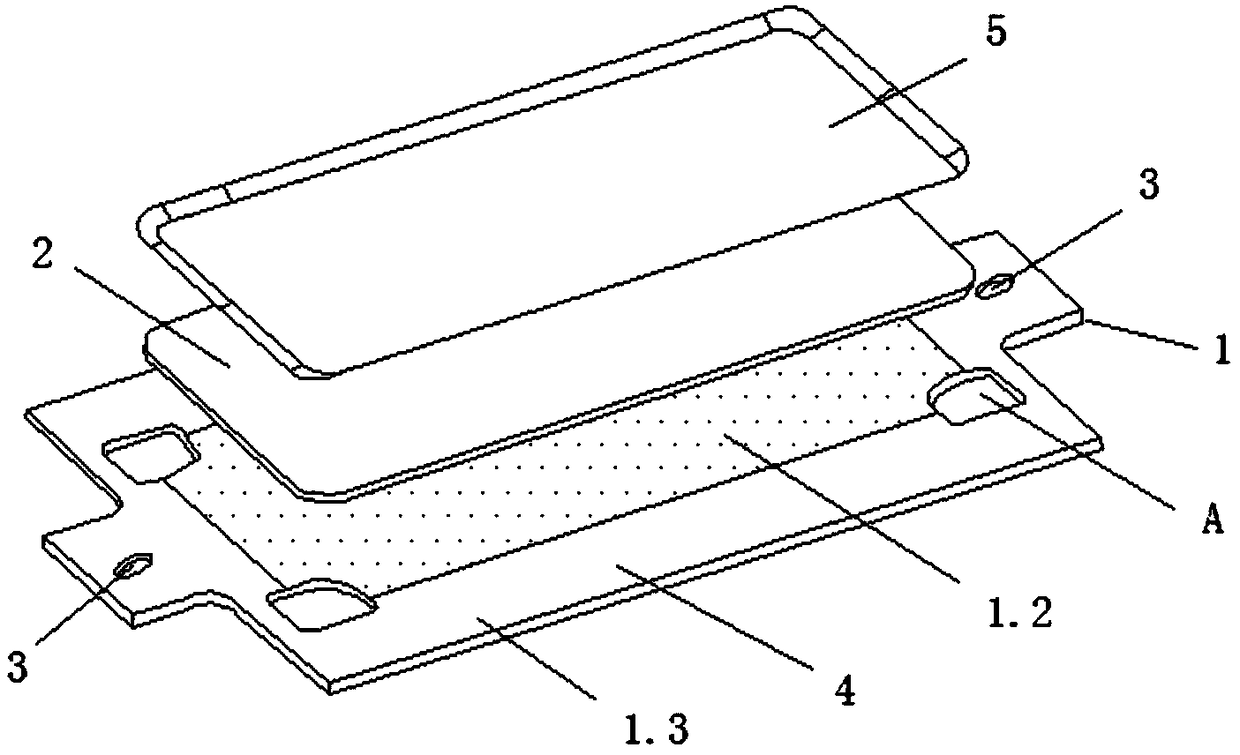

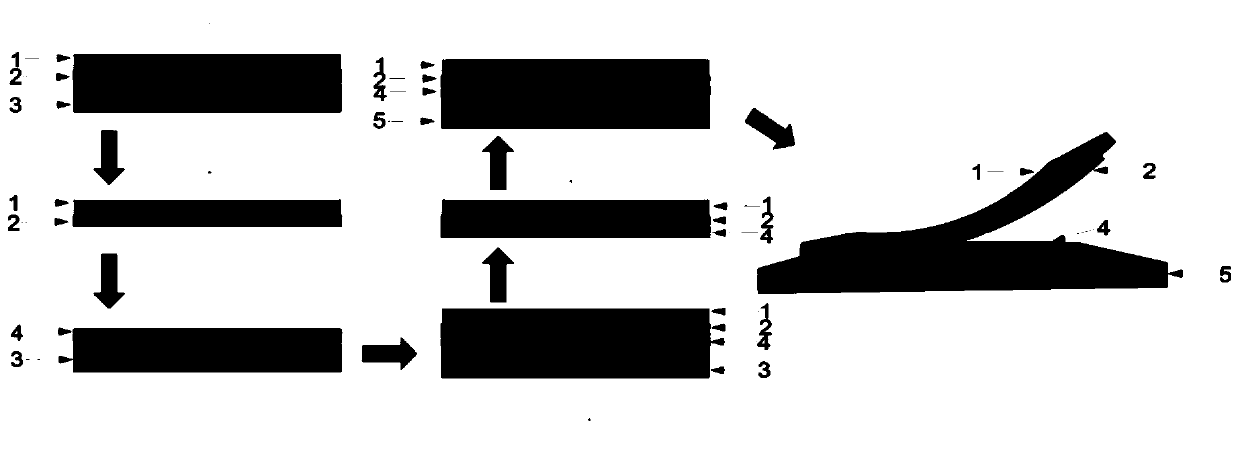

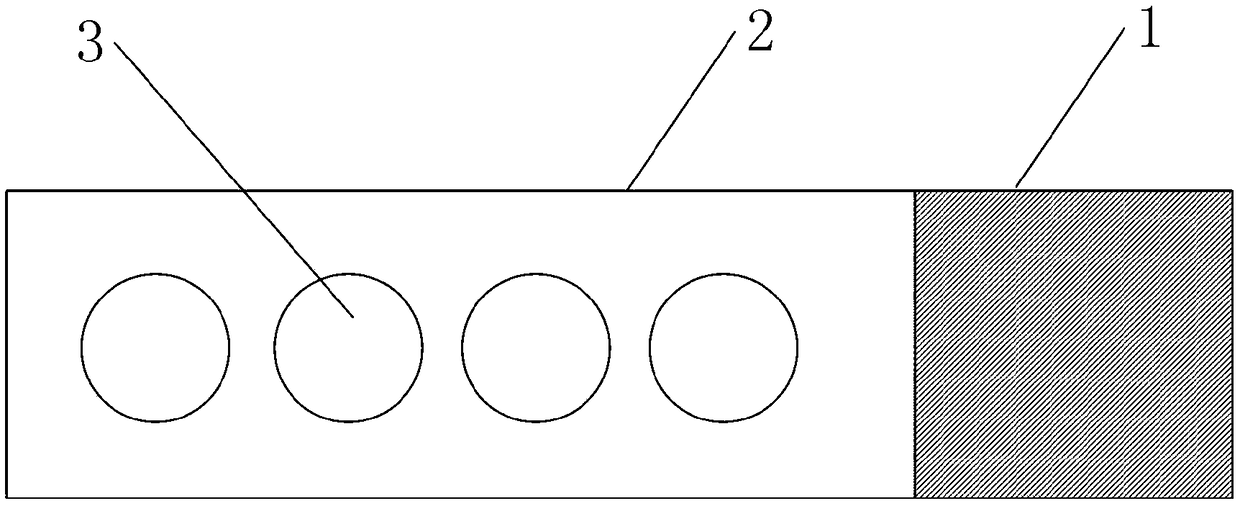

Bearing film for 3D product, composite film comprising bearing film and film laminating method

ActiveCN108724865AGuaranteed yieldImprove yieldSynthetic resin layered productsPackagingComposite filmEngineering

The invention provides a bearing film for a 3D product. The bearing film comprises a bearing film body, wherein the bearing film body comprises a first film layer, a bonding layer and a second film layer which are sequentially superposed; and a hollow part which is matched with the contour of a to-be-laminated 3D product is arranged on the second film layer. The bearing film is simple in integralstructure and is convenient to manufacture. The invention further discloses a composite film for a 3D product, and the composite film comprises the bearing film for the 3D product and an independentlyarranged film sheet; the film sheet is arranged on the hollow part of the second film layer; the back surface of the film sheet is bonded with the bonding layer; a protective layer is arranged on thefront surface of the film sheet, so that the 3D product can be laminated with the film very well; the bonding layer is designed by adopting an unique material, and the bearing film for the 3D productis easily taken off after film laminating, and residues are avoided, so that the yield of the film-laminated 3D product is high. The invention further discloses a method for laminating the compositefilm for the 3D product, and the method is simple in process step, easily controls process parameters, and is high in product yield.

Owner:LENS TECH CHANGSHA

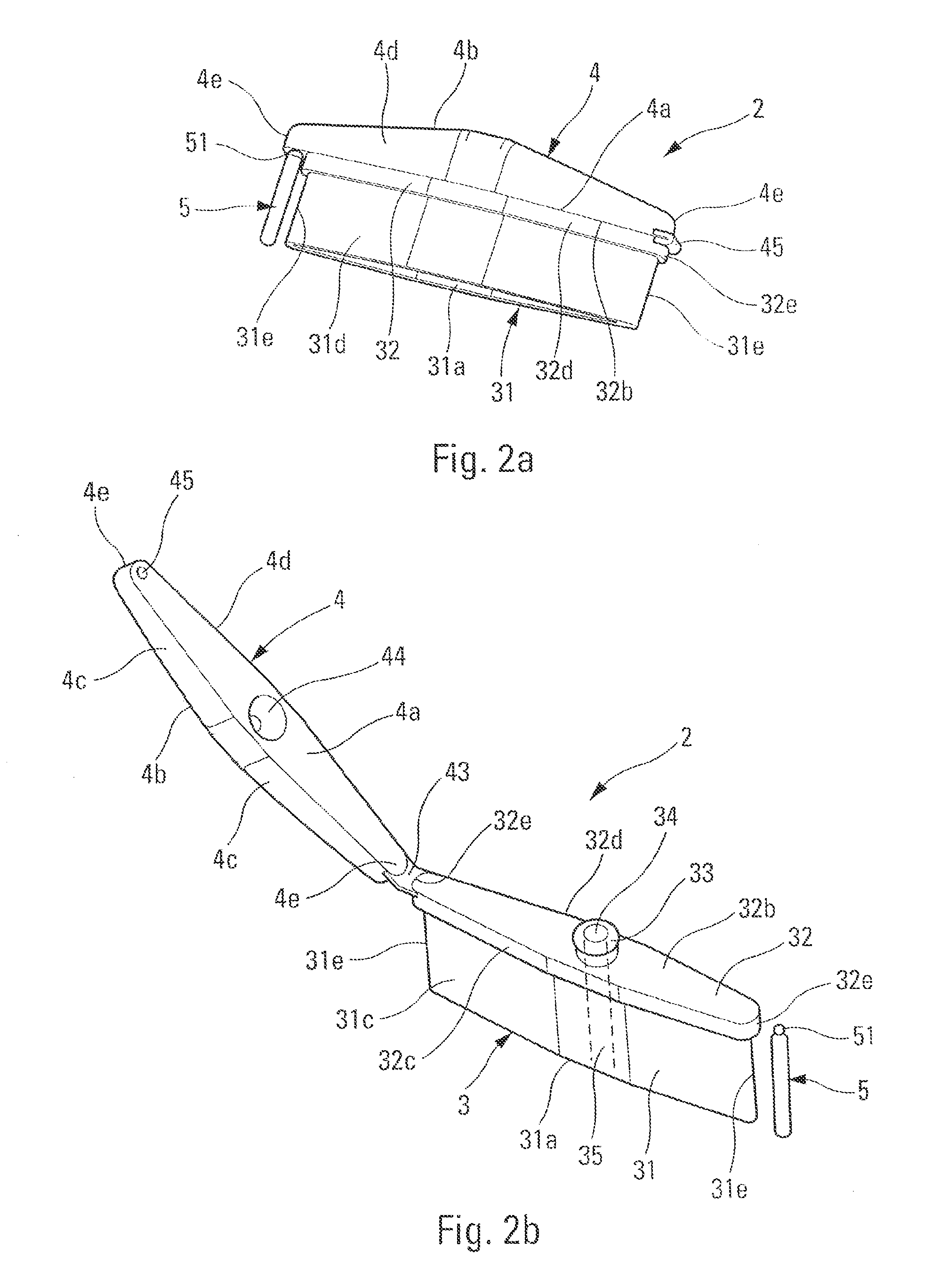

Tweezers capable of opening plastic film bag opening conveniently

The invention discloses tweezers capable of opening a plastic film bag opening conveniently. A tweezers body is composed of a tweezers handle, a left elastic tweezers arm and a right elastic tweezers arm, wherein the left elastic tweezers arm and the right elastic tweezers arm are symmetrical. A compression spring is arranged between the left elastic tweezers arm and the right elastic tweezers arm. The tweezers are mainly characterized in that left nanometer micro absorption adhesive is arranged on the right side of the left tweezers holding end of the left elastic tweezers arm and is fixedly stuck to the left tweezers holding end through left double-sided adhesive, and right nanometer micro absorption adhesive corresponding to the left nanometer micro absorption adhesive is arranged on the left side of the right tweezers holding end of the right elastic tweezers arm and is fixedly stuck to the right tweezers holding end through right double-sided adhesive; and the left tweezers holding end and the right tweezers holding end are provided with a plastic jacket. The tweezers can open the plastic film bag opening in a folder easily and conveniently.

Owner:罗福仲

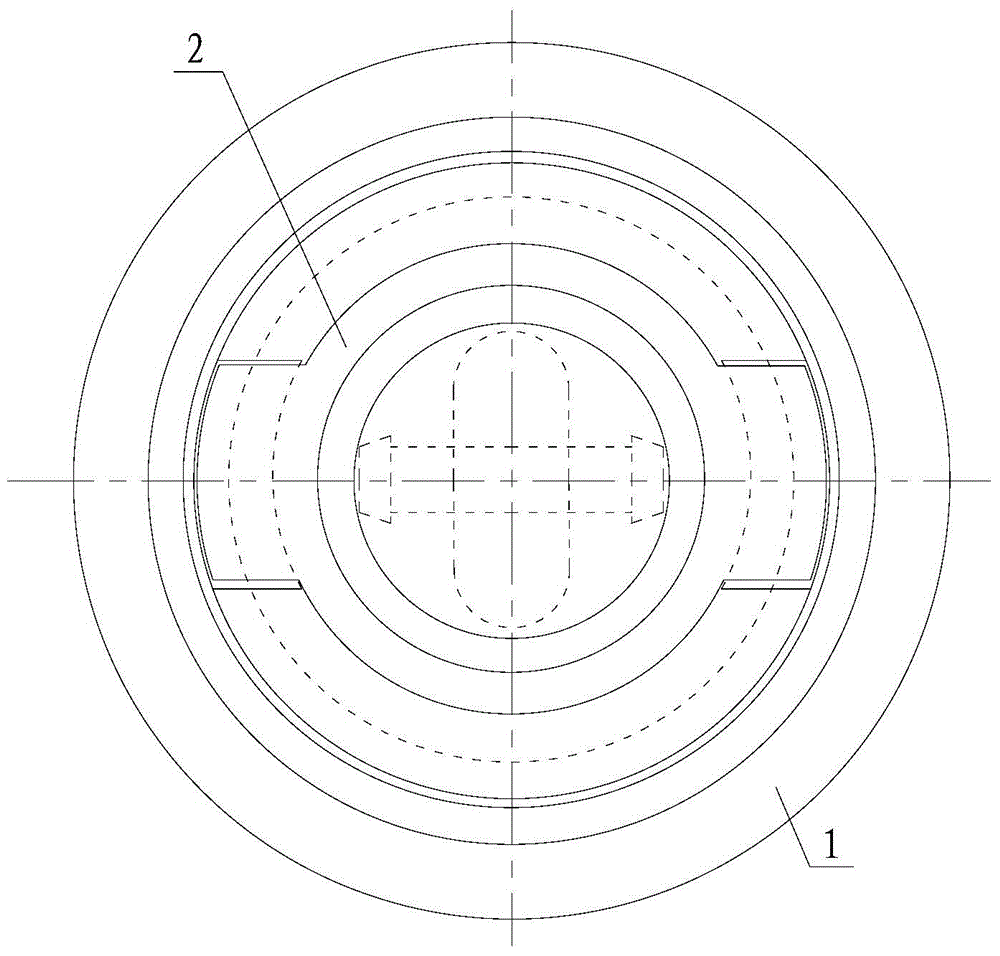

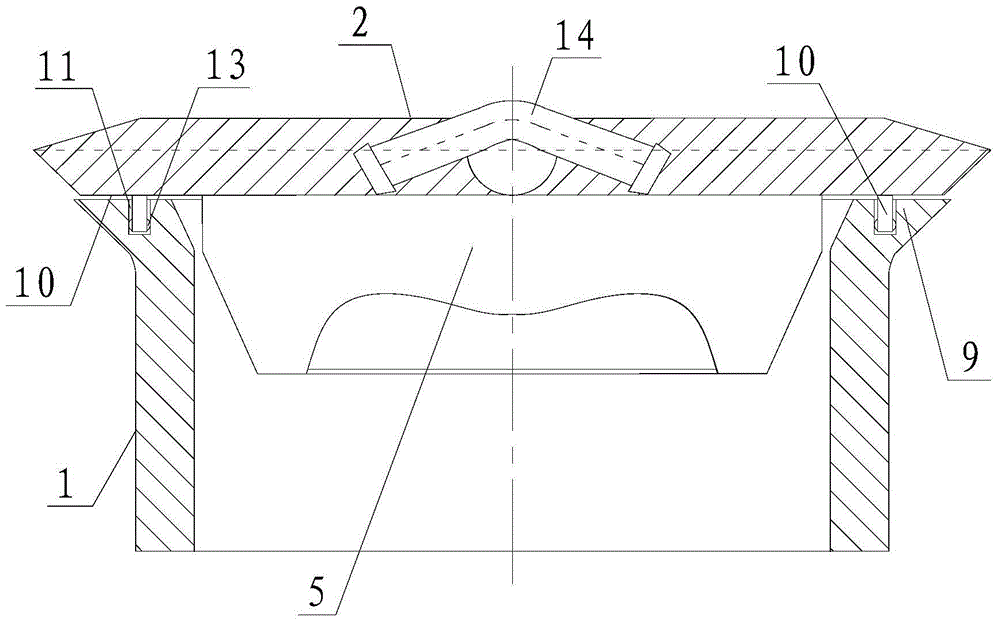

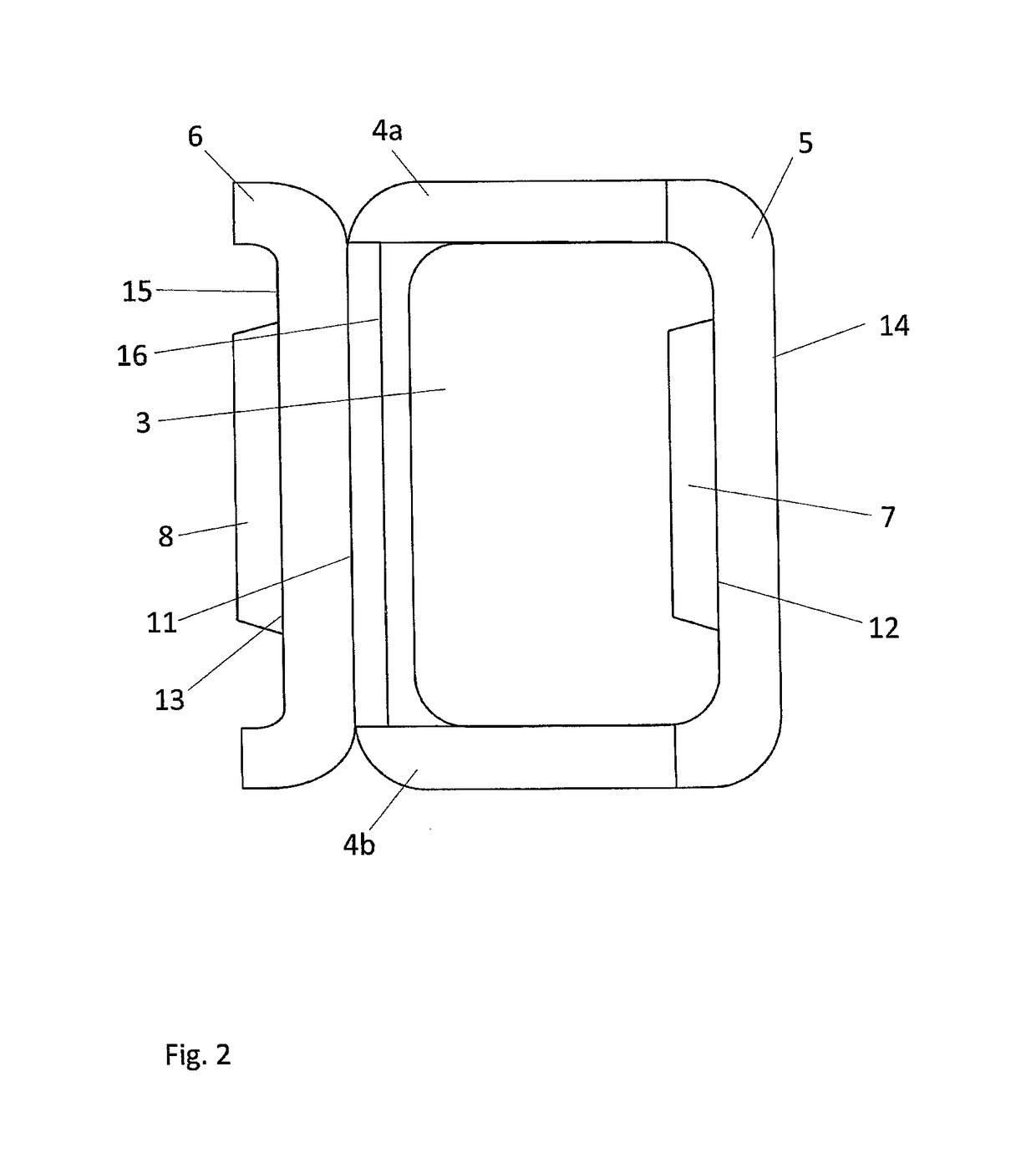

Fire-watching hole cover structure for vertical flues of top-charging coke oven combustion chamber

ActiveCN104593017AEasy to uncoverCombustible gas coke oven heatingCoke oven detailsCombustion chamberLocking mechanism

The invention discloses a fire-watching hole cover structure, particularly discloses the fire-watching hole cover structure for vertical flues of a top-charging coke oven combustion chamber, and belongs to the technical field of design and manufacturing of metallurgical production equipment accessories. Provided is the fire-watching hole cover structure which is used for the vertical flues of the top-charging coke oven combustion chamber and cannot cause a fact that a fire-watching hole cover is absorbed off by an electromagnet during a coal charging process. The fire-watching hole cover structure includes a cover seat and a cover body; the fire-watching hole cover structure also comprises a connection locking mechanism; the cover body is detachably fixed on the cover seat through the connection locking mechanism and seals a coke charging hole on the cover seat.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

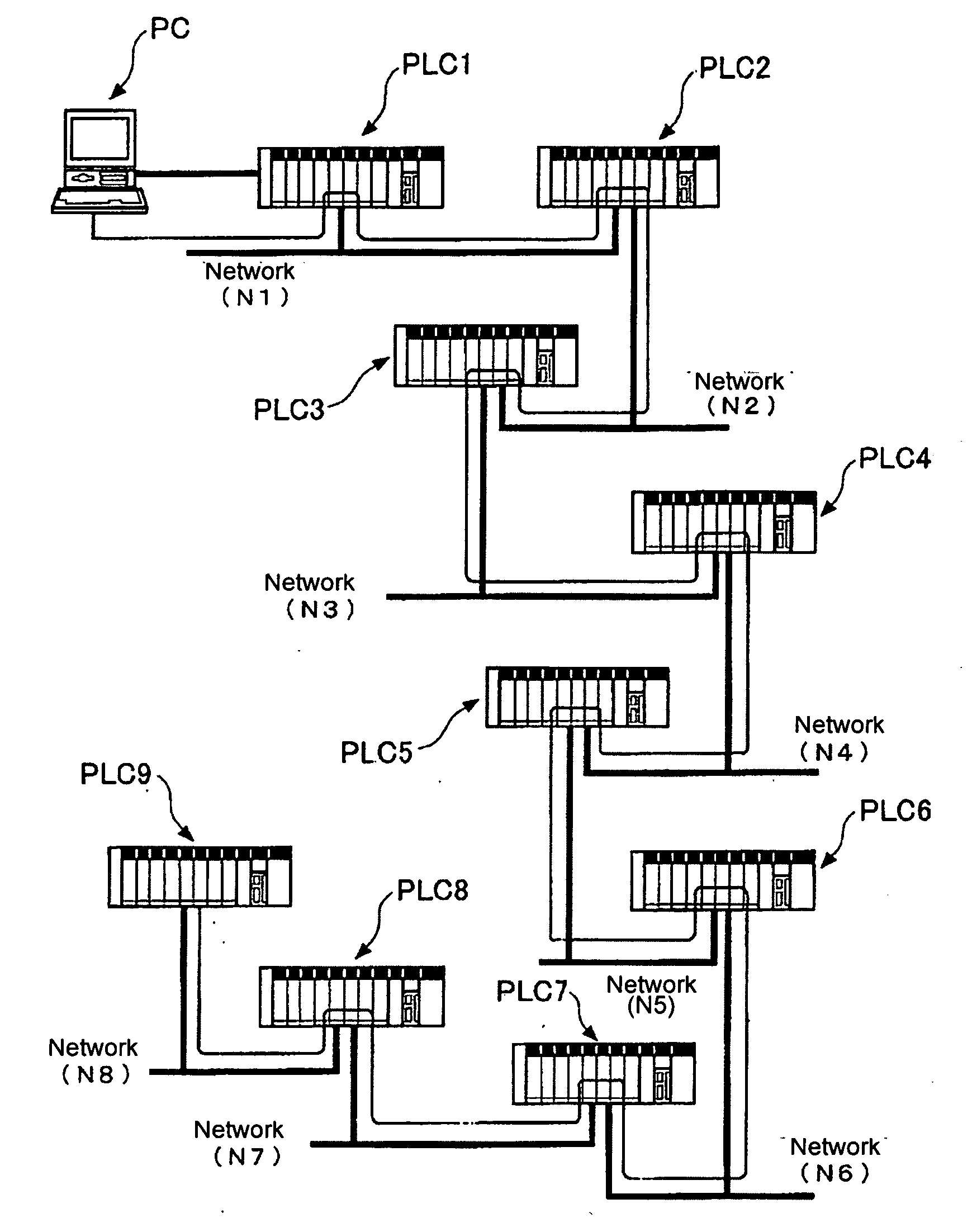

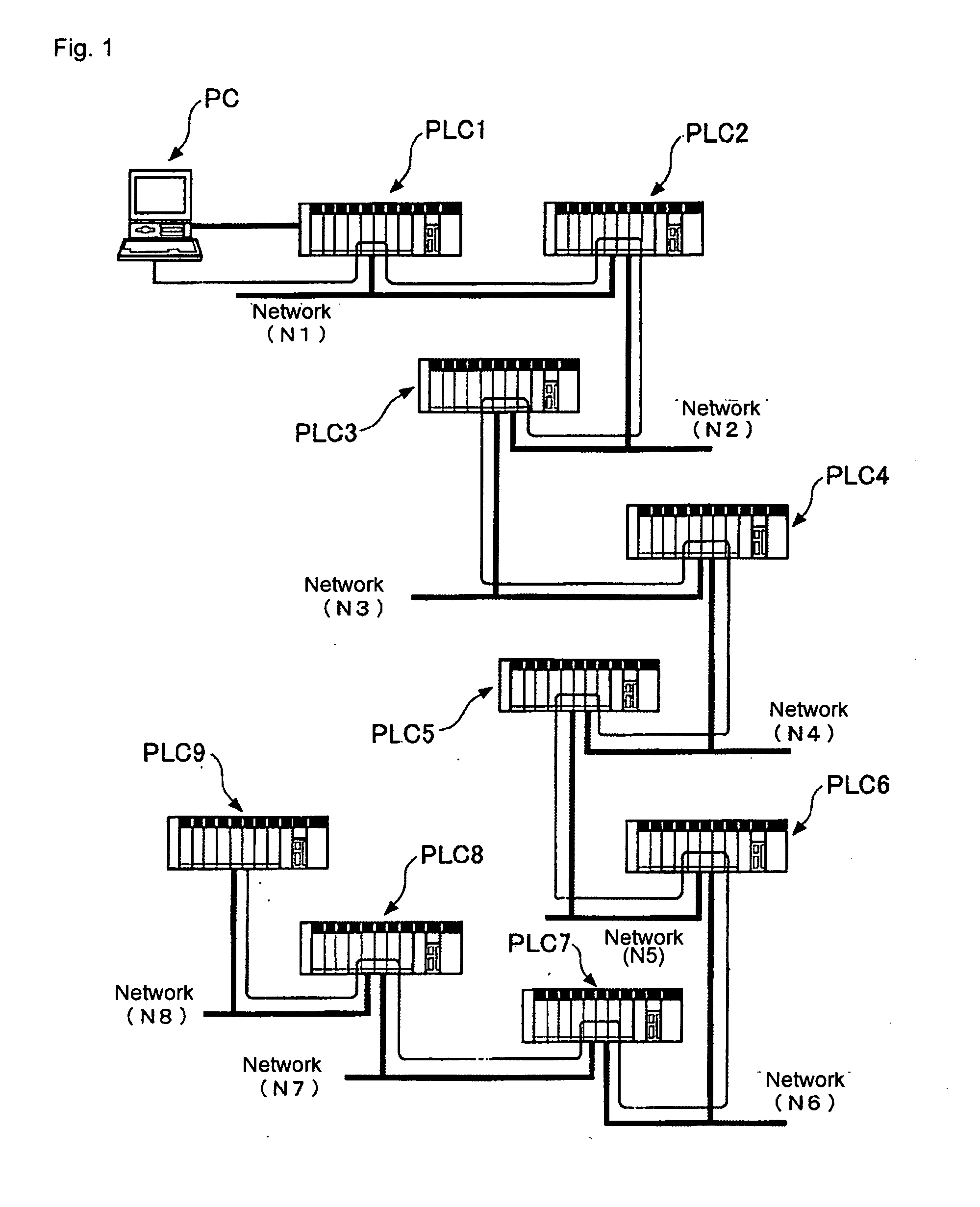

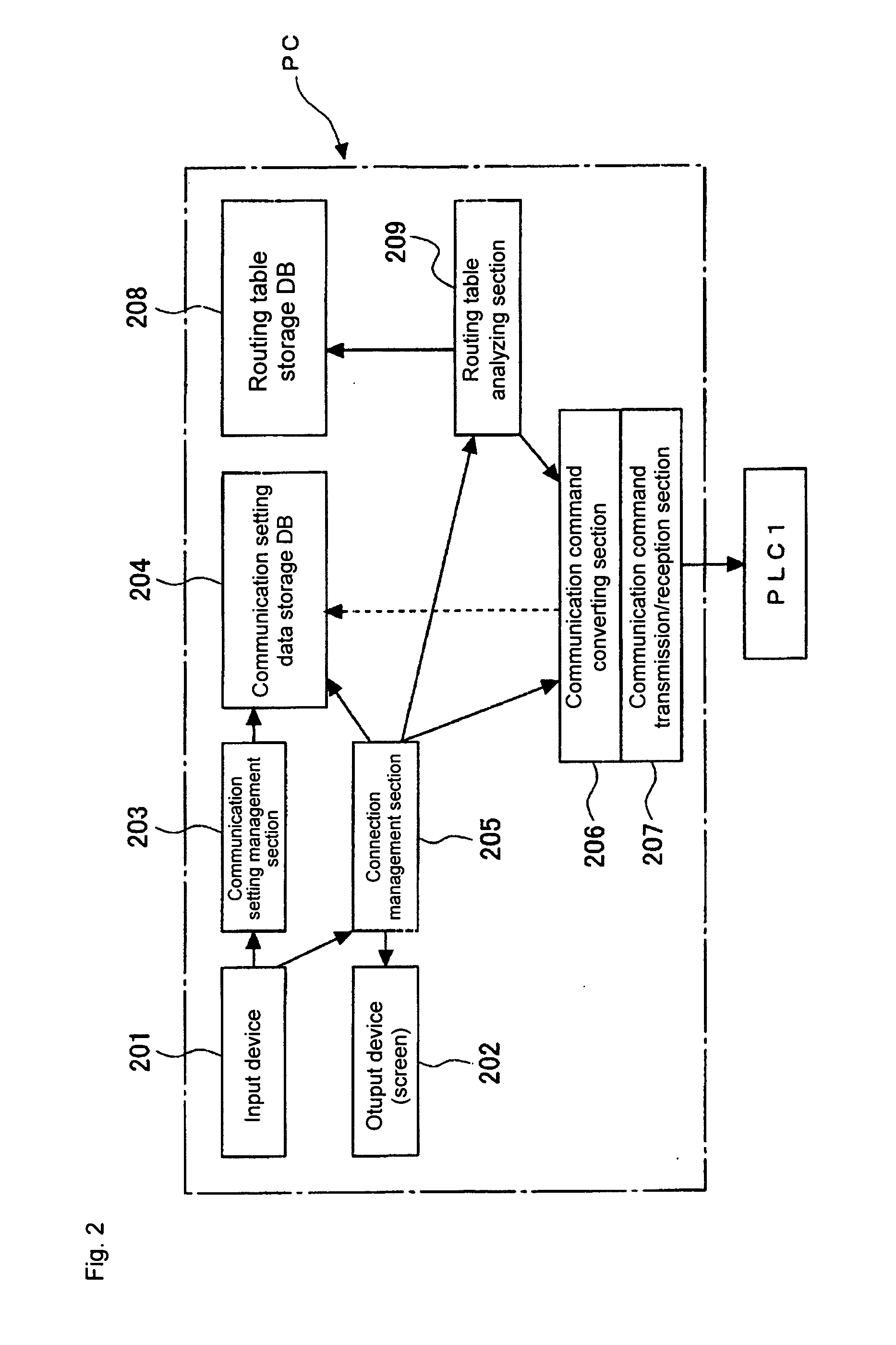

Programmable controller system

ActiveUS20060230188A1Quickly specifiedShorten the timeProgramme controlTransmissionProgrammable logic controllerEmbedded system

A programmable controller system comprises networks including a plurality of programmable controllers and a development support device. One of the programmable controllers is set as a relay programmable controller. The development support device is used by online-connecting to the relay programmable controller via a communication line and by switching connecting destination to a target programmable controller on the networks during a state of online-connecting to the relay programmable controller.

Owner:ORMON CORP

Copper printing paper self pasting label belt without backing paper

The invention provides a copper printing paper self pasting label belt without backing paper. The copper printing paper self pasting label belt comprises labels and tearing lines, wherein the labels are mutually connected through the tearing lines, each label consists of a silicon oil layer, a lamination layer, copper printing paper and a glue coating layer, one lamination layer coats the printing surface of the copper printing paper, the silicon oil layer costs the surface of the lamination layer, the glue coating layer coats the reverse surface of the printing surface of the copper printing paper, an easy-to-tear block extends from the copper printing paper at each corner of each label, a tearing line is arranged between the easy-to-tear block and the label, and the label belt is rolled into a roll shape in a mode that the glue coating layer faces the inward side. Through the design without the backing paper, the resource waste is reduced, and the cost is lowered; through the adoption of the tearing lines, the use mode that the traditional labels need to be sheared in the use process is changed; the lamination layer coats the surface of the copper printing paper, the characters and patterns on the surface of the labels can be effectively protected; the labels can be easily peeled off and torn down through the easy-to-tear block, and the use is convenient; the tail end connecting point width of each tearing line is smaller than 0.01mm, the tearing is easy, and in addition, the attractive appearance of the label is not influenced.

Owner:竹林伟业科技发展(天津)股份有限公司

Uncovering ticket print

InactiveCN109263353AHigh speedReduce turn-on timeInformation cardsComputer scienceFilm-coated tablet

The invention provides an uncovering ticket print which sequentially comprises a print body layer, a confidential information printing layer and a covering layer. The covering layer sequentially comprises an adhesive coating, a non-transparent coating, a release coating and a transparent film coating. The edge area of the covering layer is adhered to the print body layer by the adhesive coating, and the position where the confidential information printing layer is located is not adhered to the print body layer by the adhesive coating. The defect is overcome that existing scratch tickets are not hygienic, waste time, need hard pads and scraping tools and are difficultly scraped, and the shortcoming is overcome that pull handles of existing uncovering ticket prints are difficult to pull up.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

Polyolefin film capable of sealing repeatedly, composite cover film and preparation method thereof

InactiveCN109514957AImprove barrier propertiesHigh mechanical strengthSynthetic resin layered productsLaminationPolyolefinPolymer science

The invention belongs to the technical field of packaging materials, and in particular relates to a polyolefin film capable of sealing repeatedly, a composite cover film and a preparation method thereof. The composite cover film comprises an outer layer, a barrier layer and a polyolefin film. The polyolefin film is composed of a corona layer, an intermediate layer and a hot seal layer. The polyolefin film has good mechanical strength and mechanical property while having good barrier property, not only meets the packaging sealing property, but also is opened conveniently. The polyolefin film can seal repeatedly if being opened, and the using safety is not affected as a result of chips by means of cracking.

Owner:浙江保禄包装科技股份有限公司

A kind of aluminum foil sealing film and preparation method thereof

ActiveCN105059707BImprove qualityImprove uniformitySealingMetal layered productsAluminum foilPolypropylene

The invention provides an aluminum foil sealing film and a preparation method thereof, comprising a protective layer, a barrier layer and a heat-sealing layer compounded sequentially from top to bottom, the protective layer is a varnish layer or a PET film, the barrier layer is an aluminum foil layer, The heat-sealing layer is composed of 15-25wt% polybutene, 25-50wt% metallocene LLDPE and 25-60wt% HDPE. When the aluminum foil sealing film of the present invention is combined with the mouth of a polypropylene plastic bottle, the bonding strength is moderate and uniform, and it is easy to unravel, and it will not occur that the items in the polypropylene plastic bottle hit the sealing film during transportation, and the bonding force is relatively high. Small parts are easy to open, leading to the problem of sealing failure, which greatly improves the quality of aluminum foil sealing film.

Owner:ZHEJIANG GOLDSTONE PACKING

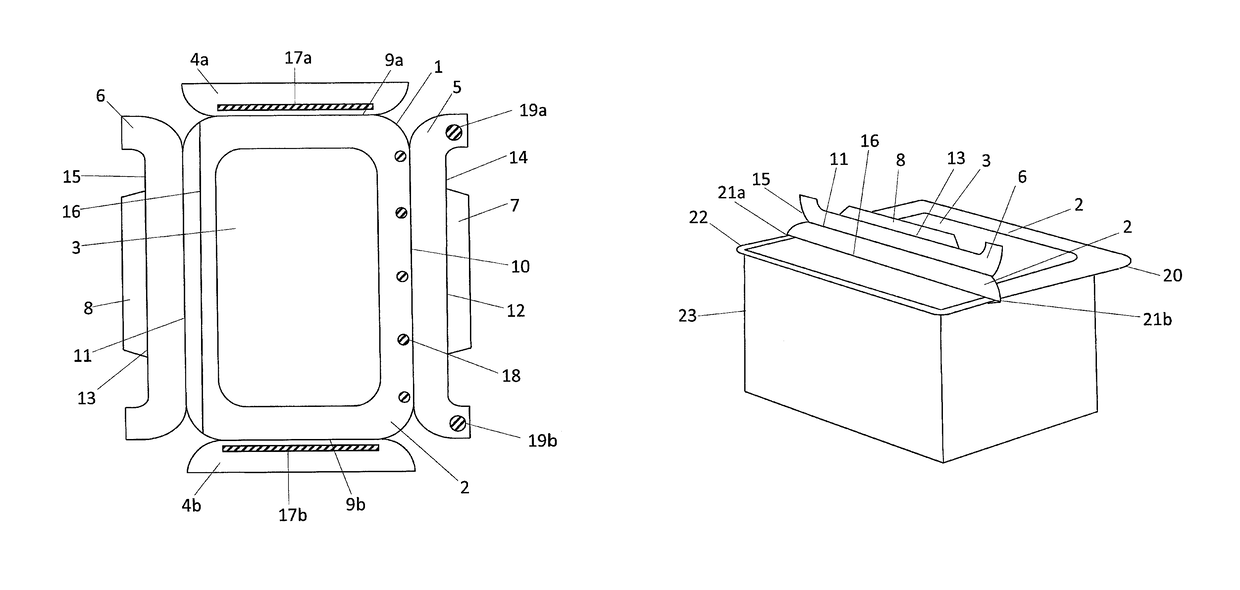

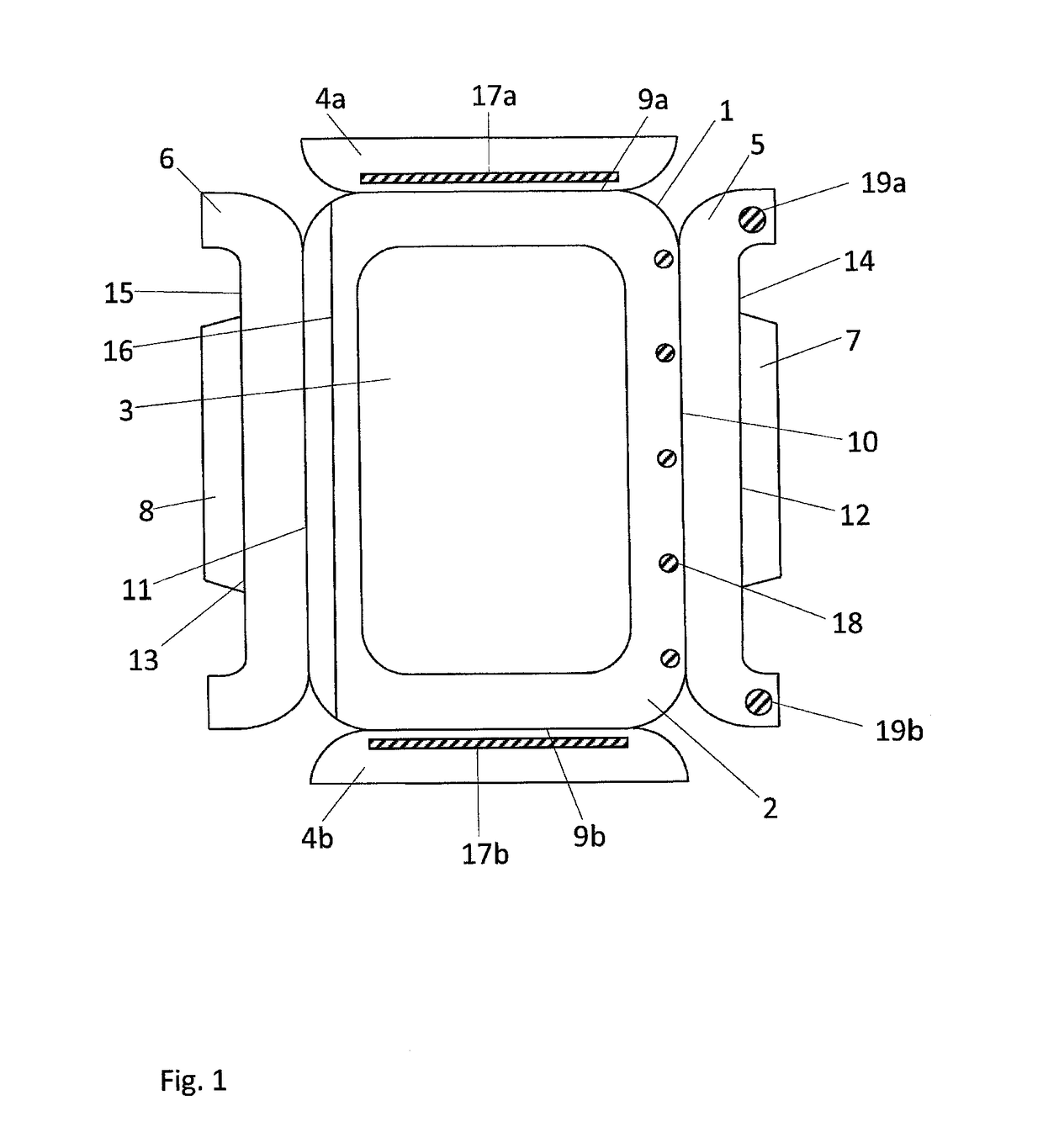

Sliding lid for food container

ActiveUS9783345B2Easy to uncoverRestrict slidingBio-packagingClimate change adaptationEngineeringFlange

Owner:VEGWARE

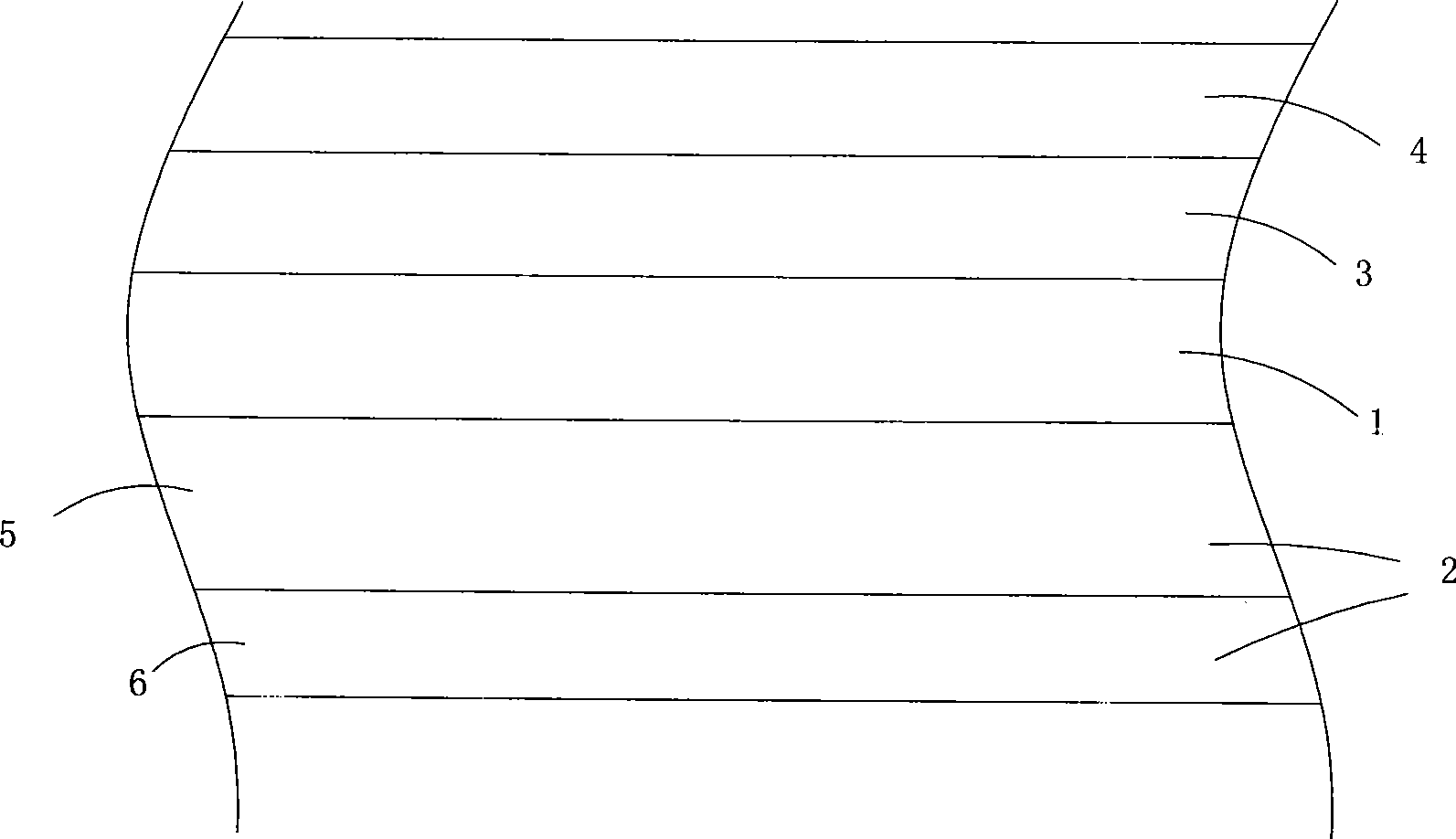

Layered cover film easy to strip

The invention discloses a layered cover film easy to strip. The layered cover film comprises an upper film and a lower film; the lower film is provided with a plurality of breather holes; an easy-to-strip layer is arranged between the upper film and the lower film; the stripping force between the easy-to-strip layer and the upper film is larger than the stripping force between the easy-to-strip layer and the lower film; and when the upper film is separated from the lower film, the easy-to-strip layer adheres to the upper film. The cover film is layered, after the cover film is stripped, the lower film is fixed to a plastic container, and contents in the container are prevented from spilling.

Owner:惠州宝柏包装有限公司

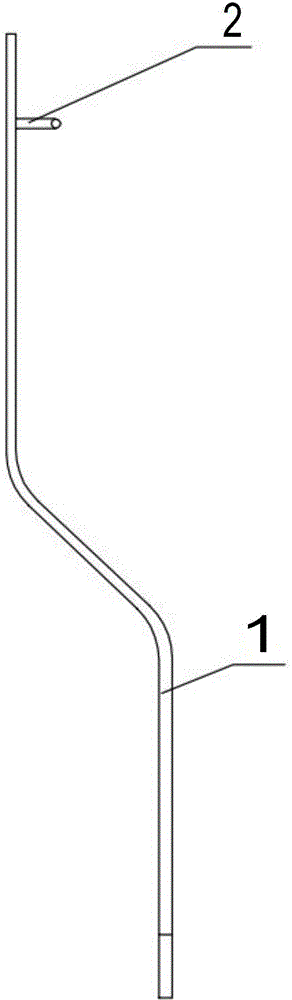

Multifunctional kitchen utensil

InactiveCN103976669AEasy to uncoverEasy to take outOpening closed containersBottle/container closureEngineeringBottle

The invention discloses a multifunctional kitchen utensil which comprises a body. The body comprises a front-end functional portion, a middle holding handle and a rear-end head which re sequentially connected, wherein the front end of the front-end functional portion is provided with a gap, and the gap forms a pot cover lifter which is gradually decreased from front to back and in a shape of at least one step. Two sides of the front end of the gap upward protrude to form two ejection rods forming a steaming plate lifter. A bottle opener is arranged at the rear end of the front-end functional portion. The rear-end head is provided with a fruit peeler. The multifunctional kitchen utensil has the advantages of having multiple functions, being convenient to use, saving materials and saving a kitchen space, integrates a screw driver, a wrench, the fruit peeler, the bottle opener, the steaming plate lifter and the pot cover lifter and is suitable for daily usage in a kitchen. The structural characteristics of the screw driver, the wrench, the fruit peeler, the bottle opener, the steaming plate lifter and the pot cover lifter are utilized, the tools are ingeniously designed on the body, a pot cover can be easily uncovered, a steaming plate can be easily taken out, and scald can be prevented.

Owner:郭德保

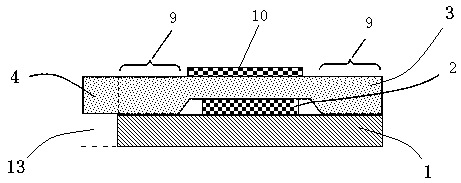

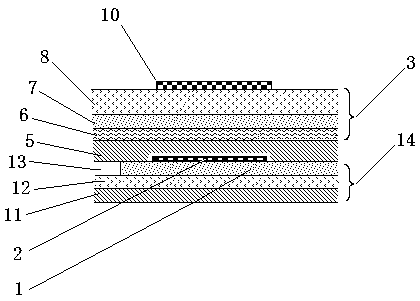

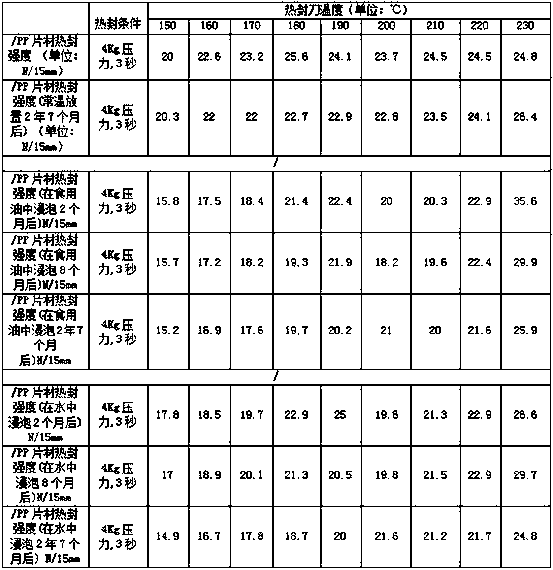

High-temperature steaming and boiling resistant easily-uncovering substrate film, easily-uncovering film containing substrate film and preparation method thereof

PendingCN110126407AEnsure safetyMeet the requirements of sterilizationSynthetic resin layered productsDomestic containersMelt flow indexUltimate tensile strength

The invention belongs to the technical field of packaging materials and specifically relates to an easily-uncovering film. An easily-uncovering substrate film with constant heat sealing strength and with a seal firmly sealed successively comprises a corona layer, an intermediate layer and a heat sealing layer from the outside to the inside that are co-extruded. The material of the corona layer isa blend of PP and metallocene HDPE. The weight ratio of PP to metallocene HDPE is 20-50: 100. The material of the intermediate layer is metallocene HDPE, and the melt index is 0.5-1 g / 10 min. The material of the heat sealing layer is an ethylene-propylene-butylene ternary copolymer. When the film of the invention is heat-sealed with a pp cup material, heat sealing strength is 15-29 N / 15 MM under the precondition of satisfying food safety, it is convenient for consumers to uncover the film and use, and the film can resist steaming and boiling of 121 DEG C.

Owner:惠州德昉高分子膜材料有限公司

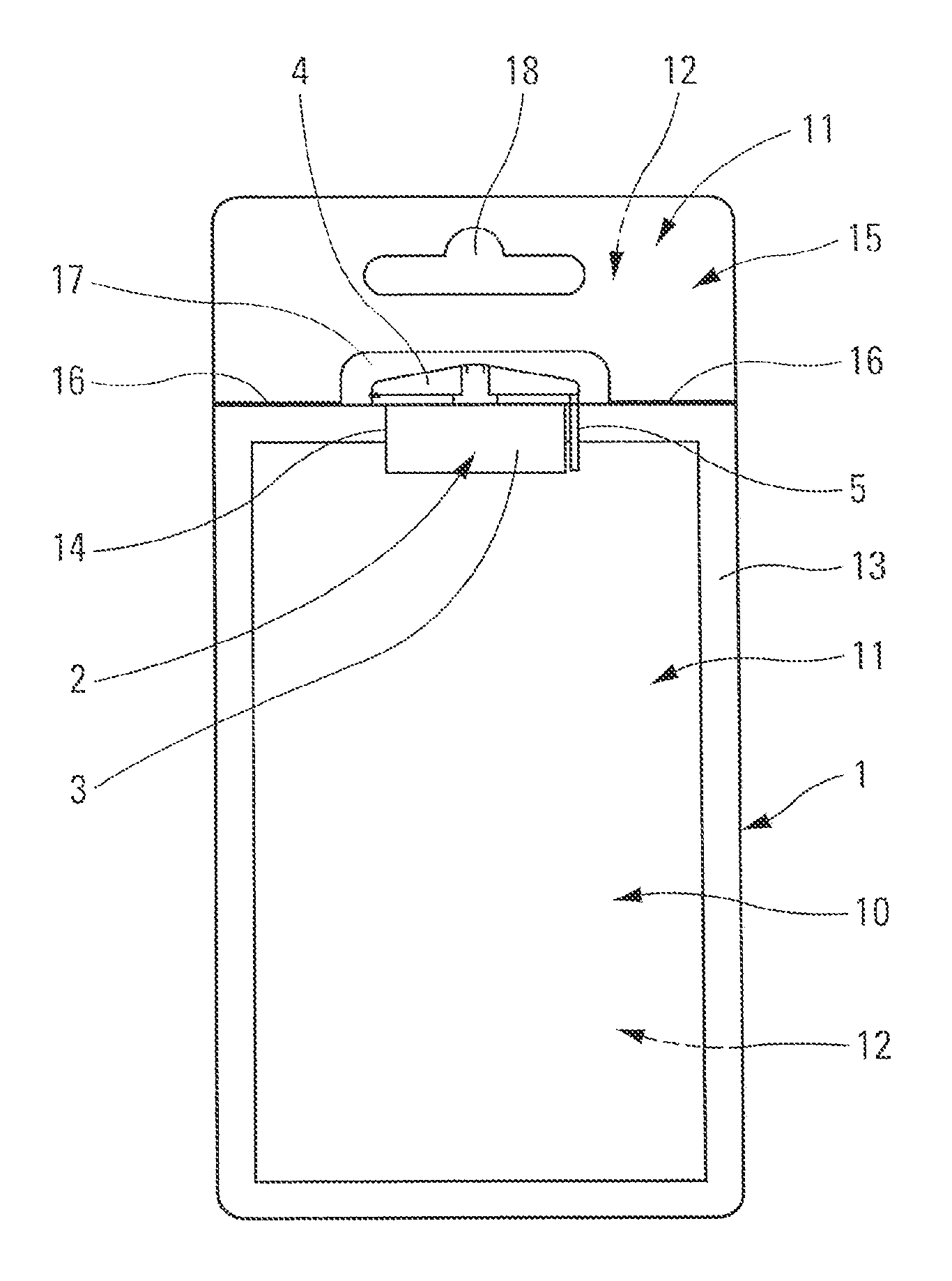

Fluid dispenser

Owner:APTAR FRANCE SAS

Medical adhesive tape

The invention discloses medical adhesive tape. The tape comprises a substrate layer. A gel coating layer is connected with the substrate layer. Clearances are provided between gels in the gel coating layer. Two sides of the adhesive tape stripe are provided with two elastic bands. Ventilation holes are formed on a cloth stripe. The center of the cloth stripe is provided with antimicrobial pledget. Two ends of two elastic bands are correspondingly provided with nylon adhesive buckles for connection purposes. The medical adhesive tape can make the skin contact with the air through the substrate layer to attain the effect of ventilation, moisture permeation and the allergy reduction, reduce the patient's pain brought by the tearing off the tape, effectively facilitate the medical personnel to tear open the adhesive tape. The tape has the advantages of being simple in structure, convenient to use, low in production cost, capable of reducing pollution, and therefore possessing good practicality.

Owner:于桂菊

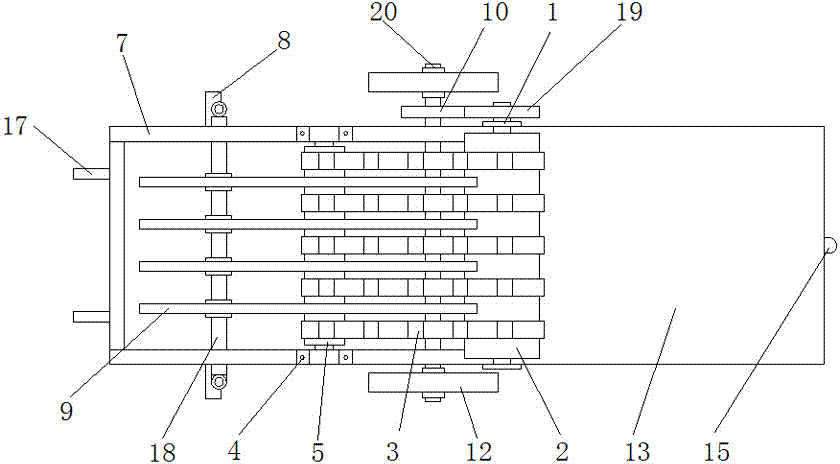

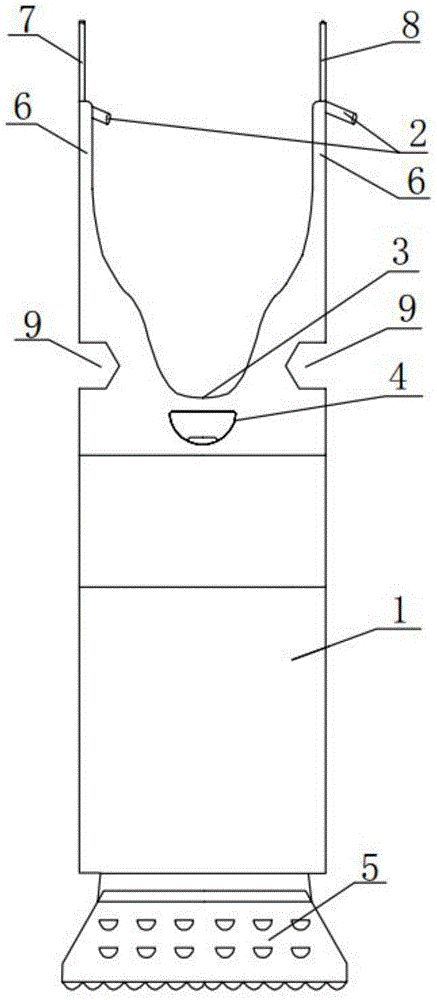

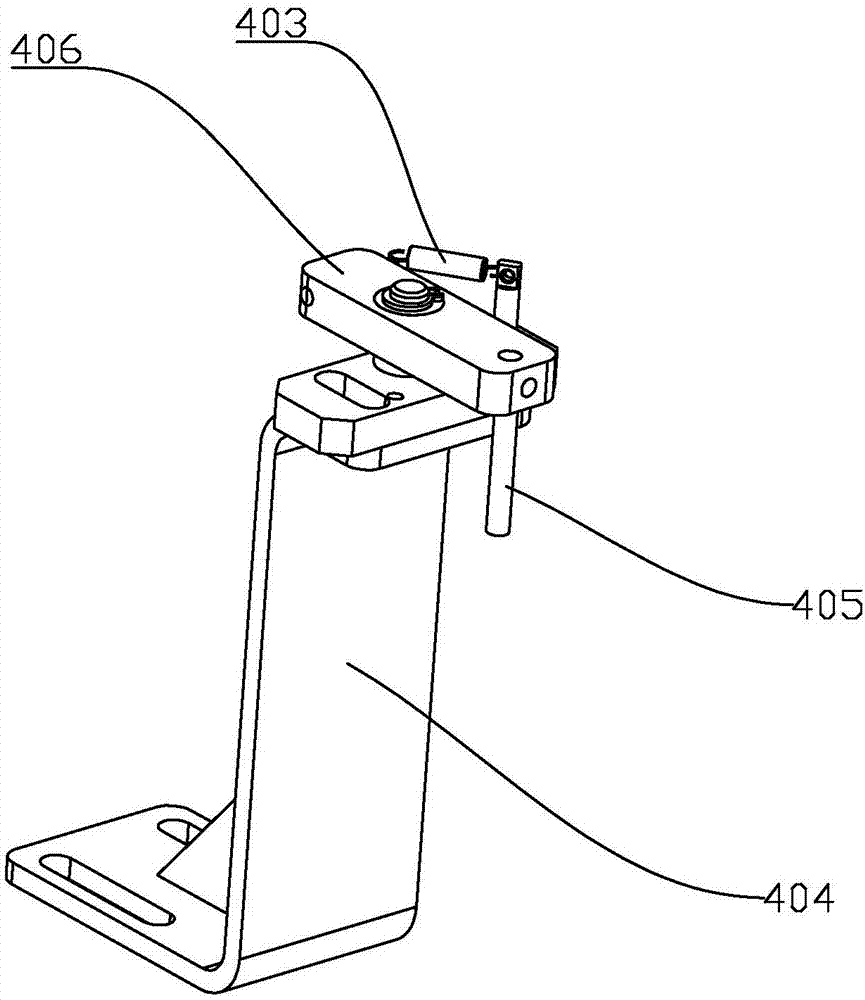

Cap screwing machine for hose

ActiveCN107381465AEasy to uncoverIncrease productivityClosing machinesThreaded caps applicationCap devicePhysics

The invention discloses a cap screwing machine for a hose. The cap screwing machine for the hose is provided with a rack. A blanking device, a drilling device, a film sealing device, a cap screwing device and a conveying device are arranged on the rack, wherein the blanking device is used for hose blanking; the drilling device is used for hose drilling; the film sealing device is used for arranging a sealing film to close the hole position after a hole is drilled in the hose; the cap screwing device is used for screwing an end cap into the hose; and the conveying device is connected with the blanking device, the drilling device, the film sealing device and the cap screwing device sequentially in a butting mode for bearing the hose to be sequentially subjected to drilling, film sealing and cap adding actions. According to the cap screwing machine adopting the structure, working procedures of blanking, drilling, film sealing and cap screwing are combined together, butting is achieved through the conveying device, and the production efficiency is high.

Owner:ZHONGSHAN NCA

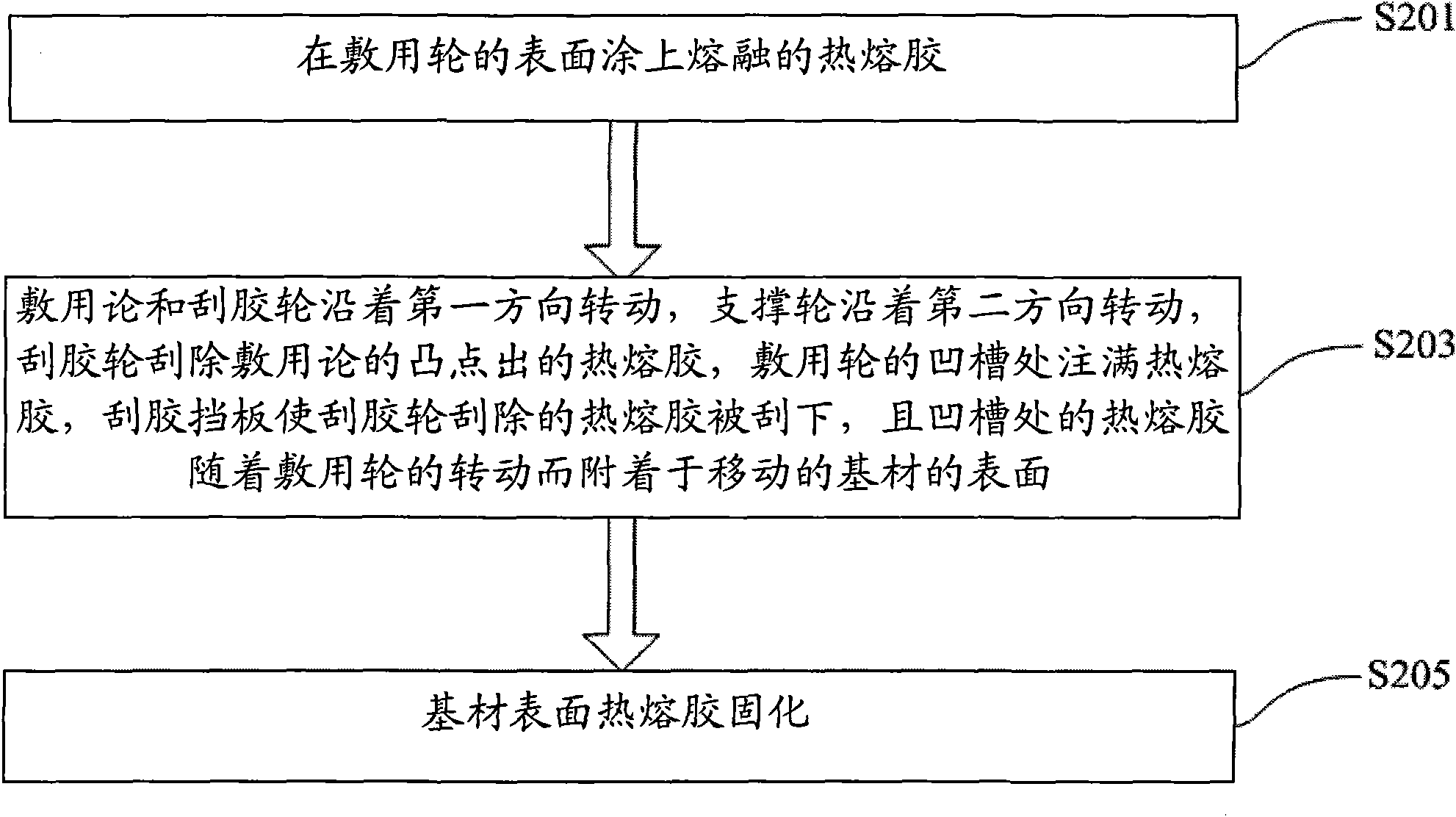

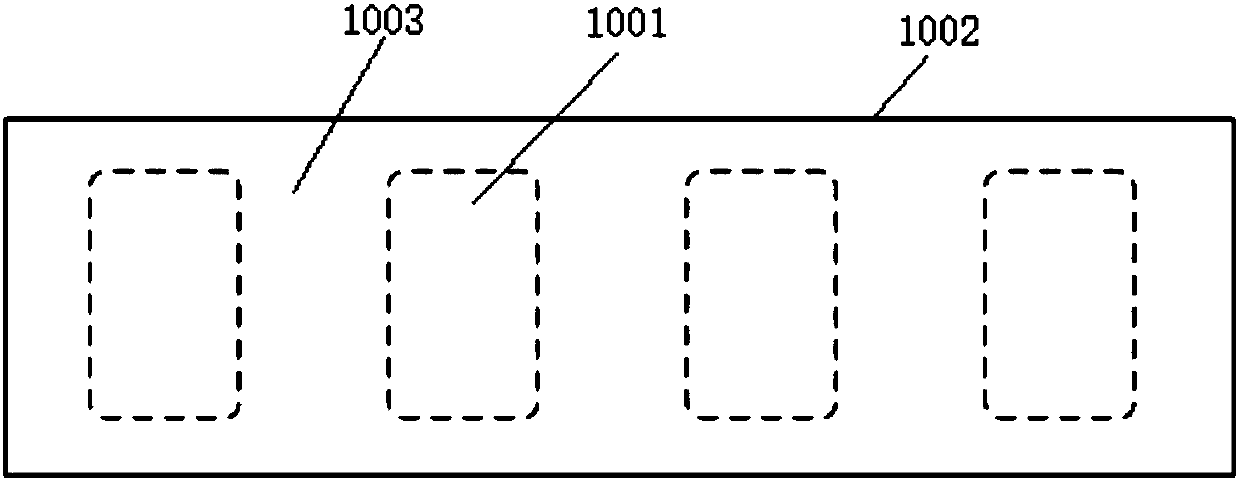

Device and method for producing adhesive tape with air holes

ActiveCN101590460AReduce dosageEasy to uncoverLiquid surface applicatorsFilm/foil adhesivesEngineeringSalient point

The invention provides a device and a method for producing an adhesive tape with air holes. The device for producing the adhesive tape with the air holes comprises an applying wheel, a glue scraping wheel, a glue scraping baffle plate and a supporting wheel, wherein the applying wheel rotates along the first direction, the surface of the applying wheel is provided with salient points, and grooves are formed among the salient points; the glue scraping wheel is tangent to the surface of the applying wheel and rotates along the first direction, and a glue injecting place is formed between the applying wheel and the glue scraping wheel; one end face of the glue scraping baffle plate clings to the glue scraping wheel; and the supporting wheel rotates along the second direction, a base material of the adhesive tape is laid on the surface of the supporting wheel and moves with the rotation of the supporting wheel, and the surface of the base material is tangent to the surface of the applying wheel. The adhesive tape produced by the device and the method has the advantages of easy tearing and good permeability, and can effectively save glue consumption.

Owner:NANJING 3H MEDICAL PROD CO LTD

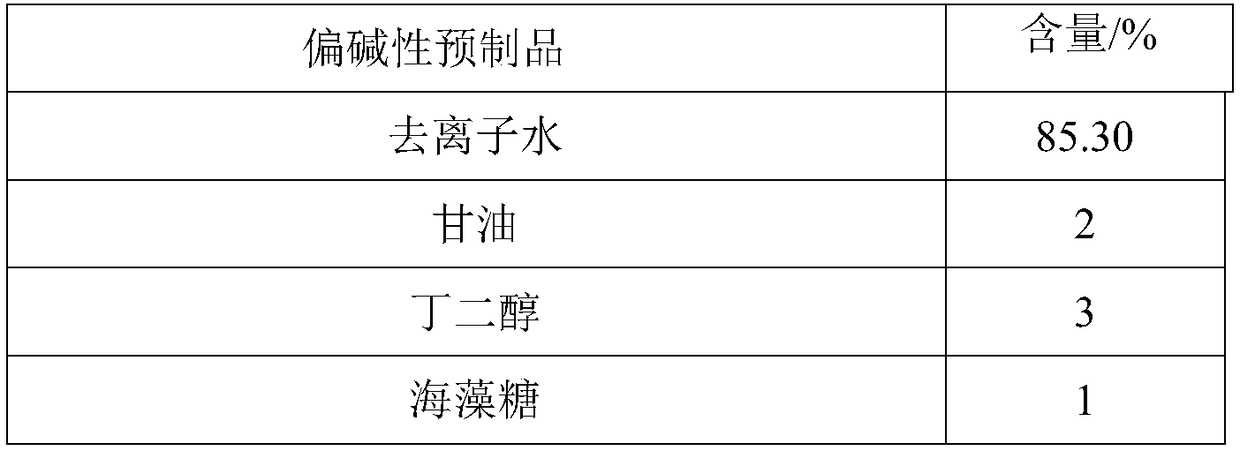

Packaging structure and packaging method

ActiveCN109835612AImprove adsorption capacityEasy to uncoverFlexible coversWrappersBiochemical engineeringSurface roughness

The invention relates to a packaging structure and a packaging method. The packaging structure comprises packaging bottom paper, a packaged object and an electrostatic protection film, wherein the packaged object is clamped between the package bottom paper and the electrostatic protection film; the portion, beyond the edge of the packaged object, of the electrostatic protection film makes contactwith the package bottom paper in an adhesion mode; and the surface roughness of the contact portion of the packaging bottom paper and the electrostatic protection film is less than 0.100 micron. According to the packaging structure and the packaging method in the embodiment, the packaging bottom paper has a low electrostatic effect, the packaging bottom paper has good adsorptivity to the electrostatic protection film, and the flatness is high. By means of biaxially-stretched synthetic paper and the electrostatic protection film, the product is effectively positioned and packaged, and the electrostatic protection film can be easily uncovered from the packaging bottom paper when the product is needed for use.

Owner:QUANZHOU LICHANG PLASTIC

Method for transferring graphene film

The invention discloses a method for transferring a graphene film, and belongs to the technical field of graphene film preparation. The method comprises the following steps: spin-coating a graphene-grown metal substrate with PMMA to form a first structural layer having a PMMA / graphene / metal substrate, etching away the metal, and performing cleaning multiple times; covering a target graphene-grownmetal substrate with a second structural layer having PMMA / graphene to form a third structural layer having a PMMA / graphene / target graphene / metal substrate, etching away the metal, and performing cleaning multiple times; and placing a fourth structural layer having PMMA / graphene / target graphene on the target substrate, performing heating, tearing off the second structural layer from the target graphene, and transferring the target graphene to the target substrate. The method for transferring a graphene film of the invention is simple to operate, and the transferred graphene film has a high transfer quality, a high cleanliness, a good integrity and no organic residue, and the PMMA / graphene can be repeatedly used as a support layer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

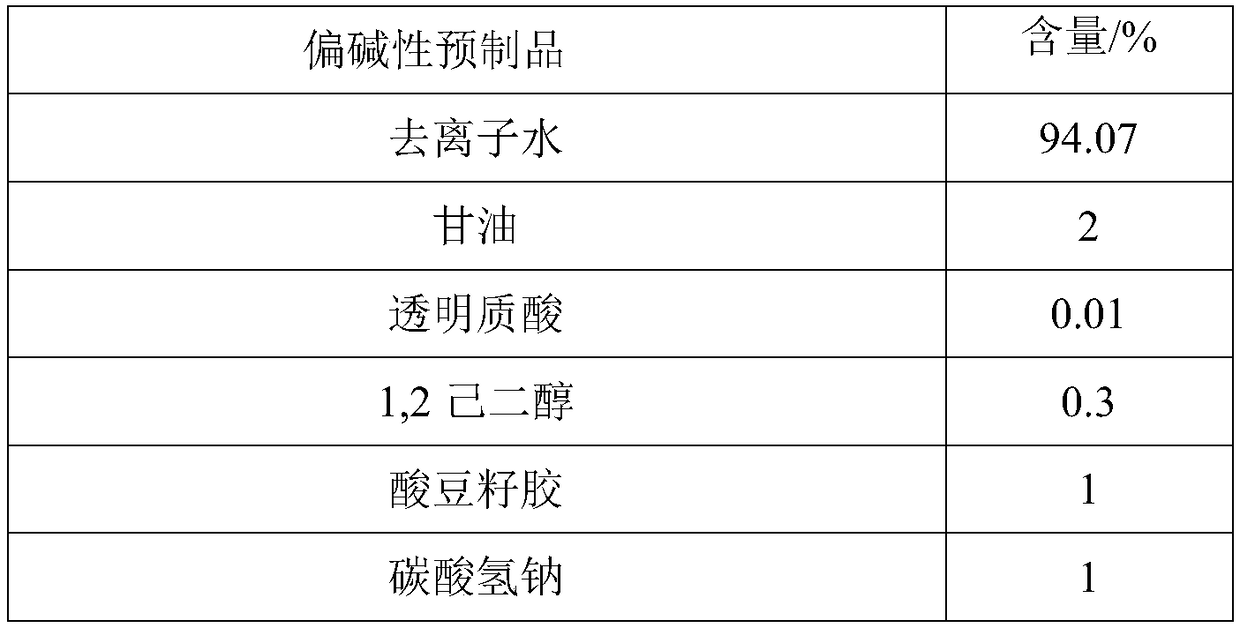

Two-agent carbonic acid foamed mask and preparation method and application method thereof

ActiveCN109077973AImprove antioxidant capacityImprove stabilityCosmetic preparationsToilet preparationsSodium bicarbonatePulsatilla Extract

The invention discloses two-agent carbonic acid foamed mask and a preparation method and application method thereof and is intended to provide a facial mask easy to clean, effective to foam, free of discoloring and good in whitening and moisturizing effect. The two-agent carbonic acid foamed mask comprises an acid prefabricated article and an alkaline prefabricated article; the acid prefabricatedarticle includes a polyol, xanthan gum, 1,2-hexanediol, citric acid, sodium citrate, polyglyceryl-10 laurate, inositol choline glycerophosphate, bisabolol, ginger root extract, opuntia streptacantha stem extract, Olea europaea fruit oil, and suitable deionized water; the alkaline prefabricated article includes a polyol, a humectant, 1,2-hexanediol, Tamarindus indica seed gum, sodium bicarbonate, dipotassium glycyrrhizinate, Zanthoxylum piperitum fruit extract, Chinese pulsatilla root extract, Usnea barbata extract, oligopeptide-1, mannitol, rice fermentation product filtrate, and suitable deionized water. The invention belongs to the technical field of cosmetics.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

Fluid dispenser

Owner:APTAR FRANCE SAS

A formaldehyde detection card for aquatic products

ActiveCN108896540AAvoid moisture pollutionEasy to useMaterial analysis by observing effect on chemical indicatorWater bathsBrick

The invention belongs to the technical field of formaldehyde detection, and discloses a formaldehyde detection card for aquatic products. The formaldehyde detection card includes a handheld area and adetection area. A plastic film is wrapped around the handheld area. A plurality of grooves are concavely arranged in the detection area. A separable plastic film is adhered to the surface of the detection area. The detection area is a colorless test paper soaked with a fehling reagent. According to the principle that formaldehyde can react with the fegling reagent, the fegling reagent immerses the detection card, and the formaldehyde can be indicated to be existed if the detection area turns brick red. The detection card is convenient in use and is suitable for popularization and application.Sodium hydroxide (NAOH) is embedded in a detector bar as a solid reagent, when copper sulphate and to-be-detected liquid are added to a sodium hydroxide embedding area, the dissolution heat release of the sodium hydroxide is used to achieve the water bath heating effect. The method is simple and rapid.

Owner:WUHAN POLYTECHNIC

Open window type visual packing box and manufacturing method thereof

PendingCN107640424AImprove shopping experienceAffect shelf lifeLamination ancillary operationsBox making operationsPulp and paper industryDesign pattern

The invention relates to an open window type visual packing box and a manufacturing method thereof. A closed visual window is arranged on the side face of a box body, a box body forming material comprises a first PE layer, a paper layer, a second PE layer and a PE film from outside to inside through uncovering and covering, the first PE layer is formed by laminating a film on the outer surface ofthe paper layer, the second PE layer is formed by laminating a film on the inner surface of the paper layer, the second PE layer and the PE film are compounded through a PE bonding layer, and an opening of the visual window is correspondingly formed in the first PE layer, the paper layer and the second PE layer. The manufacturing method comprises the steps that a film is laminated on the smooth surface of the paper layer to form the first PE layer, and a film is laminated on the coarse surface of the paper layer to form the second PE layer; the shape and the position of the visual window are designed; layout design patterns are printed, and an insulation adhesive layer is printed; the film laminating paper and the PE film are compounded; transverse cutting is performed; die cutting is performed; box pasting is performed; the top and bottom of the box are sealed. The content of the packing box is convenient to observe, the quality is reliable, leakage is prevented, and edible safety isensured.

Owner:SHANGHAI JIELONG YONGFA PRINTING & PACKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com