Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid temperature overshoot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid cooling cooling-down type thermostatic bath system and intelligent temperature control method

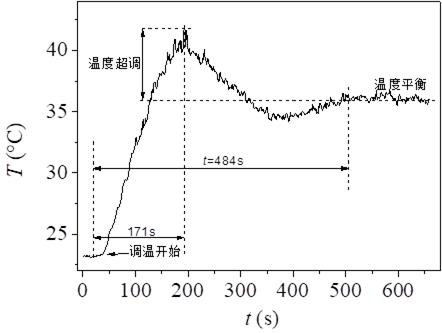

InactiveCN101219403AShorten the timeIncrease freedomWater/sand/air bathsTemperature controlEngineering

The invention relates to a liquid cooling temperature thermostatic bath system and an intelligent temperature control method thereof, comprising a cooling water tank and a cooling liquid, a liquid bath and a working liquid, and an intelligent temperature controller. The cooling water tank is provided with a water tank temperature sensor and a refrigerator, an electrical heater connected with an electrical heating executor, and a water cooler, a stirrer, a liquid bath temperature sensor, and a water inlet pipe and a water outlet pipe of the water cooler that are connected with the cooling water tank; the other end of the water inlet pipe is connected with a cooling water pump, a signal input end of the intelligent temperature controller is respectively connected with the temperature sensor of the cooling water tank and the temperature sensor of the liquid bath, while the output end is respectively connected with the electrical heating executor, a stirrer engine, the cooling water pump and the refrigerator. The system and the method can drop the temperature at a speed higher than the natural cooling by near 20 times through forced liquid cooling, and can effectively avoid the over regulating of temperature and reduce the negative impact of thermal inertia, thus greatly shortening the precision temperature controlling process and cutting down power consumption.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

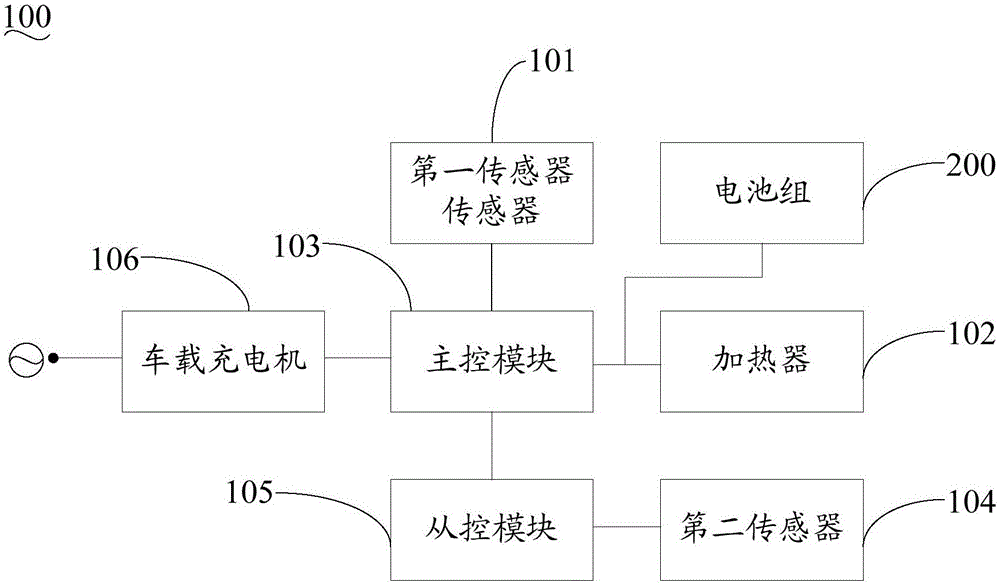

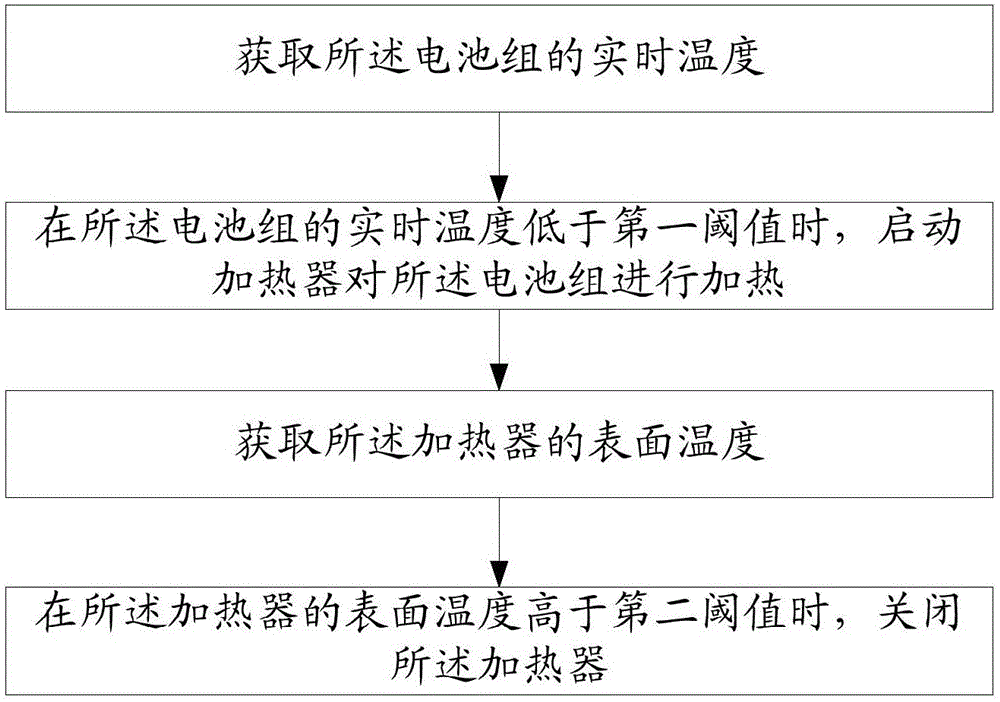

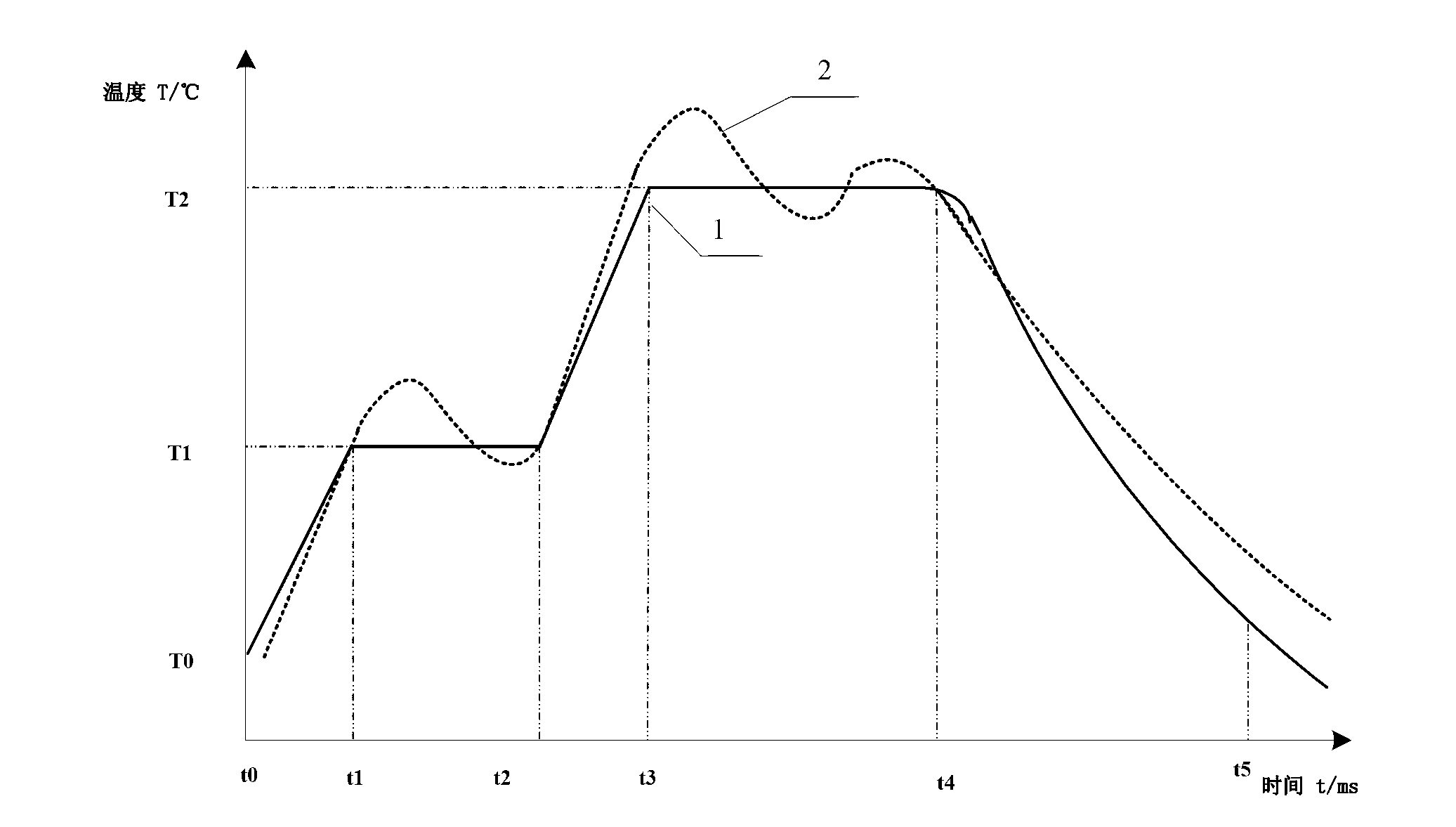

Battery charging protective device and method

ActiveCN106450519AAvoid temperature overshootPrecise regulationSecondary cells charging/dischargingTemperature controlBattery charge

The invention relates to a battery charging protective device and method; surface temperature of a heater is monitored through a second sensor; the heater may be stopped if the surface temperature of the heater is higher than a second threshold. Compared with the methods where a heater is started and stopped only in direct accordance with the temperature of a battery pack, the above method is effective in preventing excessive battery pack temperature due to temperature over-adjustment caused by heat transfer delay. Therefore, the above battery charging protective device and method enable the start and stop of the heater to be controlled precisely according to the temperature of the heater itself, temperature over-adjustment of the heater is avoided, temperature control is more precise, and safety is guaranteed.

Owner:湖南容创科技有限公司

Heating control method and heating cooking device

ActiveCN107272768AStable temperaturePlateau temperature zoneTemperatue controlEngineeringFuzzy adaptive control

The embodiments of the invention provide a heating control method and a heating cooking device, which belong to the control field of heating. The method comprises the following steps: in a first heating stage, the heating tube of the heating cooking device performs heating continuously under control, wherein the first heating stage is a heating stage in which the temperature in the cavity of the heating cooking device does not exceed a first preset temperature; in a second heating stage, the heating tube performs heating periodically under control, wherein the first heating stage is a heating stage in which the temperature in the cavity exceeds the first preset temperature but does not exceed a second preset temperature; and in a third heating stage, the heating tube performs heating under control of a fuzzy adaptive control mode, wherein the third heating stage is a heating stage in which the temperature in the cavity exceeds the second preset temperature but does not exceed a target temperature. The phenomenon of temperature overshoot in the heating process of the heating cooking device can be avoided.

Owner:MIDEA GRP CO LTD +1

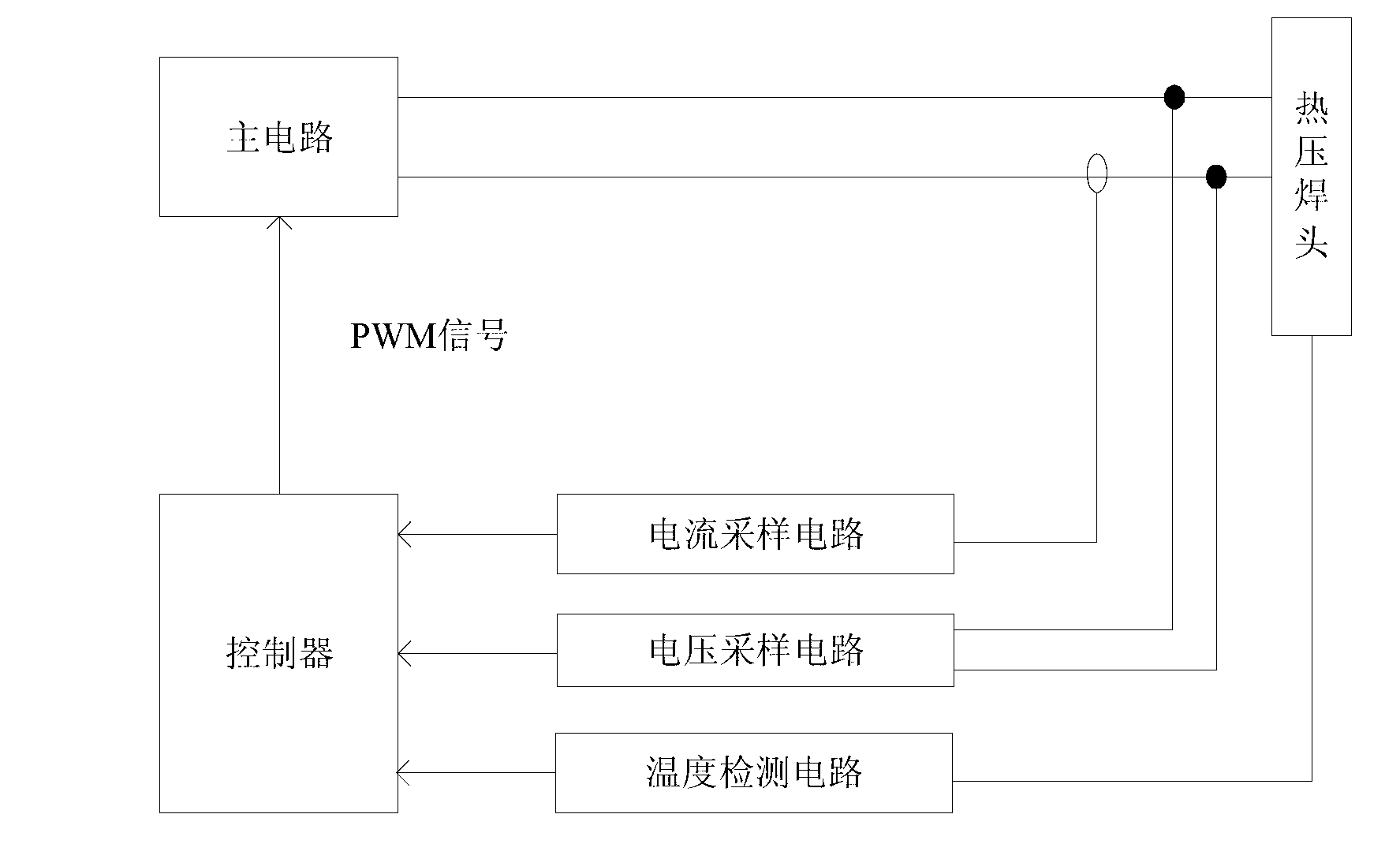

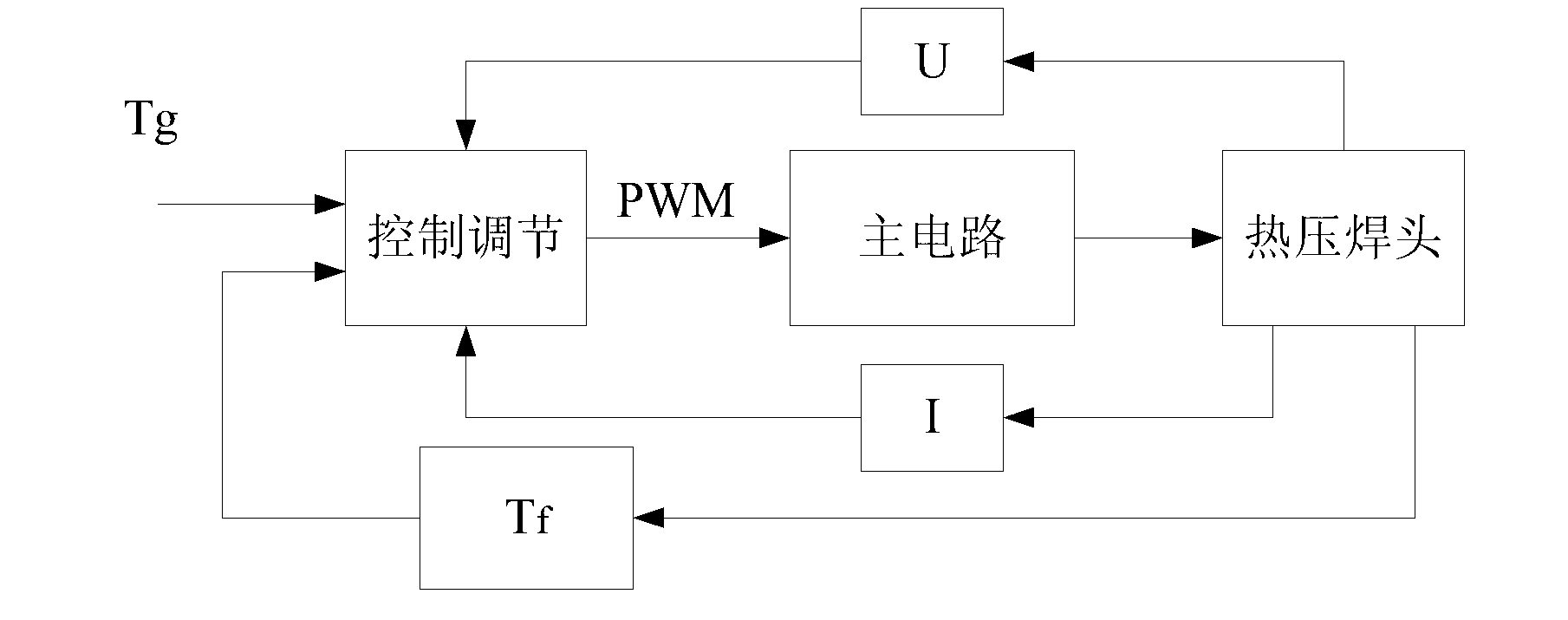

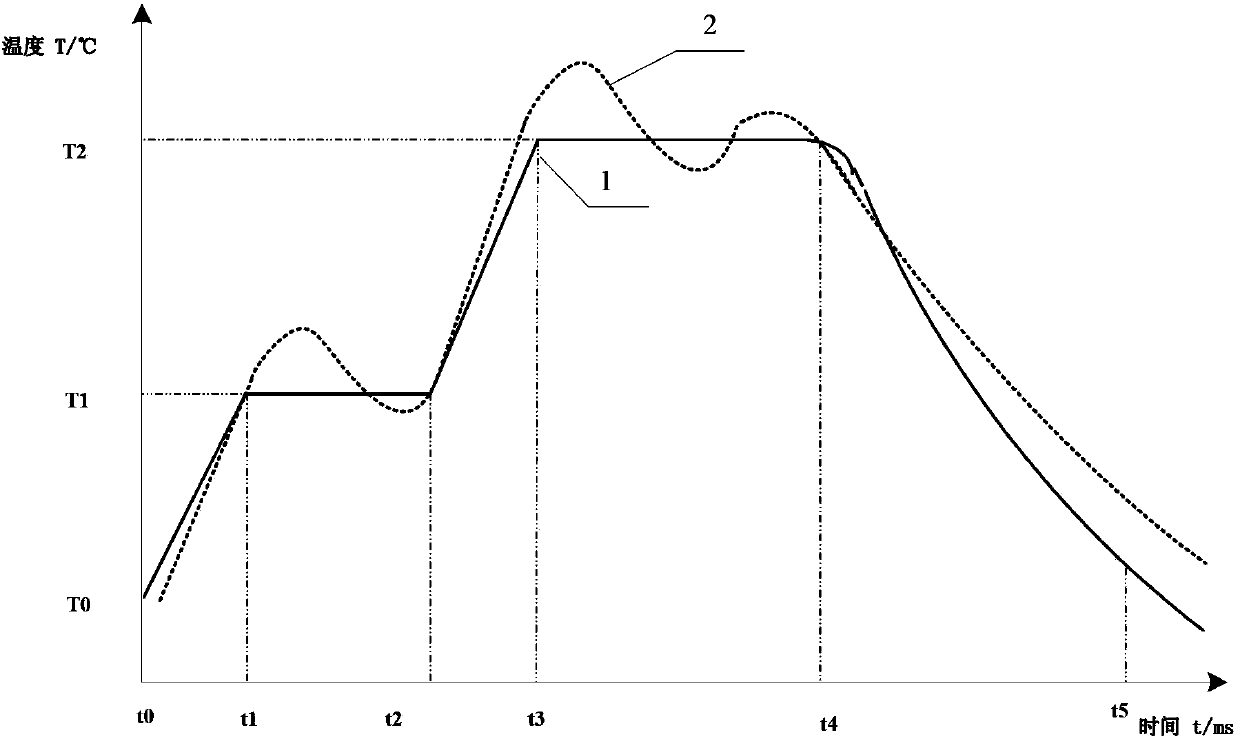

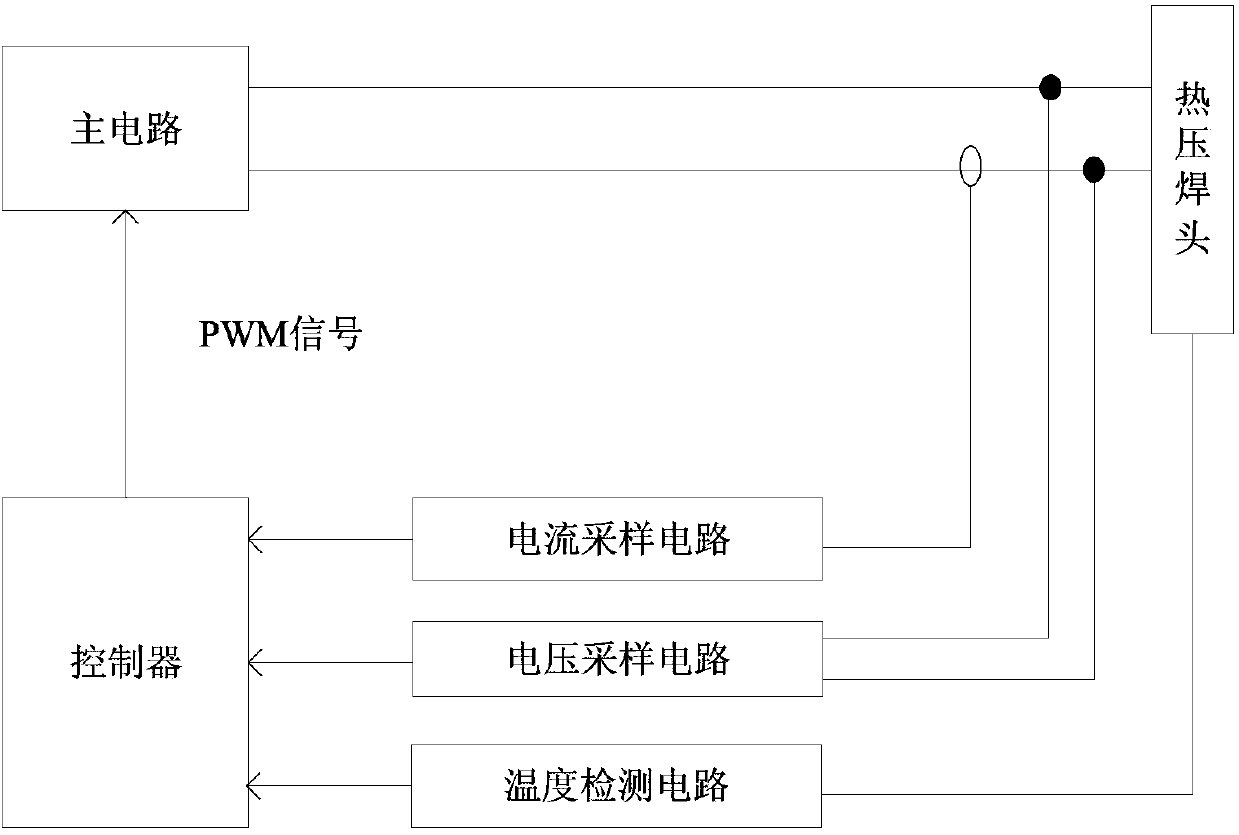

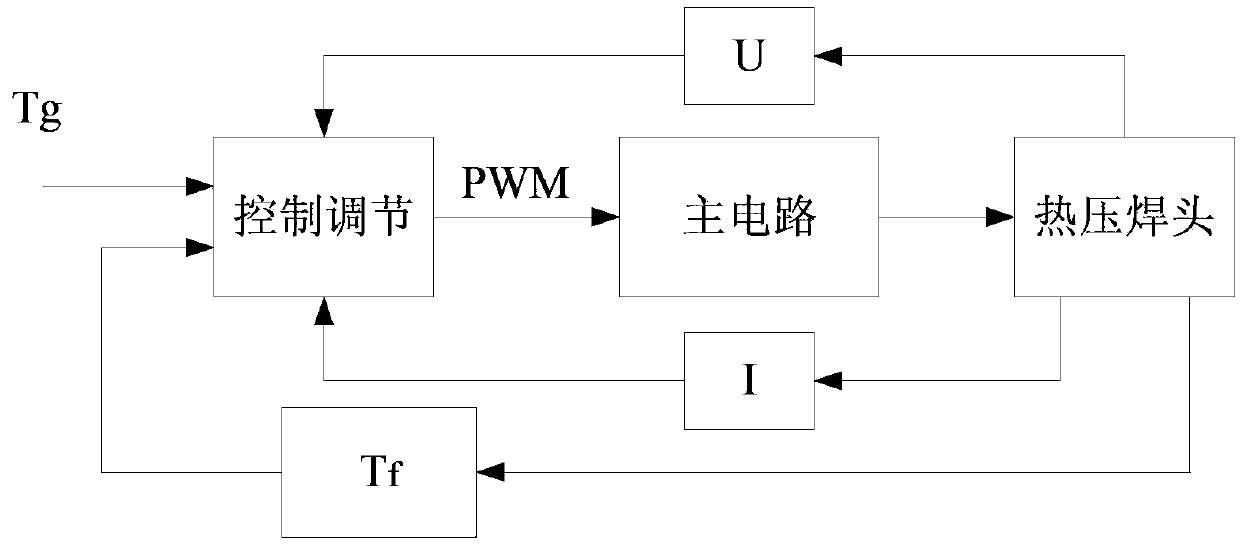

Thermal compression bonding power source

InactiveCN103264244AAccurate identificationAvoid temperature overshootWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectromotive force

A thermal compression bonding power source comprises a main circuit, a controller, a current sampling circuit, a voltage sampling circuit and a temperature detection circuit, wherein the main circuit outputs a direct current / a pulse current to a thermal compression bonding head, and the current sampling circuit, the voltage sampling circuit and the temperature detection circuit are respectively connected to the thermal compression bonding head. The main circuit adjusts the output current according to a PWM signal. The current sampling circuit collects the output current of the main circuit and obtains a feedback current value. The voltage sampling circuit collects voltages of two ends of the thermal compression bonding head and obtains a feedback voltage value. The temperature detection circuit detects the temperature of the welding position of the thermal compression bonding head and obtains a thermal electromotive force signal. The controller is used for controlling the temperature process of the thermal compression bonding head according to a preset temperature curve, obtaining a feedback temperature value according to the thermal electromotive force signal, and controlling a duty ratio of the PWM signal according to the feedback current value, the feedback voltage value and the feedback temperature value. According to the thermal compression bonding power source, identification for temperature sensing lag time is achieved, feed forward control over the temperature is conducted according to the lag time, the phenomenon of temperature overshooting caused by the temperature feedback lag is avoided, and stability of the temperature control is improved.

Owner:广州市精源电子设备有限公司 +1

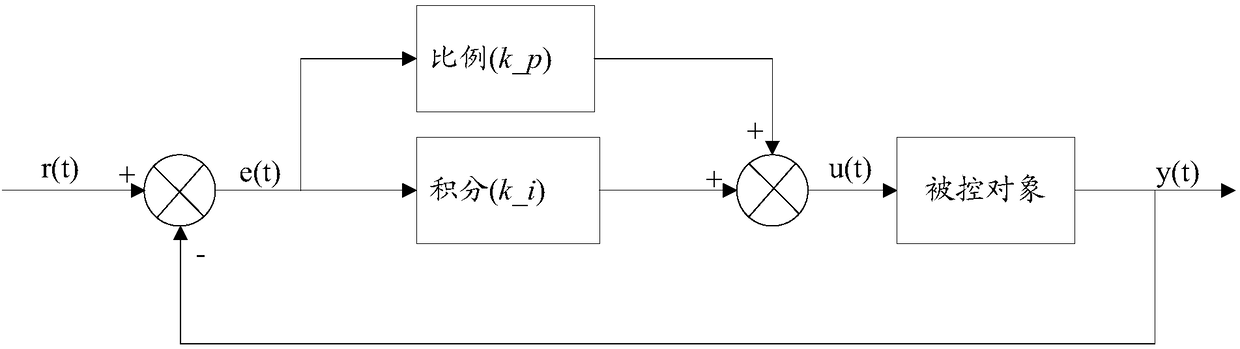

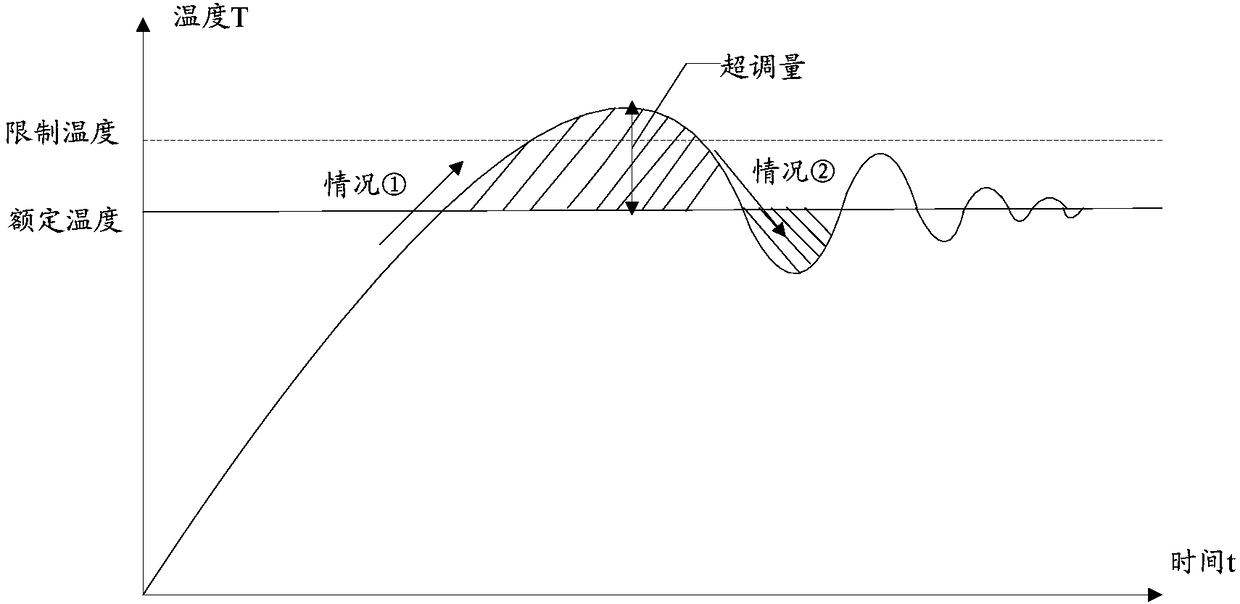

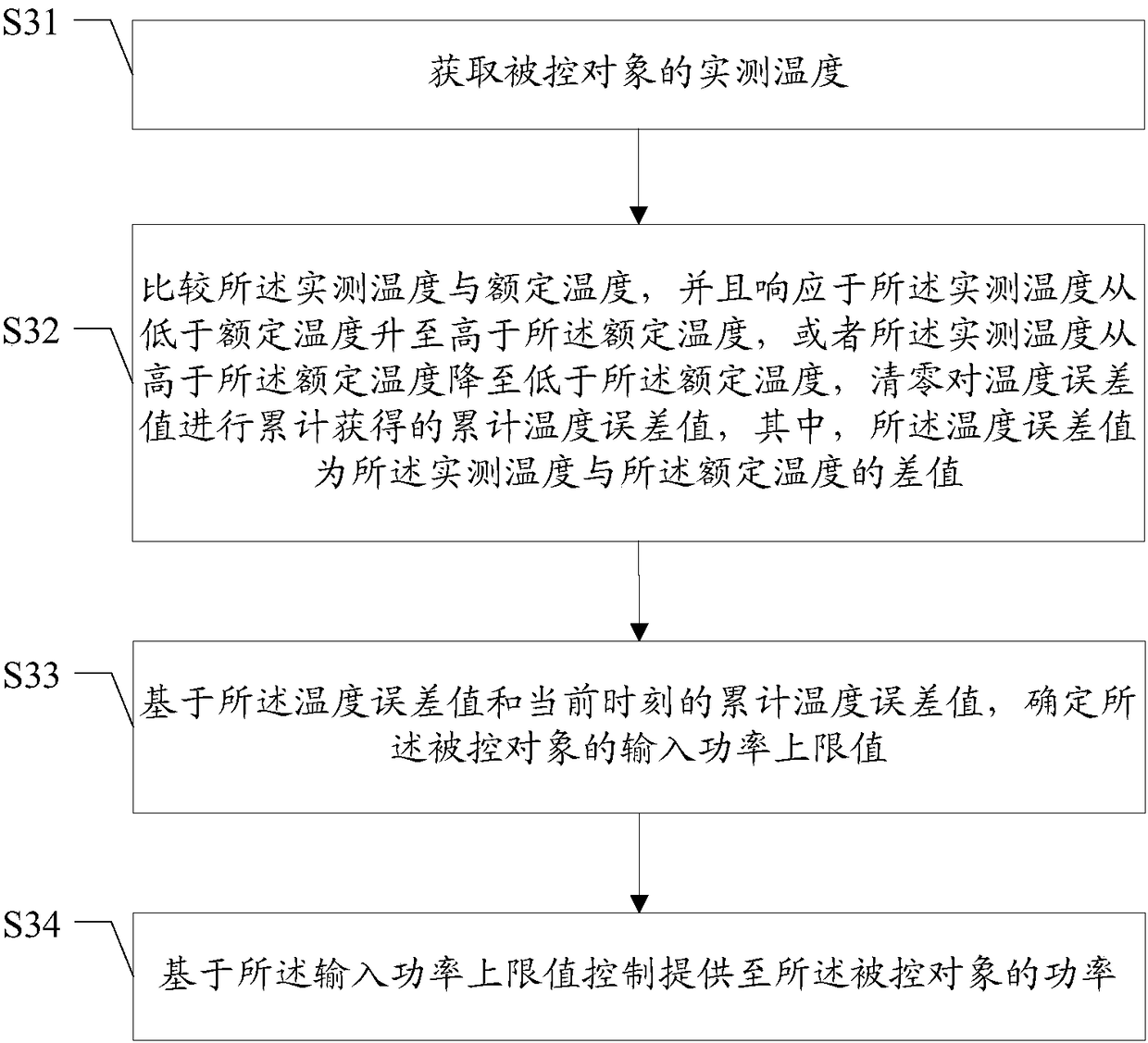

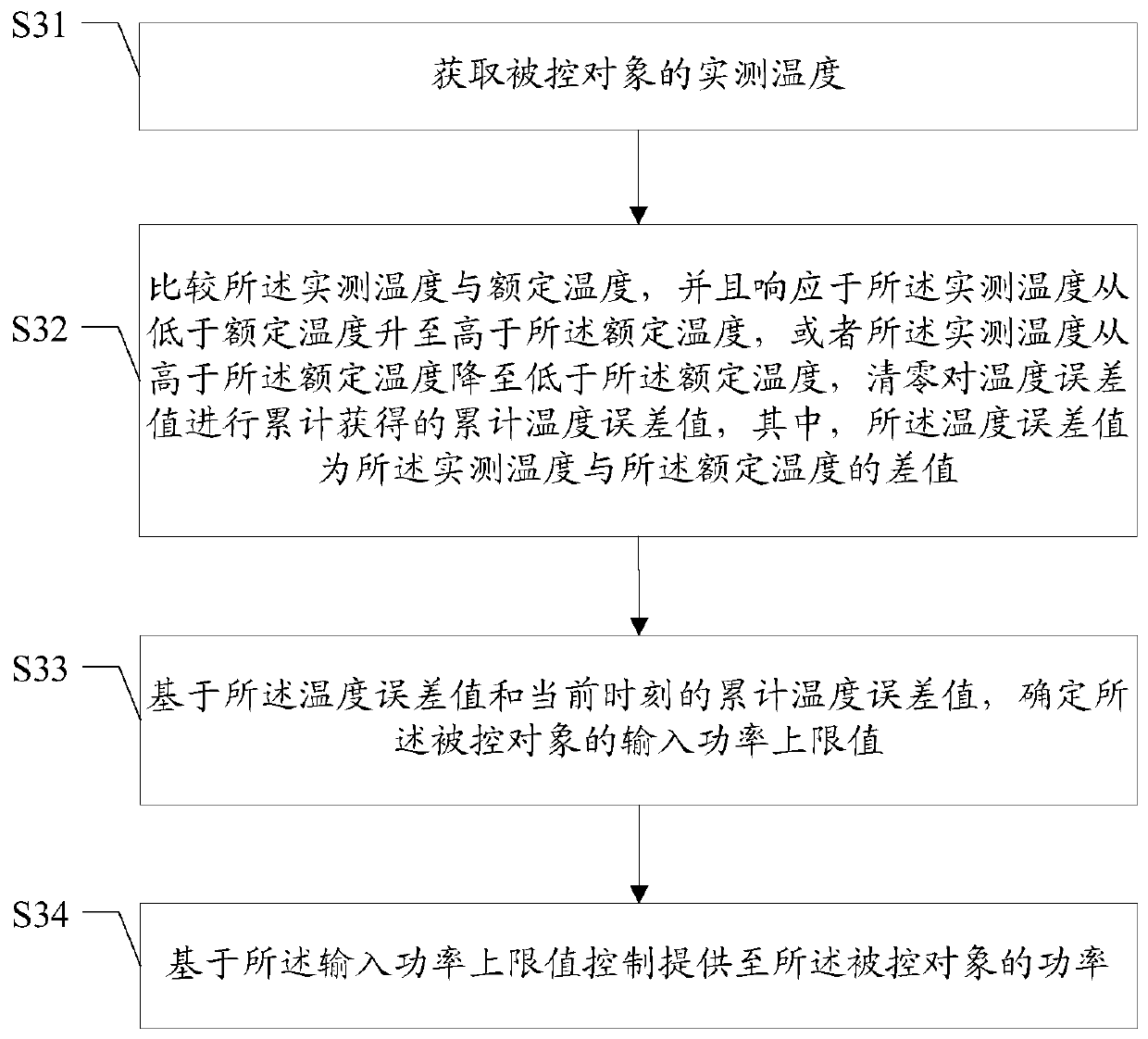

A power control method and device

ActiveCN108268082AStable temperatureAvoid temperature overshootElectric variable regulationControl powerEngineering

The invention provides a power control method and device. The method comprises the steps of: acquiring an actual measurement temperature of a controlled target; comparing the actual measurement temperature and a rated temperature, and, in response to the increase of the actual measurement temperature from a value lower than the rated temperature to a value higher than the rated temperature or thereduction of the actual measurement temperature from a value higher than the rated temperature to a value lower than the rated temperature, resetting an accumulative temperature error value acquired by accumulating temperature error values, wherein the temperature error values are the difference values between the rated temperature and the actual measurement temperature; based on the temperature error values and the accumulative temperature error value at the current moment, determining the input power upper limit value of the controlled target; controlling power provided for the controlled target based on the input power upper limit value. According to the technical solution, the temperature of a controlled target can be stabilized around a rated temperature faster, so that the performance of the controlled target can be maximized while the controlled target is protected.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

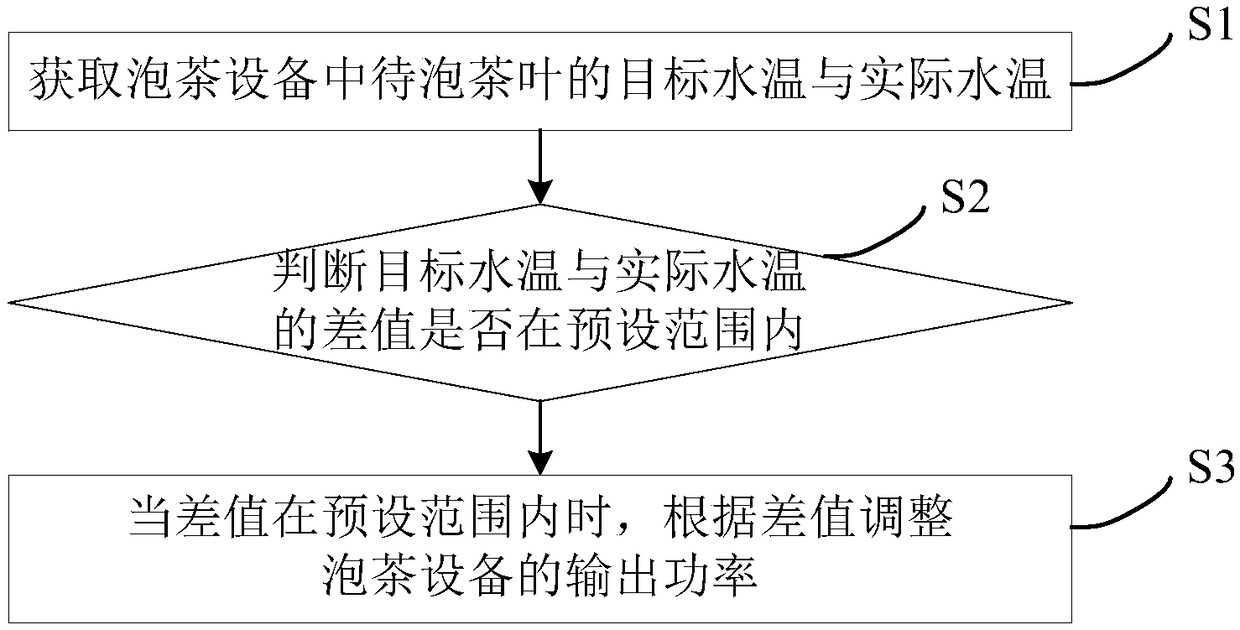

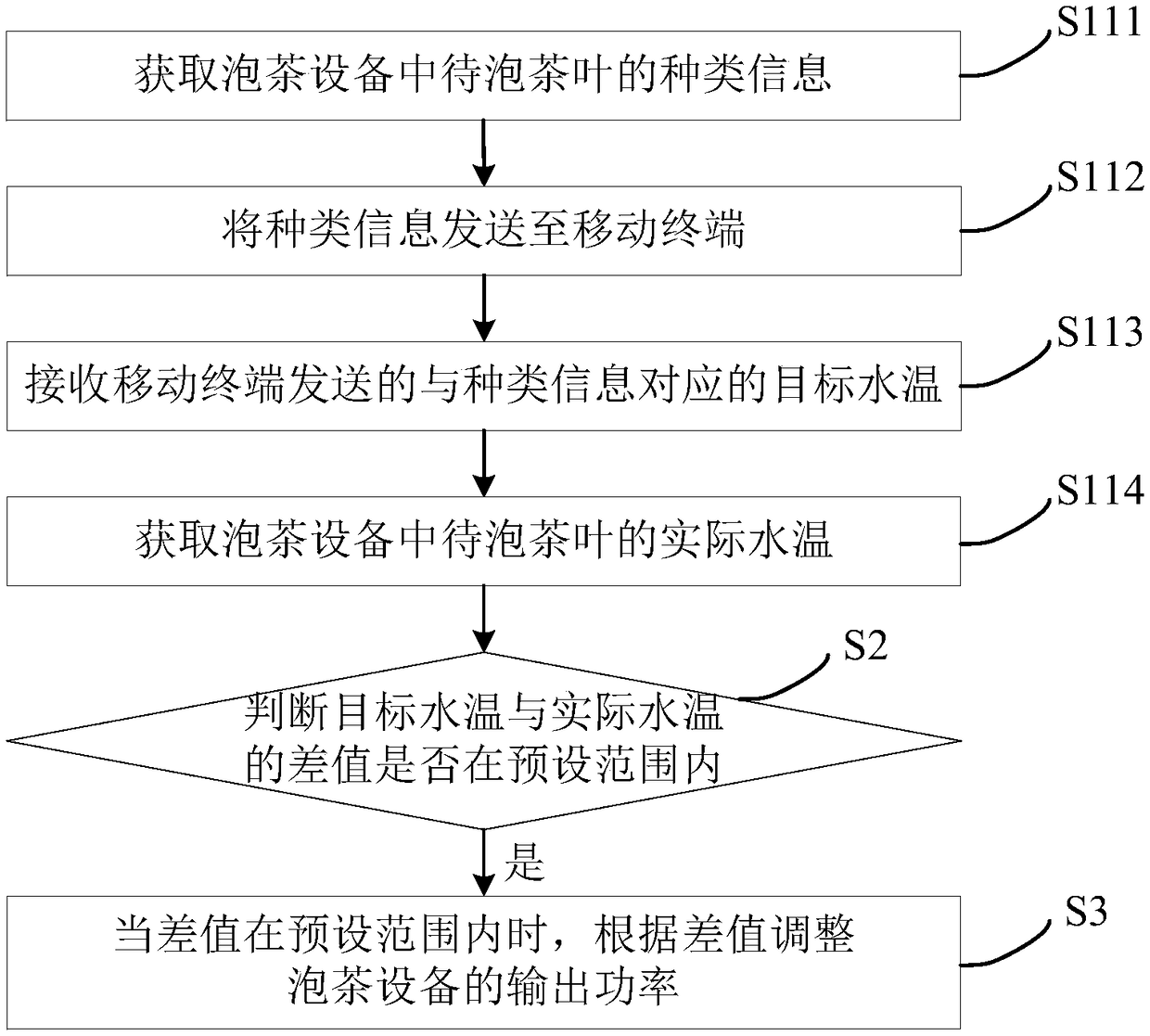

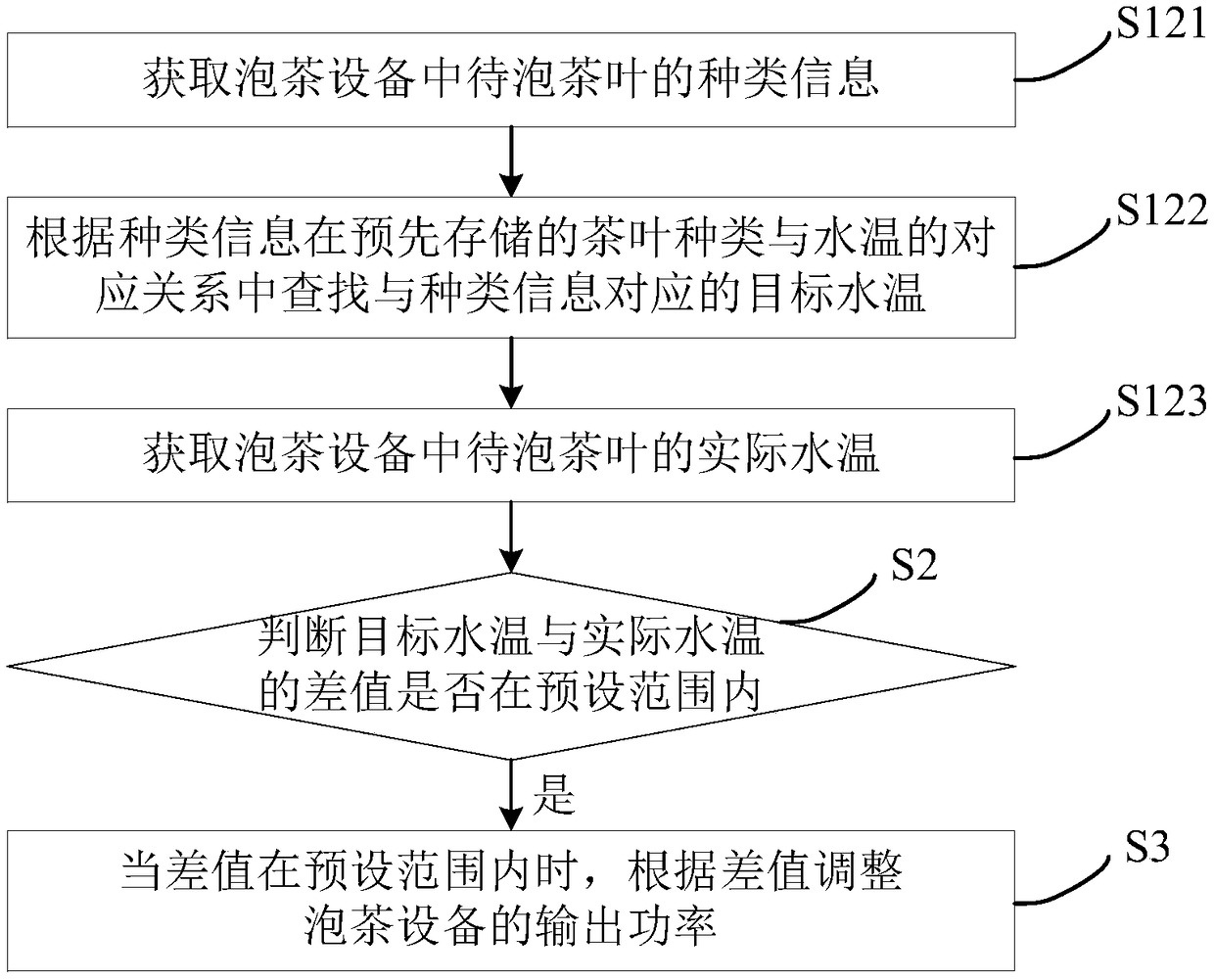

Tea making equipment control method and device, tea making equipment and readable storage medium

InactiveCN109288399AAvoid temperature overshootFragrance of teaBeverage vesselsProcess engineeringEngineering

The invention provides a tea making equipment water temperature control method and device, tea making equipment and a readable storage medium. The method includes the following steps: obtaining a target water temperature and an actual water temperature of to-be-brewed tea in the tea making equipment; determining whether a difference value between the target water temperature and the actual water temperature is within a preset range; and adjusting output power of the tea making equipment according to the difference value when the difference value is within the preset range. The method firstly obtains the difference value between the target water temperature and the actual water temperature. When the difference value is within the preset range, the actual water temperature is indicated to beclose to the target water temperature. The output power of the tea making equipment is adjusted according to the difference value so as to control a water temperature of the tea making equipment. Therefore, temperature overshoot when the tea making equipment is heated to near an appropriate temperature is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

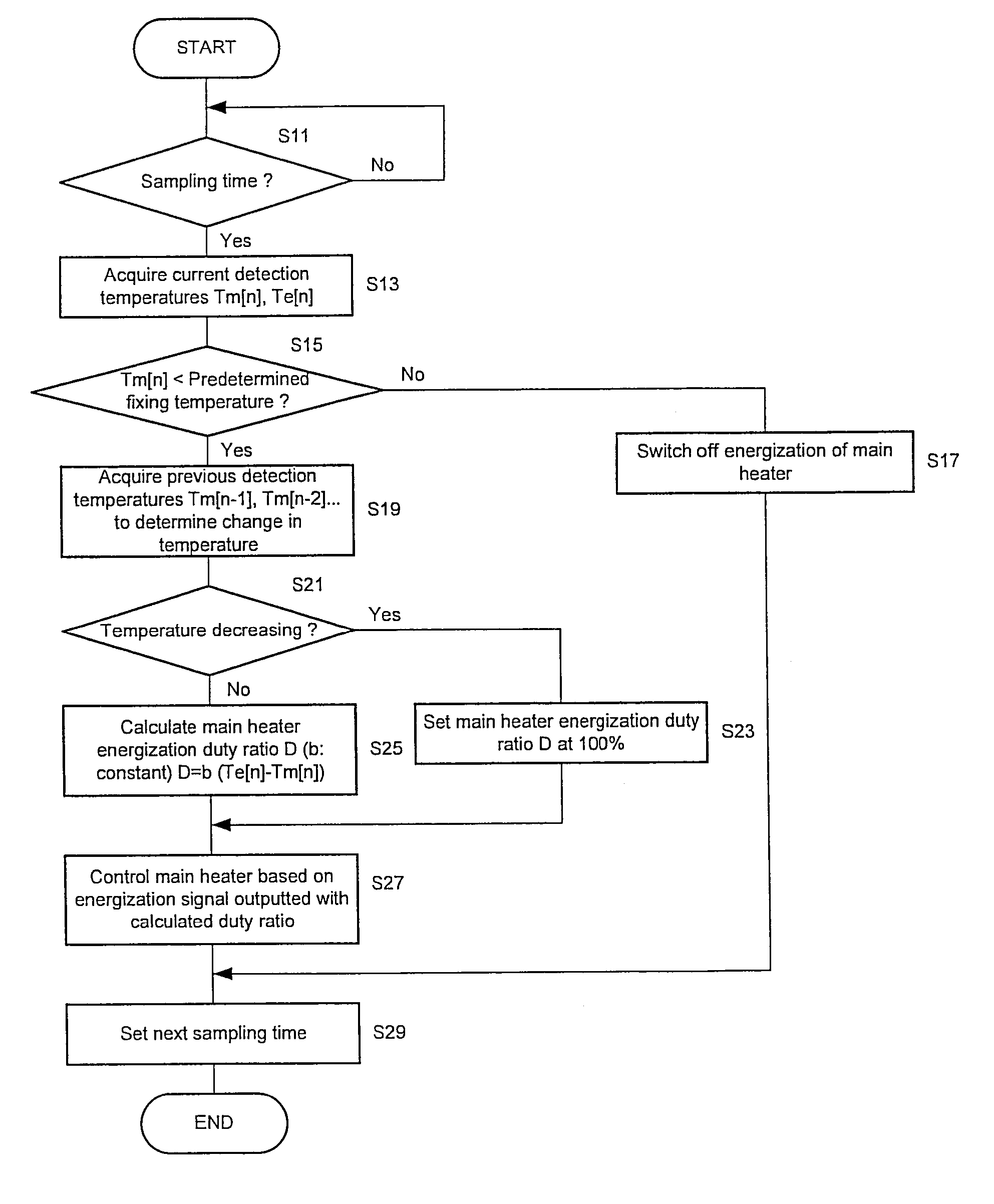

Fuser apparatus, image forming apparatus including the fuser apparatus, and fuser controlling method

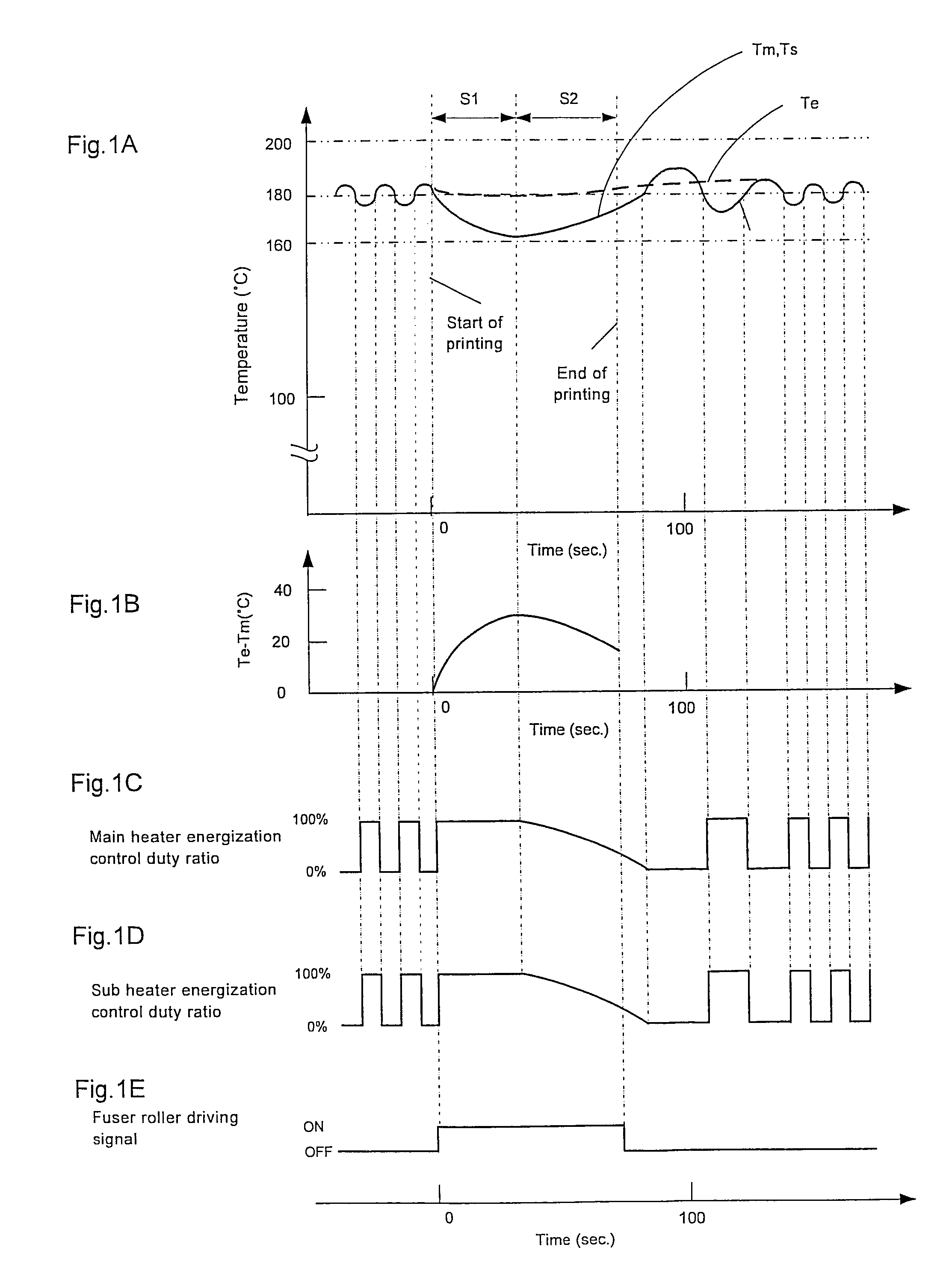

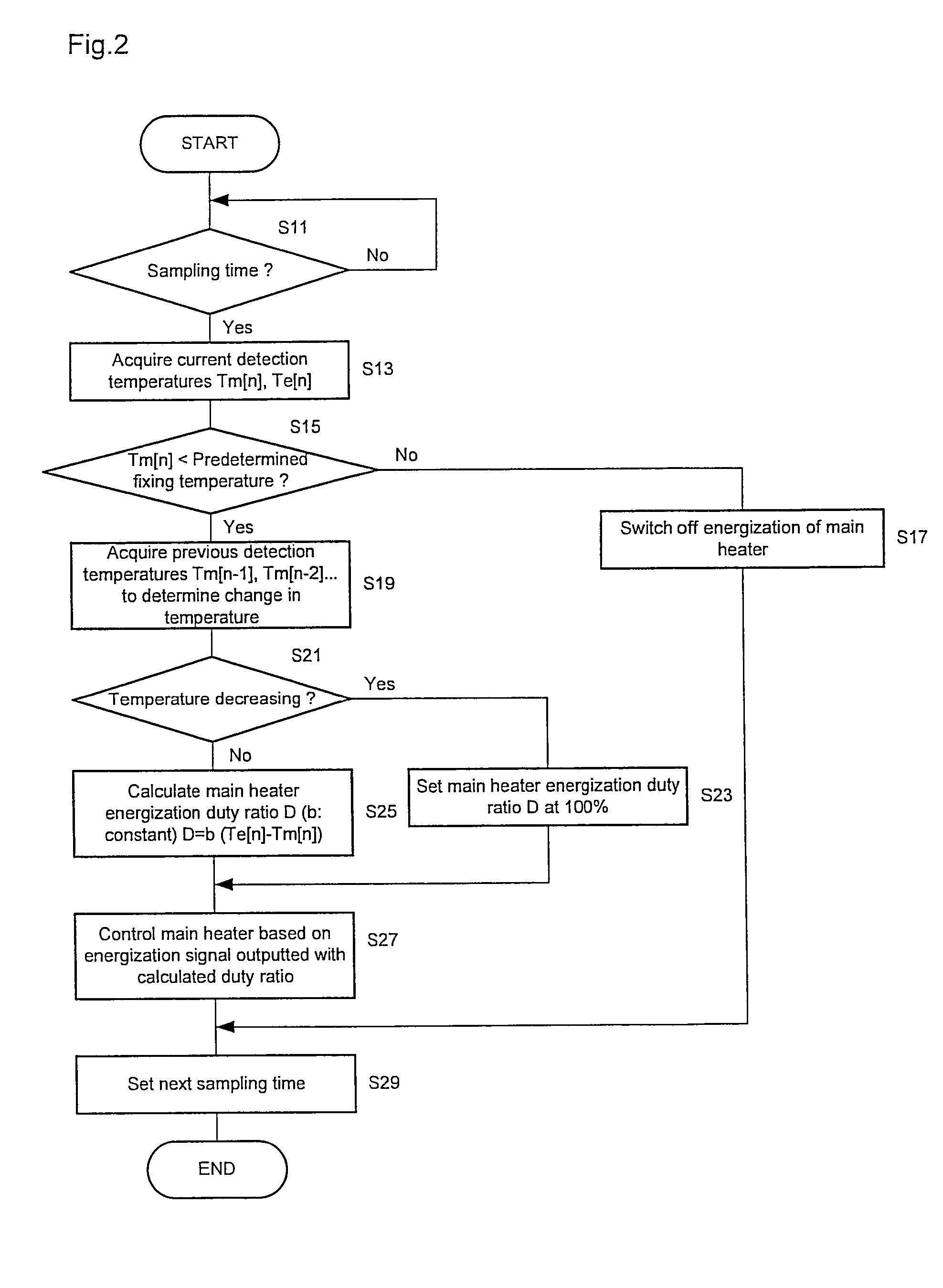

InactiveUS7636527B2Extended service lifeImprove efficiencyElectrographic process apparatusImage formationEngineering

A fuser apparatus including: a fuser member having an endless contact surface to be brought into contact with each of successively transported recording media and a non-contact surface and being arranged to apply heat to the recording medium from the contact surface to fix a toner on the recording medium; a heating member energized to supply heat to the contact surface; a contact surface temperature detecting member for detecting a temperature of the contact surface; a non-contact surface temperature detecting member for detecting a temperature of the non-contact surface; and an energization controlling member for controling energization power of the heating member; wherein the energization controlling member controls the heating member energization power so that the heating member energization power is reduced as a difference between the non-contact surface temperature and the contact surface temperature decreases.

Owner:SHARP KK

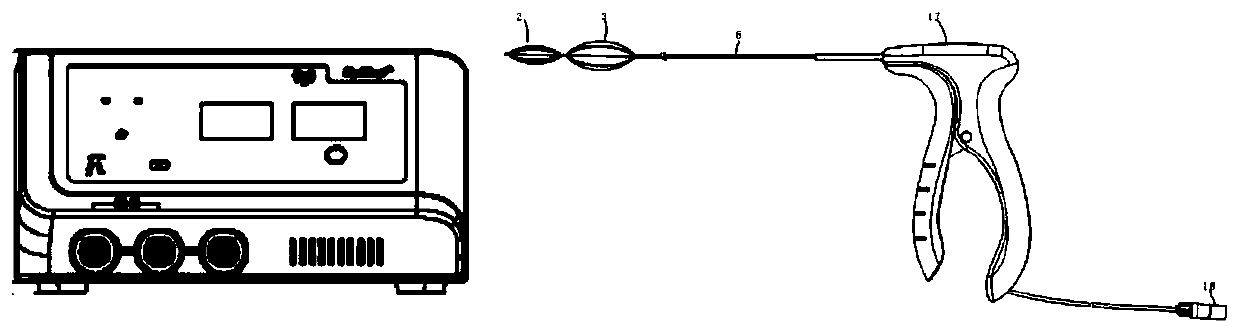

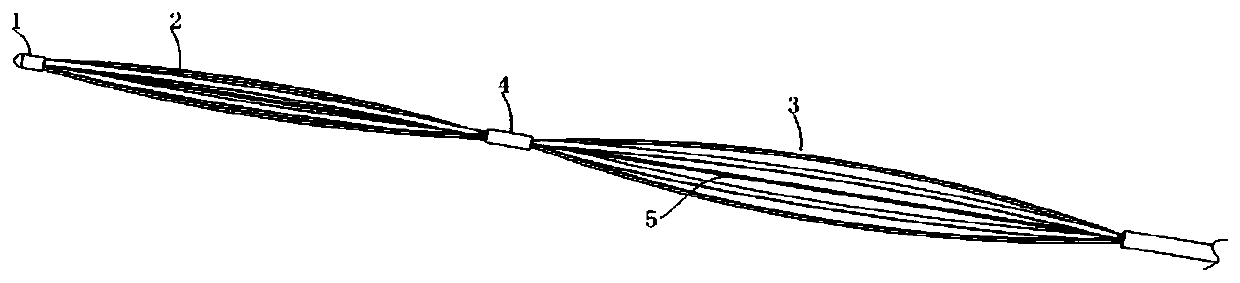

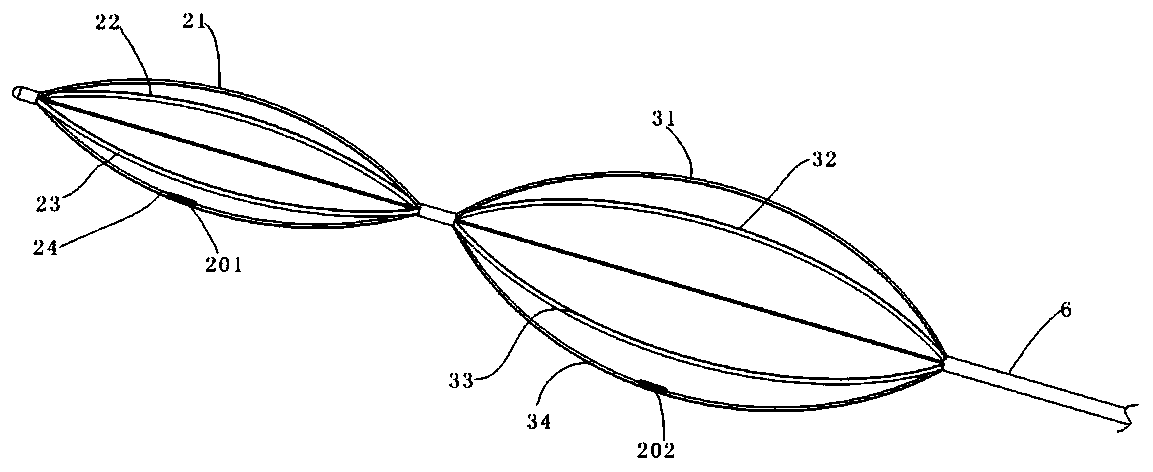

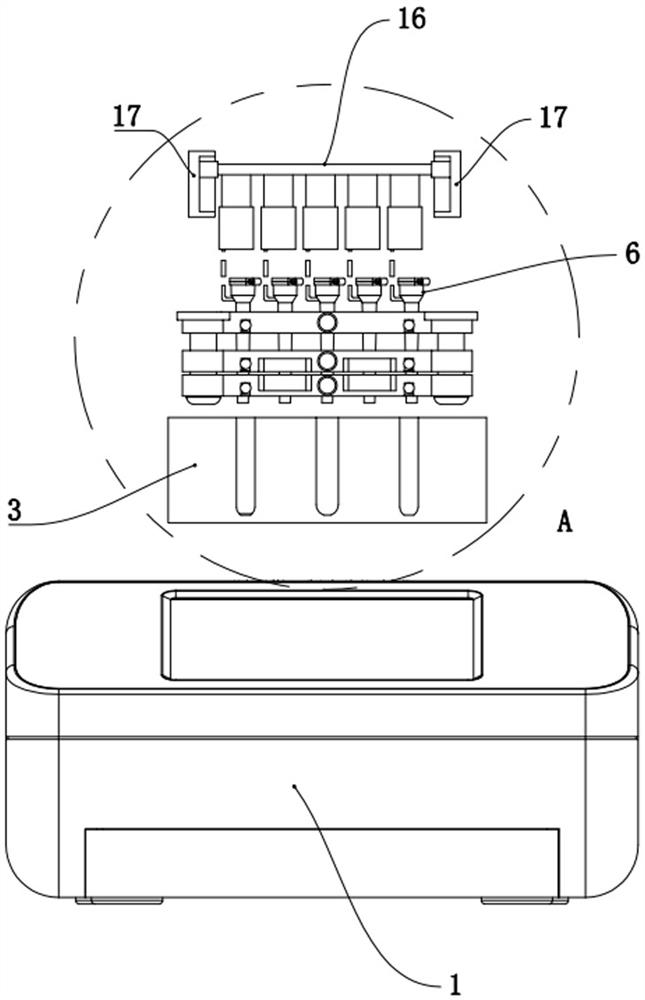

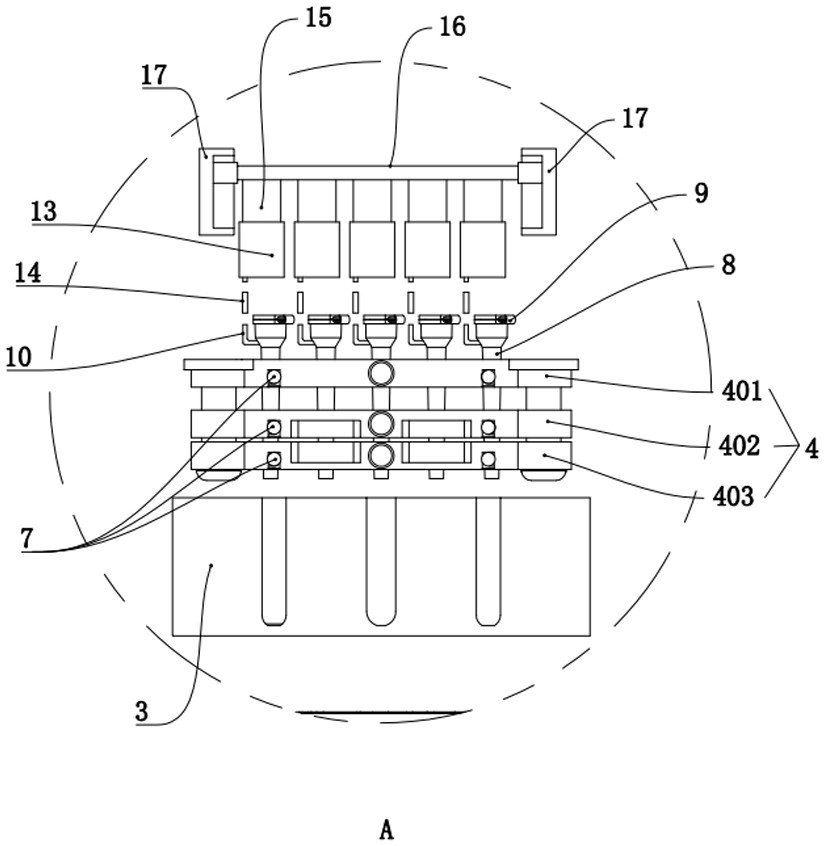

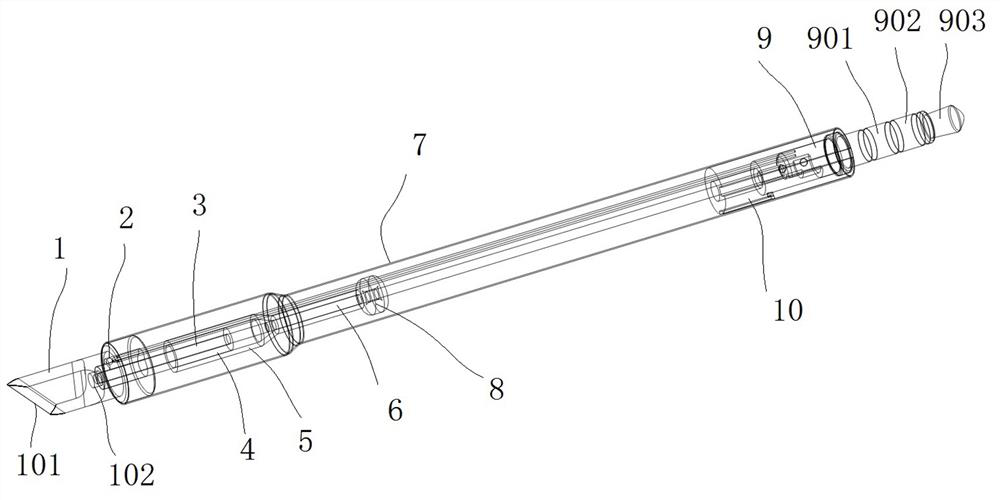

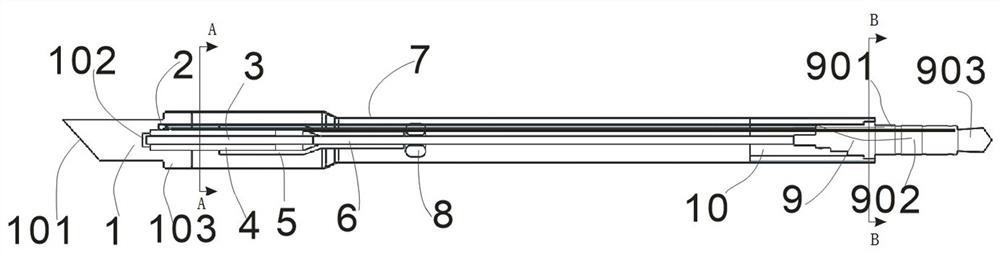

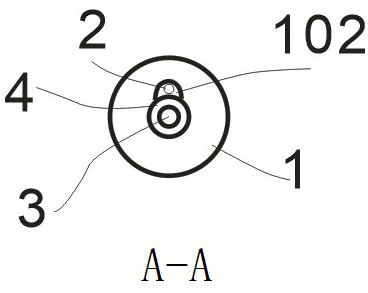

Multi-pole ablation device

ActiveCN109793568AEnsure safetyGuaranteed validityDiagnosticsInstrument handpiecesRadio frequency energyRadiofrequency ablation device

The invention discloses a radio-frequency ablation instrument and a multi-pole ablation device with the same. The radio-frequency ablation instrument is capable of judging ablation effectiveness according to one or more conditions of an impedance decrease value, an impedance change rate, impedance change rate changes or impedance change from decreasing to increasing. By adoption of a sectional control method and dynamic smoothing for regulating radio-frequency output power, ablation temperature is controlled, quick temperature rise of ablation tissues is avoided, and radio-frequency output power smooth changes in an ablation process is guaranteed. The radio-frequency ablation instrument is further provided with a special protection mechanism for preventing repeated ablation, the temperature of a to-be-ablated part is detected in each-time ablation application, and ablation is not started if the temperature of a to-be-ablated part is higher than 40-60 DEG C. The radio-frequency ablationinstrument and the multi-pole ablation device with the same can be used for sending direct current, alternating current and radio-frequency energy to lesions and used for treatment of lung diseases.

Owner:SYMAP MEDICAL (SUZHOU) LIMITED

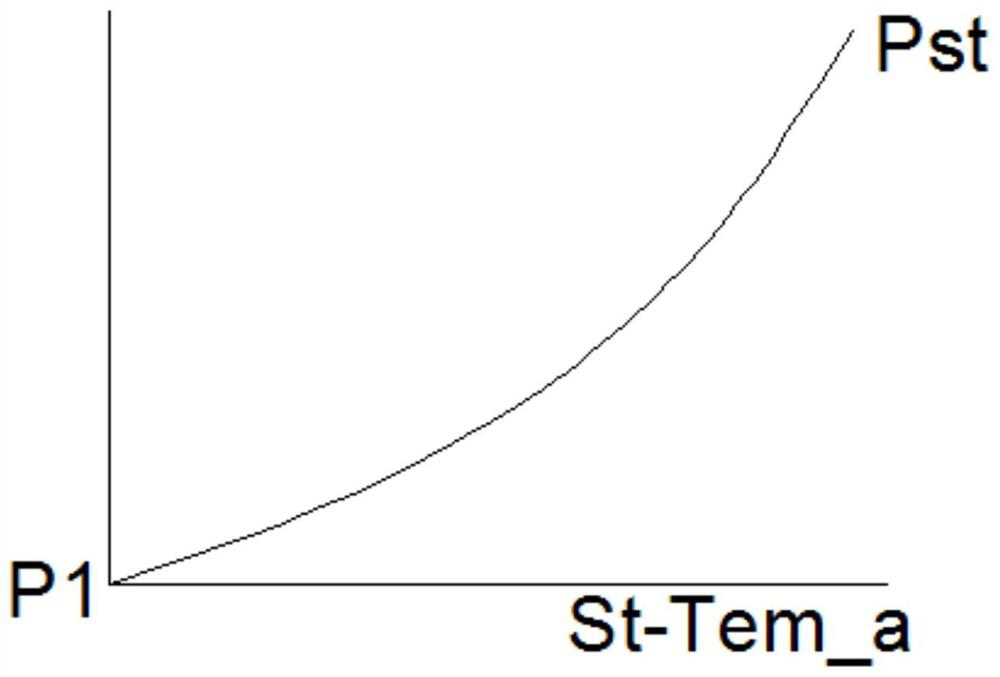

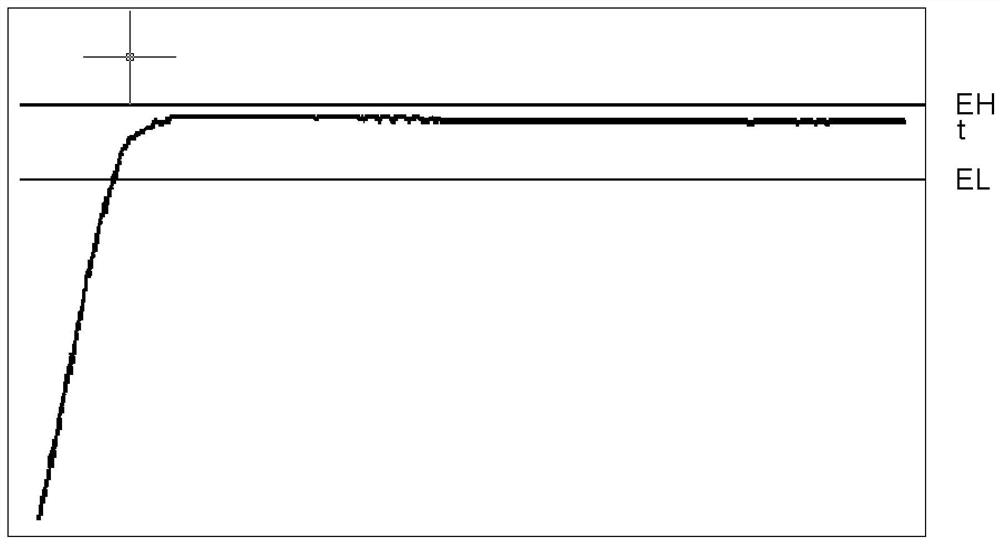

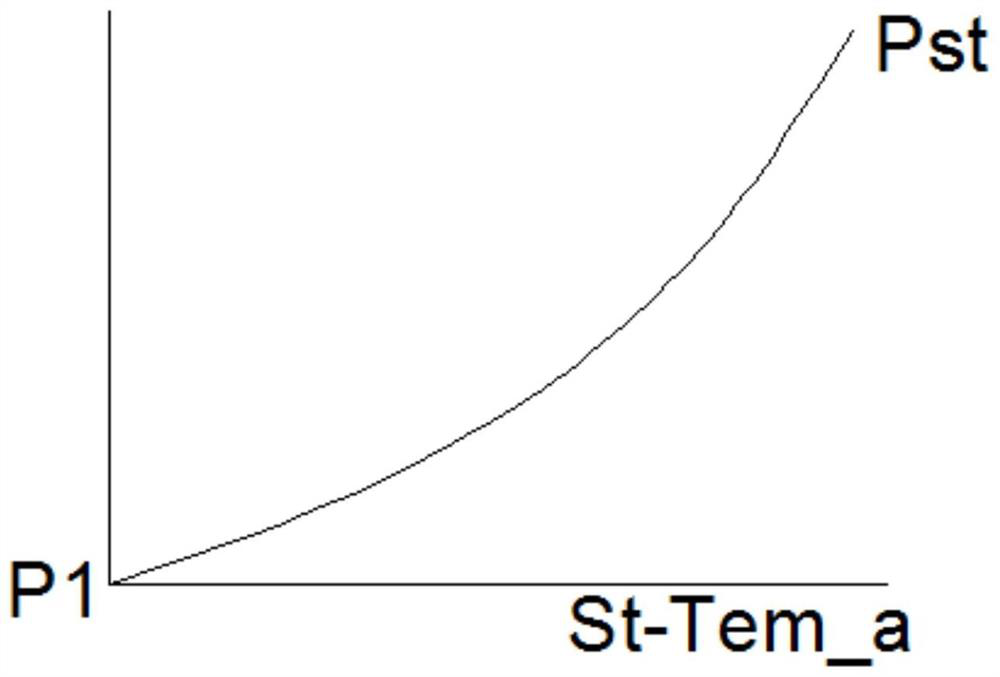

Temperature control method of CO2 incubator

ActiveCN112596561AReduced stabilityControl UniformityAuxillary controllers with auxillary heating devicesTemperature controlControl power

The invention discloses a temperature control method of a CO2 incubator. The temperature control method comprises the following steps that: a temperature control deviation value er is calculated according to a set temperature st and a real-time temperature t in the CO2 incubator; and the output power of a heating element is controlled by adopting the CO2 incubator temperature control method, and the temperature t in the CO2 incubator is controlled within an accurate range. According to the method, temperature overshoot is effectively avoided, the stability and uniformity of the box temperatureare effectively controlled, it is guaranteed that different cells can be cultured under different environment conditions, the control error of the CO2 incubator can be kept smaller than or equal to + / -0.2 DEG C in the environment of 15-35 DEG C and at the set temperature of 30-50 DEG C, and when the set value is 37 DEG C and the environment temperature is 23 DEG C, the control precision can be ensured to be less than or equal to + / -0.1 DEG C.

Owner:冰山松洋生物科技(大连)有限公司

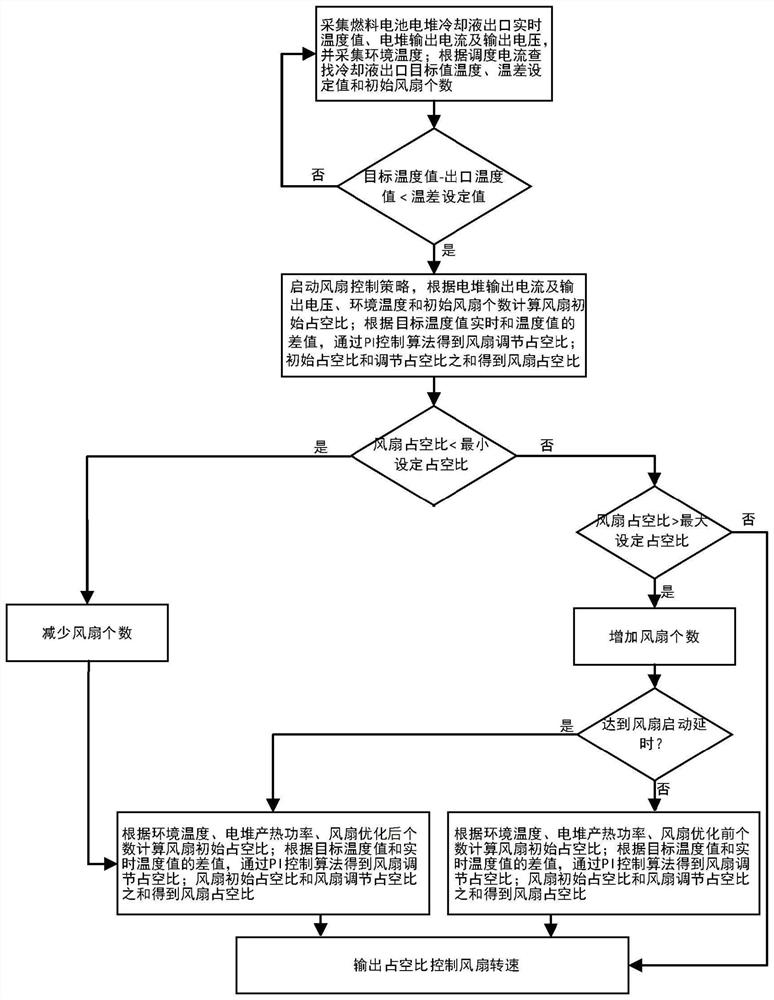

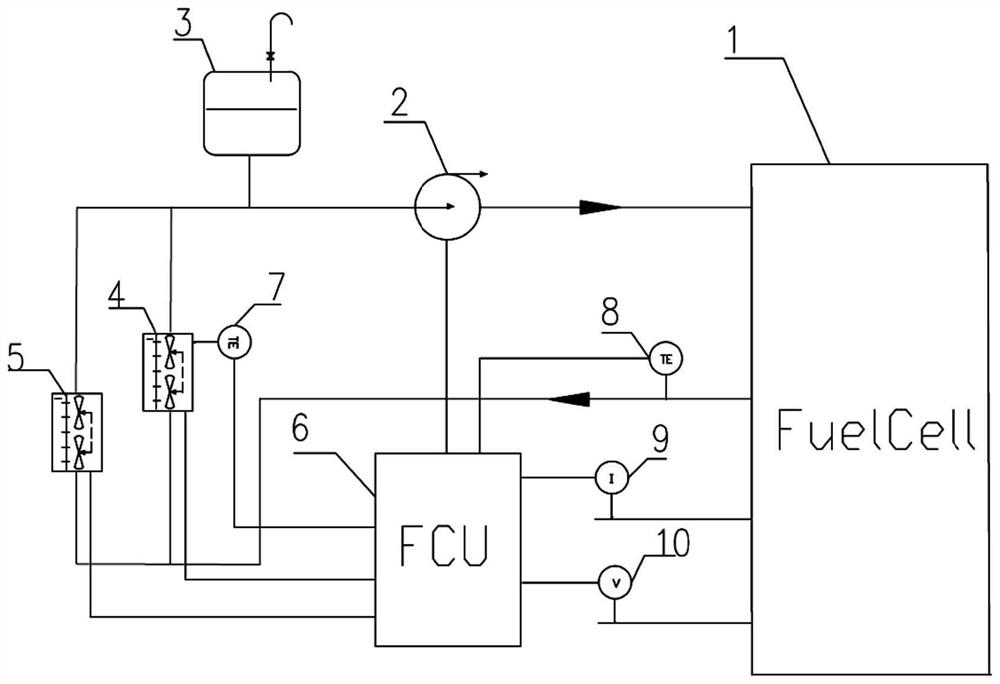

Fuel cell coolant temperature control method, system and controller thereof

PendingCN114447379AShorten closed-loop control timeSmall control deviationFuel cell heat exchangeTemperature controlFuel cells

The invention discloses a fuel cell cooling liquid temperature control method and system and a controller thereof, and the temperature control method comprises the steps: collecting the real-time temperature value and other data of a fuel cell stack cooling liquid outlet, and searching the target value temperature of the cooling liquid outlet, a temperature difference set value and the number of initial fans according to a scheduling current; whether the difference between the cooling liquid outlet target temperature value and the real-time temperature value is smaller than a temperature difference set value or not is judged, if yes, a fan control strategy is started, the fan duty ratio is calculated, then whether the fan duty ratio is larger than or equal to the minimum set duty ratio and smaller than or equal to the maximum set duty ratio or not is judged, and if yes, the fan duty ratio is directly output to control the fan rotating speed; if the duty ratio is smaller than the minimum set duty ratio, the number of fans is reduced, and the fan duty ratio is calculated for controlling the fan rotating speed; and if the duty ratio is larger than the maximum set duty ratio, the number of the fans is increased, and the fan duty ratio is calculated for controlling the fan rotating speed by considering the fan starting delay. The invention can meet the requirements of fuel cell efficiency and service life.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

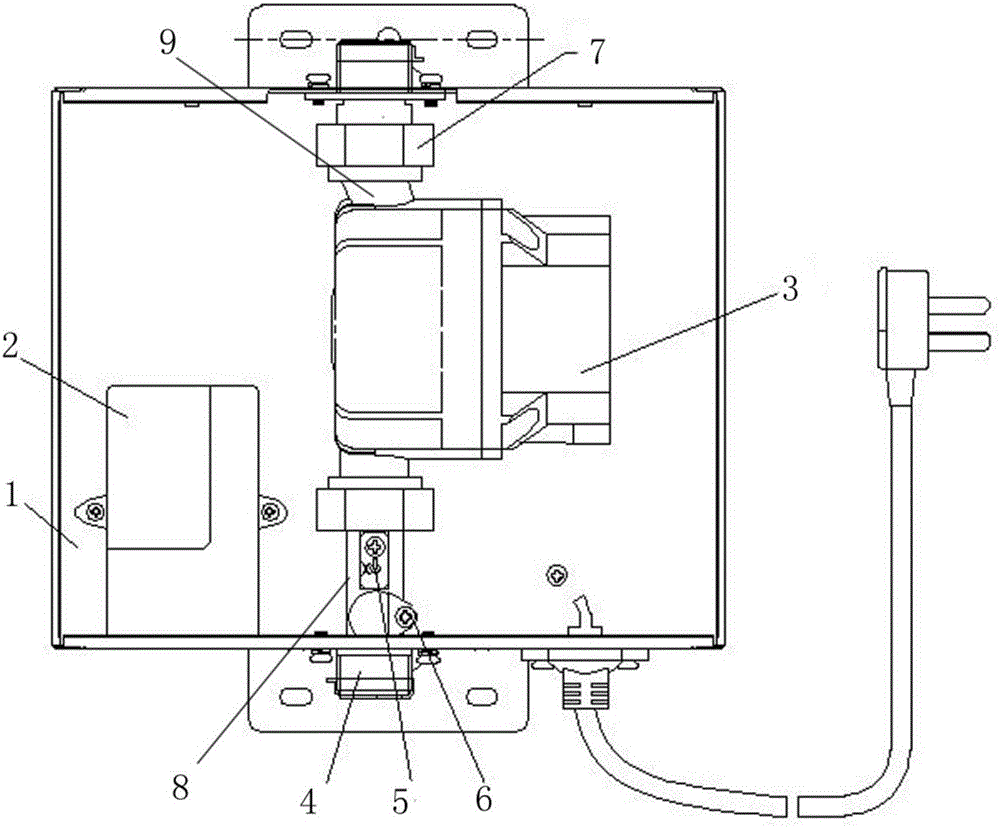

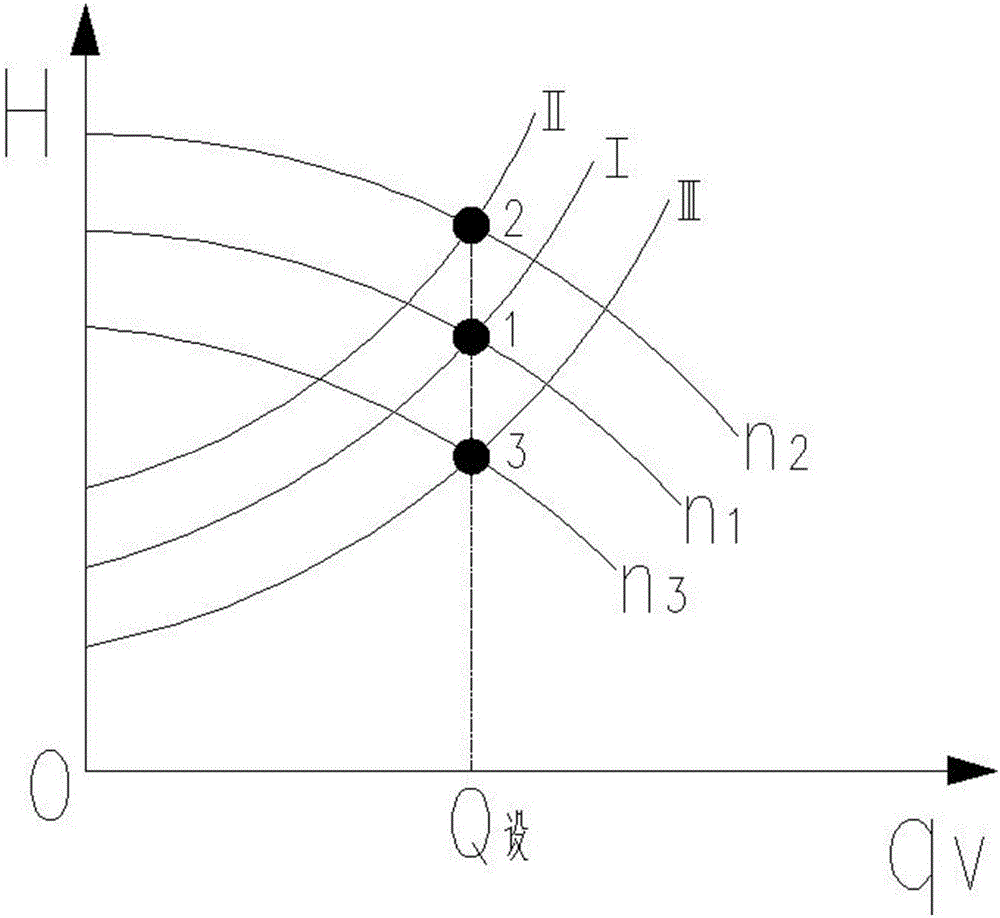

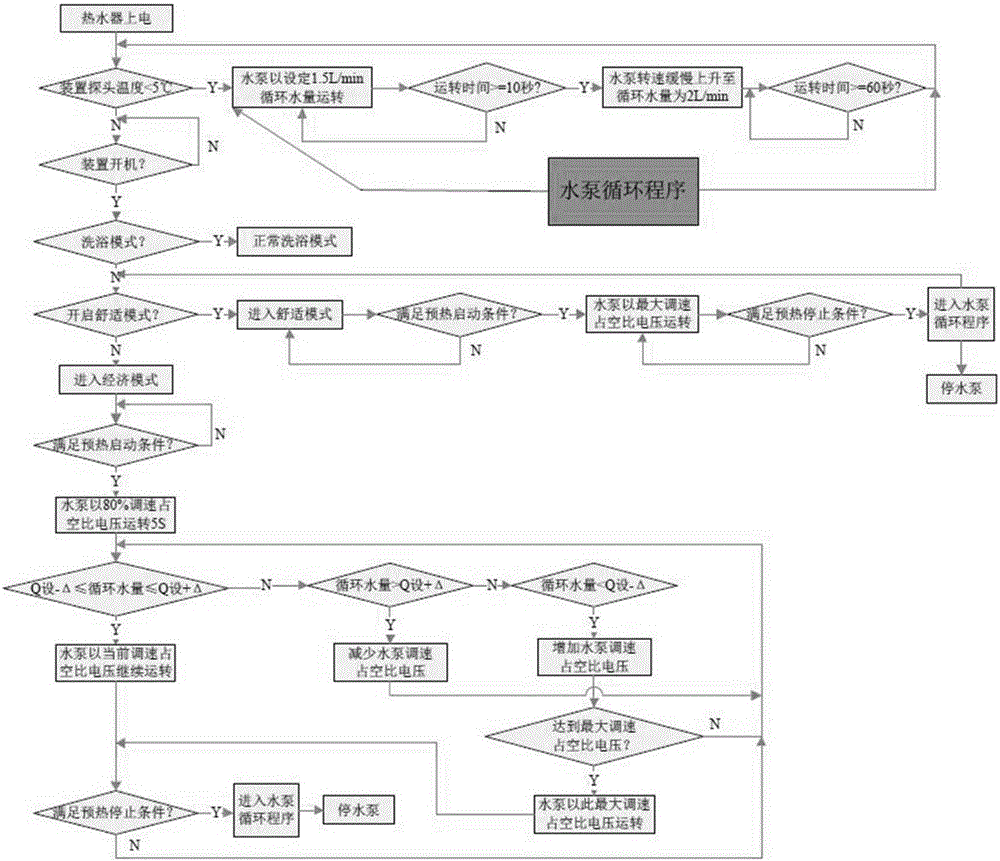

Hot-water circulation device with direct current pump and control system thereof

ActiveCN106766186ABest bathing comfortBathing comfort does not affectFluid heatersMechanical apparatusShootControl signal

The invention discloses a hot-water circulation device with a direct current pump and a control system thereof. The hot-water circulation device is characterized by comprising a shell and further comprising a controller, a direct current water pump, a water inlet pipe joint, a circulating water flow sensor, a temperature sensor and a water outlet pipe joint which are arranged in the shell, wherein a water inlet of a water heater is connected with the water outlet pipe joint; the direct current water pump, the circulating water flow sensor and the temperature sensor are respectively arranged between the water inlet pipe joint and the water outlet pipe joint; the circulating water flow sensor and the temperature sensor are respectively connected with a signal input end of the controller; the controller is connected with and controls the direct current water pump to realize a stepless speed regulation function of the water pump; the controller also can feed back a rotating speed; the circulating water flow sensor is used for supplying a control signal for the stepless speed regulation of the water pump; the temperature sensor is used as a temperature judging condition for system anti-freezing, preheating start and preheating stop; and the water inlet pipe joint is externally connected with a water return pipeline. According to the invention, the phenomenon of over-shoot system temperature can be avoided; the energy resource can be saved; and compared with the similar products, the hot-water circulation device has the advantage of more excellent performances.

Owner:GUANGDONG MACRO GAS APPLIANCE

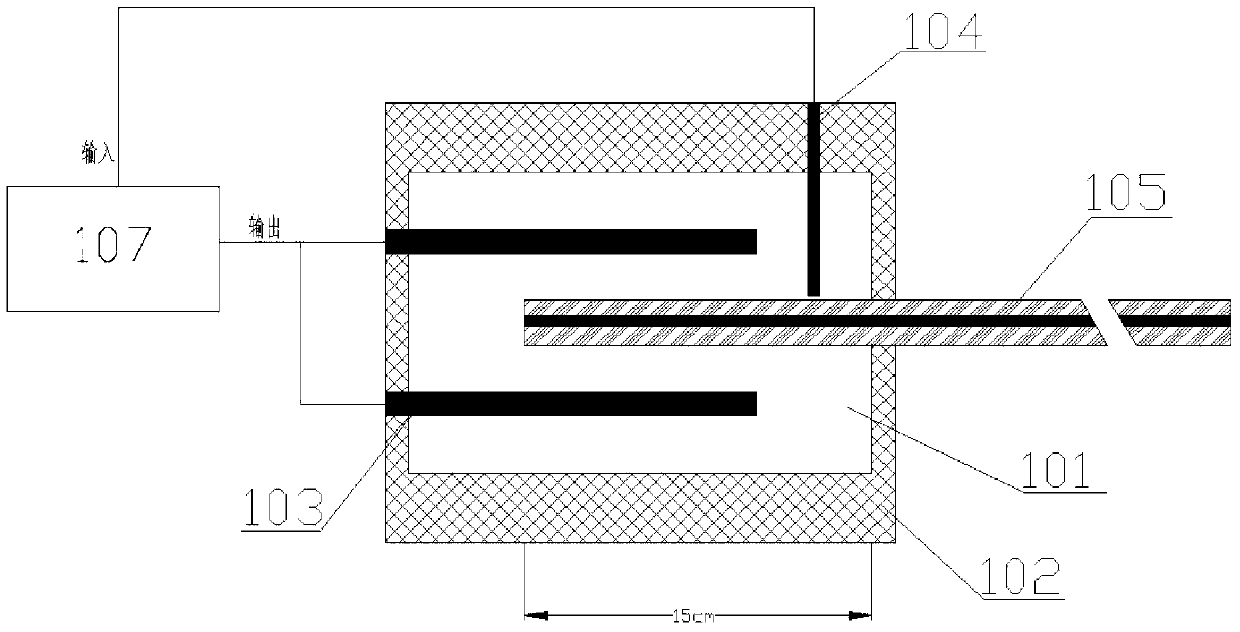

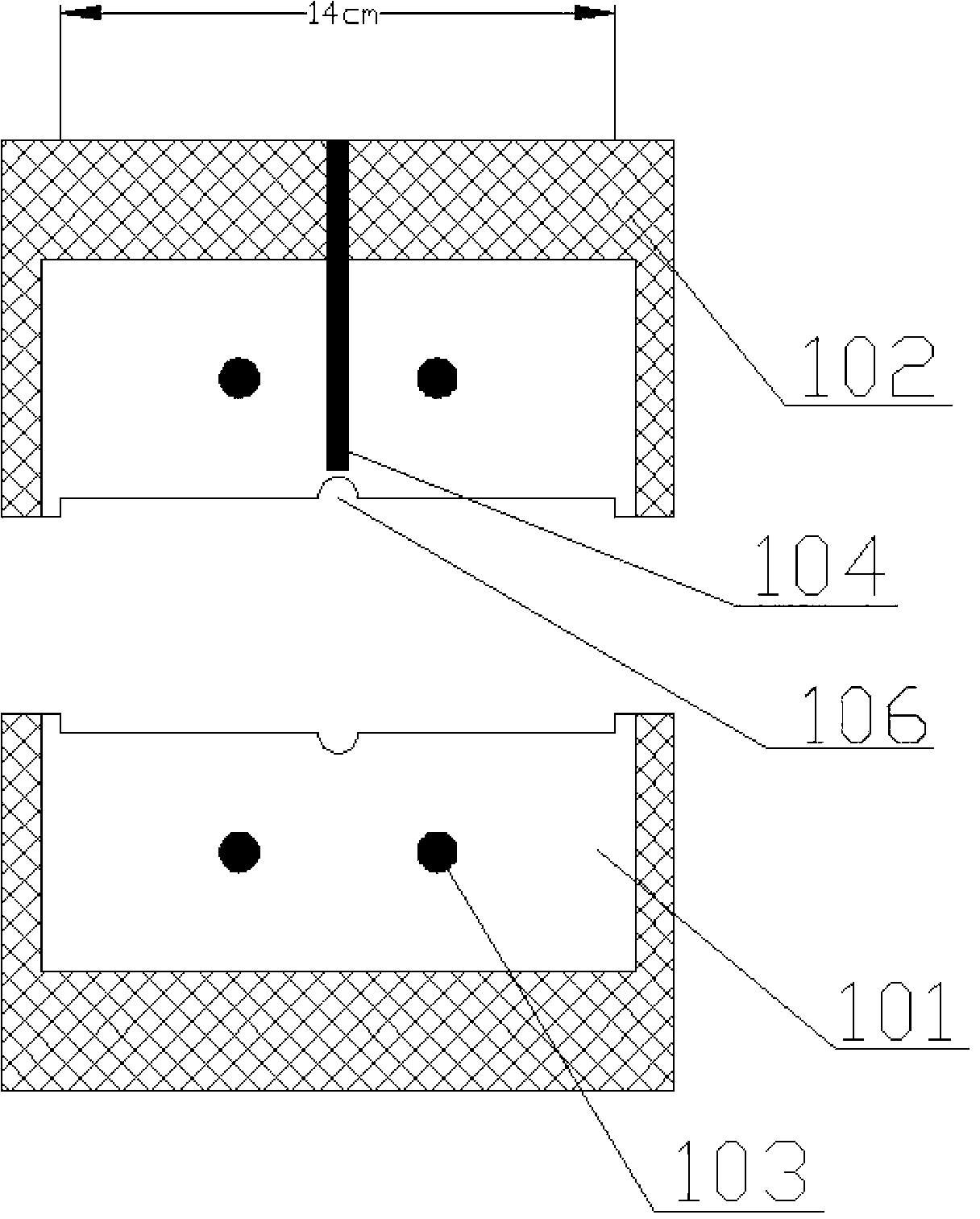

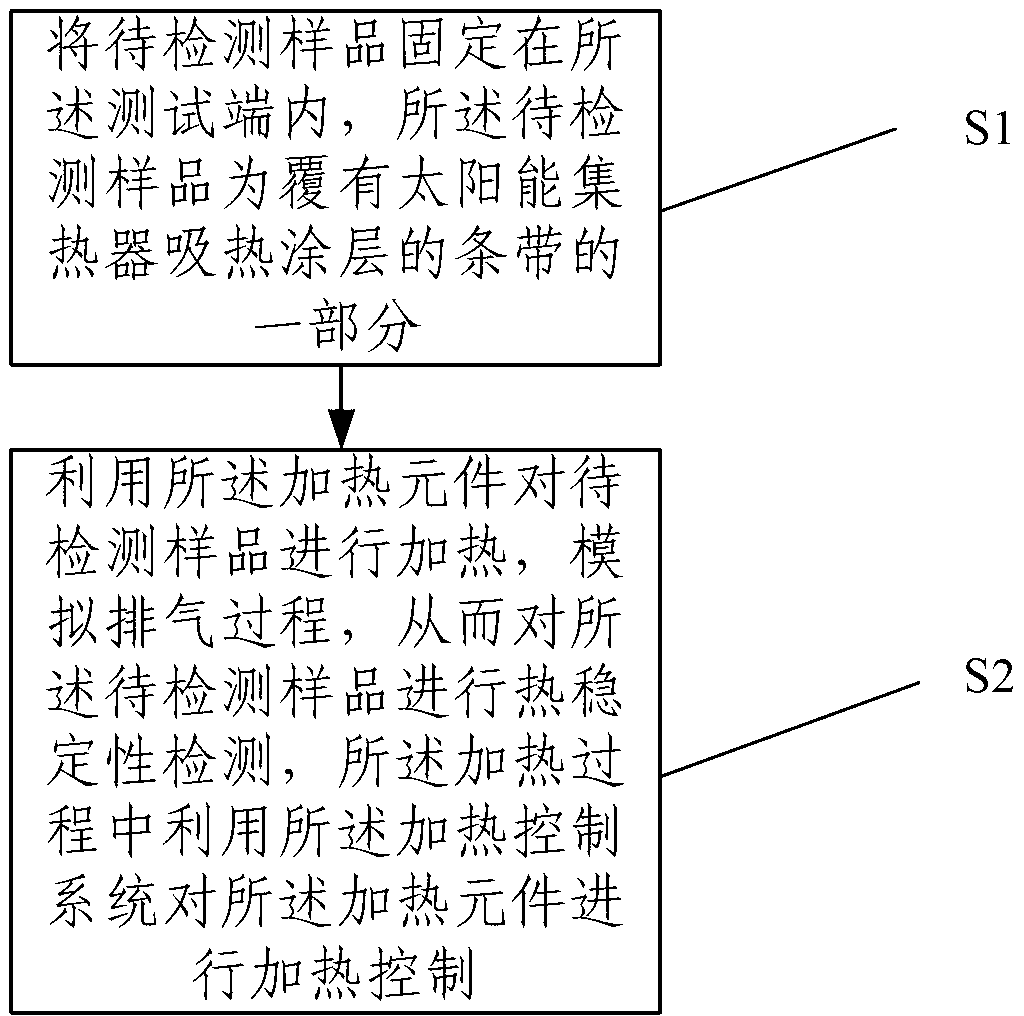

Quick thermal stability detector and detection method thereof

InactiveCN102998327ASimple structureEasy to operateMaterial thermal analysisControl systemRefractory

The invention relates to the technical field of thermal stability detection and discloses a quick thermal stability detector which comprises a test terminal and a heating control system, wherein the test terminal comprises a core made of refractory material, a heating element is arranged in the core; the heating control system comprises a sensor, a temperature controller and a relay; and the input end of the temperature controller is connected with the sensor, the output end of the temperature controller is connected with the relay, the relay is connected with the heating element to realize heating, and the sensor is arranged close to a sample to be detected. The detector can quickly and efficiently detect thermal stability with simple and convenient operation.

Owner:BEIJING SOLAR ENERGY INST

Refrigeration constant temperature control method and incubator

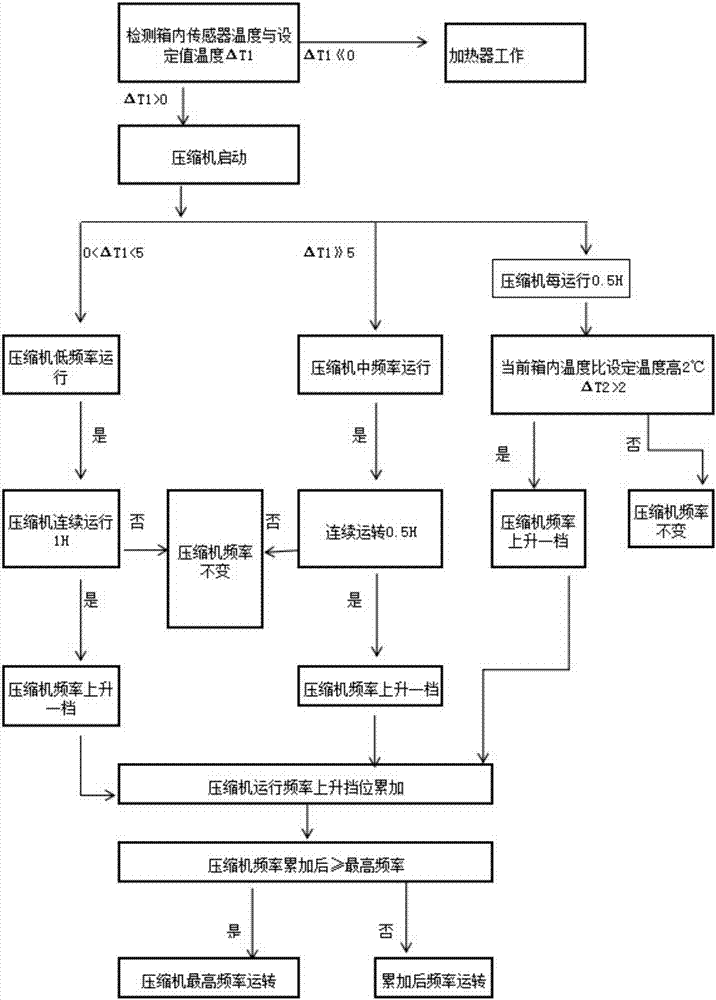

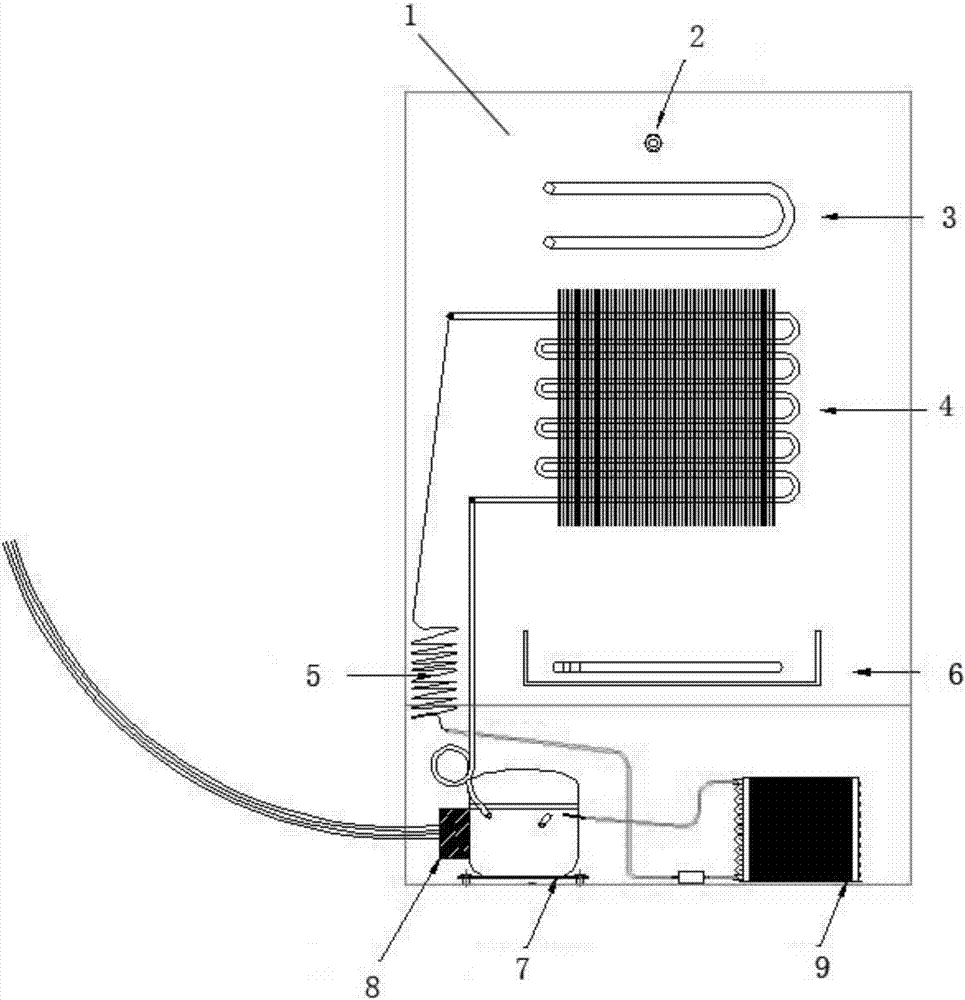

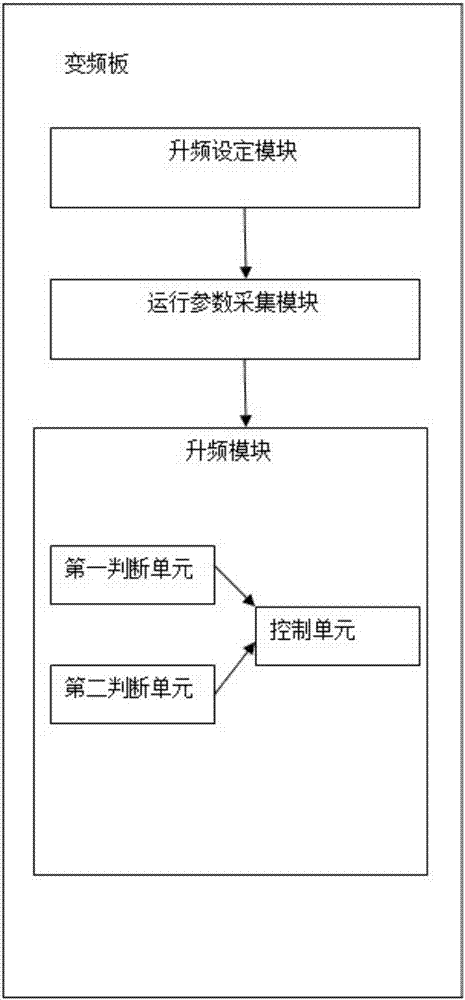

PendingCN107354240AAvoid temperature overshootExtended service lifeBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFrequency conversion

The invention relates to a refrigeration constant temperature control method and an incubator. The method comprises the following steps of step S1: detecting the temperature in the incubator and a set temperature value before the operation of an inverter compressor; step S2: setting frequency conversion conditions of the inverter compressor; step S3: after the inverter compressor is started, collecting operating parameters in the incubator; step S4: judging whether to adjust the frequency of the inverter compressor according to the operating parameters in the incubator and the frequency conversion conditions, and controlling the inverter compressor according to the result. The method and the incubator have the following advantages: the operating frequency of the inverter compressor is automatically adjusted according to a user set temperature and the operating parameters in the incubator, and a product is enabled to enter into an appropriate operation mode through measuring the loading condition in the incubator by means of collecting the current operating frequency and the time duration that the inverter compressor continuously operates in accordance with the current operating frequency, so as to avoid slow cooling caused by long time constant speed operation of the inverter compressor or a temperature overshoot phenomenon caused by excessive refrigeration, effectively prolong the service life of the product and the temperature control effect, and reduce energy consumption at the same time.

Owner:上海跃进医疗器械有限公司

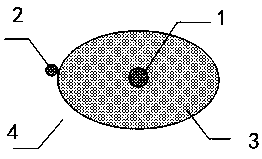

Novel tumor heat treatment equipment and control method thereof

InactiveCN108742827AThe temperature data is realReliable temperature dataSurgical instruments for heatingTemperature controlElectrical resistance and conductance

The invention relates to novel tumor heat treatment equipment. The equipment comprises a temperature controlling hot resistance heating device which is arranged in the internal center of a tumor, heats the tumor in a hot resistance heating manner and accurately controls the heating temperature of the temperature controlling hot resistance heating device, a temperature measuring device which is arranged in the intersection area of tumor tissues and normal tissues and performs constant temperature measuring in real time, and a controller which is connected with the temperature controlling hot resistance heating device to control the heating temperature of the temperature controlling hot resistance heating device and is connected with the temperature measuring device to adjust the heating temperature of the temperature controlling hot resistance heating device according to the result of whether or not the measuring value of the temperature measuring device meets a needed temperature value. According to the equipment, the temperature controlling hot resistance heating device is used for heating the tumor tissues in the center of the tumor and measuring temperature at the intersection area of the tumor tissues and the normal tissues, and therefore the temperature distribution situation of the whole tumor tissues can be reflected by combining the heating temperature of the temperature controlling hot resistance heating device and the measured temperature of the temperature measuring device to achieve complete inactivation of the tumor tissues.

Owner:俞雪利

PCR (Polymerase Chain Reaction) amplification instrument and amplification method for nucleic acid on-site variable-temperature amplification

PendingCN114350760AIncrease the number of amplificationReduce temperature disturbanceBioreactor/fermenter combinationsBiological substance pretreatmentsInsulation layerEngineering

The invention relates to the technical field of PCR (polymerase chain reaction) gene amplification, and discloses a PCR amplification instrument and an amplification method for nucleic acid on-site variable-temperature amplification, the PCR amplification instrument comprises a shell, a cover, a sample placing groove, at least three sample placing plates, a tube groove and a sample tube placed in the tube groove, and the sample placing plates are sequentially arranged in the sample placing groove at intervals from the position close to the cover to the position away from the cover; a heating pipe is arranged in the sample placing plate, the sample placing plate is coated with a heat insulation layer, and the sample pipe comprises a pipe body, a pipe cover, a breather pipe which is arranged on the pipe body close to the pipe cover and enables an inner cavity of the pipe body to be communicated with the outside, and a first sealing piece which is arranged in the pipe body in a sealing and lifting manner; according to the PCR amplification instrument for nucleic acid amplification and the amplification method, the three steps of denaturation, annealing and extension are achieved in the same amplification instrument, meanwhile, repeated heating and cooling are not needed, the amplification time is shortened, temperature overshoot is avoided, and the amplification efficiency is improved. And the quality of gene amplification is ensured.

Owner:浙江正合谷生物科技有限公司

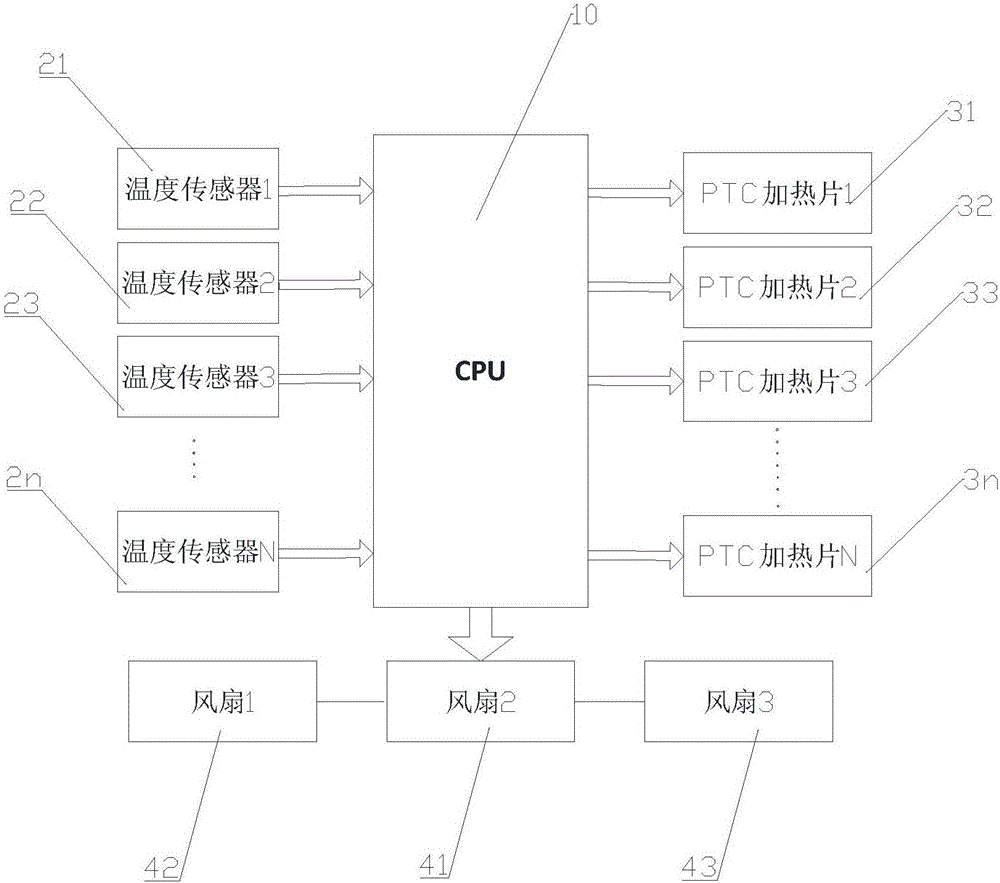

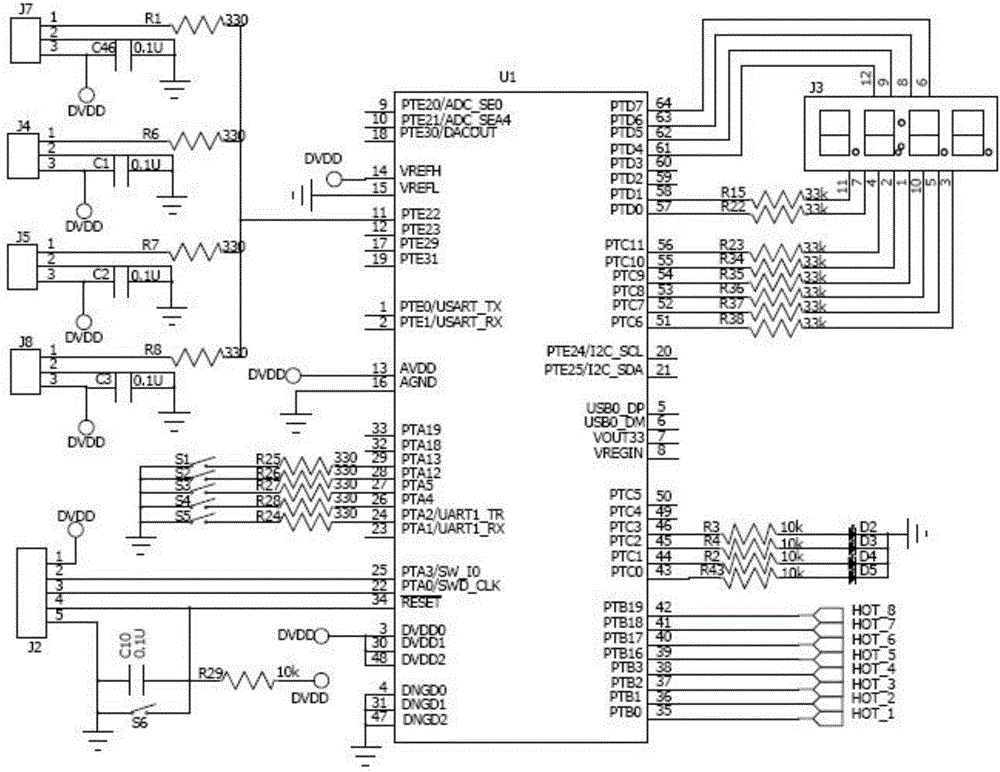

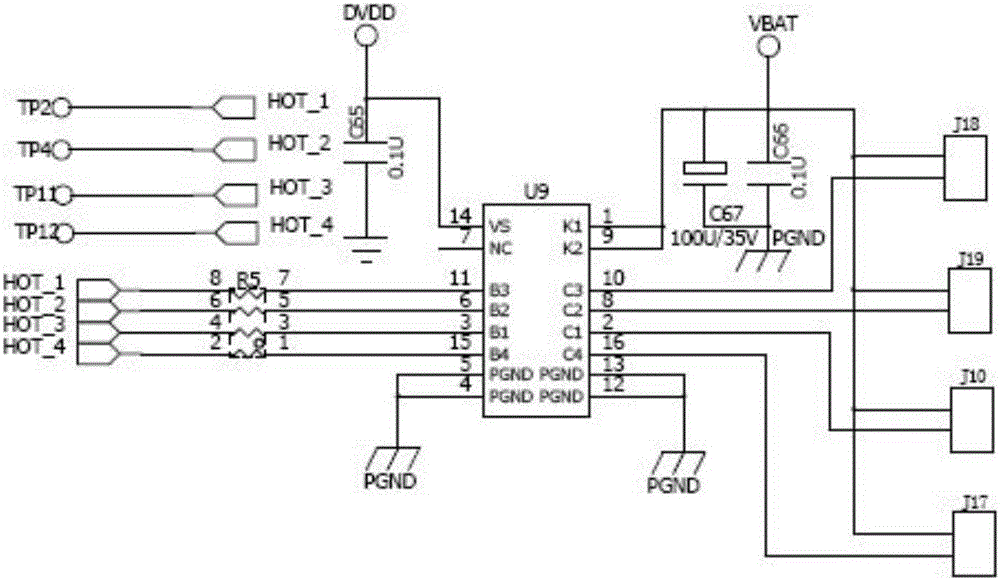

Temperature-constant controller and control method thereof

InactiveCN106227268ASmall temperature fluctuationsImprove stabilityAuxillary controllers with auxillary heating devicesAirflowElectricity

The invention discloses a temperature-constant controller and a control method thereof. The controller comprises a central processor, at least one temperature sensor, PTC heating sheets and fans, wherein the temperature sensors are electrically connected with the central processor and distributed in the surrounding of a temperature control environment, and the PTC heating sheets are electrically connected with the central processor. The temperature sensors collect temperature values of points in the surrounding of the environment, and transmit the temperature values to the central processor, the central processor compares the temperature values detected by the temperature sensors with a preset value, the PTC heating sheets are controlled to carry out heating, the fans send heat energy generated by the PTC heating sheets to the temperature control environment in a circulated manner, and an enclosed cycled thermal current is formed in the temperature control environment. According to the temperature-constant controller and the control method thereof, comprehensive temperature detecting and heating devices are used to detect the local temperature conditions in a temperature-constant box in real time, real-time local adjustment can be realized, temperature fluctuation in the whole box is lower, the stability is higher, and generation of over-temperature is inhibited effectively.

Owner:SHENZHEN SINSCHE TECH

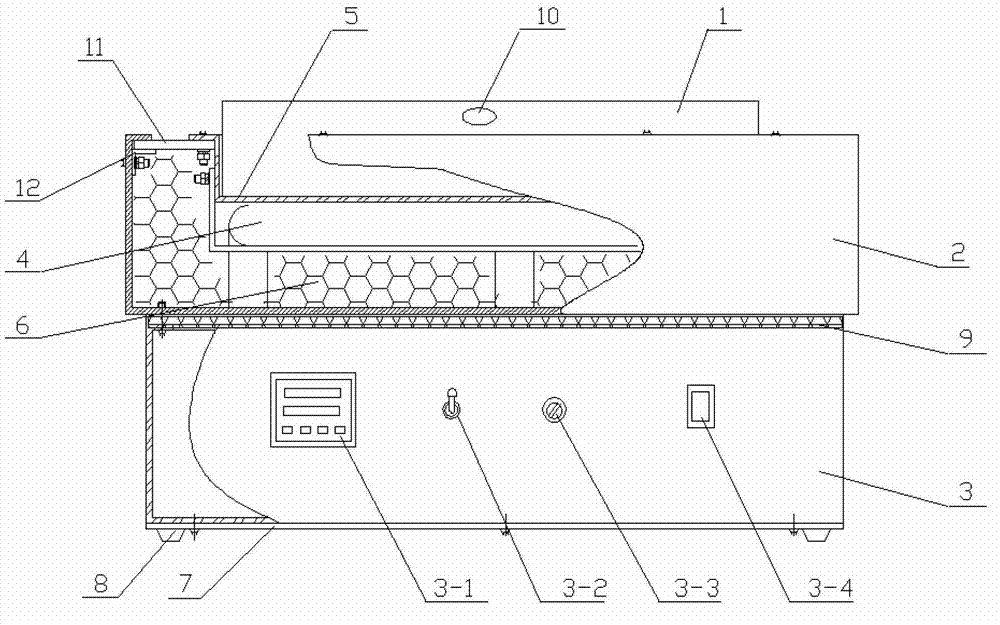

Energy-saving temperature controlling heating stage and constant temperature controlling method thereof

ActiveCN103256708AHeating up fastHigh control precisionAir heatersTemperature controlThermal insulation

The invention relates to an energy-saving temperature controlling heating stage and a constant temperature controlling method of the energy-saving temperature controlling heating stage. The energy-saving temperature controlling heating stage and the constant temperature controlling method of the energy-saving temperature controlling heating stage solve the problems that a conventional temperature controlling box is slow in temperature increase and temperature of a conventional electric heating plate can not be stably controlled. The energy-saving temperature controlling heating stage comprises a thermal insulation box cover, a heating cavity and an electric control operation box, wherein the thermal insulation box cover, the heating cavity and the electric control operation box are sequentially connected from top to bottom. A heating device and a soaking plate are arranged in the heating cavity. The upper surface of the heating device is tightly connected with the lower surface of the soaking plate. Heat insulating and preserving materials are filled in a cavity of the lower surface of the heating device. An automatic sealed ring controlling regulator, a heating switch, a power supply switch and a fuse cutout are arranged on the electric control operation box.

Owner:BEIJING JIEYALI ELECTRONICS TECH

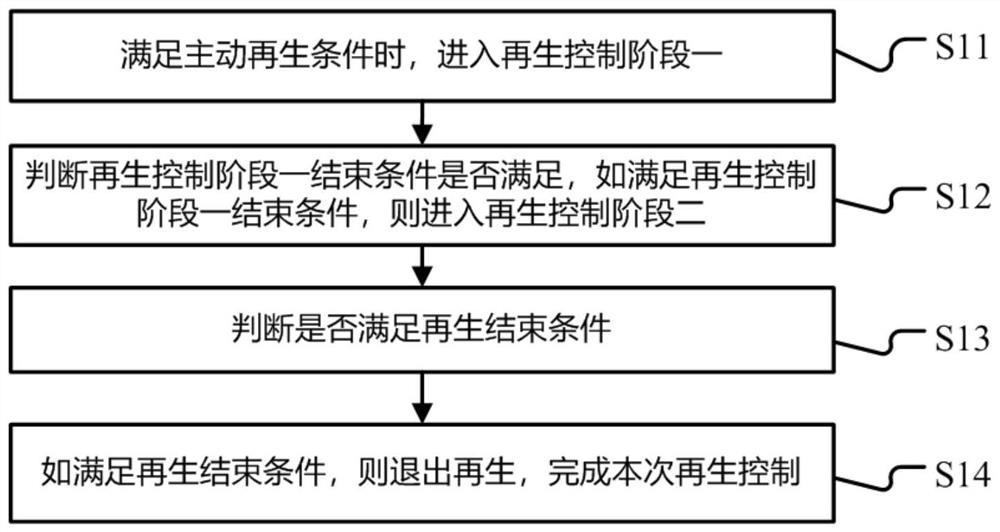

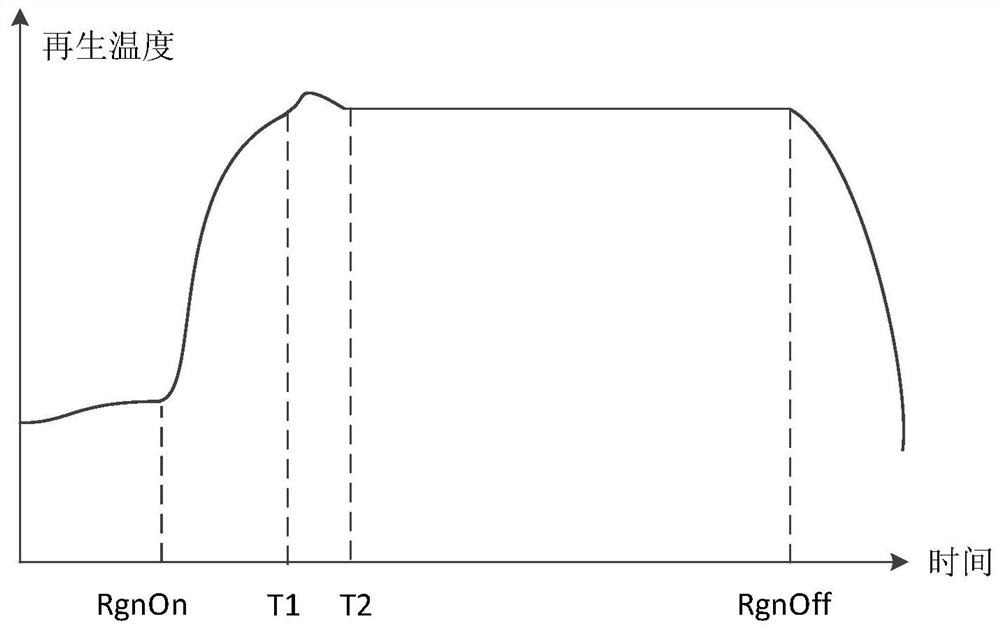

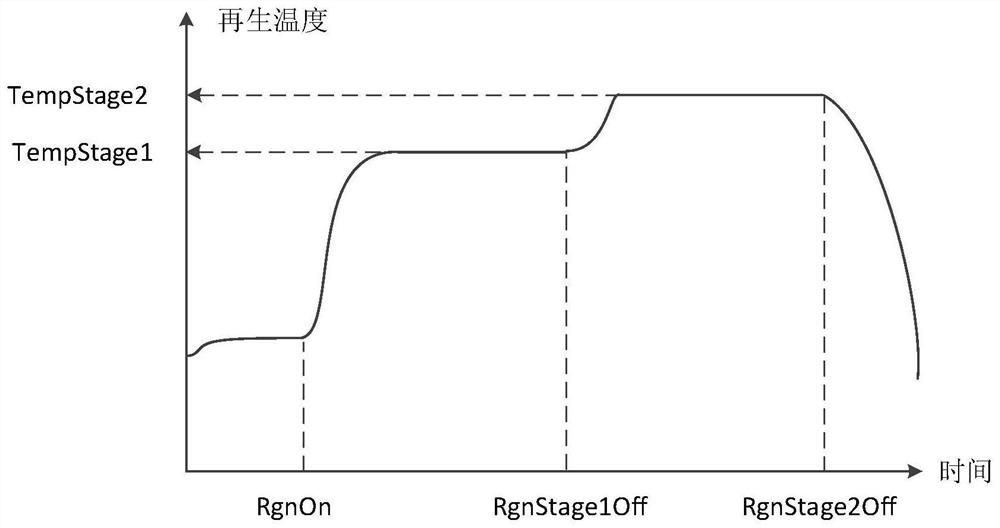

Diesel particulate filter (DPF) segmented regeneration method

ActiveCN113356986AAvoid temperature overshootBalance securityInternal combustion piston enginesExhaust apparatusTemperature controlProcess engineering

The invention provides a Diesel particulate filter (DPF) segmented regeneration method which comprises the following steps of when an active regeneration condition is met, entering a regeneration control stage I; judging whether the end condition of the regeneration control stage I is met or not, and entering a regeneration control stage II if the end condition of the regeneration control stage I is met; judging whether a regeneration ending condition is met or not; and if the regeneration ending condition is met, quitting regeneration, and completing the regeneration control. According to the method, the temperature of the DPF during active regeneration can be simply and accurately controlled, carbon in the DPF can be efficiently combusted, the phenomenon of temperature overshoot of the DPF in the active regeneration temperature control process is effectively avoided, balance between the safety of the DPF and the regeneration efficiency of the DPF is achieved, and the method is suitable for large-scale application.

Owner:SINO TRUK JINAN POWER

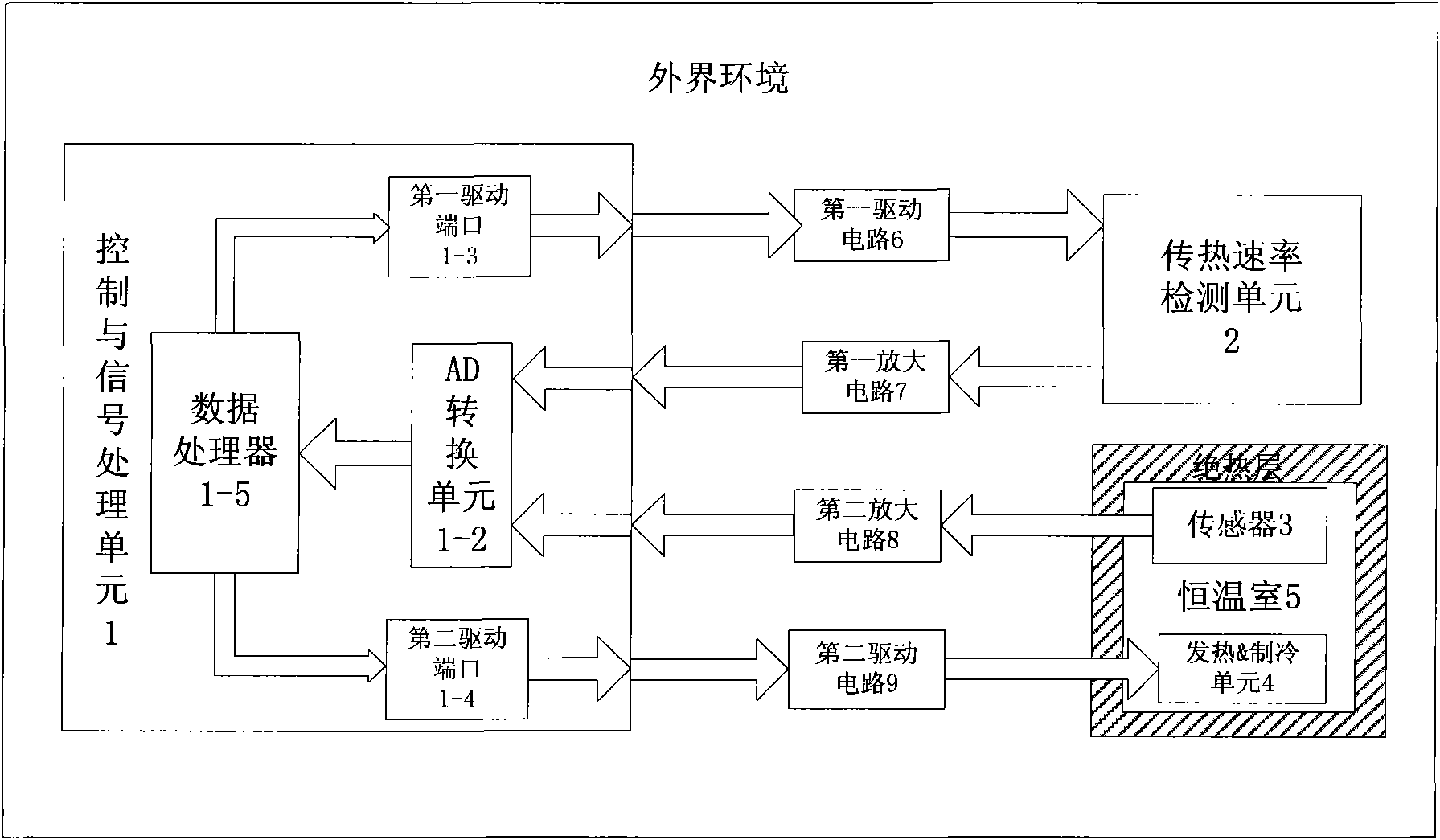

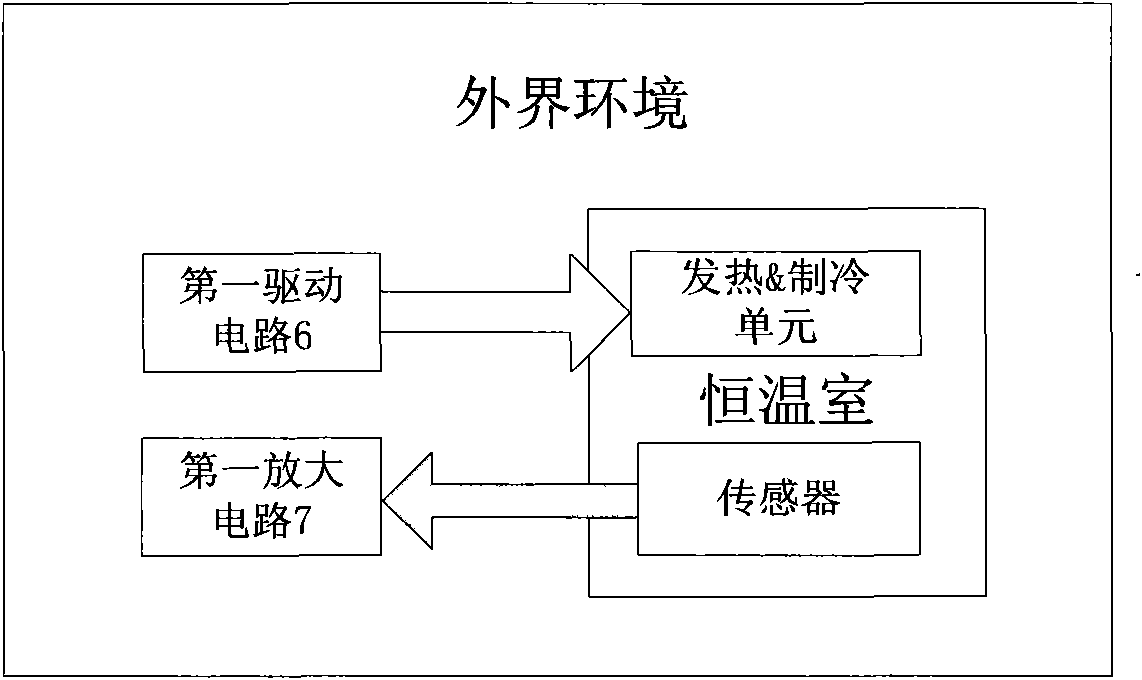

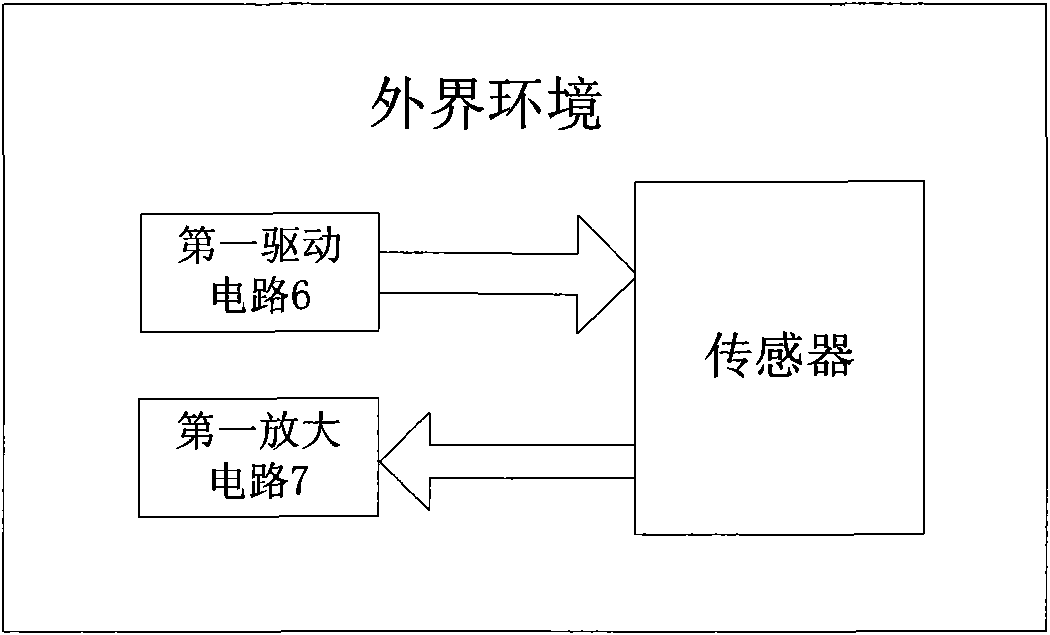

Thermostatic control device and method with detection of heat transfer rate

InactiveCN101661300ASmall thermal inertiaKnow the temperature change trend in advanceTemperatue controlTemperature controlControl system

The invention relates to thermostatic control device and method with detection of heat transfer rate, which are the brand new thermostatic control device and method with high stability and high thermostatic precision. The device comprises a control and signal processing unit (1), a heat transfer rate detecting unit (2), a sensor (3), a heating and cooling unit (4), a thermostatic chamber (5), a first drive circuit (6), a first amplifying circuit (7), a second amplifying circuit (8) and a second drive circuit (9). On the basis of a conventional closed loop temperature control system, the thermostatic control system increases a link for detecting the heat exchange rate between thermostatic space and external environment so that the thermostatic system can respond quickly to the change of external environment, reduce the fluctuation of temperature and improve the thermostatic speed and precision.

Owner:NANJING UNIV

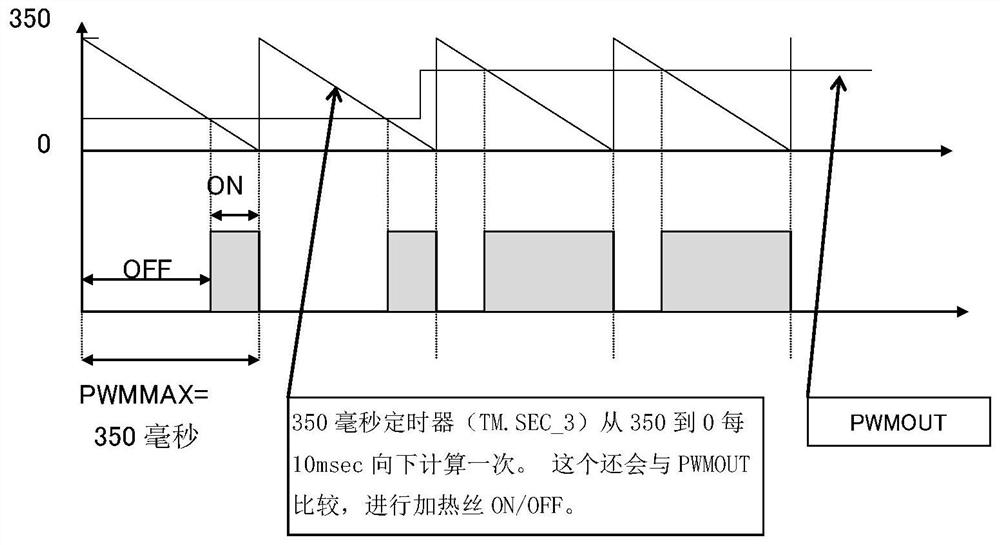

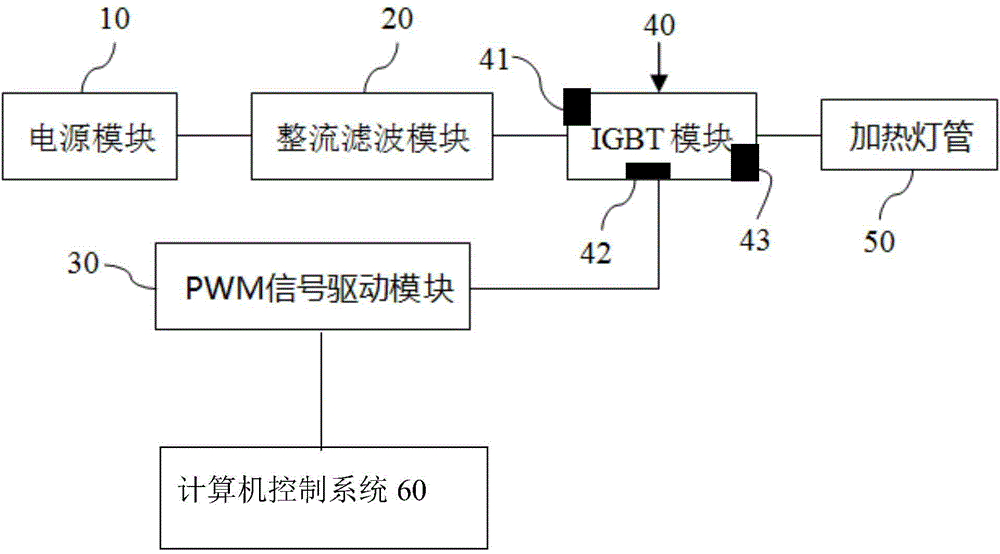

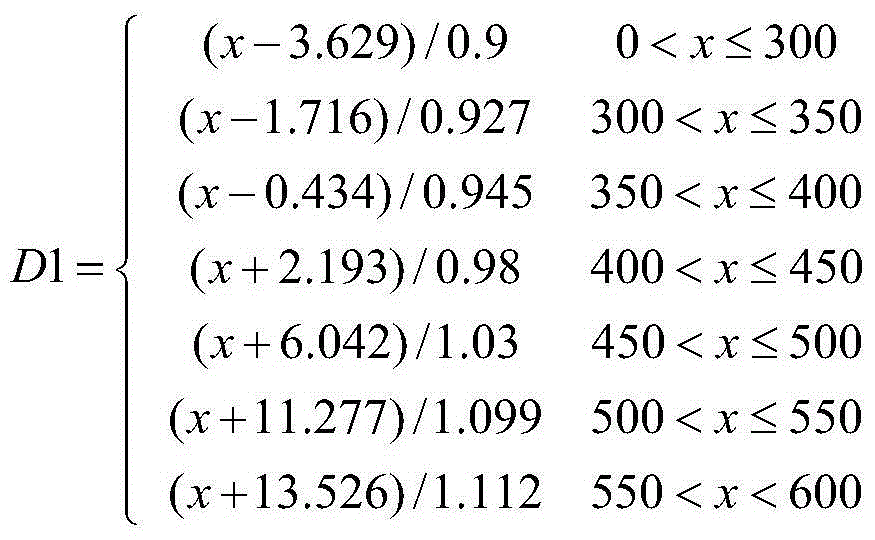

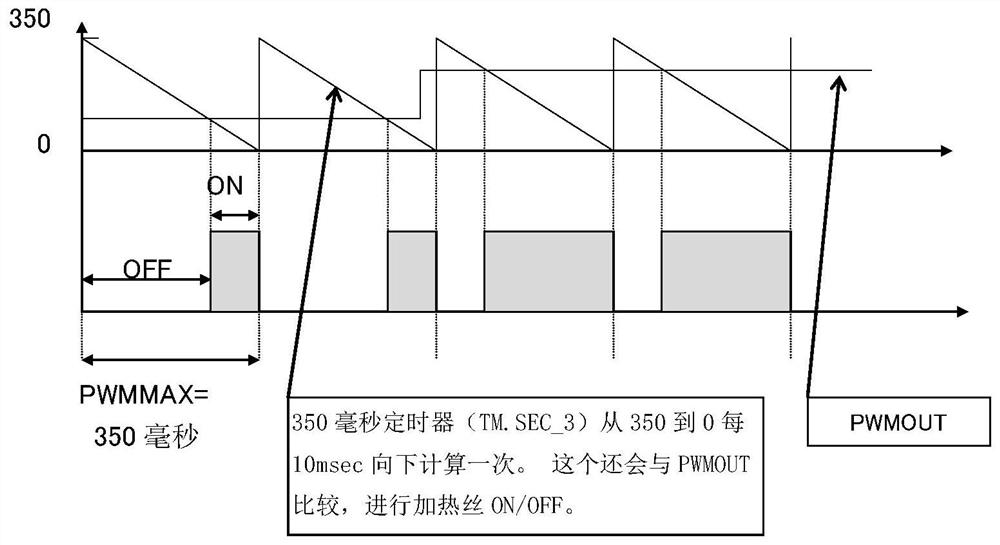

Heating device used for semiconductor fast annealing and control method

ActiveCN105990188AExtended service lifeAvoid temperature overshootPulse generation by active elementsSemiconductor/solid-state device manufacturingInstabilityInsulated-gate bipolar transistor

The invention relates to a heating device used for semiconductor fast annealing and a control method. The heating device includes a power source module, a rectifying and filtering module, an IGBT (insulated gate bipolar transistor) module, a PWM (pulse width modulation) signal driving module, a heating lamp tube group and a computer control system; the power source module is connected with the rectifying and filtering module; the IGBT module comprises an input port, a control port and an output port; the rectifying and filtering module is connected with the input port of the IGBT module; the PWM signal driving module is connected with the control port of the IGBT module; the PWM signal driving module is controlled through the computer control system and is used for controlling the on-off time of the IGBT so as to adjust the heating power of the heating lamp tube group; and the heating lamp tube group is connected with the output port of the IGBT module and is used for device heating. With the heating device used for semiconductor fast annealing and the control method of the invention adopted, an overshoot phenomenon in a fast heating process can be effectively suppressed, stable temperature rise can be realized, and at the same time, the instability of heating caused by stroboflash can be avoided, and the service lives of lamp tubes can be prolonged.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

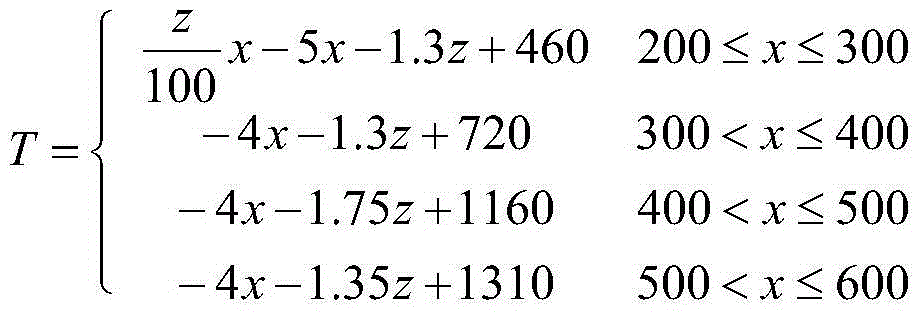

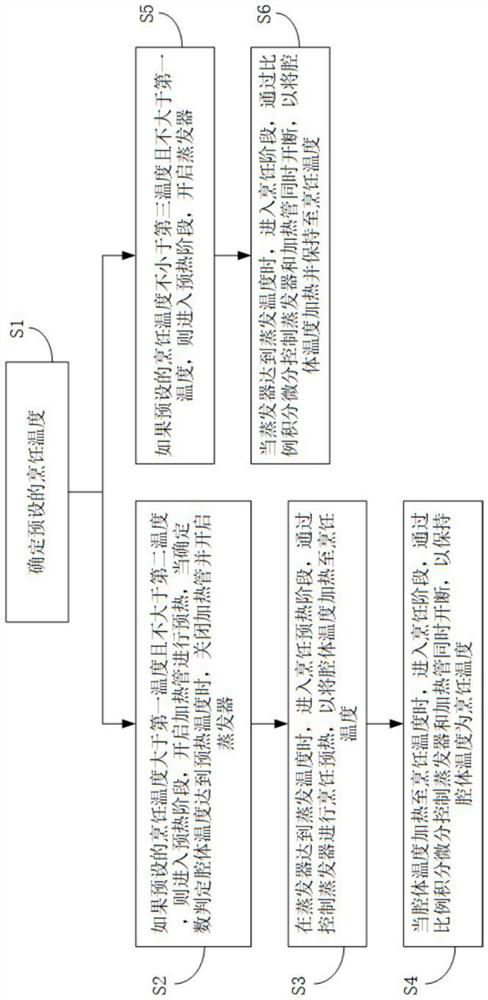

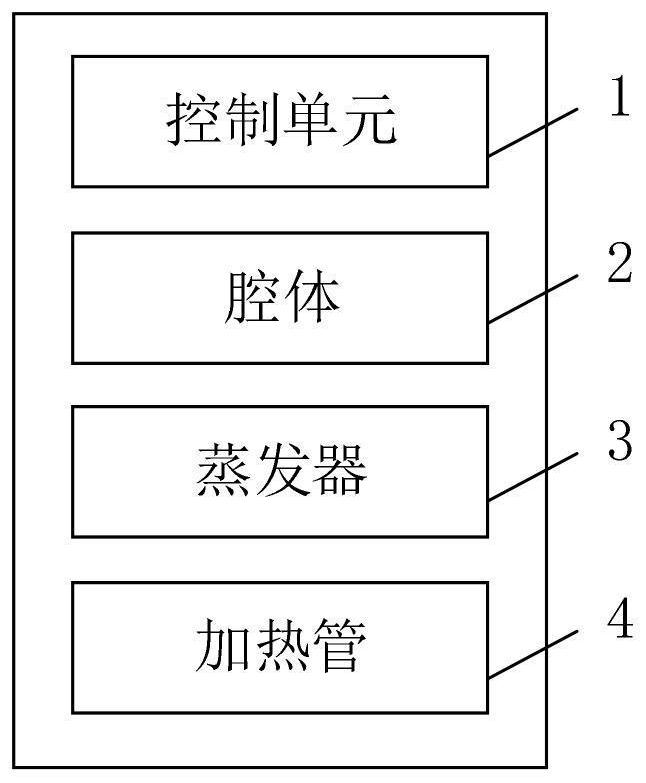

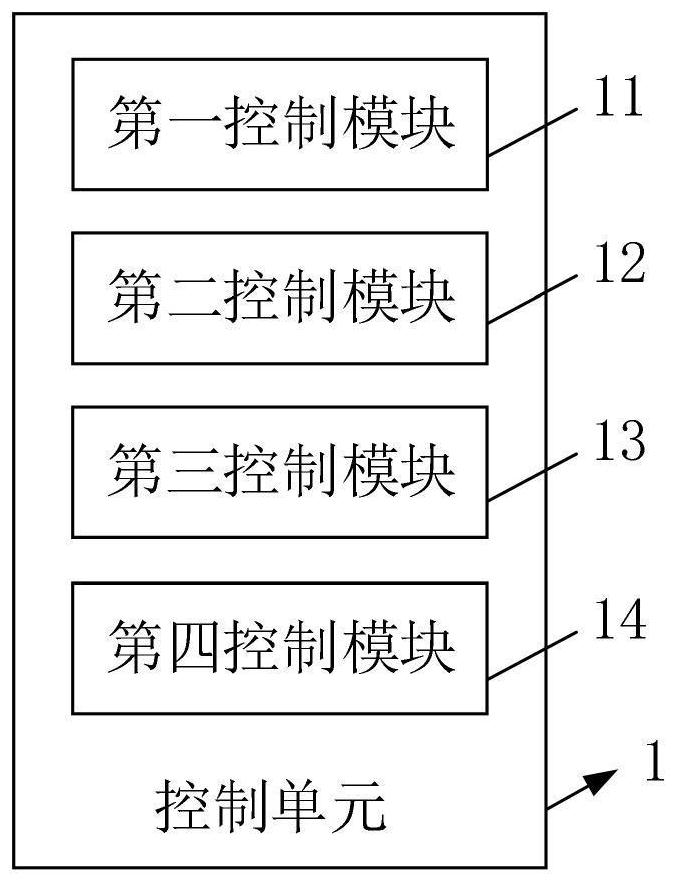

Cooking equipment and temperature control method thereof

ActiveCN114176388AAvoid temperature overshootAvoid temperature errorsSteam cooking vesselsRoasters/grillsTemperature controlProcess engineering

The invention relates to cooking equipment and a temperature control method thereof. The method comprises the following steps: determining a preset cooking temperature; if the preset cooking temperature is larger than the first temperature and not larger than the second temperature, a heating pipe is turned on, and when it is determined that the cavity temperature reaches the preheating temperature, the heating pipe is turned off, and an evaporator is turned on; when the evaporator reaches the evaporation temperature, the evaporator is controlled to conduct cooking preheating, so that the temperature of the cavity is increased to the cooking temperature; controlling the evaporator and the heating pipe to be switched on and off simultaneously through proportional-integral-derivative so as to keep the temperature of the cavity at the cooking temperature; if the preset cooking temperature is not smaller than the third temperature and not larger than the first temperature, the evaporator is started, and when the evaporator reaches the evaporation temperature, the evaporator and the heating pipe are controlled to be switched on and off at the same time through proportional-integral-derivative, so that the temperature of the cavity is increased and kept to the cooking temperature. According to the embodiment of the invention, the actual temperature in the cooking equipment is the cooking temperature by improving the temperature control capability.

Owner:VATTI CORP LTD

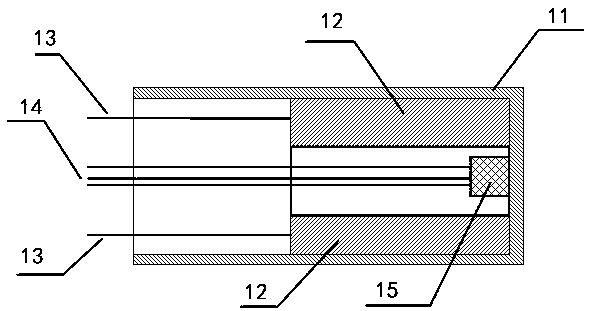

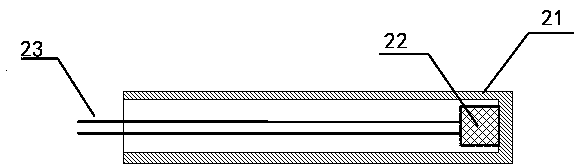

High-power-density soldering iron

InactiveCN112404638AReduce feverImprove heating efficiencySoldering ironMetallurgyHigh power density

The invention relates to a soldering iron core, in particular to a high-power-density soldering iron. The soldering iron comprises a soldering iron head, wherein the tail of the soldering iron head isarranged at the end of an outer steel pipe; the soldering iron core is arranged in the outer steel pipe; a temperature measurement discharge hole is formed in the rear end of the soldering iron head;a temperature sensor and a ceramic tube are arranged in the temperature measurement discharge hole; a discharge needle is arranged in the ceramic tube; and the head of the discharge needle is inserted into the temperature measurement discharge hole through the center of the ceramic tube. The high-power-density soldering iron has the characteristics of high heating efficiency, compact structure, excellent temperature stability and the like.

Owner:武汉文宇创新科技有限公司

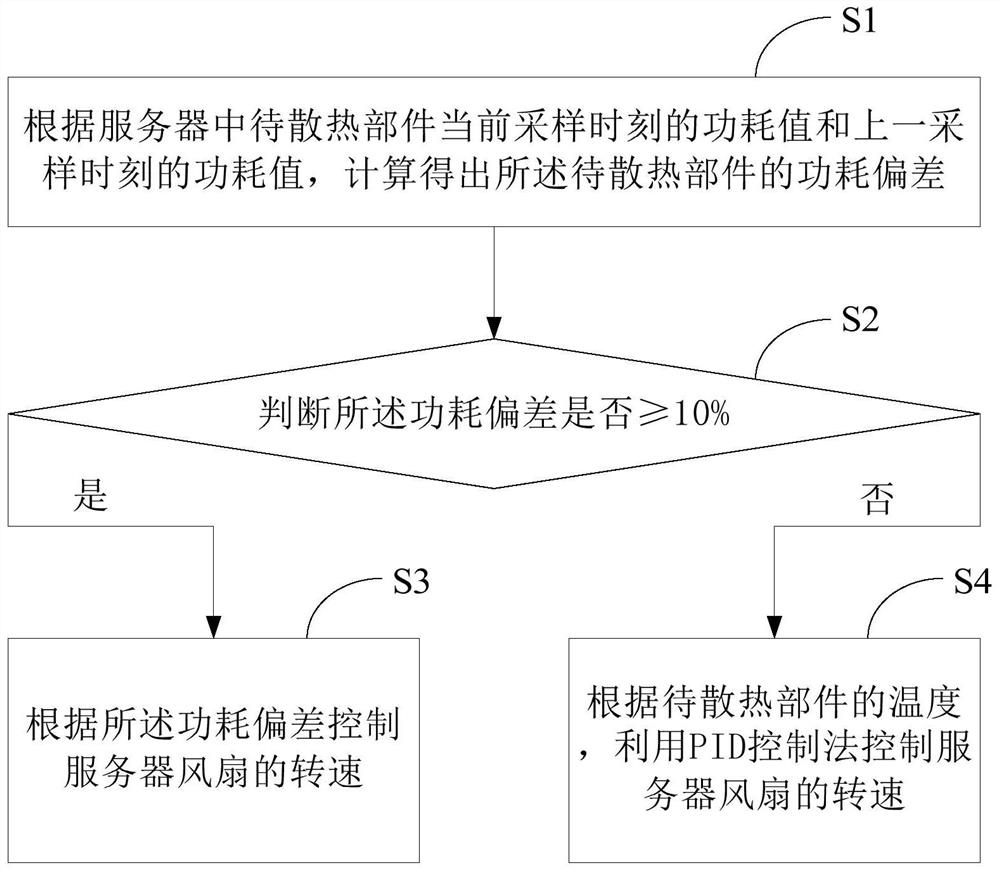

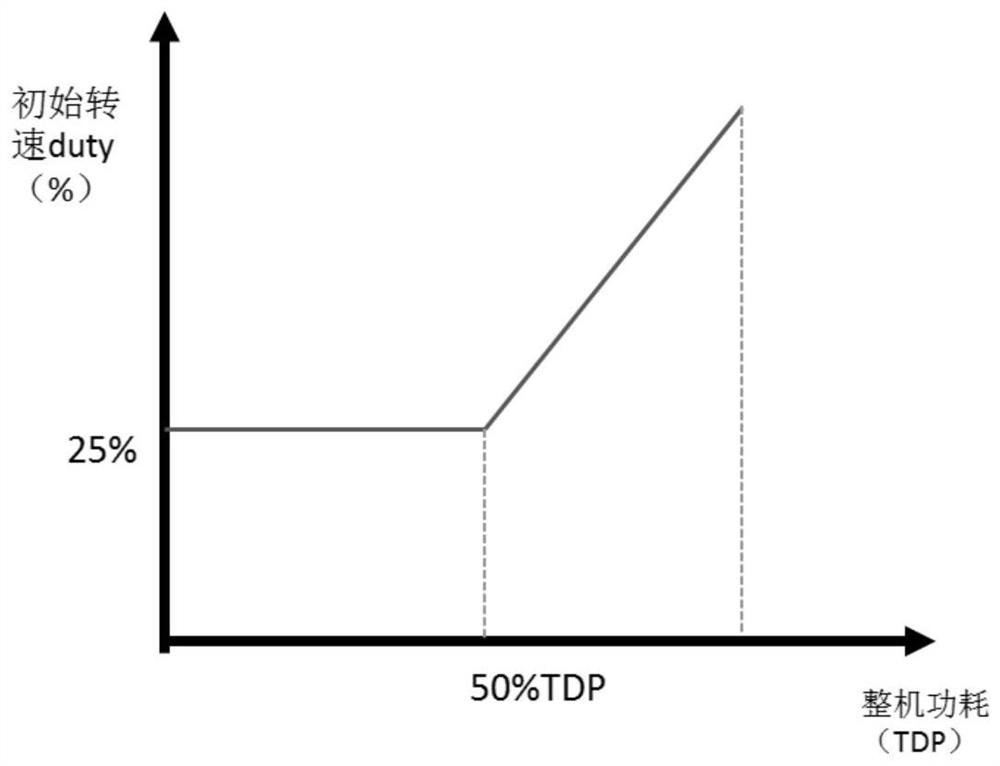

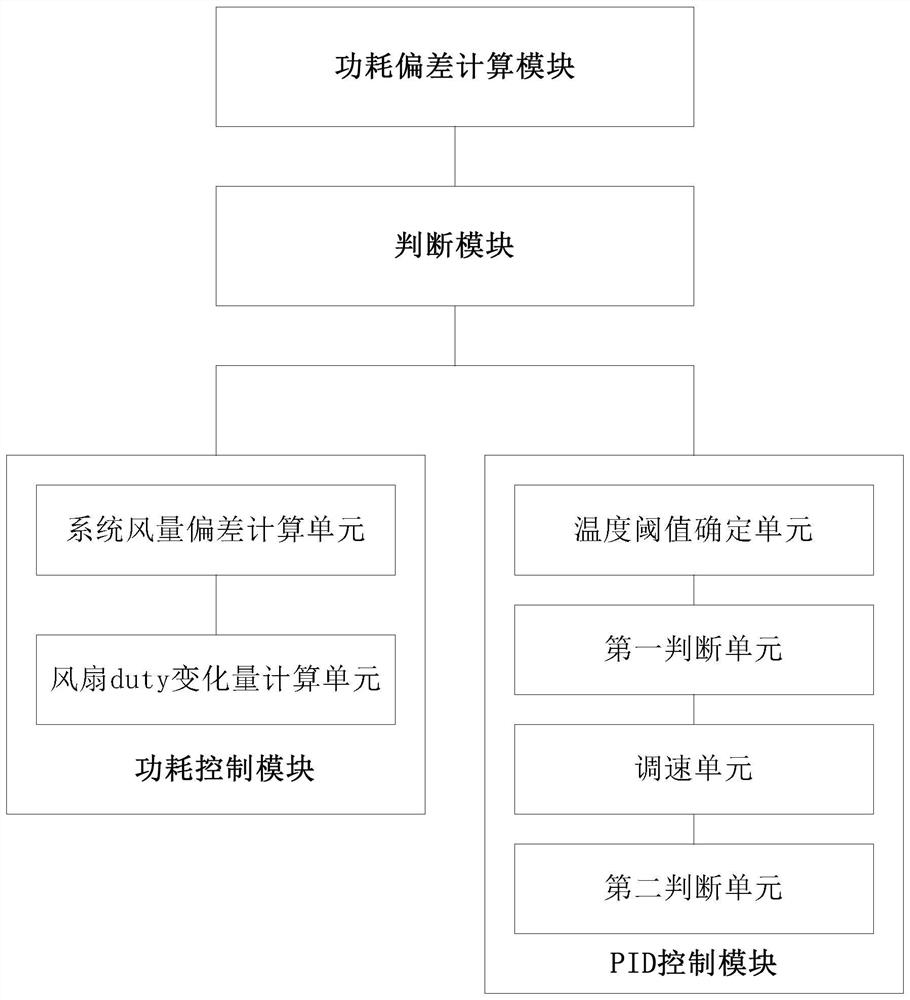

Method and system for controlling server fan based on component power consumption

ActiveCN110206747BAvoid temperature overshootReduce noiseDigital data processing detailsPump controlControl engineeringControl theory

The invention discloses a server fan control method and system based on component power consumption. The method comprises the steps that according to the power consumption value of a current samplingmoment and the power consumption value of a previous sampling moment of a to-be-cooled part in a server, a power consumption deviation of the to-be-cooled part is calculated; whether the power consumption deviation is larger than or equal to 10% or not is judged; if yes, the rotating speed of a fan of the server is controlled according to the power consumption deviation; and if not, the rotating speed of the fan of the server is controlled by utilizing a PID control method according to the temperature of the to-be-cooled part. The system mainly comprises a power consumption deviation calculation module, a judgment module, a power consumption control module and a PID control module. By means of the method and the device, the phenomena of rotating speed overshoot of the fan and temperature overshoot of the components can be avoided, the control stability of the rotating speed of the fan is improved, the noise generated by the server is lowered, and the user experience is improved.

Owner:SUZHOU METABRAIN INTELLIGENT TECH CO LTD

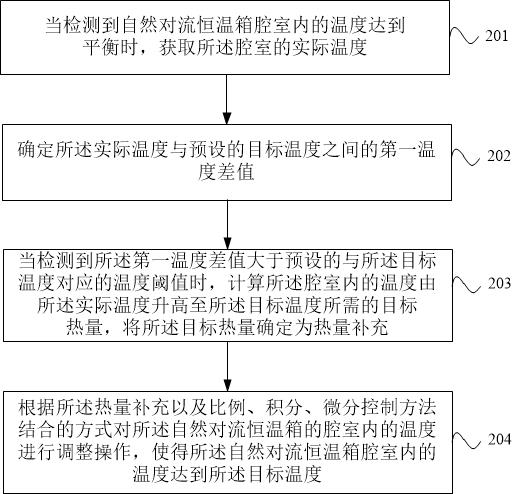

Thermotank temperature adjusting method, device and equipment, readable storage medium and product

ActiveCN114546004AAvoid temperature overshootImprove accuracyAuxillary controllers with auxillary heating devicesProcess engineeringTemperature conditioning

The invention provides a thermotank temperature adjusting method, device and equipment, a readable storage medium and a product, and the method comprises the steps: obtaining the actual temperature of a cavity when the temperature in the cavity of a natural convection thermotank is detected to be balanced; determining a first temperature difference value between the actual temperature and a preset target temperature; when it is detected that the first temperature difference value is larger than a preset temperature threshold value corresponding to the target temperature, the target heat needed for increasing the temperature in the cavity from the actual temperature to the target temperature is calculated; and adjusting the temperature in the cavity of the natural convection constant-temperature box according to a mode of combining the heat supplement and proportion, integral and differential control methods, so that the temperature in the cavity of the natural convection constant-temperature box reaches the target temperature. The temperature overshoot condition is effectively avoided, the accuracy of temperature regulation of the constant temperature box is improved, the temperature regulation time is shortened, and waste of resources can be avoided.

Owner:LONGCHEER ELECTRONICS HUIZHOU

Thermal compression bonding power source

InactiveCN103264244BAccurate identificationAvoid temperature overshootWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectromotive force

A thermal compression bonding power source comprises a main circuit, a controller, a current sampling circuit, a voltage sampling circuit and a temperature detection circuit, wherein the main circuit outputs a direct current / a pulse current to a thermal compression bonding head, and the current sampling circuit, the voltage sampling circuit and the temperature detection circuit are respectively connected to the thermal compression bonding head. The main circuit adjusts the output current according to a PWM signal. The current sampling circuit collects the output current of the main circuit and obtains a feedback current value. The voltage sampling circuit collects voltages of two ends of the thermal compression bonding head and obtains a feedback voltage value. The temperature detection circuit detects the temperature of the welding position of the thermal compression bonding head and obtains a thermal electromotive force signal. The controller is used for controlling the temperature process of the thermal compression bonding head according to a preset temperature curve, obtaining a feedback temperature value according to the thermal electromotive force signal, and controlling a duty ratio of the PWM signal according to the feedback current value, the feedback voltage value and the feedback temperature value. According to the thermal compression bonding power source, identification for temperature sensing lag time is achieved, feed forward control over the temperature is conducted according to the lag time, the phenomenon of temperature overshooting caused by the temperature feedback lag is avoided, and stability of the temperature control is improved.

Owner:广州市精源电子设备有限公司 +1

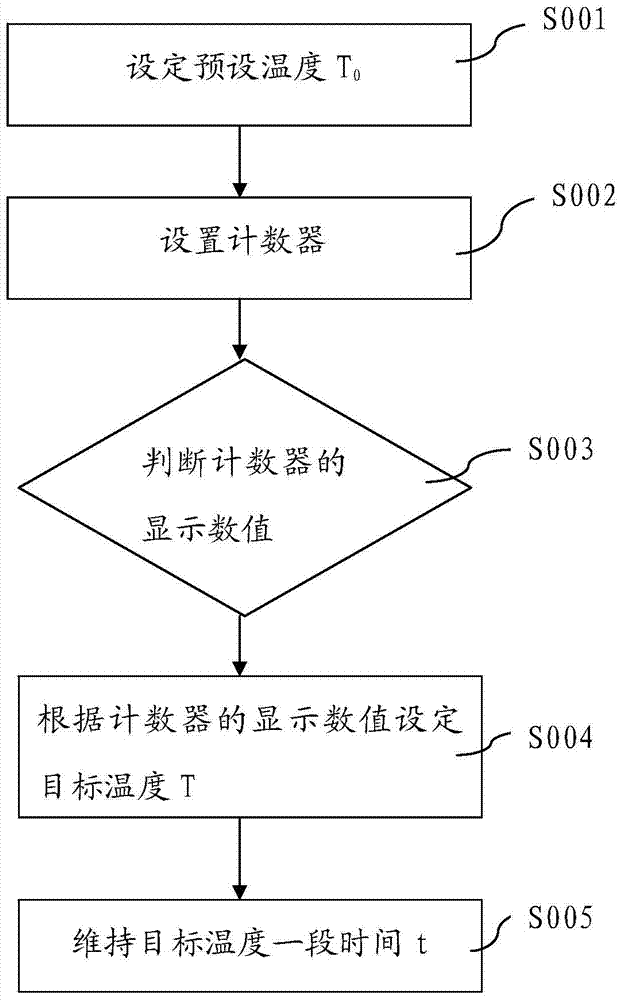

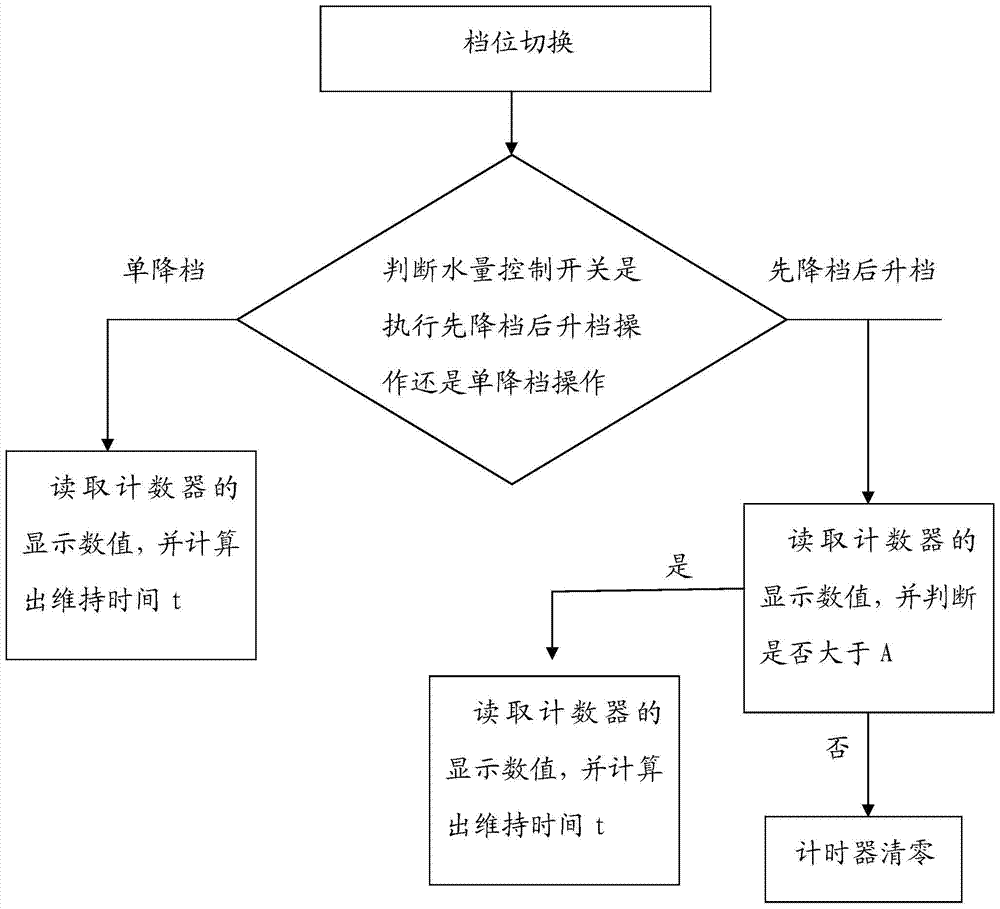

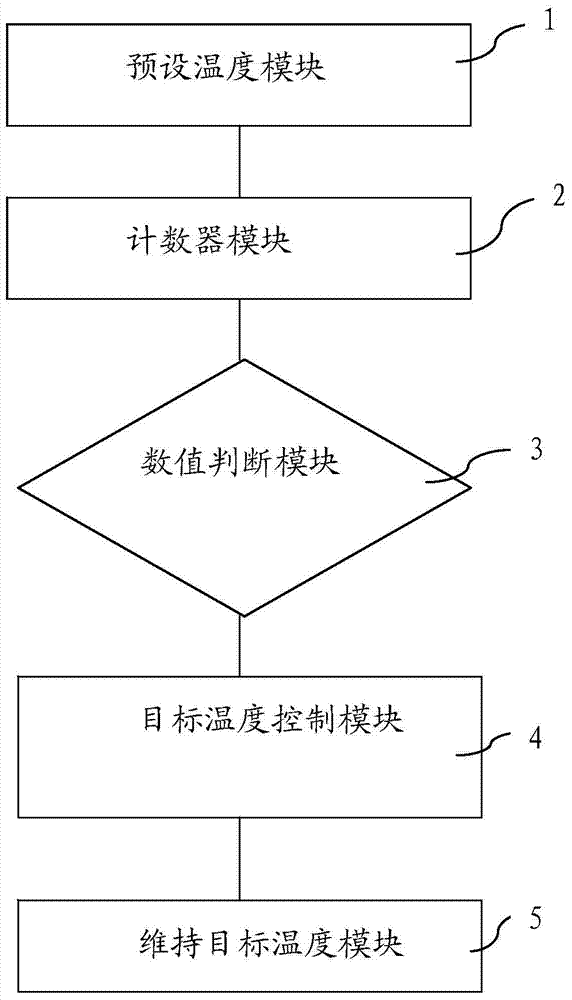

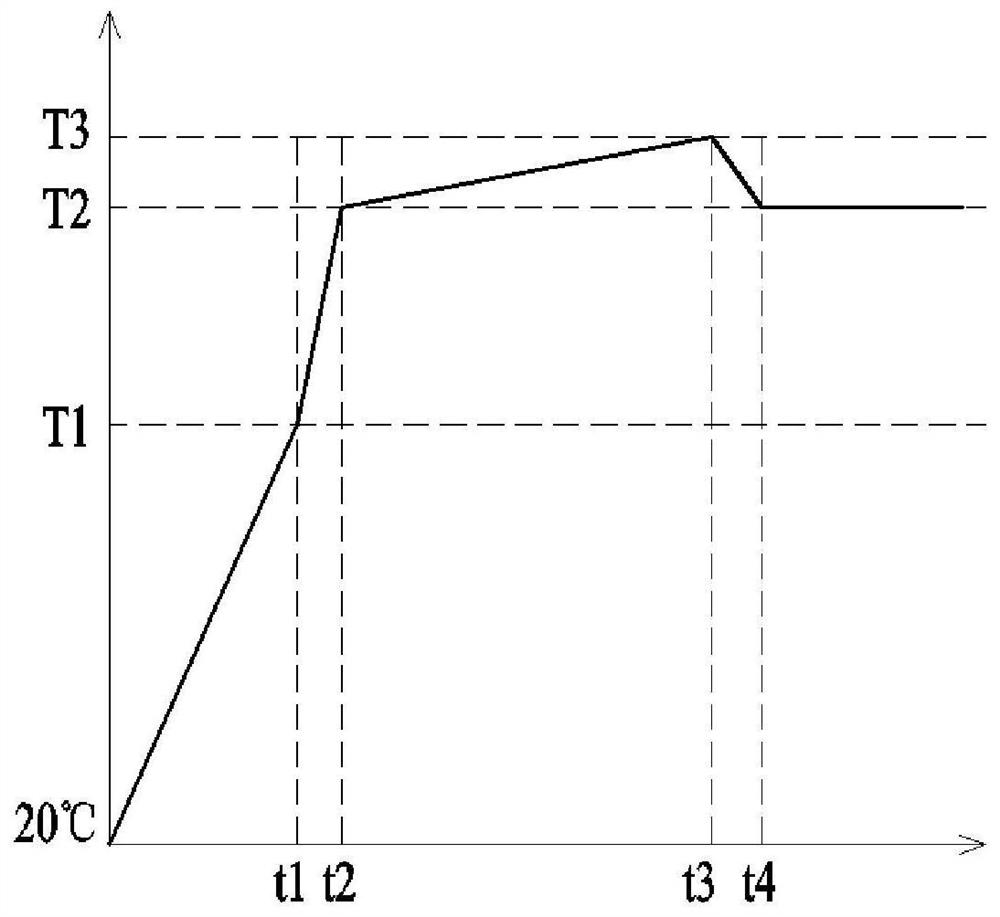

Control method and control system for preventing temperature overshoot

ActiveCN105425865BComfort experienceAvoid temperature overshootSpraying apparatusAuxillary controllers with auxillary heating devicesThermodynamicsControl system

The invention discloses a control method for preventing temperature overshoot, which includes the following steps: S001: setting the preset temperature T0; S002: setting a counter, wherein, when the water quantity control switch is switched from a low position to a high position, the counter display The value is 0; when the water volume control switch is switched from the high position to the low position, the display value of the counter is greater than 0; S003: judge the display value of the counter; S004: set the target temperature according to the judgment result of step S003, such as the display value of the counter If it is 0, set the target temperature T=T0; if the display value of the counter is greater than 0, then set the target temperature T=T0-T1; S005: maintain the target temperature T=T0-T1 for a period of time and then return to the preset temperature T0. The invention also discloses a control system for preventing temperature overshoot. The temperature overshoot prevention control method or control system provided by the present invention ensures that the temperature overshoot phenomenon is avoided when gears are switched, and brings comfortable experience to users.

Owner:SHANGHAI KOHLER ELECTRONICS TECH

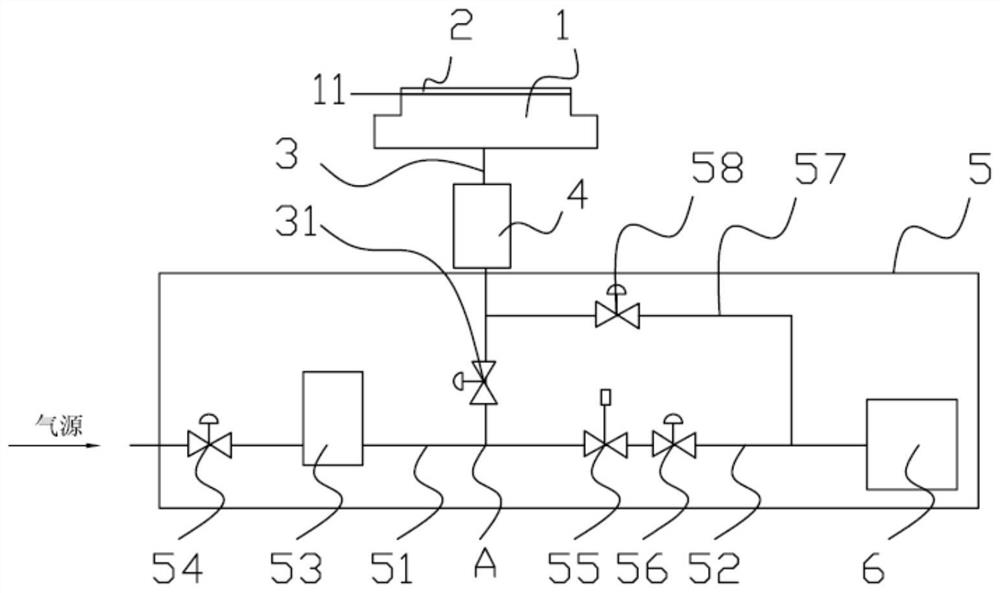

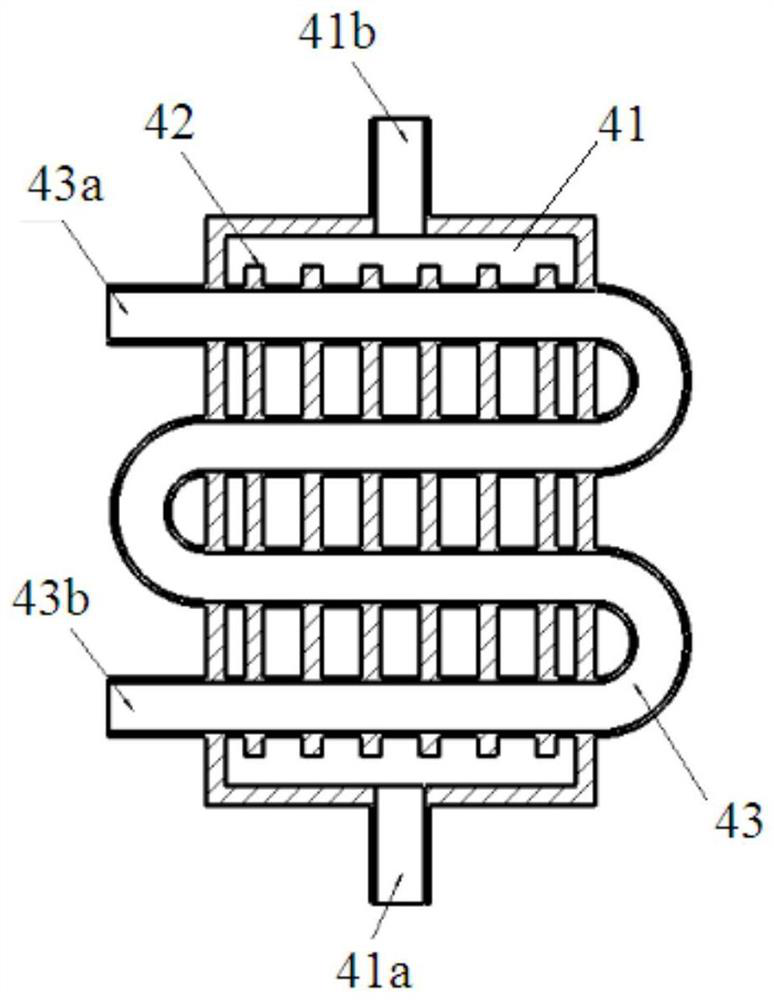

Chip temperature control system, chip temperature control method and reaction chamber

ActiveCN109427610BImprove temperature control speedHigh precisionSemiconductor/solid-state device manufacturingTemperature controlWafering

The invention provides a wafer temperature control system, a wafer temperature control method, and a reaction chamber. The wafer temperature control system includes a chuck for carrying a wafer, a heating device arranged in the chuck for heating the wafer, and a heating device for heating the wafer. The conveying device for conveying the heat exchange gas in the gap between the wafer and the chuck, the conveying device includes a conveying pipeline, and the conveying pipeline is used to convey the heat exchanging gas to the gap between the wafer and the chuck; There are temperature controllers for heating or cooling the heat exchange gas in the delivery line so that the heat exchange gas entering the gap between the wafer and the chuck reaches the target temperature. The wafer temperature control system provided by the invention can not only increase the temperature control speed of the wafer and increase the production capacity, but also can improve the accuracy of the wafer temperature control, thereby improving the uniformity of the process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

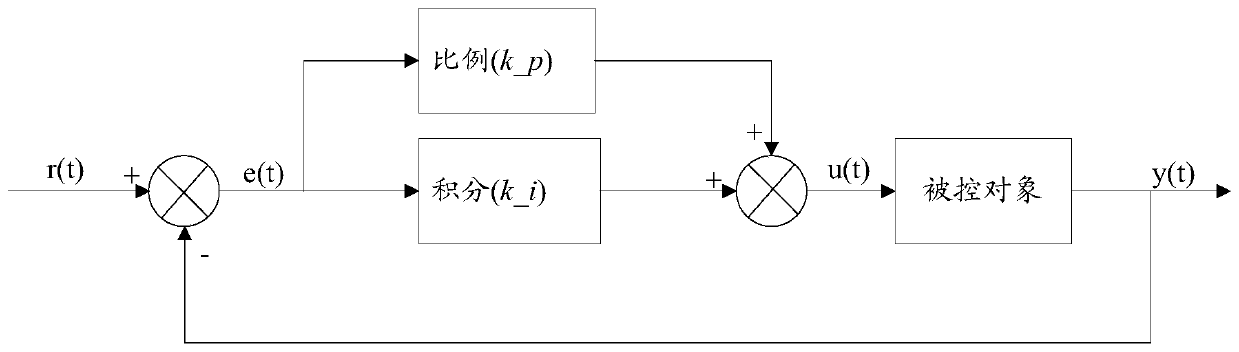

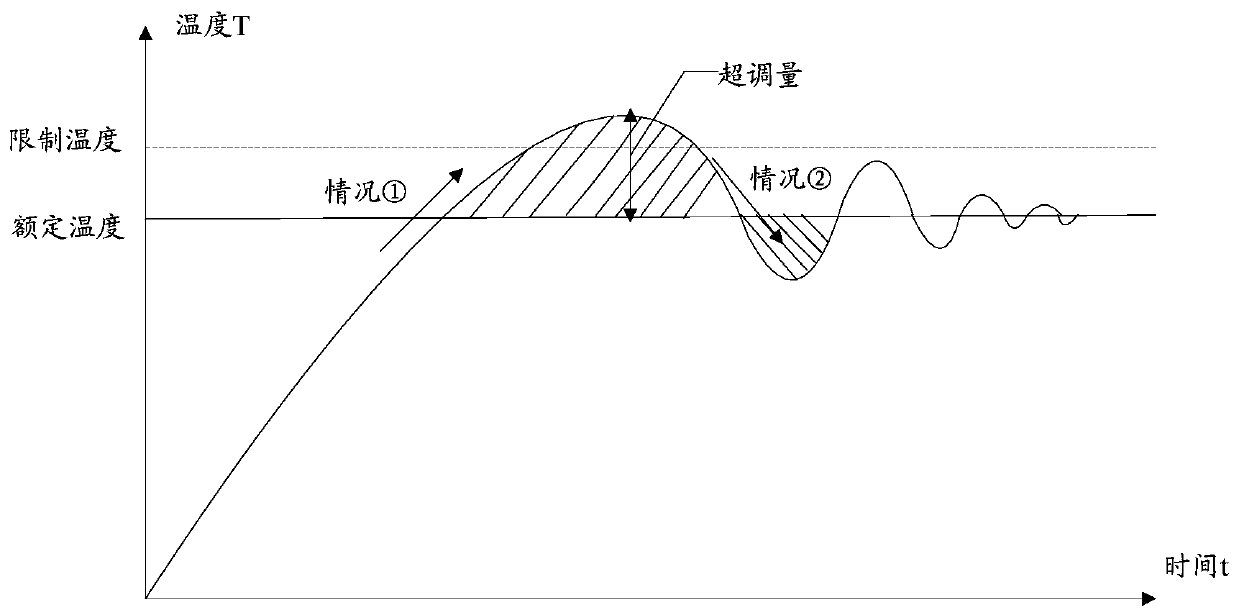

Power control method and device

ActiveCN108268082BStable temperatureReduce or avoid temperature overshoot problemsElectric variable regulationThermodynamicsControl theory

The invention provides a power control method and device. The method comprises the steps of: acquiring an actual measurement temperature of a controlled target; comparing the actual measurement temperature and a rated temperature, and, in response to the increase of the actual measurement temperature from a value lower than the rated temperature to a value higher than the rated temperature or thereduction of the actual measurement temperature from a value higher than the rated temperature to a value lower than the rated temperature, resetting an accumulative temperature error value acquired by accumulating temperature error values, wherein the temperature error values are the difference values between the rated temperature and the actual measurement temperature; based on the temperature error values and the accumulative temperature error value at the current moment, determining the input power upper limit value of the controlled target; controlling power provided for the controlled target based on the input power upper limit value. According to the technical solution, the temperature of a controlled target can be stabilized around a rated temperature faster, so that the performance of the controlled target can be maximized while the controlled target is protected.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

An energy-saving temperature-controlled heating platform and its constant temperature control method

ActiveCN103256708BHeating up fastHigh control precisionAir heatersTemperature controlPower switching

Owner:BEIJING JIEYALI ELECTRONICS TECH

a co 2 The temperature control method of the incubator

ActiveCN112596561BReduced stabilityControl UniformityAuxillary controllers with auxillary heating devicesTemperature controlControl power

The invention discloses a CO 2 The temperature control method of the incubator, including: according to the set temperature st and CO 2 The real-time temperature t inside the incubator is used to calculate the temperature control deviation value er; 2 The incubator temperature control method controls the output power of the heating element, controls the CO 2 The temperature t in the incubator is within the precise range. This method effectively avoids temperature overshoot, effectively controls the stability and uniformity of the box temperature, and ensures that different cells can be cultivated under different environmental conditions, making CO 2 When the incubator is in the environment of 15-35°C and the set temperature is 30-50°C, the control error can be kept at ≤±0.2°C. When the set value is 37°C and the ambient temperature is 23°C, the control accuracy can be guaranteed At ≤±0.1°C.

Owner:冰山松洋生物科技(大连)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com