PCR (Polymerase Chain Reaction) amplification instrument and amplification method for nucleic acid on-site variable-temperature amplification

An amplification instrument and nucleic acid technology, which is applied in the field of PCR gene amplification, can solve the problems of overshooting in temperature changes, affecting gene quality, and long time consumption, so as to avoid temperature overshooting, reduce amplification time, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

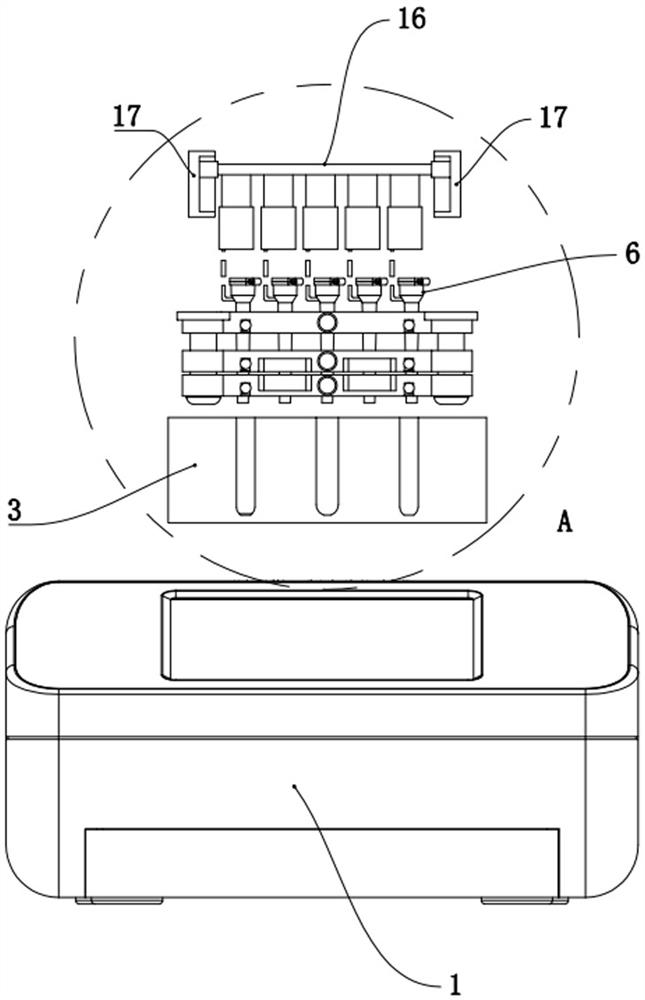

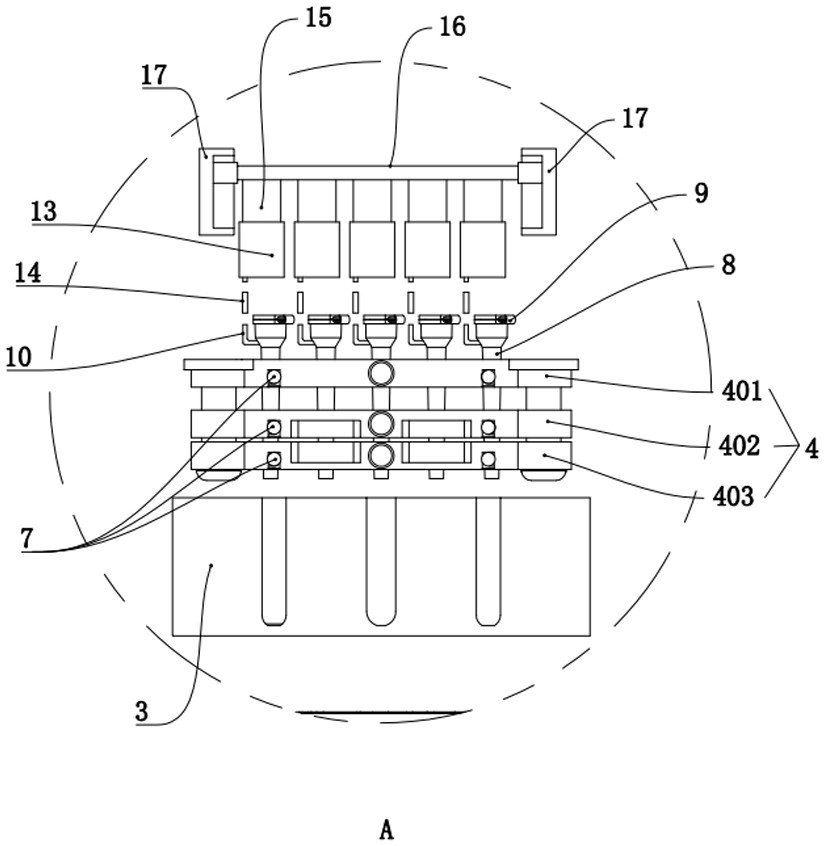

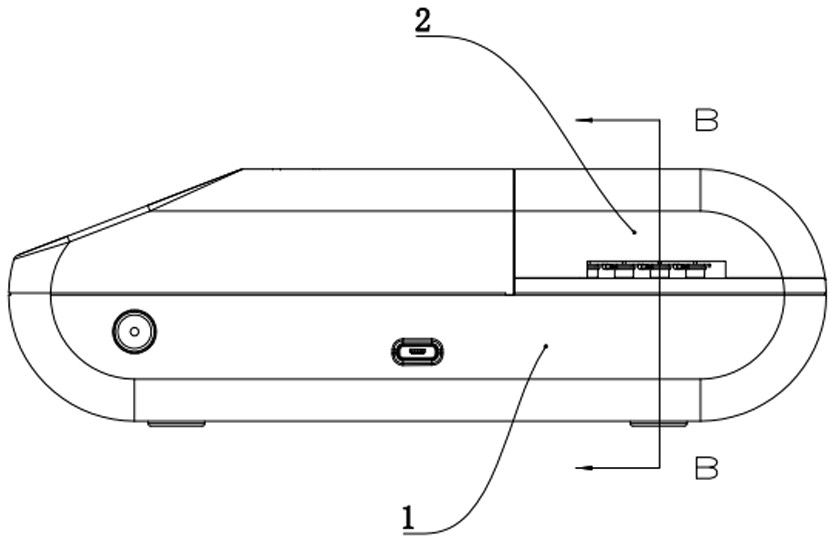

[0051] A PCR amplification instrument for on-site temperature-variable amplification of nucleic acids, referring to Figure 1 to Figure 8 , including a casing 1 and a casing 2 that can be opened or closed. A lofting groove 3 is arranged in the casing 1, a lofting plate 4 is arranged in the lofting groove 3, and a tube groove 5 is arranged on the lofting plate 4. This implementation In the example, there are 20 tube grooves 5, which can accommodate 20 sample tubes 6 at the same time. The inside of the stakeout plate 4 is provided with a heating tube 7, and the heating tube 7 is arranged in a serpentine shape in the stakeout plate 4 to increase the contact area with the stakeout plate 4, so that the stakeout plate 4 is heated more evenly, and the heating tube 7 in each stakeout plate 4 They are all separately electrically connected to the control system, and the control system controls the opening and closing of the heating tube 7 and regulates the temperature of the heating tub...

Embodiment 2

[0059] Compared with Example 1, the vent tube 10 directly communicates with the inside of the tube body 8, during the rising process of the first sealing member 11, the liquid may be sucked away through the vent tube 10, resulting in waste of liquid and affecting the test results (refer to Figure 7), the difference is that in this example, refer to Figure 9 to Figure 11 , the tube body 8 includes an inner tube 801 sealingly fitted with the tube cover 9 and an outer tube 802 sleeved outside the inner tube 801 , the first sealing member 11 is sealed and lifted inside the inner tube 801 , between the inner tube 801 and the outer tube 802 There is an accommodating space 803 sealed and formed, and the inner tube 801 is provided with a ventilation hole 22 that communicates the accommodating space 803 with the inner cavity of the inner tube 801 near the tube cover 9, and the vent tube 10 is arranged on the outer tube 802 so that the accommodating space 803 and the inner cavity of th...

Embodiment 3

[0062] Compared with Embodiment 2, the waste of liquid is avoided by setting the accommodating space 803, the cost is high and the liquid stored in the accommodating space 803 is inconvenient to dump (refer to Figure 10 ), the difference is that in this example, refer to Figure 12 , the tube body 8 is integrally formed, and the accommodating space 803 is no longer provided. The first sealing member 11 includes a sealing block 1101. The sealing block 1101 is sealed and lifted in the tube body 8. A liquid storage tank is recessed on the upper surface of the sealing block 1101. 1102 and the sealing cover 1103 that can open or close the liquid storage tank 1102. The liquid is stored in the liquid storage tank 1102 and sealed by the sealing cover 1103 to prevent the liquid from being sucked away through the vent pipe 10. The production is convenient and the cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com