Heating device used for semiconductor fast annealing and control method

A rapid annealing and heating device technology, applied in semiconductor/solid-state device manufacturing, pulse generation, electrical components, etc., can solve the problems affecting temperature stability during the heating process, long stroboscopic period of heating lamps, and fast heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better describe the technical characteristics and structure of the present invention, below in conjunction with preferred embodiments of the present invention and its accompanying picture Describe in detail.

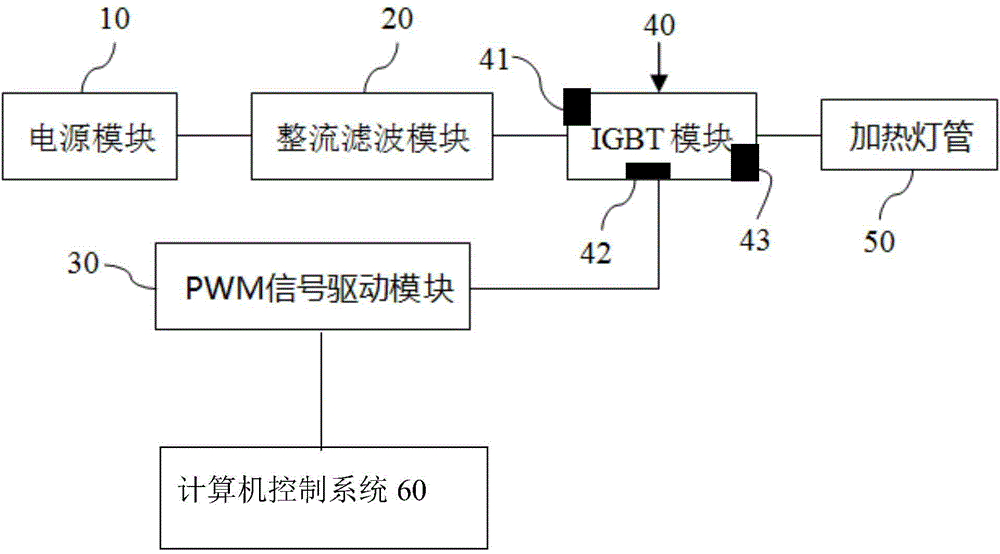

[0031] Referring to FIG. 1, a heating device for rapid annealing of semiconductors includes a power supply module 10, a rectification and filtering module 20, an IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) module 40, and a PWM (pulse width modulation) signal drive The heating lamp group 50 composed of the module 30 and several lamps includes a computer system 60 connected with the PWM signal driving module 30 for controlling and adjusting the duty cycle of the PWM signal. The power supply module 10 is connected with a rectification and filtering module 20 for providing a stable DC power supply for the heating device of this embodiment. The IGBT module 40 includes an input port 41, a control port 42, and an output port 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com