Chip temperature control system, chip temperature control method and reaction chamber

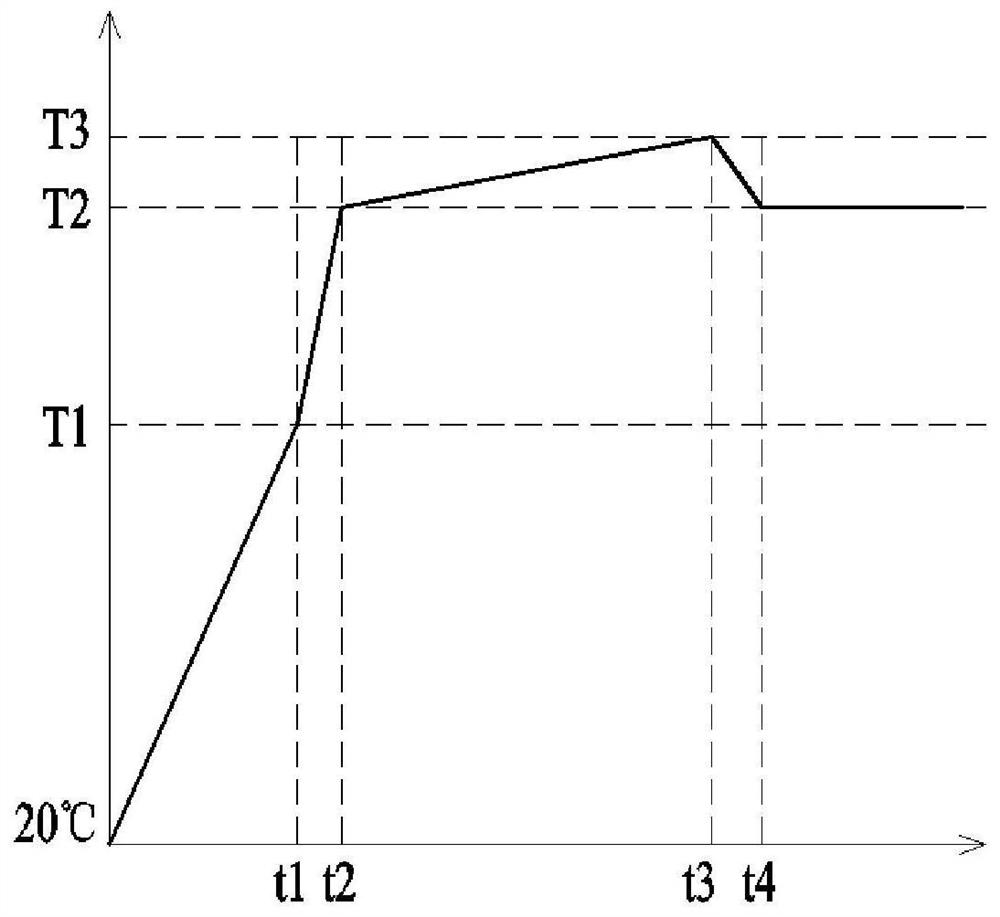

A temperature control system and wafer technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of heating power consumption, production capacity reduction, temperature overshoot, etc., to improve temperature control speed and process uniformity , to avoid the effect of temperature overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

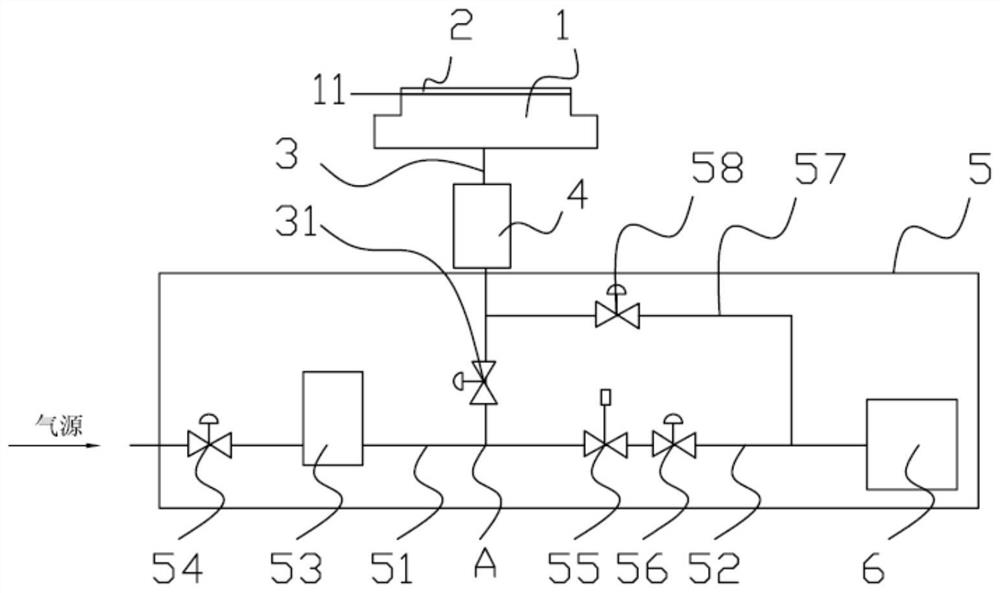

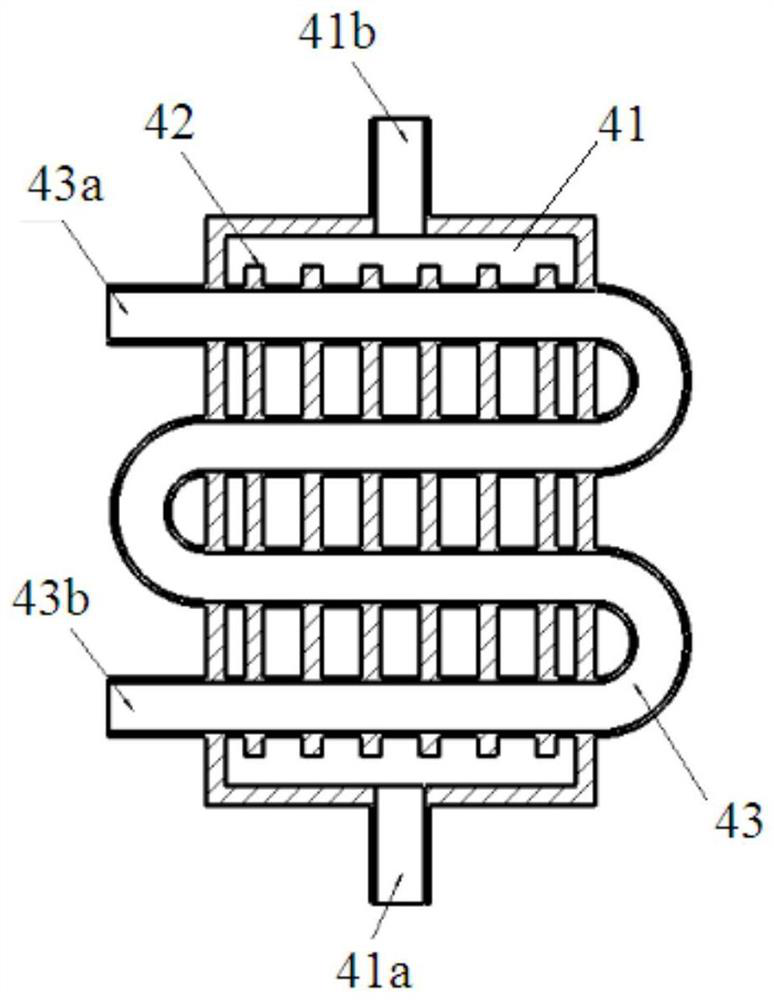

[0035] In order for those skilled in the art to better understand the technical solution of the present invention, the wafer temperature control system, wafer temperature control method and reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0036] see figure 2 An embodiment of the present invention provides a wafer temperature control system, which includes a chuck 1 and a conveying device, wherein the chuck 1 is used to carry a wafer 2, and the chuck 1 is, for example, an electrostatic chuck or a mechanical chuck. Also, a heating device (not shown in the figure) for heating the wafer 2 is provided in the chuck 1 . The delivery device is used to deliver heat exchange gas to the gap 11 between the wafer 2 and the chuck 1 to exchange heat between the wafer 2 and the chuck 1 . The heat exchange gas is, for example, helium.

[0037] The above conveying device includes a conveying pipeline 3 for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com