Thermostatic control device and method with detection of heat transfer rate

A technology of heat transfer rate and constant temperature control, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as temperature fluctuation, temperature overshoot, long adjustment time, etc., achieve accurate and stable temperature, prevent temperature Effects of overshoot and small thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

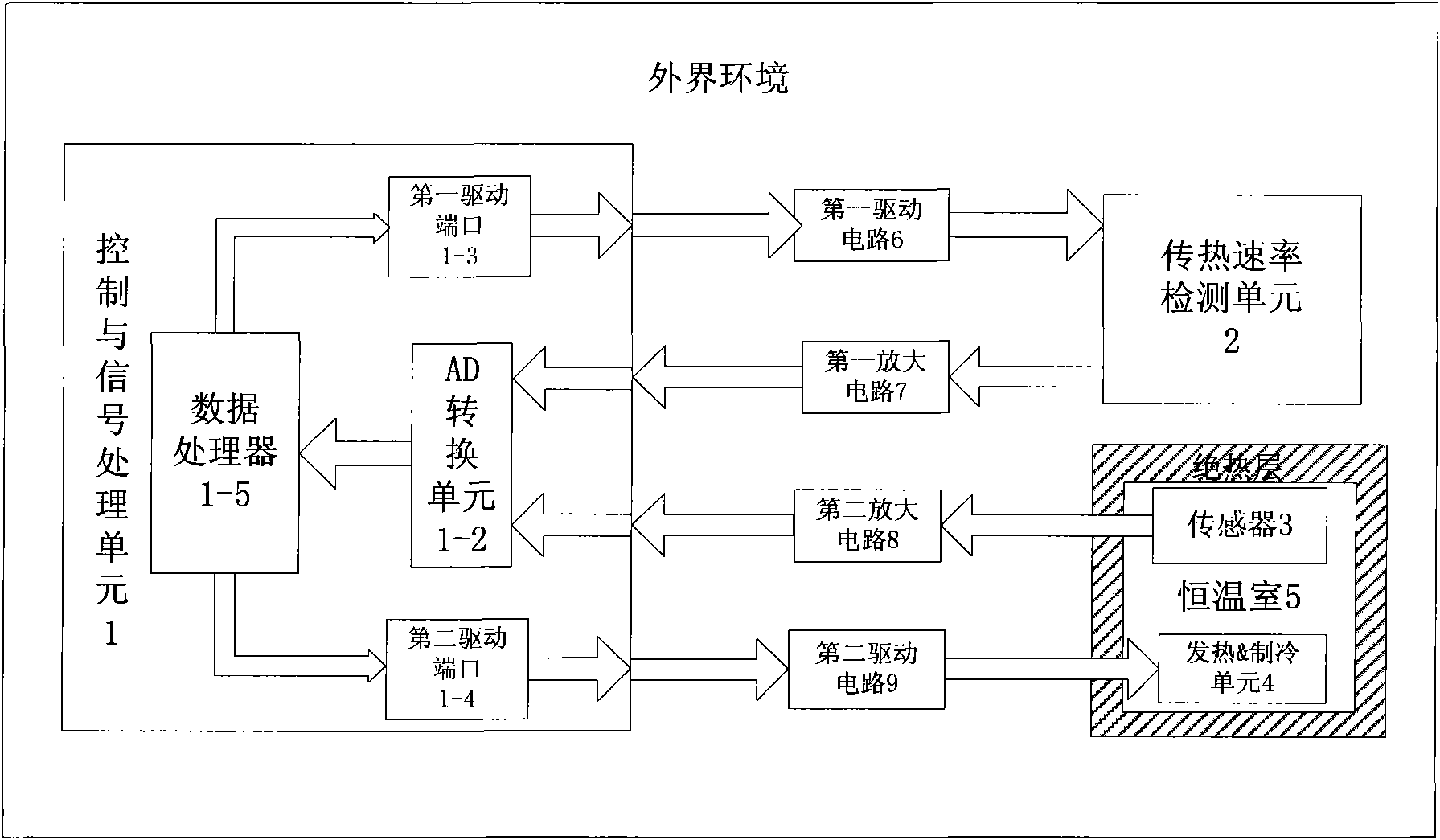

[0015] The present invention consists of a control and signal processing unit 1, a heat transfer rate detection unit 2, a sensor 3, a heating & cooling unit 4, a thermostatic chamber 5, a first driving circuit 6, a first amplifying circuit 7, a second amplifying circuit 8, and a second The driving circuit 9 is composed.

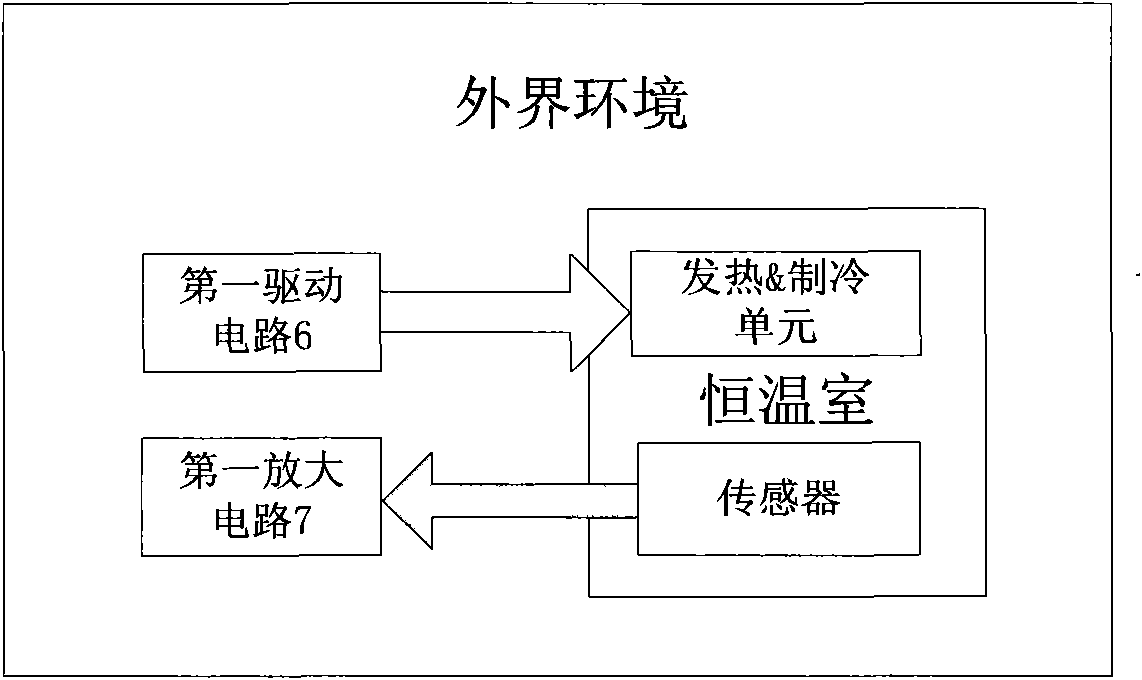

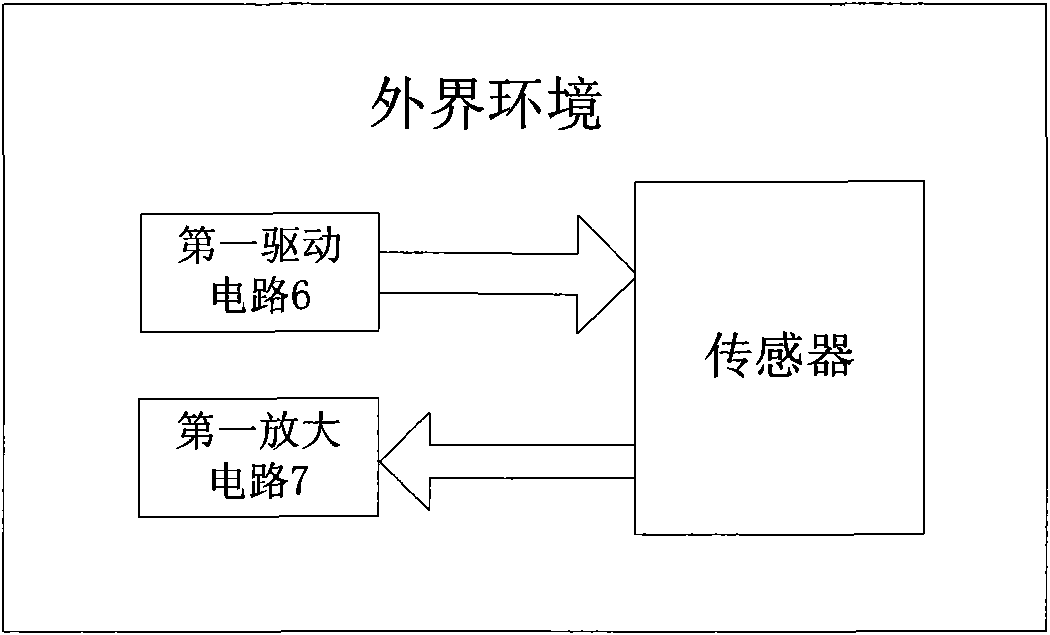

[0016] The control and signal processing unit 1 controls the second drive circuit 9 to drive the heating & cooling unit 4 through its own second drive port 1-4, and outputs heat or cooling capacity to the thermostatic chamber 5; the sensor 3 in the thermostatic chamber 5 senses the temperature signal, The temperature signal in the thermostatic chamber 5 is fed back to the control and signal processing unit 1 through the second amplifying circuit 8 . At the same time, the control and signal processing unit 1 controls the first drive circuit 6 to drive the heat transfer rate detection unit 2 to reach a temperature consistent with that in the thermostatic chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com