Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid seal leaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

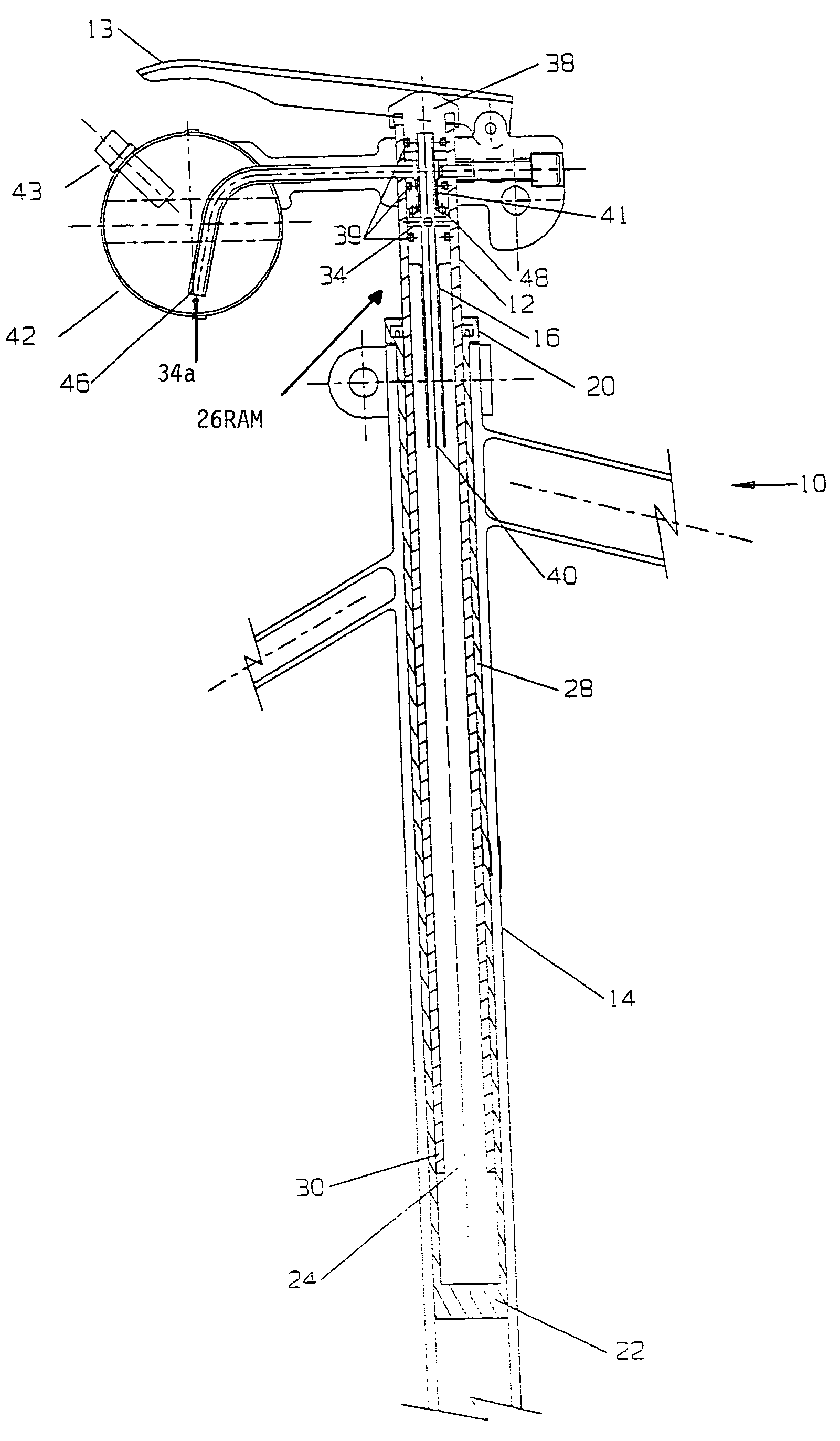

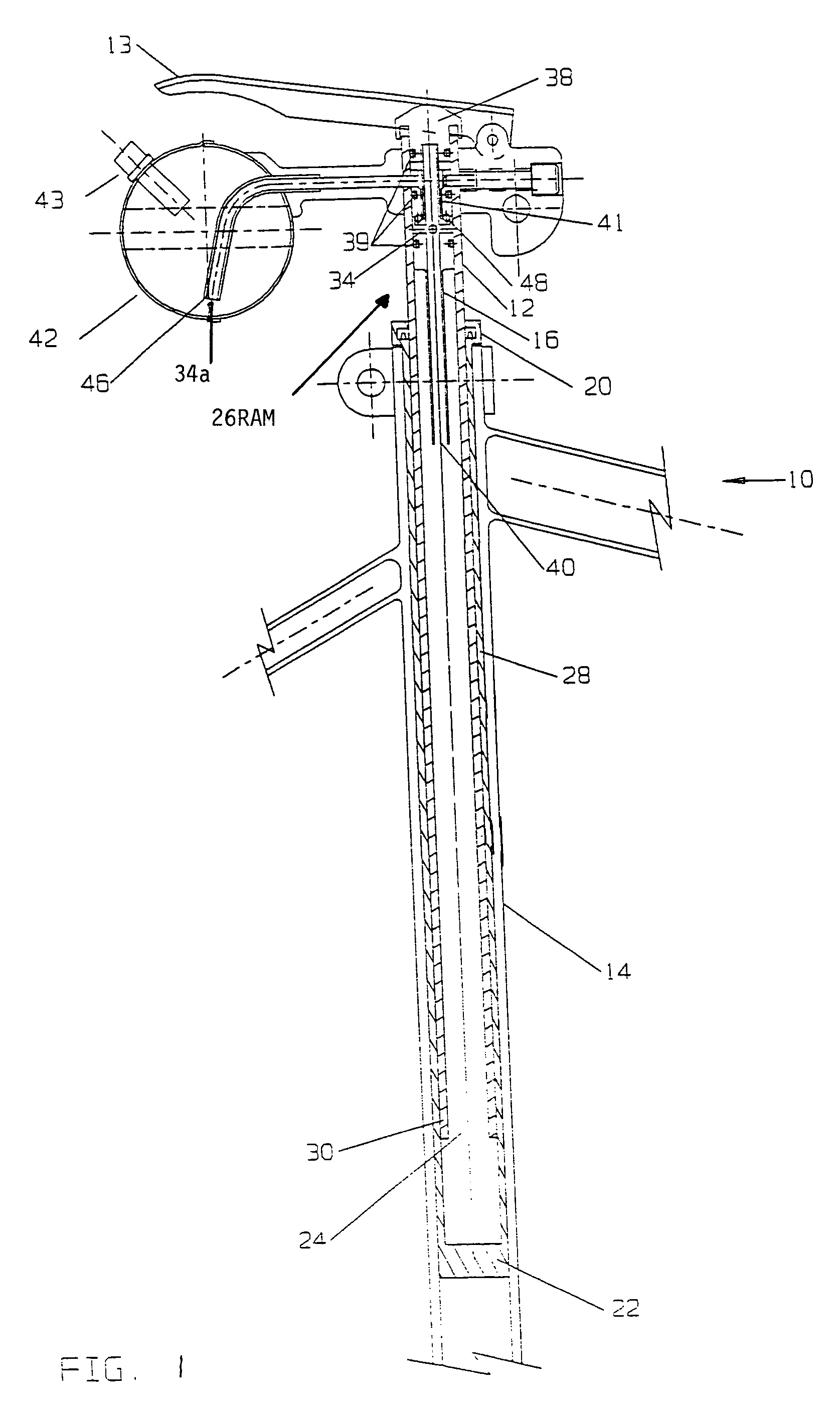

Adjustable air cushion bicycle seat

InactiveUS7025367B2Minimizing sliding friction pressureMaintain viscosityPassenger cyclesChildren cyclesHydraulic ramEngineering

An adjustable air cushion bicycle seat hydraulic ram system mounted within the seat post of a bicycle with one end of the ram attached to the bicycle seat, and the other end of the ram in communication with an internal reservoir associated with an adjustable pressurized air / oil reservoir to selectively fill the internal reservoir with a pressurized air column to form an air cushion within the ram to provide the desired ride cushion.

Owner:TOOL ENG & MFG

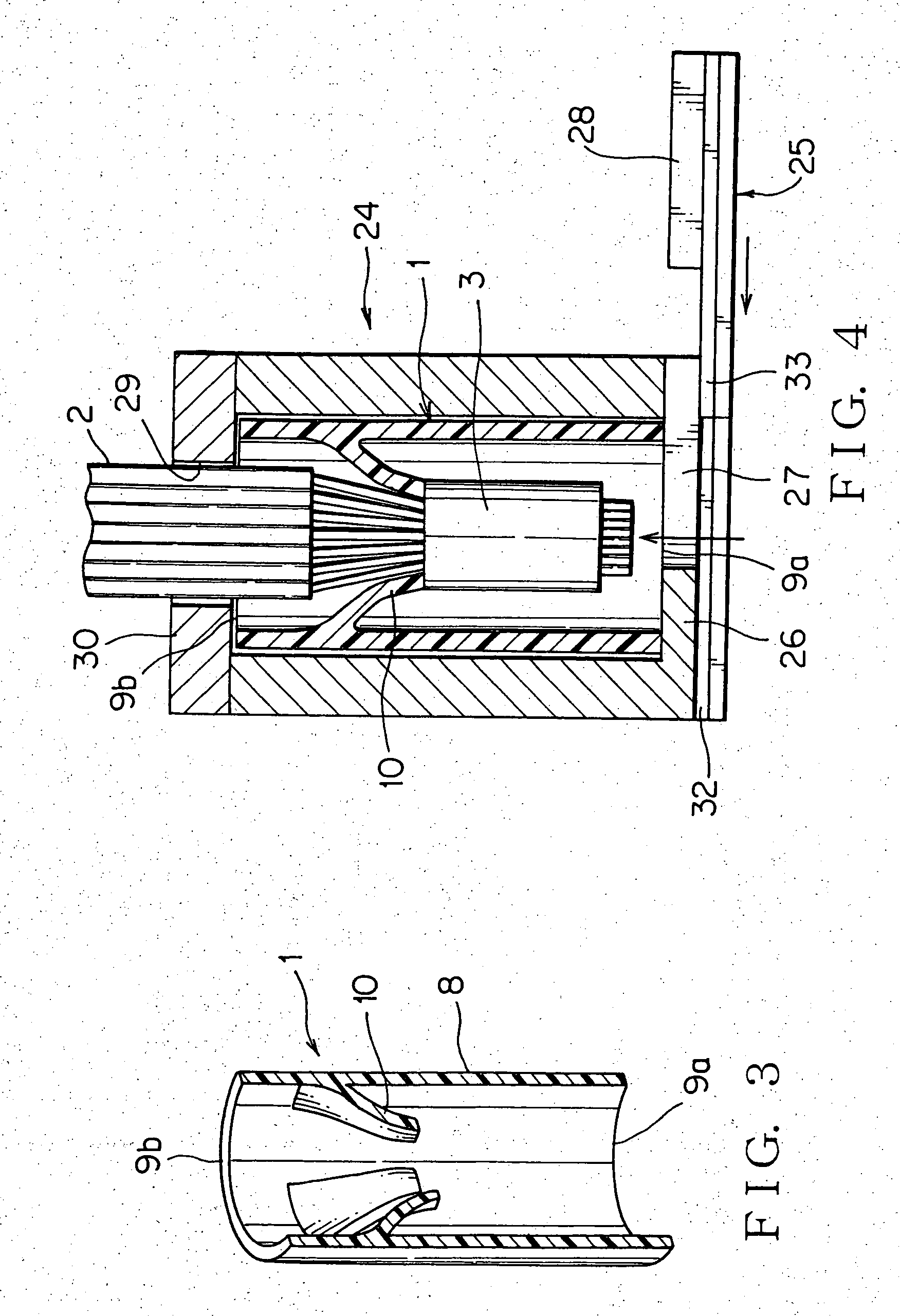

Method of waterproof of electric cable joint

InactiveUS20050178003A1Avoid Seal LeaksGood lookingDustproof/splashproof/drip-proof/waterproof/flameproof connectionCouplings bases/casesEngineeringMechanical engineering

Owner:YAZAKI CORP

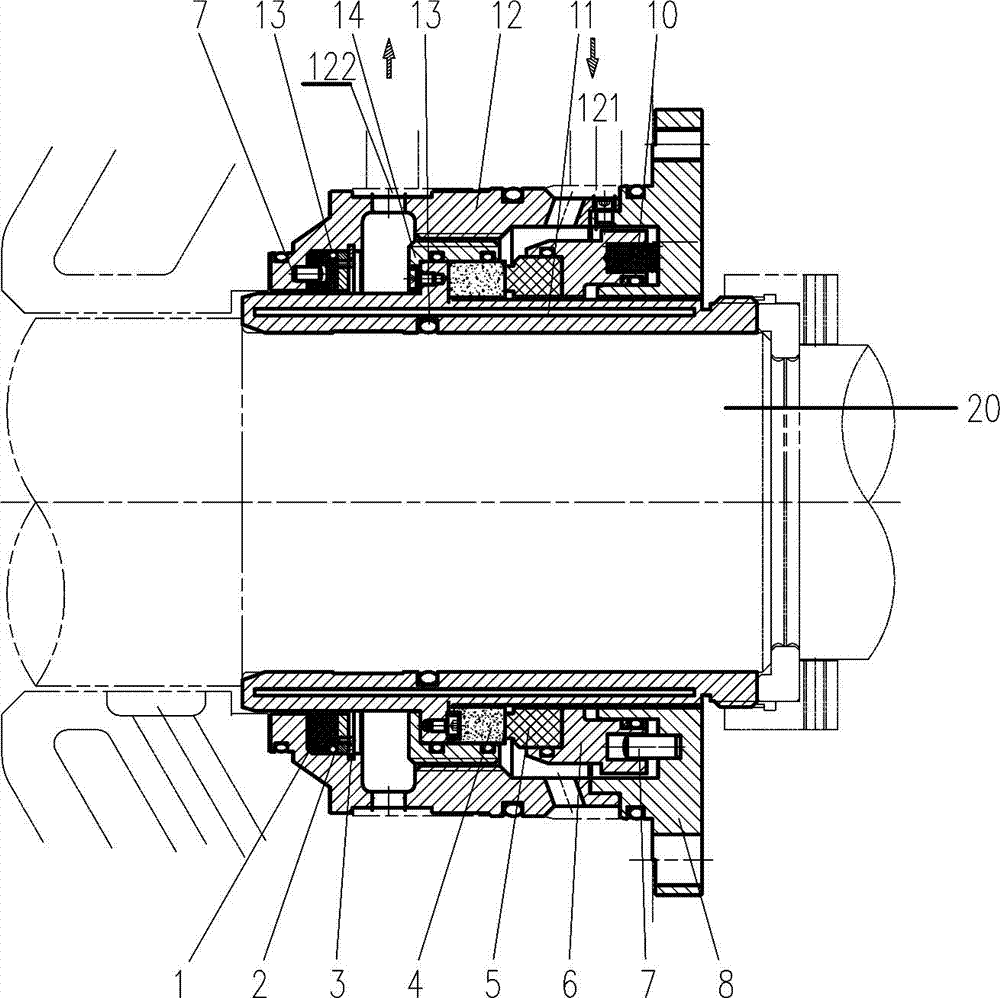

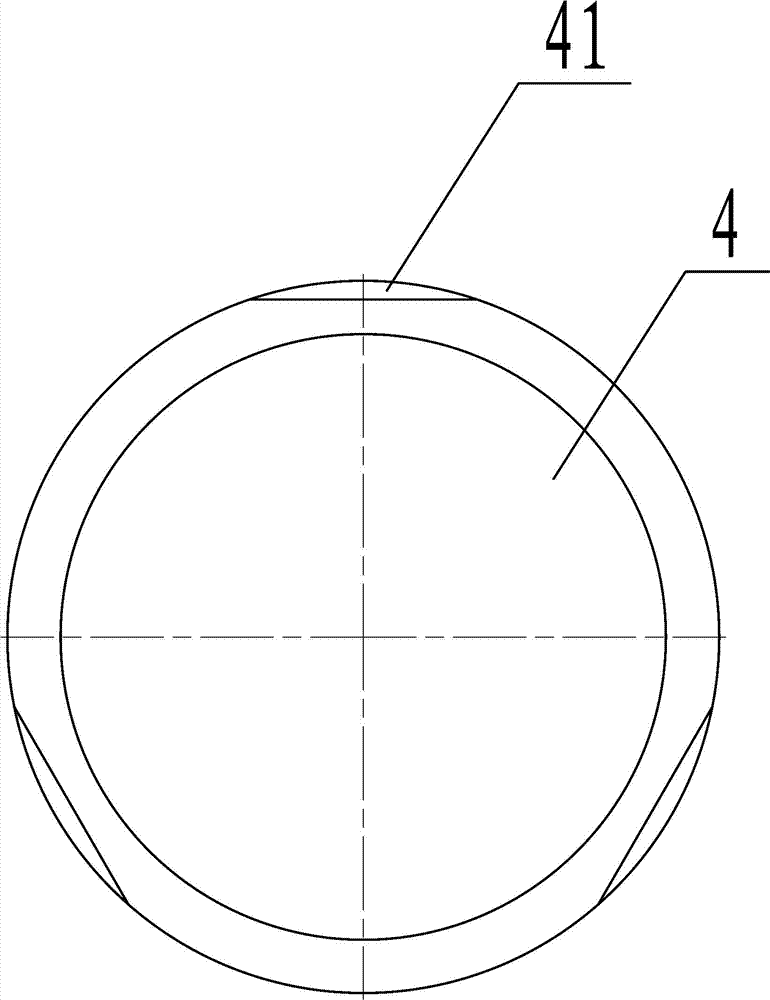

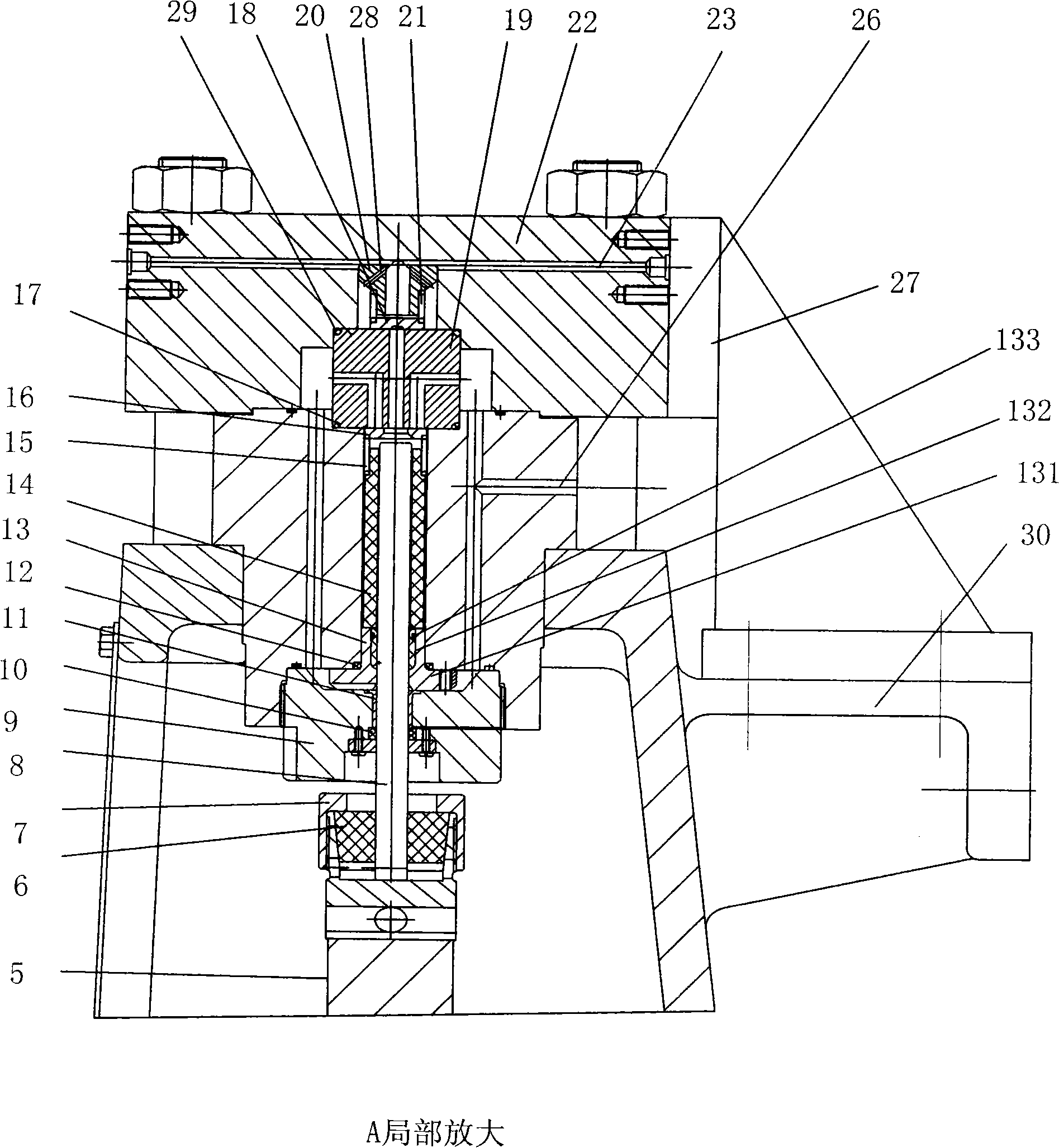

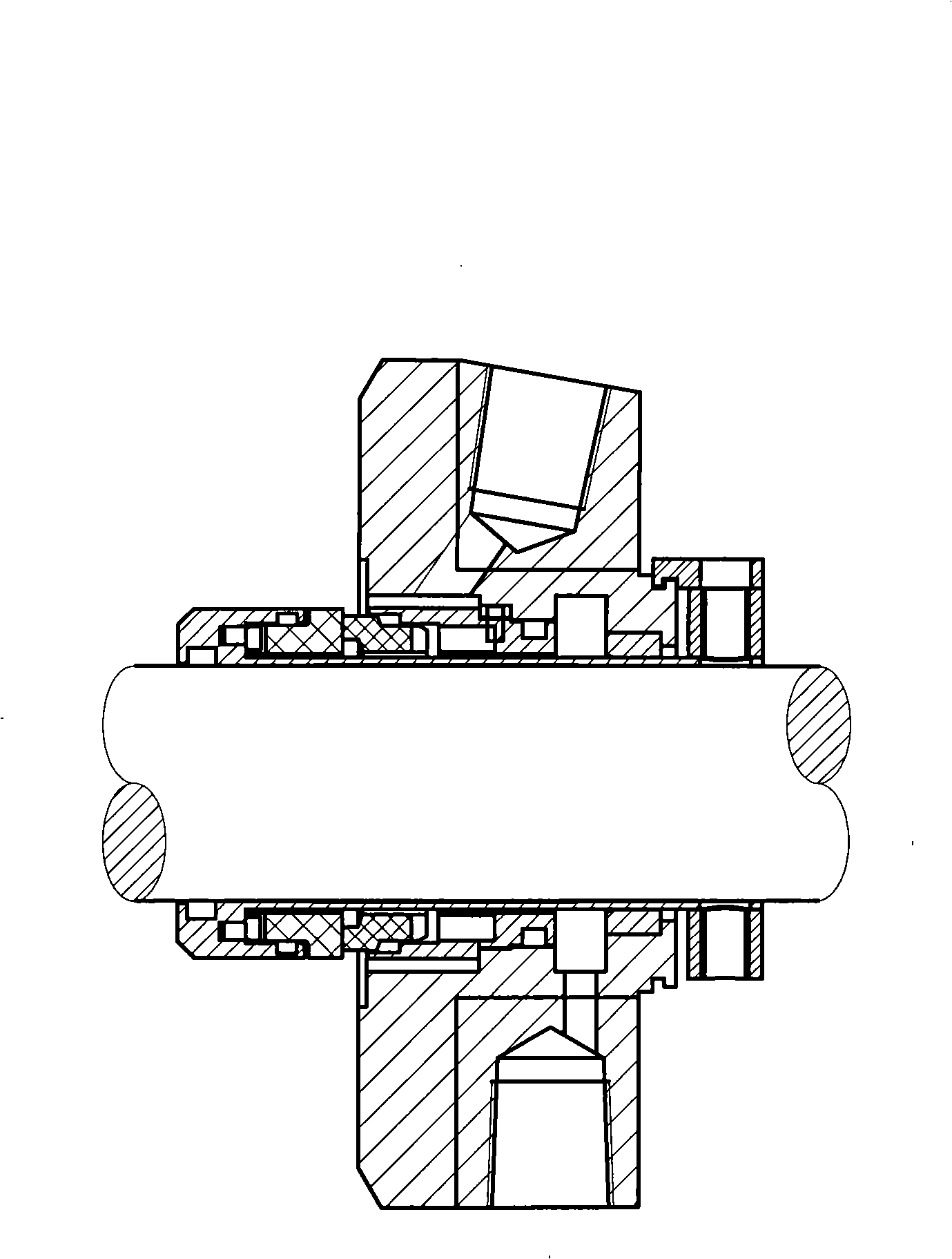

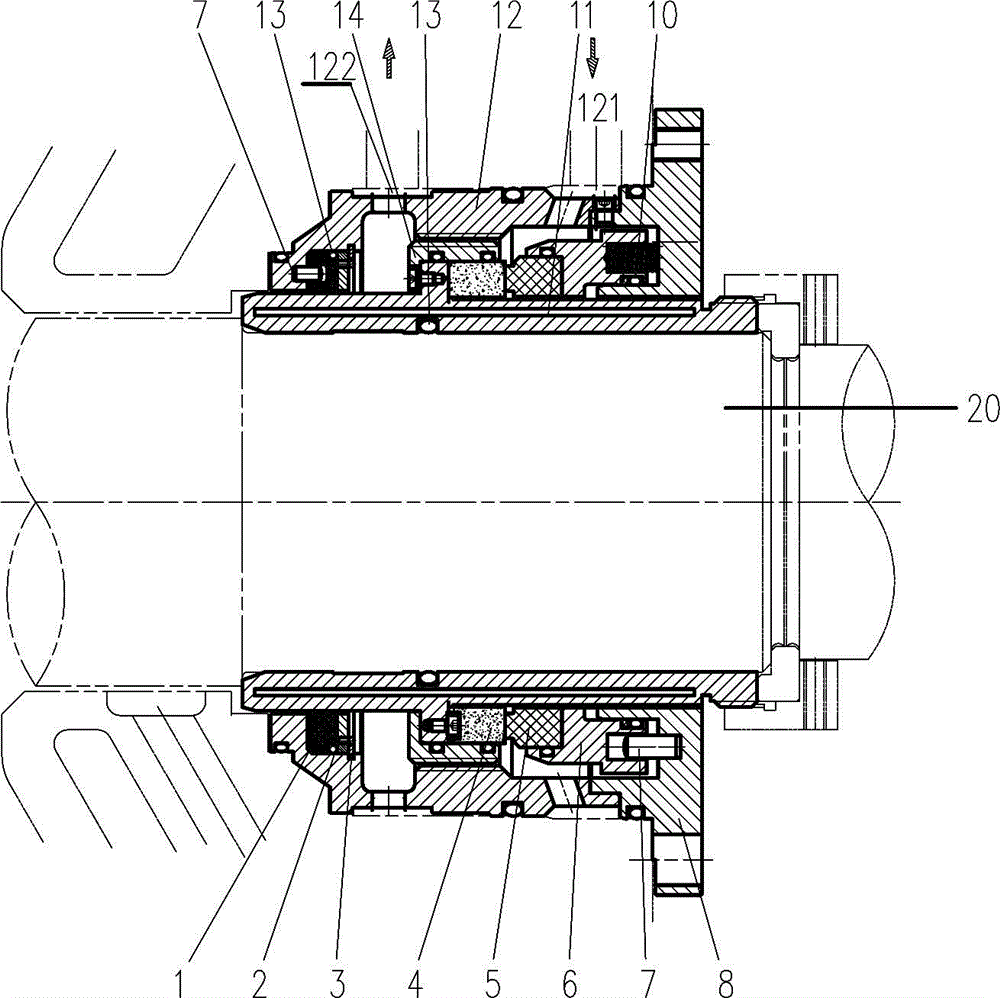

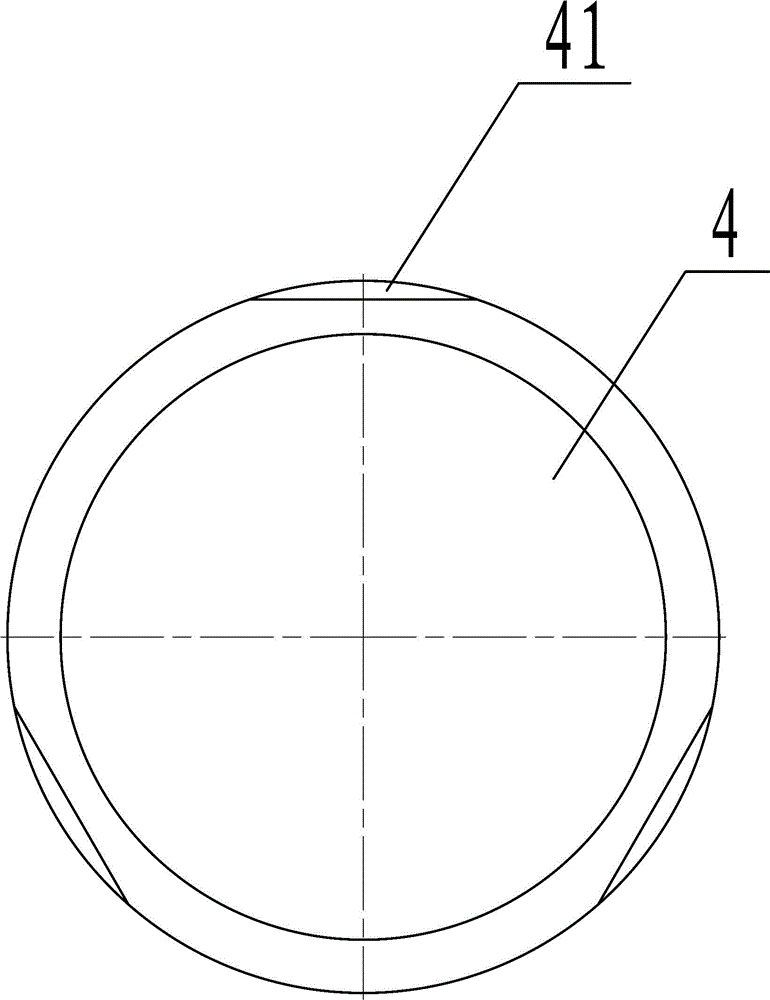

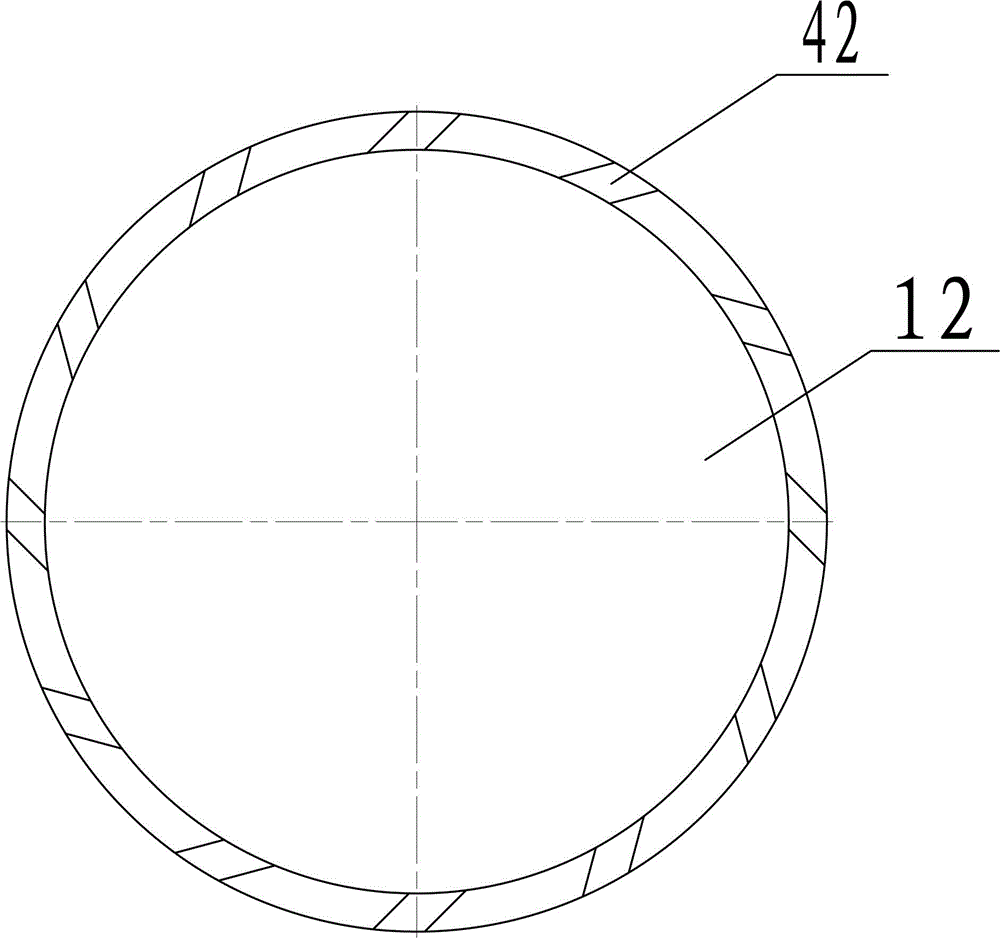

High-temperature-resistant mechanical sealing device

ActiveCN104329466AReduced mechanical propertiesReduce thermal deformationEngine sealsEngineeringRunning time

The invention relates to the field of sealing devices for fluid medium conveying pipelines, in particular to a high-temperature-resistant mechanical sealing device. The high-temperature-resistant mechanical sealing device comprises a movable ring (4), a static ring (5) and a revolving shaft (20), and is characterized by further comprising a vacuum shaft sleeve (11) and an O-shaped ring (13), wherein the inner cavity of the vacuum shaft sleeve (11) is in a high-vacuum state; the vacuum shaft sleeve (11) is fixed on the revolving shaft (20) in a sleeving manner; the movable ring (4) is fixed on the vacuum shaft sleeve (11) in the sleeving manner; the static ring is rotationally arranged on the vacuum shaft sleeve (11) in the sleeving manner; the static ring (5) and the movable ring (4) are jointed together and rotate relatively; the O-shaped ring (13) is lined between the vacuum shaft sleeve (11) and the revolving shaft (20). The high-temperature-resistant mechanical sealing device has high sealing performance, low medium leakage, long running time and long service life.

Owner:SHANGHAI LEHE FLUID MACHINERY

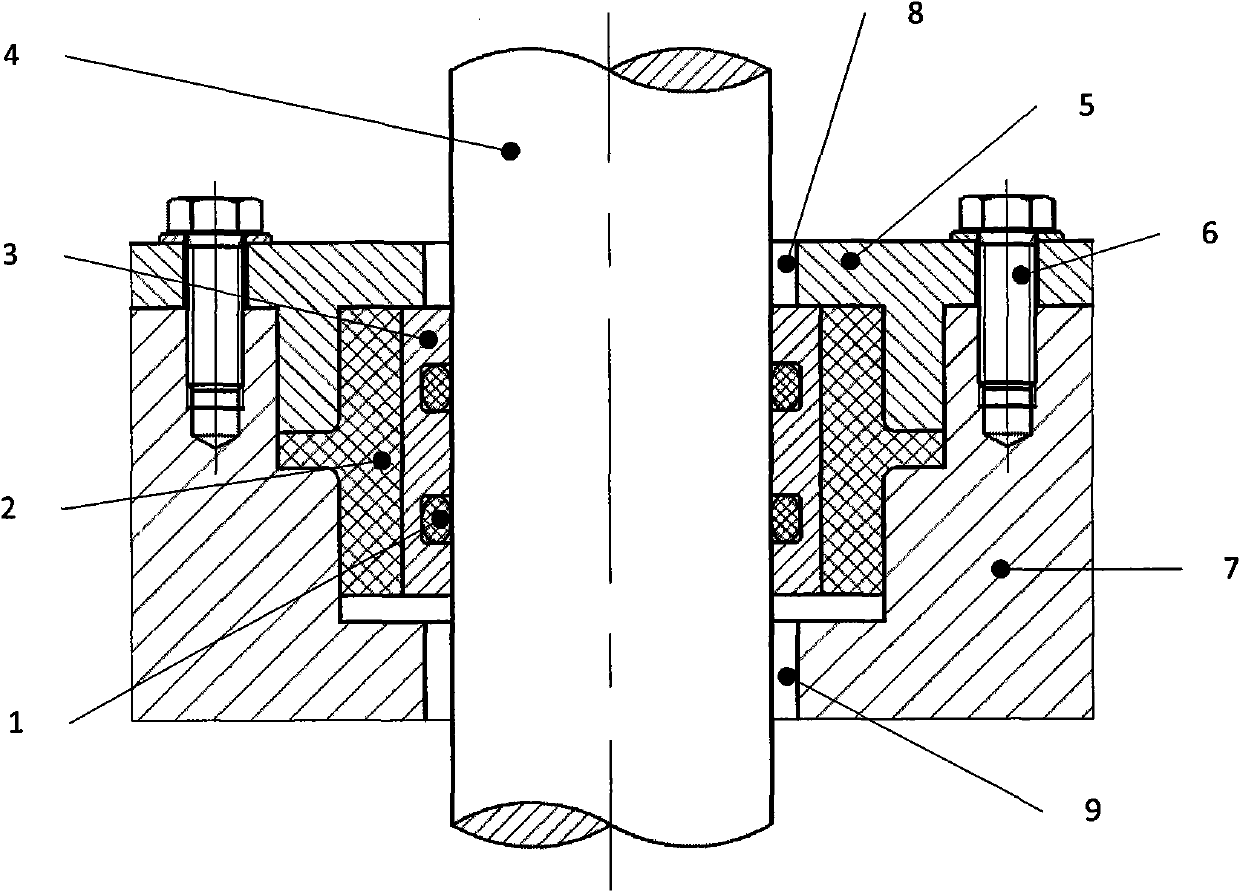

Floating shaft lever sealing structure

InactiveCN102022540AReduce operating torqueFree from routine maintenanceEngine sealsEngineeringMechanical engineering

Owner:SHANGHAI KARON VALVES MACHINERY +1

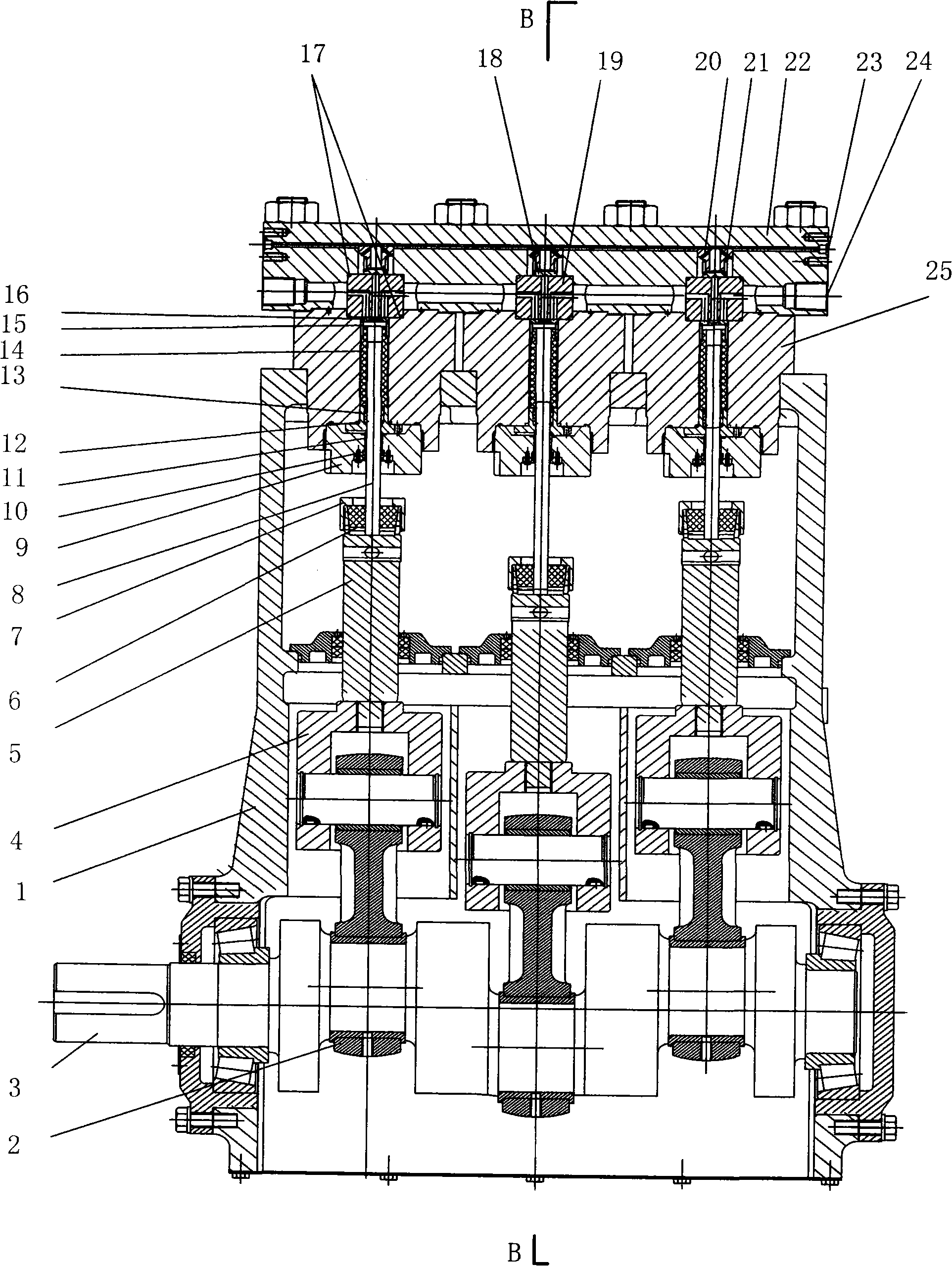

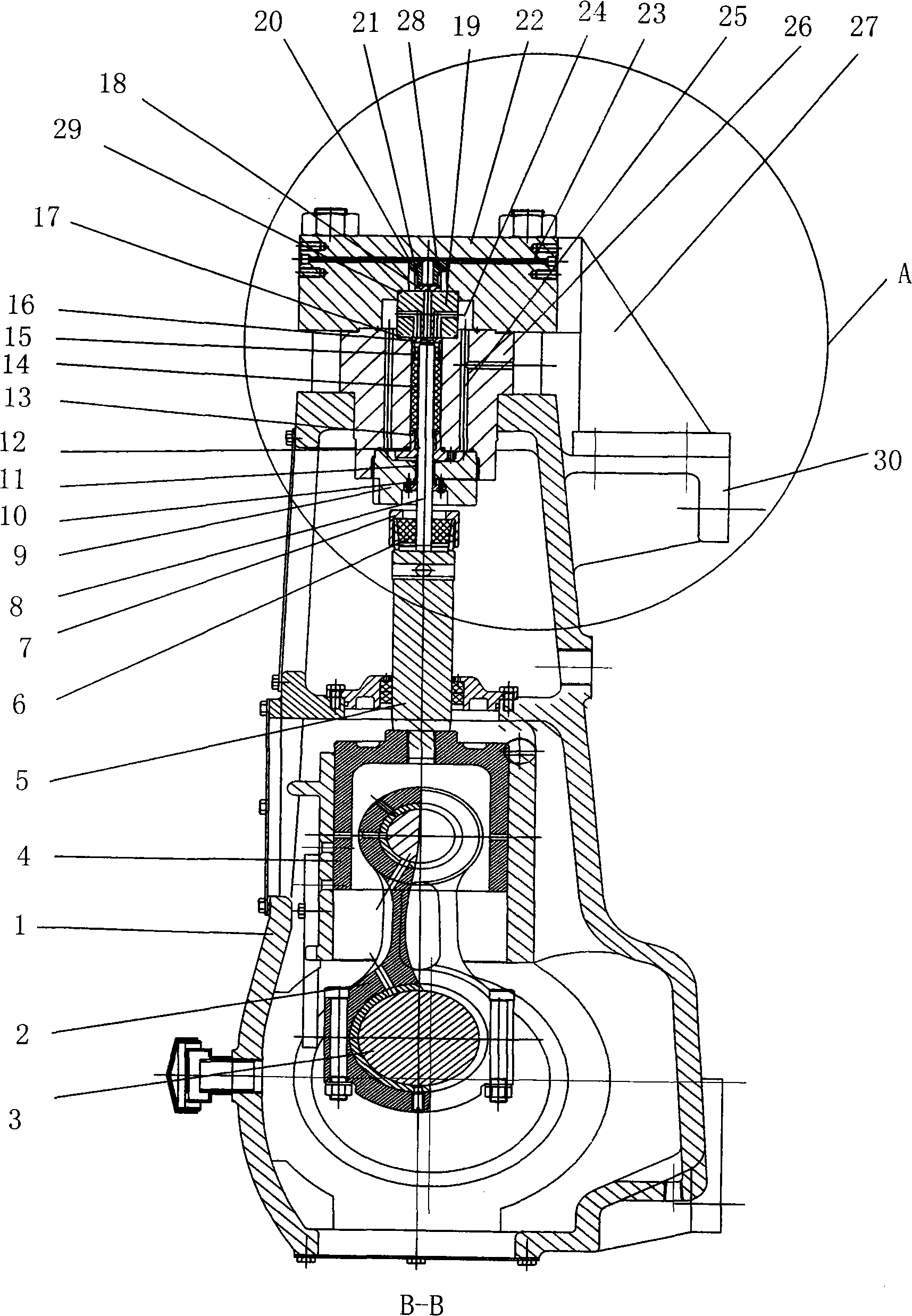

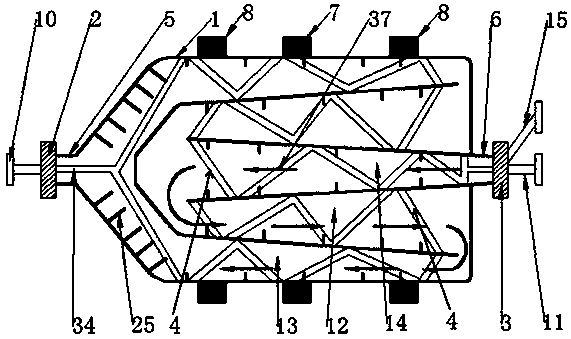

Ultra-high pressure three-plunger pump

InactiveCN101403380AUnique structural featuresImprove sealingPositive displacement pump componentsLiquid fuel engine componentsUltra high pressureInlet valve

The invention relates to an ultrahigh pressure triple plunger pump, comprising a machine body, a crank shaft connecting rod type power transmission device and a fluid end generating high pressure. The fluid end comprises a pump body, a pump cylinder, a plunger and a sealing box body. A guide valve, a drainage spring, a discharge valve, a valve seat, an inlet valve and an intake spring are arranged in series between the pump cylinder and the pump body. The pump body is provided with a low-pressure water inlet flow channel and a high-pressure water outlet flow channel. The pump cylinder is provided with a condensed water flow channel. A plunger sleeve is arranged between the pump cylinder and the plunger. A sealing component is arranged between the pump cylinder and the sealing box body. A bearing and a first sealing ring are arranged in the sealing box body. A second sealing ring is arranged between the pump cylinder and the sealing component. Two ends of the valve seat are provided with a third sealing ring and a fourth sealing ring. The pump body is of integral type structure. A group of guide holes with the function of buffering are uniformly distributed at the circumference of the guide valve. The condensed water flow channel is communicated with the low-pressure water inlet flow channel on the pump body. A bracket and sliding block type resetting structure is arranged outside the pump body. As a multi-sealing and resetting structure is adopted, the problems that the sealing of the pump is not good and the assembly and the resetting are difficult are solved.

Owner:黄山泰安达机电科技有限公司

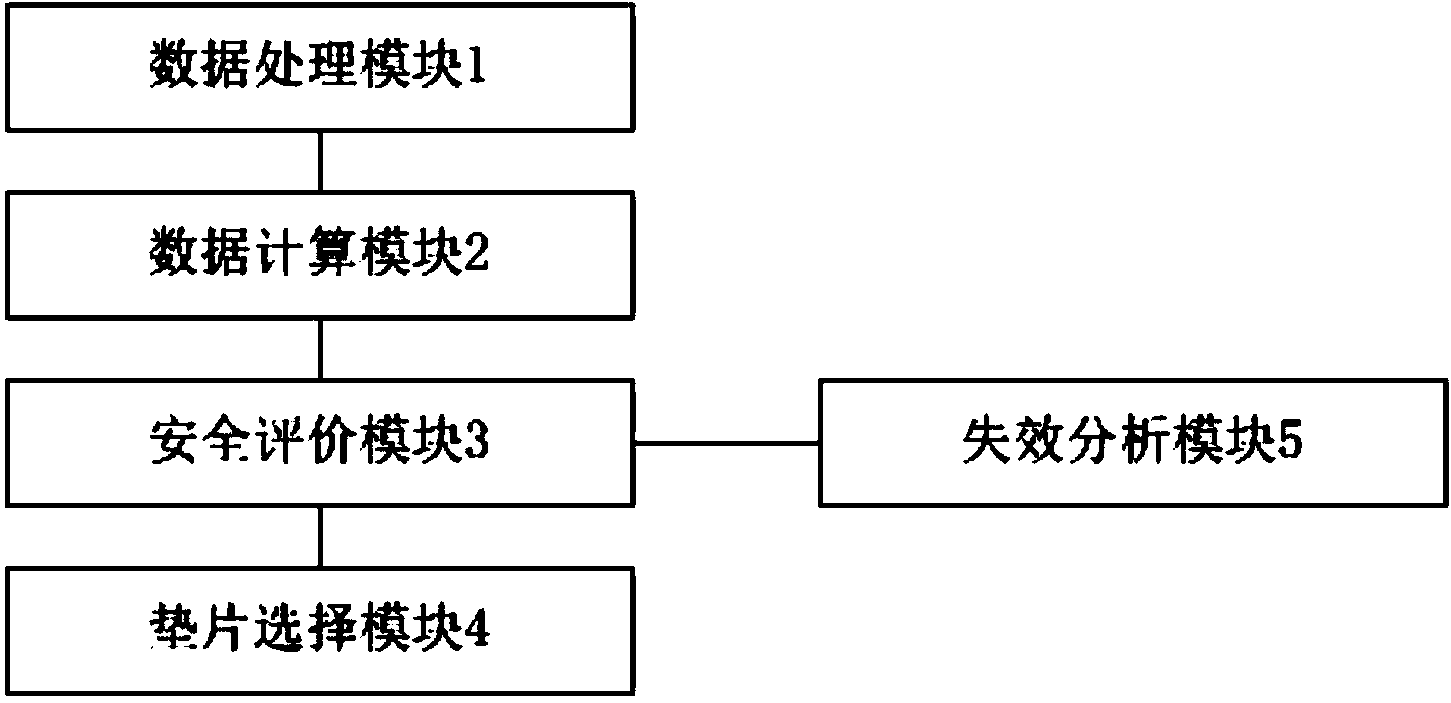

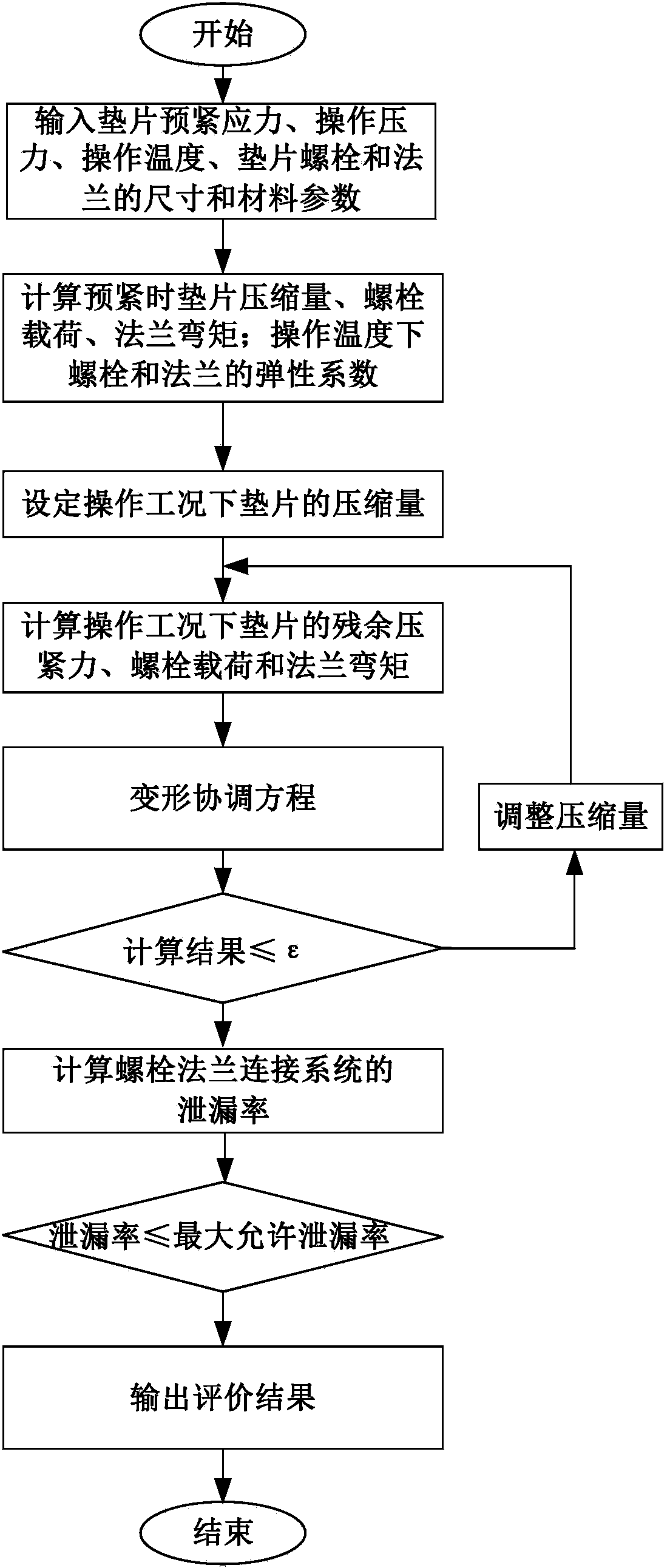

Bolt-spacer-flange connecting and sealing safety evaluating system

InactiveCN104063624AAvoid security issuesAvoid seal leaksSpecial data processing applicationsComputer moduleFlange

The invention provides a bolt-spacer-flange connecting and sealing safety evaluating system. The bolt-spacer-flange connecting and sealing safety evaluating system is characterized by comprising a data processing module, a data calculating module, a safety evaluating module and a spacer selecting module; the data processing module is used for processing tested basic data about a bolt, a spacer and a flange to establish a relationship model among the bolt, the spacer and the flange; the data calculating module is used for calculating the system leakage rate on the basis of the relationship model obtained by the data processing module among the bolt, the spacer and the flange; the safety evaluating module is used for comparing the leakage rate obtained by the data calculating module with a safety performance level preset by the system to obtain a system leakage rate level; the spacer selecting module is used for selecting the spacer needed by the system on the basis of the system leakage rate level obtained by the flange safety evaluating module. According to the safety evaluating system, safety management of a bolt-spacer-flange connecting system can be improved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

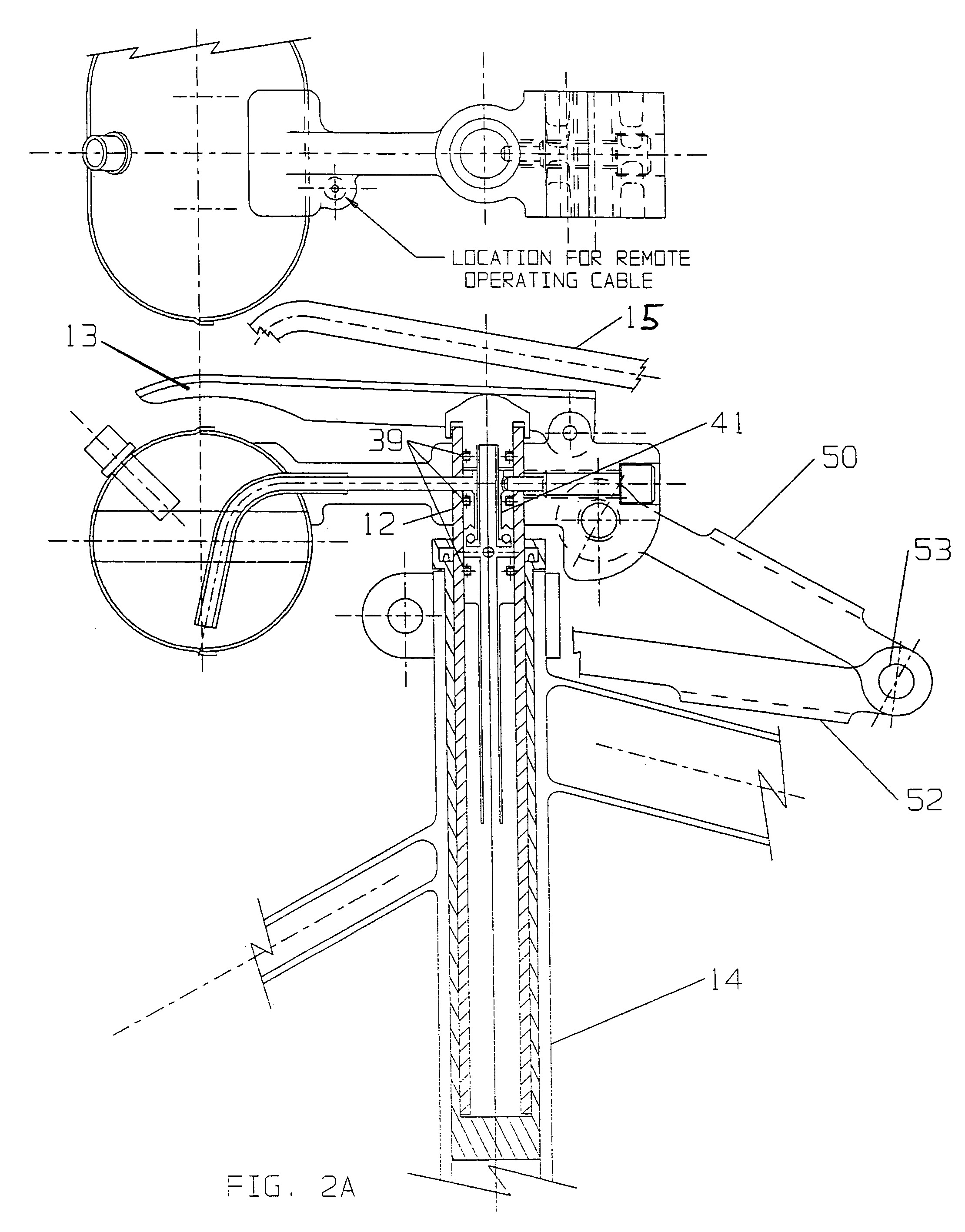

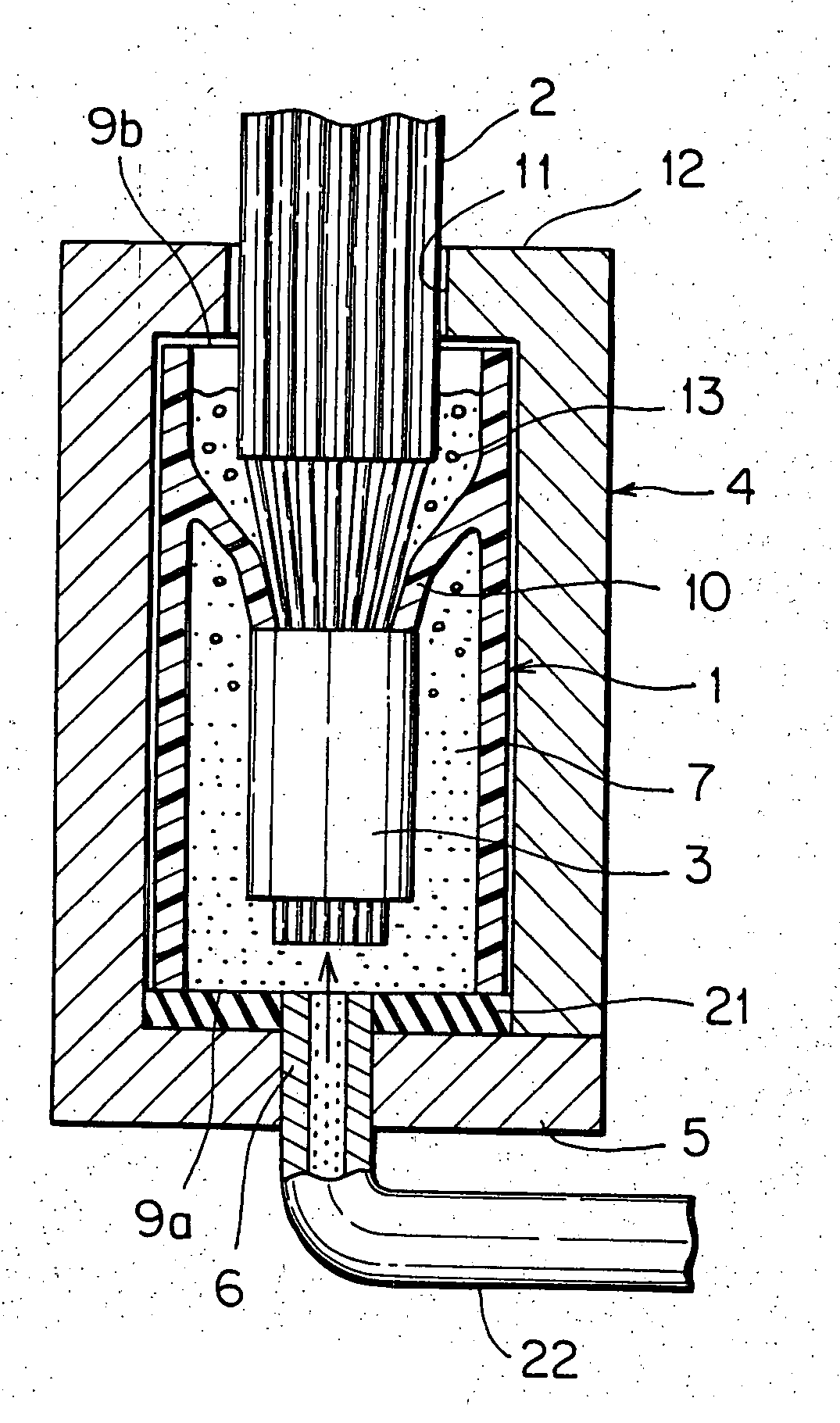

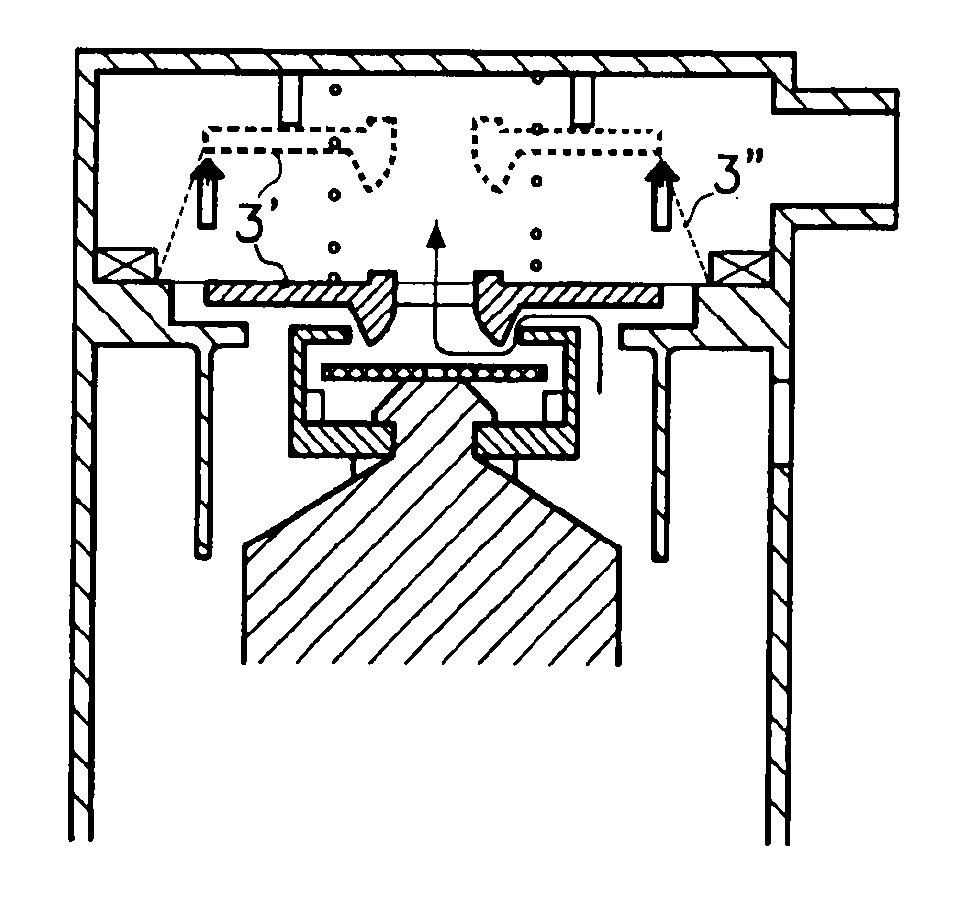

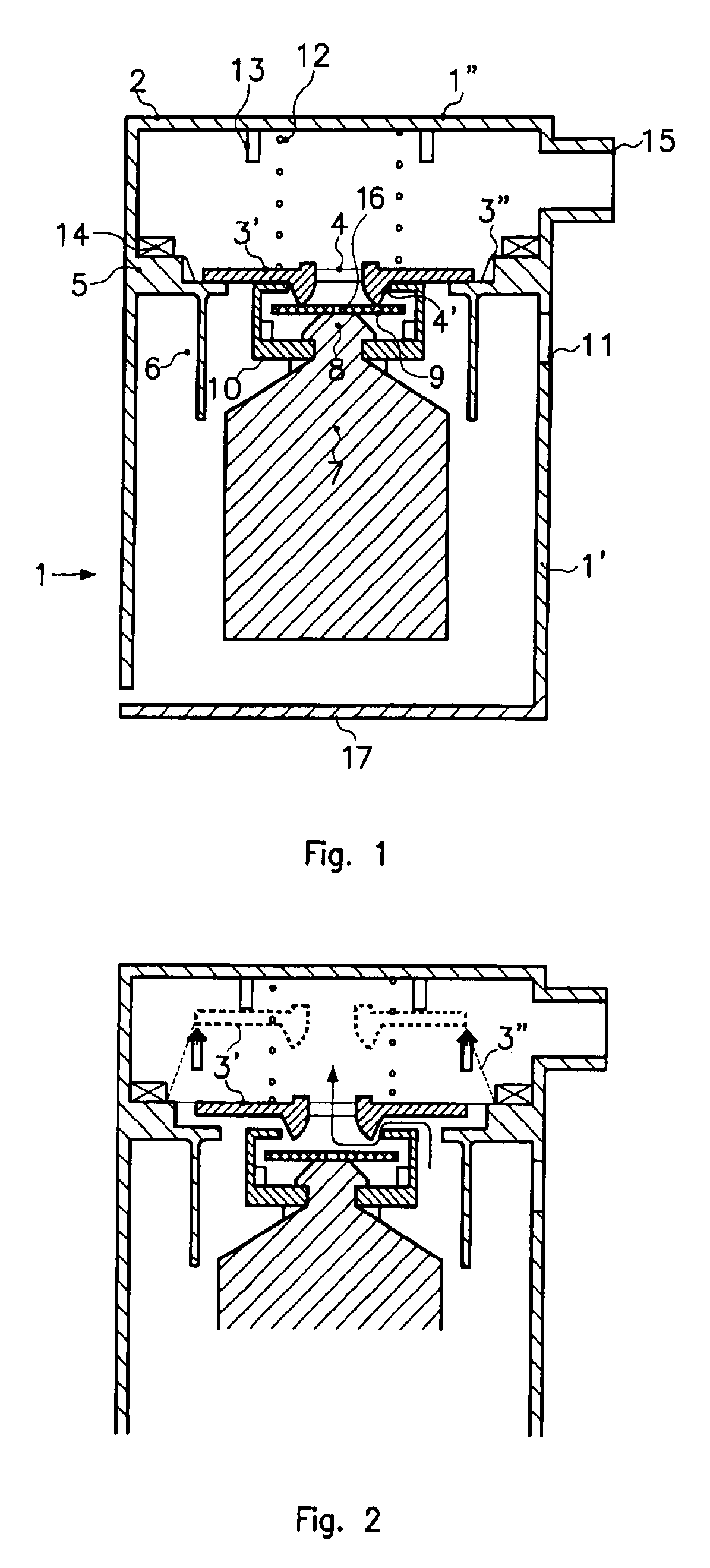

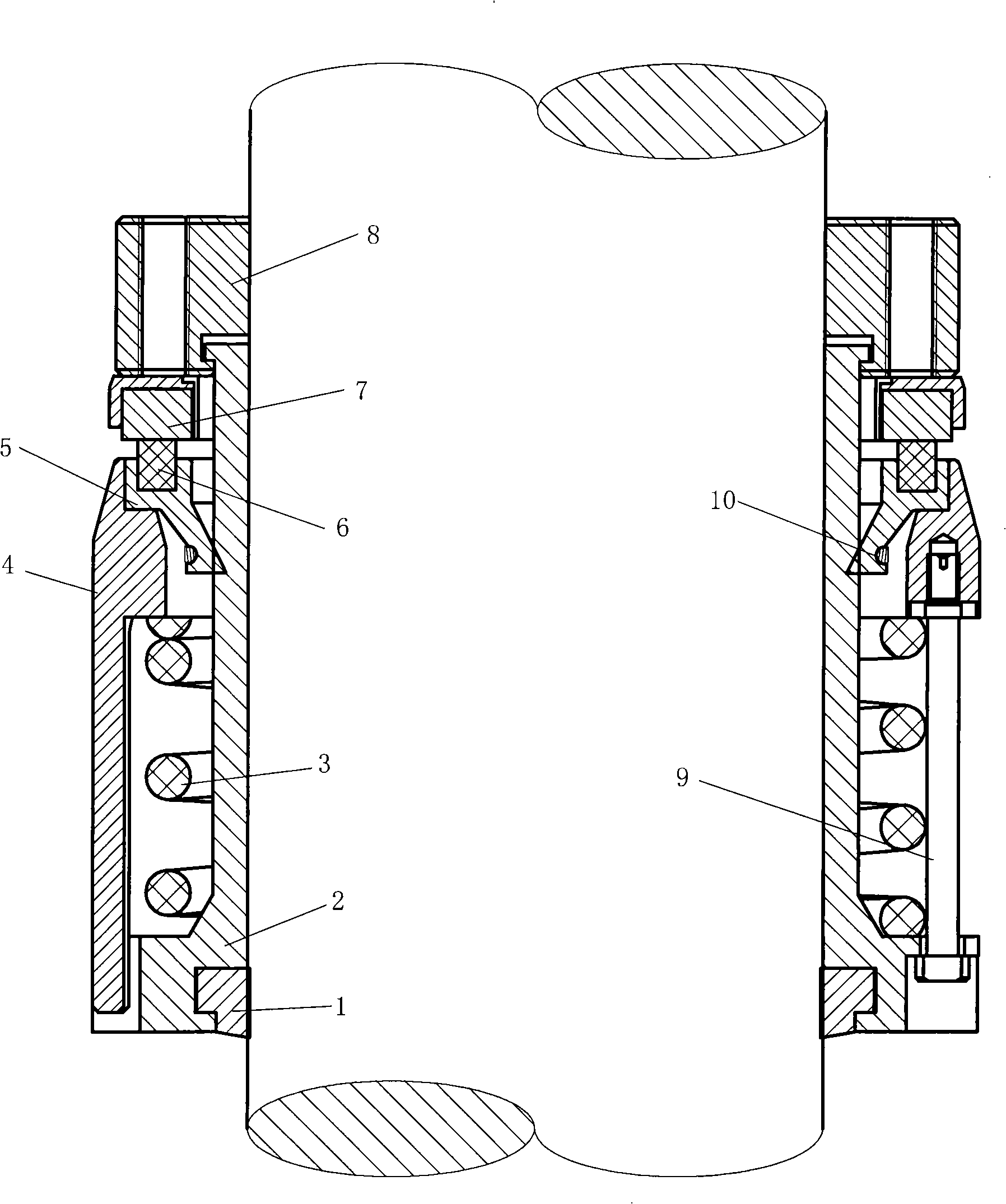

Safety valve for the venting circuit of a liquid tank

InactiveUS8267113B2Avoid Seal LeaksControlling the riskOperating means/releasing devices for valvesLarge containersLiquid tankSafety valve

Safety valve for the venting circuit of a liquid tank Safety valve for the venting circuit of a liquid tank, comprising: a) a chamber (1) provided with a cover (2), which extends at least partly into the tank and is connected via an aperture (4) to the venting circuit; b) a float (7), which can slide vertically inside the chamber (1) and close off the venting aperture (4) in a high position; and c) a moveable wall (3), which divides the chamber (1) into a lower portion (1′) in which the float (7) slides and an upper portion (1″) which connects with the venting circuit, this wall (3) being a moveable wall and having the venting aperture (4), said valve further including an aperture stop (13) integral either with the moveable wall (3) or with the cover (2).

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

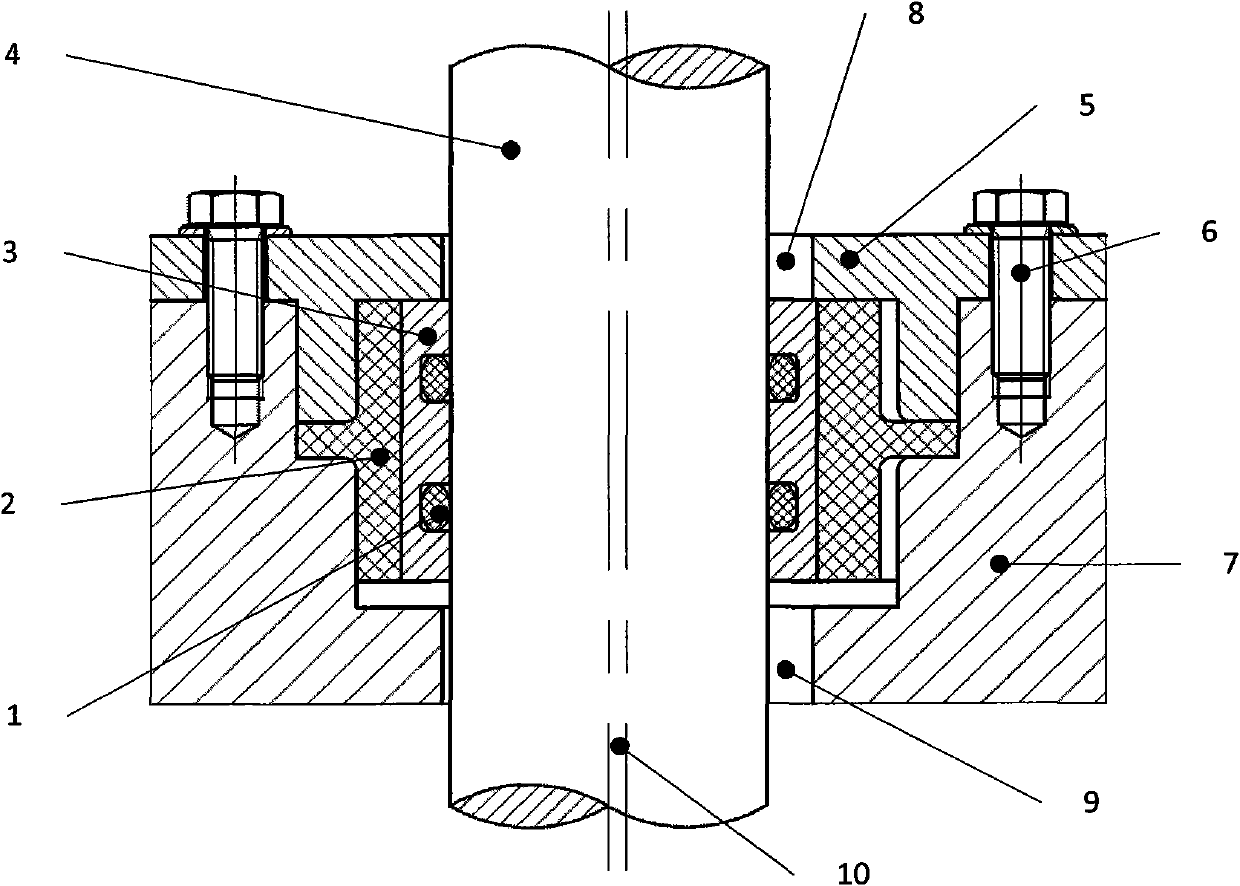

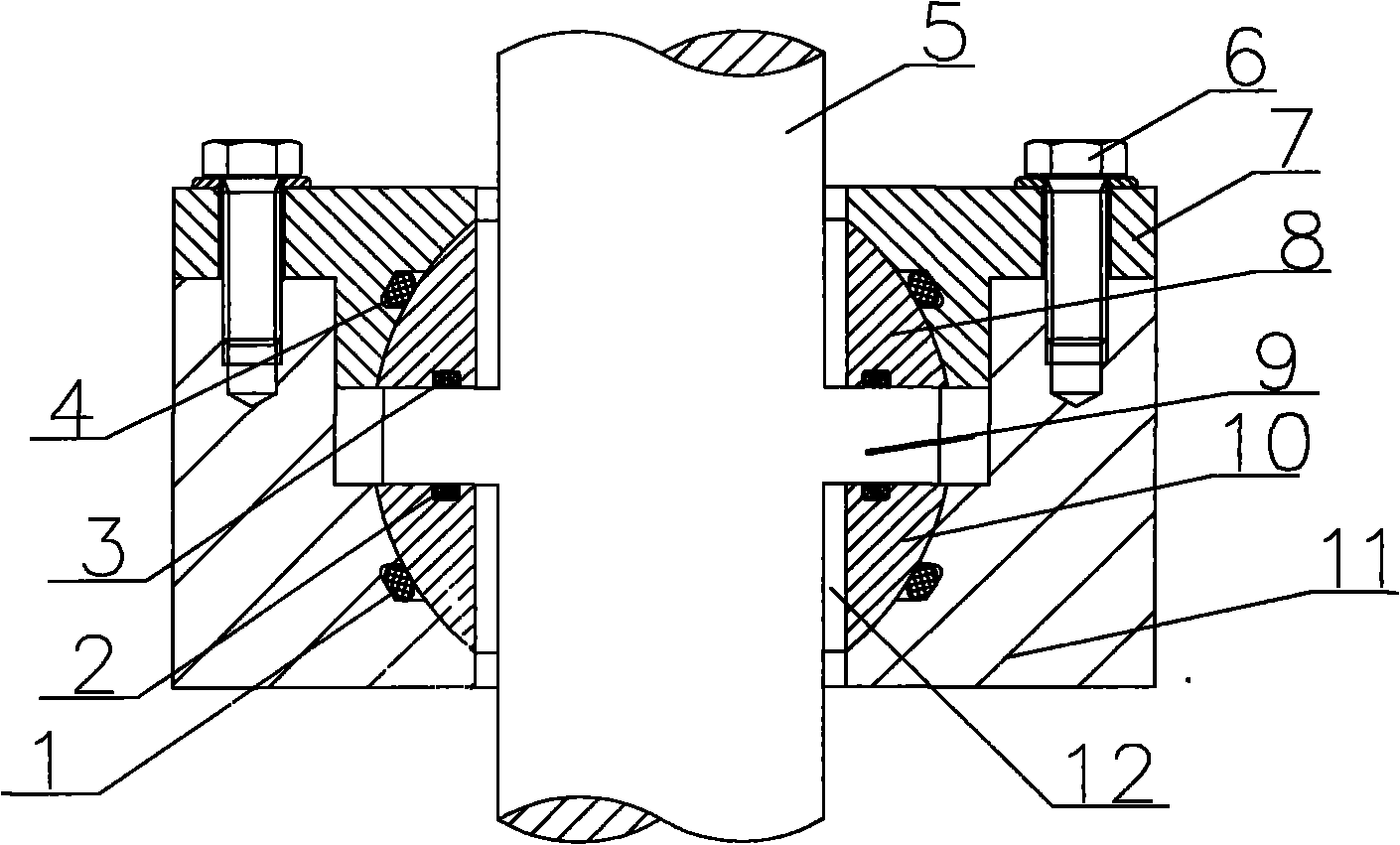

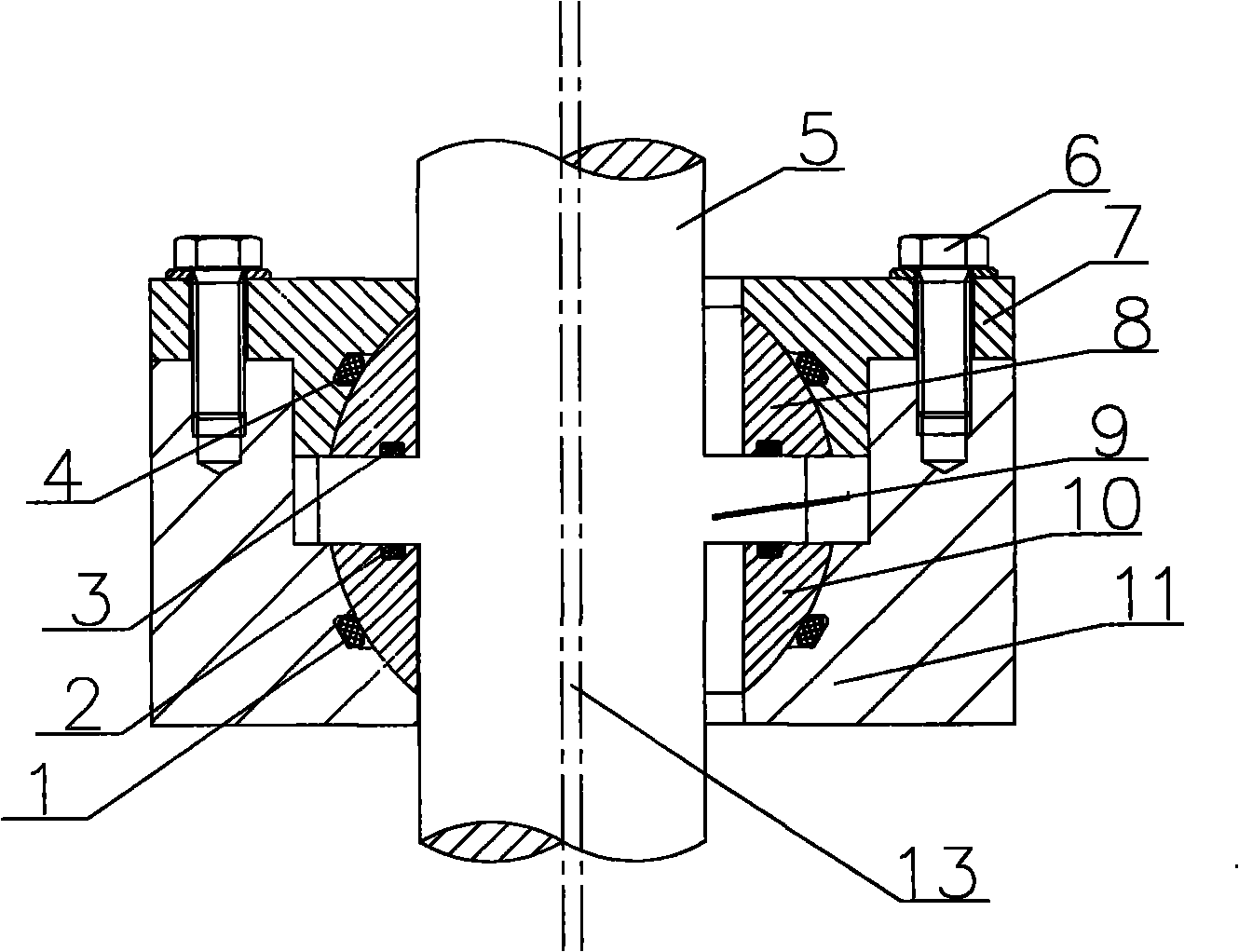

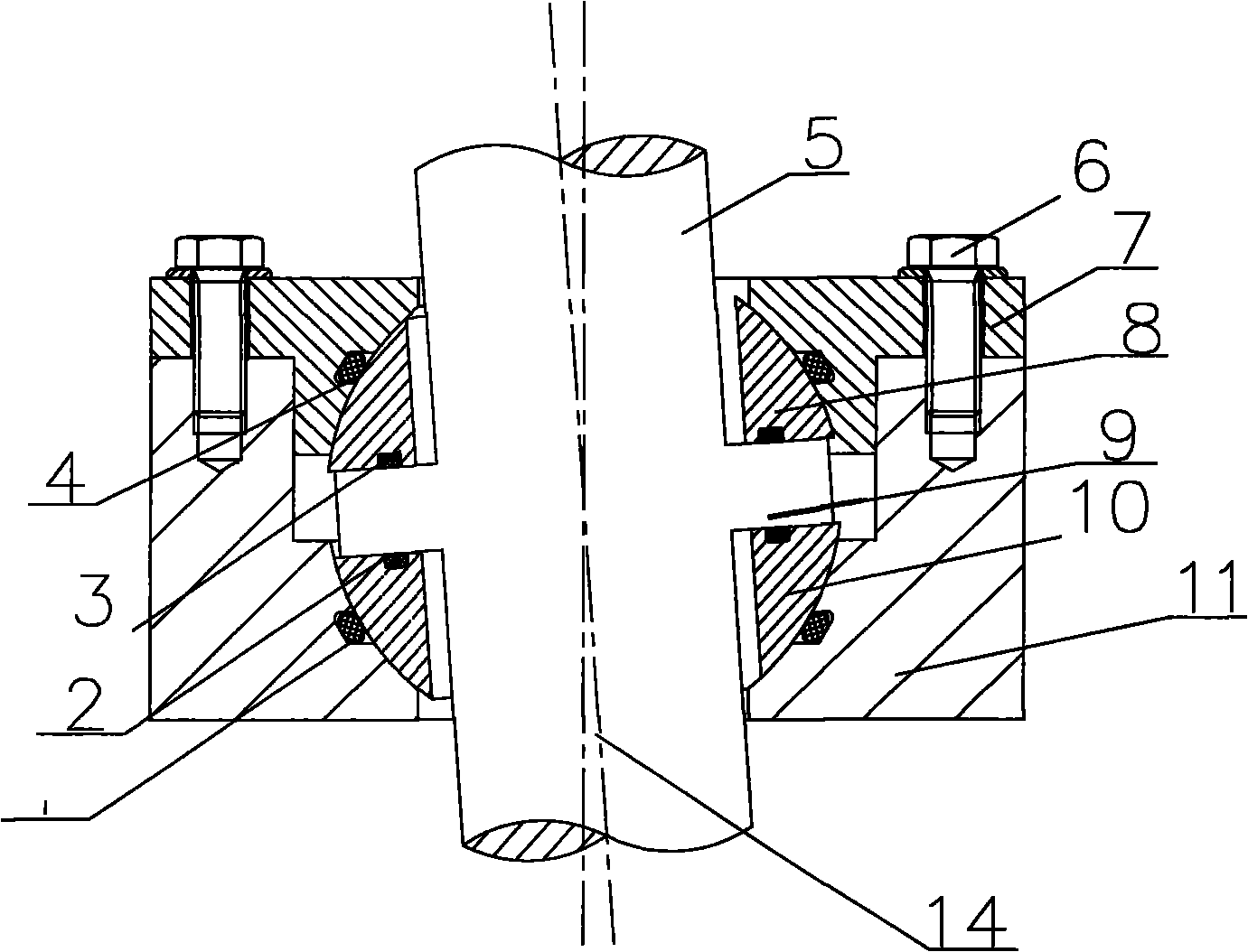

Floating sealing structure of thrust shaft rod

InactiveCN102032345AWith pressure self-sealing effectReduce operating torqueEngine sealsEngineeringFlange

The invention relates to a floating sealing structure of a thrust shaft rod. The structure comprises a first sealing ring, a second sealing ring, a third sealing ring, a fourth sealing ring, a shaft rod, a bolt, gland, a first ball ring, a second ball ring and a valve cover, wherein the first ball ring and the second ball ring are central cylindrical holes; the bottom of the middle hole of the valve core is a spherical surface matched and connected with the spherical surface of the first ball ring; the upper part of the valve cover is provided with a cylindrical hole; the gland is disc-shaped, an upper flange of the gland is fixed on the valve core through the bolt, and the hollow bottom of the gland is a spherical surface matched and connected with the spherical surface of the second ball ring; and the shaft rod is a cylindrical rod, the middle of which is provided with a shaft shoulder, and the shaft shoulder of the shaft rod is clamped between the first ball ring and the second ball ring. Compared with the prior art, the floating sealing structure has the advantages of good sealing property, long service life and the like.

Owner:SHANGHAI KARON VALVES MACHINERY +1

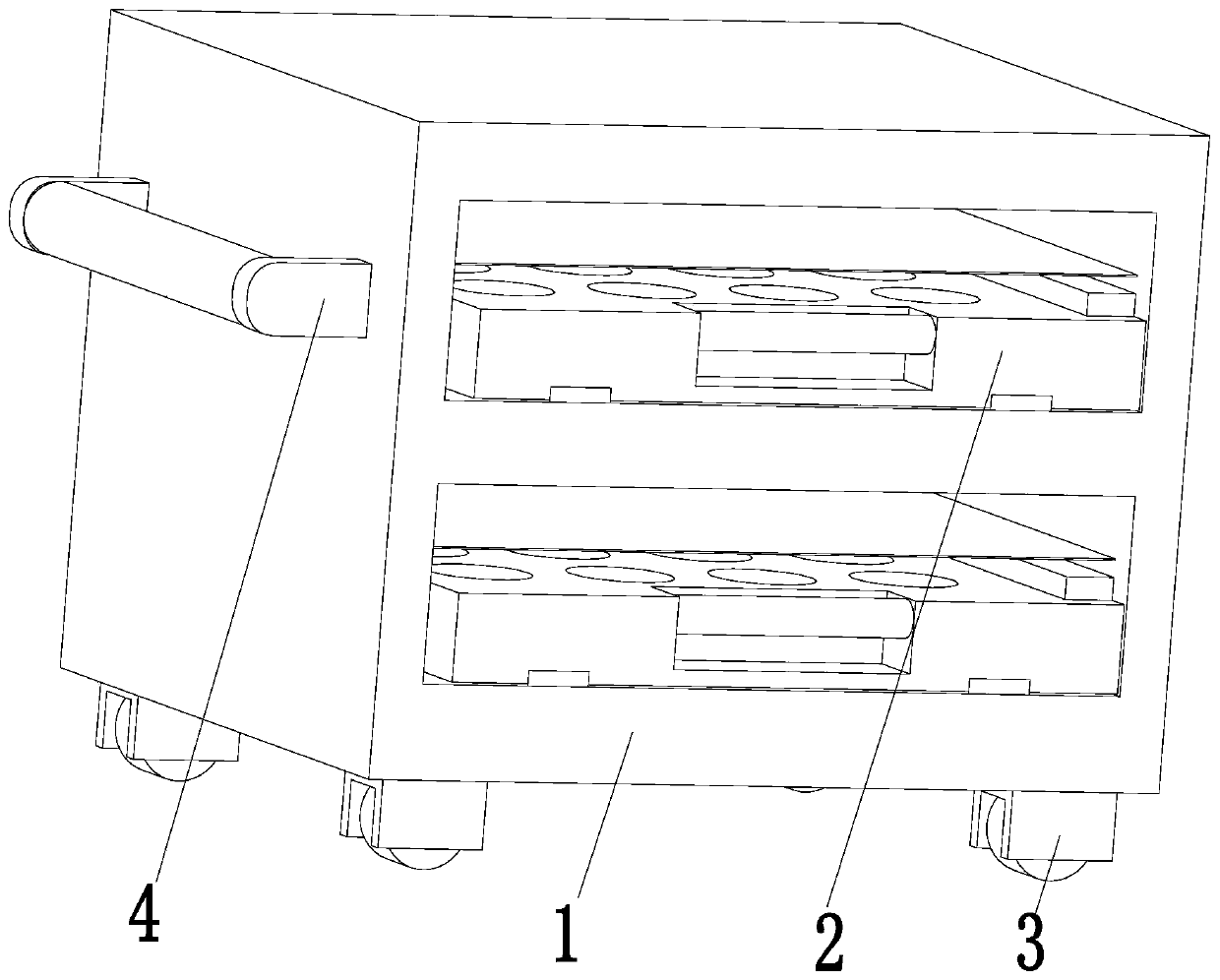

Stacking mold

The invention relates to a stacking mold which is provided with a fixed mold block, a movable mold block and a middle mold block, wherein the middle mold block is arranged between the fixed mold block and the movable mold block, and the movable mold block and the middle mold block move to the fixed mold block until the middle mold block and the fixed mold block form a first mold cavity and the movable mold block and the middle mold block form a second mold cavity; the stacking mold further comprises an injection molding flow channel, wherein the central axis of a main body of a main flow channel of the injection molding flow channel is arranged in a central plane, which is perpendicular to the direction of the moving axis of the movable mold block, of the middle mold block. According to the stacking mold, materials enter the injection molding flow channel through the middle mold block without penetrating through a parting surface, so that the pressure of each mold cavity is balanced, and additionally, the problem of seal leakage of the materials during mold opening is avoided.

Owner:GUANGDONG WEIDA INTELLIGENT EQUIP CO LTD

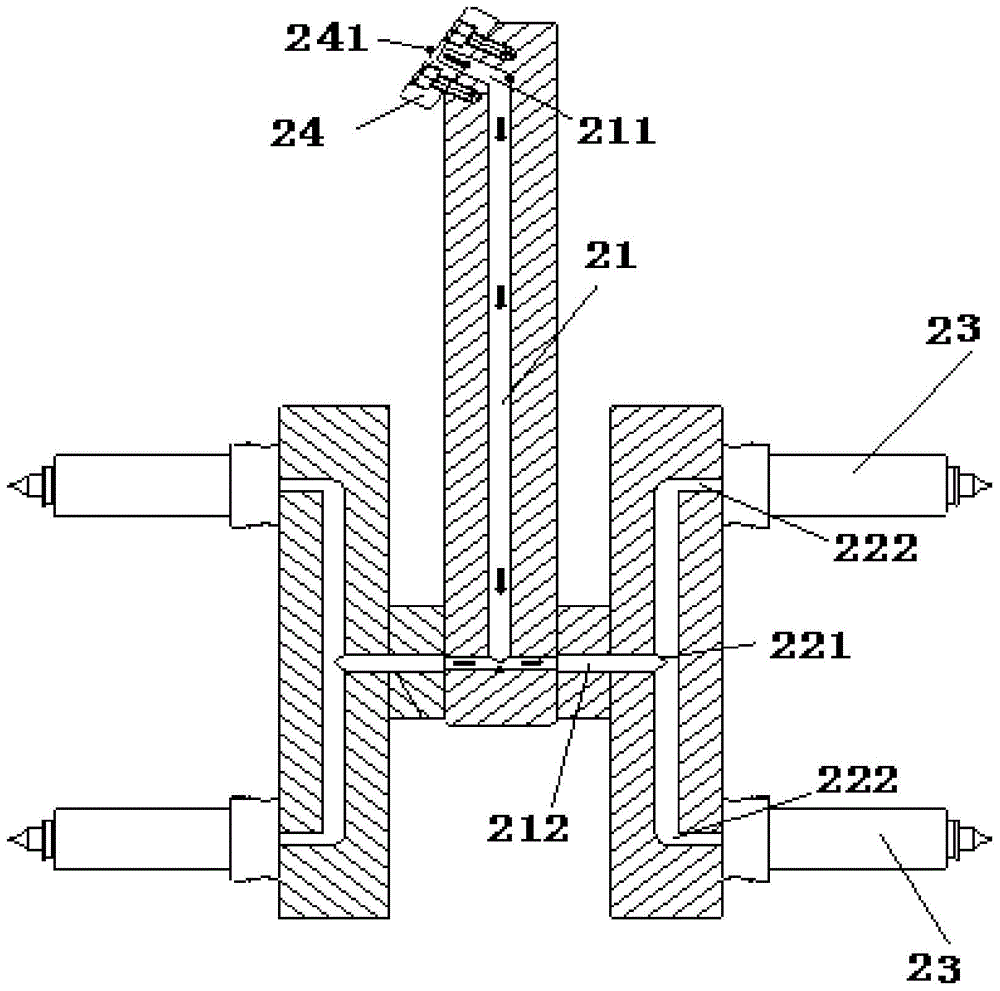

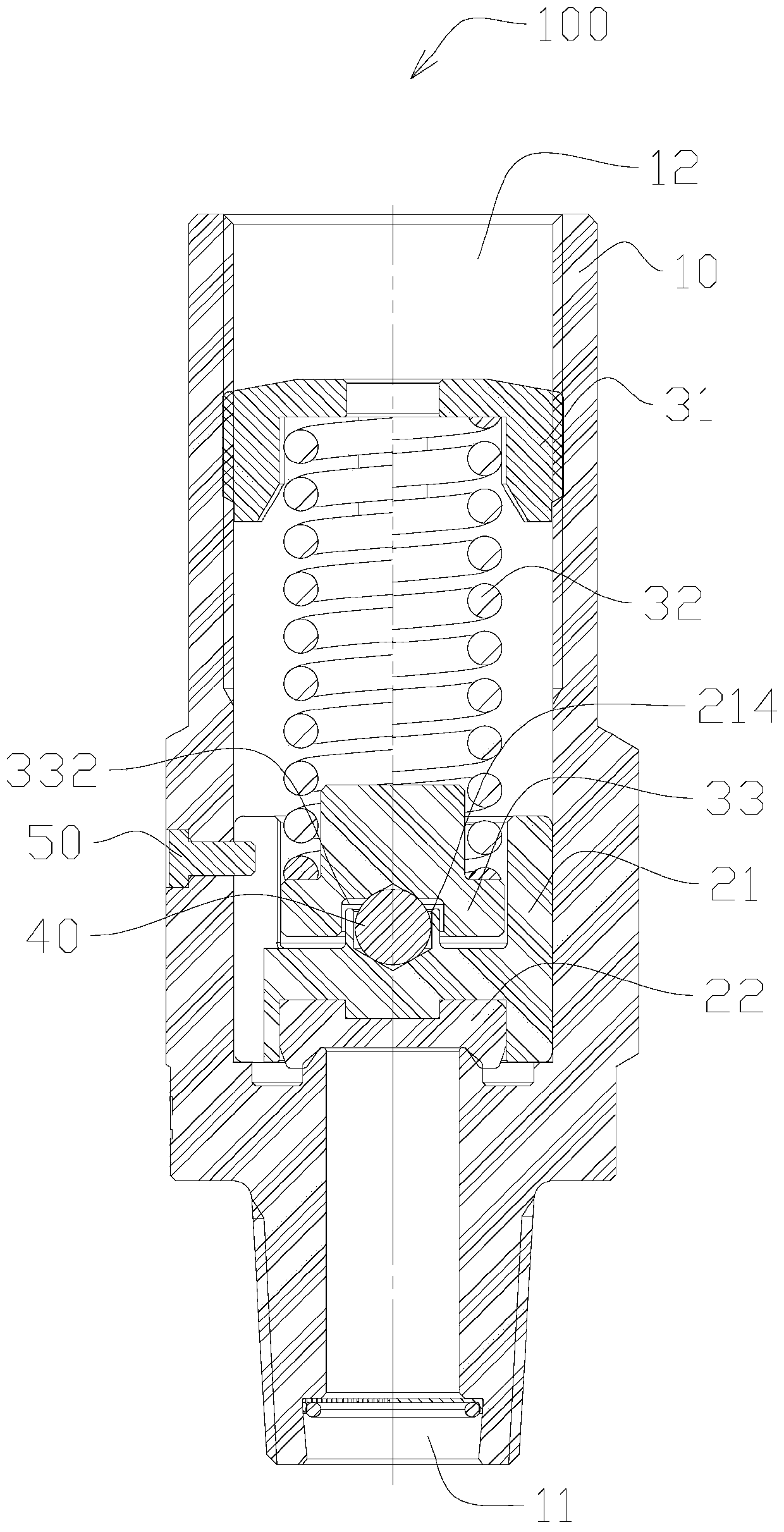

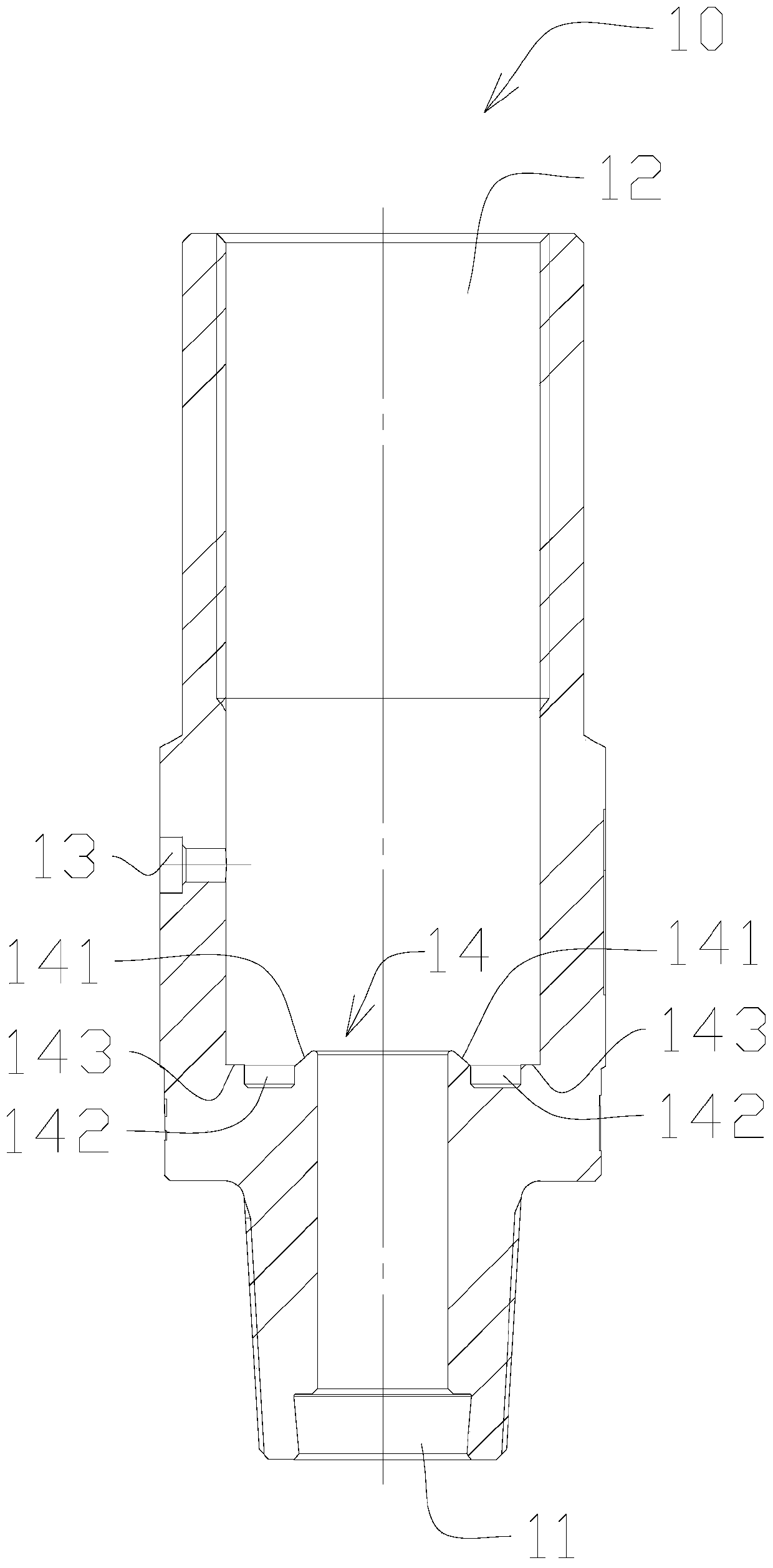

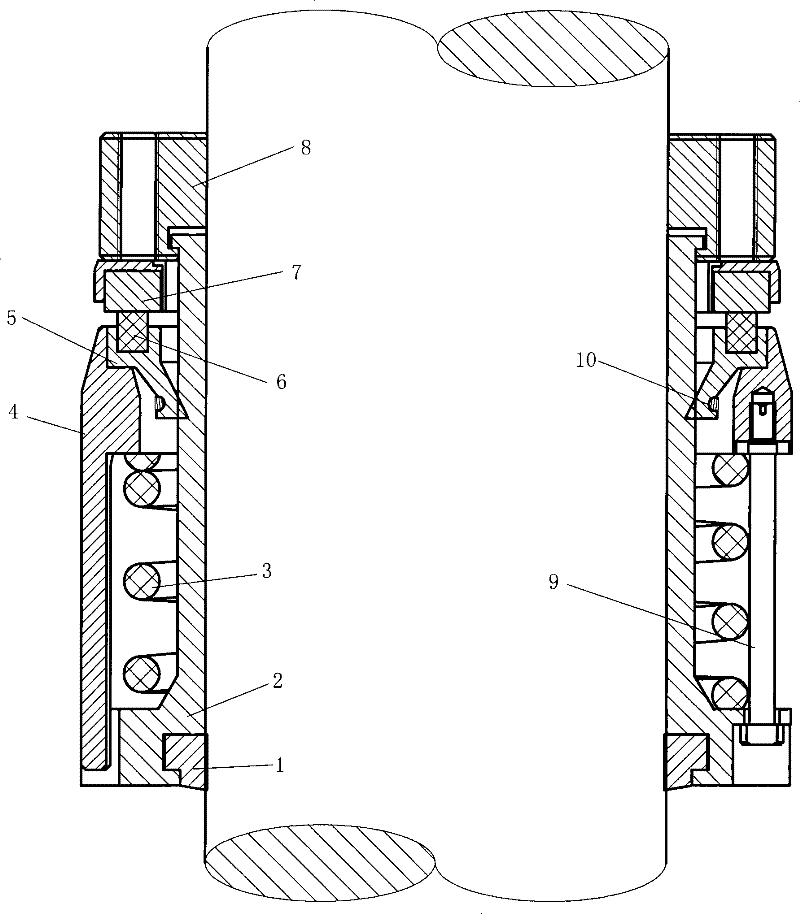

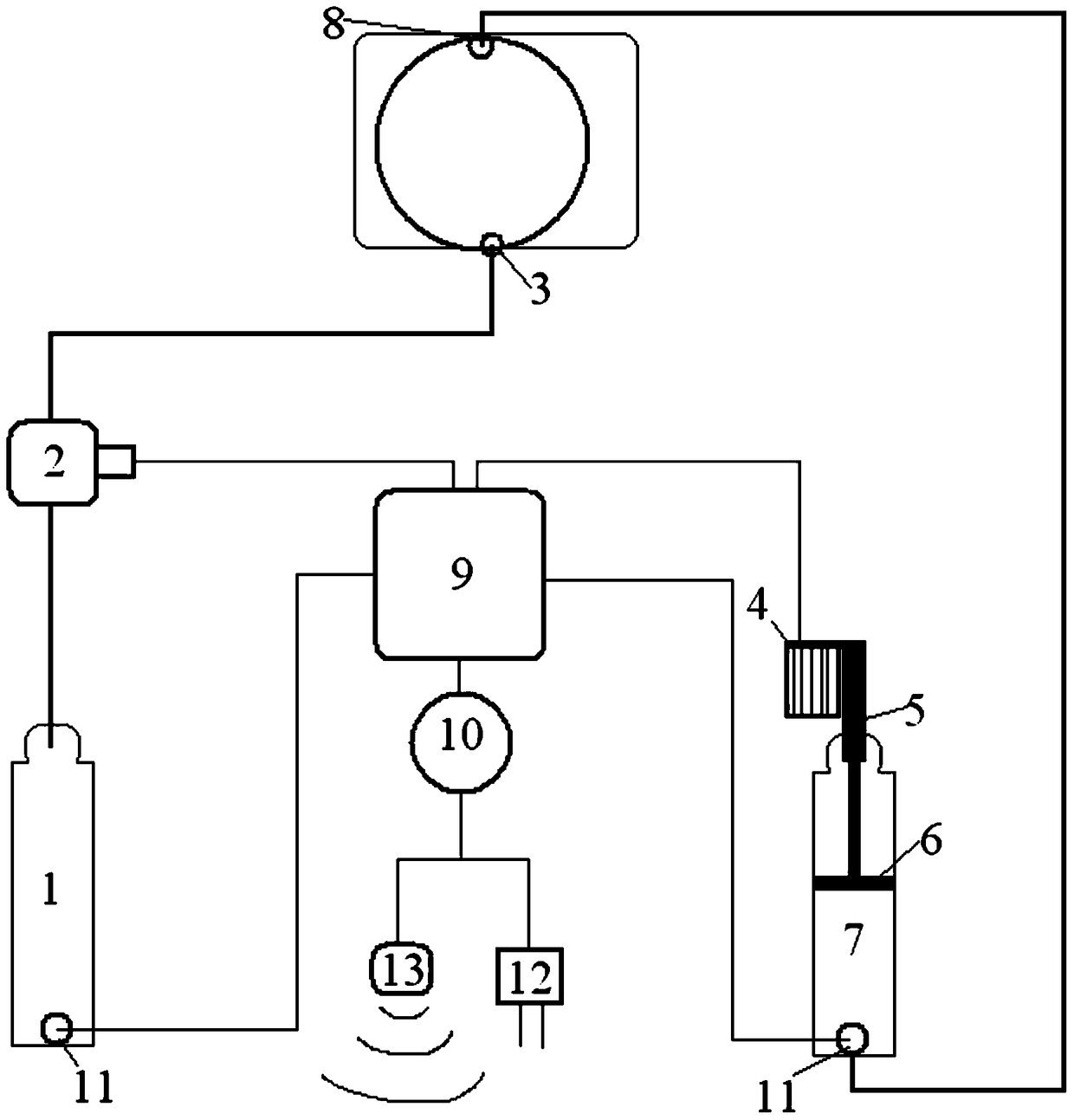

Automatic grease pumping and injecting device and method for bearing lubrication

ActiveCN105546315ATimely updateGuaranteed safe lubricationLubricant transferBearing componentsControl systemData memory

The invention provides an automatic grease pumping and injecting device and method for bearing lubrication. The device at least comprises a control system, a grease pumping system and a grease injecting device; the grease pumping system comprises a waste grease storage tank, a grease pumping pump, a pipe and a connector; the grease injecting device comprises a grease injecting pump, a novel grease storage tank, a pipe and a connector; and the control system comprises a processor, a data storage device and sensors, and the sensors are connected with the grease injecting pump and the grease pumping pump, control closing of the grease injecting pump and the grease pumping pump, are distributed on the novel grease storage tank, the waste grease storage tank and a working site, collect relevant data and transmit the data to the data storage device. The invention further provides the automatic grease pumping and injecting method. According to the technical scheme, the shortcomings in the prior art are overcome; and automatic grease pumping and injecting can be achieved, operation is simple, and the grease pumping amount and the grease injecting amount can be controlled.

Owner:HUBEI XINZHI TECH CO LTD

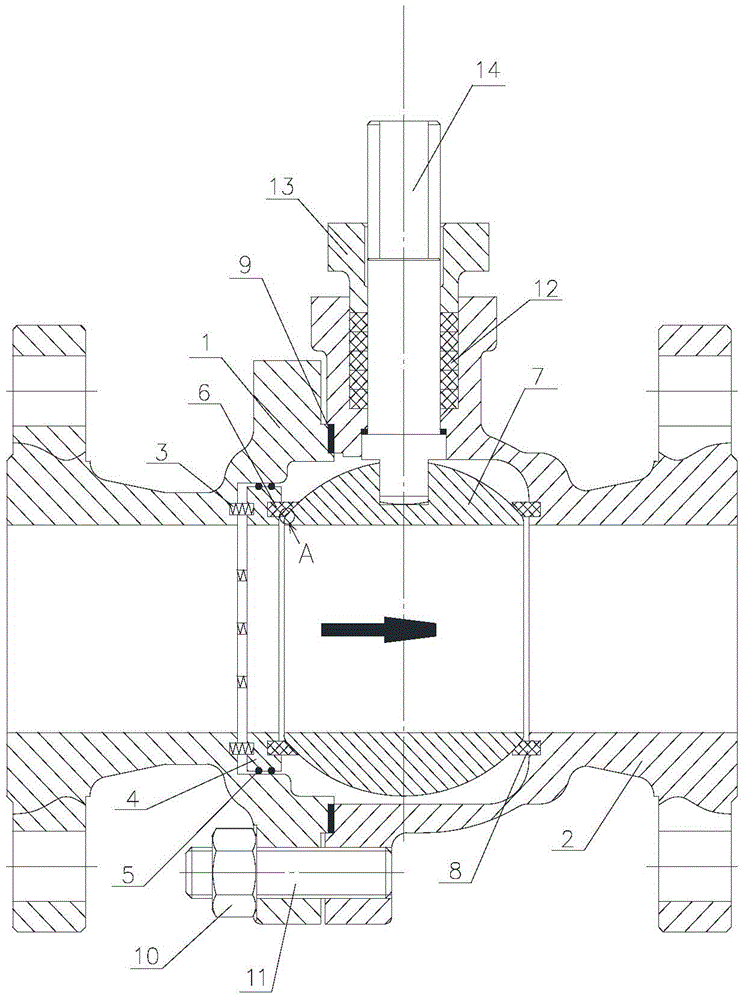

Safety double-sealed ball valve

InactiveCN104154264ARealize security protectionCompact structurePlug valvesValve housingsPressure riseInlet valve

The invention provides a safety double-sealed ball valve which comprises a valve body, a ball body (7) and a switch body. The valve body comprises an inlet valve body (1) and an outlet valve body (2) which are located at the upstream end and the downstream end of the ball body (7), the axial direction of the inlet valve body (1) and the axial direction of the outlet valve body (2) are perpendicular to the axial direction of the switch body, a gasket (9) perpendicular to the axial direction of the valve body is arranged between the inlet valve body (1) and the outlet valve body (2), a sealing device is arranged between the valve body and the ball body (7) and comprises a spring, an annular supporting ring, a valve seat and an O-shaped sealing ring, the spring, the annular supporting ring and the valve seat are sequentially arranged in the axial direction of the valve body, the O-shaped sealing ring is arranged in a groove in the outer wall of the annular supporting ring, the switch body is embedded in the outlet valve body (2), the axial direction of the switch body is perpendicular to the axial direction of the valve body, and the switch body penetrates through the center of the ball body (7). Under the condition that pressure rises in a cavity in the valve body abnormally, the ball valve can discharge pressure rapidly from an upstream or downstream pipeline, and safety protection is achieved.

Owner:洪元生

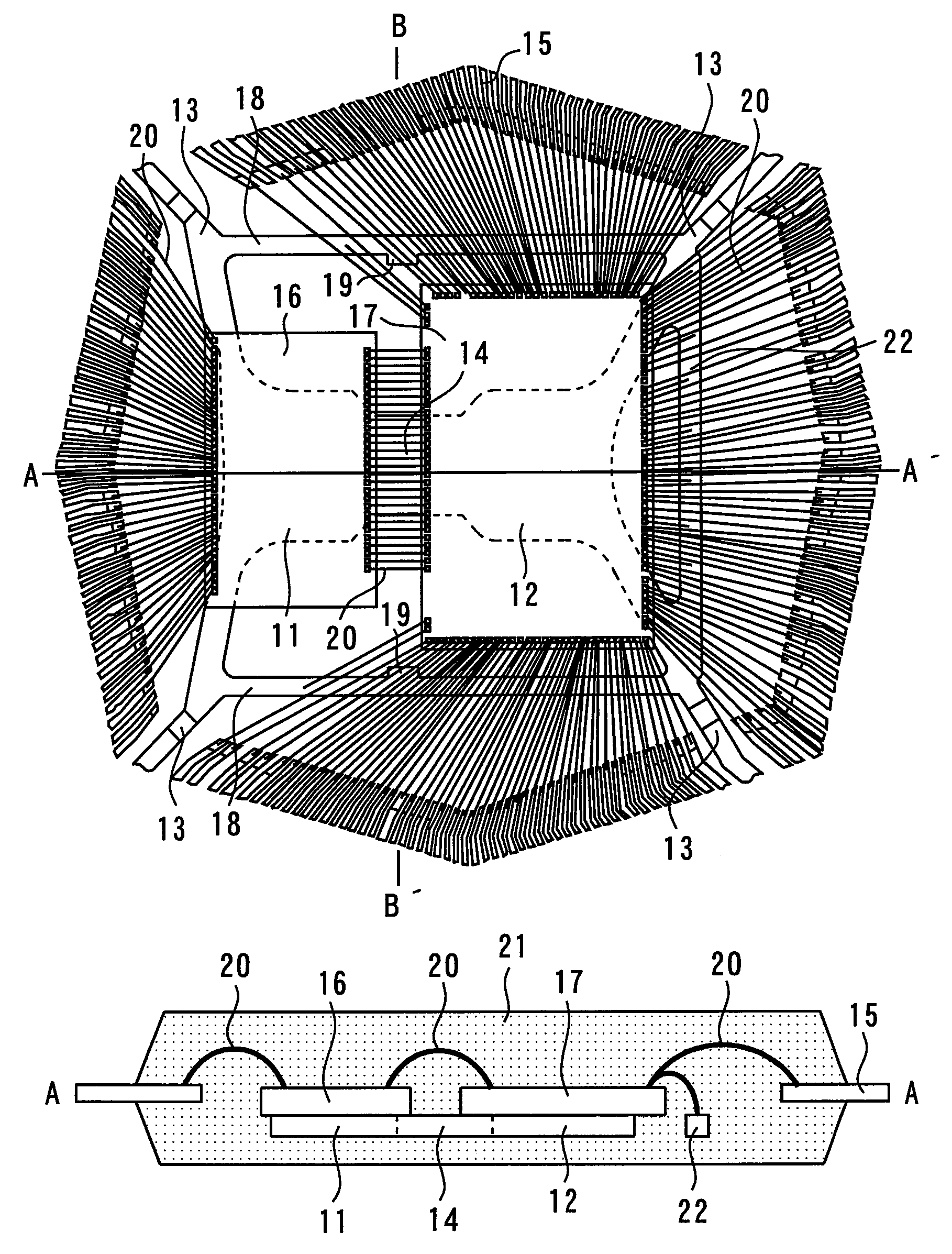

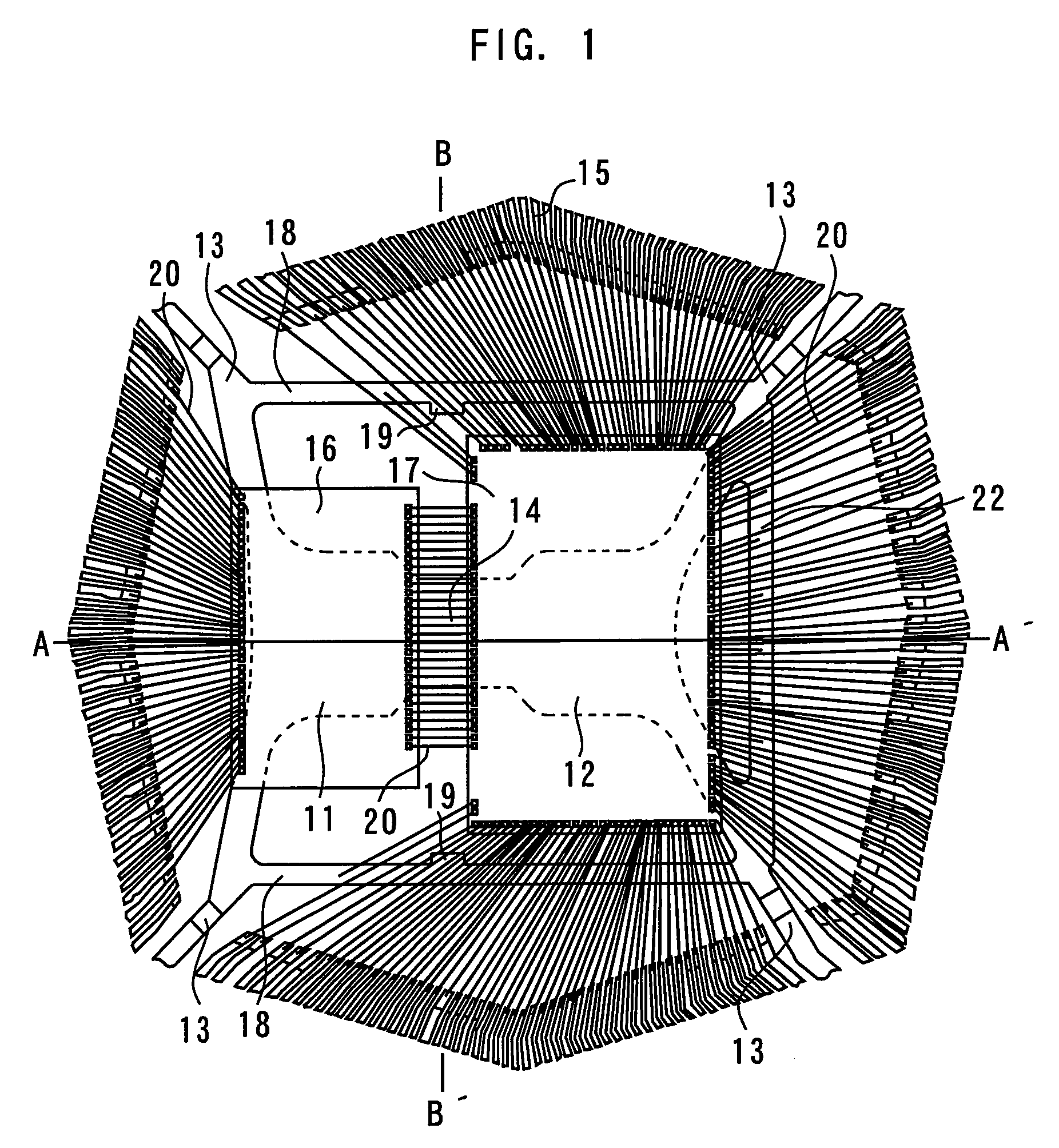

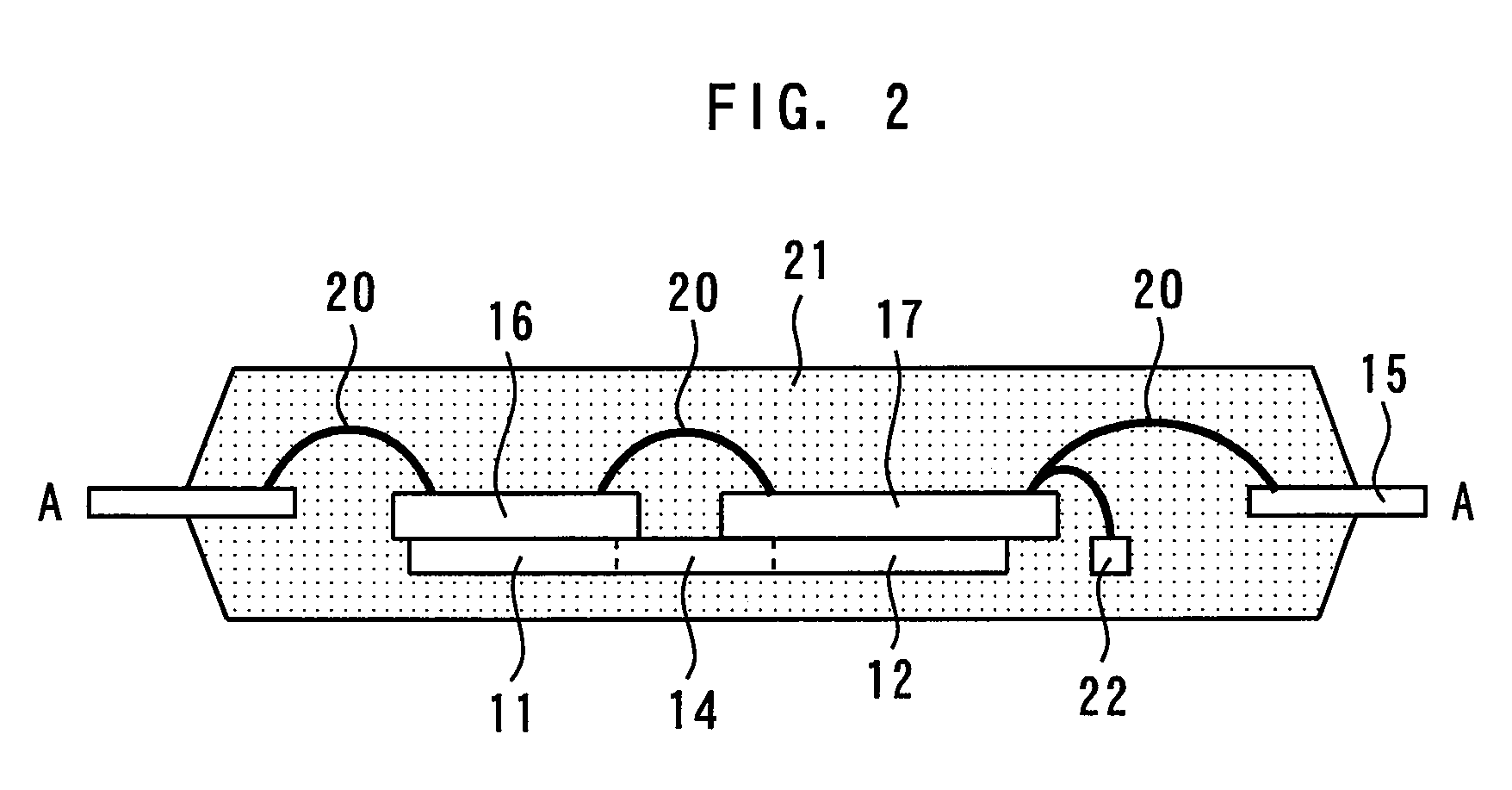

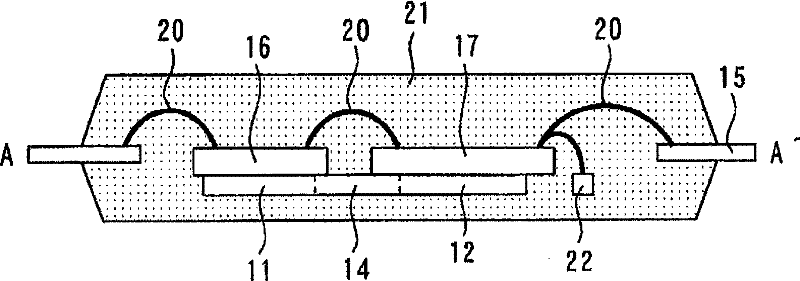

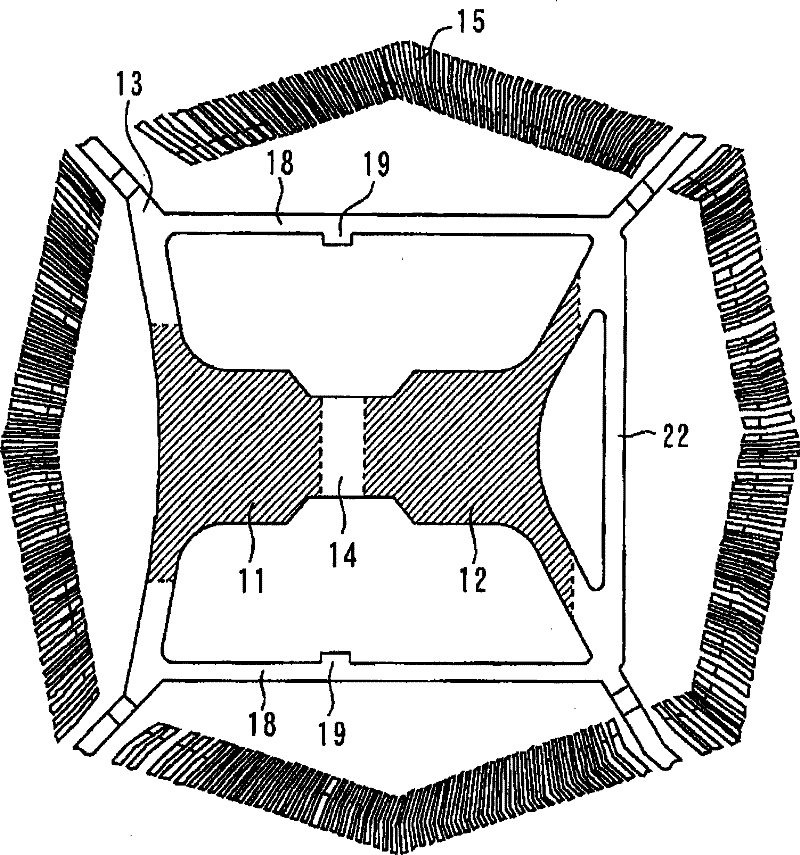

Semiconductor device

ActiveUS20090085179A1Easy alignmentEasy injectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor device comprises: a first and second die pads arranged side by side; a plurality of inner leads arranged around the first and second die pads; first and second chips mounted on the first and second die pads; a bar provided between the first and second chips and the plurality of inner leads, extending in an array direction of the first chip and the second chip; a plurality of wires that connect the first and second chips and the plurality of inner leads and connect the first chip and the second chip; and resin that seals the first and second die pads, the plurality of inner leads, the first and second chips, the plurality of wires and the bar, wherein the bar comprises a mark provided at a position corresponding to an area between the first chip and the second chip in an array direction of the first chip and the second chip.

Owner:RENESAS ELECTRONICS CORP

Liquid level sensor and method of manufacturing the same

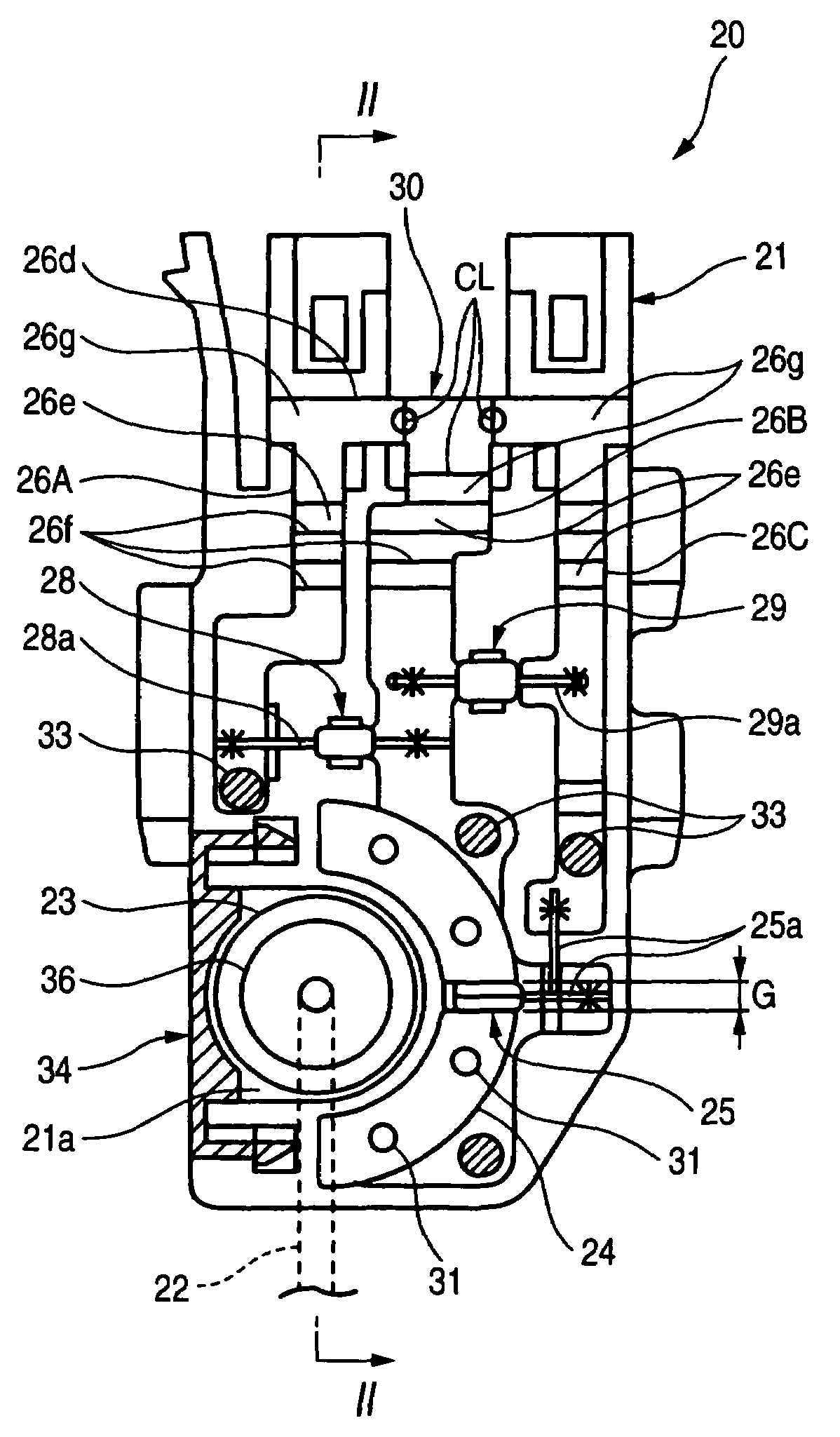

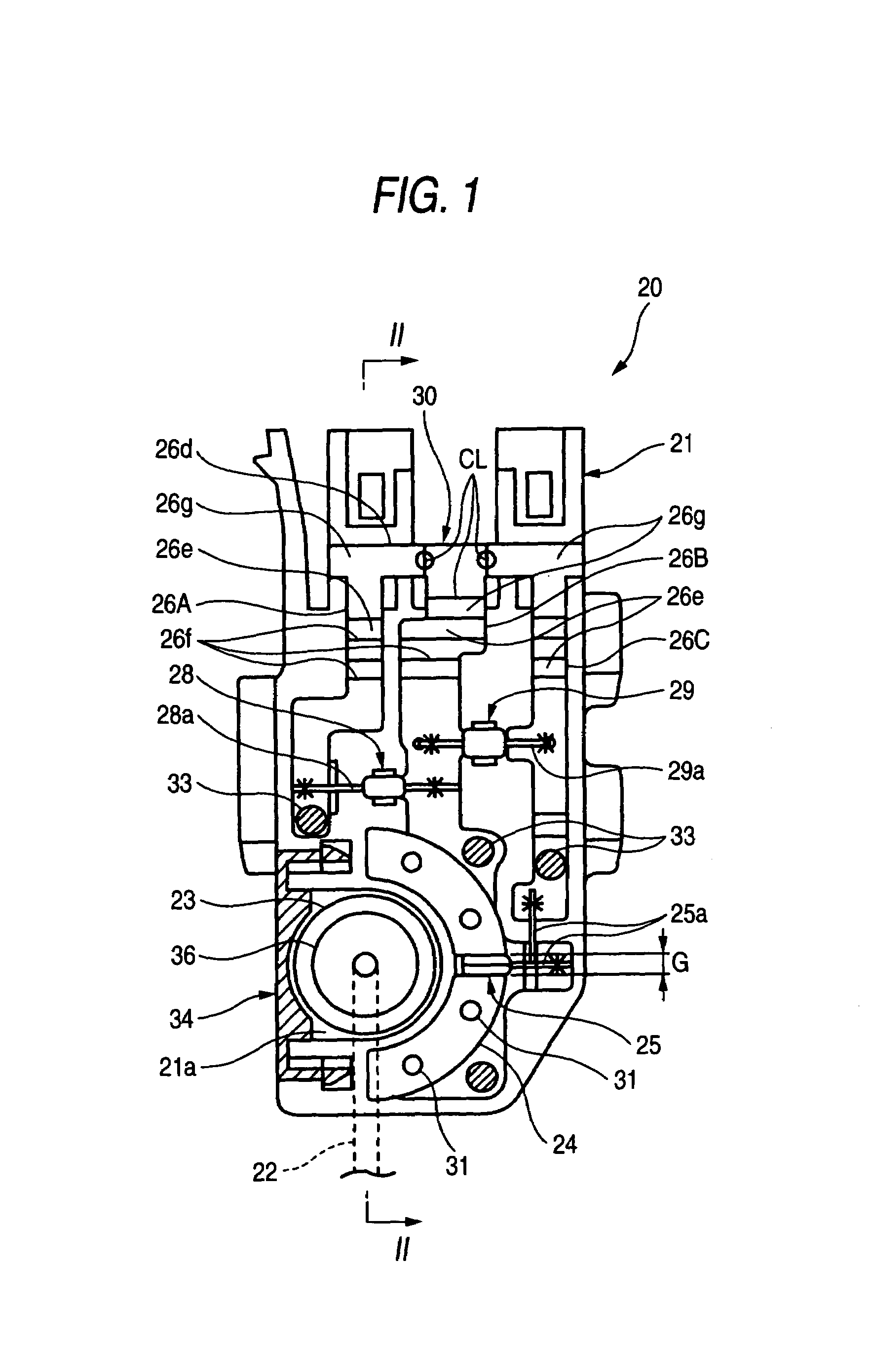

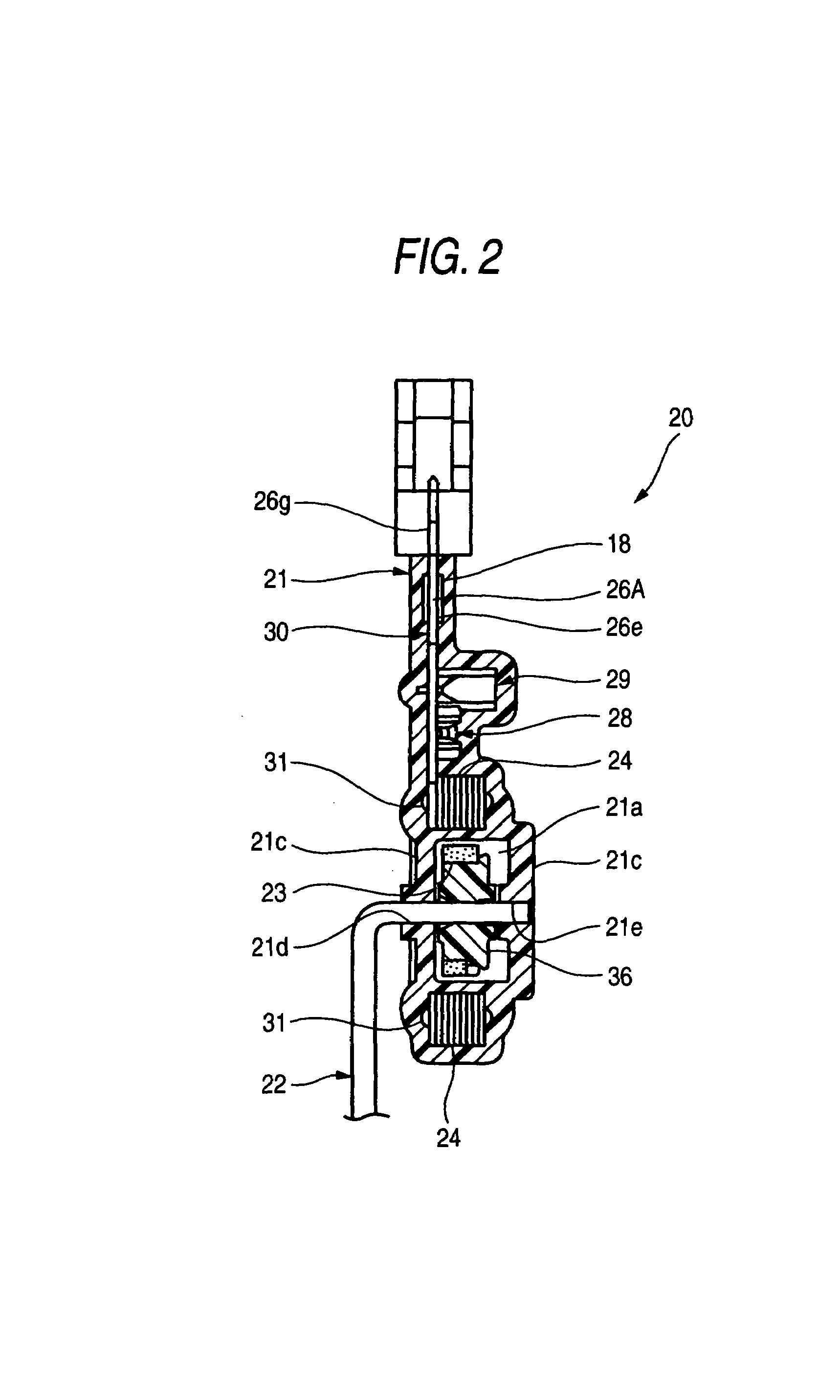

ActiveUS7225672B2Improve the level ofImprove sealingMachines/enginesLubrication indication devicesElectricityEngineering

A liquid level sensor includes a housing, a rotary shaft which is rotatably provided in the housing, a magnet which is fixed to the rotary shaft, and rotating together with the rotary shaft, a pair of stators which are disposed so as to face an outer peripheral surface of the magnet, and an electronic circuit which includes at least a set of terminals and a magnetoelectric transducing element for detecting a change of magnetic flux in the stators caused by rotation of the magnet and for outputting an electric signal. The magnetoelectric transducing element and the stators are electrically connected and fixed to the set of terminals so that a terminal assembly is formed. The housing is formed by insert molding the terminal assembly with resin so that the terminal assembly is embedded in the housing.

Owner:YAZAKI CORP

Sealing device

The invention discloses a sealing device with novel style construction, good sealing property, high mechanical shock resistance, the construction includes a shaft sleeve, a moving ring base, a moving ring, a stationary component. A sealing member is arranged on internal side of the shaft sleeve, a moving ring base is arranged on bottom of the shaft sleeve pushed by an elastic component at middle, a moving ring is arranged on top of the moving ring base, the stationary component is arranged above the moving ring, a locking device is arranged on top of the shaft sleeve. The invention has advantages of a relative rotation preventing device arranged on the moving ring base and the shaft sleeve, good sealing property of the sealing device and high mechanical shock resistance.

Owner:戴明惠

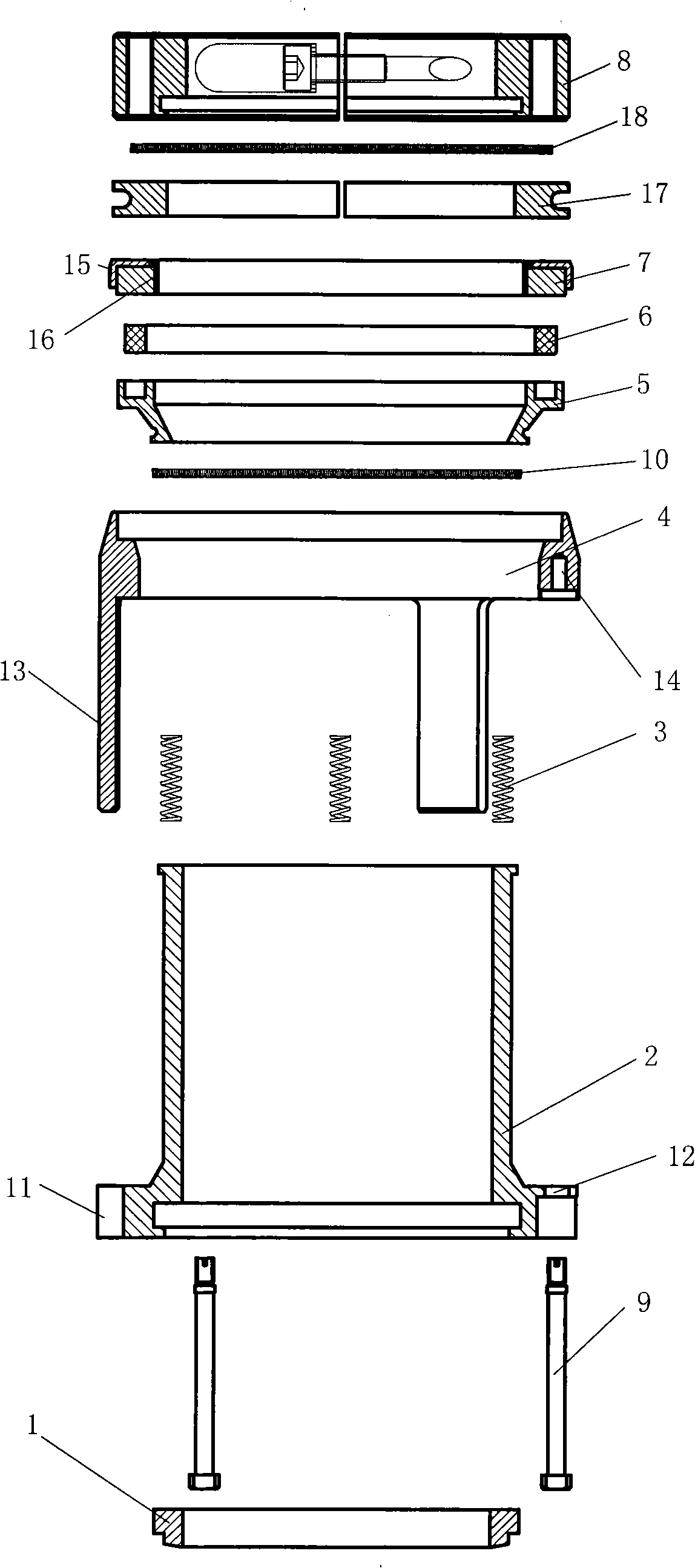

Urine detection transport frame for clinical lab

InactiveCN111252354APrevent inaccurate medical examination results and other problemsAvoid seal leaksContainers to prevent mechanical damageRigid containersEngineeringMechanical engineering

The invention relates to a urine detection transport frame for a clinical lab. The urine detection transport frame comprises a frame, fixing units, moving wheels and a handle. The fixing units are evenly arranged on the inner wall of the frame from top to bottom, the moving wheels are installed at the lower end of the frame through bearings, and the handle is installed at the left end of the frame. By the adoption of a movable transport frame structure, a worker can directly convey urine measuring glasses to an inspection department through the transport frame instead of sealing and then collecting the urine measuring glasses in a toilet; and through the structural design of fixing, sealing and meanwhile shock absorption of the urine measuring glasses, the problems that urine in the urinemeasuring glasses is spilt out and even mixed together to cause inaccurate physical examination results due to subtle vibration when the whole transport frame is conveyed to a laboratory are solved.

Owner:姜瑞凤

Preheating type combustion coil condensation heat exchanger

PendingCN110530021ASolving Corrosion ProblemsEmission reductionAir heatersIndirect carbon-dioxide mitigationEnergy absorptionNitric oxide

A preheating type combustion coil condensation heat exchanger comprises a detachable main body, and a pretreatment device for preheating and mixing the to-be-combusted gas through the own waste heat,a combustor facilitating gas combustion and a heat collecting device facilitating the energy absorption of a media are sequentially arranged on the detachable main body along the gas flowing direction. According to the present invention, various performance indexes of the heat exchanger meet the standard of GB25034-2010 gas heating water heater, the problem of condensate water corrosion can be effectively solved, the emission amount of the nitric oxide (lower than 30 mg / M3) and the CO is lower than 300 ppm, a coil pipe can be detached to be cleaned or replaced, the after-sales maintenance is facilitated, and the temperature of the combustion cavity is effectively reduced.

Owner:山东爱客多热能科技有限公司

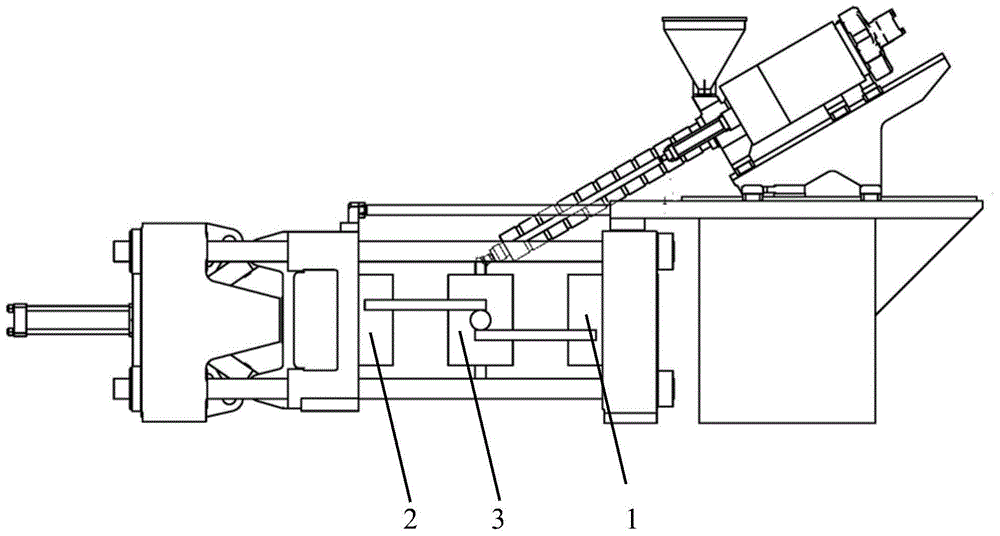

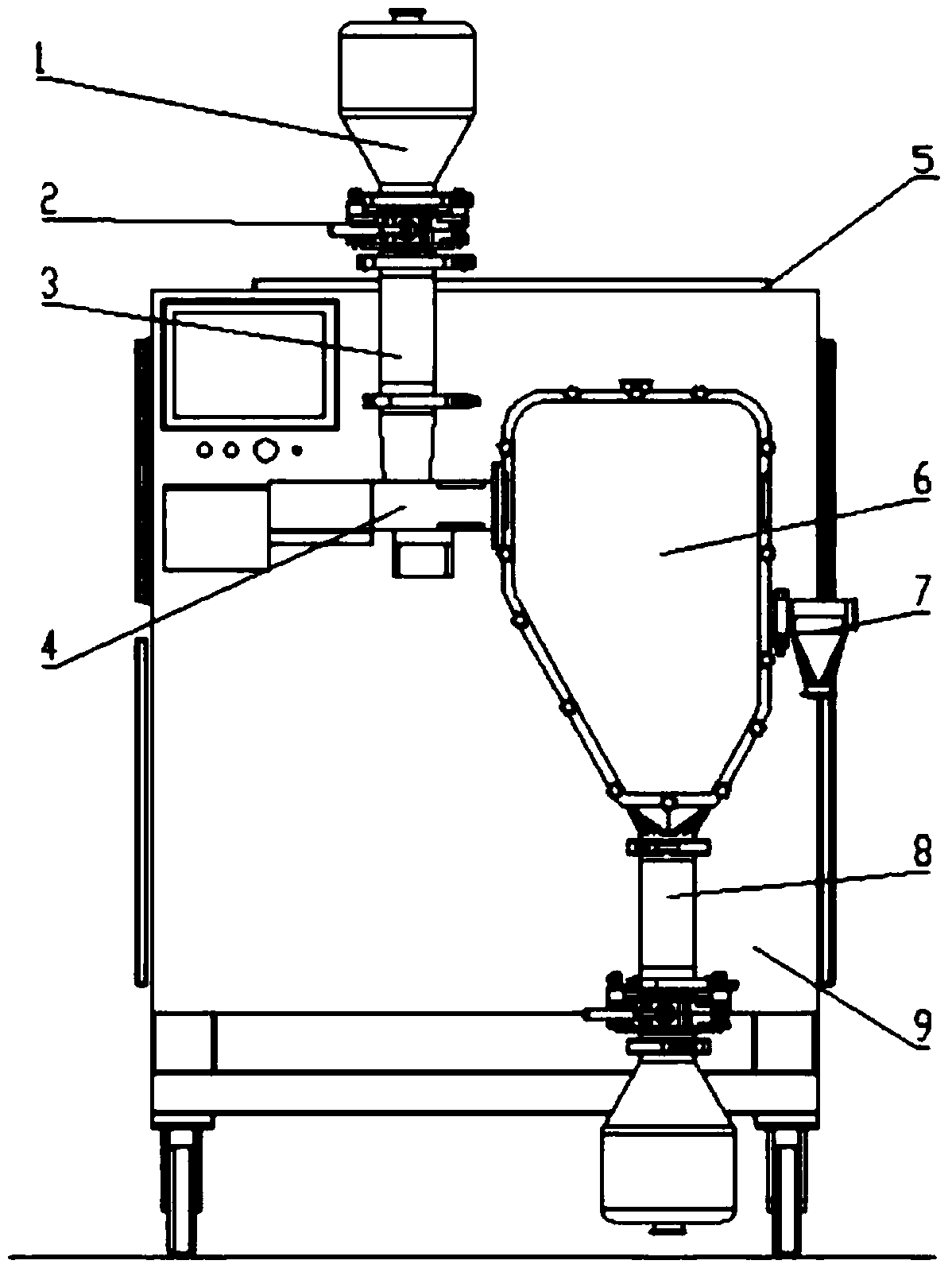

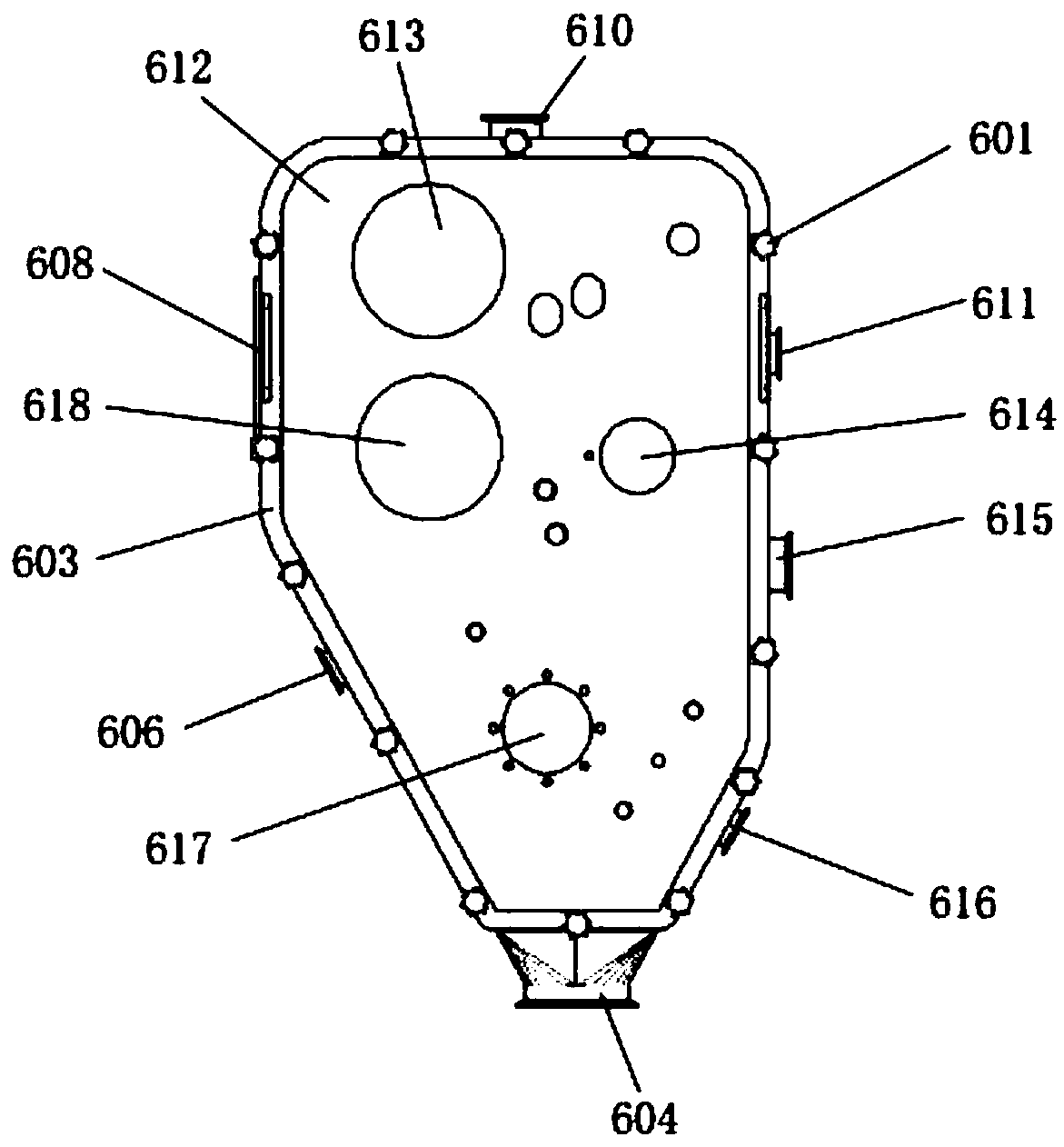

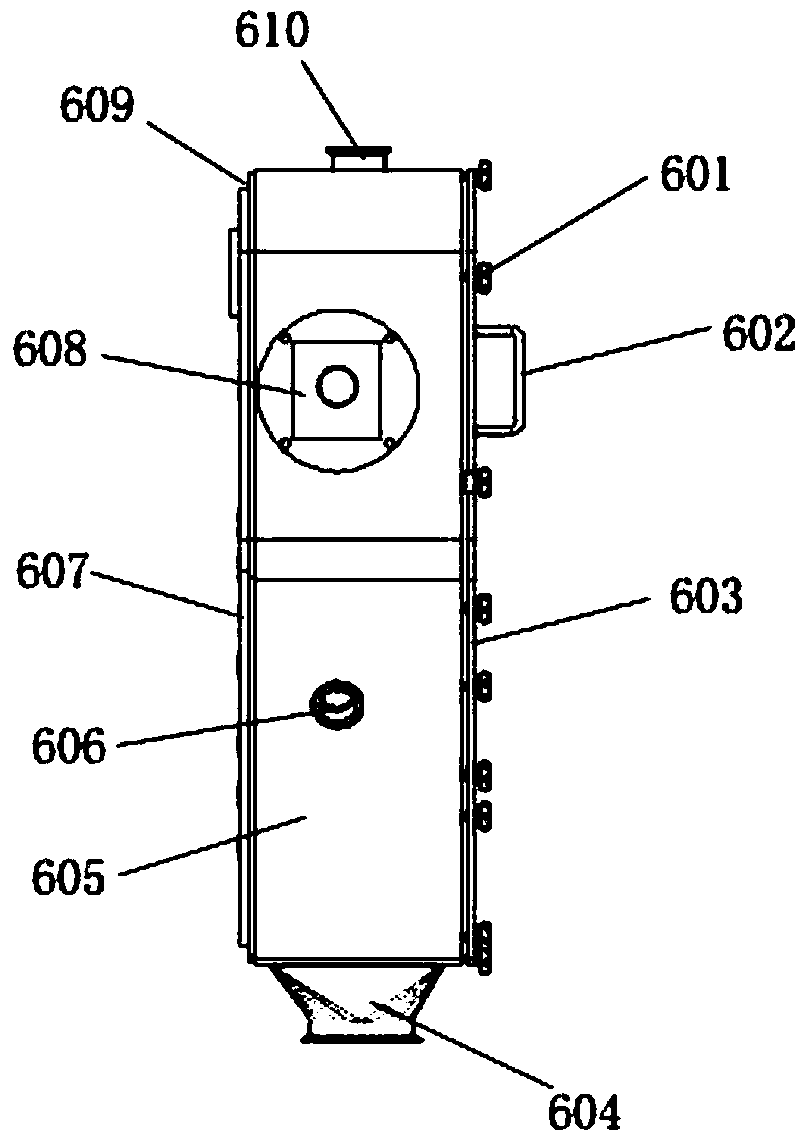

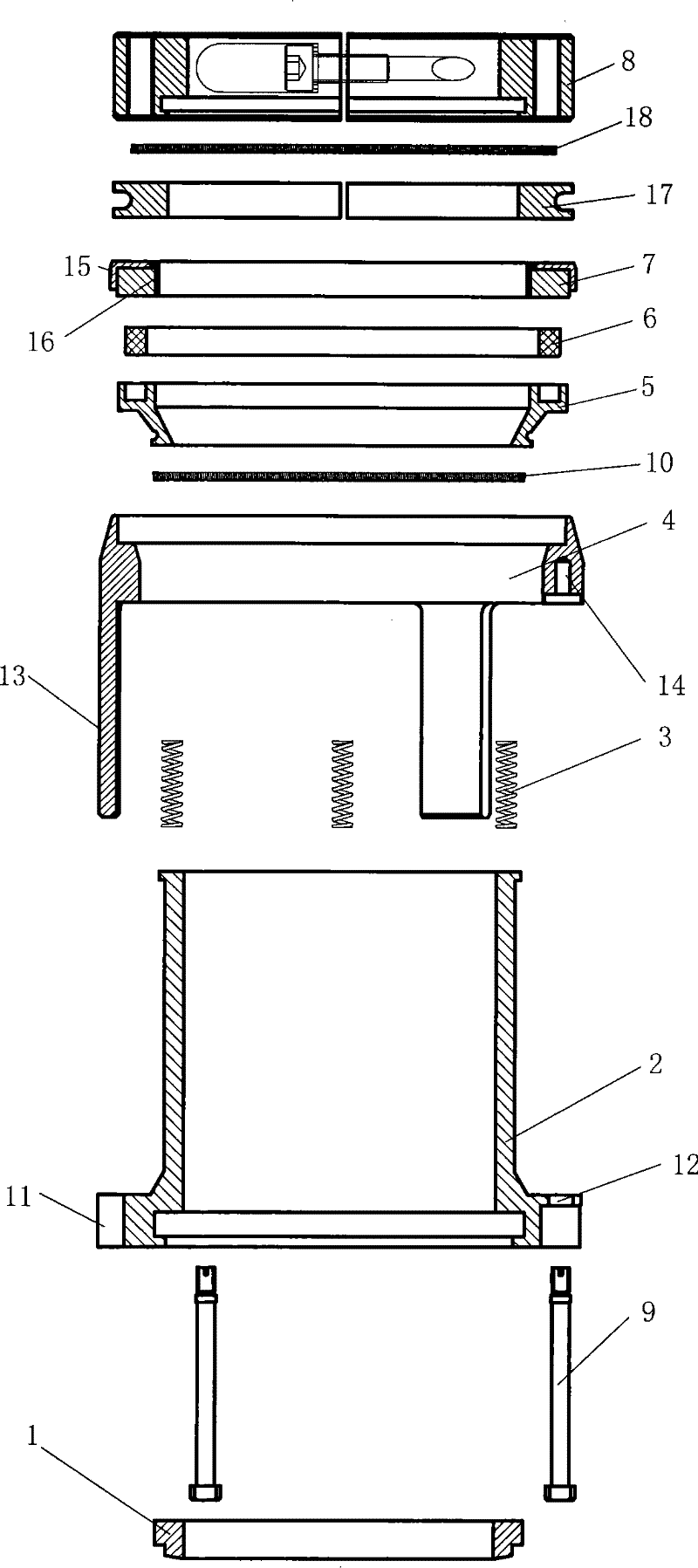

Dry-process granulating machine for anti-tumor medicines

PendingCN109513398ACompact structureReasonable designGranulation by pressingAnti-Tumor DrugsFront cover

The invention relates to a dry-process granulating machine for anti-tumor medicines. The dry-process granulating machine comprises a box body, and a material conveying device, an upper press roll, a lower press roll, a crushing mechanism and a granulating mechanism which are arranged on the box body, wherein a front cover mechanism is arranged at the outer side of the box body; the upper press roll, the lower press roll, the crushing mechanism and the granulating mechanism are respectively arranged in the front cover mechanism, and form a granulating area together with the front cover mechanism; a material charge device is arranged on the material conveying device, and the front cover mechanism is connected with a material discharge device; the front cover mechanism comprises a front coverframework, a front cover back panel and a front cover front panel, the front cover back panel is arranged at one side of the front cover framework, and the front cover front panel is arranged at theother side of the front cover framework; an installation hole of the upper press roll, an installation hole of the lower press roll, an installation hole of the crushing mechanism and an installationhole of the granulating mechanism are formed in the front cover back panel; one side of the front cover framework is provided with a material inlet, and is connected with the material conveying deviceby the material inlet via a flange. The dry-process granulating machine has the beneficial effects that the structure of the front cover mechanism is compact, the design is reasonable, and the good sealing property of the front cover structure is improved.

Owner:南京迦南比逊科技有限公司

safety valve

ActiveCN104864134BEfficient emissionsSolve the problem of ice blockageEqualizing valvesSafety valvesSafety valveImpurity

The invention discloses a safety valve which comprises a valve body, a sealing assembly and a spring assembly, and the sealing assembly and the spring assembly are installed in the valve body. The sealing assembly comprises a valve seat and a piston, a sealing seat matched with the valve seat is arranged in the valve body, the sealing seat is provided with an outer conical sealing surface, the valve seat is provided with a pit matched with the sealing seat, and the interior of the pit is provided with an inner conical surface matched with the outer conical sealing surface. According to the safety valve, condensate water and other impurities generated by moist air in the valve body at the ultralow temperature can not be deposited on the valve seat, and meanwhile the low-temperature leakage caused by low-temperature shrinkage distortion of sealing materials can be avoided.

Owner:ROTAREX STAR

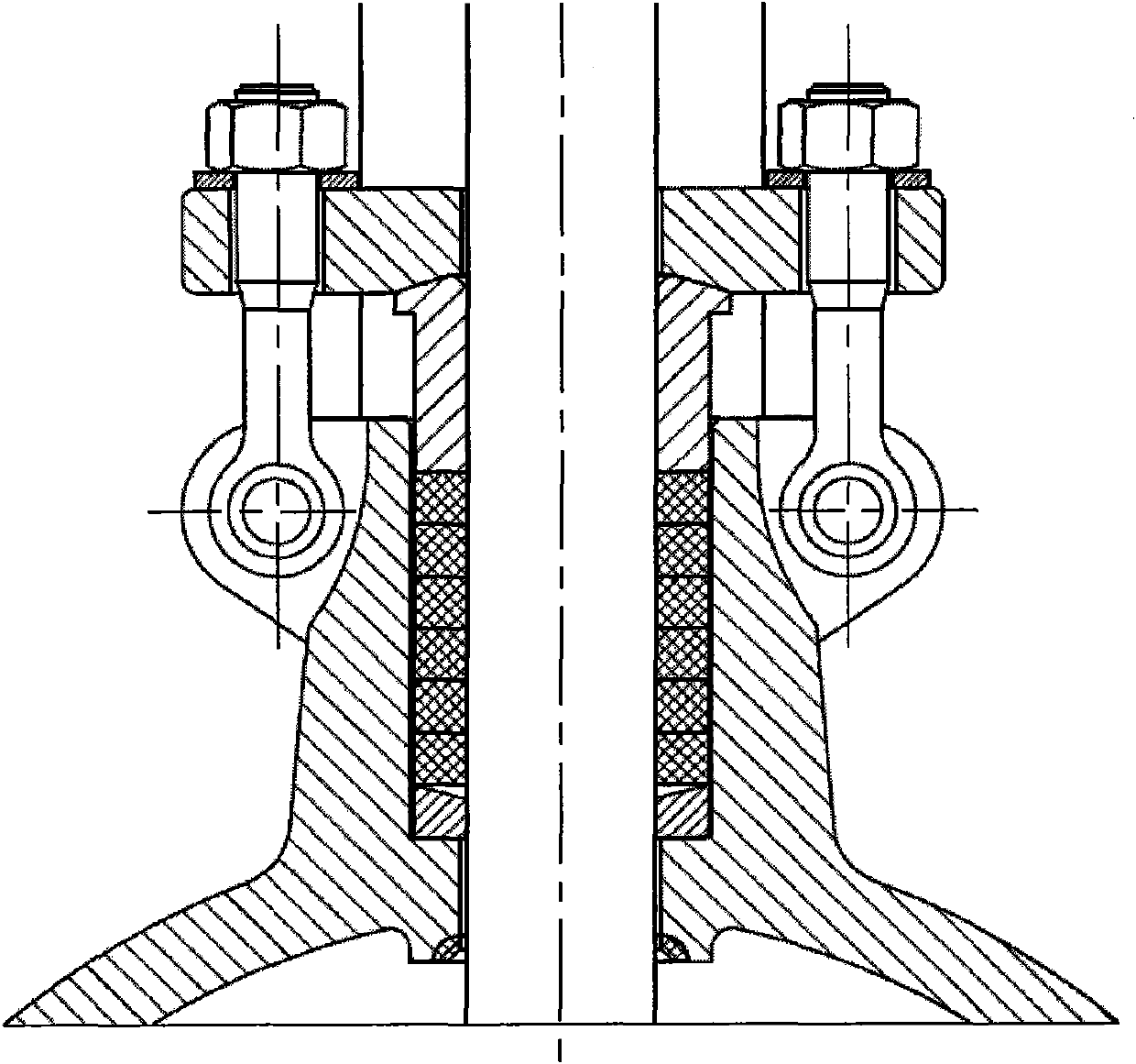

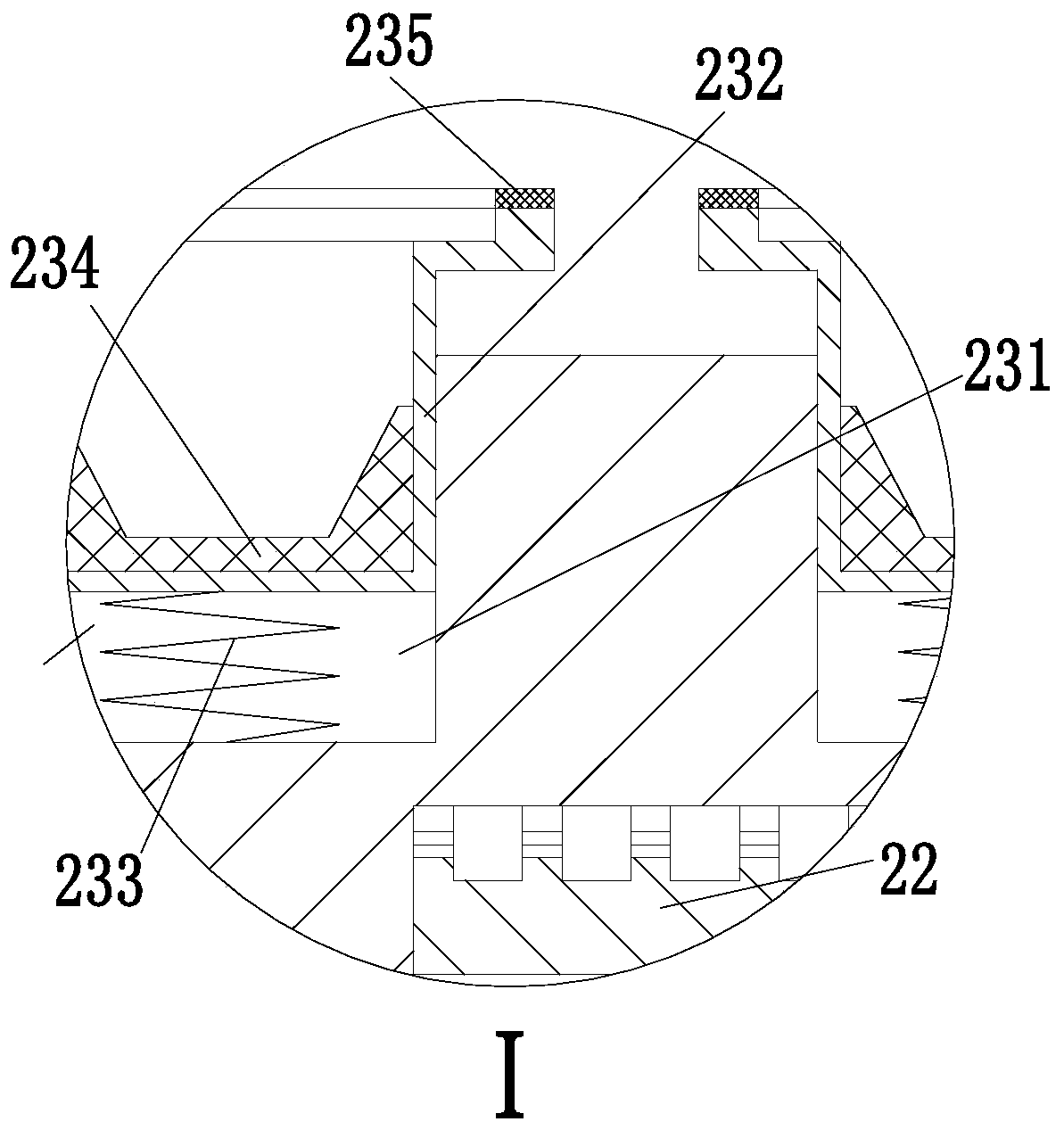

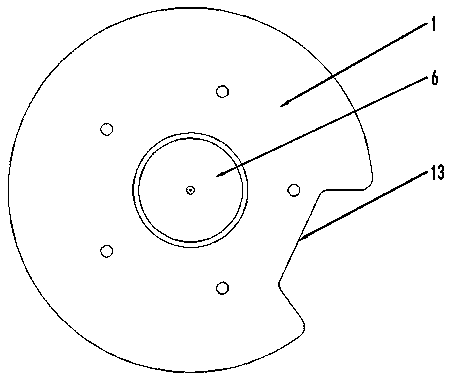

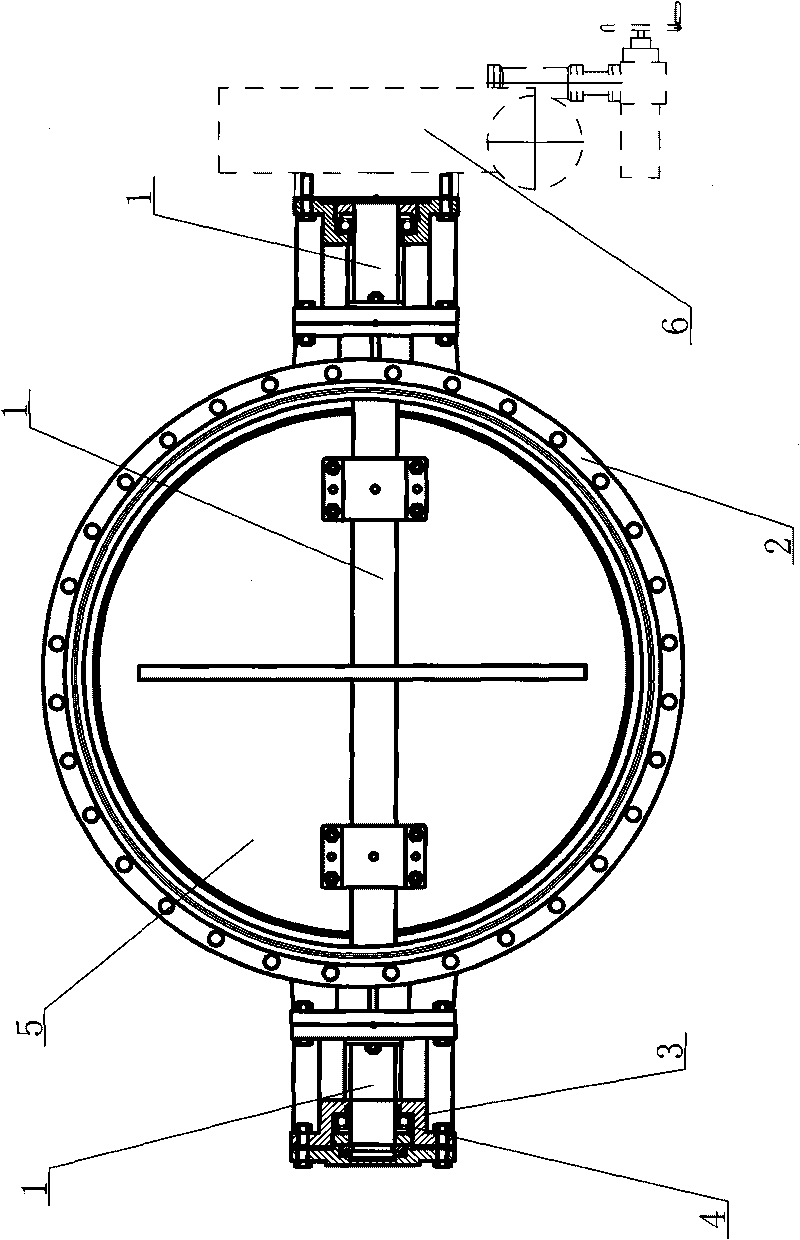

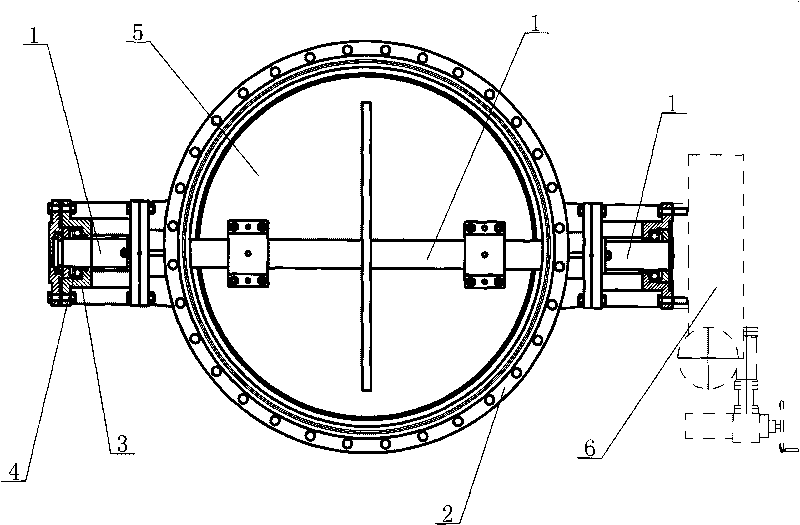

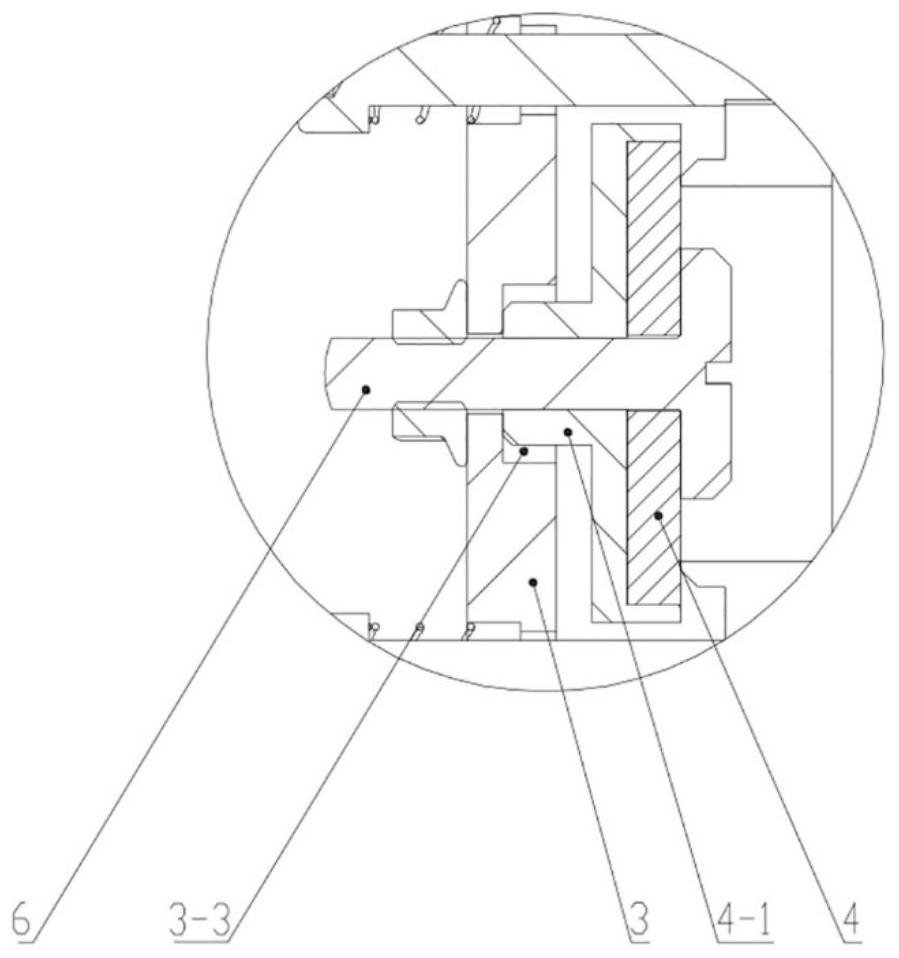

Valve shaft supporting structure of large-diameter butterfly valve

InactiveCN101713467AExtended maintenance cycleReduce maintenance costsLift valveEngineeringButterfly valve

The invention discloses a valve shaft supporting structure of a large-diameter butterfly valve, which can prevent a valve shaft from sinking. The valve shaft supporting structure comprises a valve shaft; the two ends of the valve shaft are arranged outside a valve body; and the two ends of the valve shaft are respectively arranged on a bearing seat through a supporting bearing. The valve shaft supporting structure has the advantages that the valve shaft supporting structure of the large-diameter butterfly valve adopting the mode of supporting by the two ends of the valve shaft can effectively eradicate the phenomenon of the sinking of the valve shaft and a valve plate, avoid the phenomenon of the leakage of a sealing pair caused by the misplacement of the sealing pair, and simultaneously avoid the phenomenon of expansion and shaft hung caused by the variation of temperature of pipeline media, the structure is simple, the maintenance period of the large-diameter butterfly valve is prolonged, and the maintenance cost of the large-diameter butterfly valve is effectively reduced.

Owner:江苏鑫通环保科技有限公司

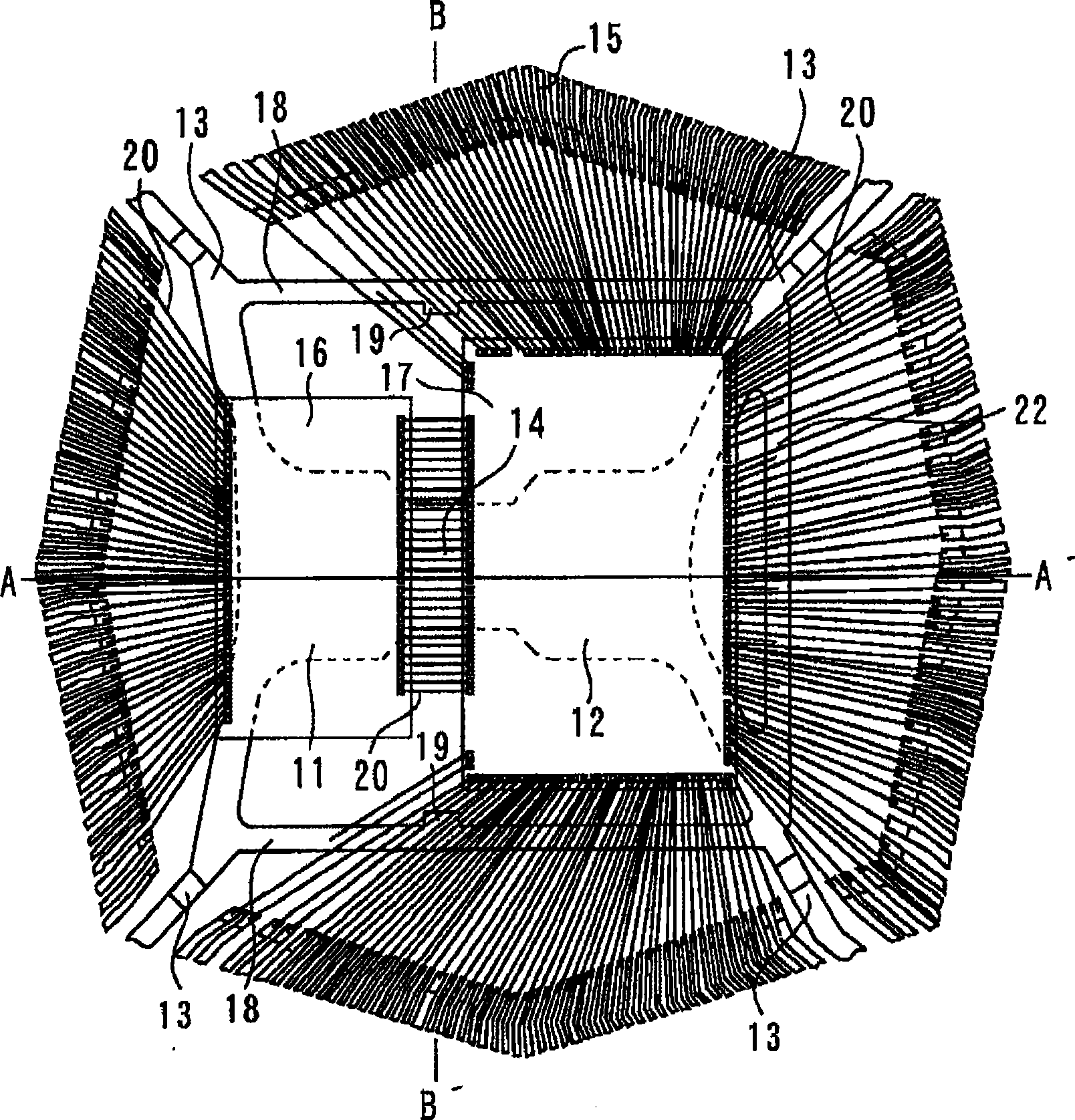

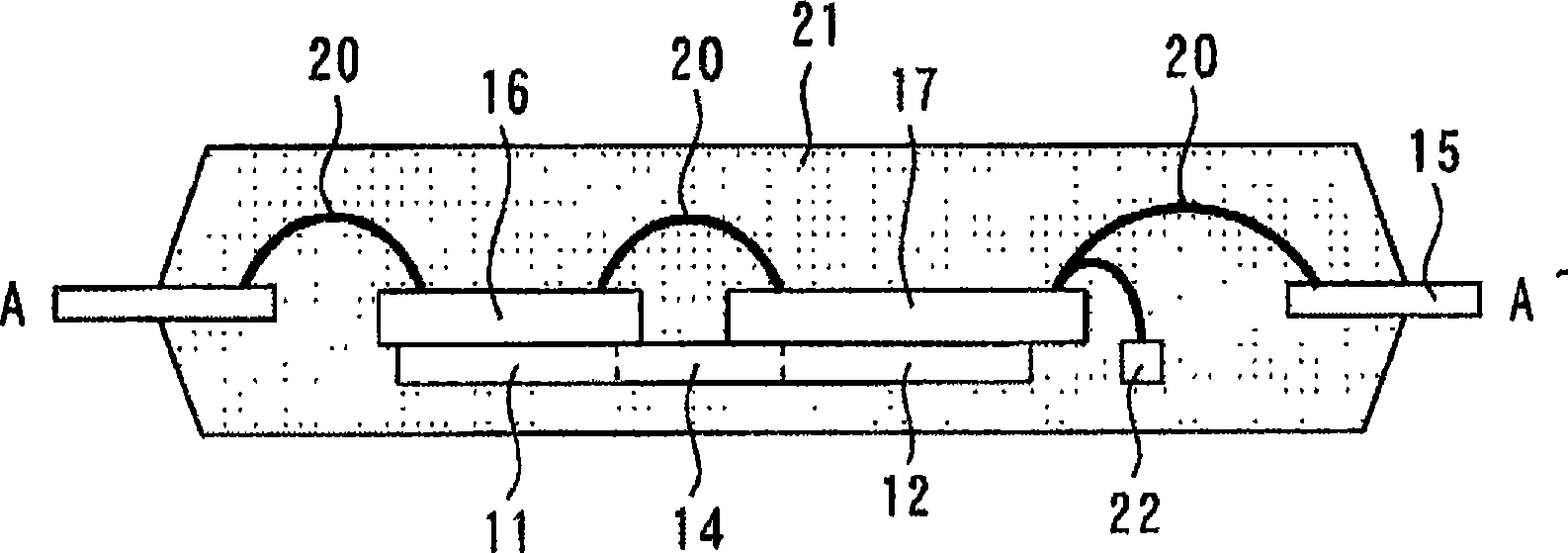

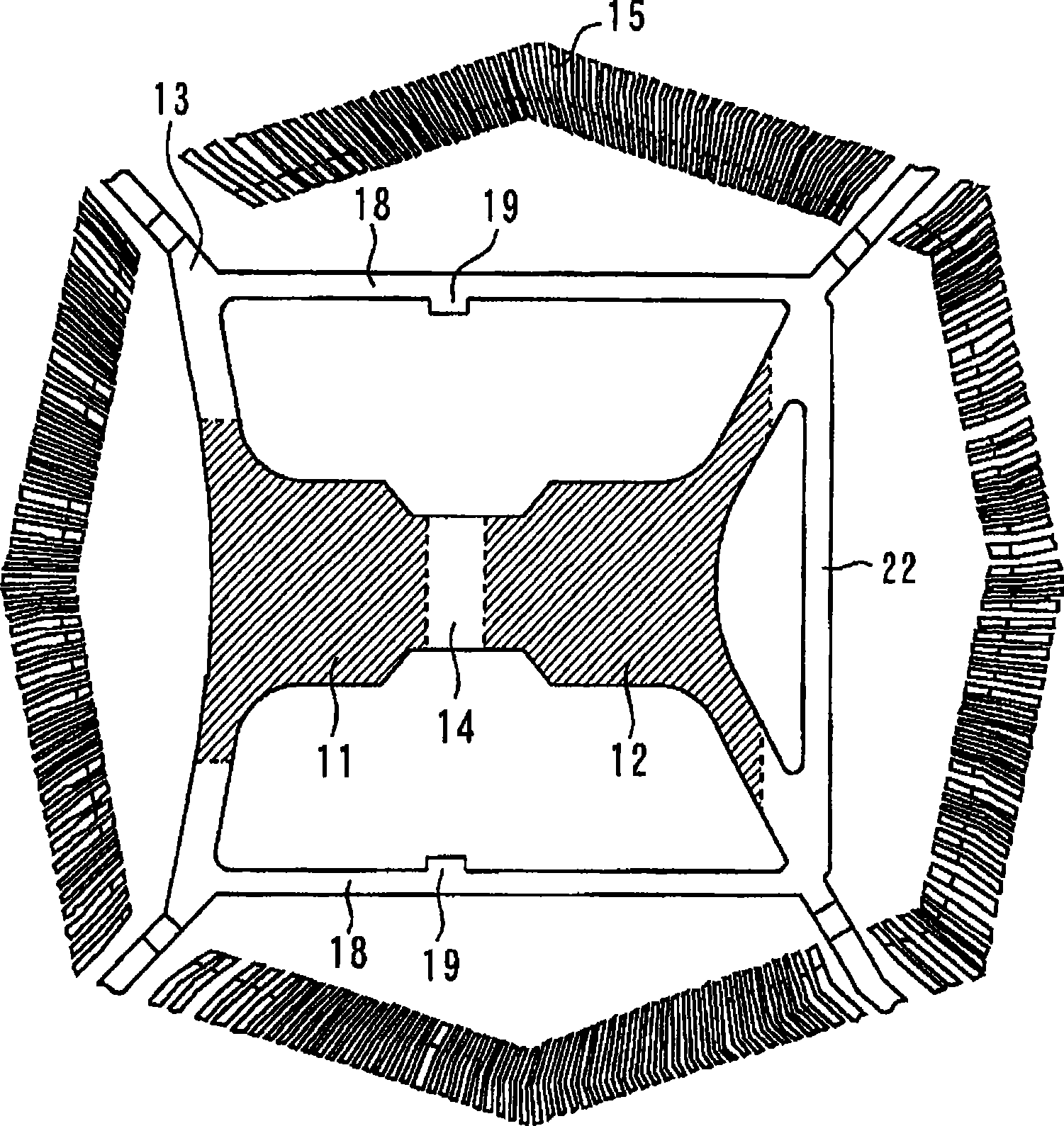

Semiconductor device

ActiveUS7915719B2Avoid Seal LeaksEasy alignmentSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

A semiconductor device comprises: a first and second die pads arranged side by side; a plurality of inner leads arranged around the first and second die pads; first and second chips mounted on the first and second die pads; a bar provided between the first and second chips and the plurality of inner leads, extending in an array direction of the first chip and the second chip; a plurality of wires that connect the first and second chips and the plurality of inner leads and connect the first chip and the second chip; and resin that seals the first and second die pads, the plurality of inner leads, the first and second chips, the plurality of wires and the bar, wherein the bar comprises a mark provided at a position corresponding to an area between the first chip and the second chip in an array direction of the first chip and the second chip.

Owner:RENESAS ELECTRONICS CORP

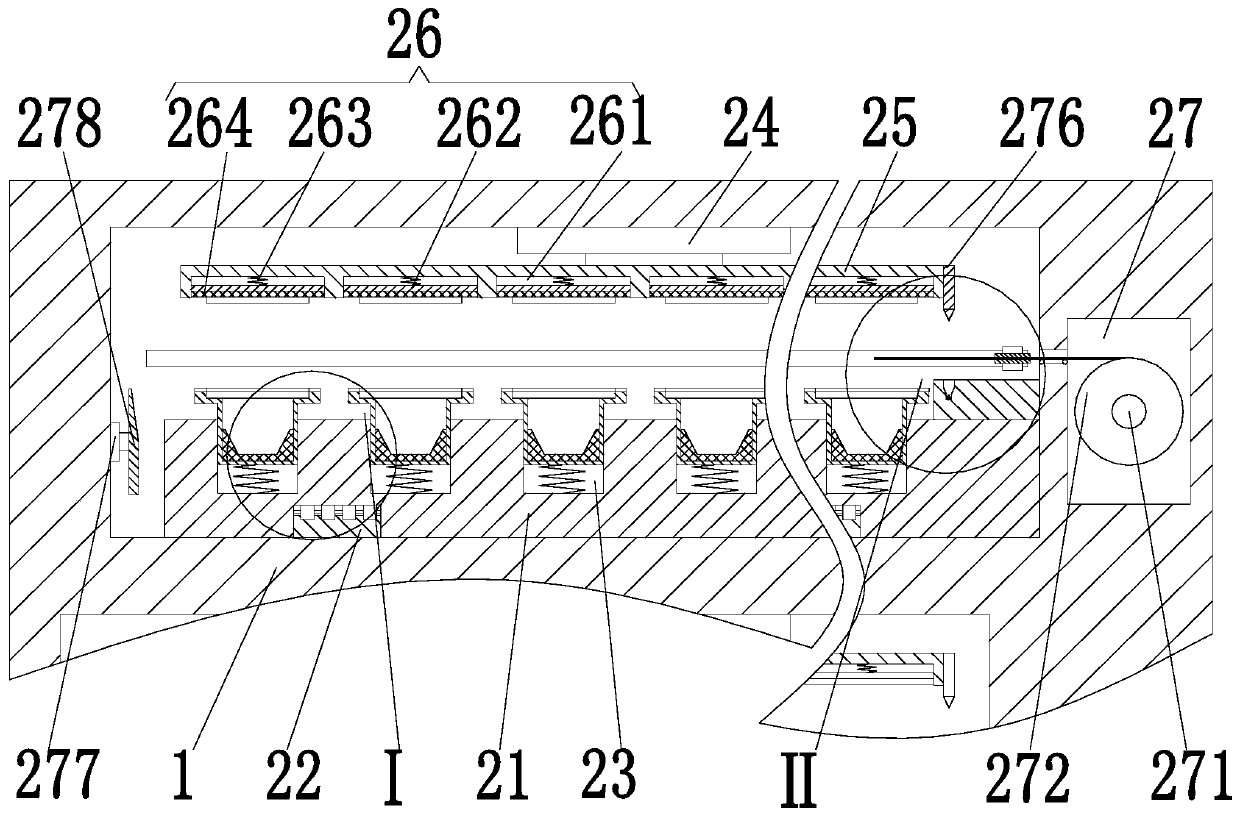

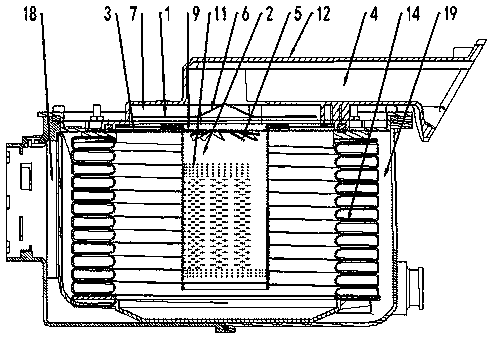

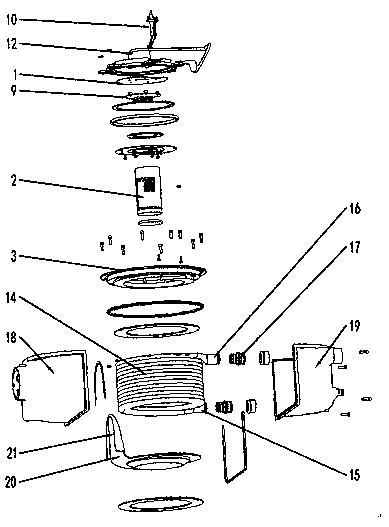

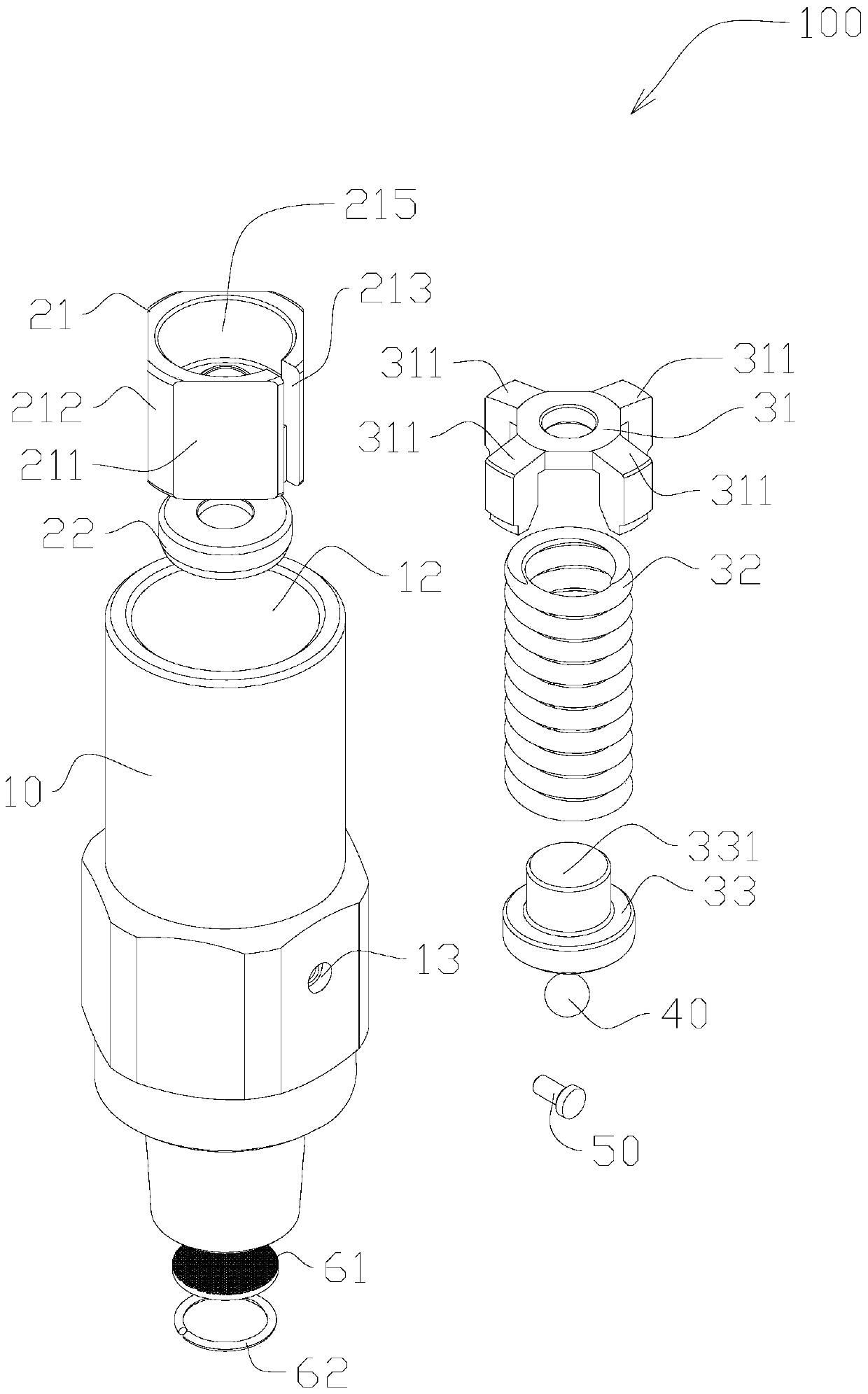

Internal heating three-cylinder vacuum drying cabin

InactiveCN110118484AAvoid Seal LeaksImprove drying efficiencyDrying solid materialsHeating arrangementHeat conductingSpiral blade

The invention discloses an internal heating three-cylinder vacuum drying cabin. The vacuum drying cabin includes a three-cylinder drying cabin, a feeding device, a discharging device, a plate-type heating device, gear rings and raceways; the three-cylinder drying cabin includes an outer drying cylinder, a middle drying cylinder, an inner drying cylinder and spiral blades; the plate-type heating device includes heat conduction hollow boards and a heat conduction pipe; the plate-type heating device is installed in the three-cylinder drying cabin; and the heat conduction and heat dissipation of heat energy carried by heat-conducting media can be performed through the plate-type heating device. The internals of the heat conduction hollow boards do not communicate with the internals of the adjacent heat conduction hollow boards, so that the using of the whole three-cylinder drying cabin cannot be affected when some heat conduction hollow board is damaged to cause leakage; an air exhaust opening exhausts moisture out of the three-cylinder drying cabin, and the plate-type heating device performs stirring and pushing on materials during drying, so that the drying uniformity of the materials can be enhanced; and the materials can be continuously taken in and out of the three-cylinder drying cabin through the feeding device and the discharging device, so that continuous vacuum drying canbe performed on the materials.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

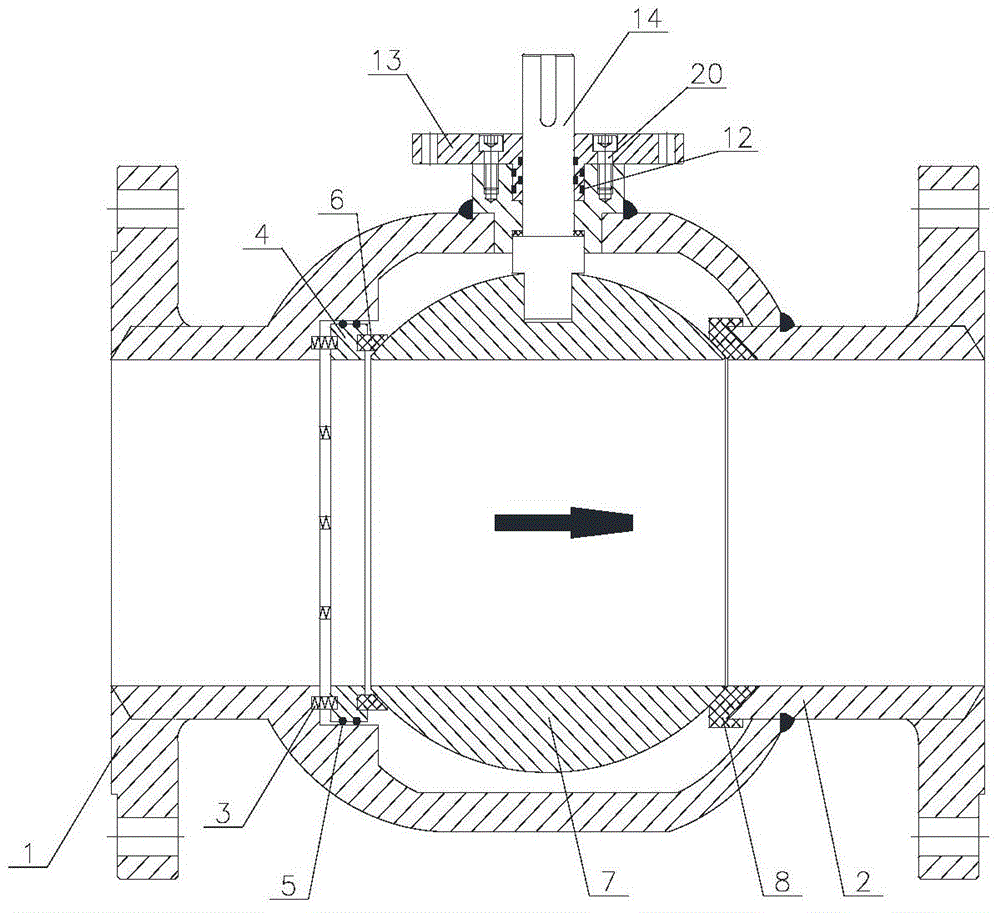

High temperature resistant mechanical seal device

ActiveCN104329466BReduced mechanical propertiesReduce thermal deformationEngine sealsEngineeringRunning time

The invention relates to the field of sealing devices for fluid medium conveying pipelines, in particular to a high-temperature-resistant mechanical sealing device. The high-temperature-resistant mechanical sealing device comprises a movable ring (4), a static ring (5) and a revolving shaft (20), and is characterized by further comprising a vacuum shaft sleeve (11) and an O-shaped ring (13), wherein the inner cavity of the vacuum shaft sleeve (11) is in a high-vacuum state; the vacuum shaft sleeve (11) is fixed on the revolving shaft (20) in a sleeving manner; the movable ring (4) is fixed on the vacuum shaft sleeve (11) in the sleeving manner; the static ring is rotationally arranged on the vacuum shaft sleeve (11) in the sleeving manner; the static ring (5) and the movable ring (4) are jointed together and rotate relatively; the O-shaped ring (13) is lined between the vacuum shaft sleeve (11) and the revolving shaft (20). The high-temperature-resistant mechanical sealing device has high sealing performance, low medium leakage, long running time and long service life.

Owner:SHANGHAI LEHE FLUID MACHINERY

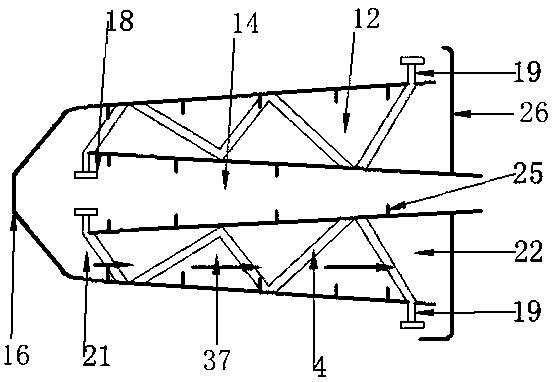

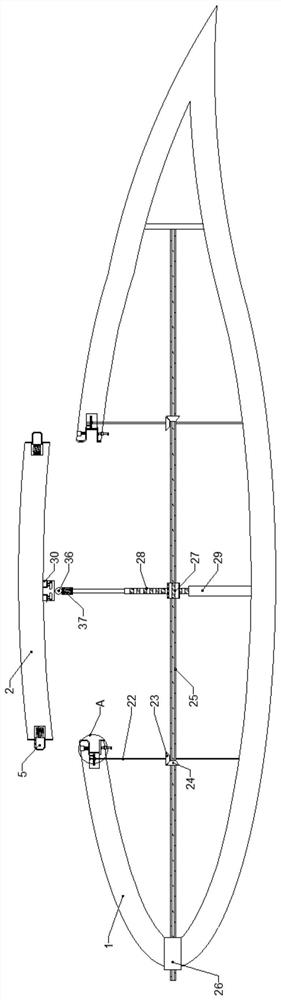

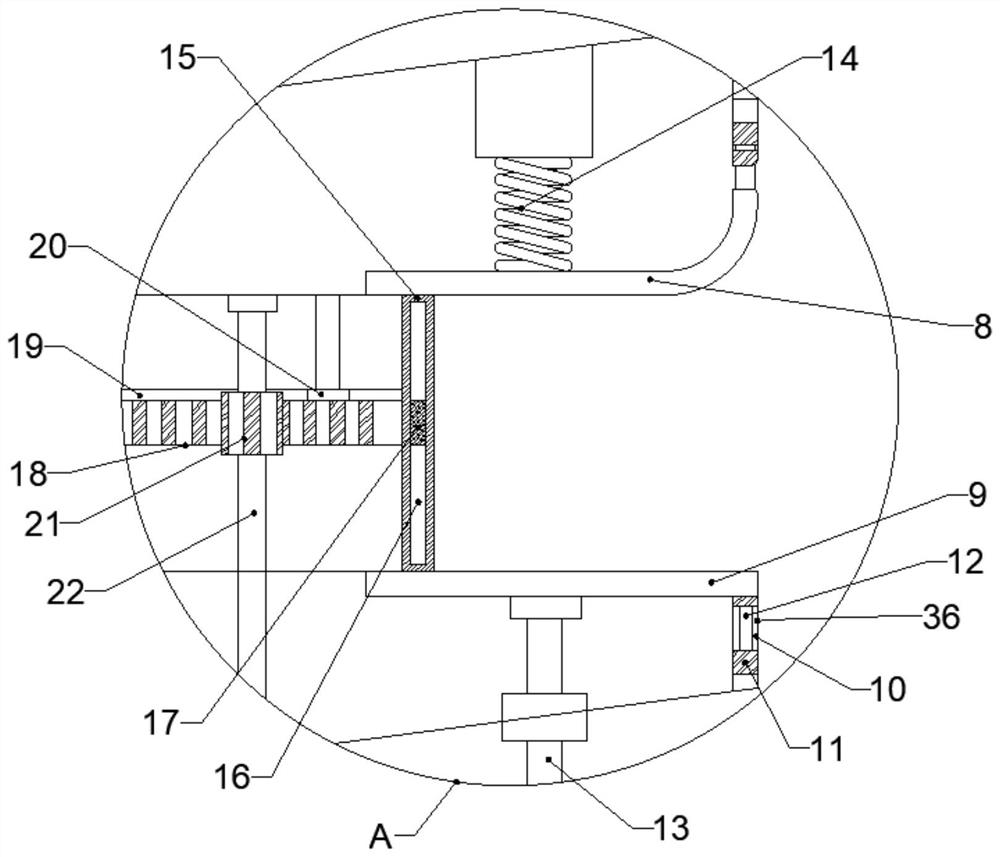

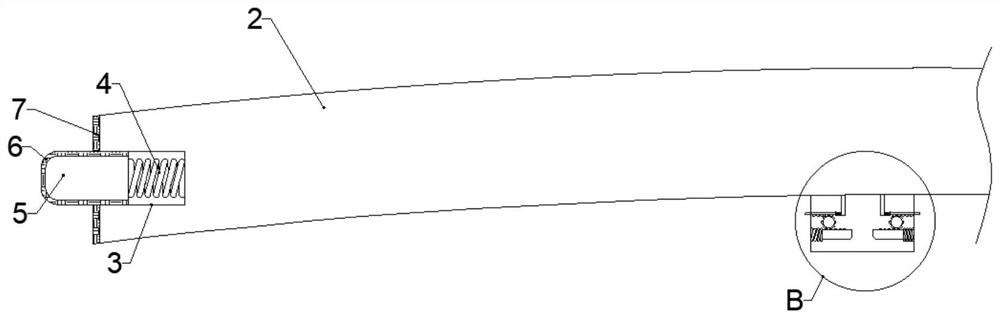

Wind driven generator blade root area surface flow control mechanism

PendingCN114753965AAvoid air intakeReduce resistanceMachines/enginesWind motor with parallel air flowWind drivenEngineering

The invention discloses a wind driven generator blade root area surface flow control mechanism which comprises a blade, a self-vibration reed, a clamping component, a first sealing plate, a second sealing plate and a clamping box, the outer surface of the blade is provided with a mounting groove matched with the self-vibration reed, the self-vibration reed is mounted in the mounting groove, and the clamping box is arranged in the mounting groove. Two third sealing plates are mounted on the end face, close to the mounting groove, of the inner wall of the blade, the third sealing plates are perpendicular to the inner wall of the blade, the two third sealing plates are oppositely mounted, a sealing groove is formed in each third sealing plate, and a sliding plate is slidably connected to the interior of each sealing groove; the clamping block can be clamped to the gap between the first sealing plate and the second sealing plate for sealing, the first sealing rubber is arranged on the outer wall of the clamping block so that sealing can be achieved between the clamping block and the first sealing plate and between the clamping block and the second sealing plate, and the effect of preventing water and air from entering is achieved.

Owner:INNER MONGOLIA UNIV OF TECH

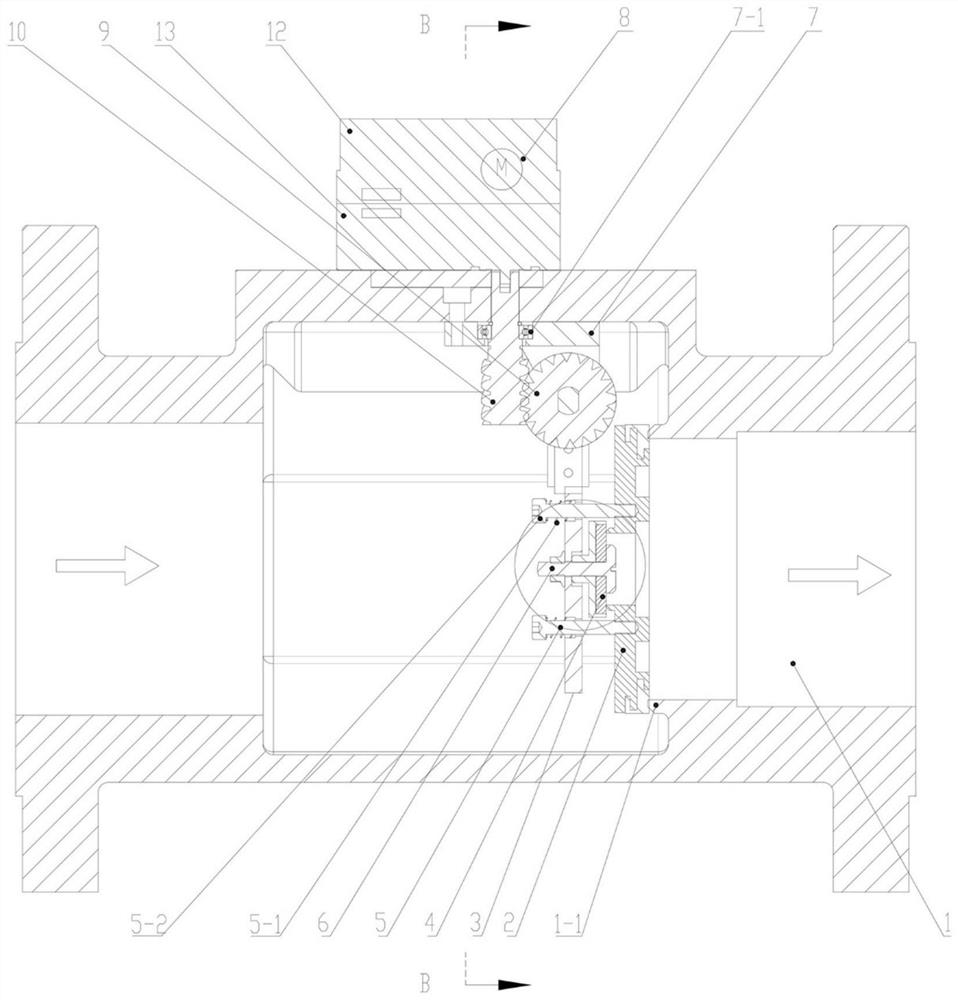

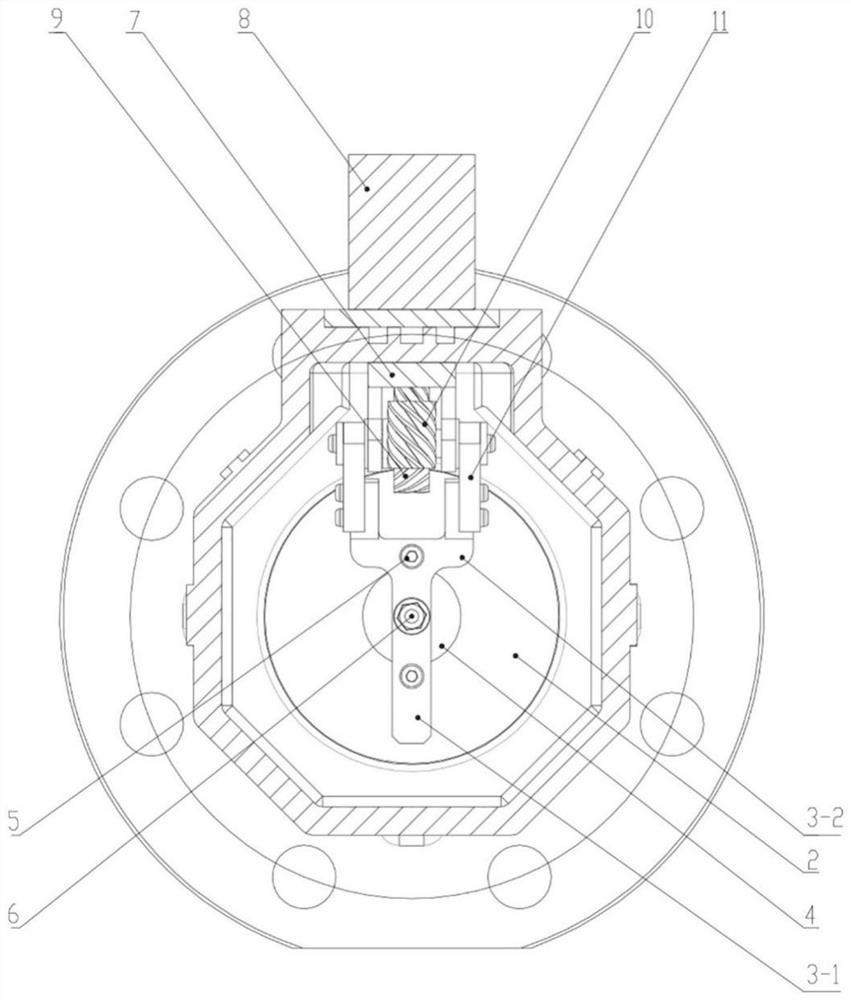

Swing type control valve

PendingCN113187907AReduce the number of turnsShorter rotation timeOperating means/releasing devices for valvesLift valveGear wheelEngineering

The invention discloses a swing type control valve. The swing type control valve comprises a swing reversing mechanism and a valve body sealing cover which are arranged in a mounting cavity, wherein the valve body sealing cover is arranged at the air outlet end of a valve body; the swing reversing mechanism comprises a speed reduction steering gear set; an input shaft of the speed reduction steering gear set is connected with a driving mechanism; an output shaft of the speed reduction steering gear set is in transmission connection with the valve body sealing cover and drives the valve body sealing cover to be opened and closed; a pilot pressure relief hole is formed in the valve body sealing cover; a pilot sealing cover matched with the pilot pressure relief hole is arranged on the valve body sealing cover; and when the control valve is opened, the swing reversing mechanism firstly opens the pilot sealing cover and then opens the valve body sealing cover. According to the swing type control valve, the valve body sealing cover can be quickly opened and closed, and a sealing surface of the valve body sealing cover and a valve body sealing opening are free of friction in the opening and closing process, so that the circumstance of damage of the sealing surface, leakage and venting are reduced, and the service life of the valve is prolonged; and pilot pressure relief is carried out through the pilot sealing cover, so that the torque required during opening is reduced, and the explosion-proof safety of a product is improved.

Owner:西安中创云联智能科技有限公司

Sealing device

The invention discloses a sealing device with novel style construction, good sealing property, high mechanical shock resistance, the construction includes a shaft sleeve, a moving ring base, a moving ring, a stationary component. A sealing member is arranged on internal side of the shaft sleeve, a moving ring base is arranged on bottom of the shaft sleeve pushed by an elastic component at middle,a moving ring is arranged on top of the moving ring base, the stationary component is arranged above the moving ring, a locking device is arranged on top of the shaft sleeve. The invention has advantages of a relative rotation preventing device arranged on the moving ring base and the shaft sleeve, good sealing property of the sealing device and high mechanical shock resistance.

Owner:戴明惠

Information management system, method and device

InactiveCN112784255AImprove securityEasy to useDigital data protectionDigital data authenticationInformation processingOriginal data

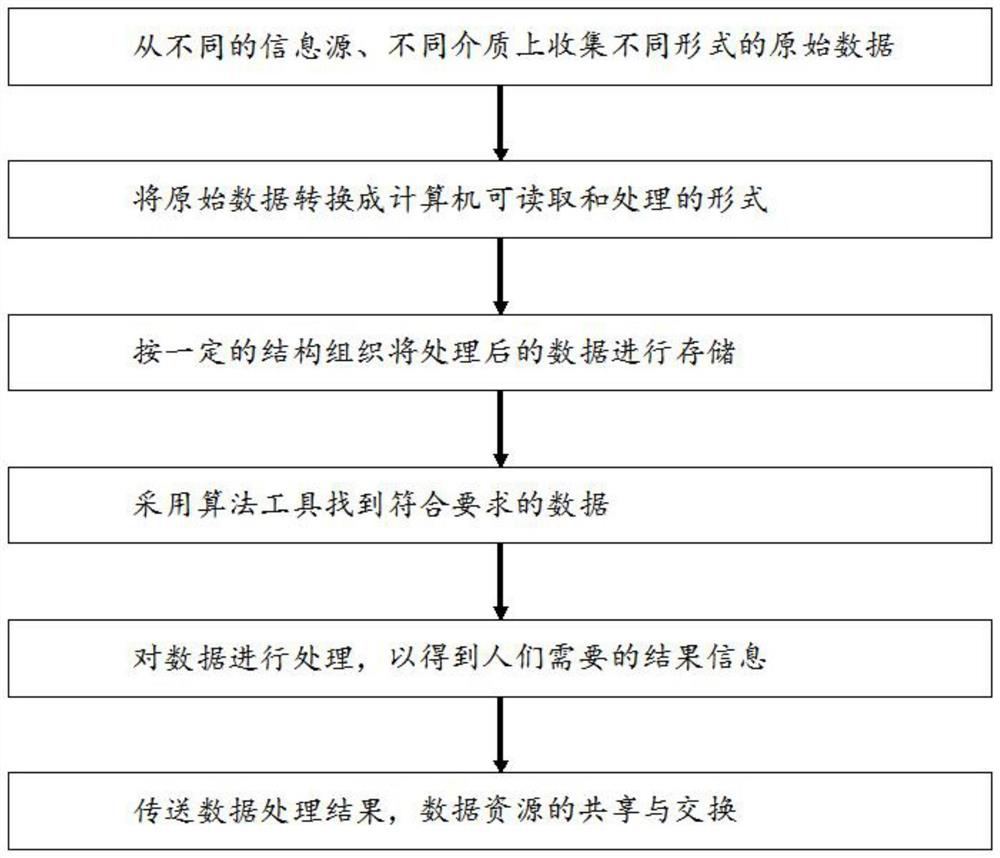

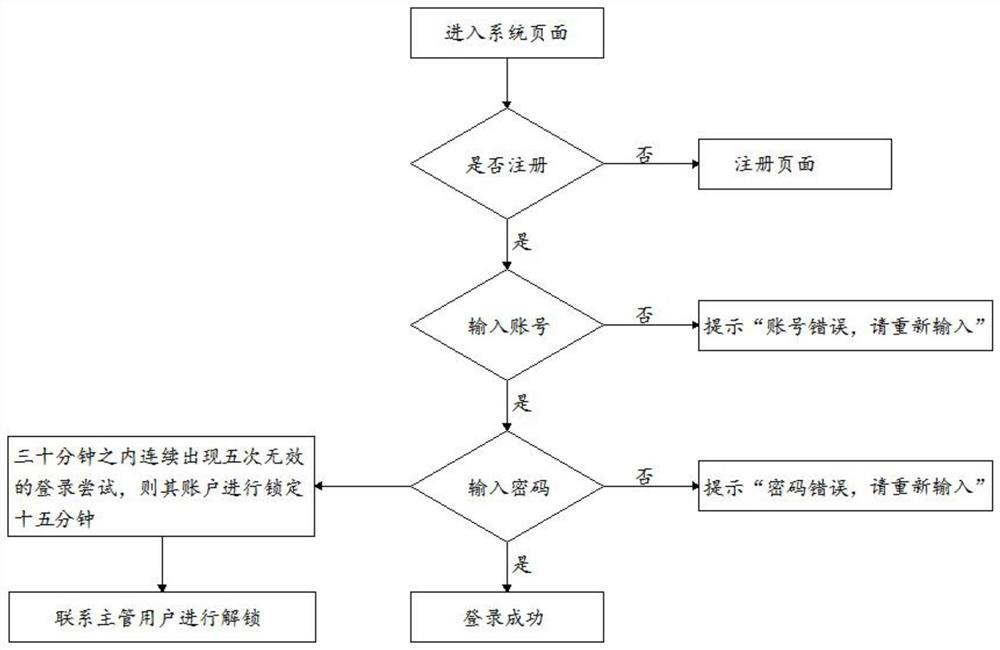

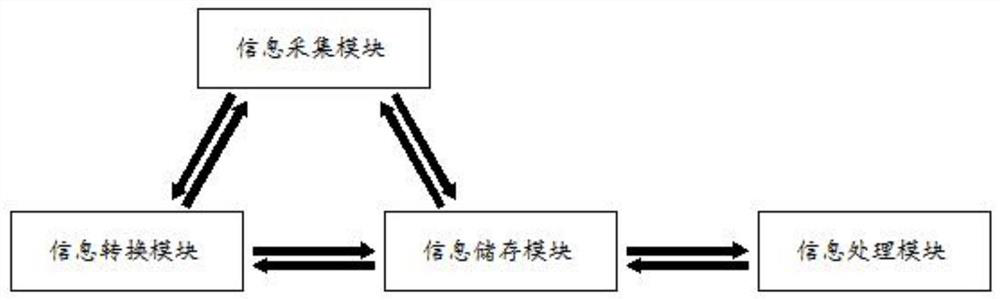

The invention relates to the technical field of information processing, and discloses an information management system which comprises data acquisition, data conversion, data storage, data retrieval, data processing, data management and data transmission. According to the information management system, method and device, original data in different forms are collected from different information sources and different media through the information collection module, the original data are converted into a form capable of being read and processed by a computer through an information conversion module, the collected information is classified through the information conversion module, and the classified information is stored; the stored classified information is processed in batches through an information processing module, and the effect of simple, convenient and efficient information processing is achieved; meanwhile, the security of information management is preliminarily improved by setting a login account and a password, the security of information management is further improved by limiting and regularly modifying the password, and the effects of simplicity and convenience in use and high security are achieved.

Owner:NANYANG INST OF TECH

Semiconductor device

InactiveCN101399258BAvoid Seal LeaksSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

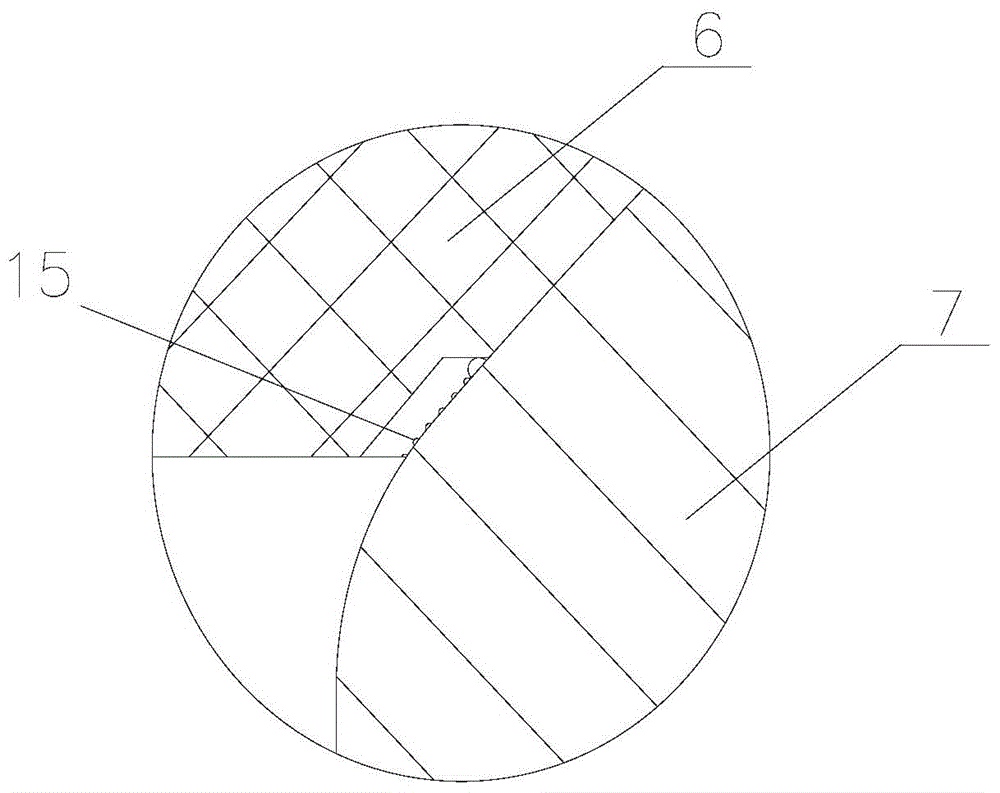

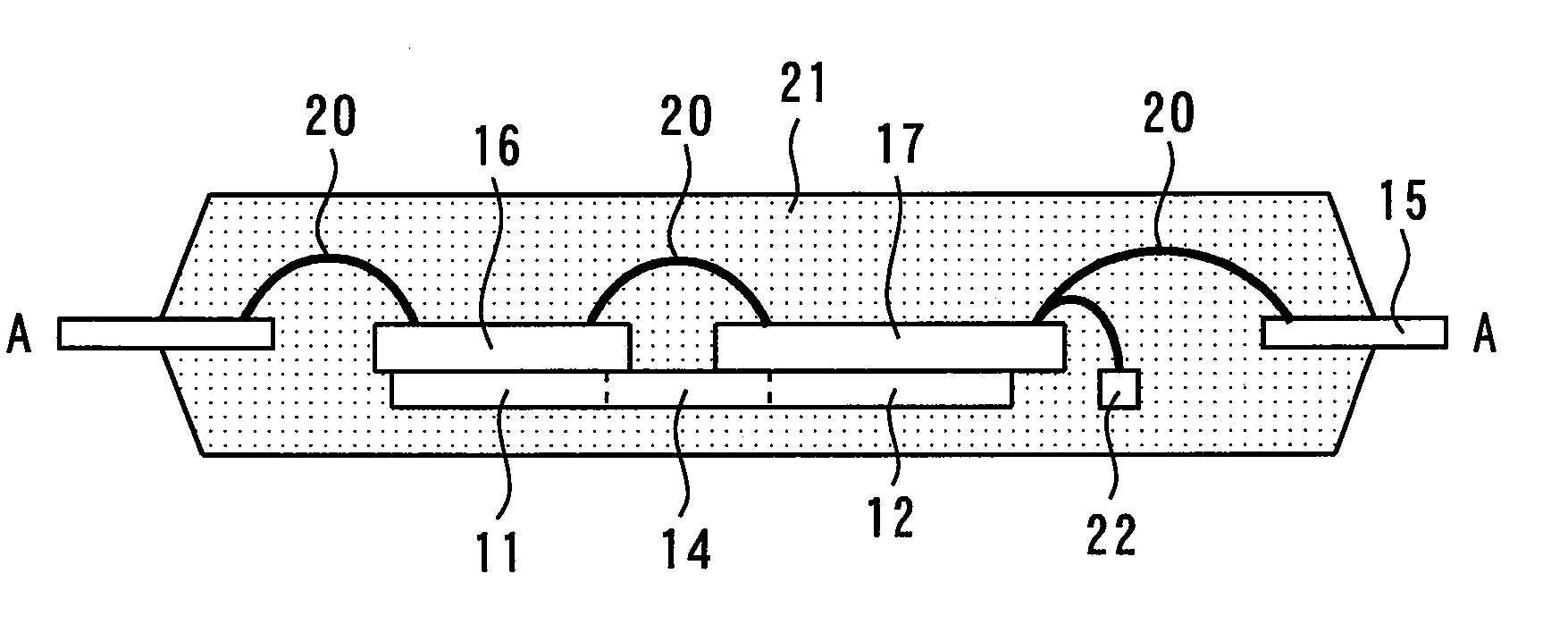

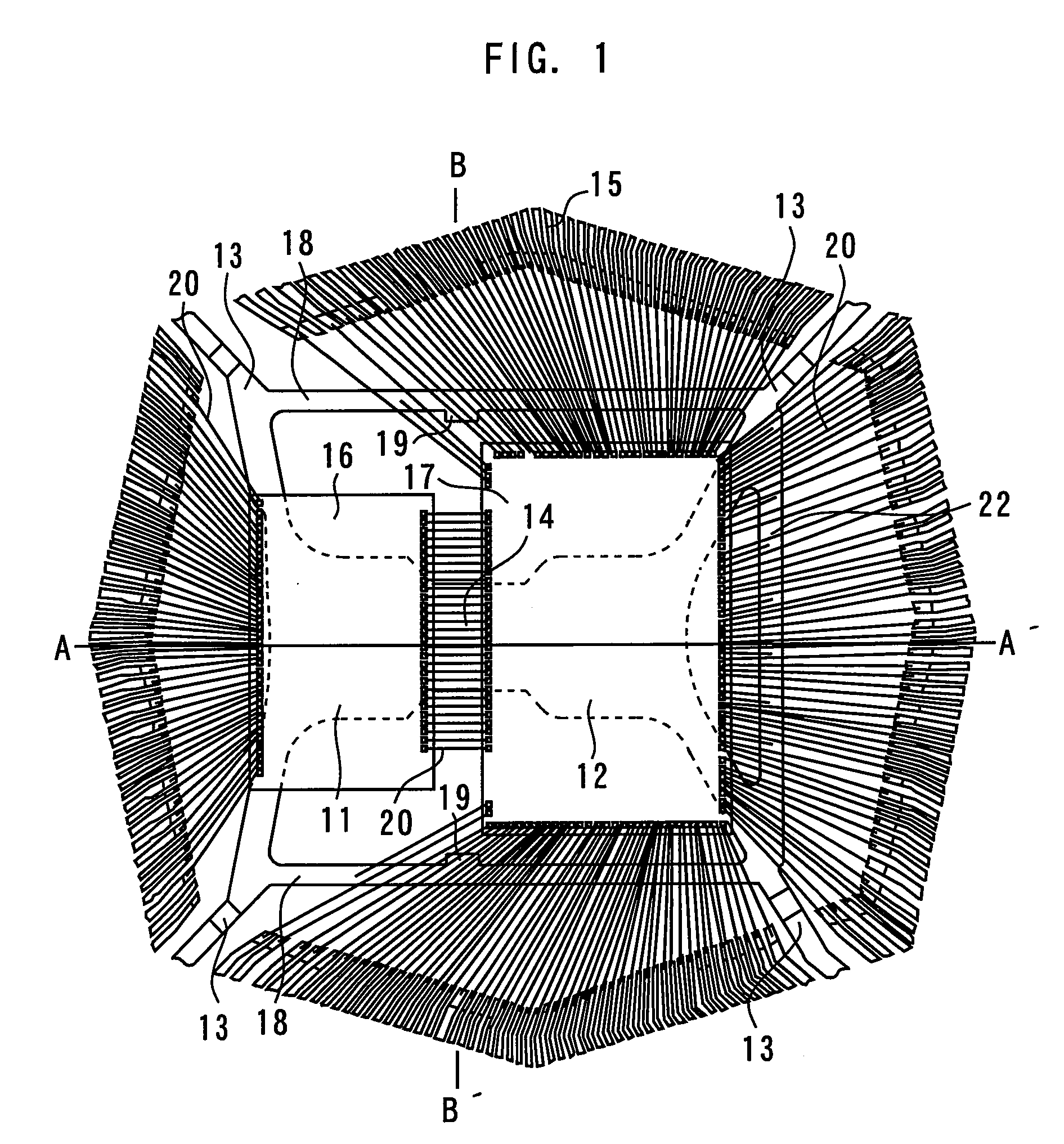

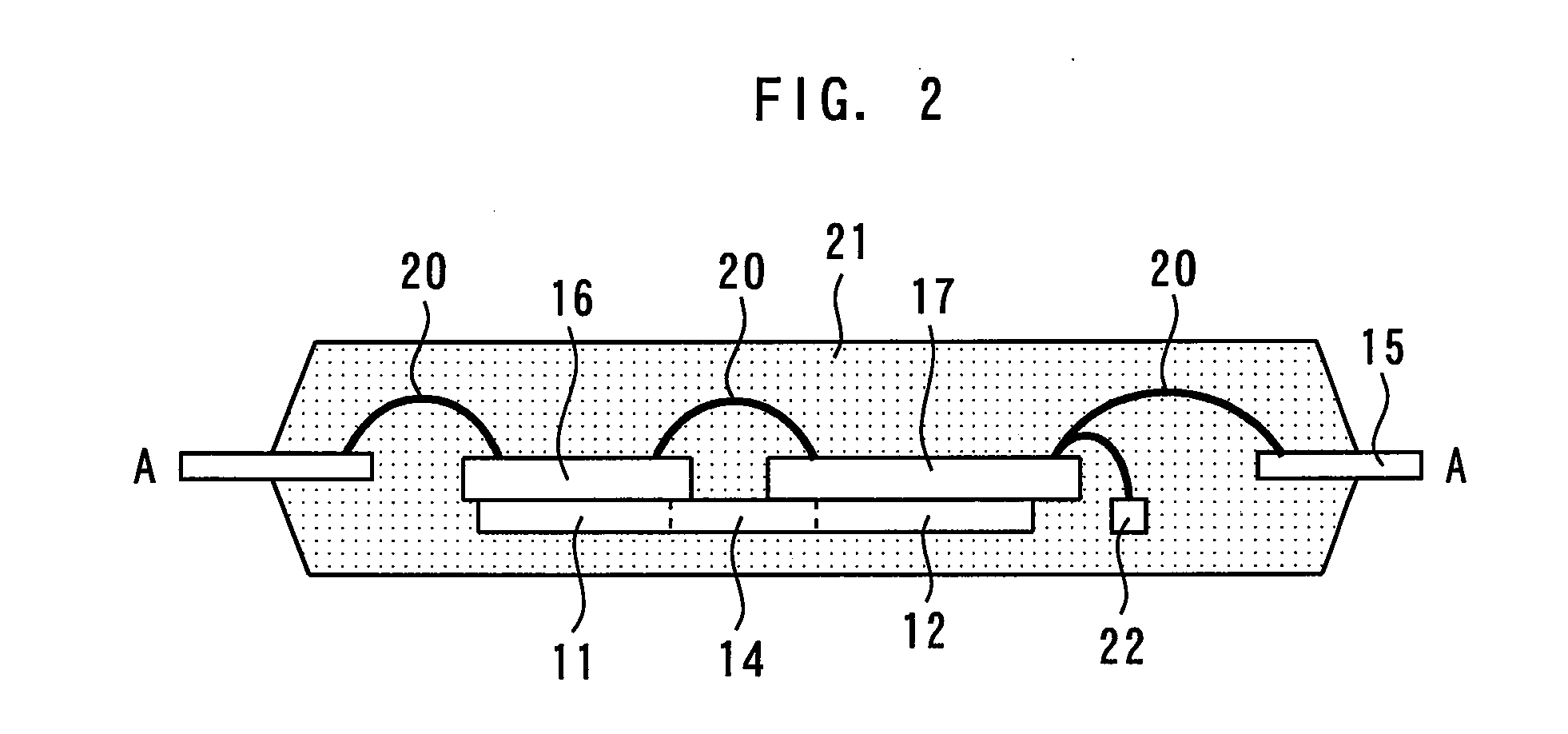

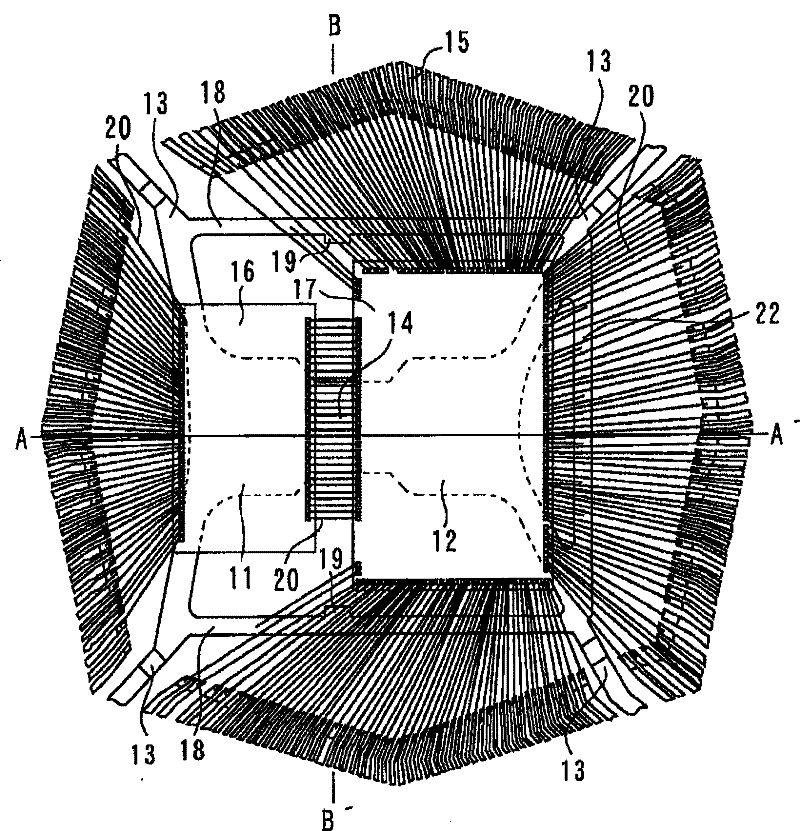

This invention refers to a semiconductor device capable of easily performing chip contraposition when a lower die pad carries two chips in transversely arranged. A plurality of inner leads (15) is arranged around the first and second die pads which are arranged side by side. First and second chips (16, 17) are mounted on the first and second die pads (11, 12). A bar (18) is provided between the first and second chips (16, 17) and the plurality of inner leads (15), extending in an array direction of the first chip (16) and the second chip (17). A plurality of wires connects the first and second chips (16, 17) and the plurality of inner leads (15) and connects the first chip (16) and the second chip (17); and a resin (21) seals the first and second die pads, the plurality of inner leads, the first and second chips, the plurality of wires and the bar, wherein the bar (18) comprises a bump (19) as a mark provided at a position corresponding to an area between the first chip (16) and the second chip (17) in an array direction of the first chip and the second chip.

Owner:RENESAS ELECTRONICS CORP

An automatic grease-suction and grease-injection device and method for bearing lubrication

ActiveCN105546315BTimely updateGuaranteed safe lubricationLubricant transferBearing componentsLiposuctionControl system

The invention provides an automatic grease pumping and injecting device and method for bearing lubrication. The device at least comprises a control system, a grease pumping system and a grease injecting device; the grease pumping system comprises a waste grease storage tank, a grease pumping pump, a pipe and a connector; the grease injecting device comprises a grease injecting pump, a novel grease storage tank, a pipe and a connector; and the control system comprises a processor, a data storage device and sensors, and the sensors are connected with the grease injecting pump and the grease pumping pump, control closing of the grease injecting pump and the grease pumping pump, are distributed on the novel grease storage tank, the waste grease storage tank and a working site, collect relevant data and transmit the data to the data storage device. The invention further provides the automatic grease pumping and injecting method. According to the technical scheme, the shortcomings in the prior art are overcome; and automatic grease pumping and injecting can be achieved, operation is simple, and the grease pumping amount and the grease injecting amount can be controlled.

Owner:HUBEI XINZHI TECH CO LTD

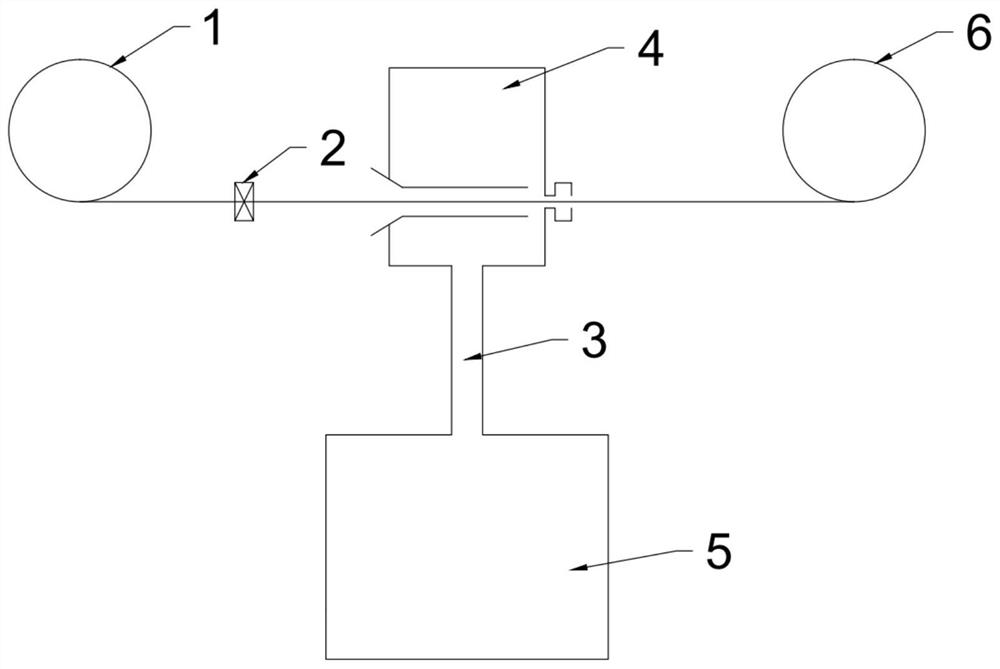

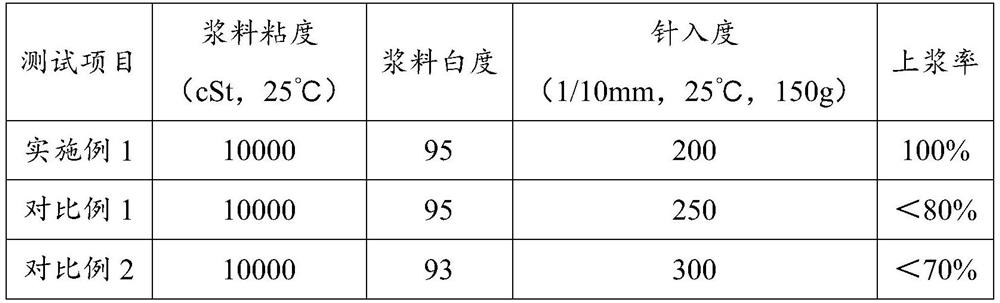

Deep thread sealing slurry line and manufacturing method and device thereof

PendingCN112030565AAvoid Seal LeaksHigh viscosityFibre typesLiquid/gas/vapor textile treatmentCelluloseFiber

The invention is applicable to the field of deep pipeline thread sealing materials, and provides a deep thread sealing slurry line and a manufacturing method and device thereof. The manufacturing method of the deep thread sealing slurry line comprises the following step that slurry is extruded to be applied to chemical fiber filaments, and thus the deep thread sealing slurry line is obtained; wherein the slurry is prepared from the following components in parts by weight: 40-45 parts of dimethyl silicone oil, 30-35 parts of talcum powder, 5-10 parts of white carbon black and 5-10 parts of hydroxypropyl methyl cellulose. The thread sealing slurry line with high viscosity, high strength and excellent sealing performance is prepared by coating the chemical fiber filaments with corresponding slurry, has the characteristics of wear resistance, self-lubricating property, high and low temperature resistance, aging resistance and corrosion resistance, can be used for a long time within a widetemperature range, and is not cured within the temperature range, so that the original viscosity and self-lubricating property are maintained, and the better adhesion is realized in the mounting process.

Owner:四会市昊天密封材料有限公司

Semiconductor device

InactiveCN101399258AReduce widthEasy to injectSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

This invention refers to a semiconductor device capable of easily performing chip contraposition when a lower die pad carries two chips in transversely arranged. A plurality of inner leads (15) is arranged around the first and second die pads which are arranged side by side. First and second chips (16, 17) are mounted on the first and second die pads (11, 12). A bar (18) is provided between the first and second chips (16, 17) and the plurality of inner leads (15), extending in an array direction of the first chip (16) and the second chip (17). A plurality of wires connects the first and second chips (16, 17) and the plurality of inner leads (15) and connects the first chip (16) and the second chip (17); and a resin (21) seals the first and second die pads, the plurality of inner leads, the first and second chips, the plurality of wires and the bar, wherein the bar (18) comprises a bump (19) as a mark provided at a position corresponding to an area between the first chip (16) and the second chip (17) in an array direction of the first chip and the second chip.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com