Deep thread sealing slurry line and manufacturing method and device thereof

A thread sealing and manufacturing method technology, applied in textile and papermaking, liquid/gas/vapor textile processing, fiber processing, etc., can solve the problems of cutting damage to raw material tape, increased workload, and reduced viscose wettability. , to achieve the effect of preventing thread seal leakage, maintaining stability and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

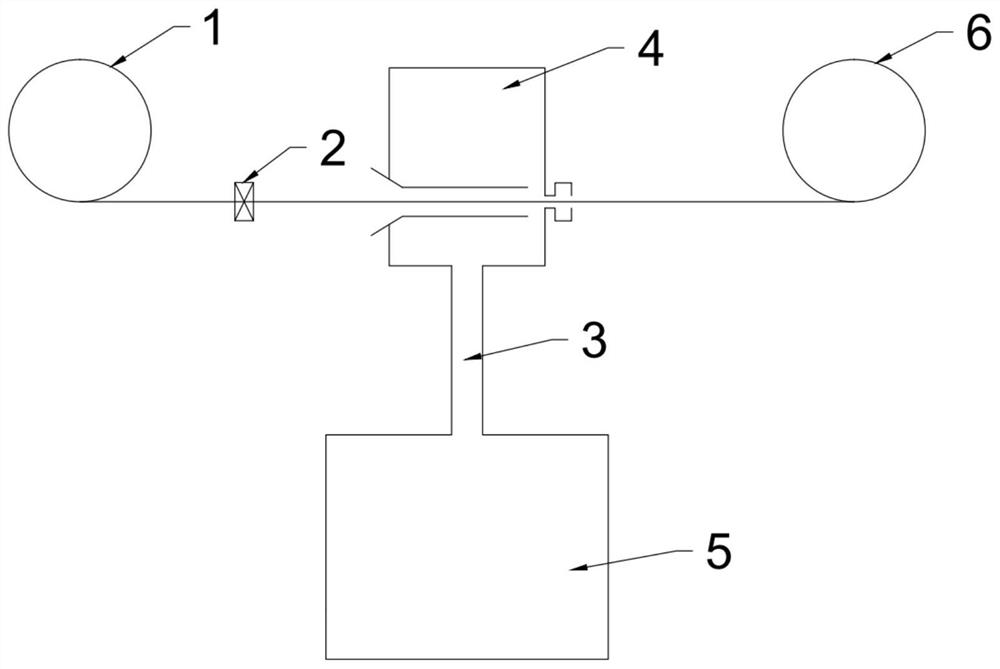

[0032] as attached figure 1 As shown, it is a schematic structural diagram of a manufacturing device for a deep thread sealing slurry line provided by an embodiment of the present invention. The manufacturing device includes:

[0033] Extrusion die 4, used for extruding and sizing chemical fiber filaments;

[0034] Pay-off mechanism 1, used to send chemical fiber filaments to the extrusion die 4;

[0035] The slurry feeding mechanism 5 is used to deliver the slurry to the extrusion die 4 to sizing the chemical fiber filaments being extruded.

[0036] Wherein, the slurry supply mechanism 5 can include a slurry supply barrel and a plunger pump, and the slurry supply barrel can be communicated with the extrusion die 4 through the plunger pump and the slurry supply high-pressure pipe 3; Guide wheels 2 can also be provided between them, so that the chemical fiber filaments can be stably sent to the extrusion die 4 for extrusion and sizing.

[0037] In addition, the manufacturing...

Embodiment 2

[0039] This embodiment provides a method for manufacturing a deep thread sealing slurry line using the manufacturing device provided in the above embodiment 1, which includes the following steps:

[0040] S1. Weigh 42.5kg of simethicone oil, 3.25kg of talcum powder, 0.75kg of white carbon black, and 0.75kg of hydroxypropyl methylcellulose, and set aside. Among them, the viscosity of simethicone oil at 25°C is 10000cSt, the appearance is a colorless transparent oily liquid, and the relative density is 0.971~0.976; 2 o 3 Calculation) ≤ 0.02%, loss on ignition (1000°C) ≤ 6.00%, magnet extract ≤ 0.04%, moisture ≤ 0.5%, particle size 5000 mesh, whiteness > 93, pH value 8 ~ 10; in white carbon black SiO 2 Content (dry product) ≥ 90%, sieve residue (45μm) ≤ 0.5%, heating loss 4.0-8.0%, ignition loss (dry product) ≤ 7.0%, pH value 5.0-8.0, total copper content ≤30mg / kg, total manganese content ≤50mg / kg, total iron content ≤1000mg / kg, DBP absorption value 2.00~3.50cm / g; particle siz...

Embodiment 3

[0045] This embodiment provides a method for manufacturing a deep thread sealing slurry line using the manufacturing device provided in the above embodiment 1, which includes the following steps:

[0046]S1. Weigh 4 kg of simethicone oil, 3.5 kg of talcum powder, 1 kg of white carbon black, and 1 kg of hydroxypropyl methylcellulose, and set aside. Among them, the viscosity of simethicone oil at 25°C is 8000cSt, the appearance is a colorless transparent oily liquid, and the relative density is 0.971~0.976; 2 o 3 Calculation) ≤ 0.02%, loss on ignition (1000°C) ≤ 6.00%, magnet extract ≤ 0.04%, moisture ≤ 0.5%, particle size 5000 mesh, whiteness > 93, pH value 8 ~ 10; in white carbon black SiO 2 Content (dry product) ≥ 90%, sieve residue (45μm) ≤ 0.5%, heating loss 4.0-8.0%, ignition loss (dry product) ≤ 7.0%, pH value 5.0-8.0, total copper content ≤30mg / kg, total manganese content ≤50mg / kg, total iron content ≤1000mg / kg, DBP absorption value 2.00~3.50cm / g; particle size of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| loss on ignition | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com