Ultra-high pressure three-plunger pump

A plunger pump, ultra-high pressure technology, applied in pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve problems such as poor sealing, difficult assembly and repeated positioning, and achieve excellent High elasticity, high impact strength and low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

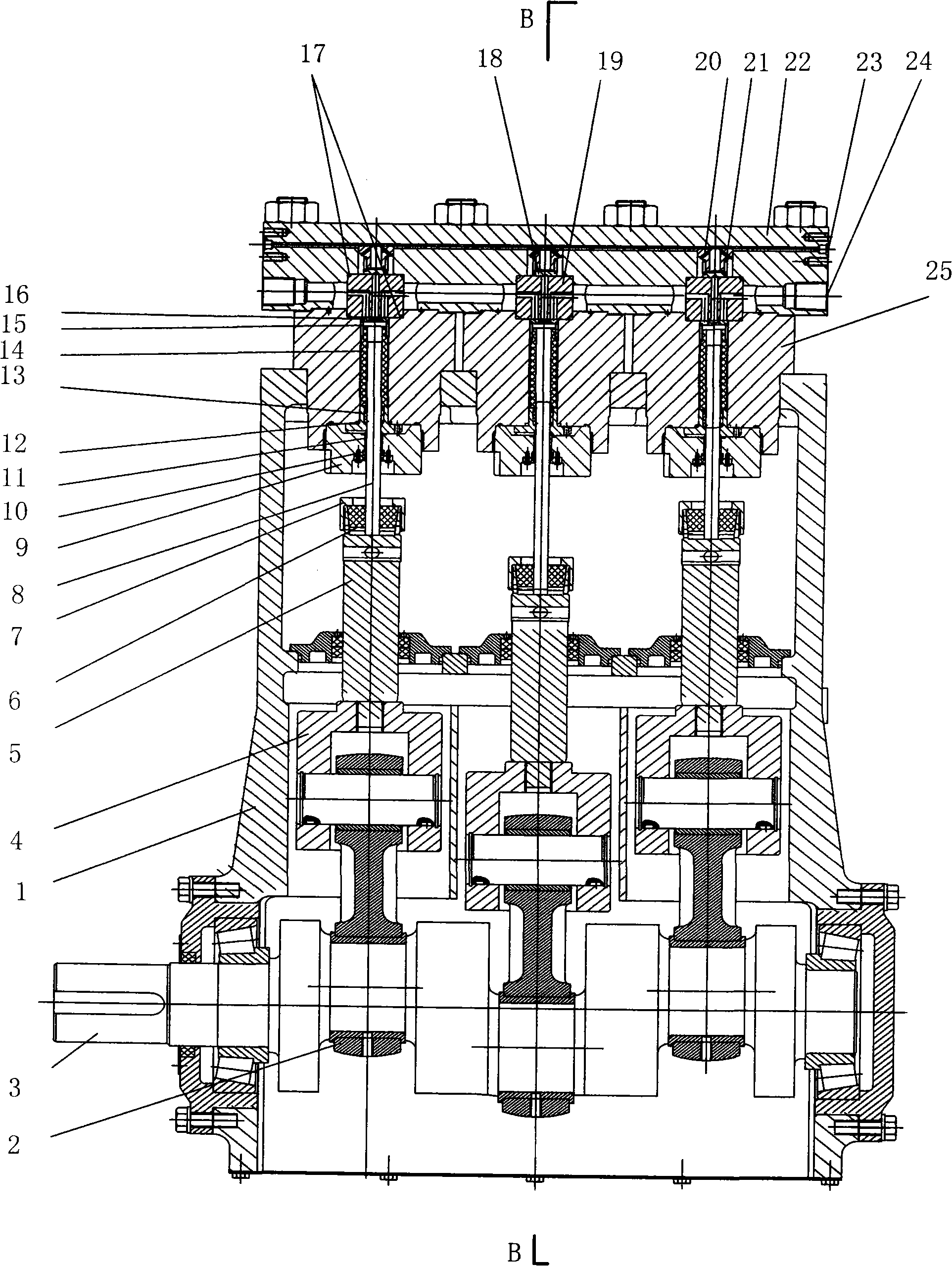

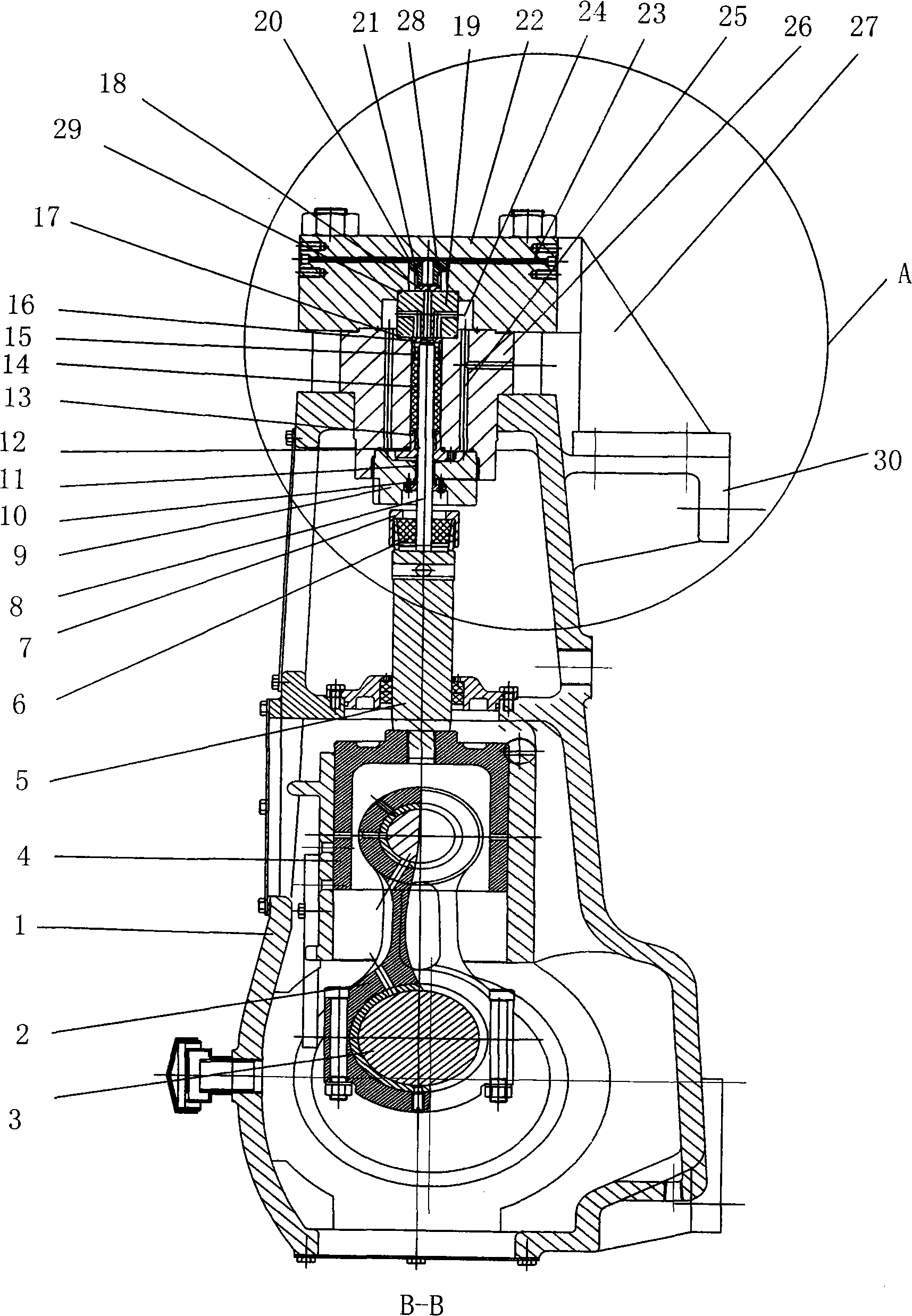

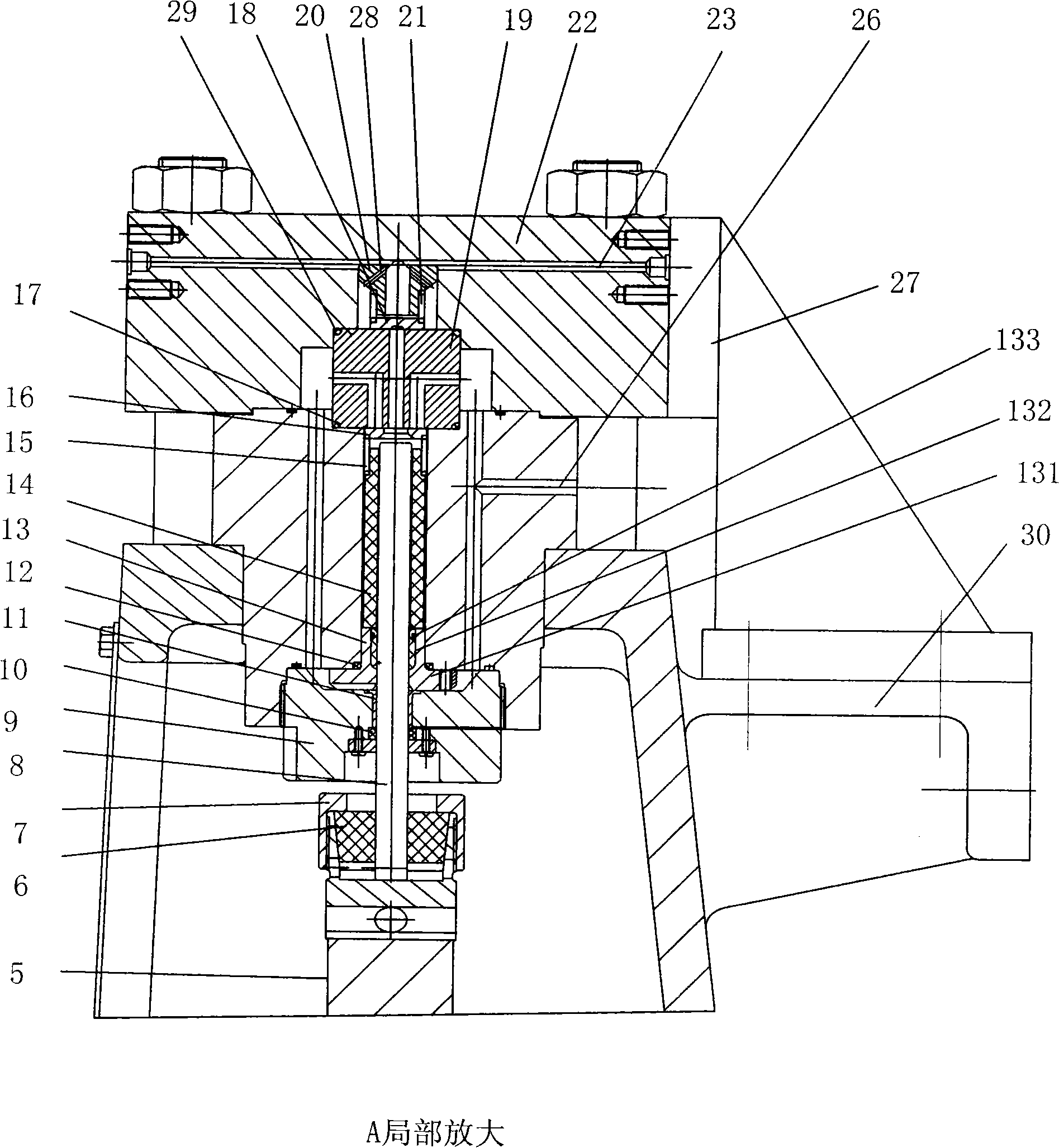

[0036] Such as figure 1 , 2, Shown in 3 and 4, an ultra-high pressure three-piston pump includes a fuselage 1, a crankshaft-connecting rod type power transmission device arranged in the fuselage and a hydraulic end generating high pressure. The crankshaft-link type power transmission device includes a crankshaft 3 , a connecting rod 2 , a crosshead 4 , an intermediate rod 5 , an elastic jacket 6 , and a pressure cap 7 . The hydraulic end includes a pump body 22, a pump cylinder 26, a plunger 8 and a sealing box 9; between the pump cylinder 26 and the pump body 22 there are also a pilot valve 20, a liquid discharge spring 21, and a discharge valve in sequence. 18, valve seat 19, suction valve 16, liquid inlet spring 15. The pump body 22 is provided with a low-pressure water inlet channel 24 and a high-pressure water outlet channel 23 . The pump cylinder 26 is provided with a cooling water channel 25 . A plunger sleeve 14 is arranged between the pump cylinder 26 and the plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com