A kind of aluminum, vanadium co-doped double-layer porous wall titanium alloy nanotube array visible light catalyst and its preparation method and application

A nanotube array, titanium alloy technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Complex preparation, low utilization of sunlight, etc., to achieve the effects of excellent visible light catalytic performance, rich pore structure, and independent tube wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

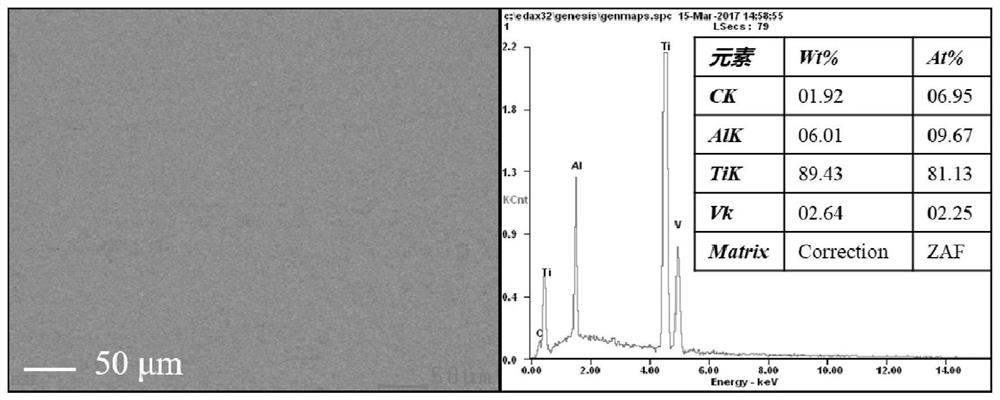

[0034] (1) Titanium alloy pretreatment: Process titanium alloy sheet TC4 into a sheet shape of 20 mm × 30 mm × 2 mm, put it into absolute ethanol and deionized water for 20 minutes, and dry at room temperature for 2 hours. The main chemical properties of the alloy titanium sheet TC4 used are: The composition is: Ti: 89.43%, Al: 6.01%, V: 2.64%, C: 1.92%.

[0035] (2) Electrochemical polishing: a two-electrode system is used, and the cathode is a pure titanium sheet (the effective area is 400mm 2 ), the anode is titanium alloy TC4, the area to be polished is 2×400mm 2, The distance between the two electrodes is 3cm, the electrolyte is NaCl in ethylene glycol solution, and the chloride ion concentration is 1mol / L. Polish at room temperature for 10 minutes under 30V DC constant voltage, put into absolute ethanol and deionized water for 20 minutes each, and dry at room temperature for 2 hours.

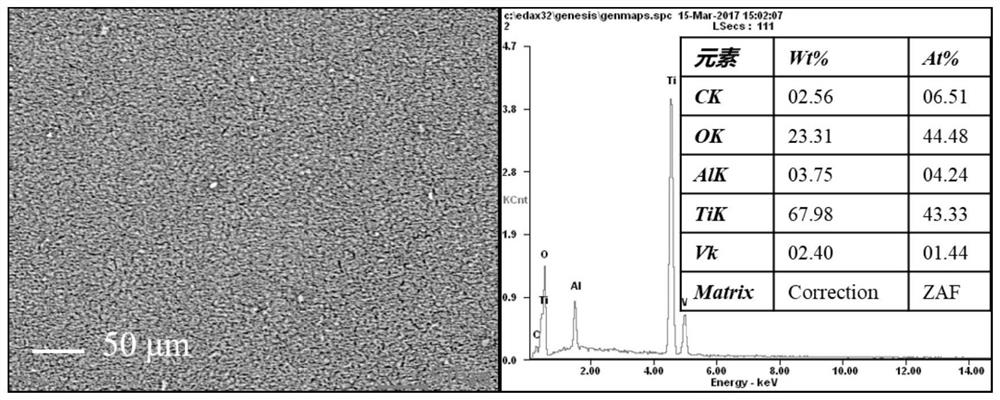

[0036] (3) Anodizing: Two-electrode system is used, the cathode is pure titanium she...

Embodiment 2

[0038] (1) Titanium alloy pretreatment: Process titanium alloy sheet TC4 into a sheet shape of 20 mm × 30 mm × 2 mm, put it into absolute ethanol and deionized water for 20 minutes, and dry at room temperature for 2 hours. The main chemical properties of the alloy titanium sheet TC4 used are: The composition is: Ti: 89.43%, Al: 6.01%, V: 2.64%, C: 1.92%.

[0039] (2) Electrochemical polishing: a two-electrode system is used, and the cathode is a pure titanium sheet (the effective area is 400mm 2 ), the anode is titanium alloy TC4, the area to be polished is 2×400mm 2 , The distance between the two electrodes is 3cm, the electrolyte is NaCl in ethylene glycol solution, and the chloride ion concentration is 1mol / L. Polish at room temperature for 10 minutes under 30V DC constant voltage, put into absolute ethanol and deionized water for 20 minutes each, and dry at room temperature for 2 hours.

[0040] (3) Anodizing: Two-electrode system is used, the cathode is pure titanium sh...

Embodiment 3

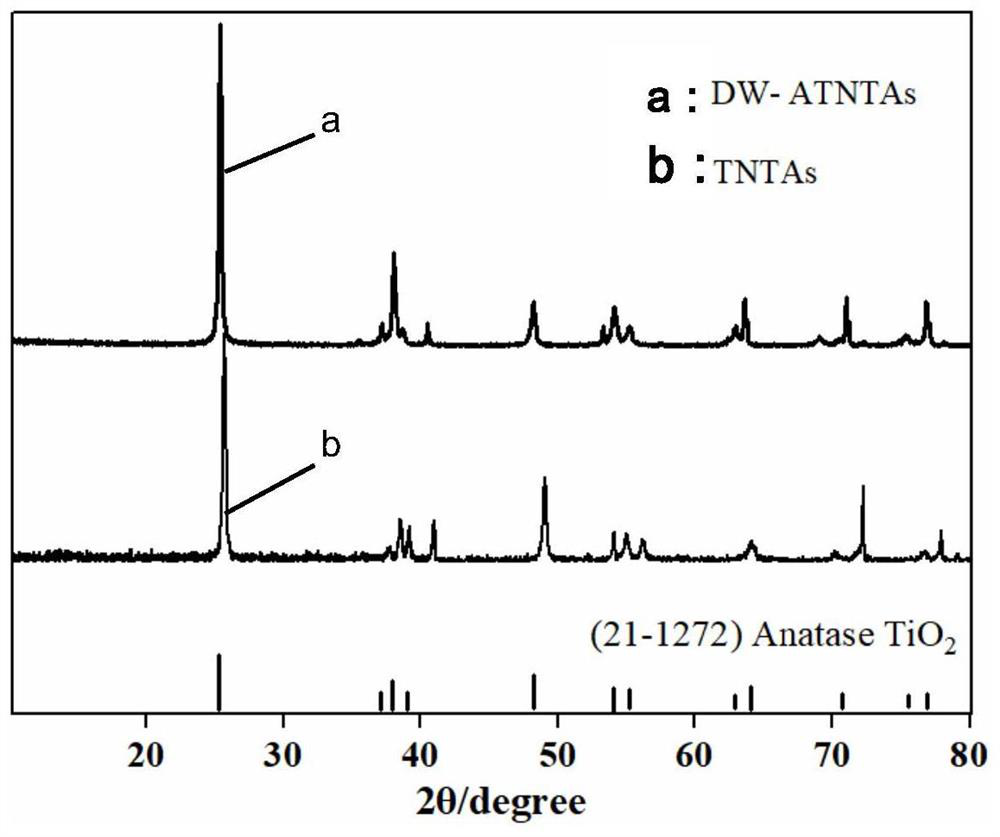

[0042] (1) Preparation of anatase aluminum and vanadium co-doped double-layer porous-walled titanium alloy nanotube arrays: the double-walled amorphous aluminum and vanadium co-doped titanium alloy nanotube arrays prepared in Example 1 were placed in a Calcined at 500°C for 2h in a Furnace, air atmosphere. The temperature rise program is firstly raised from room temperature to 250°C at a rate of 2°C / min, kept at 250°C for 30 minutes, raised to 500°C at a rate of 1°C / min, kept at a constant temperature for 2 hours, and finally dropped to room temperature at a rate of 3°C / min. Anatase aluminum and vanadium co-doped double-layer porous wall titanium alloy nanotube arrays were obtained, which were denoted as DW-ATNTAs.

[0043] (2) Preparation of anatase aluminum, vanadium co-doped single-layer porous-walled titanium alloy nanotube array: the single-walled amorphous aluminum-vanadium co-doped titanium alloy nanotube array prepared in Example 2 was placed in a Calcined at 500°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com