Swing type control valve

A control valve, swing-type technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of unsatisfactory stability and reliability, reduce electrical safety and reliability, increase driving burden, etc. Accurate accuracy and structural stability, reducing damage and leakage, improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

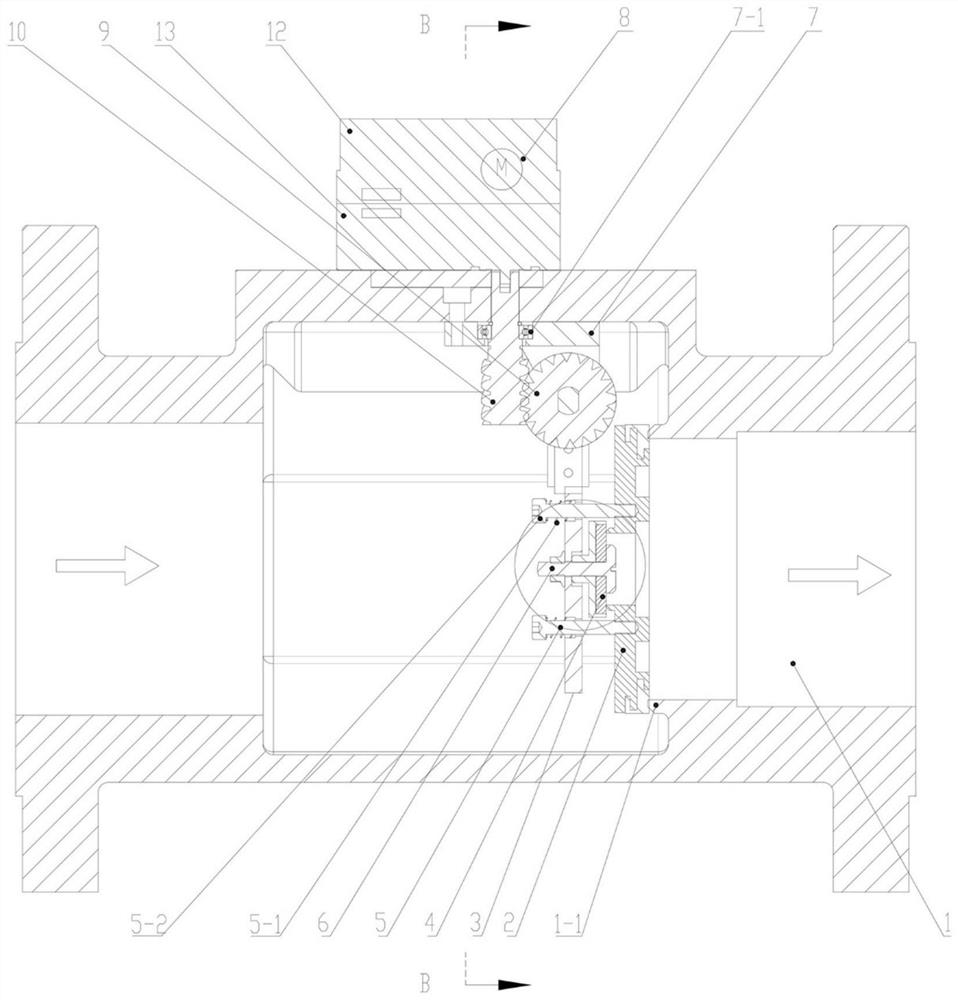

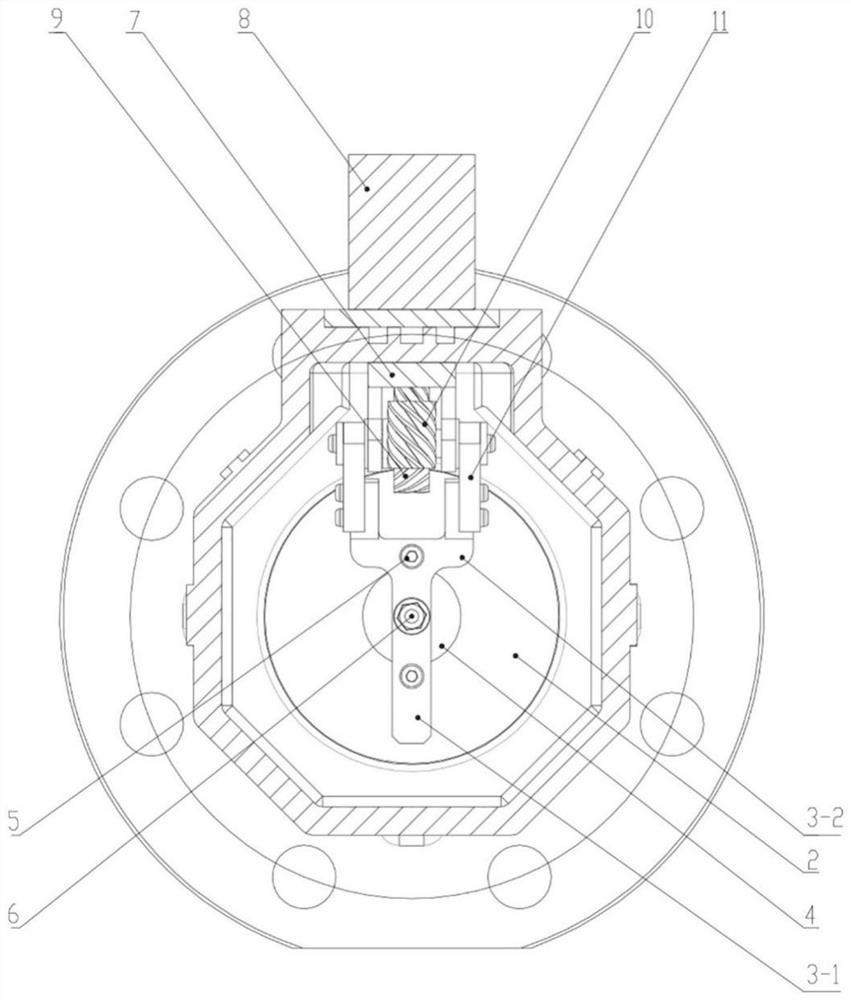

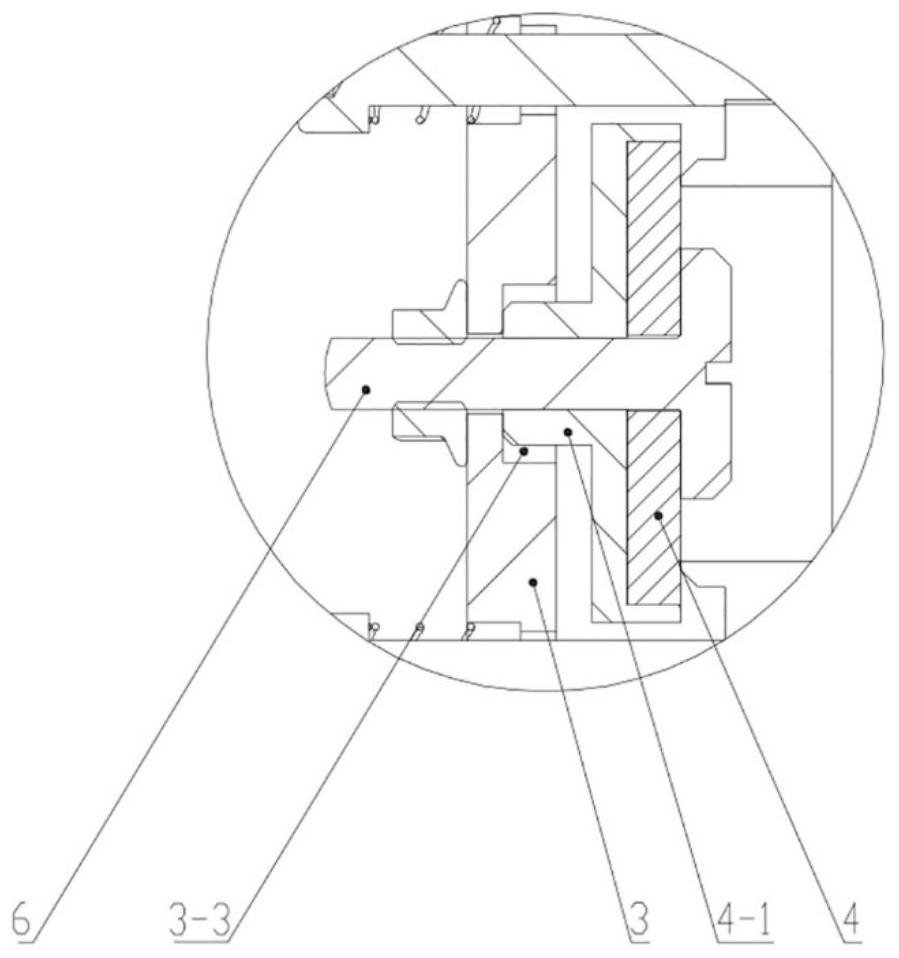

[0037] Such as Figure 1 to Figure 3 As shown, the present invention includes a valve body 1, and the valve body 1 includes an air inlet end, an installation cavity and an air outlet end successively connected from the air inlet end to the air outlet end, and also includes a driving mechanism 8, a swing reversing mechanism and a valve body sealing cover 2. The swing and reversing mechanism and the valve body sealing cover 2 are both set in the installation cavity, and the valve body sealing cover 2 is set at the gas outlet and matches the inner diameter of the gas outlet; the swing and reversing mechanism includes the swing bracket 7 and the deceleration steering The gear set, the deceleration steering gear set is arranged in the installation cavity through the swing bracket 7, the input shaft of the deceleration steering gear set is connected to the drive mechanism 8, the output shaft of the deceleration steering gear set is connected to the swing arm 3 through the link plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com