Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Avoid prolonged soaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Residue and juice separating device

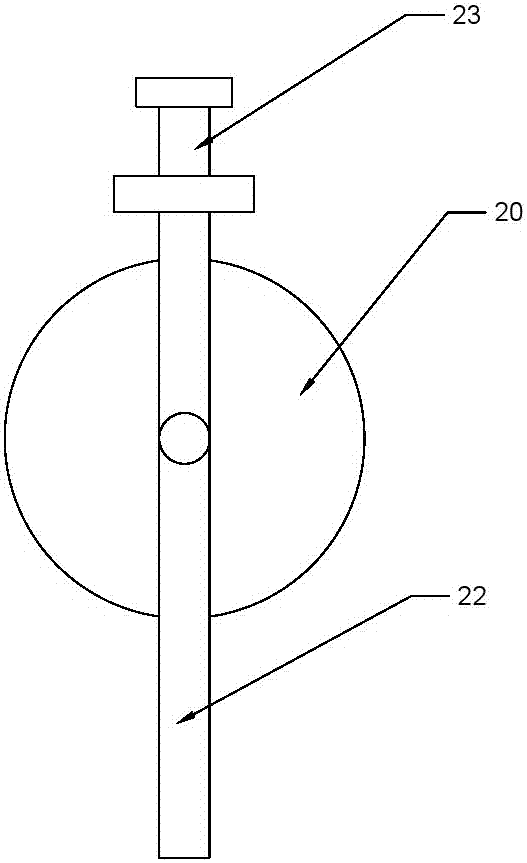

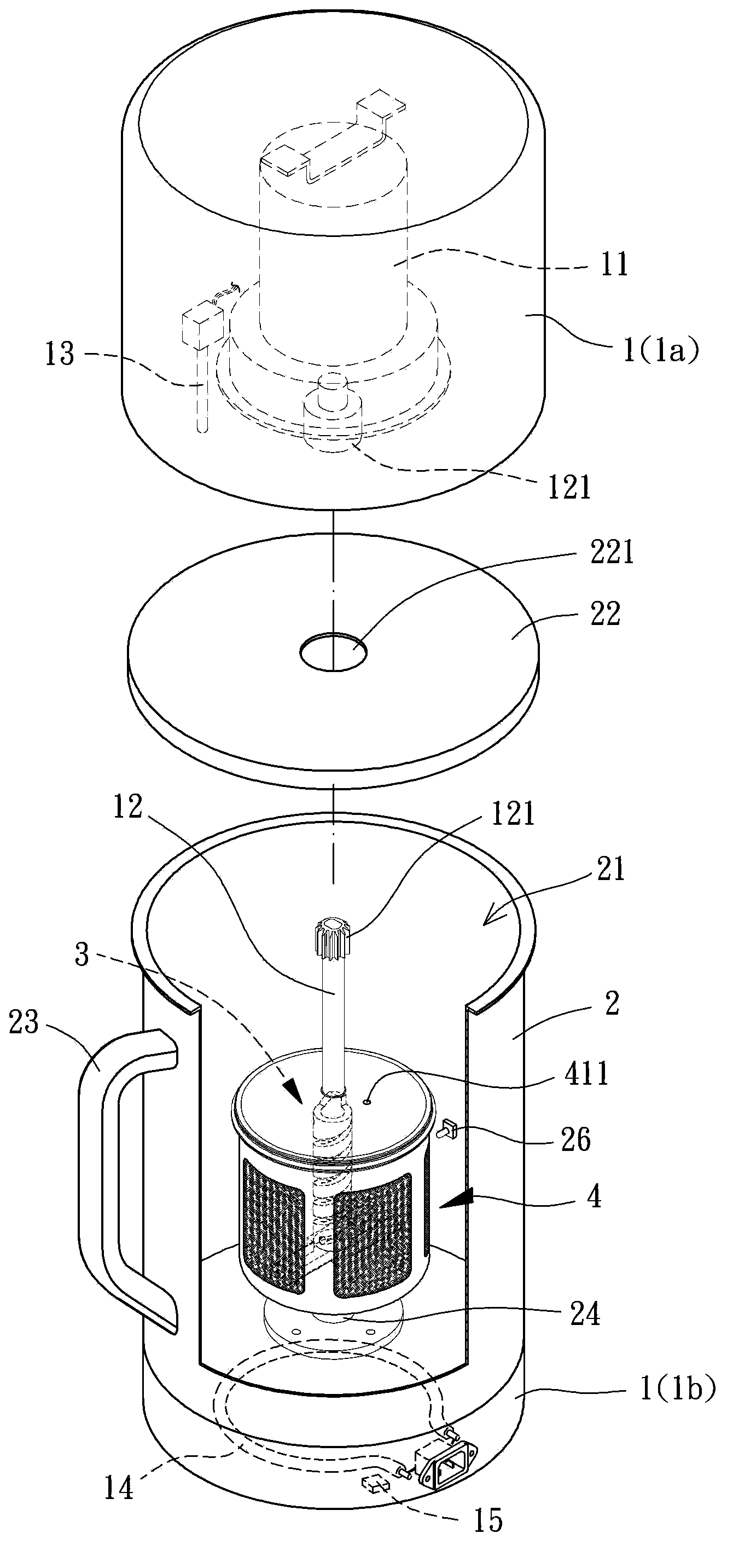

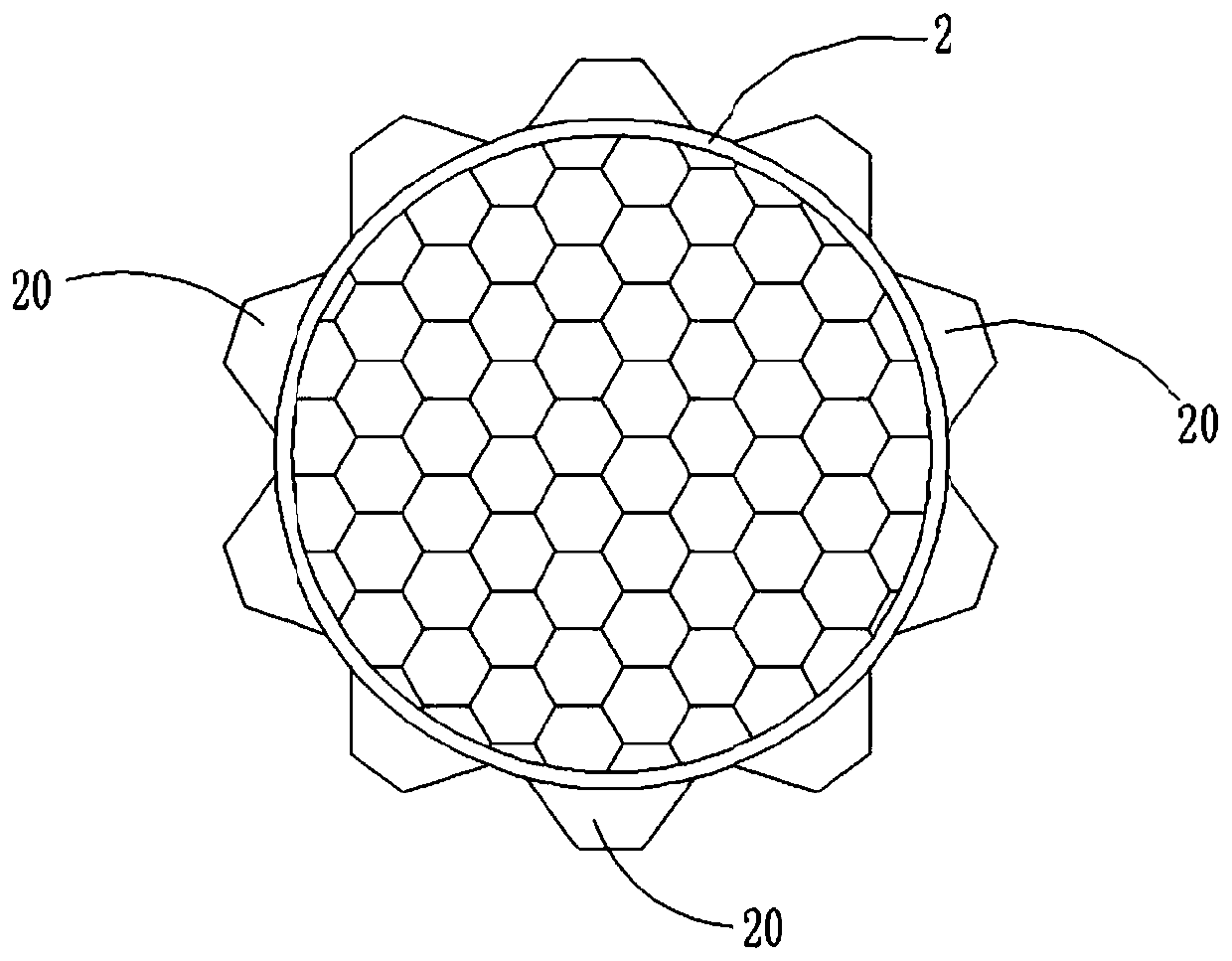

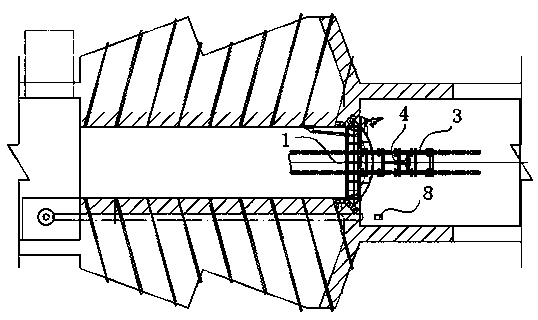

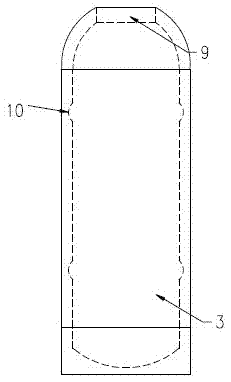

A residue and juice separating device can separate processing material from water to store, and the mixing, the smashing, the homogenizing and the following processing of the separated processing material and the water are operated by a booking way. The residue and juice separating device comprises an engine base, a container and a residue collecting component, wherein the engine base is provided with a power element which drives a rotating shaft to rotate, the rotating shaft is provided with a first screw thread part, the rotating shaft is provided with a sleeve, the sleeve can rotate in a synchronized mode with the rotating shaft and move axially relative to the rotating shaft, the outer wall of the sleeve is provided with a plurality of blades, the container is provided with an opening which is combined with the engine base, the processing material can be placed into the residue collecting component through an opening, the liquid can be oozed out of the residue collecting component, the residue collecting component is provided with a second screw thread part, and the second screw thread part can be in screw connection with the first screw thread part of the rotating shaft and can be separated from the upper end and the bottom end of the first screw thread part.

Owner:陈建荣

Sampling type sewage monitoring and analyzing system and method

InactiveCN107132324AExtended service lifeReduce contact timeTransmission systemsWithdrawing sample devicesHigh concentrationMicrocomputer

The invention belongs to the field of sewage monitoring, aims to solve the technical problem that an existing monitor is corroded by high-concentration sewage when the monitor monitors a sewage discharge outlet, and the service life of the monitor is severely affected, and particularly discloses a sampling type sewage monitoring and analyzing system. The sampling type sewage monitoring and analyzing system comprises a monitor, a single-chip microcomputer, a GPRS module and a sewage sampling system, wherein the monitor comprises a pH sensor, a COD detecting terminal and a heavy metal concentration detection sensor; the single-chip microcomputer is connected with the pH sensor, the COD detecting terminal and the heavy metal concentration detection sensor and used for receiving the monitoring signals of the pH sensor, the COD detecting terminal and the heavy metal concentration detection sensor; the GPRS module is connected with the single-chip microcomputer and used for transmitting the monitoring signals and receiving the control signal of the single-chip microcomputer. The invention further discloses a sampling type sewage monitoring and analyzing method.

Owner:CHONGQING UNIV OF ARTS & SCI

Feeding habit domesticating device and method for carnivorous fish

ActiveCN105594646ALow input costTo achieve the purpose of domesticationClimate change adaptationPisciculture and aquariaFish oilFishery

The invention relates to the field of fish breeding, and mainly relates to a feeding habit domesticating device and method for carnivorous fish. The feeding habit domesticating device comprises an aeration device, a fish oil feeding device, and a bait containing component disposed in water, and outlets of both the aeration device and the fish oil feeding device are communicated with the bottom of the bait containing component. When the feeding habit domesticating device is in use, the bait containing device containing bait is put in water, and normally formula feed cheaper than living bait is selected as the bait; airflow is pumped into the bait containing component from the bottom thereof through the aeration device, then the bait positioned inside the bait containing component is raised with the airflow to be in the status of vertical floating motion, at the same time, fish oil with strong fishlike smell is fed into the bait containing component from an air inlet through the fish oil feeding device to be evenly fixed with the bait so as to further make fish take the fed bait for swimming live fish, and the fish are promoted to eat the non-living bait so as to achieve the purpose of feeding habit domesticating.

Owner:安徽长江渔歌渔业股份有限公司

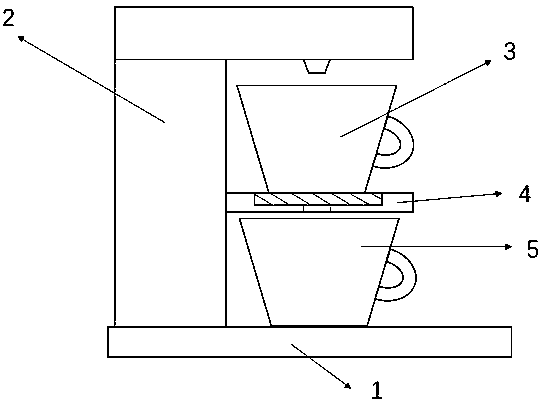

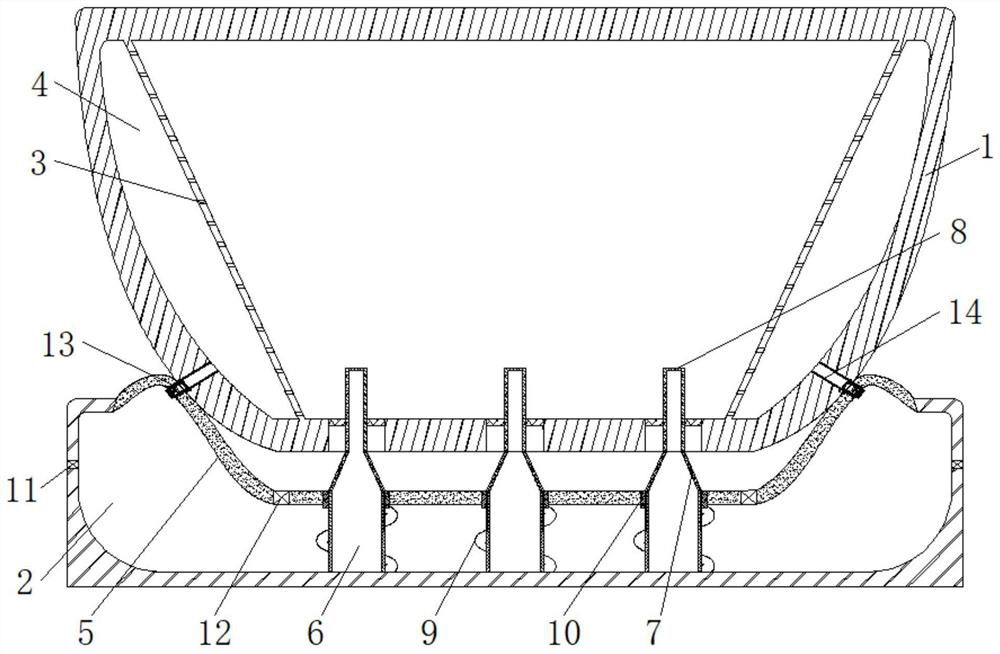

Intelligent tea drinking machine

The invention relates to the field of intelligent home, and particularly relates to an intelligent tea drinking machine. The intelligent tea drinking machine comprises a control base, a heating waterinjection device, a tea brewing cup, a tea filtering plate and a tea filtering cup, wherein the control base and the heating water injection device are connected into a whole; an instant heater and awater pump in the heating water injection device are controlled through selecting press keys on the base by a user; after being heated to a specific temperature, the water is injected into the tea brewing cup; after brewing for a certain time, through holes on the tea filtering plate are automatically opened to realize tea slag filtering; the tea water flows to the tea filtering cup; the control base carries the tea filtering cup and has a heat insulation function for a certain time. According to the invention, the brewing temperature and the brewing time can be automatically set by program according to different types of the tea; the best brewing scheme of green tea, black tea, oolong tea (light oolong), white tea, yellow tea and dark green tea is realized; the requirements of a drinker on the mouthfeel and the nutrition can be met to the maximum degree.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Residue and juice separating device

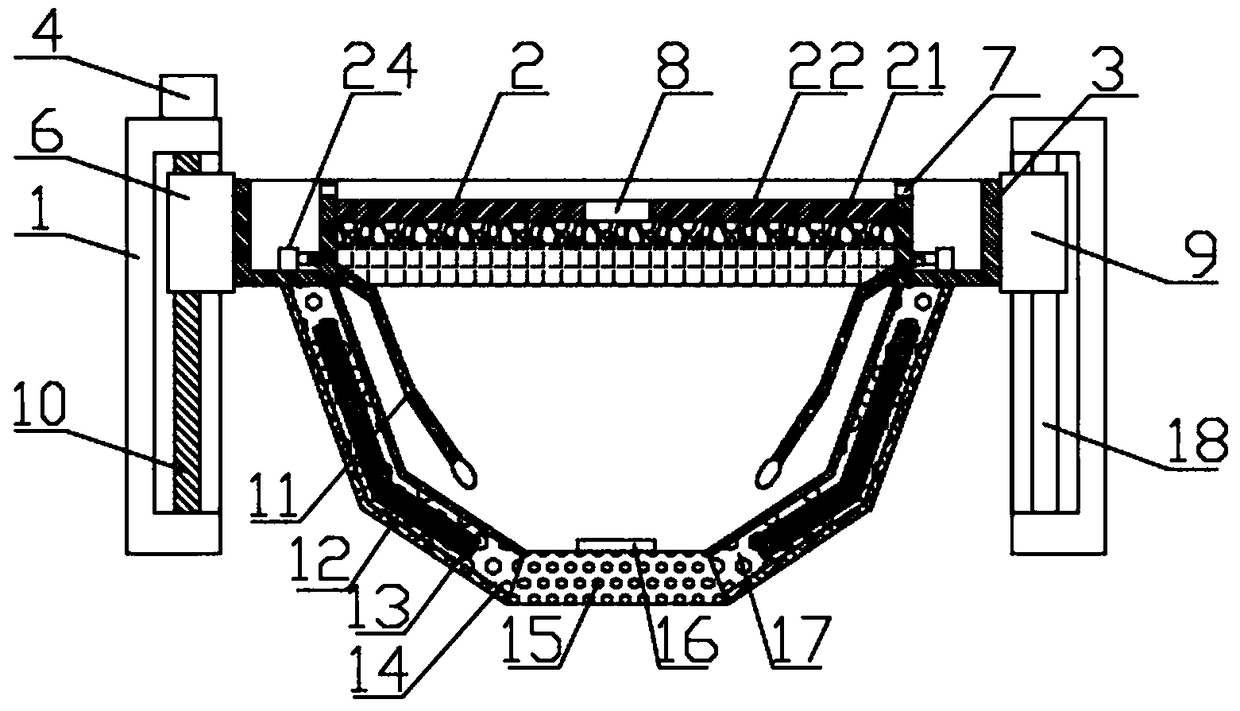

InactiveCN103976631AEasy to be cleanedAvoid prolonged soakingBeverage vesselsStrainersPower componentPulp and paper industry

A residue and juice separating device can separate processing material from water to store, and the mixing, the smashing, the homogenizing and the following processing of the separated processing material and the water are operated by a booking way. The residue and juice separating device comprises an engine base, a container, a cutter group and a residue collecting component, wherein the engine base is provided with a power component which drives a rotating shaft to rotate, the rotating shaft is provided with a pin piece, the pin piece protrudes at least one surface of the rotating shaft, the container is provided with an opening which is combined with the engine base, the cutter group sleeves the rotating shaft through a guiding piece, the guiding piece is provided with at least one guiding groove, the pin piece arranged on the rotating shaft penetrates through the guiding groove, so that the cutter group can rotate relative to the rotating shaft and move axially, the cutter group is provided with at least one blade part, the blade part is connected with the guiding piece, the processing material can be placed into the residue collecting component through an opening, the liquid can be oozed out of the residue collecting component, the residue collecting component is arranged on the rotating shaft in a penetrating mode, the cutter group can be contained in the residue collecting component, and a cover is used for sealing the opening.

Owner:陈建荣

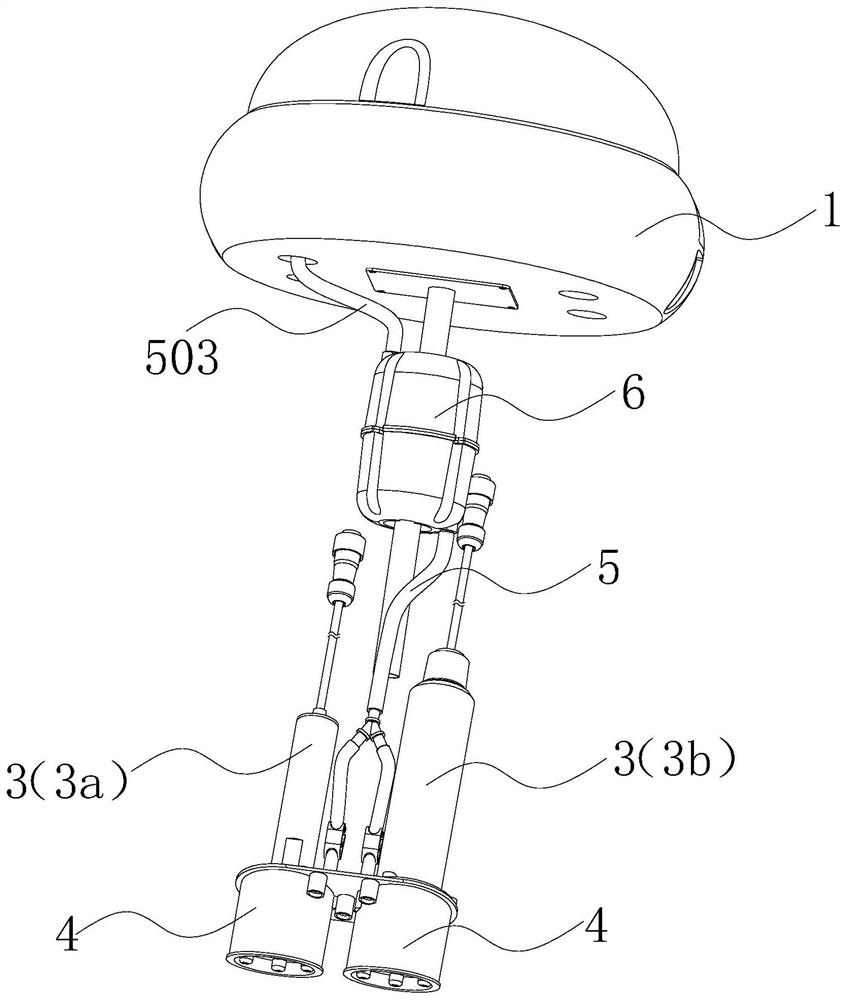

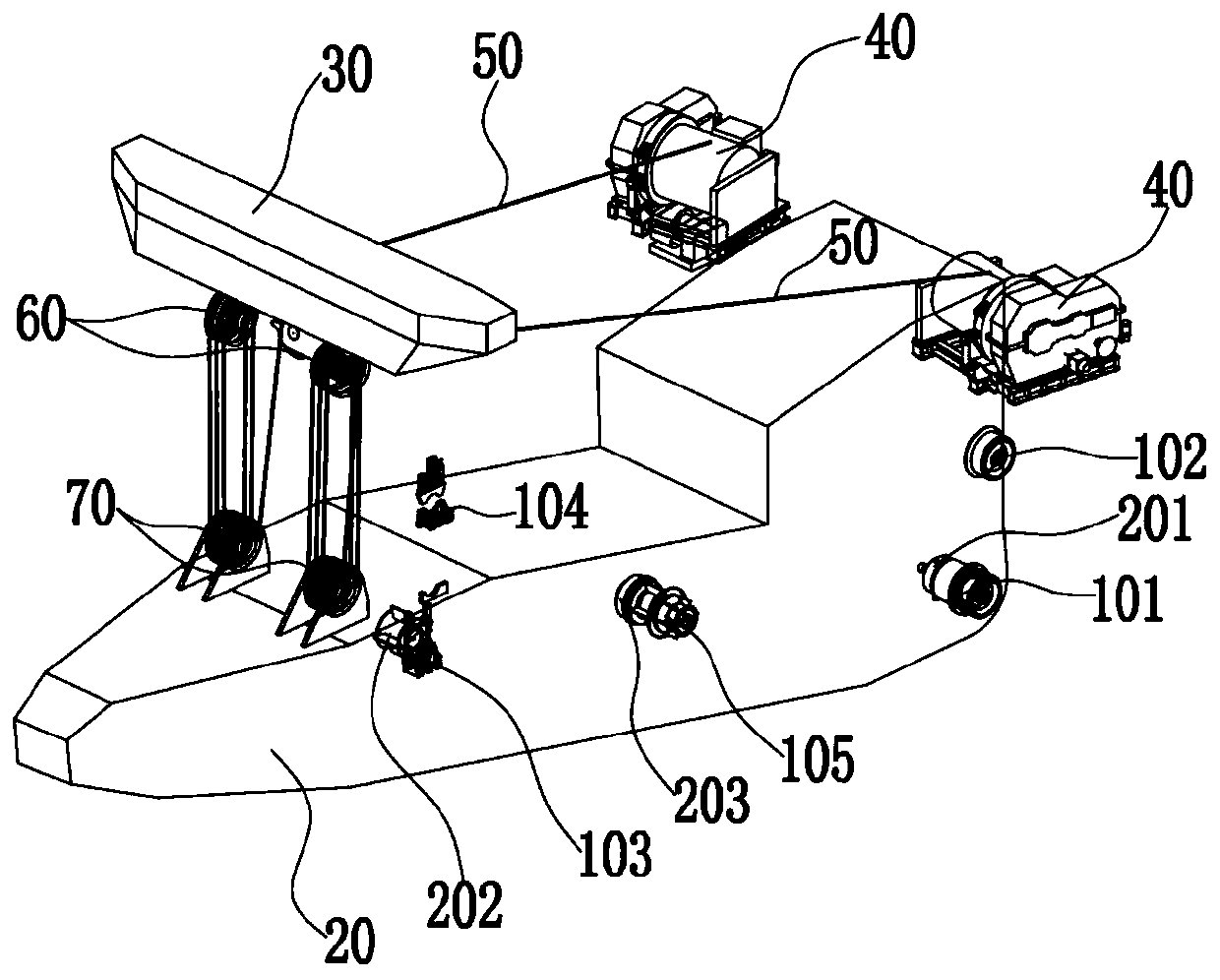

Marine culture environment unmanned information collection system and method

PendingCN108445883AAvoid prolonged soakingExtended service lifeMeasurement devicesPropulsion power plantsCollection systemCLOUD experiment

The present invention discloses a marine culture environment unmanned information collection system and method, concretely relates to the technical field of marine culture environment monitoring. Thesystem comprises a collection terminal, a cloud and a client. The collection terminal comprises a ship body, the ship body is provided with a signal receiving device (comprising a GPS antenna and an information transmission module antenna), two sides of the ship body are respectively arranged at floating devices, the upper surface of the ship body is provided with a motor, a solar receiving deviceand a wind speed sensor, an anti-collision ultrasonic wave module is arranged at the front section of the ship body, the center of the ship body is provided with a device compartment, a sensor compartment and a discharge compartment, the rail portion of the ship body is provided with a propulsion device, the device compartment is internally provided with a plurality of electronic devices, the sensor compartment is provided with a foldable baffle plate, the sensor compartment is internally provided with a folding rack and a sensor module, and the folding rack drives the stretching of the sensor module under the drive of the motor.

Owner:QINGDAO HUANGHAI UNIV

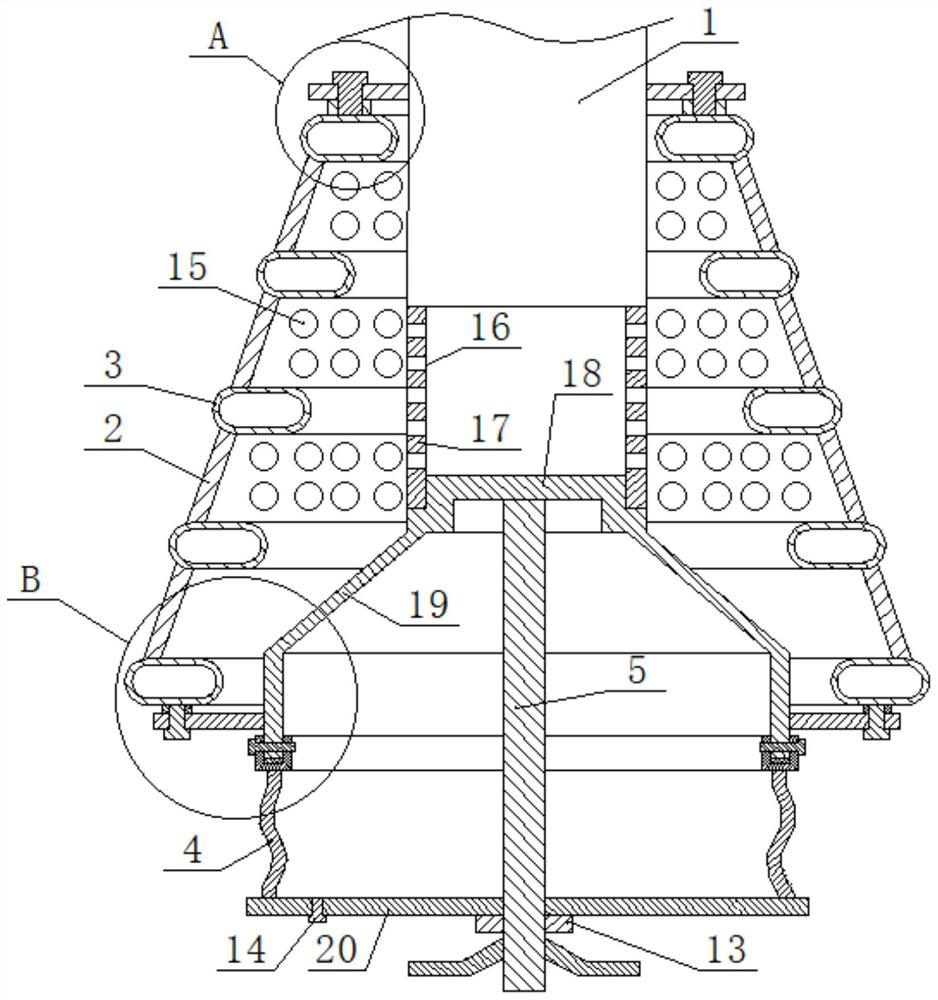

Recovery protection device of an unmanned boat

The invention discloses a recovery protection device of an unmanned boat, including docks, the dock is provided with a liftable tire frame, floating bodies, control boards and sensors, a float body isuniformly arranged below the tire frame, a supply pump and a pumping pump are respectively arrange on that floating body, a supply pump and a pumping pump are uniformly connected with a control circuit board, the control circuit board is connected with the sensor, the control circuit board controls the work of the water supply pump and the pump through the transmission data of the sensor, the floating body is lifted and moved by the water supply pump and the pump, a finite position column is arranged between the dock and the jig frame, and the jig frame is lifted and moved along the limit column through the floating body. The invention ensures that the whole tire frame and the boat leave the water surface through the buoyancy of the floating body, thereby avoiding the boat from being immersed in the sea water for a long time, avoiding the possibility that the boat is easy to grow marine organisms and causes the speed of the boat to be reduced. The invention has the advantages of simple structure, low cost, convenient use, charging and sailing for the ship, intelligent control, energy saving and environmental protection.

Owner:SHENZHEN HISPEED BOATS TECH +2

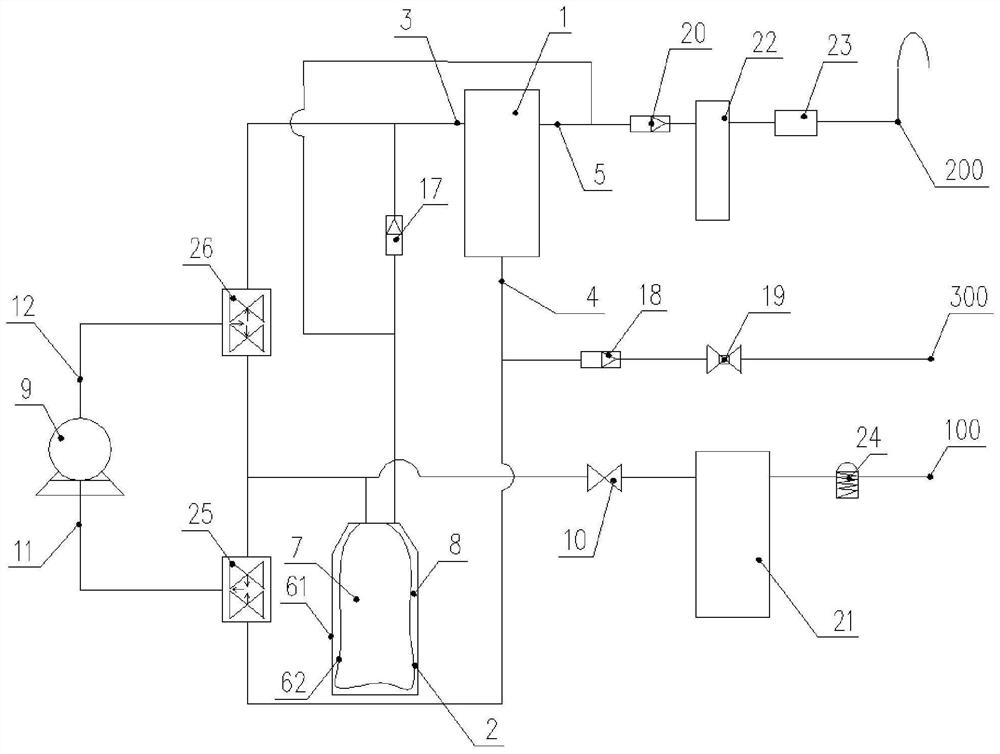

pH value online detecting device and control method and calibration pre-judging method thereof

ActiveCN109856220AAvoid prolonged soakingExtend your lifeChemical analysis using titrationMaterial electrochemical variablesTitrationControl unit

The invention discloses a pH value online detecting device and a control method and a calibration pre-judging method thereof. The device comprises a detecting tank, a cleaning tank, a maintenance tank, a control unit, a lifting and horizontal moving device, a pH measuring electrode and a pH display analyzing instrument. The detecting tank, the cleaning tank and the maintenance tank are arranged side by side under the lifting and horizontal moving device. The pH measuring electrode is fixed to the lifting and horizontal moving device. The control unit controls the movement of the lifting and horizontal moving device, thereby driving the pH measuring electrode to perform lifting and horizontal moving movement to be immersed or removed from the detecting tank, the cleaning tank and the maintenance tank. The pH value online detecting device realizes high-speed and accurate switching of the detection, cleaning and maintenance functions through the lifting and horizontal moving device, prolongs the life of the electrode, and ensures the sensitivity of the electrode. In addition, the pH value online detecting device solves the problem of when a pH meter is calibrated through a continuousstandard titration method, thereby optimizing a calibration period of the pH meter, reducing the labor cost, and finally realizing online high-precision detection of the pH value of a solution.

Owner:CENT SOUTH UNIV

Automatic cleaning device for aquatic product sensor

PendingCN113624932AExtend cleaning and maintenance intervalsAvoid prolonged soakingPreparing sample for investigationTesting waterAquatic productWater quality

The invention provides an automatic cleaning device for an aquatic product sensor. The device comprises a floating body; an inflation / deflation member mounted on the floating body; at least one water quality sensor connected with the floating body; and closed containers arranged on the peripheries of the water quality sensor probes in a sleeving mode, wherein flushing holes opposite to the water quality sensor probes are formed in the closed containers, and the closed containers are communicated with the inflation / deflation member through pipelines, wherein the inflation / deflation member is used for inflating or deflating the closed containers, so that water in the closed containers is discharged, or external water enters the closed containers through the flushing holes to clean the water quality sensor probes. The device has the beneficial effects that the air pressure in the airflow pipeline and the closed containers is changed through the inflation / deflation member, so that isolation protection can be formed on the sensor probes, and the adhesion and failure rate are reduced; and the water quality sensor probes can be cleaned, the detection precision is ensured, the cleaning effect is good, and the cleaning and maintenance period of the aquatic product sensor in different aquaculture water bodies is prolonged.

Owner:荆州中易物联科技有限公司

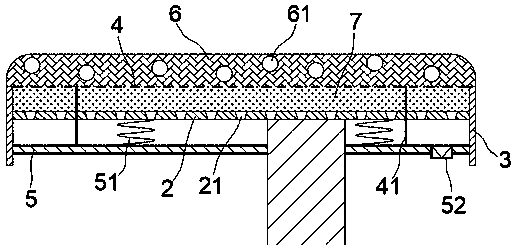

Waterproof vehicle seat

The invention relates to a waterproof vehicle seat which comprises a connecting column, a support plate and an enclosing edge. An upper part of the support plate is provided with a squeeze plate, anda lower part of the support plate is provided with a flow guide plate. The squeeze plate and the air guide plate are connected through a connecting rod passing through the support plate; the support plate and the air guide plate are connected through a reset tension spring; a comfortable layer made of soft material is filled between the decorative layer and the extrusion plate; a water absorbing layer made of an elastic water absorbing material is arranged between the extrusion plate and the support plate; the squeeze plate is made of a perforated plate, and unidirectional flow guiding holes allowing only downward flow of rainwater are equidistantly arranged on the support plate; a drain valve allowing only rainwater to be discharged is arranged on the air guide plate; the invention has novel structure and unique principle, effectively removes the accumulated rainwater in the vehicle seat under the premise of ensuring the comfort of the vehicle seat, effectively prevents the vehicle seat from aging, weakens the internal mildew breeding, and prolongs the service life of the vehicle seat.

Owner:WENLING DONGFANGHONG CYCLE PARTS

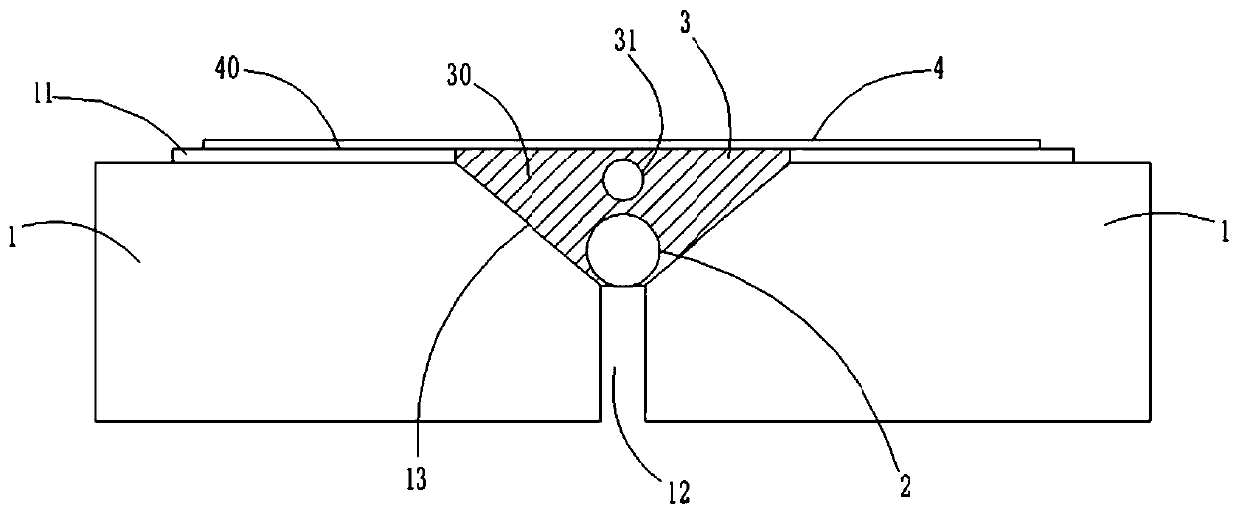

Concrete panel joint surface flexible water stopping anti-icing structure and mounting method

InactiveCN111455937AStrong bondGood compression performanceEarth-fill damsRock-fill damsJoint surfaceGeotechnical engineering

The invention discloses a concrete panel joint surface flexible water stopping anti-icing structure. The concrete panel joint surface flexible water stopping anti-icing structure comprises concrete panels, an elastic supporting piece, a compressible plastic caulking material and flexible anti-seepage coatings; the two adjacent concrete panels form a V-shaped groove; the elastic supporting piece isclamped at the bottom of the V-shaped groove; the compressible plastic caulking material is embedded in the V-shaped groove; and the flexible anti-seepage coatings are arranged on the two adjacent concrete panels. A mounting method of the concrete panel joint surface flexible water stopping anti-icing structure comprises the steps of polishing the upper surfaces of the concrete panels to expose coarse aggregates, clamping the elastic supporting piece in the V-shaped groove, putting the compressible plastic caulking material into the V-shaped groove in a layered manner, coating an interface agent to the upper surfaces of the adjacent concrete panels, and laying the flexible anti-seepage coatings. The concrete panel joint surface flexible water stopping anti-icing structure has the advantages that the construction is good, the anti-seepage capability is good, the durability is high, and the concrete panel joint surface flexible water stopping anti-icing structure is suitable for new projects in severe cold areas.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

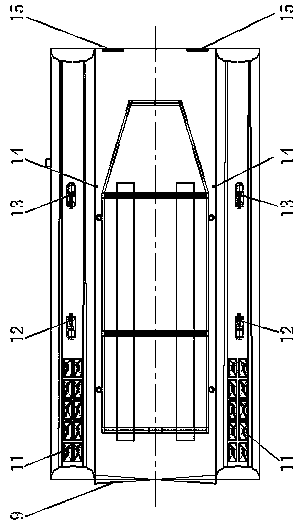

Mine-used intelligent watertight gate

The invention discloses a mine-used intelligent watertight gate comprising a watertight gate body, a gate operation driving cylinder, a self-dismounting rail, a digital water level alarm and a control panel. The watertight gate body is arranged at an access and is connected with the access through the gate operation driving cylinder. The digital water level alarm is arranged in water area on the outer side of the watertight gate body and is communicated with the control panel. The self-dismounting rail is arranged below the watertight gate body and is connected with a front route rail through clamping blocks, is hinged with a back route rail through lapping blocks, and is connected with a multi-connecting rod mechanism. A rail driving cylinder is arranged on the multi-connecting rod mechanism. The mine-used intelligent watertight gate has the advantages of reducing basic excavated volume and preventing the driving cylinder from immersing in water for a long time, is convenient to mount, operate and maintain, and has high practicability.

Owner:YANGZHOU LONGXIN MACHINERY

Intelligent electric cooker

InactiveCN106821014AAvoid prolonged soakingAvoid mixingCooking-vessel lids/coversVessels with intergral heatingWater sourceFood material

An intelligent electric cooker comprises a cooker cover, an inner container and a control unit, wherein an accommodating box is embedded into the cooker cover, and the control unit controls opening and closing of the accommodating box when preset conditions are met. The cooker cover is provided with a water injection hole communicated with an external water source and the inner container, and the control unit controls opening and closing of the water injection hole when the preset conditions are met. When preset time is met, water is injected through the water injection hole, long-time soaking of water and rice or other food materials can be prevented, the food materials are put into the inner container when the preset time is met, long-time mixing of the food materials can be prevented, and the taste of foods is ensured.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

Dredger

InactiveCN110835934AEasy maintenanceEasy to operateMechanical machines/dredgersStructural engineeringMechanical engineering

The invention relates to the technical field of ship engineering and discloses a dredger. When the dredger is in the working state, main trunnions are mounted on a first low-position trunnion seat anda first high-position trunnion seat correspondingly, so that the minimum and maximum excavation requirements can be met, and switching between the first low-position trunnion seat and the first high-position trunnion seat can also be carried out according to the operation condition, so that the height of the rotation point of a bridge frame is changed, and the work requirements of different digging depths can be met on the same dredger; in the non-working state such as long-time shutdown or dispatching, locking trunnions on the two sides of the front portion of the bridge frame are mounted ina second low-position trunnion seat or a second high-position trunnion seat, and the connection between the front portion of the bridge frame and a ship body is realized; due to the fact that both the main trunnions and the locking trunnions have the selection of two height positions of the low-position trunnion seat and the high-position trunnion seat, maintenance and overhaul operations of thedredger are facilitated; and meanwhile, the requirements of the heavy bridge frame can be met through mutual cooperation of the trunnions and the trunnion seats, and the adaptability of the dredger ishigh.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Cabbage mustard soilless culture method

InactiveCN106942033AGuaranteed normal growthCrunchy and sweetAgriculture gas emission reductionCultivating equipmentsNormal growthTetrarrhena juncea

The invention discloses a cabbage mustard soilless culture method. The cabbage mustard soilless culture method comprises the steps of seedling culture, preparation of culture equipment, preparation of a culture medium, transplanting, pest control and other management. The cabbage mustard soilless culture method realizes planting of cabbage mustard on water, water cultivation is added in the mode that hygrophilous and waterlogging-intolerant vegetable is planted in soil and nutrient solutions, cultivation water is fully utilized, the root of cabbage mustard is prevented from being soaked in water for a long time, accordingly, root rotting is avoided, and normal growth of cabbage mustard is guaranteed. Cabbage mustard cultivated by the cabbage mustard soilless culture method is crisp and sweet in taste and pollution-free and belongs to truly healthy green vegetable.

Owner:汉寿县龙阳镇华诚蔬菜专业合作社

Device applied to assisting in treating oral inflammation of geckos

InactiveCN104094893AEasy to openEasy accessVeterinary instrumentsAnimal husbandryMedicineTherapeutic effect

The invention discloses a device applied to assisting in treating oral inflammation of geckos. The device comprises a shell, a first barrier, a second barrier, a medicine supply box, at least one atomizing nozzle, a miniature self-priming water pump, a first driving device and at least one biting nozzle. An elongated groove is formed in the shell and is provided with two end walls which are lower than the side walls of the groove; the first barrier and the second barrier are respectively pivotally connected to the upper edges of the two end walls of the groove, and a first through hole is formed in the first barrier; the medicine supply box is arranged right above an opening of the groove, is connected to the shell by connecting pieces and comprises a first medicine supply cavity and a second medicine supply cavity, and the first medicine supply cavity and the second medicine supply cavity are at least longitudinally combined with each other; the atomizing nozzles penetrate the bottom of the medicine supply box and is communicated with the inside of the first medicine supply cavity via a hose; the miniature self-priming water pump and the first driving device are arranged in the first medicine supply cavity; each biting nozzle is arranged at the tail end of a pipeline which extends out of the second medicine supply cavity. The device has the advantages that the device is simple in structure and convenient to operate, the geckos can actively cooperate during treatment in a trapping mode, and accordingly the treatment efficiency and treatment effects can be improved.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Food supporting box capable of permeating and isolating through film small holes

PendingCN113264272APrevent outflowAvoid blottingRigid containersExternal fittingsWater storageUltrasonic welding

The invention discloses a food supporting box capable of permeating and isolating through film small holes. The food supporting box comprises a box body, wherein a bloody water collecting groove is formed in the bottom of the box body; a punched water absorption pad is arranged to seal a groove opening of the bloody water collecting groove; the punched water absorption pad is of a multi-layer structure; the upper layer of the punched water absorption pad is a waterproof punched film, and the lower layer is a water absorption material layer; and the waterproof punched film and the water absorbing material layer are compounded together one above the other. The food supporting box realizes isolation of bloody water and food, and is large in the water storage space at the bottom of the supporting box; and the punched water absorption pad is fixed through ultrasonic welding, and cannot turn over during transportation, so that the bloody water can be effectively prevented from overflowing and is prevented from making direct contact with meat products and other food, long-term soaking is prevented, and the shelf life of the meat products and other food can be prolonged.

Owner:OTOR TECHNOLOGY CO LTD

Method for planting water spinach in mountain areas and forest areas

InactiveCN106258362AIncrease humidityImprove qualityPlant cultivationCultivating equipmentsTerrainNormal growth

The invention discloses a method for planting water spinach in mountain areas and forest areas. The method comprises the following steps: 1) soil preparation and orchard establishment: establishing a low-lying planting orchard at a mountainous tall arbor forest area at the tree density of less than one tree per 5m; 2) seed soaking and germination accelerating; 3) sowing; 4) field management; 5) pest control and prevention; 6) harvesting. The planting orchard is established in the mountainous forest area, so that the amount of chemical fertilizers molten into soil is low, and the wildness of the water spinach is ensured; meanwhile, the wetness of the soil in the orchard is increased, the water demand of the water spinach is met, and the soil fertility is relatively high through deposition of fallen leaves throughout the year; the natural fertilizers of the fallen leaves and the like do not contain any harmful chemical component, so that the wildness property of the water spinach is not lowered while normal growth of the water spinach is ensured; the water spinach planted in the orchard has higher quality and pure mouthfeel, and is environmentally friendly.

Owner:文县科学技术局

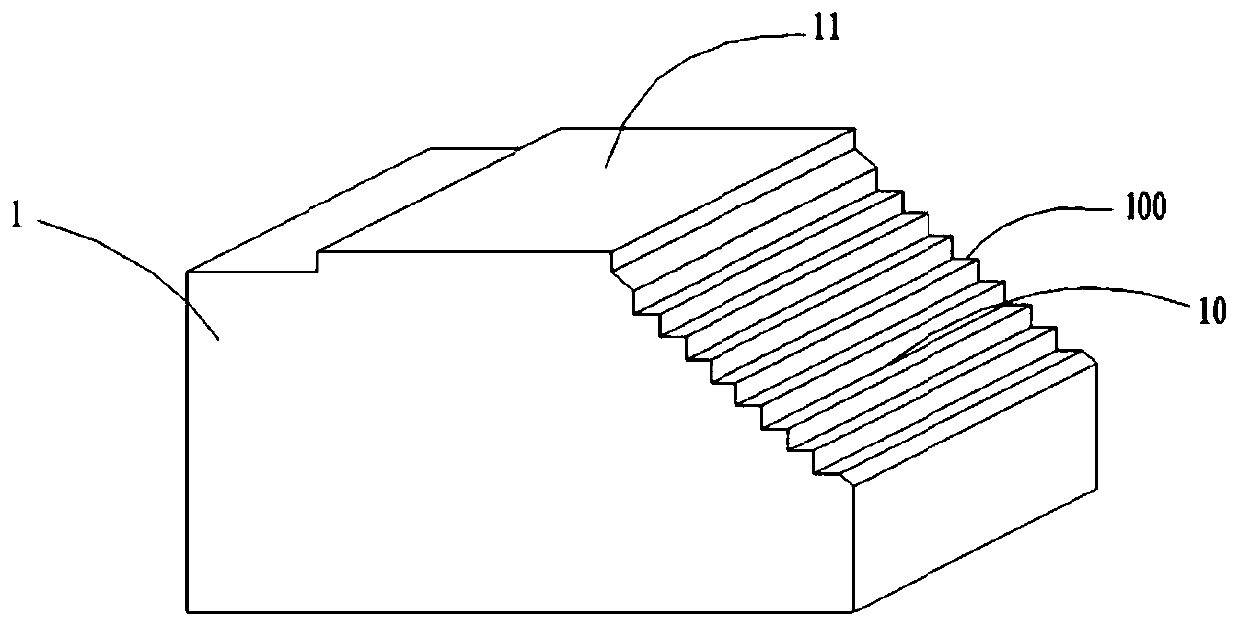

Filter assembly with membrane capable of being soaked with pure water

InactiveCN110776062ASolve penetrationAvoid prolonged soakingSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisWater rinsingWater flow

The invention discloses a filter assembly with a membrane capable of being soaked with pure water. The filter assembly comprises a membrane soaking tank and a fine filter element; the fine filter element is provided with a raw water inlet for raw water to flow into the fine filter element, a concentrated water outlet for concentrated water to flow out of the fine filter element and a pure water outlet for pure water to flow out of the fine filter element; the membrane soaking tank comprises a shell, an inner container is arranged in the shell, and a water flow channel is arranged between the inner container and the shell; a pressurizing assembly for pressurizing a water path is arranged between the membrane soaking tank and the fine filter element; water flows along the concentrated wateroutlet, the pressurizing assembly and the water flow channel to form a water backflow path in the element; water flows along the inner container and the raw water inlet to form a pure water membrane soaking path; and water flows through the pure water outlet and the inner container to form a pure water backflow path. The filter assembly has the advantages of reduction of the TDS value of the firstcup of water after restarting of a water purification system in a standby state, and effectiveness in avoiding of pure water waste caused by flushing of a permeable membrane with a large amount of pure water.

Owner:GUANGDONG WAPU TECH CO LTD

Blackening technology for copper product

PendingCN112111734AGood anti-reflectionAvoid prolonged soakingMetallic material coating processesOxidation resistantSurface oxide

The invention discloses a blackening technology for a copper product. The technology includes the following steps that 1, degreasing and decontaminating are performed, and specifically, stains on thesurface of the product are removed; 2, overflowing and rinsing are performed, and specifically, the stains on the surface of the product are washed; 3, pickling and activating are performed, and specifically, oxides on the surface of the product are removed; 4, overflowing and rinsing are performed, and specifically, the stains are washed; 5, blackening for the first time is performed, and specifically, a light-color blackening layer is formed; 6, overflow and rinsing are performed; 7, blackening for the second time is performed, and specifically, a stable blackening layer is formed; 8, overflow and rinsing are performed; 9, sealing is performed, and specifically, an anti-oxidation film is formed outside the blackening layer of the finished product; 10, overflow and rinsing are performed;11, drying is performed; 12, vibration and grinding are performed to remove dust, and specifically, accumulated dust and impurities on the surface of the product are removed. According to the blackening technology of the copper product, the requirements that the blackening layer of the product does not leak copper in a long-time salt spray test and does not fade for a long time in high-temperature, high-humidity, thermal-shock and low-temperature cold-shock continuous tests can be met, and the product has the good light reflection resistance and refraction resistance.

Owner:NINGBO POWERMETAL IND

Kiering method and bleaching agent for gauze

ActiveCN106758129AImprove bleaching effectReduce harmDry-cleaning apparatus for textilesSodium acetateBreaking strength

The invention discloses a bleaching agent for gauze. The bleaching agent comprises hydrogen peroxide (H2O2), a stabilizer and a bleaching auxiliary, wherein the stabilizer is soluble silicate; the bleaching auxiliary is a mixture of dimethyl sulfoxide (DMSO), sodium polyacrylate (PAAS) and sodium acetate. In the bleaching agent, the content of analytically pure H2O2 of which the mass percentage is 30% is 5-15ml / L, the content of the stabilizer is 5-10g / L, and the content of the bleaching auxiliary is 7-20g / L. The invention further discloses a bleaching method applicable to the bleaching agent. The bleaching method comprises the following steps: washing, deoiling, degreasing, bleaching, rinsing with clean water, and washing artificially. By adopting the bleaching agent for the gauze, the whiteness degree can be increased, a good break strength retention rate can be maintained, and a good bleaching effect can be achieved. Meanwhile, by adopting the bleaching process method disclosed by the invention, application of the bleaching agent can be very well met, and the effects of the bleaching agent can be sufficiently brought into play.

Owner:MEDWELL MEDICAL PROD

Multifunctional delayed drainage port suitable for rainwater infiltration drainage and bioretention facility

InactiveCN105863022AExtended stayAvoid prolonged soakingSewerage structuresSewage drainingLine tubingOutfall

The invention provides a multifunctional delayed drainage port suitable for a rainwater infiltration drainage and bioretention facility. The multifunctional delayed drainage port comprises a concrete foundation, an overflow well wall, a municipal water outlet and a top overflow channel and further comprises an infiltration drainage channel. The infiltration drainage channel comprises an infiltration drainage channel pipe arranged on the side wall of the overflow well wall, an inner side opening of the infiltration drainage is communicated with a well body through the overflow well wall, an outer side opening of the infiltration drainage is communicated with a rainwater facility, and the infiltration drainage channel and the top overflow channel are connected with a municipal pipeline through the well body and the municipal water outlet. The multifunctional delayed drainage port has the advantages that the multifunctional delayed drainage port is particularly suitable for rainwater facilities, like grass swales and rainwater gardens, needing infiltration drainage and has the functions of delayed adjustment and graded control according to different rainfall adjustment, rainwater retention of the rainwater facility is prolonged, infiltration drainage water can be collected and drained, long-time soaking of the plants is prevented, and normal growth of the plants is protected.

Owner:BEIJING YUREN RUNKE ECOLOGICAL TECH CO LTD

Filtering assembly capable of flushing bubble film

PendingCN112429809ASolve penetrationAvoid prolonged soakingSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisReverse osmosisEngineering

The invention discloses a filtering assembly capable of flushing a bubble film. The filtering assembly comprises a water driving assembly and a fine filtering element; a raw water inlet, a concentrated water outlet and a pure water outlet are formed in the fine filtering element; the fine filtering element further comprises a raw water port communicated with the outside, the water driving assemblycomprises a first driving space and a second driving space, and an elastic deformation part is arranged between the first driving space and the second driving space; a pressurizing assembly is arranged between the water driving assembly and the fine filtering element; the filtering assembly is provided with a pure water making path, an in-core water backflow path, a pure water bubble film path and a pure water backflow path. According to the filtering assembly, the problem of permeation of a reverse osmosis membrane can be solved by utilizing concentrated water remained in the fine filteringelement and pure water stored in the water driving assembly to realize backflow, so that the reverse osmosis membrane is prevented from being soaked in the concentrated water for a long time; and purewater is used for replacing water on the raw water side of the fine filtering element, so that the TDS value of a first cup of water after the water purification system is restarted from a standby state is reduced.

Owner:GUANGDONG WAPU TECH CO LTD +1

Device for preventing water from accumulating for tree planting

ActiveCN109041905AAvoid blockingAvoid overall overheatingSelf-acting watering devicesReceptacle cultivationWater resourcesDrive motor

The invention discloses a device for preventing water from accumulating for tree planting. The device comprises two fixing plates which are buried in the earth surface, wherein the opposite sides of the two fixing plates are provided with grooves respectively, one of the grooves is internally provided with a guiding rod, the two ends of the guiding rod are fixedly connected to the opposite inner walls of the corresponding groove respectively, the other groove is internally provided with a threaded rod, one end of the threaded rod is rotationally connected to the inner wall of the correspondinggroove, the upper end of one of the fixing plates is fixedly connected with a driving motor, the tail end of an output shaft of the driving motor penetrates through the side wall of the correspondingfixing plate and is fixedly connected with the end, away from the inner wall of the corresponding groove, of the threaded rod, the threaded rod is sleeved with a first movable block, the first movable block is in threaded connection with the threaded rod, and the guiding rod is sleeved with a second movable block. The device for preventing the water from accumulating for tree planting not only improves the convenience degree of the device for preventing the water from accumulating during use, increases the use range of the device for preventing the water from accumulating, but also increasesthe utilization rate of the water resources.

Owner:佛山市嘉沃农业科技合伙企业(有限合伙)

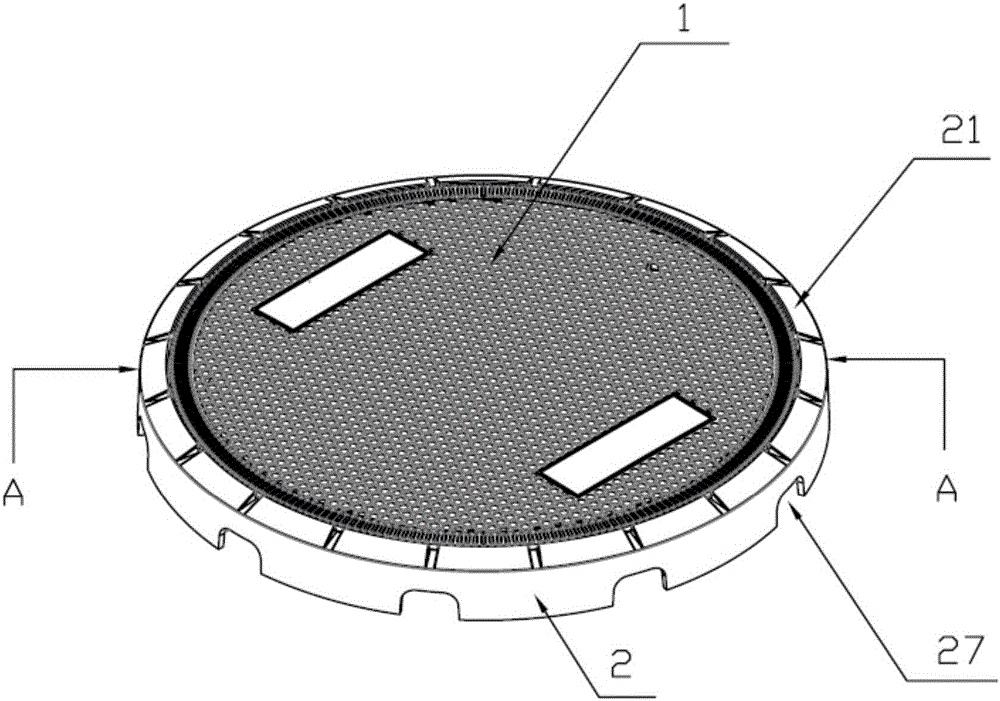

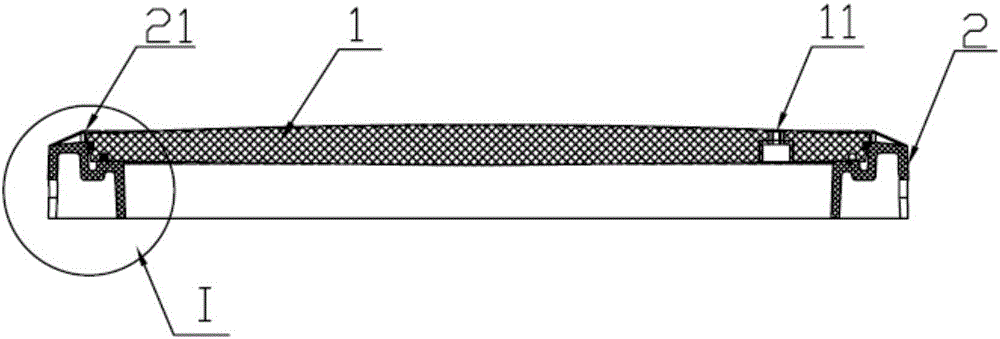

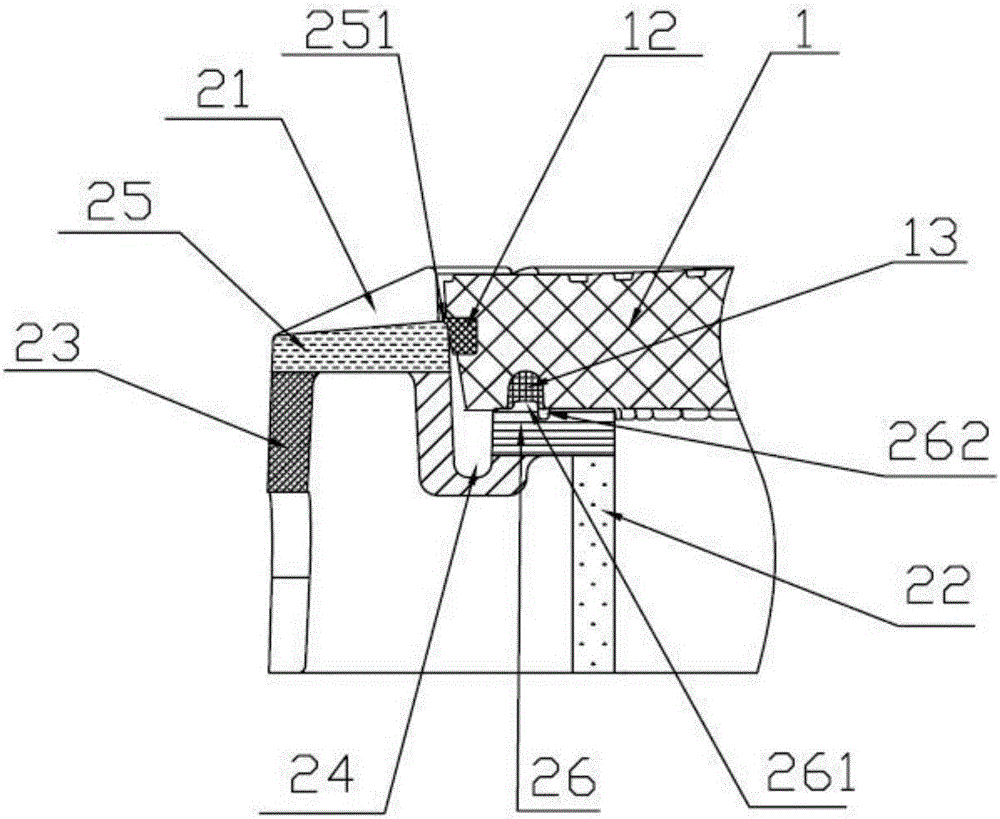

Composite well lid with double sealing belts and drainage portions

ActiveCN106120869AEasy dischargeAvoid prolonged soakingArtificial islandsUnderwater structuresEngineeringMechanical engineering

Owner:HENGSHUI YOUJIETE PETROLEUM EQUIP TECH CO LTD

Miniature water flow power generation device and intelligent water meter

InactiveCN110529328AExtended service lifeAvoid prolonged soakingHydro energy generationMachines/enginesImpellerWater flow

The invention relates to the technical field of water flow power generation, and provides a miniature water flow power generation device and an intelligent water meter applying the miniature water flow power generation device. The miniature water flow power generation device is characterized in that a miniature generator body and a magnetic transmission impeller are separately arranged on the outer side and the inner side of a water pipe, so a magnetic driving wheel on the input shaft of the miniature-generator body can be in magnetic transmission connection with the magnetic transmission impeller, so that the input shaft is prevented from being soaked in water for a long time, and the service life of the whole miniature-generator body is prolonged. Besides, the miniature generator body with low power is selected, power can be generated under the condition of micro water flow, water pressure loss is small, and the installation requirements of the intelligent water meter are met. And meanwhile, by arranging energy storage equipment and an energy management system, weak electric energy can be collected, and the electric energy collected by the energy storage equipment is subjected tooutput management through the energy management system, so that the charging requirement of an intelligent electric meter is met.

Owner:SANCHUAN WISDOM TECH CO LTD

Cup

The invention relates to the technical field of articles for daily use and provides a cup. The cup comprises a cup body and a cup lid and further comprises a tea-water separation structure. The cup can separate tea and water and avoid long-time tea leaf soaking, effectively retains the nutrient substance in tea leaves and improves the taste of tea water.

Owner:徐必乔

Self-fixing electric tracing band

InactiveCN108966384AAvoid prolonged soakingExtended service lifeOhmic-resistance heating detailsHeating element shapesGlass fiberArchitectural engineering

The invention relates to a self-fixing electric tracing band, which comprises a lead wire, wherein the outer surface of the lead wire is wrapped with an inner wire tube protective layer, the outer surface of the inner wire tube protective layer is wrapped with a fireproof glass fiber braid layer, the upper surface of the protective layer is provided with a first connecting wing, a circular throughhole is formed in the surface of the first connecting wing, a second connecting wing is arranged on the lower surface of the protective layer, and the surface of the second connecting wing is fixedlyconnected with a connecting belt. Thus, through the cooperative use of the connecting belt and a limiting ring, the electric tracing band is tightly fixed on the surface of a pipeline when the electric tracing band is being fixed, the connecting belt is an elastic telescopic belt and can be used by pipelines of different diameters in a certain range, the operation is simple, other materials required for installation do not need to be sought additionally, the installation and storage are convenient, and the installation efficiency and the stability of the electric tracing band are improved.

Owner:江苏凯博防爆电气有限公司

Lifting type water pump

ActiveCN114517792AAvoid prolonged soakingLong-term protectionPump componentsGeneral water supply conservationStructural engineeringEnvironmental engineering

The invention belongs to the field of water pumps, and particularly relates to a lifting type water pump which comprises a pump body, a water inlet of the pump body is formed in the bottom, a suspension assembly is arranged on the water inlet and used for floating the pump body, the side face of the pump body is connected with the inner wall of a water pool in an up-down sliding mode through a lifting assembly, and the suspension assembly comprises an outer shell. The water inlet is formed in the outer shell, a plurality of first filtering holes are formed in the side face of the outer shell, the bottom of the outer shell is connected with a suspension body, and the energy-saving and environment-friendly pump has the beneficial effects that energy is saved, the environment is protected, and long-term operation of the pump body is protected.

Owner:XIHUA UNIV

Anti-overflow flowerpot

InactiveCN113994830AAvoid prolonged soakingReduce chalkingSelf-acting watering devicesCultivating equipmentsSoil scienceEnvironmental engineering

The invention relates to the technical field of home decorations, and discloses an anti-overflow flowerpot. The flowerpot comprises: a pot body, wherein a base is arranged at the bottom of the pot body, a partition plate is mounted on the side wall of an inner cavity of the pot body, and a space water supplementing cavity is formed between the partition plate and the inner side wall of the pot body. A fixing frame is arranged in the base, a rubber bag capable of deforming and a water absorption frame capable of absorbing water are arranged on the fixing frame, and an expansion cavity formed by the fixing frame, the rubber bag, and the water absorption frame is filled with water absorbing expansive soil. The expansive soil can absorb part of water when internal water is too much and the absorbed water can be used for supplementing water in the later period; a supporting effect can be achieved owing to the fact that the volume of the expansive soil is increased after expansion, the pot body and the base are thereby separated, it is prevented that the pot body is soaked in water for a long time, and pulverization of the pot body is reduced; finally, the expansive soil is used for detecting whether the soil in the pot body is in a water shortage state or not so that water can be supplemented in time, and the potted plant survival rate can be increased.

Owner:郭陈

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com