Filtering assembly capable of flushing bubble film

A filter component and component technology, applied in the field of water purification, can solve problems such as high TDS value and water quality that cannot meet the filtration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

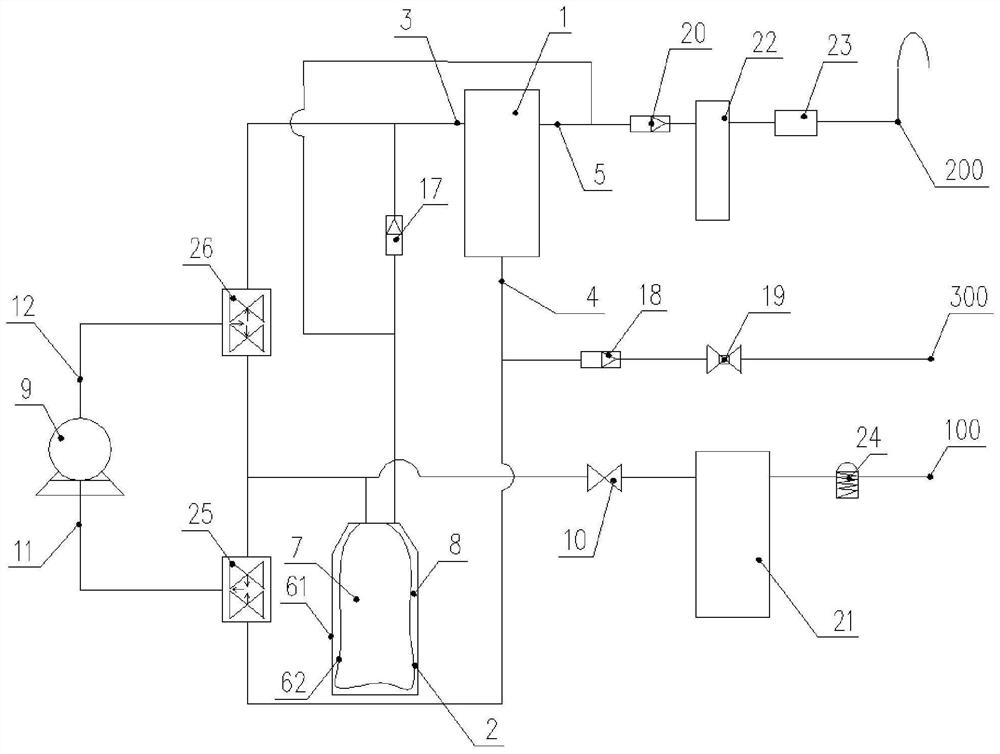

[0032] Such as figure 1 As shown in the filter assembly, the filter assembly includes a fine filter element 1 and a water drive assembly 2 as a fine filter element, wherein the fine filter element 1 is provided with a raw water inlet 3 for raw water to flow into the fine filter element 1, and for concentrated water to flow out The concentrated water outlet 4 of the fine filter element 1 and the pure water outlet 5 for pure water to flow out of the fine filter element 1; the water driving assembly 2 includes a housing 61, and the housing 61 is provided with a pressure-deformable inner tank 62, A first driving space 7 is formed in the inner tank 62, a second driving space 8 is provided between the inner tank 62 and the housing 61, and the second driving space 8 surrounds the inner tank 62 in the housing 61 layout.

[0033] In this embodiment 1, the booster component is applied as a booster pump 9, the water inlet of the booster pump 9 is provided with a booster inlet 11, and th...

Embodiment 2

[0047] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, if figure 2 As shown, the water driving assembly is set in the structural form of a box; the central position in the box is provided with an elastic film to divide one side of the space in the box into the first driving space, and the other side is divided into The second driving space.

Embodiment 3

[0049] The difference between this embodiment 3 and embodiment 1 is that in this embodiment 3, if image 3 As shown, the above-mentioned second control valve 13 and third control valve 14 can be integrated in the prior art to implement the application of the control valve in the form of the first combination valve 25 . Similarly, the above-mentioned fourth control valve 15 and sixth control valve 16 can be integrated, and the corresponding control valves can be applied in the form of the second combined valve 26 . Through the application of the first combination valve 25 and the second combination valve 26 , it is possible to simplify and adjust the pipelines in the waterway, so as to meet the requirements of installation and application in different environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com