Automatic cleaning device for aquatic product sensor

An automatic cleaning and water quality sensor technology, which is applied in the direction of testing water, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of blocked water pumps, unsatisfactory cleaning effect, and affecting measurement accuracy, so as to reduce adhesion rate and failure efficiency, prolong the cleaning and maintenance cycle, and ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

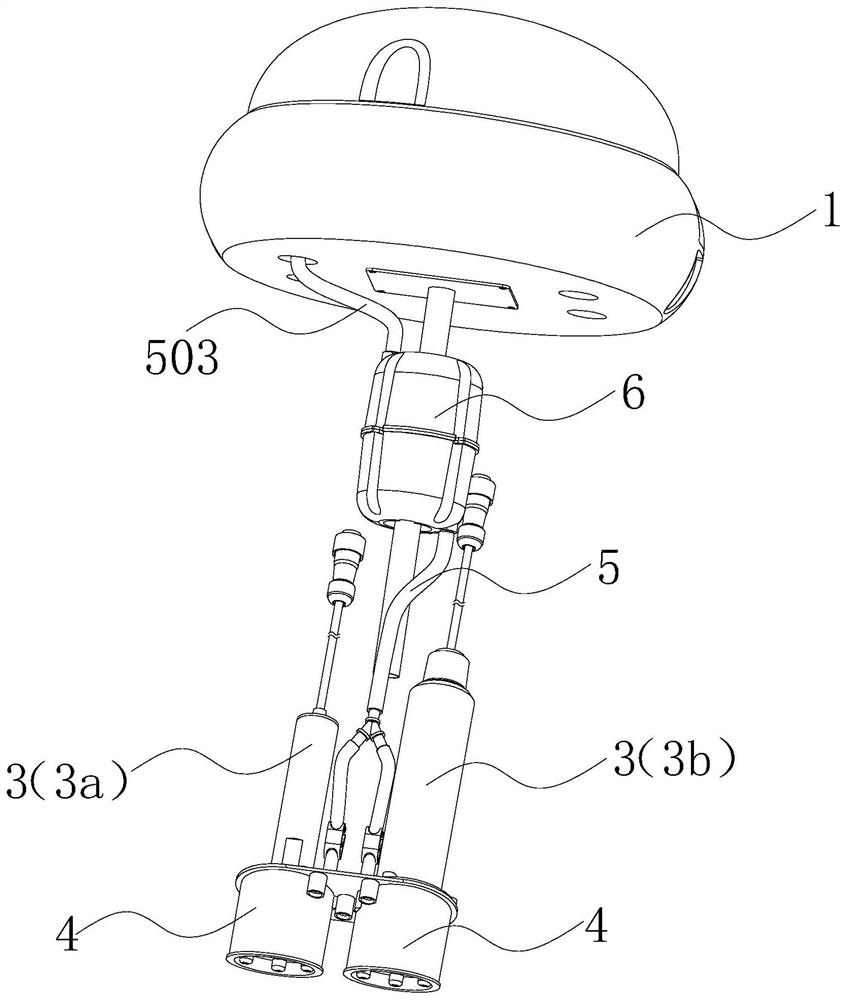

[0026] Please refer to figure 1 and 2 , The embodiment of the present invention provides an automatic cleaning device for aquatic sensors, including a floating body 1, an inflation and exhaust component 2, at least one water quality sensor 3, and a closed container 4 sleeved on the periphery of each water quality sensor probe 301.

[0027] Specifically, the floating body 1 makes use of the buoyancy of the water body to float the entire aquatic sensor automatic cleaning device on the water surface. The floating body 1 can be designed as a cavity structure of various shapes, which is not limited. In this embodiment, the floating body 1 includes a floating ball 102 and a floating ball top cover 101 detachably connected to the upper part of the floating ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com