Double-end multifunctional miniature diaphragm pump for atmospheric sampling equipment

A micro-diaphragm pump and atmospheric sampling technology, used in mechanical equipment, pumps, pump components, etc., can solve the problems of small effective measurement range, accelerated diaphragm corrosion and aging, large power loss, etc., to solve the problem of periodic flow fluctuations, The effect of prolonging the cleaning and maintenance cycle and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

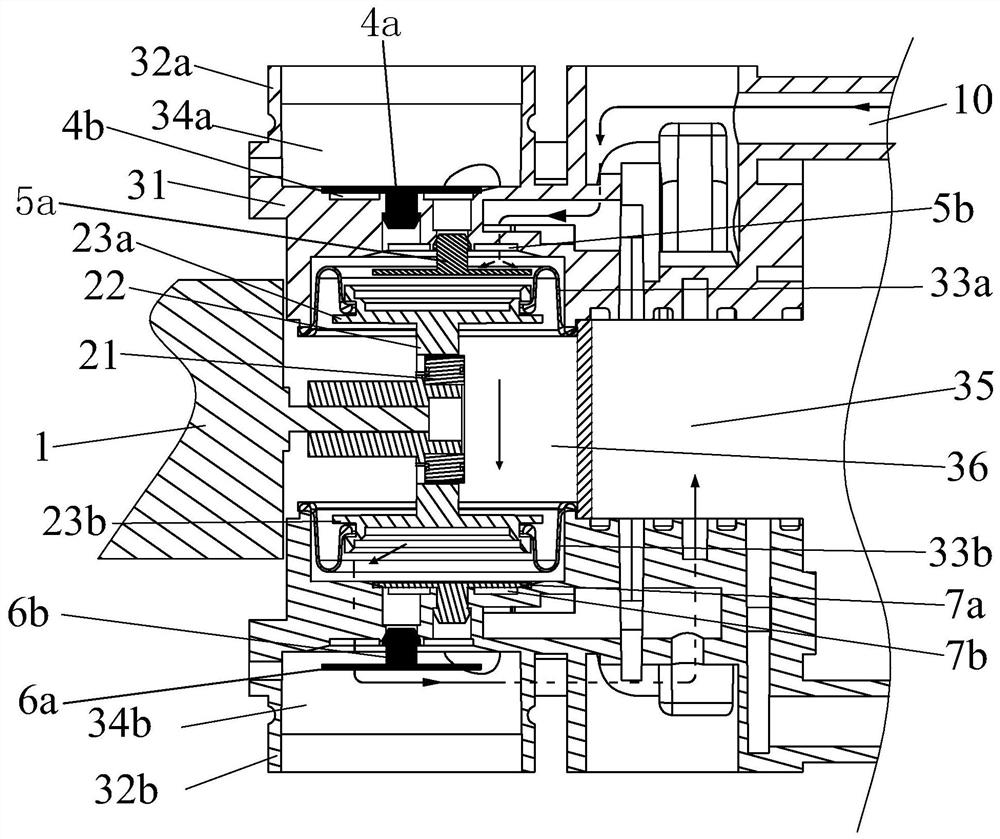

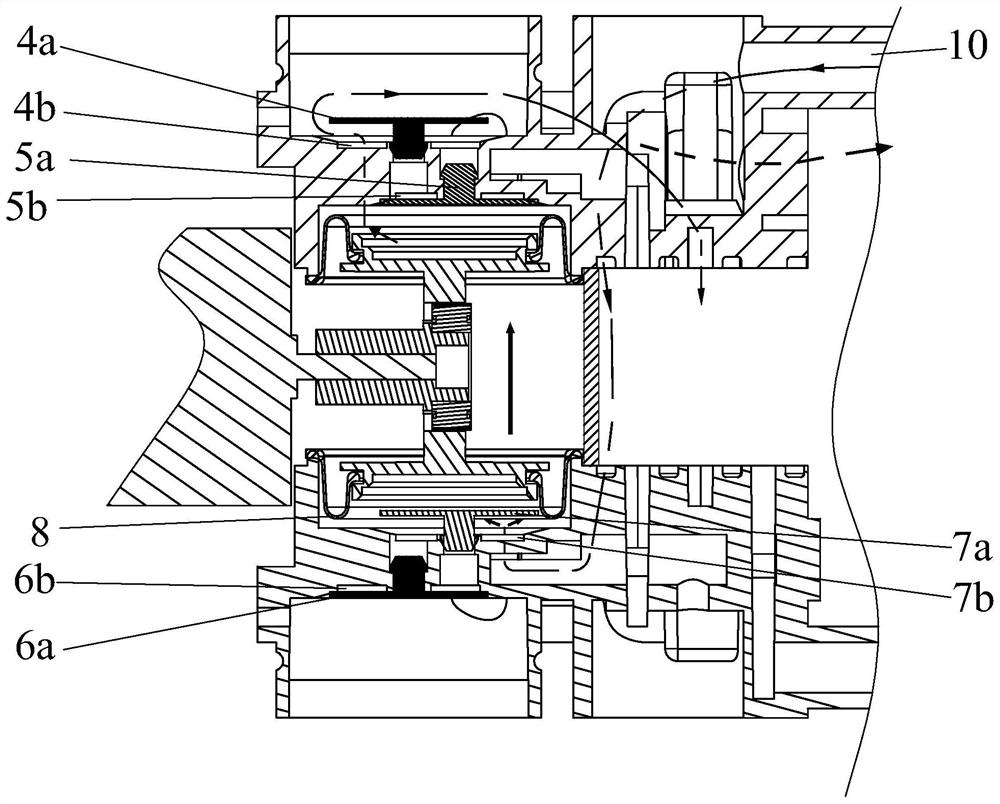

[0026] Referring now to the drawings, embodiments of the present invention are described, and similar components similar to the figures represent similar elements.

[0027] In the present disclosure, the present disclosure, such as "left", "right", "first", "second", or the like, the like, "left" or "right" only It cannot be understood as an instruction or implied that the actual positional relationship, "first", "second" feature can be expressed or implied to represent a technical feature including one or more of the same or structural approximation, functionality, and cannot be understood as an indication Or implies importance, primary relationships.

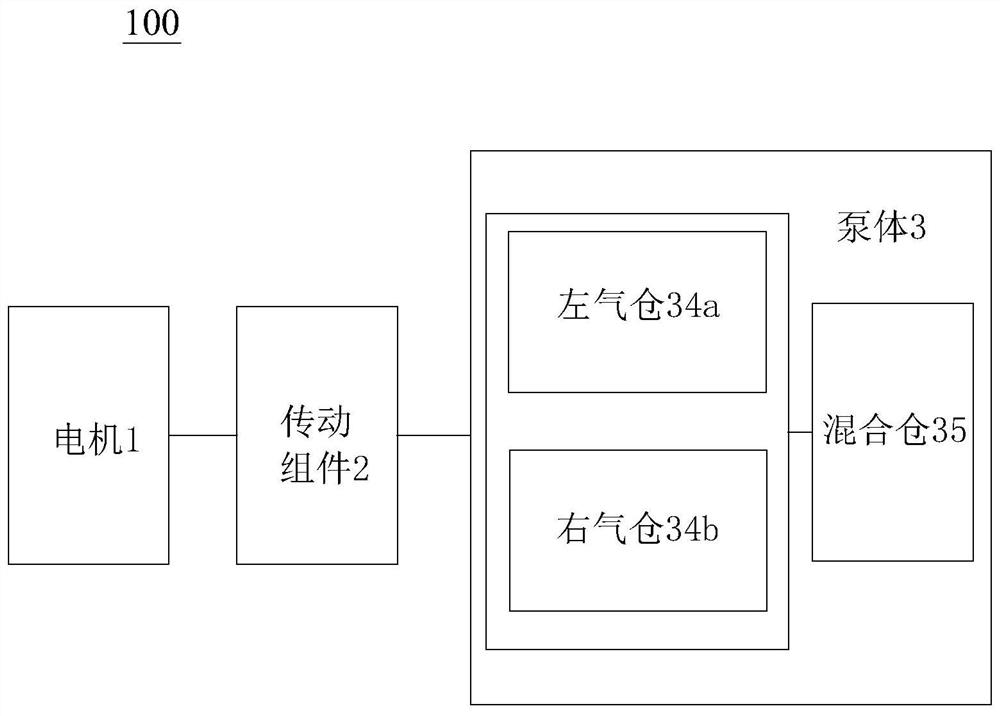

[0028] As mentioned above, such as figure 1 As shown, the embodiment of the present invention provides a two-head multi-function microfear pump 100 for atmospheric sampling equipment, including: motor 1, transmission assembly 2, and pump body 3.

[0029] It should be noted that in the drawings in the specification without affectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com