Reaction chambers and semiconductor processing equipment

A reaction chamber and process technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high processing accuracy and cost, increase equipment complexity, etc., achieve simple structure, solve long cleaning and maintenance cycles, Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

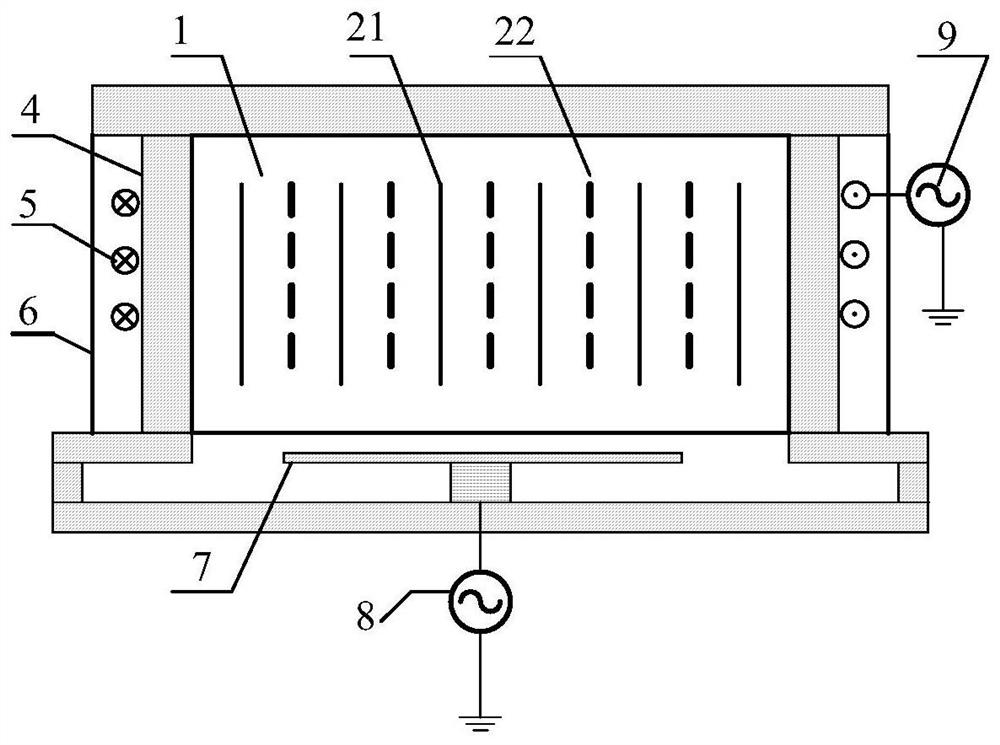

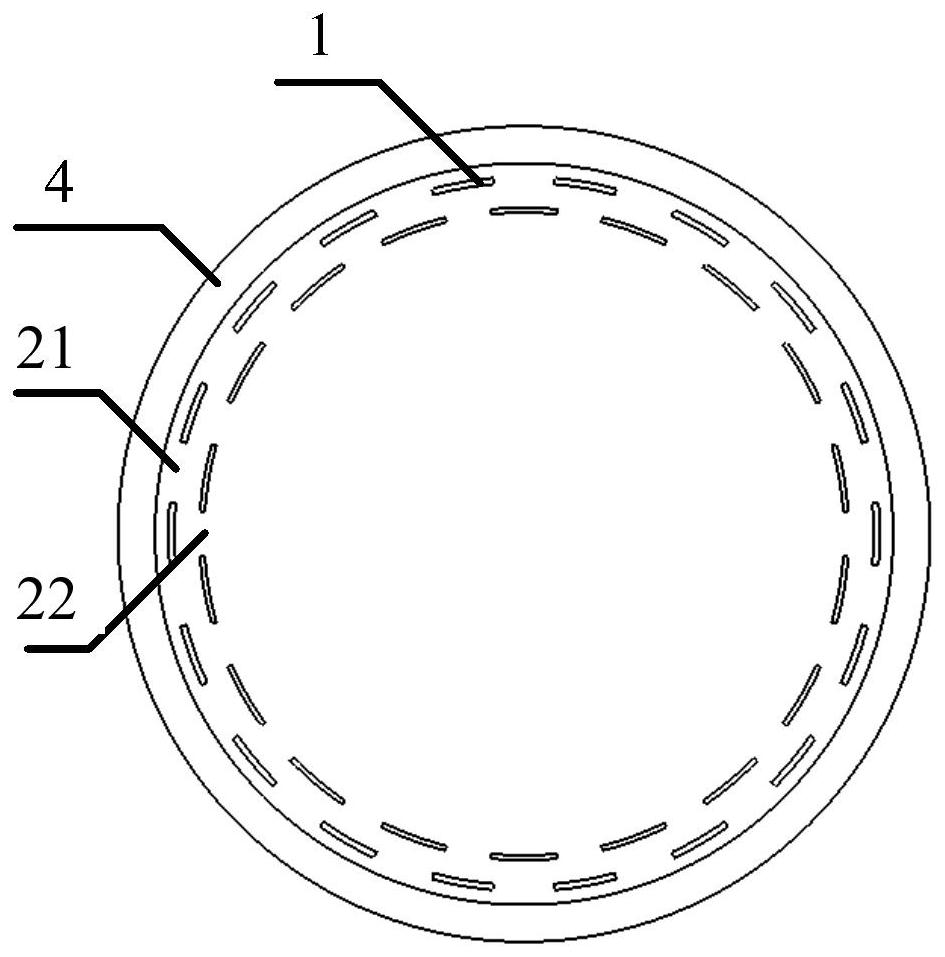

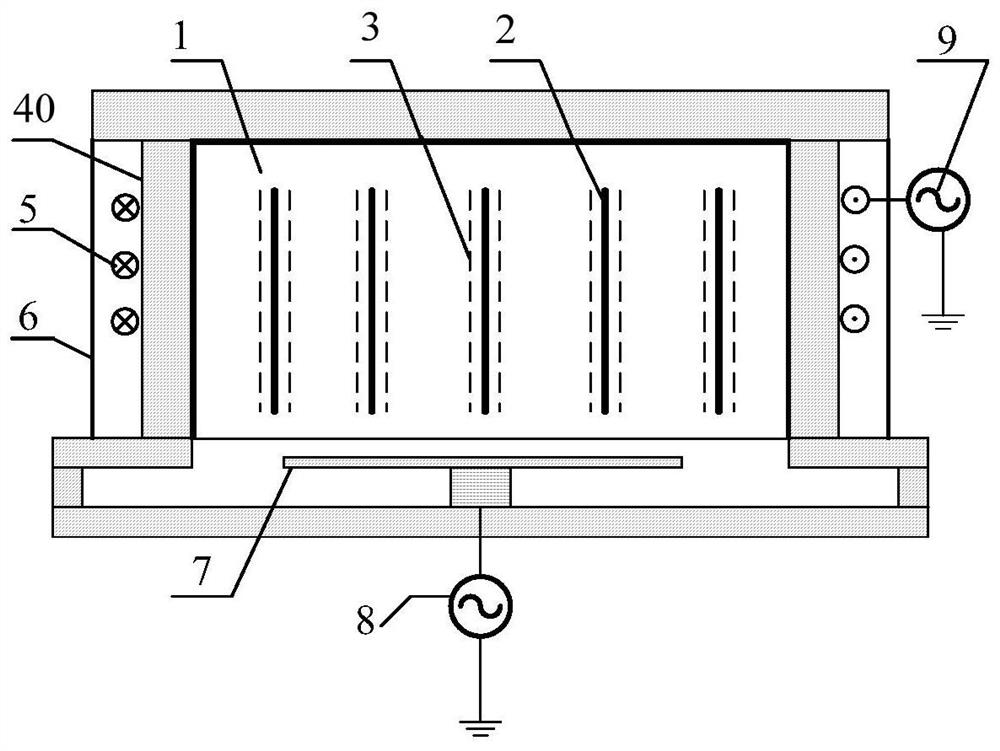

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the reaction chamber and semiconductor processing equipment of the present invention will be further described in detail below with reference to the drawings and specific implementation methods.

[0029] This embodiment provides a reaction chamber, the reaction chamber includes a vacuum-sealed barrel and a Faraday shield embedded in the vacuum-sealed barrel, the Faraday shield is provided with a slit running through the thickness of the Faraday shield, wherein the vacuum-sealed barrel The inner wall of the inner wall is provided with a recess at a region corresponding to the slit, and the recess is used to accommodate process by-products from the slit of the Faraday shield. In the reaction chamber, a recess is formed on the inner wall of the vacuum-sealed barrel to form an accommodating space for by-products deposited on the vacuum-sealed barrel during the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com