Concrete panel joint surface flexible water stopping anti-icing structure and mounting method

A concrete panel and installation method technology, which is applied in dams, water conservancy projects, sea area projects, etc., can solve the problems of large deformation of panel joints, bolts freezing and pulling off, difficult to ensure quality, etc., to reduce the possibility of joint water seepage performance, maintain the water-stop effect, and improve the effect of anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

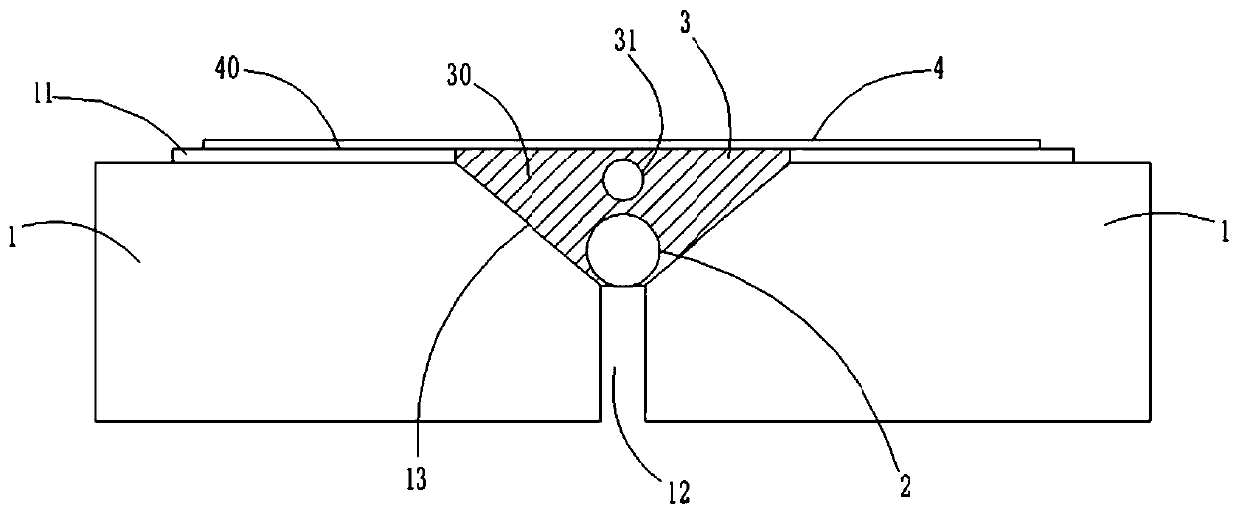

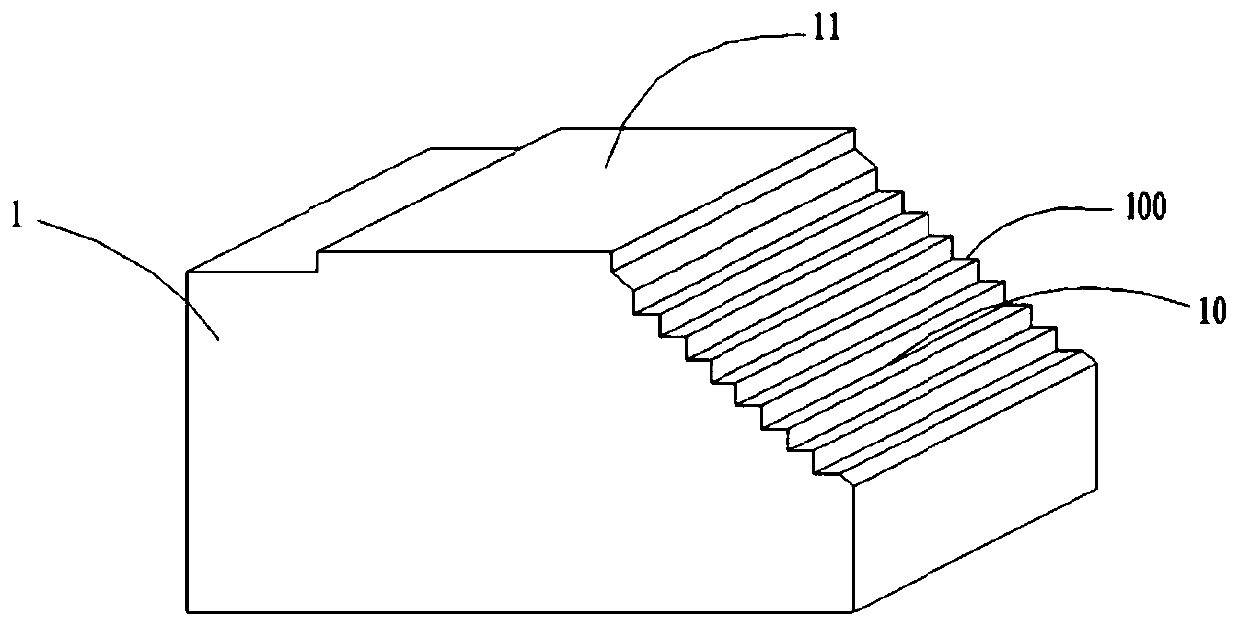

[0023] Embodiment 1: as figure 1 , 2 A flexible water-proof and ice-proof structure on the joint surface of concrete panels is shown, including concrete panels 1, elastic supports 2, compressible plastic caulking materials 3 and flexible anti-seepage coatings 4; the concrete panels 1 are provided with wedge-shaped parts 10 , the wedge-shaped part 10 is evenly provided with a plurality of step parts 100; the upper surface of the concrete panel 1 is provided with a diversion shoulder 11, the diversion shoulder 11 is flush with the upper end of the wedge-shaped part 10, and there is a joint between two adjacent concrete panels 1 Seam 12, a V-shaped groove 13 is formed between the wedge-shaped parts 10 on two adjacent concrete panels 1, and the width of the surface of the V-shaped groove 13 is 120mm;

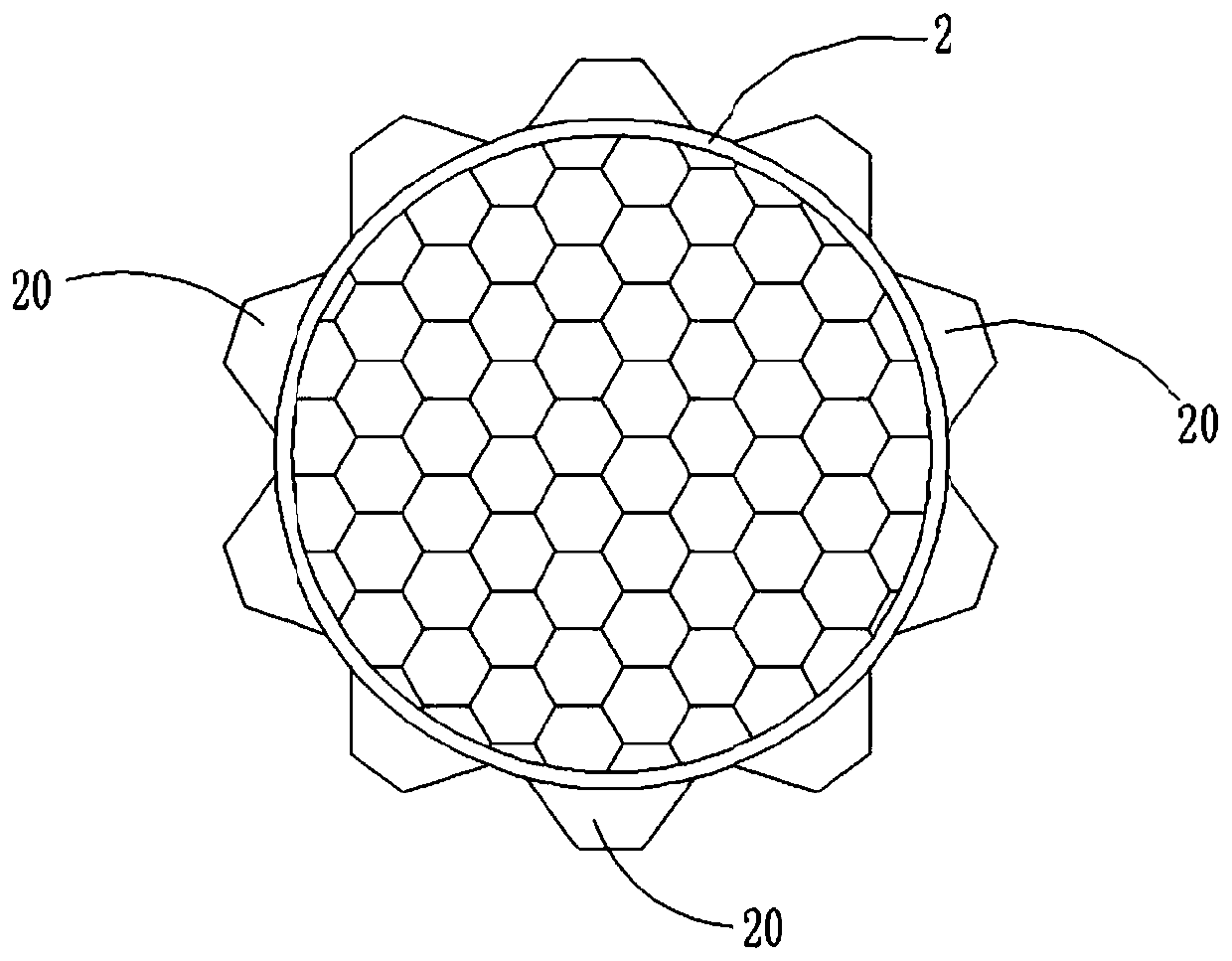

[0024] Such as figure 1 , 3 As shown, the elastic support 2 is movably clamped at the bottom of the V-shaped groove 13; the elastic support 2 is a rubber rod, and the inside of t...

Embodiment 2

[0031] Embodiment 2: as figure 1 , 2 A flexible water-proof and ice-proof structure on the joint surface of concrete panels is shown, including concrete panels 1, elastic supports 2, compressible plastic caulking materials 3 and flexible anti-seepage coatings 4; the concrete panels 1 are provided with wedge-shaped parts 10 , the wedge-shaped part 10 is evenly provided with a plurality of step parts 100; the upper surface of the concrete panel 1 is provided with a diversion shoulder 11, the diversion shoulder 11 is flush with the upper end of the wedge-shaped part 10, and there is a joint between two adjacent concrete panels 1 Seam 12, a V-shaped groove 13 is formed between the wedge-shaped parts 10 on two adjacent concrete panels 1, and the width of the surface of the V-shaped groove 13 is 100mm;

[0032] Such as figure 1 , 3 As shown, the elastic support 2 is movably clamped at the bottom of the V-shaped groove 13; the elastic support 2 is a rubber rod, and the inside of t...

Embodiment 3

[0039] Embodiment 3: as figure 1 , 2 A flexible water-proof and ice-proof structure on the joint surface of concrete panels is shown, including concrete panels 1, elastic supports 2, compressible plastic caulking materials 3 and flexible anti-seepage coatings 4; the concrete panels 1 are provided with wedge-shaped parts 10 , the wedge-shaped part 10 is evenly provided with a plurality of step parts 100; the upper surface of the concrete panel 1 is provided with a diversion shoulder 11, the diversion shoulder 11 is flush with the upper end of the wedge-shaped part 10, and there is a joint between two adjacent concrete panels 1 Seam 12, adjacent two 140mm;

[0040] Such as figure 1 , 3 As shown, the elastic support 2 is movably clamped at the bottom of the V-shaped groove 13; the elastic support 2 is a rubber rod, and the inside of the elastic support 2 is a honeycomb structure. , the honeycomb structure has excellent compression resistance, and the anti-variation protrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com