Metal organic skeleton/graphene oxide oil-water separation membrane and preparation method thereof

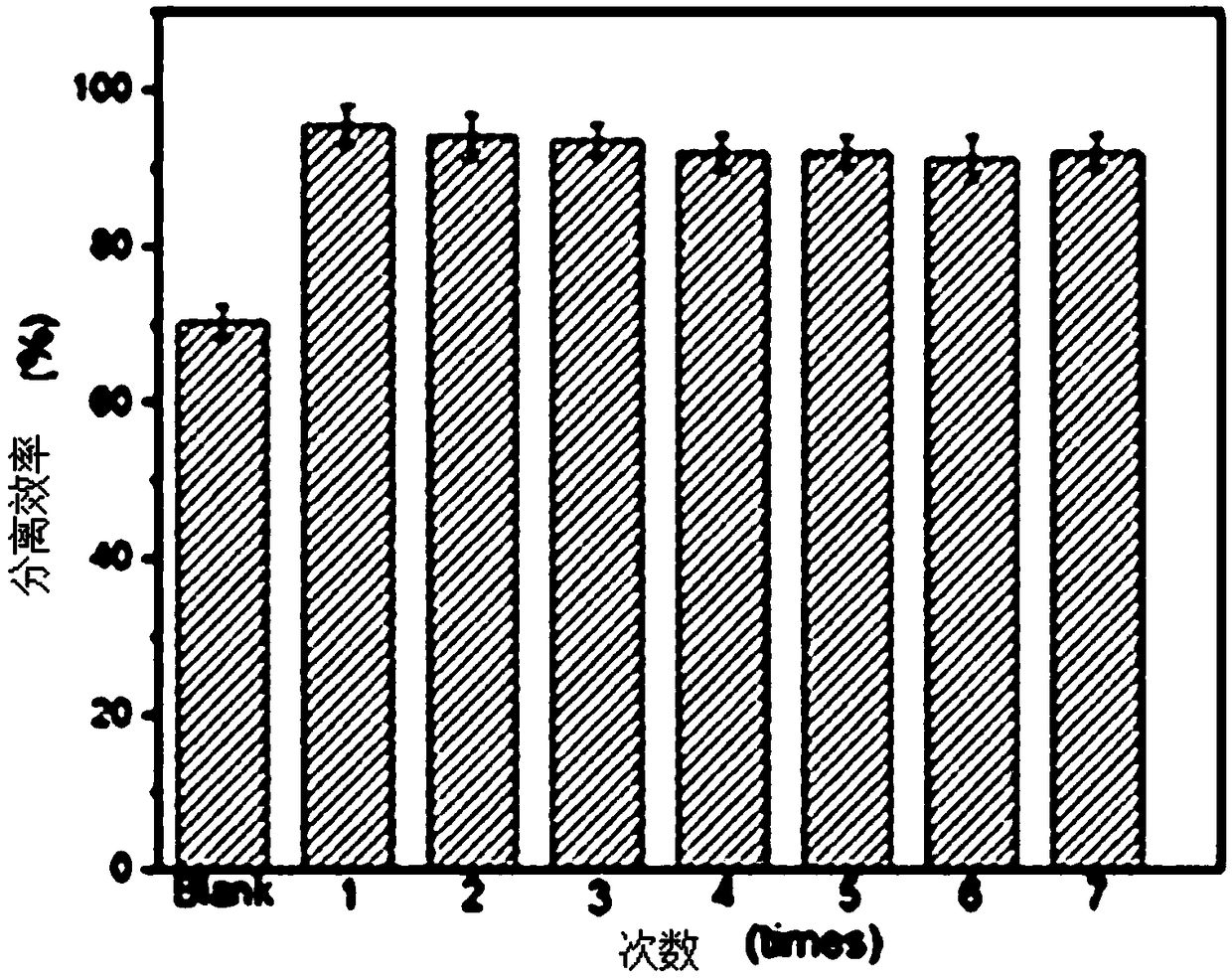

A metal-organic framework and oil-water separation membrane technology, applied in the field of water treatment, can solve the problems of secondary pollution of water bodies, difficult solid-liquid separation, etc., and achieve the effects of strong reusability, easy availability of raw materials, and improved oil-water separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a metal-organic framework / graphene oxide oil-water separation membrane, the steps are as follows:

[0034] (1) cutting a circular PVDF ultrafiltration membrane with a diameter of 50mm and soaking it in ethanol,

[0035] (2) Prepare 50 mL of dopamine hydrochloride Tris-HCl buffer solution with pH=8.5, dopamine hydrochloride concentration of 1 mg / mL, and Tris concentration of 10 mmol / L, take out the PVDF filter membrane soaked in ethanol, and rinse the surface with deionized water After adding ethanol, put it into the dopamine hydrochloride Tris-HCl solution, and soak it for 12 hours under the dark condition;

[0036] (3) The PVDF base film after soaking in step (2) is taken out, dried at 65° C., and then the base film is soaked in 0.15% trimesoyl chloride (TMC) solution for 15 min; after soaking, use isoparaffin Isopar G solvent washes excess TMC from the membrane surface.

[0037] (4) The base film soaked in step (3) was immersed in ZIF-8 / GO me...

Embodiment 2

[0040] A preparation method of a metal-organic framework / graphene oxide oil-water separation membrane, the steps are as follows:

[0041] (1) cutting a circular PVDF ultrafiltration membrane with a diameter of 50mm and soaking it in ethanol,

[0042] (2) Prepare 50 mL of dopamine hydrochloride Tris-HCl buffer solution with pH=8.5, dopamine hydrochloride concentration of 1.5 mg / mL, and Tris concentration of 10 mmol / L, take out the PVDF filter membrane soaked in ethanol, and rinse it with deionized water Put the ethanol on the surface into the dopamine hydrochloride Tris-HCl solution, and soak for 12 hours under the condition of avoiding light.

[0043] (3) The PVDF base film after soaking in step (2) is taken out, dried at 65° C., and then the base film is soaked in 0.1% trimesoyl chloride (TMC) solution for 18 min; after soaking, use isoparaffin Isopar G solvent washes excess TMC from the membrane surface.

[0044](4) The base film soaked in step (3) was immersed in ZIF-8 / GO...

Embodiment 3

[0047] A preparation method of a metal-organic framework / graphene oxide oil-water separation membrane, the steps are as follows:

[0048] (1) cutting a circular PVDF ultrafiltration membrane with a diameter of 50mm and soaking it in ethanol,

[0049] (2) Prepare 50 mL of dopamine hydrochloride Tris-HCl buffer solution with pH=8.5, dopamine hydrochloride concentration of 2 mg / mL, and Tris concentration of 10 mmol / L, take out the PVDF filter membrane soaked in ethanol, and rinse off the surface with deionized water The ethanol was put into the dopamine hydrochloride Tris-HCl solution, and soaked for 12 hours under the dark condition.

[0050] (3) The PVDF base film after soaking in step (2) is taken out, dried at 65° C., and then the base film is soaked in 0.3% trimesoyl chloride (TMC) solution for 15 min; after soaking, use isoparaffin Isopar G solvent washes excess TMC from the membrane surface.

[0051] (4) The base film soaked in step (3) was immersed in ZIF-8 / GO methanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com