Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

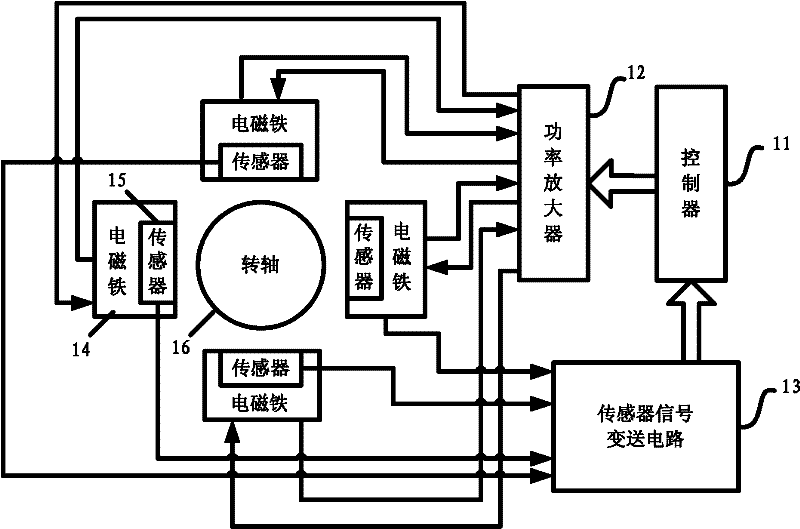

42results about How to "Avoid mechanical contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

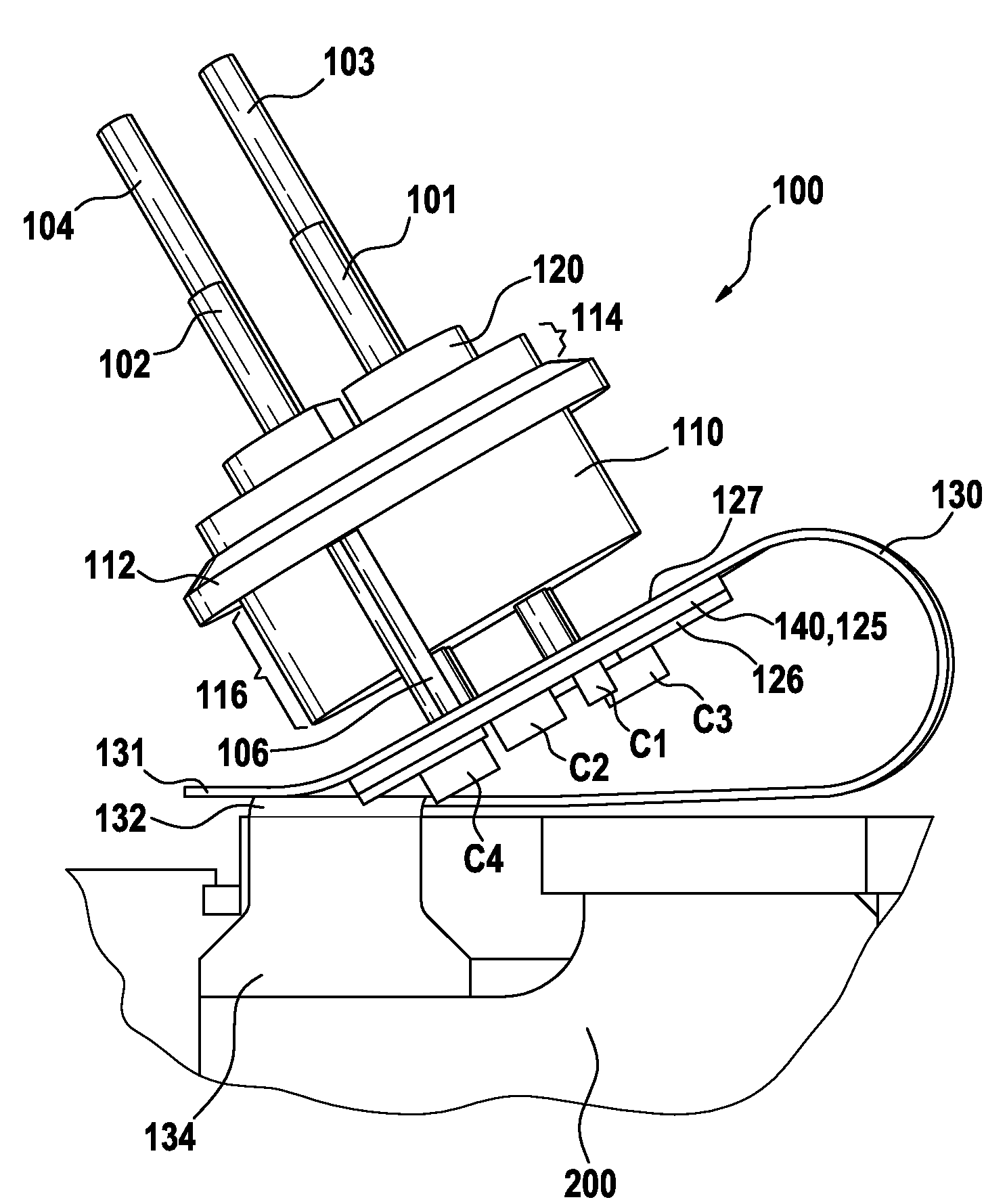

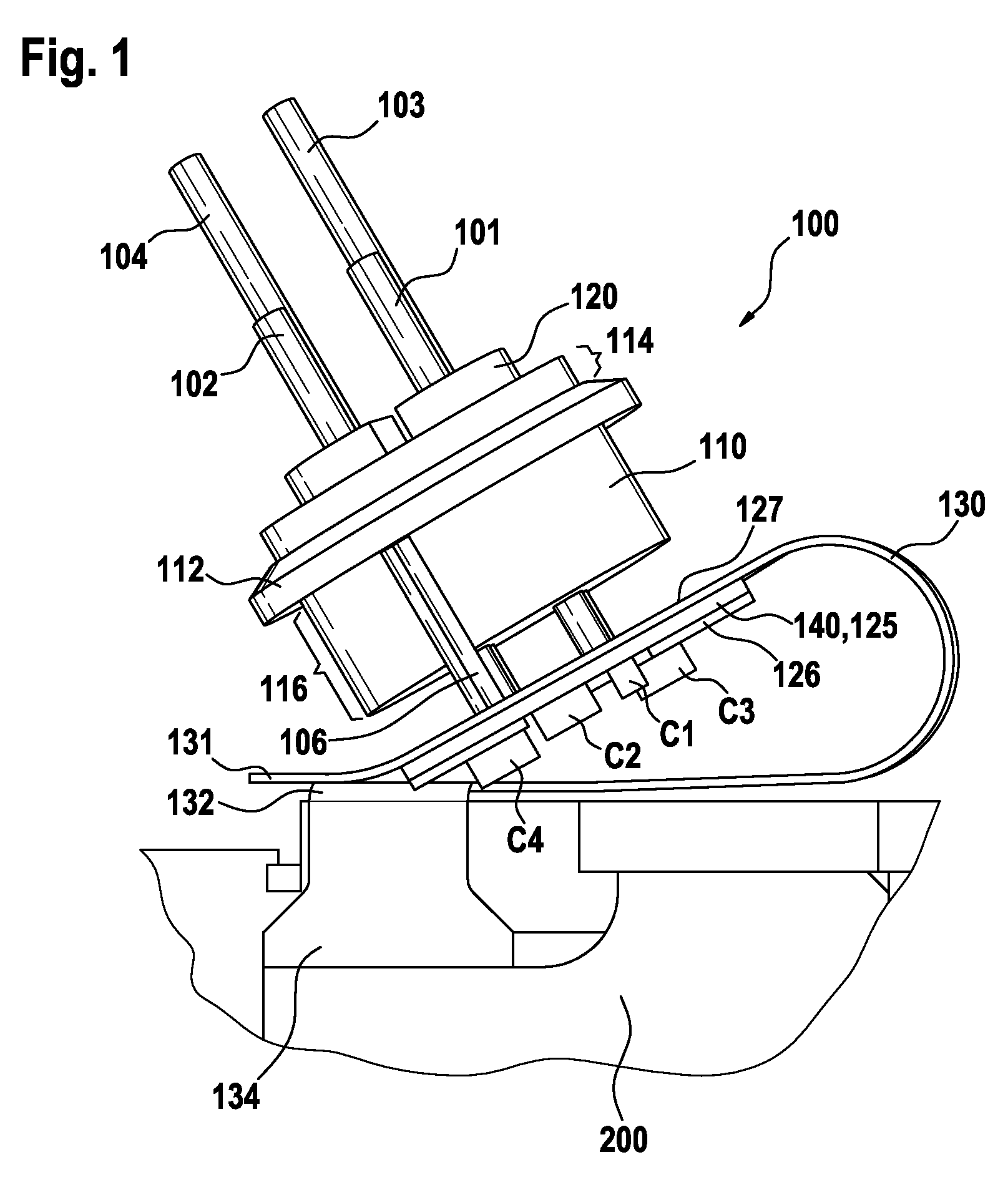

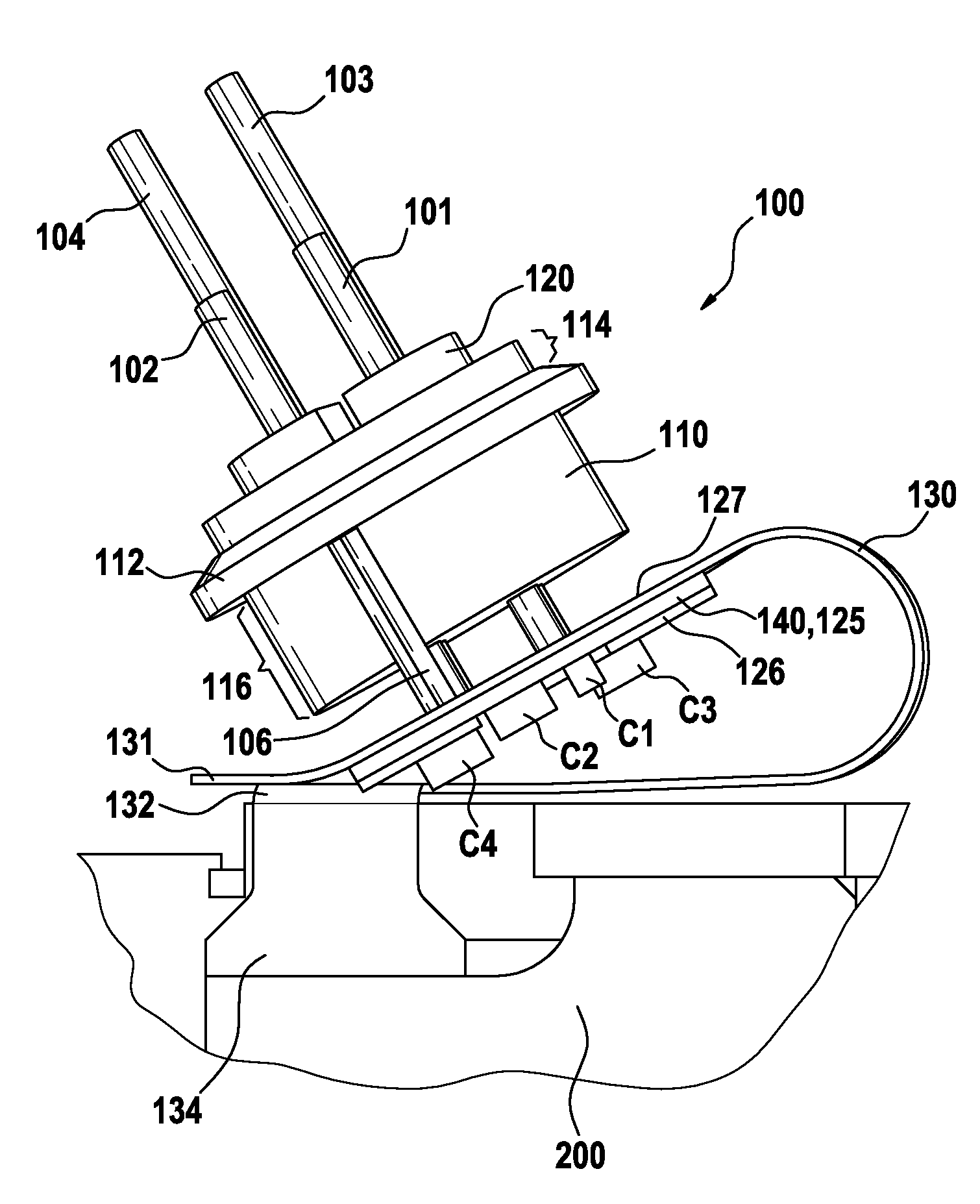

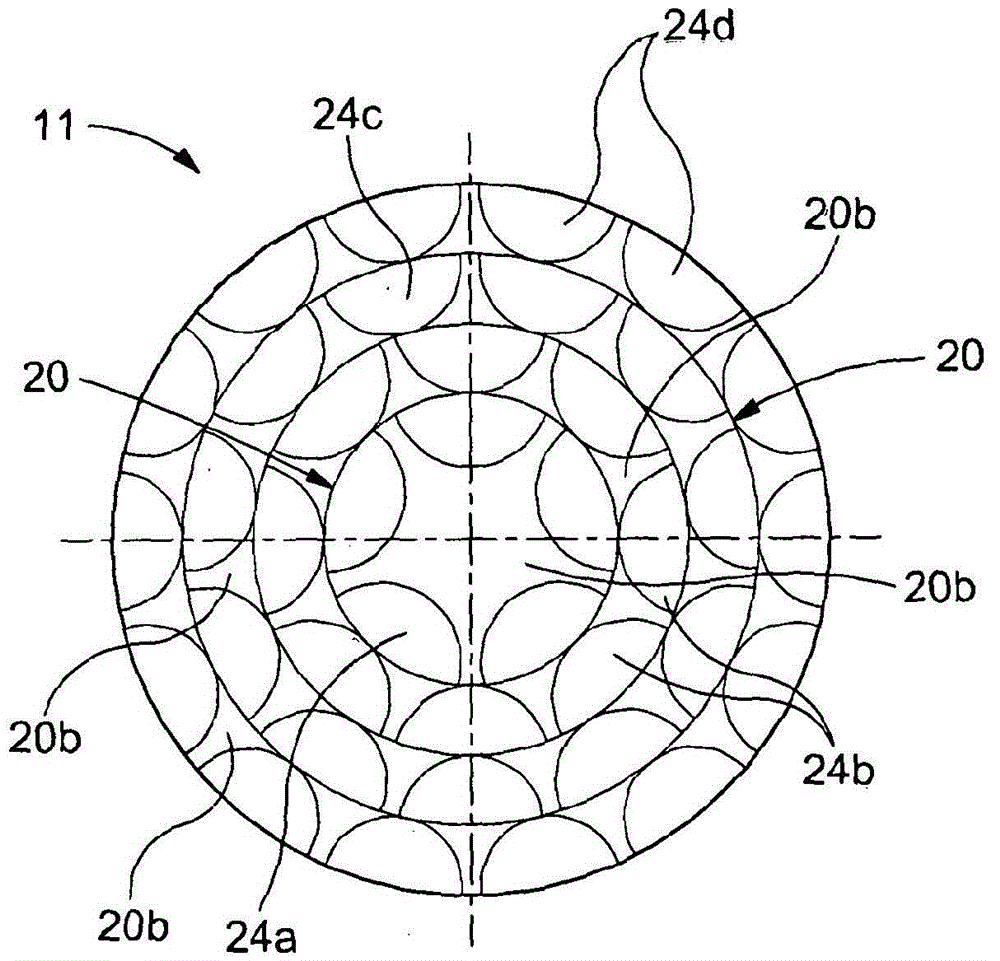

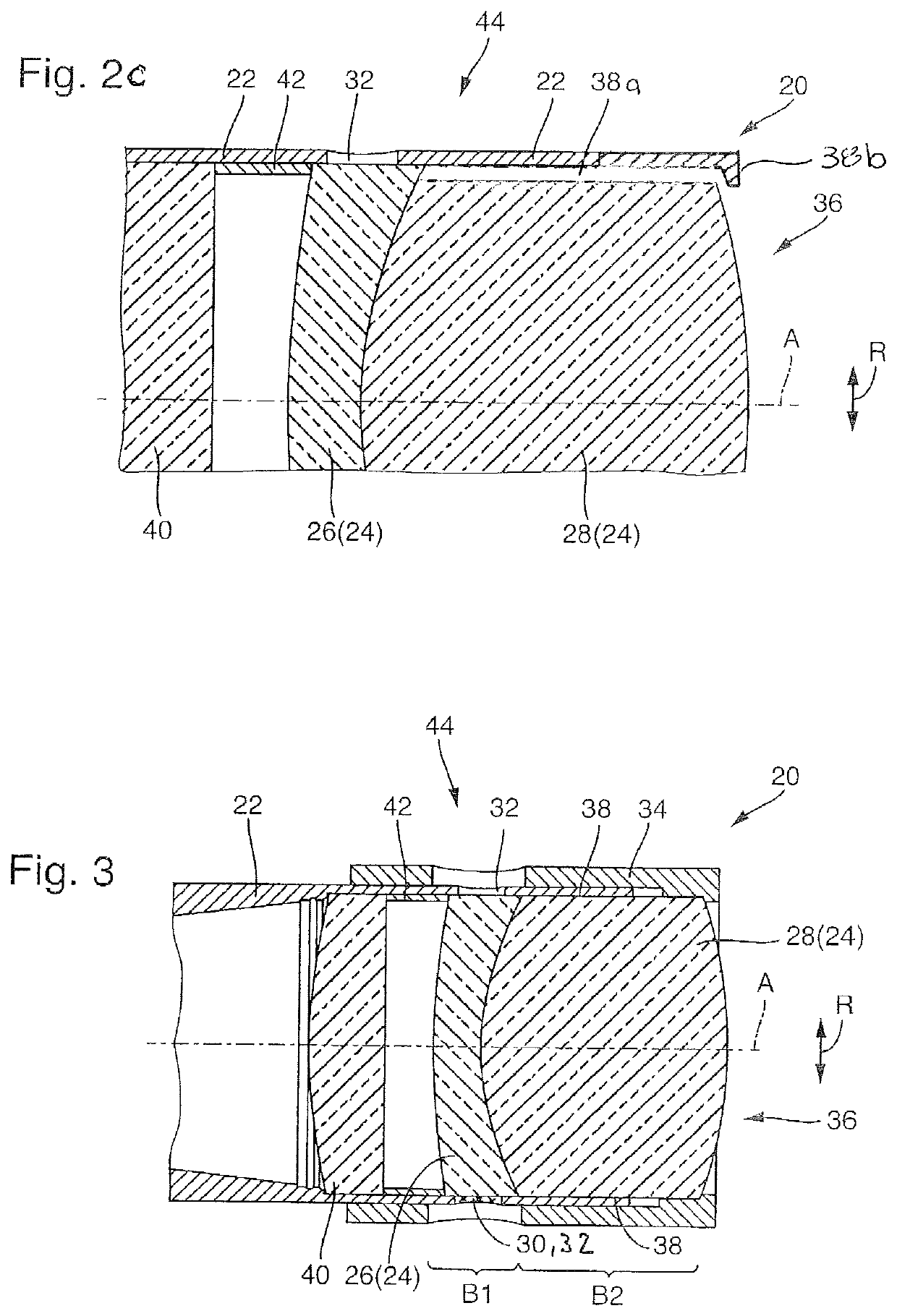

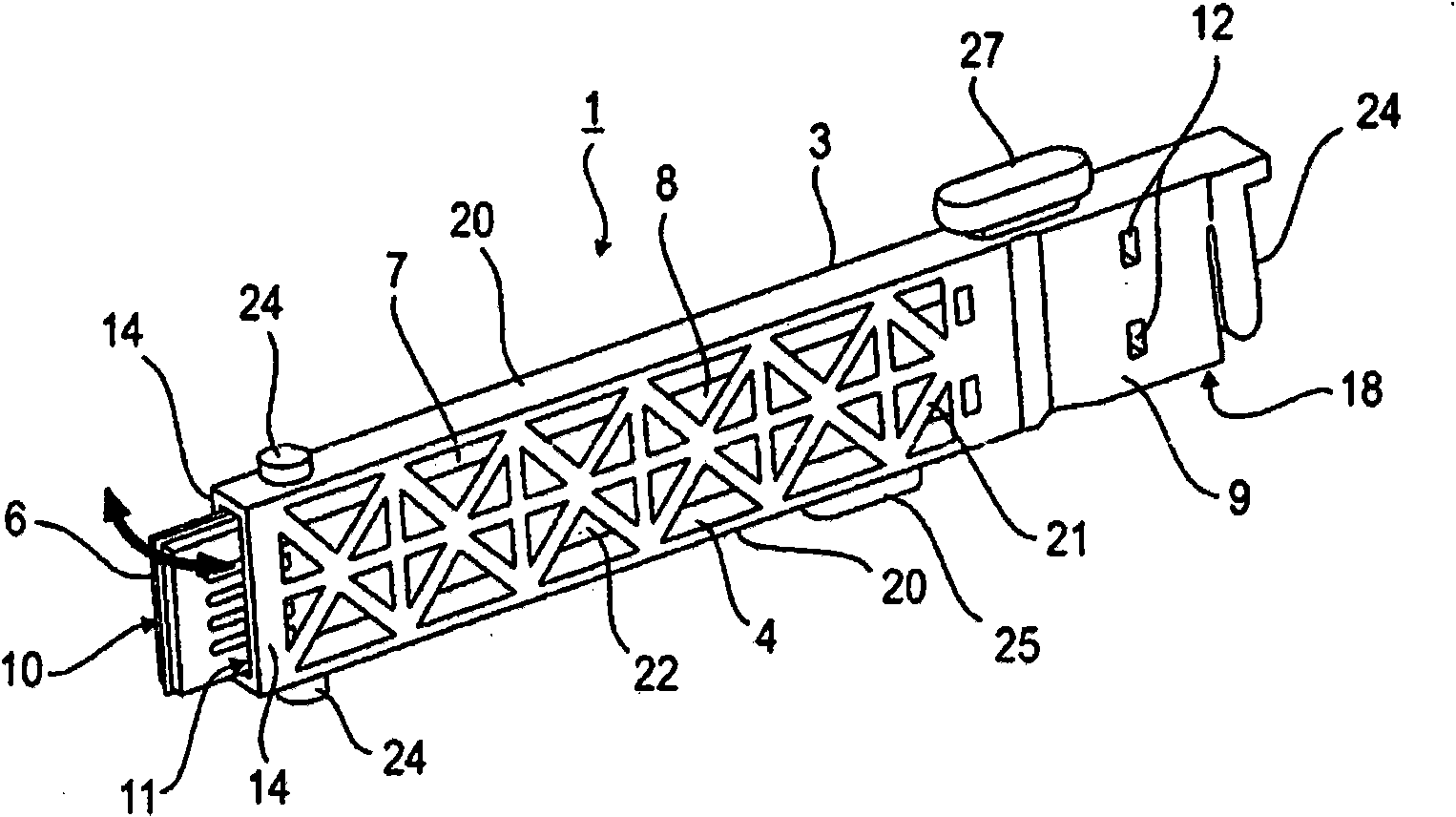

Filtering assembly and a feedthrough assembly

InactiveUS20080247117A1Inhibit currentGuaranteed uptimeAnti-noise capacitorsElectrotherapyCapacitanceEngineering

Filtering assembly for a feedthrough, for implantable medical devices, having operating conductive pin(s) and a ground conductive pin. The filtering assembly has:first insulating substrate,first conductive layer accommodated at first side of first insulating substrate and second conductive layer accommodated at second side of first insulating substrate opposing first side,first conductive layer comprises a conductive ground ring accommodated that surrounds the circumference of one end of the operating conductive pins and capacitive element(s), wherein each of the capacitive element(s) provides on the first side a connection to the operating conductive pin(s) and on the second side a connection to the ground ring, wherein the ground ring is connected to the ground pin,the second conductive layer comprises a ground plane providing connection to the ground ring of the first conductive layer and a connection to the ground pin.Further directed to a feedthrough assembly comprising the inventive filtering assembly.

Owner:BIOTRONIK SE & CO KG

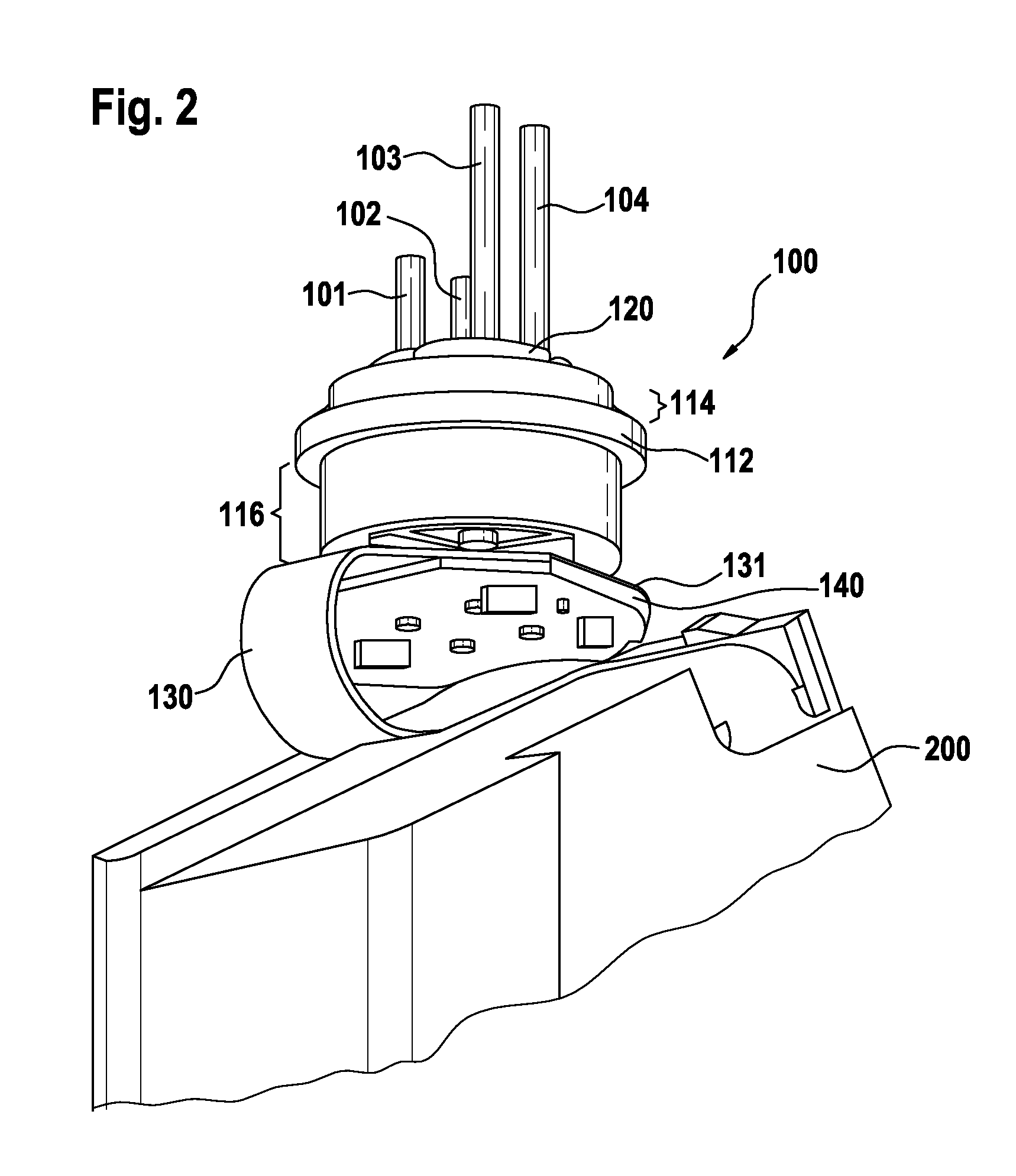

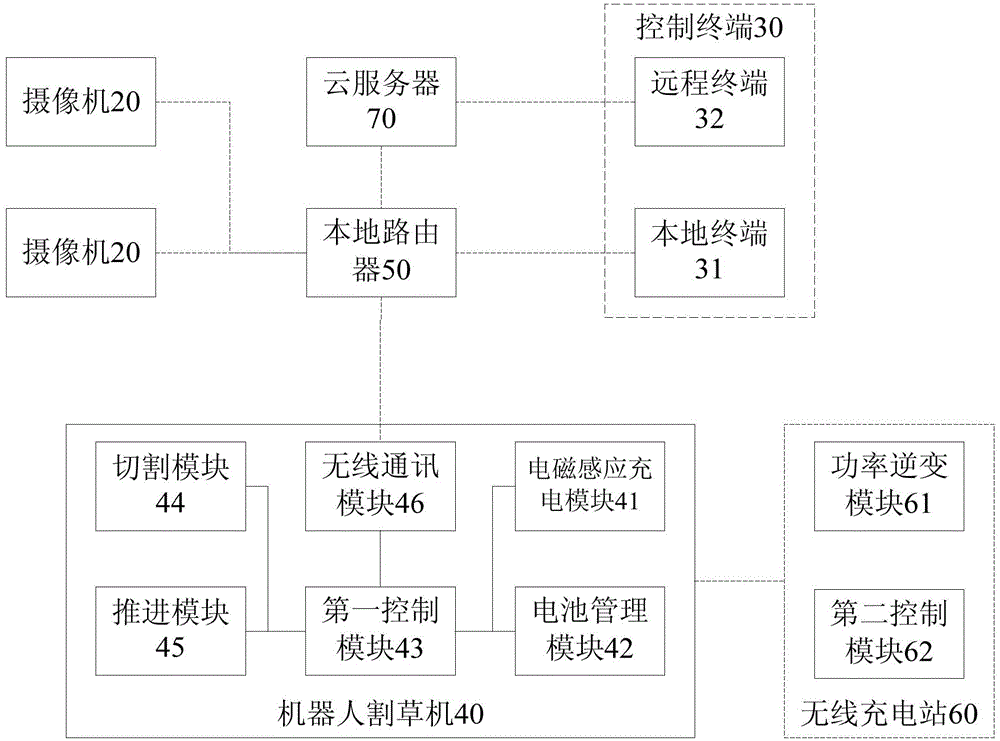

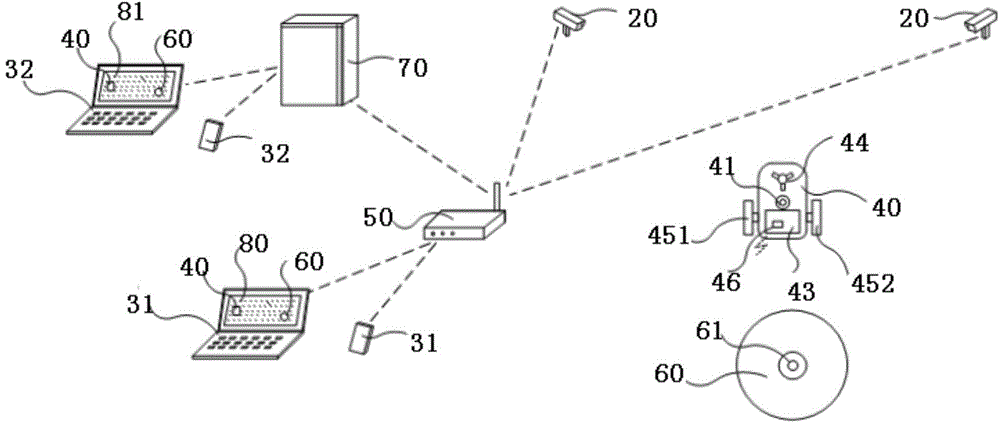

Robot mowing system capable of customizing mowing zone and control method thereof

InactiveCN104699101ANot affectedMowing path freedomPosition/course control in two dimensionsVehiclesSimulationComputer terminal

The invention discloses a robot mowing system capable of customizing mowing zone and a control method of the robot mowing system. The system comprises at least one camera, a control terminal, a robot mowing machine and a local router; the camera is used for collecting an image of the mowing zone and sending the image to the control terminal through a local router; the control terminal is used for controlling the camera to collect the image of the mowing zone, and generating and customizing an environmental drawing of the mowing zone corresponding to the customized mowing zone and a corresponding space coordinate system according to the image of the mowing zone; a first space coordinate (X1, Y1) of the robot mowing machine is marked in the environmental drawing of the mowing zone c; moreover, the control terminal is further used for controlling the work of the robot mowing machine according to a first control instruct input by a user, and monitoring the working state of the robot mowing machine by monitoring the position change of the first space coordinate (X1, Y1) in a space coordinate system. The robot mowing system needs not to preset a boundary lead, and can customize the mowing zone in real time; moreover, the mowing path is more free, and not influenced by the boundary lead.

Owner:SHENZHEN TOPBAND CO LTD

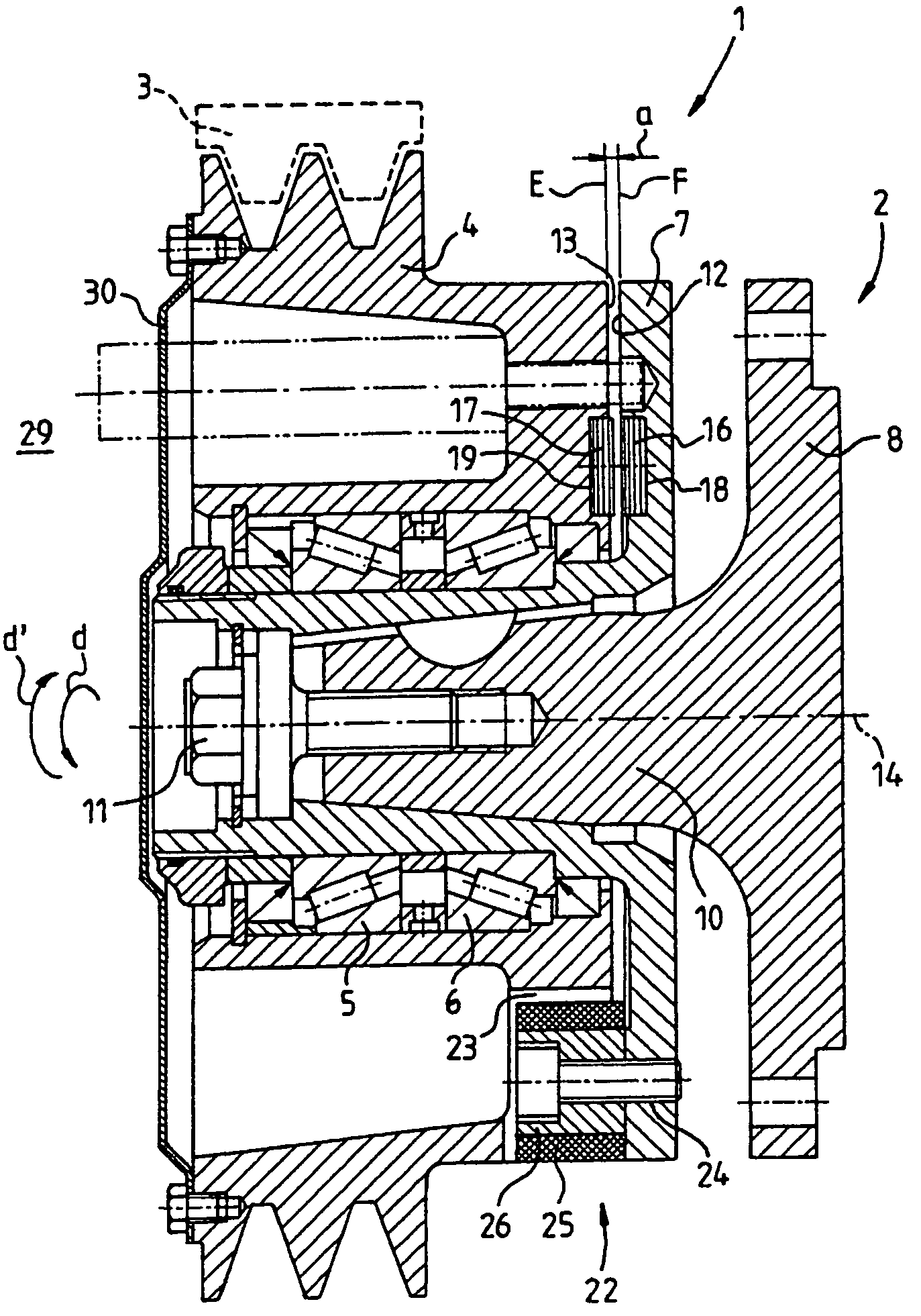

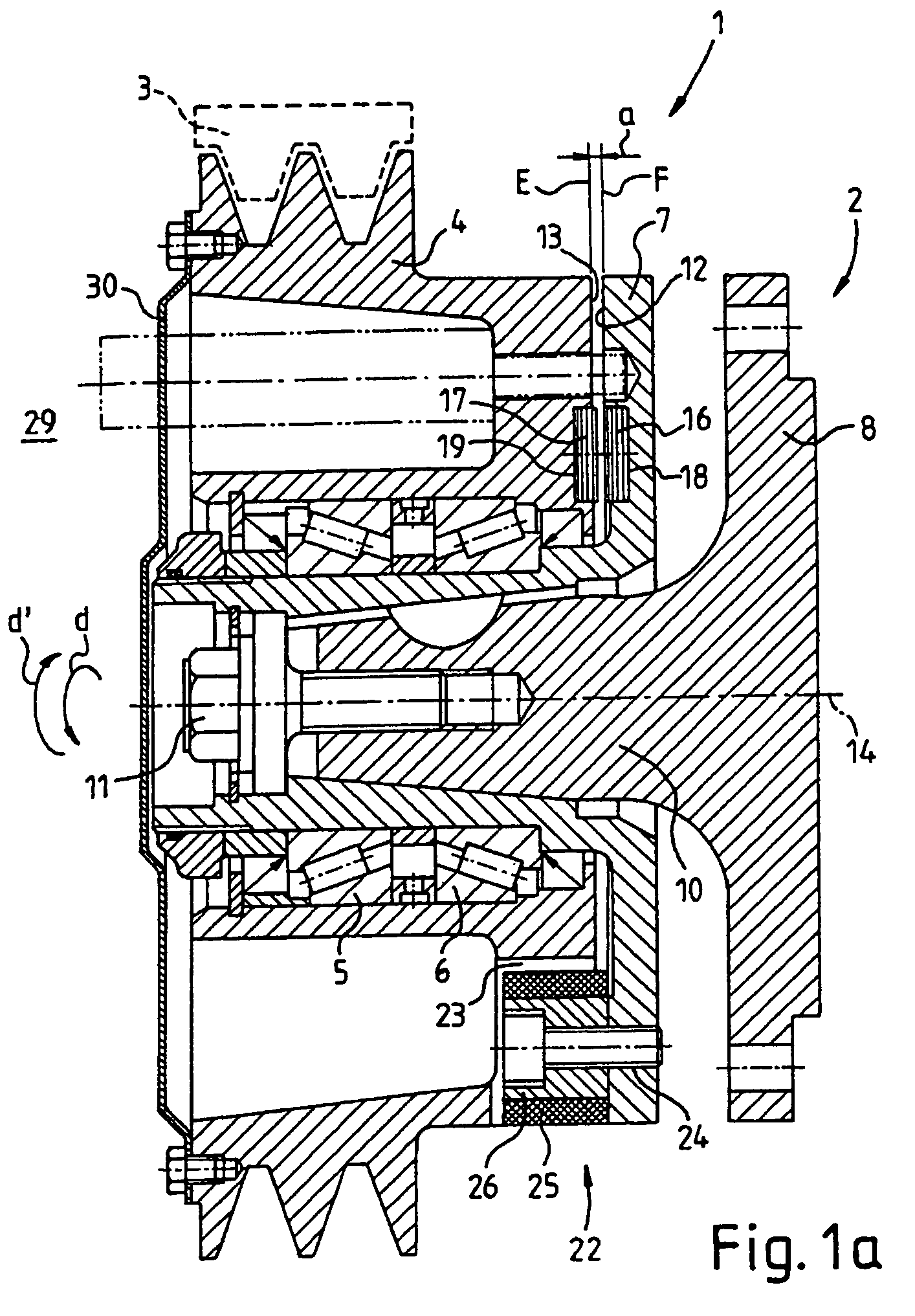

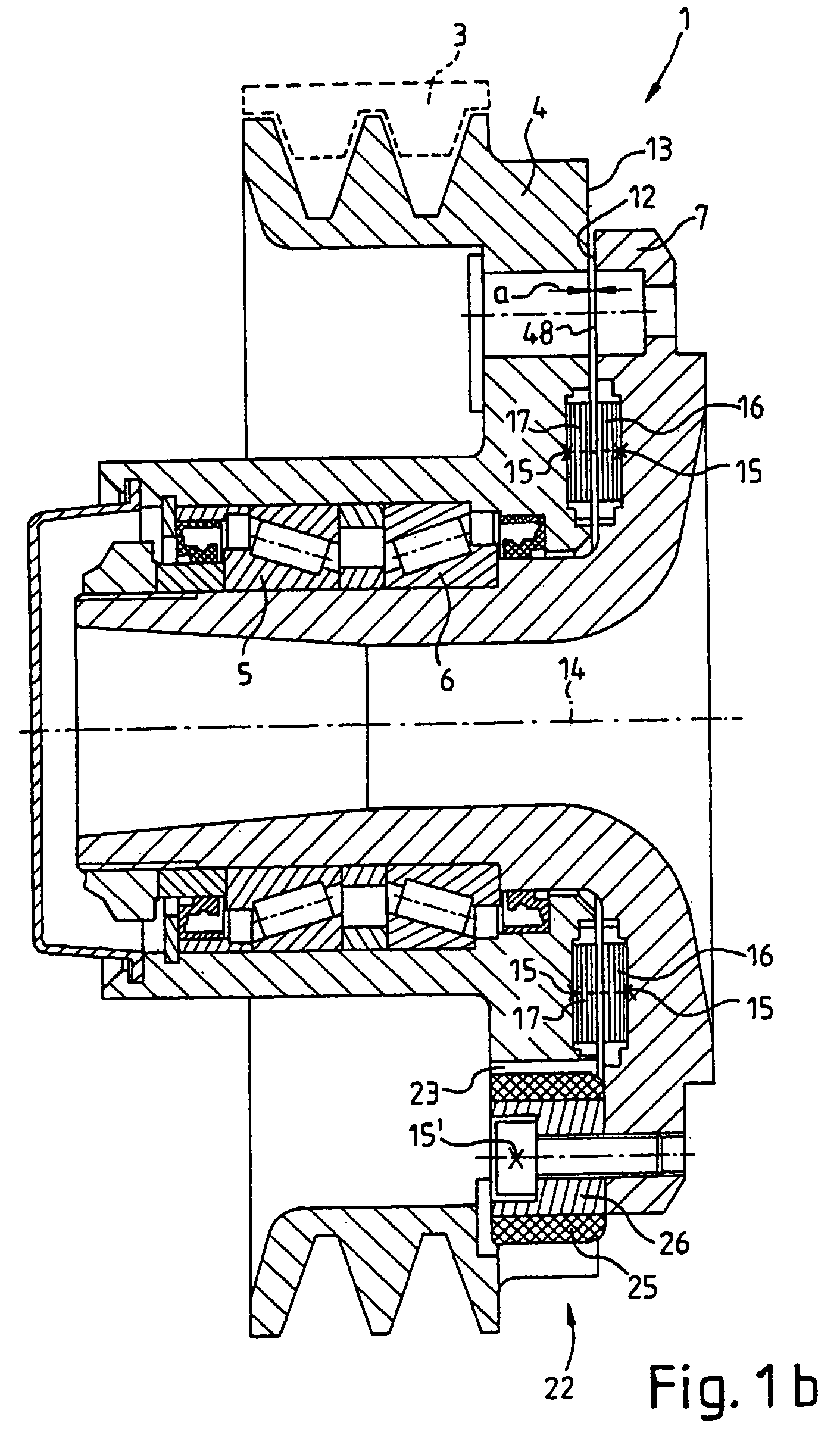

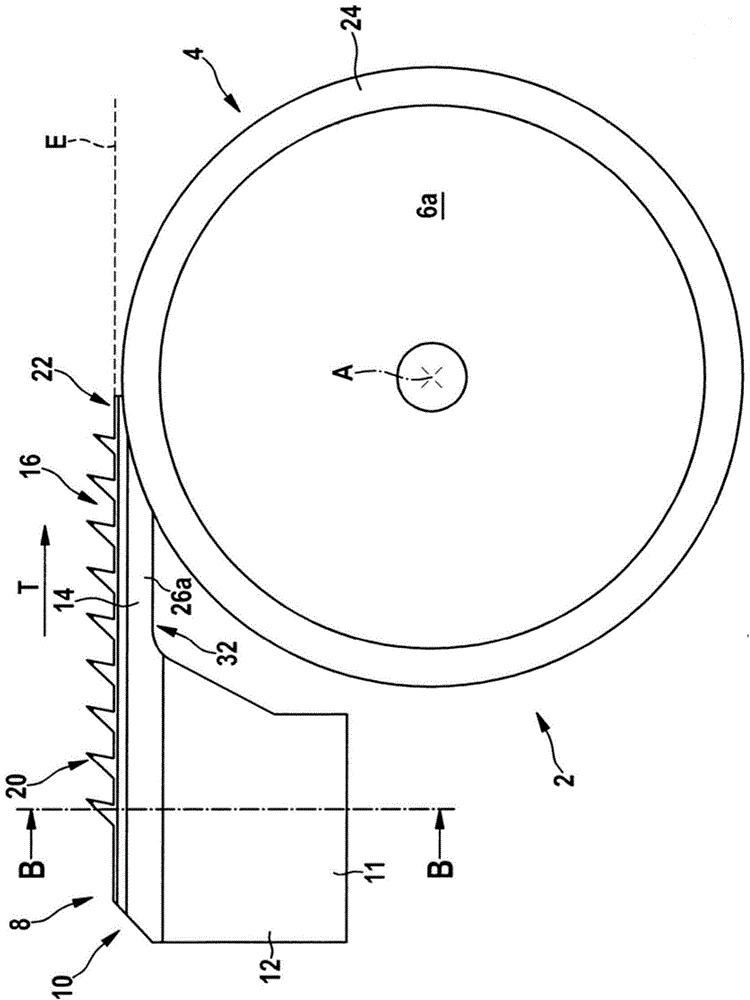

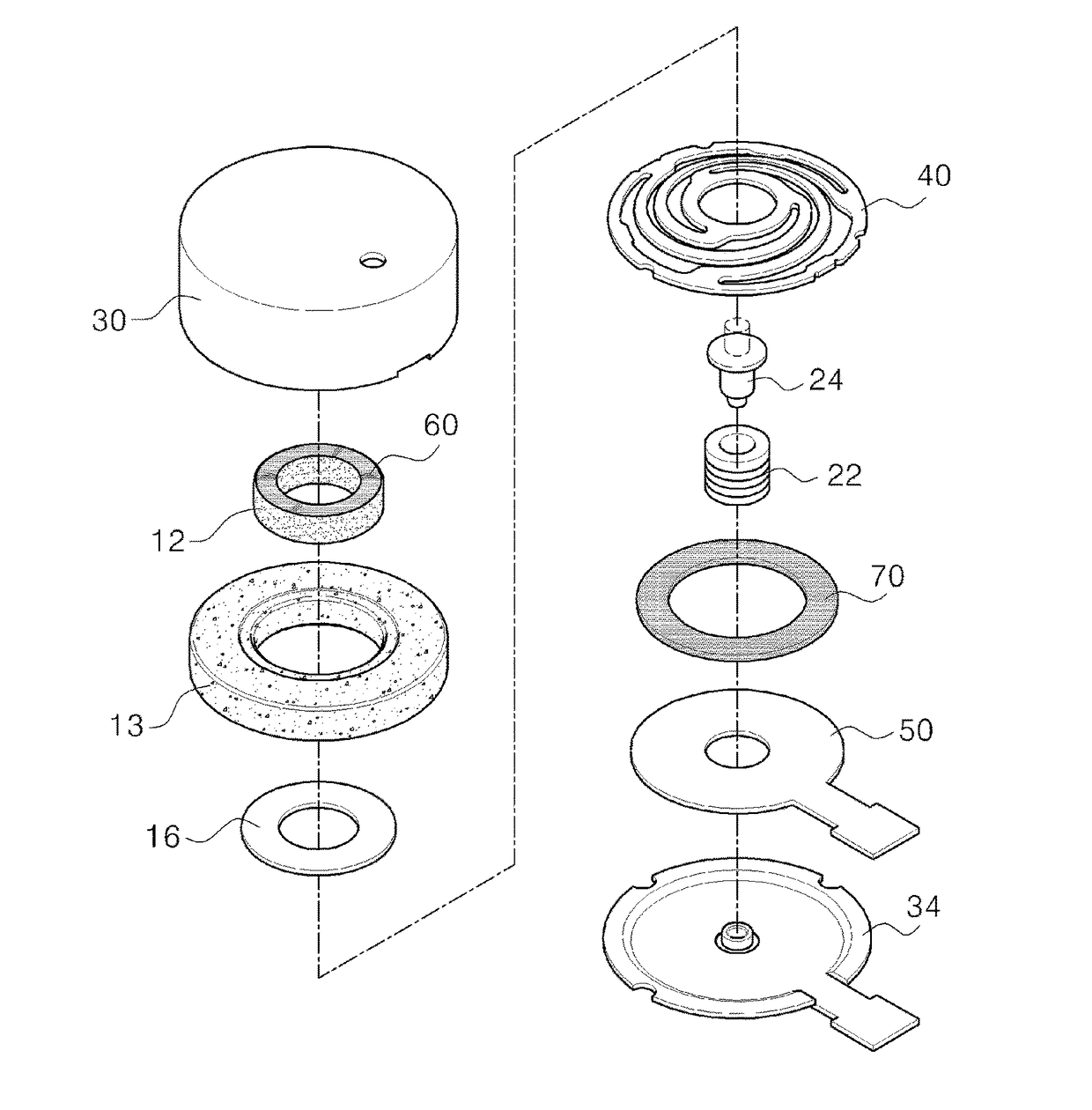

Device for damping torsional vibrations

InactiveUS7013859B2Simple structural designLow costRotating vibration suppressionDynamo-electric brakes/clutchesEngineeringTorsional vibration

The invention relates to a device (1) for damping torsional vibrations, having a driving and a driven component (4, 7). Provision is made in this case to provide between the components individual magnets (16, 17) which lie opposite each other and can be displaced in a limited manner with respect to each other in an angular range, the torsional capacity of the two components with respect to each other being limited by mechanical stops (22).

Owner:KARL HEINZ LINNIG GMBH & CO KG

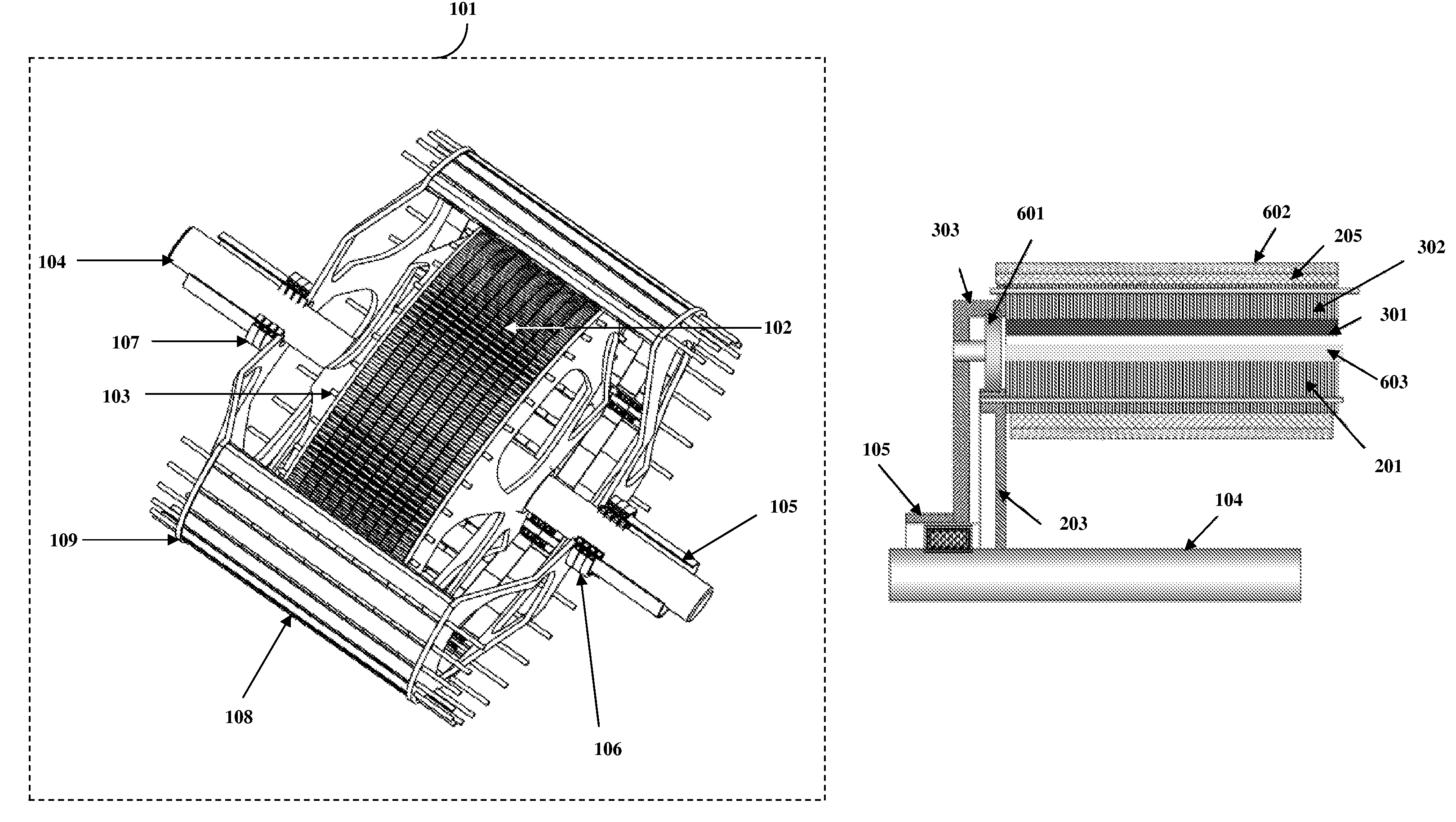

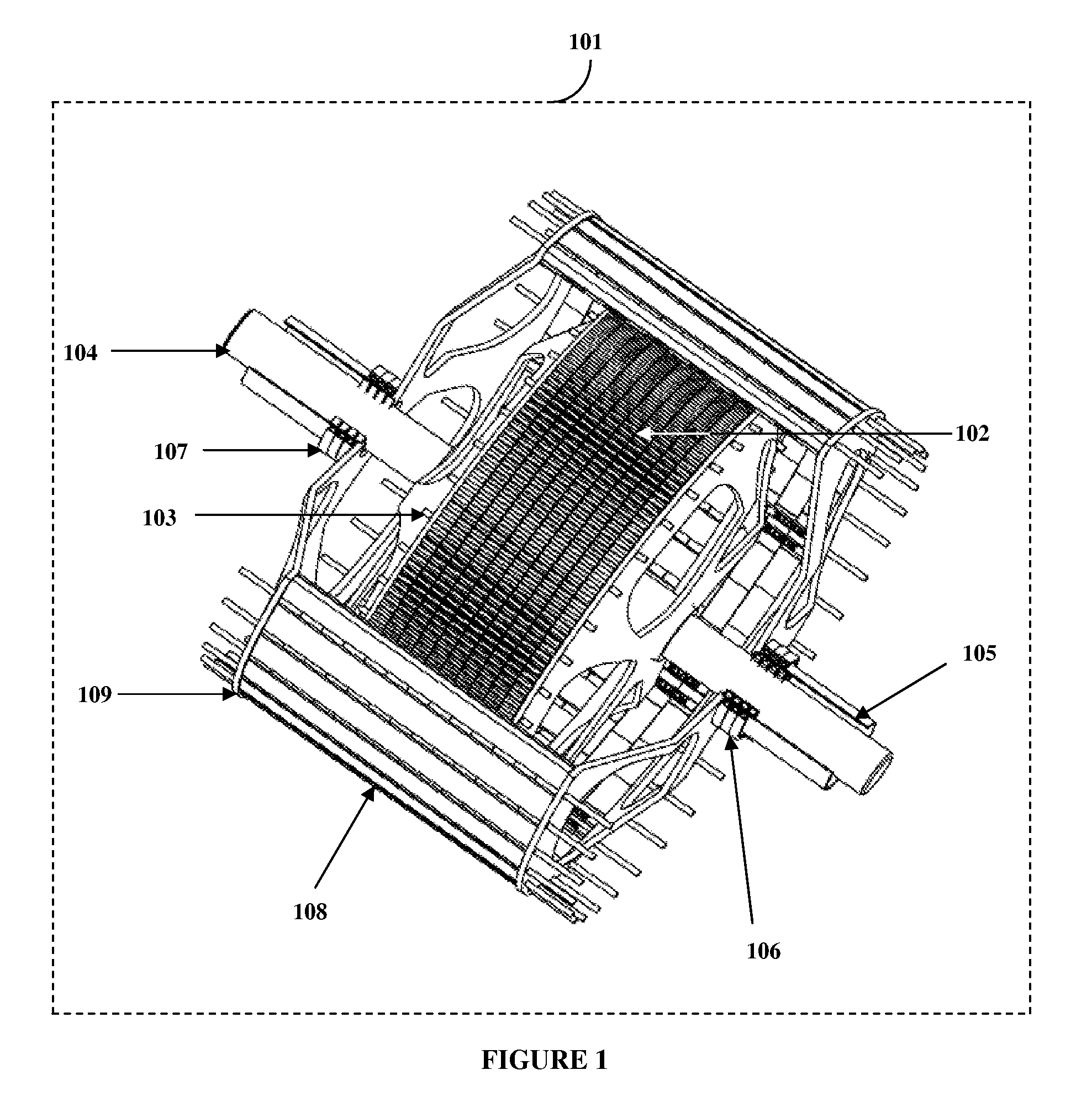

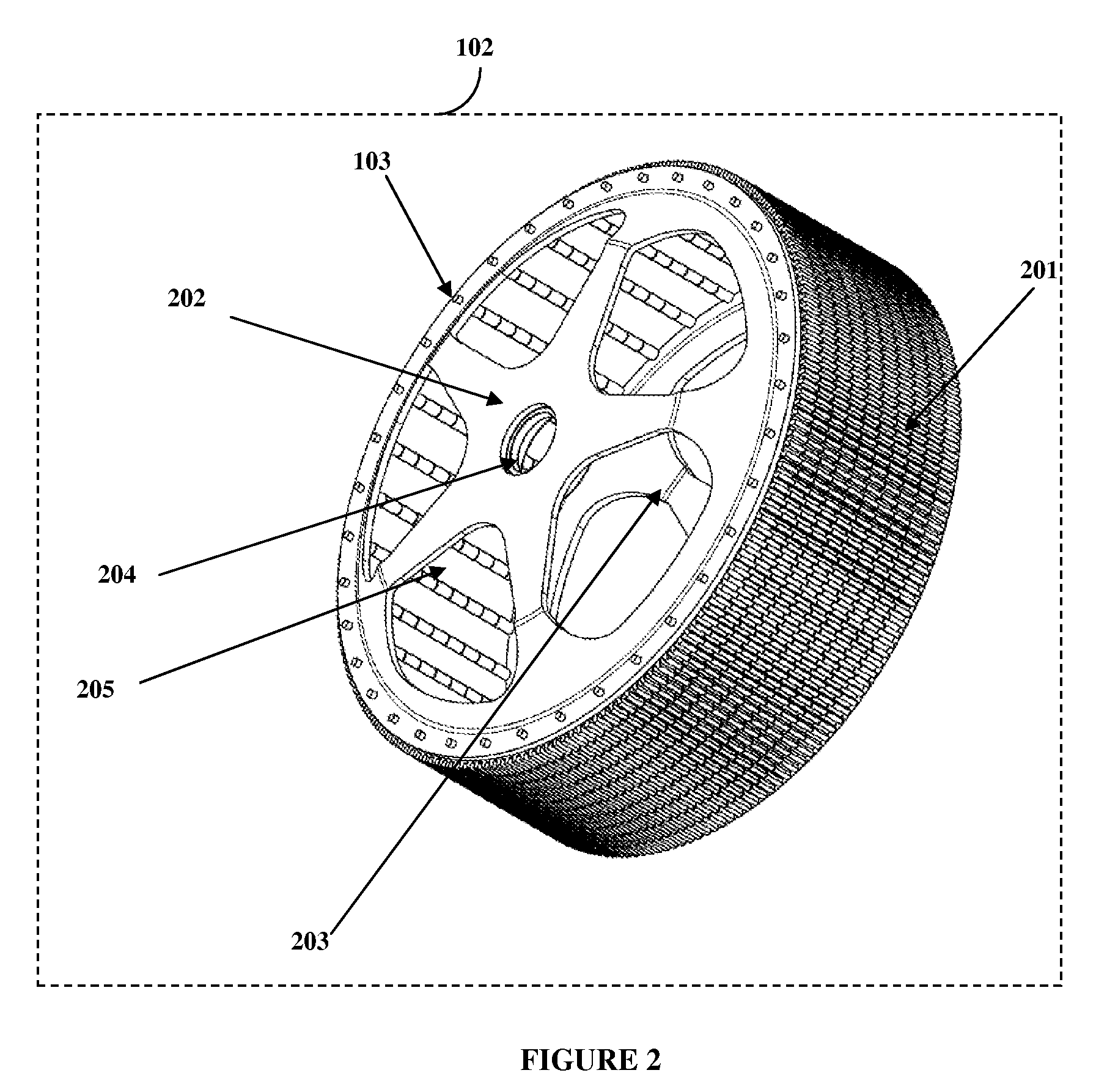

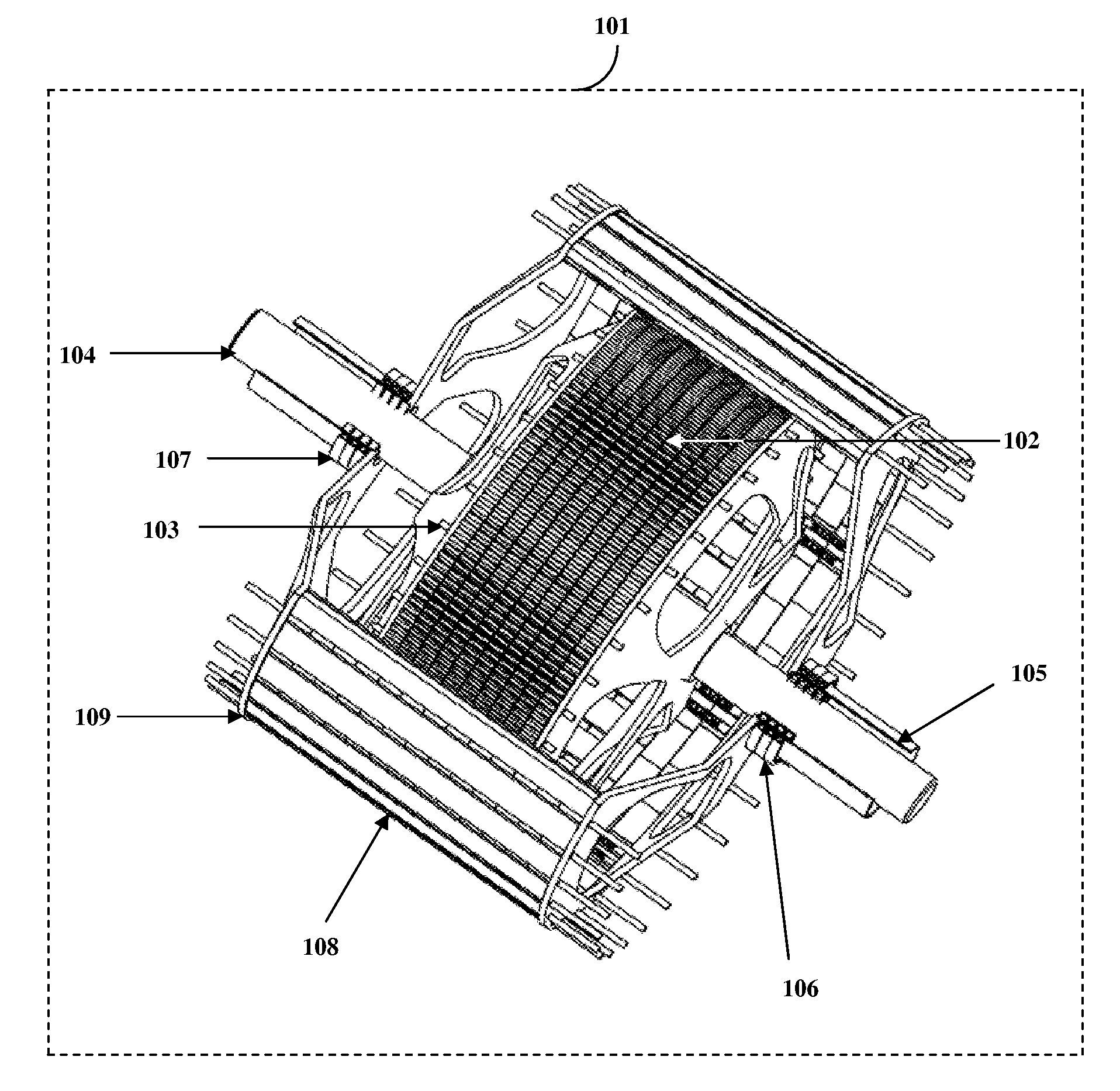

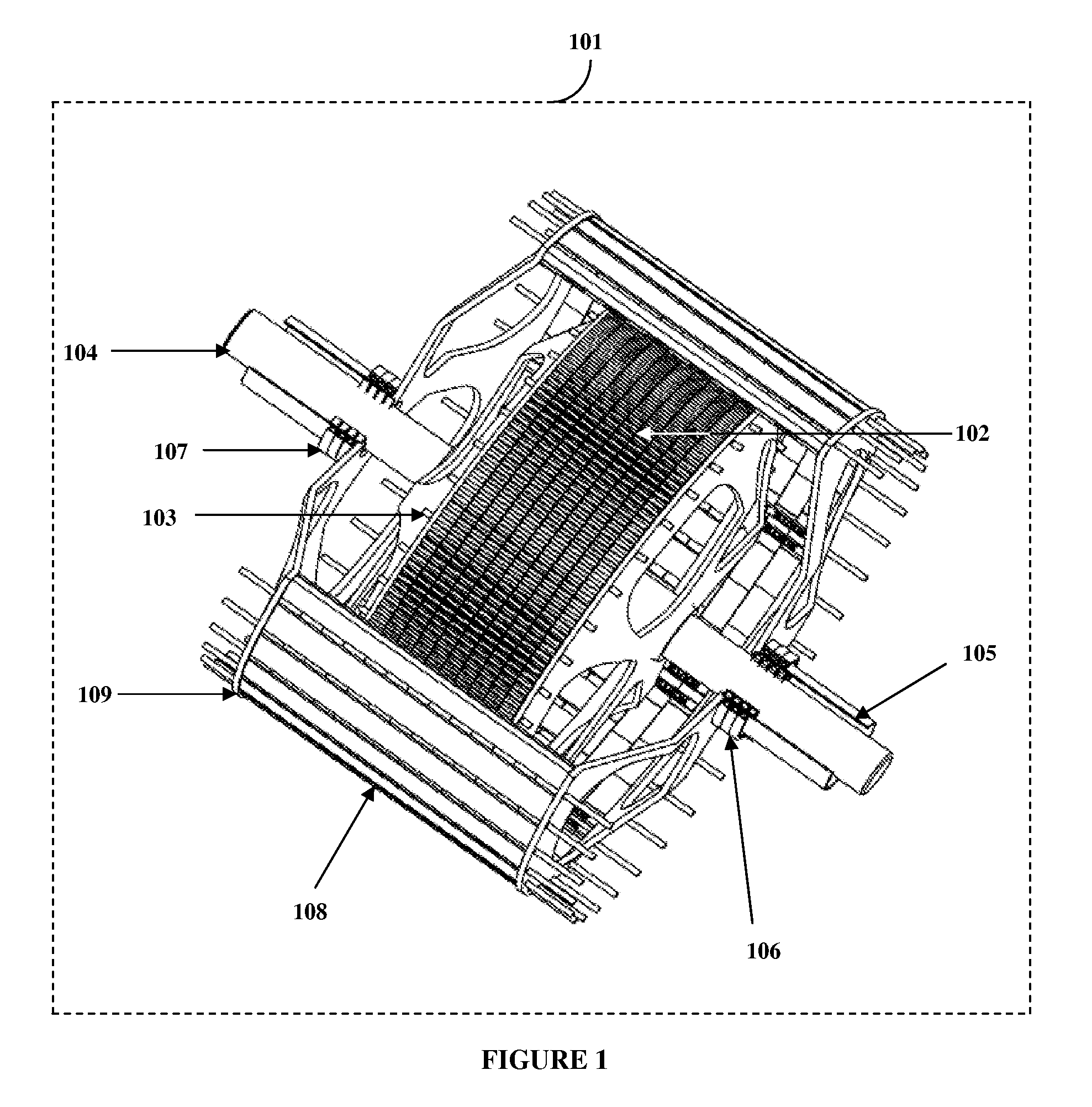

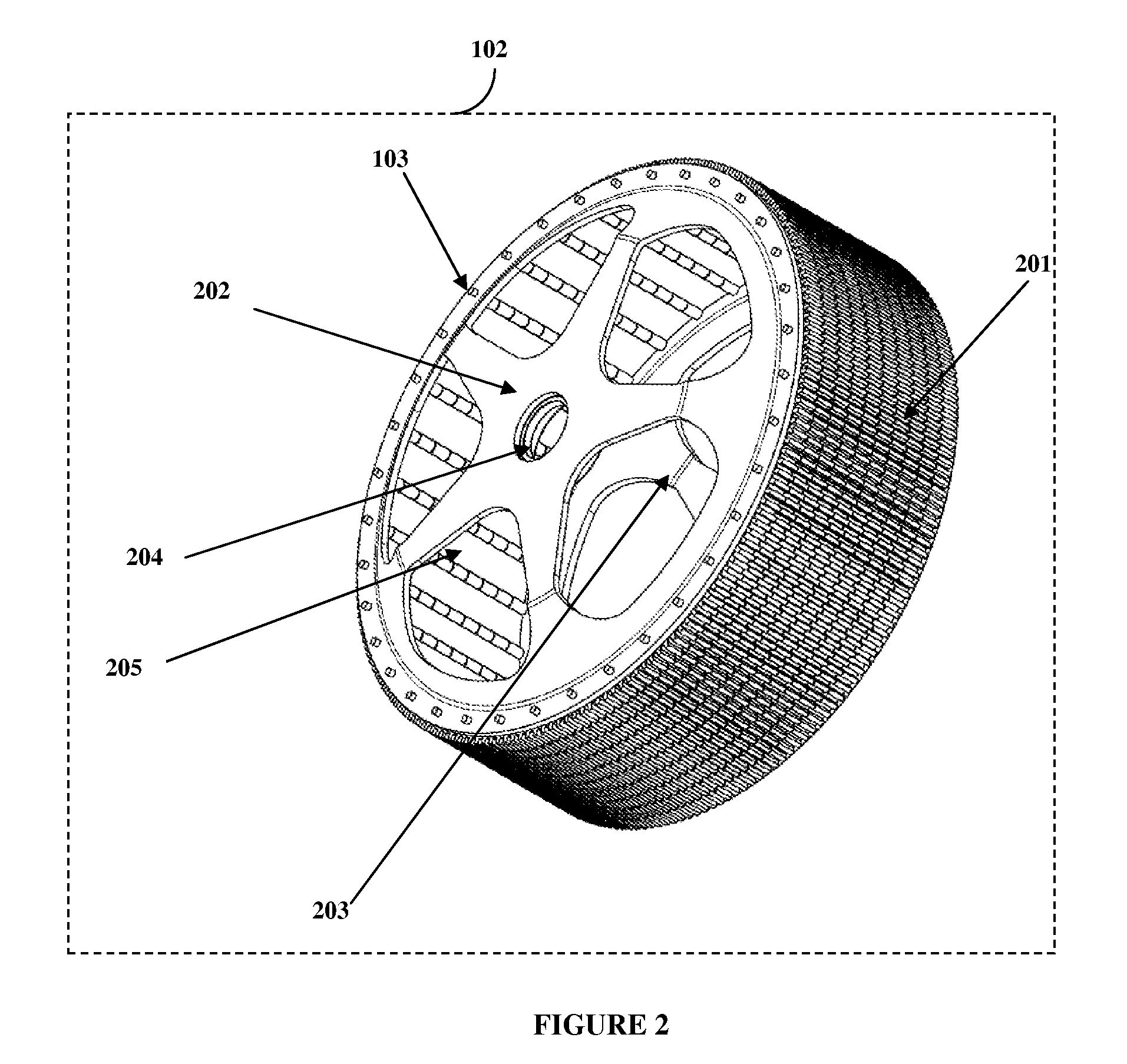

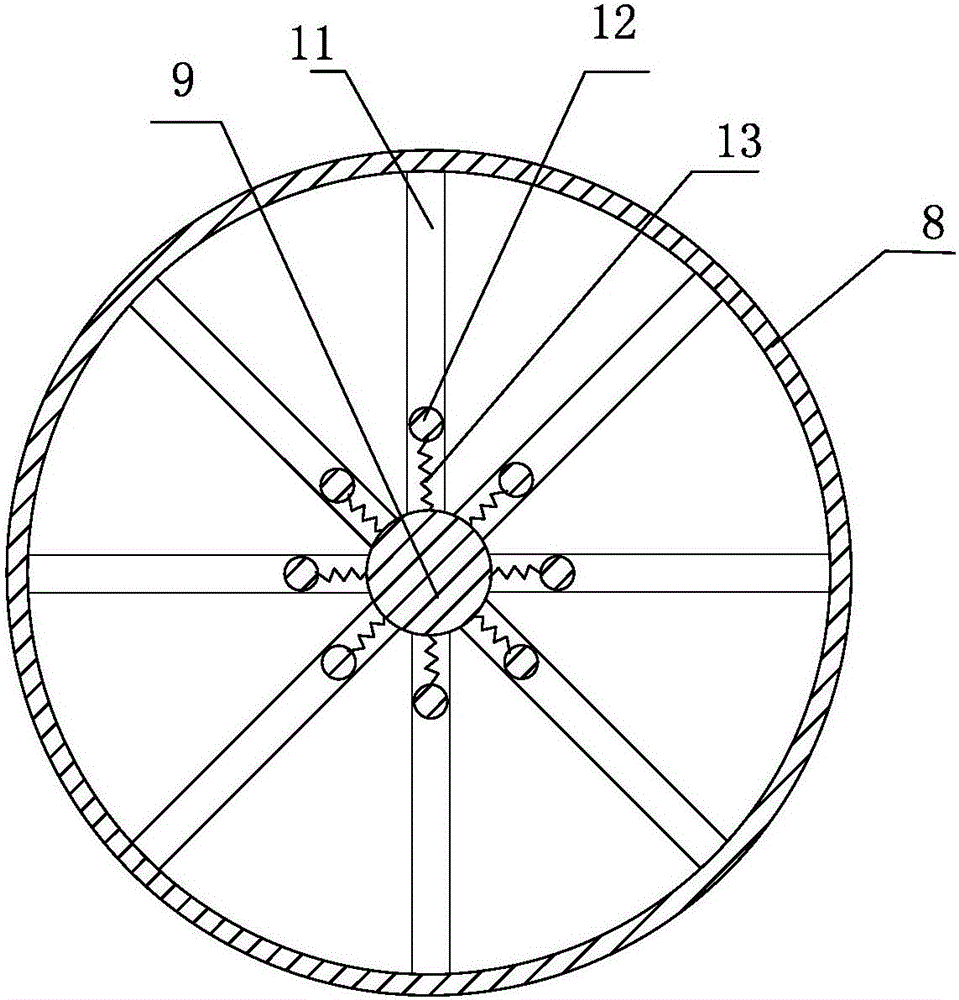

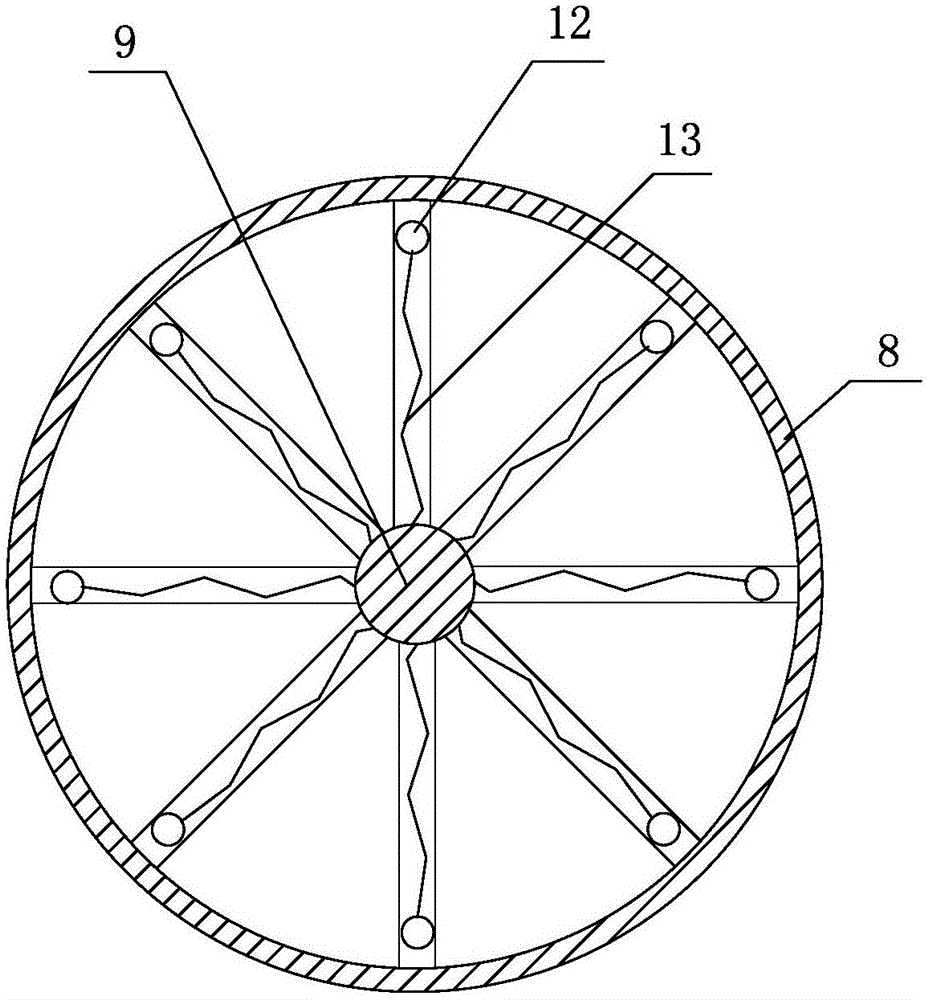

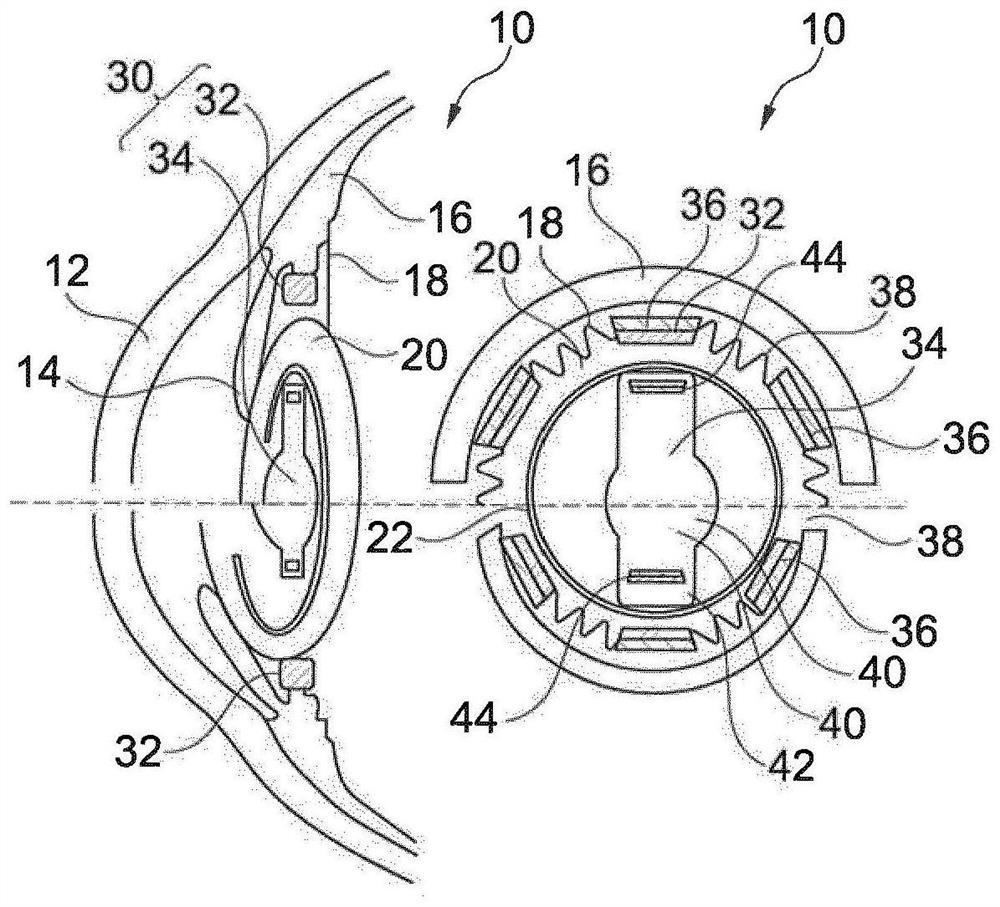

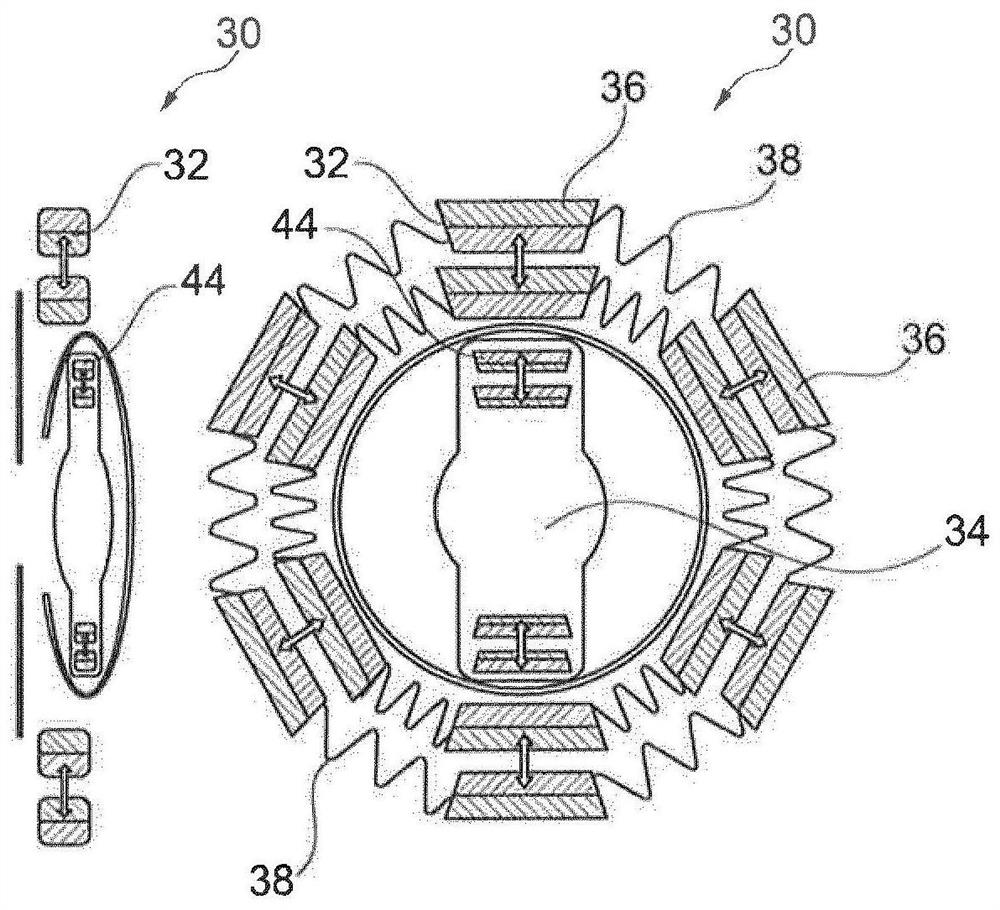

Contra rotating generator

InactiveUS7679249B2Increase speedLow costMagnetic circuit rotating partsGas turbine plantsEngineeringCam

Disclosed herein is an apparatus of a contra rotating generator. The contra rotating generator comprises a cylindrical armature supported on an inner shaft. The inner shaft rotates in a first direction. A cylindrical magnetic field rotor is supported on an outer shaft. The outer shaft is oriented coaxially to the inner shaft. The outer shaft contra rotates opposite to the first direction. A plurality of cam followers maintains uniform air gap between outer surface of the cylindrical armature and inner surface of the cylindrical magnetic field rotor. The uniform air gap prevents mechanical contact between the cylindrical armature and the cylindrical magnetic field rotor. A sprag clutch prevents unidirectional rotation of the inner shaft and the outer shaft. The contra rotation between the cylindrical armature and the cylindrical magnetic field rotor increases relative magnetic flux speed for generating electrical power at low speeds of operation.

Owner:APPA KARI +1

Contra rotating generator

InactiveUS20080211236A1Increase relative magnetic flux speedReduced generator physical dimensionMagnetic circuit rotating partsGas turbine plantsEngineeringCam

Disclosed herein is an apparatus of a contra rotating generator. The contra rotating generator comprises a cylindrical armature supported on an inner shaft. The inner shaft rotates in a first direction. A cylindrical magnetic field rotor is supported on an outer shaft. The outer shaft is oriented coaxially to the inner shaft. The outer shaft contra rotates opposite to the first direction. A plurality of cam followers maintains uniform air gap between outer surface of the cylindrical armature and inner surface of the cylindrical magnetic field rotor. The uniform air gap prevents mechanical contact between the cylindrical armature and the cylindrical magnetic field rotor. A sprag clutch prevents unidirectional rotation of the inner shaft and the outer shaft. The contra rotation between the cylindrical armature and the cylindrical magnetic field rotor increases relative magnetic flux speed for generating electrical power at low speeds of operation.

Owner:APPA KARI +1

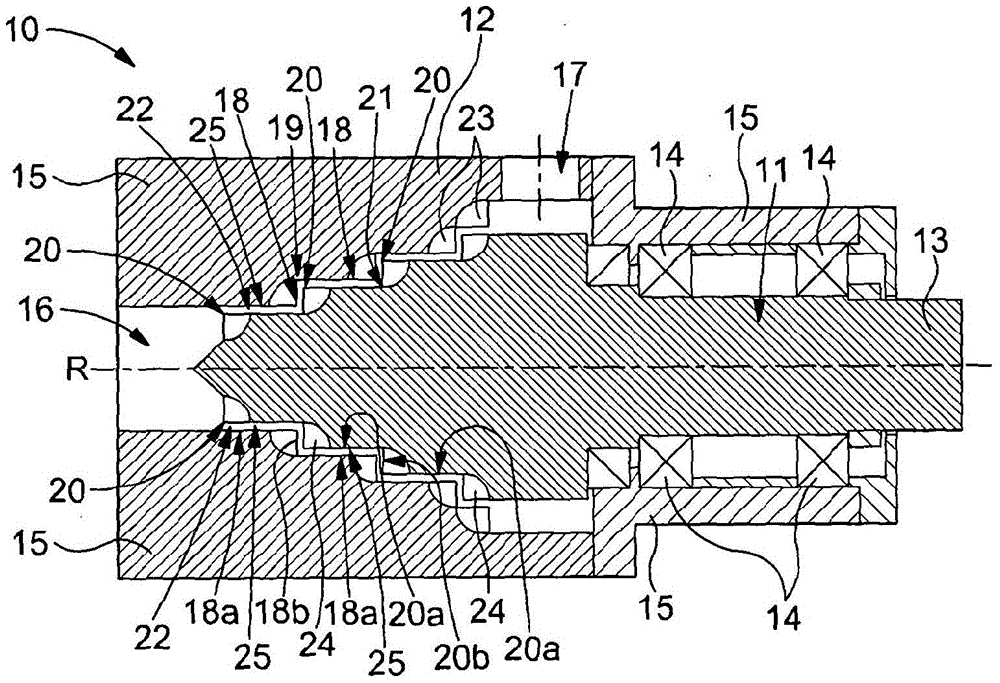

Filtering assembly and a feedthrough assembly

InactiveUS7511938B2Guaranteed uptimeLow thermal conductivityAnti-noise capacitorsElectrotherapyCapacitanceGround plane

Filtering assembly for a feedthrough, for implantable medical devices, having operating conductive pin(s) and a ground conductive pin. The filtering assembly has:first insulating substrate,first conductive layer accommodated at first side of first insulating substrate and second conductive layer accommodated at second side of first insulating substrate opposing first side,first conductive layer comprises a conductive ground ring accommodated that surrounds the circumference of one end of the operating conductive pins and capacitive element(s), wherein each of the capacitive element(s) provides on the first side a connection to the operating conductive pin(s) and on the second side a connection to the ground ring, wherein the ground ring is connected to the ground pin,the second conductive layer comprises a ground plane providing connection to the ground ring of the first conductive layer and a connection to the ground pin.Further directed to a feedthrough assembly comprising the inventive filtering assembly.

Owner:BIOTRONIK SE & CO KG

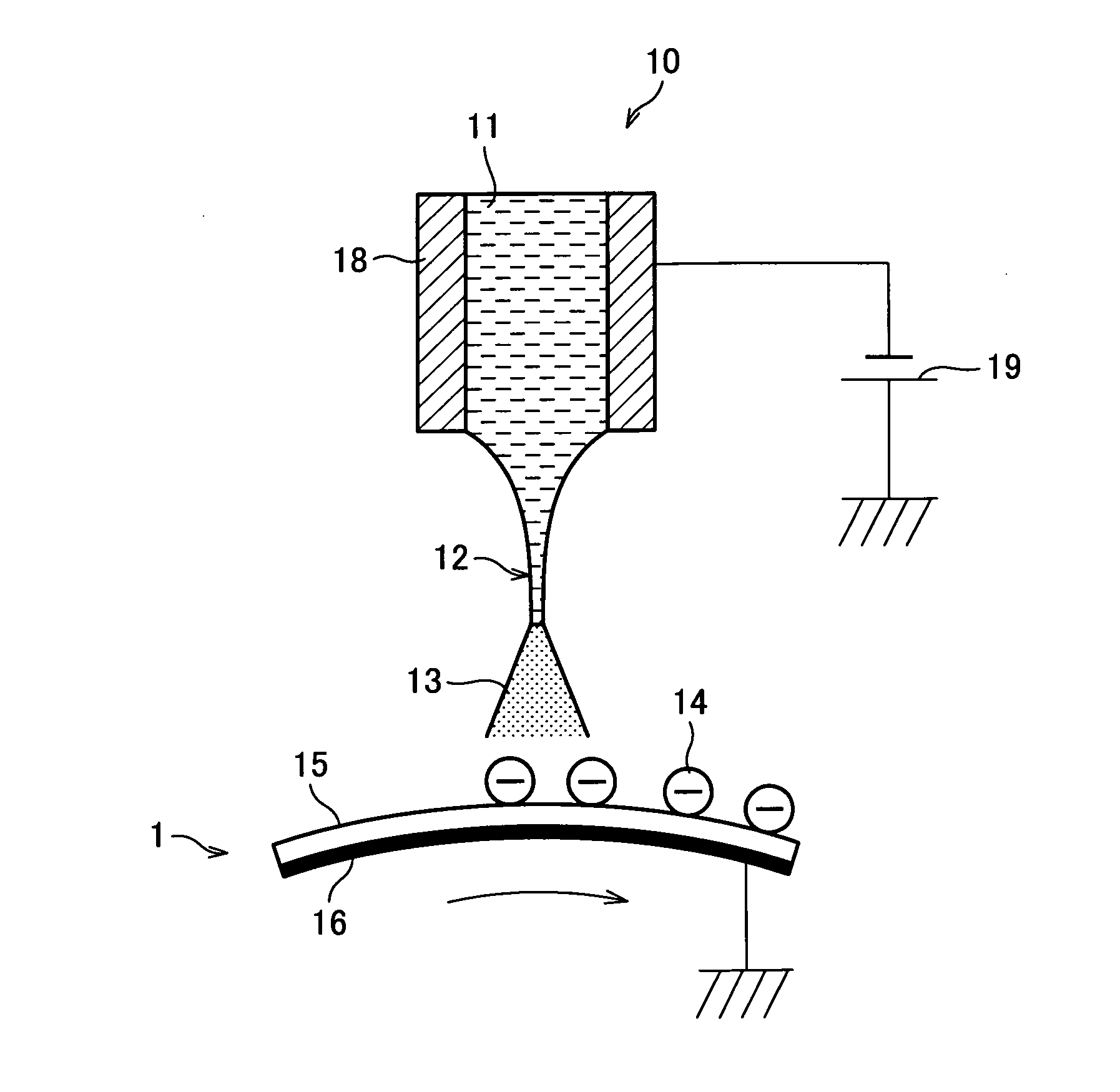

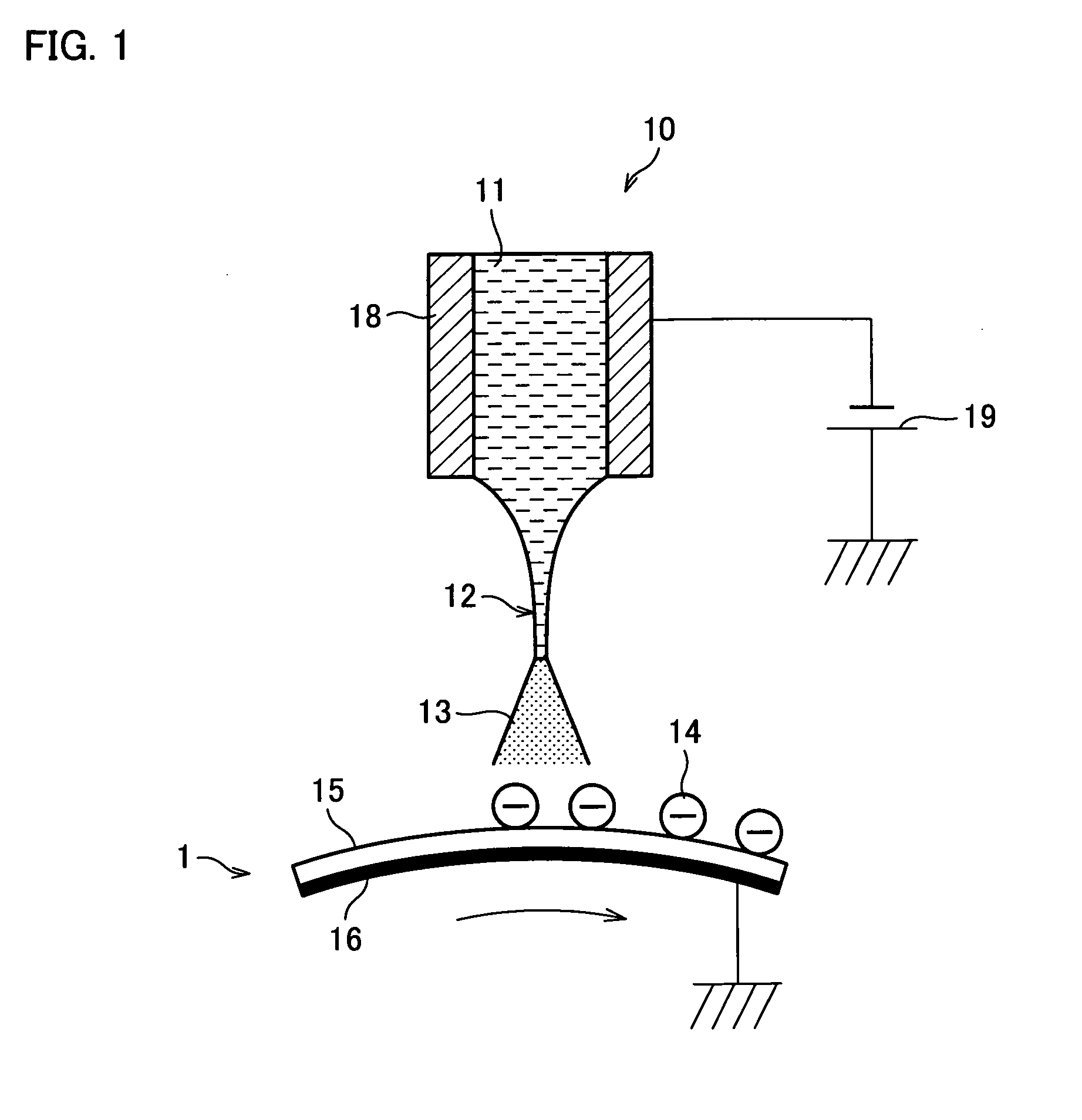

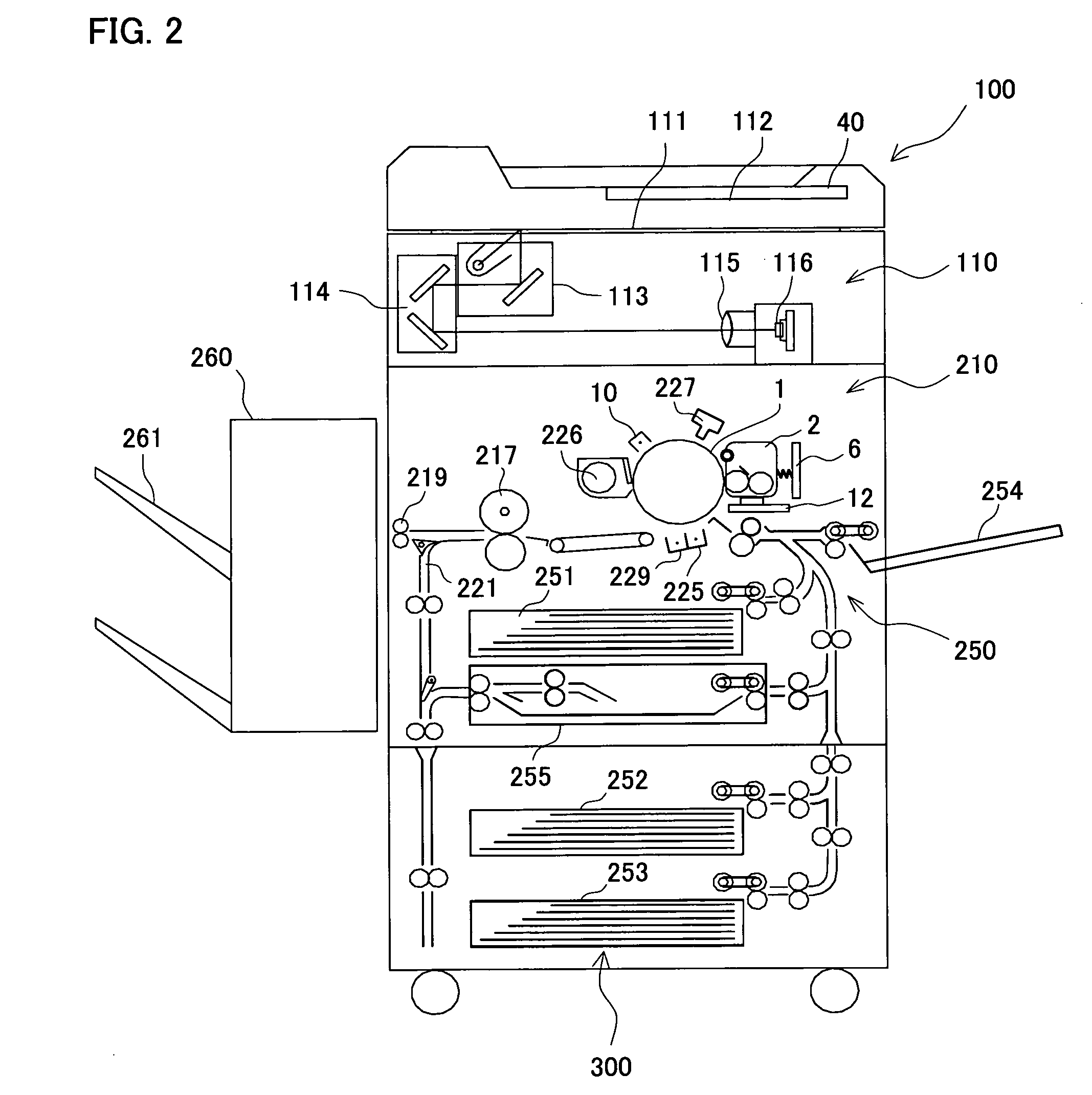

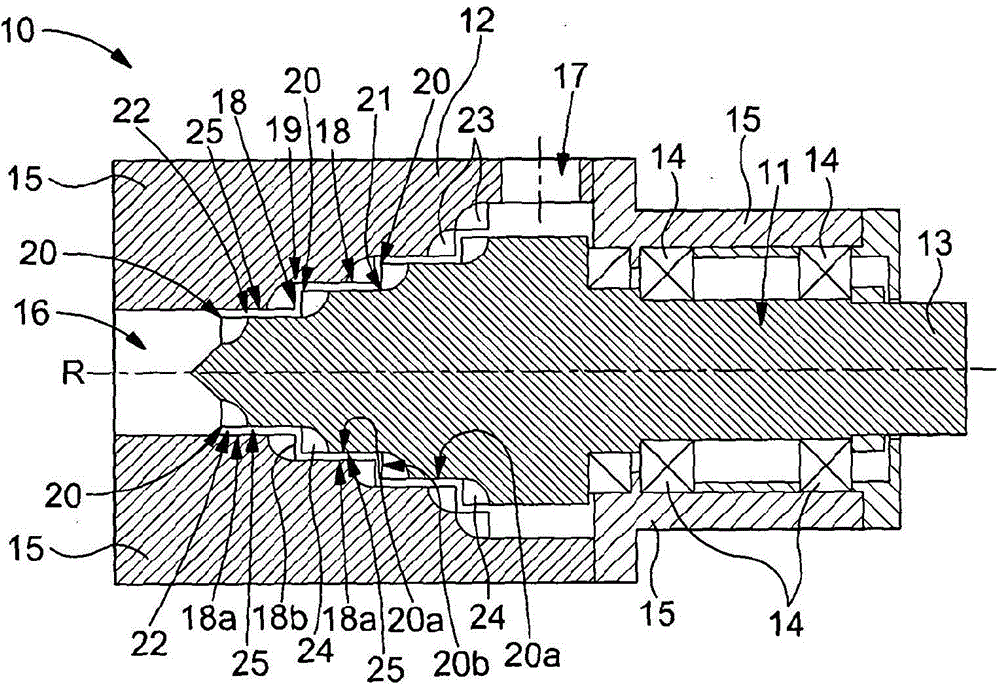

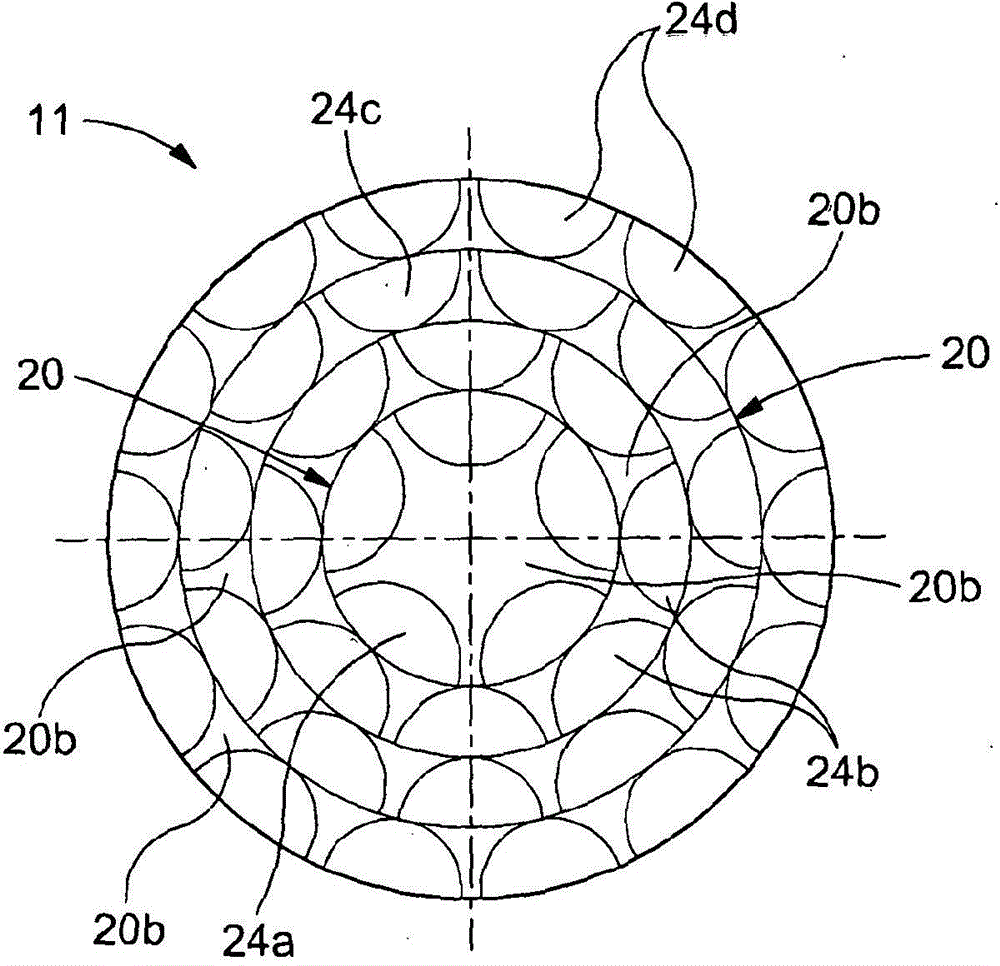

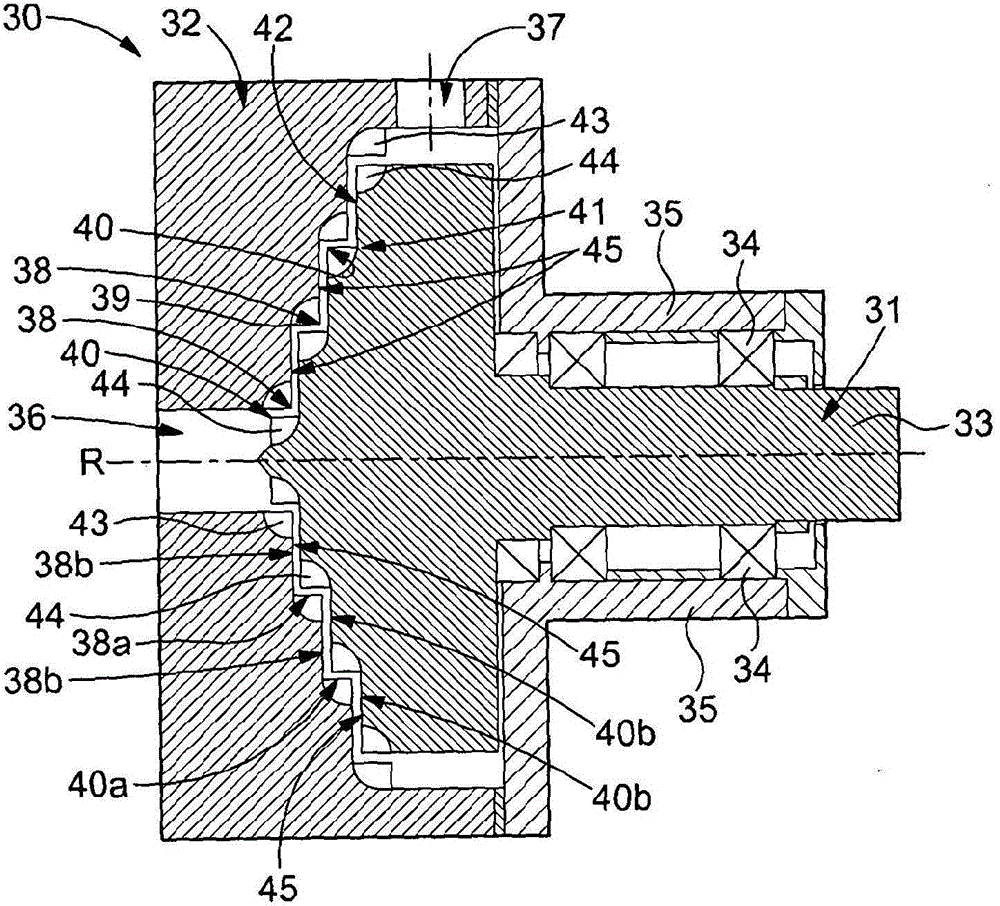

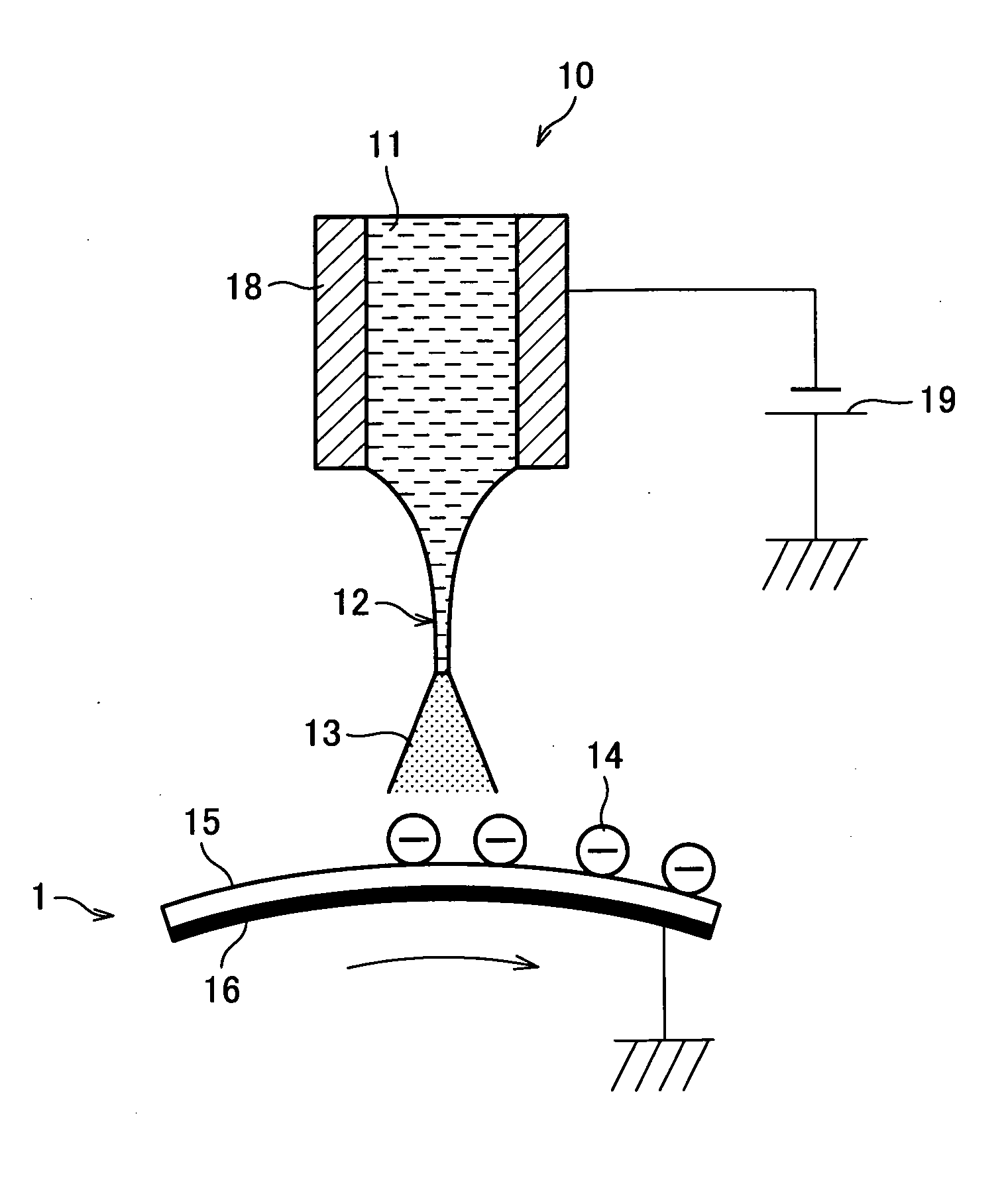

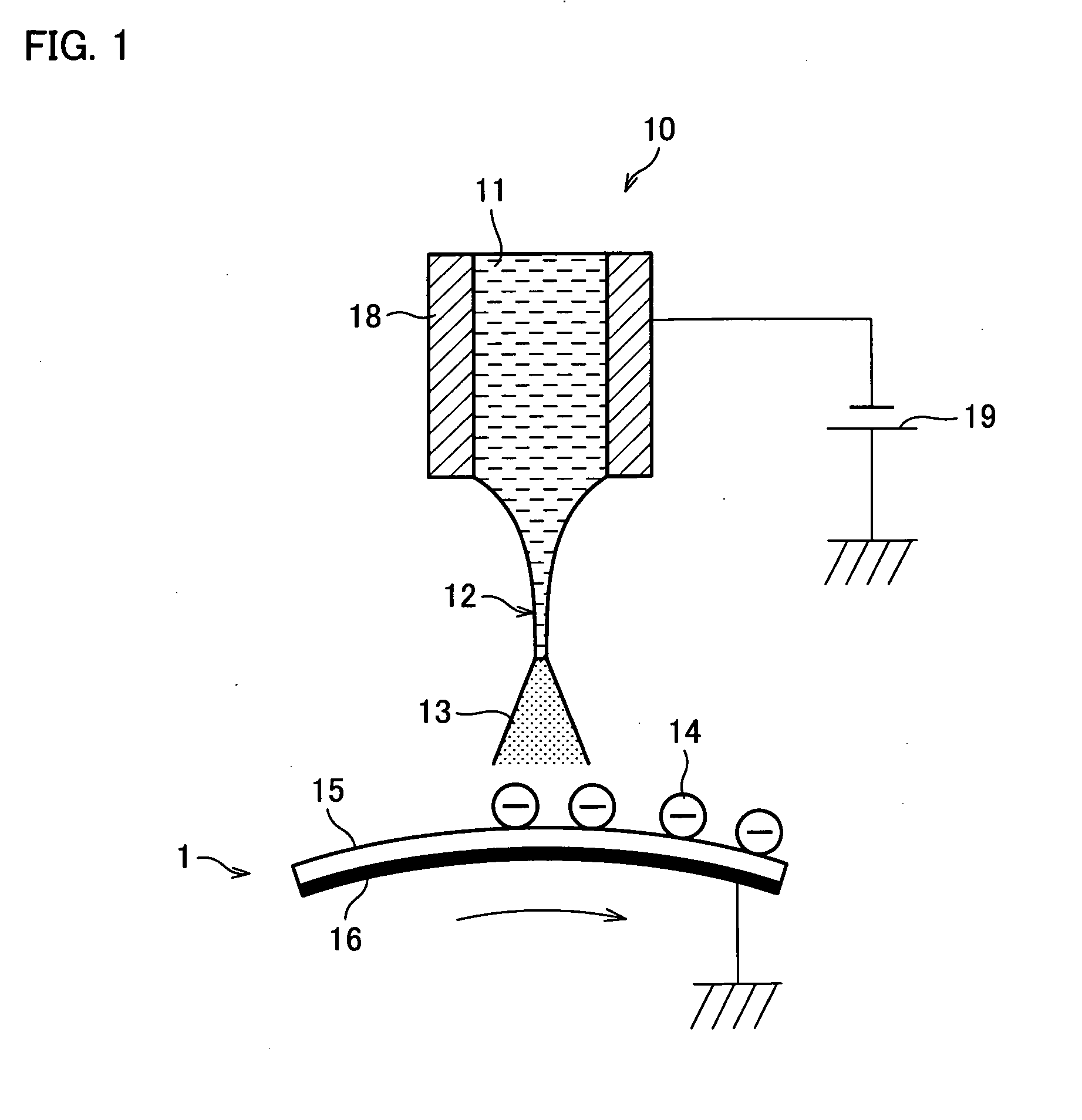

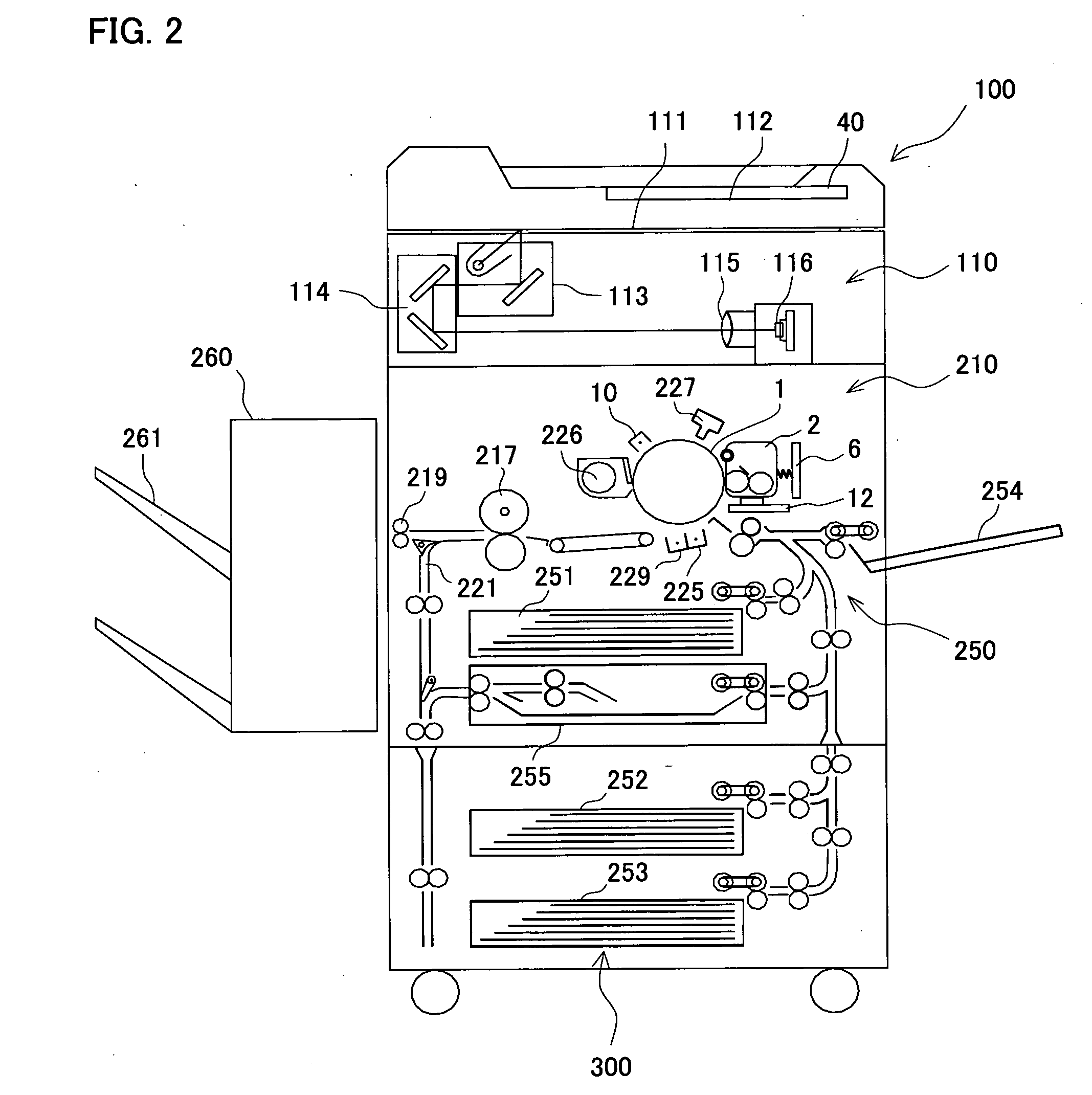

Charging device and image forming device using same

InactiveUS7970318B2Reduce ozone productionPrevent degradationElectrographic process apparatusCorona dischargeLatent imageImage formation

A charging device (10) includes electrospray means for inducing electrospraying through application of a voltage to an incoming liquid (11), in order to produce charged liquid droplets (13). The device (10) charges a photoreceptor drum (1) by means of the liquid droplets (13). Hence, the invention provides a charging device capable of reducing ozone production while preventing the charging device and the electrostatic latent image carrier from degrading or wearing out from friction between the device and the carrier and provides also an image forming device incorporating the charging device.

Owner:SHARP KK

Improved dynamic mixer

InactiveCN104159661ALow costReduce complexityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

Owner:MAELSTROM ADVANCED PROCESS TECH

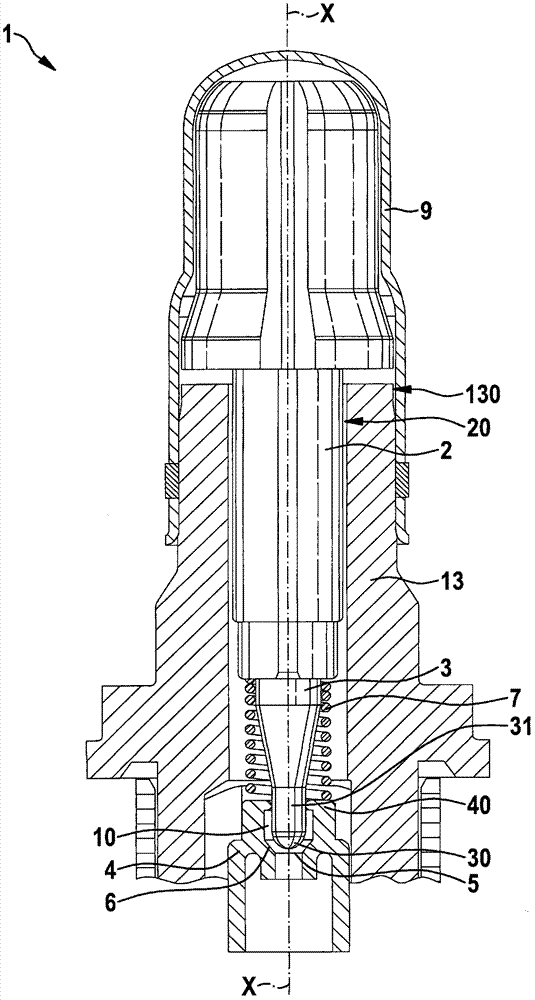

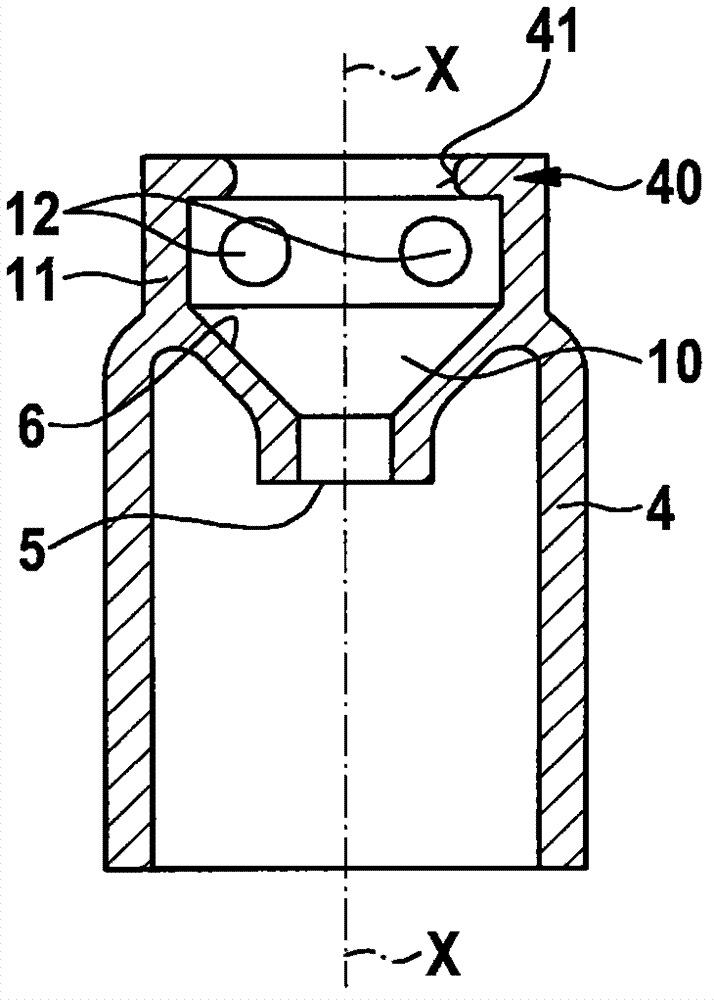

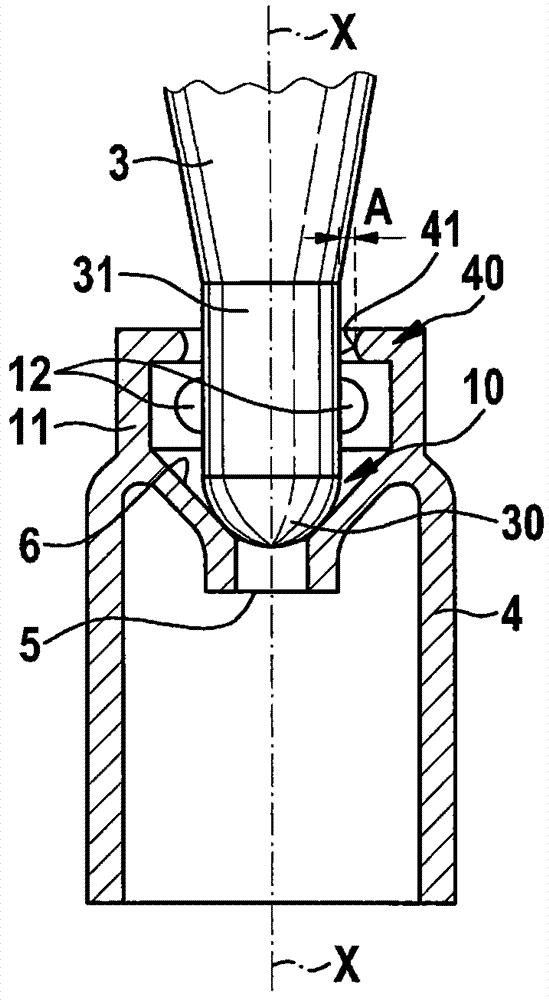

Solenoid valve for controlling fluid

InactiveCN102758948AShorten the tolerance chainSteer tight and preciseOperating means/releasing devices for valvesBraking systemsSolenoid valveEngineering

A solenoid valve for controlling a fluid comprising an armature, a valve member which has a dome-shaped end region and which is connected to the a mature and is movable jointly with the armature, a first guidance region being provided on the armature, and a valve body with a valve seat, with a through orifice, the valve member opening and closing the through orifice on the valve seat, and with a guide element which defines a second guidance region for guiding the valve member and which guides the valve member when the solenoid valve is open, the guide element being formed in one piece with the valve body.

Owner:ROBERT BOSCH GMBH

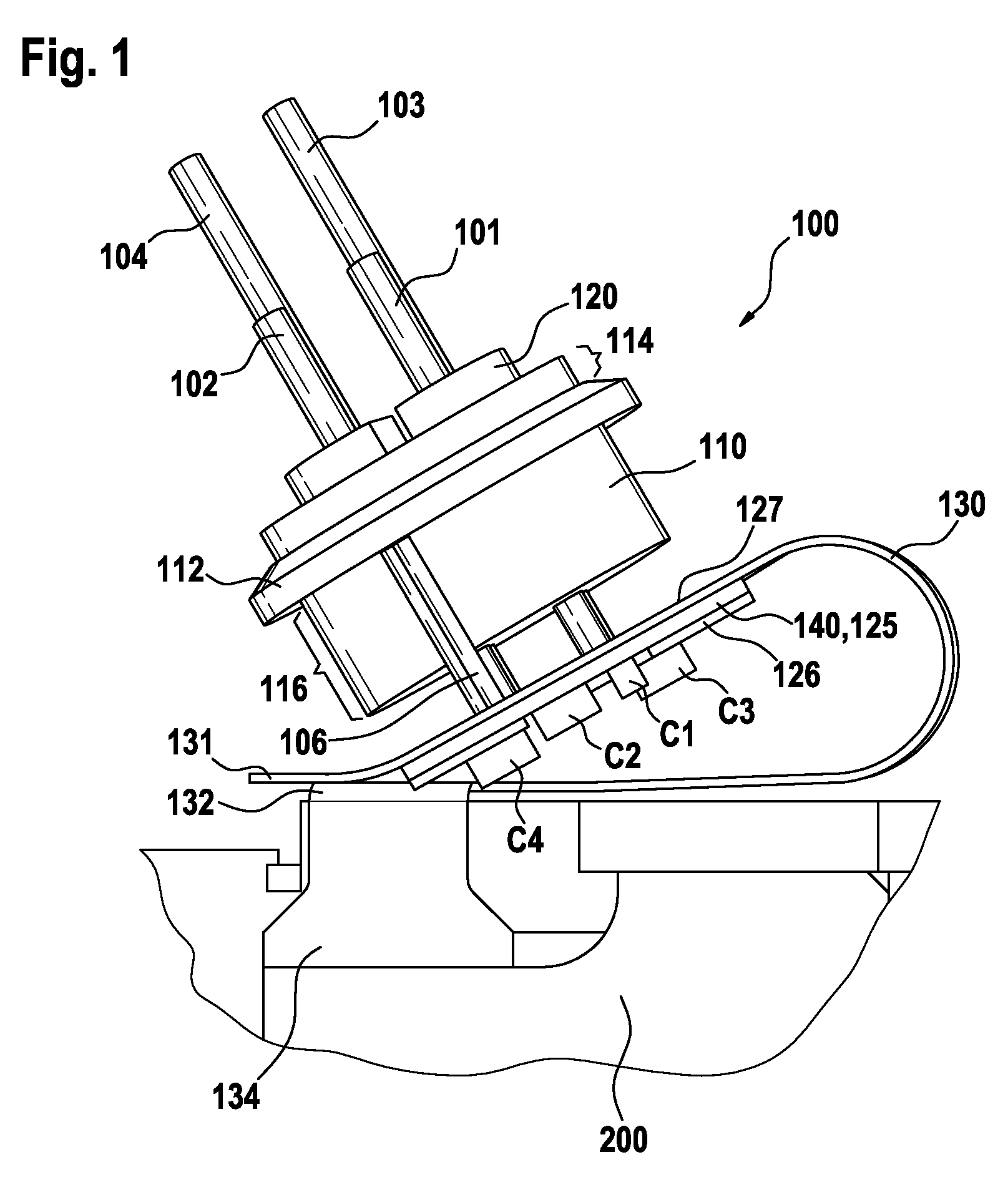

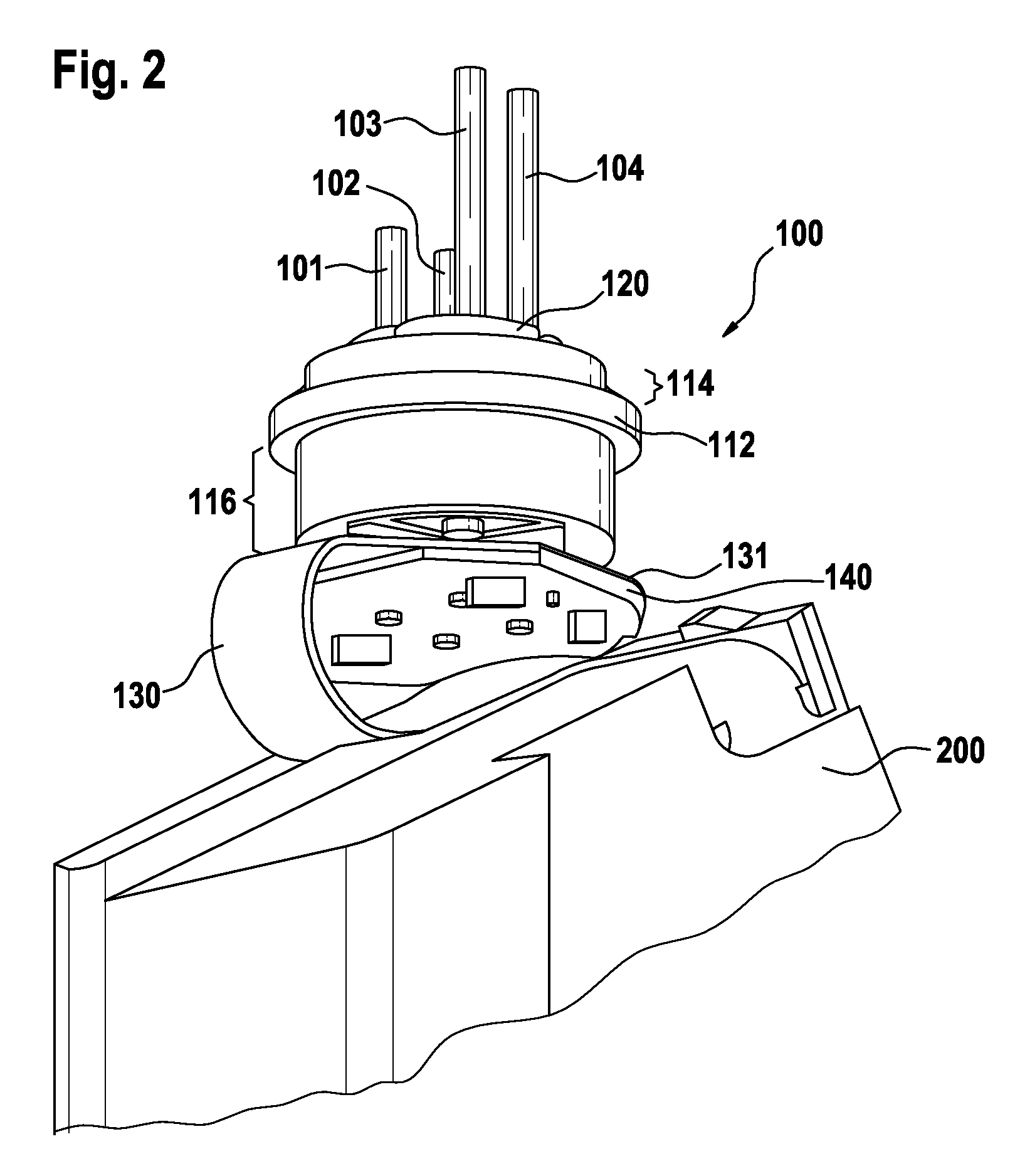

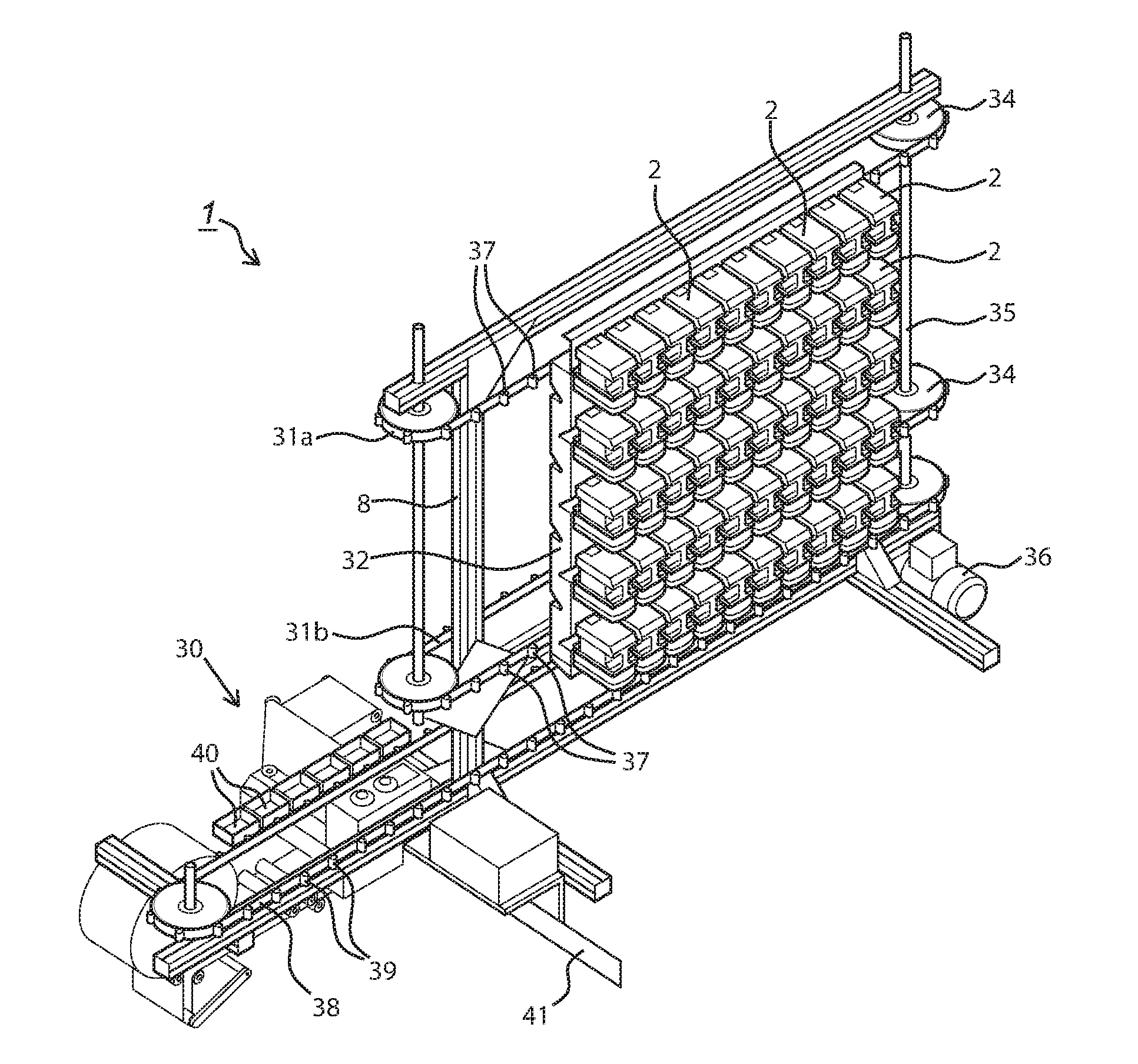

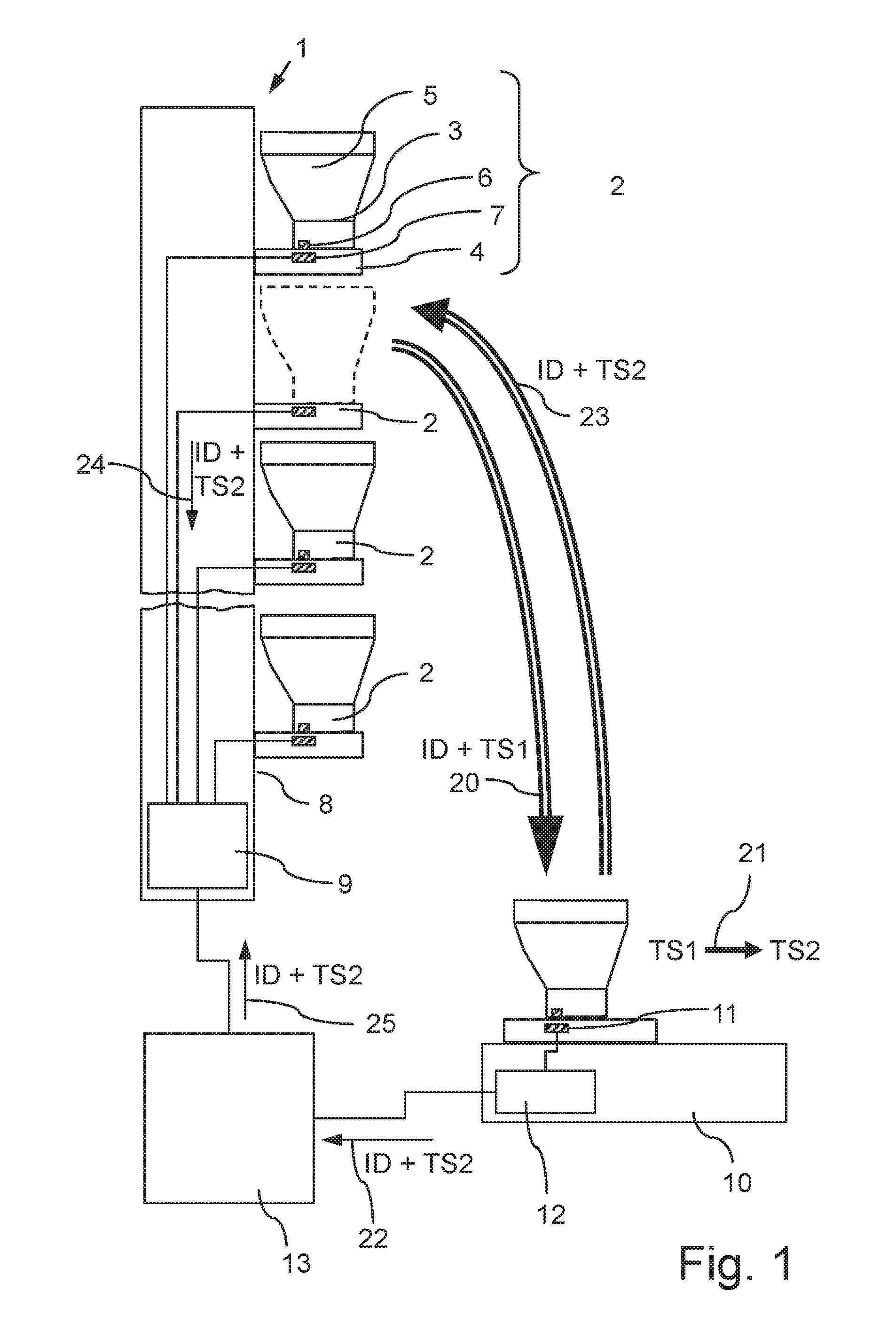

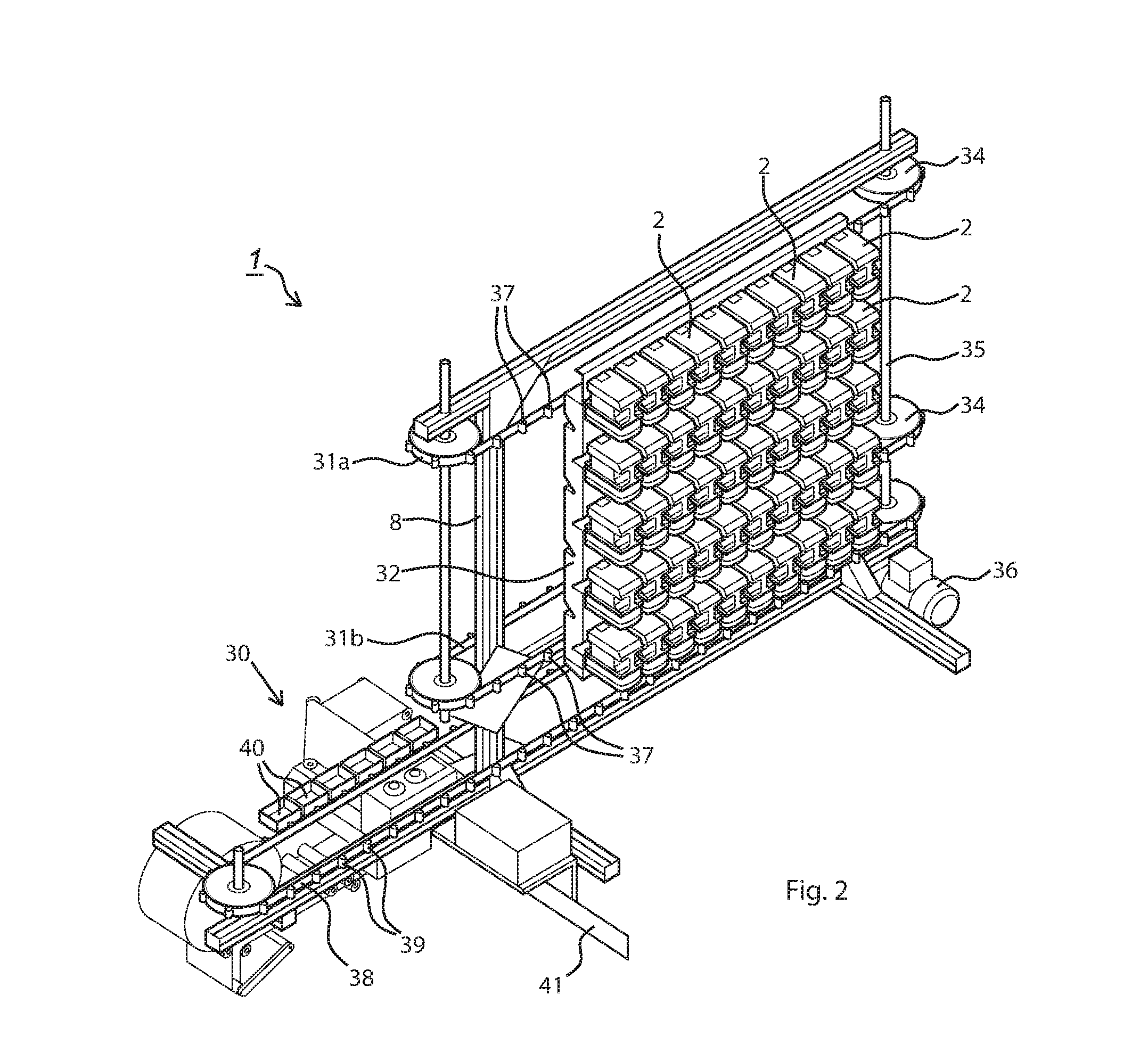

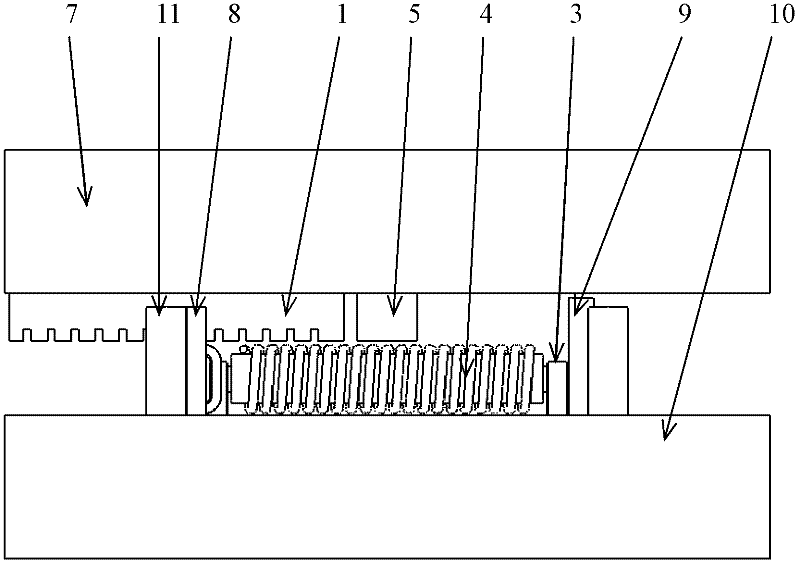

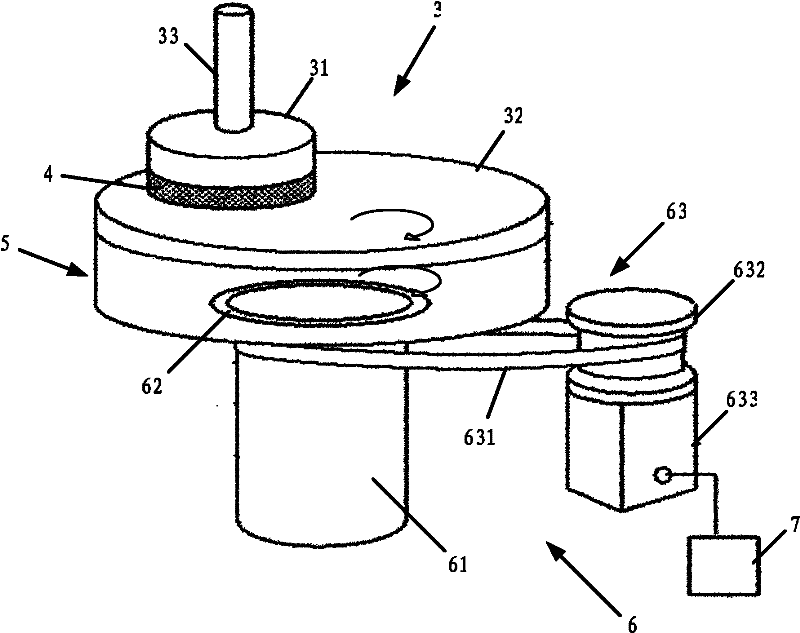

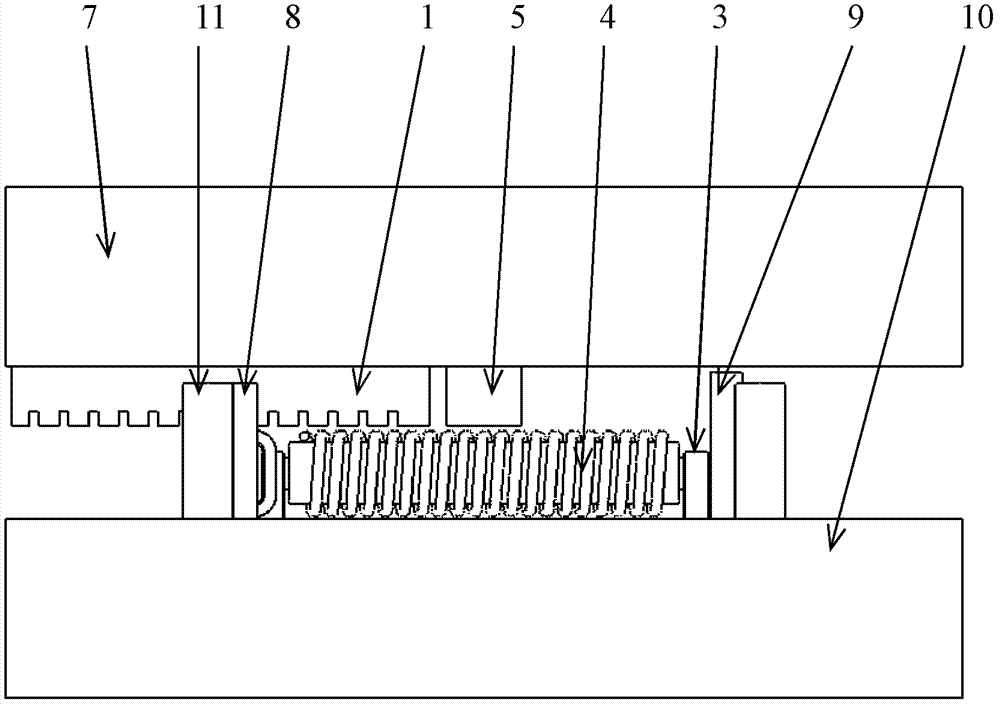

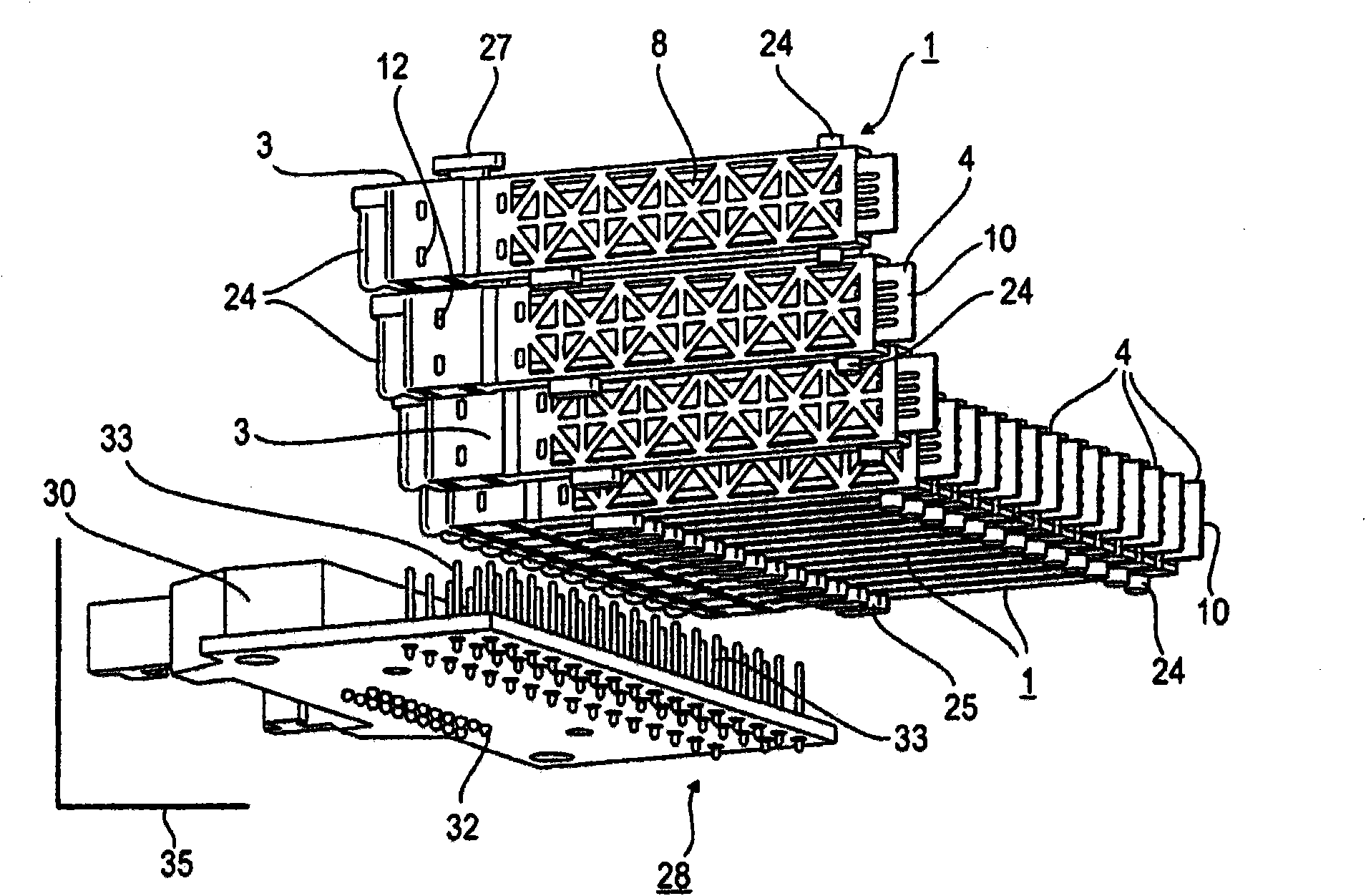

Assembly for packaging drug portions in dispensation packs and method for refilling a reservoir of a storing and metering station of a dispensing machine with drug portions

ActiveUS20160193114A1Improve reliabilityAvoid mechanical contactOral administration devicePackaging automatic controlEngineeringCharging station

The invention relates to an arrangement for packing drug portions into dispensing packages. A dispensing machine includes a plurality of storing and metering stations having a plurality of drug portions, a packing device that receives the drug portions dispensed by the storing and metering stations and places them into dispensing packages, and a control device. Each storing and metering station includes a stationary part fixed to a frame, a removable part containing a refillable reservoir and has an information memory for storing an identifier of the removable part. A reading device for reading the information memory is functionally assigned to the stationary part. Each information memory contains a memory location for a filling code. Every time the reservoir has been refilled, the filling code is changed at the charging station so that the refilling can be detected by the control device when the information memory is read by the reading device after the removable part has been placed back onto the stationary part of the same or a different storing and metering station.

Owner:CAREFUSION GERMANY 326

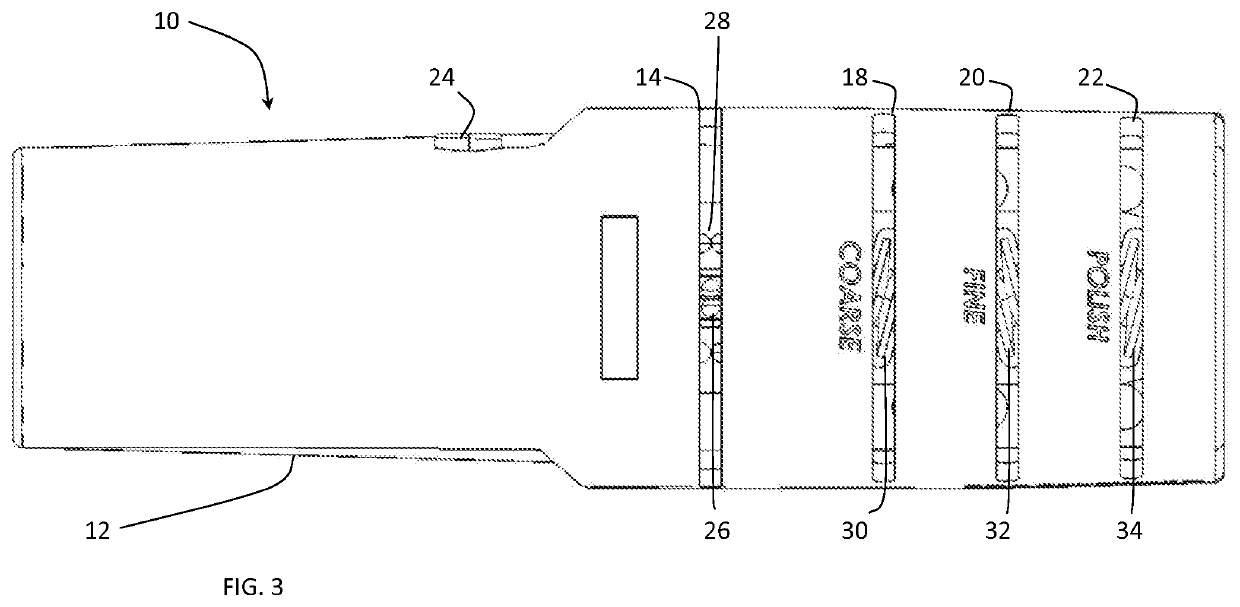

Systems for Blade Sharpening and Contactless Blade Sharpness Detection

ActiveUS20200361049A1Avoiding unnecessary material removalEfficient and effectiveOther manufacturing equipments/toolsAutomatic grinding controlDisplay deviceEngineering

A blade sharpness detection system for determining a sharpness of a blade and a combined blade sharpening and blade sharpness detection system for permitting both blade sharpening and a determination of blade sharpness without mechanical contact with the cutting edge of the blade. An optical inspection unit is operative to inspect blade sharpness optically, and a blade positioning and guidance mechanism is disposed to position and guide the blade in relation to the optical inspection unit. An output display is operative to provide a visual output of the sharpness of the blade. The optical inspection unit, which can be a reflective optical sensor, and the blade positioning and guidance mechanism are retained by a pivotable support structure. The positioning and guidance mechanism can be formed by first and second pairs of rotatable spheres, each pair of rotatable spheres disposed in immediate juxtaposition to act as rolling supports for the blade.

Owner:TSUKANOV VITALY +3

Charging Device and Image Forming Device Using Same

InactiveUS20090041501A1Reduce ozone productionPrevent degradationElectrographic process apparatusCorona dischargeLatent imageImage formation

A charging device (10) includes electrospray means for inducing electrospraying through application of a voltage to an incoming liquid (11), in order to produce charged liquid droplets (13). The device (10) charges a photoreceptor drum (1) by means of the liquid droplets (13). Hence, the invention provides a charging device capable of reducing ozone production while preventing the charging device and the electrostatic latent image carrier from degrading or wearing out from friction between the device and the carrier and provides also an image forming device incorporating the charging device.

Owner:SHARP KK

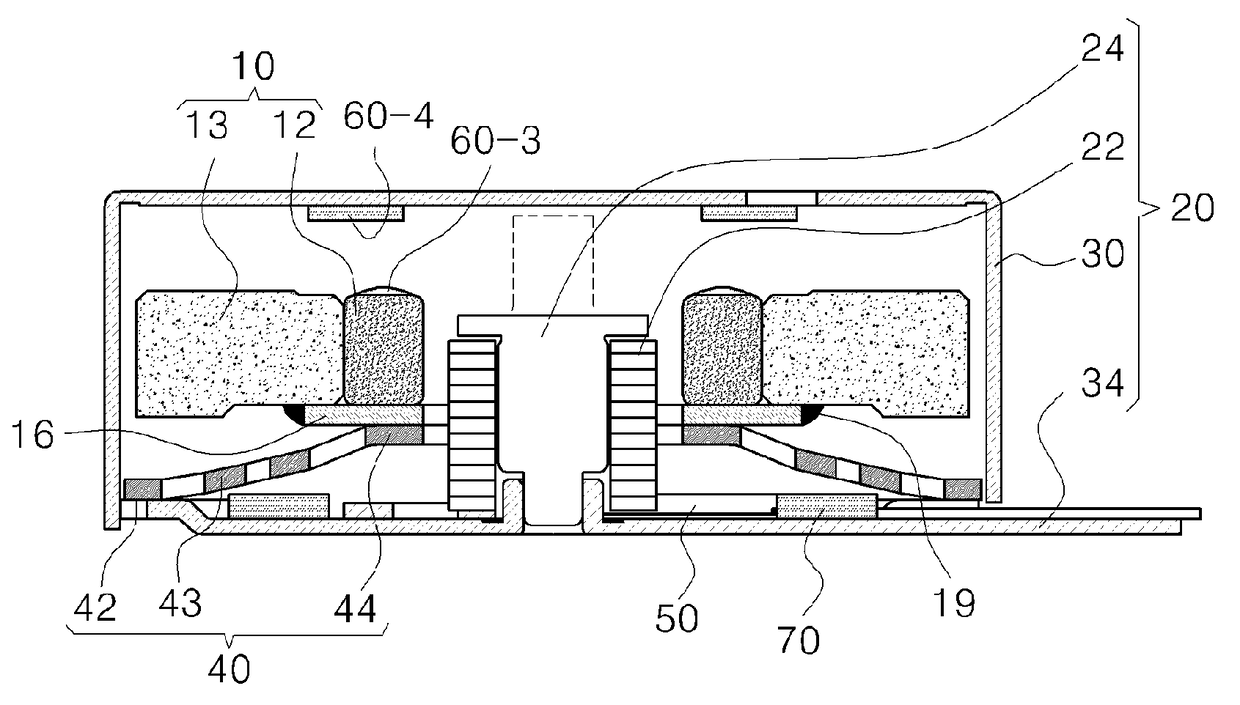

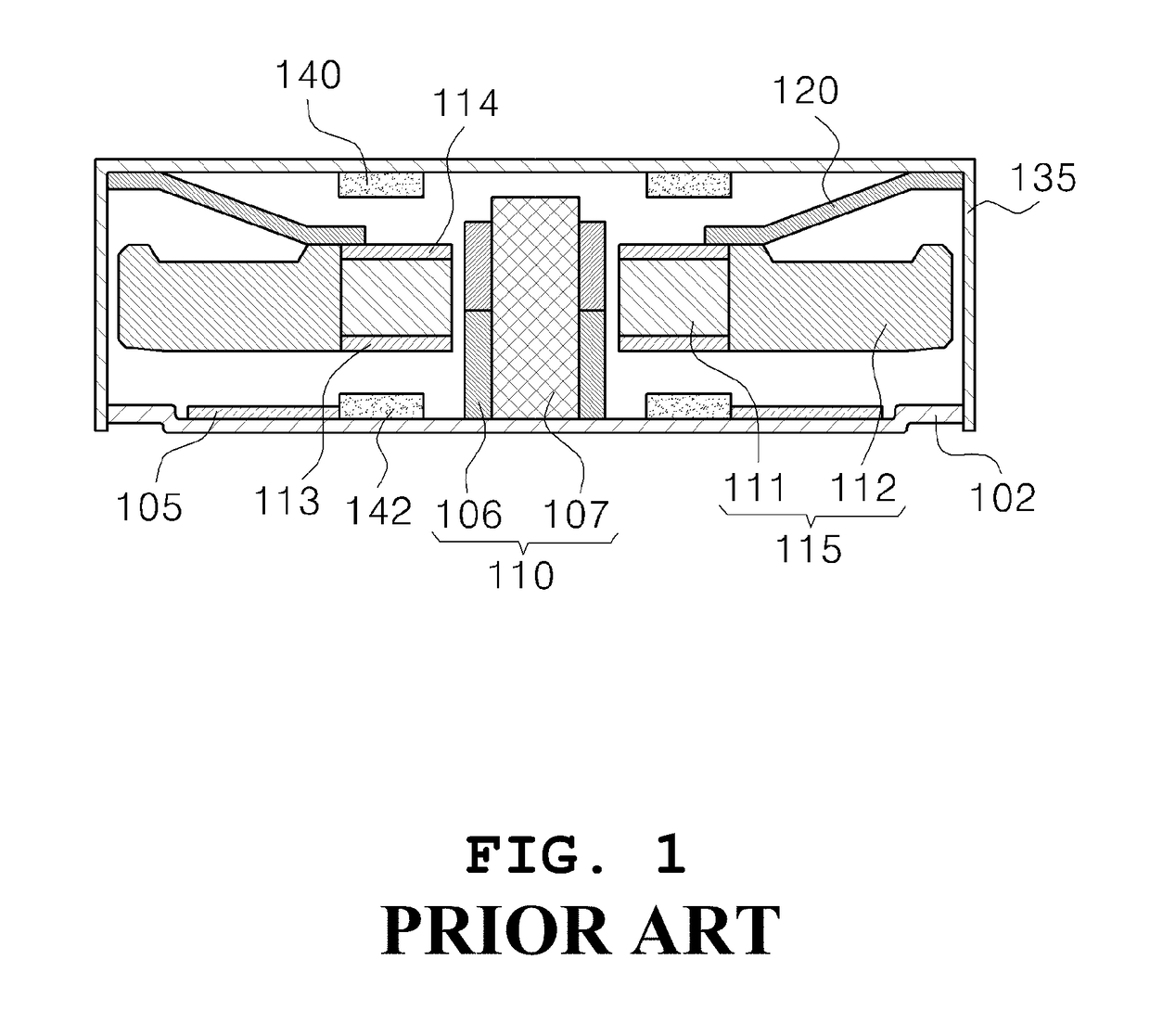

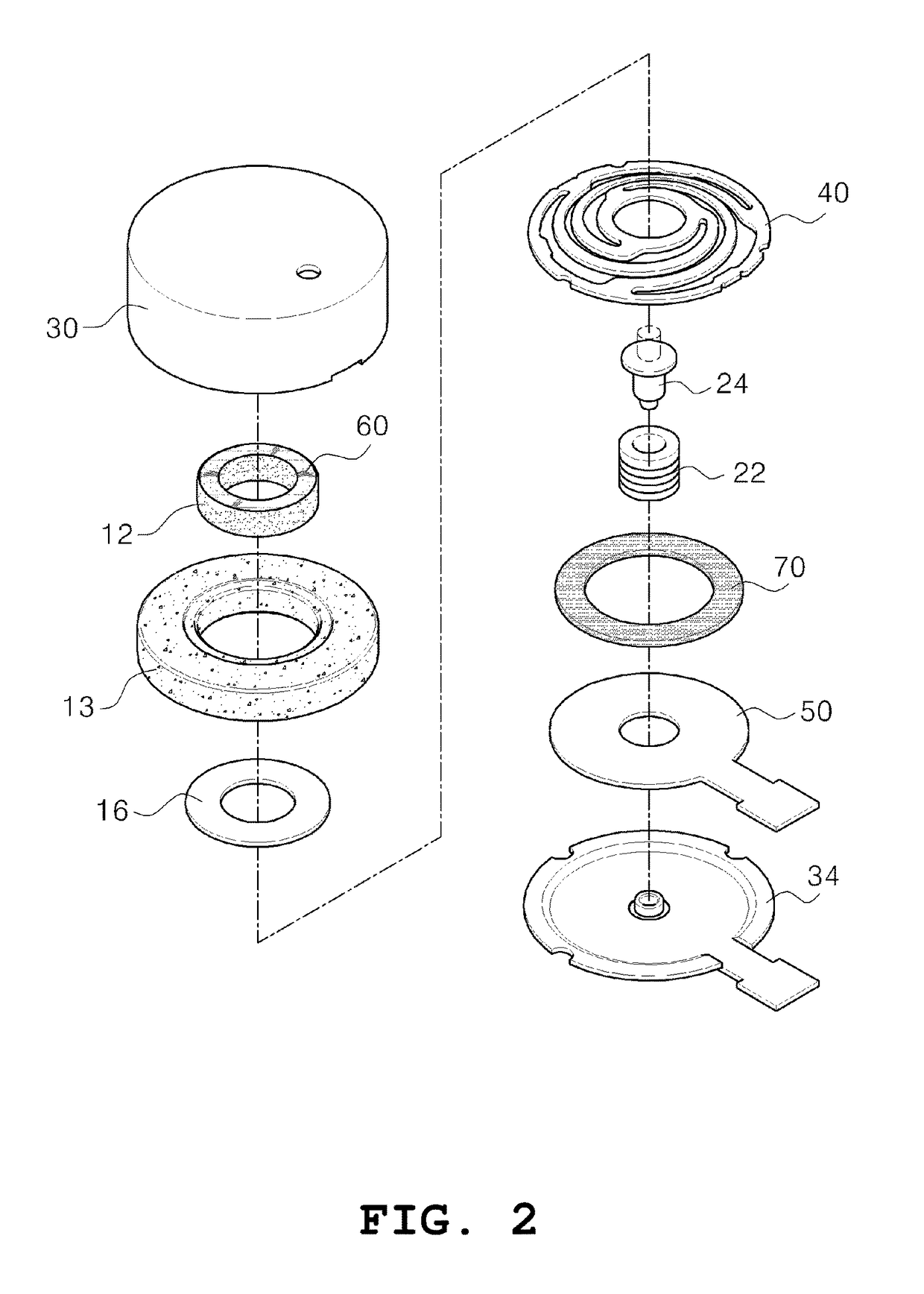

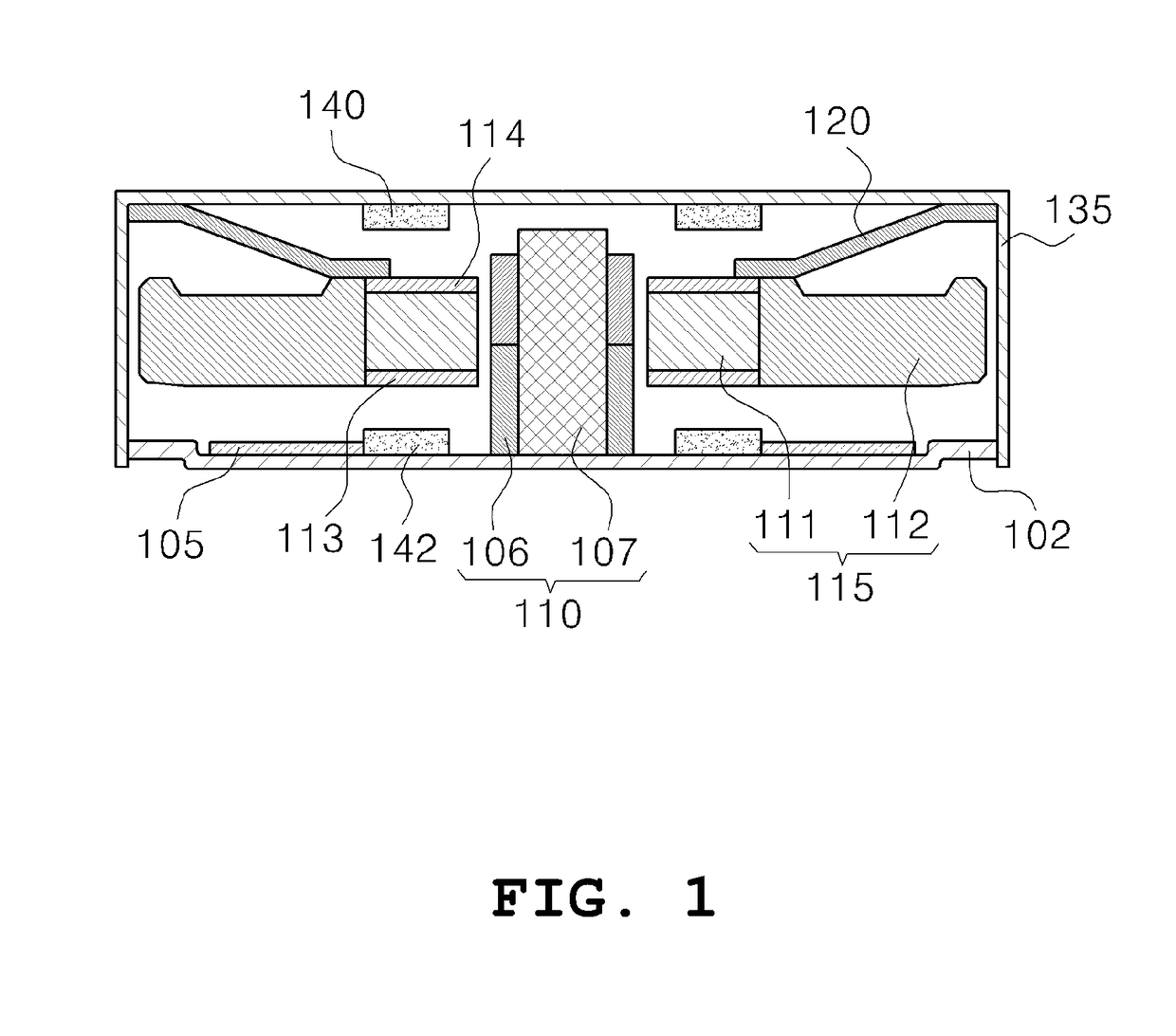

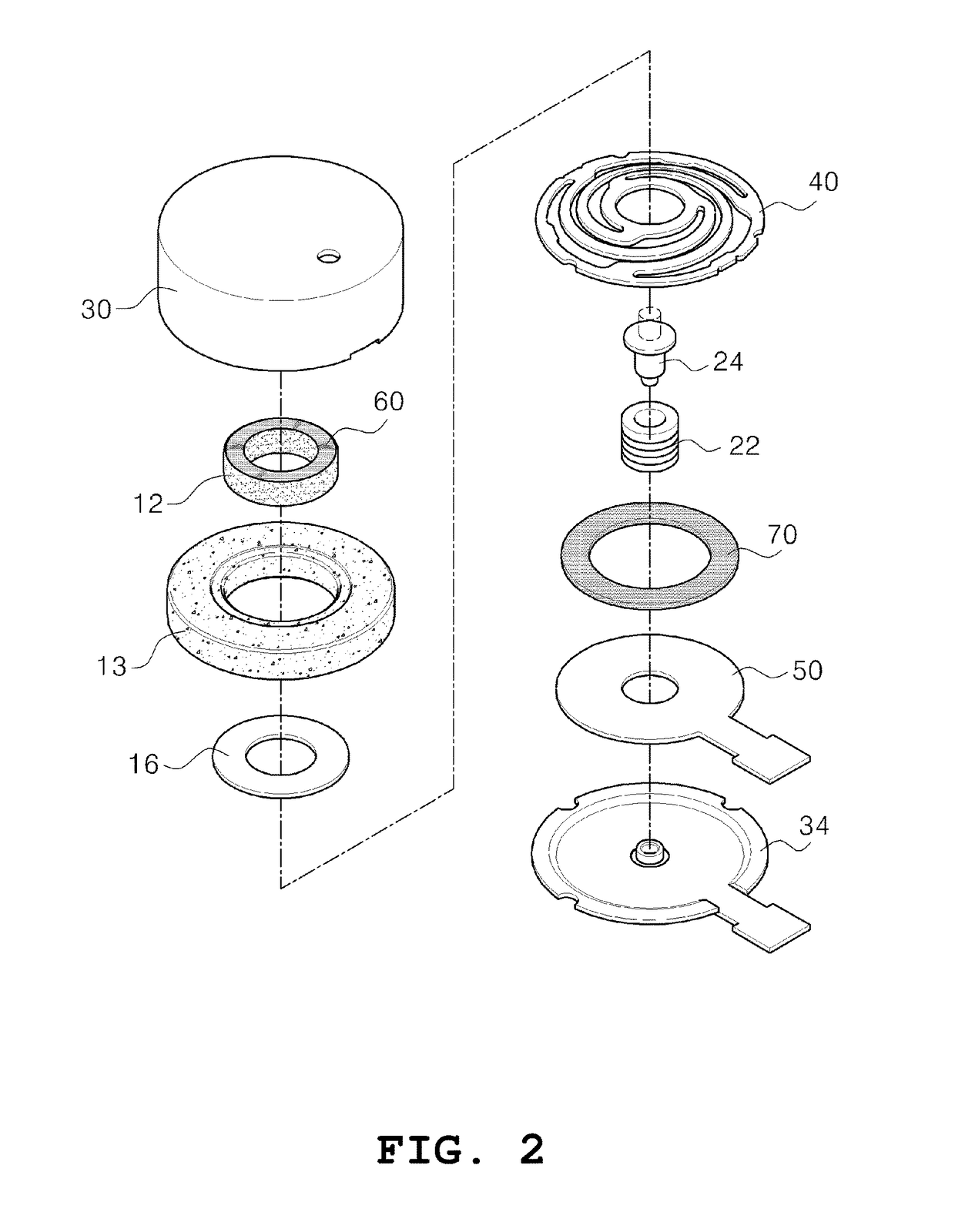

Linear vibration generation device

ActiveUS9762111B2Sufficient stroke distanceIncrease heightMechanical vibrations separationSupports/enclosures/casingsLinear vibrationMagnet

Owner:JAHWA ELECTRONICS

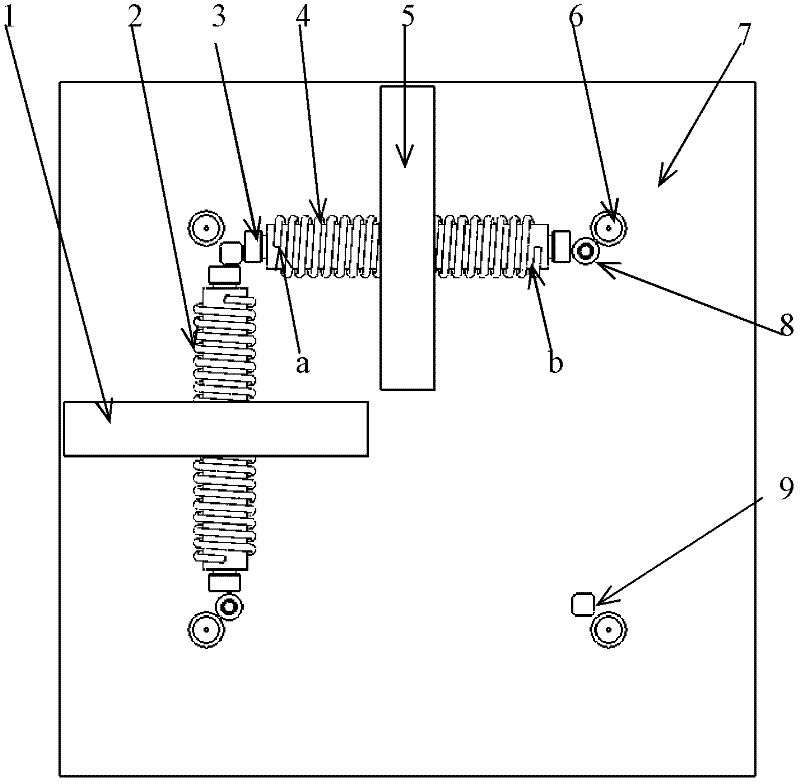

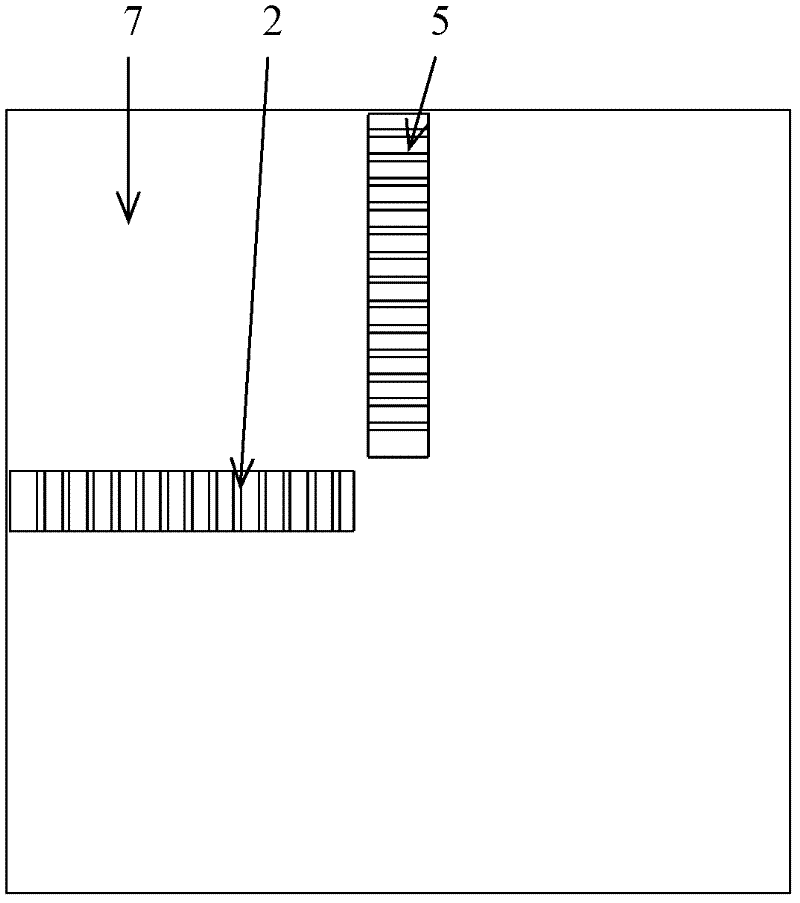

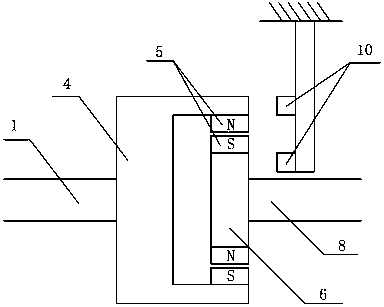

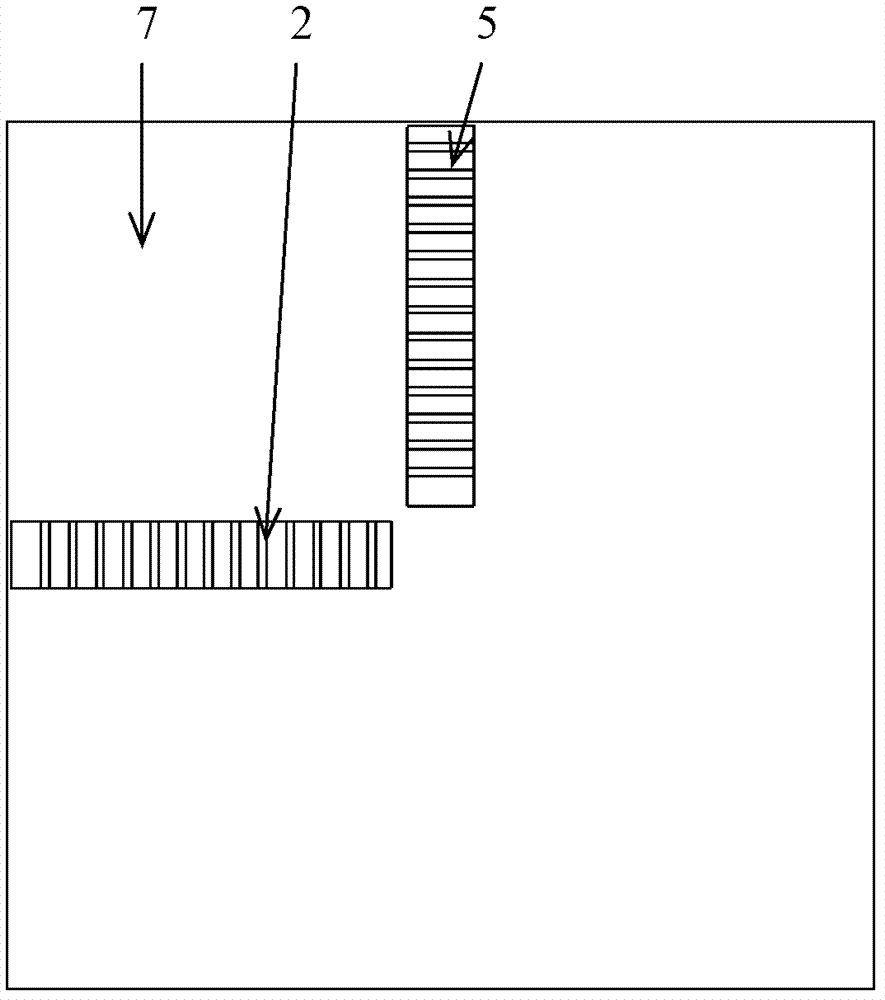

A planar motor with two-axis decoupling structure

ActiveCN102270908AAvoid mechanical contactRealize two-dimensional plane motionPropulsion systemsMagnetEngineering

The invention discloses a planar motor in a double-shaft decoupling structure. The planar motor disclosed by the invention comprises a base and a working platform arranged above the base, wherein a first driving coil, a second driving coil, a pneumatic suspension body, a clearance sensor and a position sensor are arranged on the base; the first and second driving coils are perpendicularly laid onthe same plane; a first permanent magnet and a second permanent magnet which are perpendicularly laid on the same plane are arranged on the working platform; the first permanent magnet is perpendicular to the first driving coil; the second permanent magnet is perpendicular to the second driving coil; and a controller is respectively connected with the two driving coils, the two sensors and the pneumatic suspension body. The double-shaft coplane decoupling structure of the invention ensures that two-dimensional motion driven by two shafts on the same plane can be realized, the structure is simplified and the reliability of a system is improved.

Owner:无锡金力威环保科技有限公司

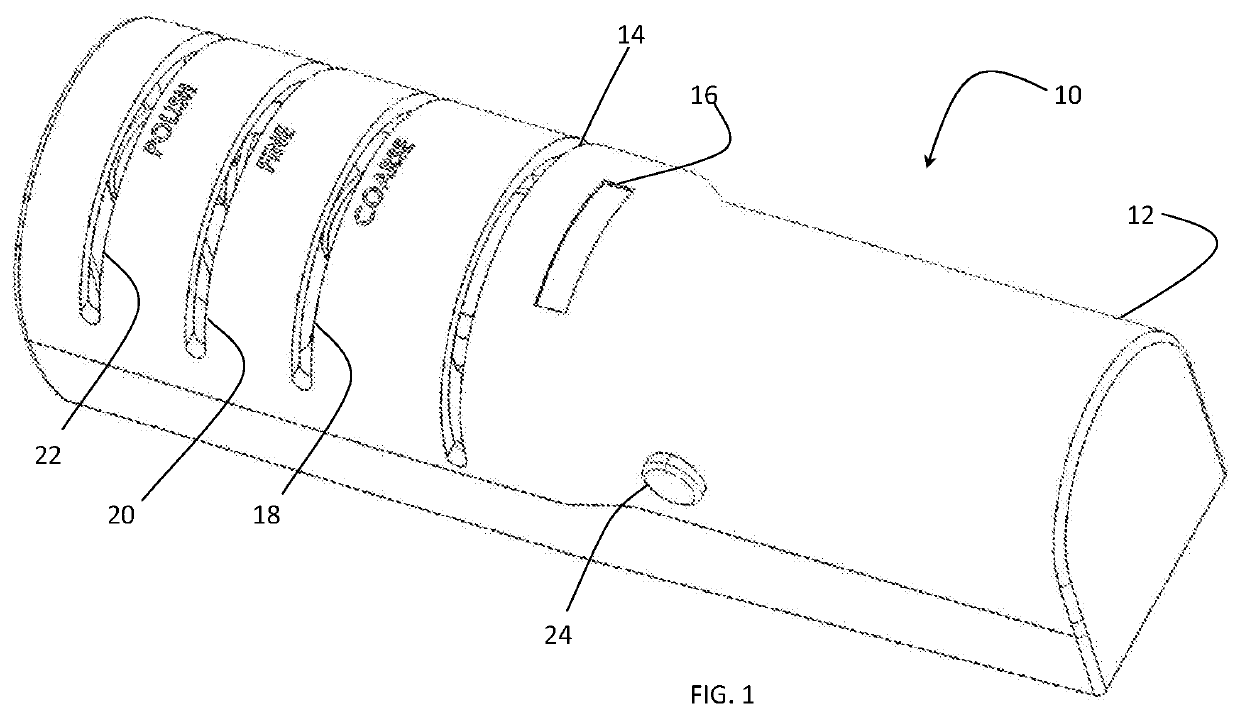

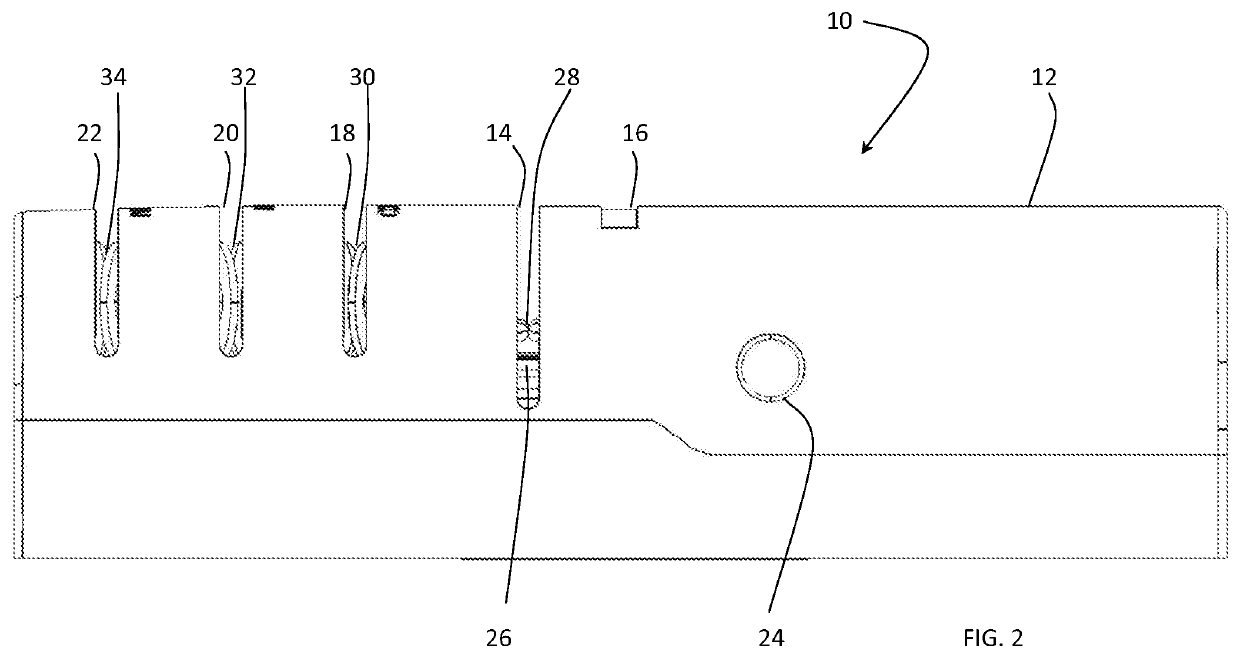

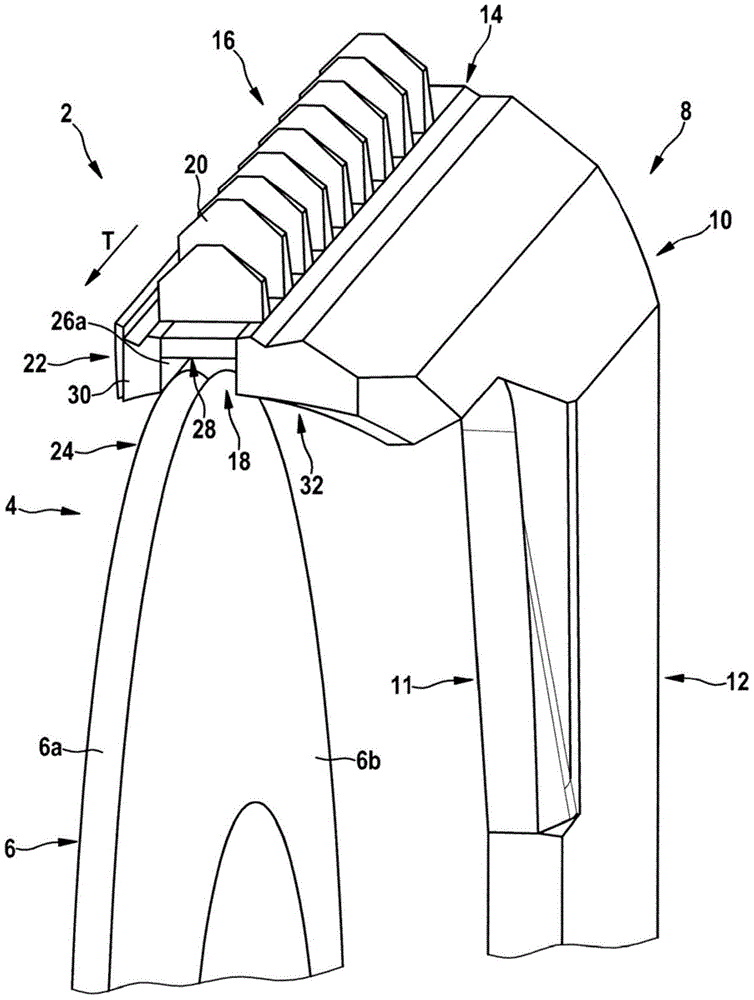

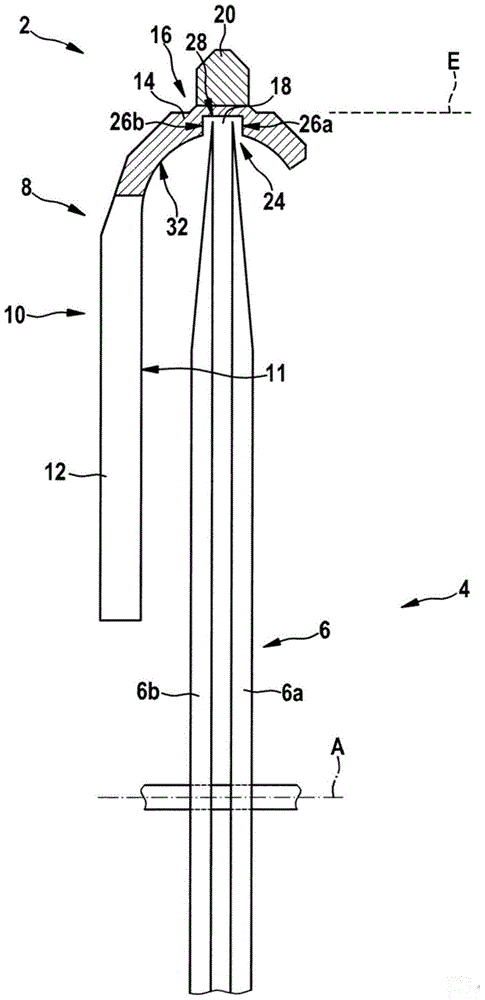

Device for processing fish

ActiveCN104427881AContact does not produceAvoid mechanical contactFish filletingFish processingEngineering

The invention relates to an L-shaped support body (10) for accommodating a fish and for conveying said fish, aligned such that the fish tail goes in first through a cutting unit (4) having a circular knife pair (6) of a fish processing device, which has an continuously circulating conveyor, wherein the support body (10) has a main body (12) for fastening said support body to the conveyor and a bearing web (14), which protrudes beyond a side wall (11) of the main body (12) and which has a support edge (16) arranged at the top for accommodating the center bones of the fish to be accommodated, wherein the bearing web (14) has a groove (18) arranged at the bottom, which groove is designed as a counter unit for the circular-blade pair (6). The invention further relates to a corresponding device for processing fish.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

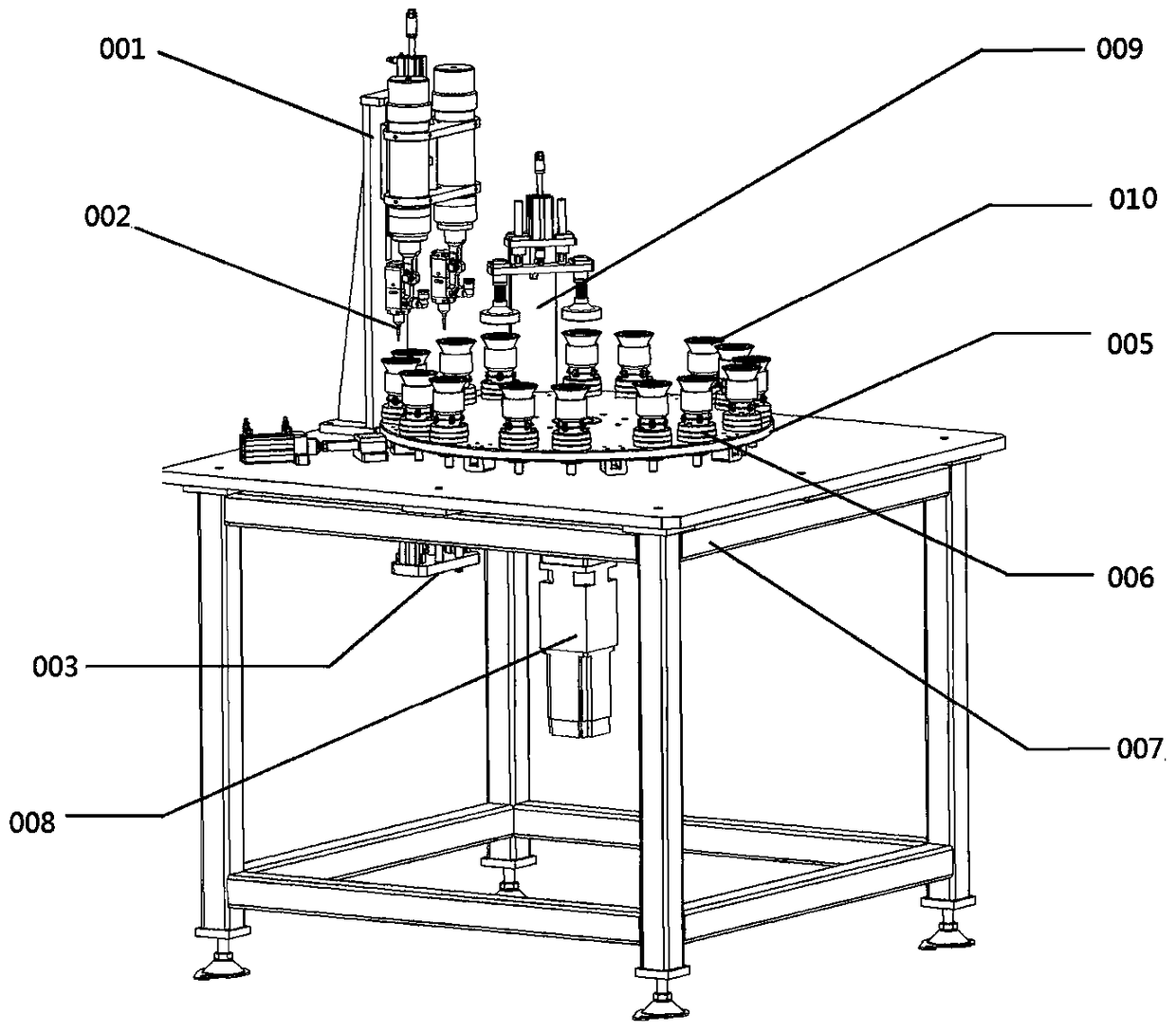

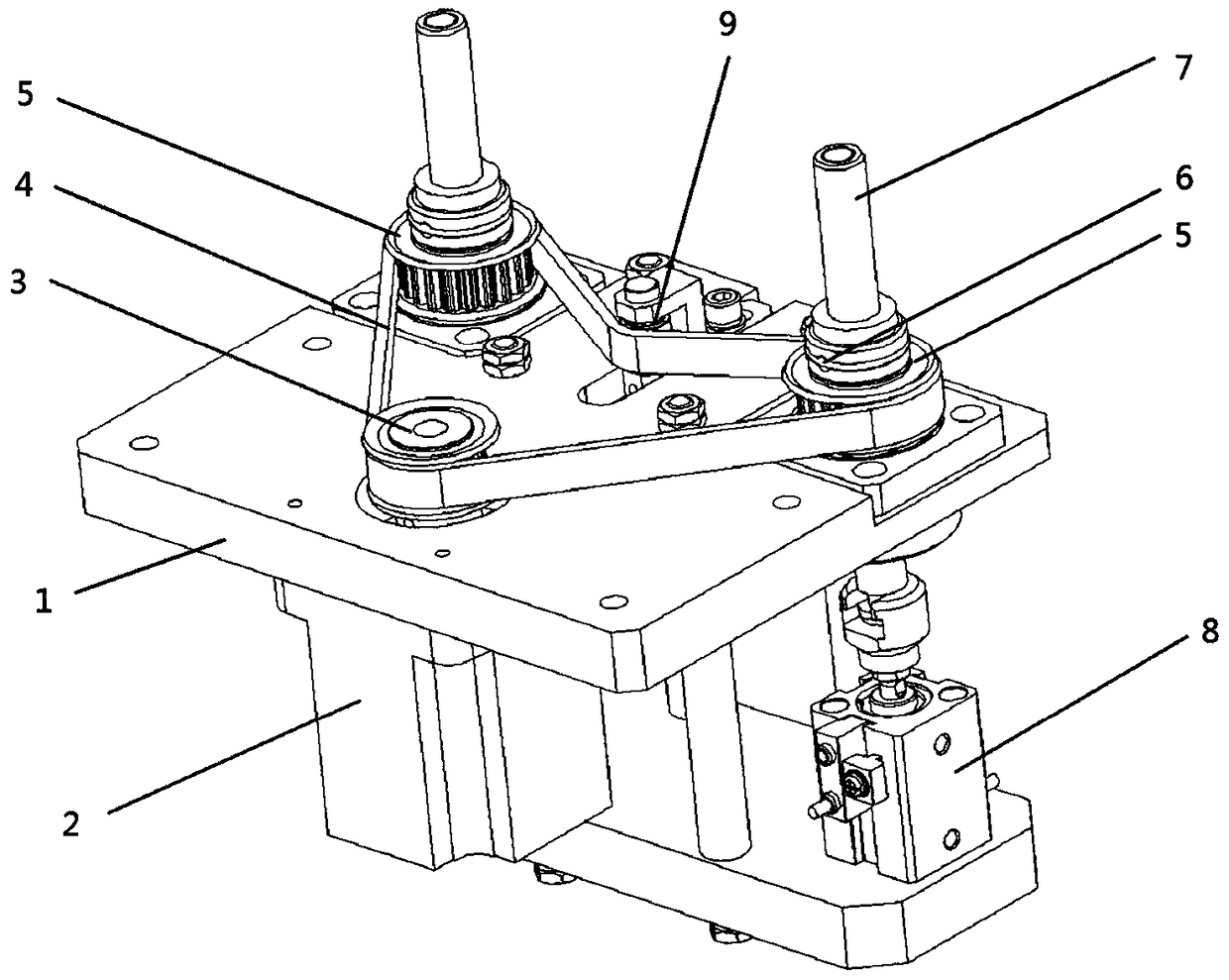

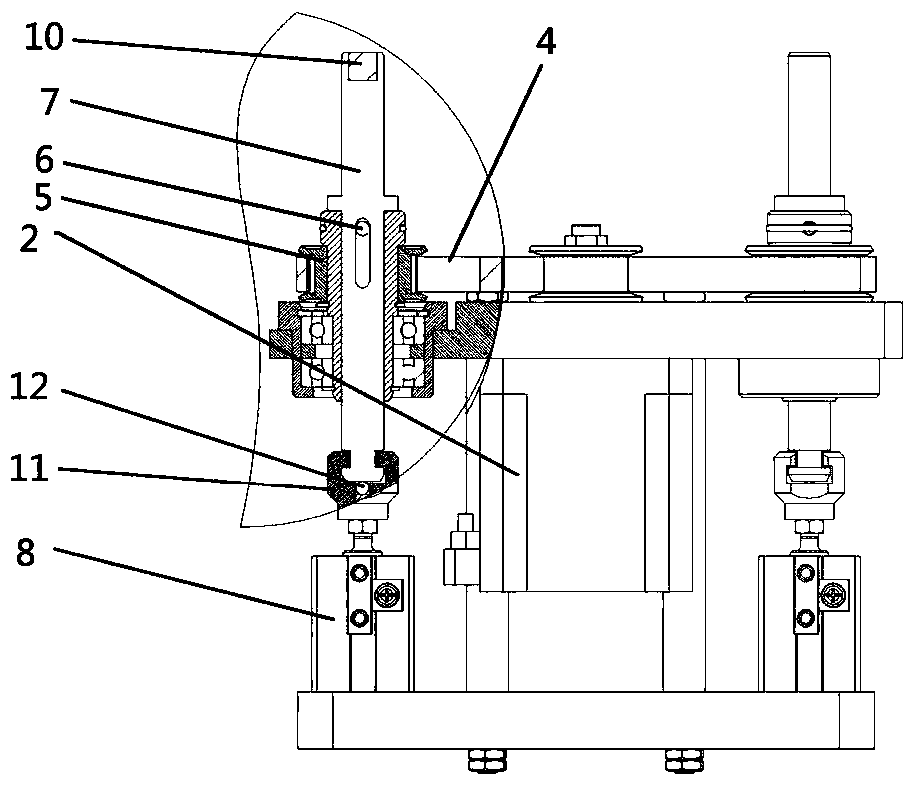

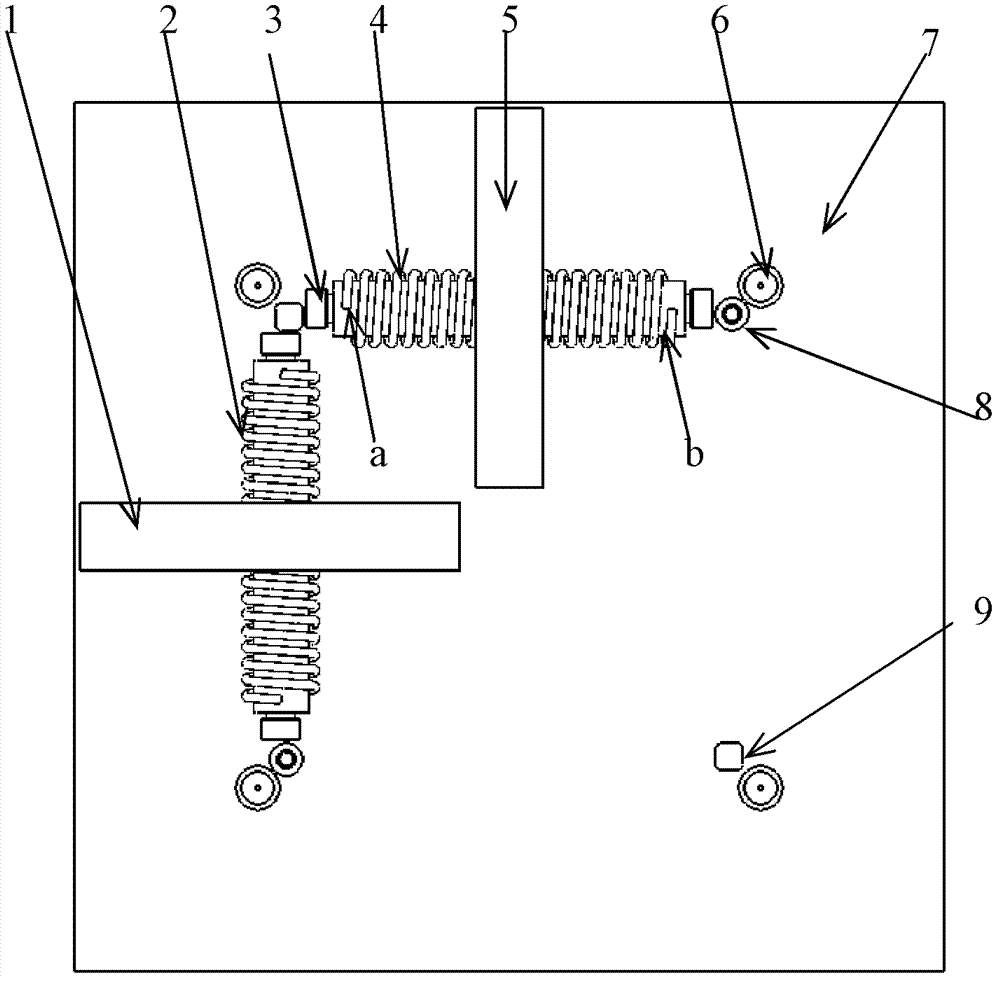

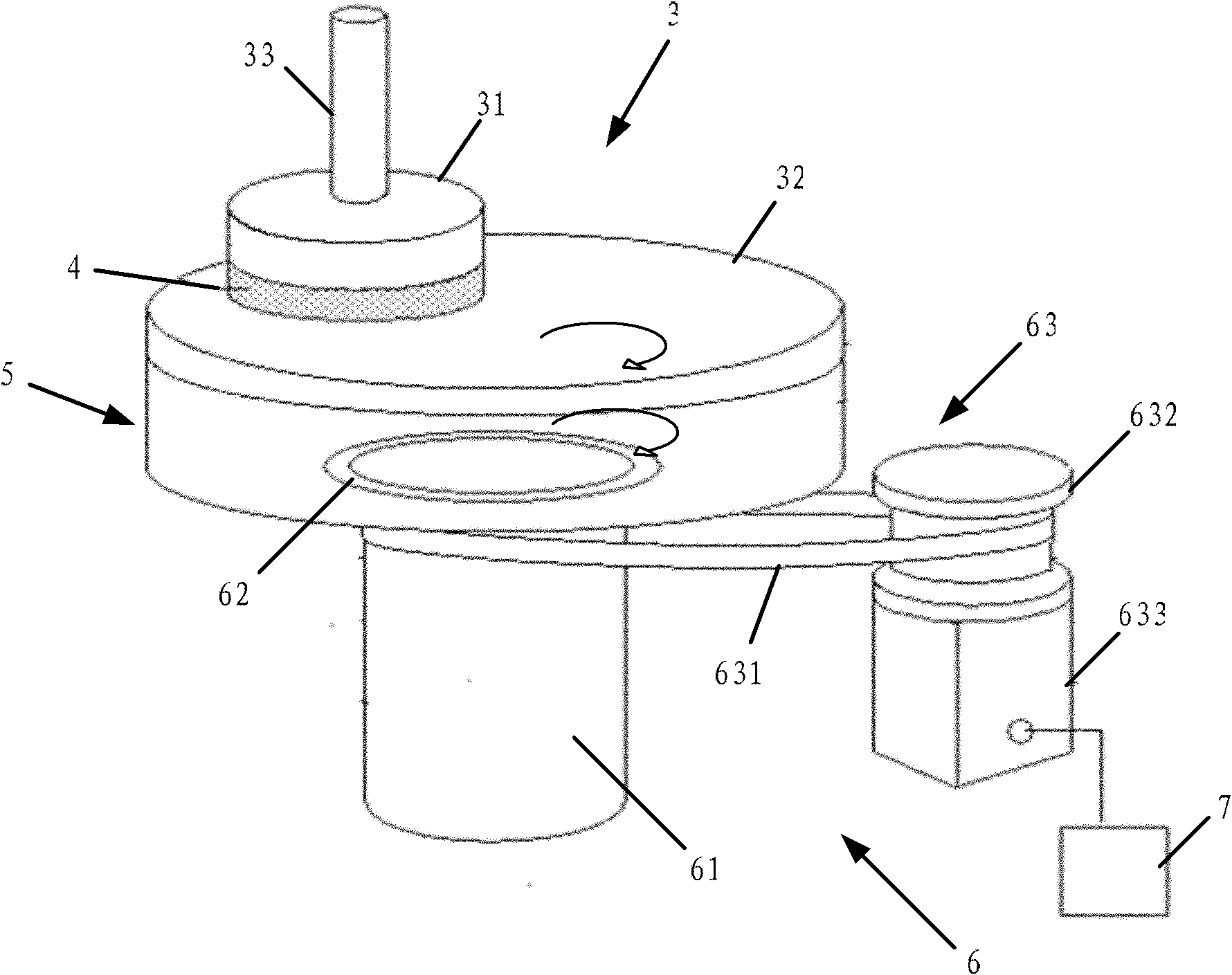

A kind of led lamp base dispensing machine

ActiveCN104492657BGlue stableDispensing effect is easy to controlLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention relates to the technical field of automatic LED lamp production equipment and in particular relates to an LED lamp cap dispenser. The LED lamp cap dispenser comprises a dispensing assembly, a dispensing needle, a dispensing rack, a rotary driving assembly, a base mounting disc, a lamp cap positioning seat and a mounting disc motor, wherein the base mounting disc is rotationally arranged on the dispensing rack; the mounting disc motor is arranged on the dispensing rack and can drive the base mounting disc to rotate; the lamp cap positioning seat is rotationally arranged on the base mounting disc; and the rotary driving assembly can drive the lamp cap positioning seat to rotate. According to the LED lamp cap dispenser disclosed by the invention, the lamp cap positioning seat is driven to rotate, rotation of the LED lamp cap on the automatic production line is realized, the dispensing needle is stationary in the dispensing process, stable dispensing in the operation of the dispensing assembly is promoted, the problem that the dispensing needle is vibrated and collided is solved, and the dispensing effect is easy to control.

Owner:佛山市顺德区格律诗自动化科技有限公司

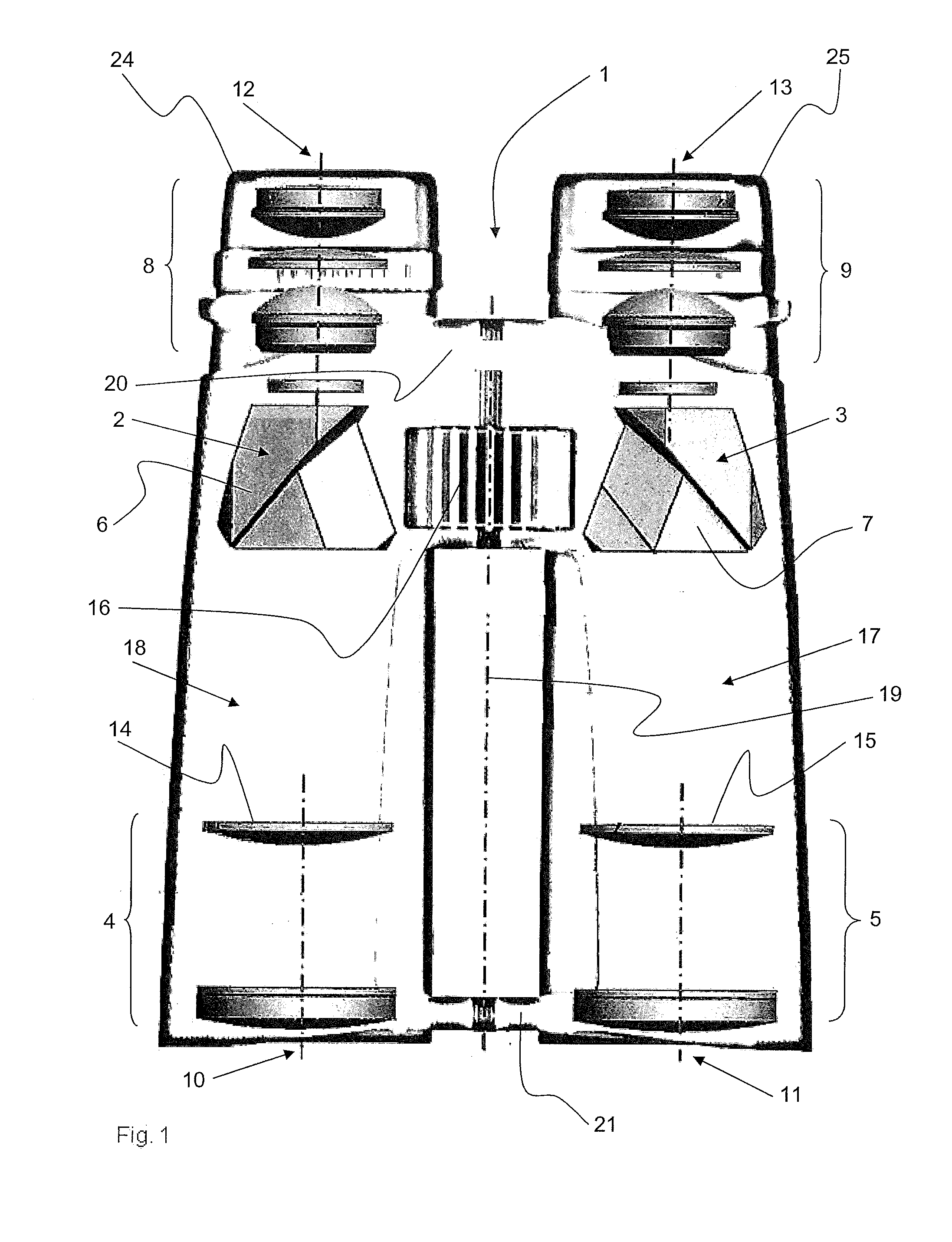

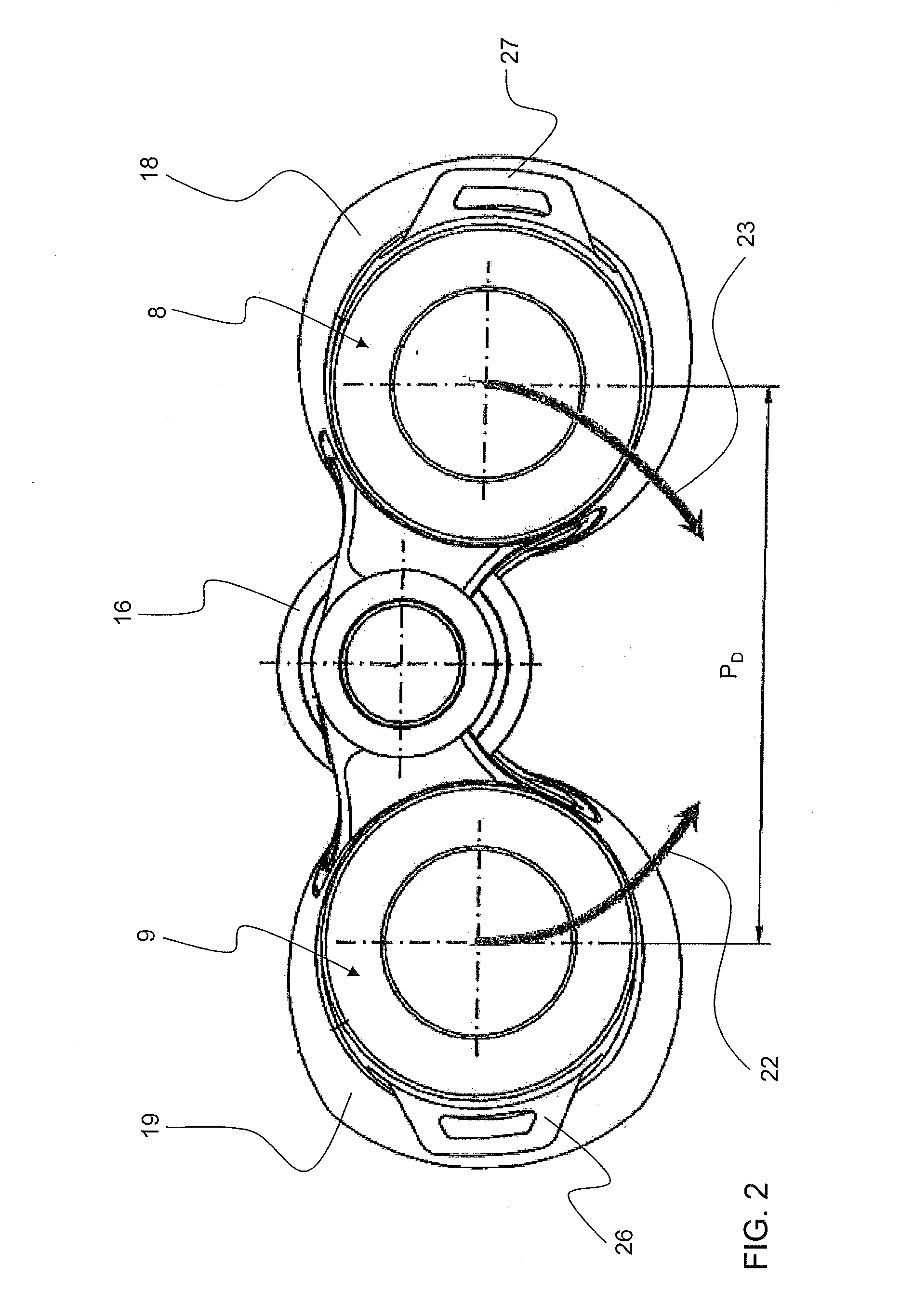

Long-range optical apparatus including binoculars

ActiveUS20150049382A1Mitigate high requirement on manufacturing toleranceImprove robustnessTelescopesEngineeringBinocular distance

Owner:CARL ZEISS SMT GMBH

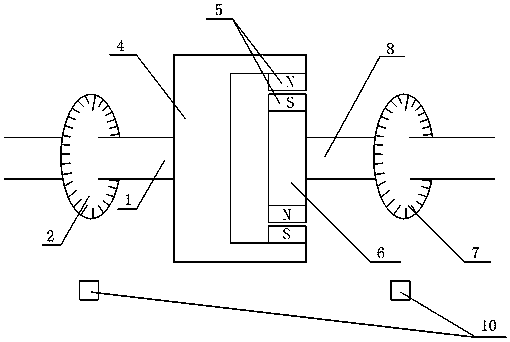

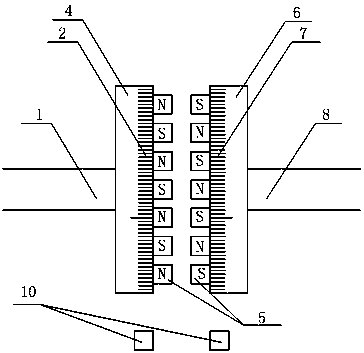

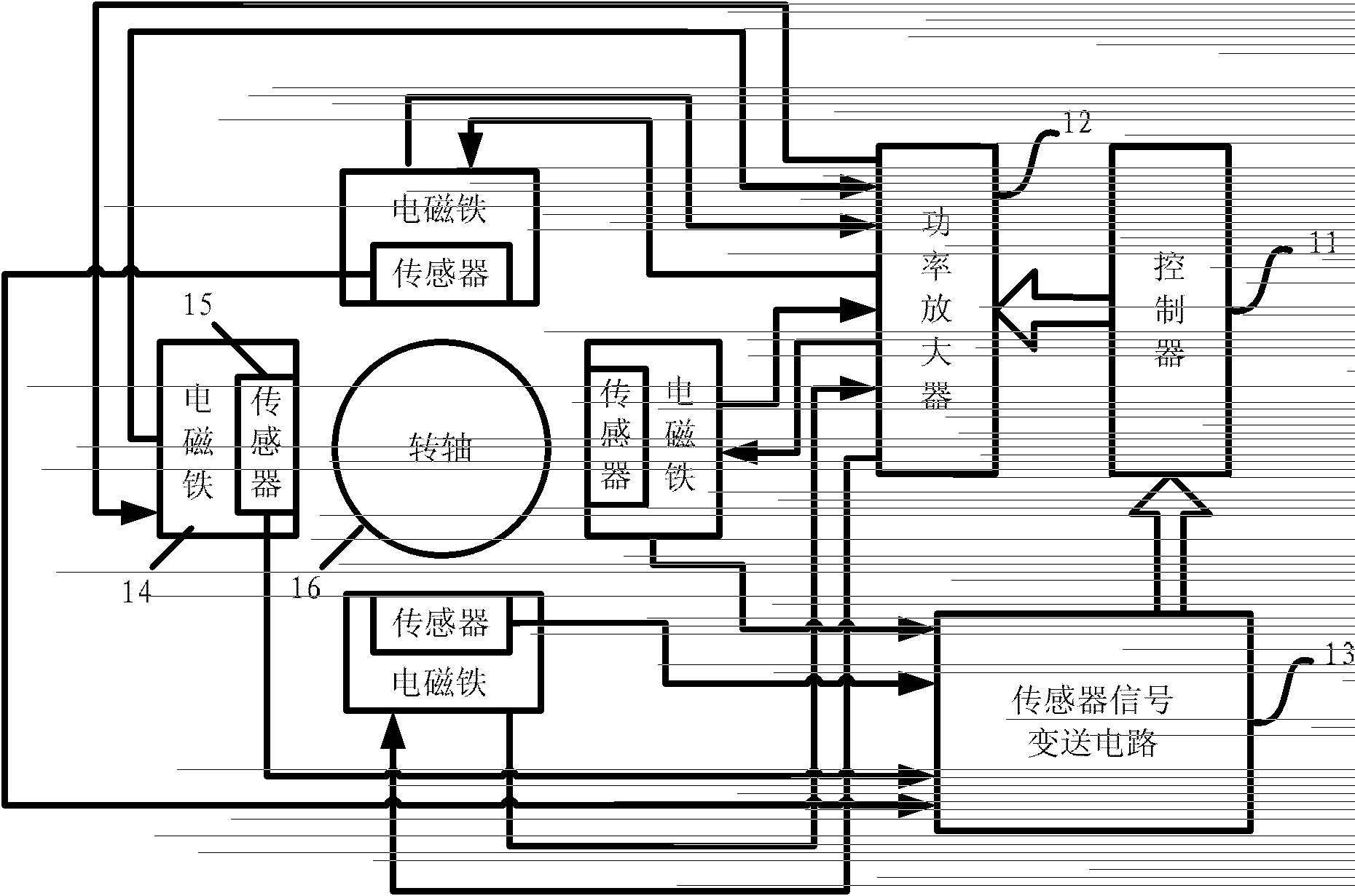

Torque measuring device based on magnetic coupling

InactiveCN109540360AExtended service lifeImprove reliabilityWork measurementTorque measurementFriction lossCoupling

The invention discloses a torque measuring device based on a magnetic coupling. The device utilizes the principle of interaction of magnetic fields to realize torque transmission between two rotatingshafts. The degree of distortion of a magnetic line in a magnetic field is used, and the torque magnitude is measured through the angular position difference between two rotor magnetic poles. The combination of the functions of a contactless coupling and a torque sensor is realized. The structure of a system is simplified, and the friction loss of the system is eliminated. Strain gage displacementdeformation, which is caused by repeated measuring of the mechanical connection structure of the existing torque sensor, and the problem of inaccurate torque measurement is prevented. The reliabilityof the system and the convenience of torque detection are improved.

Owner:SHANGHAI UNIV

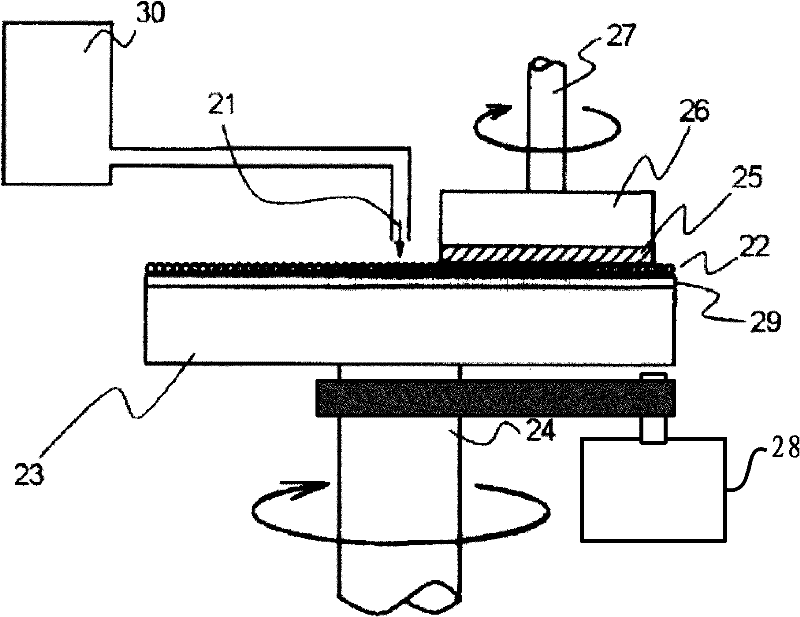

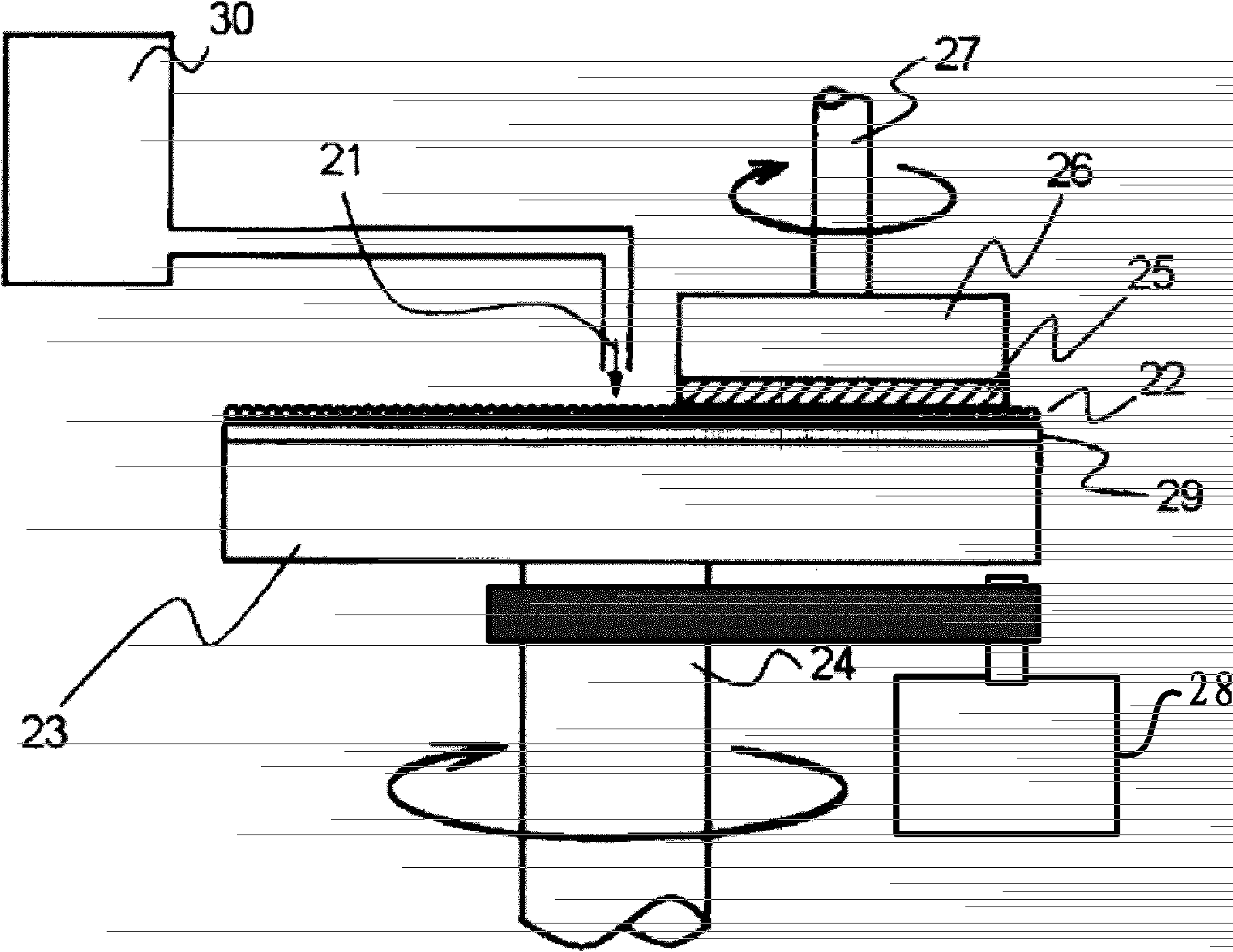

Chemical mechanical grinding device

ActiveCN102476349AAvoid wear and tearReduce noiseLapping machinesWork carriersFriction lossEnergy loss

The invention discloses a chemical mechanical grinding device, comprising a grinding mechanism, a carrying mechanism and a rotating mechanism connected with the carrying mechanism. The rotating mechanism comprises a driver, the carrying mechanism at least comprises a rotating bearing, and the rotating bearing is a magnetic suspension bearing. In the chemical mechanical grinding device disclosed by the invention, the magnetic suspension bearing is mainly taken as a grinding pad bearing, and a grinding pad is suspended above the magnetic suspension bearing by virtue of magnetic suspension force, thus no mechanical contact is arranged between the grinding pad and the magnetic suspension bearing. The invention aims at applying the magnetic suspension bearing technology to the semiconductor technology industry, so as to substitute the traditional mechanical bearing, thus defects caused by the fact that the mechanical bearing is used, such as mechanical friction loss, energy loss, oil pollution, noise and the like can be overcome. Besides, the magnetic suspension bearing provided by the invention also has the advantages that service life is longer compared with the mechanical bearing and loss caused by wafer scrapping owning to bearing problem is greatly reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

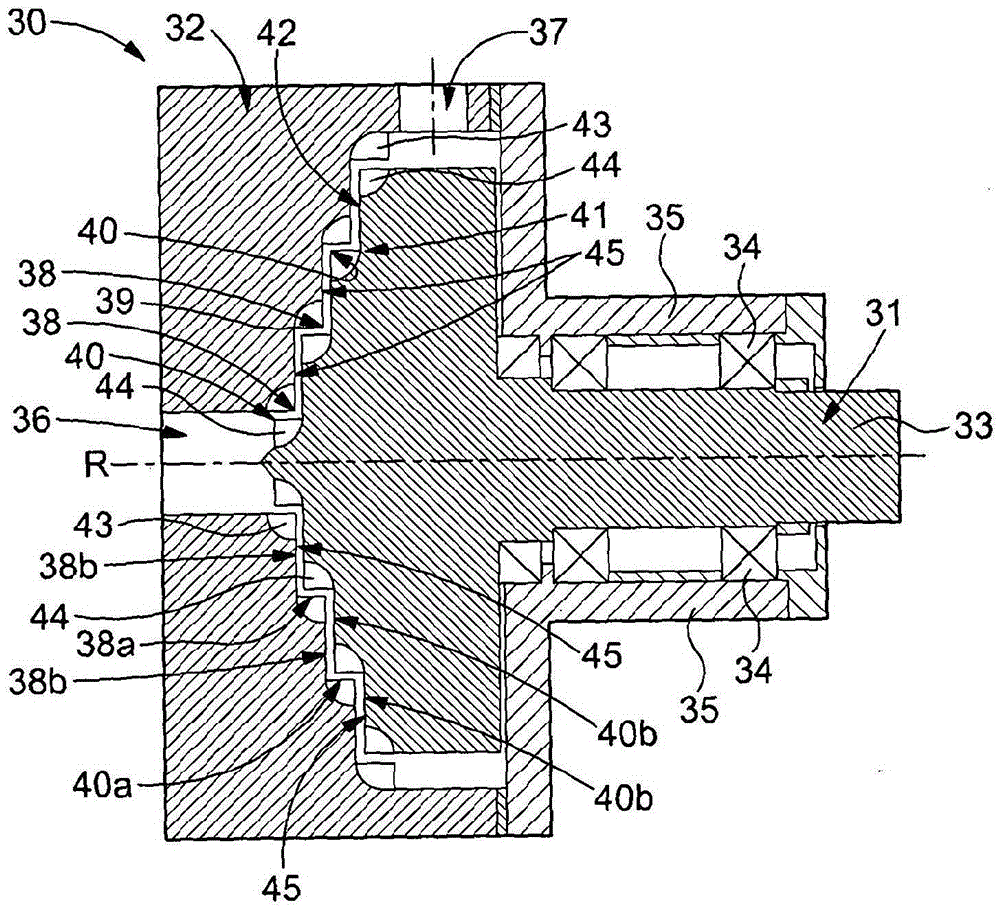

Improved power mixer

InactiveCN104159661BLow costReduce complexityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

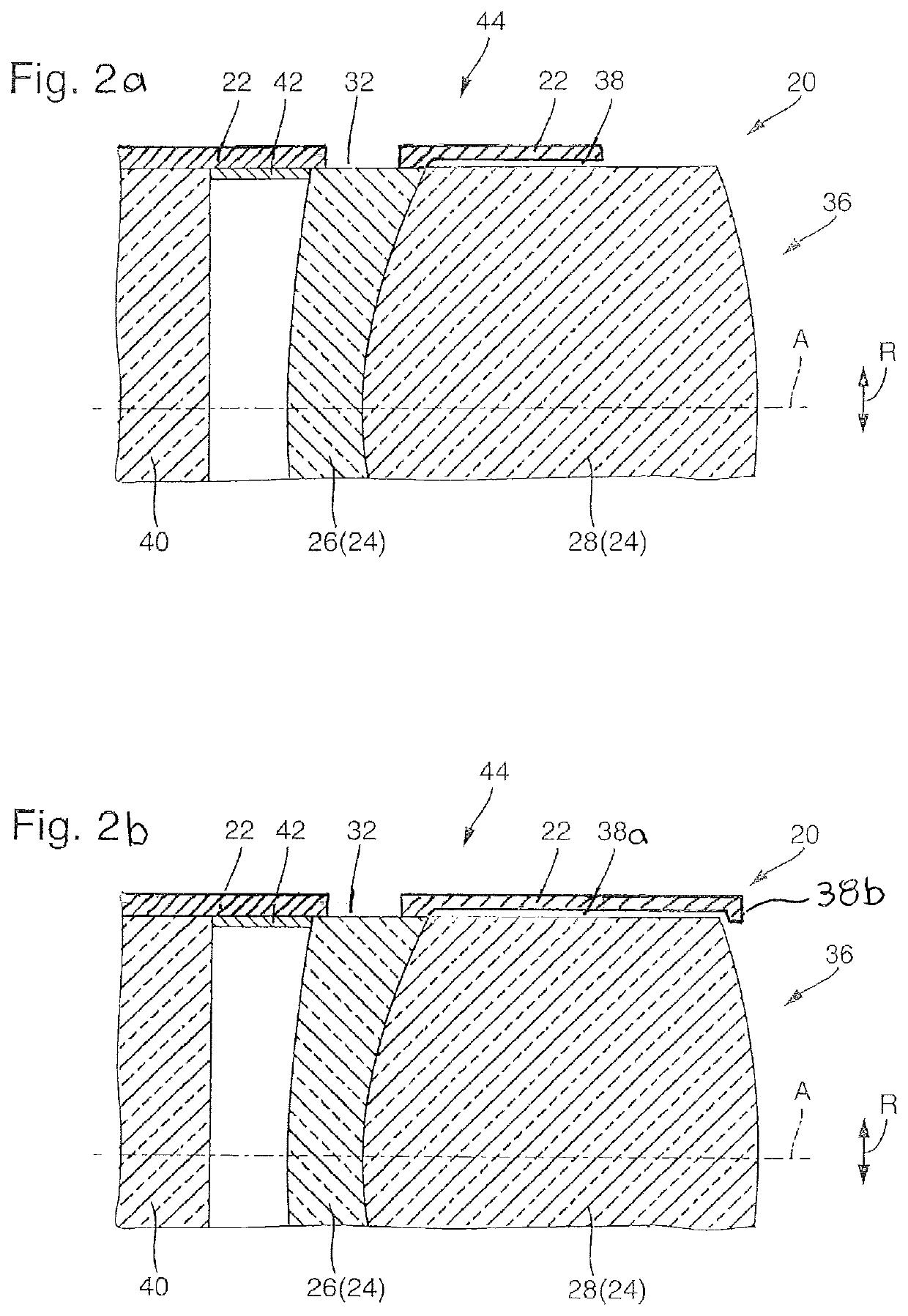

A dynamic mixer (50) comprising: two mixing elements (51), (52) rotatable relative to each other about a predetermined axis of rotation, each said mixing element having a mixing surface between which between an inlet (56) and an outlet (57) for the materials to be mixed; each said mixing surface comprises a series of annular steps centered on a predetermined axis of rotation and has a plurality of cavities defining flow channels bridging adjacent steps on each of two mixing elements; each of said mixing surfaces being mutually positionable such that one mixing element's The steps extend towards recesses formed between the steps of the other mixing element, whereby cavities present in one mixing face are offset in axial or transverse direction with respect to cavities present in the other mixing face, and overlap in an axial direction or a transverse direction with a cavity present on another mixing surface such that material moving between the mixing surfaces of the two mixing elements from the inlet to the outlet is transferable between the overlapping cavities; Wherein at least one step of one of the mixing elements and at least one adjacent step of the other mixing element extend further in the axial direction than in the transverse direction, or vice versa, so that between the two mixing elements a volume of approximately Consistent with at least one annular mixing zone.

Owner:MAELSTROM ADVANCED PROCESS TECH

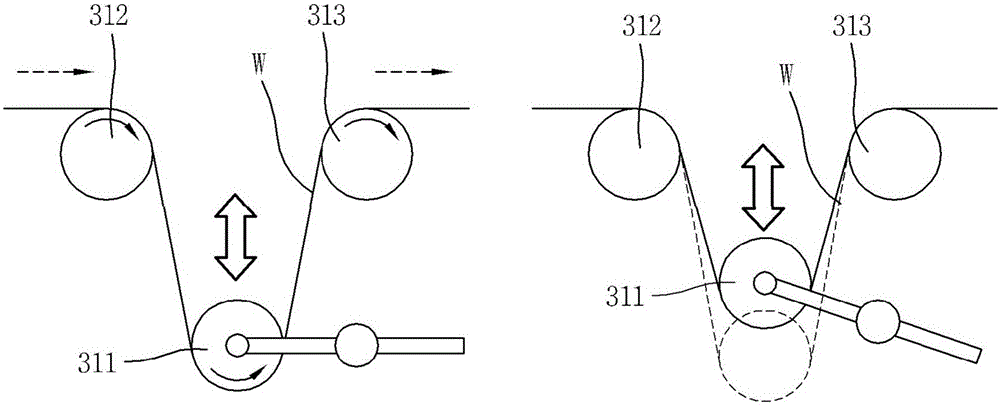

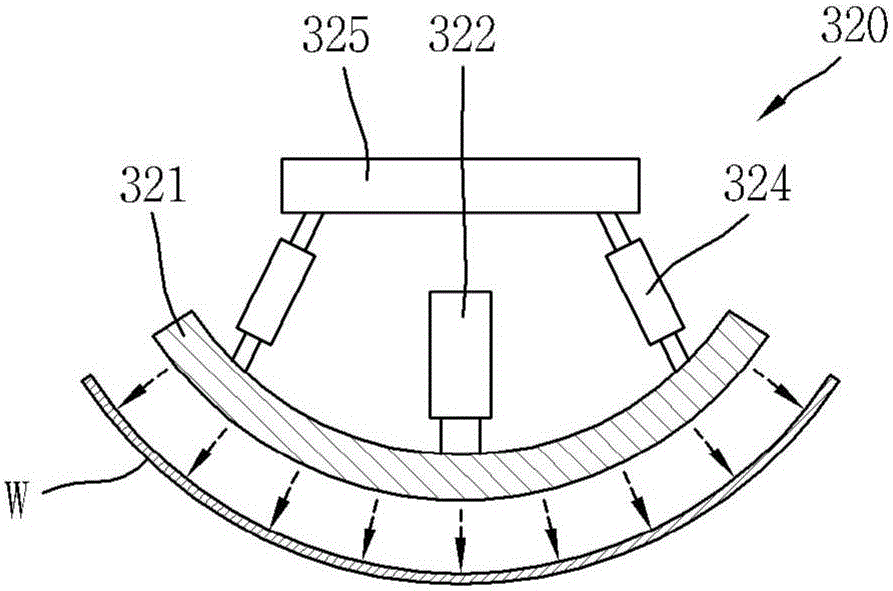

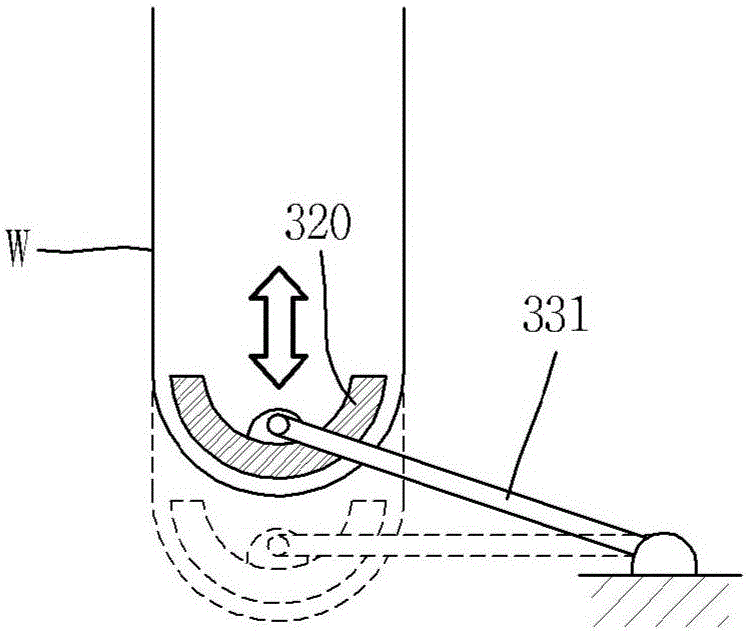

Tension control device and continuous web processing method using same

ActiveCN105683076AReliable transmissionAvoid mechanical contactWebs handlingUltrasonic vibrationEngineering

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Planar motor in double-shaft decoupling structure

ActiveCN102270908BAvoid mechanical contactRealize two-dimensional plane motionPropulsion systemsEngineeringPlanar motor

The invention discloses a planar motor in a double-shaft decoupling structure. The planar motor disclosed by the invention comprises a base and a working platform arranged above the base, wherein a first driving coil, a second driving coil, a pneumatic suspension body, a clearance sensor and a position sensor are arranged on the base; the first and second driving coils are perpendicularly laid onthe same plane; a first permanent magnet and a second permanent magnet which are perpendicularly laid on the same plane are arranged on the working platform; the first permanent magnet is perpendicular to the first driving coil; the second permanent magnet is perpendicular to the second driving coil; and a controller is respectively connected with the two driving coils, the two sensors and the pneumatic suspension body. The double-shaft coplane decoupling structure of the invention ensures that two-dimensional motion driven by two shafts on the same plane can be realized, the structure is simplified and the reliability of a system is improved.

Owner:无锡金力威环保科技有限公司

Linear vibration generation device

ActiveUS20170141666A1Sufficient stroke distanceIncrease heightMechanical vibrations separationSupports/enclosures/casingsEngineeringLinear vibration

Disclosed is a linear vibration generating device including: a stator including a bracket on which a coil is seated, and a case made of a magnetic material which is engaged to the bracket to form an inner space; a vibrator including a permanent magnet for generating a vibration force in cooperation with the coil, and a weight enclosing a circumference of the permanent magnet; a resilient member which is positioned between the vibrator and the stator to resiliently support vertical oscillation of the vibrator; and a plate which is positioned between the resilient member and the vibrator.

Owner:JAHWA ELECTRONICS

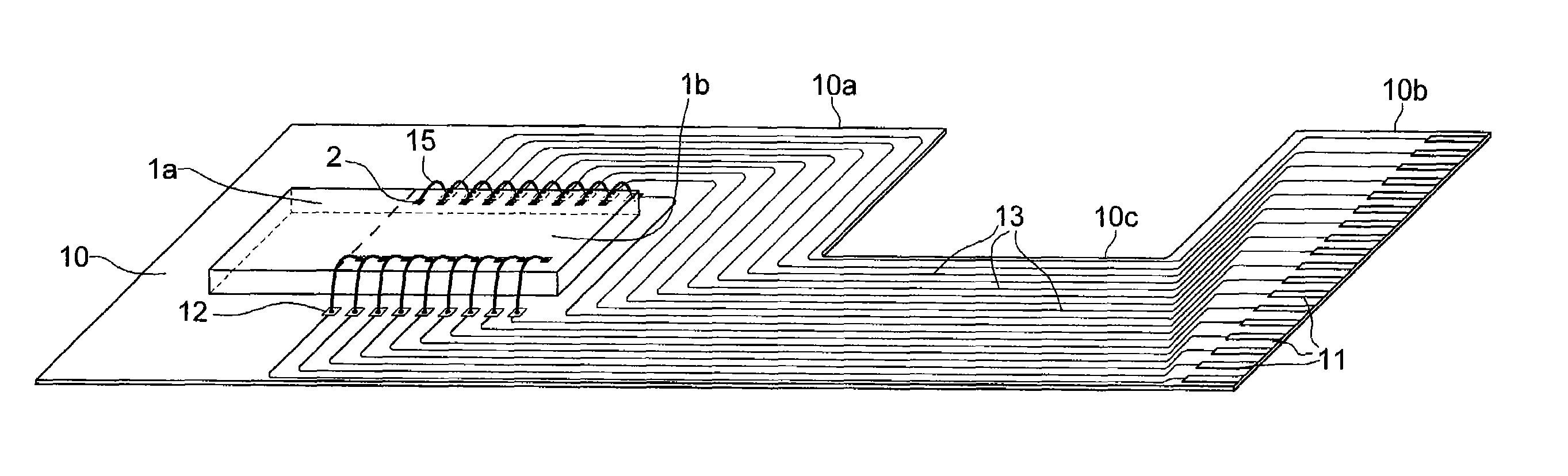

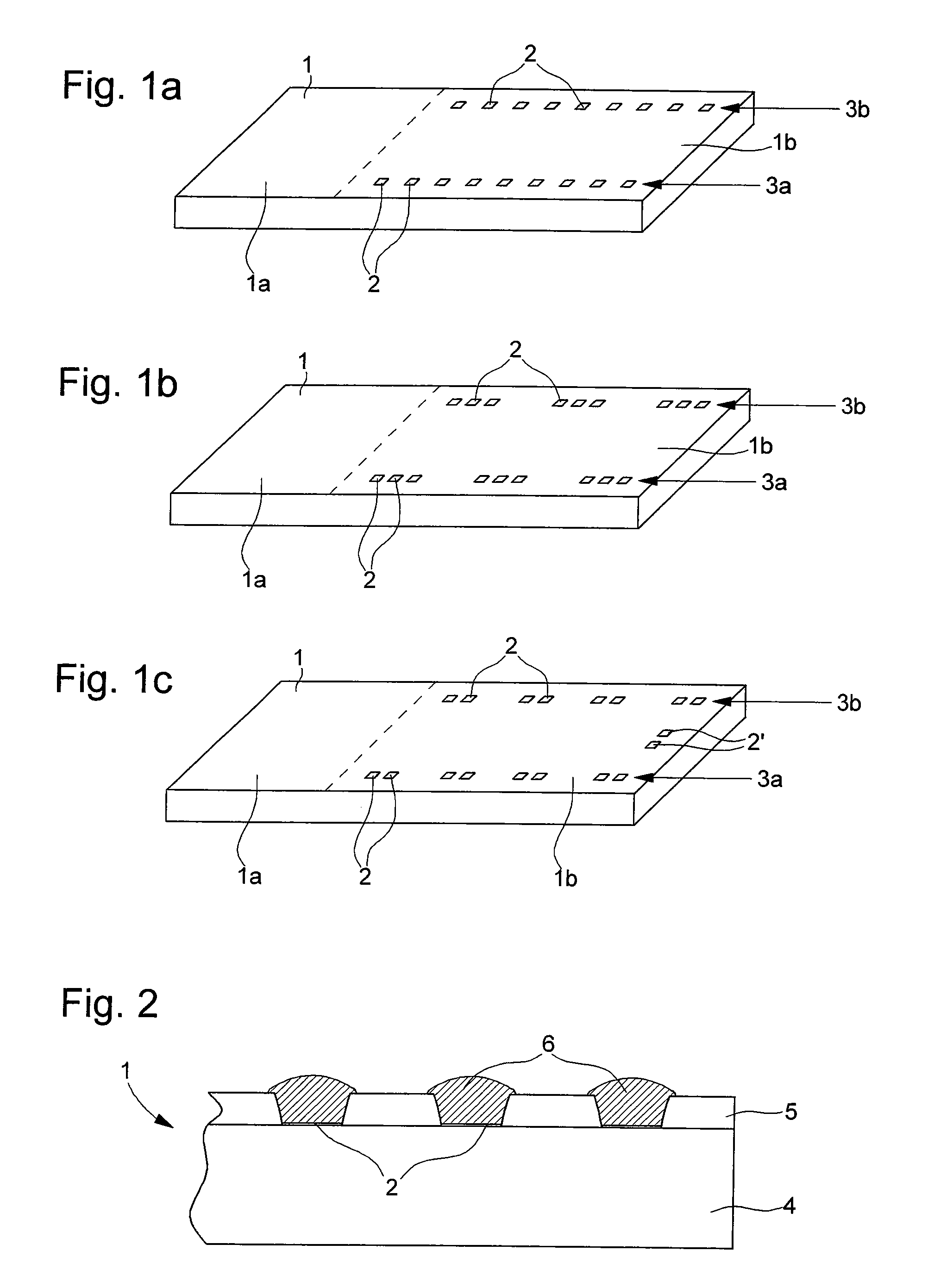

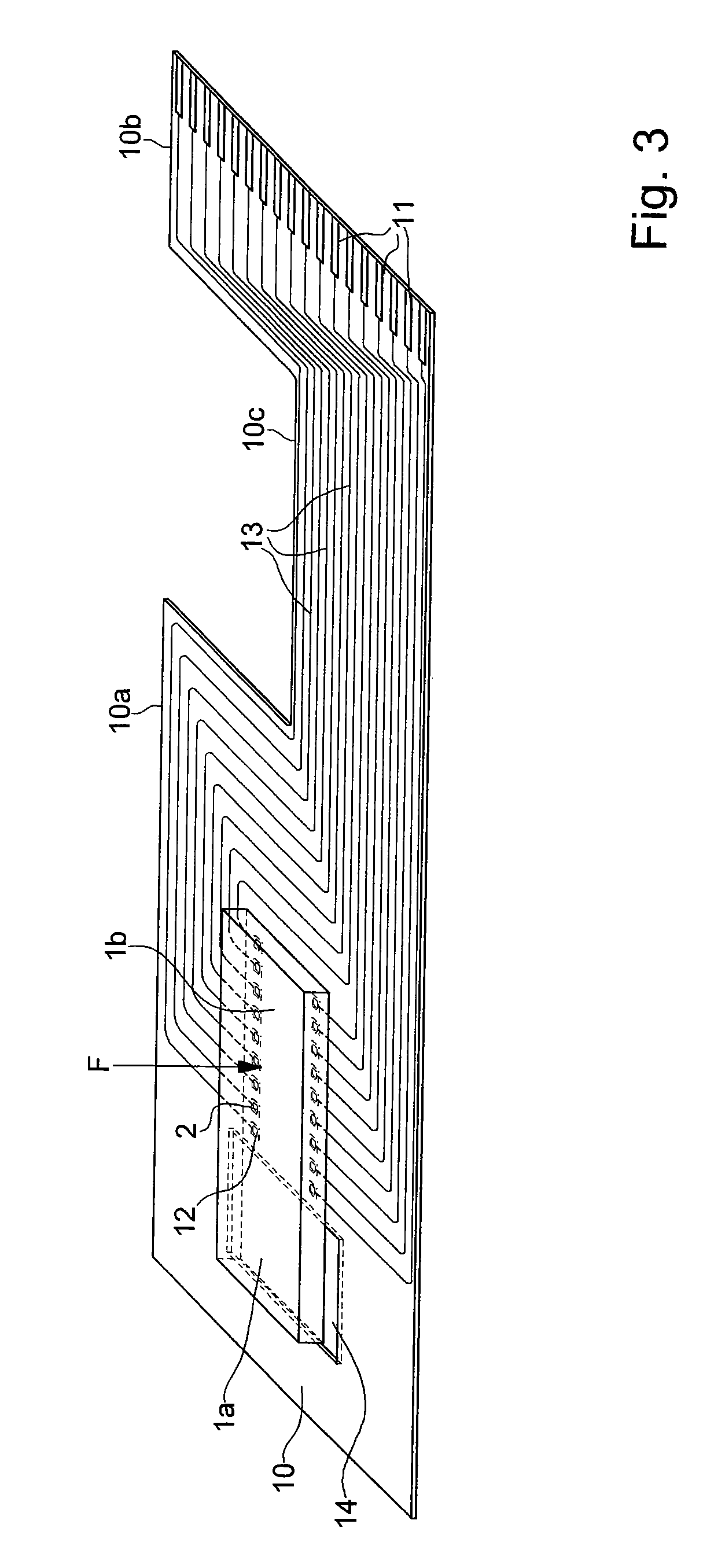

Integrated photoreceptor circuit and optoelectronic component including the same with electric contact pads arranged solely on side of the processing area which is juxtaposed with the photosensitive area

ActiveUS7579579B2Small sizeAvoid mechanical contactSolid-state devicesMaterial analysis by optical meansContact padProcess region

The integrated photoreceptor circuit includes a photosensitive area for picking up light and a processing unit area for processing the signals provided by the photosensitive area. This photoreceptor circuit includes electric contact pads, which are arranged symmetrically solely on the side of the processing unit area, which is juxtaposed with the photosensitive area. The integrated photoreceptor circuit is mounted on a first portion of a flexible substrate. The contact pads of the integrated photoreceptor circuit are electrically connected to electrical connection pads of the printed circuit of the flexible substrate. A second portion of the flexible substrate carries electrical connection terminals, which are connected to the connection pads via conductive paths, arranged in part on a connecting portion between the first and second portions. A through aperture in the first portion may be provided opposite the photosensitive area only of the photoreceptor circuit.

Owner:EM MICROELECTRONIC-MARIN

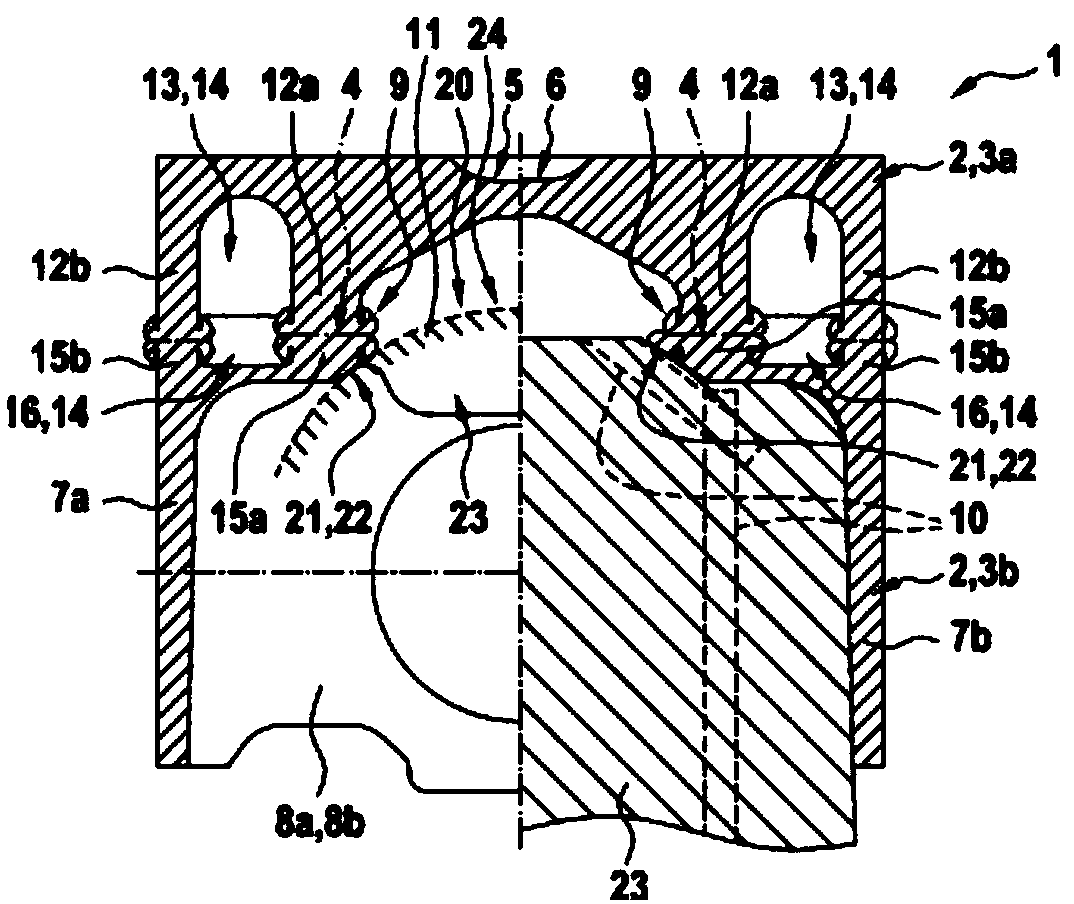

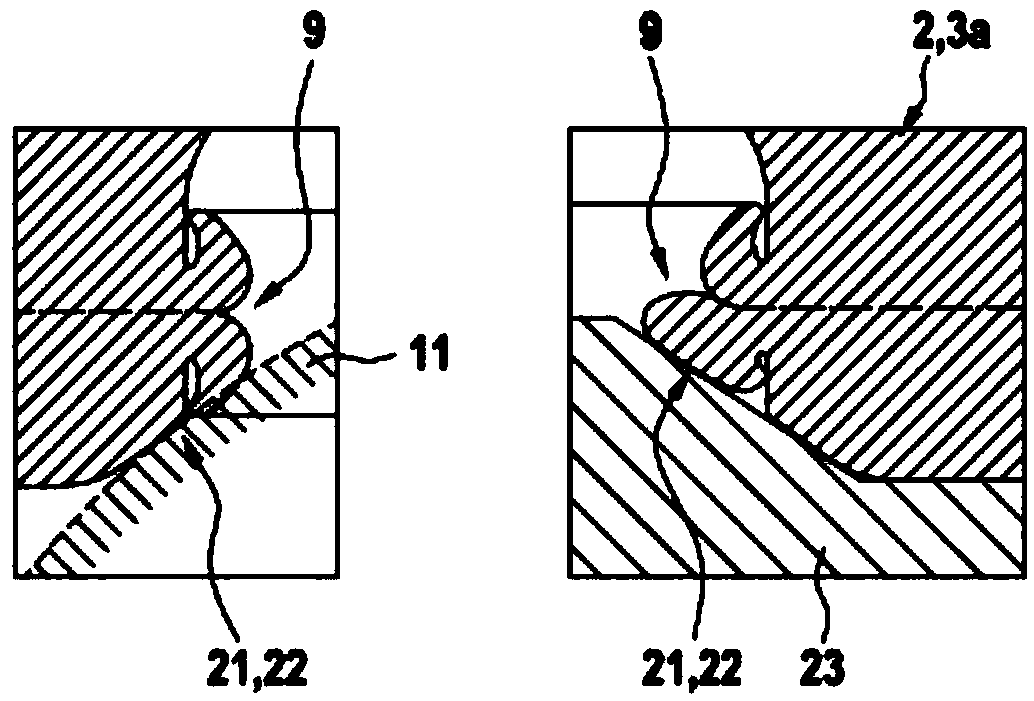

Method for producing a piston for a combustion engine from a piston upper part and a piston lower part

ActiveCN109128483AAvoid overall overheatingUnrestricted spaceMachines/enginesPistonsFriction weldingInternal combustion engine

A method for producing a piston (2) for an internal combustion engine may include arranging a piston upper part (3a) and a piston lower part (3b) in a friction welding device. The piston upper part (3a) may include a piston head with a combustion recess. The piston lower part may include two mutually opposite skirt elements connected to one another via two mutually opposite pin bosses. The methodmay also include arranging a deflecting device configured to deflect at least one weld bead one of on and in the friction welding device. The method may further include joining the piston upper part (3a) and the piston lower part (3b) to one another via friction welding.

Owner:MAHLE INT GMBH

Eyepiece device for a surgical instrument

Owner:OLYMPUS WINTER & IBE

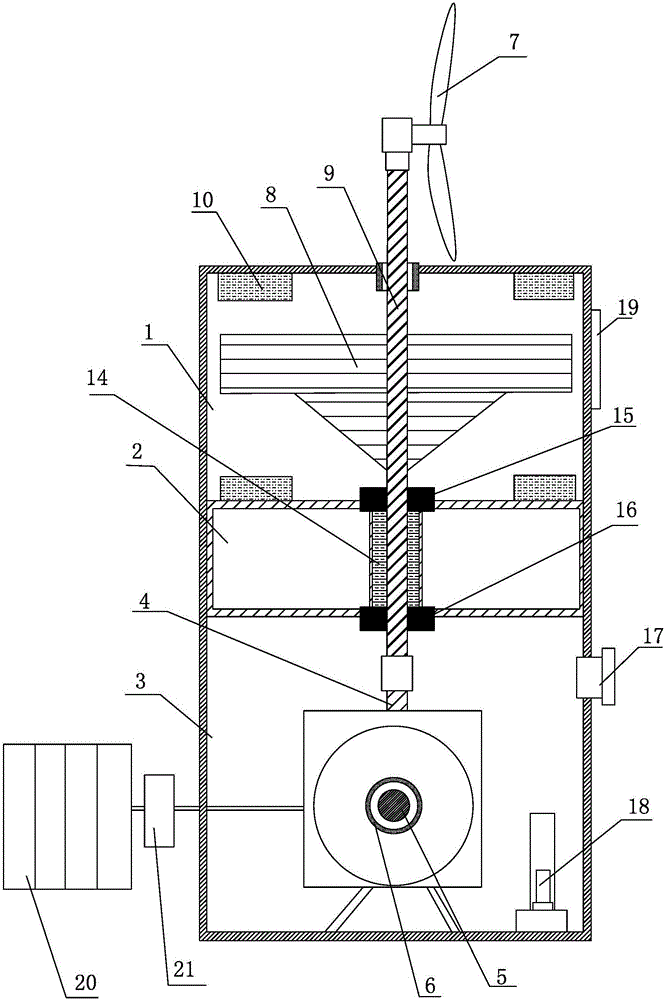

Vacuum magnetic suspension power generation system

ActiveCN106677987AImprove power generation efficiencyImprove utilization efficiencyWind energy with electric storageWind energy with kinetic energyThermal energy storageEngineering

The invention aims to provide a vacuum magnetic suspension power generation system and mainly solves the technical problem of improving electric energy endurance of electric traffic tools. The vacuum magnetic suspension power generation system comprises a power generation box, a power generator, a wind power energy capturing device, a power energy storage and supply device, a vacuum sealing device and a power storage device, wherein the power generation box comprises a power energy storage box, a vacuum sealed partition box and a vacuum power generation box; the vacuum sealed partition box is located between the power energy storage box and the vacuum power generation box; the vacuum sealing device is mounted in the vacuum sealed partition box; the power energy storage and supply device is mounted in the power energy storage box and comprises an energy storage rotation shaft and an energy storage rotation disc; the energy storage rotation disc is mounted on the energy storage rotation shaft; the upper end of the energy storage rotation shaft is connected with a power output shaft of the wind power energy capturing device which is mounted on the outer side of the power generation box; the lower end of the energy storage rotation shaft passes through the vacuum sealing device and is connected with a power input shaft which is mounted in the vacuum power generation box; two ends of a rotor of the power generator, are mounted by a magnetic suspension bearing. The vacuum magnetic suspension power generation system has the beneficial effect of high power generation efficiency.

Owner:刘骏

Chemical mechanical grinding device

ActiveCN102476349BAvoid mechanical contactAvoid wear and tearLapping machinesWork carriersFriction lossEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

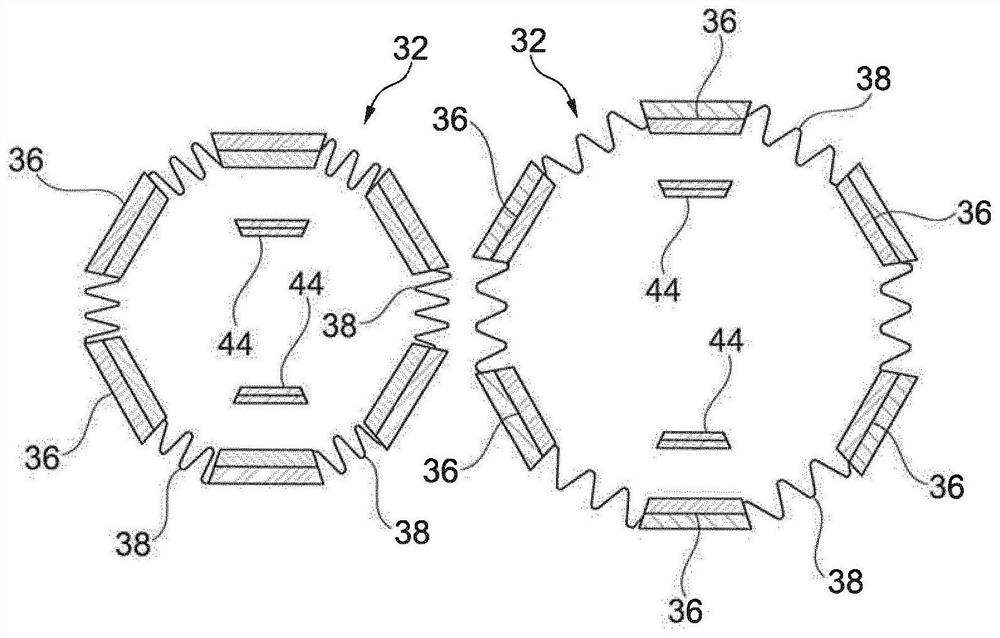

Intraocular lens system, intraocular lens and ciliary body implant

PendingCN114828779AReduce the chance of complicationsAvoid complicationsIntraocular lensIntraocular lensCiliary epithelium

The invention relates to an intraocular lens system (30) for implantation in an eye (10). The intraocular lens system (30) comprises a ciliary body implant (32) having a ciliary body magnet element (36), the ciliary body implant (32) being implantable in the eye (10) such that the ciliary body magnet element (36) follows at least partially a movement of a ciliary body (16) of the eye (10). The intraocular lens system (30) also includes an intraocular lens (10) having a lens magnet element (44). In this case, the ciliary body implant (32) and the intraocular lens (34) are formed separately from one another and the intraocular lens system (30) is designed to control the refractive effect of the intraocular lens (34) by means of an interaction in the eye (10) between the ciliary body magnet element (36) and the lens magnet element (44). The invention also relates to a ciliary body implant (32) and an intraocular lens (34).

Owner:CARL ZEISS MEDITEC AG

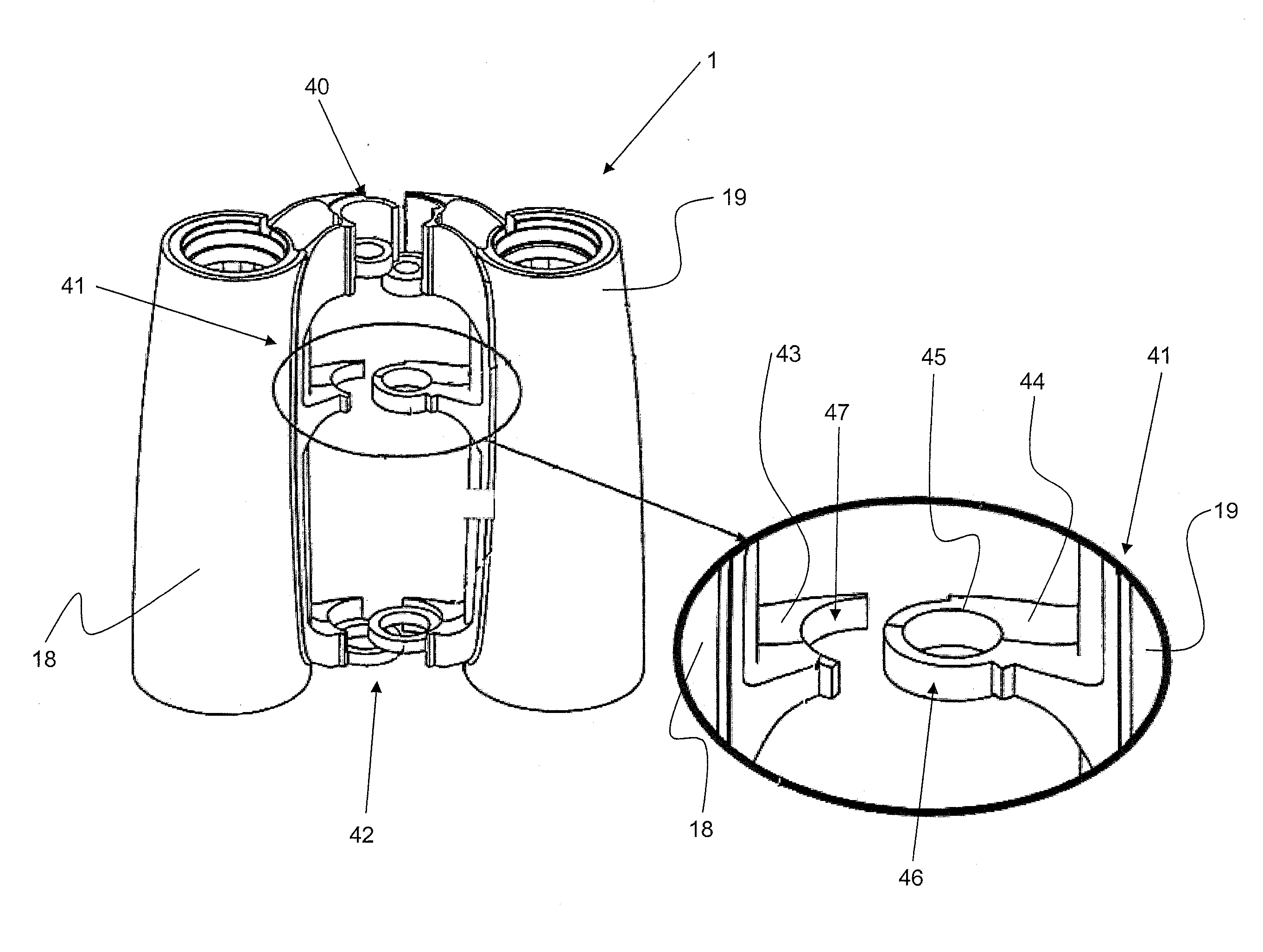

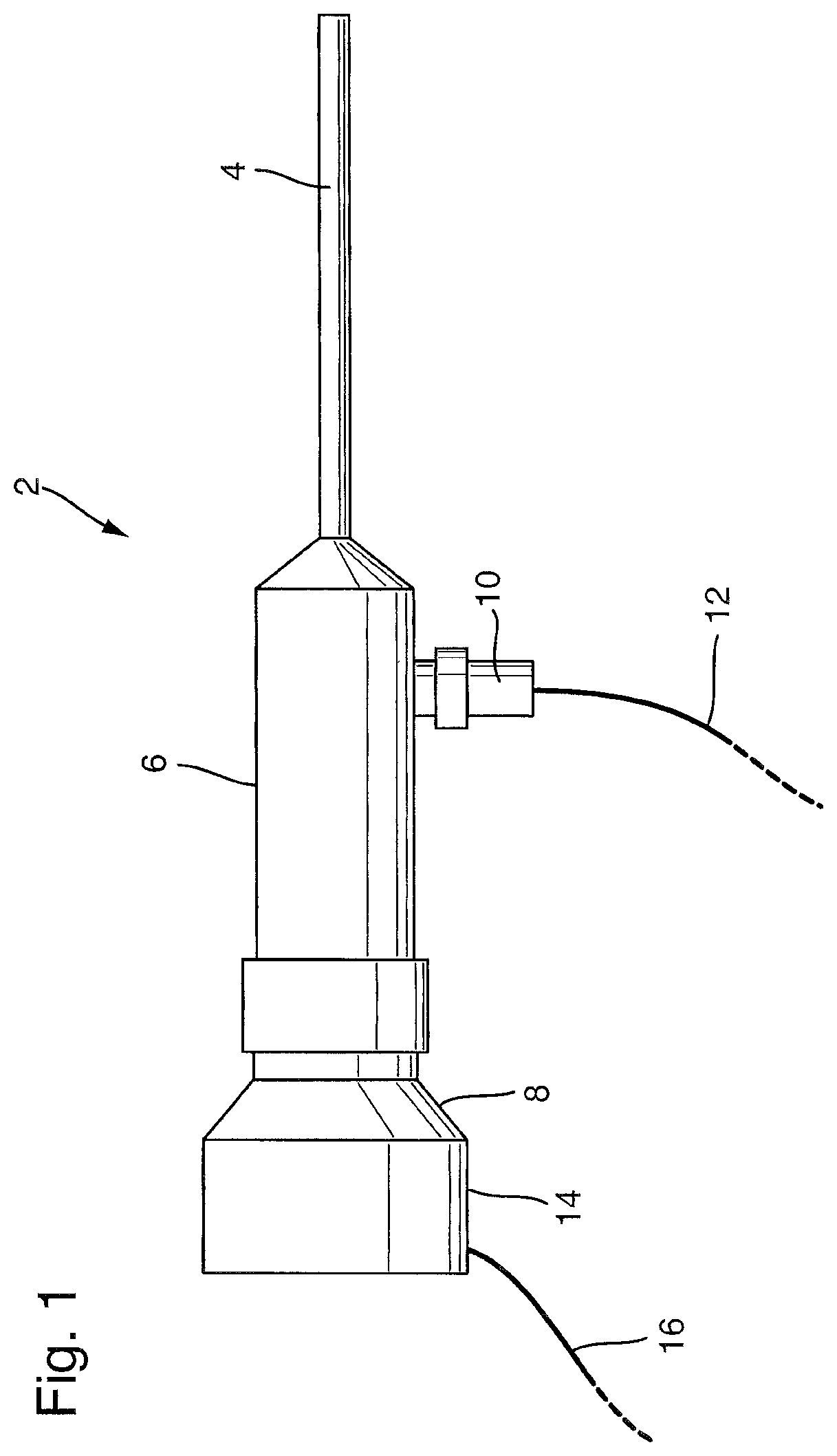

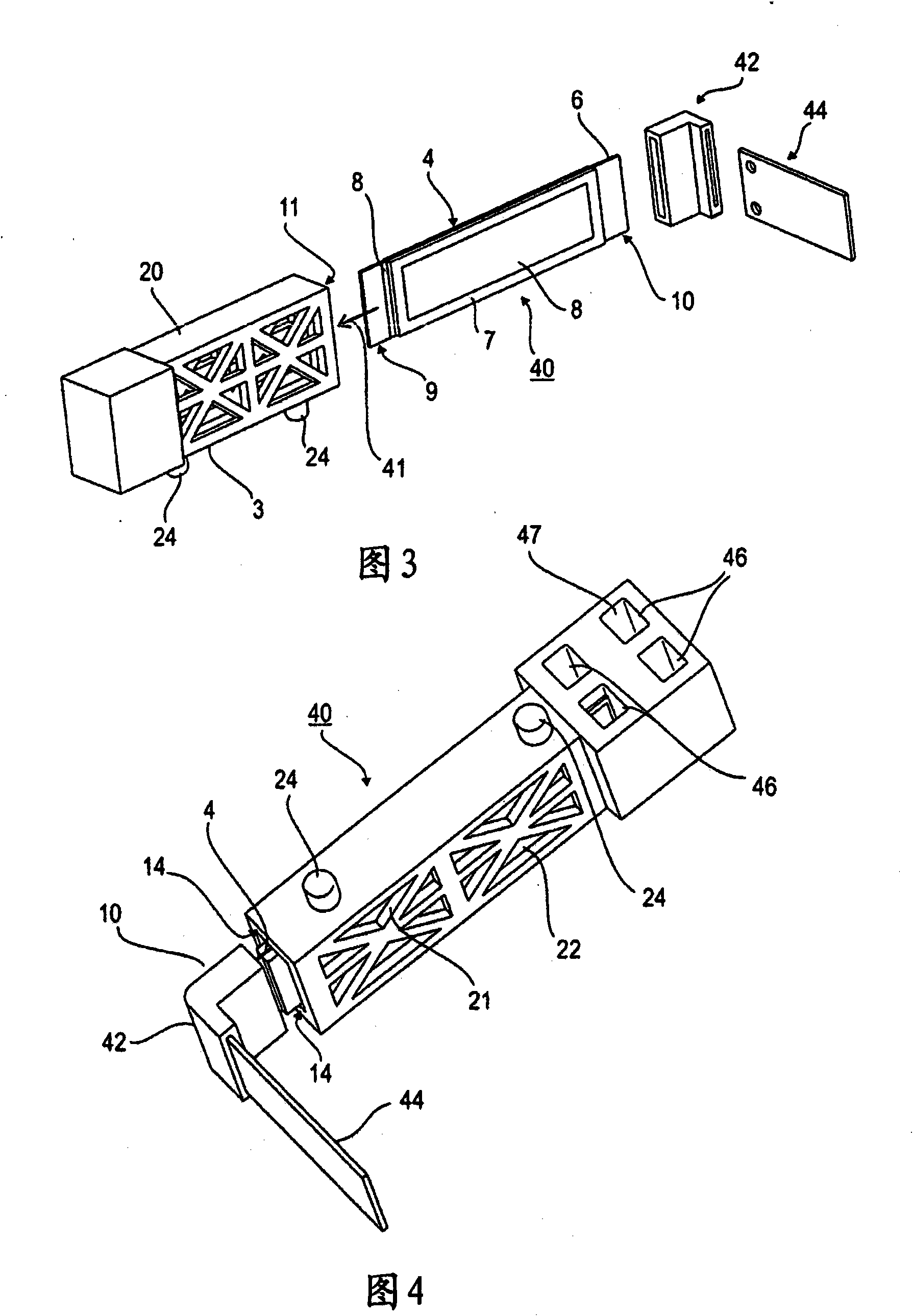

Bending actuator element and bending actuator module

The invention relates to a bending actuator element (1, 40) comprising a protective casing (3) and a bending actuator (4) accommodated therein, and a flat support (6) and a piezoelectrically active coating (7) applied to at least one side thereof. The bending actuator (4) is substantially enclosed by the protective casing (3) and is directly fastened in the protective casing (3) with its fixed end (9). The invention further relates to a bending actuator module (28) having a plurality of said bending actuator elements (1, 40). The fact that the bending actuator (4) is immobilized inside a protective casing (3) allows a unit that can be easily mounted, the risk of being damaged due to the destruction of the piezoelectric coating (7) during mounting or transport being substantially reduced compared to bending actuators of the prior art.

Owner:JOHNSON MATTHEY PIEZO PROD GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com