A planar motor with two-axis decoupling structure

A plane motor, plane phase technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing system instability, complex structure, etc., to improve system reliability and positioning accuracy, the overall structure is simple, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

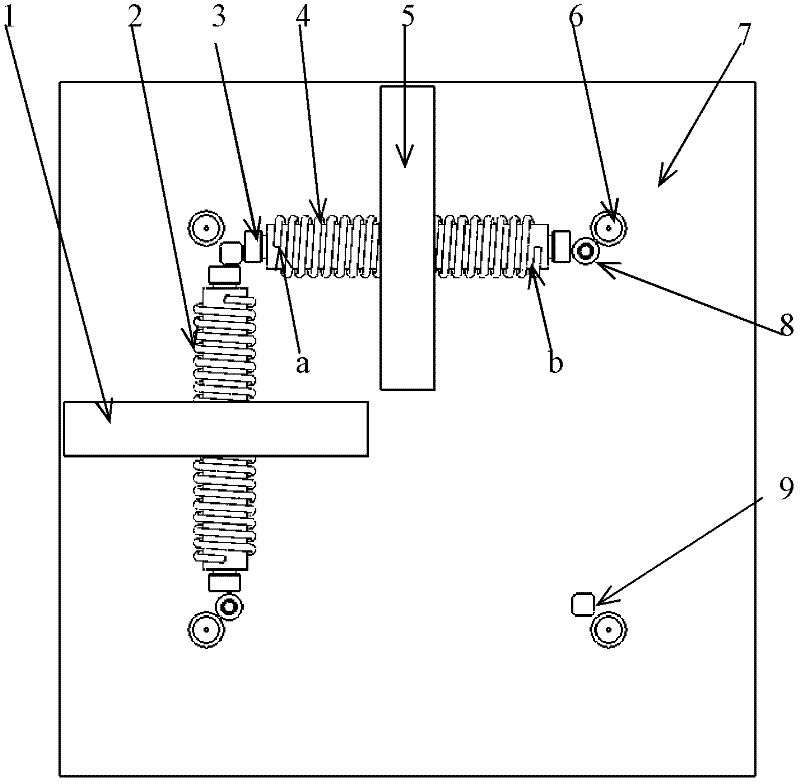

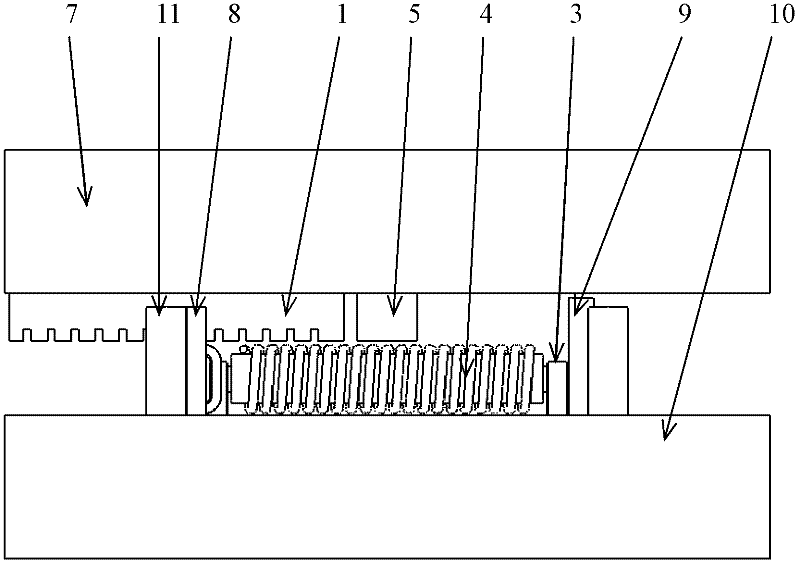

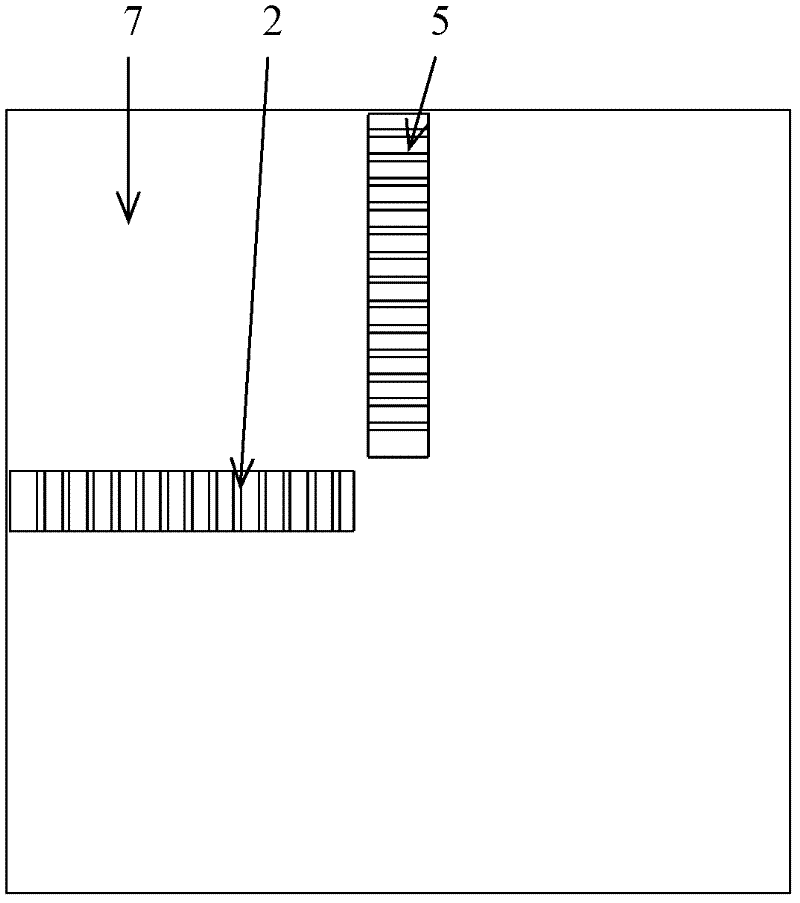

[0022] Figure 14 It is a three-dimensional structure diagram of the present invention, figure 1 It is the overall plane structure diagram of the planar motor with biaxial decoupling structure of the present invention. The planar motor device with biaxial decoupling structure of the present invention is specifically composed of two parts, namely the workbench and the base body. The workbench is composed of a work platform 7 and permanent magnets 1 and 5 placed vertically on the platform, and the base body includes a base 10 and drive coils 2 and 4 arranged thereon, an air suspension 6. Composed of sensor 8, static support 9, coil positioner 3, etc. The driving coils 2 and 4 are vertically placed on the base and fixed by a coil positioner 3 , wherein the driving coil 2 is perpendicular to the permanent magnet 1 , and the driving coil 4 is perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com