Improved dynamic mixer

A technology of dynamic mixing and mixer, applied in mixers, mixers with rotating agitation devices, chemical instruments and methods, etc., can solve the possibility of reducing, the lack of self-pumping and self-cleaning of cylindrical cavity transfer mixers Capability, reduced possibility of asymmetric transmission, etc., to achieve the effect of reducing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

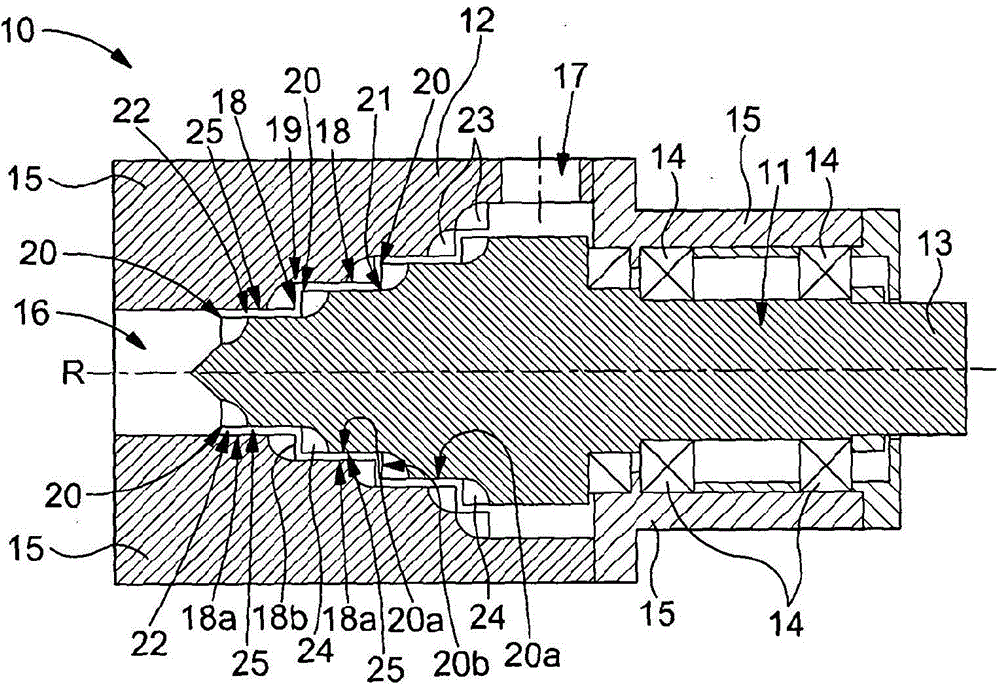

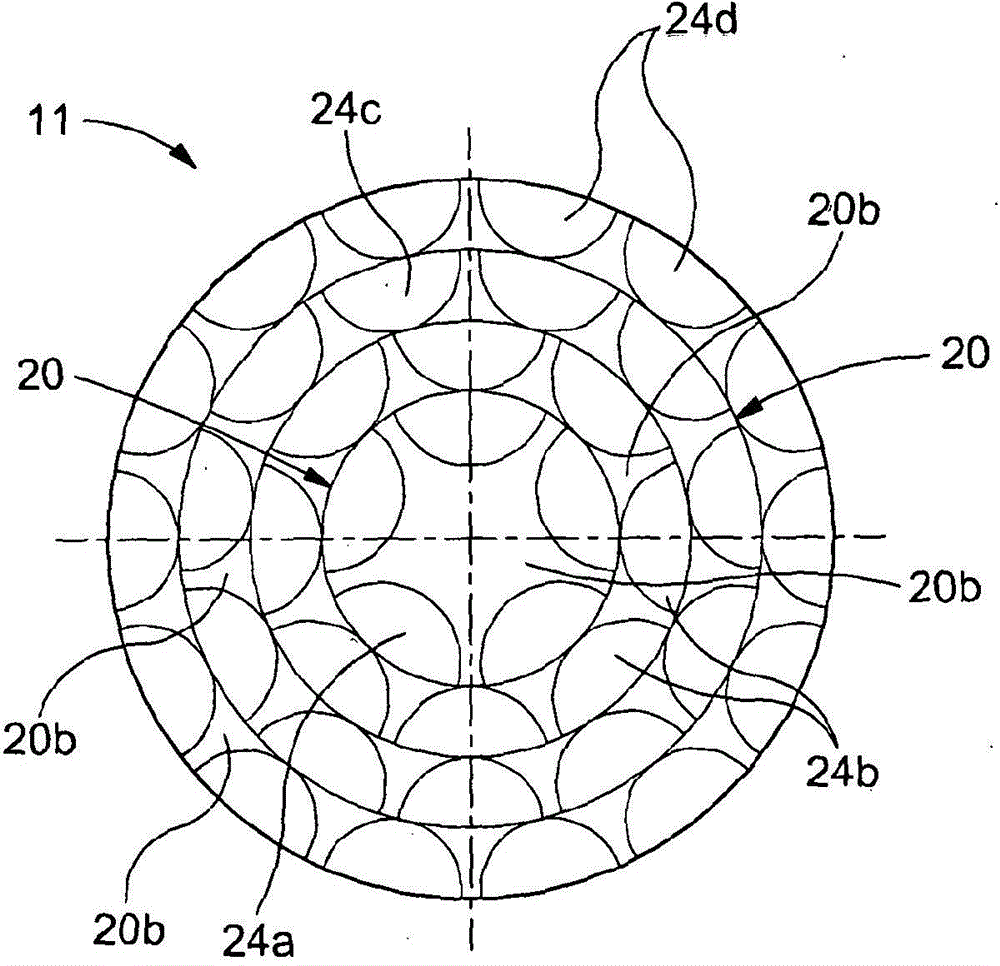

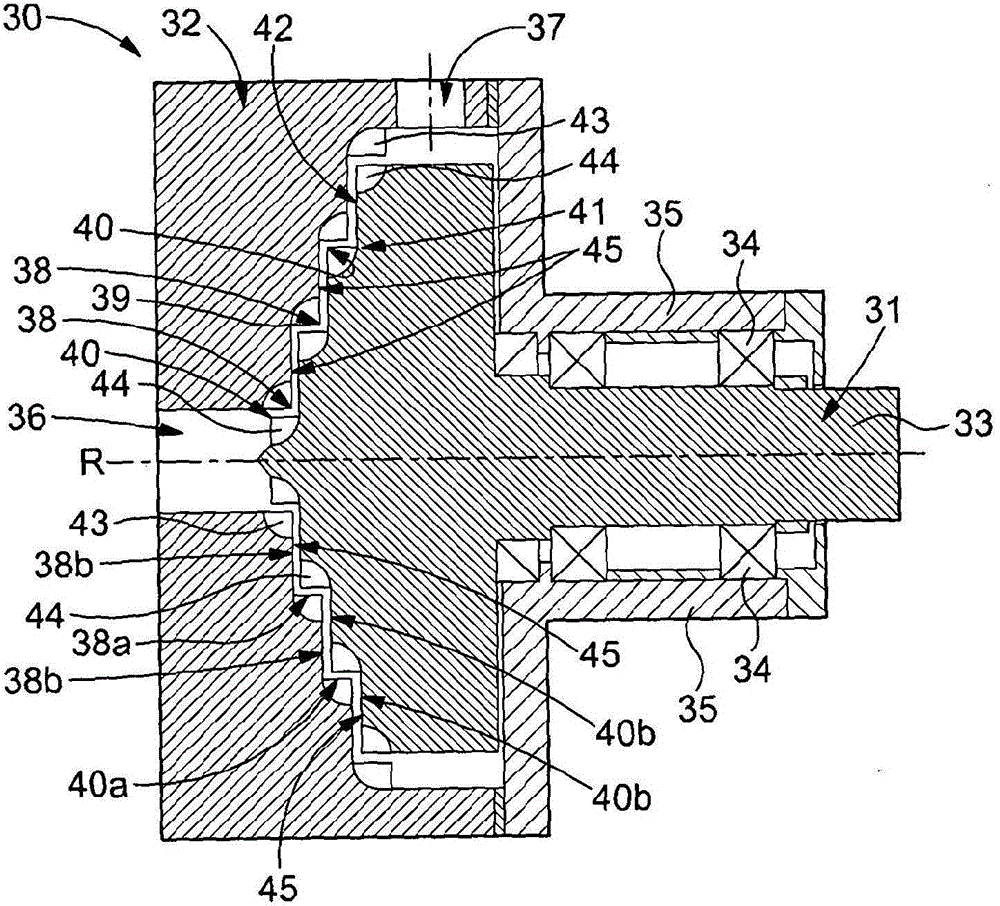

[0049] refer to figure 1 , the shown dynamic mixer 10 comprises two mixing elements in the form of an inner rotor 11 and an outer stator 12 which are rotatable relative to each other, in this case the rotor 11 surrounds the stationary stator 12 The predetermined axis of rotation R is rotatable. The rotor 11 is mounted on a shaft 13 supported in bearings 14 within a housing 15 . The stator 12 is mounted on a housing 15 . The stator 12 defines a mixer inlet 16 and a mixer outlet 17 .

[0050] A series of four annular steps 18 extend along the generally conical inner mixing surface of the stator 12, each step 18 being defined by a first surface 18a and a second surface 18b, the first surface 18a being cylindrical and centered on the axis R (thereby an axial surface), the second surface 18b is planar and perpendicular to the axis R (thereby a transverse surface). A recess 19 is formed where the first surface 18 a of one step 18 meets the second surface 18 b of an adjacent step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com