Tension control device and continuous web processing method using same

A processing method and web technology, applied in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of small elongation, increase the mechanical contact damage of thin glass webs, etc., and achieve the effect of avoiding mechanical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, with reference to the accompanying drawings, a description will be given of an embodiment of the present invention.

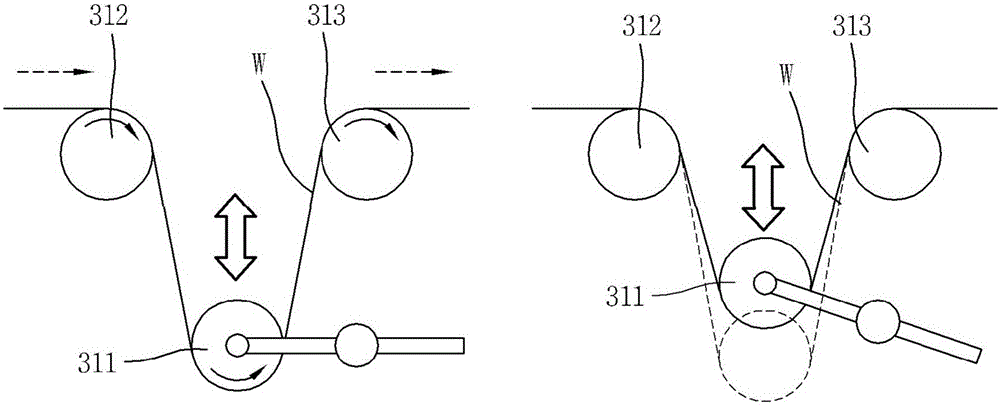

[0020] Roll-to-roll or roll-to-sheet processes for continuous web handling use non-contact floats to control tension disturbances that occur during transport of the web.

[0021] The present invention relates to the handling of a web formed from a brittle material such as a thin glass web, and more particularly to a tension control device comprising a non-contact float for transporting a web formed of a brittle material and a A continuous web processing method using the device.

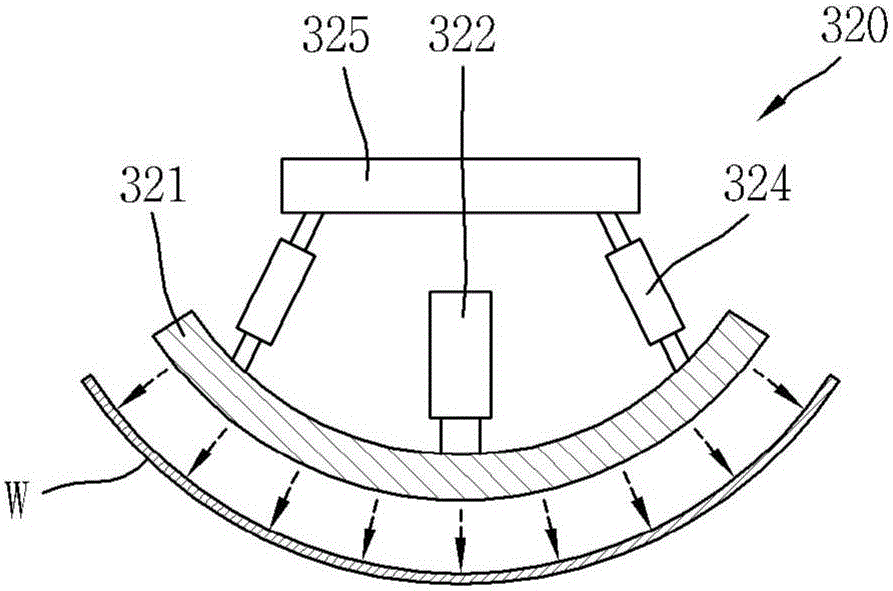

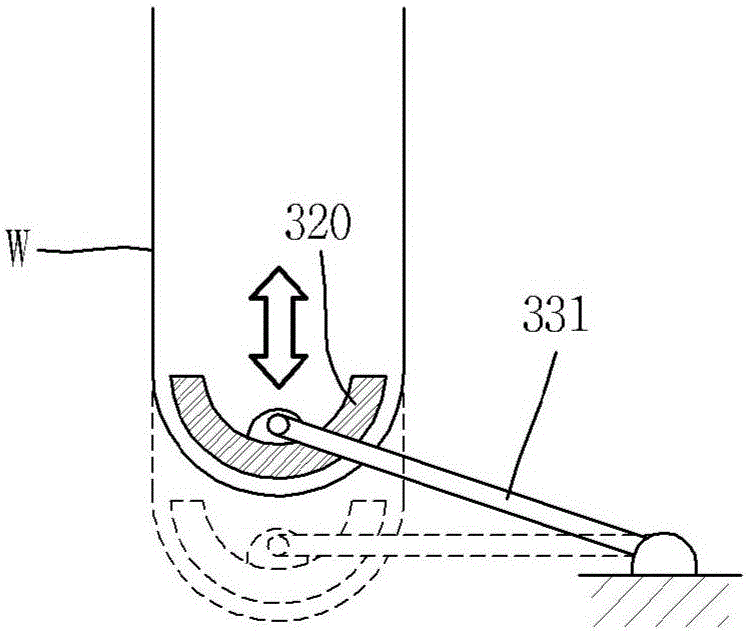

[0022] figure 2 The basic principle of the tension adjustment according to the invention is schematically shown.

[0023] The tension adjusting device according to the present invention includes a floating member 320 . figure 2 The floating member 320 shown includes a first ultrasonic vibrator 321 , an ultrasonic generator 322 , a shock absorber 324 and a fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com