Method for producing a piston for a combustion engine from a piston upper part and a piston lower part

An internal combustion engine, piston technology, applied in the direction of pistons, mechanical equipment, engine components, etc., to prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

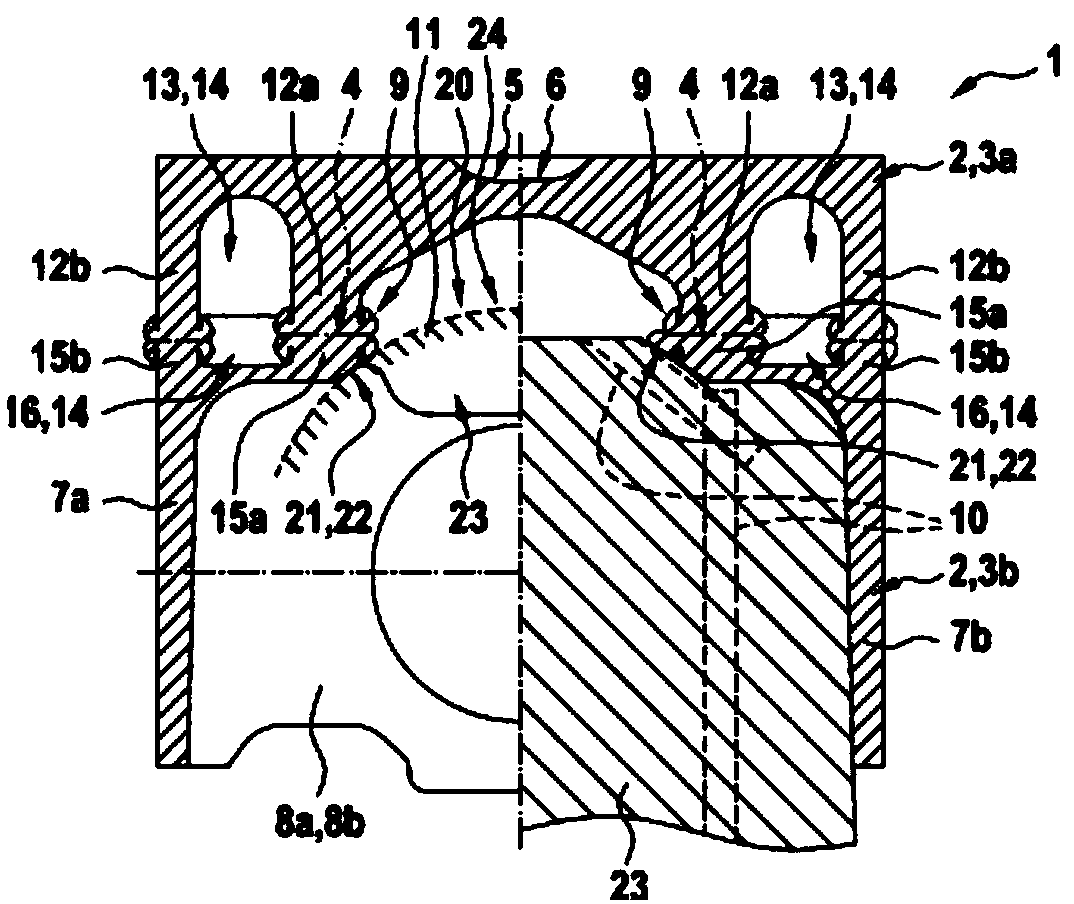

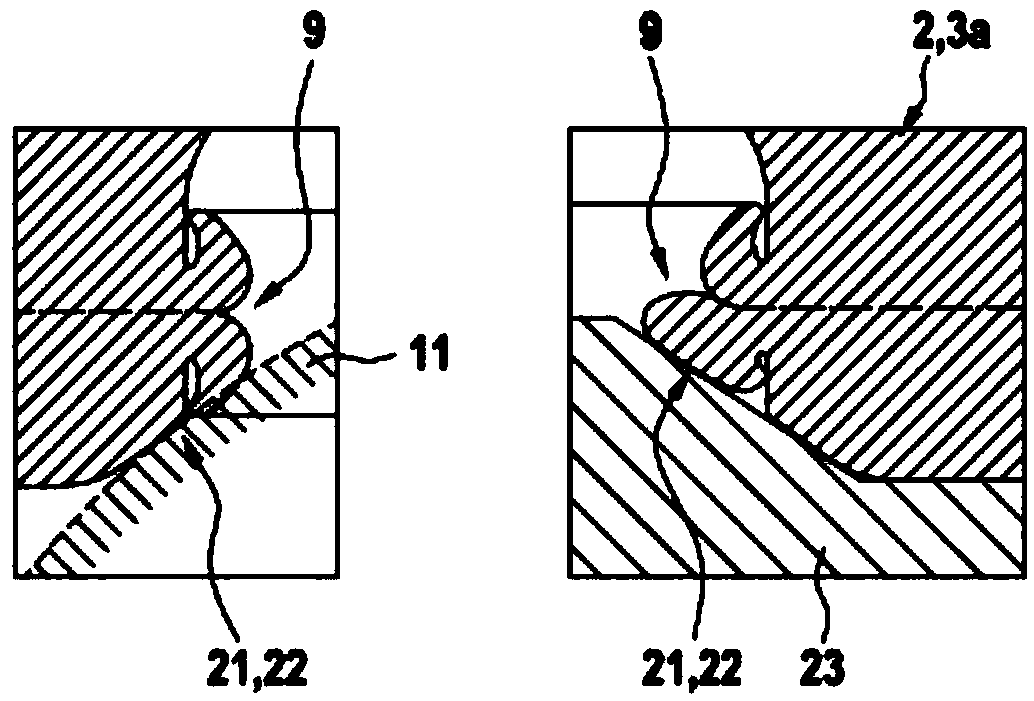

[0026] figure 1 and figure 2 An example of a friction welding device 1 according to the invention for producing a piston 2 for an internal combustion engine consisting of a piston upper part 3 a and a piston lower part 3 b each made of steel is shown. The friction welding device 1 is used to join the piston upper part 3a and the piston lower part 3b by friction welding. The friction welding device 1 comprises a clamping device 23 (only partially shown in the figure) in which the upper piston part 3a and the lower piston part 3b can be clamped for friction welding. A more precise technical design of the friction welding device 1 is known to those skilled in the relevant art, so a more detailed explanation will be omitted below.

[0027] The piston upper part 3 a comprises a piston head 5 with a combustion recess 6 . The piston lower part 3b has two mutually opposite skirt elements 7a, 7b which are connected to one another via two mutually opposite pin seats 8a, 8b. The pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com