Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid hitting the knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

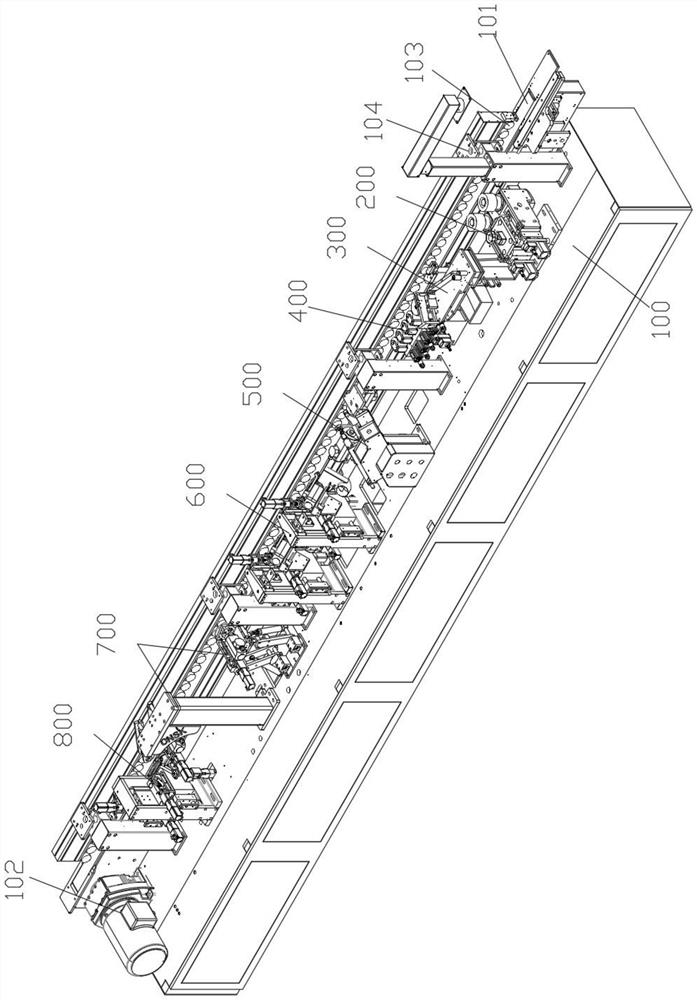

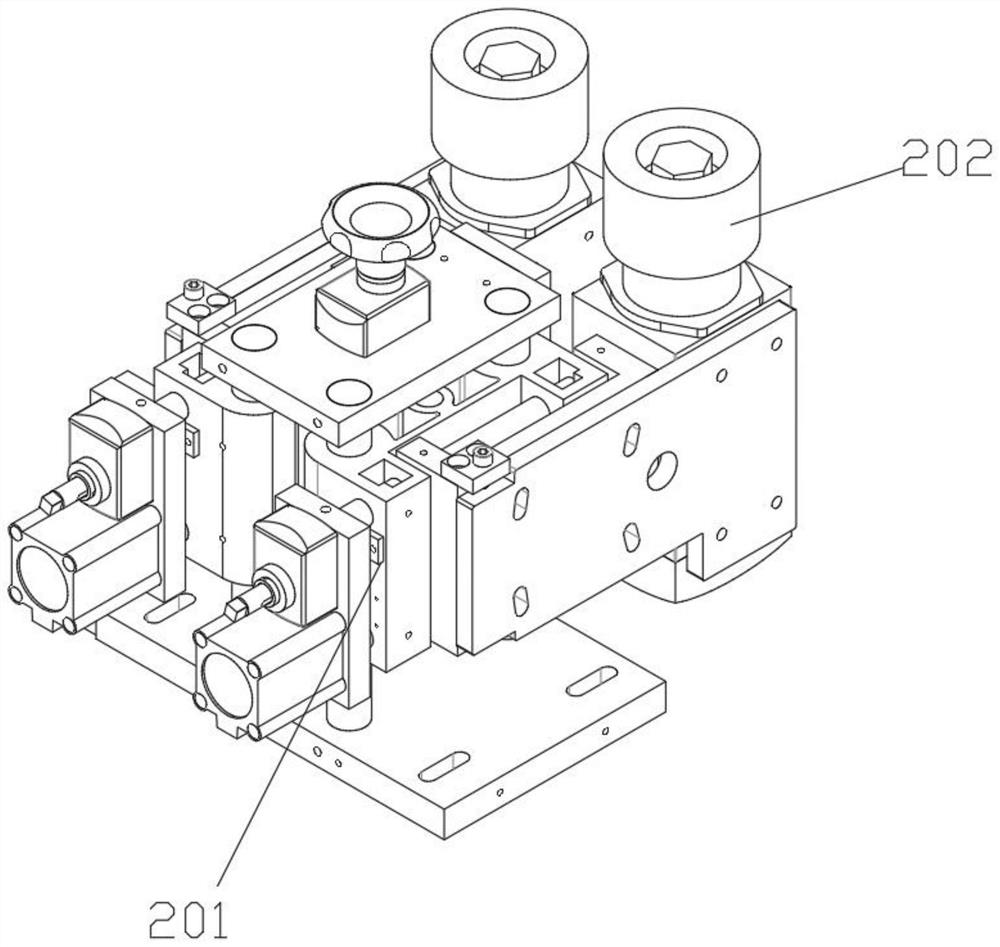

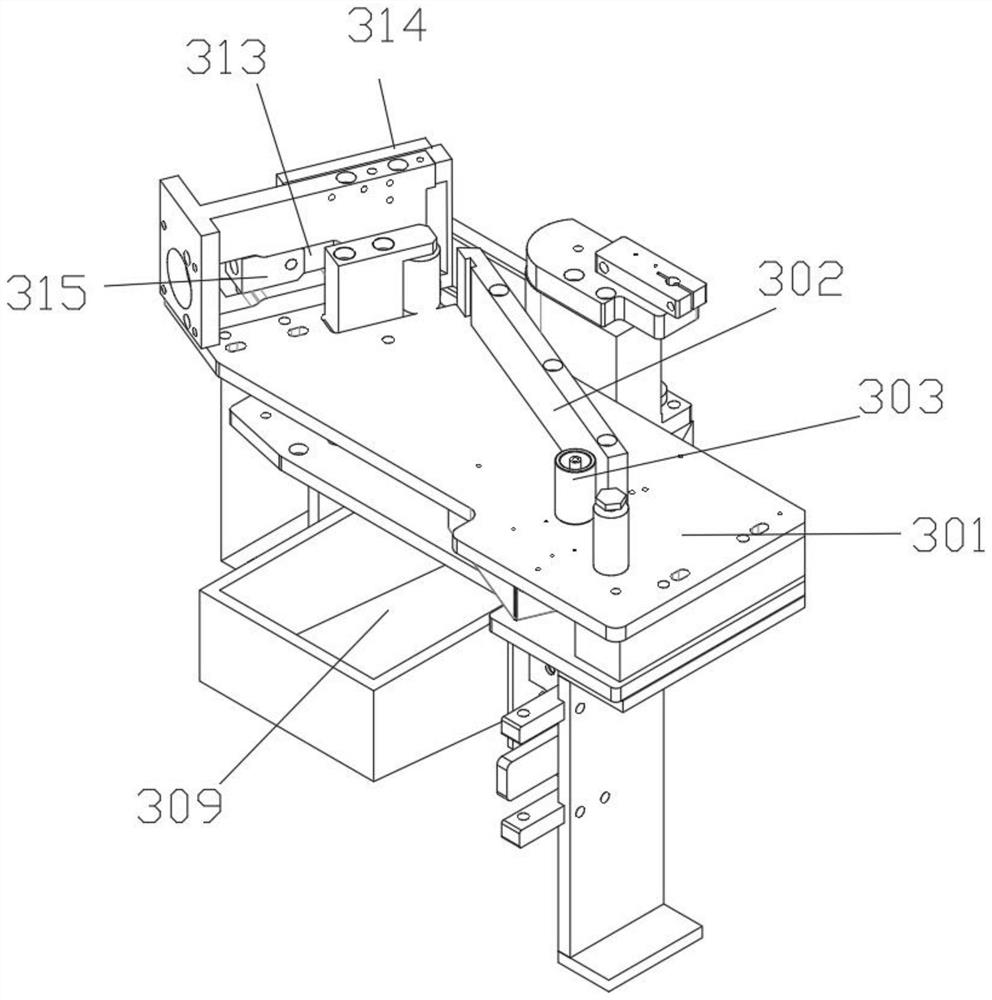

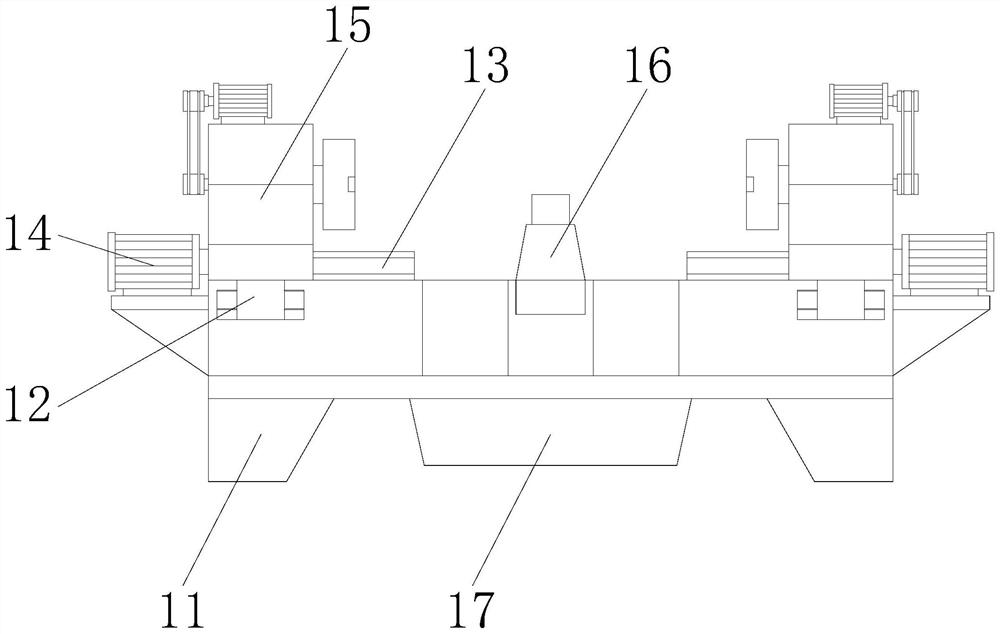

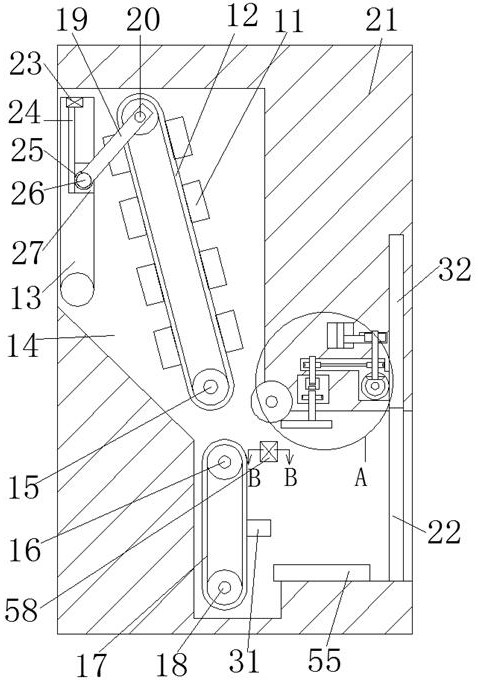

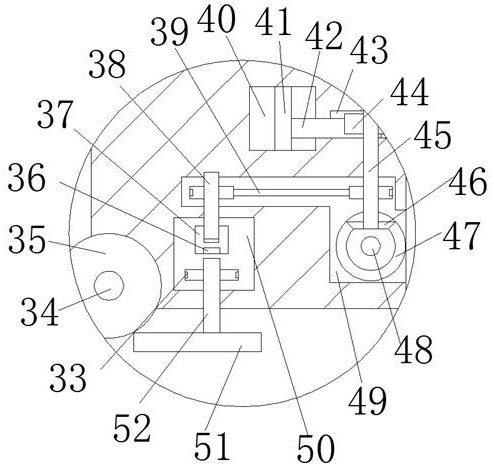

Full-automatic servo straight edge sealing machine

PendingCN111633773AHigh degree of automationImprove machining accuracyOther plywood/veneer working apparatusMulti-purpose machinesMilling cutterControl system

The invention discloses a full-automatic servo straight edge sealing machine. The full-automatic servo straight edge sealing machine comprises a workbench, a conveying belt and a PLC control system; and the conveying belt is used for conveying wood. and full-automatic servo straight edge sealing machine also comprises a side belt feeding mechanism, a straight edge press-fitting mechanism, a double-track side belt trimming mechanism, an up-and-down finishing mechanism, an up-and-down tracking mechanism and an up-and-down scraper mechanism which are arranged beside the conveying belt in sequence; a thickness identification assembly electrically connected with the PLC control system is arranged on the side belt feeding mechanism, and is used for acquiring the thickness of a side belt; the up-and-down finishing mechanism comprises a finishing knife module; the up-down tracking mechanism comprises a tracking milling cutter module; the up-and-down scraper mechanism comprises a scraper module; and the finishing cutter module, the tracking milling cutter module and the scraper module are electrically connected with the PLC control system. Cutters in the modules above can be automatically adjusted according to data obtained by the PLC control system from the thickness identification assembly without shutting down to control manually, processing parameters of side belts in different thicknesses are adapted, and the full-automatic servo straight edge sealing machine has the advantages of high automation degree, high processing precision and high working efficiency.

Owner:东莞市繁茂木工机械设备有限公司

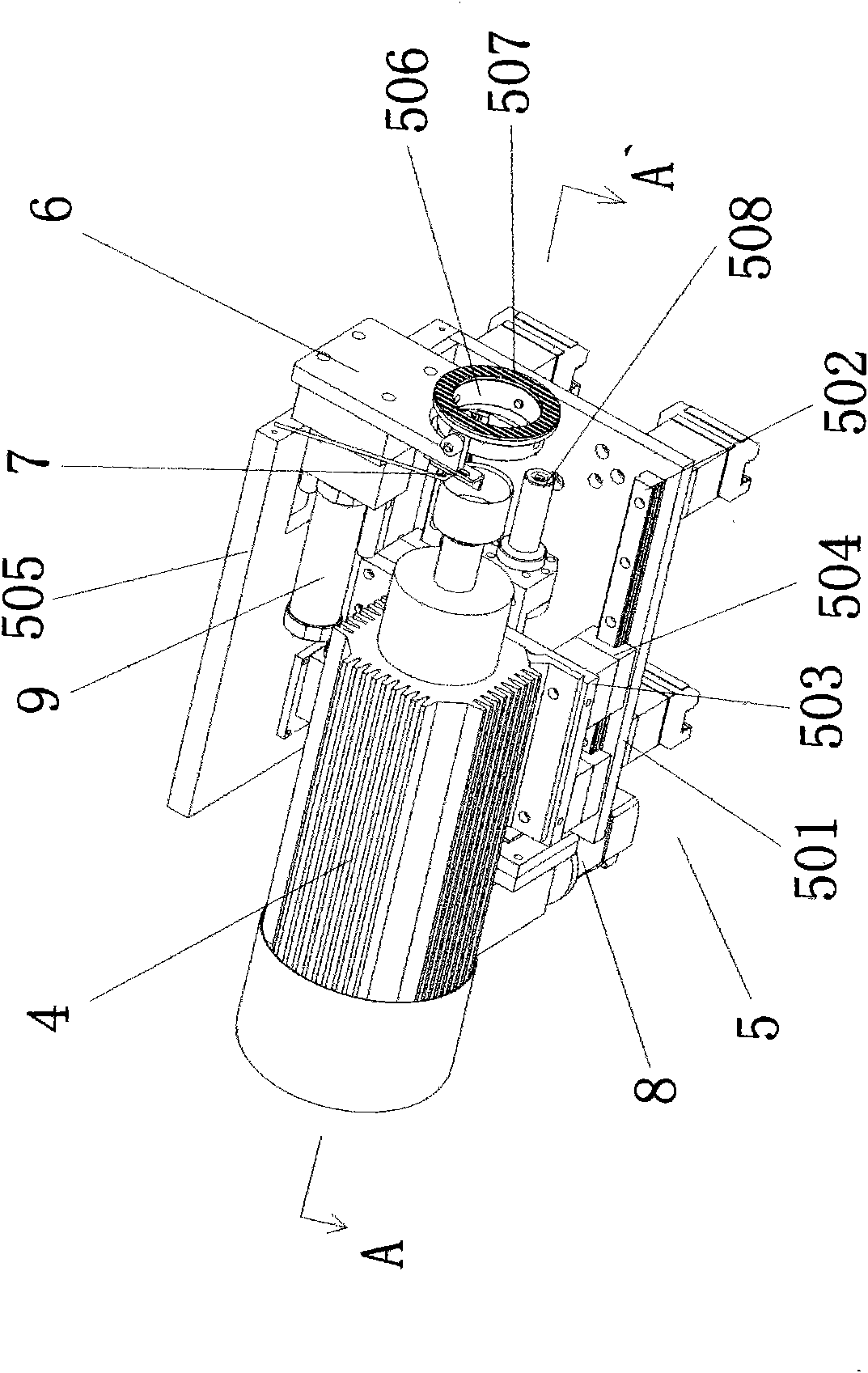

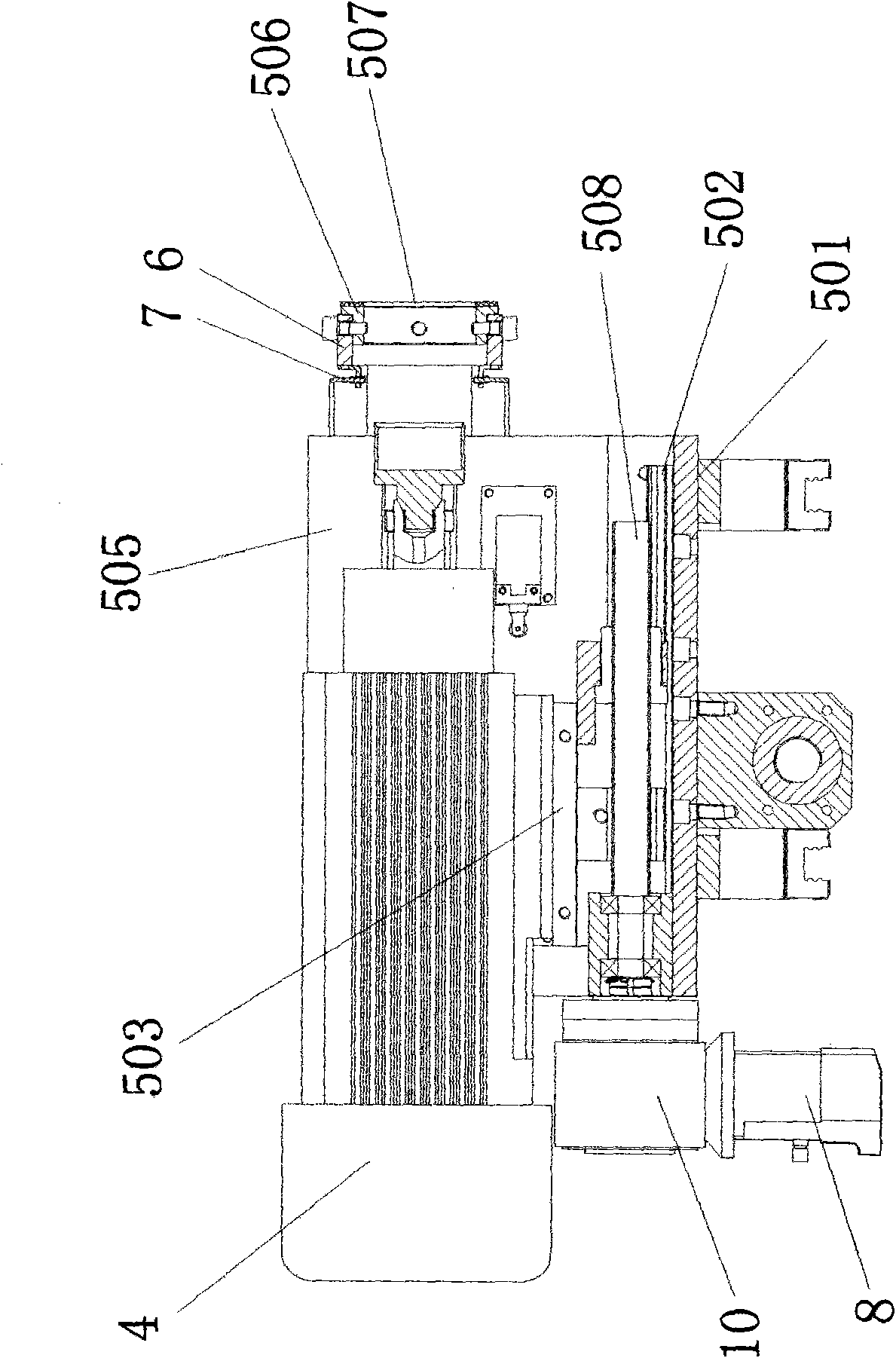

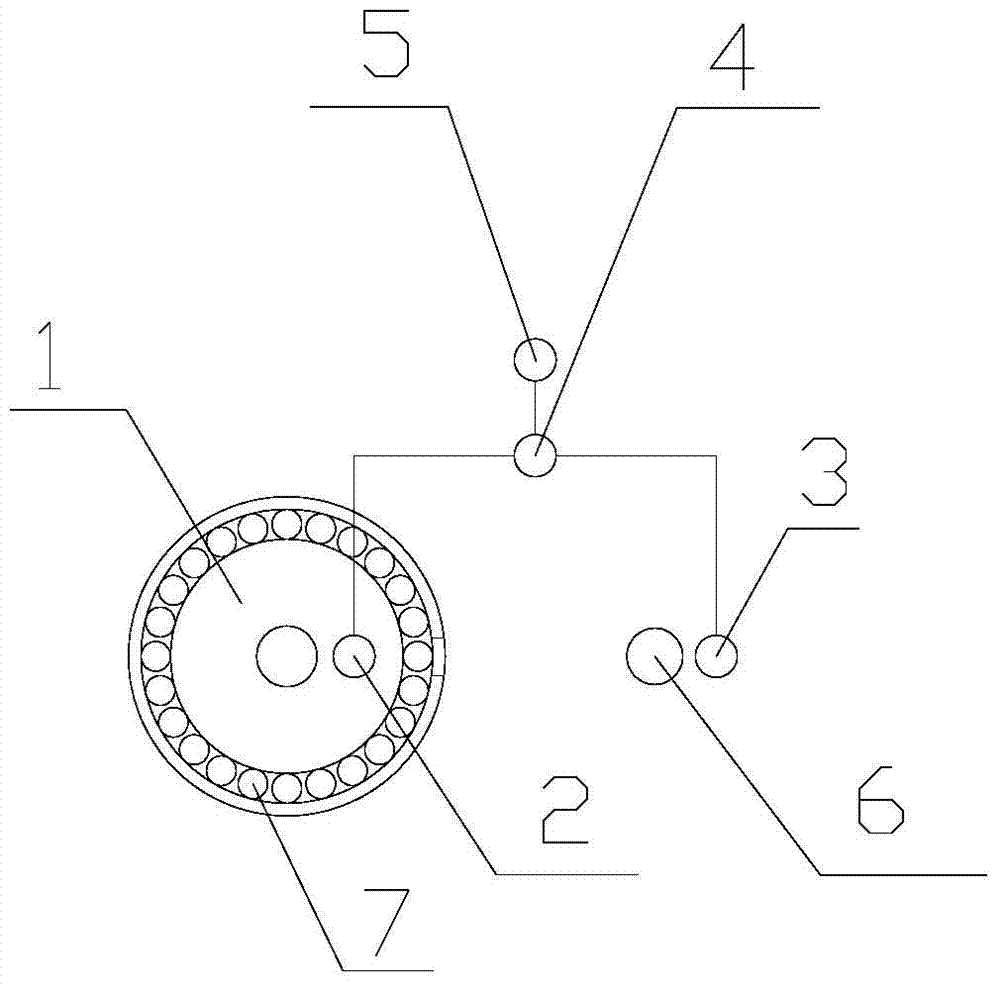

High-speed vertical glass drilling machine

InactiveCN101642821AImprove drilling accuracyImprove work efficiencyBoring/drilling componentsBoring/drilling machinesDrive motorNumerical control system

The invention relates to the technical field of glass processing machinery, belongs to a glass drilling processing machine, and particularly relates to an electric control feeding mechanism of a drilling motor of a vertical glass drilling machine. The electric control feeding mechanism of the drilling motor of the vertical glass drilling machine comprises a base, a glass supporting frame and an upright post, wherein the upright post is provided with the drilling motor; a horizontal shifting module is arranged between the drilling motor and the upright post; a drilling bit port of the drillingmotor is provided with a clamping plate; the clamping plate is provided with a drilling bit feeding position inductive switch; a servo motor for driving the driving motor to advance and retreat is also arranged between the drilling motor and the horizontal shifting module; and the inductive switch and the servo motor are connected with each other and controlled by a numerical control system. The electric control feeding mechanism of the drilling motor of the vertical glass drilling machine has the following advantages that: 1, due to the adoption of the servo motor and a speed reducer, the drilling precision is improved; and 2, the inductive switch is used to implement the simultaneous working of a front drilling bit and a back drilling bit, the drilling bit at one side is fed to a certainpreset position and then is stopped and dropped back, and the drilling bit at the other side is fed continuously, so the working efficiency is high, and cutter crash appearing in double-side feedingis avoided.

Owner:EI AUTOMATION EQUIP

Anti-collision tool changer

InactiveCN103567797AAvoid hitting the knifeImprove productivity and safetyMeasurement/indication equipmentsPositioning apparatusElectrical and Electronics engineeringMachining

The invention discloses an anti-collision tool changer, which is applied to a numeric control machining center. The tool changer comprises a cutter head, a tool changer body, cutters and a control device, wherein the tool changer body is arranged on the cutter head, the cutter head is provided with a movable bin gate, the tool changer body is provided with a plurality of cutter mounting positions, the cutters are arranged on the cutter mounting positions, the cutter head is provided with a first sensing piece and a second sensing piece, the first sensing piece is used for sensing whether a spindle is provided with the cutters or not, the second sensing piece is used for sensing whether cutters are arranged on the cutter mounting positions corresponding to the spindle or not, the first sensing piece and the second sensing piece are in communication connection with the control device, and the control device is in communication connection with a control host of the numeric control machining center. The cutter colliding phenomenon is effectively avoided, and the production efficiency and the safety are improved.

Owner:ANHUI PROVINCE JIEYONGDA INTELLIGENT MACHINE

Cutter collision preventing method for machining center

InactiveCN104062942AAvoid hitting the knifeExtended service lifeProgramme controlComputer controlCombined useEngineering

The invention discloses a cutter collision preventing method for a machining center. A plurality of measures are adopted, and methods for preventing cutter collision of the machining center are listed completely from three aspects, namely procedure improvement, misoperation avoidance and cutter compensation verification, and a solution method is proposed. The cutter collision preventing method is capable of effectively preventing cutter collision for the machining center by use of certain programming skills, and by verifying the procedure by use of various methods and avoiding misoperation by virtue of correct coordinate system and cutter length compensation and radius compensation settings and combined use of hands and eyes in the operation process, and therefore, the service life of the machining center can be increased and the repair cost can be saved.

Owner:ANHUI HUALONG PRECISION MACHINERY CO LTD

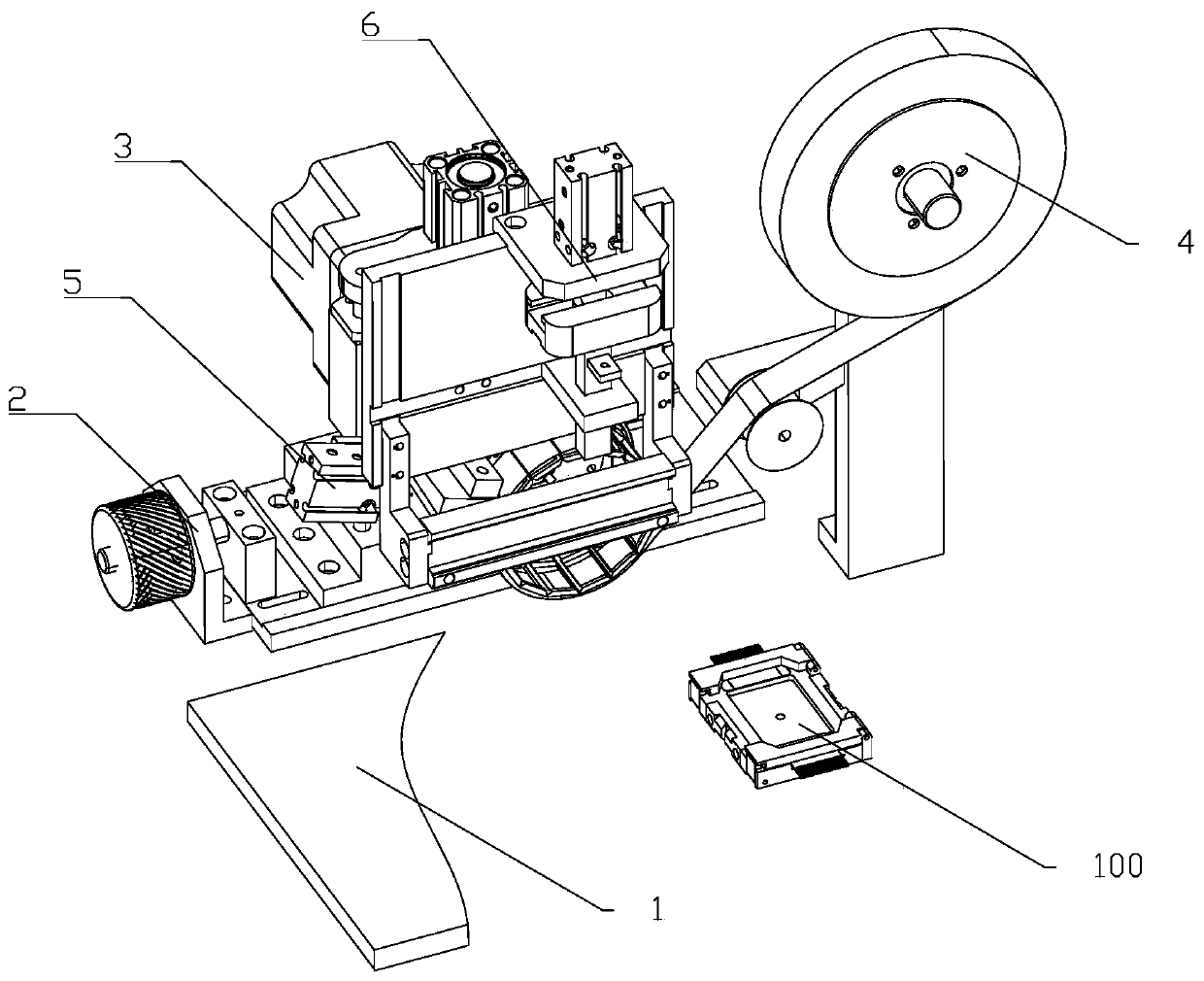

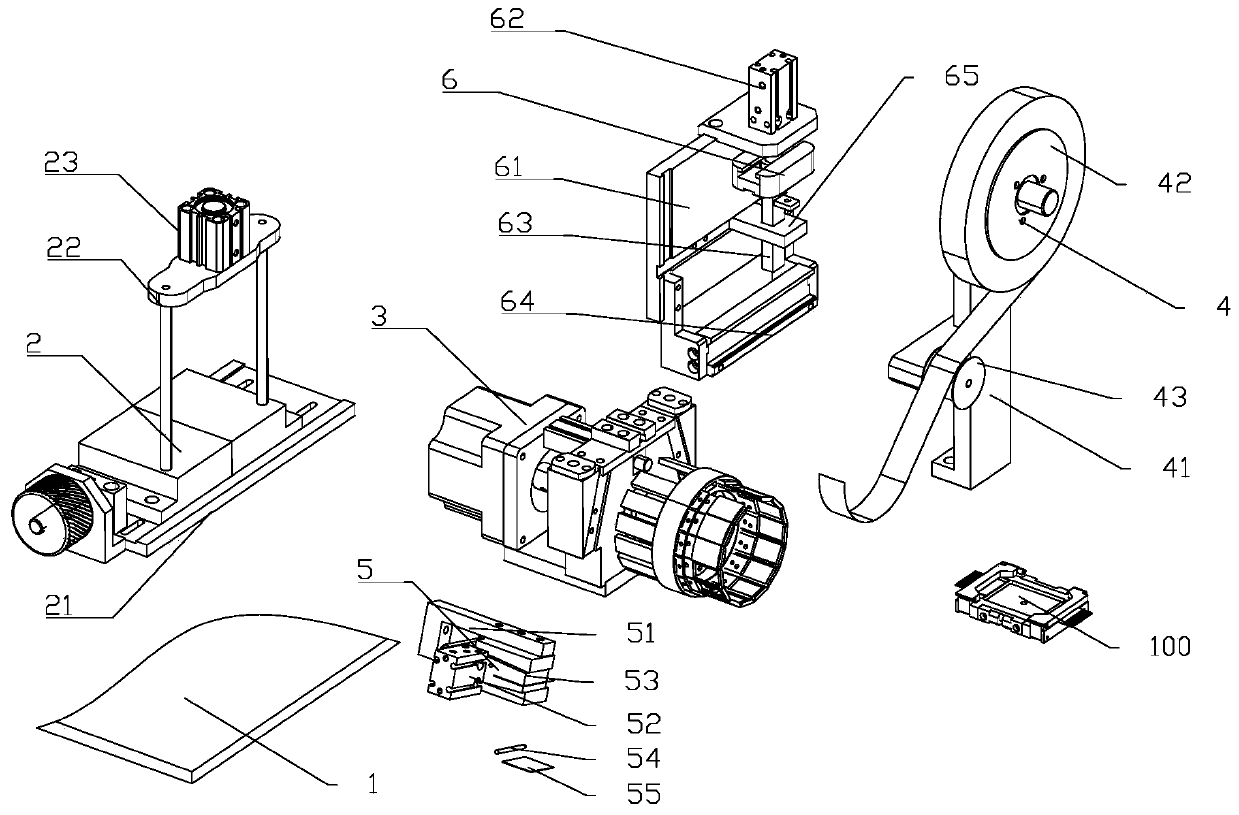

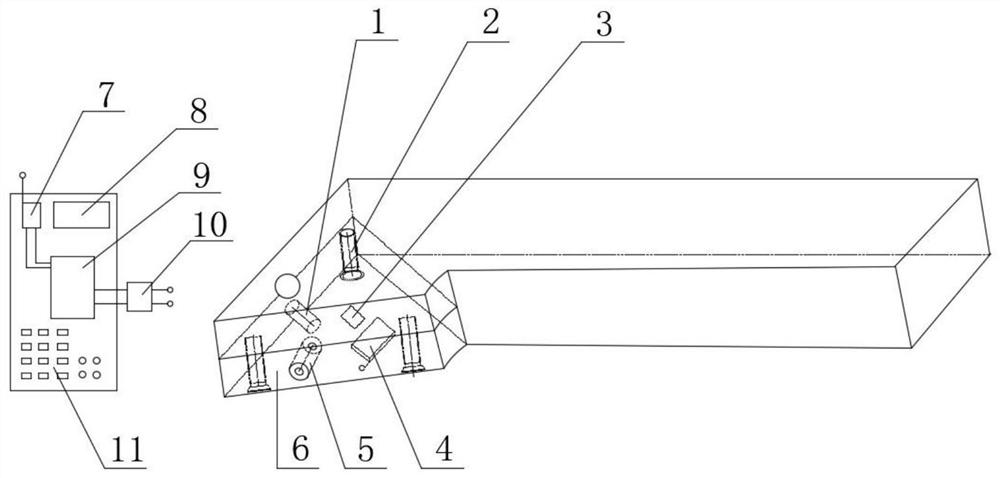

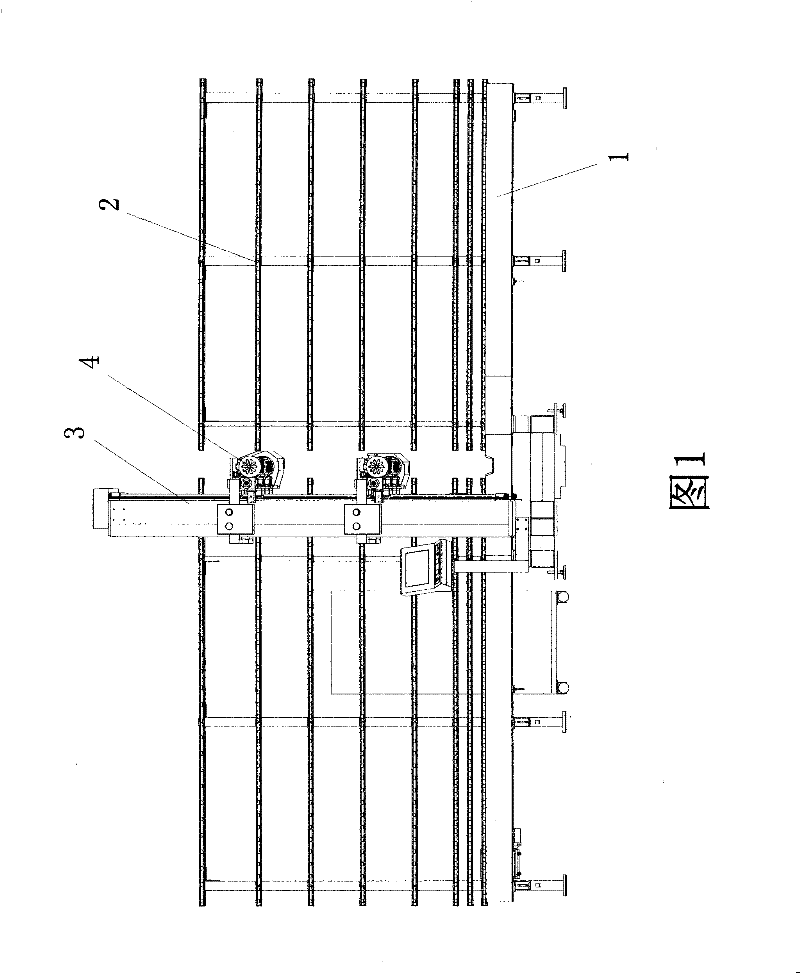

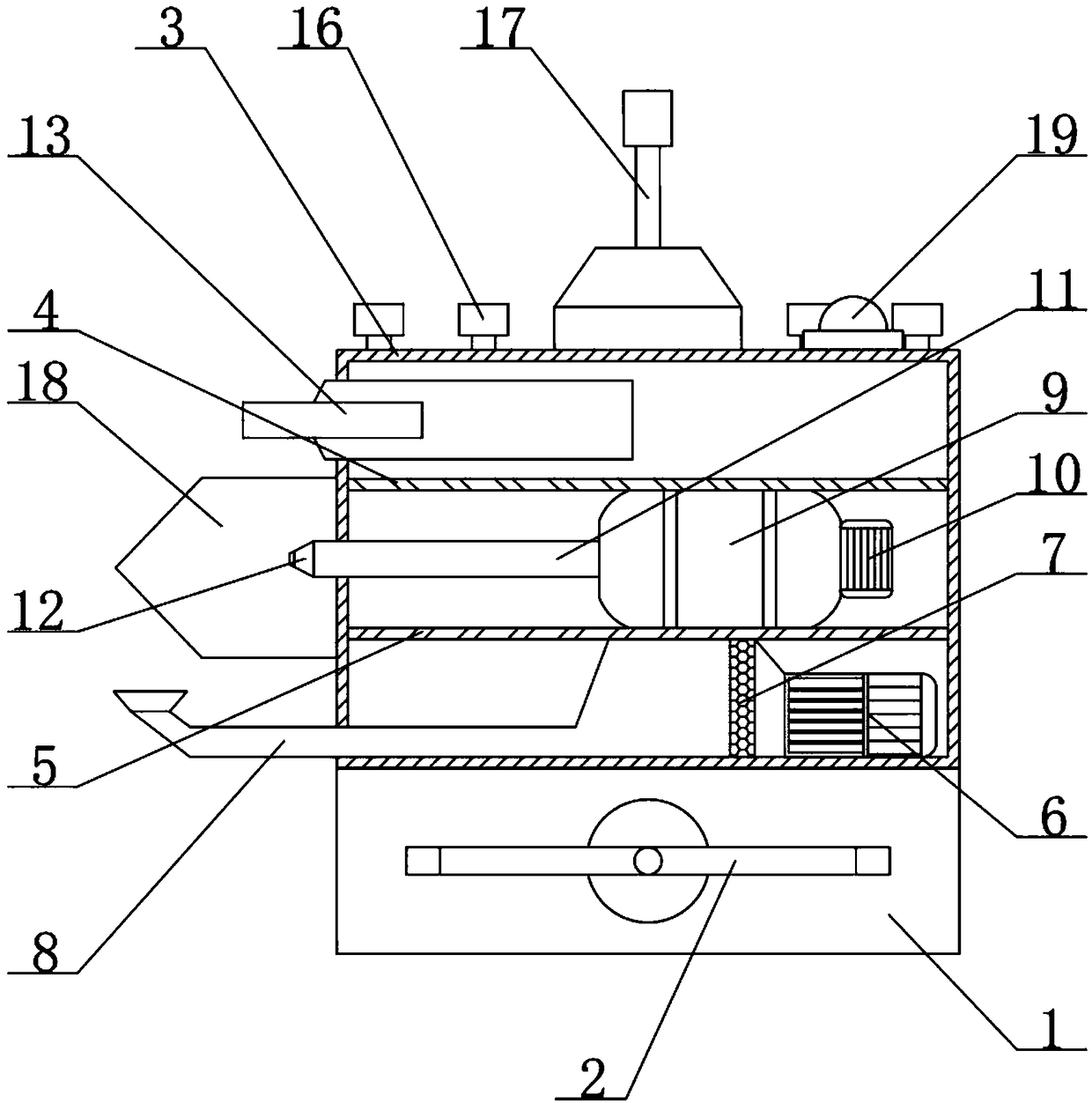

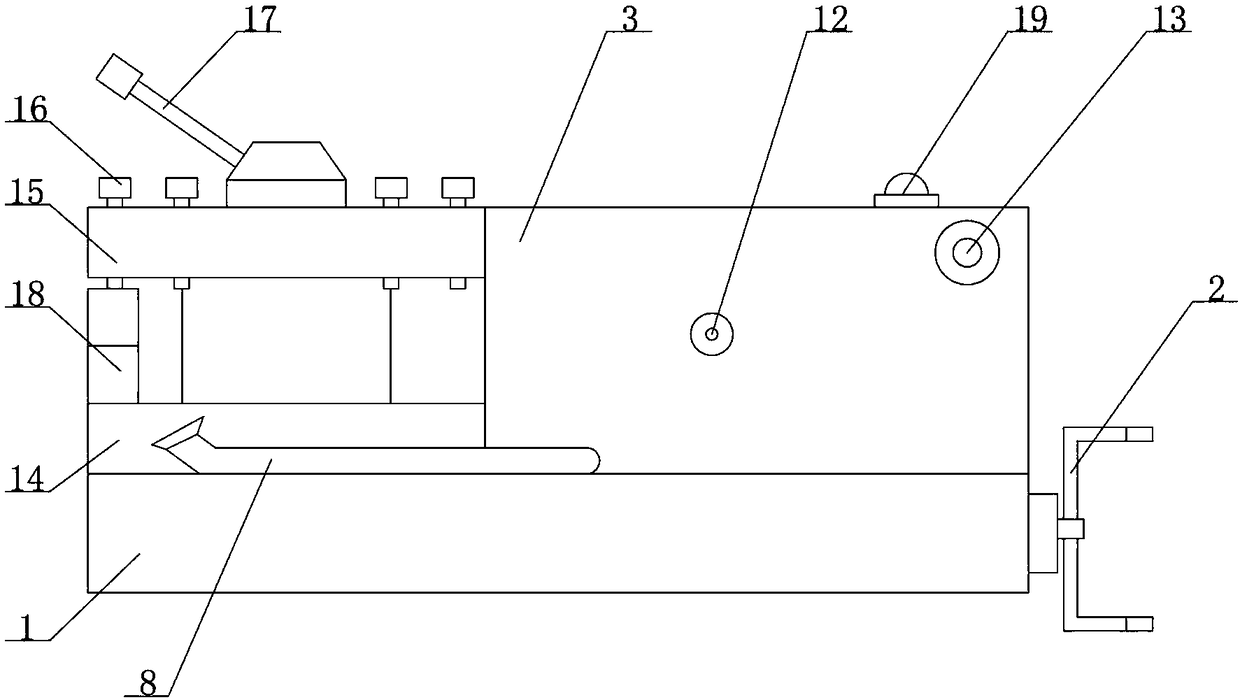

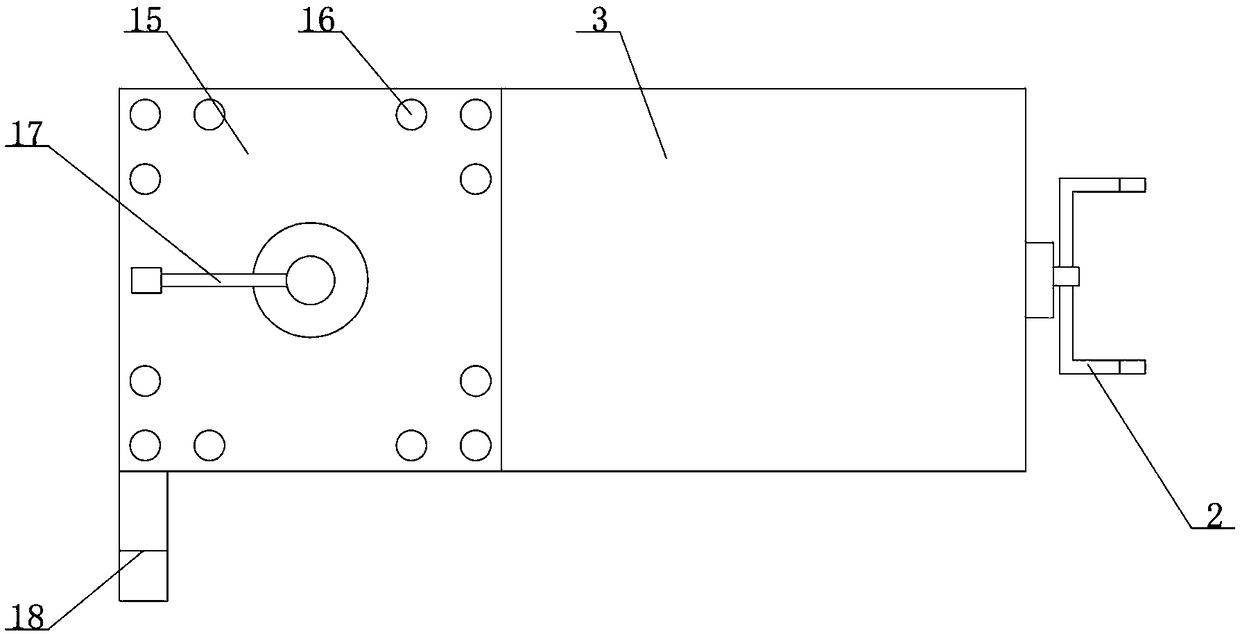

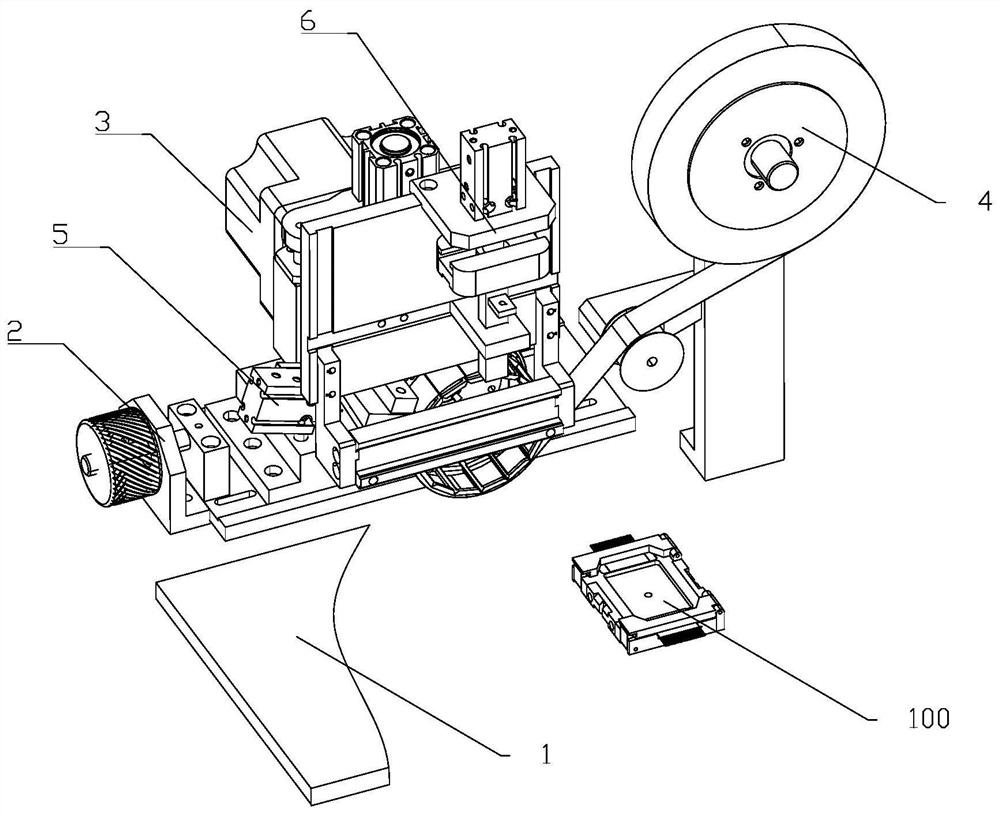

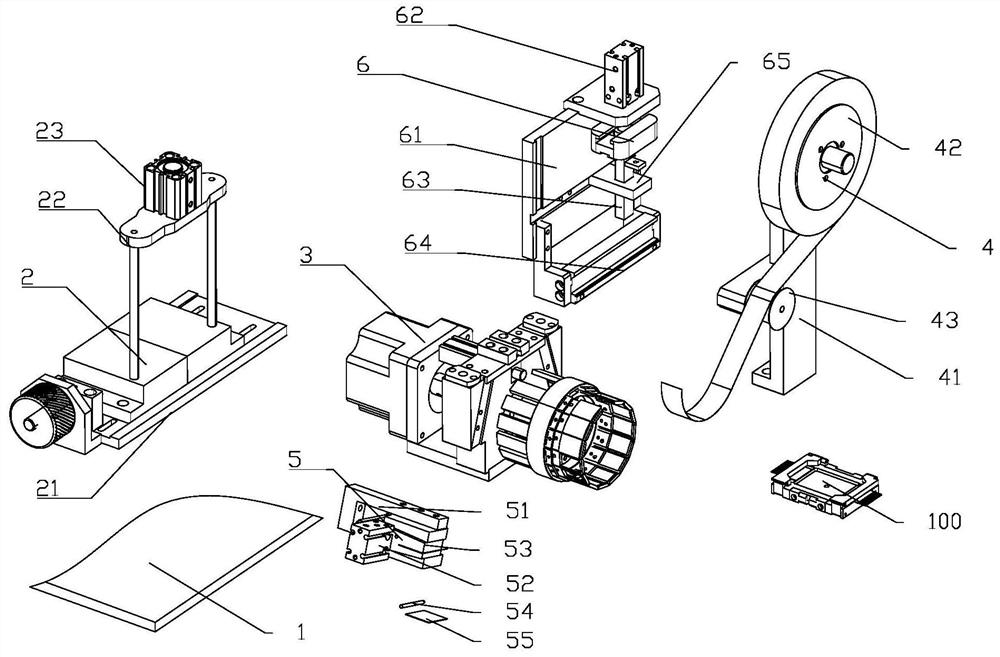

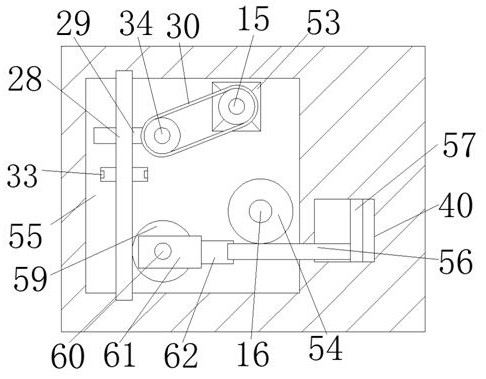

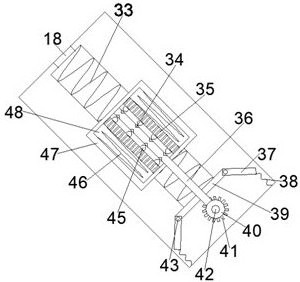

Flat cable end tape attaching device and method

ActiveCN110648805AQuality improvementSame lengthManufacturing wire harnessesStructural engineeringMechanical engineering

The invention relates to the field of flat cable tape attaching and particularly relates to a flat cable end tape attaching device. The device comprises a rack, a base assembly, a winding drum assembly, a film feeding assembly, a cutting assembly and a pressing assembly, wherein the base assembly is installed on the machine frame, the winding drum assembly is connected with the base assembly, thepressing assembly is installed on the machine frame and located over the winding drum assembly, the cutting assembly is obliquely arranged on the winding drum assembly, the film feeding assembly is arranged on the machine frame and located on the side of the winding drum assembly, the winding drum assembly is used for winding a single-sided adhesive tape and sending out the cut single-sided adhesive tape, the cutting assembly is used for carrying out fixed-length cutting of the single-sided adhesive tape on the winding drum assembly, and the pressing assembly is used for attaching the cut single-sided adhesive tape to a surface of a flat cable. The device is advantaged in that a rotary adhesive tape receiving strip is arranged, so working efficiency is improved, the rotary winding drum assembly can achieve feeding, cutting and material moving, no waiting exists between procedures, connection is orderly, and the tape attaching speed is increased.

Owner:昆山展诚电子科技有限公司

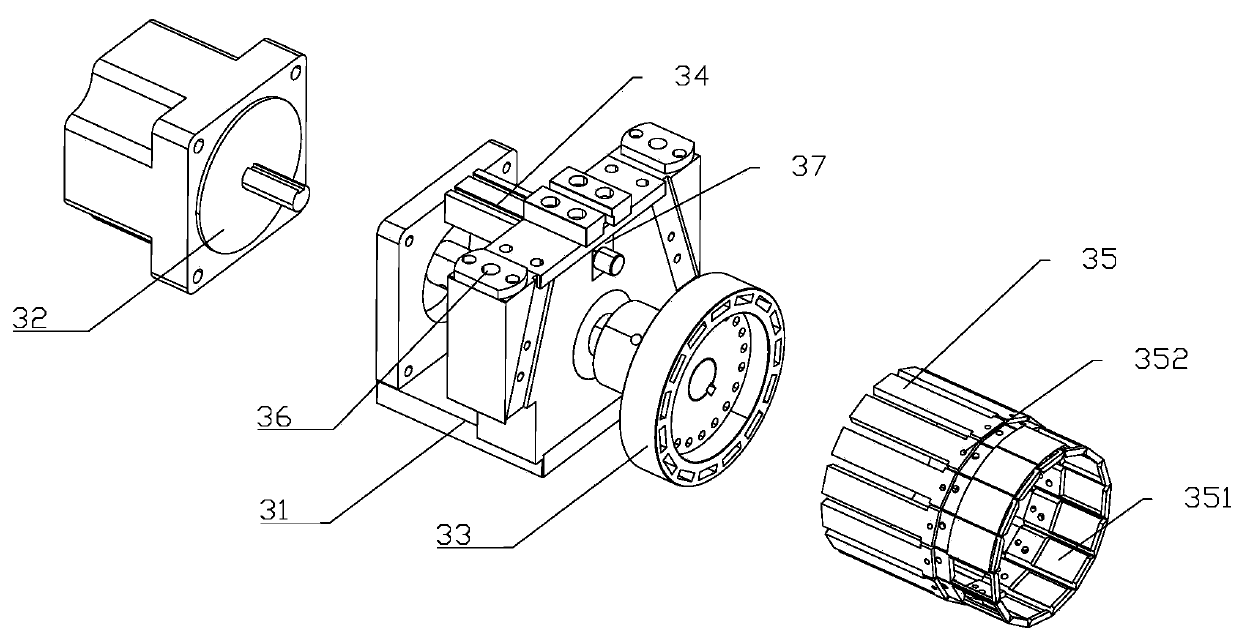

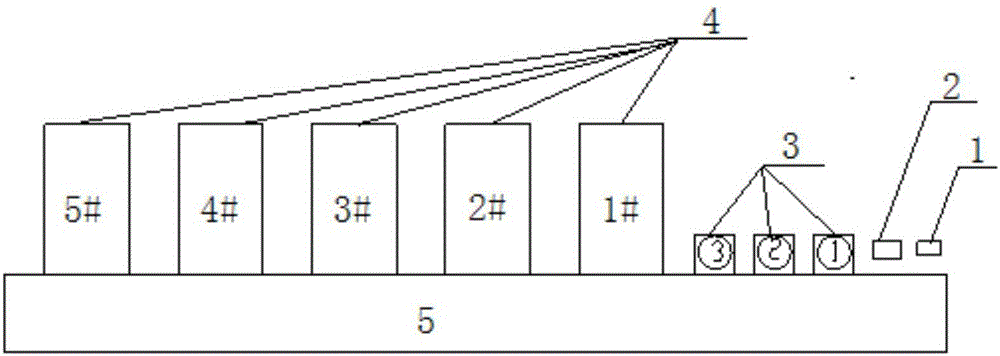

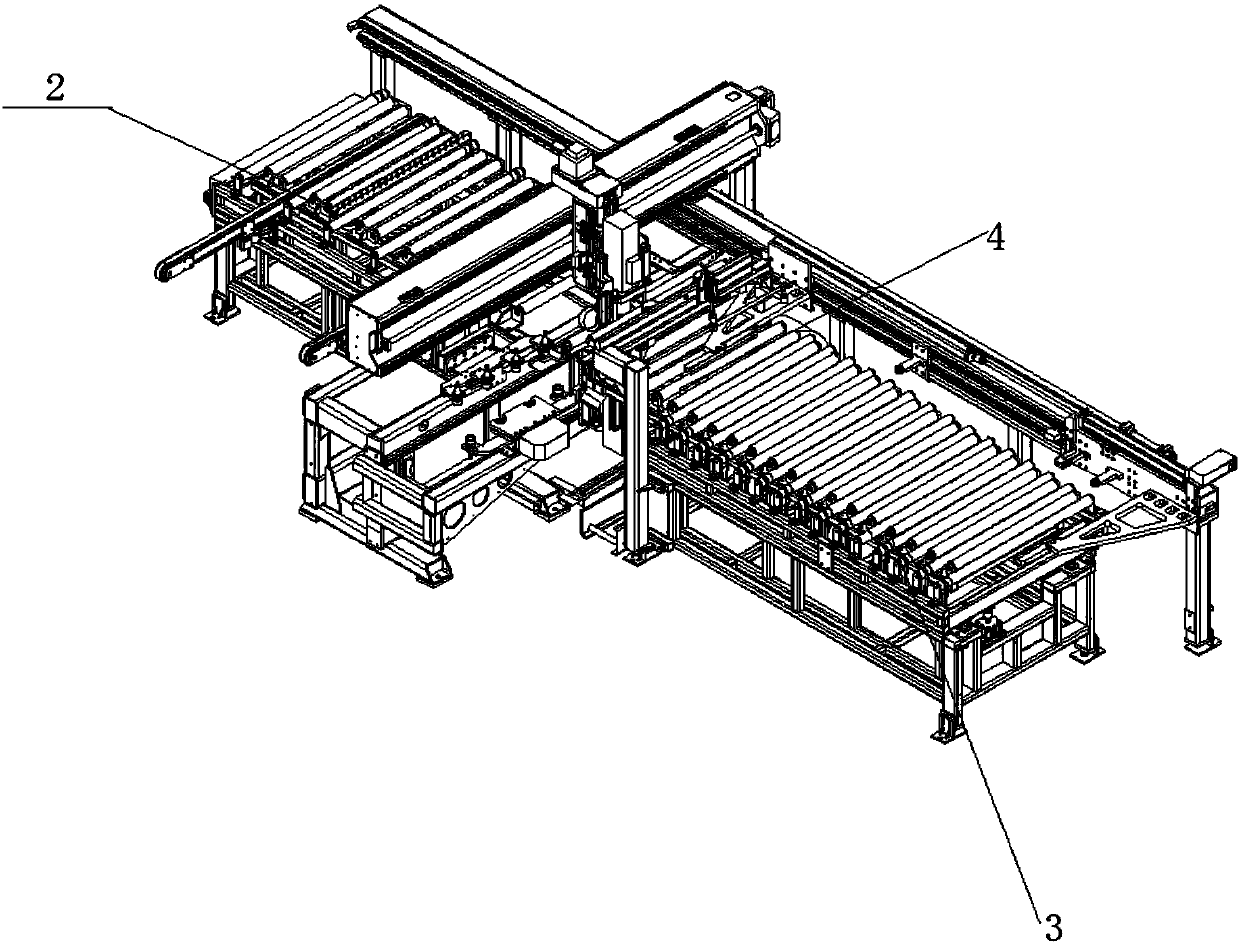

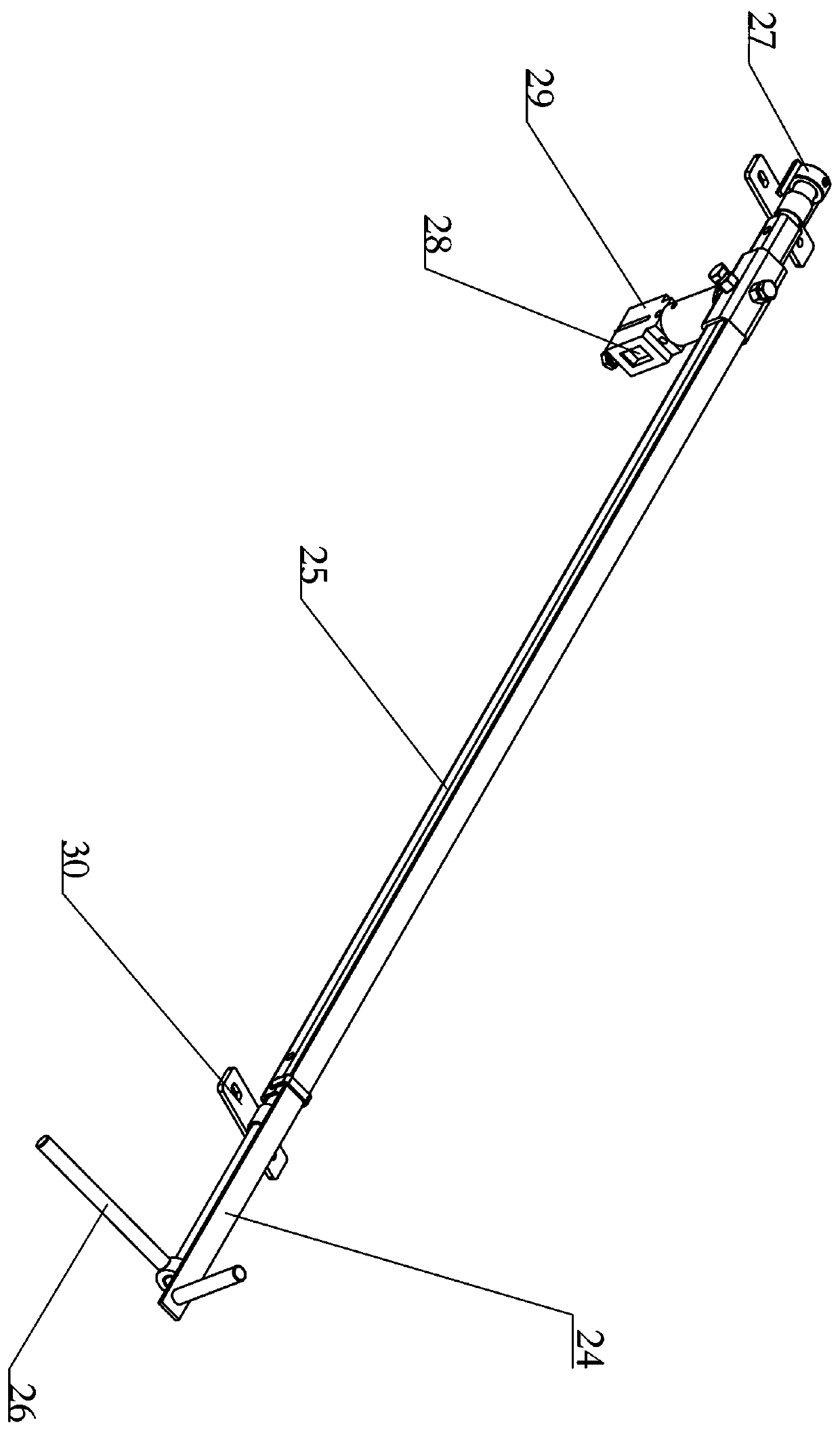

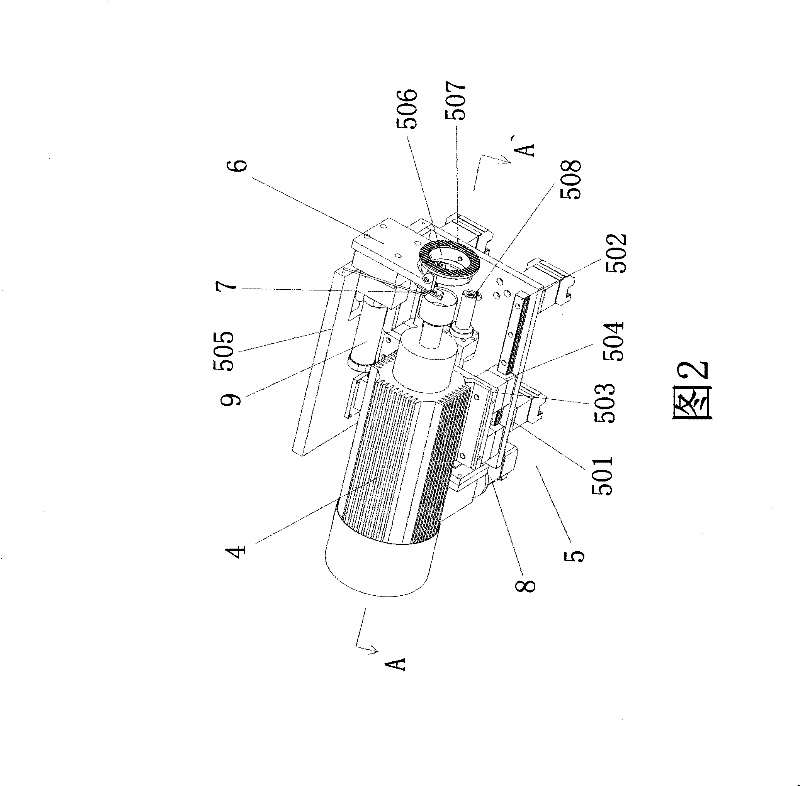

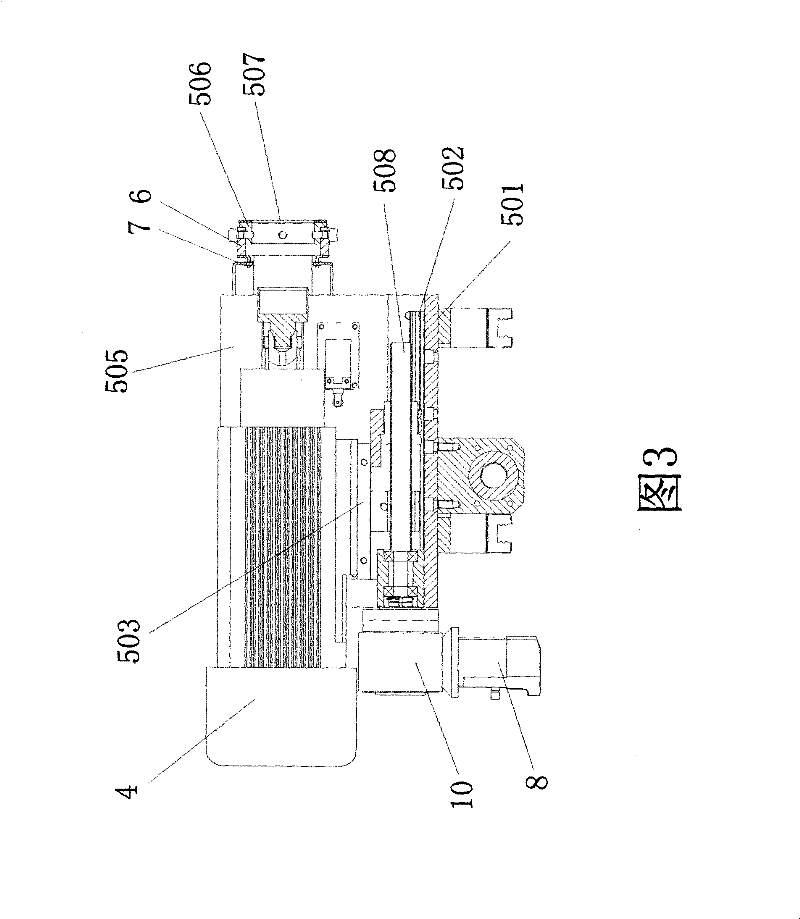

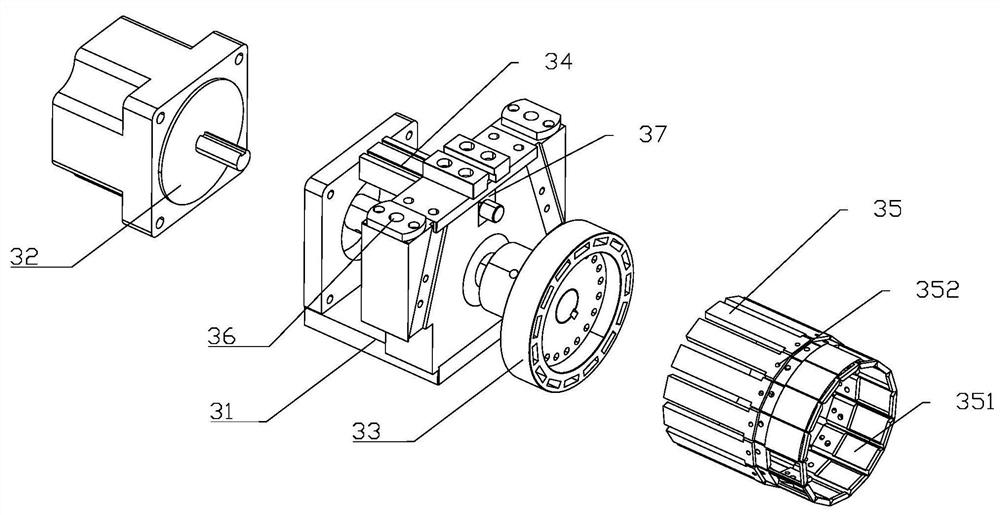

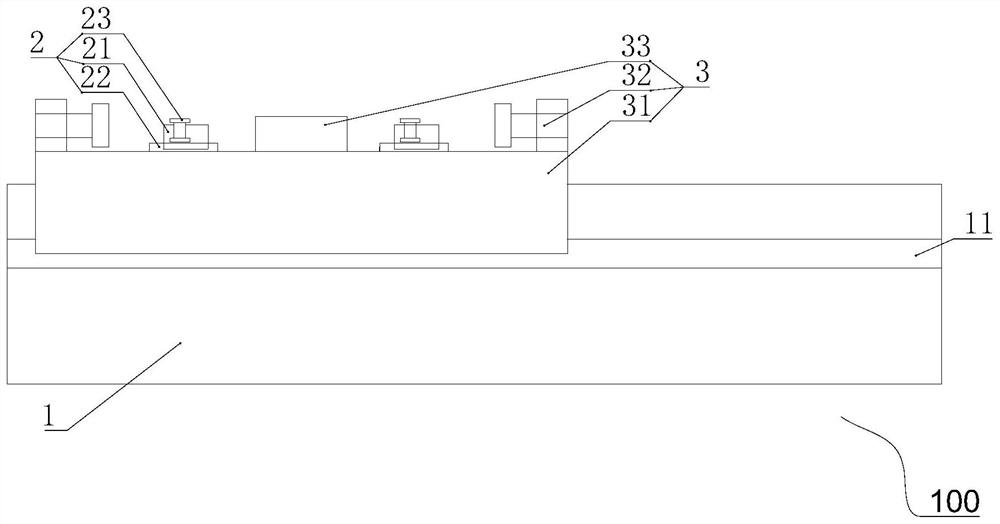

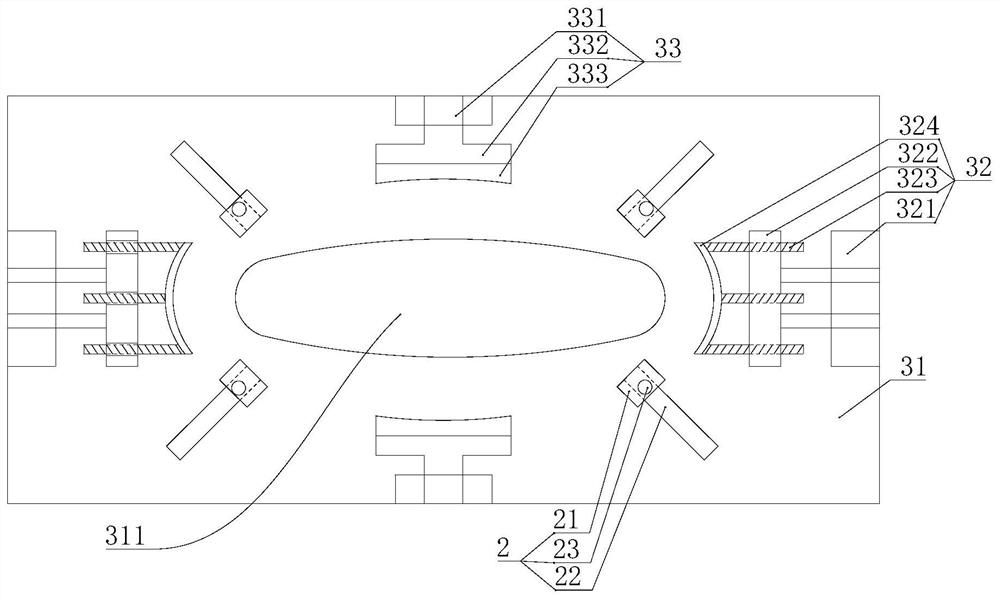

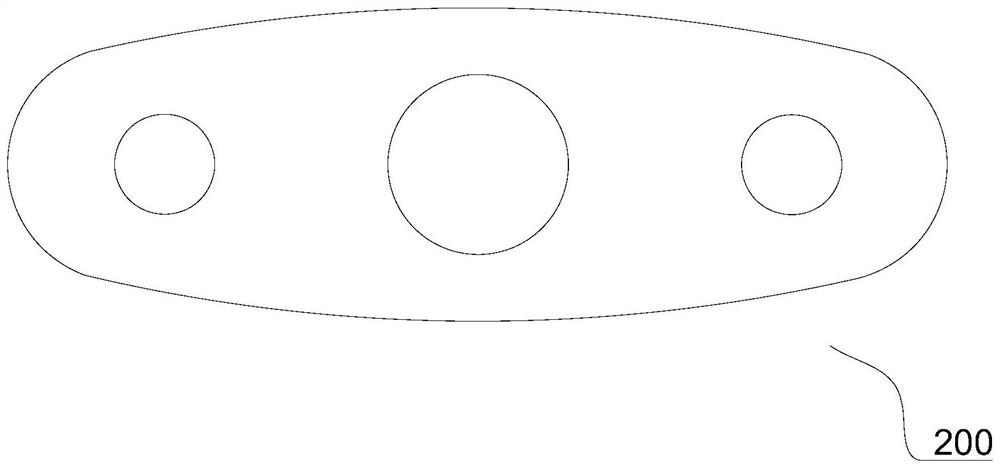

Flexible production line for axle box body machining and machining method

ActiveCN106392663AImprove craftsmanshipPrecise positioningOther manufacturing equipments/toolsPositioning apparatusNumerical controlProduction line

The invention provides a flexible production line for axle box body machining. The production line comprises a tool setting gauge, a control system, a linear tray system, a plurality of machining centers, a feeding station and a discharging station. Operation tables are distributed on the same side; the linear tray system comprises a machine tool and a plurality of trays; an axle box body can be fixed to the top of each tray; the bottom of each tray is detachably fixed to the machine tool; each tray can correspond to any one of the machining centers; and the control system can control all the machining centers to separately conduct numerical control machining on the axle box bodies on the trays. The invention further provides a flexible production line machining method for axle body machining. According to the flexible production line for axle box bodies and the machining method, multiple machines can be controlled by one person, the production efficiency is improved, and the product quality is ensured.

Owner:CRRC QINGDAO SIFANG CO LTD

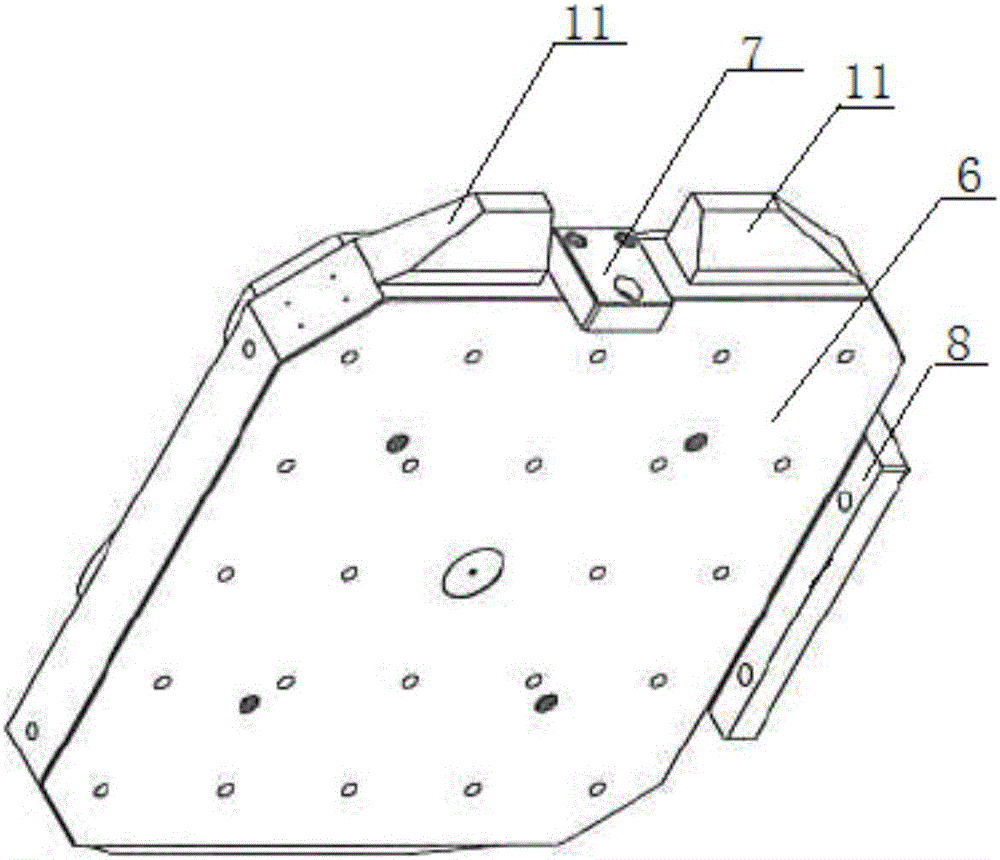

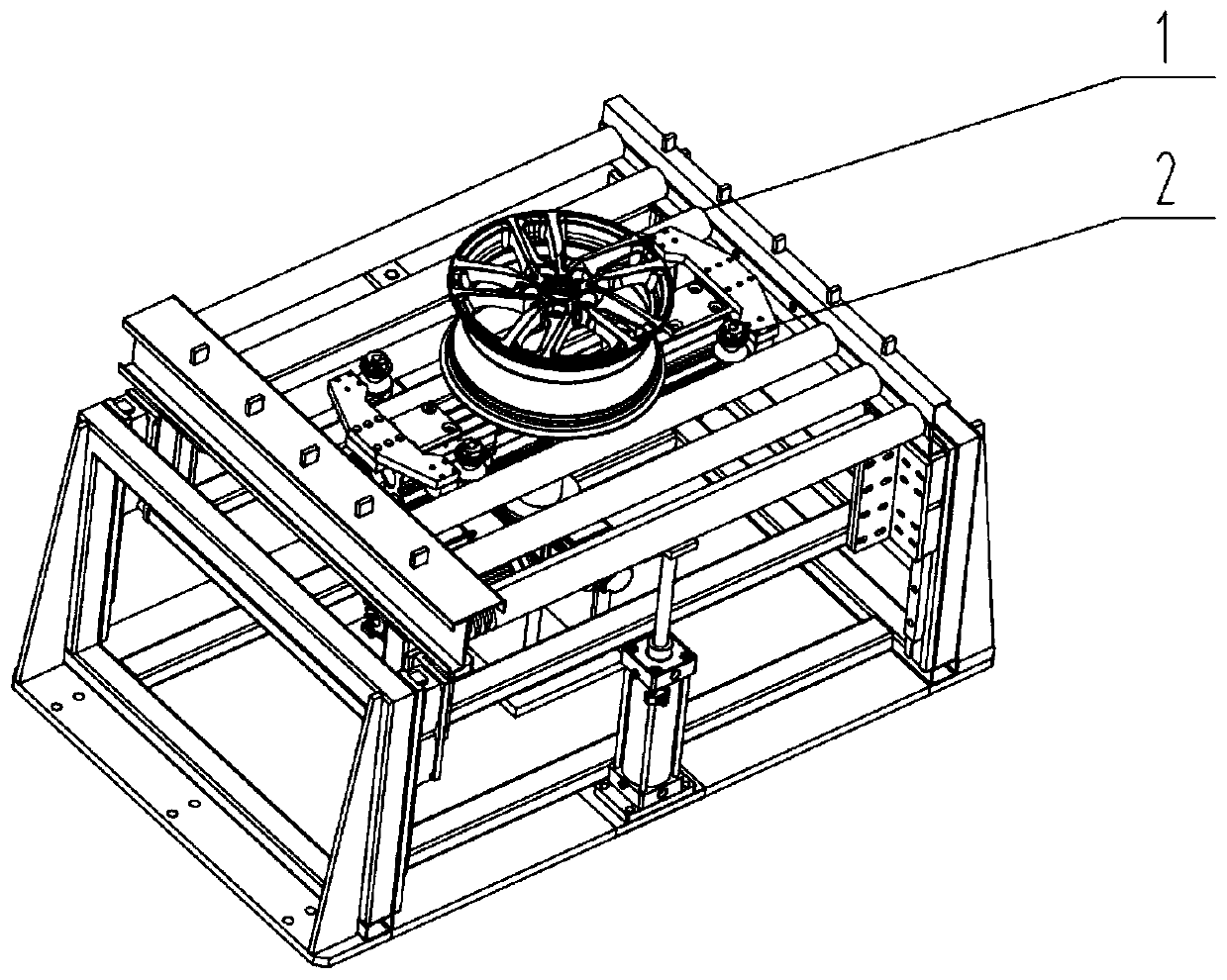

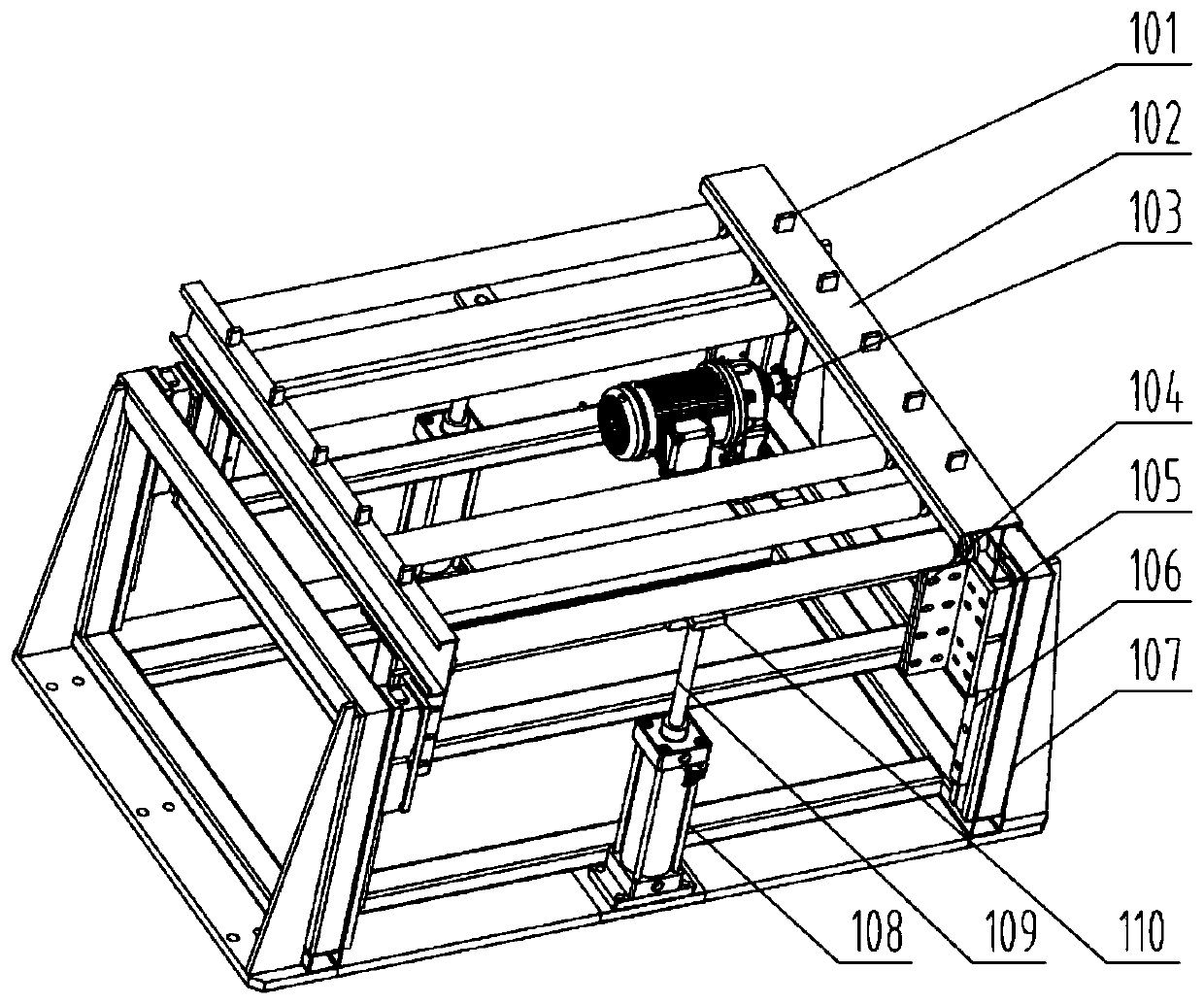

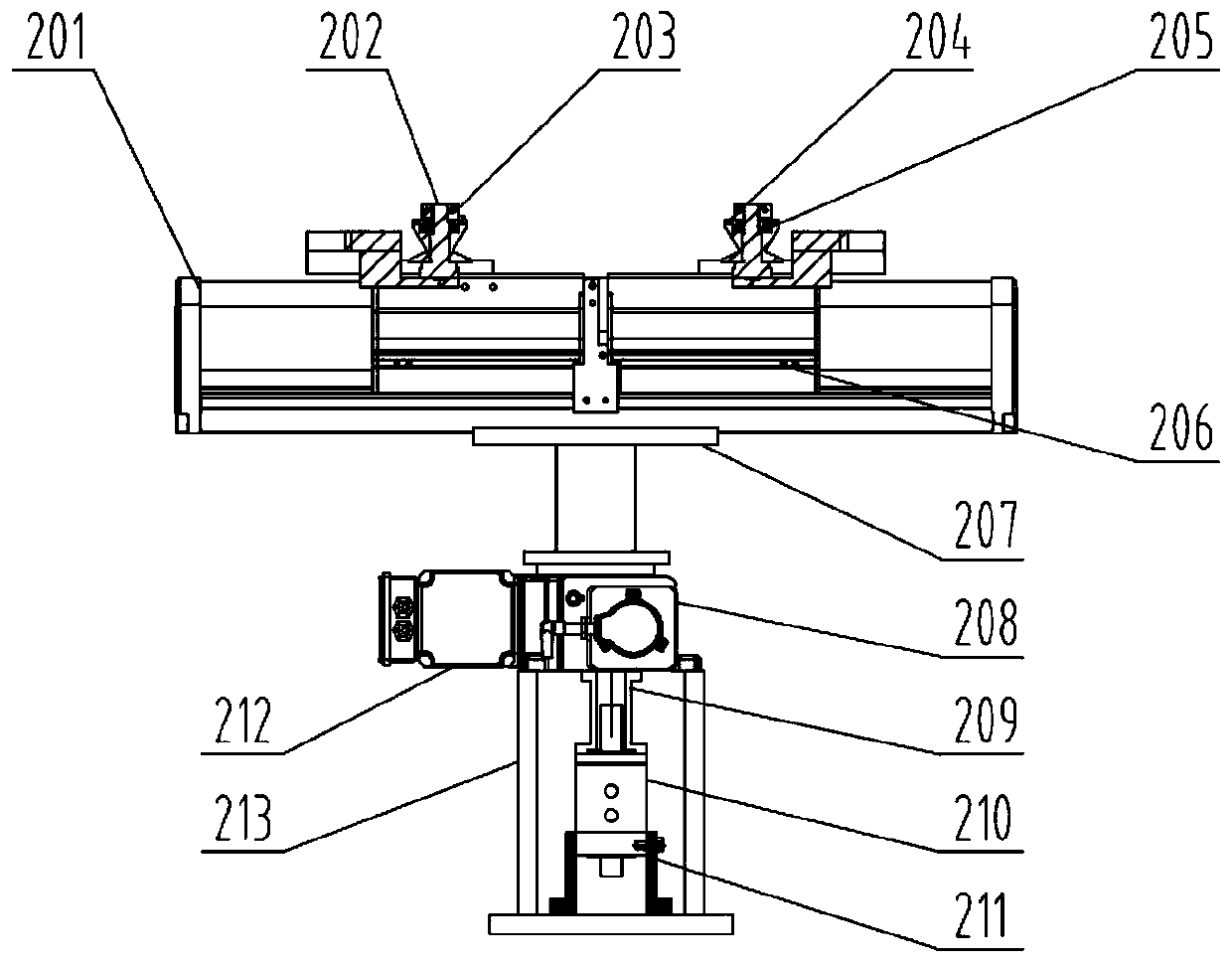

Through type arbitrary-angle rotating clamp for aluminum wheel

PendingCN111069952AGuaranteed to be in balanceMaintain balancePositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a through type arbitrary-angle rotating clamp for an aluminum wheel. The through type arbitrary-angle rotating clamp for the aluminum wheel is composed of a conveying assemblyand a positioning assembly, wherein a roller path in the conveying assembly conveys a wheel to a designated position detected by a photoelectric switch; a V wheel in the positioning assembly positionsand supports the wheel; the roller path is pulled to the lower position along a linear guide rail through a piston rod; a motor B drives a cam divider and the V wheel on the cam divider to position the wheel to rotate to an arbitrary angle for machining operation; and after machining is completed, the piston rod pushes the roller path to the upper position along the linear guide rail, the V wheelin the positioning assembly loosens the wheel, the roller path conveys the wheel out, and the next working cycle is started. The through type arbitrary-angle rotating clamp for the aluminum wheel aims at achieving the positive effects that the deburring design is adopted for an aluminum wheel window, the labor cost is saved, the labor intensity is relieved, the automation degree is improved, andthe positive effects are achieved in the hub machining work.

Owner:QINHUANGDAO XINYUE INTELLIGENT EQUIP CO LTD

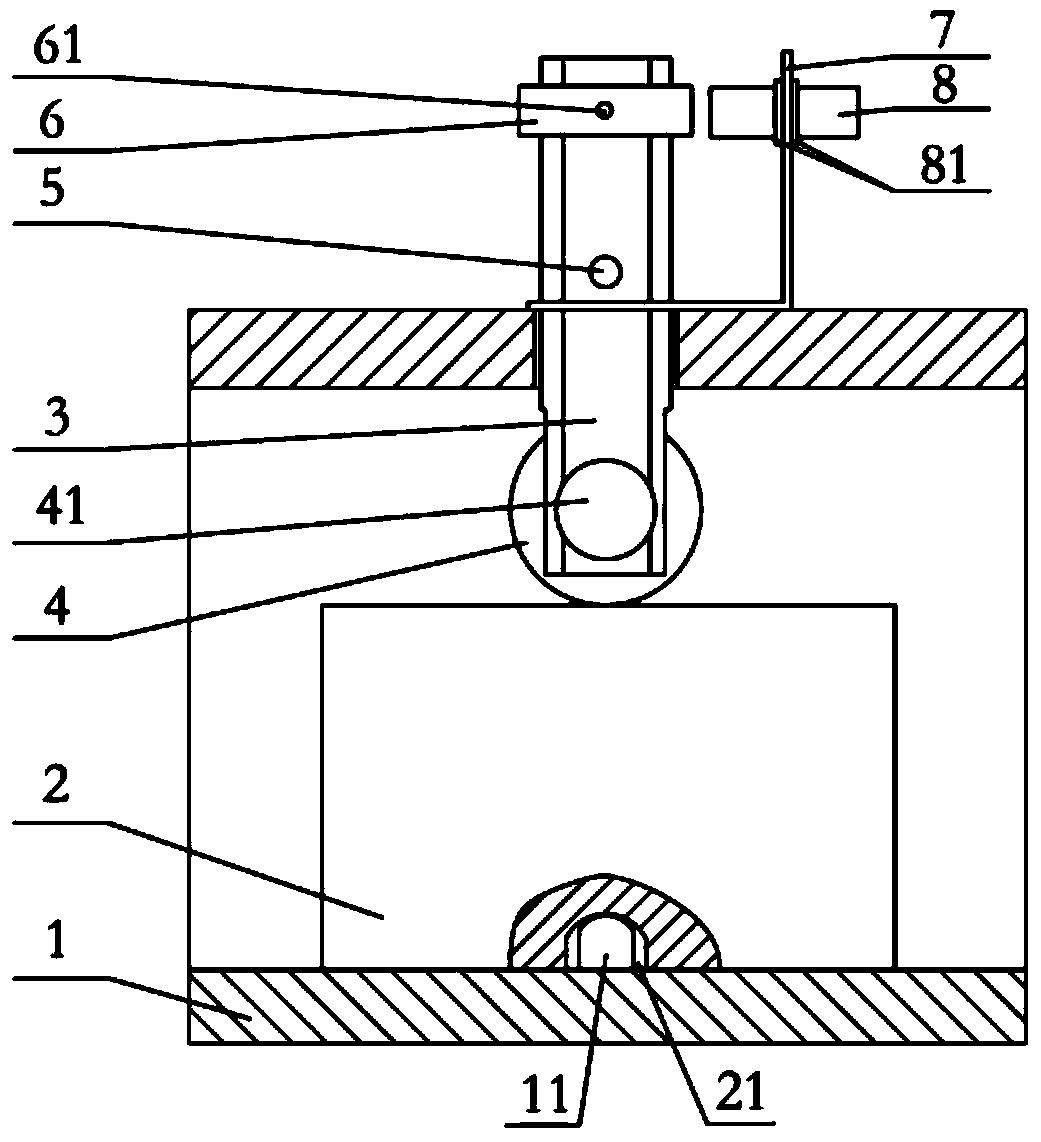

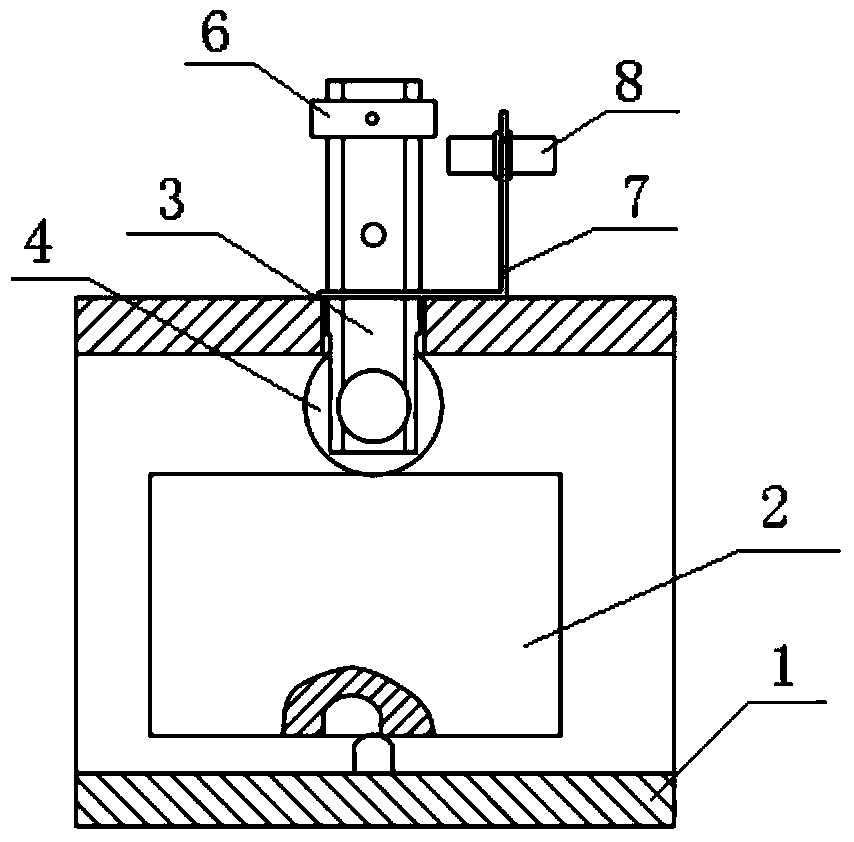

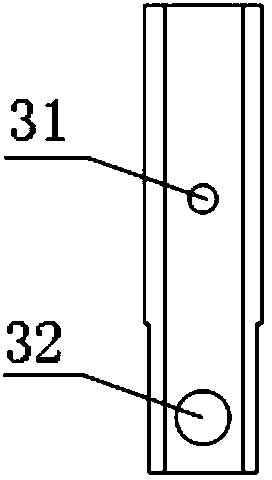

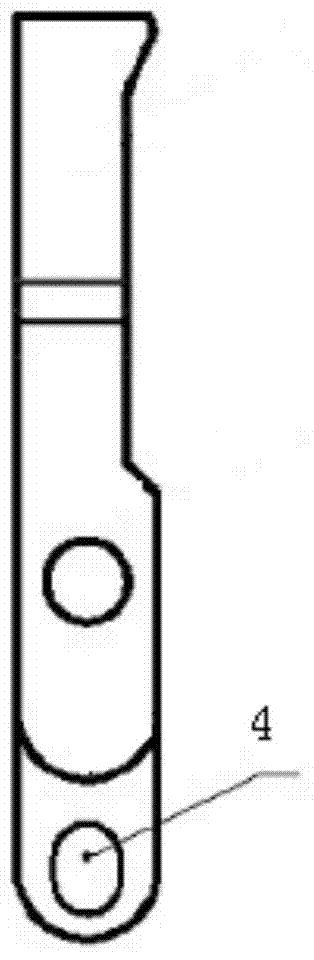

Bolt error-proofing device of machine tool

InactiveCN104002182AAvoid hitting the knifeImprove securityMeasurement/indication equipmentsPositioning apparatusEngineeringMachine tool

The invention discloses a bolt error-proofing device of a machine tool. The bolt error-proofing device is arranged on the top surface of a clamp body of the machine tool; the bolt error-proofing device comprises a sliding rod, a bearing, an induction block and a proximity switch; the sliding rod is arranged on the top surface of the clamp body in a sliding and penetrating mode; the lower end of the sliding rod extends to an area which is formed in the clamp body and used for placing a workpiece; the bearing is arranged on the lower end portion of the sliding rod; the bearing can be in abutting connection with the upper surface of the workpiece and can roll along the upper surface of the workpiece; the induction block is arranged on the upper end portion of the sliding rod; the proximity switch is fixedly arranged above the top surface of the clamp body; when a bolt of the workpiece is positioned correctly, the induction block is located in an induction area of the proximity switch so as to enable the proximity switch to switch on; when the bolt of the workpiece is positioned incorrectly to jack the workpiece, the induction block is far away from the induction area of the proximity switch so as to enable the proximity switch to switch off. According to the bolt error-proofing device of the machine tool, the safety and the reliability of equipment operation can be improved and the damage cost of a cutting tool and the workpiece is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

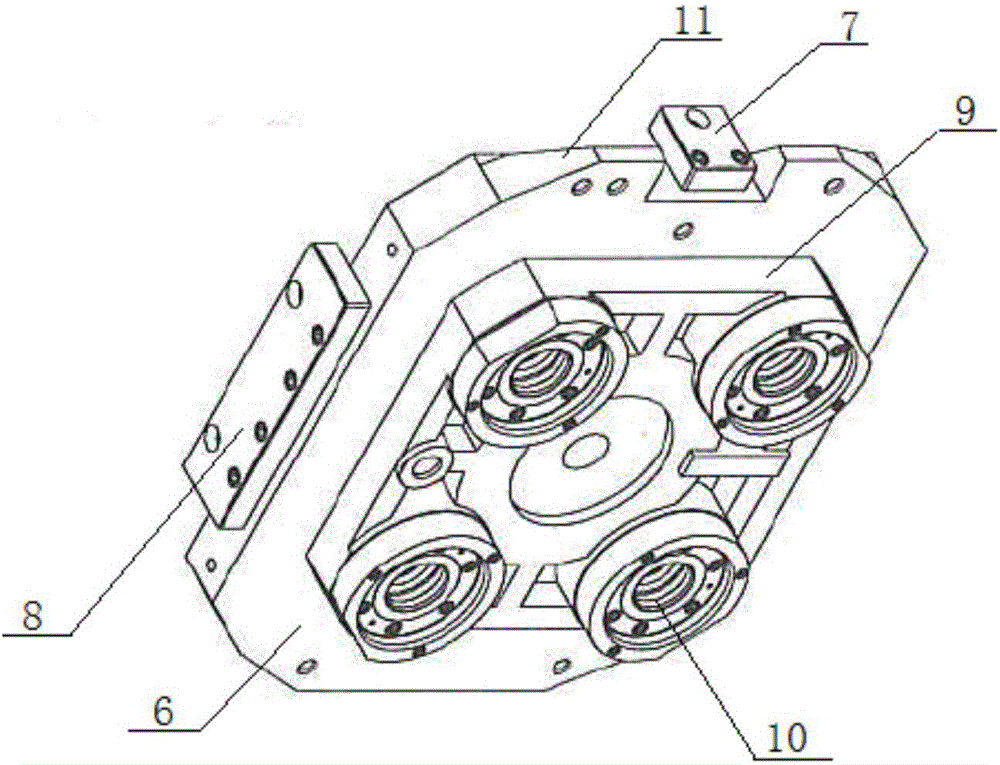

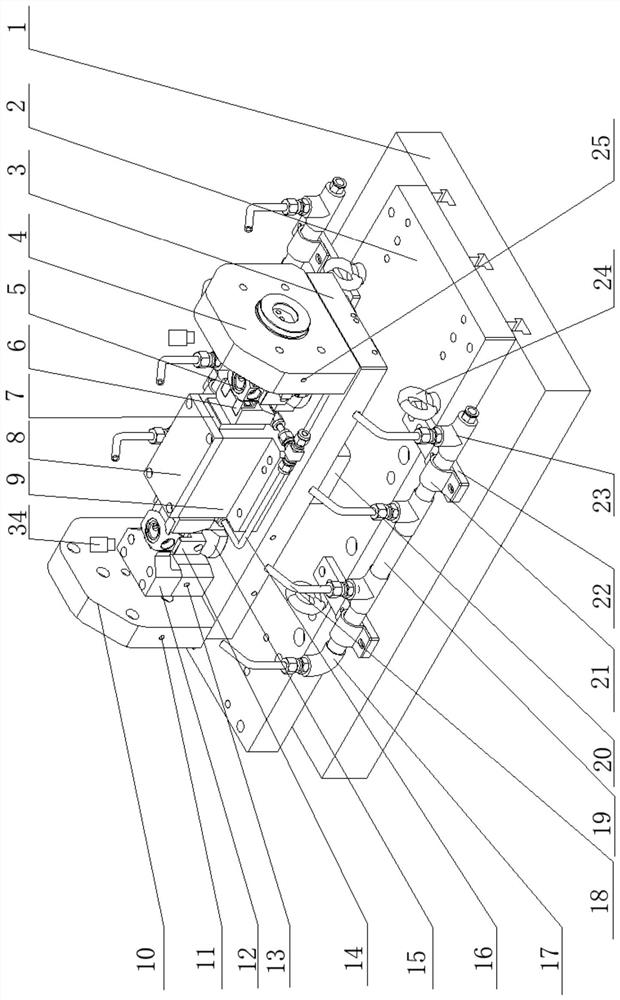

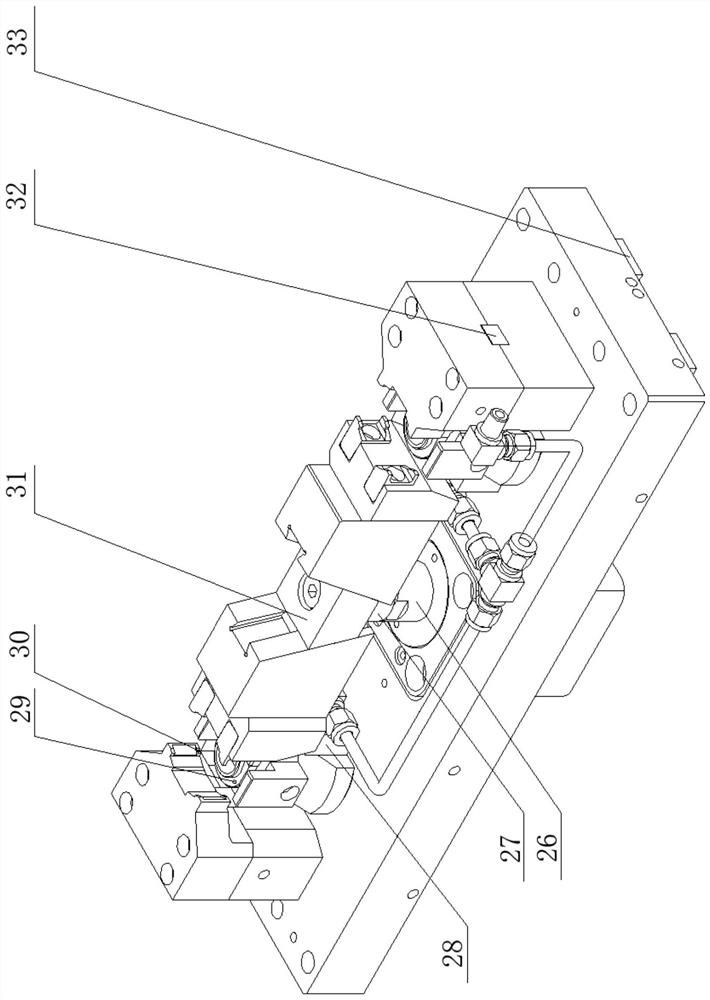

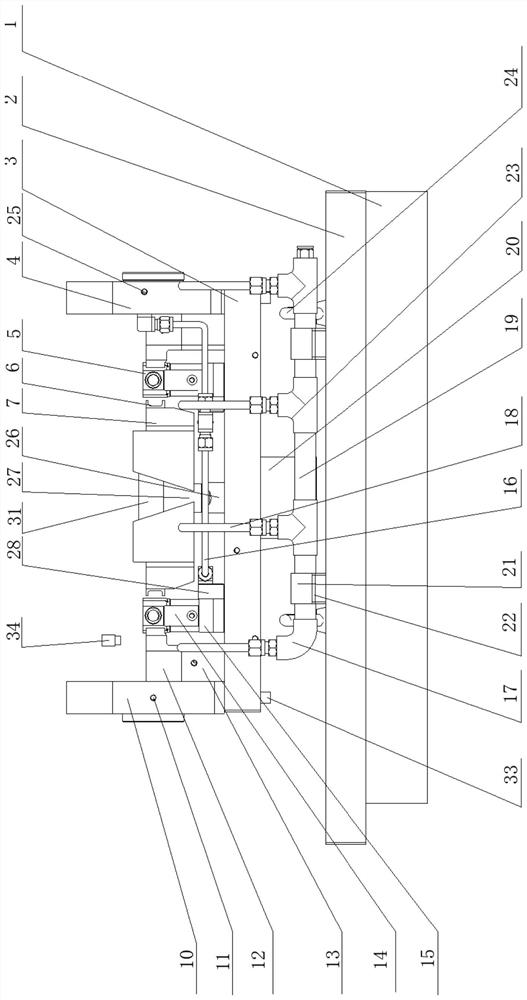

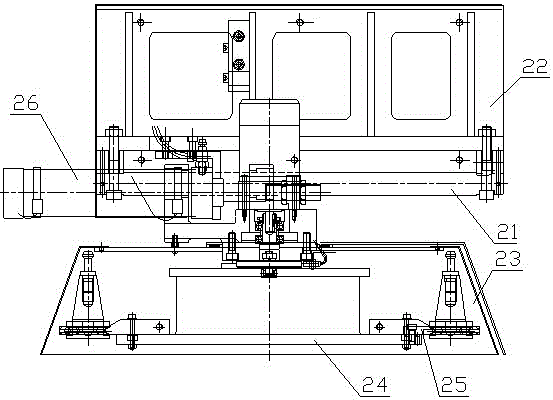

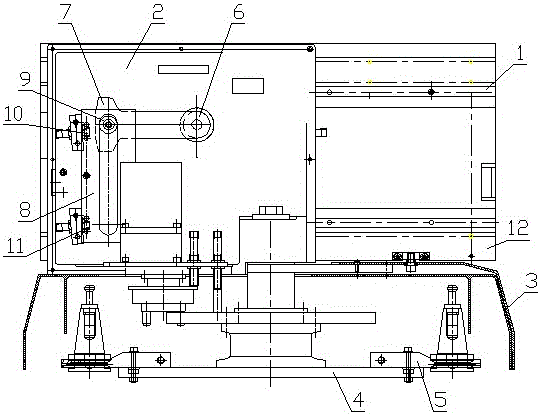

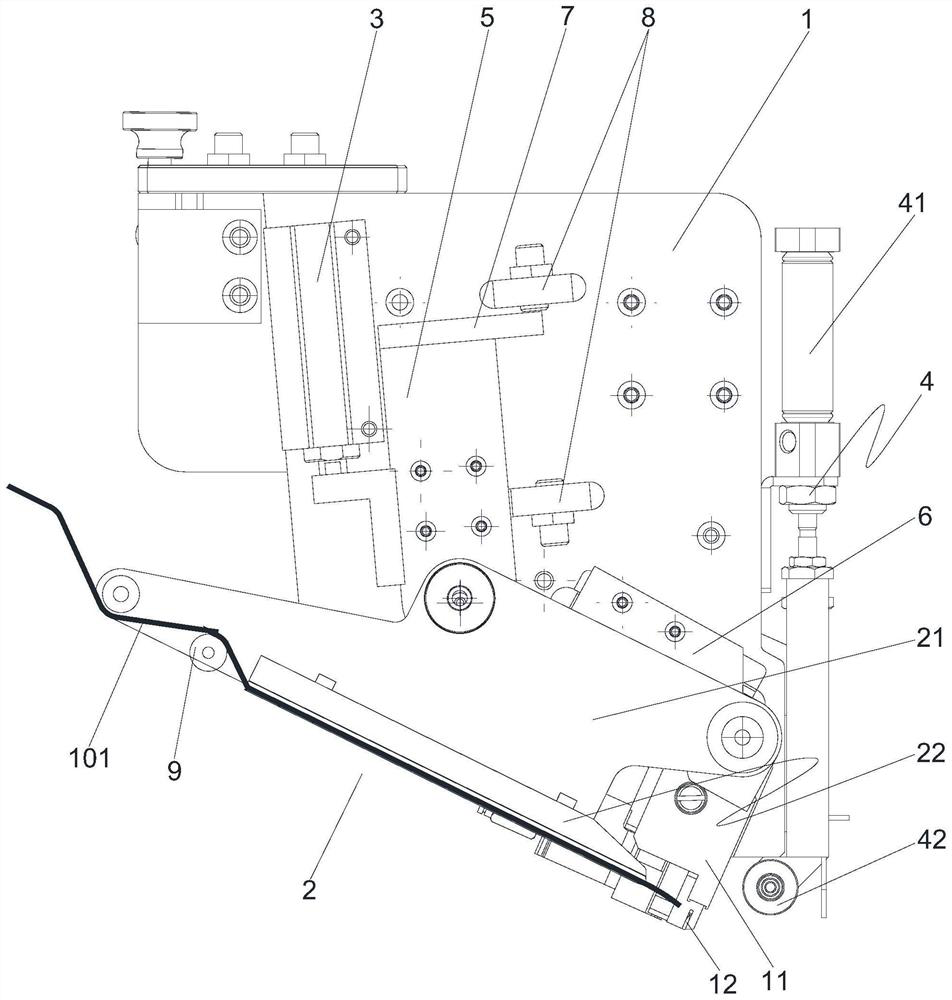

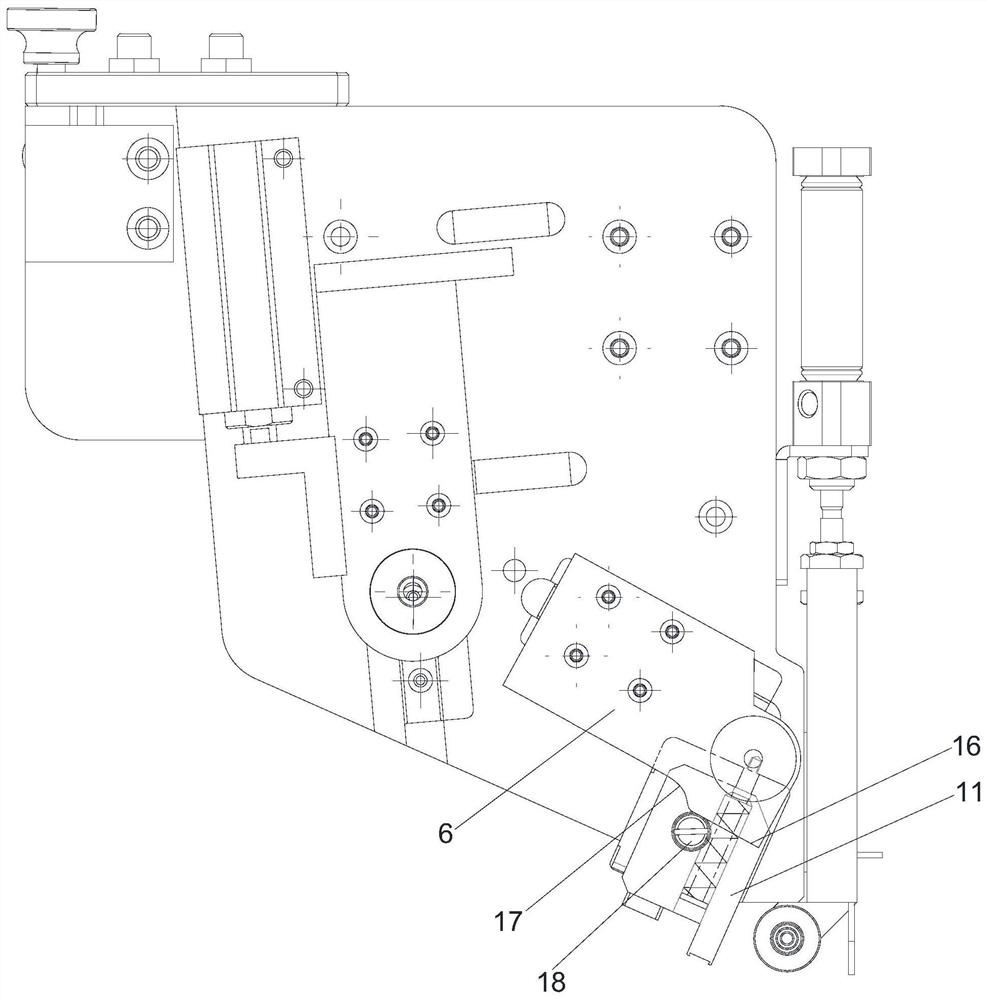

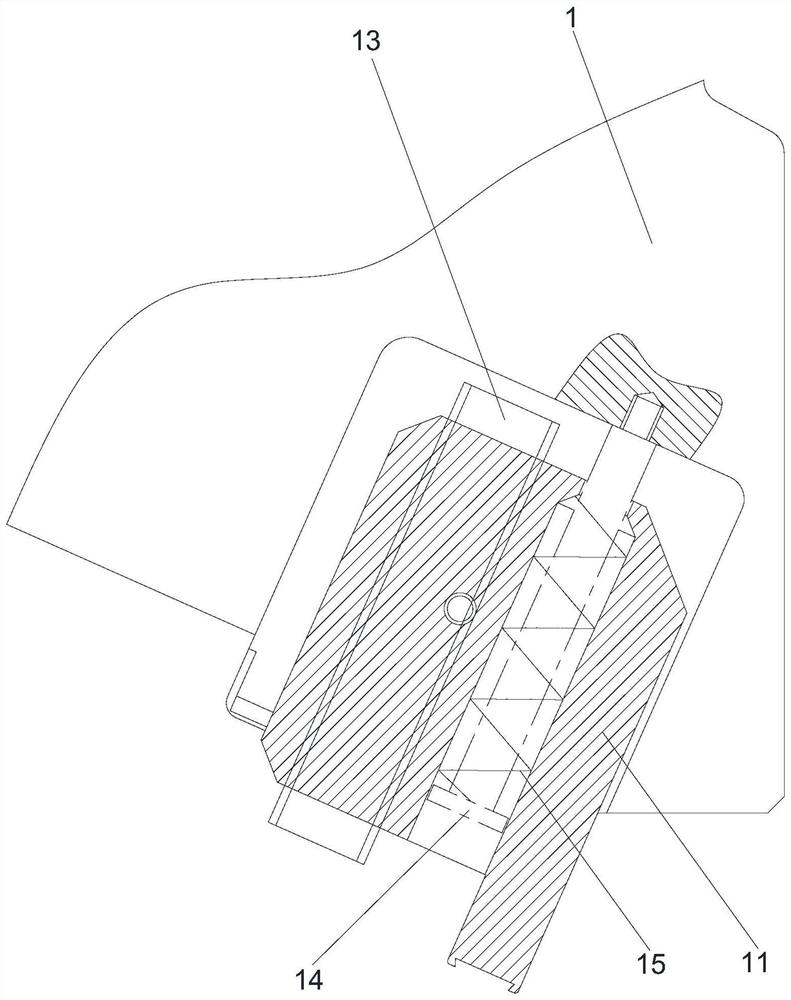

Hydraulic clamp for cutting machining of pump head of high-pressure fuel pump

PendingCN113385939AImprove work efficiencyHigh positioning accuracyMeasurement/indication equipmentsOther manufacturing equipments/toolsControl engineeringProcess engineering

A hydraulic clamp for cutting machining of a pump head of a high-pressure fuel pump comprises a supporting part in the vertical direction, a first clamping part in the horizontal direction, a second clamping part in the horizontal direction, an inclined wedge horizontal pushing mechanism arranged between the first clamping part in the horizontal direction and the second clamping part in the horizontal direction, and air tightness monitoring devices arranged on the first clamping part and the second clamping part. According to the hydraulic clamp, power in the vertical direction is converted into clamping force in the horizontal direction through the inclined wedge horizontal pushing mechanism, machining of two products is completed through one-time clamping, and the working efficiency is greatly improved; the air tightness monitoring devices are arranged to improve the positioning precision of product clamping, and the situation that the machining precision of a product is low due to the fact that a clamping gap is too large is avoided; and the height of a special wedge-shaped block is lower than that of an installed workpiece, tool collision during tool machining and switching is avoided, invalid production time is shortened, and production efficiency and stability are further improved.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

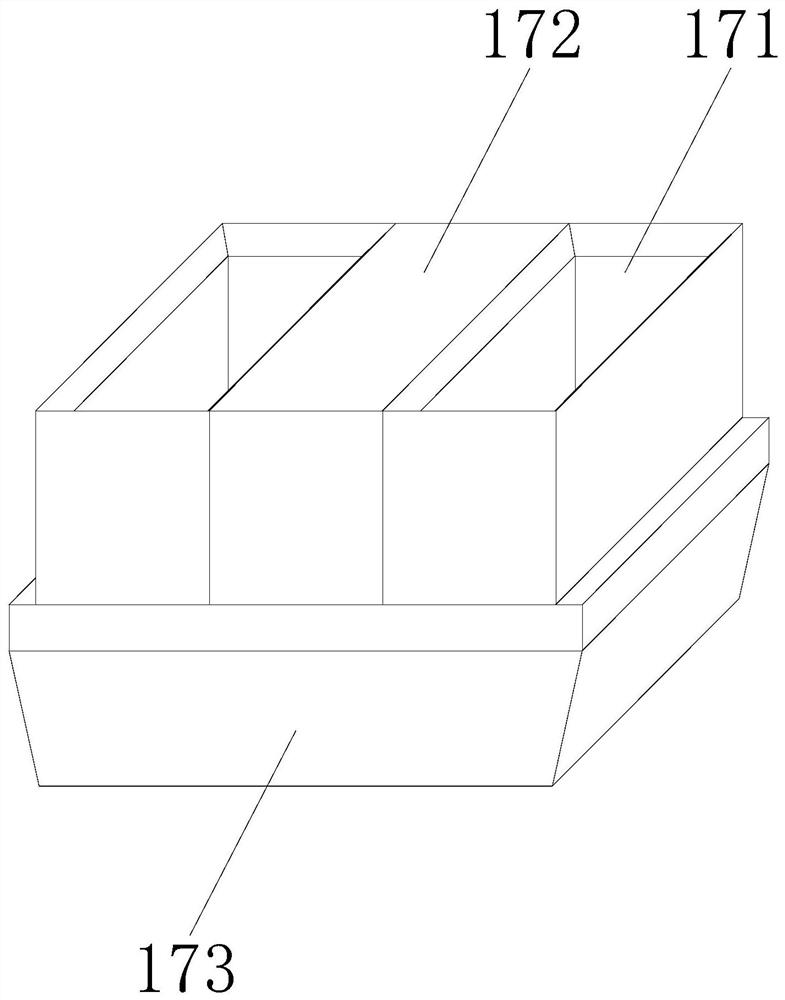

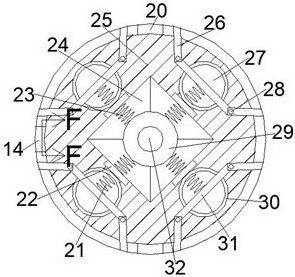

Bamboo hat magazine tool

InactiveCN106041592ASmooth tool changeImprove reliabilityPositioning apparatusMetal-working holdersEngineeringRotation control

The invention discloses a bamboo hat type tool magazine, which comprises a frame, a guide rail arranged on the frame, a tool changing box, a tool bin, a cutter head placed in the tool bin, and several tool holders installed on the cutter head. And the cutterhead rotation control device is characterized in that the tool change box is installed on the guide rail, the tool magazine is fixedly connected with the tool change box, and a reversible motor, a crank, and a slider fixedly connected with the tool change box are also arranged on the frame. Seat, one end of the crank is connected with the output shaft of the motor, and the other end is installed in the chute of the slide seat; as a further improvement of the present invention, a roller is provided at the end where the crank matches the chute, and the roller is arranged in the chute; The invention has the advantages of stable tool change, good reliability and high safety.

Owner:内江市桐言汽车配件制造有限公司

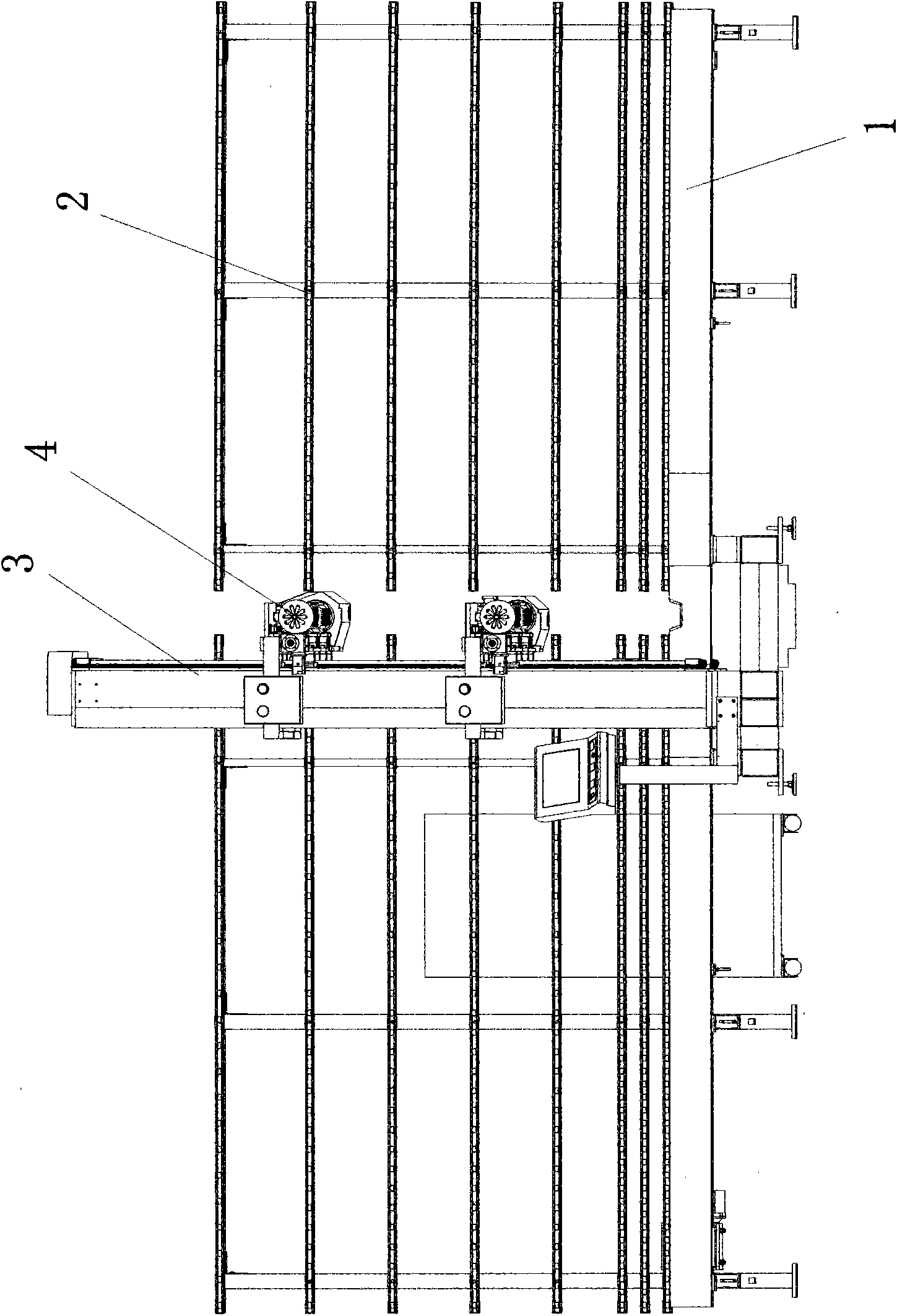

Cutter staggered double-face engraving machine

PendingCN108032659AThere will be no knife collisionImprove processing efficiencyOther artistic work equipmentsModel makingEngineeringMechanical engineering

The invention relates to a cutter staggered double-face engraving machine. The cutter staggered double-face engraving machine comprises an upper processing unit and a lower processing unit which are arranged along the Y axis. The upper processing unit is located on the upper portion of the Z axis. The lower processing unit is located on the lower portion of the Z axis. Z-axis cutter heads of the upper processing unit and the lower processing unit are staggered in the Y-axis direction in the cutting process. The X axis is perpendicular to the Y axis. The Z axis is perpendicular to an XOY plane.According to the cutter staggered double-face engraving machine, cutters are staggered in the Y-axis direction, power is separated, upper and lower cutter steps conduct processing on the two sides correspondingly, and the phenomenon that the upper and lower cutters collide each other cannot occur.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

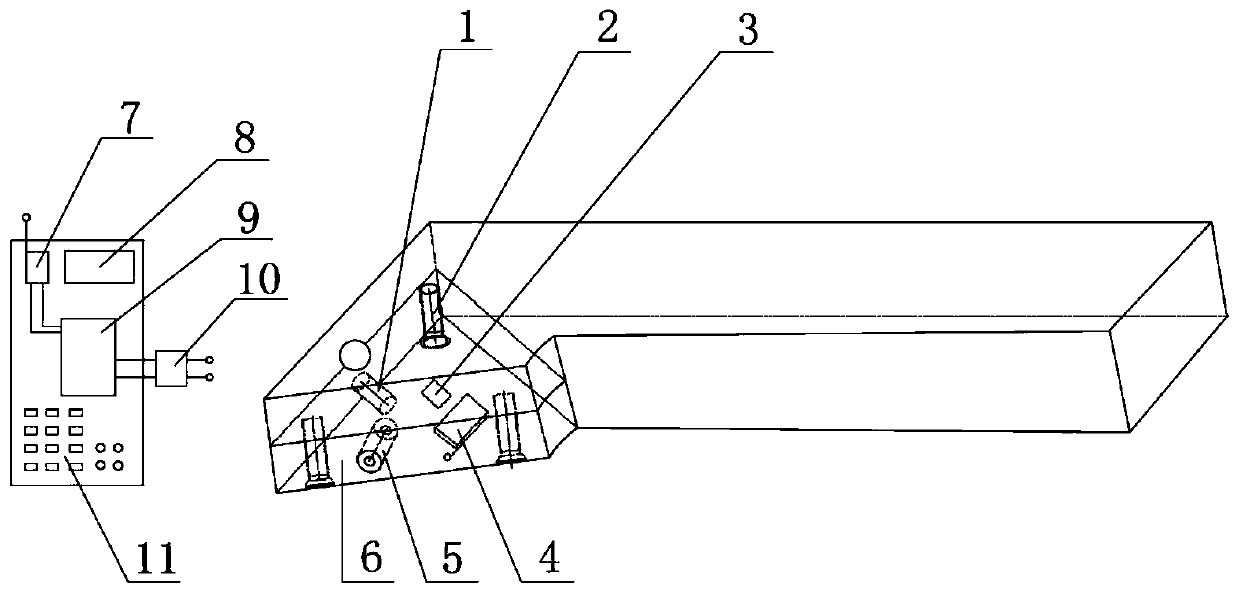

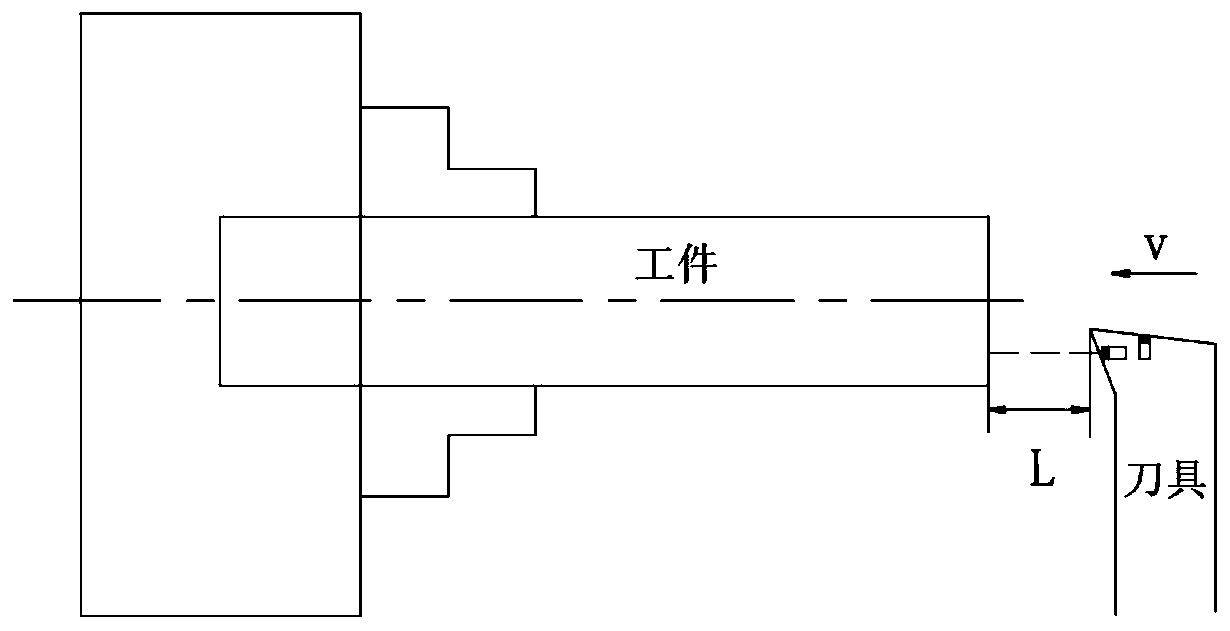

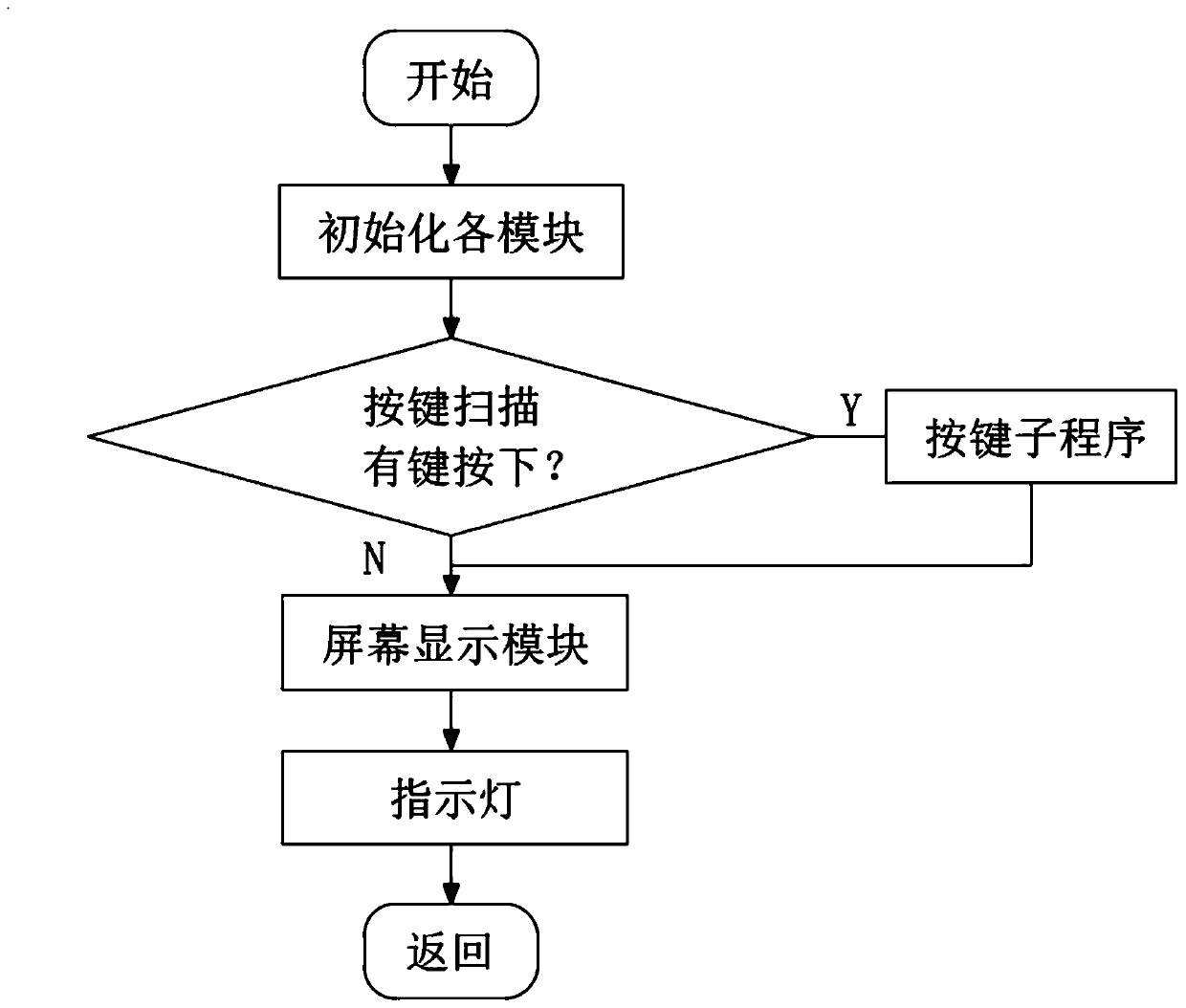

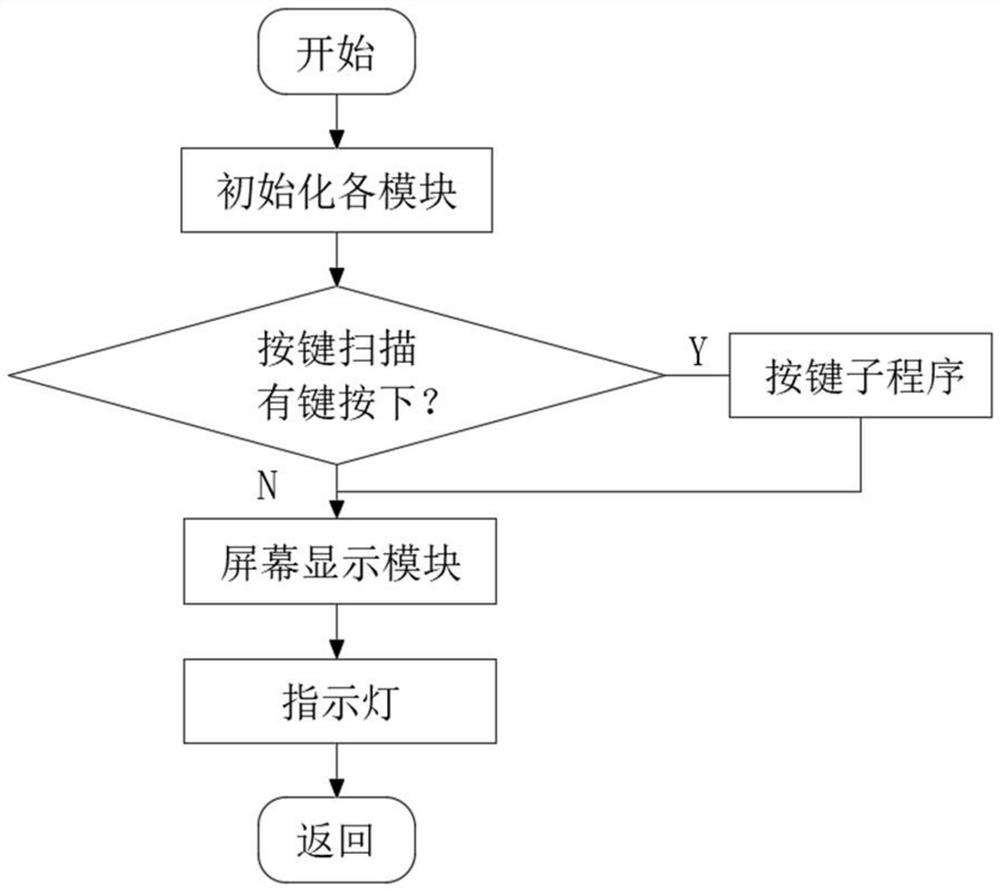

Replaceable anti-collision intelligent device for numerical control outer circle turning tool

ActiveCN111590095AAccurate detection distanceImprove real-time performanceAuxillary equipmentDetectorMachining process

The invention discloses a replaceable anti-collision intelligent device for a numerical control outer circle turning tool. The device comprises an ultrasonic radial detector, a fastening bolt, a PCB,a wireless transmitting module, an ultrasonic axial detector, a shell, a wireless receiving module, a display screen, a controller, a thyristor and keys. According to the device, the distance betweena tool nose and an obstacle can be automatically detected, a tool speed is calculated, a tool collision trend is automatically judged, and safety guarantee is provided for tool collision avoidance ofnumerical control turning. An ultrasonic sensor has a detachable function like a blade, and is accurate in detection distance and high in real-time performance, the controller can conveniently set a detection distance and a detection speed, different machine tool characteristics and actual machining requirements are met, and the flexibility is good. In the machining process, the anti-collision device can effectively avoid personal injury and machine tool damage caused by the fact that a tool collides with a workpiece or the obstacle, and the application prospect is wide.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Slitting device for cutting machine for potato tuber production

PendingCN110199609AImprove production efficiencyAchieve fine-tuningPotato seed cluttersEngineeringDisc cutter

The invention provides a slitting device for a cutting machine for potato tuber production. The slitting device is characterized by comprising a frame, a disc cutter component, a disc cutter adjustment and a milling tool mechanism; disc cutters parallel to each other and arranged vertically are mounted on a cutter shaft; the cutter shaft perpendicular to a potato tuber conveying direction is fixedto the middles of left and right supports of the frame through a bearing having vertical blocks at the two ends; one end of the cutter shaft is fitted with a transmission chain wheel; the disc cutteradjustment is perpendicular to the potato tuber conveying direction, and two sides of the disc cutter adjustment are mutually symmetric and are fitted to bottom sides of the left and right supports respectively; the milling tool mechanism parallel to the cutter shaft is fixed to the middles of bevel steel plates of the left and right support and is positioned above the disc cutter adjustment. Theslitting device is suitable for primarily slitting potato tubers so that manpower cost is reduced, and cutting efficiency is improved; the slitting device is highly reliable and widely applicable.

Owner:山东思代尔农业装备有限公司 +1

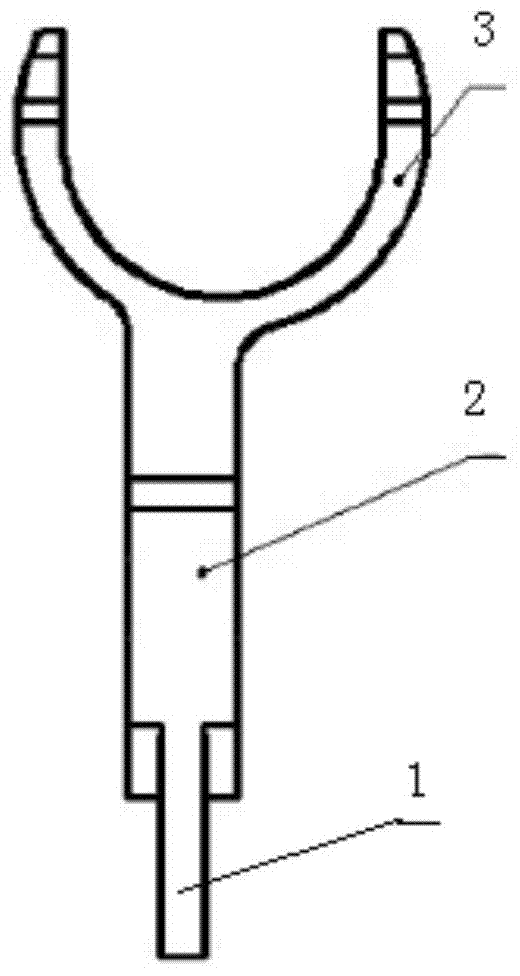

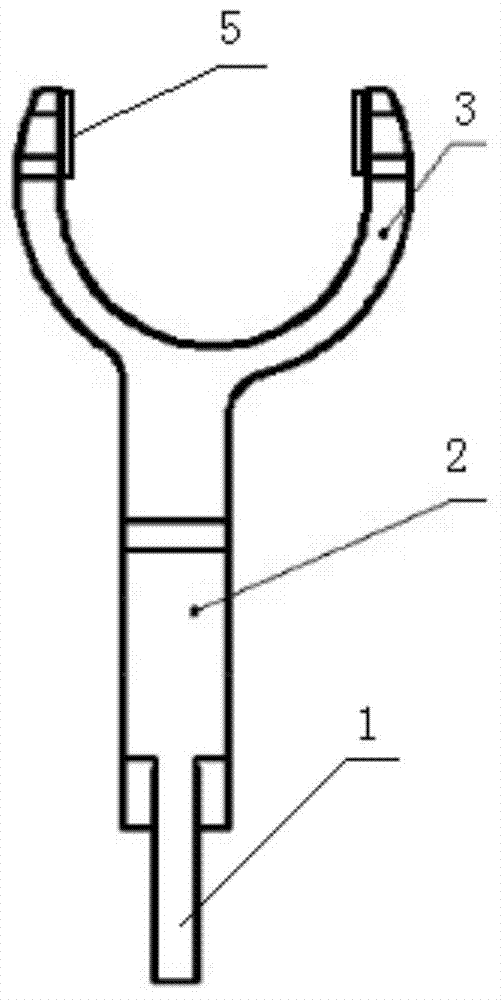

Caterpillar track knob fixing poking fork

InactiveCN103495876AAvoid hitting the knifeAvoid wear and tearPositioning apparatusMetal-working holdersWear resistantCaterpillar

The invention relates to the technical field of fixtures for machining caterpillar track knobs, in particular to a caterpillar track knob fixing poking fork. The caterpillar track knob fixing poking fork comprises a poking fork handle, a poking fork shaft and a poking fork claw. The poking fork claw is of a U-shaped structure, wear-resistant layers are arranged on the end portions of the poking fork claw, the poking fork shaft is eccentrically and perpendicularly fixed to the bottom of the poking fork claw, and the poking fork handle is connected with the poking fork shaft. Because the caterpillar track knob fixing poking fork comprises the poking fork handle, the poking fork shaft and the poking fork claw and the poking fork claw is of the U-shaped structure, a workpiece can be pressed tightly, and the situation that the workpiece which is not pressed tightly collides with a tool is effectively avoided; because the wear-resistant layers are arranged on the end portions of the poking fork claw, impact resistance is good, wear or cracking of the ends of the poking fork claw is effectively avoided, and service life is prolonged; besides, cost is low, and noise is low; in addition, because the poking fork shaft is eccentrically and perpendicularly fixed to the bottom of the poking fork claw and the poking fork handle is connected with the poking fork shaft, structural design is reasonable, the size is small, and replacement is easy.

Owner:KUNSHAN KAINUOER METAL PROD

Anti-collision knife method of machining center

InactiveCN104062942BAvoid hitting the knifeExtended service lifeProgramme controlComputer controlCombined useSimulation

The invention discloses a cutter collision preventing method for a machining center. A plurality of measures are adopted, and methods for preventing cutter collision of the machining center are listed completely from three aspects, namely procedure improvement, misoperation avoidance and cutter compensation verification, and a solution method is proposed. The cutter collision preventing method is capable of effectively preventing cutter collision for the machining center by use of certain programming skills, and by verifying the procedure by use of various methods and avoiding misoperation by virtue of correct coordinate system and cutter length compensation and radius compensation settings and combined use of hands and eyes in the operation process, and therefore, the service life of the machining center can be increased and the repair cost can be saved.

Owner:ANHUI HUALONG PRECISION MACHINERY CO LTD

A replaceable anti-collision intelligent device for CNC turning outer circle tool

The invention is a replaceable intelligent anti-collision device for a CNC turning outer circle tool. The device includes: an ultrasonic radial detector, fastening bolts, PCB, a wireless transmitting module, an ultrasonic axial detector, a shell, a wireless receiving module, a display screen, a controller, a thyristor and buttons. The invention can automatically detect the distance between the tip of the tool and the obstacle, calculate the speed of the tool, automatically judge the trend of tool collision, and provide safety guarantee for avoiding tool collision in numerical control turning processing. Like the blade, it has the function of disassembly and assembly. The ultrasonic sensor has accurate detection distance and high real-time performance. The controller can easily set the detection distance and detection speed to meet the characteristics of different machine tools and actual processing needs. It has good flexibility. In processing, the use of the anti-collision device can effectively avoid personal injury and machine tool damage caused by a tool hitting a workpiece or an obstacle, and has broad application prospects.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

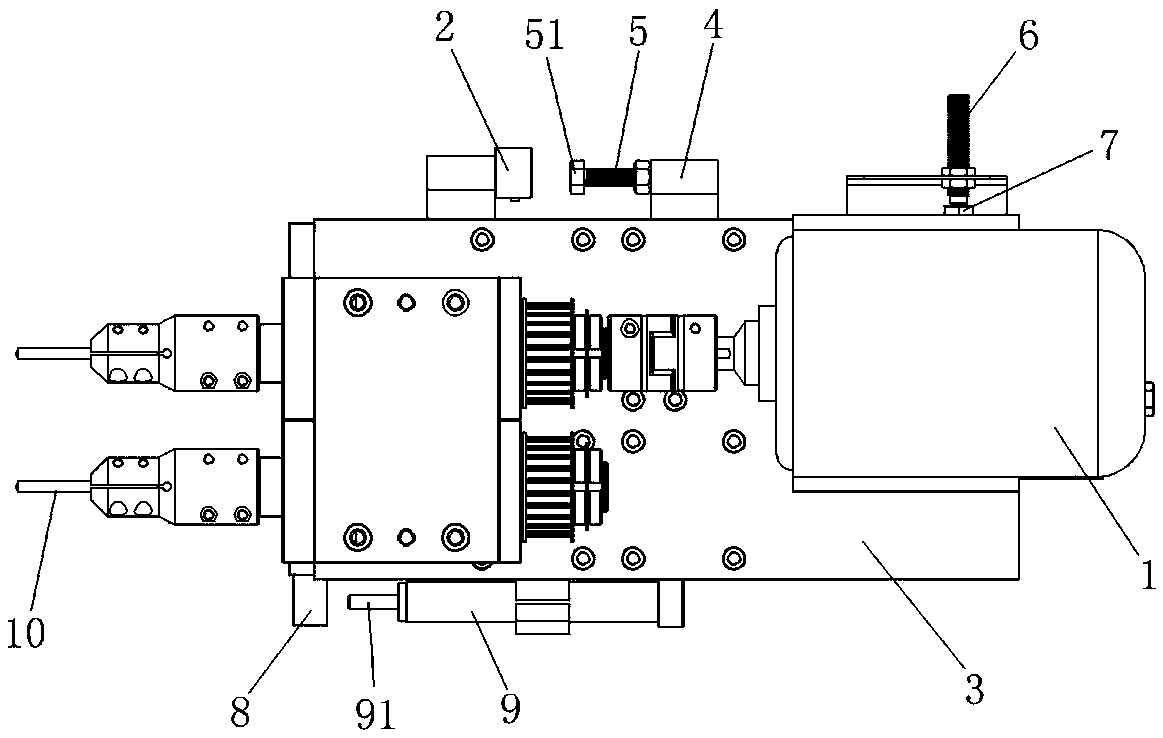

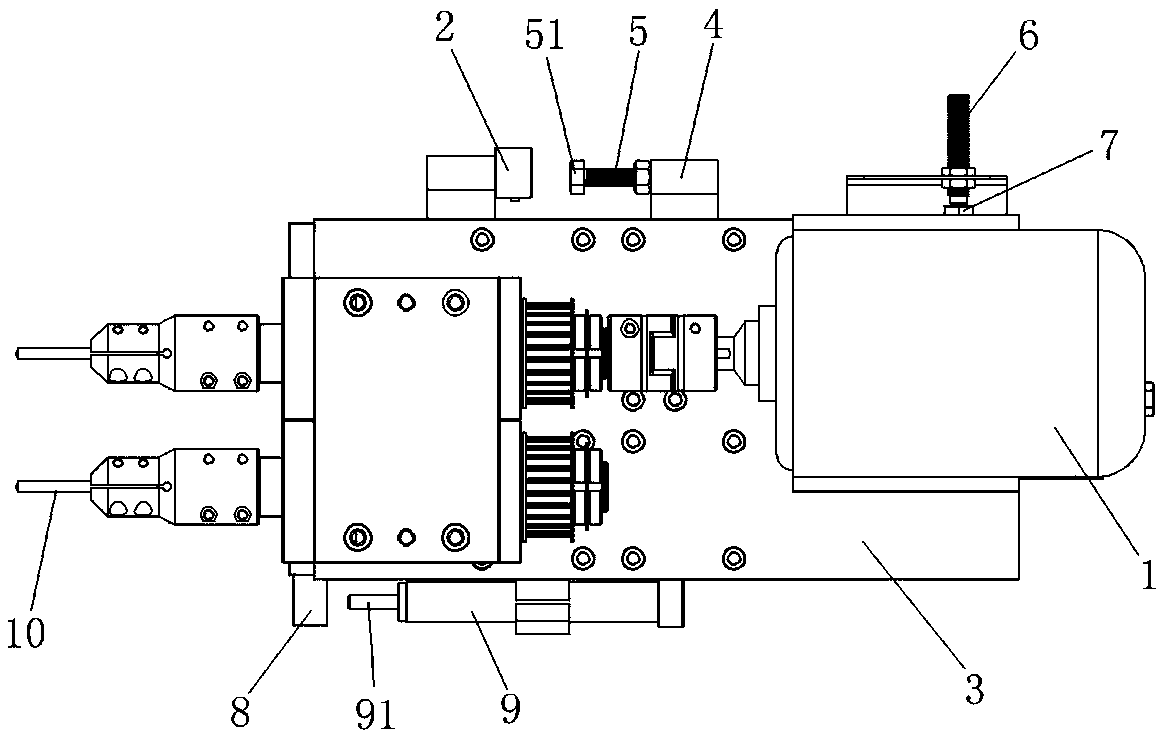

Control structure of power head

InactiveCN109834509AShrink in timeExtended service lifeAutomatic control devicesFeeding apparatusElectric machineEngineering

The invention provides a control structure of a power head, and belongs to the technical field of machinery. The power head solves the problems that an existing power head is low in automation degreeand poor in control effect. The control structure of the power head comprises a control unit for controlling the action of a motor and an air cylinder of the power head, a ground switch arranged on the side part of the power head, and an adjusting switch which is arranged on the side part of a power head supporting plate and is arranged corresponding to the ground switch, the ground switch and theadjusting switch are correspondingly connected with the control unit, the adjusting switch is provided with a threaded hole extending in the moving direction of the supporting plate, the threaded hole is in inner thread connection with a bolt, the rod head of the bolt faces the ground switch, and when the rod head of the bolt is in contact with the ground switch, the control unit controls a piston rod of the air cylinder to contract. The control structure of the power head has the advantages of being high in automation degree, good in control effect and the like.

Owner:温岭市雪鹏机械有限公司

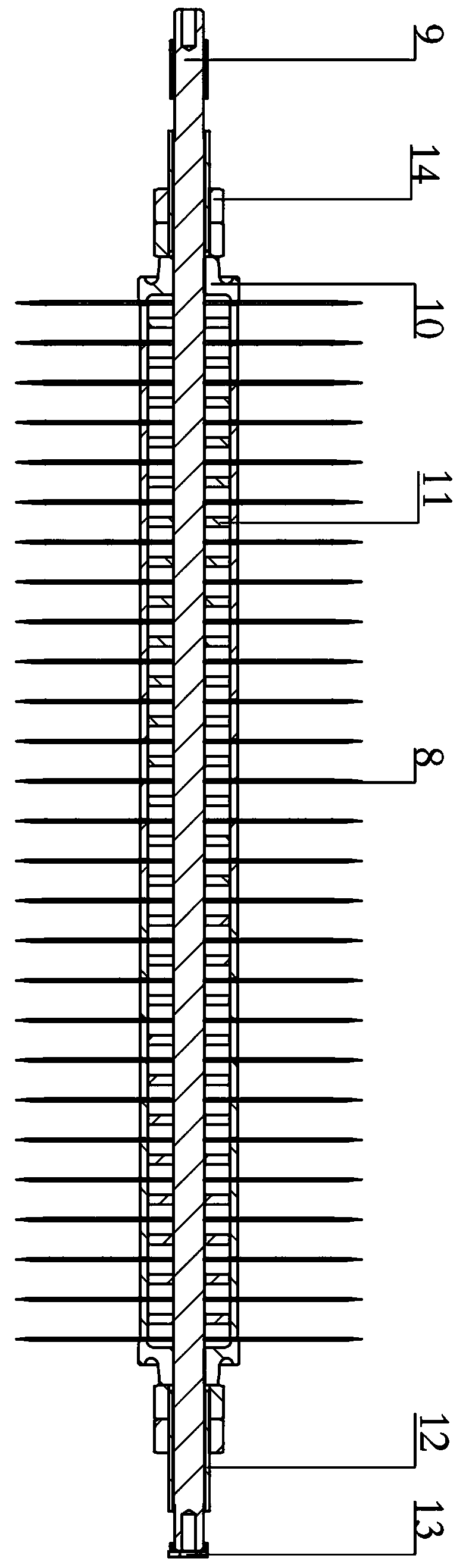

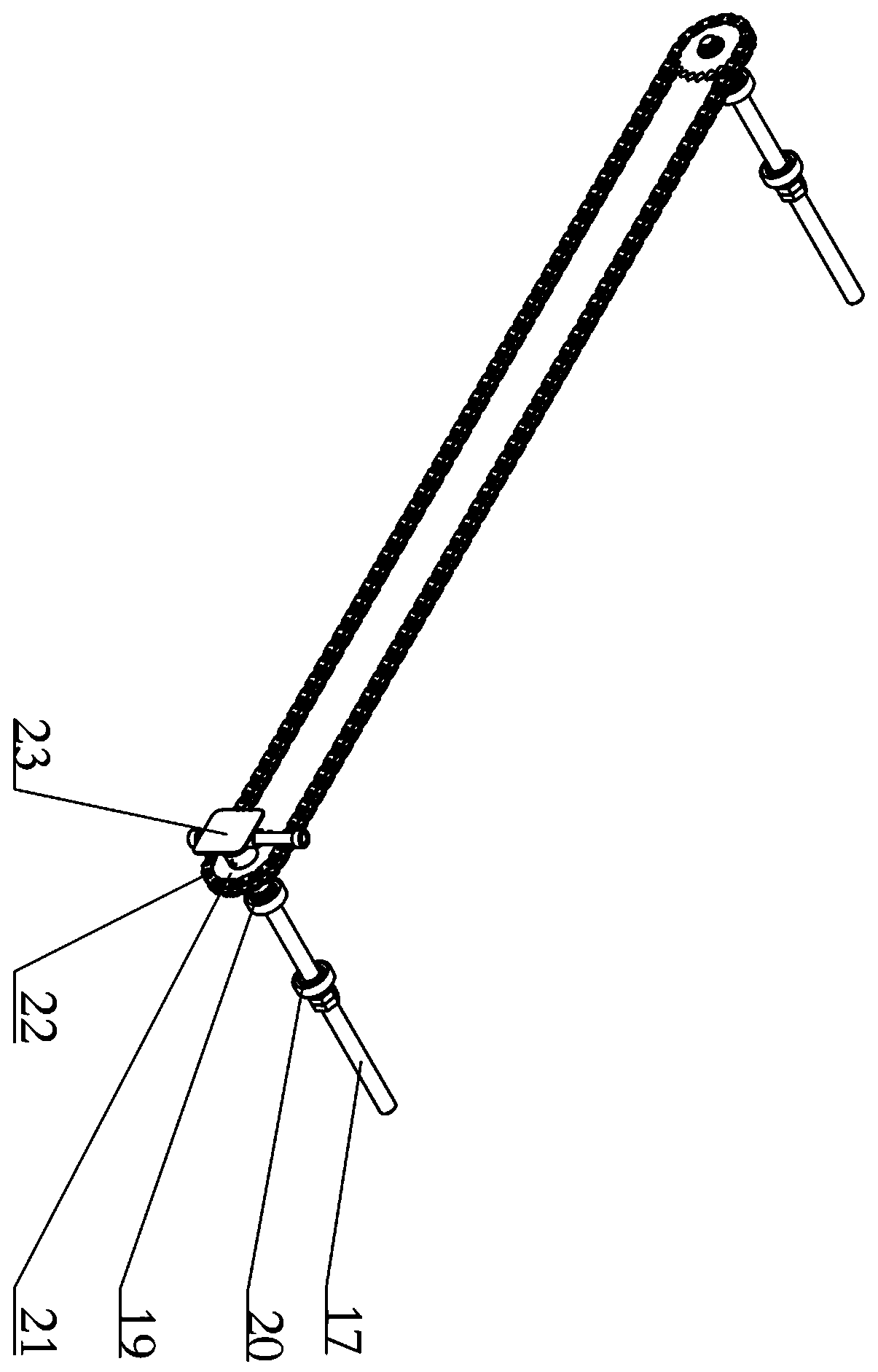

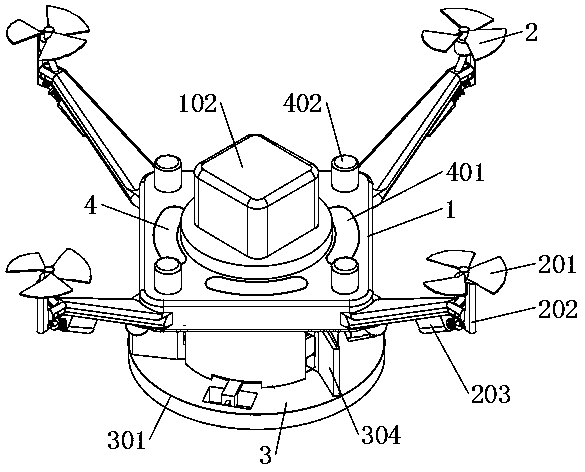

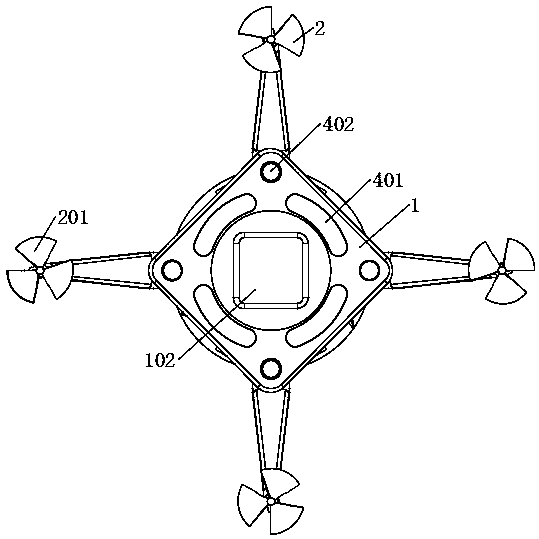

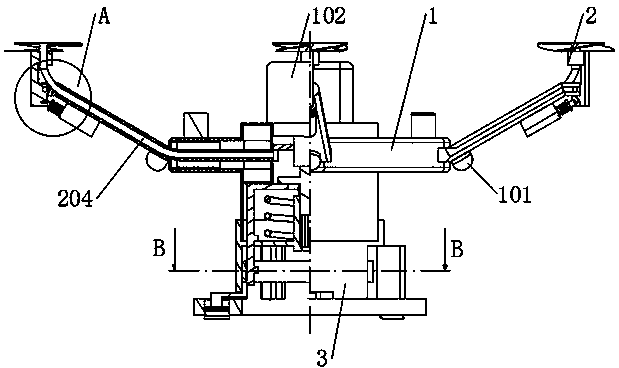

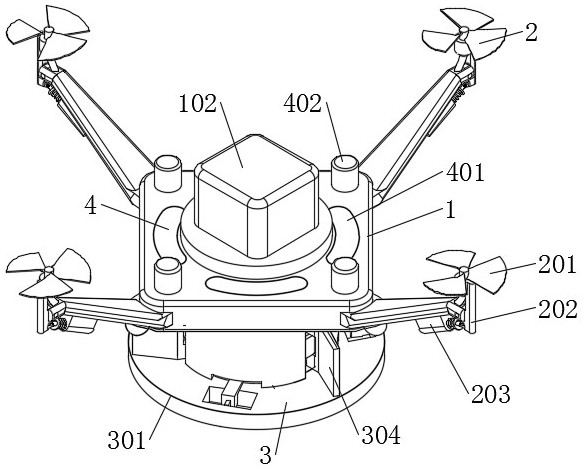

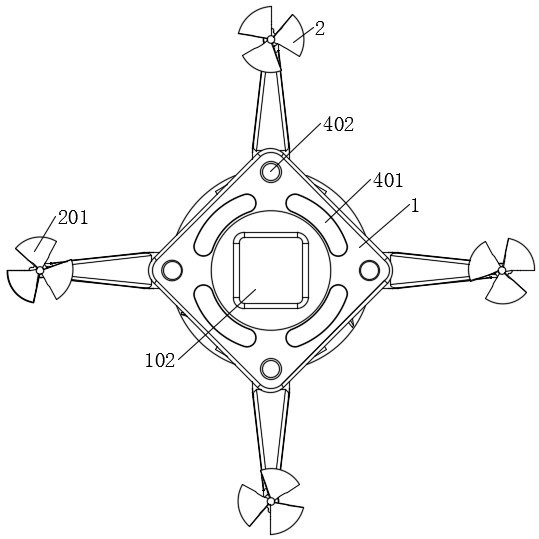

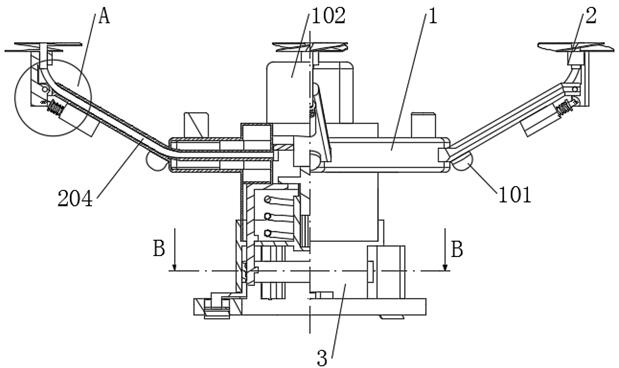

Intelligent underwater hull cleaning robot

InactiveCN111017134AAvoid scratching the hullAvoid hitting the knifeVessel cleaningHullsBuoyancy regulationBuoyant flow

The invention discloses an intelligent underwater hull cleaning robot. The robot comprises a robot body, a driving mechanism, a cleaning device and a buoyancy adjusting mechanism, wherein at least three sets of wings are arranged on the outer side of the robot body in an annular array mode; the driving mechanism is arranged at the ends of the wings; the rotating cleaning mechanism is arranged in the middle of the robot body; the buoyancy adjusting mechanism is arranged in the robot body; the cleaning mechanism comprises a mounting cylinder; the mounting cylinder and the machine body are rotationally mounted; the rotary axis of the mounting cylinder is perpendicular to the robot body; the upper end of the mounting cylinder is closed; a plurality of through holes are formed in the circumferential wall of the cylinder of the mounting cylinder; a water disturbing plate is rotationally arranged at each through hole; a plurality of through mounting grooves are formed in the outwards-turned edge of the bottom of the mounting cylinder; and a scraping knife is mounted in each mounting groove in a matched mode. The intelligent underwater hull cleaning robot can flush the scraping knives during cleaning operation and hide the scraping knives during non-cleaning operation.

Owner:SHANDONG JIAOTONG UNIV

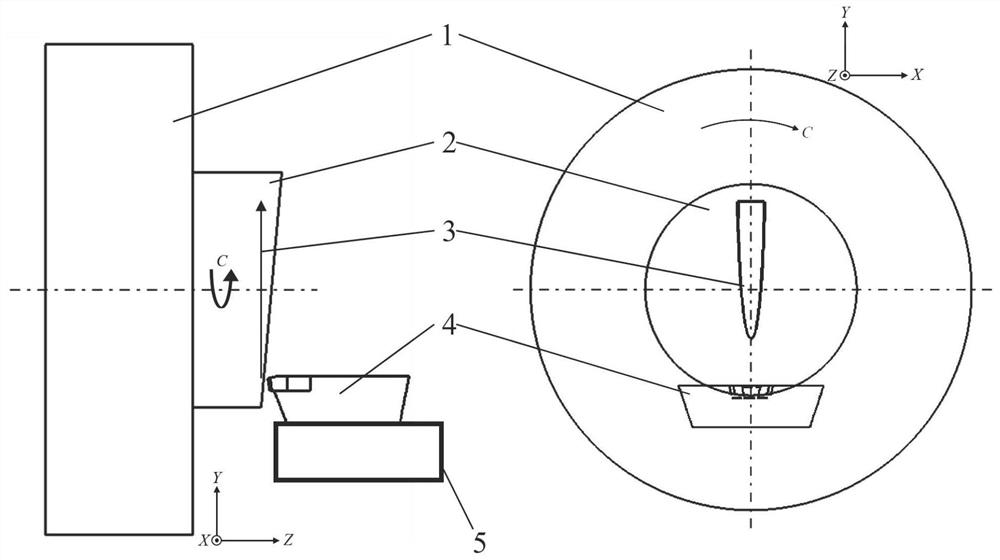

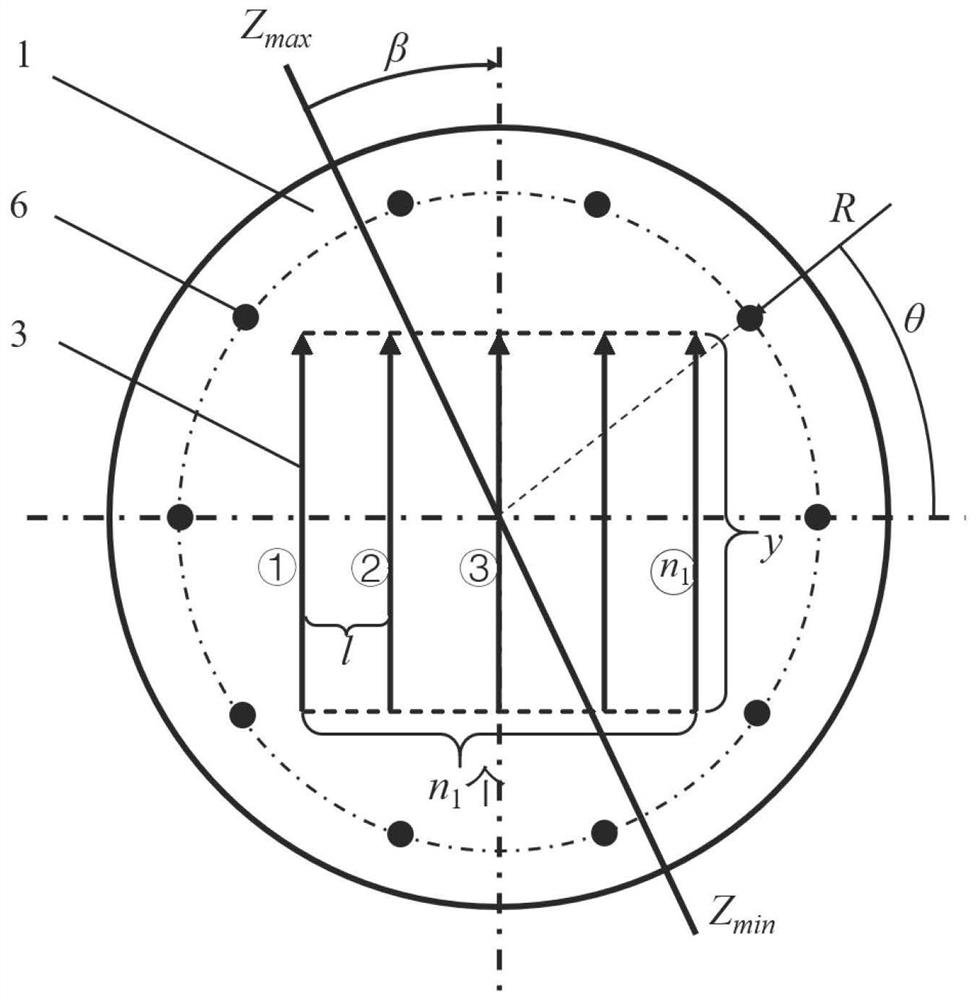

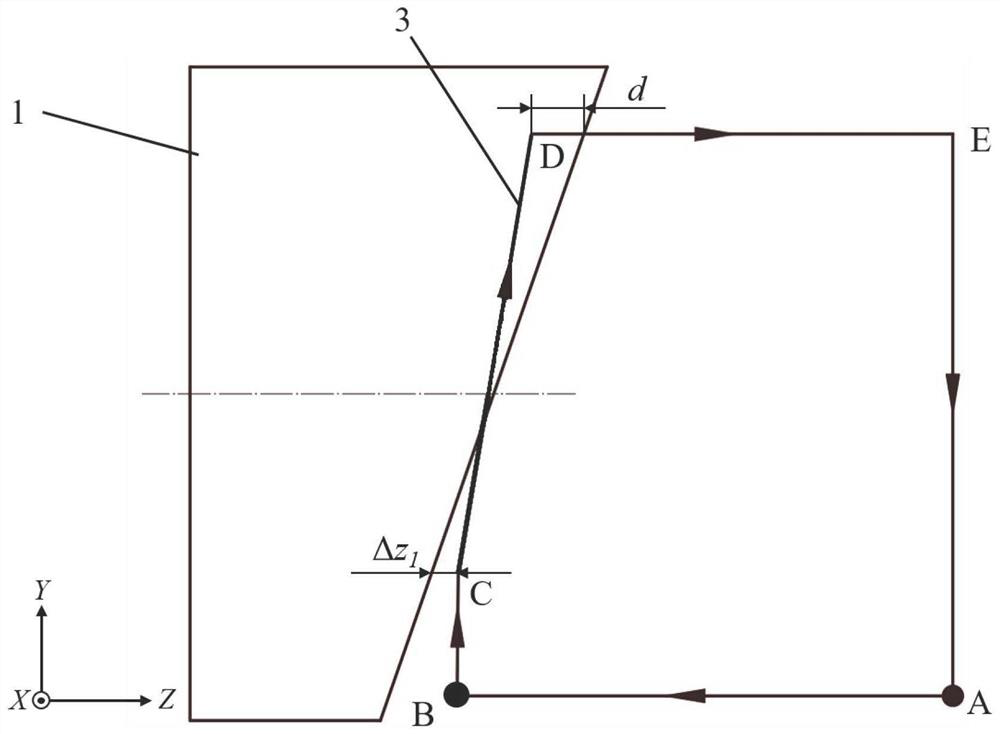

Ultra-precise deterministic scribing processing system and method for secondary clamping of high-hardness and high-brittleness material

ActiveCN112238535AReduced surface flatness requirementsImprove experimental efficiencyWorking accessoriesFine working devicesLeast squaresEngineering

The invention relates to an ultra-precise deterministic scribing processing system and method for secondary clamping of a high-hardness and high-brittleness material. In order to solve the problem that the cutting depth cannot be deterministically controlled in the linear scribing process due to the surface inclination generated by secondary clamping of a workpiece, the invention provides a set ofmethods for workpiece inclination detection, scribing tool setting and tool path planning in two scribing modes. A sampling point on the surface of the workpiece is obtained by matching in-situ detection of a dynamometer and accurate tool setting of a tool nose and the surface of the workpiece, and a workpiece plane equation is fitted by applying a least square method; then, by planning a scribing path, uncontrollable cutting depth factors caused by surface inclination in the cutting process are effectively prevented; and through segmented optimization of the complete path of a cutter, the experiment efficiency and the success rate are greatly improved on the basis of realizing ultra-precise deterministic scribing.

Owner:HARBIN INST OF TECH

An intelligent underwater hull cleaning robot

InactiveCN111017134BAvoid scratchesGuaranteed work performanceVessel cleaningHullsBuoyancy regulationMarine engineering

Owner:SHANDONG JIAOTONG UNIV

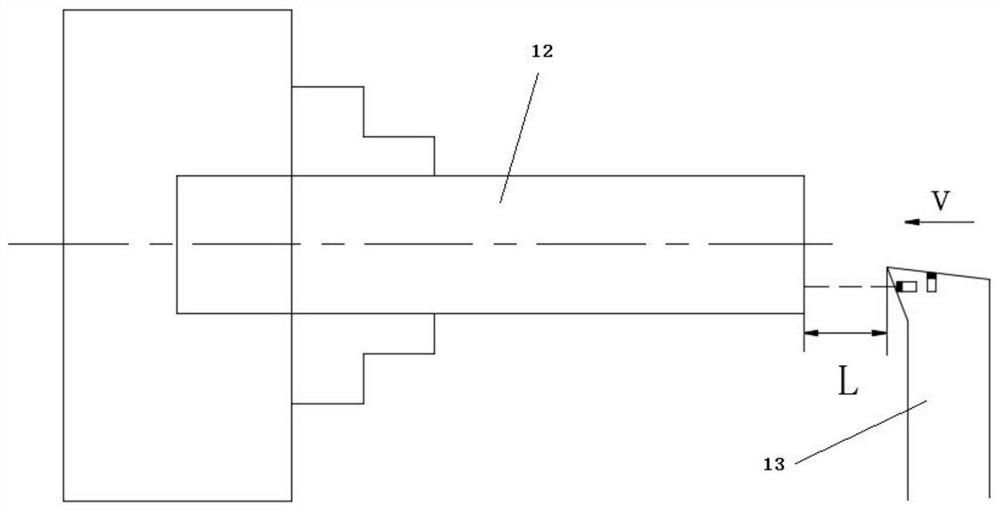

High-speed vertical glass drilling machine

InactiveCN101642821BImprove drilling accuracyImprove work efficiencyBoring/drilling componentsBoring/drilling machinesEngineeringDrive motor

The invention relates to the technical field of glass processing machinery, belongs to a glass drilling processing machine, and particularly relates to an electric control feeding mechanism of a drilling motor of a vertical glass drilling machine. The electric control feeding mechanism of the drilling motor of the vertical glass drilling machine comprises a base, a glass supporting frame and an upright post, wherein the upright post is provided with the drilling motor; a horizontal shifting module is arranged between the drilling motor and the upright post; a drilling bit port of the drillingmotor is provided with a clamping plate; the clamping plate is provided with a drilling bit feeding position inductive switch; a servo motor for driving the driving motor to advance and retreat is also arranged between the drilling motor and the horizontal shifting module; and the inductive switch and the servo motor are connected with each other and controlled by a numerical control system. The electric control feeding mechanism of the drilling motor of the vertical glass drilling machine has the following advantages that: 1, due to the adoption of the servo motor and a speed reducer, the drilling precision is improved; and 2, the inductive switch is used to implement the simultaneous working of a front drilling bit and a back drilling bit, the drilling bit at one side is fed to a certain preset position and then is stopped and dropped back, and the drilling bit at the other side is fed continuously, so the working efficiency is high, and cutter crash appearing in double-side feedingis avoided.

Owner:EI AUTOMATION EQUIP

Waste sweeping device for lathe

InactiveCN109420778AEasy maintenanceImprove processing efficiencyAuxillary equipmentMaintainance and safety accessoriesEconomic benefitsMachining

The invention relates to the technical field of machining, in particular to a waste sweeping device for a lathe. The waste sweeping device comprises a base, wherein one side of the base is equipped with a feeding regulating handle; the upper end surface of the base is fixedly connected with a housing; a first partition and a second partition are fixedly connected inside the housing; the bottom endinside the housing is fixedly connected with a fan; the left side of the fan is equipped with a filter screen; and the left side of the filter screen is fixedly connected with a first pipeline. The waste sweeping device is simple in structure, is complete in function, can recycle waste in a processing process, is clean and sanitary, can cool the tool bit, enables the tool bit to work for a long time, and improves processing efficiency; and when the device is too close to a processed part, an alarm lamp alarms to prevent tool collision, so that safety performance is higher, and the tool bit can be further reinforced, and therefore, the waste sweeping device is safer, has great economic benefits and a wide market prospect, and is worthy of being popularized and used.

Owner:DEQING JINGYING INFORMATION TECH CO LTD

End gluing device and gluing method for cable arrangement

ActiveCN110648805BQuality improvementSame lengthManufacturing wire harnessesEngineeringMechanical engineering

The invention relates to the field of flat cable tape attaching and particularly relates to a flat cable end tape attaching device. The device comprises a rack, a base assembly, a winding drum assembly, a film feeding assembly, a cutting assembly and a pressing assembly, wherein the base assembly is installed on the machine frame, the winding drum assembly is connected with the base assembly, thepressing assembly is installed on the machine frame and located over the winding drum assembly, the cutting assembly is obliquely arranged on the winding drum assembly, the film feeding assembly is arranged on the machine frame and located on the side of the winding drum assembly, the winding drum assembly is used for winding a single-sided adhesive tape and sending out the cut single-sided adhesive tape, the cutting assembly is used for carrying out fixed-length cutting of the single-sided adhesive tape on the winding drum assembly, and the pressing assembly is used for attaching the cut single-sided adhesive tape to a surface of a flat cable. The device is advantaged in that a rotary adhesive tape receiving strip is arranged, so working efficiency is improved, the rotary winding drum assembly can achieve feeding, cutting and material moving, no waiting exists between procedures, connection is orderly, and the tape attaching speed is increased.

Owner:昆山展诚电子科技有限公司

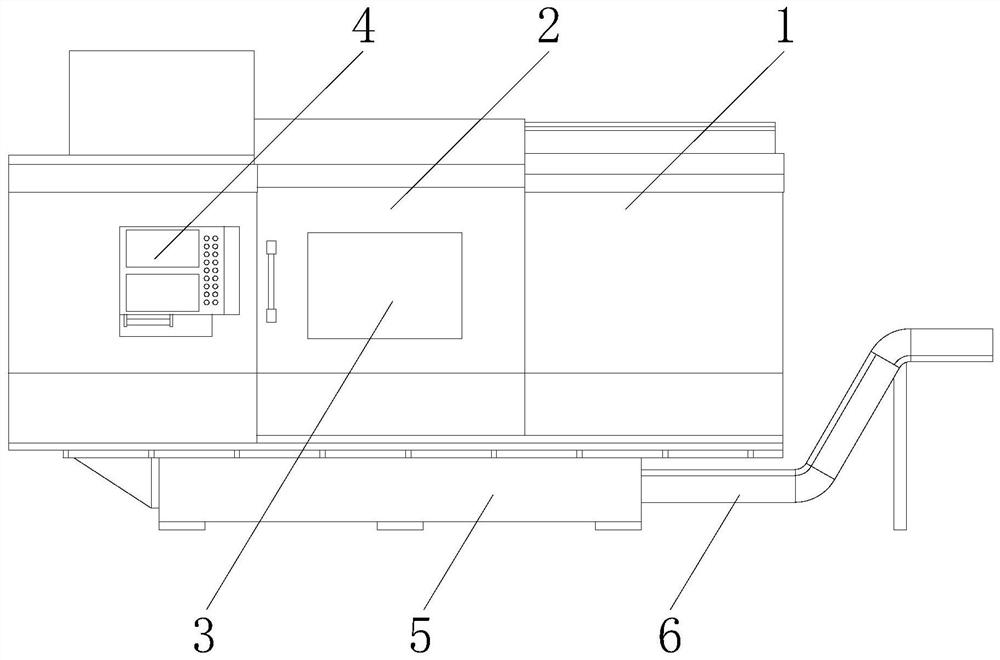

A dual-spindle core-moving CNC lathe

ActiveCN112222432BEasy dischargeAvoid hitting the knifeAutomatic/semiautomatic turning machinesAuxillary equipmentFixed frameScrap

The invention discloses a double-spindle core-moving type numerical control lathe, the structure of which comprises a main machine of the lathe, a movable door, a window, a control panel, a fixed base, and a chip discharge pipe. A movable door is arranged at the front end of the main machine of the lathe, and a The waste chips enter the inside of the chip guide grooves on both sides, the toggle lever on the right turns clockwise, and the toggle lever on the left turns counterclockwise to ensure that the long strips of waste chips inside the chip guide grooves on both sides The chips are moved from top to bottom, and the hook plate can cut off the long strips of waste to prevent the collision between the workpiece and the tool. The shielding horizontal plate initially blocks the long strips of waste, and when the toggle lever is rotated, the spring is automatically reset after the toggle lever is rotated to separate from the plate body, so that the opening and closing plate is closed between the shielding horizontal plates , to prevent long strips of waste from entering the interior of the fixed frame, and ensure that the toggle lever can effectively dial down the waste.

Owner:广东卡路斯数控机床有限公司

Special-shaped workpiece drilling clamping table and use method thereof

InactiveCN111992762ALimit longitudinal movementAvoid hitting the knifePositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a special-shaped workpiece drilling clamping table and a use method thereof. The special-shaped workpiece drilling clamping table comprises a mounting base, a limiting assemblyand a clamping assembly. The clamping assembly is arranged at the top of the mounting base, and the clamping assembly comprises a clamping base, adjusting and fixing assemblies and extruding and fixing assemblies. A machining through hole is formed in the middle of the clamping base to reserve a machining position. The adjusting and fixing assemblies are oppositely arranged on the clamping base and located on the wide edges of the two sides of the clamping base. The extruding and fixing assemblies are oppositely arranged on the clamping base and located on the long edges of the two sides of the clamping base. The limiting assembly is arranged at the top of the clamping base to limit the clamping positions of workpieces. According to the special-shaped workpiece drilling clamping table andthe use method thereof, the limiting assembly is arranged and can quickly position the positions of the workpieces on the base; the adjusting and fixing assemblies can adapt to the workpieces with different sizes and radians, and meanwhile the adjusting and fixing assemblies can limit the longitudinal motion of the workpieces; and the transverse motion of the workpieces can be limited through theextruding and fixing assemblies, the machining stability is further improved, and the machining quality is effectively improved.

Owner:太仓市双雄精工有限公司

Surgical knife storage and providing device

The invention discloses a surgical knife storage and providing device. The device comprises a machine body, wherein an S-shaped working cavity is formed in the machine body; openings are formed in theupper side and the lower side of the working cavity; a partition plate is rotationally installed at the opening in the upper side of the working cavity; a rotating groove with a rightward opening isformed in the right side wall of the partition plate; rotating shafts are rotationally installed on the front wall and the rear wall of the rotating groove; transmission gears are fixedly installed onthe rotating shafts; a push rod rack extending upwards is installed on the left side wall of the rotating groove in a sliding mode; and the upper side of the push rod rack extends out of the partition plate and is fixedly connected with a hand sensor. The device is simple in structure and convenient to operate; the partition plate rotates to enable a knife conveying belt to extend out of the working cavity and drive the hand sensor to extend out at the same time, the partition plate can seal the working cavity when not used, and therefore the interior of the working cavity is clean and dust entering the working cavity is reduced.

Owner:温州朝向科技有限公司

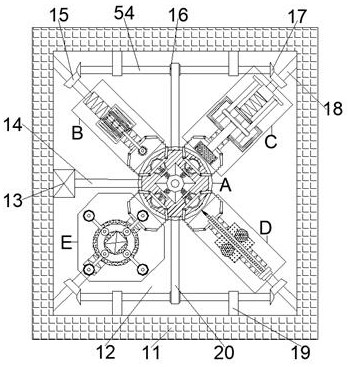

Intelligent manufacturing device for small turning, milling, drilling and grinding synchronous machining

InactiveCN112338557AAvoid hitting the knifeImprove processing efficiencyOther manufacturing equipments/toolsMachining processSmart manufacturing

The invention discloses an intelligent manufacturing device for small turning, milling, drilling and grinding synchronous machining. The device comprises a machining box, a machining cavity with a forward opening is formed in the machining box, a sliding opening block is slidably connected to the rear wall of the machining cavity, and a closed cavity with a forward opening is formed in the front end of the sliding opening block. Pressure springs are fixedly connected to the upper end and the lower end away from each other of the closed cavity. According to the device, some manufacturing-related devices can be combined, turning, milling, drilling and grinding are combined through linkage, workpieces are synchronously machined, meanwhile, no interference exists in the machining process, toolcollision of the workpieces due to linkage is avoided, and the four working steps of turning, milling, drilling and grinding can also be separately and independently carried out for independently machining the workpieces, so that the machining efficiency of the workpieces is improved, and the synchronism among the working steps is also improved.

Owner:PUJIANG SIHONG MASCH TECH CO LTD

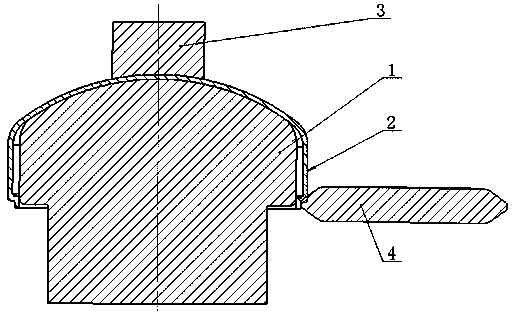

Connecting method for thin-wall shells

InactiveCN105537856AHigh matching precisionSmall forming forceMetal working apparatusEngineeringUltimate tensile strength

The invention provides a connecting method for thin-wall shells. The connecting method for the thin-wall shells is used for achieving connection between the two thin-wall shells, the connecting ends of the thin-wall shells are cylinders, and the diameters of the thin-wall shells are the same. According to the connecting method for the thin-wall shells, the end of one thin-wall shell is subjected to spinning necking or flaring and trimming and then is matched with the other thin-wall shell; and then manners of welding and the like are adopted for connection. The connecting method has the beneficial effects that the spinning necking or flaring method is adopted, the technology is simple, and operation is easy; trimming is conducted after spinning necking or flaring, secondary positioning is not needed, the machining safety coefficients are high, and the service life of a tool is long; the thin-wall shells obtained after spinning necking or flaring are high in size precision, easy to match and high in connecting strength.

Owner:SHANGHAI JIAOTONG UNIV

Attaching mechanism of foam attaching device used for touch screen

PendingCN112192856AHigh degree of automationImprove processing efficiencyMetal working apparatusInput/output processes for data processingTouchscreenControl theory

The invention discloses an attaching mechanism of a foam attaching device used for a touch screen. The attaching mechanism comprises an attaching fixed plate, a feeding swing arm, a feeding driving device, a pressing assembly, a cutting-off assembly, a first sliding block and a second sliding block, wherein the first sliding block and the second sliding block cooperate with each other. The feedingdriving device is installed on the attaching fixed plate, an output shaft of the feeding driving device is hinged to the middle or the rear end of the feeding swing arm through the first sliding block, and the first sliding block is obliquely and slidably installed on the attaching fixed plate through a first sliding rail assembly. The second sliding block is obliquely and slidably installed on the attaching fixed plate through a second sliding rail assembly, and the second sliding block is hinged to the front end of the feeding swing arm in a cooperation manner. The feeding swing arm is provided with a feeding groove which extends in the front-back direction and is used for allowing foam strips to penetrate. The pressing assembly is installed on the attaching fixed plate and located in front of the feeding swing arm. The cutting-off assembly is installed on the attaching fixed plate and used for cutting off the foam strips. The attaching mechanism has the advantages of being high inprocessing efficiency and the like.

Owner:张传刚

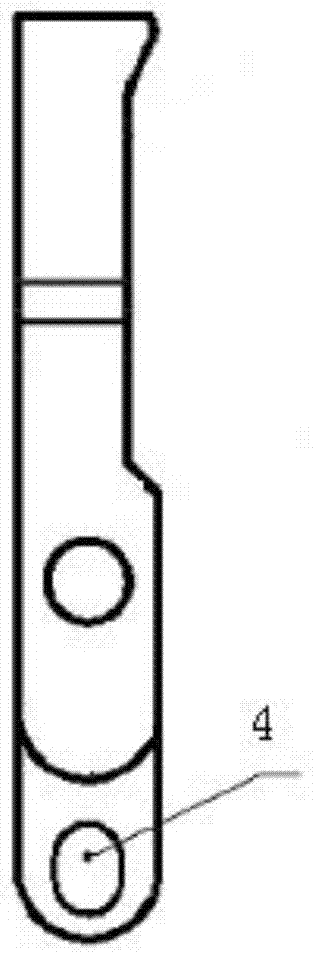

Fixing shifting fork for caterpillar links

InactiveCN103481076AAvoid wear and tearAvoid hitting the knifePositioning apparatusMetal-working holdersEngineeringCaterpillar

The invention relates to the technical field of caterpillar link clamp machining and particularly relates to a fixing shifting fork for caterpillar links. The fixing shifting fork comprises a shifting fork shank, a shifting fork shaft and a U-shaped shifting fork claw. Protrusions are arranged at ends of the shifting fork claw, the shifting fork shaft is fixed below the shifting fork claw eccentrically and perpendicularly, and the shifting fork shank is connected with the shifting fork shaft. According to the fixing shifting fork, the fixing shifting fork comprises the shifting fork shank, the shifting fork shaft and the shifting fork claw, the shifting fork claw is U-shaped, to that a workpiece can be tightly pressed, tool crashing caused by the fact that the workpiece cannot be pressed tightly is effectively prevented; the protrusions are arranged at ends of the shifting fork claw, so that abrasion of the ends of the shifting fork claw is prevented, and the service life is prolonged; the shifting fork shaft is fixed below the shifting fork claw eccentrically and perpendicularly, and the shifting fork shank is connected with the shifting fork shaft, so that the fixing shifting fork is reasonable in structural design, small in size and simple to exchange and operate.

Owner:KUNSHAN KAINUOER METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com