Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Fast glue application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

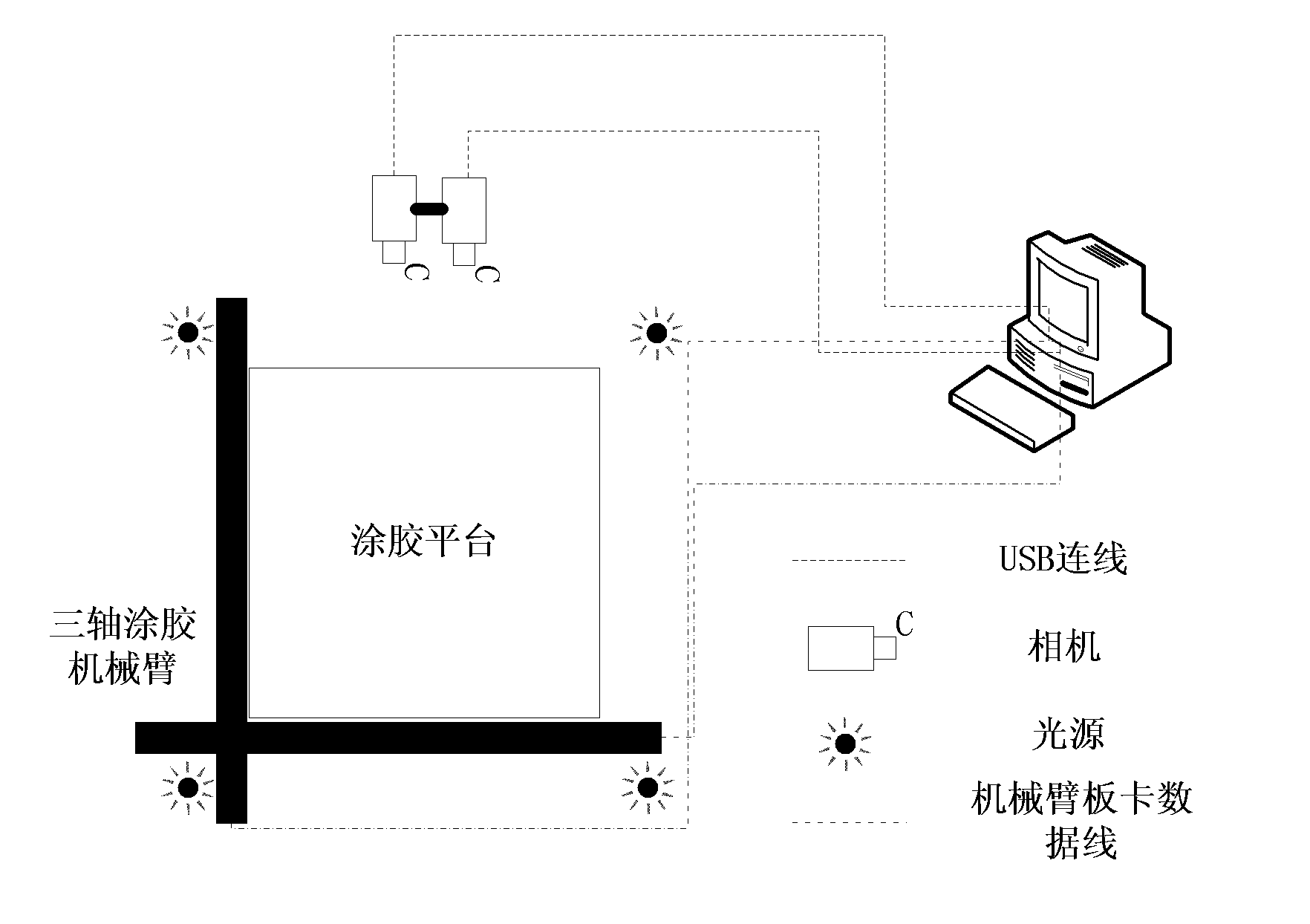

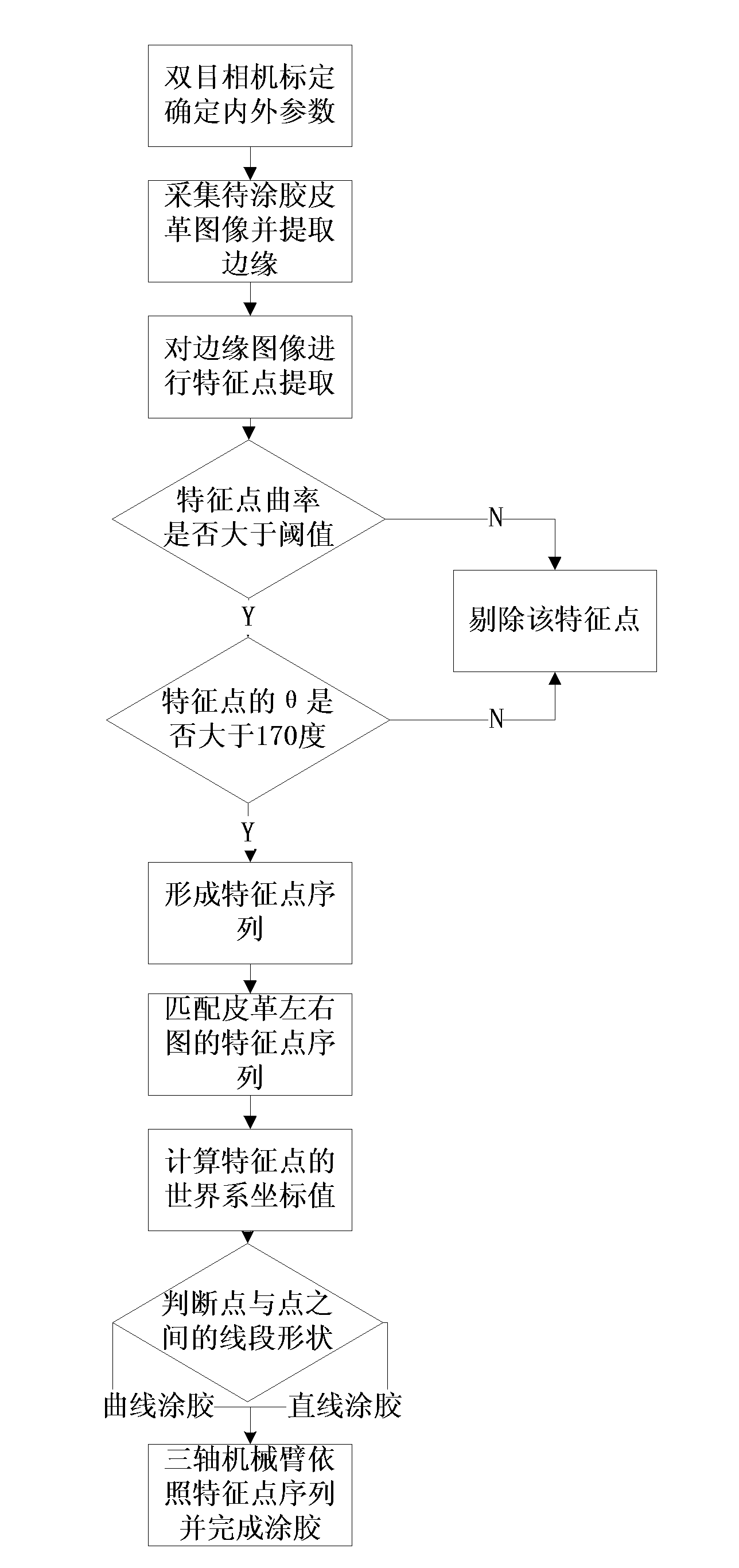

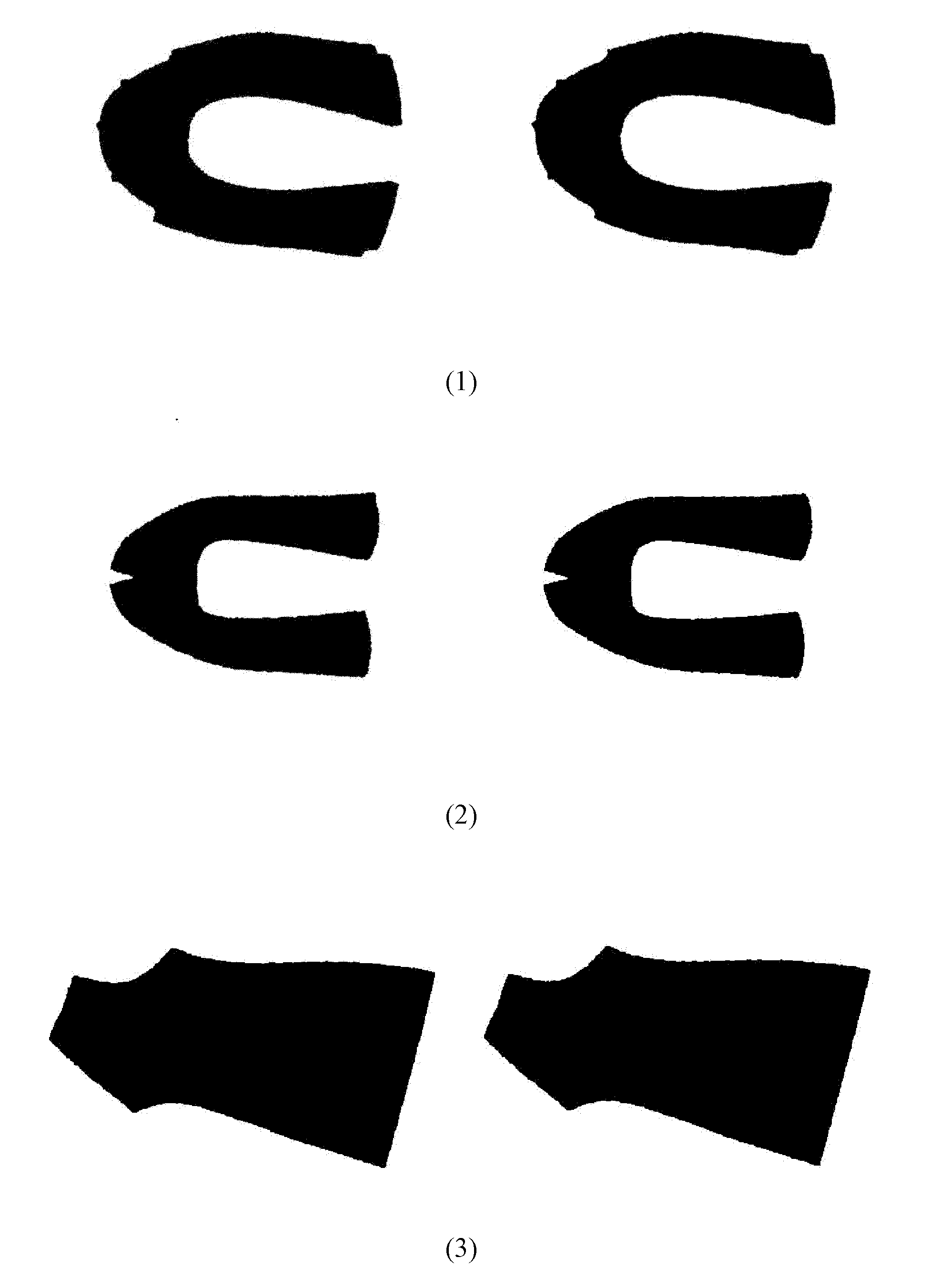

Method for controlling single-layer leather gluing based on binocular vision

ActiveCN102107179AImprove image qualityFacilitate industrial automationLiquid surface applicatorsImage analysisManipulatorHat matrix

The invention provides a method for controlling single-layer leather gluing based on binocular vision. As a binocular camera and a three-shaft gluing manipulator are adopted, the method comprises the following steps of: 1) performing three-dimensional calibration on the fixed binocular camera; 2) collecting a binocular image of single-layer leather and extracting an edge outline of the binocular image; 3) extracting characteristics according to the edge outline image in the step 2); 4) matching according to the characteristic points in the step 3); 5) reducing real coordinate values of a gluing platform system corresponding to the characteristic points in the step 4) according to a weight projection matrix value; and 6) inputting the real coordinate values of the characteristic points into a gluing coordinate queue of the three-shaft gluing manipulator to control the manipulator to finish the gluing. By the method, the working efficiency is improved, the single-layer leather is conveniently integrated to the processing of a production line, the precision is high, and harms to the health of workers can be avoided.

Owner:ZHEJIANG UNIV OF TECH

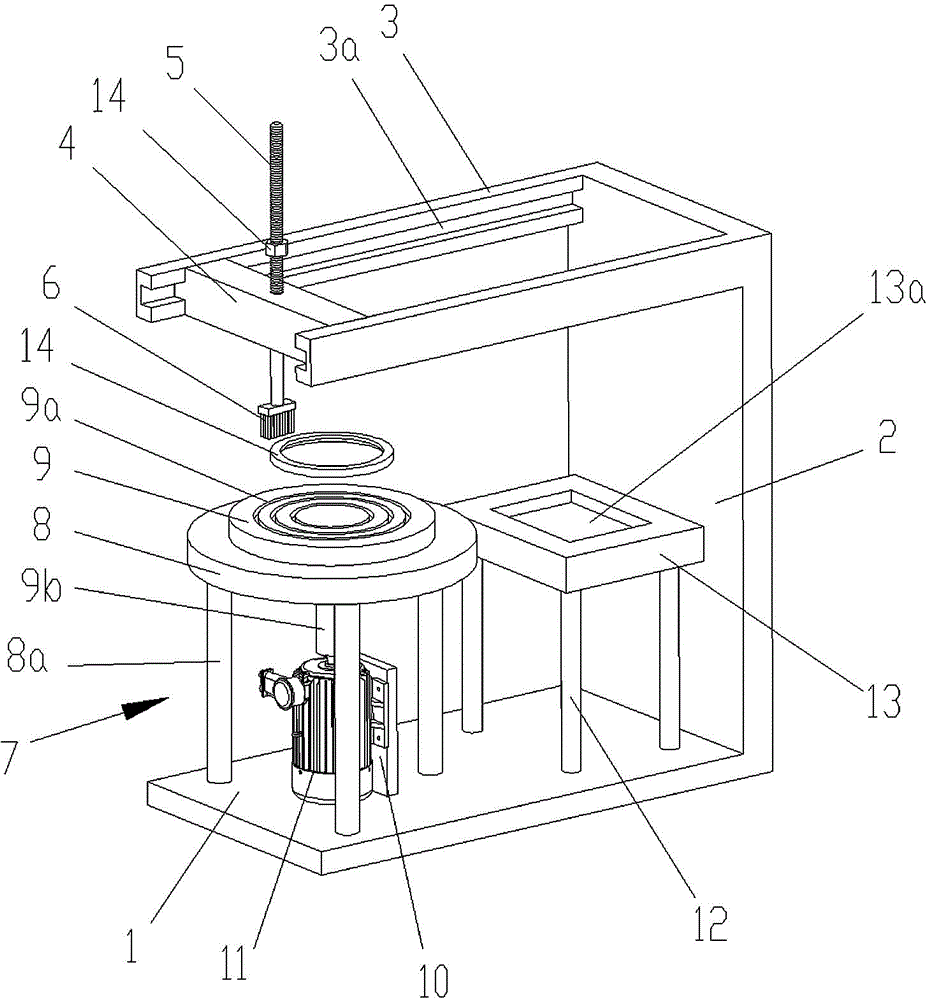

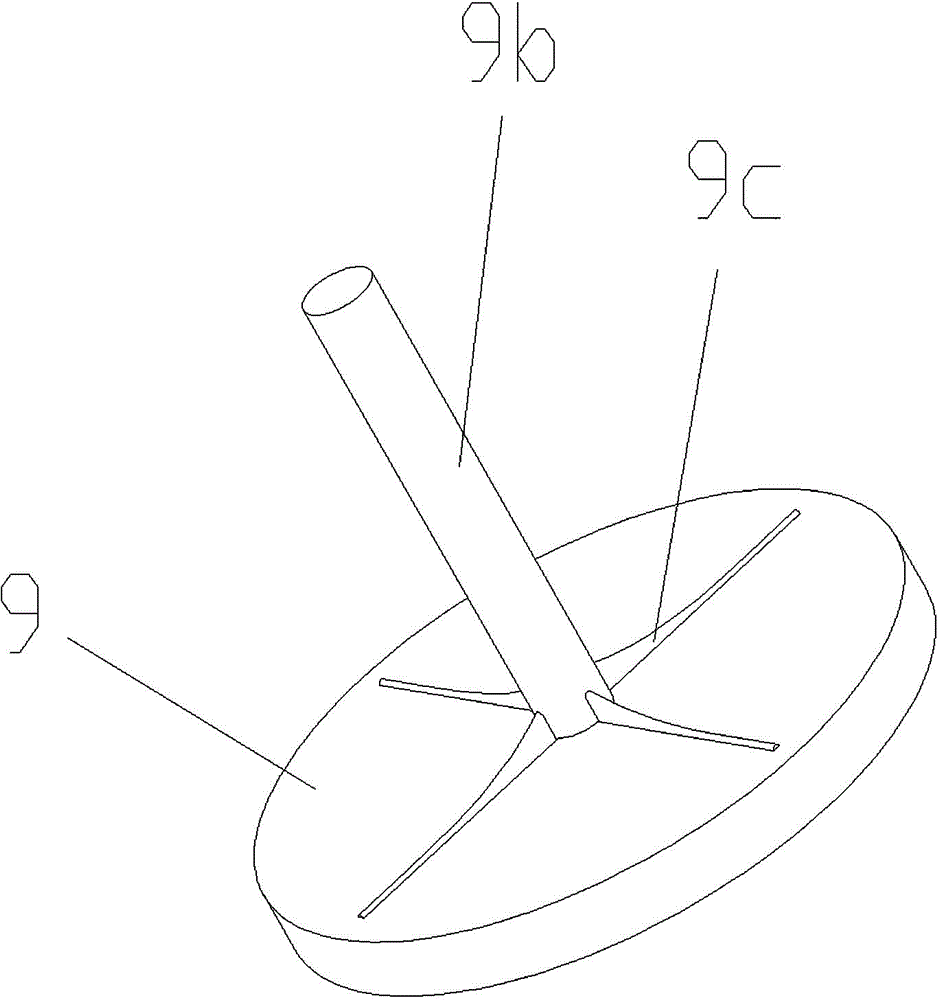

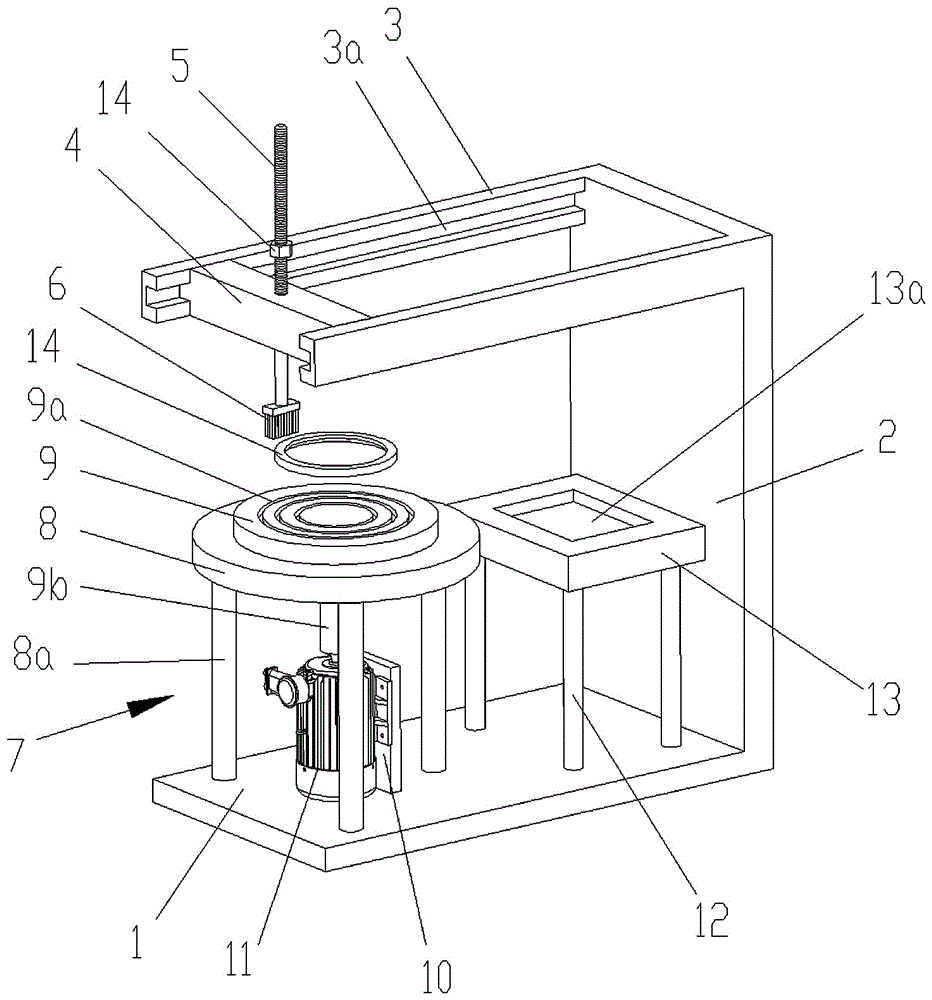

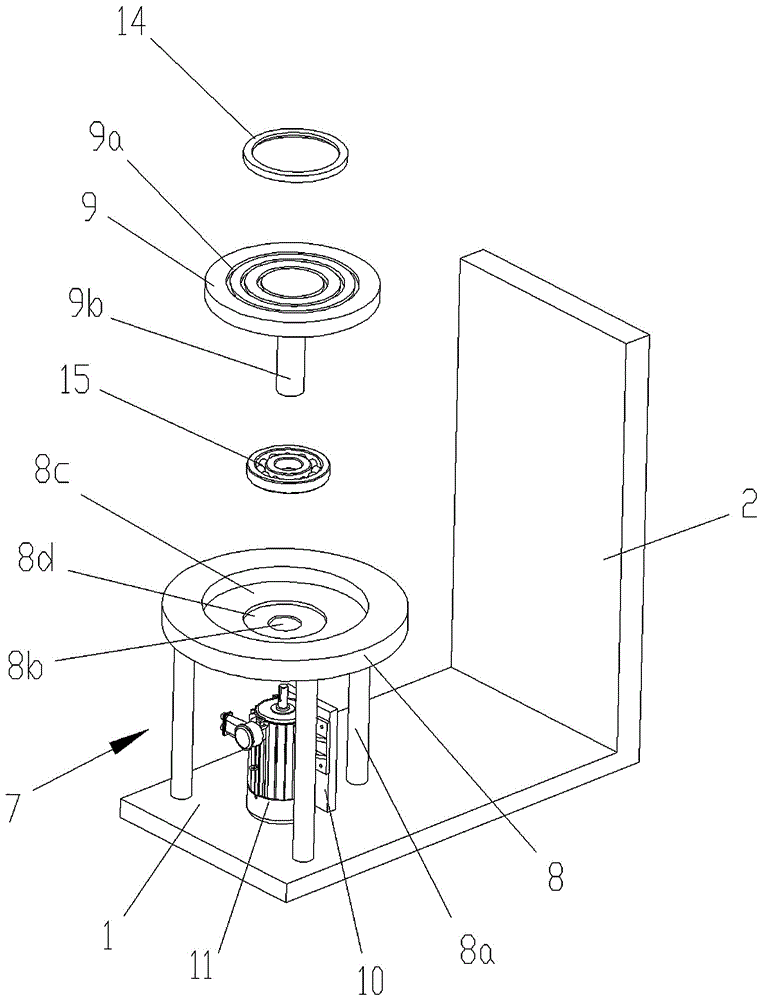

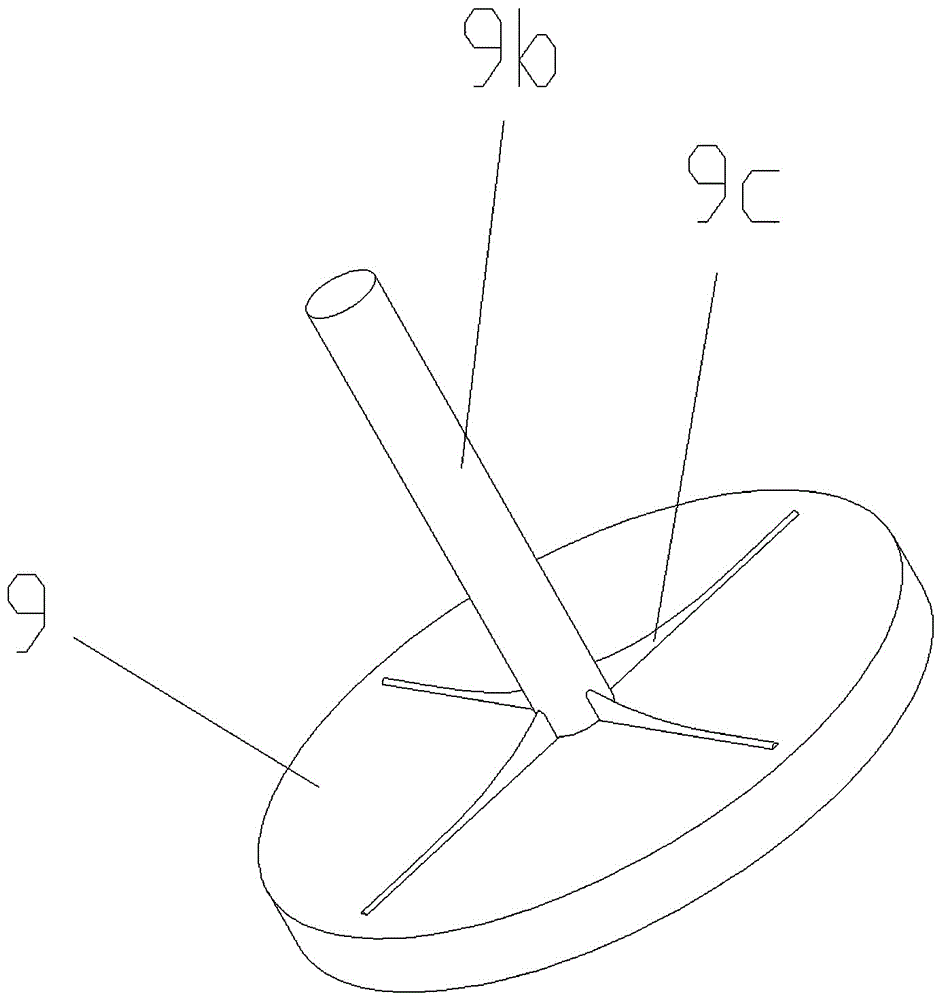

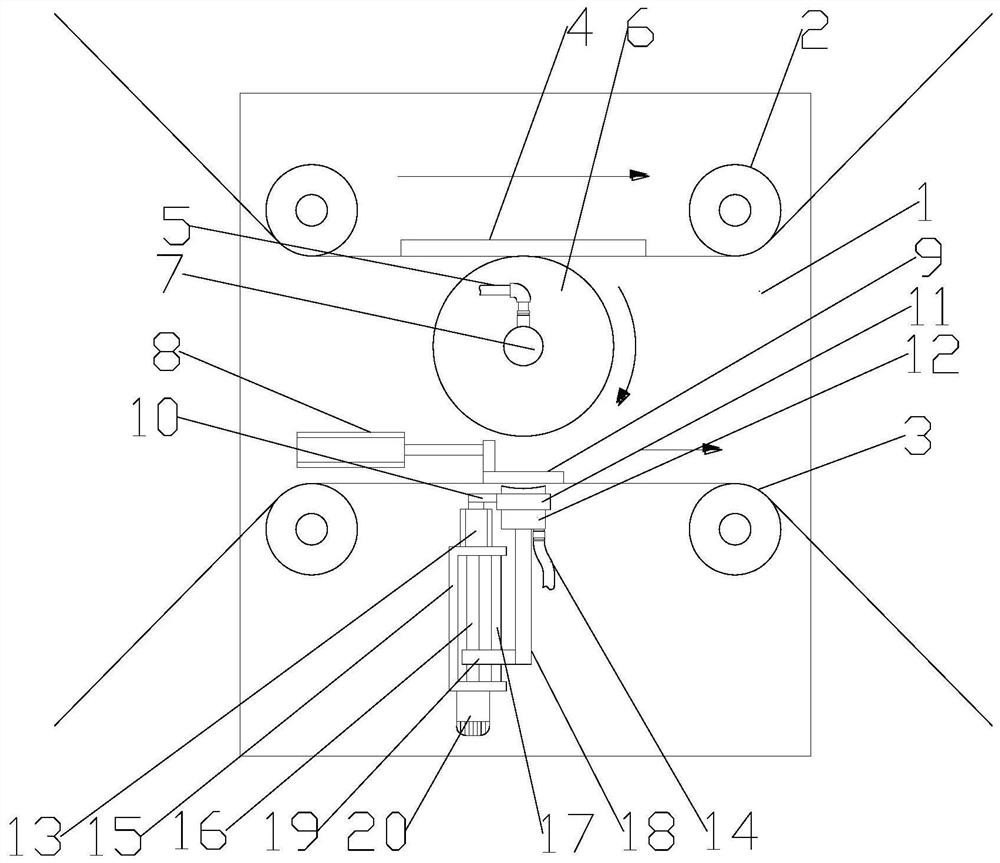

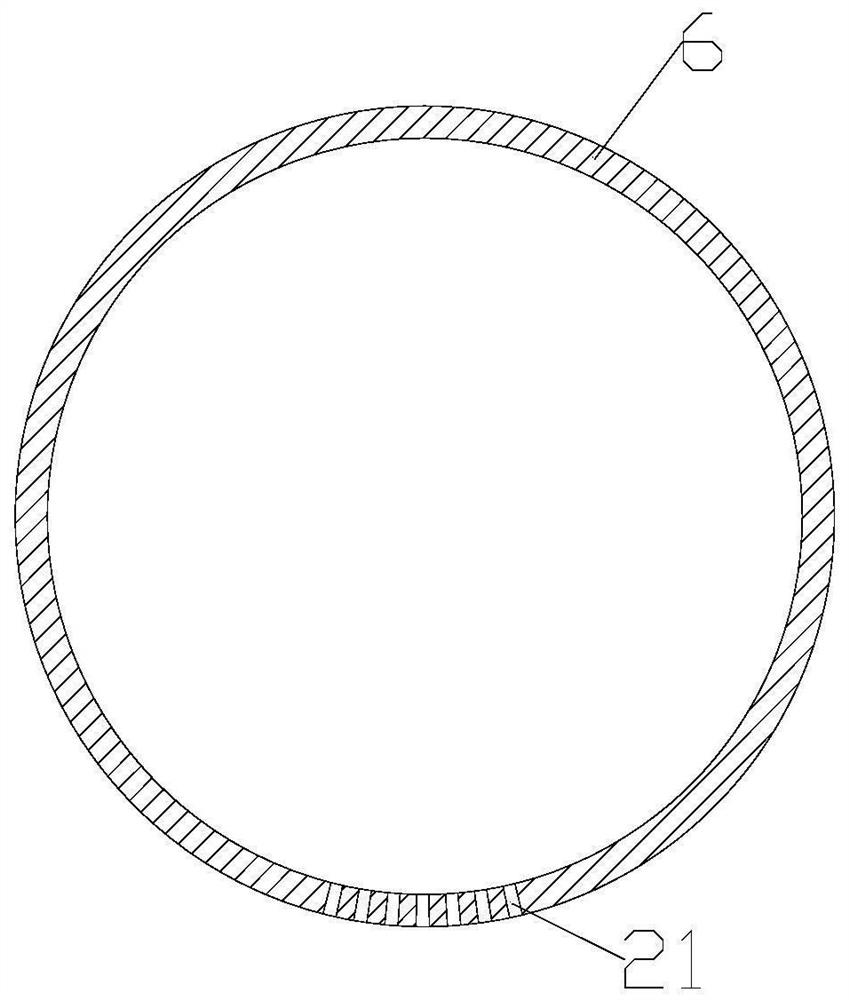

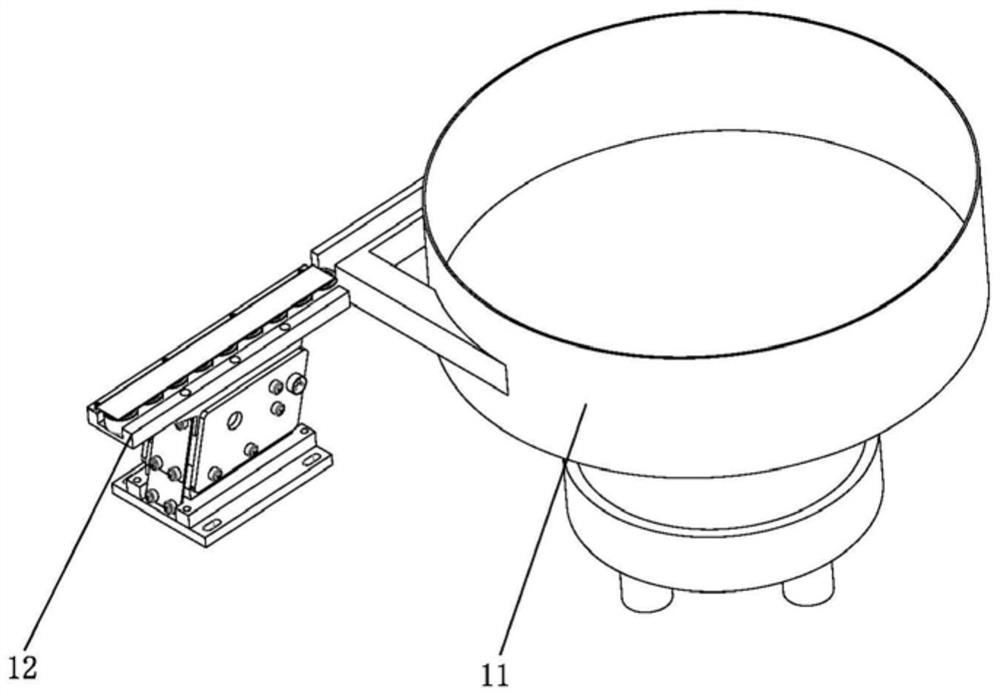

Gluing device for filter upper cover sealing ring

The invention relates to a gluing device for a filter upper cover sealing ring. The gluing device is characterized by comprising a bottom plate (1), wherein a bracket (7) is connected to the bottom plate; a rotating disc (9) is supported and connected to the bracket in running fit; a group of concentric annular grooves (9a) is formed in the rotating disc; a rotating shaft (9b) is arranged on the lower side of the rotating disc; the circle center of the annular grooves is arranged on the axis of the rotating shaft; a motor (11) is arranged below the bracket; an output shaft of the motor is connected with the rotating shaft; a guide seat (3) is fixedly connected to one side of the bottom plate by virtue of an upright plate (2); a sliding plate (4) is slidably connected to the guide seat; and a hairbrush (6) is adjustably connected to the sliding plate by virtue of a connecting piece (5). The gluing device disclosed by the invention has the advantages that the device is simple in structure and low in cost, the filter upper cover sealing ring is clamped in the corresponding annular groove in the rotating disc, the rotating disc is driven to rotate by virtue of the motor, the sealing ring is glued, the gluing speed is high and uniform, and the gluing effect is good.

Owner:来安县永阳知识产权运营有限公司

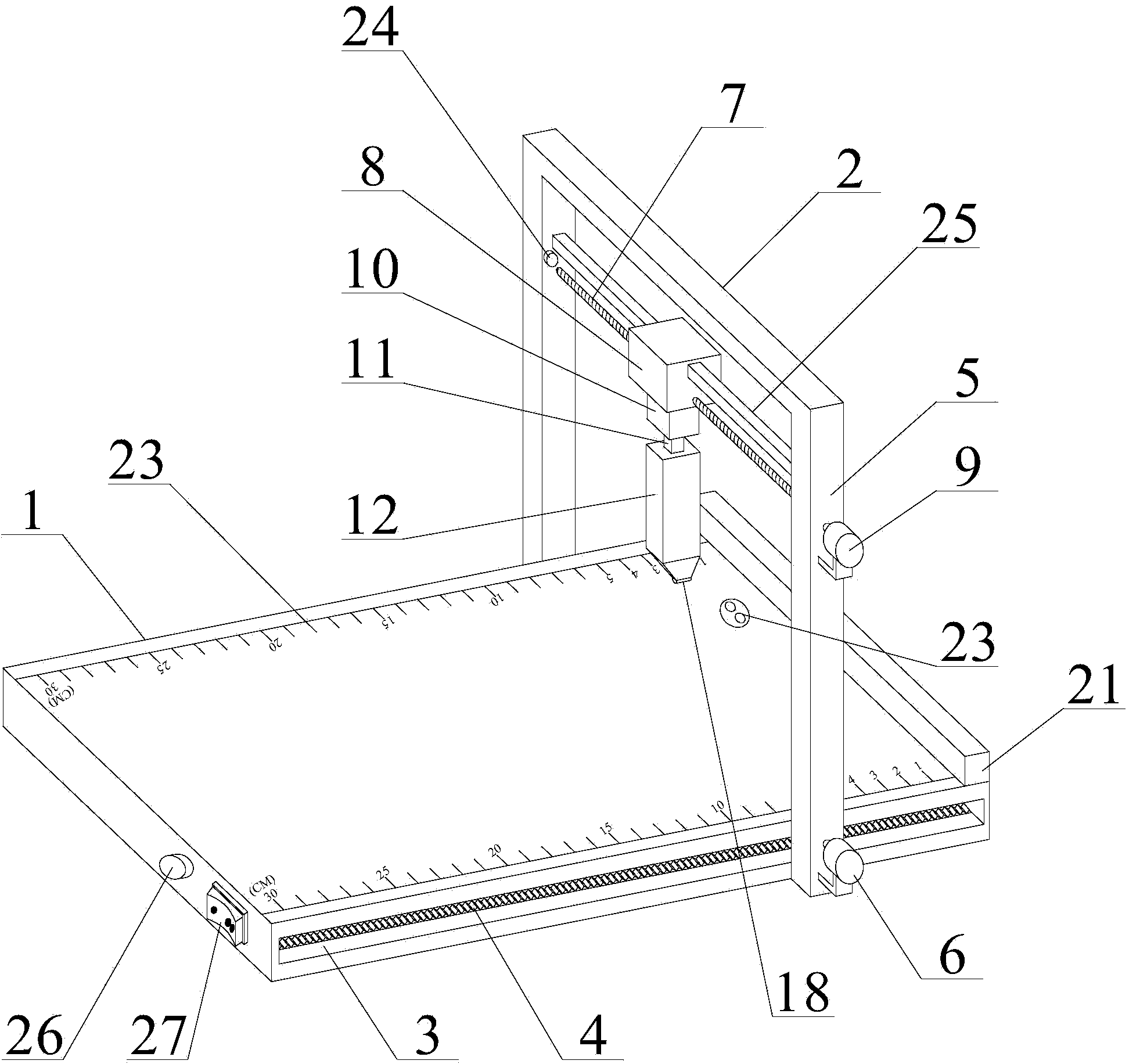

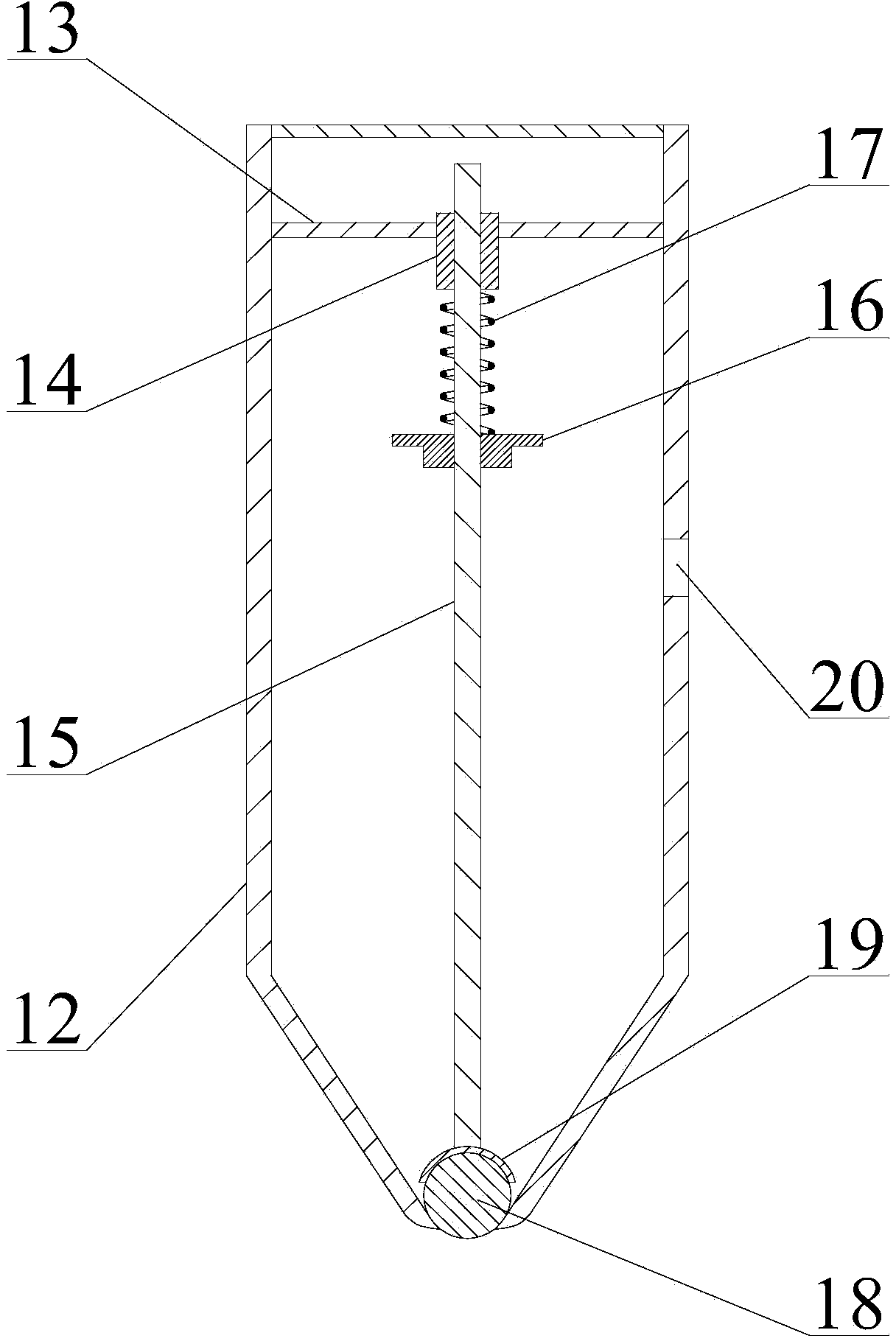

Small alternating current-direct current automatic glue spreader

InactiveCN103586163AAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machinePush pull

The invention discloses a small alternating current-direct current automatic glue spreader, and belongs to the field of office supplies. The glue spreader solves the problems that the manual glue spreading speed is low, the spreading is nonuniform, and adhesion is caused easily. Racks (4) are fixed in a cavity (3) of a bottom plate (1) of the glue spreader; gears meshed with the racks (4) are fixed on a cross rod of a gantry (2); a first motor (6) is fixed with one end of the cross rod; a screw rod (7) between two uprights (5) is sleeved with a slide block (8); a second motor (9) is fixed with one end of the screw rod (7); a push-pull electromagnet (10) is fixed below the slide block (8); a glue bottle (12) is fixed at the lower end of the push-pull electromagnet (10); the lower end of the glue bottle (12) is in an inverted trapezoid shape; a glue outlet is a strip-shaped port, and is closed by a cylindrical pressure head (18); and a pressure sheet (19) is fixed at the lower end of a threaded rod (15). The glue spreader has the advantages that the glue spreader is high in glue spreading speed, uniform in glue spreading, time-saving, labor-saving, and convenient to move and carry.

Owner:NORTHEAST GASOLINEEUM UNIV

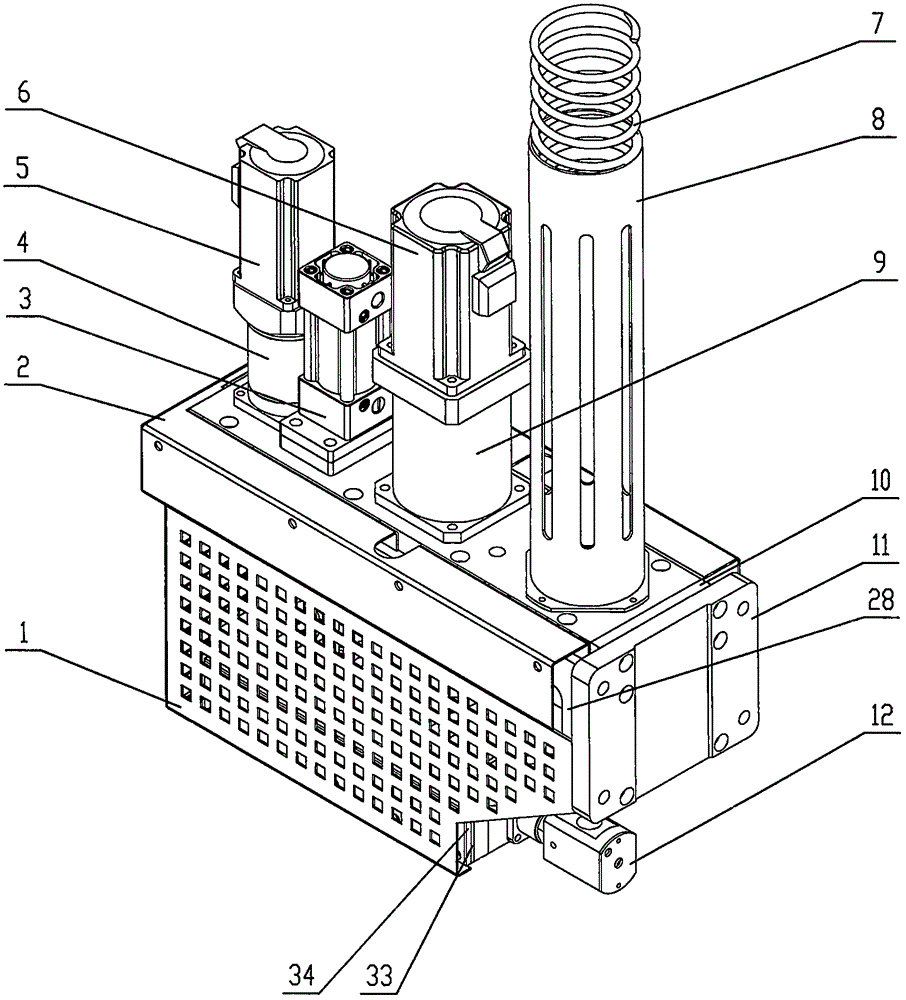

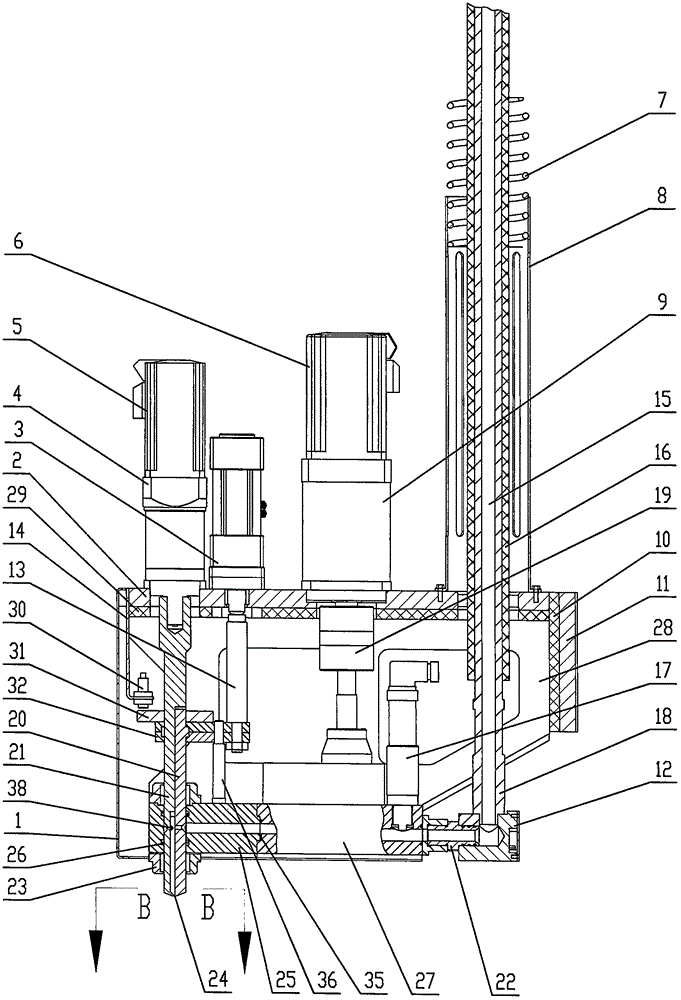

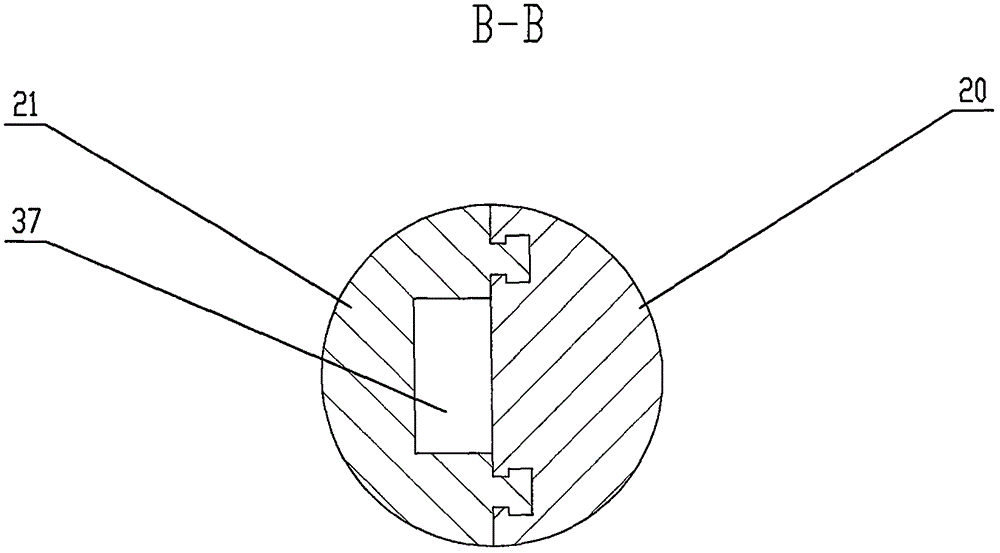

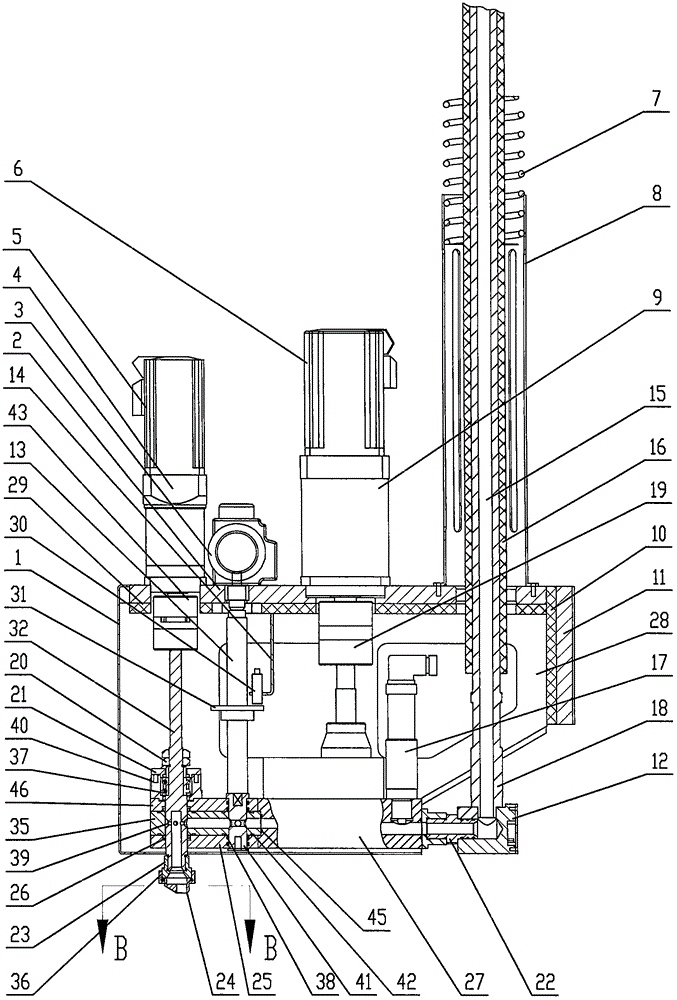

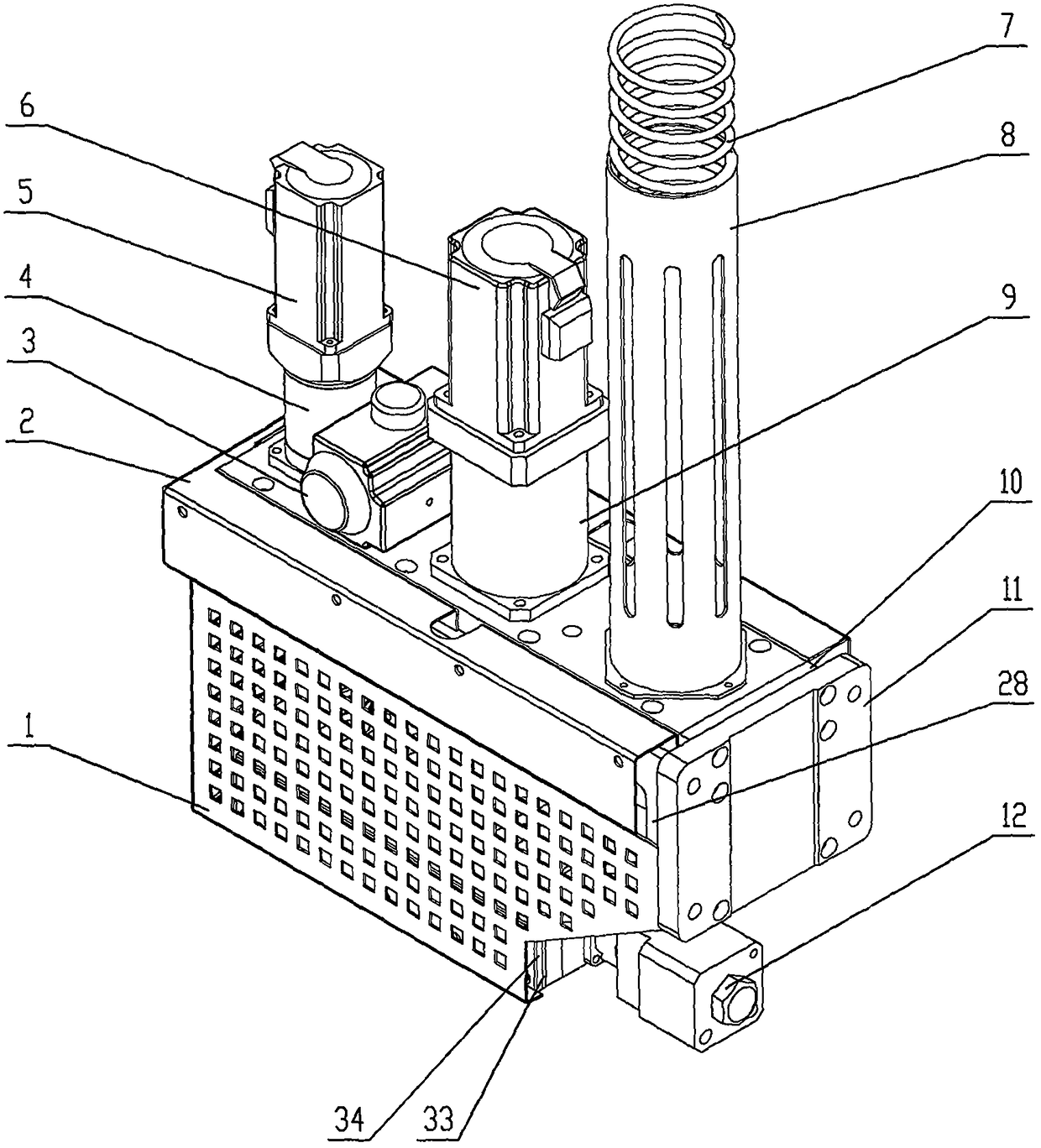

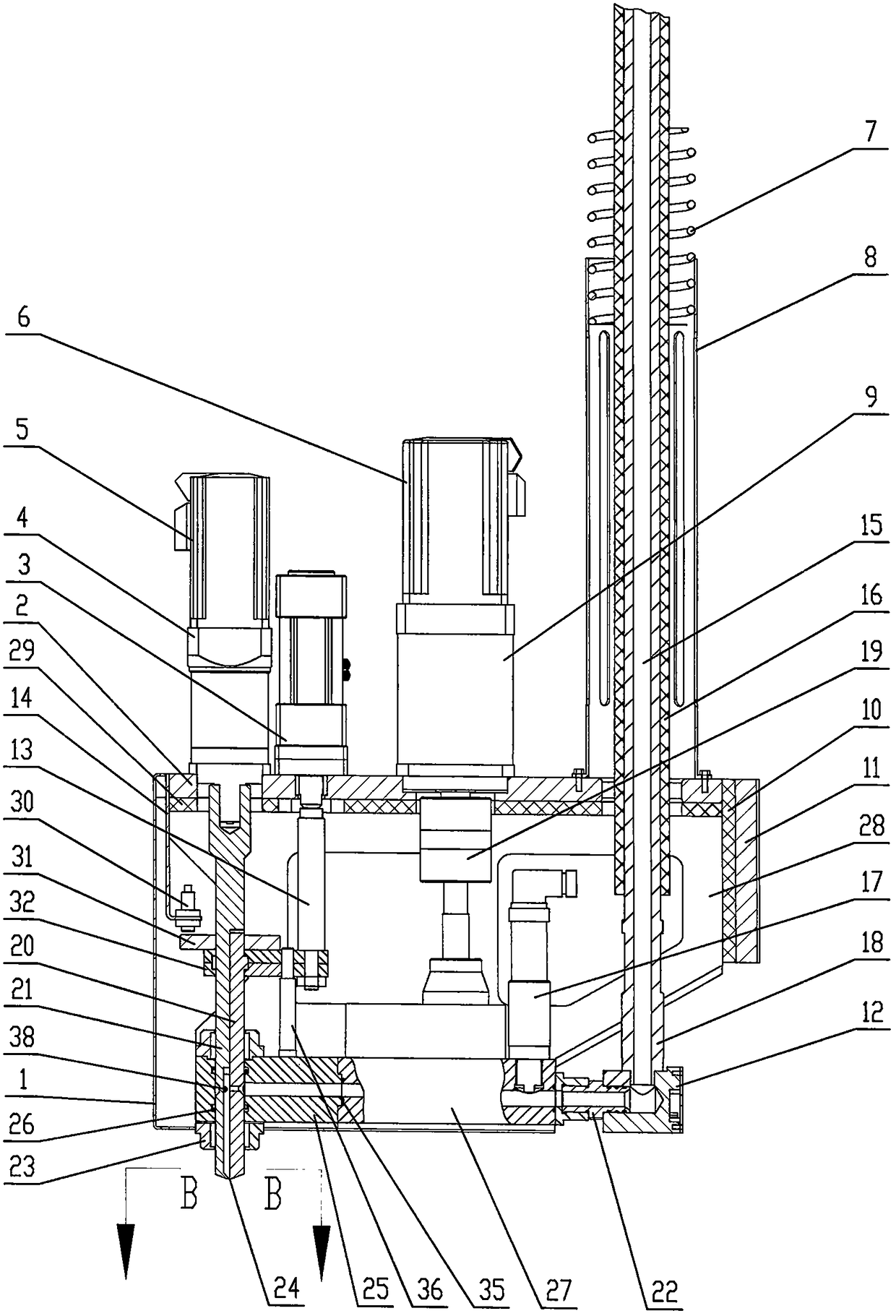

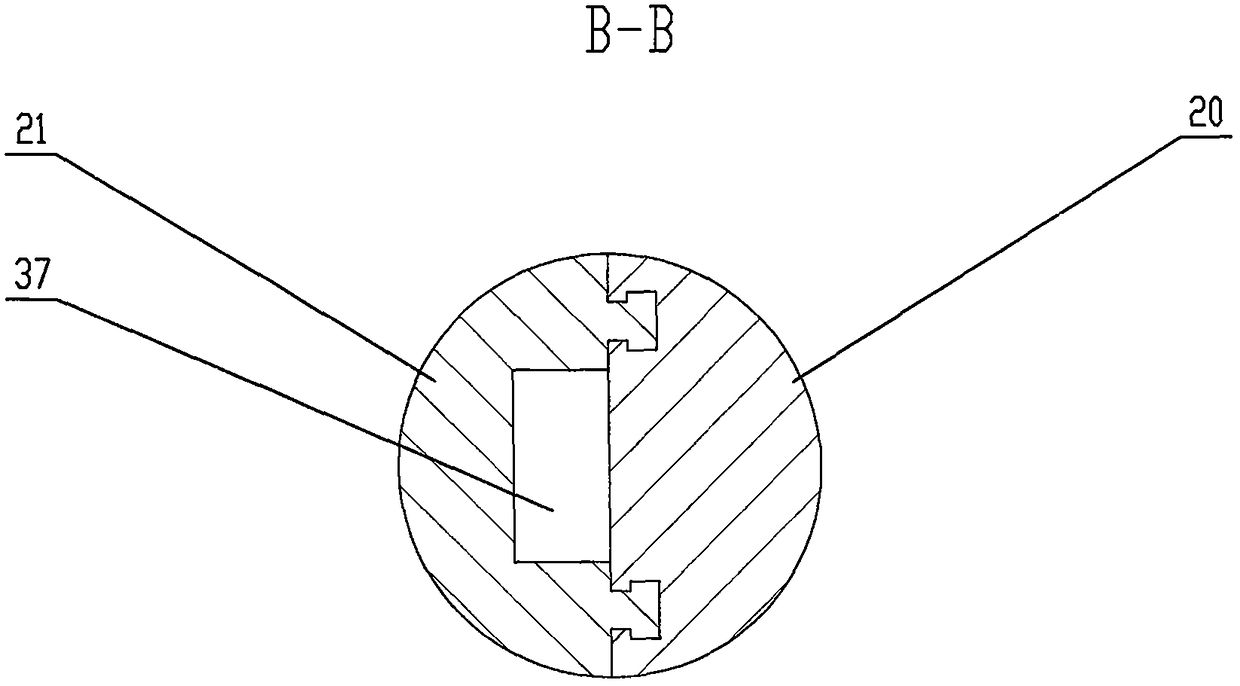

Gelatinizing head with rotary gelatinizing nozzles

ActiveCN105728263AAchieve rotationLow costLiquid surface applicatorsCoatingsAerospace engineeringNozzle

The invention discloses a gelatinizing head of gelatinizing equipment, and relates to a gelatinizing head with rotary gelatinizing nozzles for one-component glue. The gelatinizing head comprises a gelatinizing nozzle rotating mechanism, a gelatinizing nozzle opening and closing mechanism, a glue supply metering device and a glue supply conveying device which are fixed on a frame composed of a fixed plate, an insulation board B, an insulation board A, a fixed seat and a support plate; the gelatinizing nozzle rotating mechanism comprises a motor A, a speed reducer A, a gelatinizing nozzle A, a gelatinizing nozzle B, a transition body, a guide holder and a seal ring A, the motor A, the speed reducer A and the gelatinizing nozzle B are fixedly connected in sequence, the gelatinizing nozzle A and the gelatinizing nozzle B are combined through a trapezoidal slideway or a dovetail slideway, the gelatinizing nozzle A can move along the gelatinizing nozzle B in the axial direction, a movable plate is fixedly connected with a boss on the upper portion of the gelatinizing nozzle A, and the motor A and the speed reducer A rotatably drive the gelatinizing nozzles to rotate intermittently or continuously. Gelatinizing nozzle rotating is achieved, complex gelatinizing equipment is not needed, three-axis gantry gelatinizing equipment can also complete gelatinizing of workpieces, and the application range of the gelatinizing equipment is widened.

Owner:DALIAN HUAGONG INNOVATION TECH

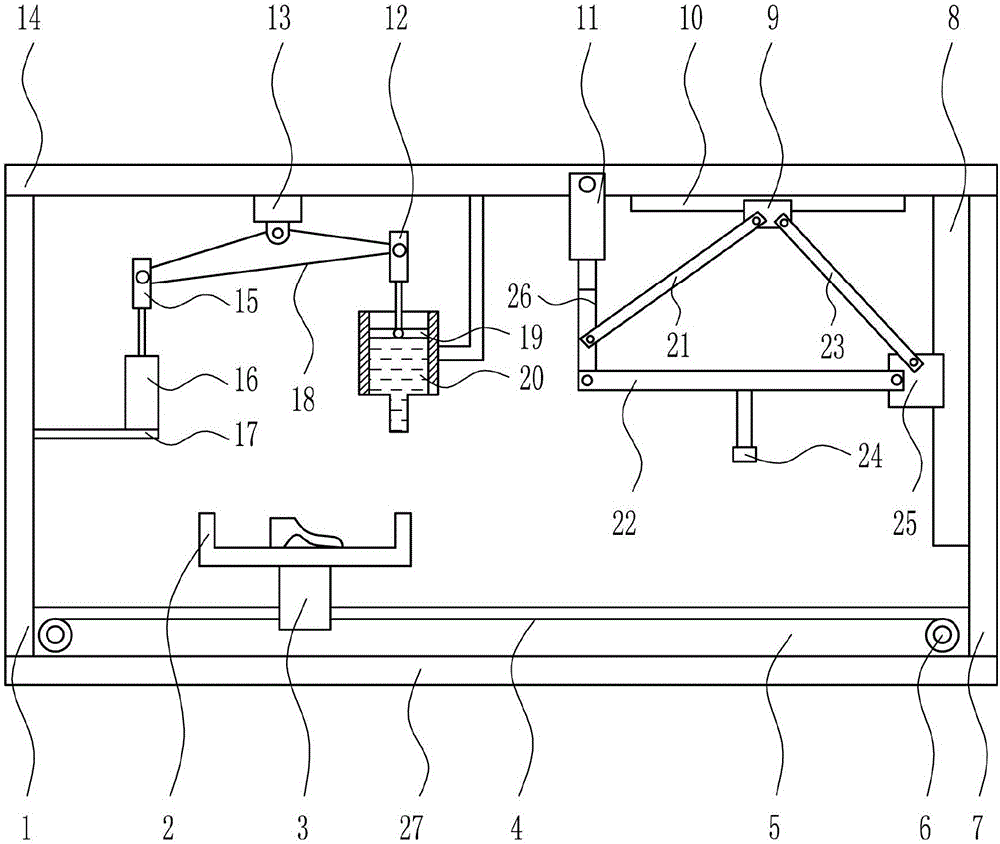

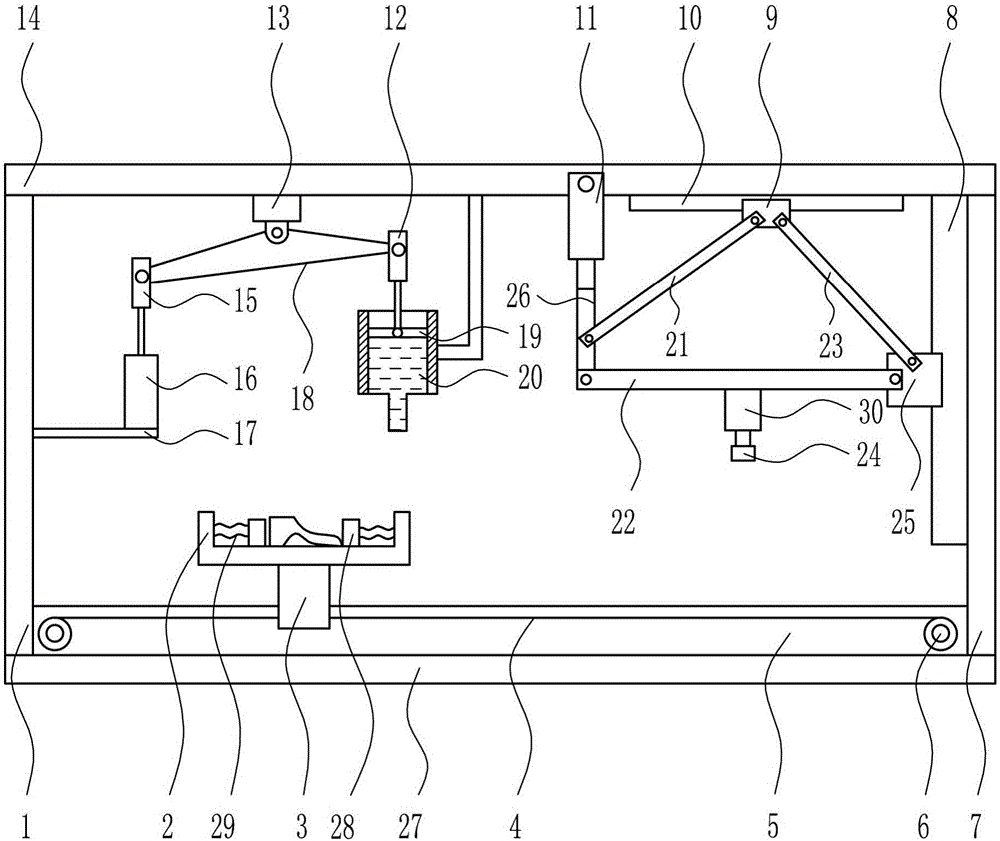

Shoemaking gumming device

InactiveCN106108264APrevent sliding left and rightFully gluedShoe gluingMechanical engineeringPiston

The invention relates to a gumming device, in particular to a shoemaking gumming device, and aims to provide the shoemaking gumming device being accurate in gumming position, comprehensive in gumming, and visual enough for observation. The shoemaking gumming device comprises a left bracket, an accommodating rack, a first slider, a stay wire, a first slide rail, an electric reel, a right bracket, a second slide rail, a third slider, a third slide rail, a first electric push rod, a fifth connecting rod, a supporting seat, a top plate, a fourth connecting rod, a cylinder, a fixing plate, a swing rod, a piston, a cylinder body, a third connecting rod, a second connecting rod, a first connecting rod, a pressing block, a second slider, a lifting rod and a bottom plate. The shoemaking gumming device has the effects of being accurate in gumming position, comprehensive in gumming, and visual enough for observation; being fast in gumming speed, reasonable in design, and convenient to use, the shoemaking gumming device is highly practical.

Owner:ZHEJIANG KAJIALI SHOES CO LTD

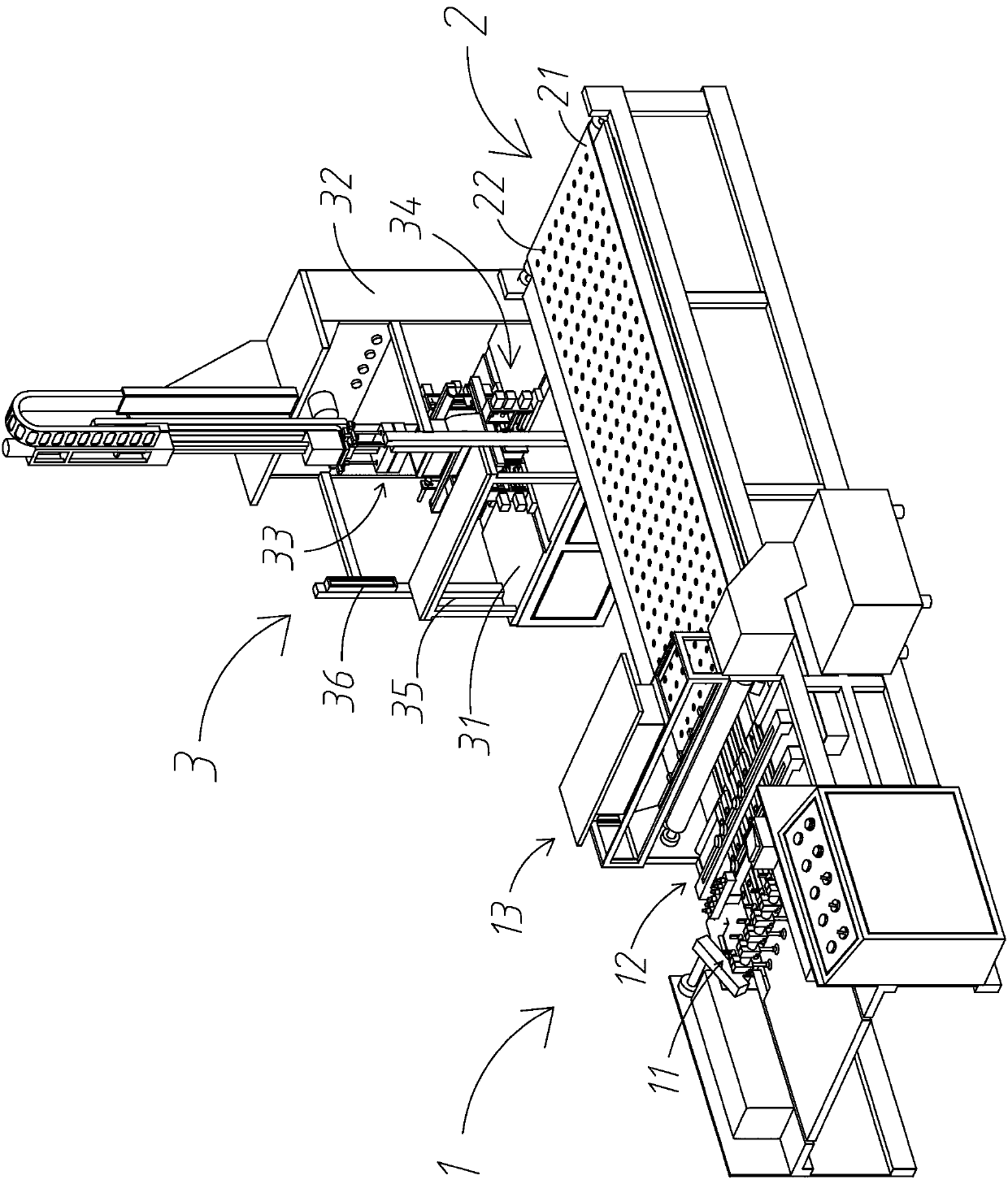

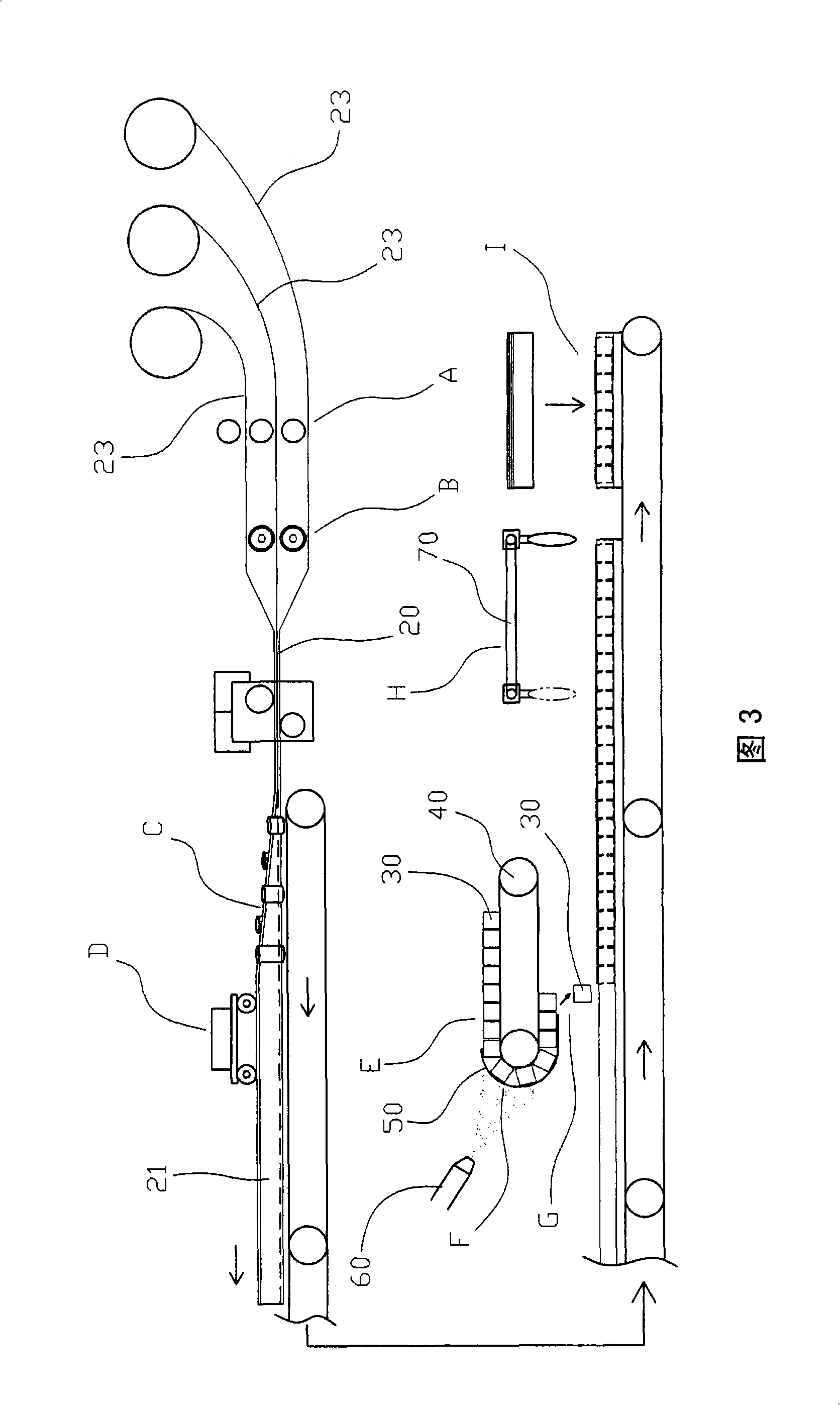

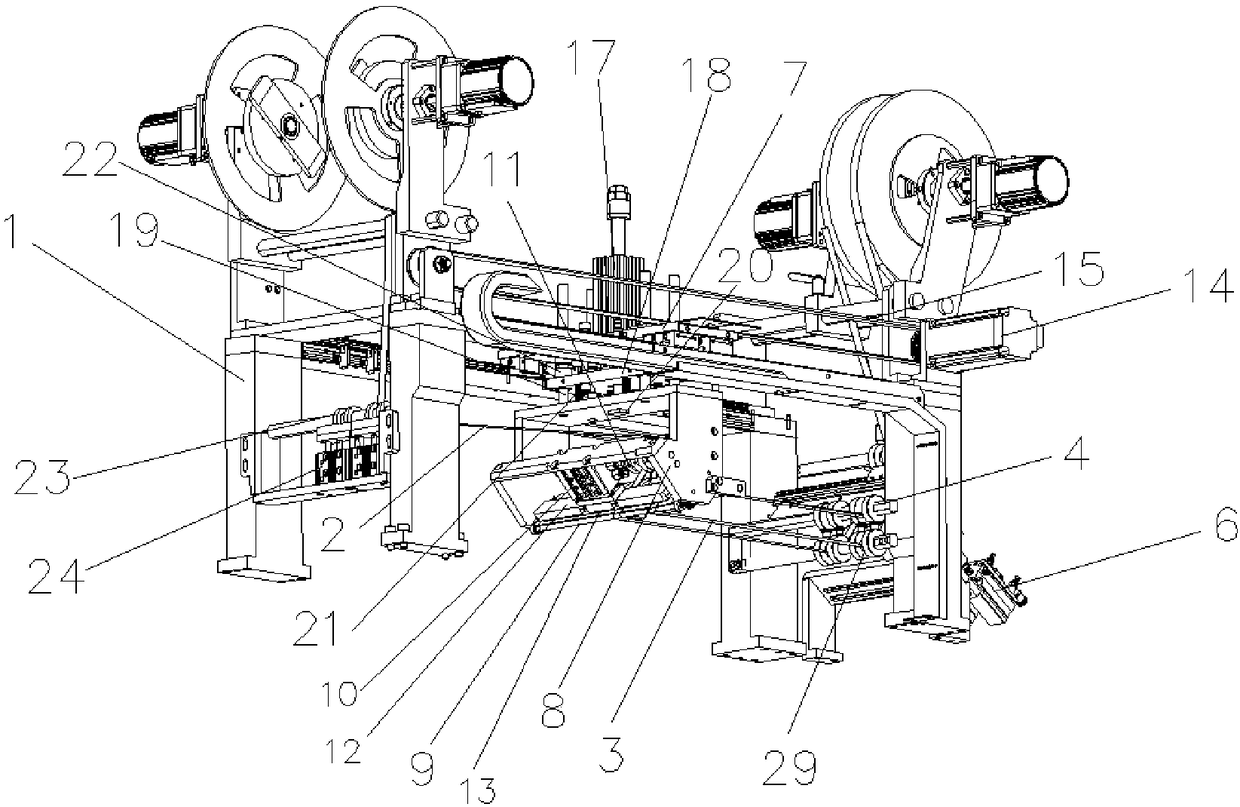

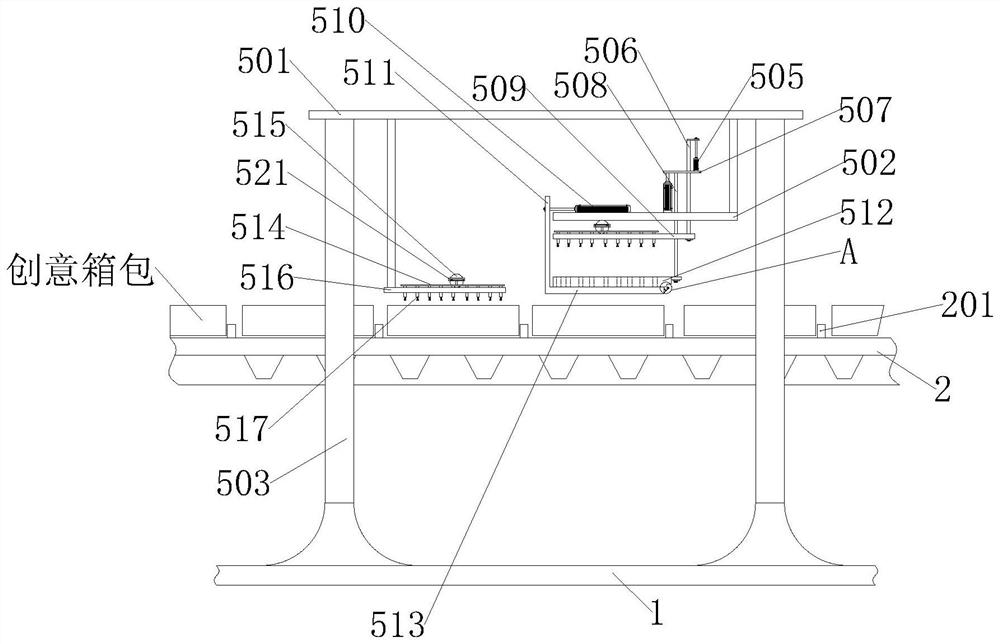

Gluing and material packaging production line for packaging box

PendingCN107804029AReduce labor intensityFast glue applicationBox making operationsPaper-makingCardboardEngineering

The invention provides a gluing and material packaging production line for a packaging box. The production line comprises a gluing mechanism, a transition conveying mechanism and a material packagingmechanism; the gluing mechanism comprises a feeding device, a conveying device for conveying paper and a gluing device for gluing the paper which are sequentially arranged according to a processing procedure; the material packaging mechanism comprises a workbench, a portal frame arranged on the workbench, an upward edge-pressing device arranged on the portal frame and a downward edge-pressing device arranged on the workbench and corresponds to the upward edge-pressing device; the downward edge-pressing device comprises four mounting seats which are arranged around the periphery of the packaging box, and forward and backward edge-pressing devices, leftward and rightward edge-pressing devices, packaging box opening horizontal edge folding devices, pressing devices for four side edges and lifting devices used for lifting the packaging box are sequentially arranged on the mounting seats from top to bottom. According to the production line, manual gluing is not needed, the gluing speed is high, gluing is uniform, the material packaging efficiency is high, the labor intensity of workers can be reduced, and the material packaging quality is high.

Owner:东莞市瑞丰源工艺包装制品有限公司

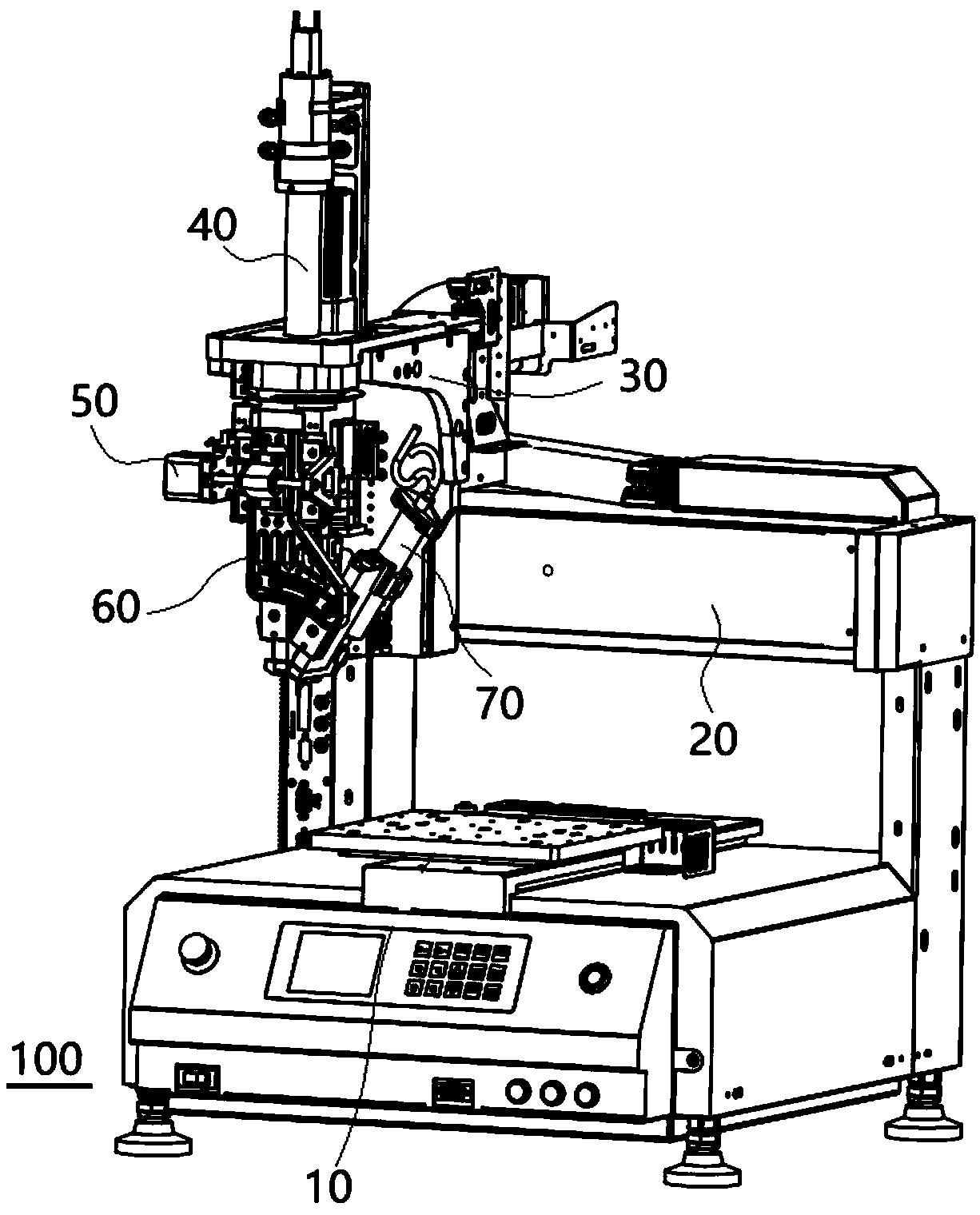

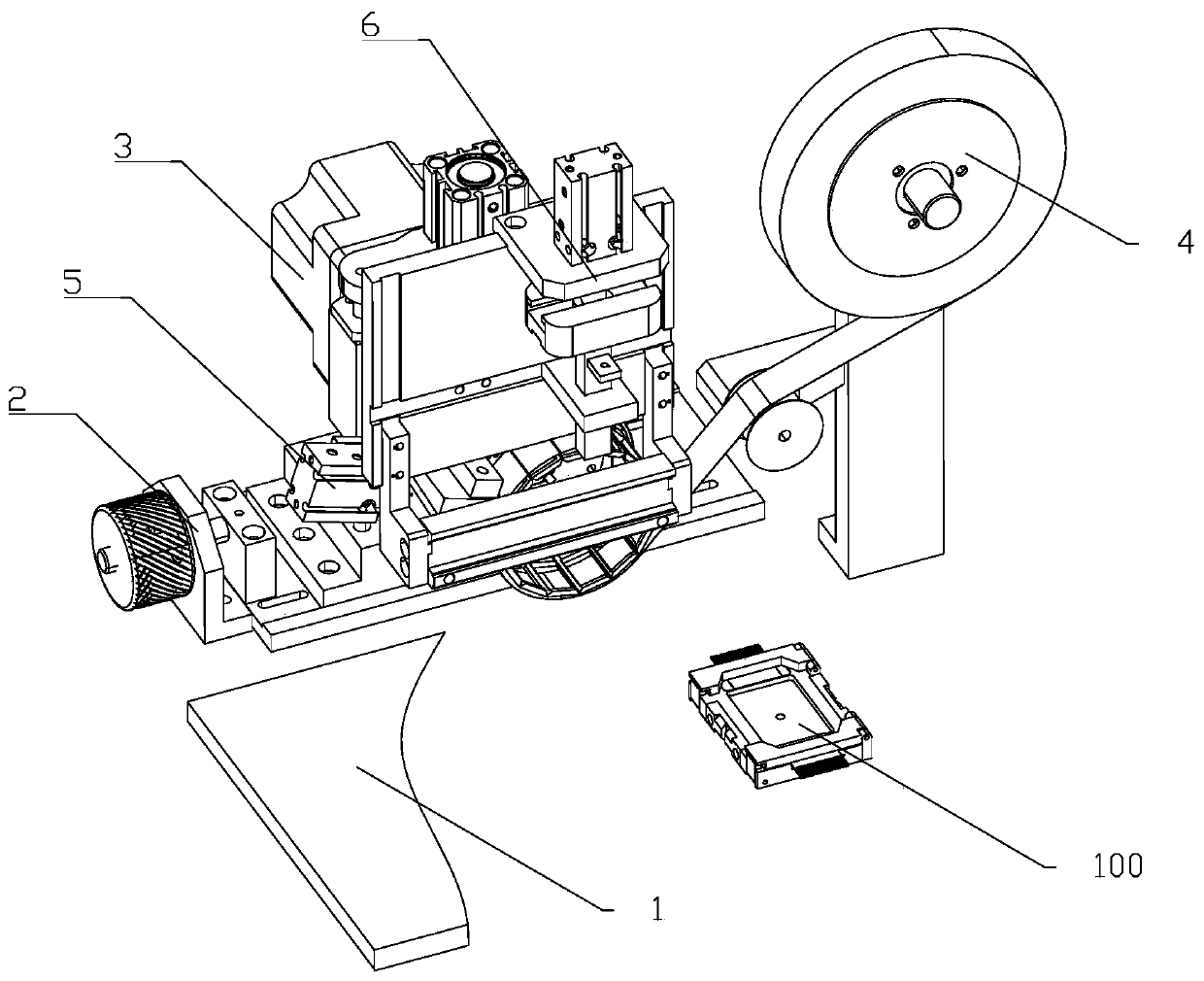

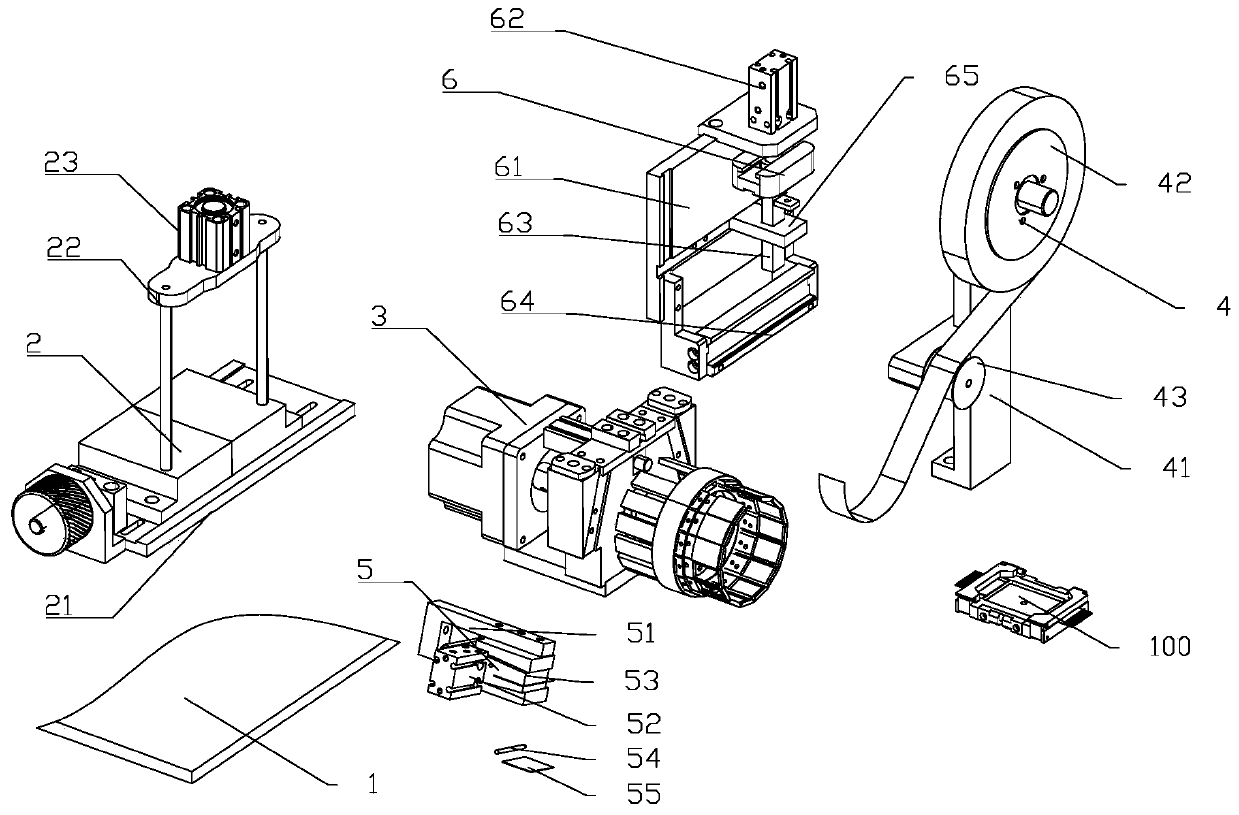

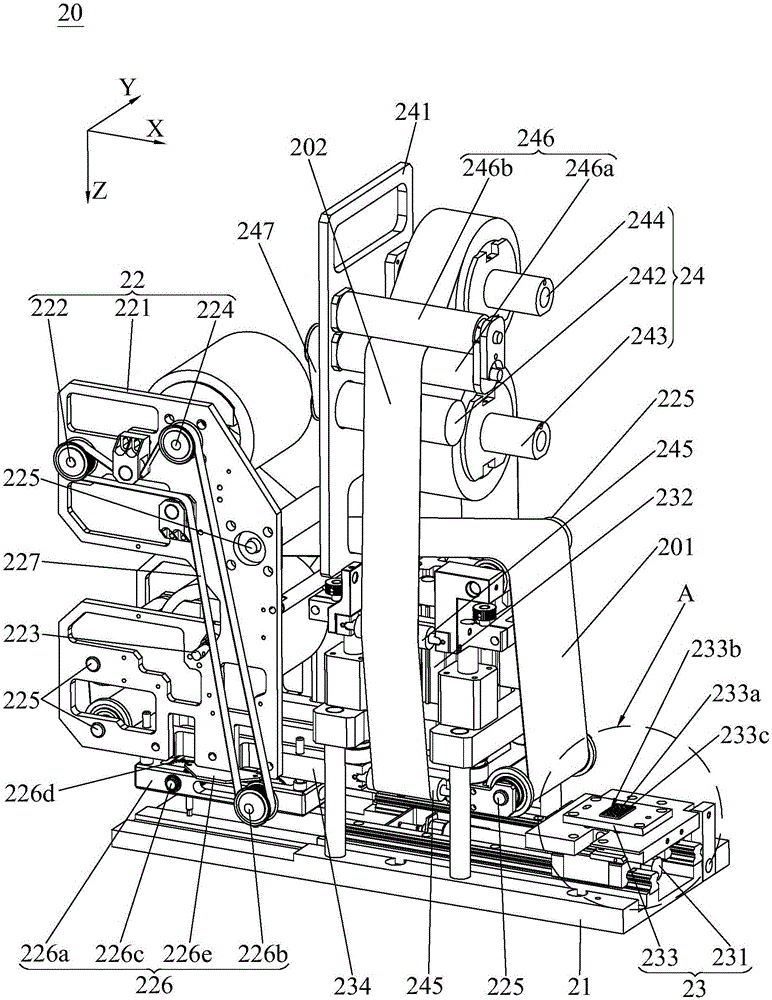

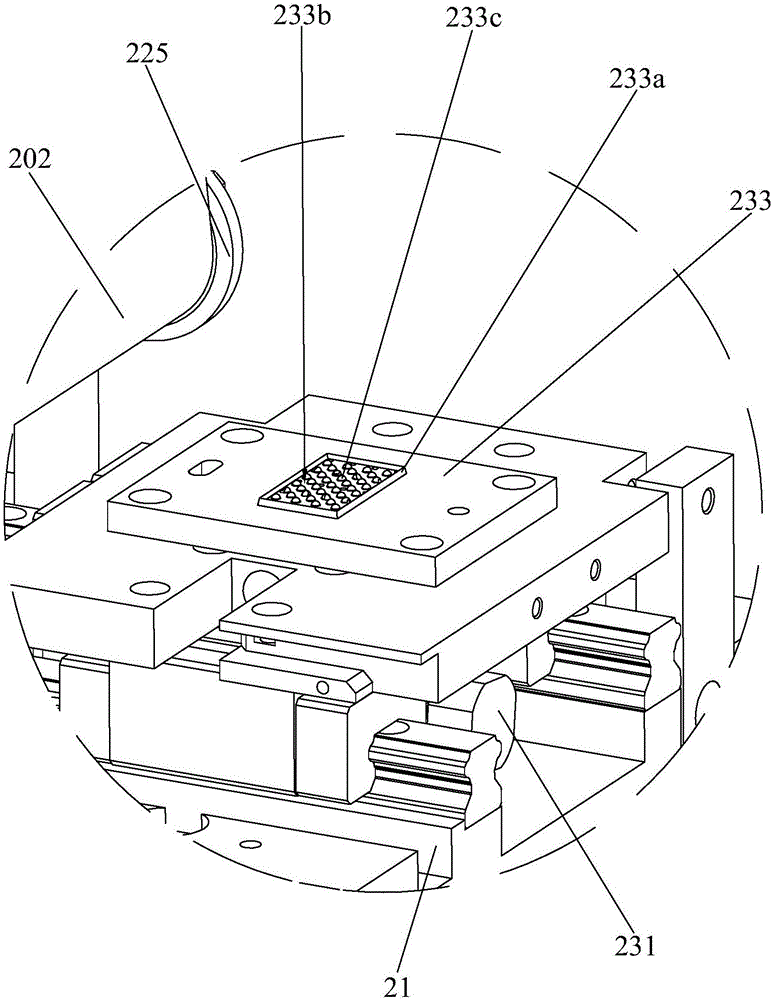

Coater and coating method thereof

ActiveCN109107833AFast glue applicationSimple and fast operationLiquid surface applicatorsCoatingsAdhesiveMechanical engineering

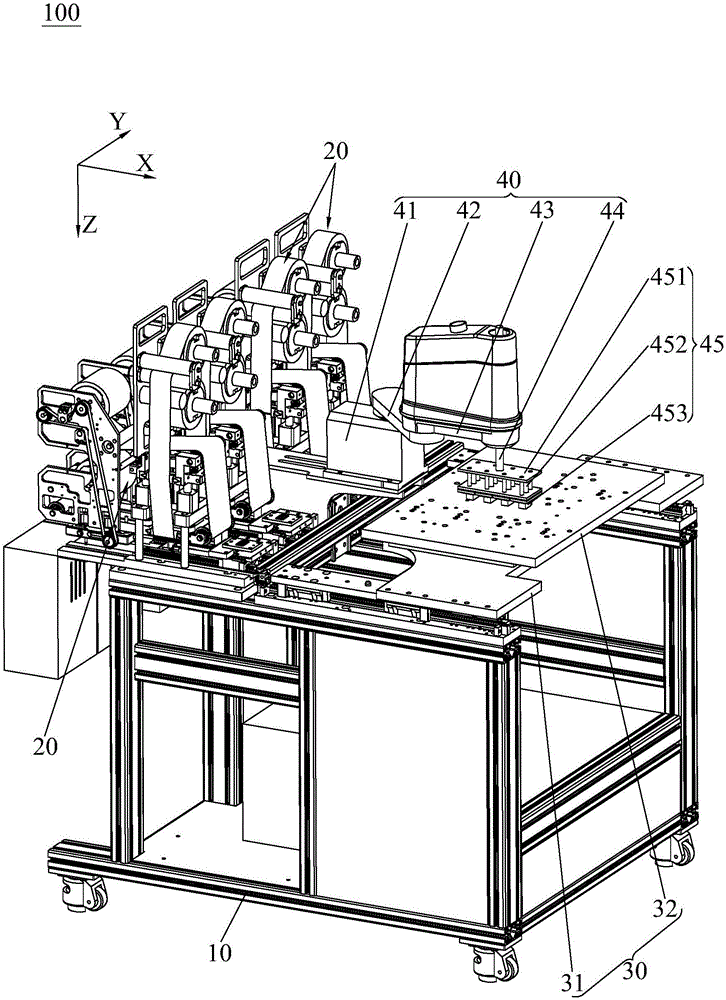

The invention discloses a coater and a coating method thereof, the coater can apply an adhesive on the inside or outside of an arc-shaped workpiece. The coater comprises an operating platform, a supporting platform, a three-axis moving platform, a rotational adjustment assembly, a radius adjustment assembly, an inclination angle adjustment assembly, and a coating assembly; the operating platform can be used for the placement of the arc-shaped workpiece; the three-axis moving platform is movably arranged on the supporting platform along the X-axis, Y-axis and Z-axis directions, the X axis and the Y axis respectively extend along horizontal direction and are perpendicular to each other, and the Z axis extends along a vertical direction; the rotational adjustment assembly is arranged on the three-axis moving platform and can pivot around the Z axis; the radius adjustment assembly can pivot around the axes extending along the horizontal direction in order to adjust the horizontal distanceof at least part of the radius adjustment assembly relative to the Z axis; the inclination angle adjustment assembly is connected to the radius adjustment assembly, and the angle of at least part of the inclination angle adjustment assembly relative to the vertical direction can be adjusted; and the coating assembly is connected to the inclination angle adjustment assembly. The coater according tothe embodiment of the invention is convenient to operate, and can quickly apply the adhesive on the inside and outside of a circular arc.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Novel medical hot melt resin carrier gel matrix and its preparation method and application

ActiveCN101288772AStimulating smallNo allergiesOil/fats/waxes non-active ingredientsSheet deliveryDrug releaseSkin irritant

The invention provides a novel medicinal thermal melting resin vector adhesive matrix which is made from a thermoplastic elastomer, medical resin, softerner, skin transdermal enhancer and excipient which are mixed in a way of melting according to a certain percentage. The novel medicinal thermal melting resin adhesive prepared by the invention is a substitute for traditional black plaster, adhesive plasters, cataplasm and attached agent matrix excipient. The novel medicinal thermal melting resin vector adhesive matrix of the invention achieves the requirement of new medicinal excipient declared by SFDA in aspects of preparation process, production equipment, drug standard, pilot-scale study, drug stability, experimental storage, etc. Emplastrum as the matrix which is produced by the novel medicinal thermal melting resin vector adhesive of the invention has the characteristics of large drug loading, fast drug releasing rate, high stability, small skin irritation, short production cycle, high efficiency, safety, environmental protection, etc.

Owner:GANSU CHEEZHENG TIBETAN MEDICINE CO LTD

Ointment for treating coronary disease and its production process

InactiveCN1813912AImprove ischemic stateGood curative effectOrganic active ingredientsAerosol deliveryCoronary artery diseaseMyrrh

The present invention discloses a Guanxin adhesive plaster and its production process. It is made up by using the Chinese medicinal materials of salvia root, ligusticum root, Chinese angelica root, carthamus flower, myrrh, clove, frankincense, dalbergia wood, camphor, xylene musk, menthanol, diphenhydramine hydrochloride, borneol and medical carrier rubber plaster matrix through a certain preparation process. Besides, said invention also provides the concrete steps of said preparation process.

Owner:李秀花

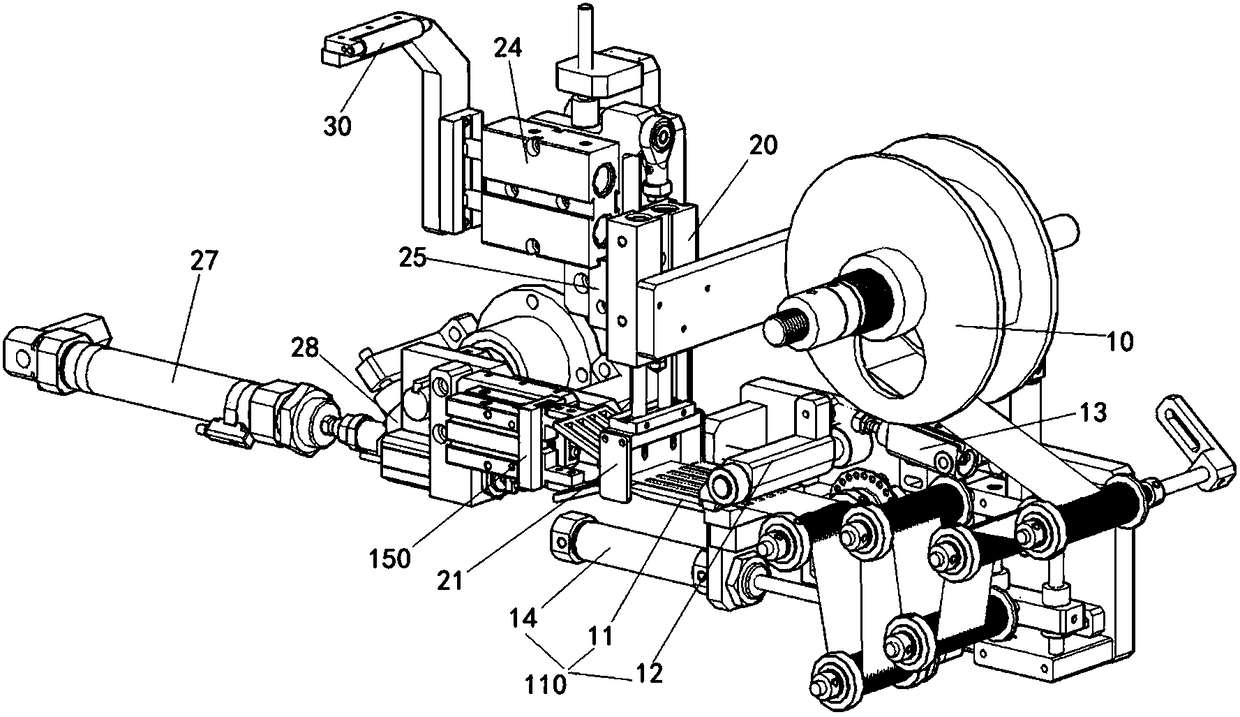

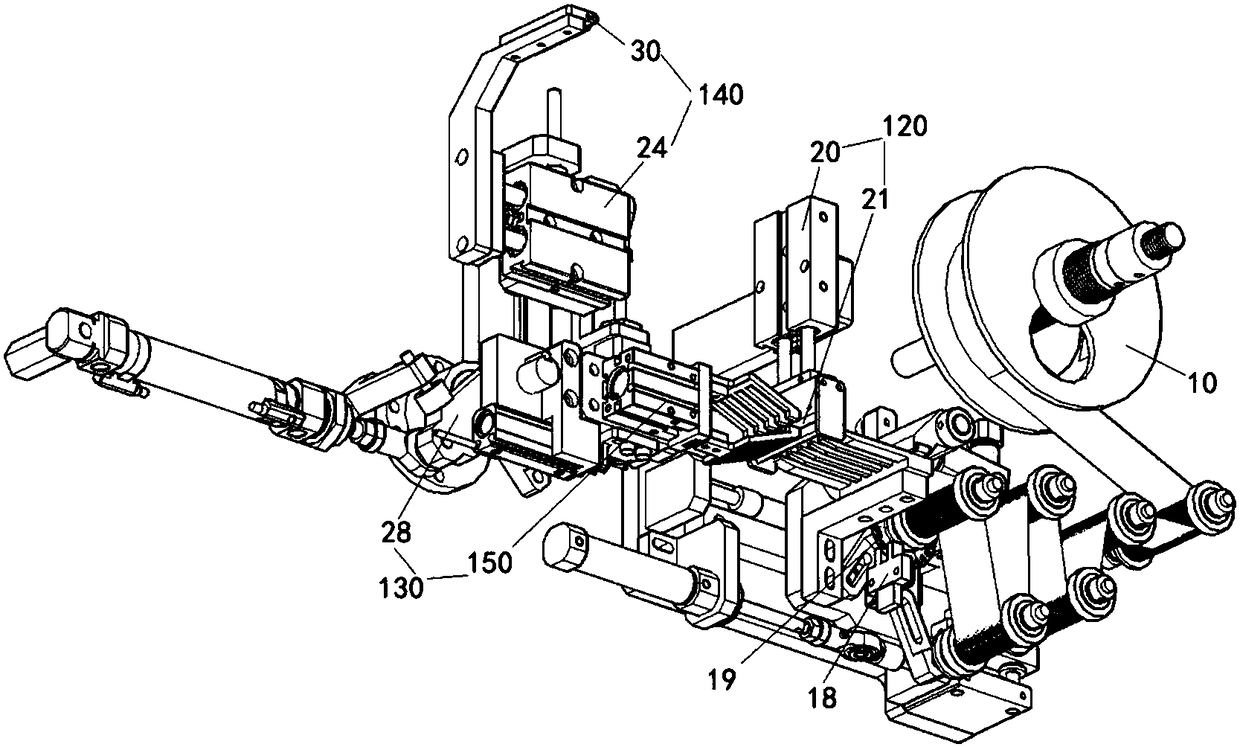

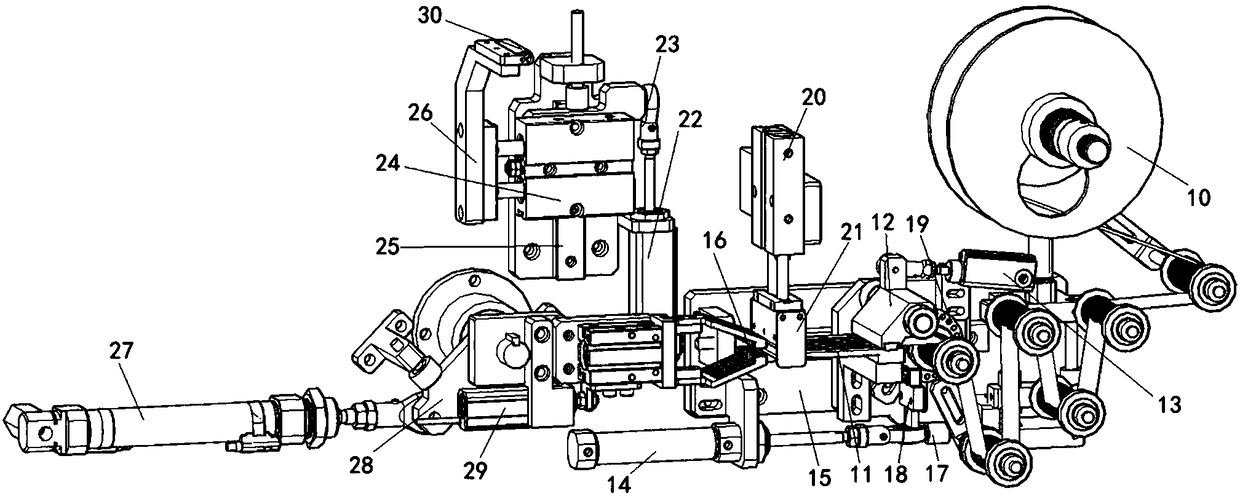

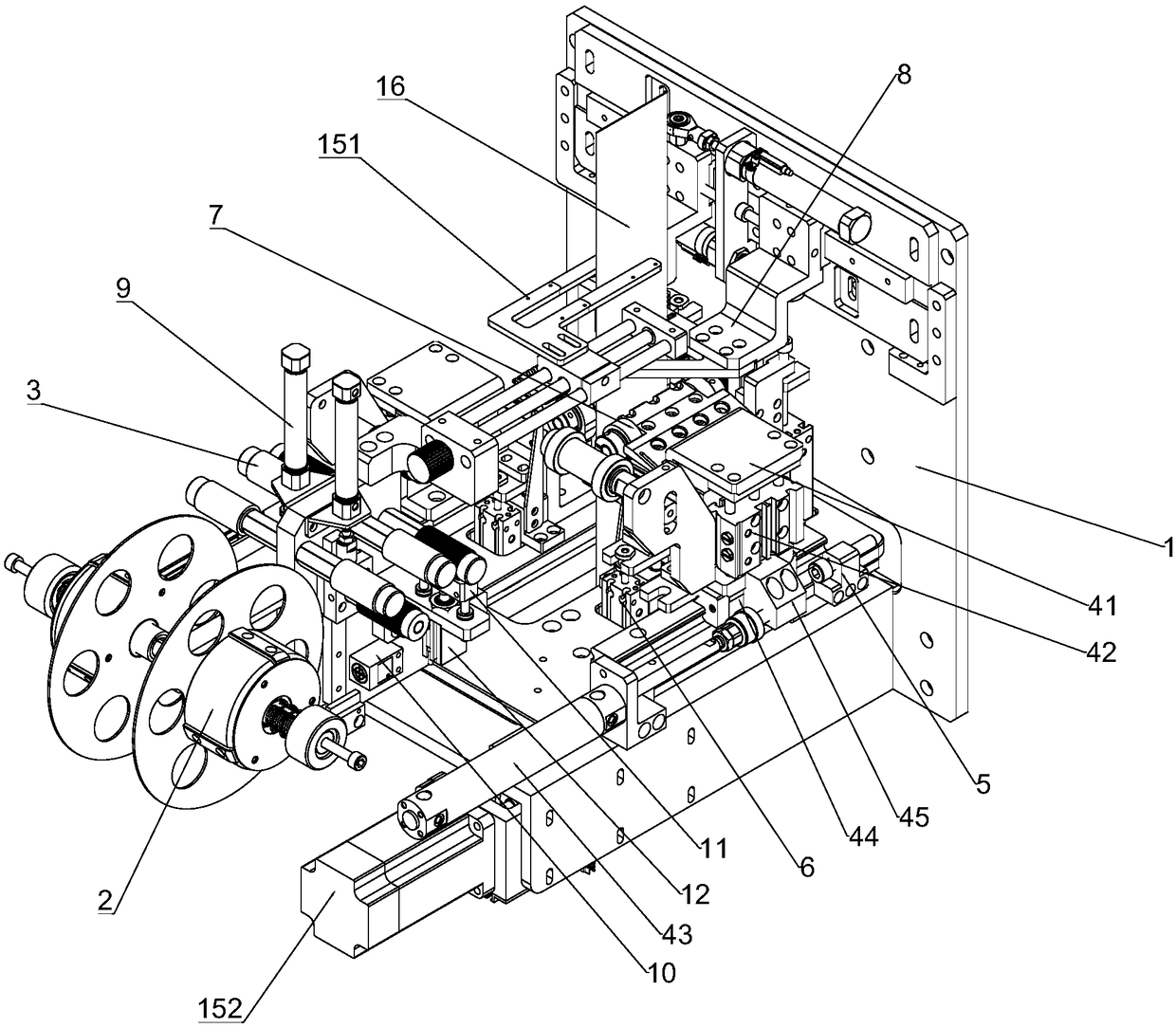

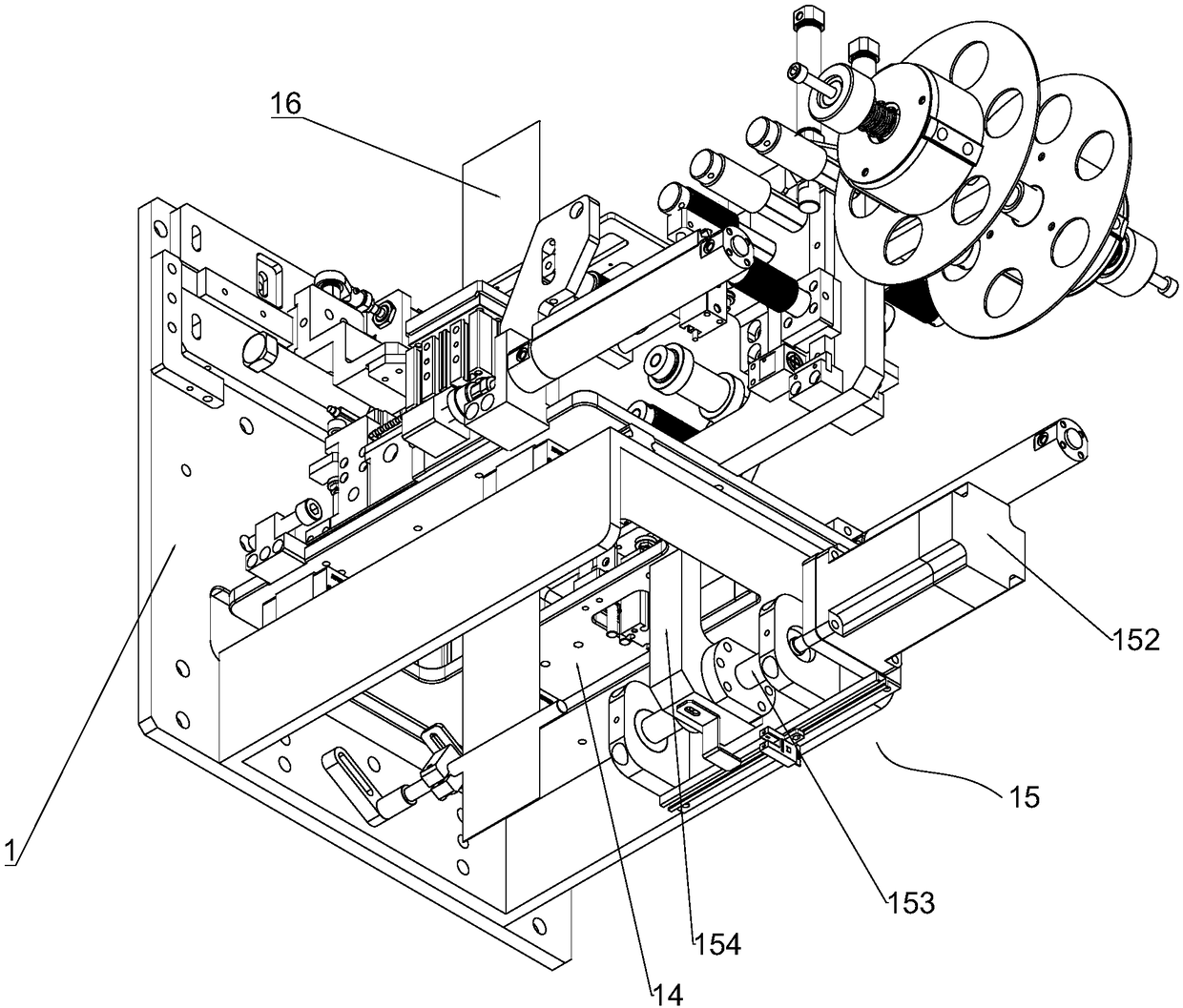

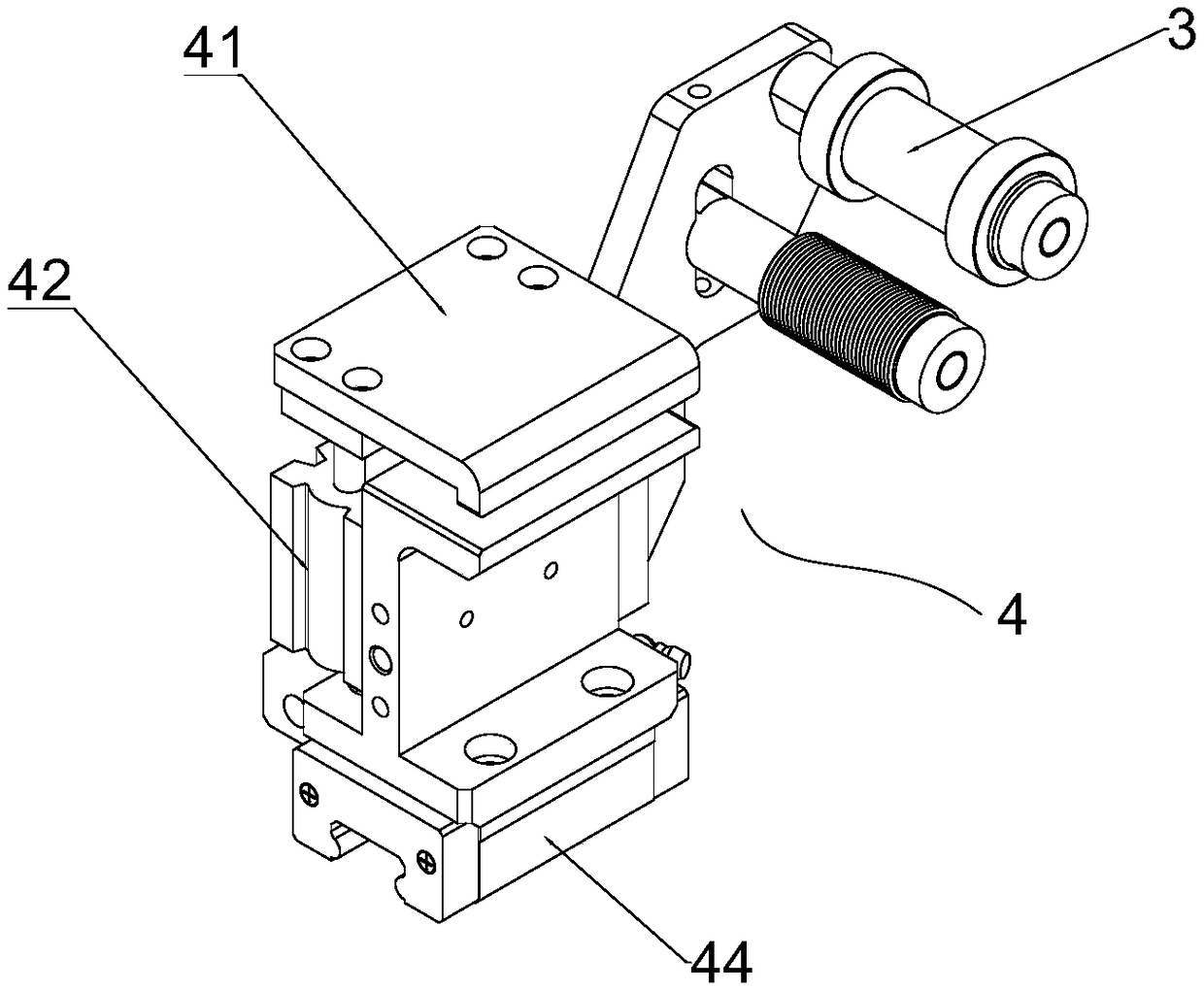

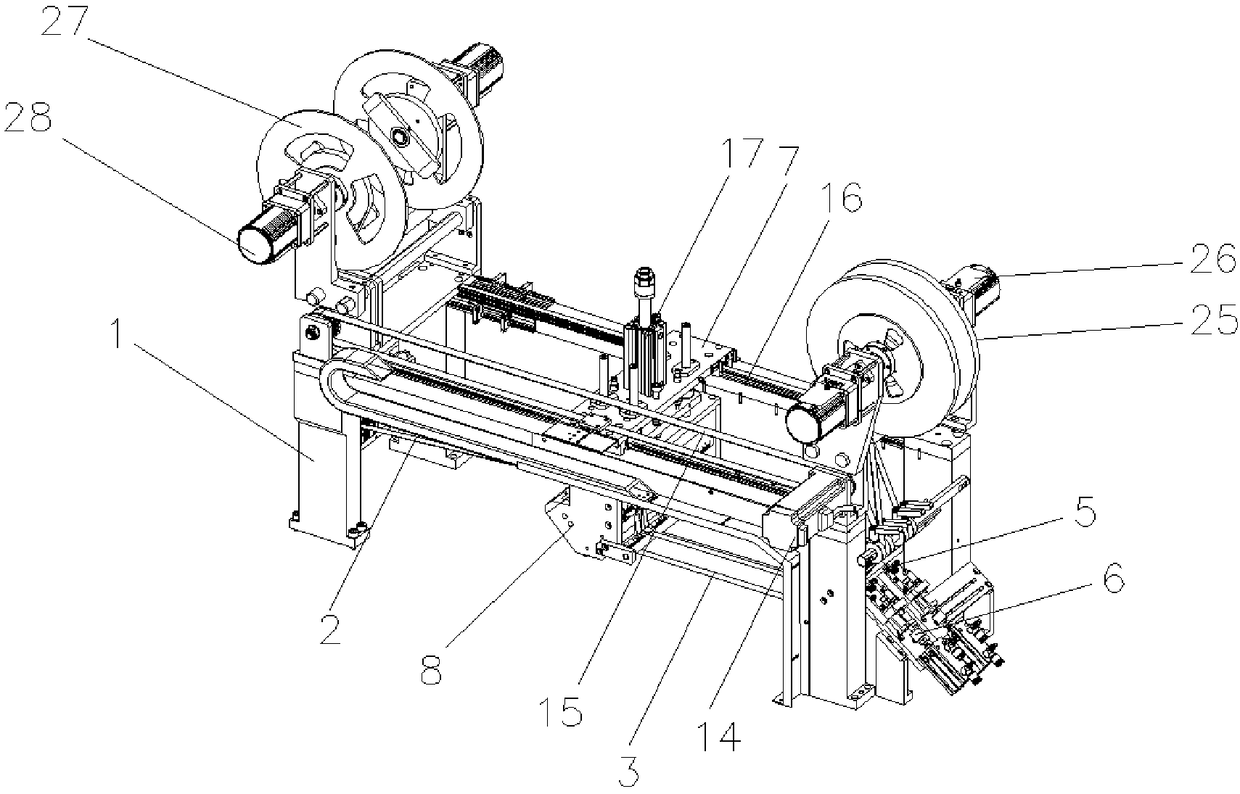

Flat cable end tape attaching device and method

ActiveCN110648805AQuality improvementSame lengthManufacturing wire harnessesStructural engineeringMechanical engineering

The invention relates to the field of flat cable tape attaching and particularly relates to a flat cable end tape attaching device. The device comprises a rack, a base assembly, a winding drum assembly, a film feeding assembly, a cutting assembly and a pressing assembly, wherein the base assembly is installed on the machine frame, the winding drum assembly is connected with the base assembly, thepressing assembly is installed on the machine frame and located over the winding drum assembly, the cutting assembly is obliquely arranged on the winding drum assembly, the film feeding assembly is arranged on the machine frame and located on the side of the winding drum assembly, the winding drum assembly is used for winding a single-sided adhesive tape and sending out the cut single-sided adhesive tape, the cutting assembly is used for carrying out fixed-length cutting of the single-sided adhesive tape on the winding drum assembly, and the pressing assembly is used for attaching the cut single-sided adhesive tape to a surface of a flat cable. The device is advantaged in that a rotary adhesive tape receiving strip is arranged, so working efficiency is improved, the rotary winding drum assembly can achieve feeding, cutting and material moving, no waiting exists between procedures, connection is orderly, and the tape attaching speed is increased.

Owner:昆山展诚电子科技有限公司

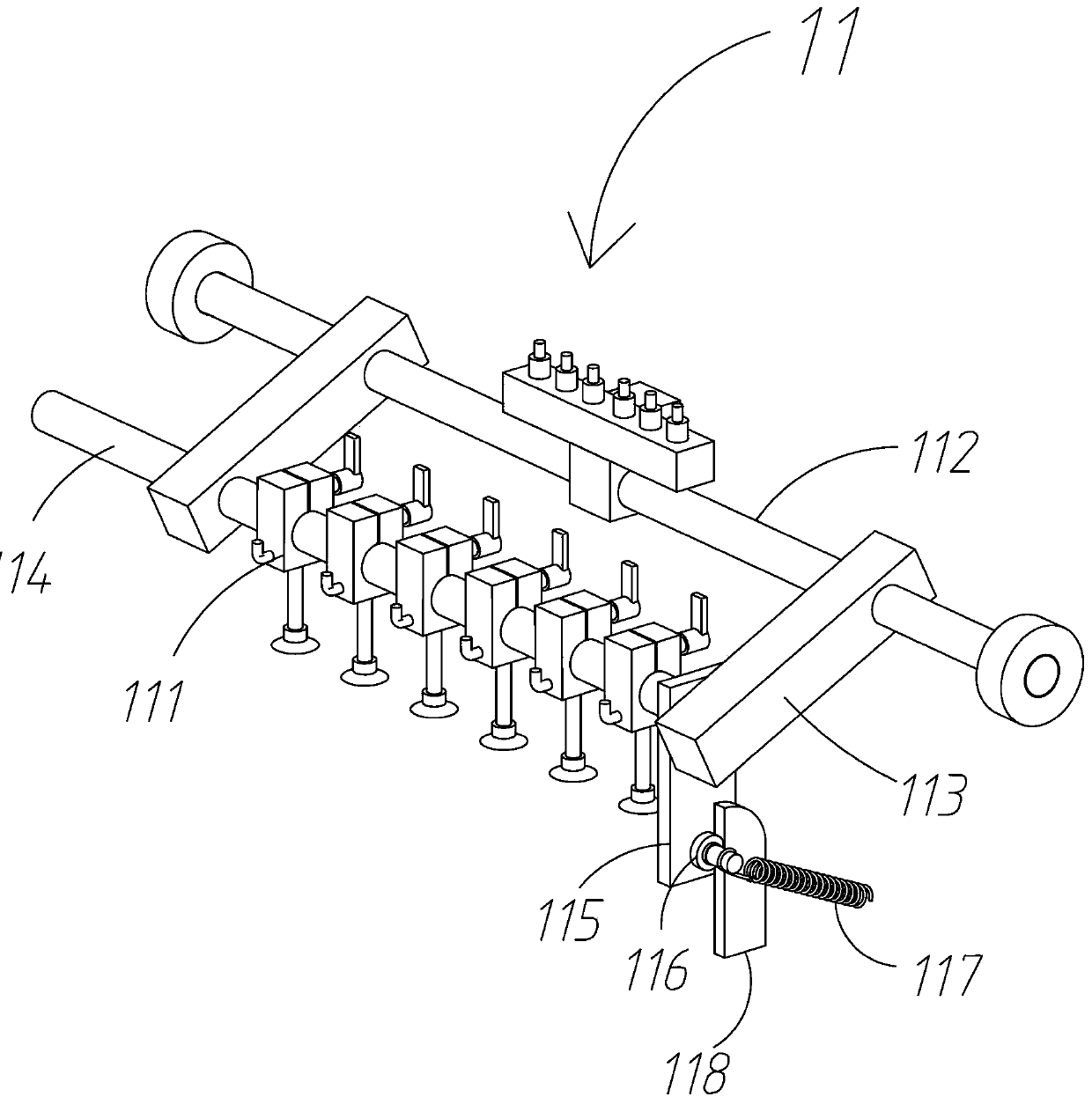

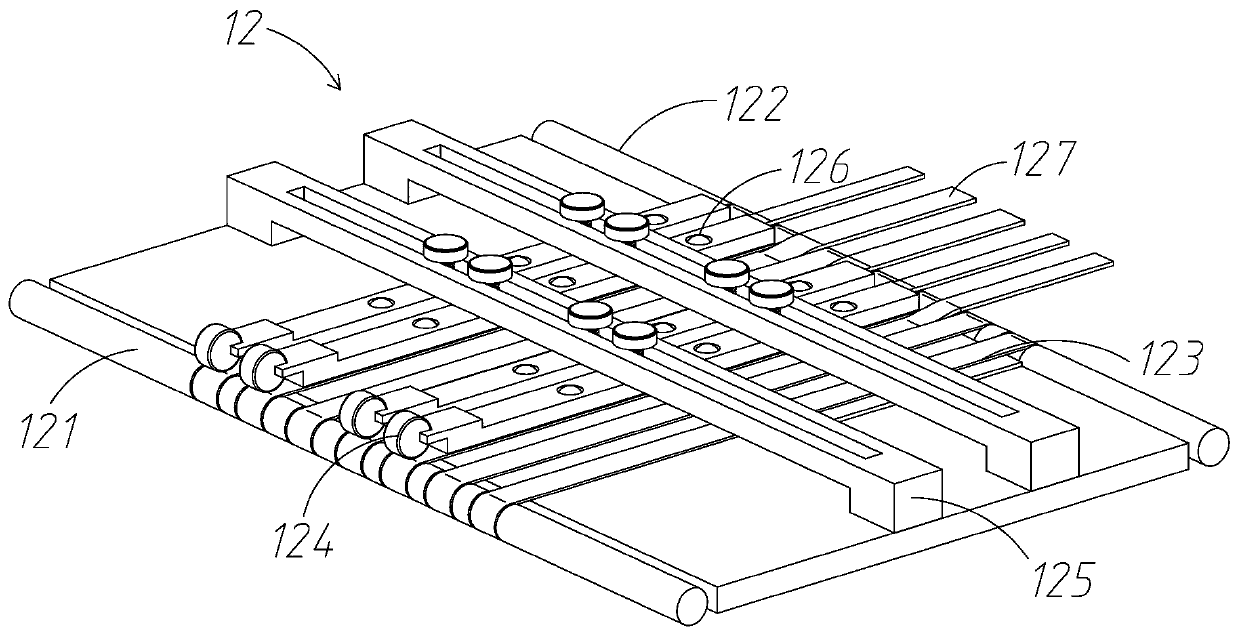

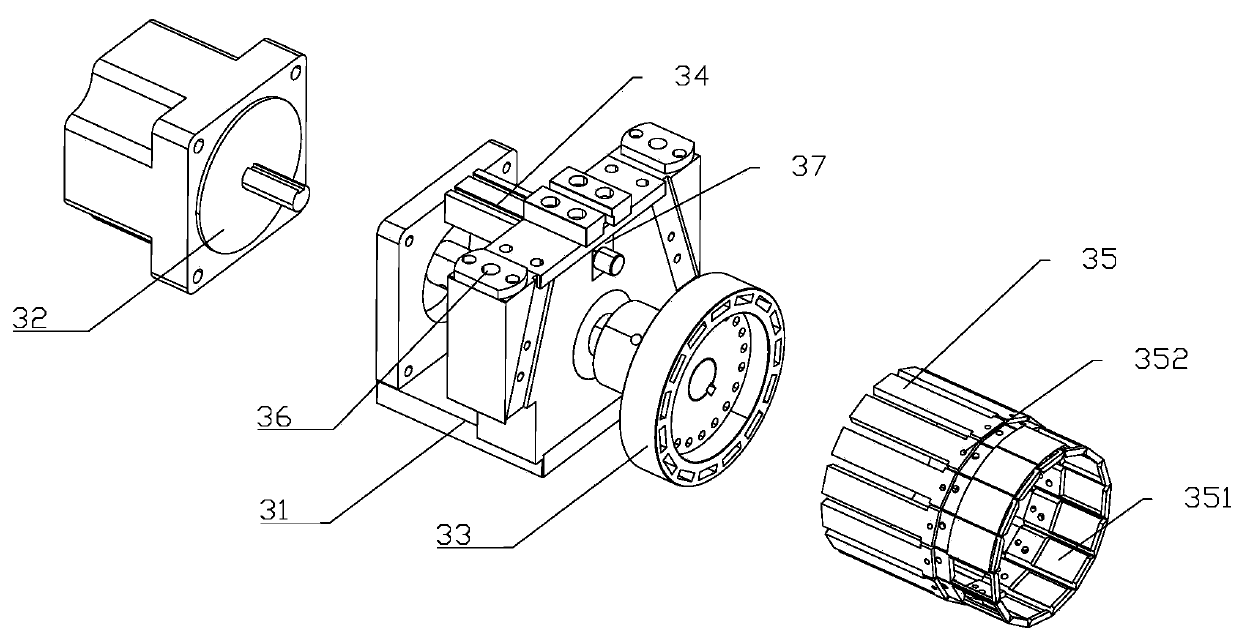

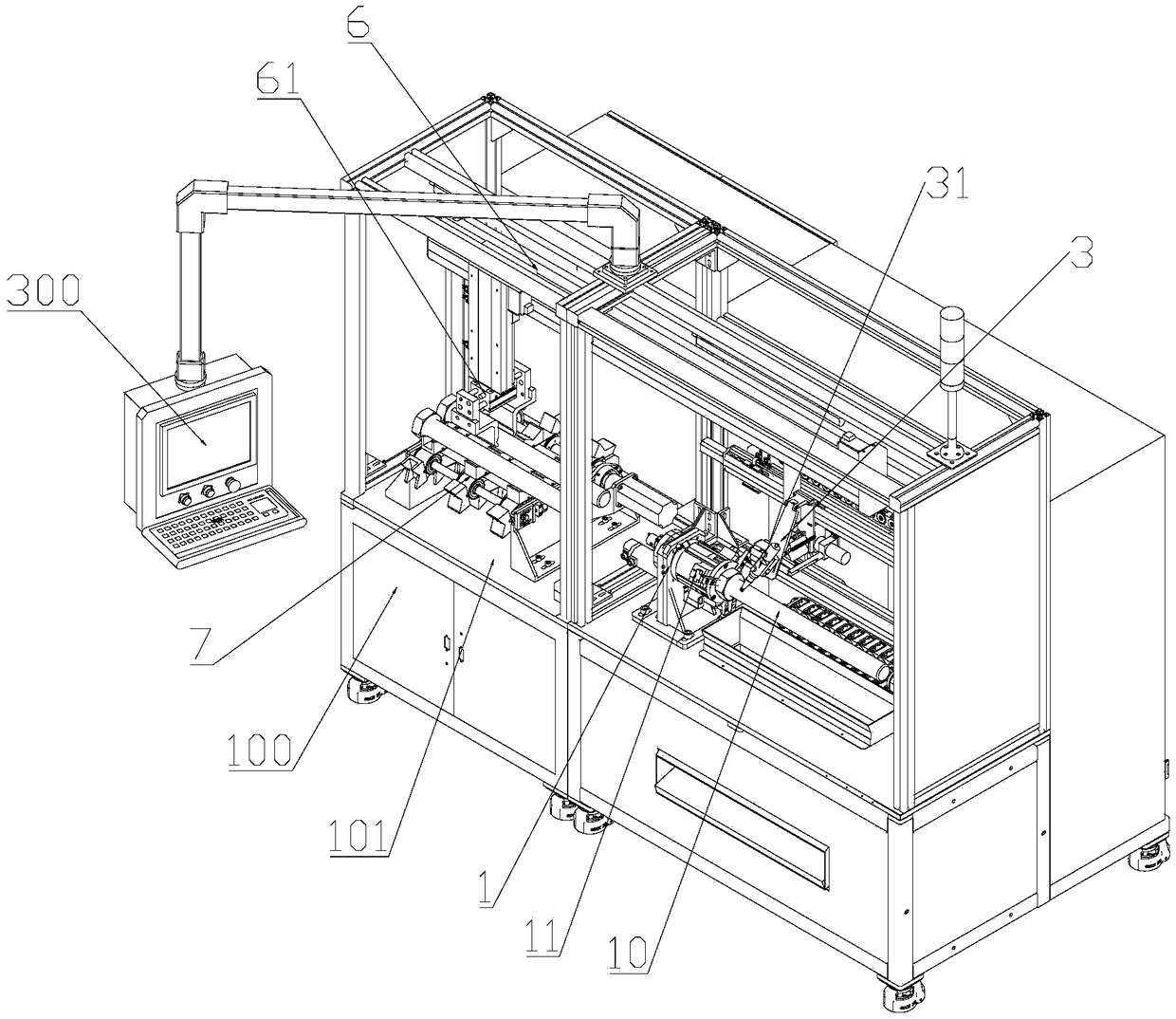

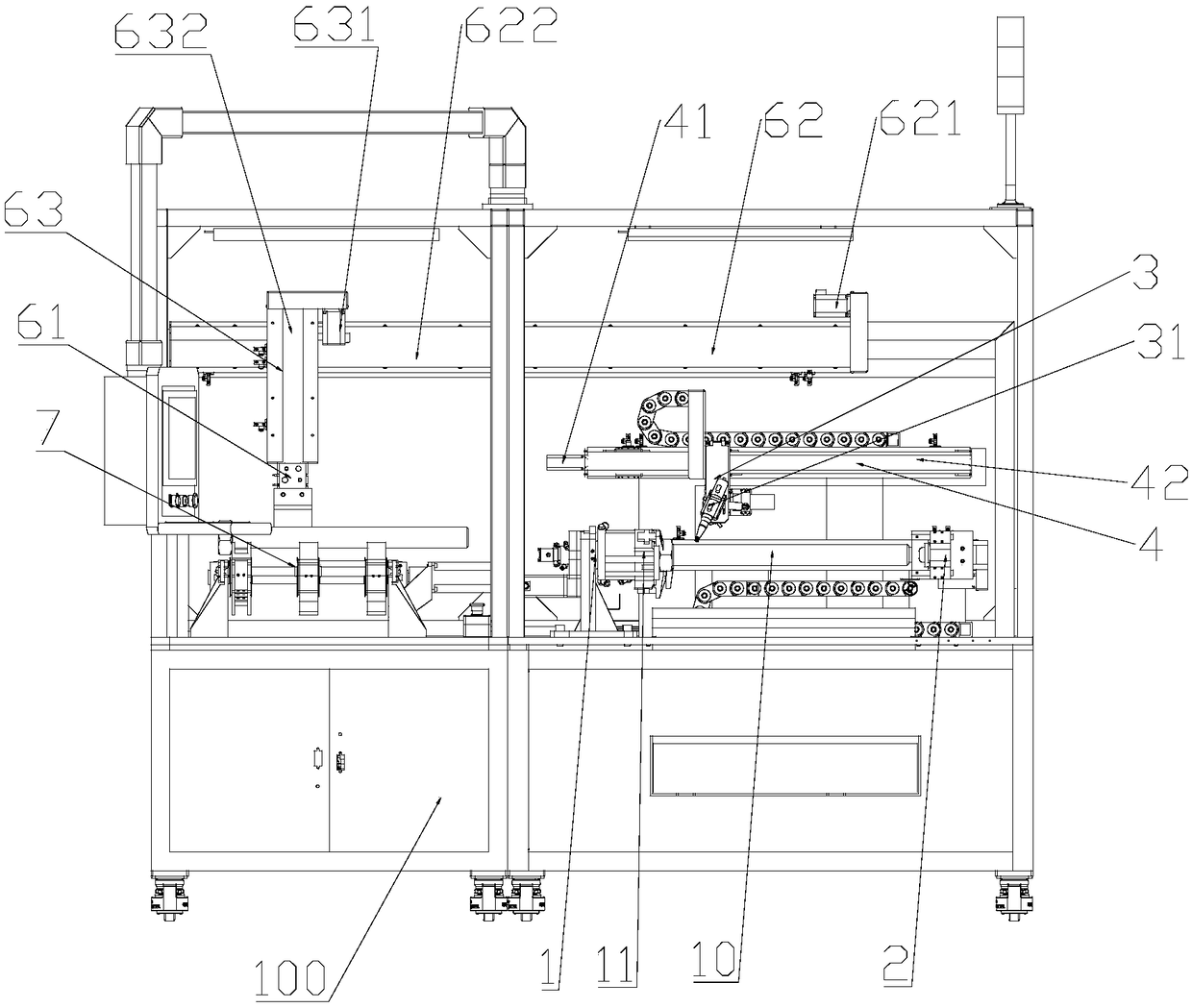

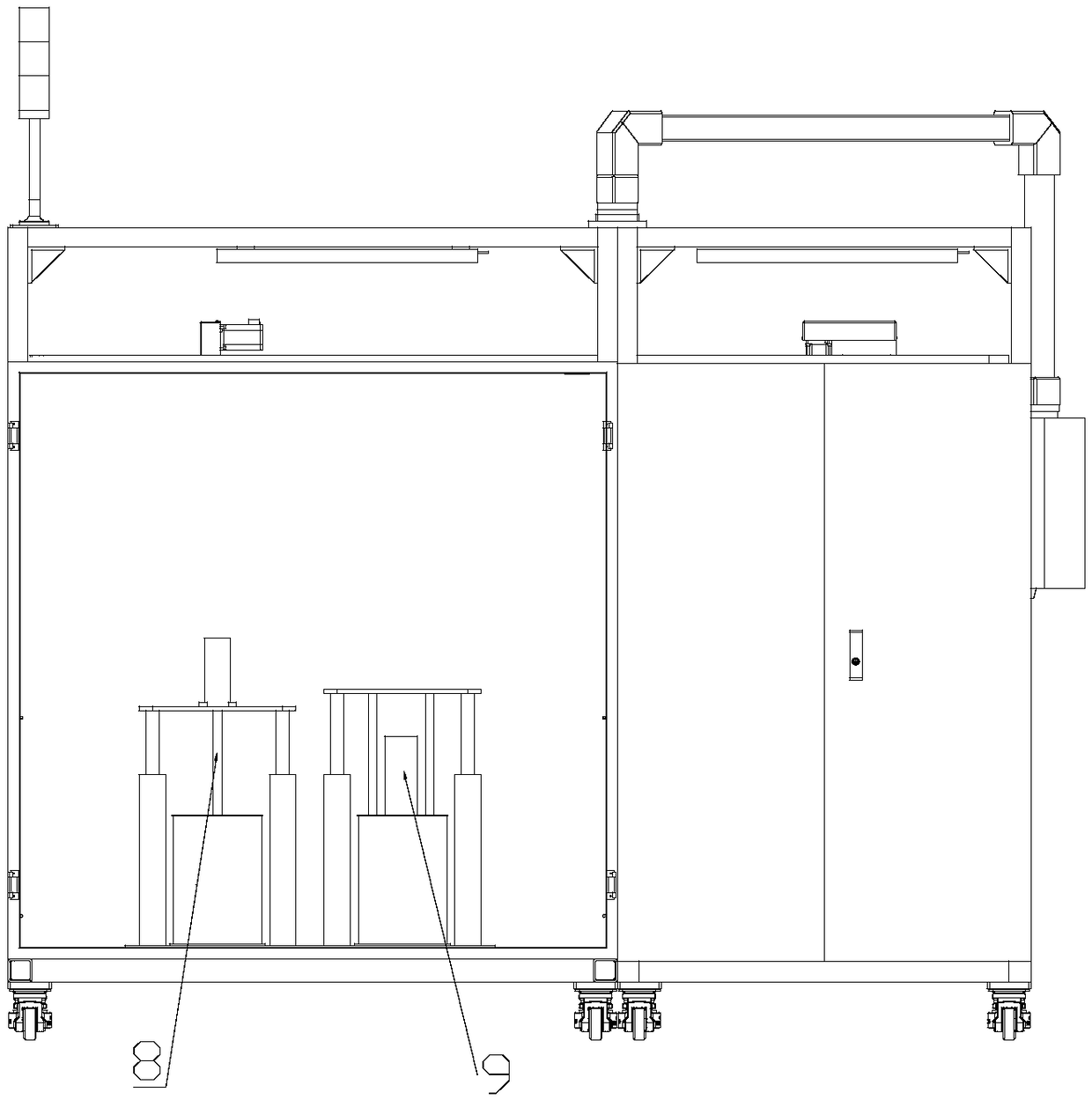

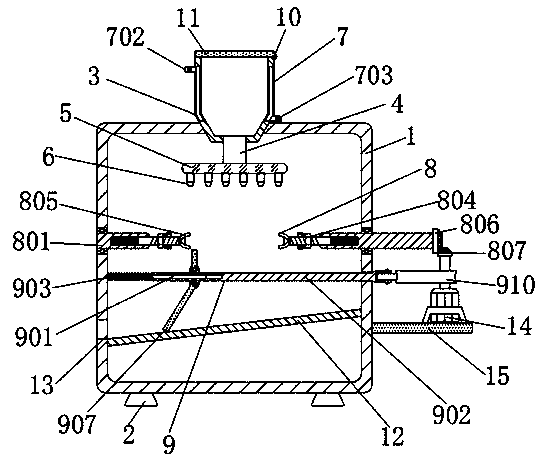

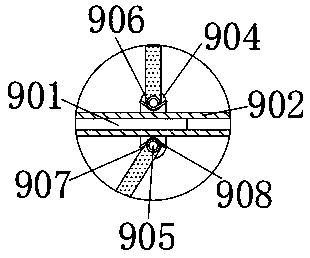

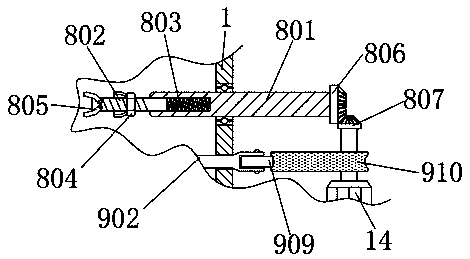

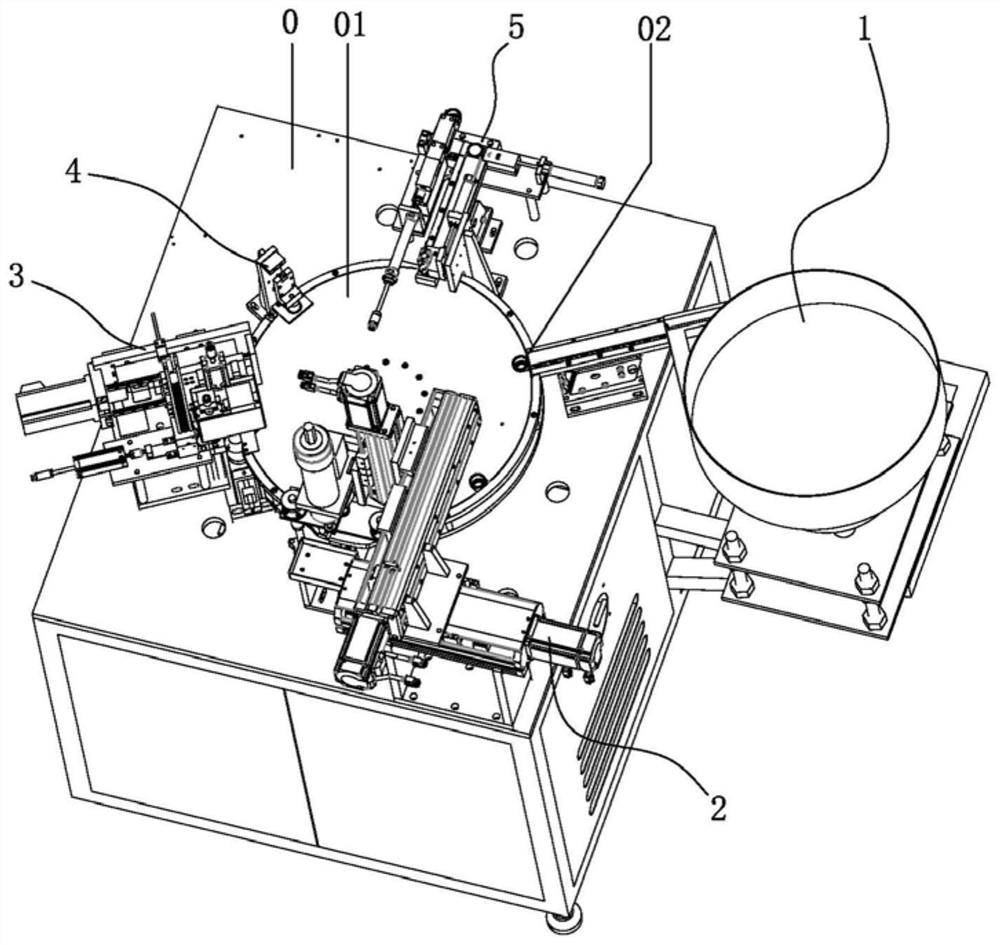

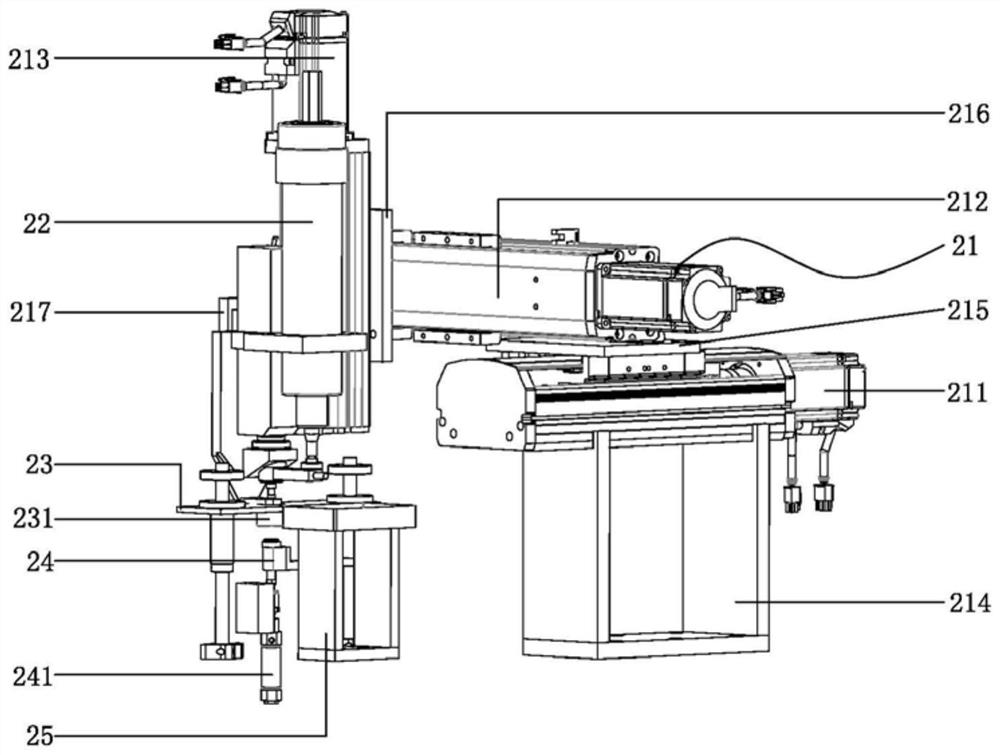

Numerical control dispensing equipment and dispensing method

InactiveCN108787325AFast glue applicationReduce laborLiquid surface applicatorsCoatingsNumerical controlEngineering

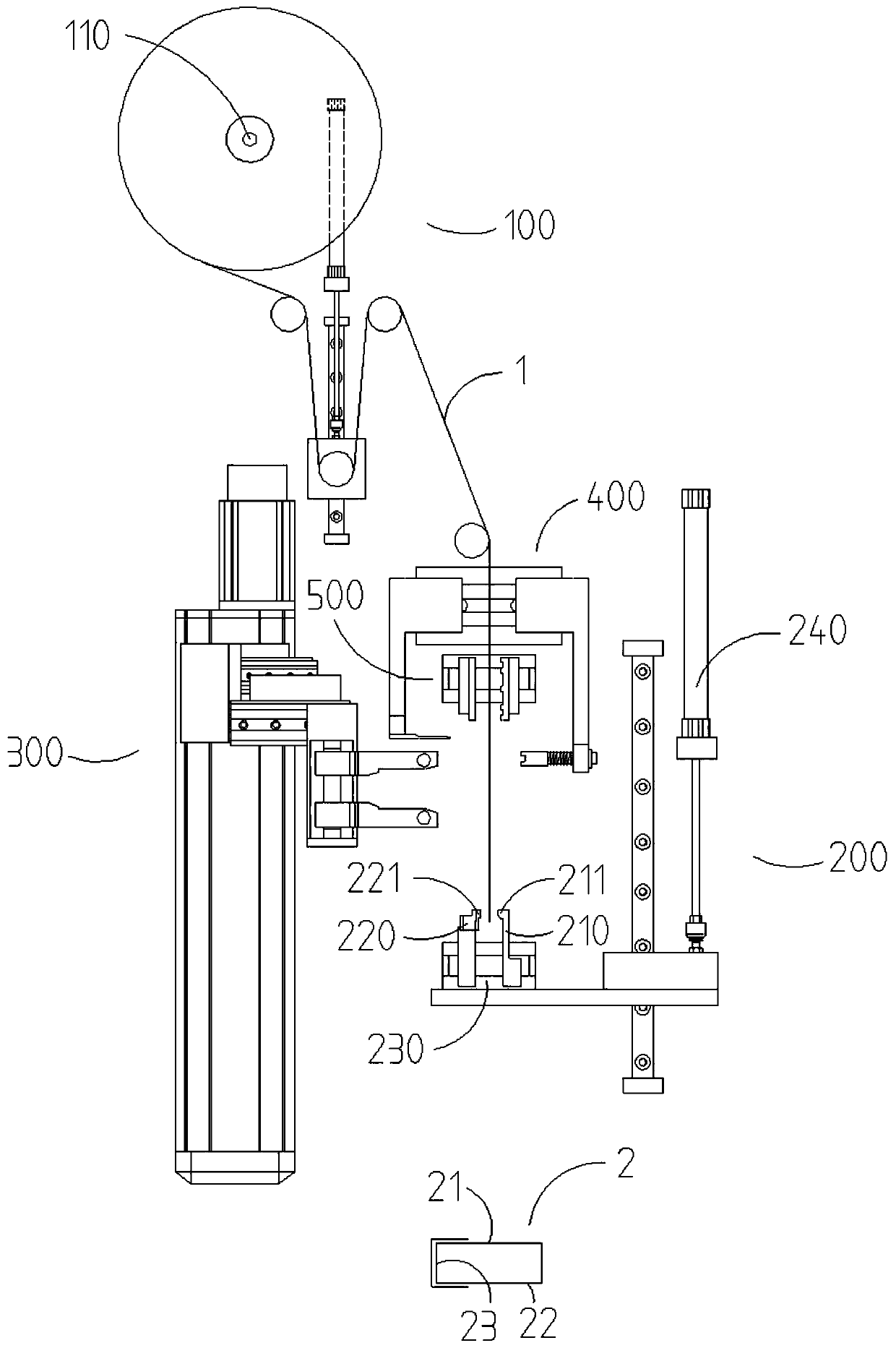

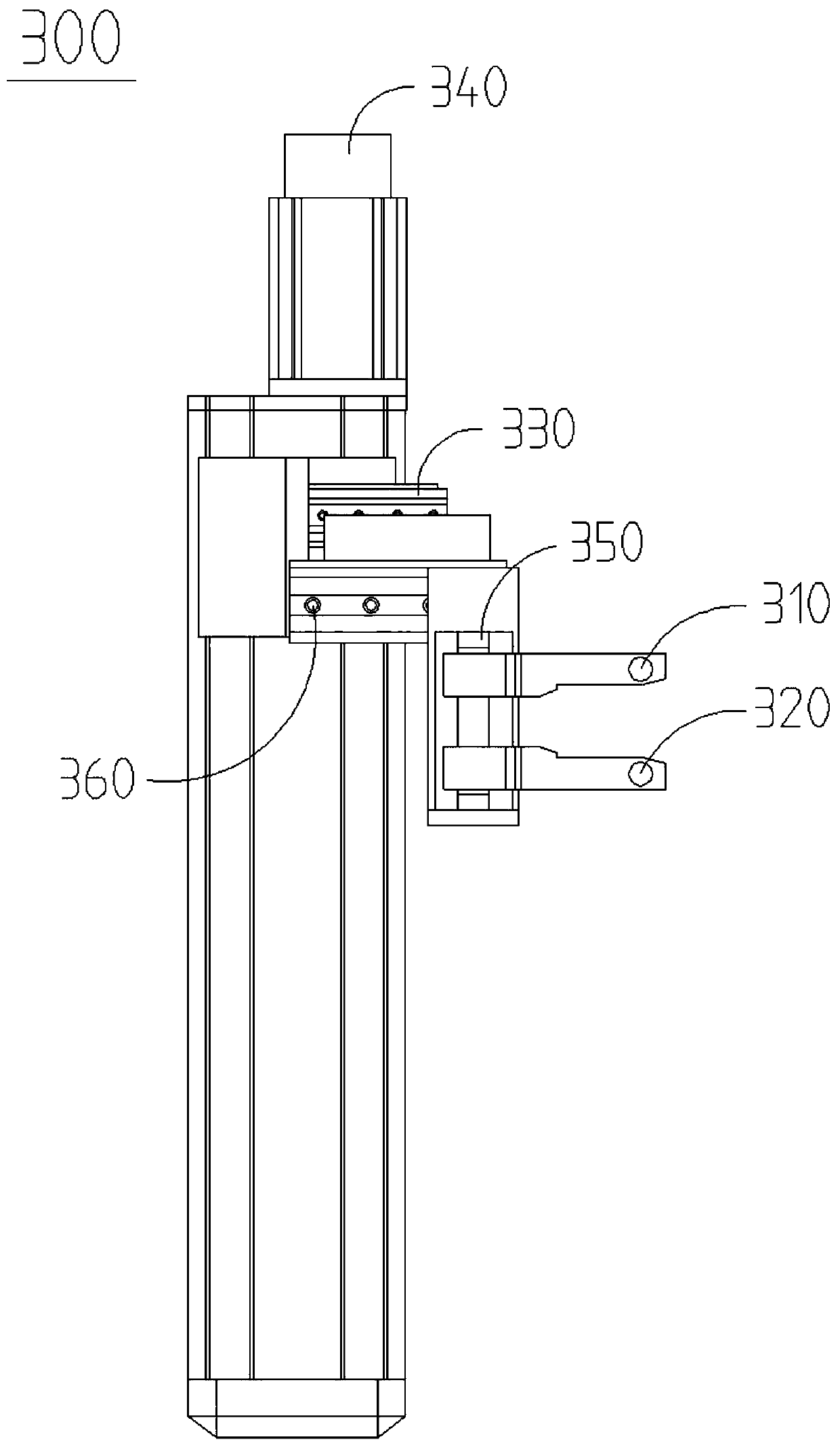

The embodiment of the invention provides numerical control dispensing equipment and a dispensing method. The numerical control dispensing equipment comprises a spindle mechanism (1), a push-tighteningmechanism (2) and a dispensing mechanism (3). The spindle mechanism (1) and the push-tightening mechanism (2) are oppositely arranged along the first specified axis. The spindle mechanism (1) comprises a workpiece clamping part (11) capable of rotating around the first specified axis and used for clamping the first end of a workpiece (10). The push-tightening mechanism (2) comprises a push-tightening part (21) capable of rotating around the first specified axis and used for abutting against the second end of the workpiece (10). The dispensing mechanism (3) comprises a dispensing gun (31) capable of moving at the first preset position and / or the second preset position in the direction parallel to the first specified axis. According to the numerical control dispensing equipment, the gluingprocess of the workpiece can be automatically completed, and the labor intensity of workers is relieved; and compared with a manual gluing mode, the gluing speed is higher, long-time uninterrupted working can be achieved, and thus the work efficiency is greatly improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Lithium battery adhesive sticking device

PendingCN108232325AImprove glue application efficiencyPrecise length controlNon-aqueous electrolyte cellsFinal product manufactureAdhesive beltReciprocating motion

The invention discloses a lithium battery adhesive sticking device. The lithium battery adhesive sticking device comprises a controller, an adhesive discharging mechanism, an adhesive conveying mechanism, an adhesive cutting worktable capable of doing reciprocating motion, an adhesive cutting mechanism, a mechanical arm assembly and an adhesive pressing assembly, which are mounted on a mounting plate, wherein the controller is connected with the adhesive conveying mechanism, the adhesive cutting mechanism, the mechanical arm assembly and the adhesive pressing assembly; the mechanical arm assembly comprises a mechanical arm and a mechanical hand; the adhesive conveying mechanism comprises an adhesive conveying air cylinder; an adhesive tape is introduced into the adhesive cutting worktable;the adhesive conveying air cylinder is used for moving the adhesive cutting worktable to the lower side of the adhesive cutting mechanism; the mechanical hand is used for clamping the head part of the adhesive tape; when the residual adhesive tape is cut off on the adhesive cutting worktable by the adhesive cutting mechanism, the adhesive cutting worktable is reset; an adhesive tape section whichis cut off by the mechanical arm is conveyed to an adhesive sticking station to be clung to a lithium battery element; the controller is used for controlling the adhesive pressing assembly and sticking the section of adhesive tape to the lithium battery element. According to the lithium battery adhesive sticking device disclosed by the invention, the adhesive tape with a pre-set length can be cut, the dosage of the adhesive tape is monitored and full-automatic, rapid and efficient adhesive sticking is realized.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

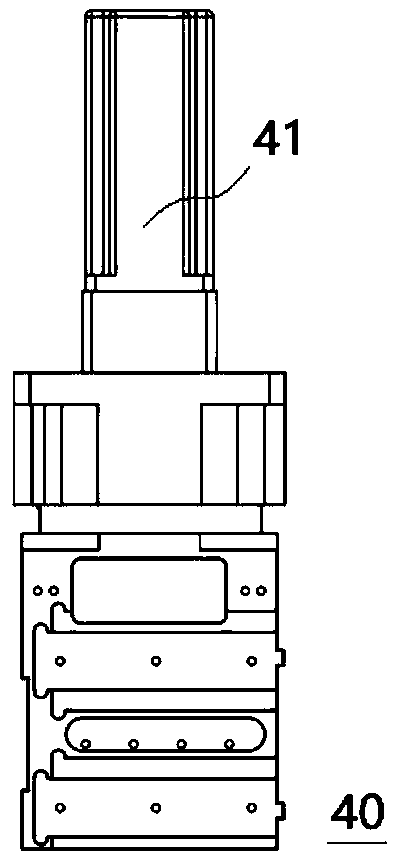

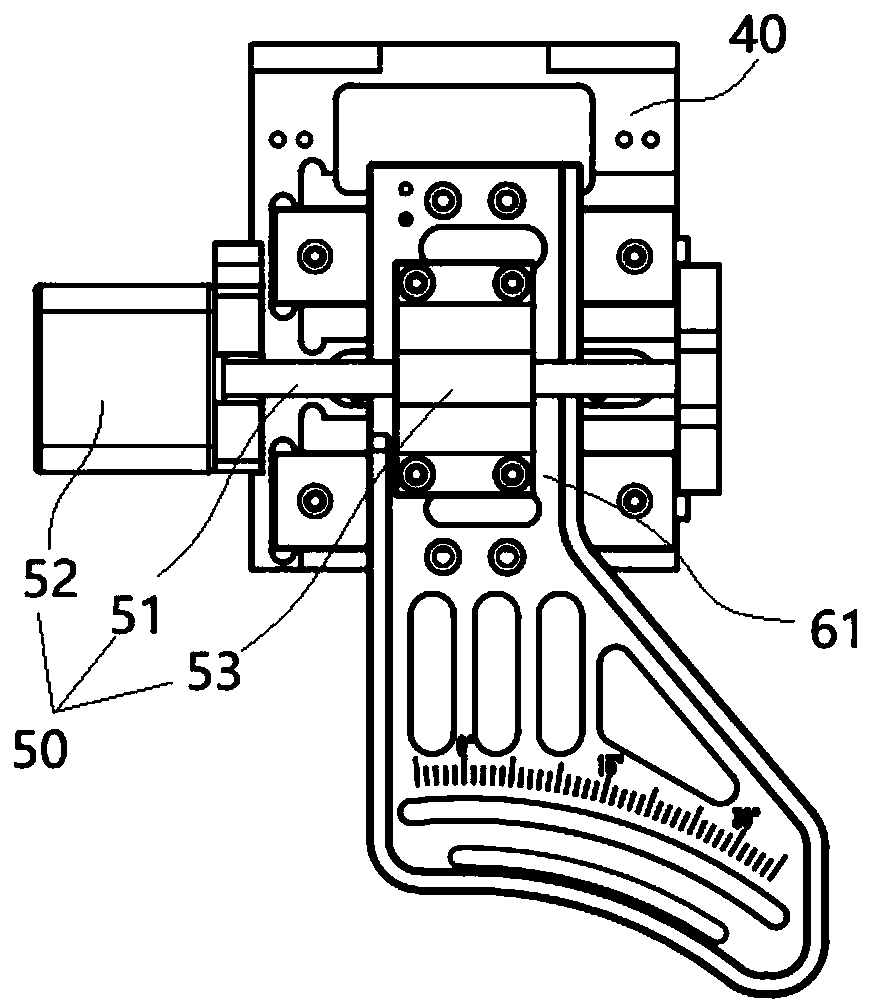

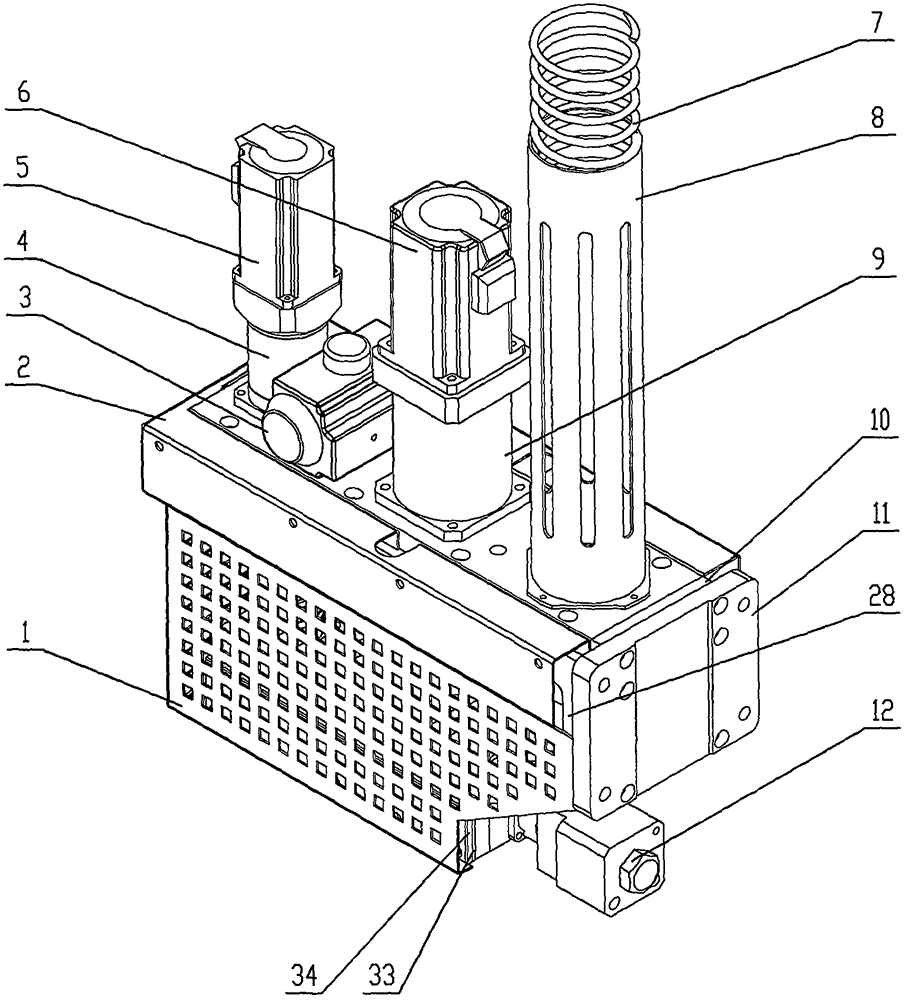

Glue application head with rotary glue application nozzle

The invention discloses a glue application head of glue application equipment and discloses a glue application head with a rotary glue application nozzle for one-component glue. The glue application head comprises a glue nozzle rotating mechanism, a glue nozzle opening and closing mechanism, a glue supply metering device and a glue supply conveying device, wherein the mechanisms and the devices are fixed to a frame composed of a fixed plate, a heat insulation plate B, a heat insulation plate A, a fixed base and a support plate; the glue nozzle rotating mechanism comprises motors A and speed reducers A, wherein the motors A and the speed reducers A are sequentially connected; a bearing base is installed on an upper transition body; the upper transition body, a flow channel body and a lower transition body are each provided with two concentric holes in the vertical direction, and the lower end of a rotating shaft penetrates through the concentric holes in the left side of the upper transition body, the left side of the flow channel body and the left side of the lower transition body; the glue application nozzle is connected to a transition part through a locking nut; the rotating shaft is provided with a plurality of glue inlet holes in the radial direction; the motors A rotate for driving the glue application nozzle to rotate intermittently or continuously. According to the glue application head, the glue application nozzle can rotate, complicated glue application equipment is not needed, three-axis gantry glue application equipment can complete glue application with the uniform glue thickness, the equipment manufacturing cost is lowered, and the cost is reduced.

Owner:DALIAN HUAGONG INNOVATION TECH

Glue nozzle rotating glue head

ActiveCN105772329BAchieve rotationLow costLiquid surface applicatorsCoatingsElectric machineryReducer

The invention discloses a glue application head of glue application equipment and discloses a glue application head with a rotary glue application nozzle for one-component glue. The glue application head comprises a glue nozzle rotating mechanism, a glue nozzle opening and closing mechanism, a glue supply metering device and a glue supply conveying device, wherein the mechanisms and the devices are fixed to a frame composed of a fixed plate, a heat insulation plate B, a heat insulation plate A, a fixed base and a support plate; the glue nozzle rotating mechanism comprises motors A and speed reducers A, wherein the motors A and the speed reducers A are sequentially connected; a bearing base is installed on an upper transition body; the upper transition body, a flow channel body and a lower transition body are each provided with two concentric holes in the vertical direction, and the lower end of a rotating shaft penetrates through the concentric holes in the left side of the upper transition body, the left side of the flow channel body and the left side of the lower transition body; the glue application nozzle is connected to a transition part through a locking nut; the rotating shaft is provided with a plurality of glue inlet holes in the radial direction; the motors A rotate for driving the glue application nozzle to rotate intermittently or continuously. According to the glue application head, the glue application nozzle can rotate, complicated glue application equipment is not needed, three-axis gantry glue application equipment can complete glue application with the uniform glue thickness, the equipment manufacturing cost is lowered, and the cost is reduced.

Owner:DALIAN HUAGONG INNOVATION TECH

Tape applicator

PendingCN108807841AAdapt to continuous needsRealize automatic glue applicationElectrode manufacturing processesEngineeringMechanical engineering

The invention discloses a tape applicator, comprising a total fixed plate, and a tape unreeling disc, a coating wheel, a tape pinching mechanism, a tape cutting mechanism, a rotating applying plate and two patting plates on the total fixed plate, wherein a tape unreeled through the tape unreeling disc is transferred from the coating wheel to the tape pinching mechanism and then is transferred ontoa support table through the tape pinching mechanism, a pinching driving mechanism is connected with the rotating applying plate, and the rotating applying plate is located above the support table androtates to the tape and sticks to the half side of the tape, the tape cutting mechanism cuts off the tape, an object to be glued passes between the two patting plates, the tape stuck on the rotatingapplying plate is rotated to the object to be glued, the two patting plates stick to each other oppositely to press the other half of the tape stuck on the rotating applying plate to the object to beglued, and the rotating applying plate rotates to be separated from the stuck half of the tape. The tape applicator can be used for applying tapes very fast, and can adapt to tapes of different lengths and accurately and firmly attach tapes onto lugs to ensure the quality of products.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

A gluing head with gluing nozzle rotation

The invention discloses a gelatinizing head of gelatinizing equipment, and relates to a gelatinizing head with rotary gelatinizing nozzles for one-component glue. The gelatinizing head comprises a gelatinizing nozzle rotating mechanism, a gelatinizing nozzle opening and closing mechanism, a glue supply metering device and a glue supply conveying device which are fixed on a frame composed of a fixed plate, an insulation board B, an insulation board A, a fixed seat and a support plate; the gelatinizing nozzle rotating mechanism comprises a motor A, a speed reducer A, a gelatinizing nozzle A, a gelatinizing nozzle B, a transition body, a guide holder and a seal ring A, the motor A, the speed reducer A and the gelatinizing nozzle B are fixedly connected in sequence, the gelatinizing nozzle A and the gelatinizing nozzle B are combined through a trapezoidal slideway or a dovetail slideway, the gelatinizing nozzle A can move along the gelatinizing nozzle B in the axial direction, a movable plate is fixedly connected with a boss on the upper portion of the gelatinizing nozzle A, and the motor A and the speed reducer A rotatably drive the gelatinizing nozzles to rotate intermittently or continuously. Gelatinizing nozzle rotating is achieved, complex gelatinizing equipment is not needed, three-axis gantry gelatinizing equipment can also complete gelatinizing of workpieces, and the application range of the gelatinizing equipment is widened.

Owner:DALIAN HUAGONG INNOVATION TECH

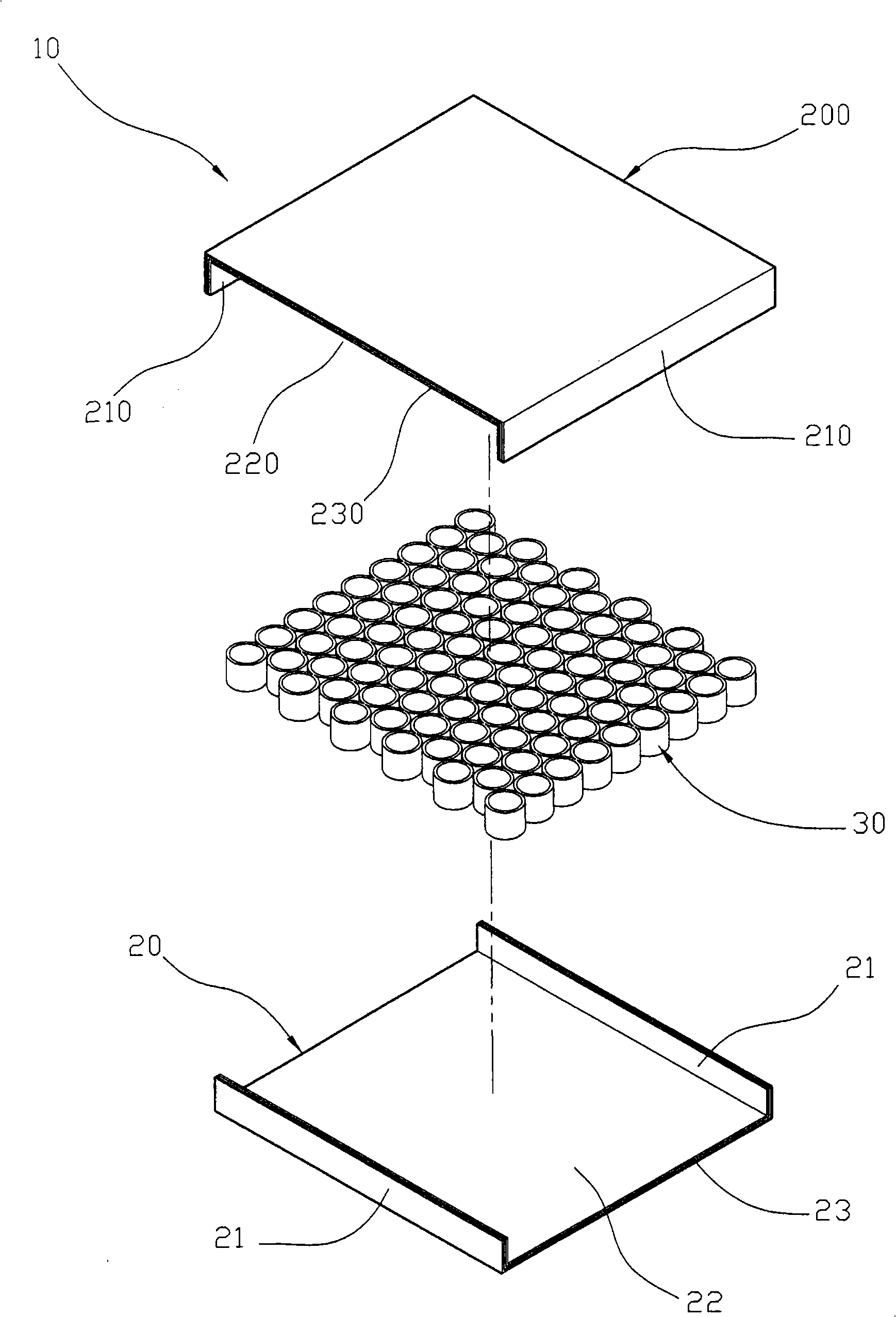

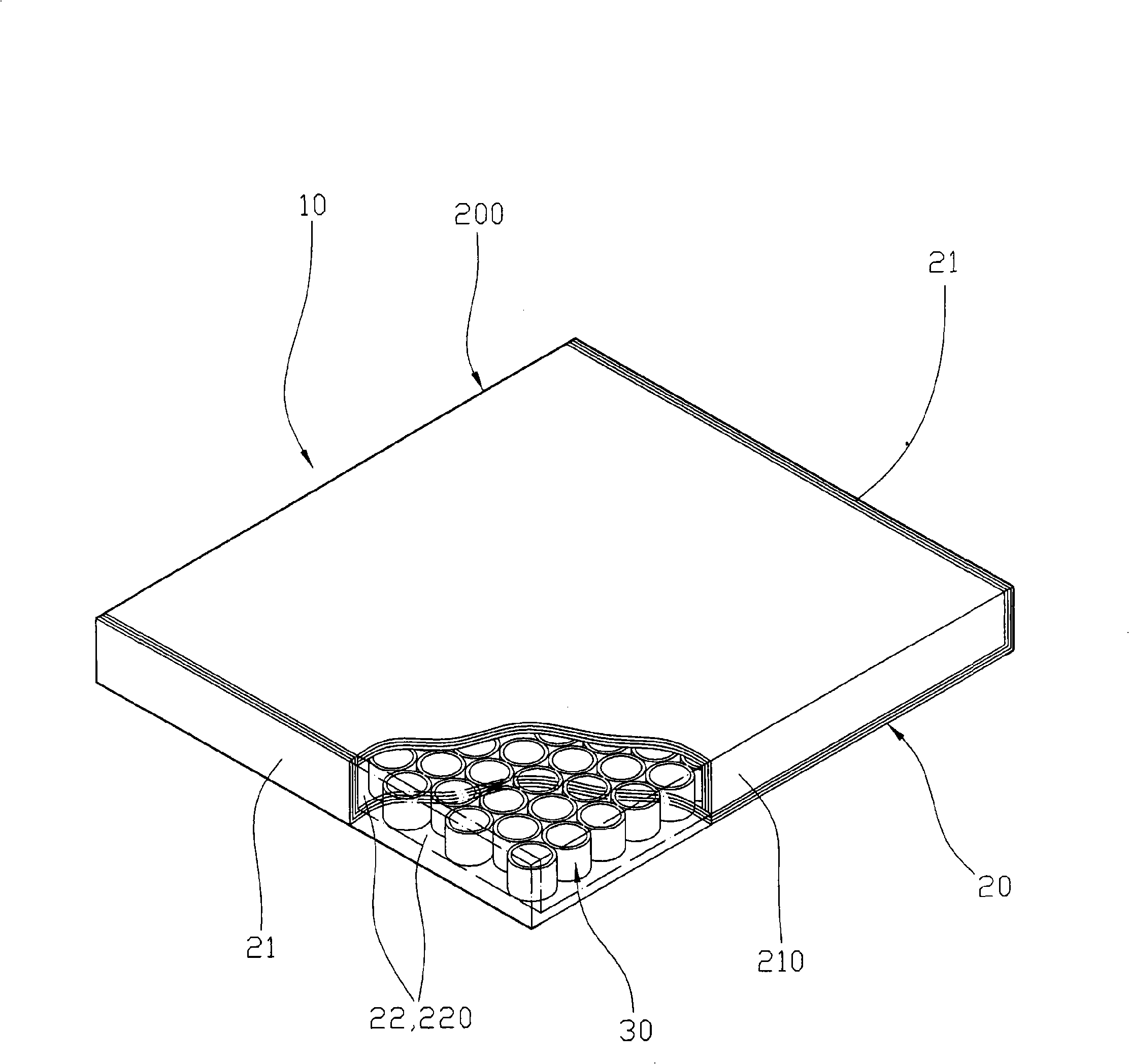

Method for producing paper sheet material

InactiveCN101327670AImprove moisture resistanceConvenient way of gluingPaper/cardboard articlesCardboardPulp and paper industry

The invention provides a paper-making sheet manufacturing method. After steps of paper material indentation, paper material rubberizing, cover plate molding, cover plate pressing, paper tube transportation, paper tube rubberizing, paper tube distributing, paper sheet cutting and paper material molding on paper sheet materials, two staggered involutive crustiform cover plates and a plurality of paper tubes are successively processed into molded paper materials. Through the method, the paper material manufacturing can be finished conveniently, rapidly and automatically. Labor uses are greatly lowered. Productivity is increased. The production cost is lowered. And the use of the paper-making sheet is provided with better moisture proof, sound proof and insulation effects.

Owner:吴惠玲

Gluing device for bamboo wood product production

InactiveCN110328086ANot easy to condenseQuick collectionSpraying apparatusPulp and paper industryWood product

The invention discloses a gluing device for bamboo wood product production. Supporting legs are fixedly connected to the bottom four corners of a box body, an anti-consolidation assembly is arranged in a feeding hopper, a fixing assembly is arranged in the box body, a scraping assembly is arranged below the fixing assembly, and a motor is fixedly connected to the top of a transverse plate. According to the gluing device for bamboo wood product production, through cooperation of the anti-consolidation assembly, the feeding hopper and a cover plate, in the working process of the gluing device, the gluing procedure is prevented from being slowed down due to the fact that glue is prone to being consolidated due to ultra-low external temperature, through cooperation of the fixing assembly, themotor and the transverse plate, the gluing device can rotatably glue bamboo wood products by 360 degrees, and therefore the gluing speed is higher, and the gluing time is shortened; through cooperation of the scraping assembly, the motor and the transverse plate, glue on the surfaces can be more uniform and comprehensive, no dead corner exists in gluing, surplus glue can be quickly collected to berecycled, and the risk of consolidation of the glue in the gluing device can be avoided.

Owner:福建省将乐好家园木业有限公司

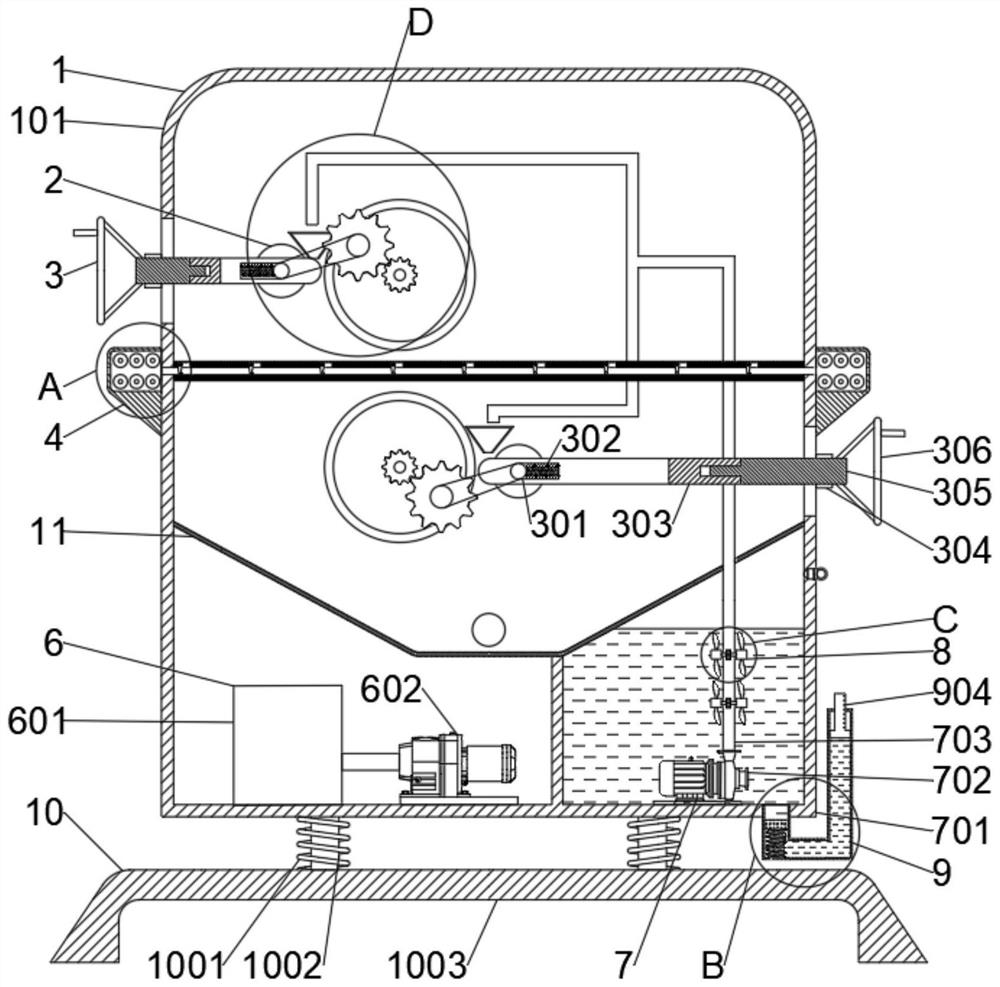

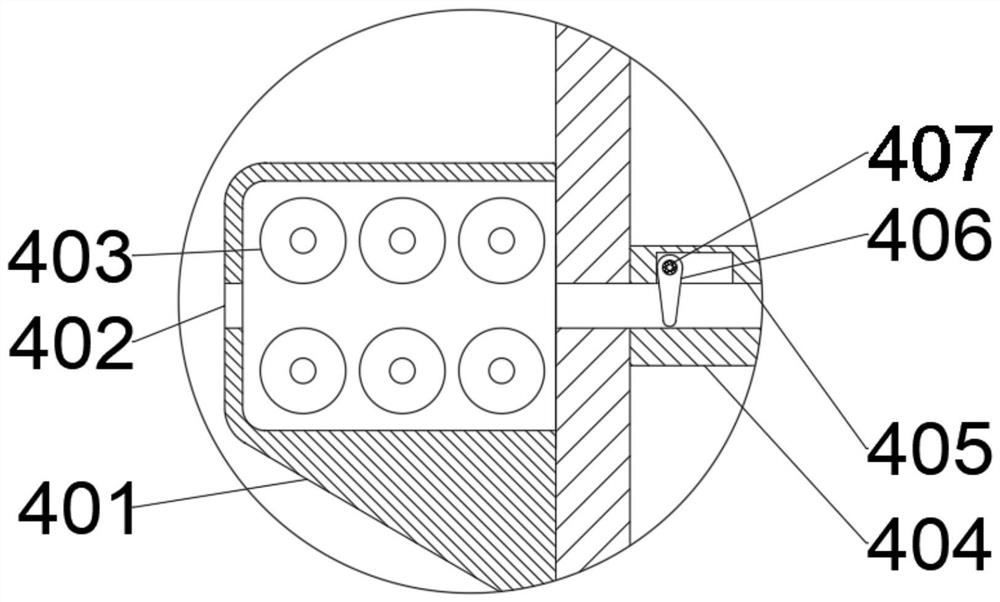

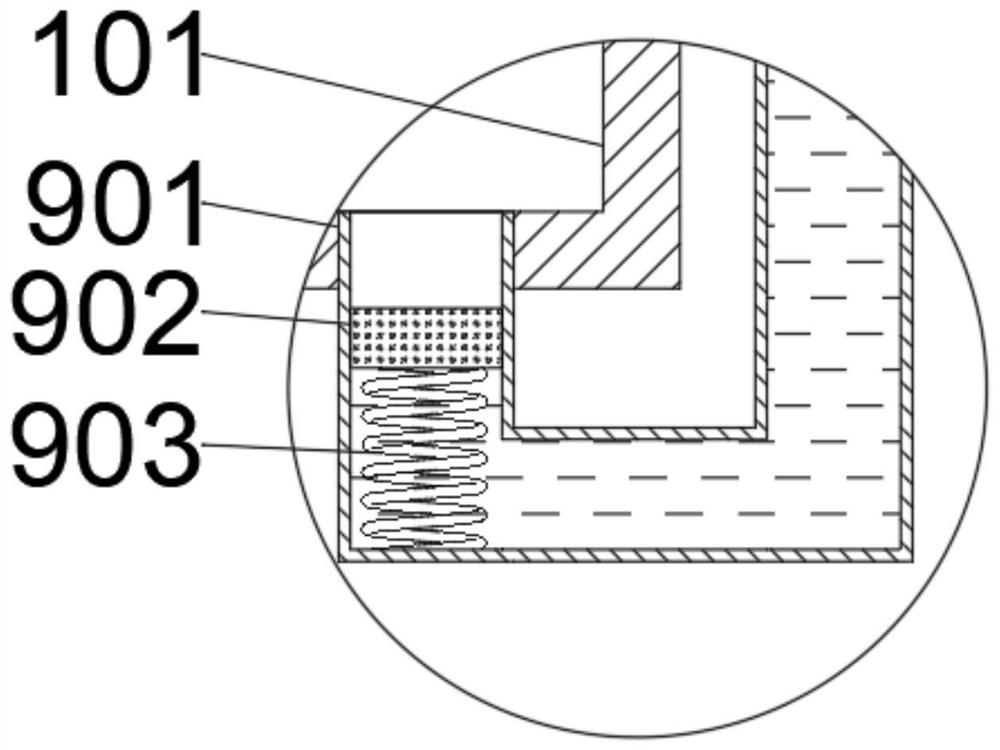

Processing platform for plywood gluing

InactiveCN112277104ATo achieve the effect of feedingControl glue amountAdhesive application devicesEngineeringStructural engineering

The invention discloses a processing platform for plywood gluing. The processing platform for plywood gluing comprises a device shell, and the device shell comprises a mounting frame, an upper mounting plate and a lower mounting plate, and the upper mounting plate and the lower mounting plate are slidably connected to the side face of the mounting frame; a guide mechanism is arranged on the mounting frame, the guide mechanism comprises guide blocks fixedly connected to the two sides of the mounting frame and inlet and outlets formed in the outer sides of the guide blocks, the interiors of theguide blocks are hollow, rolling wheels are symmetrically arranged on the upper sides and the lower sides of the guide blocks, guide rails are further arranged at the positions, corresponding to the inlet and outlets in the guide blocks, in the mounting frame, each guide rail is composed of an upper guide rail body and a lower guide rail body which are fixedly connected to the mounting frame, a clamping tongue is rotatably connected to one side of each groove, and a reset spring is arranged at the joint of each clamping tongue and the corresponding upper guide rail body; and gluing mechanismsare correspondingly arranged on the upper mounting plate and the lower mounting plate. Compared with a traditional device, the device can enable gluing to be more sufficient and uniform through the guide mechanism and the gluing mechanisms.

Owner:TAOJIANG HONGSEN WOOD IND

Paperboard adhesive adhering mechanism

ActiveCN108943851AAvoid wrinklesFacilitate precise moldingBox making operationsPaper-makingCardboardAdhesive

The invention discloses a paperboard adhesive adhering mechanism. A double-sided adhesive tape feeding module can provide double-sided adhesive tape for a double-sided adhesive tape attaching module;a release paper receiving module can receive no-adhesive release paper led out of the double-sided adhesive tape attaching module; a turning roller is rotationally installed on a rack; double-sided adhesive tape led out of a face adhesive feeding module is turned through the turning roller; one side of double-sided adhesive tape release paper tightly adheres to the surface of the turning roller; aknife edge of a cutting knife installed on the rack in a linear sliding manner can cut off the adhesive face of the double-sided adhesive tape on the surface of the turning roller; a horizontal slider slides along a straight line and is positioned on the rack; a head portion is installed on the lower side of the horizontal slider in a rising and falling manner; an attaching roller is installed onthe head portion; the double-sided adhesive tape led out of the position of an adhesive face cutting device is turned through the attaching roller and then is led out of the head portion; and a clamping mechanism can lamp the release paper turned through the attaching roller. The paperboard adhesive adhering mechanism achieves that the double-sided adhesive tape is pulled at fixed length and is subjected to adhesive adhering at fixed length, the adhesive adhering speed is high, the adhesive adhering position is accurate, and subsequent paper box accurate forming is facilitated.

Owner:昆山谛镨科自动化科技有限公司

A glue coating device for the sealing ring of the upper cover of the filter

ActiveCN104588257BSimple structureLow costLiquid surface applicatorsCoatingsSlide plateRotating disc

The invention relates to a gluing device for a filter upper cover sealing ring. The gluing device is characterized by comprising a bottom plate (1), wherein a bracket (7) is connected to the bottom plate; a rotating disc (9) is supported and connected to the bracket in running fit; a group of concentric annular grooves (9a) is formed in the rotating disc; a rotating shaft (9b) is arranged on the lower side of the rotating disc; the circle center of the annular grooves is arranged on the axis of the rotating shaft; a motor (11) is arranged below the bracket; an output shaft of the motor is connected with the rotating shaft; a guide seat (3) is fixedly connected to one side of the bottom plate by virtue of an upright plate (2); a sliding plate (4) is slidably connected to the guide seat; and a hairbrush (6) is adjustably connected to the sliding plate by virtue of a connecting piece (5). The gluing device disclosed by the invention has the advantages that the device is simple in structure and low in cost, the filter upper cover sealing ring is clamped in the corresponding annular groove in the rotating disc, the rotating disc is driven to rotate by virtue of the motor, the sealing ring is glued, the gluing speed is high and uniform, and the gluing effect is good.

Owner:来安县永阳知识产权运营有限公司

Adhesive pasting mechanism, adhesive pasting device and adhesive wrapping equipment

PendingCN111115337AFast glue applicationImprove glue application efficiencyLabelling flat rigid surfacesArticle deliveryEngineeringMechanical engineering

The invention discloses an adhesive pasting mechanism. A first adhesive taking piece, a second adhesive taking piece, a first adhesive pasting drive assembly and a second adhesive pasting drive assembly are included. After the first adhesive pasting drive assembly drives the first adhesive taking piece and the second adhesive taking piece to obtain adhesive tape, the second adhesive pasting driveassembly drives the first adhesive taking piece and the second adhesive taking piece to move towards a workpiece. The workpiece gets into the gap between the first adhesive taking piece and the secondadhesive taking piece, adhesive tape extracted by the first adhesive taking piece is pasted to the first face of the workpiece, adhesive tape extracted by the second adhesive taking piece is pasted to the second face of the workpiece, the adhesive tape between the first adhesive taking piece and the second adhesive taking piece is pasted to the third face, connected with the first face and the second face, of the workpiece, and accordingly workpiece three-face adhesive pasting is rapidly achieved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

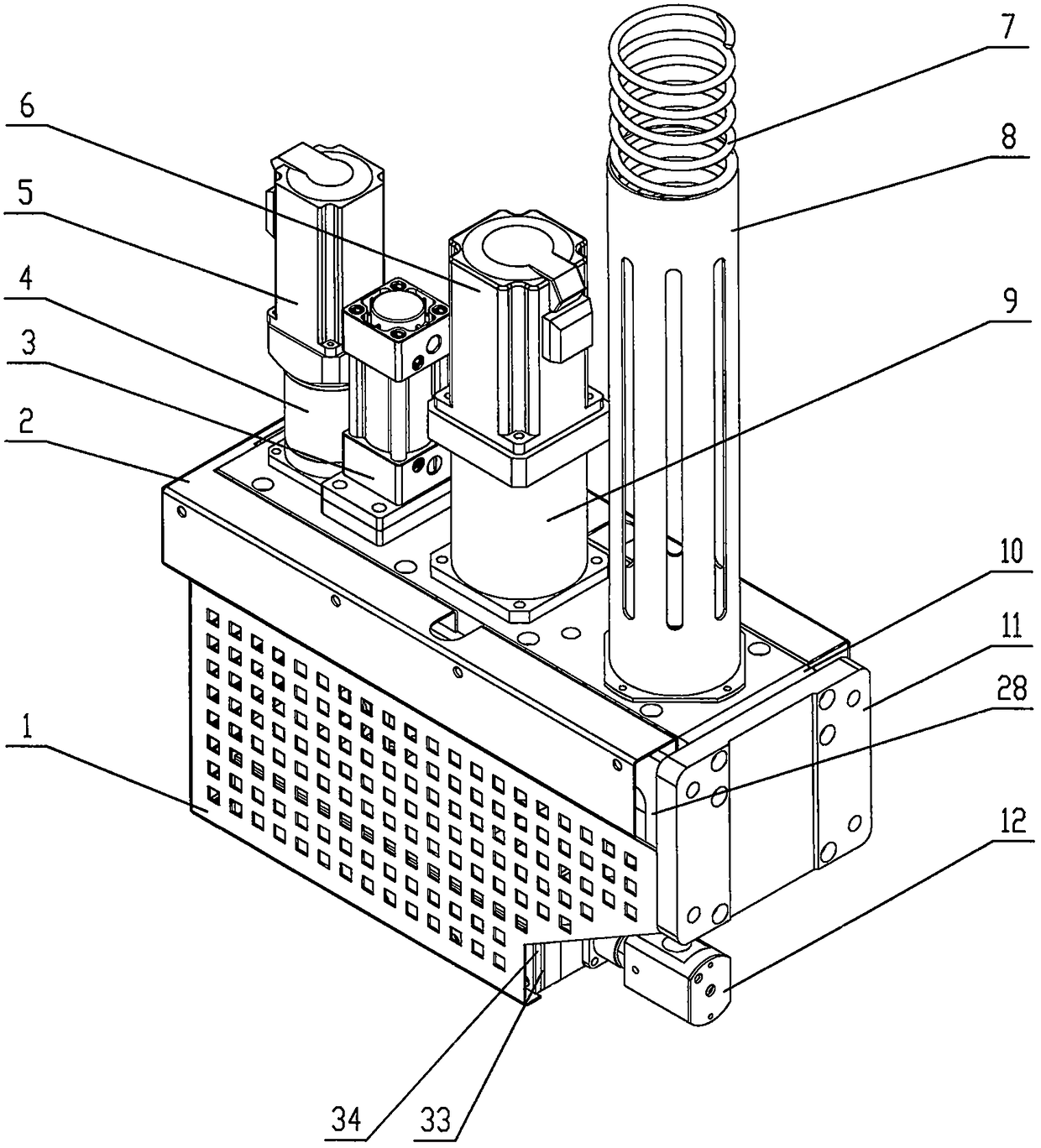

Automatic cutting and rubberizing machine

ActiveCN106626686AReduce usage requirementsRealize the way of workingLamination ancillary operationsLaminationEngineeringManipulator

The invention discloses an automatic cutting and rubberizing machine, which comprises a rack, a bearing platform, a rubberizing manipulator, and at least one cutter, wherein the cutter comprises a fixed base plate, an adhesive film-conveying mechanism, and an adhesive film-cutting mechanism, the fixed base plate is arranged on the rack, the adhesive film-conveying mechanism and the adhesive film-cutting mechanism are both arranged on the fixed base plate, the adhesive film-conveying mechanism conveys a to-be-cut strip-shaped adhesive film into the adhesive film-cutting mechanism, the adhesive film-cutting mechanism cuts out sheet adhesive films from the strip-shaped adhesive film, and the adhesive film-conveying mechanism rolls the strip-shaped adhesive film cut by the adhesive film-cutting mechanism; the bearing platform is arranged on the rack, to-be-rubberized products are borne by the bearing platform, and the bearing platform can drive the borne products to move; and the rubberizing manipulator attaches the sheet adhesive films at preset positions on the products. The automatic cutting and rubberizing machine disclosed by the invention can implement automatic cutting and rubberizing, and has the advantages of high rubberizing speed, manual operation replacement, production cost reduction and accurate rubberizing position.

Owner:SHENZHEN ZHENQIN ELECTRONICS TECH

Battery pole piece rubberizing device

PendingCN114068877AHigh degree of automationFast glue applicationElectrode manufacturing processesStructural engineeringPole piece

The invention provides a battery pole piece rubberizing device which is used for rubberizing a film on the surface of a pole piece and comprises a rack, two first traction rollers which are horizontally arranged are arranged at the upper end of the rack, two second traction rollers which are horizontally arranged are arranged at the lower end of the rack, a rotationally connected pressing roller is arranged in the middle of the rack, and the pressing roller is of a hollow structure. A plurality of first negative pressure holes are formed in the outer wall of the pressing roller, a center shaft of the pressing roller is connected with a rotating connector, the rotating connector is connected with a first negative pressure pipe, a square-frame-shaped cutter attached to the edge of a rubber sheet is arranged under the pressing roller, and a top block is arranged in the cutter in a sleeved mode. According to the rubberizing device provided by the invention, continuous rubberizing work is carried out before the pole piece is slit, the pole piece is still conveyed during rubberizing, the time delayed by shutdown is reduced, and compared with a manual rubberizing mode, the rubberizing device is high in automation degree and high in rubberizing speed, the production period of a battery is shortened, and the productivity is improved.

Owner:安徽瑞露科技有限公司

Process for producing external ointment

The production process of adhesive plaster preparation for external application includes the following steps: A. using a certain quantity of thermosol and adding it into mixing tank, heating to 40-170 deg.C, after the thermosol is completely molten, adding selected correspondent medicine according to the ratio of 0.3-100g:1g, stirring uniformly to obtain raw material for making plaster; B. spreading and applying the above-mentioned raw material on the mounting material so as to obtain black adhesive plaster; and C. applying the prepared plaster raw material on the cloth, and using recombination machine to combine lining material on it, cutting and forming so as to obtain various hot-melt adhesive plaster preparations.

Owner:王永刚

AC and DC dual-purpose small automatic glue coating machine

InactiveCN103586163BAvoid stickingReduce cumbersome operationsLiquid surface applicatorsCoatingsElectric machineryPush pull

AC and DC dual-purpose small automatic glue applicator. It belongs to the field of office supplies. It solves the problems of slow manual glue application, uneven coating and easy adhesion. A rack (4) is fixed in the cavity (3) of the bottom plate (1) of the gluing machine, a gear meshing with the rack (4) is fixed on the cross bar of the door frame (2), and the first motor (6 ) is fixed with one end of the crossbar; the lead screw (7) between the two columns (5) is covered with a slider (8), and the second motor (9) is fixed with one end of the lead screw (7); the lower part of the slider (8) A push-pull electromagnet (10) is fixed, and a rubber bottle (12) is fixed at the lower end of the push-pull electromagnet (10). The glue port is closed by a cylindrical pressure head (18); the lower end of the threaded rod (15) is fixed with a pressure piece (19). The invention has the advantages of fast glue application speed, uniform glue application, time saving and labor saving, and convenient movement and portability.

Owner:NORTHEAST GASOLINEEUM UNIV

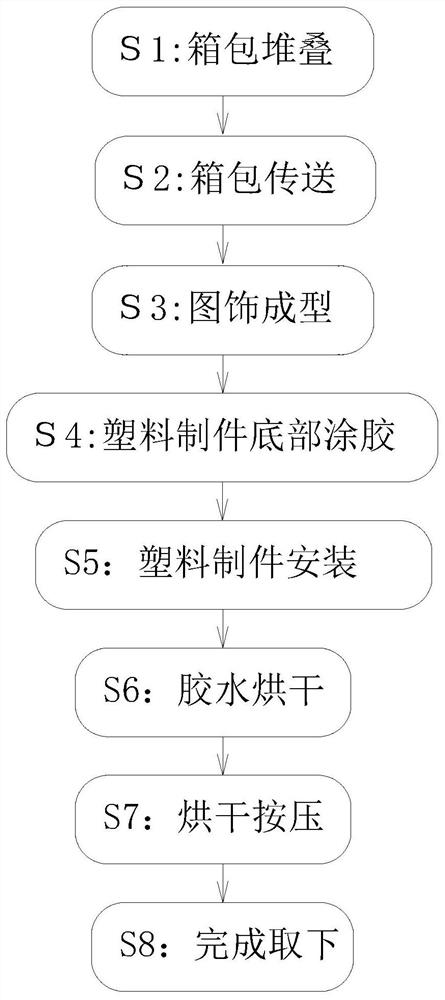

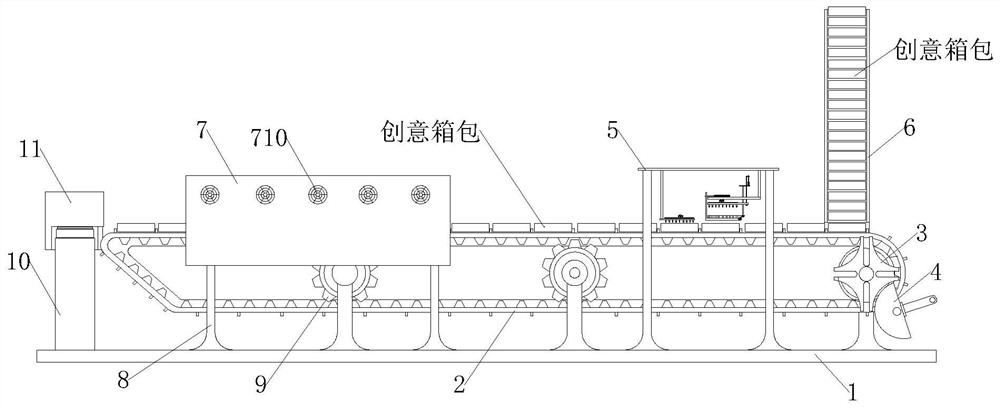

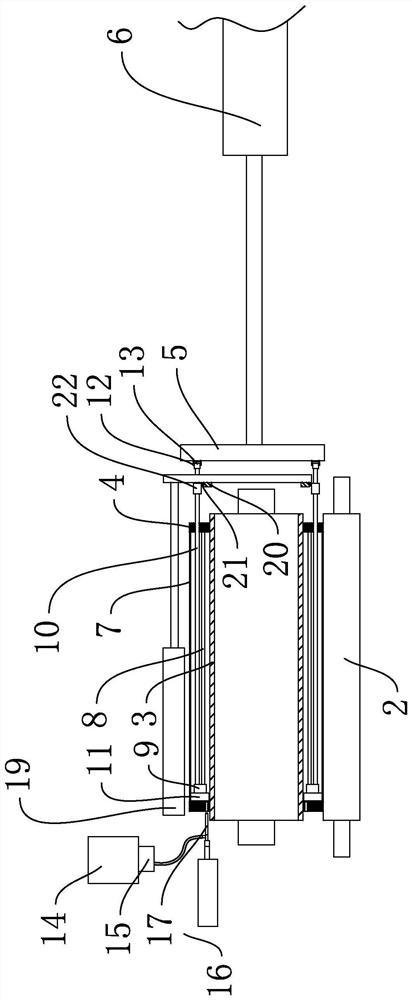

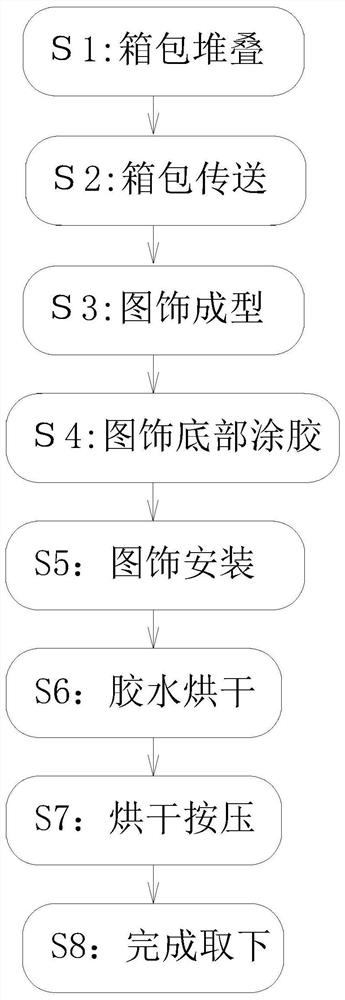

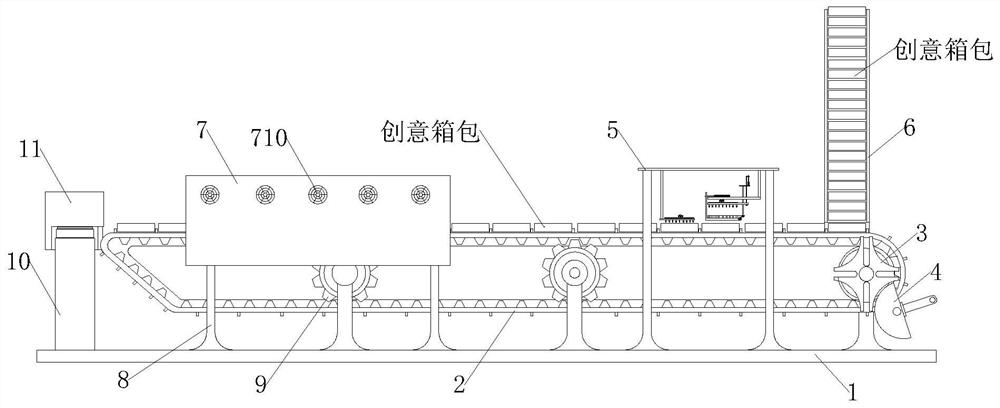

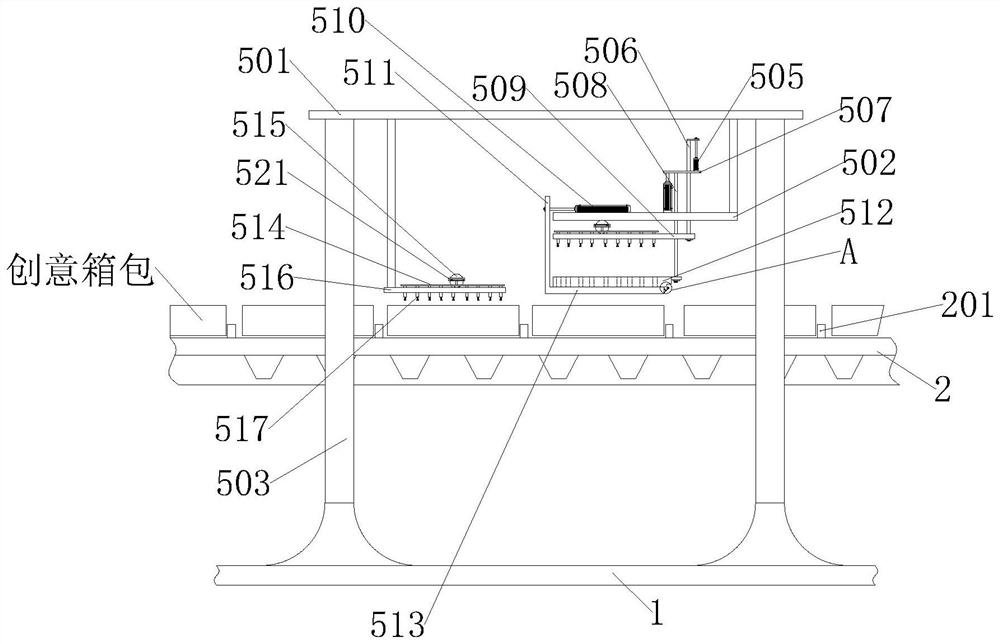

Forming and manufacturing process for creative luggage connecting accessories

InactiveCN113199774AAvoid thermal melting and heat damageReduce temperature heatingOther accessoriesDomestic articlesAdhesive glueHot blast

The invention provides a forming and manufacturing process for creative luggage connecting accessories, and relates to the technical field of luggage production and processing. The forming and manufacturing process comprises the following steps of S1, carrying out luggage stacking, specifically, stacking luggage in square tubes of a luggage frame in order; S2, carrying out luggage conveying, specifically, intermittently transferring the luggage stacked in the step S1 through a conveying belt so that all the luggage passes through the position below a fixed base and stays for a short time; and S3, carrying out cooling forming, specifically, pouring plastic gel into a forming cavity of the fixed base, and cooling and forming the plastic gel through the forming cavity to obtain a plastic piece. According to the forming and manufacturing process, hot air generated by a first heating pipe in a heating chamber is sucked through a suction fan, then is blown out through a plurality of first air nozzles, and is directly irradiated on the surface of glue at the joint of the plastic piece and the creative luggage, the circumstance that the hot air excessively irradiates the surface of the plastic piece is reduced, and hot melting and heat damage to the formed plastic piece are avoided.

Owner:东阳市创意箱包有限公司

A kind of cover gasket automatic assembly equipment

ActiveCN112844959BImprove assembly efficiencyReduce labor costsMaterial gluingPretreated surfacesStructural engineeringIndustrial engineering

An automatic cover pad assembly equipment disclosed in the present invention includes a frame and a turntable arranged on the frame. The turntable is provided with several cover body positioning grooves. Cover feeding system, cover gluing system, gasket feeding system, cover gasket pressing system, and discharge system; the technical scheme of the present invention will cover feeding, gluing and gasket feeding, and finished products The process of discharging and other processes are mechanized, with low labor cost, high production efficiency, no static electricity during assembly, high precision of cover gasket matching, and the gasket can be assembled into the cover body by bonding, so as to ensure that the gasket is not easy to fall off .

Owner:ZHEJIANG AIJIREN TECH

A sticky note glue coating device

ActiveCN113649233BFast glue applicationImprove gluing efficiencyLiquid surface applicatorsCoatingsAdhesive glueElectric machinery

The invention provides a sticky note glue coating device, which belongs to the technical field of machinery. A sticky note glue coating device, comprising a frame, a first conveyor belt is arranged on the frame, a gluing mechanism for gluing is arranged above the first conveyor belt, and the gluing mechanism includes a second conveyor belt, several long The strip-shaped rubber storage parts, moving plate, first push rod motor, and the second conveyor belt are arranged above the first conveyor belt, and the rubber storage parts are fixed on the second conveyor belt at equidistant intervals. The opening opened in the length direction of the part and the sliding hole opened on the side of the rubber storage part, the screen plate is fixed on the opening, the guide rod is fixed inside the rubber storage part, the slide block is slid on the guide rod, and the slide block is fixedly connected with the slide bar , the slide bar slides through a slide hole, the slide bar is fixed with a rubber storage scraper, and the rubber storage scraper has a rubber storage chamber.

Owner:嘉兴华善文具制造股份有限公司

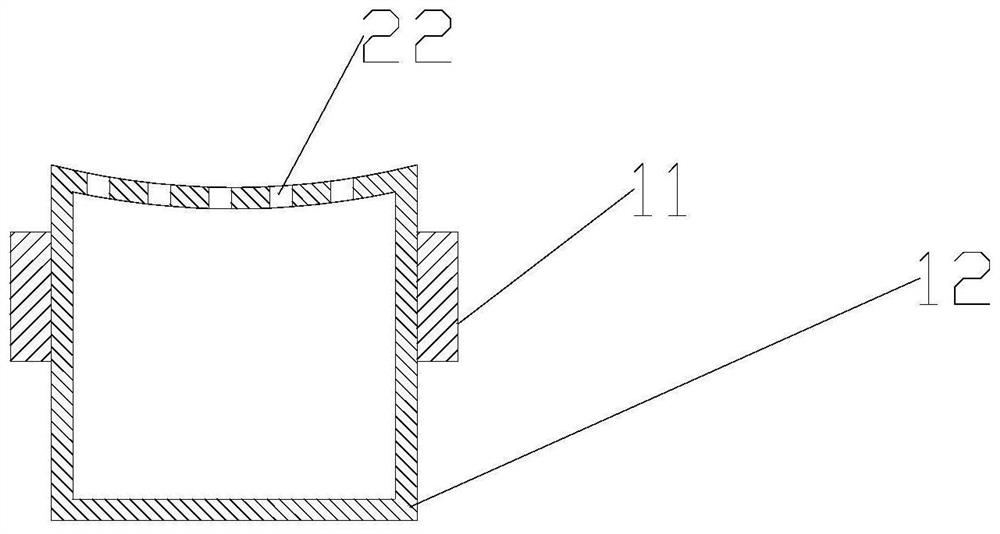

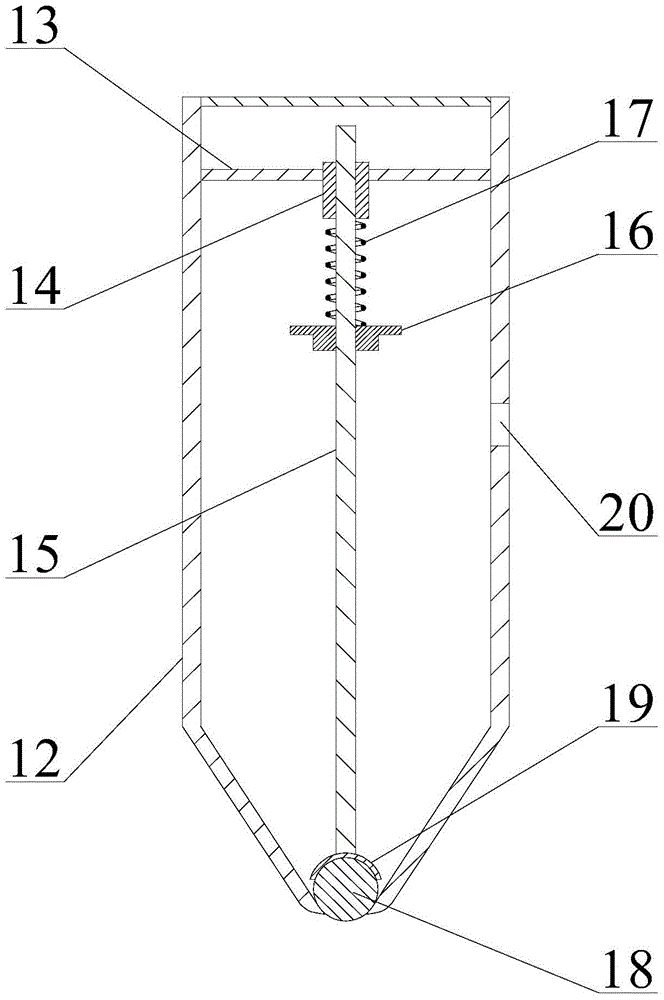

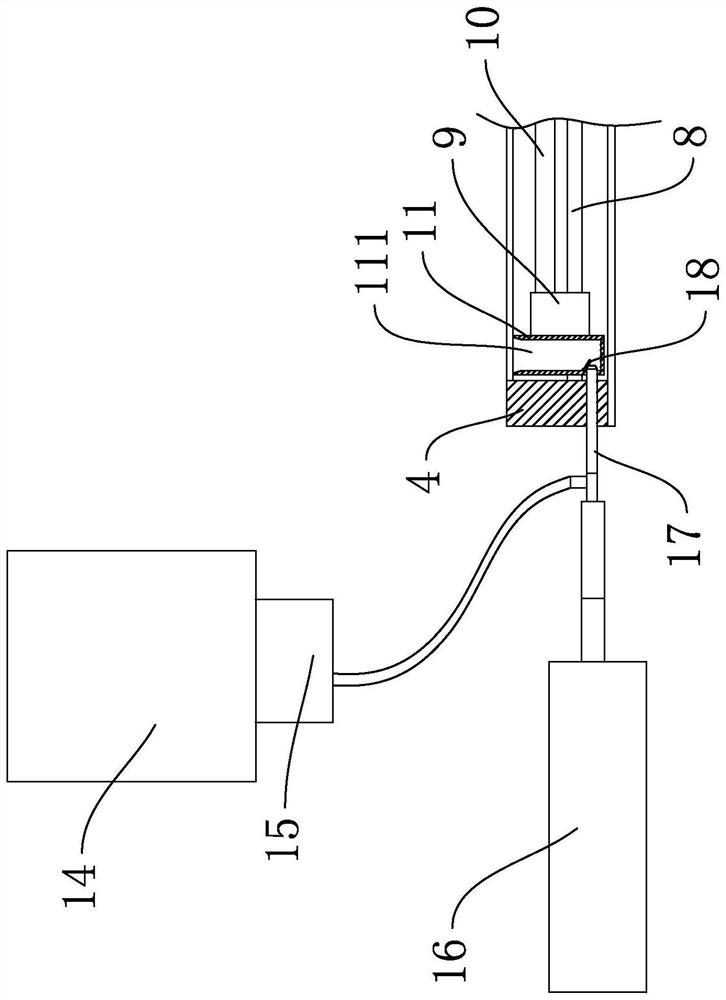

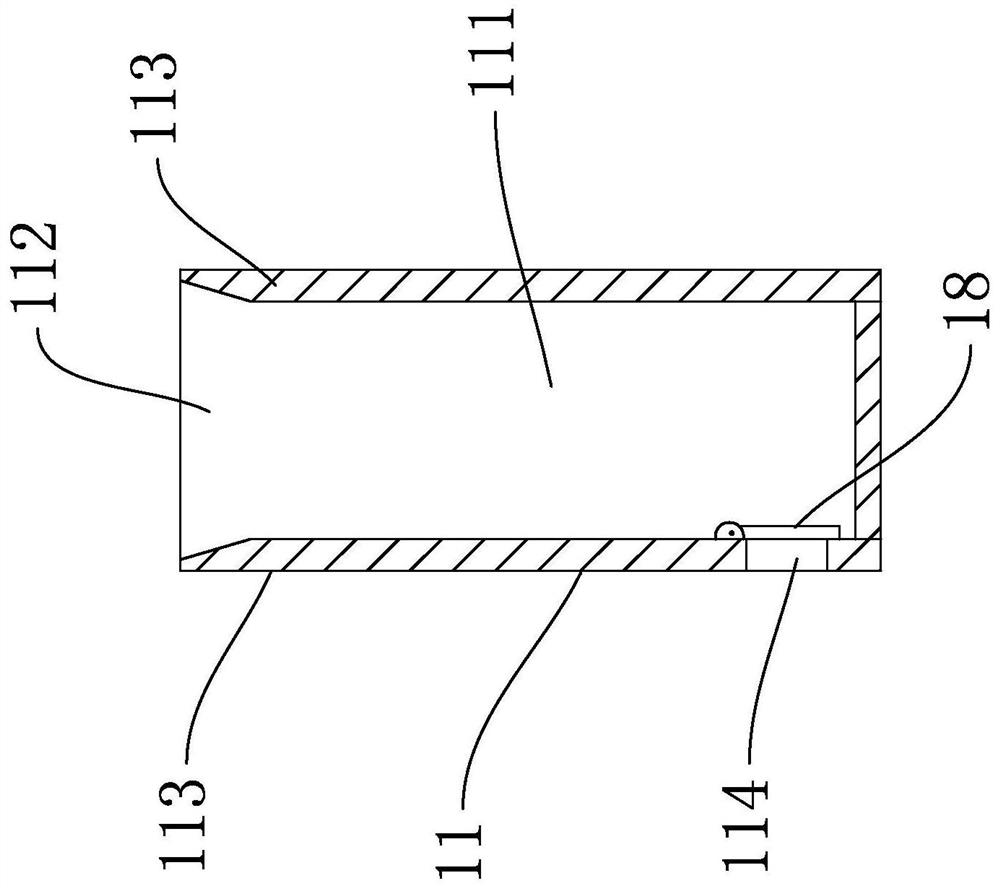

Creative luggage surface pattern decoration forming preparation technology

InactiveCN113182141AUniform pouringEasy to pourMaterial gluingSpraying apparatusSurface patternAdhesive glue

The invention provides a creative luggage surface pattern decoration forming preparation technology, and relates to the technical field of luggage production and machining. The technology comprises the following steps that S1, luggage stacking is performed, specifically, luggage is stacked in square tubes of a luggage rack in order; S2, the luggage is conveyed, specifically, the luggage stacked in S1 is intermittently transferred through a conveying belt, and all the luggage passes through the lower side of a fixed base and stays temporarily; S3, pattern decoration forming is performed, specifically, pattern decoration gel is poured into a forming cavity of the fixed base, and the pattern decoration gel is cooled through the forming cavity, so that the pattern decoration gel can be rapidly shaped. A glue shoveling blade at the right end of a third gluing sealing plate slides back and forth at the bottom end of a third forming plate, glue adhering to the bottom surface of the third forming plate in the moving process of a glue rolling roller on the bottom end surface of the third forming plate is scraped, and the gluing uniformity of the glue rolling roller is improved.

Owner:东阳市创意箱包有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com