Lithium battery adhesive sticking device

A glue sticking device, lithium battery technology, applied in secondary batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low efficiency, uncontrollable length, cumbersome sticking process design, etc., to improve sticking speed, The effect of improving the efficiency of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

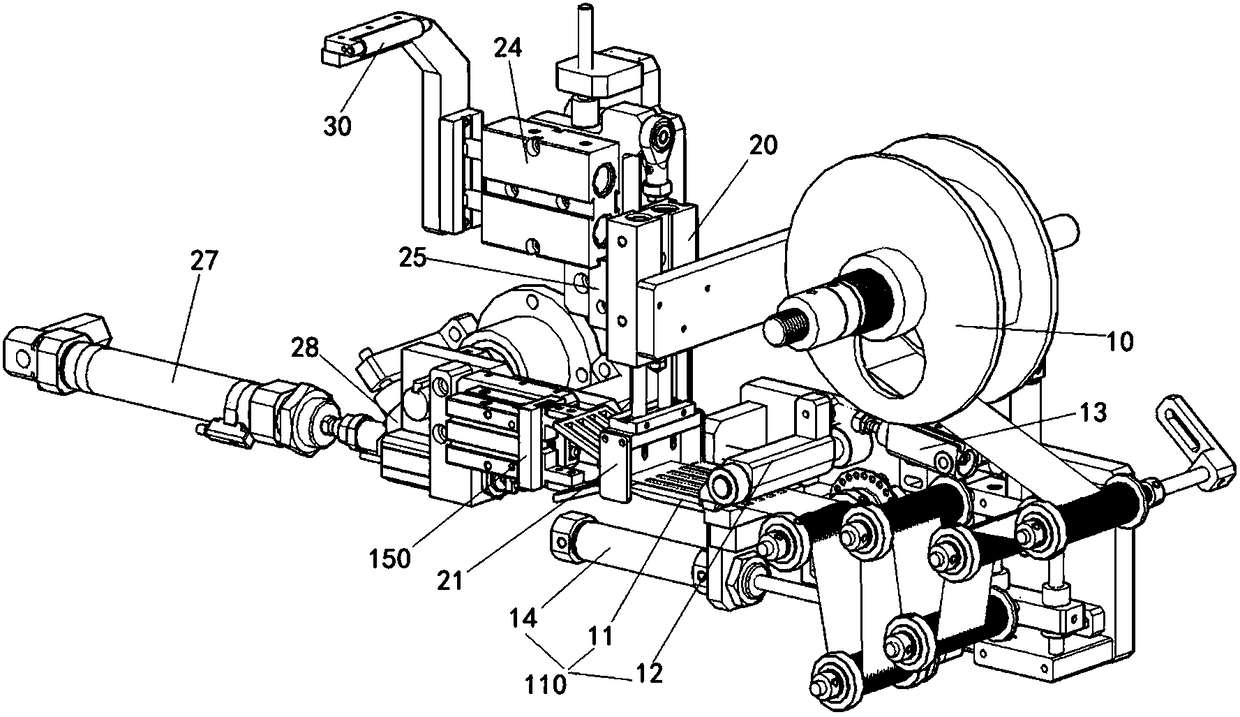

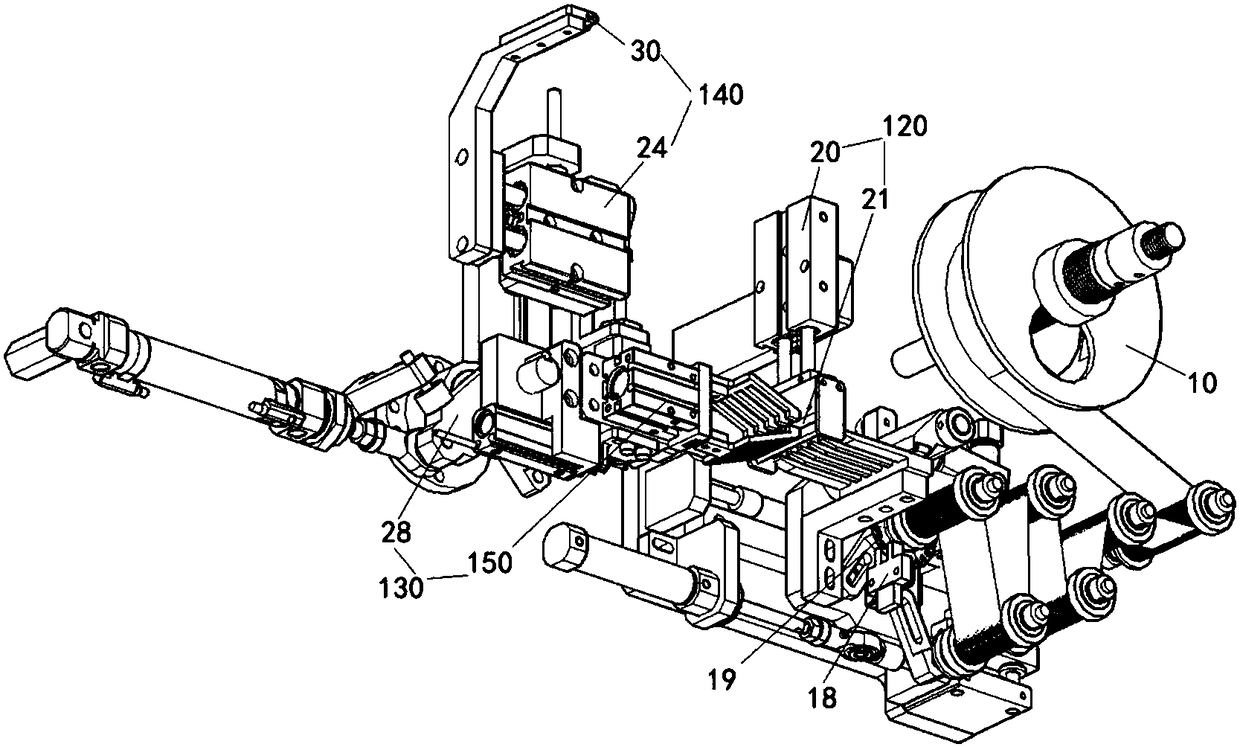

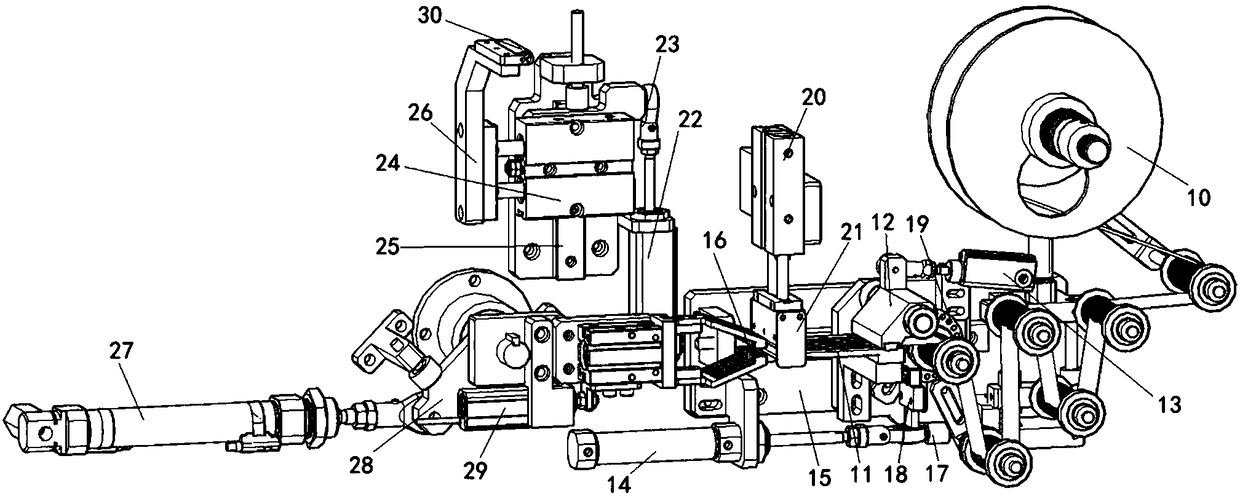

[0023] Please refer to Figure 1 to Figure 3 , the lithium battery gluing device of this embodiment,

[0024] A lithium battery gluing device, used for gluing wound lithium battery elements at a gluing station, including a controller 200 all installed on a mounting plate, a glue releasing mechanism, a glue feeding mechanism, and a reciprocating motion The glue cutting workbench 110, the glue cutting mechanism, the mechanical arm assembly 130 and the glue pressing assembly 140.

[0025] The controller 200 is connected with the glue feeding mechanism, the glue cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com