Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Improve glue application efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

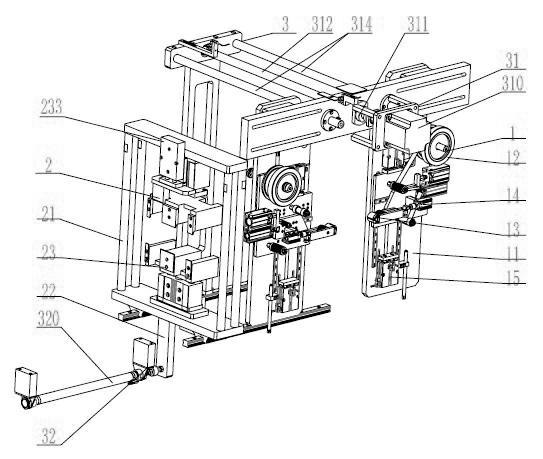

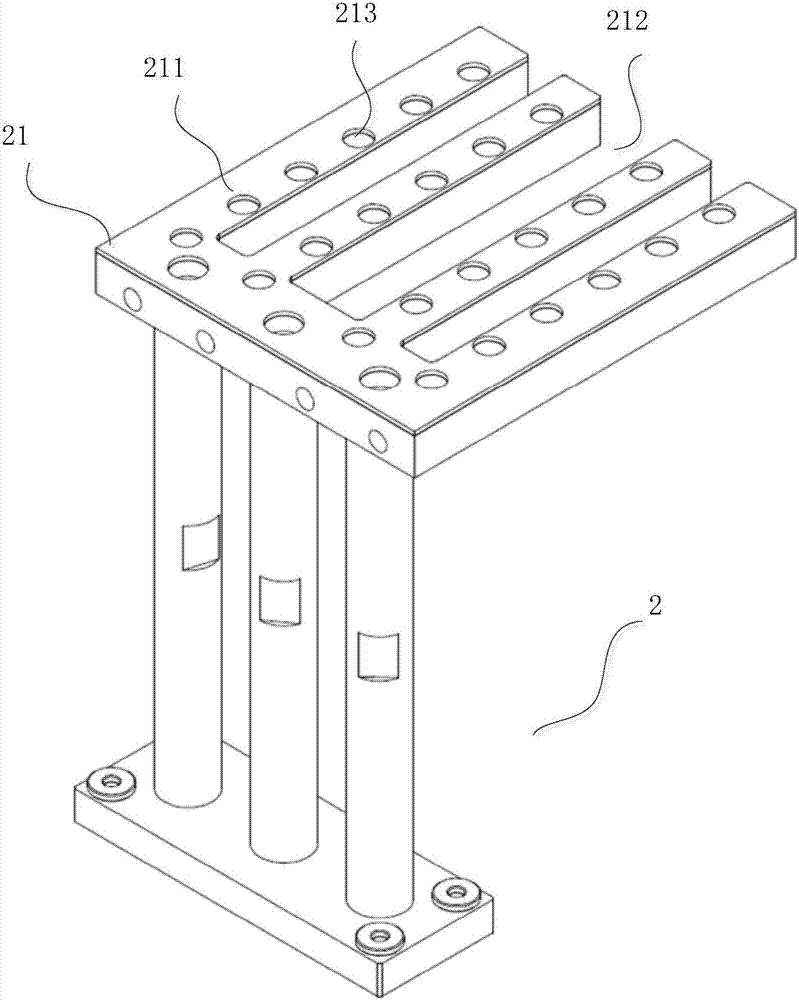

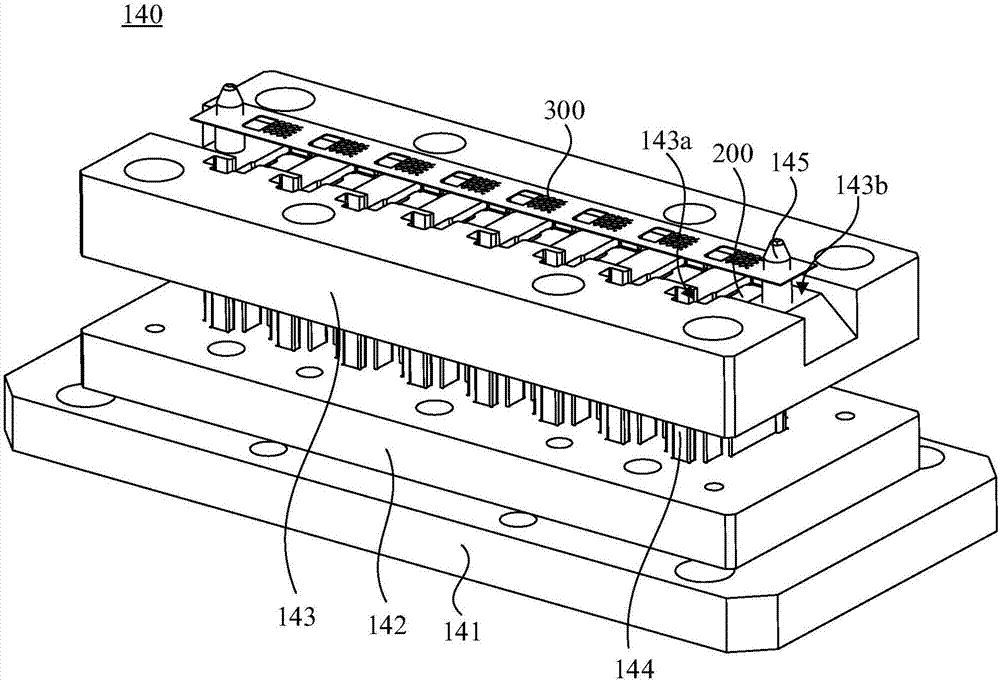

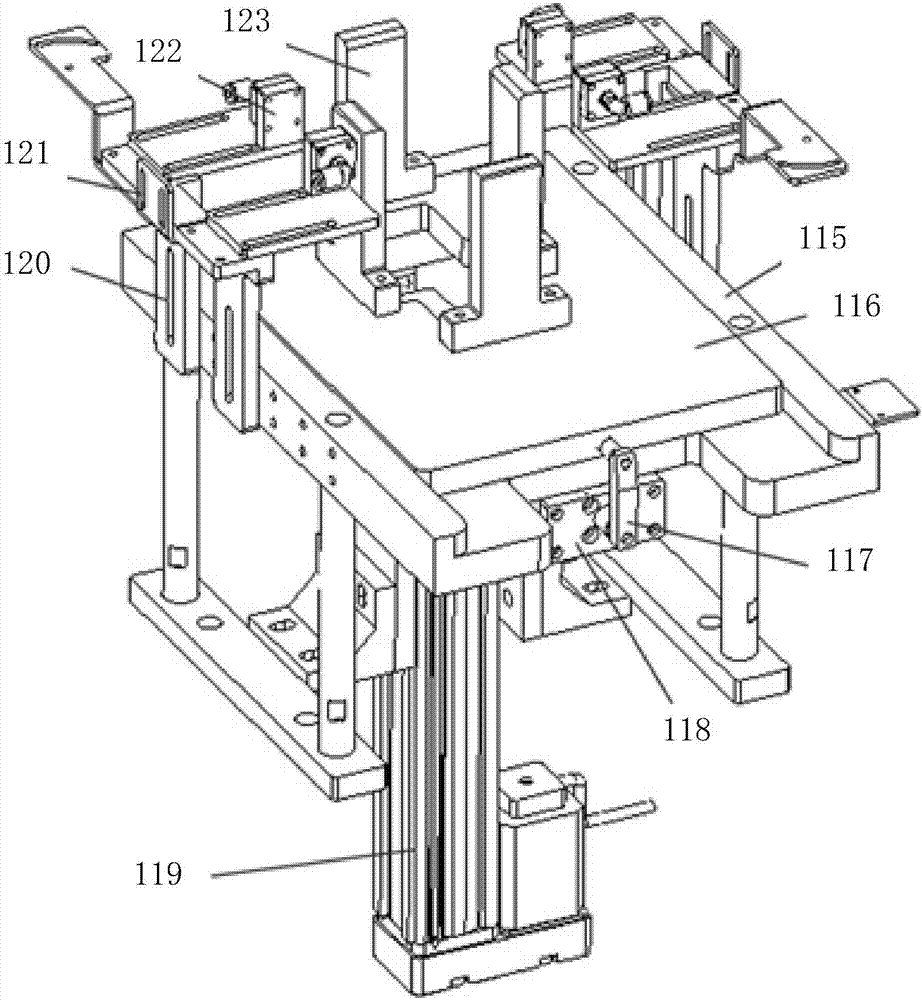

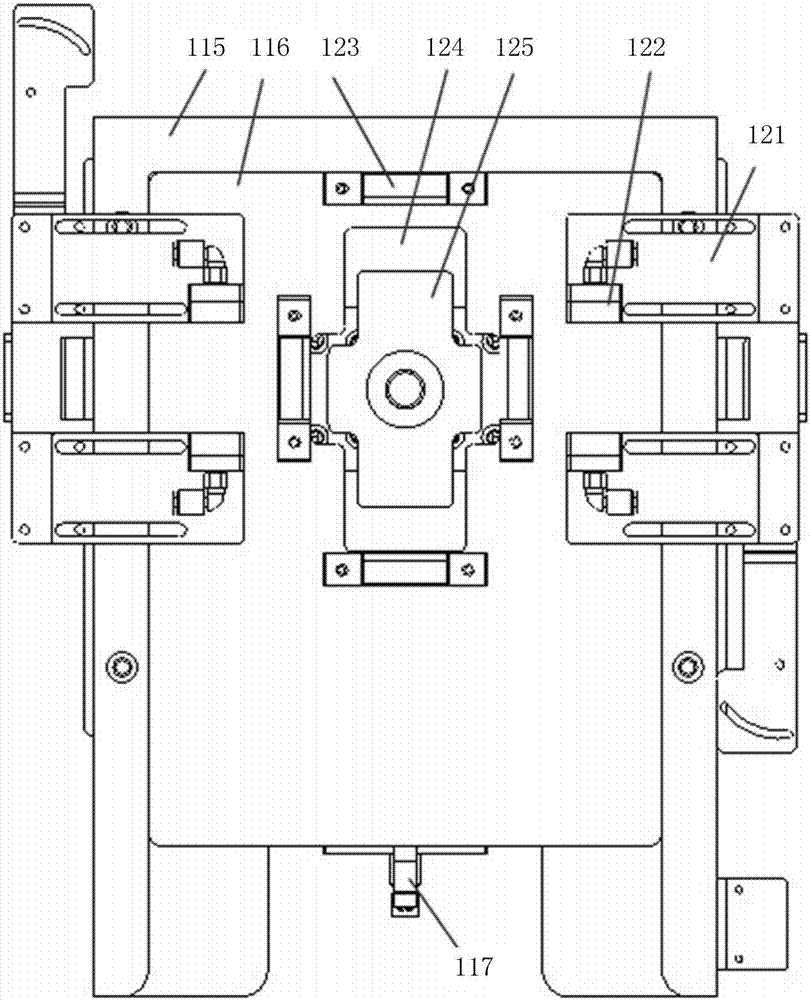

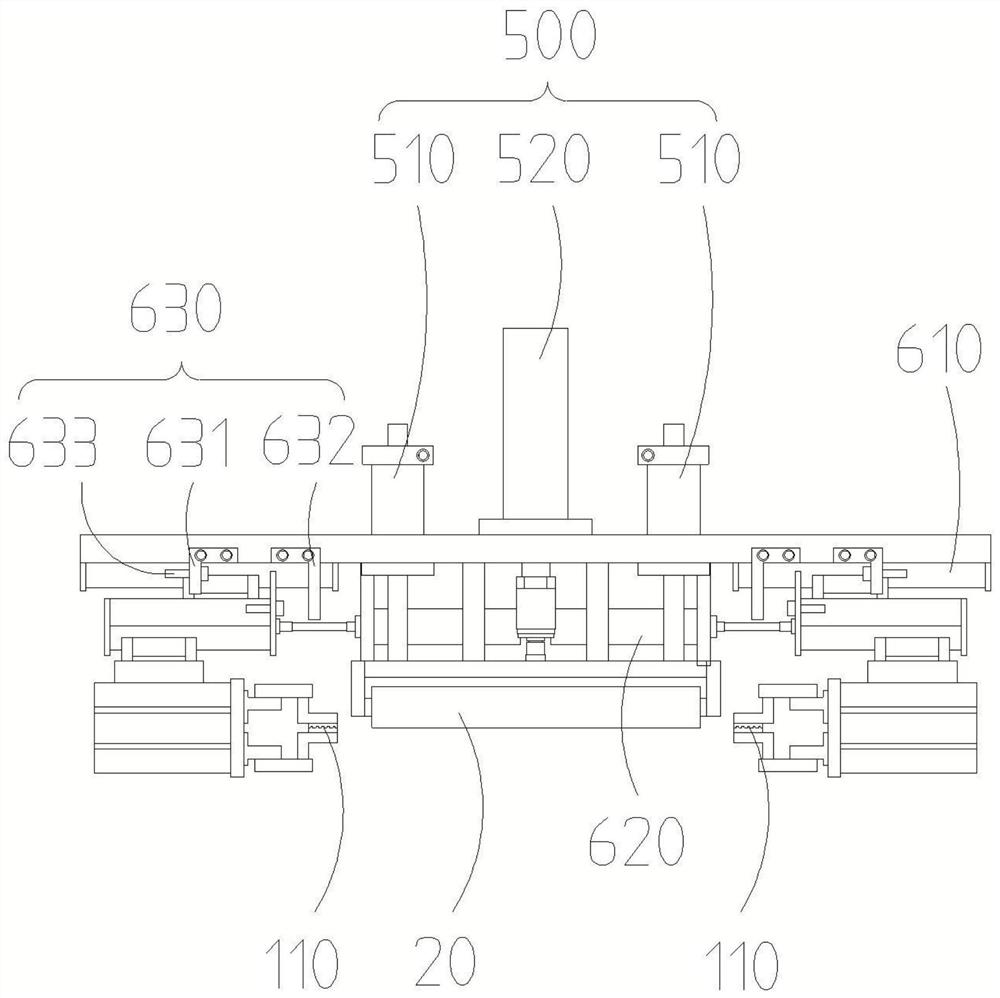

Laminated cell side surface adhesive tape sticking device

ActiveCN102514976AGuaranteed stabilityGuaranteed accuracyFinal product manufactureElectrolyte accumulators manufactureAdhesive beltEngineering

The invention discloses a laminated cell side surface adhesive tape sticking device, which comprises an adhesive tape sticking mechanism, an adhesive tape fixing mechanism and a moving mechanism. The adhesive tape sticking mechanism comprises two groups of adhesive tape sticking components which are arranged to be opposite one another. A space for the adhesive tape fixing mechanism to enter is left between the adhesive tape sticking components. The adhesive tape fixing mechanism comprises two groups of clamping units which are arranged to be opposite one another and is used for clamping a laminated cell and exposing at least partial side surface of the laminated cell and the side parts of a top end and a bottom end which are connected with the corresponding side surfaces. The moving mechanism comprises a clamping moving unit which is used for driving the adhesive tape fixing mechanism and an adhesive tape sticking moving unit which is used for driving the adhesive tape sticking mechanism. After the adhesive tape sticking mechanism is configured, the adhesive tape sticking mechanism drives the adhesive tape sticking components at an adhesive tape sticking position to stick an adhesive tape from the side part of the top end to the side part of the bottom end of the laminated cell along the side surface of the laminated cell, or from the side part of the bottom end to the side part of the top end of the laminated cell. The adhesive tape sticking device has the advantages that the adhesive tape sticking success rate is high, especially the laminated cell can be prevented from being deformed, the stability of the laminated cell can be guaranteed and the quality of the laminated cell is improved.

Owner:深圳市和合自动化有限公司

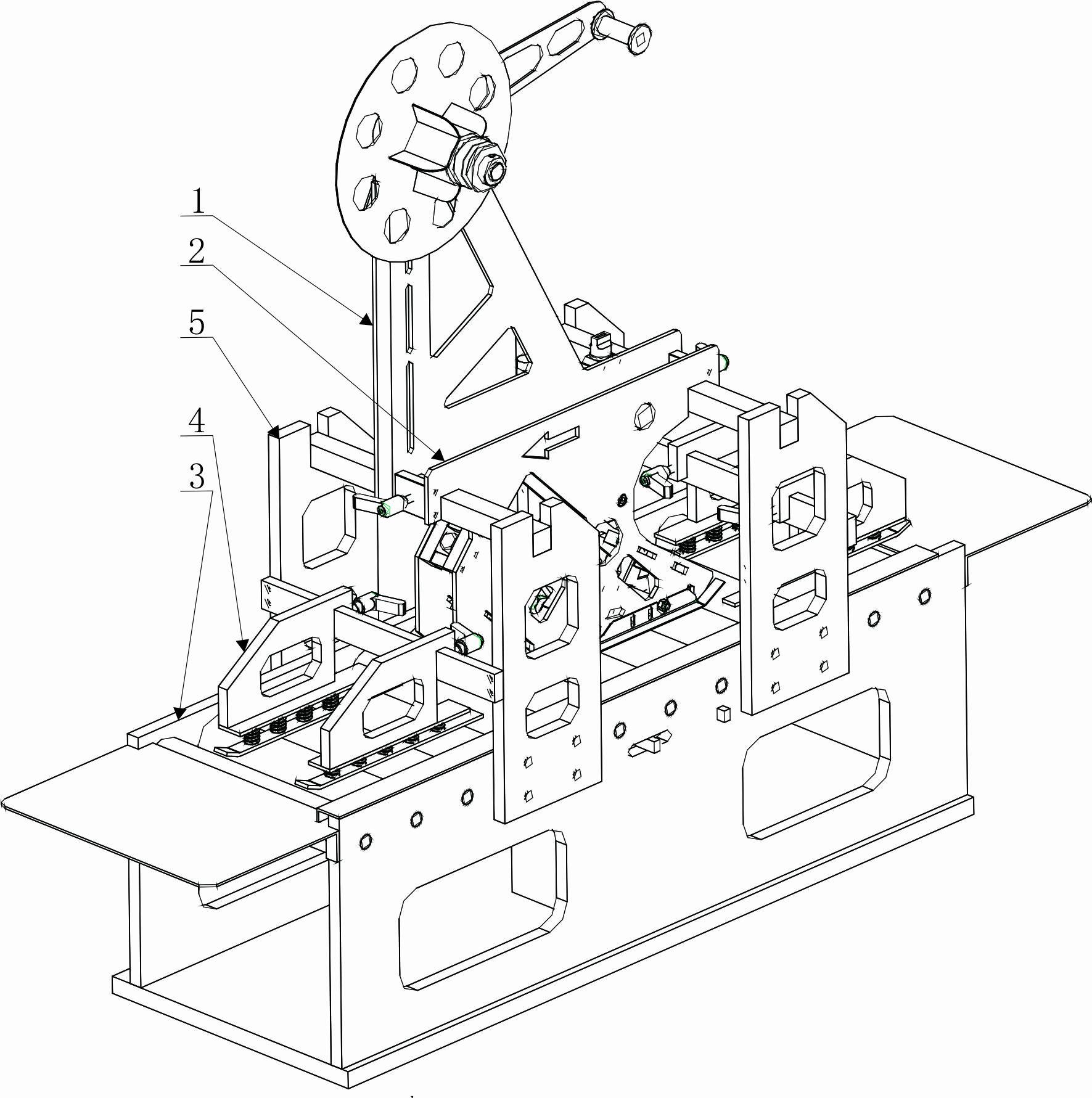

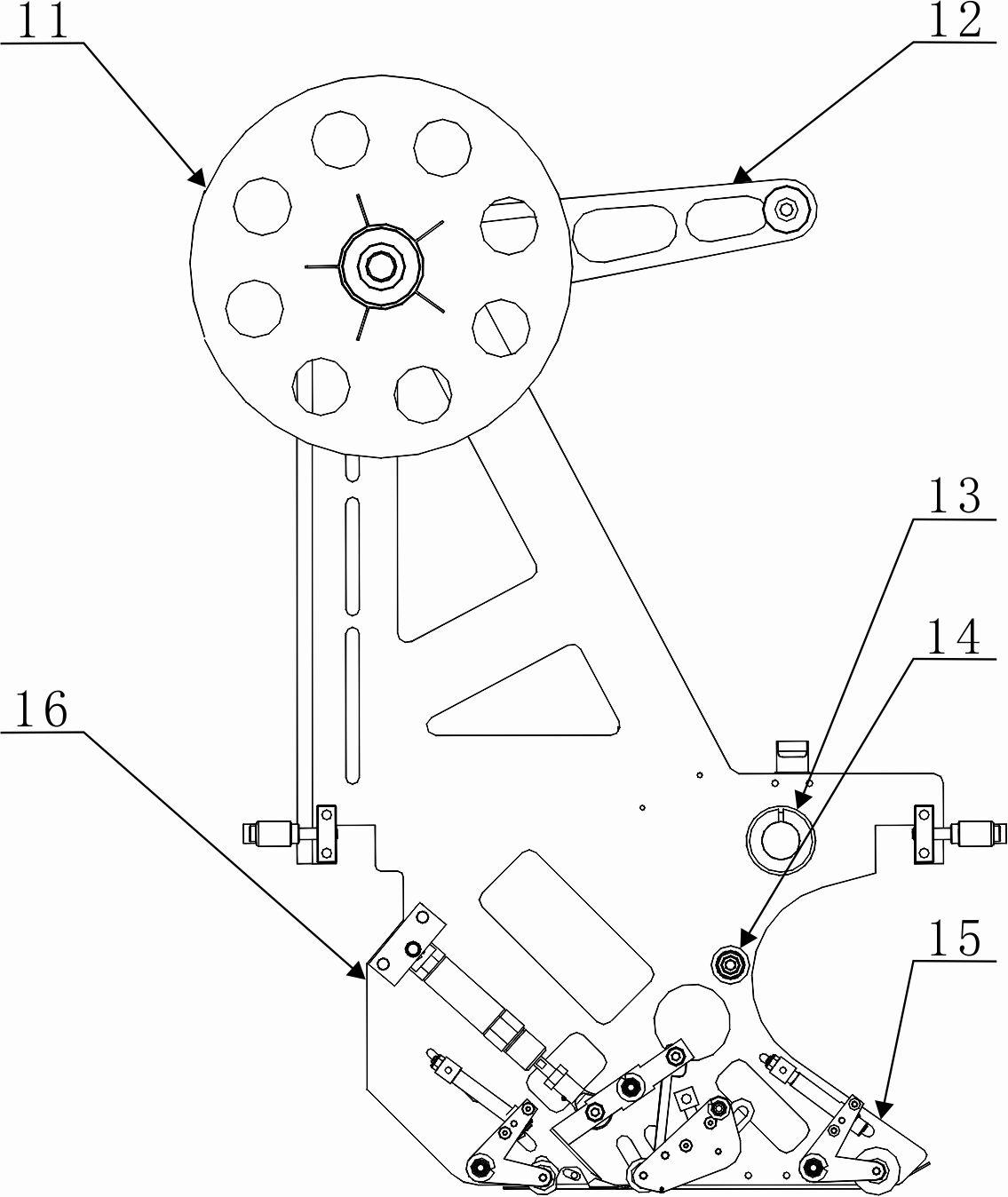

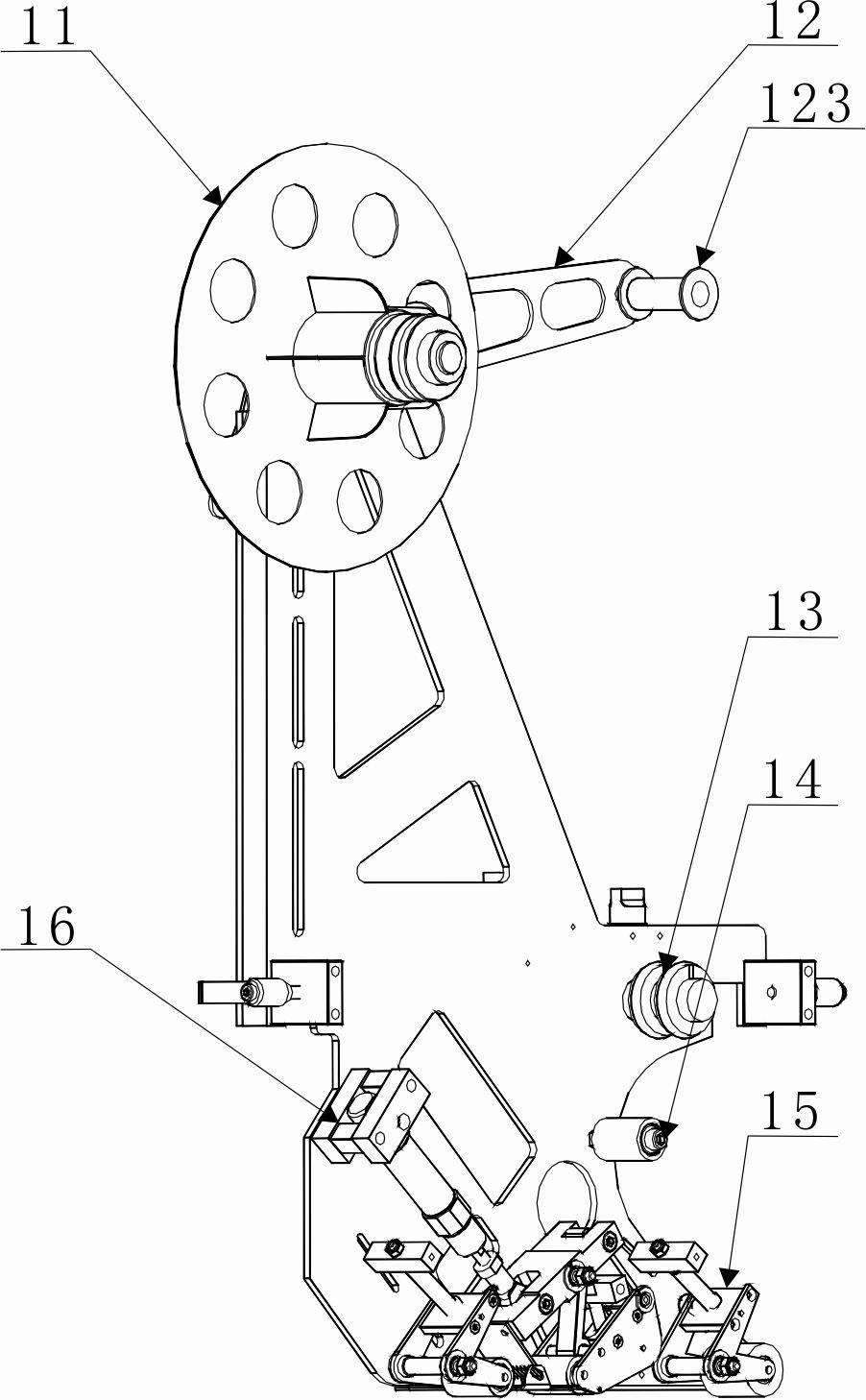

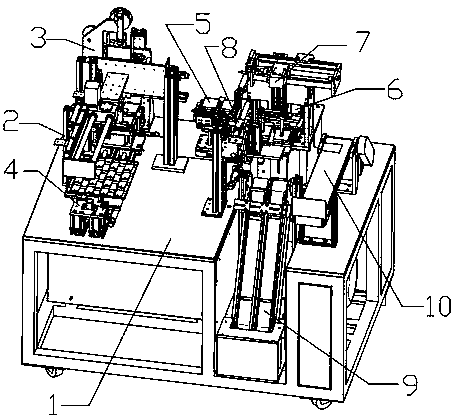

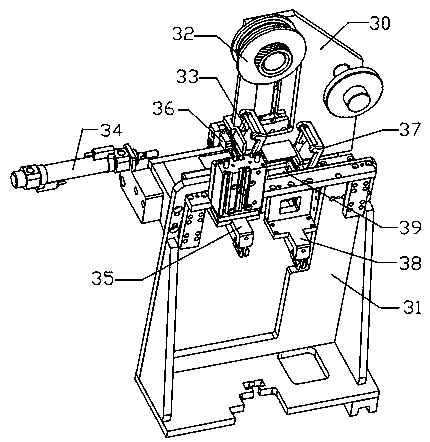

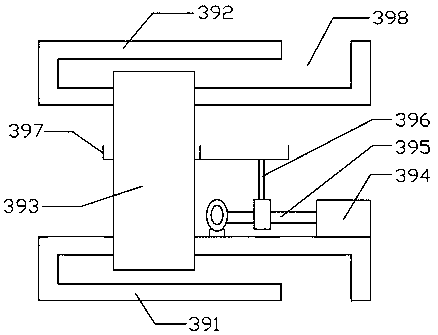

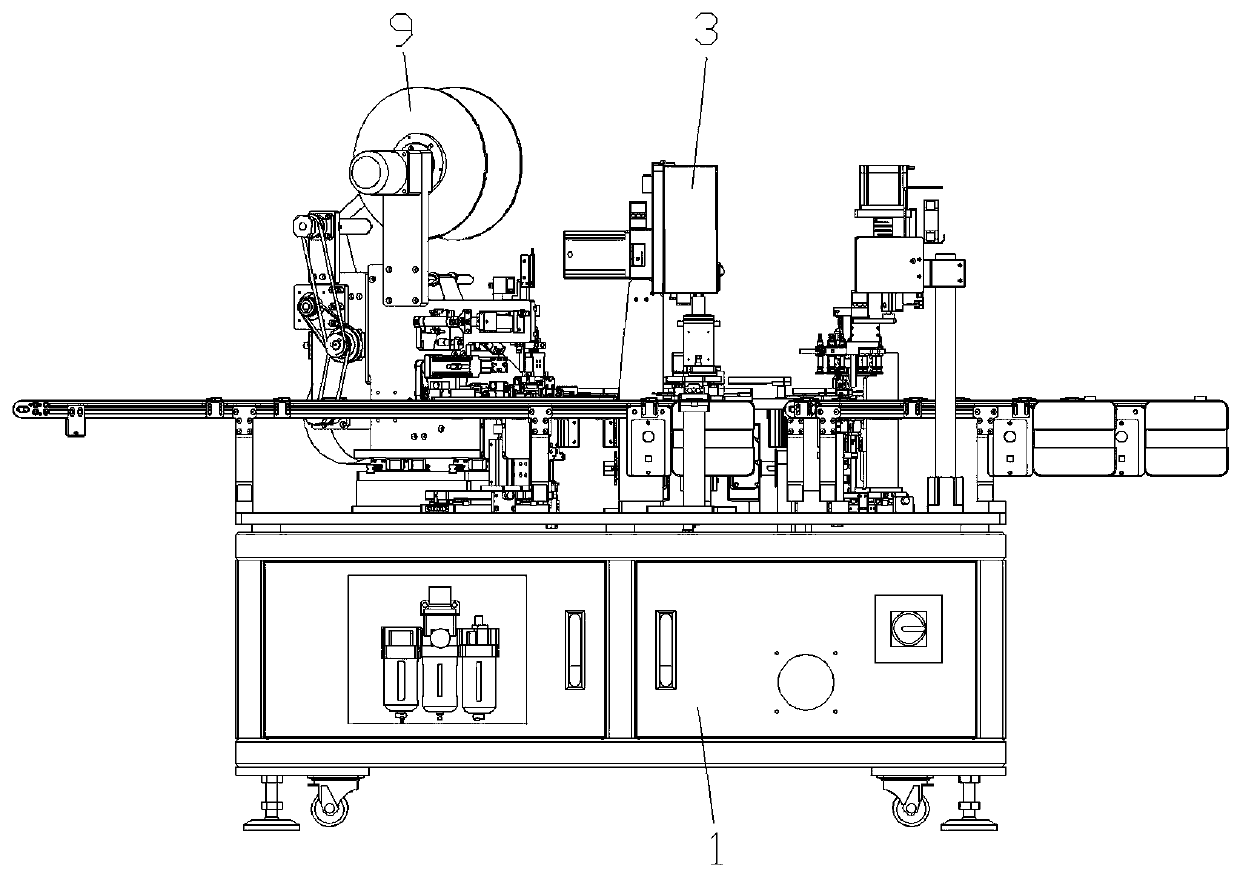

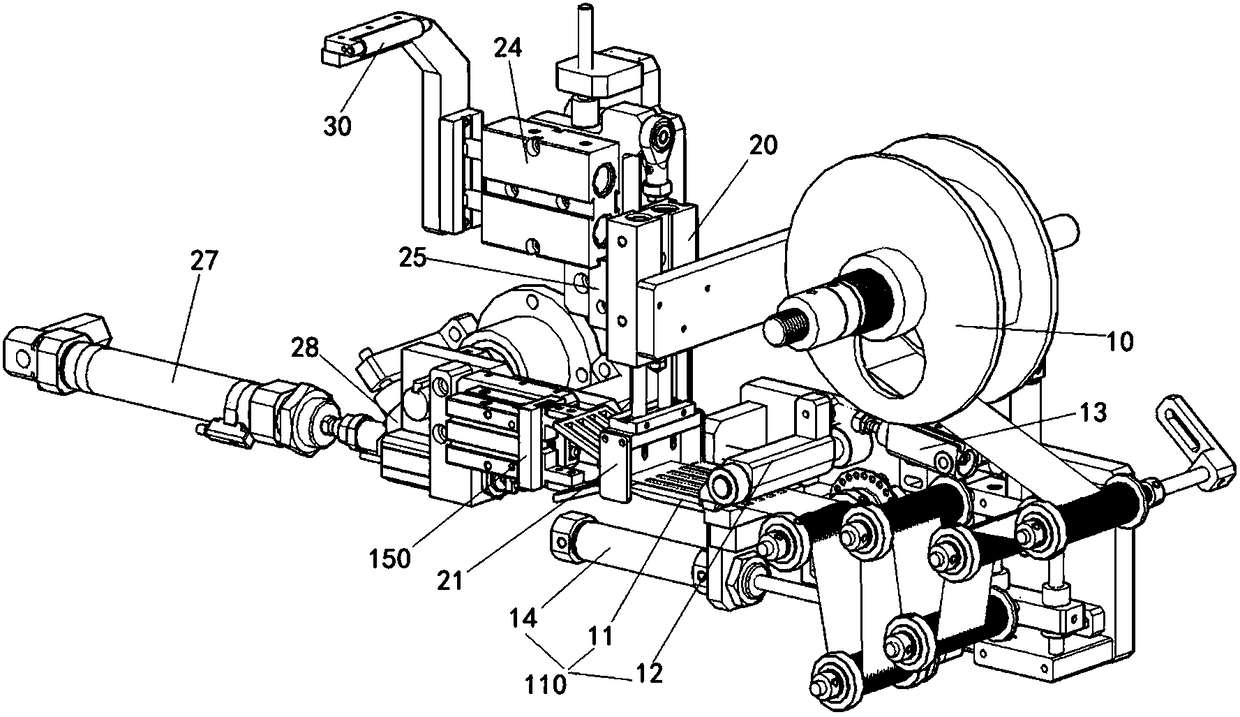

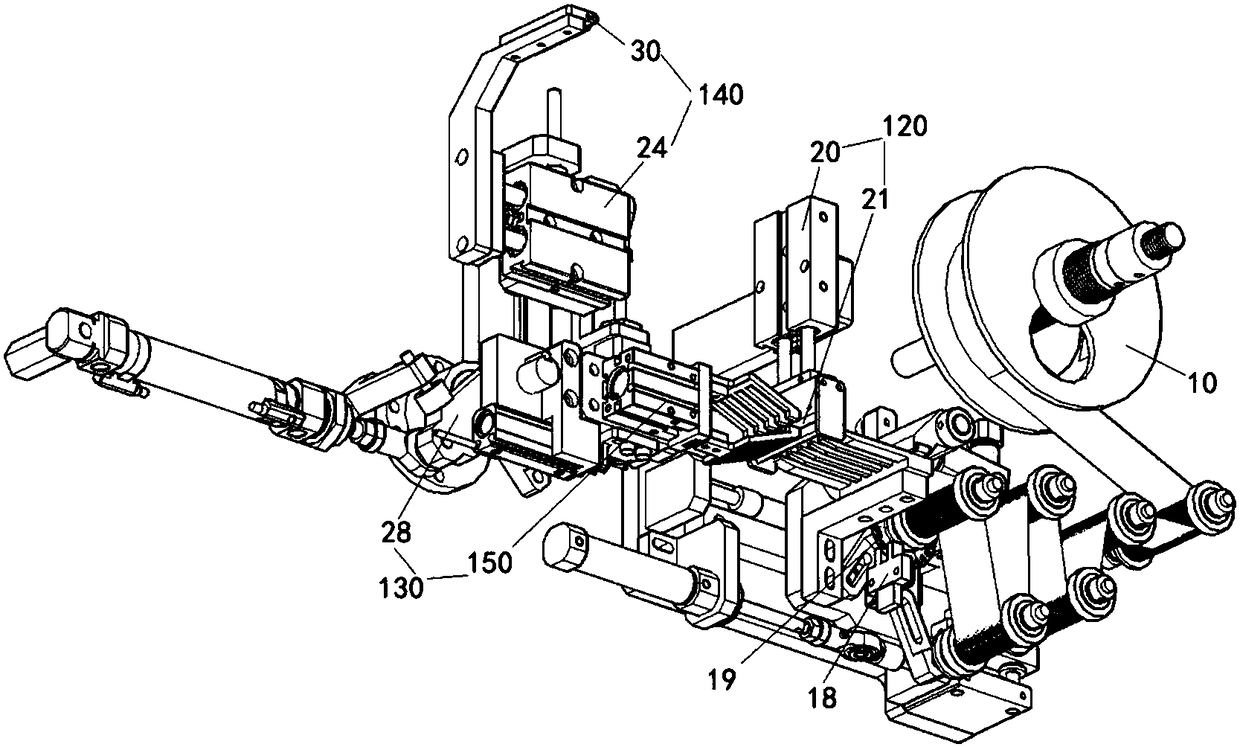

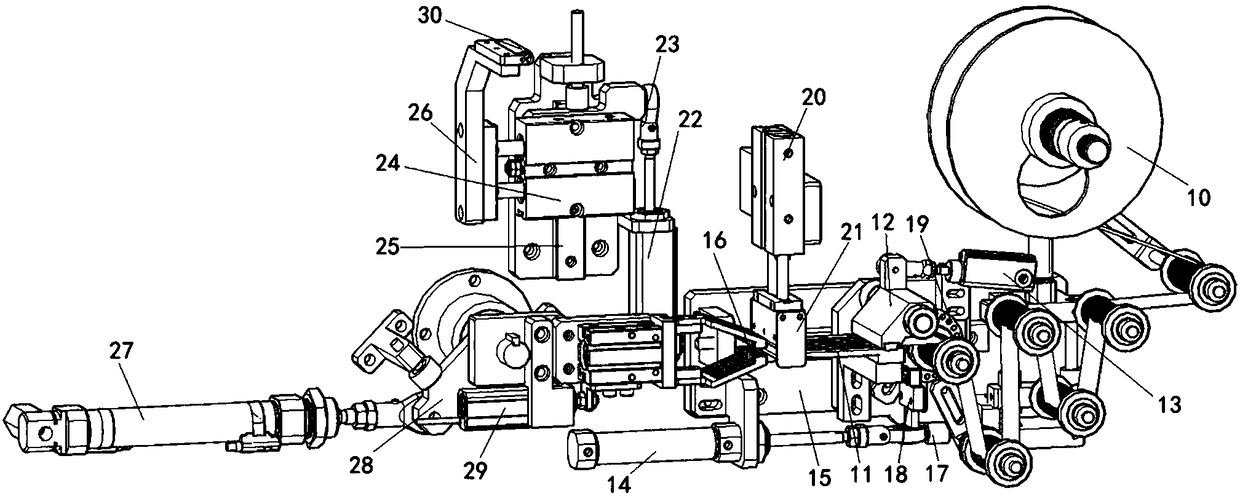

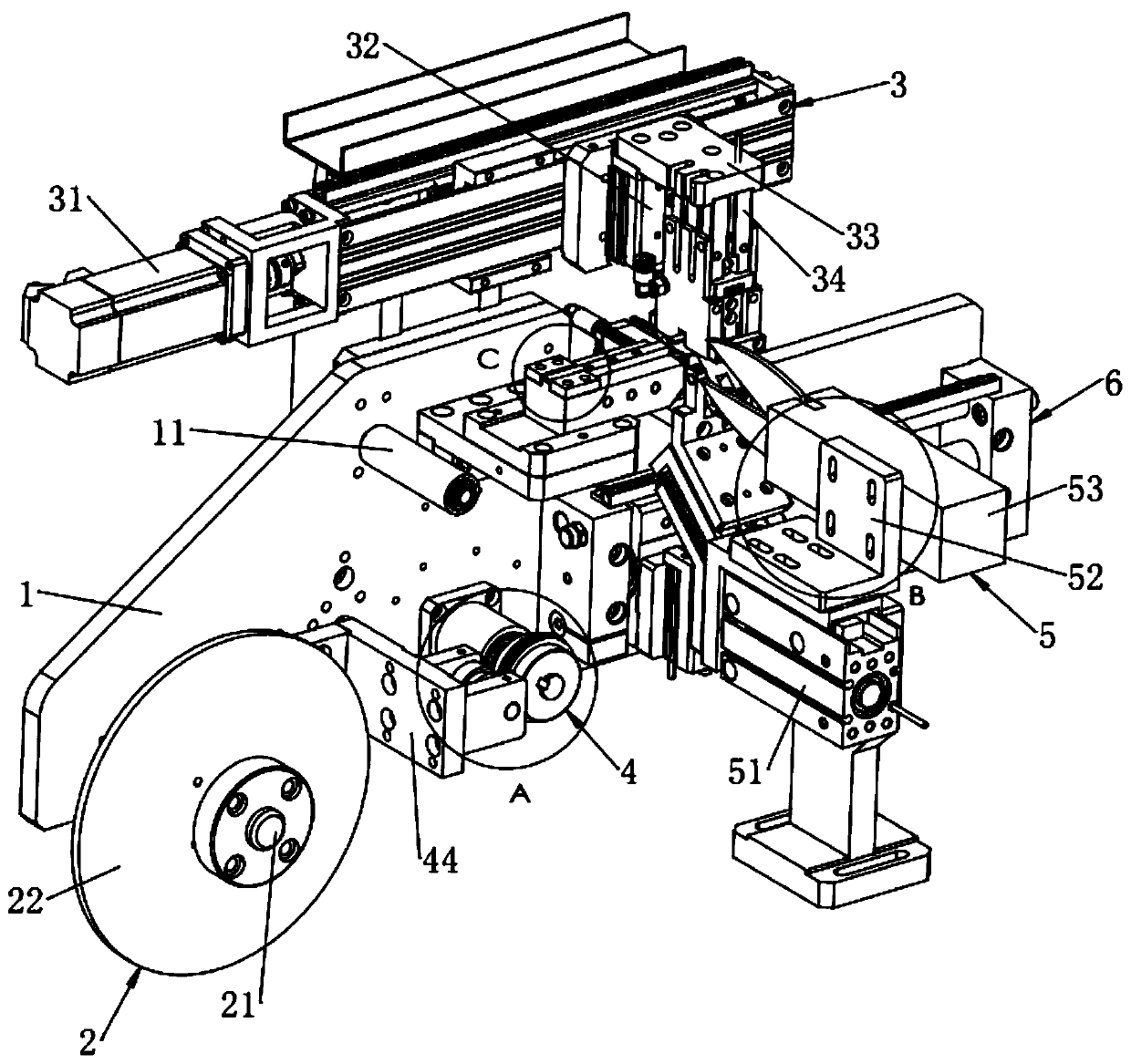

Novel tape adhering machine

ActiveCN102674069AImprove glue application efficiencySimple structureArticle deliveryKnuckleEngineering

The invention discloses a novel tape adhering machine which comprises at least one tape adhering head and a base, wherein the tape adhering head comprises a main mounting plate a and an assorted mounting plate which is matched with the main mounting plate a; a tape fixing wheel and a cutting mechanism are arranged on the main mounting plate a; the tape fixing wheel is arranged at the top of the main mounting plate a for fixing a tape; the cutting mechanism is arranged at the lower part of the main mounting plate a; the cutting mechanism is provided with a cylinder to drive a prepressing module and a cutter to complete the tape adhering and cutting tasks; and the base is used for fixing the tape adhering head and conveying materials which are required to be adhered. The novel tape adhering machine utilizes the lever principle to complete the tape adhering and cutting tasks through a driving link which consists of the cylinder and a knuckle bearing, so the adhering efficiency is greatly increased, in addition, the structure of the tape adhering head is also correspondingly simplified, and the cost is lowered; and moreover, the novel tape adhering machine meets different specification requirements on the materials which are needed to be adhered, and the adhering effect is improved.

Owner:POLYGON AUTOMATION TECH CHENGDU

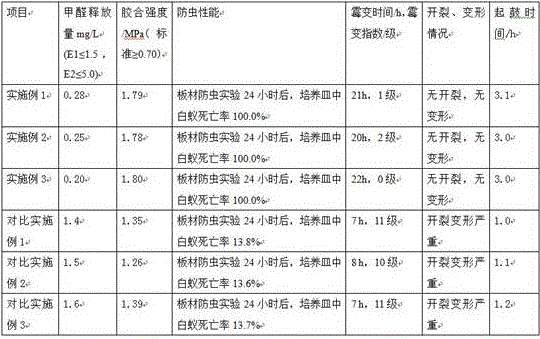

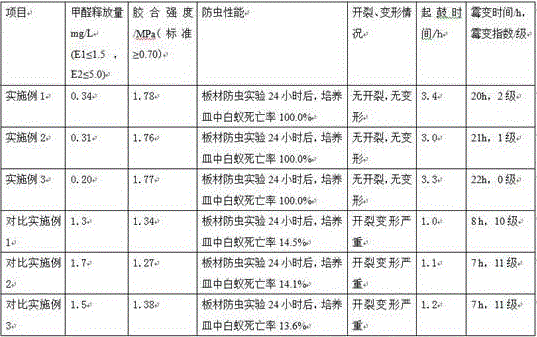

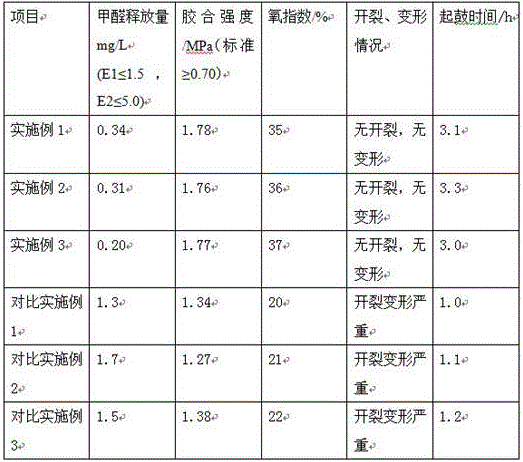

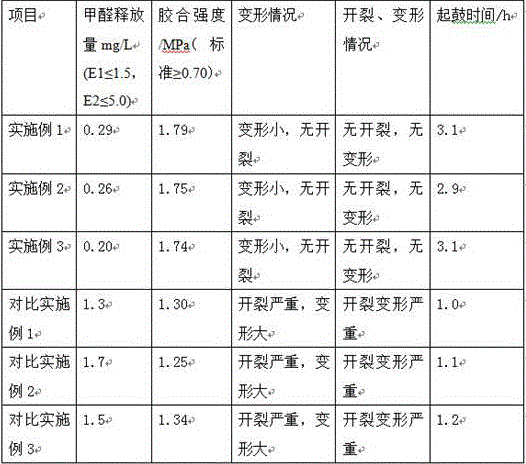

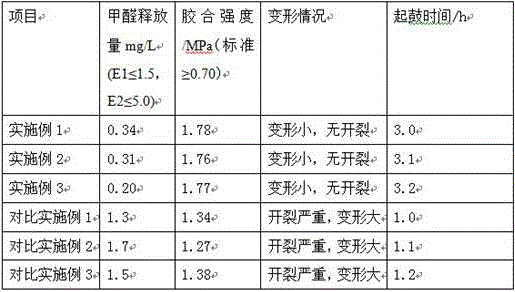

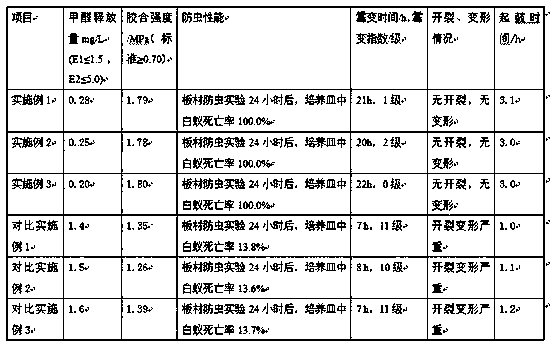

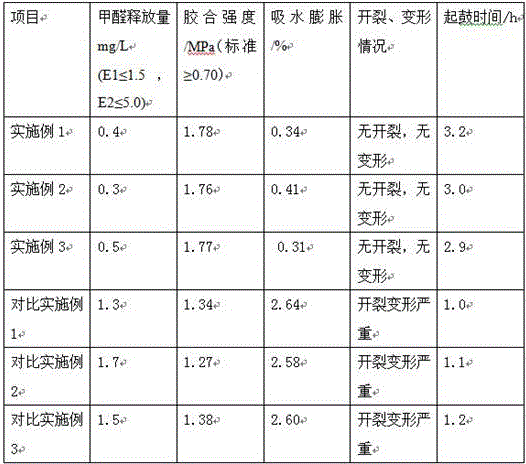

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

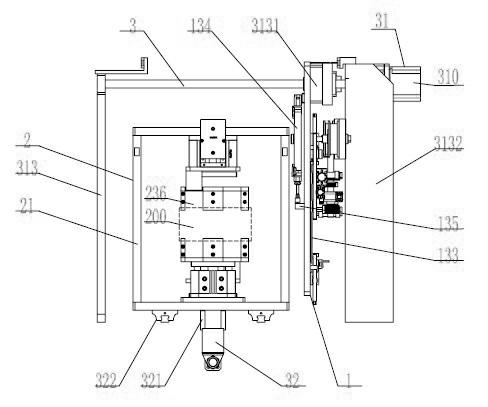

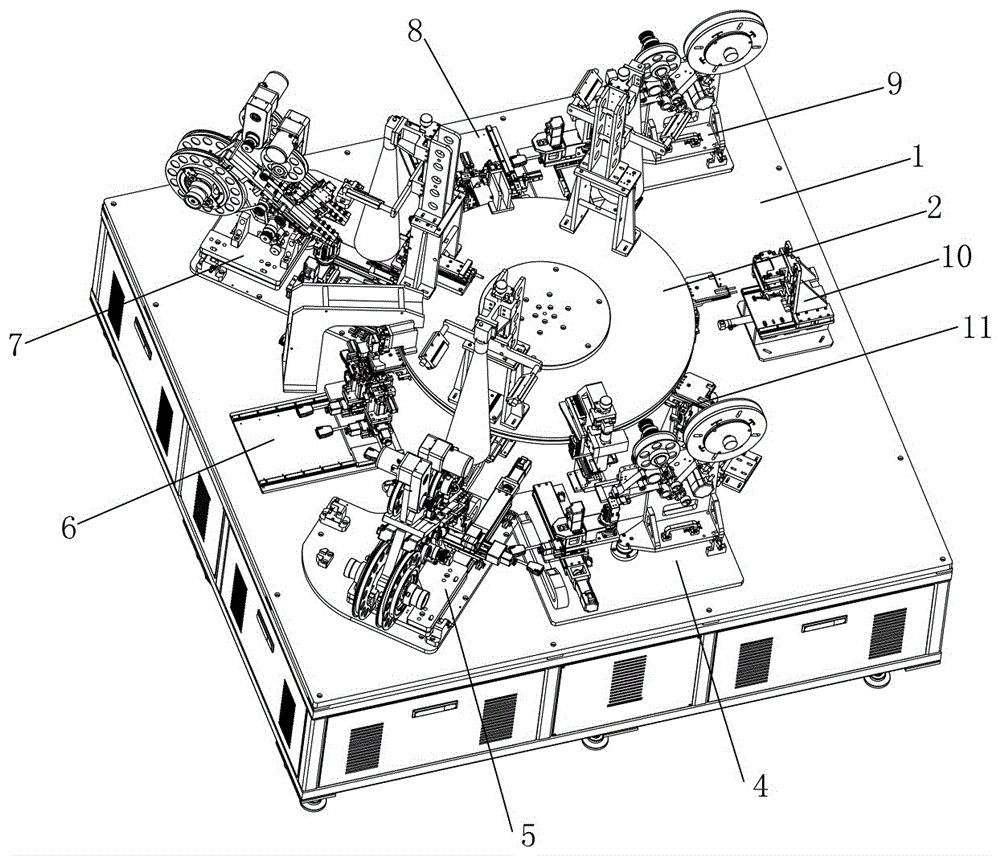

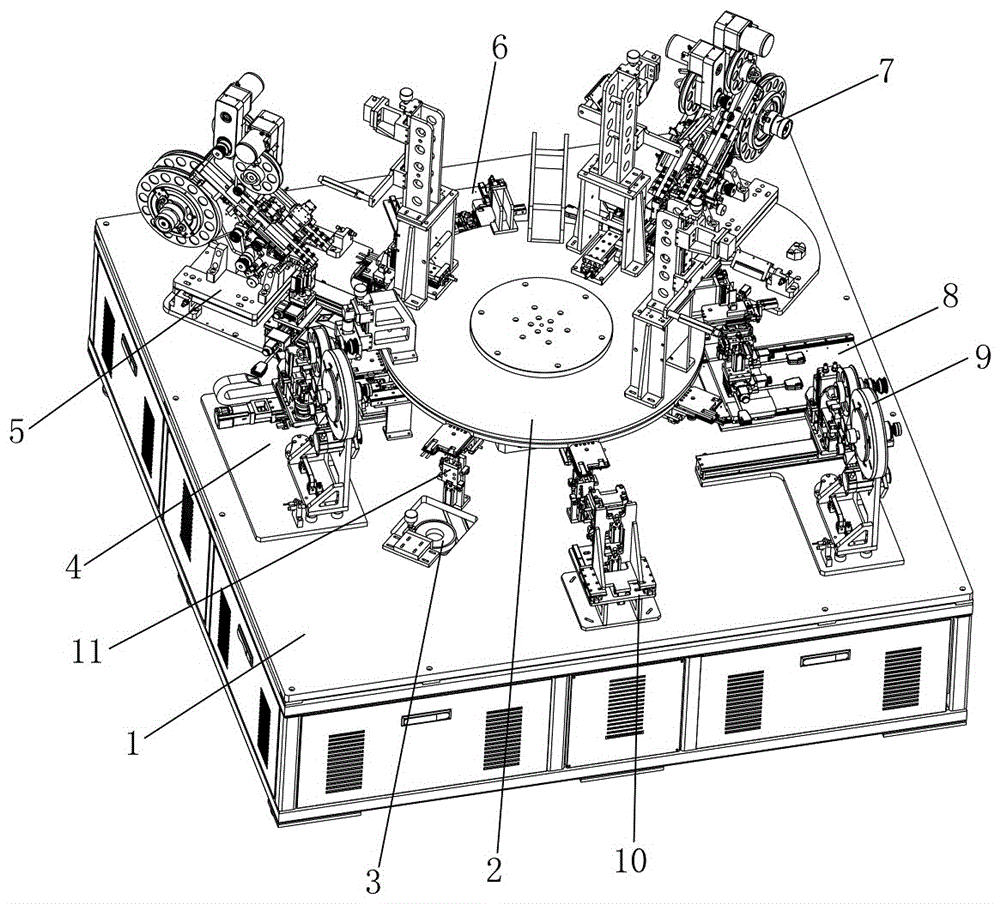

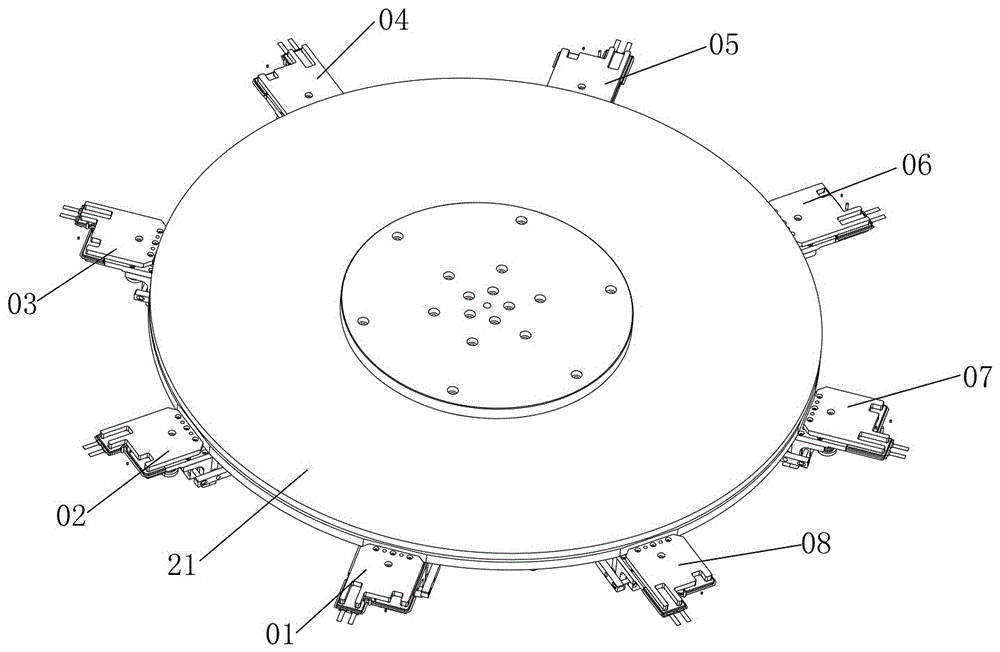

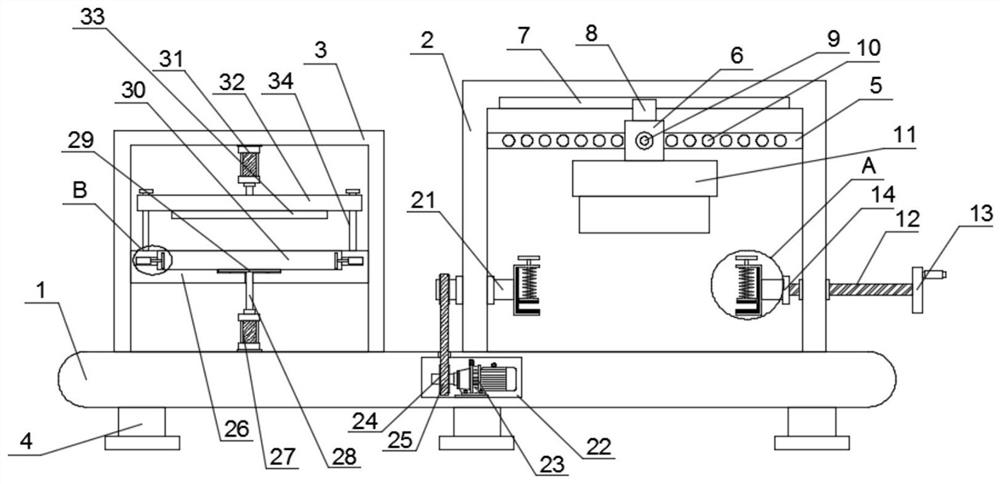

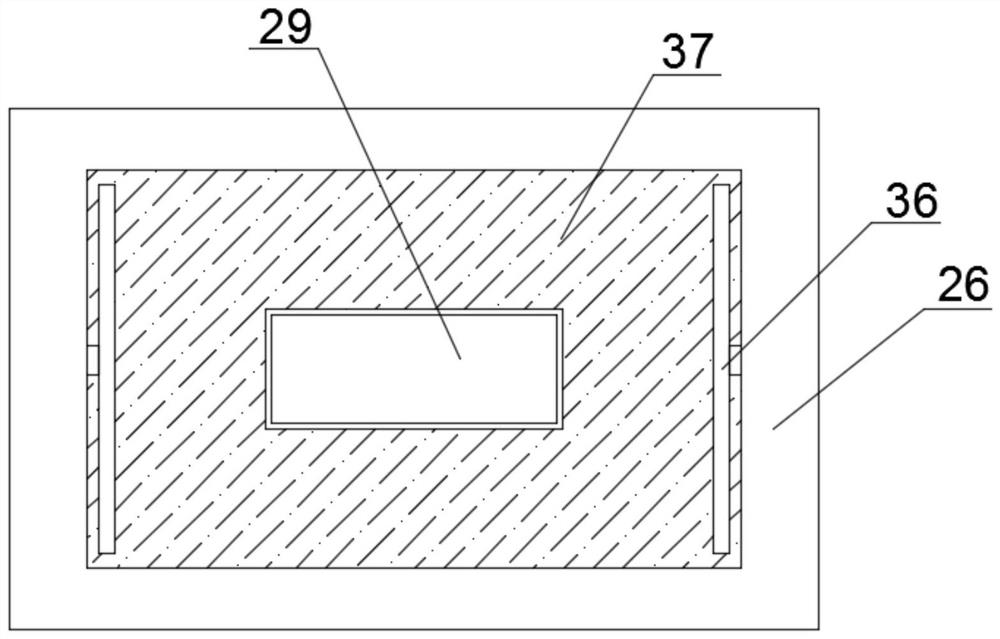

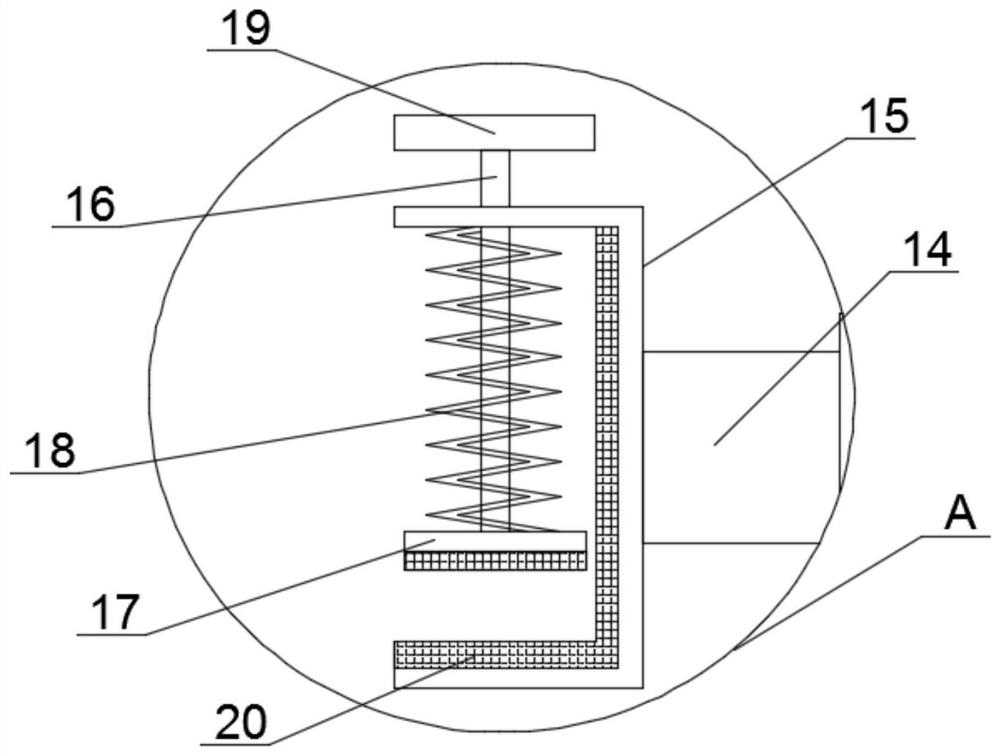

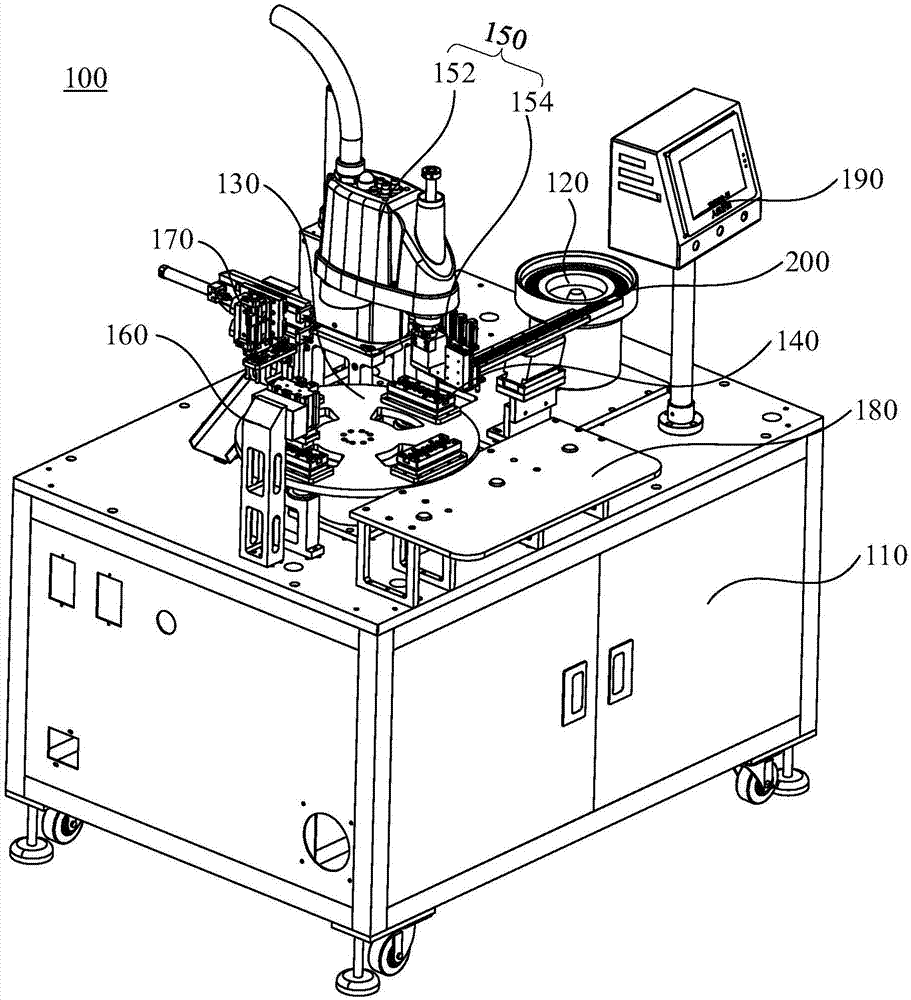

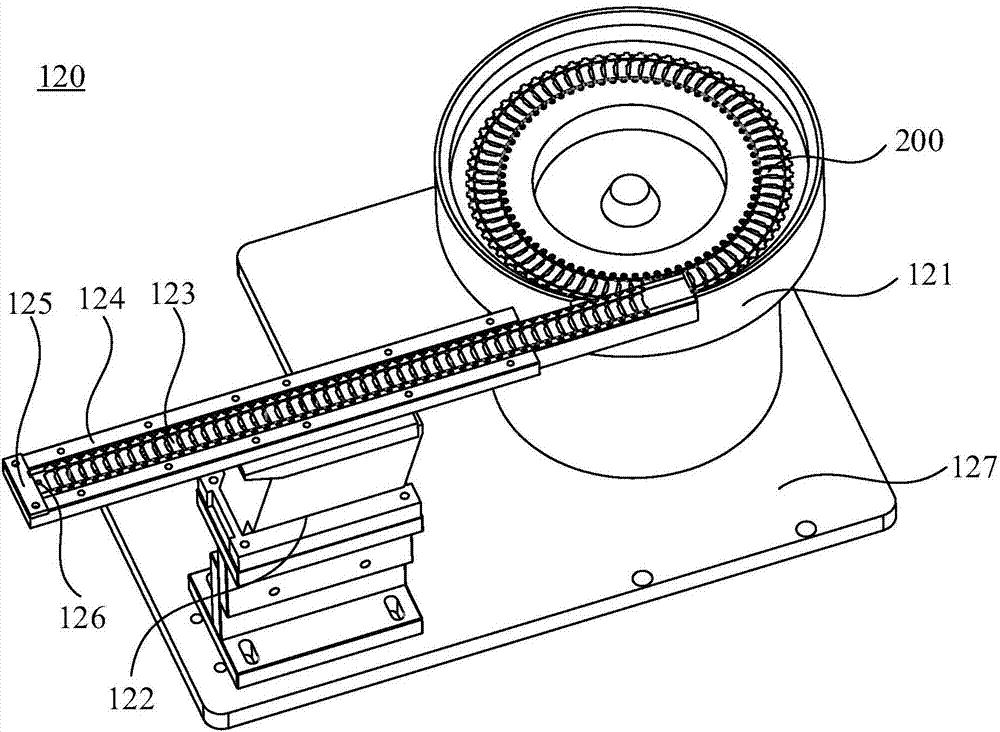

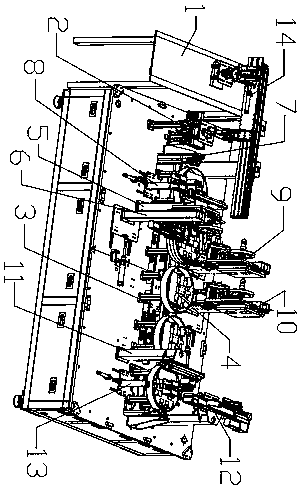

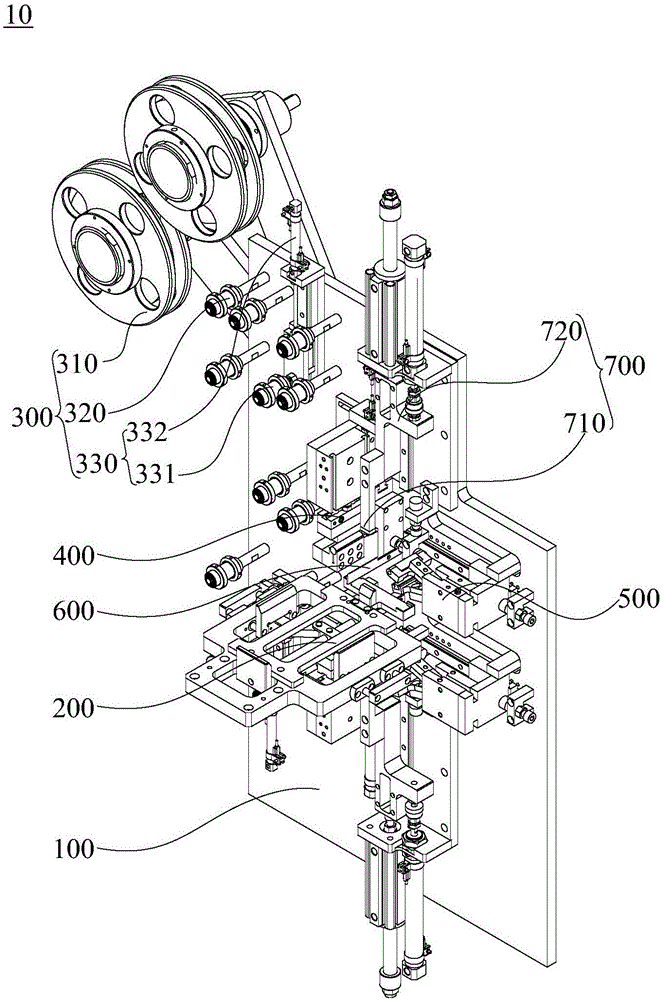

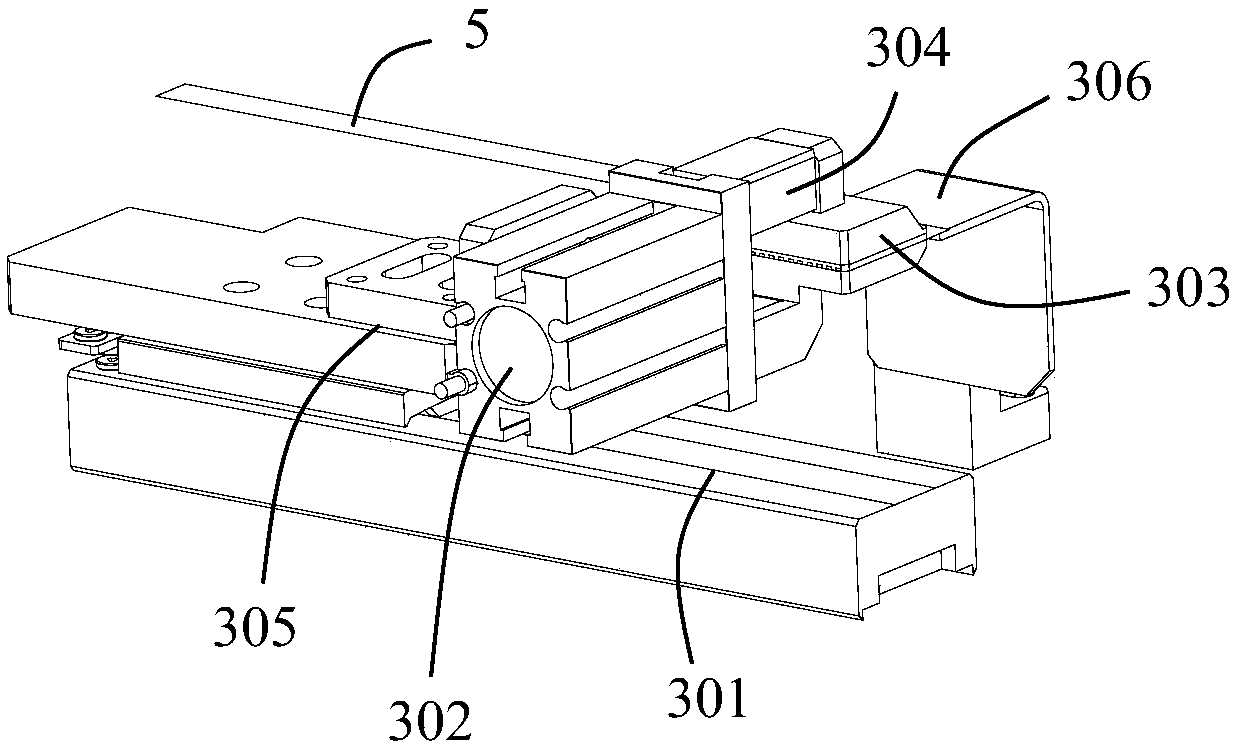

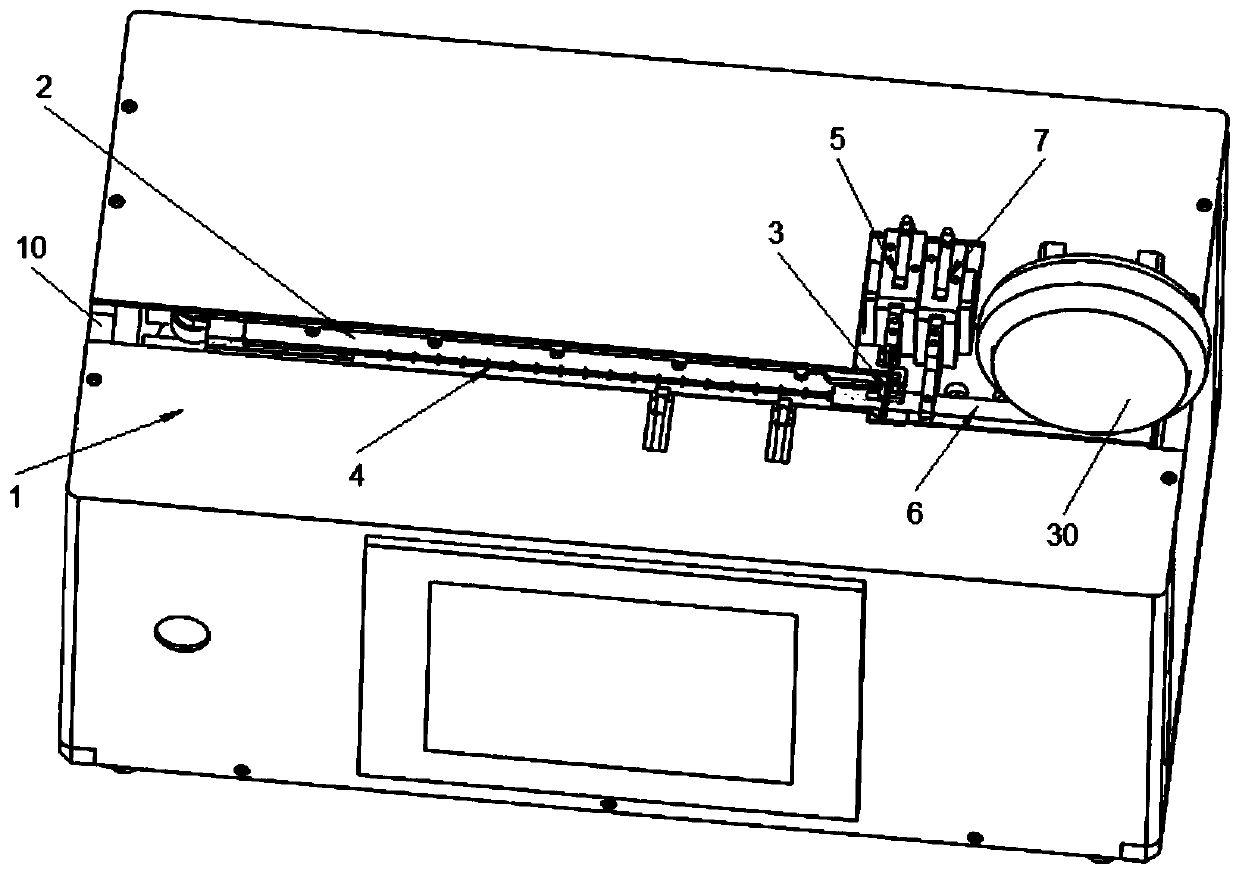

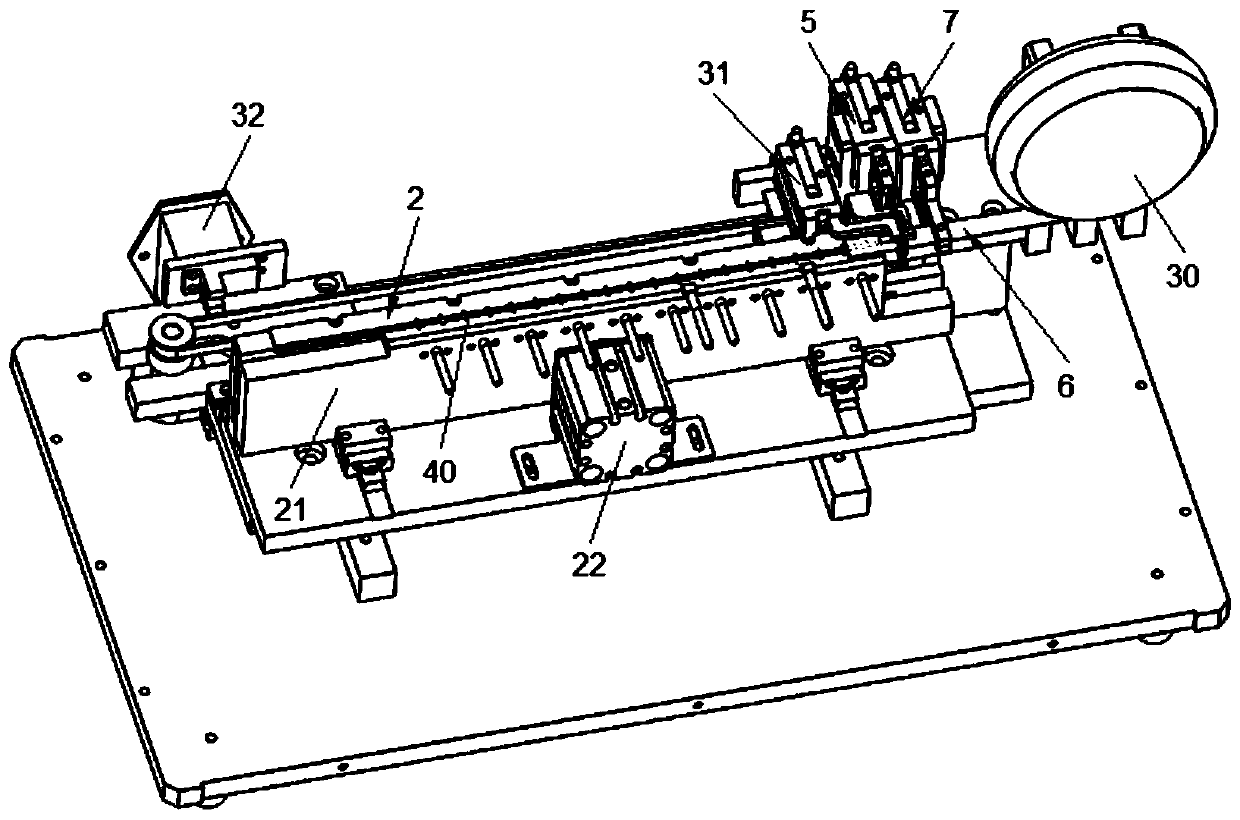

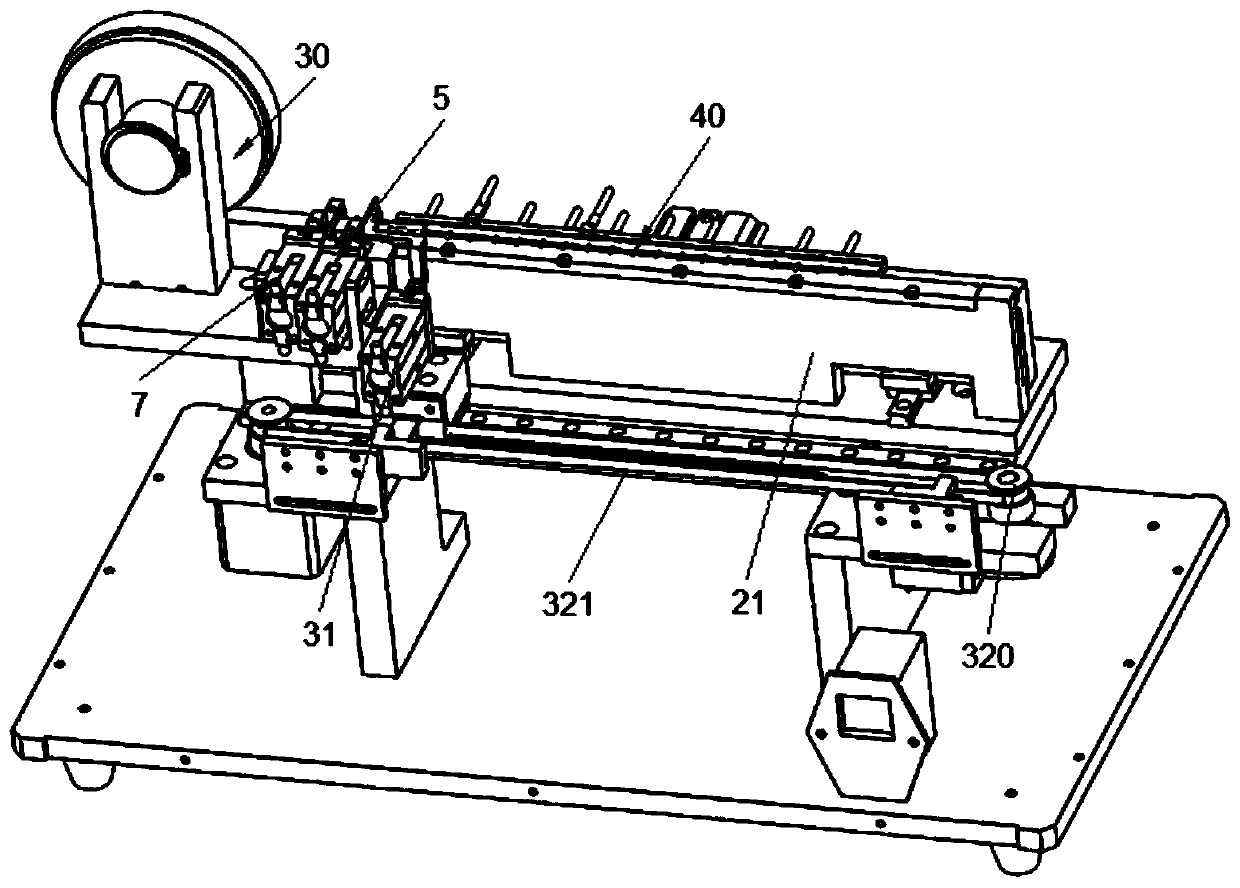

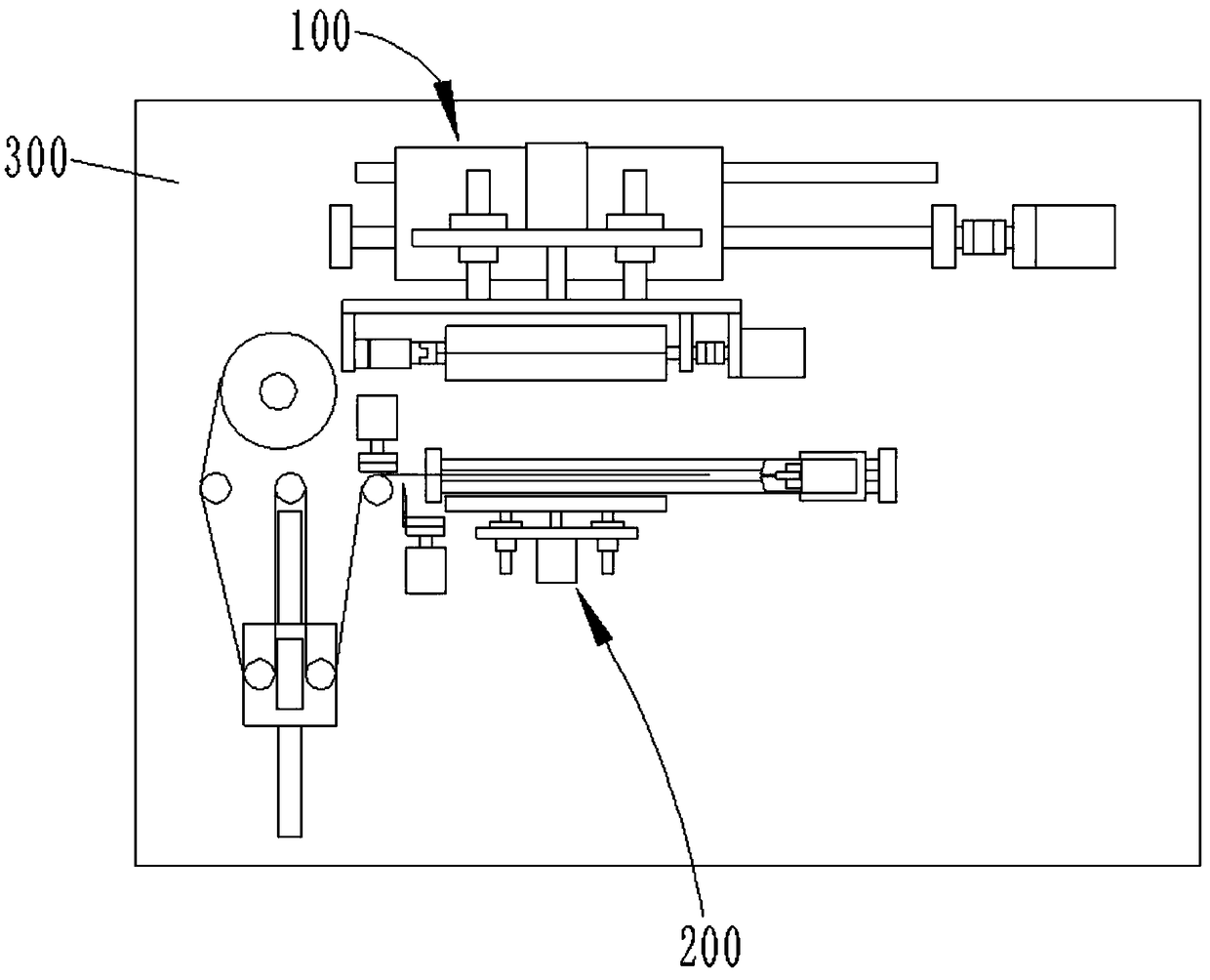

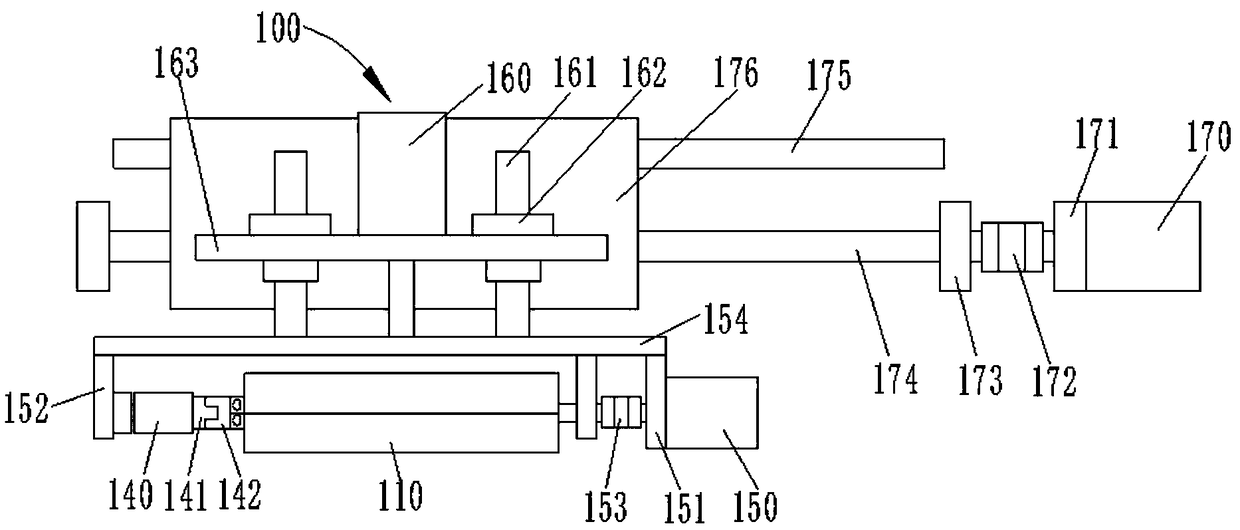

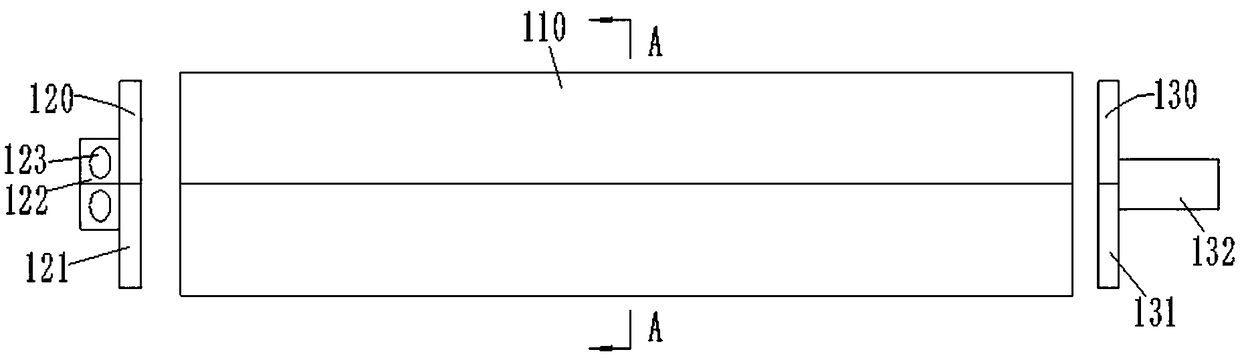

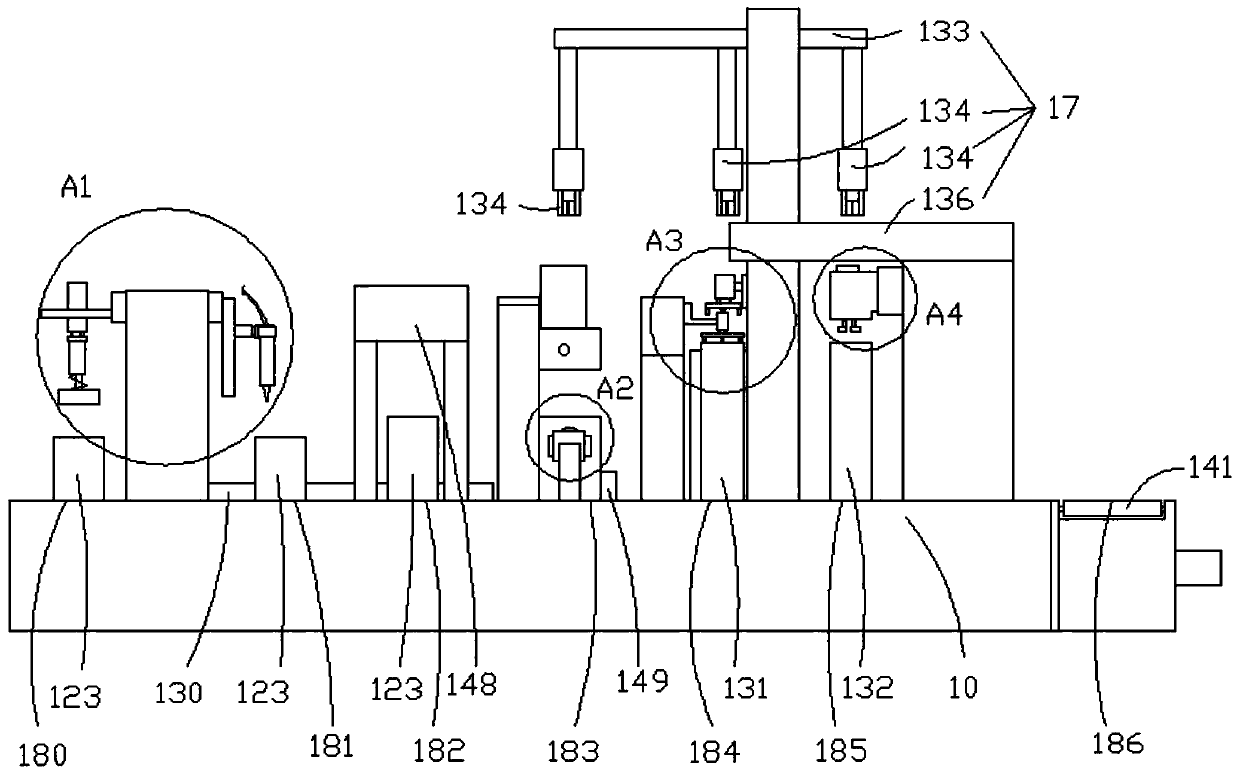

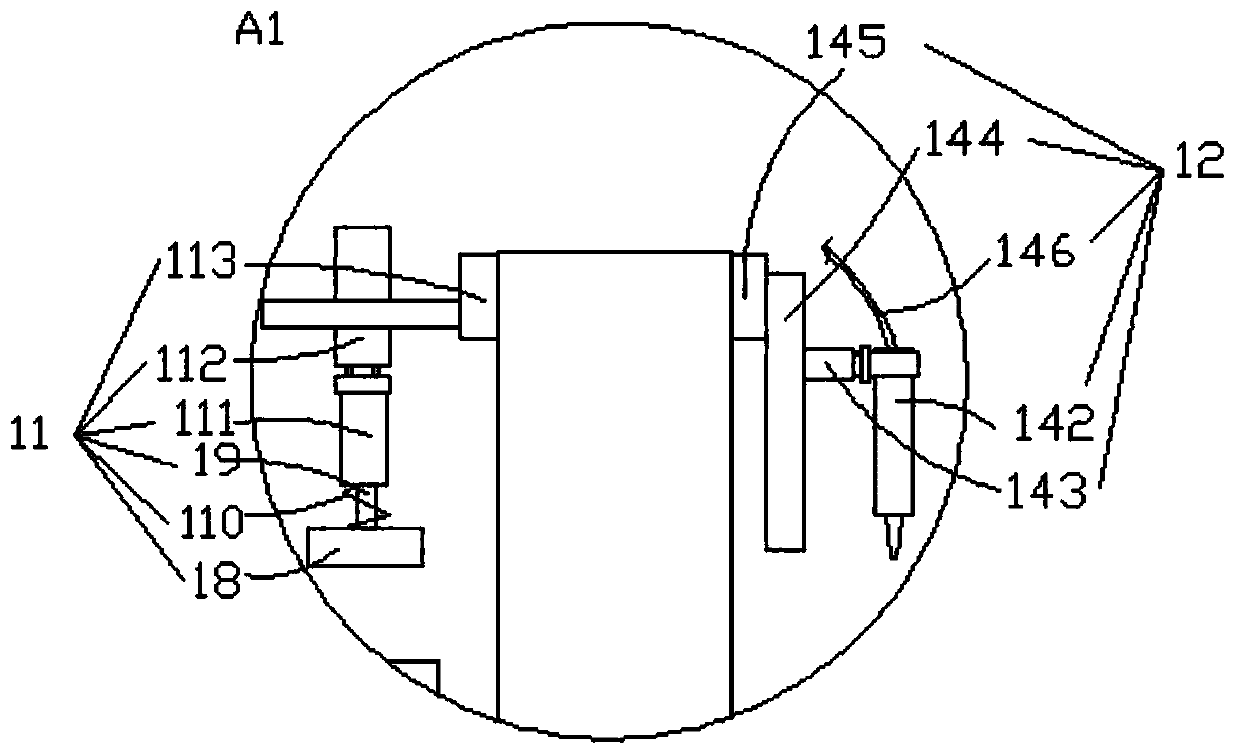

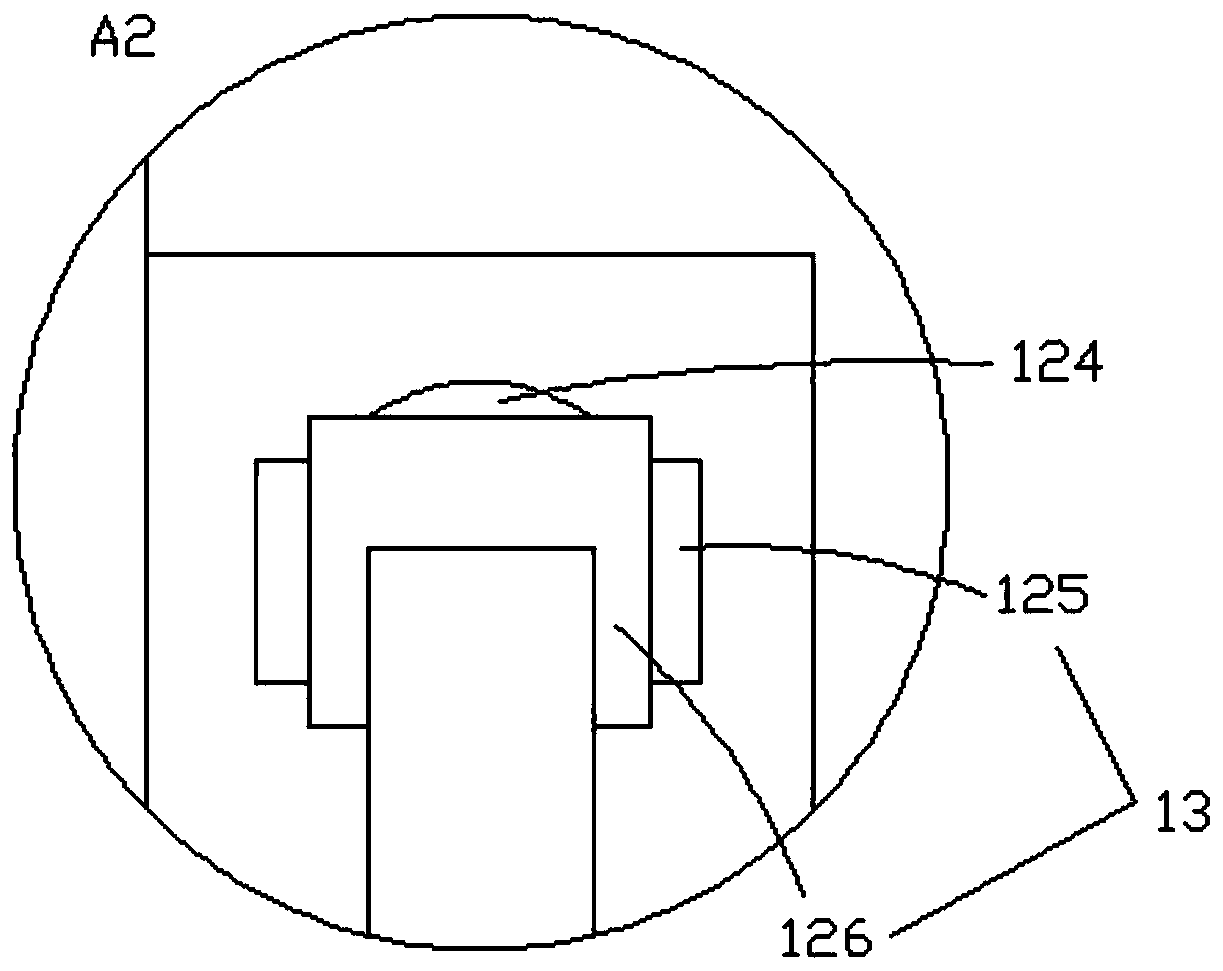

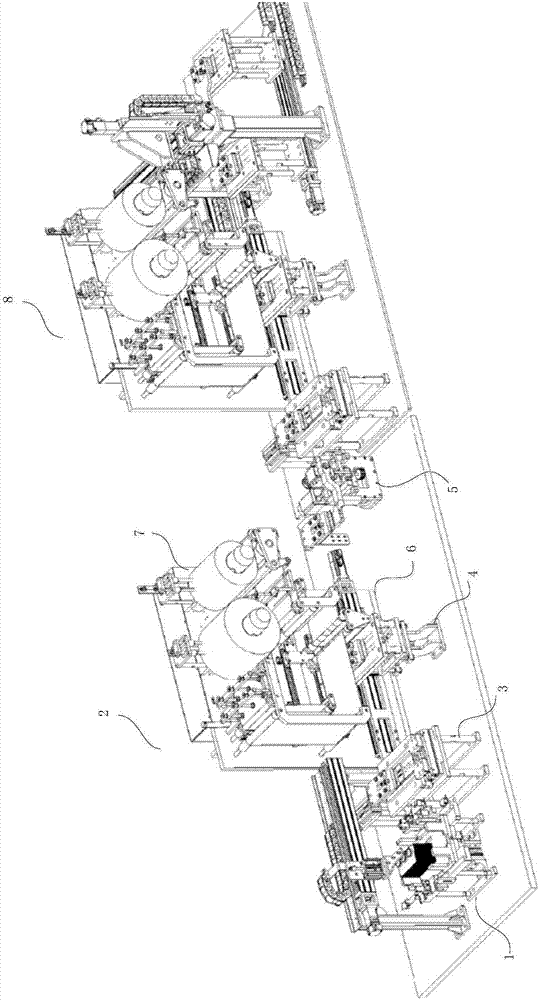

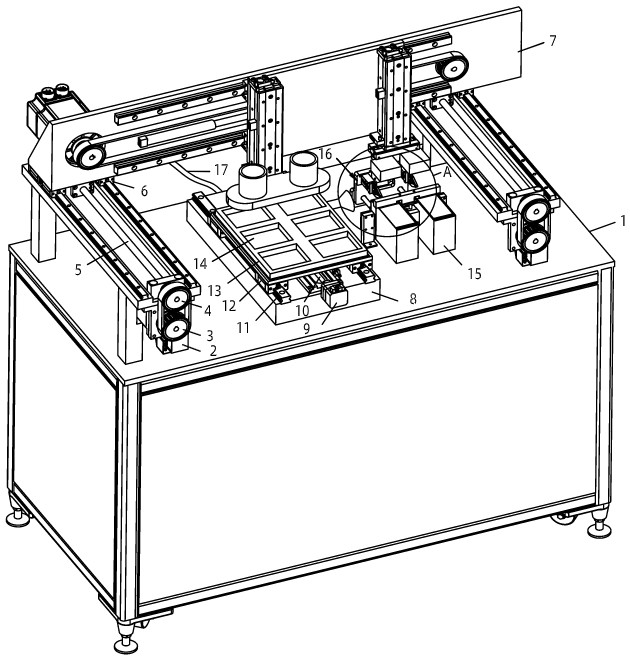

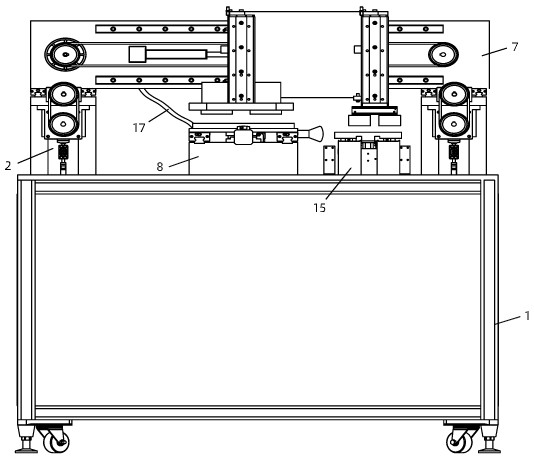

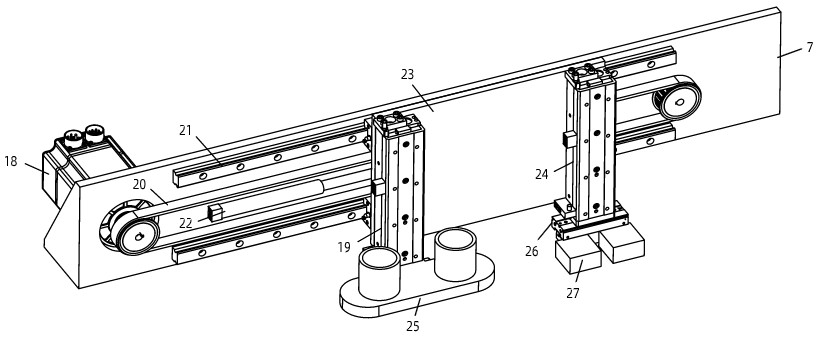

Special-shaped battery aluminum-plastic film automatic adhesive-coating production line and adhesive-coating process thereof

PendingCN106848116AEasy for automatic assembly and retrievingImprove glue application efficiencyFinal product manufactureCell component detailsProduction linePlastic film

The invention discloses a special-shaped battery aluminum-plastic film automatic adhesive-coating production line and a adhesive-coating process thereof; the production line comprises a machine frame, a adhesive-coating platform, a front round sheet adhesive pasting mechanism, a first adhesive-pasting mechanism, a first adhesive-coating mechanism, a second adhesive-pasting mechanism, a second adhesive-coating mechanism, a reverse round sheet adhesive pasting mechanism and a hot pressing mechanism; the adhesive-coating platform is rotatably arranged on the machine frame; the front round sheet adhesive pasting mechanism, the first adhesive-pasting mechanism, the first adhesive-coating mechanism, the second adhesive-pasting mechanism, the second adhesive-coating mechanism, the reverse round sheet adhesive pasting mechanism and the hot pressing mechanism are respectively correspondingly arranged on the adhesive-coating platform; the adhesive-coating platform rotatably moves to make a special-shaped battery switched among the work stations to successively complete the steps of feeding, front round sheet adhesive pasting, first and third gummed paper pasting, first and third gummed paper coating, second and fourth gummed paper pasting, second and fourth gummed paper coating, reverse round sheet adhesive pasting and hot pressing. The adhesive-coating production line and the adhesive-coating process thereof are applied to automatic adhesive coating of cross sections of aluminum-plastic films of irregular shaped battery side edges.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

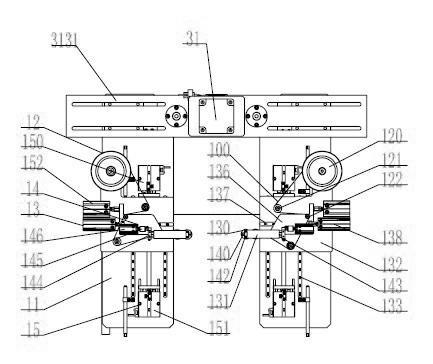

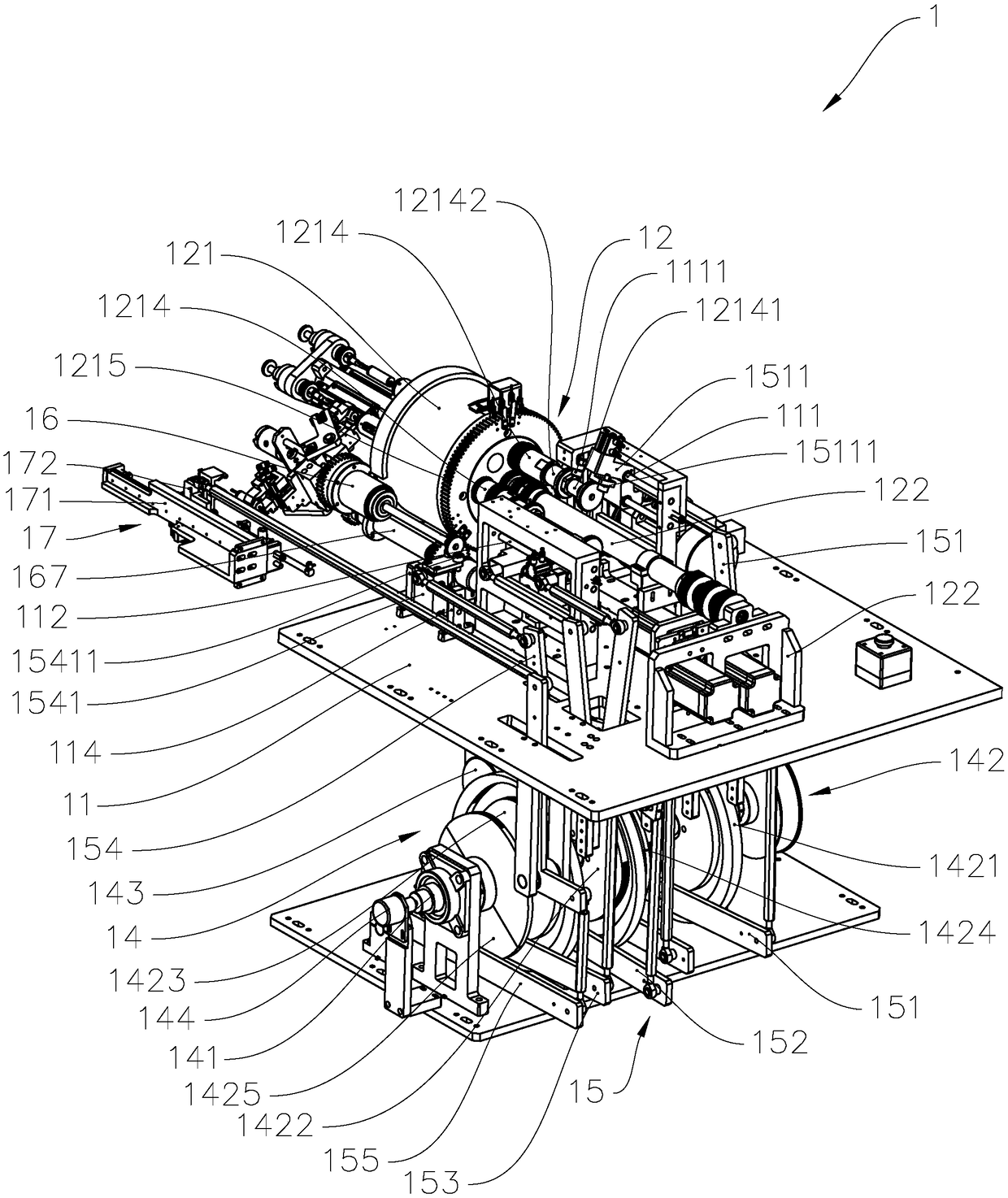

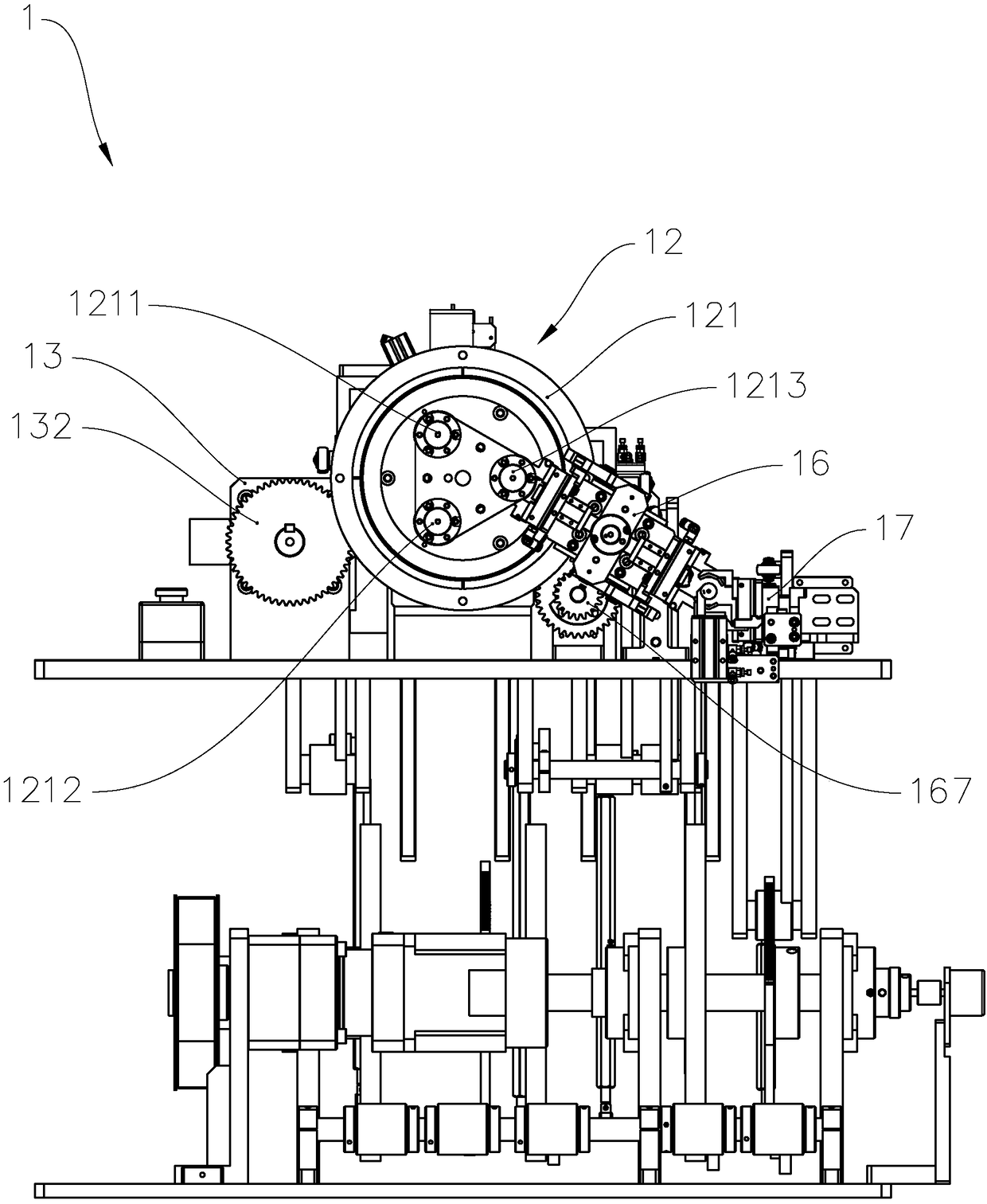

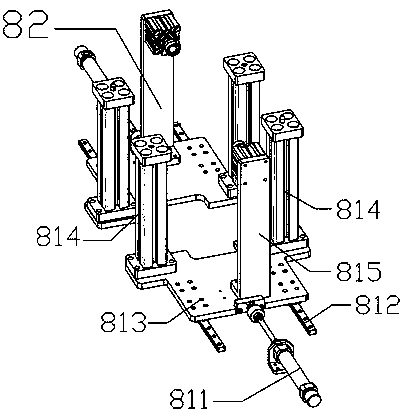

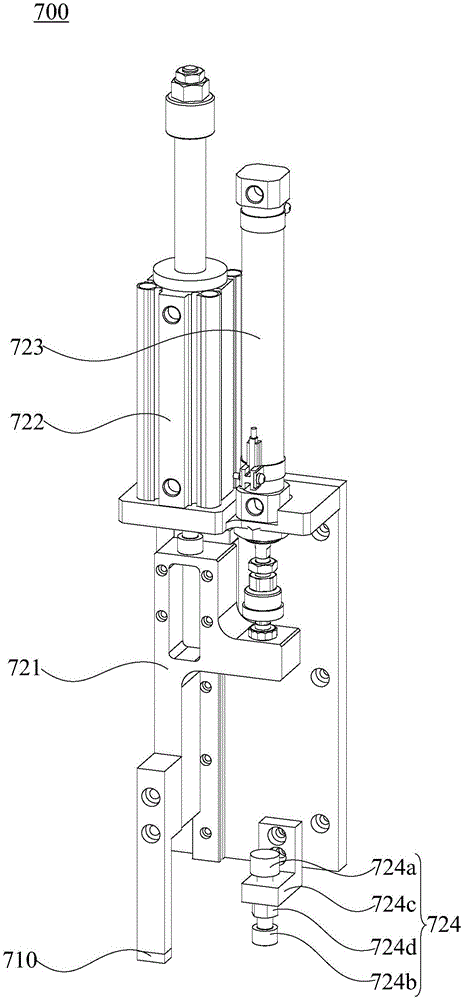

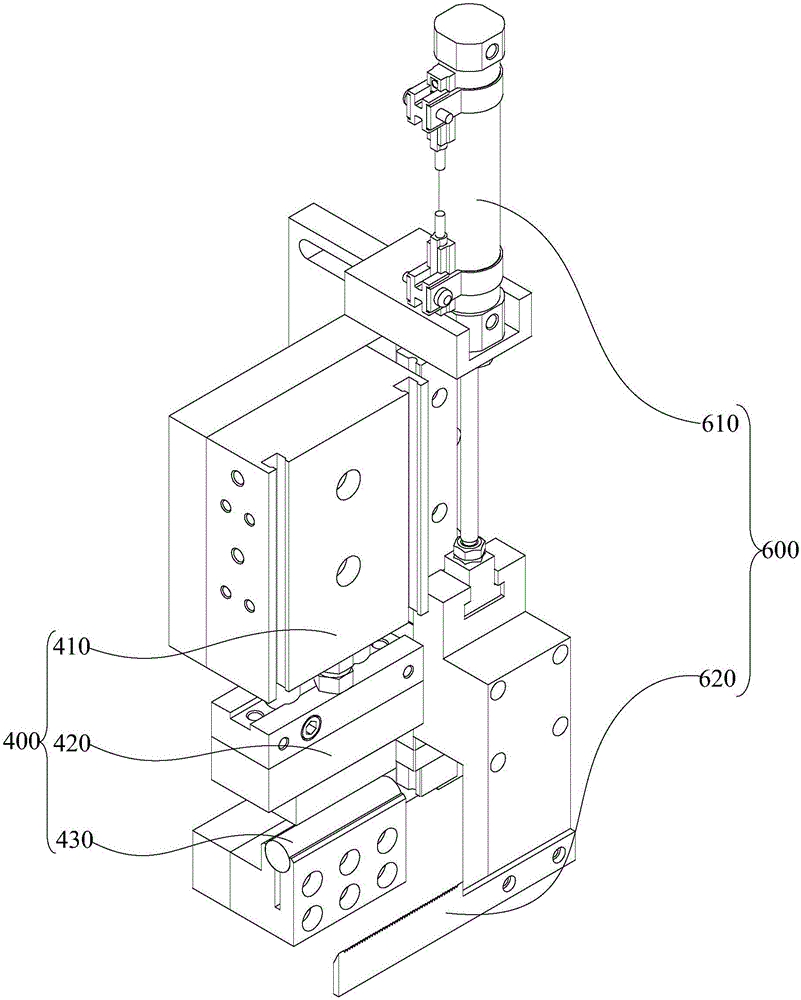

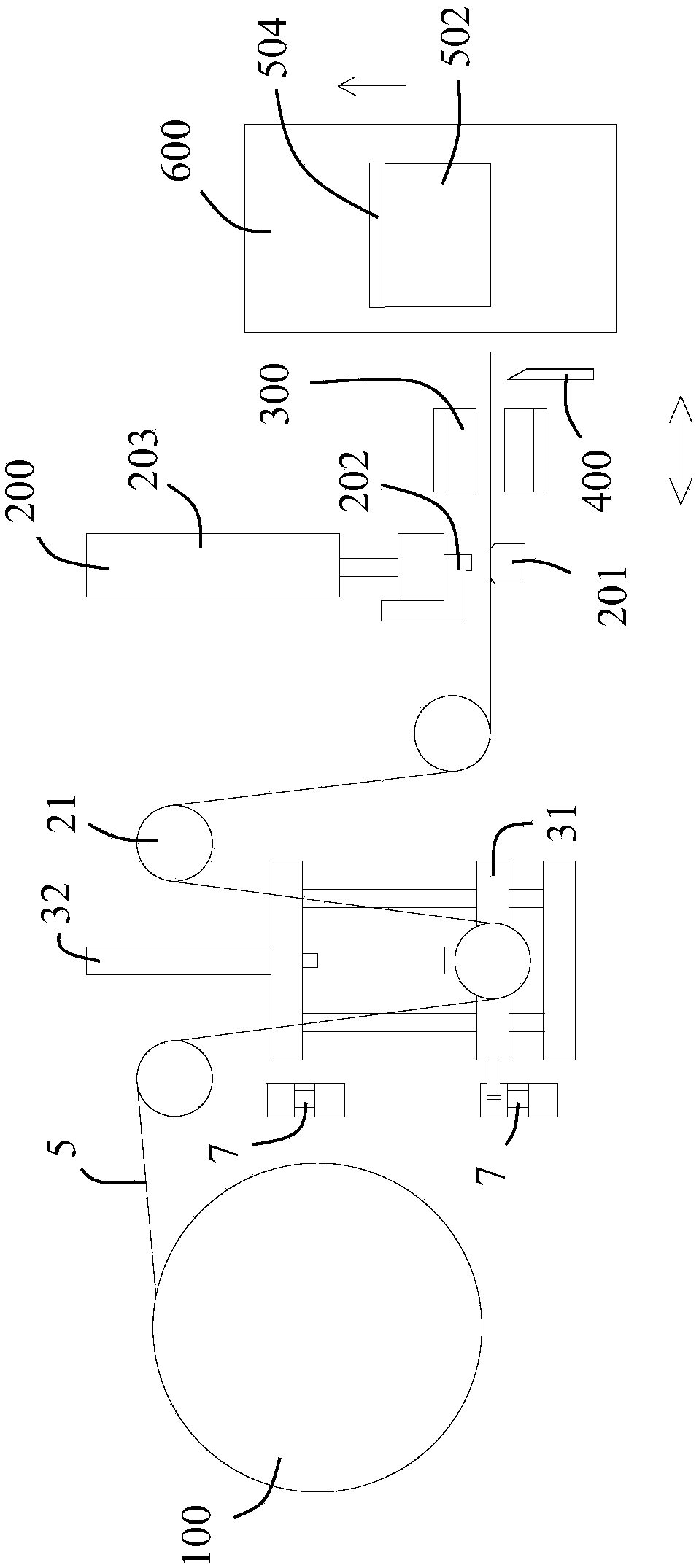

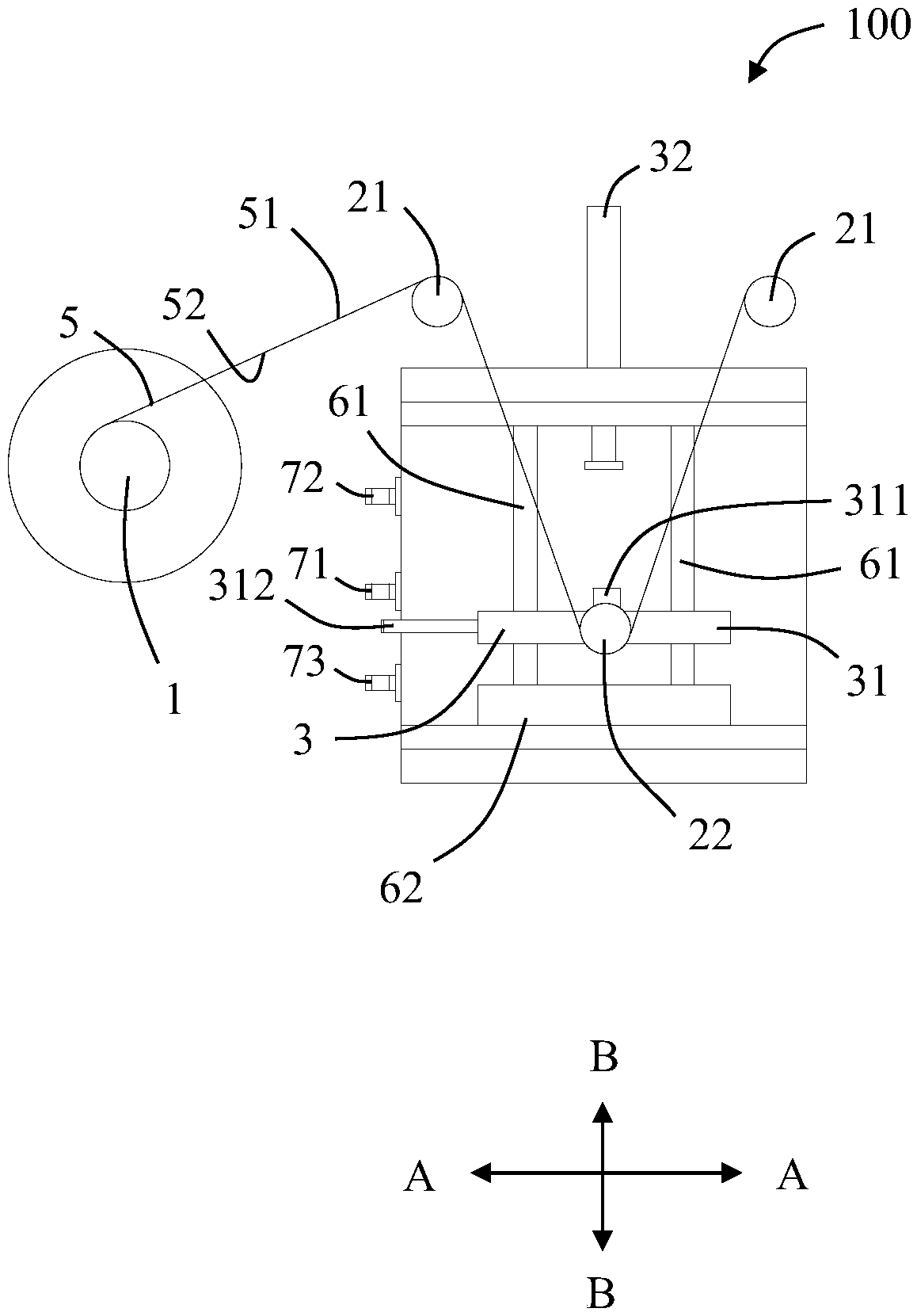

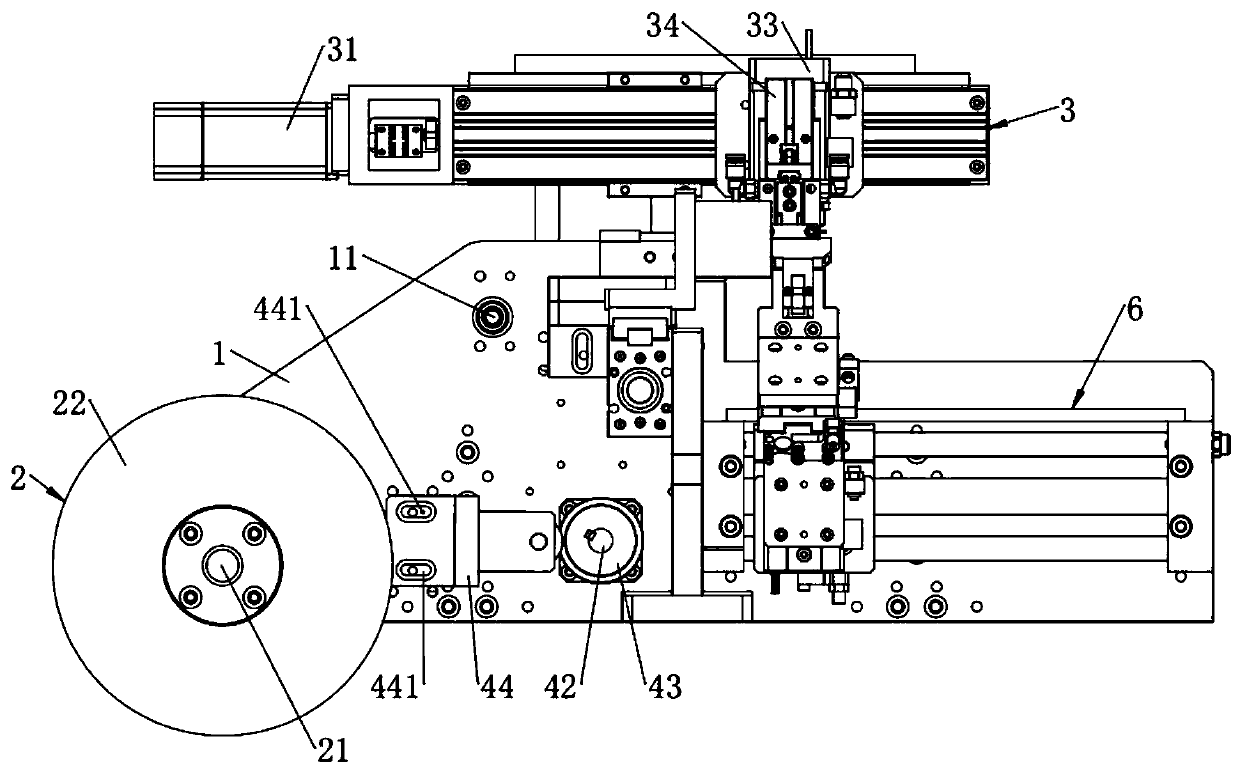

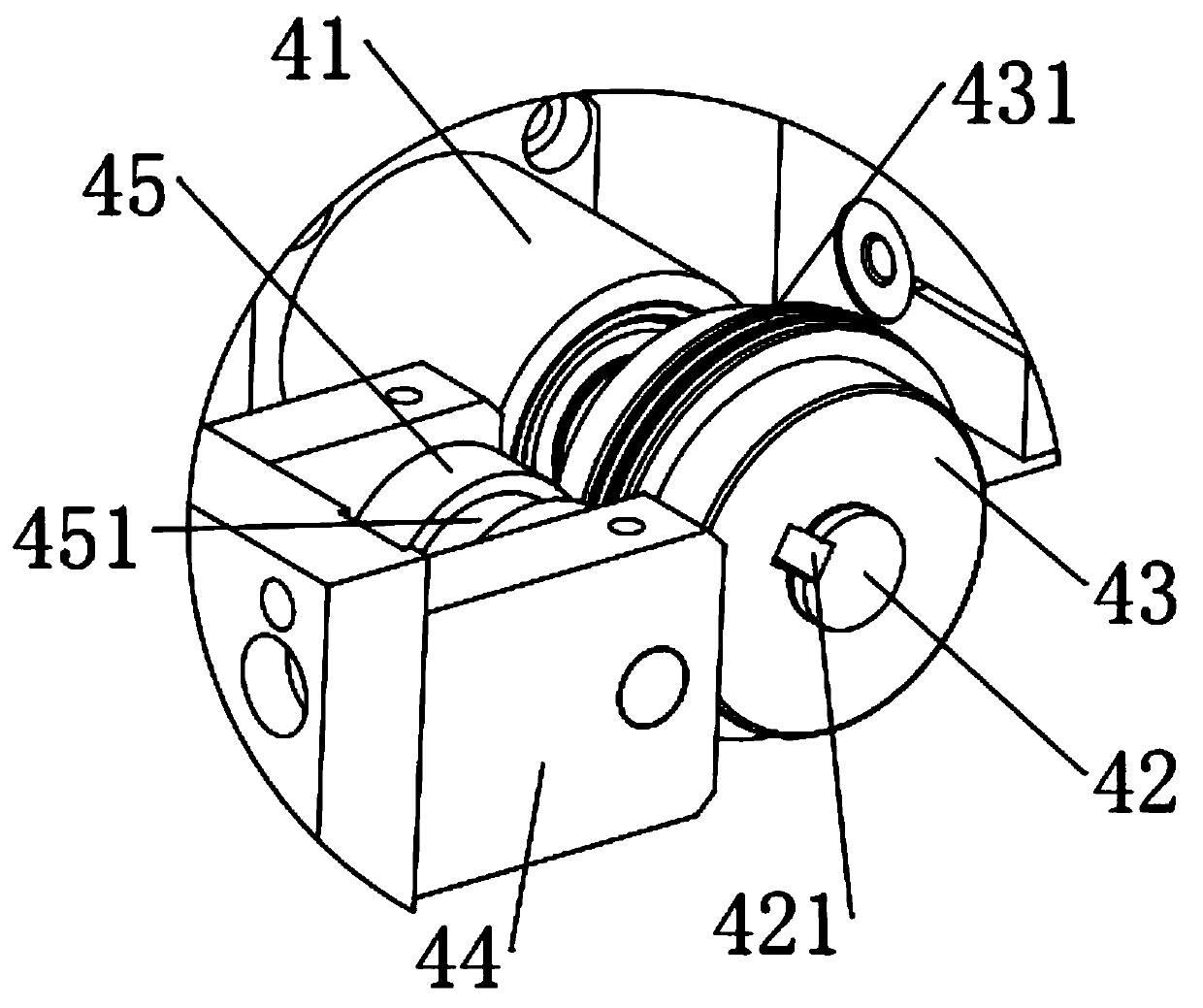

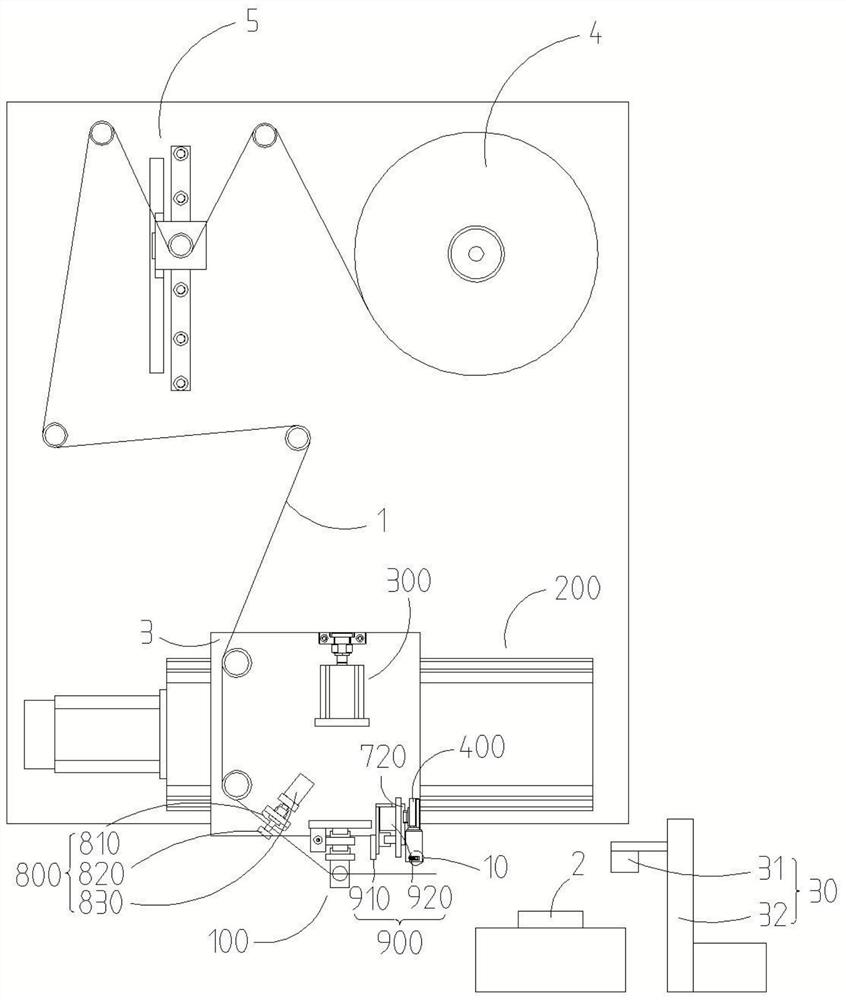

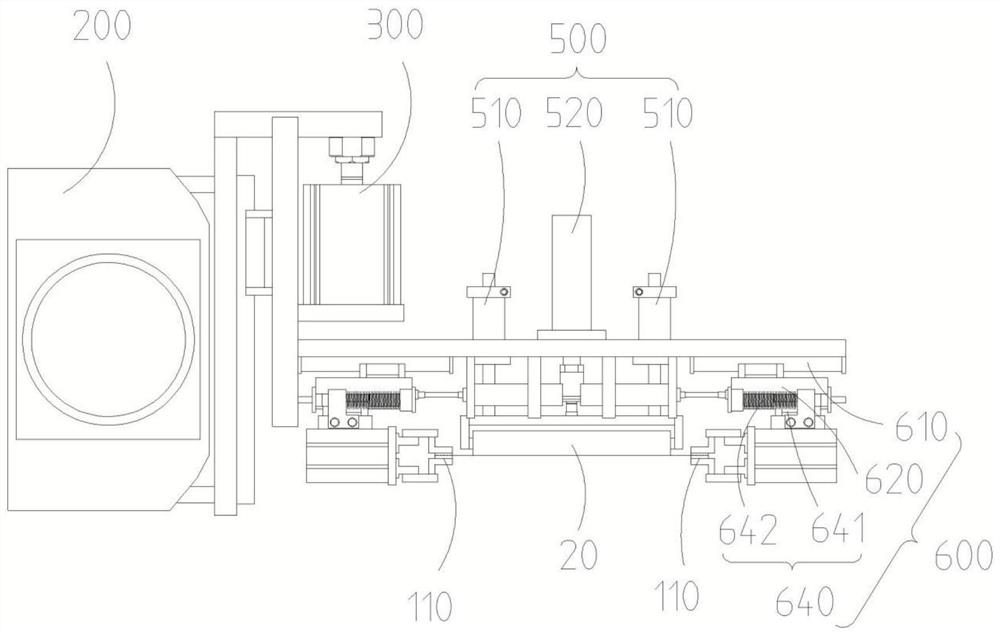

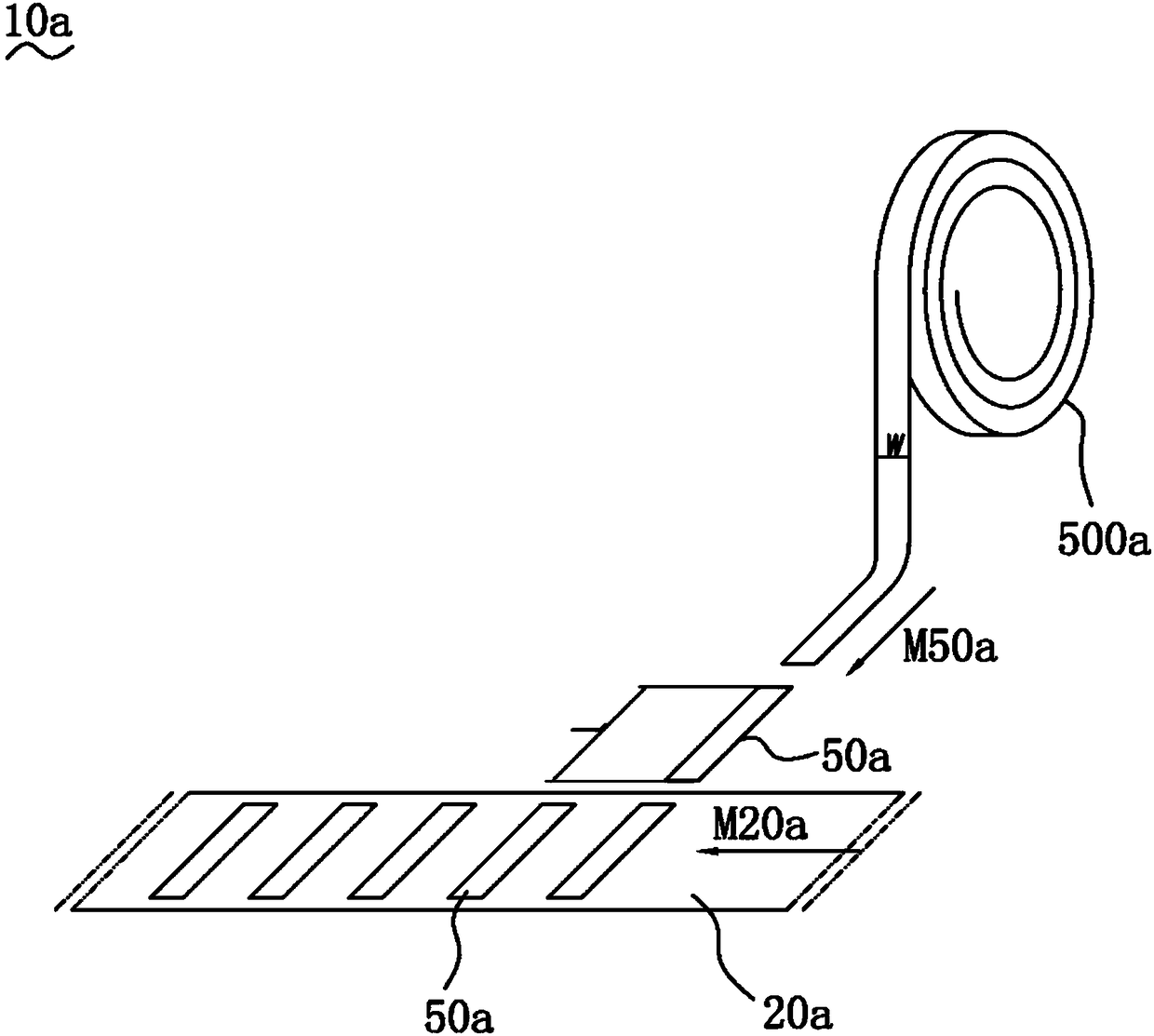

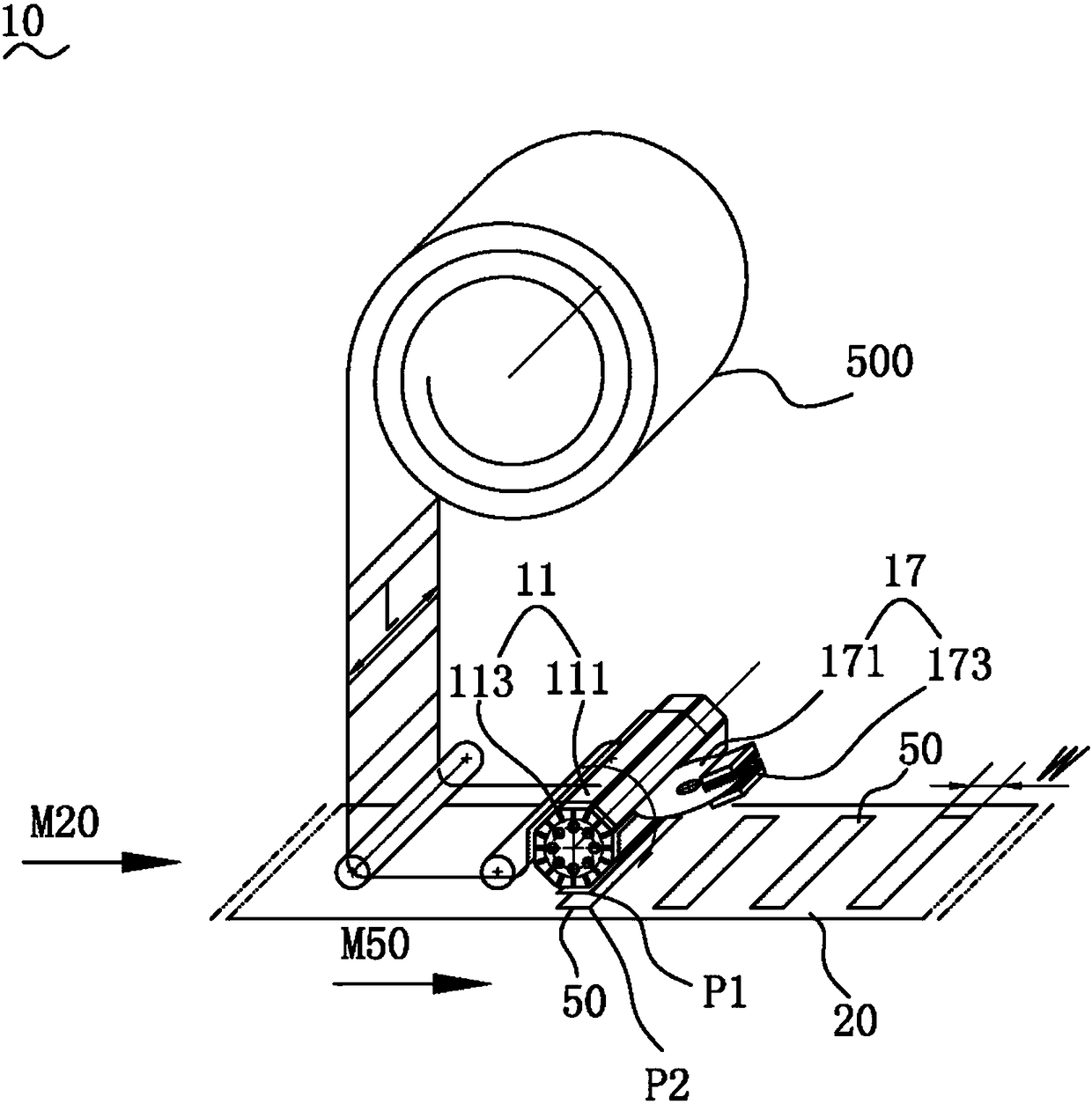

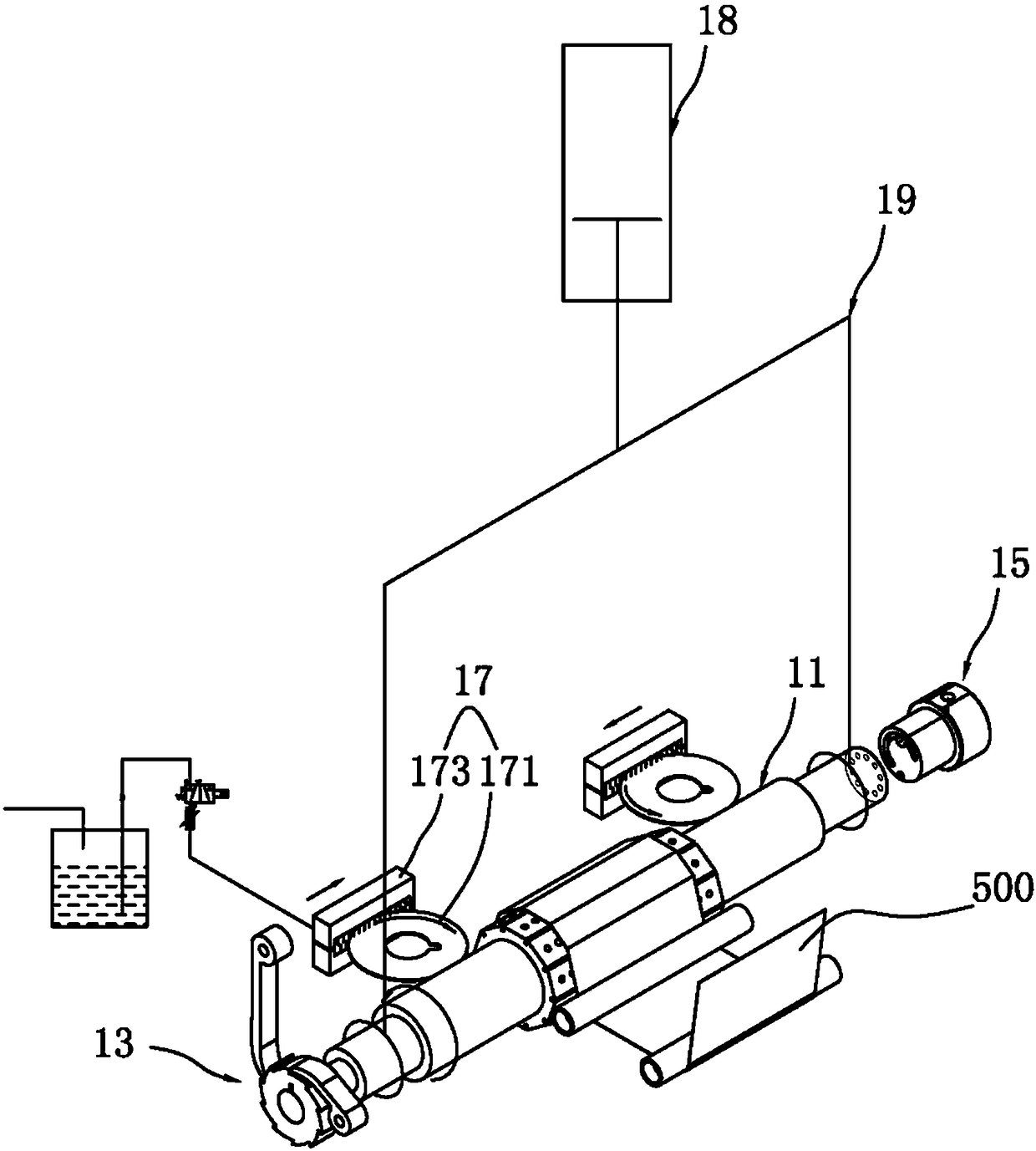

Cylindrical battery cell film-making and winding machine

PendingCN108808121ACompact structureWork reliablyFinal product manufactureCylindrical casing cells/batteryWinding machinePole piece

The invention provides a cylindrical battery cell film-making and winding machine, comprising a rack, and a winding head device, a pole piece inserting and cutting device, a diaphragm cut-off device and a gluing device which are connected with the rack, wherein the winding head device comprises a winding unit provided with a winding head, a first driving unit and a swing arm group unit; the winding head comprises a first station, a second station and a third station which are respectively provided with winding needles; each winding needle is provided with a first needle body and a second needle body; the first driving unit comprises a roller shaft as well as a first cam, a second cam and a third cam which are installed on the roller shaft; the swing arm group unit comprises a first swing arm group, a second swing arm group and a third swing arm group; the first cam drives the first swing arm group to control the first needle body of the first station to move along the axial direction of the winding head, the second cam drives the second swing arm group to control the first needle body of the third station to move along the axial direction of the winding head, and the third cam drives the third swing arm group to control the second needle body of the third station to move along the axial direction of the winding head. The cylindrical battery cell film-making and winding machinehas the advantages of being reliable in work, high in processing accuracy and rapid in production efficiency.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

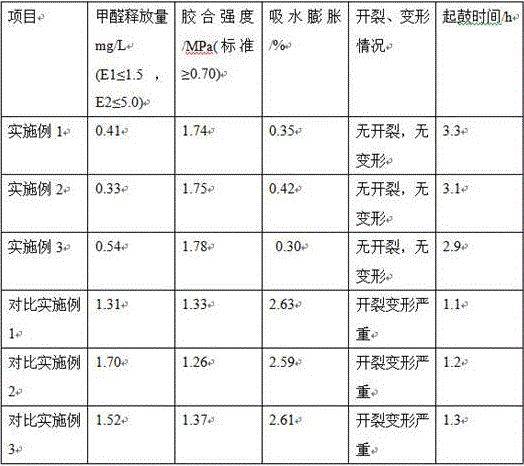

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

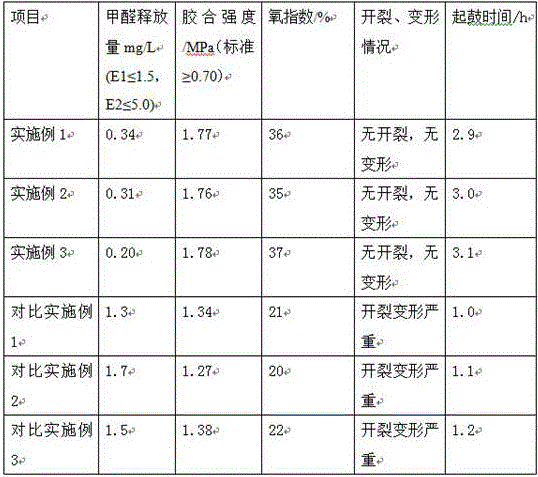

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

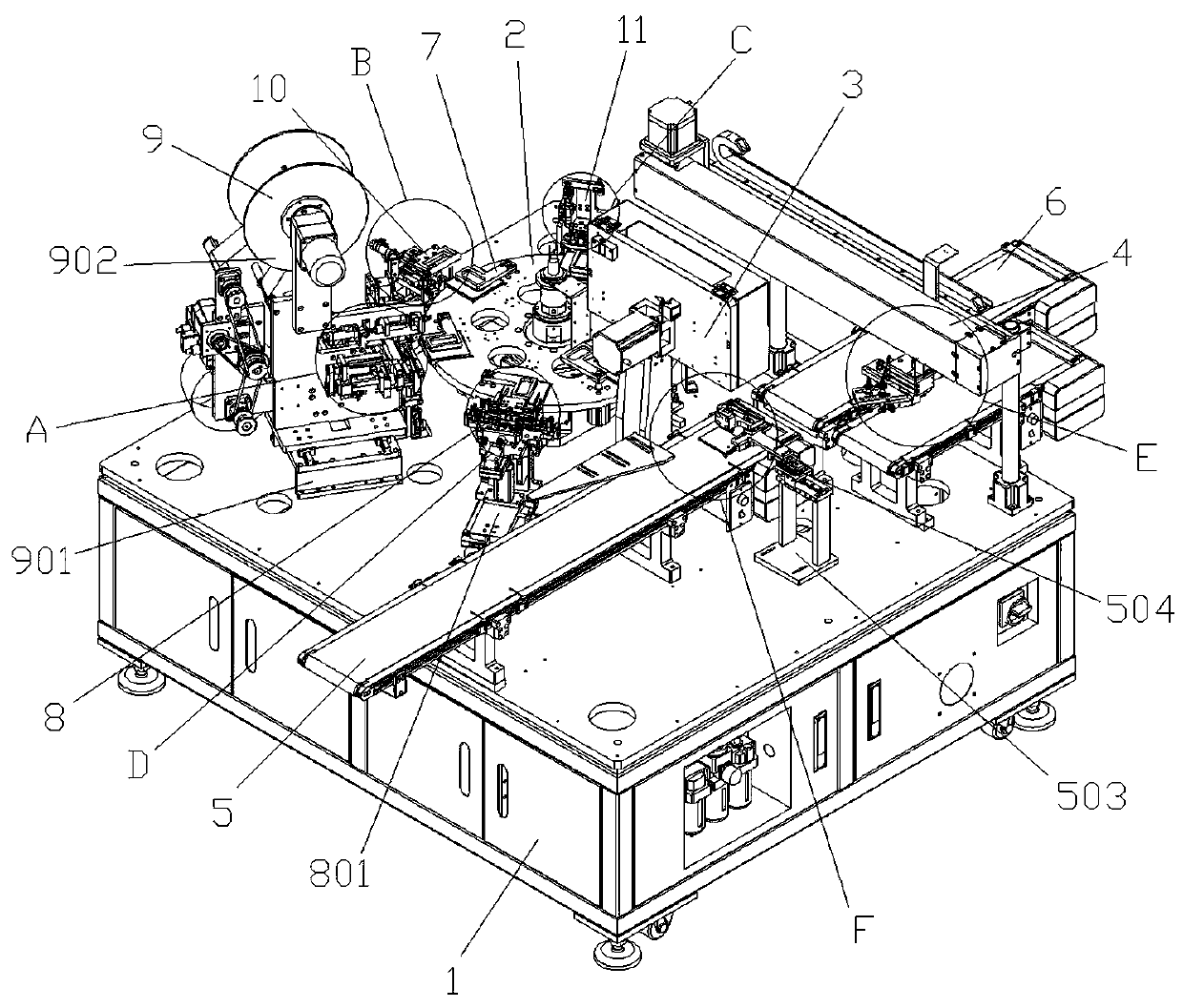

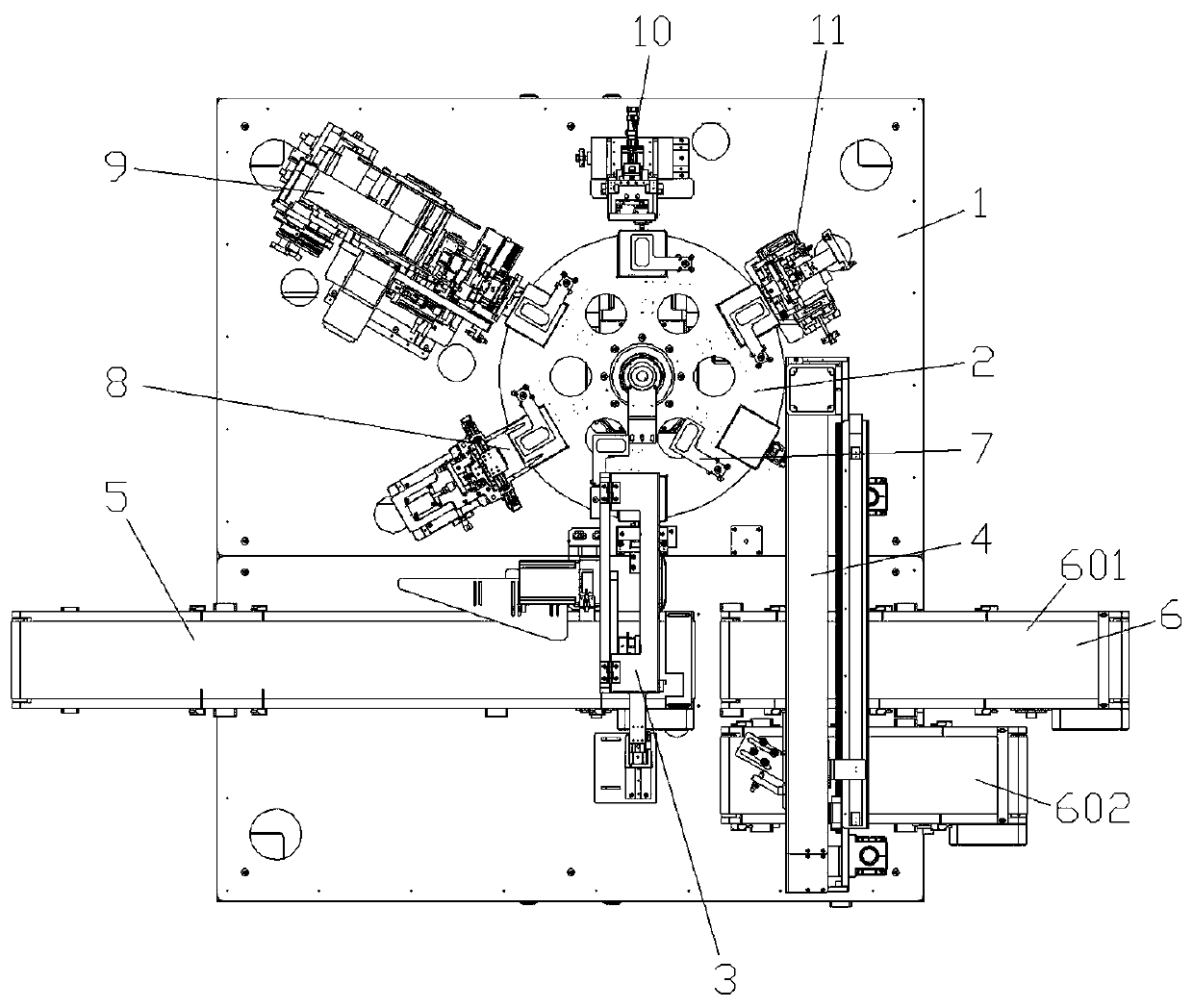

Efficient and automatic new energy square battery glue pasting, detecting and sorting integrated equipment

InactiveCN109433656ACompact structureShorten the gluing processAssembling battery machinesFinal product manufactureManipulatorEngineering

The invention relates to efficient and automatic new energy square battery glue pasting, detecting and sorting integrated equipment. A workbench is included and provided with a first conveying device.The upper portion of a material containing disc is provided with a plurality of square batteries. A feeding mechanical arm is arranged on one side of the first conveying device. A temporary containing table is arranged on the rear side of the feeding mechanical arm. A double-face glue pasting mechanism for conducting glue pasting on the front faces and the back faces of the batteries at the sametime is arranged above the temporary containing table. A quality detection device is arranged on the right side of the double-face glue pasting mechanism. A transfer mechanical arm is arranged on therear side of the double-face glue pasting mechanism. A second conveying device is arranged on the right side of the quality detection device. An appearance detecting device is arranged on the front side of the second conveying device. A sorting device is arranged on the front side of the appearance detecting device. A defective product collecting device and a finished product collecting device arearranged on the front side and the right side of the sorting device correspondingly. The efficient and automatic new energy square battery glue pasting, detecting and sorting integrated equipment conducts glue pasting and detecting work on the square batteries in a full-mechanization manner, the structure is compact, and the glue pasting quality and efficiency are greatly improved; and defectiveproducts are removed and are prevented from being mixed into finished products, and the qualification rate of the finished products is improved.

Owner:杨文康

Battery cell rubberizing and packaging equipment and method for new energy lithium battery

InactiveCN112448040AEasy to fixHigh precisionFinal product manufactureLi-accumulatorsNew energyStructural engineering

The invention discloses new energy lithium battery cell rubberizing and packaging equipment, and the equipment comprises a mounting plate; a first mounting frame is fixedly mounted at the top of the mounting plate, a sliding rod is fixedly mounted in the first mounting frame, a sliding block is slidably connected to the sliding rod, and an inserting rod is slidably connected to the sliding block;a plurality of inserting holes for inserting the inserting rods are formed in the sliding rod at equal intervals, a film sticking machine is fixedly mounted at the bottom of the sliding block, a threaded through hole is formed in one side of the first mounting frame, and a threaded rod is in threaded connection with the interior of the threaded through hole; the threaded rod penetrates through thethreaded through hole and extends to one end in the first mounting frame to be rotationally connected with a first rotating rod, and the other side of the first mounting frame is rotationally connected with a second rotating rod. According to the invention, the battery cell rubberizing and packaging equipment for the new energy lithium battery is simple in structure, convenient to operate and stable in fixing effect, the rubberizing accuracy is improved, the packaging efficiency is high, and the production efficiency is improved.

Owner:李伟涛

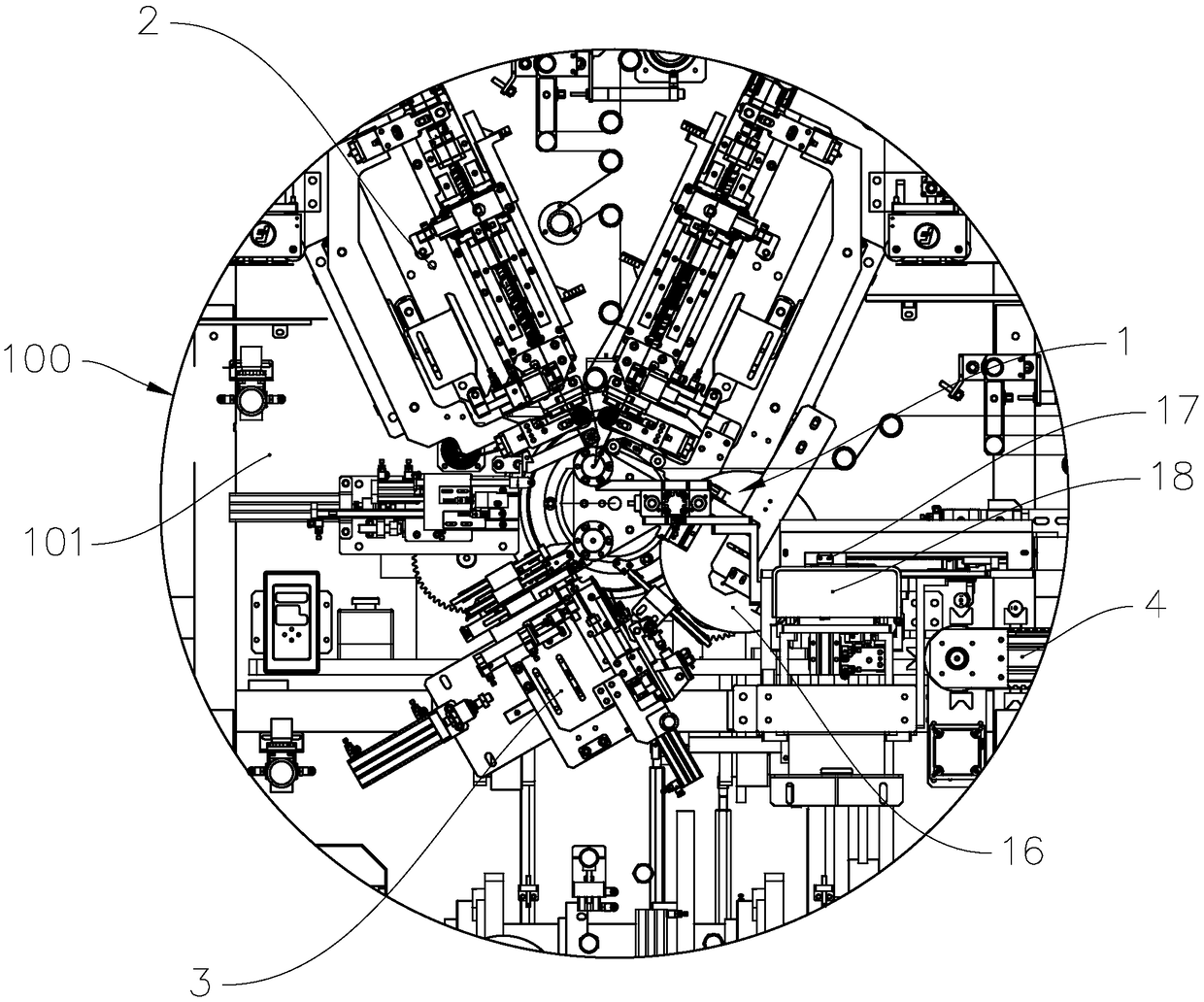

Automatic head glue pasting machine

PendingCN110901084AImprove glue application efficiencyDomestic articlesConveyor partsMechanical engineeringEngineering

The invention discloses an automatic head glue pasting machine and aims to provide the automatic head glue pasting machine with high glue pasting efficiency. The automatic head glue pasting machine comprises a machine table. A rotary disc module, a charging module, a discharging module, a feeding belt and a discharging belt are arranged on the machine table, a plurality of product clamps are arranged on the rotary disc module in a fit manner, a product positioning module, a glue pasting module, a glue rolling module and a gummed paper pressure-maintaining module are successively arranged around the rotary disc module, one end of the charging module is arranged on the feeding belt while the other end of the charging module is located above the rotary disc module, the charging module is located between the product positioning module and the gummed paper pressure-maintaining module, one end of the discharging module is arranged on the discharging belt while the other end of the discharging module is located above the rotary disc module, and the discharging module is located between the charging module and the gummed paper pressure-maintaining module. The automatic head glue pasting machine is applied to the technical field of the automatic head glue pasting machines.

Owner:ZHUHAI KESITE POWER SUPPLY

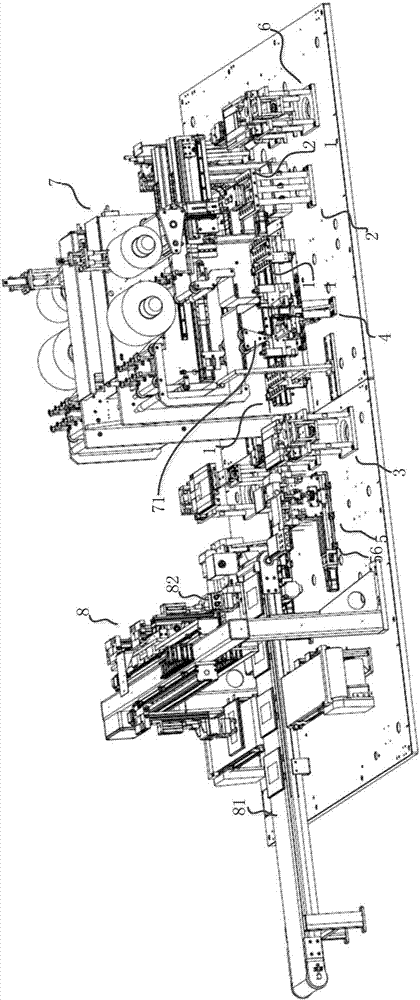

Gluing production line

PendingCN107039672AImprove quality and efficiencyImprove glue application efficiencyAssembling battery machinesFinal product manufactureProduction lineEngineering

The invention discloses a gluing production line. The gluing production line comprises a transmission mechanism, a turnover device, a first arrangement device, a carrying mechanism, a floating bearing device, gluing equipment and a second arrangement device, wherein the transmission mechanism, the turnover device, the first arrangement device, the carrying mechanism, the floating bearing device, the gluing equipment and the second arrangement device are sequentially arranged according to a gluing process, the transmission mechanism is used for transmitting a material to be glued to the turnover device, the turnover device is used for carrying the material after being turned over to the first arrangement device, the carrying mechanism is used for carrying the material of which a position is arranged by the first arrangement device to the floating bearing device, the gluing equipment is used for gluing the material on the floating bearing device, and the second arrangement device is used for arranging the position of the material after being glued. Compared with the prior art, the gluing production line has the advantages that the gluing quality and the gluing efficiency can be improved, and the qualified rate of a product is improved.

Method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin

InactiveCN106313200AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher, and moreover an antioxidant and an ultraviolet absorbent are also added to prepare the weather-resistant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good weather resistance. The total-eucalyptus plywood produced by the method disclosed by the invention is excellent in weather resistance and is relatively high in environmental disruption tolerance.

Owner:南宁市林润木业有限公司

Adhesive sticking device

ActiveCN107124832AImprove stabilityImprove glue application efficiencyNon-metallic protective coating applicationEngineeringManipulator

The invention relates to an adhesive sticking device, which comprises a rack, a material supply mechanism, a turntable, a material taking mechanism, a material pressing mechanism and a feeding mechanism, wherein the material supply mechanism is arranged on the rack, and is used for discharging workpieces in order one by one; the turntable is arranged on the rack in a rotating manner, and multiple carriers are arranged on the outer edge of the turntable at equal intervals; the material taking mechanism comprises a mechanical hand and a first adsorption component arranged on the mechanical hand, the mechanical hand is used for driving the first adsorption component to move between the carriers and the material supply mechanism, and the first adsorption component is used for taking and placing the workpieces; the material pressing mechanism is used for pressing an adhesive tape downwards to be closely attached to the workpieces placed on the carriers; the feeding mechanism is used for moving the workpieces closely attached to the adhesive tape out of the carriers. Compared with a traditional manual adhesive sticking manner, the adhesive sticking device has the advantages that manual workpiece placement errors can be greatly reduced, thereby ensuring the accuracy of the adhesive sticking positions of the workpieces and improving the stability of the adhesive sticking quality of the workpieces; in addition, the adhesive sticking efficiency of the workpieces can be greatly improved, and the labor cost investment can be reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

Automatic packaging equipment for lithium battery cell

ActiveCN109638307AKeep cleanImprove glue quality and efficiencyNon-aqueous electrolyte cellsFinal product manufactureManipulatorEngineering

The invention relates to automatic packaging equipment for a lithium battery cell. The device comprises an operation table, a feeding conveying device is arranged on the left side of the operation table, a positioning assembly is arranged on the right side of the feeding conveying device, a battery conveying device is arranged on the right side of the positioning assembly, a plurality of containing positions are arranged on the upper portion of the battery conveying device at equal intervals, and a protective clamp disc is arranged on each containing position. A first sealing cover taking andplacing mechanical arm, a first side face rubberizing device, a second side face rubberizing device, a first tail rubberizing device, a second tail rubberizing device, a fifth sealing cover taking andplacing mechanical arm and a battery discharging mechanical arm are sequentially arranged on the portion, located on one side of the battery conveying device, of the operation table in the battery conveying direction. The lithium battery is fully protected through the silica gel foam and the battery cell shell in the sealing cover, vibration in the conveying process is avoided, and the stabilityof the lithium battery in the conveying process is guaranteed. The full-mechanical operation is realized, the structure is compact, the packaging quality and efficiency of the lithium battery are improved, and the market application value is high.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

Lithium battery adhesive sticking device

PendingCN108232325AImprove glue application efficiencyPrecise length controlNon-aqueous electrolyte cellsFinal product manufactureAdhesive beltReciprocating motion

The invention discloses a lithium battery adhesive sticking device. The lithium battery adhesive sticking device comprises a controller, an adhesive discharging mechanism, an adhesive conveying mechanism, an adhesive cutting worktable capable of doing reciprocating motion, an adhesive cutting mechanism, a mechanical arm assembly and an adhesive pressing assembly, which are mounted on a mounting plate, wherein the controller is connected with the adhesive conveying mechanism, the adhesive cutting mechanism, the mechanical arm assembly and the adhesive pressing assembly; the mechanical arm assembly comprises a mechanical arm and a mechanical hand; the adhesive conveying mechanism comprises an adhesive conveying air cylinder; an adhesive tape is introduced into the adhesive cutting worktable;the adhesive conveying air cylinder is used for moving the adhesive cutting worktable to the lower side of the adhesive cutting mechanism; the mechanical hand is used for clamping the head part of the adhesive tape; when the residual adhesive tape is cut off on the adhesive cutting worktable by the adhesive cutting mechanism, the adhesive cutting worktable is reset; an adhesive tape section whichis cut off by the mechanical arm is conveyed to an adhesive sticking station to be clung to a lithium battery element; the controller is used for controlling the adhesive pressing assembly and sticking the section of adhesive tape to the lithium battery element. According to the lithium battery adhesive sticking device disclosed by the invention, the adhesive tape with a pre-set length can be cut, the dosage of the adhesive tape is monitored and full-automatic, rapid and efficient adhesive sticking is realized.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Method for adopting high-temperature-resisting composite urea resin for producing whole-eucalyptus solid wood composite floor

ActiveCN106272849AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerAntioxidant

The invention discloses a method for adopting high-temperature-resisting composite urea resin for producing a whole-eucalyptus solid wood composite floor. The method includes the steps of board rotary slicing, veneer drying, gluing, three times of cold pressing, standing maintaining, three times of hot pressing, heat dissipating maintaining, slab fixed-thickness sanding, base material surface layer gluing, maintaining grooving and paint spraying, drying and sizing. The production method is characterized in that the high-temperature-resisting composite urea resin is prepared by adopting melamine modified urea resin as the main material of an adhesive, adding oxidized starch as a viscosity complexing agent, adopting polyvinyl alcohol as a toughening agent, adopting hydrogenated rosin as an antioxidant, adopting polyisocyanate as a curing agent, adopting isobutyl triethoxy silane as a bridging agent, adopting phenolate lignin as a formaldehyde catching agent and adding high-temperature-resisting filler. The high-temperature-resisting composite urea resin prepared through the method is used for producing the whole-eucalyptus solid wood composite floor so that the whole-eucalyptus solid wood composite floor can have good heat resistance performance, no obvious crack phenomenon happens under high-temperature and high-strength ultraviolet irradiation or long-time ultraviolet irradiation, and economic losses are reduced.

Owner:广西横县正林木业有限公司

Automatic adhesive pasting machine

ActiveCN106532130AEnsure consistencyGuaranteed reliabilityFinal product manufactureCell component detailsEngineeringMechanical engineering

The invention relates to an automatic adhesive pasting machine, which comprises a discharging mechanism, a clamping mechanism, an adhesive pulling mechanism, an adhesive cutting mechanism and an adhesive pasting mechanism, wherein the discharging mechanism, the clamping mechanism, the adhesive pulling mechanism, the adhesive cutting mechanism and the adhesive pasting mechanism are matched with one another, so that automatic adhesive paper discharging, adhesive paper feeding and automatic pasting of adhesive paper are achieved, the adhesive pasting efficiency on battery tabs is greatly improved and the labor intensity and the manufacturing cost are reduced. Meanwhile, the phenomena of pasting leakage and loose pasting of the adhesive paper caused by manual adhesive pasting are avoided, the adhesive pasting consistency and reliability are effectively ensured and the quality of a product is improved.

Owner:SHENZHEN BROTHERS AUTOMATION TECH CO LTD

Glue sticking component and glue sticking device

PendingCN109360941AEasy to cutImprove reliabilityPrimary cell electrodesEngineeringMechanical engineering

The invention relates to a glue sticking component, which comprises a glue sticking component. The glue sticking component comprises a bearing platform for carrying a tape, a turnover plate capable ofbeing turned over with respect to the support platform, and a glue sticking roller. The turnover plate is used for turning over the adhesive tapes which are positioned on the bearing platform and cutoff, and the glue sticking roller is used for pressing the overturned adhesive tape against a pole piece for sticking glue. The invention also relates to a glue sticking device which comprises an unwinding mechanism, a clamping jaw component for clamping the adhesive tape, a cutting device and theglue sticking component.The clamping jaw component is used for pulling the adhesive tape onto the bearing platform, and the cutting device is used for cutting the adhesive tape. Compared with the prior art, the clamping jaw assembly can pull the adhesive tape onto the bearing platform, and then the adhesive tape is cut by the cutting device, so that the cutting is facilitated. In addition, the cut adhesive tape is turned over to a gluing station through the turnover plate, and glue sticking process is carried out through the gluing roller, so that the glue sticking efficiency is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

PCB golden finger tape attaching equipment and tape attaching method

PendingCN110678005AHigh precision of glue applicationImprove glue application efficiencyNon-metallic protective coating applicationAdhesive beltEngineering

The invention discloses PCB golden finger tape attaching equipment and a tape attaching method. The tape attaching equipment comprises a workbench, a clamping device, a tape feeding device, a negativepressure structure and a tape cutting device. The workbench is provided with a linearly extending slot. The clamping device is arranged at the slot, is used for clamping a PCB, and has two clamping surfaces capable of moving relatively. The tape feeding device comprises a material roll, a tape clamping assembly and a first driving device. The tape clamping assembly is used for clamping a tape onthe material roll; the first driving device is used for driving the tape clamping assembly to move along the slot; the negative pressure structure is arranged under the workbench and is used for forming negative pressure towards the position below the workbench in the area where the clamping device is located; and the tape cutting device is arranged beside the material roll and used for cutting off the tape pulled out by the tape clamping assembly. The tape attaching equipment realizes full-automatic tape attaching, is simple to operate and is basically suitable for tape attaching of various different types of PCBs.

Owner:湖北兆元科技有限公司

Automatic cutting and attaching device for double-sided tapes

PendingCN109455562AImprove glue application efficiencyArticle deliveryMechanical engineeringVideo tape

The invention provides an automatic cutting and attaching device for double-sided tapes. The automatic cutting and attaching device comprises an assembly plate, an attaching mechanism arranged on theassembly plate and a tape supplying mechanism; the tape supplying mechanism is used for providing double-sided tapes of a preset length automatically; the attaching mechanism is used for attracting multiple double-sided tapes continuously and attaching the multiple double-sided tapes to-be-taped parts of products; the attaching mechanism comprises a translation mechanism arranged on the assembly plate, a lifting mechanism arranged on the driving end of the translation mechanism and a tape taking mechanism arranged on the driving end of the lifting mechanism; the translation mechanism can drivethe lifting mechanism and the tape taking mechanism to move horizontally; the lifting mechanism can drive the tape taking mechanism to move vertically; the tape taking mechanism can attract multipledouble-sided tapes; the tape taking mechanism comprises a first motor and an attaching wheel; and the first motor can drive the attaching wheel to rotate. By adopting the automatic cutting and attaching device, multiple double-sided tapes of the preset length can be attracted in one step; besides, the multiple double-sided tapes can be continuously attached to to-be-taped positions of products inone step; and the tape attaching efficiency is high.

Owner:江阴西联复合材料有限公司

Method for producing whole eucalyptus plywood by using compound urea-formaldehyde resin against insects and mildew

ActiveCN106182218BReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAntioxidant

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

Automatic rubberizing equipment, method for tearing rubber ring body paper and automatic rubberizing method

PendingCN111299082AImprove glue application efficiencySticking effect is stableLiquid surface applicatorsMaterial gluingAdhesive glueRubber ring

The invention relates to automatic rubberizing equipment, a method for tearing rubber ring body paper and an automatic rubberizing method. The equipment comprises a workbench. A cleaning station, a gluing station, a glue curing station, a 180-degree turnover station, a bonding station, a pressing station and a finished product discharging station are sequentially arranged on the workbench. A cleaning assembly, a gluing assembly, a glue curing assembly, a turnover assembly, a body paper tearing assembly, a press assembly, a first moving assembly and a second moving assembly are further arrangedon the workbench. The first moving assembly is used for moving three sets of rotating fan blades corresponding to the first three stations back by one station, and the second moving assembly is usedfor moving three sets of rotating fan blades corresponding to the fourth station, the fifth station and the sixth station back by one station. During use, workers only need to provide the rotating fanblades and rubber rings, a series of subsequent procedures is automatically completed by the equipment, manpower is greatly saved, and unified quality of batched products can be guaranteed easily.

Owner:深圳亿和模具制造有限公司

Mechanism for automatically sticking double faced adhesive tape on arc-shaped surface

PendingCN110589593AAutomatic glue applicationHigh degree of automationArticle deliveryAdhesiveAutomation

The invention discloses a mechanism for automatically sticking a double faced adhesive tape on an arc-shaped surface. The mechanism comprises a rack, a double faced adhesive tape storage device, an adhesive conveying device, a pull-down film tearing device, a cutting device and an automatic adhesive adhering device, wherein the double faced adhesive tape storage device is arranged on one side of the rack and is used for storing the double faced adhesive tape, the adhesive conveying device is arranged on the rack and used for pulling out the double faced adhesive tape on the double faced adhesive tape storage device, the pull-down film tearing device is arranged on the rack and is used for performing pull-down film tearing on the double faced adhesive tape on the double faced adhesive tapestorage device, the cutting device is arranged on the rack and is used for cutting the double faced adhesive tape, and the automatic adhesive adhering device is arranged on the rack and used for grabbing the double faced adhesive tape and automatically adhering the double faced adhesive tape to the arc-shaped surface of a product. The functions of automatic adhesive conveying, automatic film tearing, automatic cutting and automatic adhesive adhering on the arc-shaped plane for the double faced adhesive tape are achieved, and the advantages that the automation degree is high, and the adhesive adhering efficiency is high are achieved.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

Method for producing full-eucalyptus parquet through dampproof composite urea resin

InactiveCN106239646AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesFiberPolyvinyl alcohol

A method for producing a full-eucalyptus parquet through dampproof composite urea resin comprises the following steps of wood board sheet rotary cutting, veneer drying, gluing, three-time cold pressing, standing curing, three-time hot pressing, heat dissipation curing, slab fixed-thickness sanding, base material surface layer gluing, curing slotting and spraying drying sizing. According to the key of the production method, melamine modified urea resin is adopted as a main adhesive material, and oxidized starch is added as a sticky complexing agent; polyvinyl alcohol serves as a toughening agent; magnesium oxide serves as an anti-aging agent; hexamine and triglycidyl isocyanurate serve as a curing agent; vinyltriethoxysilane serves as a bridging fiber agent; and phenolate lignin is the dampproof composite urea resin prepared through a formaldehyde capture agent and an added dampproof agent. The composite urea resin has the beneficial effects of being low in formaldehyde residual volume and good in water resistance and dampproof performance, so that the produced full-eucalyptus parquet is low in formaldehyde residual volume and is not prone to expansion after absorbing water, arching and deformation are not likely to happen, and an abrasion resisting layer is not prone to damage.

Owner:南宁市创锦胶合板有限责任公司

Gluing production line

ActiveCN107039673AImprove quality and efficiencyImprove glue application efficiencyAssembling battery machinesFinal product manufactureProduction lineGlue line

The invention discloses a gluing production line. The gluing production line comprises a feeding mechanism, a first gluing line, a turnover device and a second gluing line, wherein the feeding mechanism, the first gluing line, the turnover device and the second gluing line are sequentially arranged according to a gluing process, the feeding mechanism is used for transmitting a material to be glued to the first gluing line for gluing a first surface, and the turnover device is used for turning over and sending the material of which one surface is glued to the second gluing line for gluing a second surface of the material. Compared with the prior art, the gluing production line has the advantages that the gluing quality and the gluing efficiency can be improved, and the qualified rate of a product is improved.

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

Adhesive tape pasting mechanism and adhesive tape pasting device

PendingCN112952178AReduce stepsRealize the needs of pasting gluePrimary cell manufactureAssembling battery machinesAdhesive beltEngineering

The invention discloses an adhesive tape pasting mechanism and an adhesive tape pasting device. The adhesive tape pasting mechanism comprises an adhesive tape pulling assembly, a first compression roller, anadhesive tape cutting assembly, a first driving assembly and a second driving assembly. After the adhesive tape pulling assembly pulls the adhesive tape, the first driving assembly and the second driving assembly can drive the adhesive tape pulling assembly and the adhesive tape to move towards the to-be-pasted piece until the adhesive tape is pasted to the to-be-pasted piece; the first compression roller driving assembly can drive the first compression roller to compress the adhesive tape on the to-be-pasted piece; after the adhesive tape pulling assembly loosens the adhesive tape, the first driving assembly can reversely drive the adhesive tape pulling assembly to return, and the first compression roller can flatten the adhesive tape along with the adhesive tape pulling assembly; when the first compression roller reaches the edge of the to-be-pasted piece, the first compression roller driving assembly can drive the first compression roller to paste the adhesive tape to the second face of the to-be-pasted piece along the edge of the to-be-pasted piece; by means of the first compression roller driving assembly and the first compression roller, the adhesive tape can be bent along the to-be-pasted part while the adhesive tape is flattened and tightly attached, and the pasting requirements of the two faces of the to-be-pasted piece are met; and the pasting efficiency is high.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

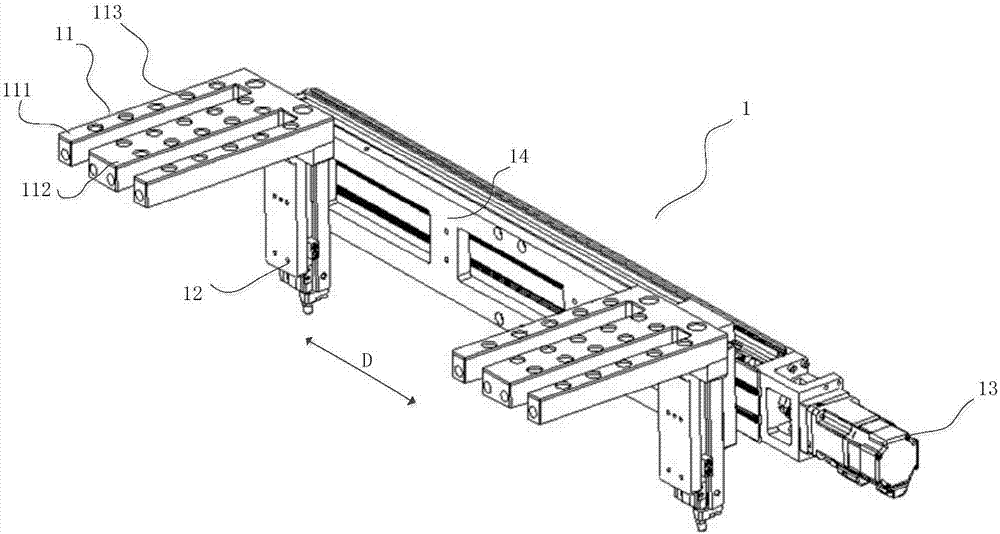

Adhesive tape pasting device

ActiveCN109110545AImprove precision controlImprove glue application efficiencyArticle deliveryWebs handlingMechanical engineering

The invention provides an adhesive tape pasting device. The adhesive tape pasting device comprises an adhesive tape pulling roller and a vacuum communication mechanism. The outer contour of the adhesive tape pulling roller is a column. A plurality of adhesive tape carrying faces are arranged on the radial outer surface of the adhesive tape pulling roller. Each adhesive tape carrying face is provided with a plurality of holes. An adhesive tape can be sucked on the adhesive tape carrying faces of the adhesive tape pulling roller. A first end face is arranged at one axial end of the adhesive tapepulling roller and is provided with a plurality of air holes. The holes formed in each adhesive tape carrying face correspondingly communicate with one air hole. The vacuum communication mechanism isprovided with a second end face. The second end face is provided with a first matched connection opening and a second matched connection opening. Axial force is applied to correspondingly paste the second end face on the first end face. The adhesive tape pulling roller can rotate relative to the vacuum communication mechanism, so that the first matched connection opening communicates with part ofthe air holes, and the second matched connection opening communicates with the rest of the air holes. By adoption of the adhesive tape pasting device, the control accuracy of the size of the adhesivetape can be improved, the adhesive tape pasting efficiency is improved; and adhesive tape pasting device is simple in structure, reliable in motion and convenient to operate and maintain.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

Vibrator tape pasting equipment

ActiveCN112092400AAutomatic strippingAchieve strippingLayered productsLaminationComposite materialManufacturing engineering

The invention relates to the field of tape pasting equipment, in particular to vibrator tape pasting equipment. The vibrator tape pasting equipment comprises an operation table, two supports, a back plate and a bottom frame, the supports and the bottom frame are fixed to the top of the operation table, and the bottom frame is located between the two supports. The problems that in the prior art, vibration isolation is conducted by pasting a foam adhesive tape on a vibrator manually, adhesive tape raw materials comprise a protective film and the foam adhesive tape, the protective film needs to be stripped manually and then the foam adhesive tape needs to be taken out to be pasted, the manual adhesive tape stripping and pasting efficiency is low, the automation degree is low, and the adhesivetape stripping and pasting quality is difficult to control, in addition, the stripped protective film needs to be cleaned in time, existing vibrator tape pasting equipment is lack of a part for cleaning the stripped protective film in time, the steps of taking a tape sheet, pasting the film and then taking the tape sheet again need to be conducted in sequence in the using process of the whole tape pasting equipment, a new tape sheet cannot be taken while the film is pasted, and thus the efficiency of the whole operation step is greatly reduced can be solved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com