Efficient and automatic new energy square battery glue pasting, detecting and sorting integrated equipment

A prismatic battery, new energy technology, applied in sorting, assembling battery machines, secondary battery manufacturing, etc., can solve the problems of slow lamination process, affect the quality of lamination, low efficiency, etc., and improve the quality and efficiency of lamination , The effect of shortening the gluing process and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

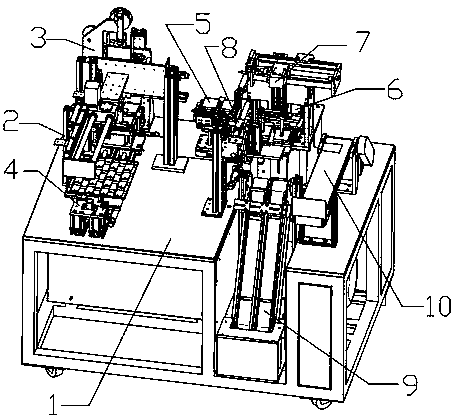

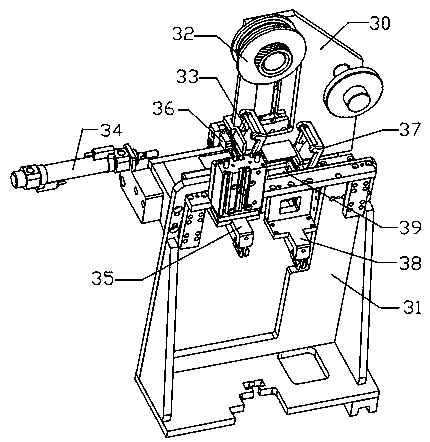

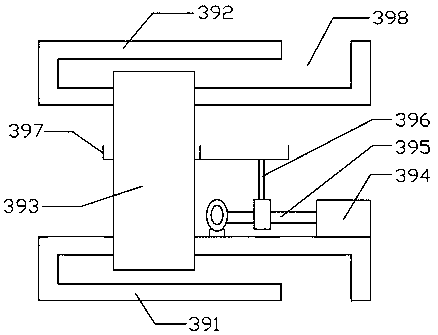

[0031] Embodiment 1, a new energy square battery 393 high-efficiency automatic gluing and detection and sorting integrated equipment, including a workbench 1, the lower part of the workbench 1 is equipped with a PLC control device, characterized in that: the workbench 1 is equipped with a The first conveying device 4 for conveying the feeding tray, the upper part of the discharging tray is provided with a plurality of square batteries 393, one side of the first conveying device 4 is provided with a feeding manipulator 2, and the rear side of the feeding manipulator 2 is provided with a temporary platform , the top of the temporary storage platform is provided with a double-sided gluing mechanism 3 for simultaneously gluing the front and back of the battery, the right side of the double-sided gluing mechanism 3 is provided with a quality inspection device 5, and the rear side of the double-sided gluing mechanism 3 A transfer manipulator is provided, the right side of the quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com