Automatic head glue pasting machine

A head and glue machine technology, applied to conveyor objects, household components, household appliances, etc., can solve problems such as high defective rate, low attachment accuracy, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

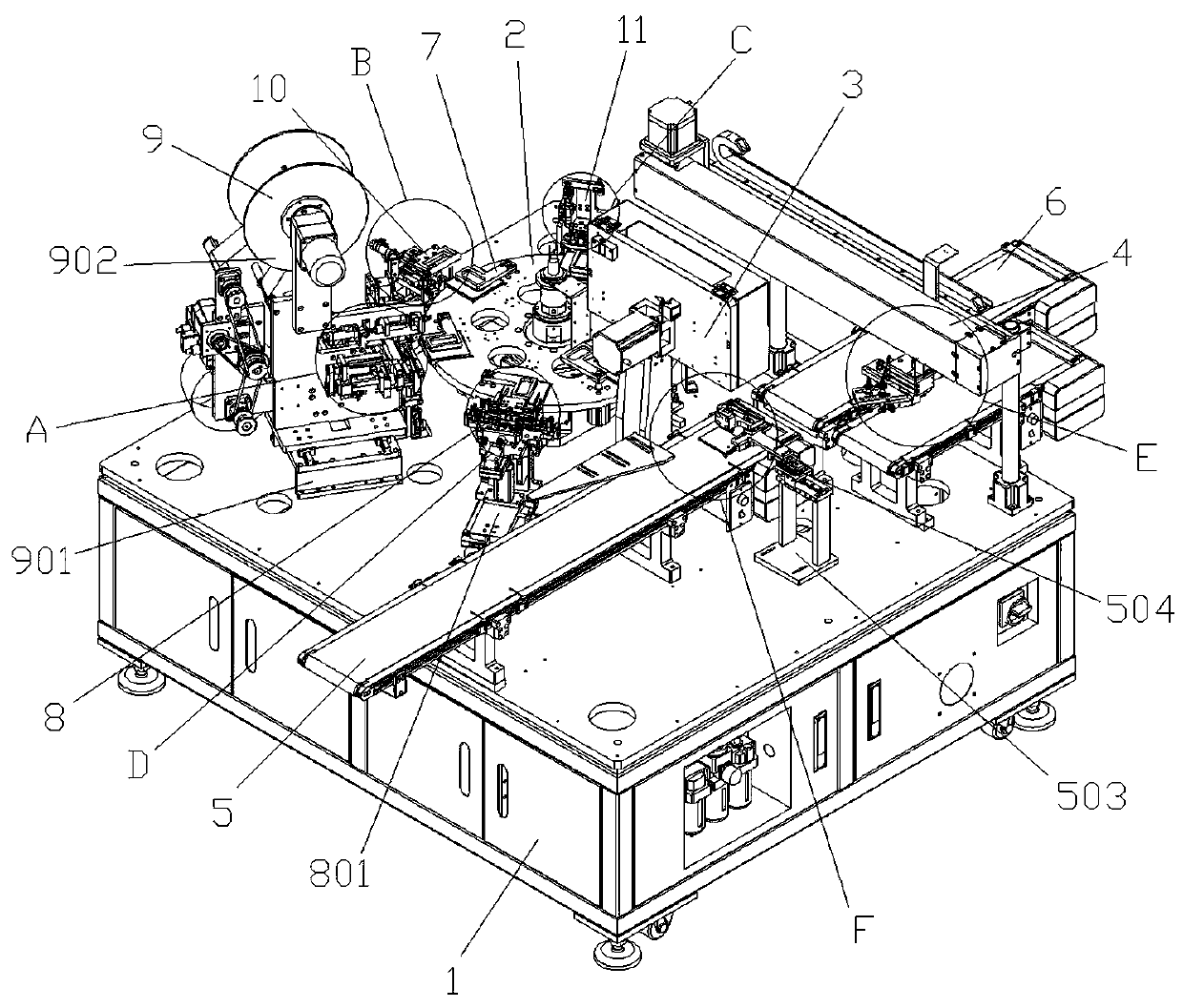

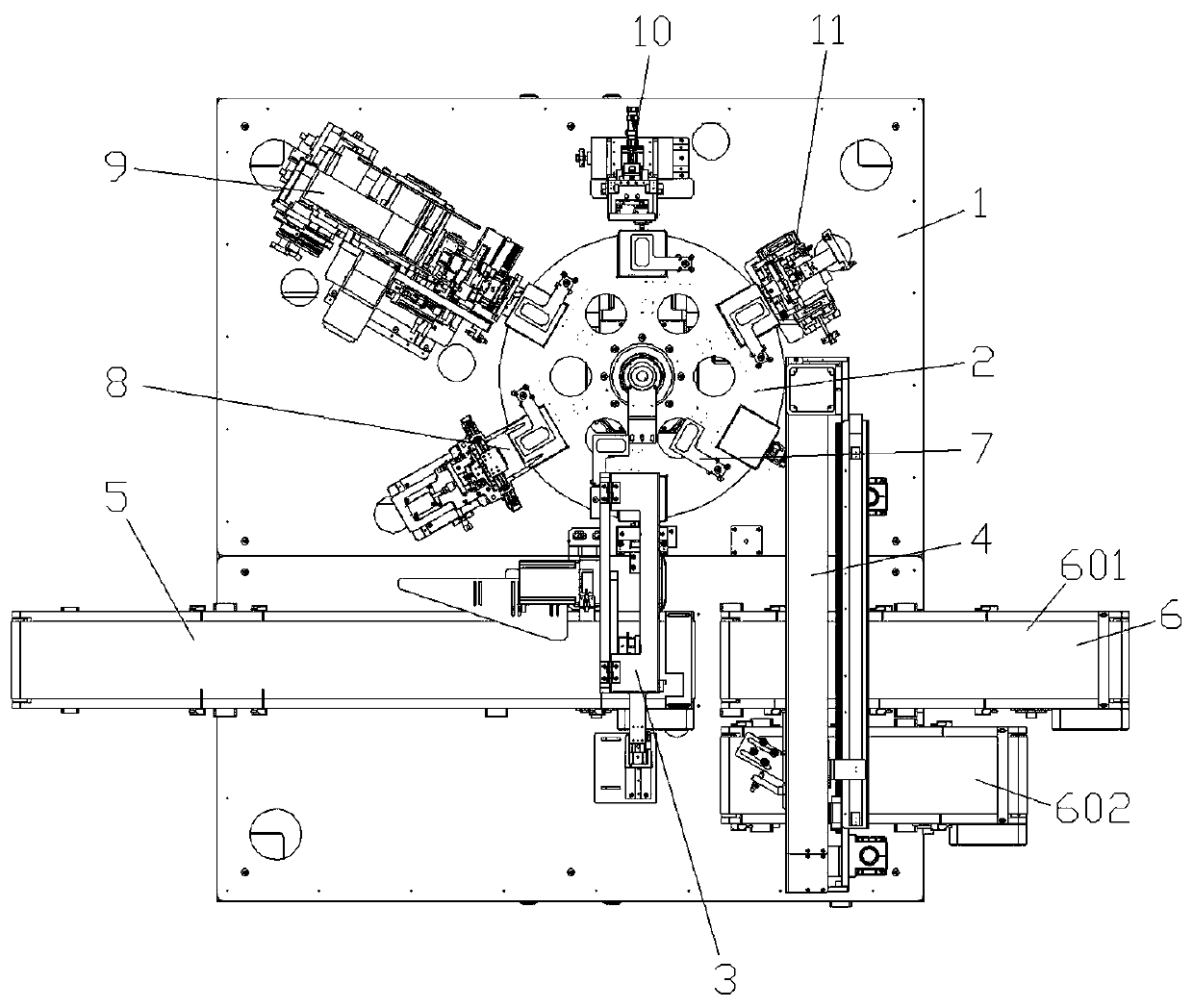

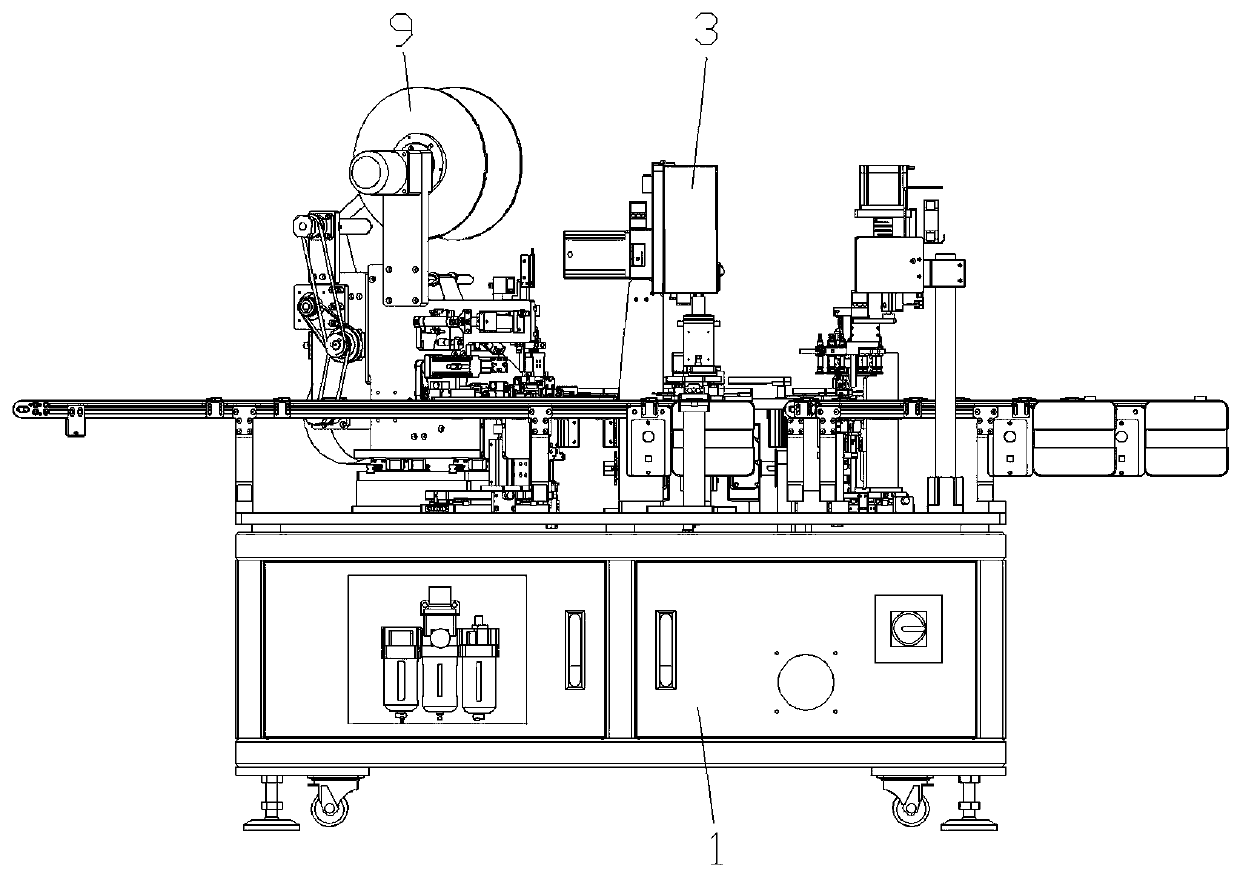

[0026] like Figure 1 to Figure 10 As shown, in the present embodiment, the present invention comprises machine platform 1, and described machine platform 1 is provided with turntable module 2, feeding module 3, unloading module 4, feeding belt 5 and unloading belt 6 , the turntable module 2 is equipped with a plurality of product fixtures 7, and the periphery of the turntable module 2 is successively provided with a product positioning module 8, a gluing module 9, a rubber rolling module 10 and an adhesive tape holding Module 11, one end of the feeding module 3 is arranged on the feeding belt 5, the other end is located above the turntable module 2, and is located at the product positioning module 8 and the adhesive tape Between the pressure holding modules 11, one end of the unloading module 4 is arranged on the unloading belt 6, and the other end is located above the turntable module 2, and is located between the loading module 3 and The gummed paper is kept between the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com