Paperboard adhesive adhering mechanism

A gluing mechanism and cardboard technology, which is applied to paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of easy misplacement, wrinkles on the glue surface, and low efficiency of double-sided adhesive application, so as to facilitate precise molding, Precise gluing position and high gluing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

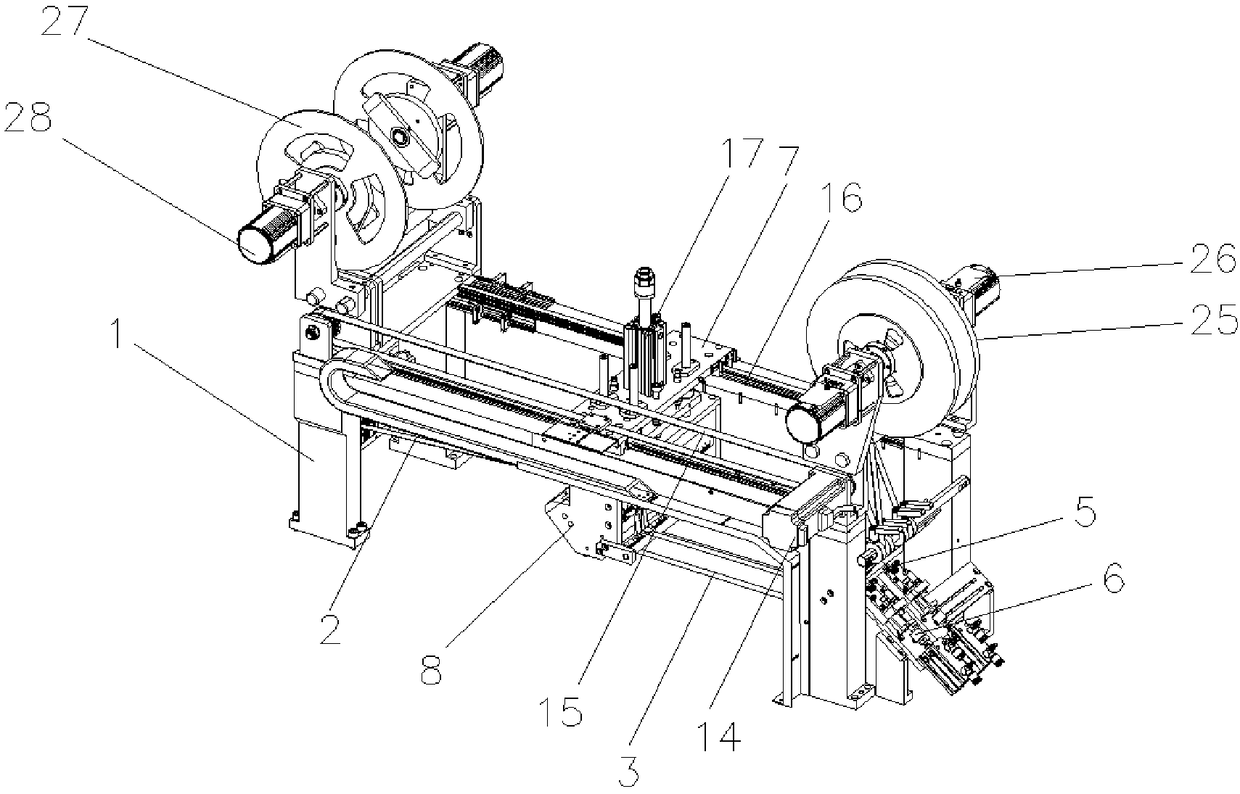

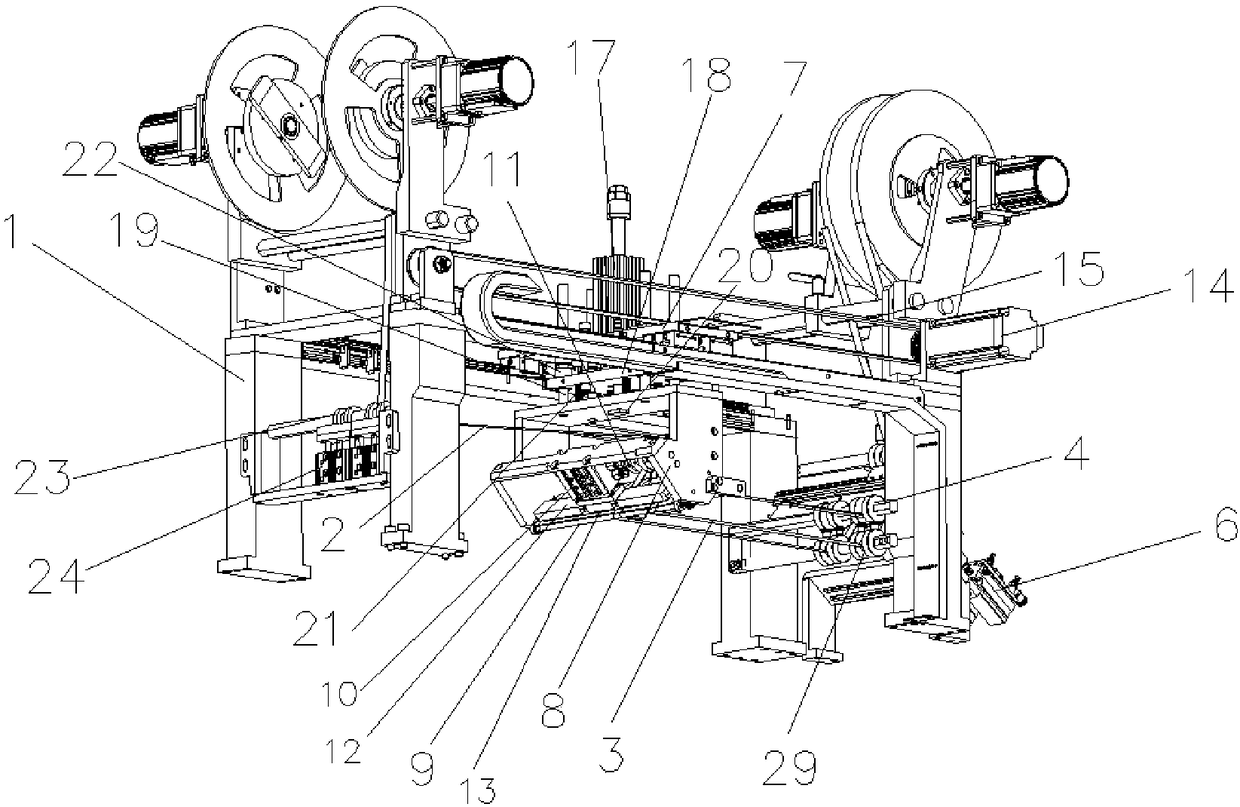

[0021] Embodiment: A kind of cardboard gluing mechanism, comprises frame 1, double-sided tape feeding module, glue surface cutting device, release paper receiving module, double-sided tape attaching module and controller, wherein:

[0022] The double-sided adhesive supply module and the release paper receiving module are respectively installed on the frame 1. The double-sided adhesive supply module can provide double-sided adhesive 2 for the double-sided adhesive attachment module, and the release paper receiving module The module can collect the adhesive-free release paper 3 drawn from the double-sided adhesive attachment module;

[0023] The rubber surface cutting device includes a turning roller 4, a cutting knife 5 and a cutting drive device 6. The turning roller 4 is rotatably mounted on one end of the frame 1, and the double-sided adhesive 2 drawn from the surface glue supply module passes through the Turning roller 4 turns, double-sided adhesive tape 2 release paper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com