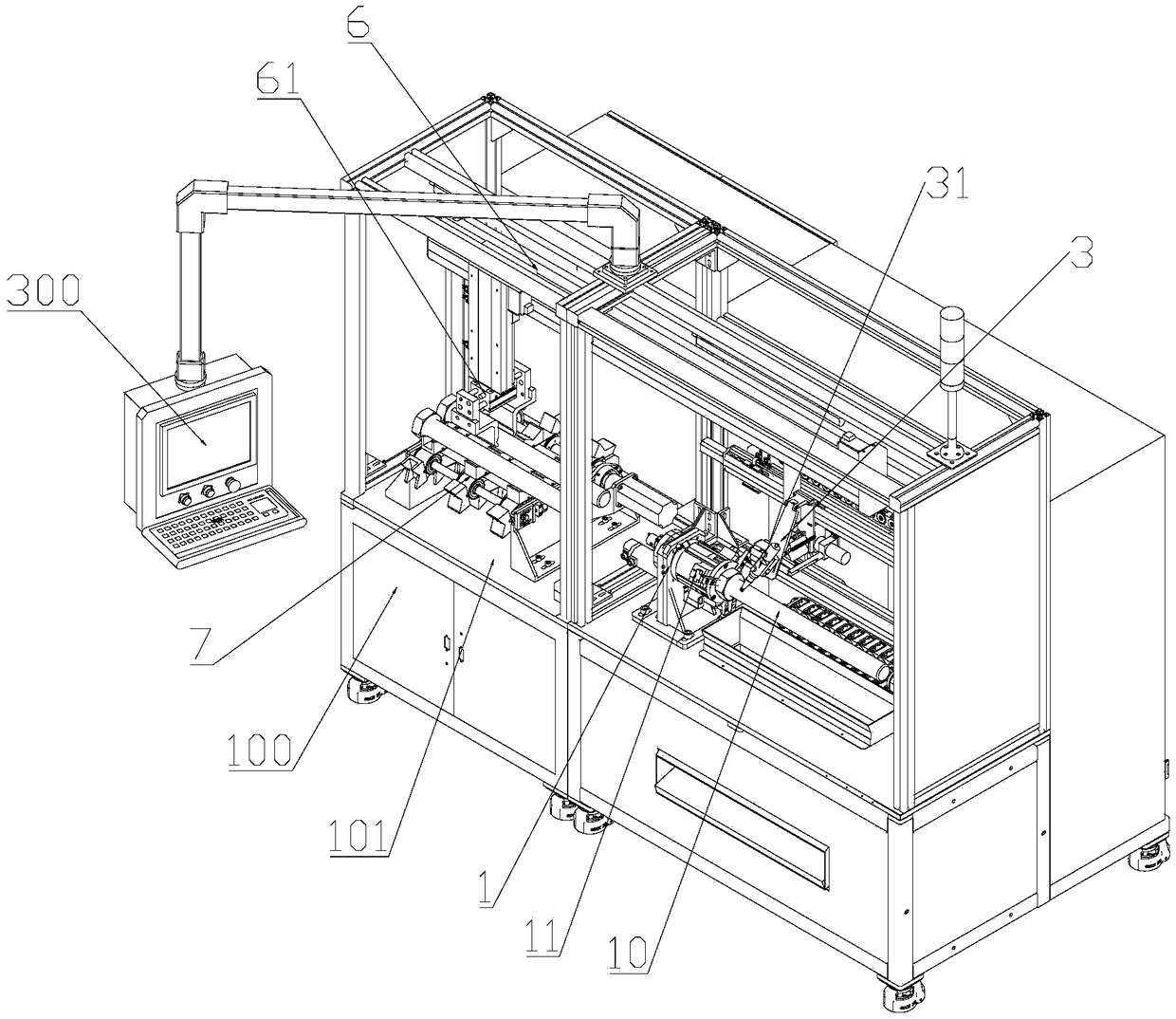

Numerical control dispensing equipment and dispensing method

A dispensing and equipment technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low production efficiency, heavy repetitive labor, etc., achieve fast glue application, reduce labor load, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1 of the present application provides the first dispensing extension method, and the schematic flow chart of the method is as follows Figure 13 shown, including the following steps:

[0090] S101 : Control the workpiece clamping part 11 to clamp the first end of the workpiece 10 .

[0091] Optionally, in the embodiment of the present application, before S101, the numerical control dispensing equipment may also reset each component according to the dispensing mode information of the workpiece 10 .

[0092] S102: Control the first slide rail driving part 41 to drive the pushing mechanism 2 to move along the first slide rail 42, so that the pushing mechanism 2 is close to the second end of the workpiece 10.

[0093] S103 : Control the tightening drive part 24 to drive the tightening slider 23 to move along the tightening base 22 , so that the tightening part 21 abuts against the second end of the workpiece 10 .

[0094] S104: Control the workpiece clamping pa...

Embodiment 2

[0099] Embodiment 2 of the present application provides the second dispensing extension method, the schematic flow chart of the method is as follows Figure 14 shown, including the following steps:

[0100] S201 : Control the manipulator 200 to transport the workpiece 10 to the conveyor belt 71 .

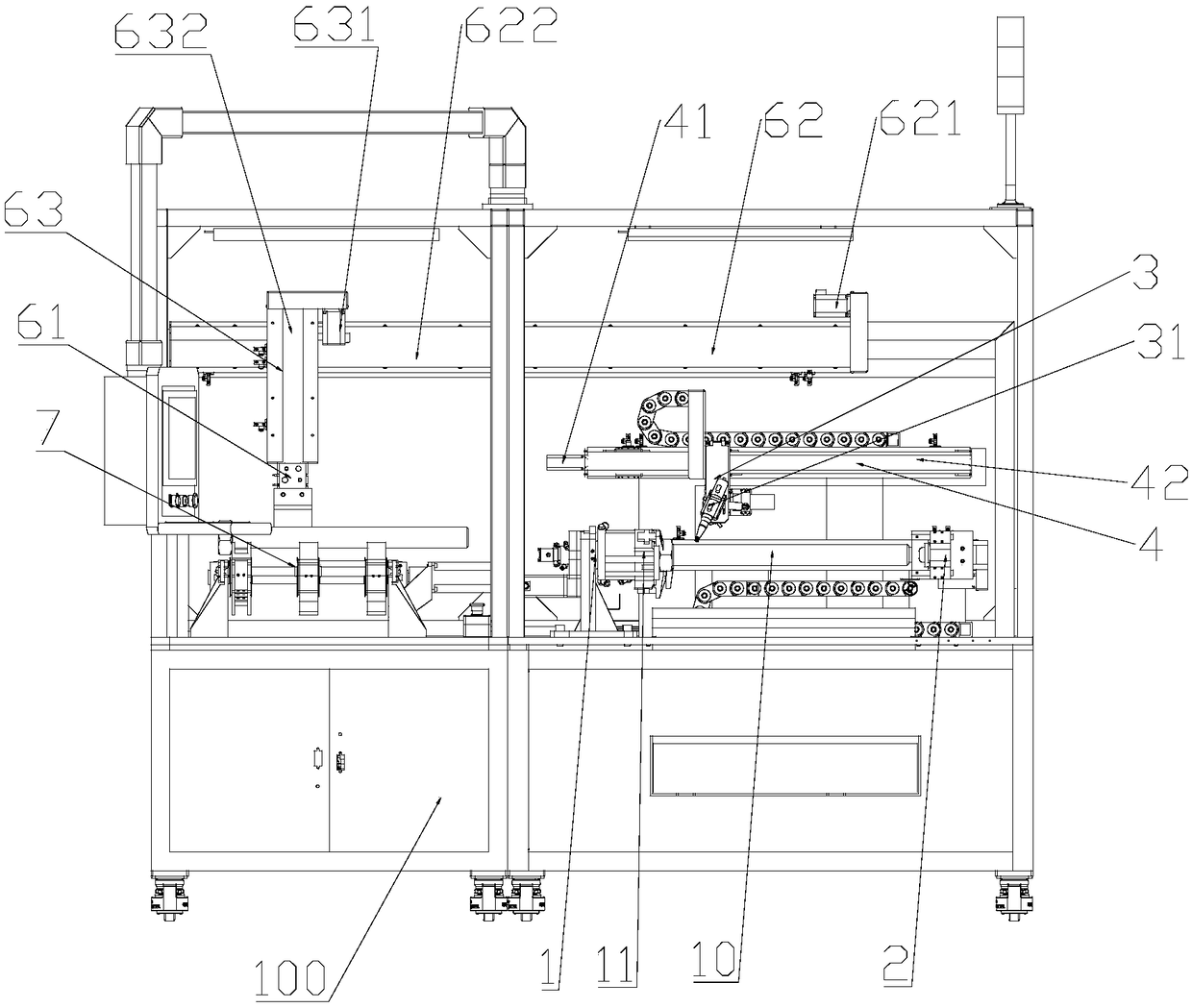

[0101] S202: Control the conveyor belt 71 to transfer the workpiece 10 to the first workpiece position.

[0102] S203: Control the workpiece grasping part 61 to grab the workpiece 10 at the first workpiece position, and transport the workpiece 10 to the second workpiece position for clamping by the workpiece clamping part 11 .

[0103] Specifically, in S203, the sliding table 633 is driven to move by controlling the third sliding rail driving part 621, so that the fourth sliding rail mechanism 63 can move along with the sliding table 633 along the third sliding rail 622, and the fourth sliding rail driving part 631 drives the workpiece grasping part 61 to move along the fourth sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com