Gluing and material packaging production line for packaging box

A production line and box gluing technology, applied in packaging, transportation, packaging, decorative art, etc., can solve the problems of large amount of glue, uniform glue coating, and low packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

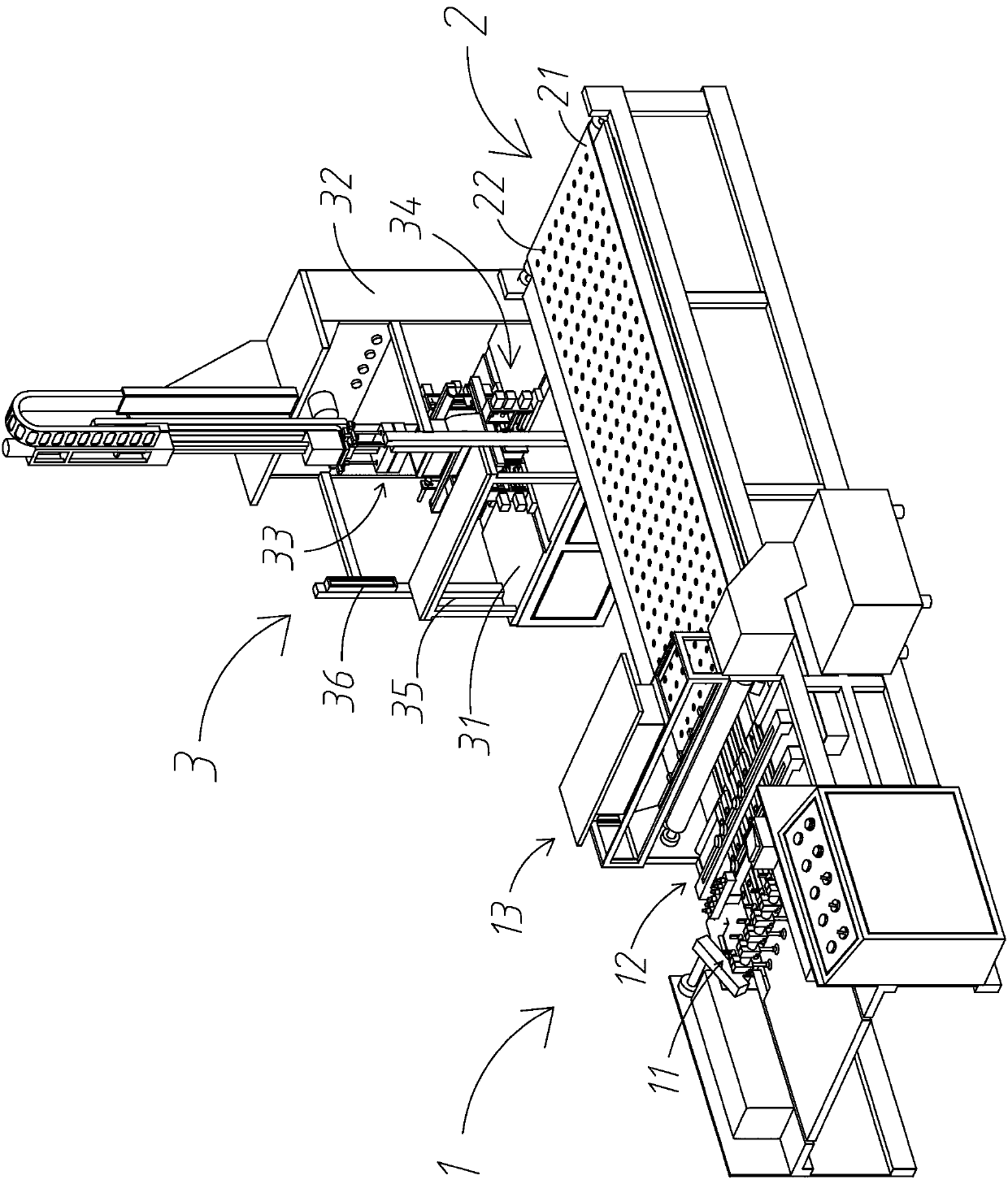

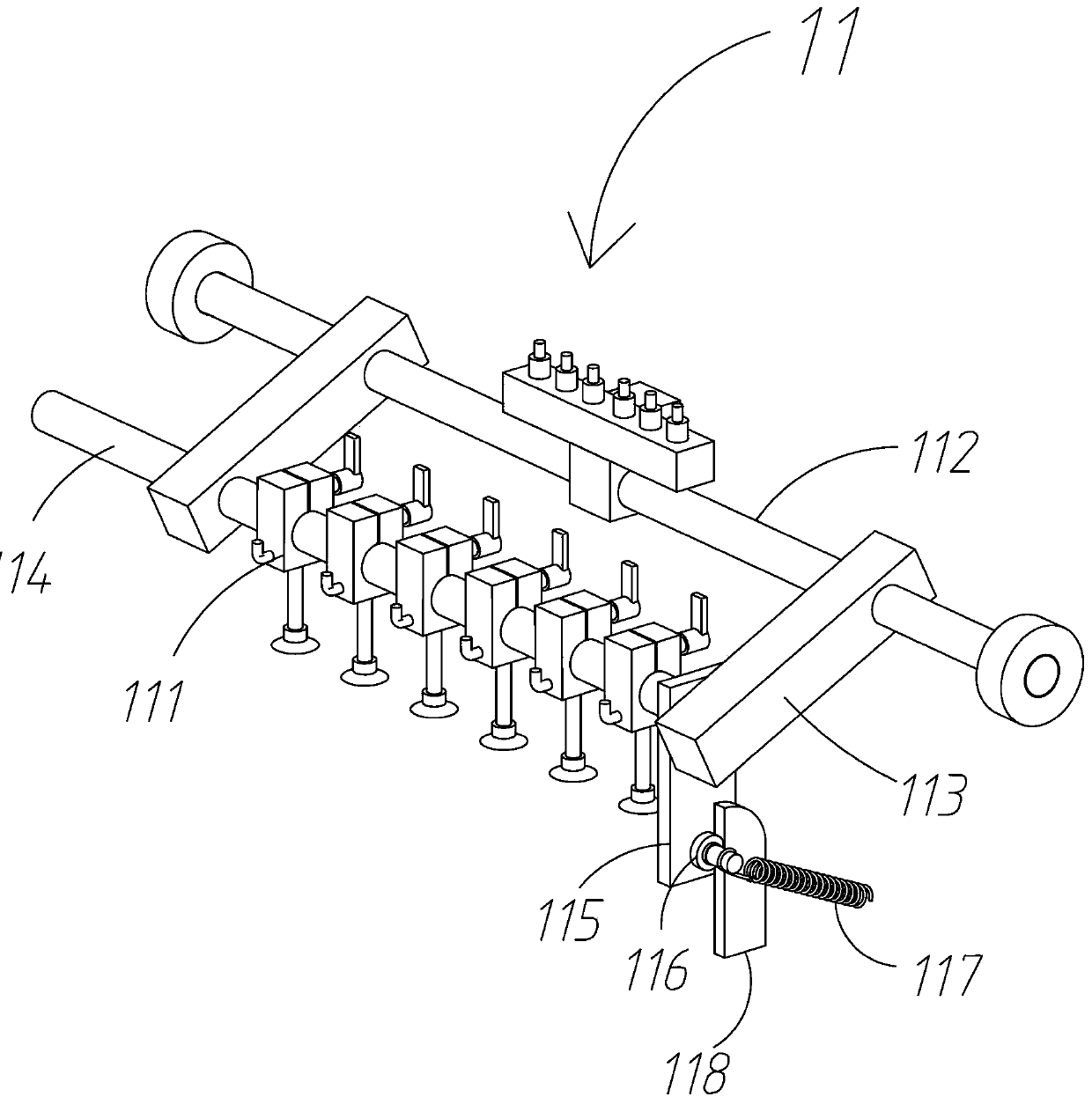

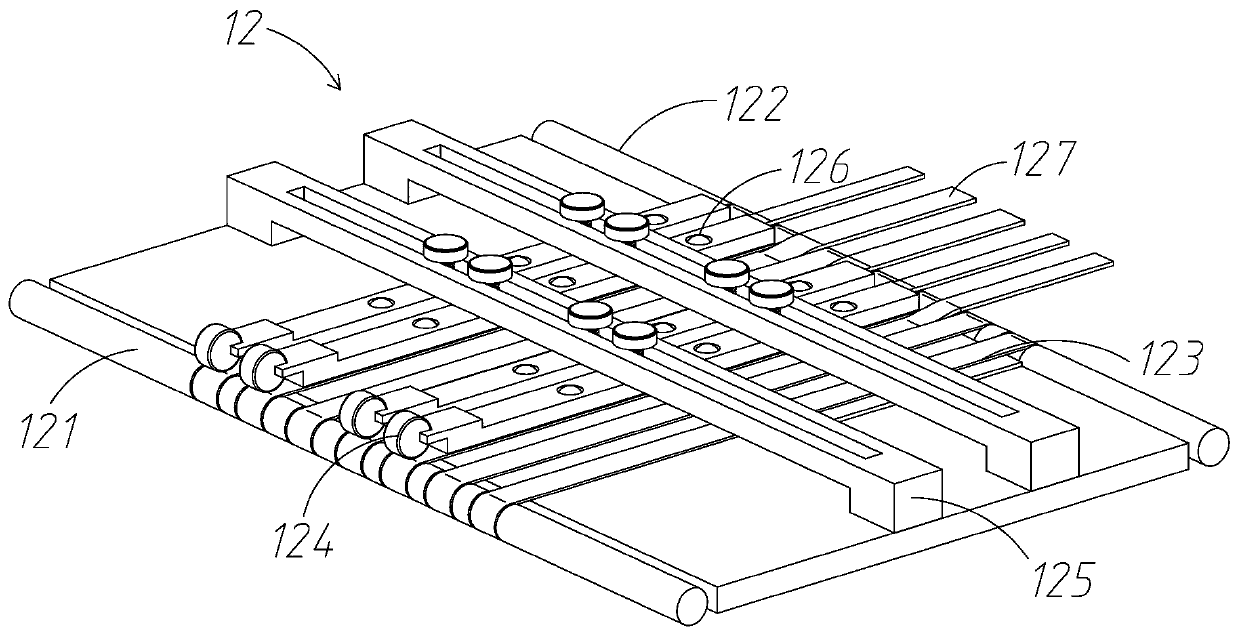

[0024] Such as figure 1 As shown, a packaging box gluing and wrapping production line includes a gluing mechanism 1, a transition conveying mechanism 2 and a wrapping mechanism 3, the gluing mechanism 1 is arranged at the front end of the transition conveying mechanism 2, and the wrapping mechanism 3. It is arranged on the left side of the rear end of the transition conveying mechanism 2. The gluing mechanism 1 includes a feeding device 11 for feeding the paper, a conveying device 12 for conveying the paper, and a coating device for coating the paper, which are arranged in sequence according to the processing procedures. The gluing device 13 of the glue, the material wrapping mechanism 3 includes a workbench 31, a gantry 32 arranged on the workbench 31, an upper edge-holding device 33 installed on the gantry 32 and an upper edge clamping device 33 installed on the workbench 31 and connected with the workbench 31. The lower edge-holding device 34 corresponding to the upper edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com