Bamboo hat magazine tool

A hat-type tool magazine and tool box technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of easy wear of cylinder seals, low safety, poor reliability, etc., and achieve good reliability, high safety, Smooth tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

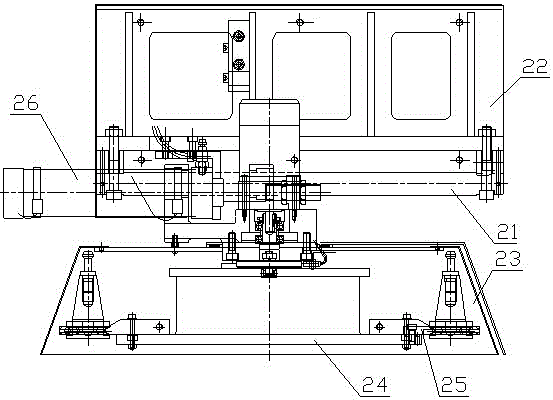

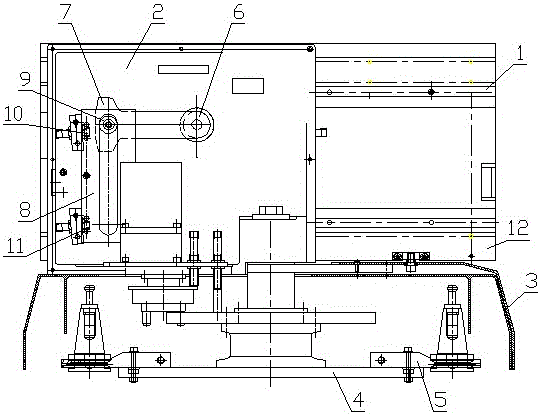

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Depend on figure 2 As shown, the electric bamboo hat type tool magazine includes a frame 12, a guide rail 1 arranged on the frame 12, a tool change box 2 installed on the guide rail 1, a tool storehouse 3 connected to the tool change box 2, and a tool storehouse The cutter head 4 in 3, several tool holders 5 installed on the cutter head 4, and the cutter head rotation control device are also provided with a reversible motor 6, a crank 7 on the frame 12, and are fixedly connected with the tool change box 2 One end of the sliding seat 8, the crank 7 is connected with the output shaft of the motor 6, and can rotate forward and reverse with the output shaft, and the other end is provided with a roller 9, which is arranged in the chute of the sliding seat 8, and can be moved along the chute To move, detection switches 10 and 11 are respectively provided at the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com