Through type arbitrary-angle rotating clamp for aluminum wheel

A technology of rotating fixtures and arbitrary angles, which is applied in the field of machining and wheel machining automation, can solve problems such as poor working environment, low work efficiency, and high labor intensity, and achieve labor cost savings, labor intensity reduction, and a reasonable overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

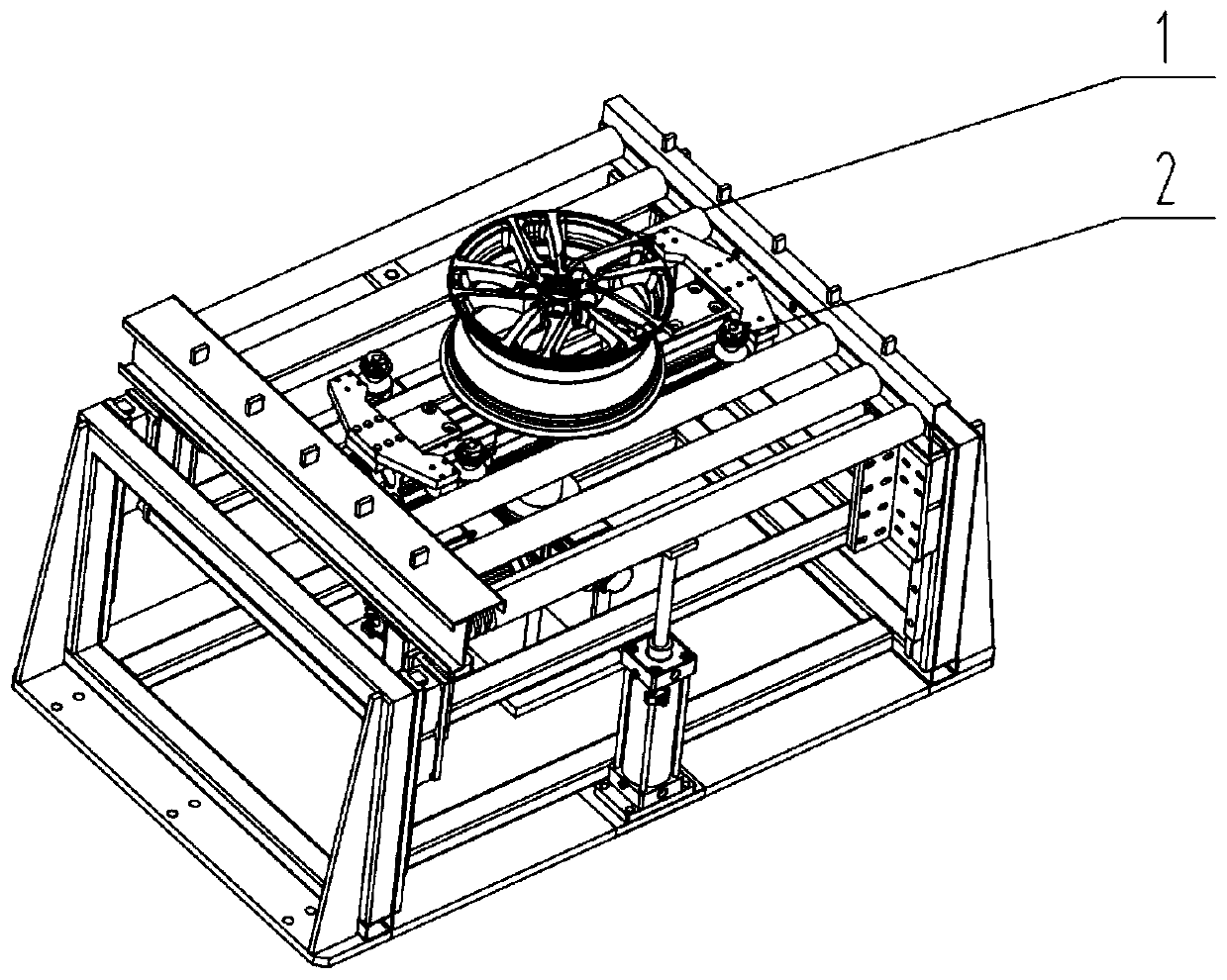

[0029] like Figure 1-4 As shown, a through-type aluminum wheel arbitrary angle rotation fixture disclosed in the present invention is composed of a conveying assembly 1 and a positioning assembly 2;

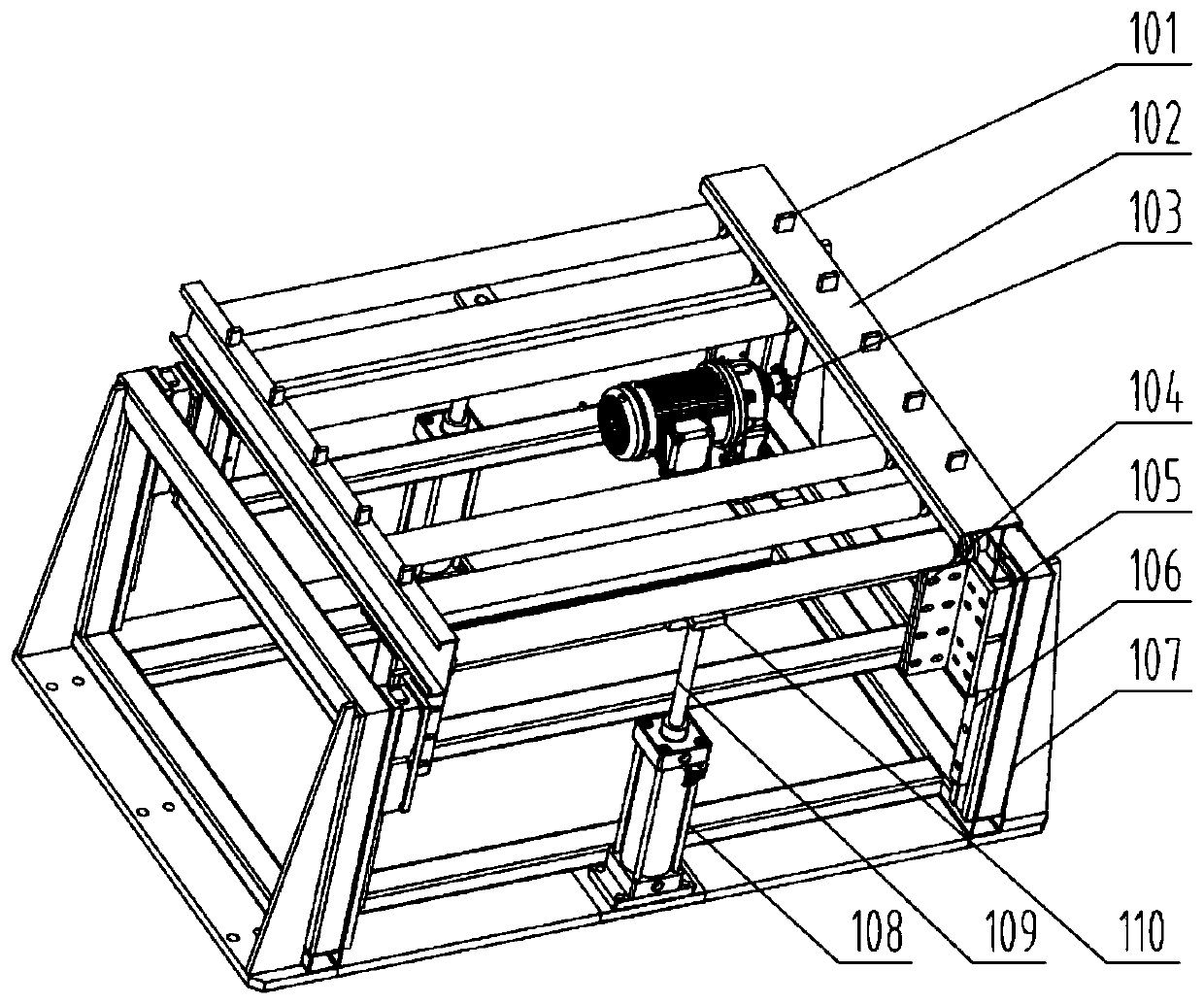

[0030] Wherein the conveying assembly 1 includes: a photoelectric switch 101, a raceway 102, a motor A103, a connecting bracket 104, a slider 105, a linear guide rail 106, a base A107, a cylinder block 108, a piston rod 109, and a cylinder connecting frame 110;

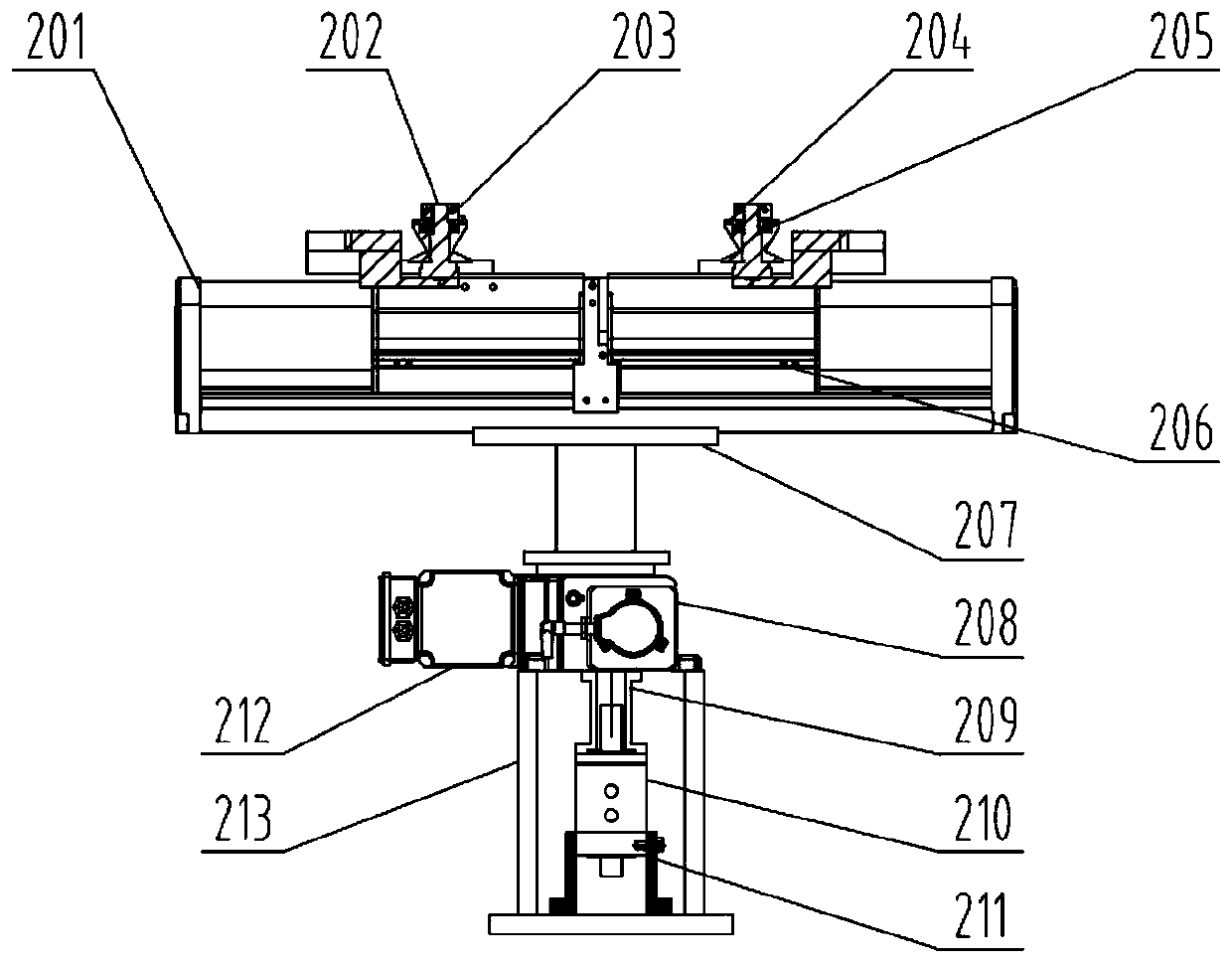

[0031] The positioning assembly 2 includes: a centering cylinder block 201, a support shaft 202, a locking block 203, an upper gland 204, a one-way bearing 205, a centering cylinder slider 206, a connecting flange 207, a cam divider 208, a transition Frame 209, slip ring 210, slip ring base 211, motor B212, base B213, transition plate 214, V wheel 215, support frame 216, plate 217;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com