Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Avoid direct human contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

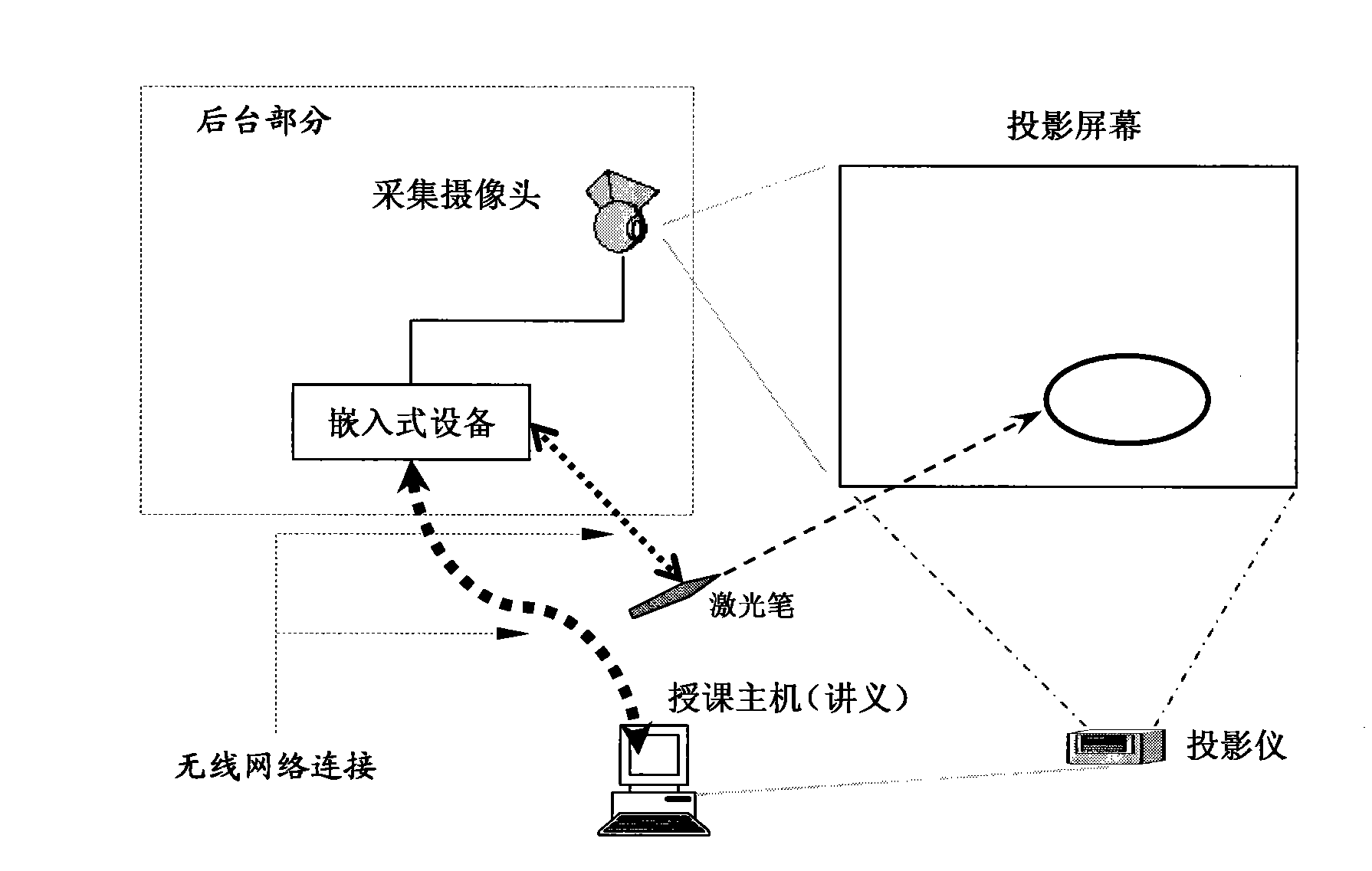

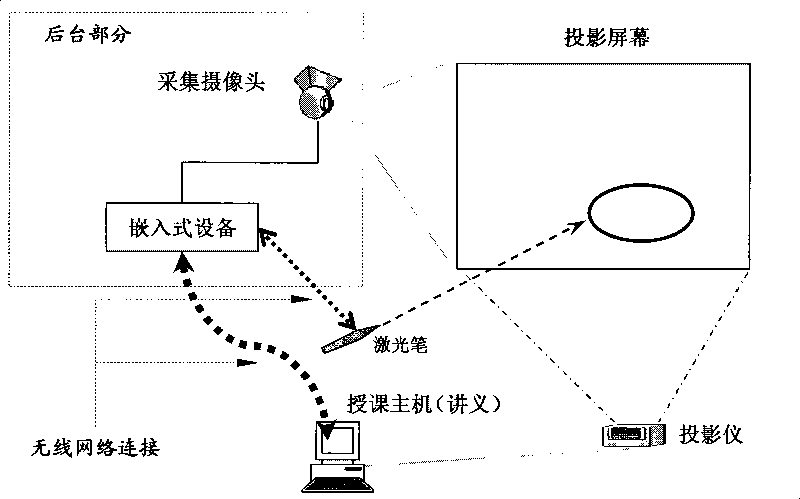

Laser pen indication and luminescent spot track recognizing method

InactiveCN101251784ATeaching continuity and freedomProduce wear and tearReadingCharacter and pattern recognitionLight spotComputer vision

The present invention discloses a laser pen indicating and light spot trajectory identification method which belongs to the interactive reorganization technical field. Step 1, according to laser pen indicating information, a user obtains video information of a display screen from a video input device; step 2, an embedded device extracts light spots from the acquired video information, and determines the positions of the light spots after a de-noising process; step 3, the position coordinates of the light spots are transmitted to a computer which controls a target screen; step 4, according to the position coordinates of the light spots, the computer which controls the target screen recognizes the light spot trajectory; with the specific light spot information, the trajectory information indicated by the user is obtained; when the recognition is succeeded, step 5 is carried out; step 5, after the trajectory recognition is succeeded, the trajectory of the recognition result of the original trajectory is optimized, so that a new trajectory is obtained; the optimized result is displayed with visually optimized effect on the target screen to replace the indication effect of the step 3. The method can be applied in various interactive recognition display circumstances so as to carry out highly effective light spot analysis and trajectory recognition.

Owner:SHANGHAI JIAO TONG UNIV

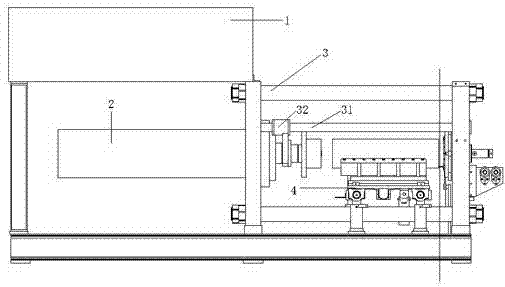

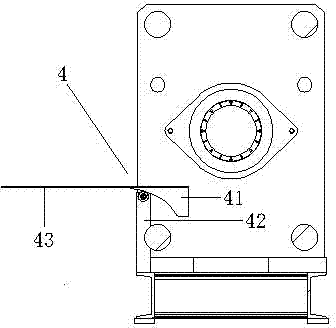

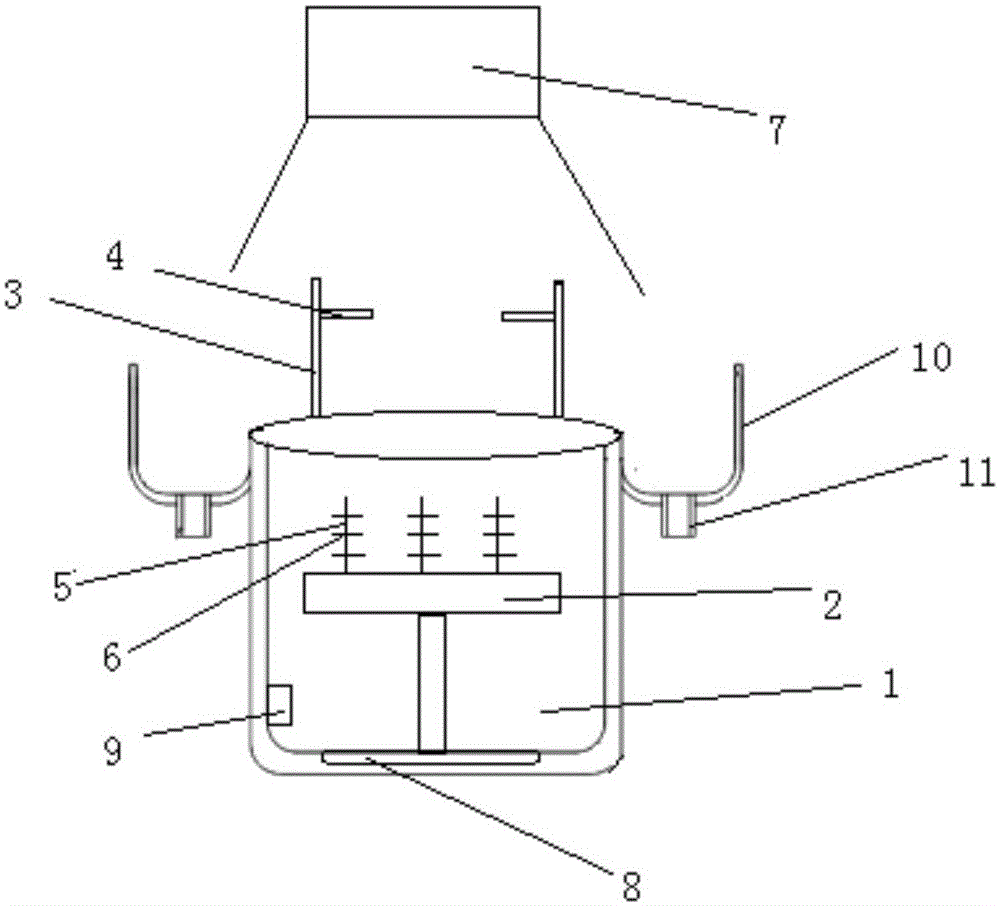

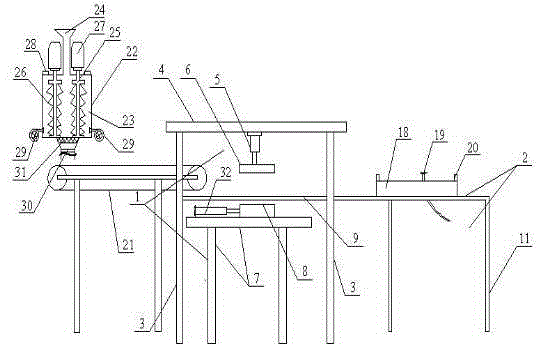

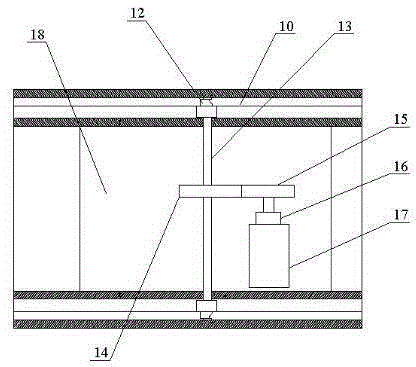

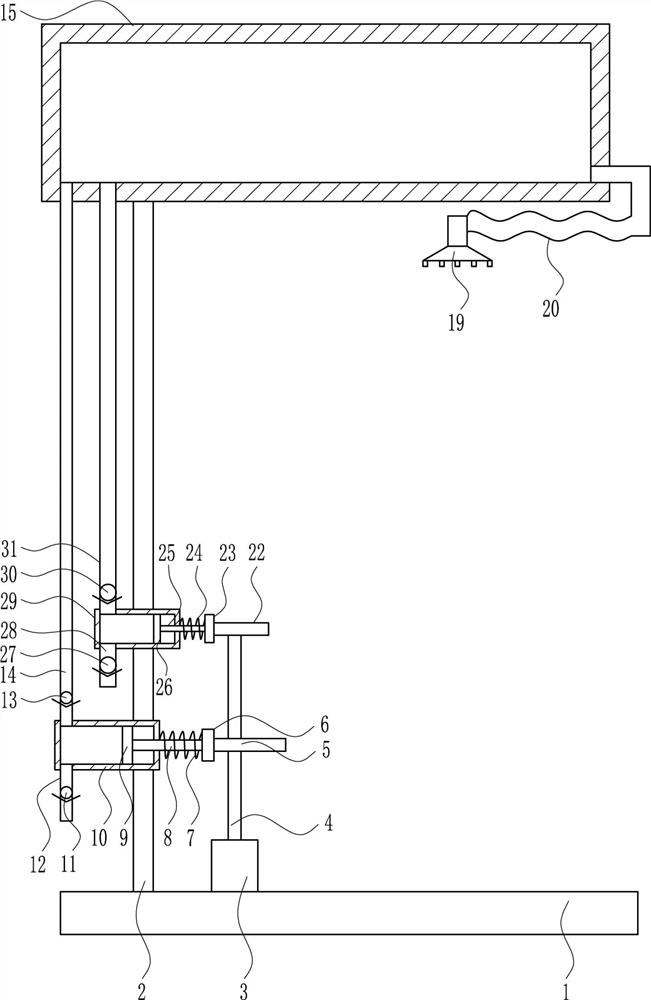

Waste recovery system for metal bar heat stripping machine

InactiveCN103170872ASimple structureAvoid direct human contactMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses a waste recovery system for a metal bar heat stripping machine. The waste recovery system comprises a horizontal feeding frame body, a hydraulic cylinder, a transverse moving device and a material carrying wheel device, wherein the hydraulic cylinder is fixedly arranged on the horizontal feeding frame body, the transverse moving device is fixedly connected with the horizontal feeding frame body through screws, and the material carrying wheel device is connected with the transverse moving device. The waste recovery system is simple in structure. The material carrying wheel device and the transverse moving device are matched to be used, so waste stripped by the stripping machine can fall onto a waste plate accurately, waste skin is turned into a waste tank automatically, a way of directly touching the waste through labor is avoided, work safety is ensured, work efficiency is effectively improved, and the waste recovery system is suitable for industrialized production.

Owner:TAICANG BEST MECHANICAL EQUIP

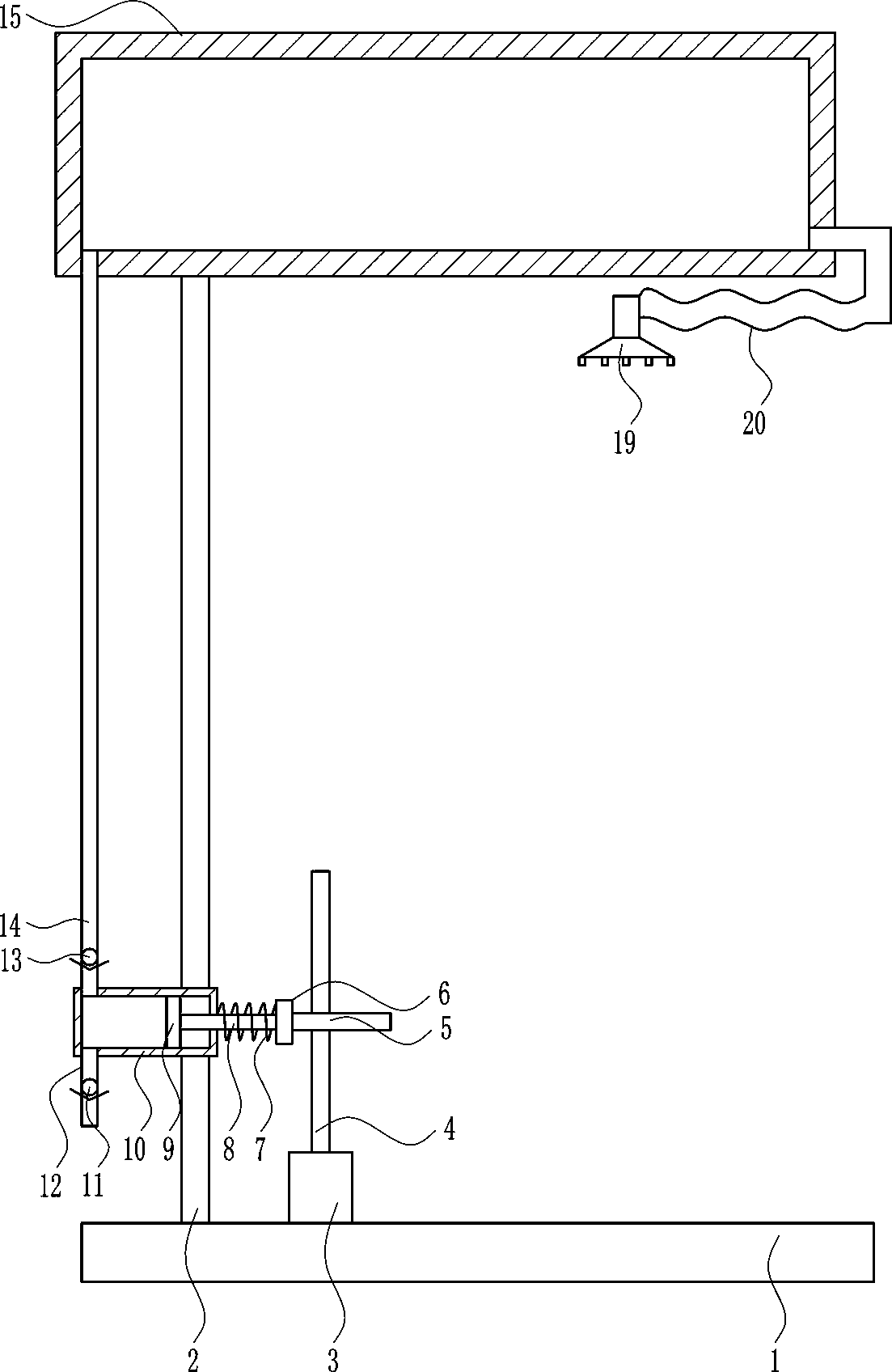

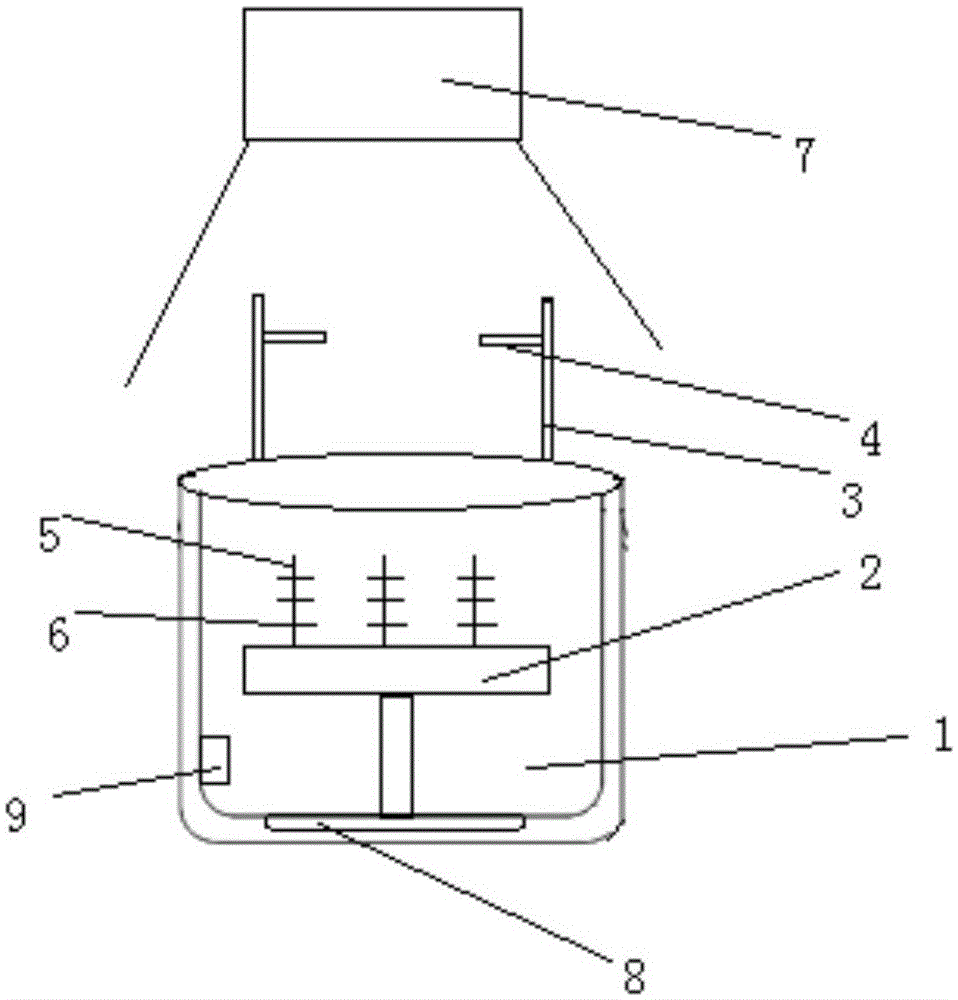

Surgical garment cleaning device for medical care

InactiveCN108425209AEasy to cleanIncrease the cleaning areaWashing machine with receptaclesTextiles and paperCouplingSecondary Infections

The invention relates to a garment cleaning device, in particular to a surgical garment cleaning device for medical care. Against the technical problem to be solved, the invention provides a surgicalgarment cleaning device for medical care, which can save manpower and time and ensure safety of cleaning workers. The surgical garment cleaning device for medical care includes a base, a first supporting rod, a motor, a first rotating shaft, a first cam, a first connecting plate, a first spring and a first moving rod and the like. The motor is mounted on the upper portion of the base, the first rotating shaft is mounted on an output shaft of the motor through a coupler, and the first cam is mounted on the first rotating shaft. The surgical garment cleaning device for medical care has the advantages of being capable of saving manpower and time and ensuring safety of the cleaning workers. By the use of the device, clothes disinfection work after an operation can be completely quickly, manualdirect contact can be avoided, secondary infection of bacteria can be avoided, people's personal safety is ensured, and the development of the medical treatment cause is promoted.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

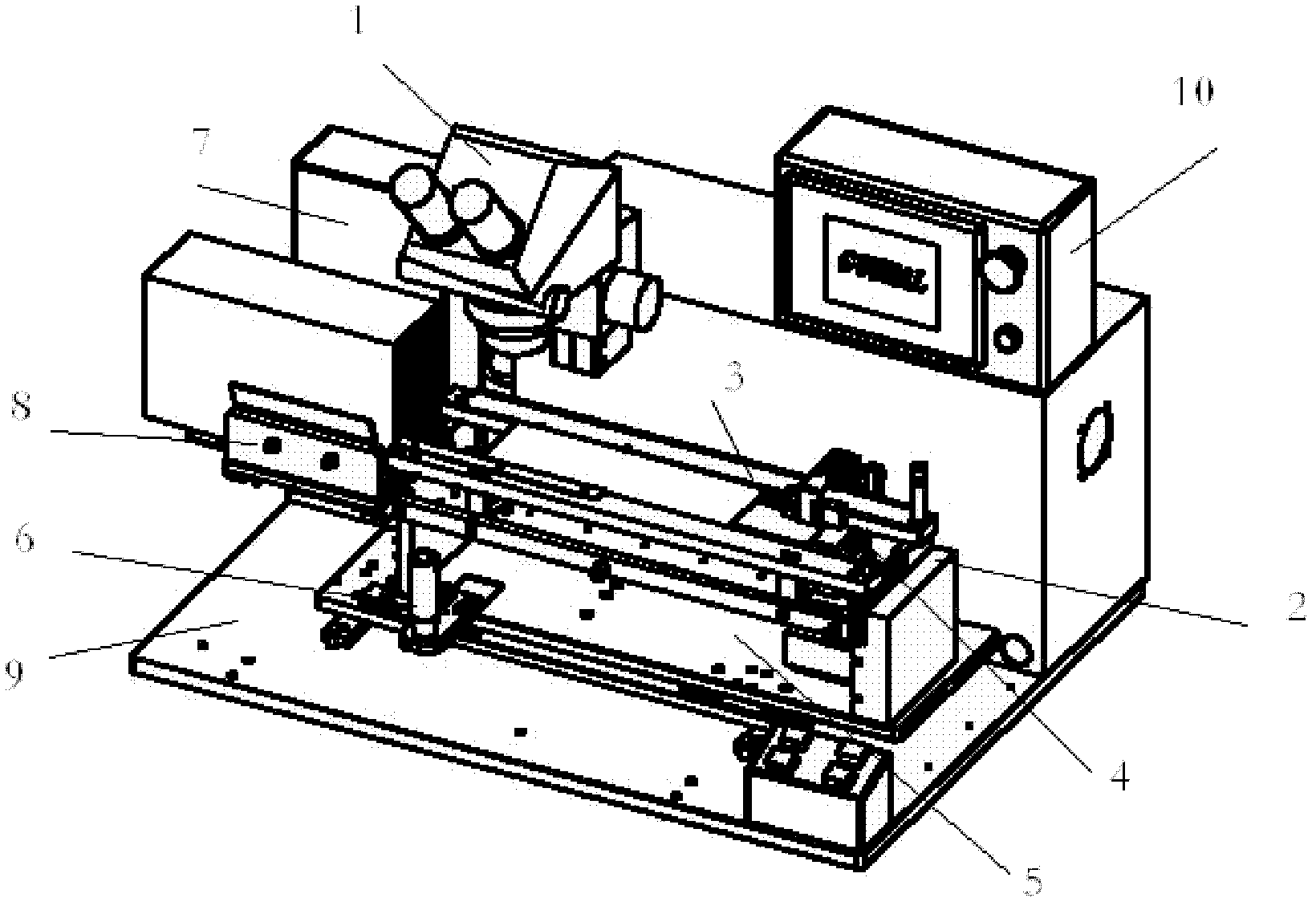

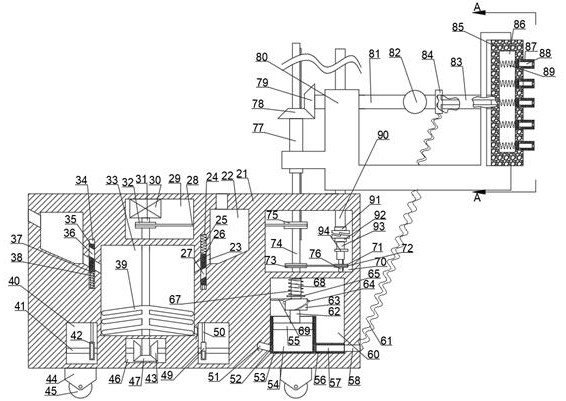

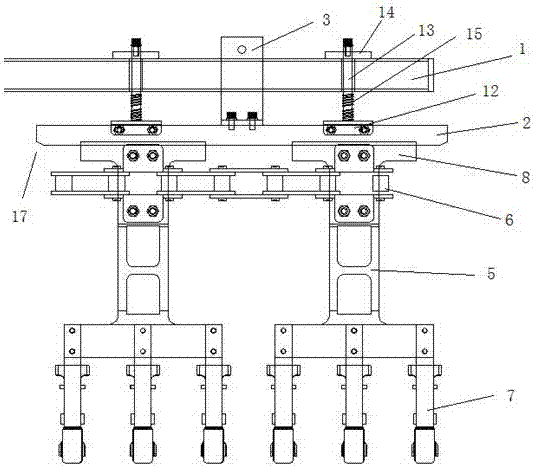

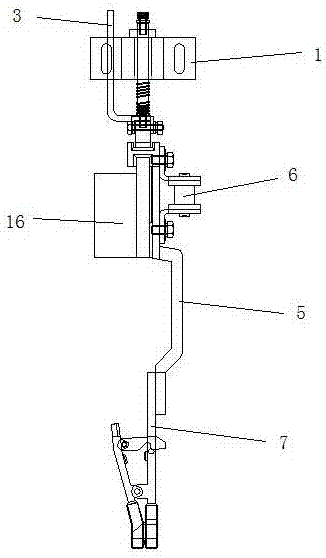

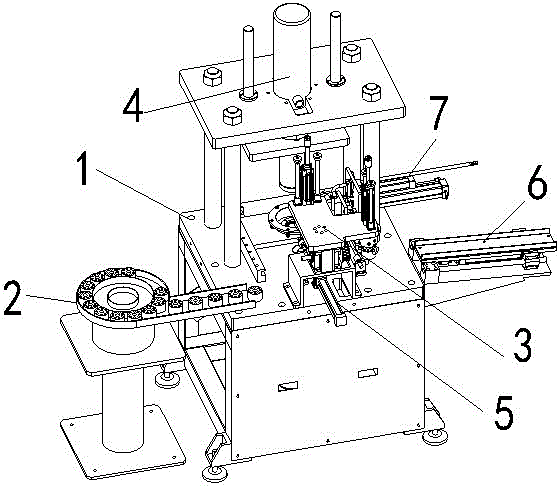

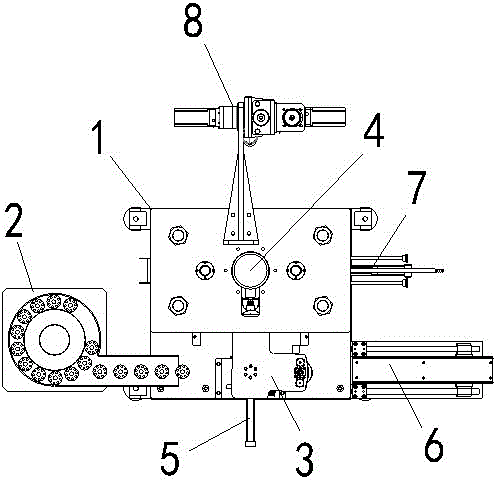

Hand-free ternary inspection machine

InactiveCN102760670AAvoid direct human contactMeet safety requirementsSemiconductor/solid-state device testing/measurementProgrammable logic controllerEngineering

The invention relates to a hand-free ternary inspection machine, which comprises a stereomicroscope, an X-axis guide rail and moving claws on the X-axis guide rail, an X-axis and Y-axis manual mobile table, a material box lifting mechanism and a material box clamping device, wherein the X-axis guide rail can move in a stepping manner; the moving claws on the X-axis guide rail are used for clamping bars by a pneumatic feeding mechanism on the X-axis guide rail; a guide rail width adjusting assembly is also arranged on the X-axis guide rail; the X-axis and Y-axis manual mobile table is arranged on a bottom plate; the material box lifting mechanism is arranged on the X-axis and Y-axis manual table and the material box clamping device is arranged on the material box lifting mechanism; and the X-axis guide rail, the material box lifting mechanism and the pneumatic feeding mechanism are respectively connected with a PLC (Programmable Logic Controller). The hand-free ternary inspection machine disclosed by the invention has the beneficial effects of completely preventing personnel from being in direct contact with a packaged product by using a convenient PLC-based control technology and meeting the safety protection requirement.

Owner:上海功源电子科技有限公司

Automatic wall putty smearing device

InactiveCN111827633AGuaranteed smoothAvoid direct human contactBuilding constructionsStructural engineeringBevel gear

The invention discloses an automatic wall putty smearing device. The automatic wall putty smearing device comprises a machine body, wherein a power space is formed in the machine body, raw material spaces with openings are symmetrically formed in the left side and the right side of the power space, one side wall of each raw material space communicates with a raw material runner, one side walls ofthe two raw material runners communicate with stirring spaces, bevel gear spaces are formed in the lower sides of the stirring spaces, extrusion spaces are formed in right sides of the bevel gear spaces, and connecting spaces are formed in the upper sides of conveying openings. According to the automatic wall putty smearing device, a building interior wall can be effectively decorated, uneven parts of the surface of a base layer are removed, the flatness and smoothness of a wall surface are kept, meanwhile, the flatness of the wall surface is guaranteed, compared with traditional wall putty modification, manual direct contact with putty paint is avoided, harm caused by the fact that putty powder enters the nasal cavity and the oral cavity of a worker is greatly reduced, harm to the healthof the worker is avoided, and meanwhile the problem that a high wall is difficult to brush is solved.

Owner:新昌县韵母电子有限公司

Automatic bag-binding trash can

ActiveCN107244507AAvoid direct human contactEasy to operate and hygienicRefuse receptaclesEngineeringSanitation

The invention relates to the field of trash cans and discloses an automatic bag-binding trash can. The automatic bag-binding trash can comprises a can body with an opening and a bag-binding device, wherein the bag-binding device is connected onto the opening of the can body and comprises a fixed disc and a bag-binding rope; the fixed disc is provided with a through hole; the through hole penetrates through the upper surface and the lower surface of the fixed disc and is formed in the opening of the can body; a via hole and a sliding chute are formed in the inner side wall of the fixed disc, and the sliding chute is formed in the circumferential direction of the fixed disc; a first end of the bag-binding rope penetrates through the via hole and is twined on the fixed disc in a retractable manner; and a second end of the bag-binding rope is arranged in the sliding chute in a sliding manner. According to the automatic bag-binding trash can, one end of the bag-binding rope in the bag-binding device is put away and released, and the other end of the bag-binding rope moves along the sliding chute of the fixed disc to be close to the via hole to finally draw in the trash bag opening in the trash can, so that the trash bag in the trash can is prevented from being directly packaged manually and environmental protection and sanitation are realized.

Owner:SHANTOU NANHA ELECTRICAL

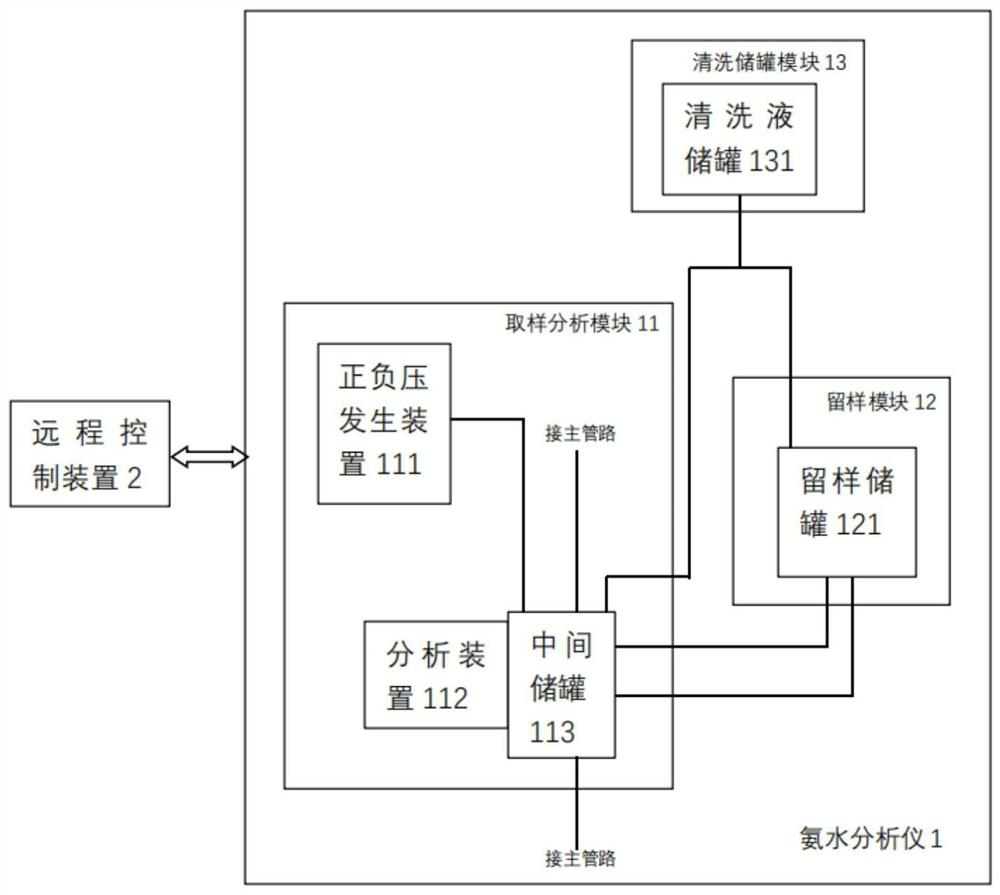

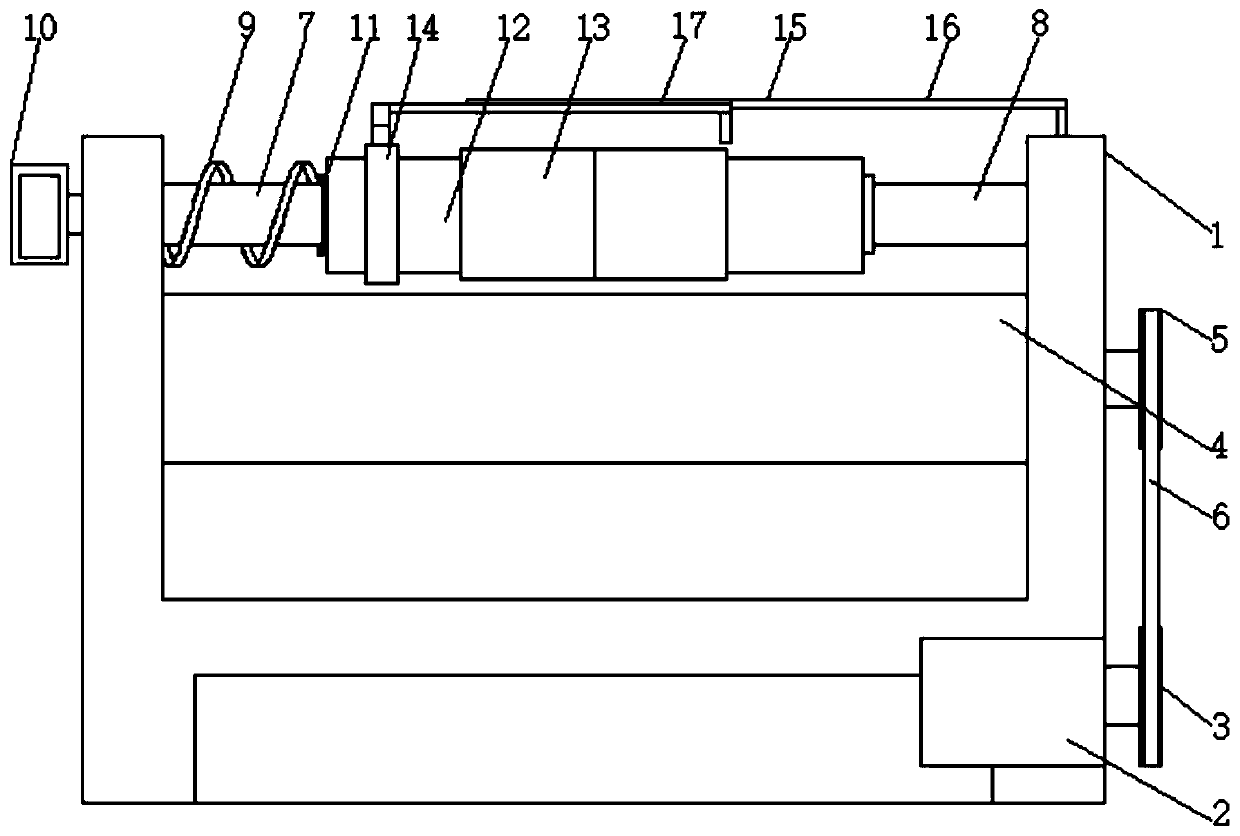

System for analyzing canned ammonia water on line by using ammonia water analyzer

ActiveCN112946203AAvoid direct human contactHigh precisionMaterial analysisPressure generationRemote control

The invention discloses a system for analyzing canned ammonia water on line by using an ammonia water analyzer. The system comprises an ammonia water analyzer and a remote control device, the ammonia water analyzer comprises a sampling analysis module and a sample reserving module, the sampling analysis module comprises a positive and negative pressure generation device, an analysis device and an intermediate storage tank; an inlet and an outlet of the intermediate storage tank are connected with a filling main pipeline, the analysis device is arranged on the intermediate storage tank, the positive and negative pressure generation device is connected with one end of the intermediate storage tank, The sample reserving module module comprises a reserved sample storage tank, and an inlet and an outlet of the reserved sample storage tank are connected with the intermediate storage tank; the remote control device is in wireless communication connection with the ammonia water analyzer. Compared with the prior art, the system has the advantages that the ammonia water sample can be uniformly obtained and automatically discharged through remote control in the ammonia water unloading process, comprehensive samples can be automatically obtained for inspection, ammonia water parameters are automatically detected, harm of ammonia water to the human body is reduced, and errors generated by manual operation are avoided.

Owner:厦门微控科技有限公司

Anti-overflow rinsing device for lens

InactiveCN105057259AGuaranteed cleanlinessPrevent proliferationDirt cleaningCleaning using liquidsEngineeringWater pipe

The invention discloses an anti-overflow rinsing device for a lens. The anti-overflow rinsing device for the lens is characterized in that the anti-overflow rinsing device comprises a rinsing tank and an upper cover; the rinsing tank is connected with a pure water drip washing device; the pure water drip washing device comprises a lifting platform, supports, shower nozzles and a water storing tank; the lifting platform is arranged in the rinsing tank; lens racks are detachably connected on the lifting platform; a plurality of fixing frames are arranged on the lens racks; the fixing frames are provided with a plurality of lens clamps; the supports are arranged on the left and right sides of the rinsing tank; the shower nozzles are fixed on the supports and connected with the water storing tank through water pipes; a water pump is arranged in the water storing tank; the outer sides on the top edges of the rinsing tank are provided with U-shaped grooves; the sidewall heights of the most peripheral part of the U-shaped grooves are greater than the edge height of the top of the rinsing tank; the groove bottoms of the U-shaped grooves are provided with water outlets; the rinsing tank is further provided with a heating device; a controller is connected with the heating device and the pure water dip washing device and used for controlling the opening and closing of the upper cover.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

Circuit board cathode conveying device

PendingCN107287648ARealize pick and placeEasy to pick and placeCurrent conducting devicesEngineeringMechanical engineering

The invention relates to a circuit board cathode conveying device. The circuit board cathode conveying device comprises a machine frame and a plurality of conducting blocks hung on the lower portion of the machine frame. Conducting strips are connected to the conducting blocks. A guide rail is arranged below the conducting blocks and slidably provided with a plurality of electrode trolleys. The upper portions of the electrode trolleys make contact with the conducting blocks to form electric connection. The electrode trolleys are connected through a chain. The lower end of each electrode trolley is at least provided with one opening-closing clamp which comprises a fixed end fixed to the electrode trolley and a free end for driving the opening-closing clamp to be opened or closed. The machine frame is further provided with a pushing assembly for driving the free ends and a pulling assembly for driving pulling blocks to swing. According to the circuit board cathode conveying device, the multiple electrode trolleys are driven to operate on the guide rail through the chain, electric connection is formed through the conducting strips, the conducting blocks and the electrode trolleys, the electrode trolleys are immersed into an electroplating pool to be converted into stable electrodes, and accordingly, efficient and stable production is achieved through the circuit board electroplating technology.

Owner:广东成功自动化设备有限公司

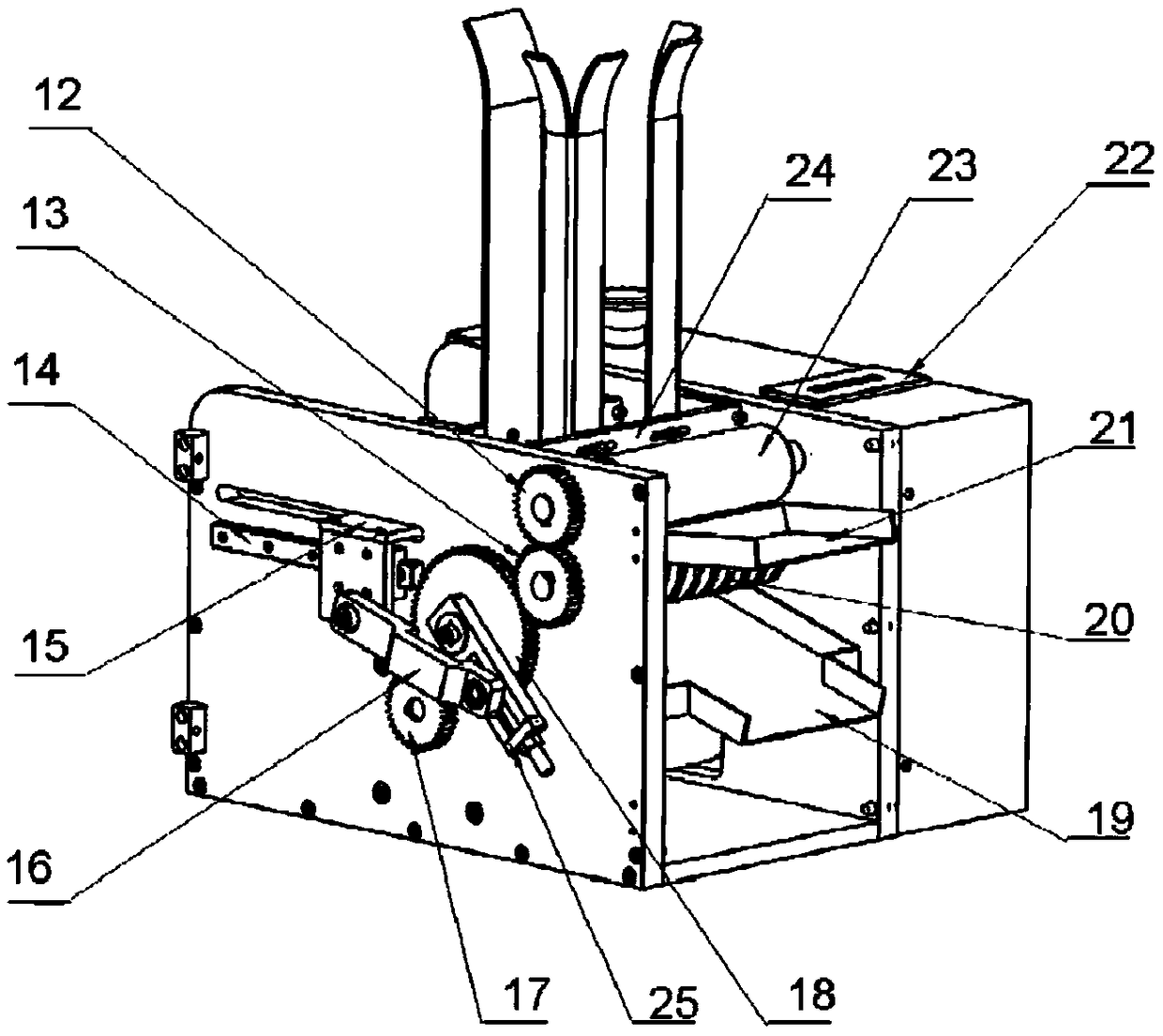

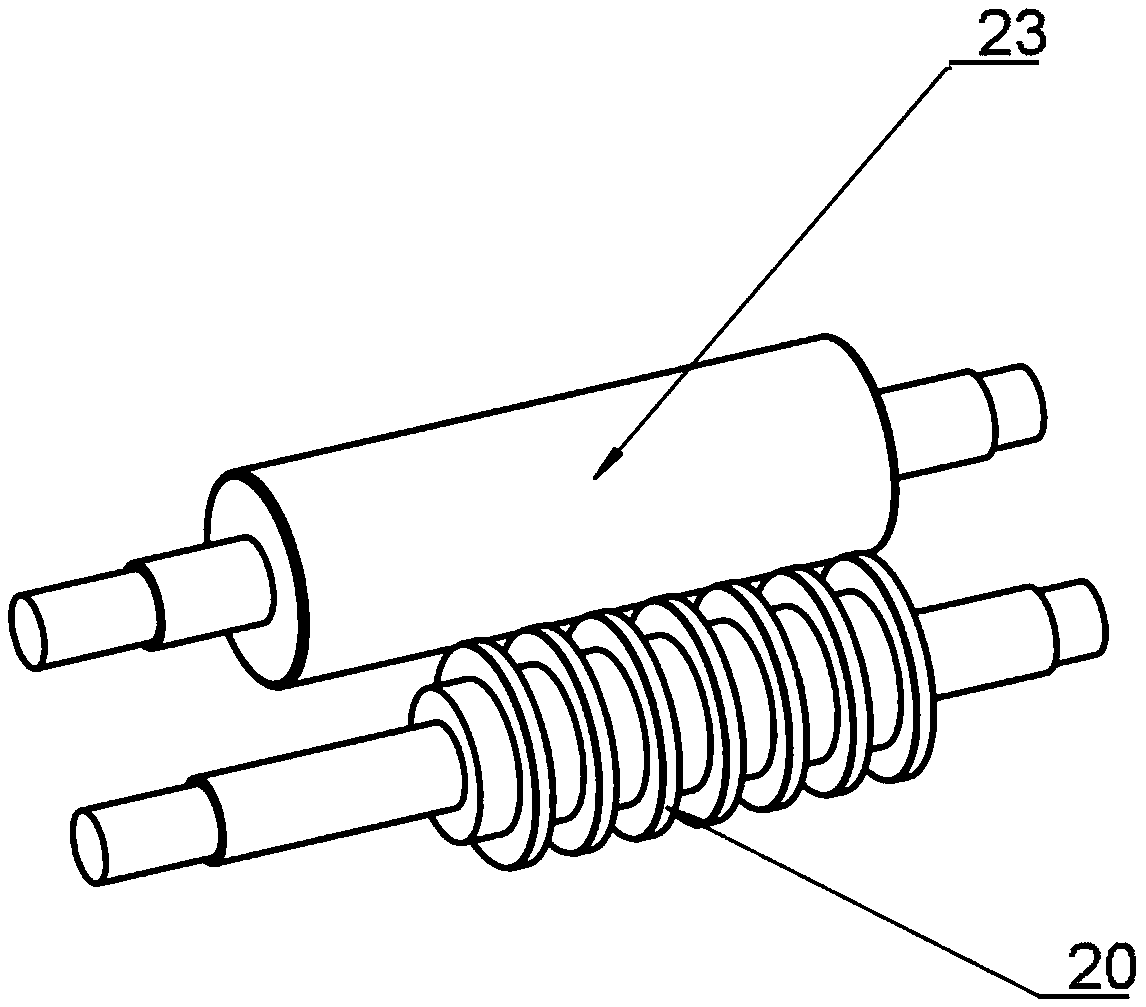

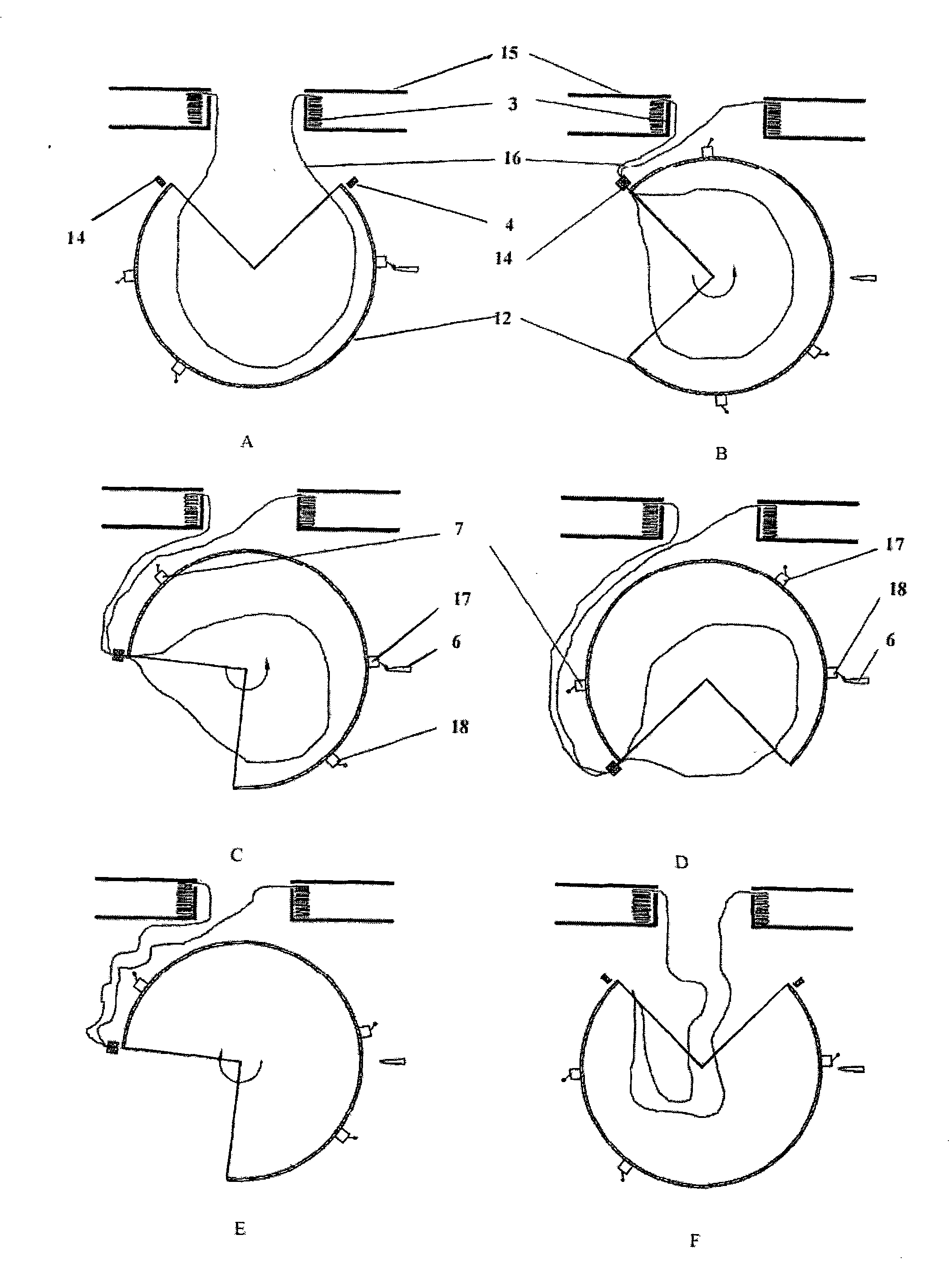

Sheet reeling machine capable of feeding and discharging continuously

InactiveCN109877194AEasy to operateReduce spacingMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a sheet reeling machine capable of feeding and discharging continuously, and relates to the technical field of sheet reeling machines. The sheet reeling machine capable of feeding and discharging continuously comprises a machine frame, a driving device is embedded in the right side of the machine frame, a main gear is fixedly connected to an output end of the driving device, and a conveying shaft is movably connected to the lower portions of the left side and the right side of the inner wall of the machine frame. The problem that the time interval between sheet reelingoperation and discharging operation of an existing sheet reeling machine is long to influence the machining efficiency is solved. According to the sheet reeling machine capable of feeding and discharging continuously, a movable rod, a returning spring, a compression roller, shaping sleeves and a pull frame are matched with one another to be used, under driving of the driving device, the conveyingshaft can convey a sheet, under the action of the shaping sleeves, the sheet can be quickly shaped, the pull frame is pulled, the shaped sheet can be separated from the two shaping sleeves, so that discharging operation can be rapidly carried out, the discharging time interval is reduced, the machining efficiency is improved; and in addition, the operation steps of discharging are more time-saving compared with that of existing discharging operation, so that operation by an operator is more convenient, and the purpose of convenient use is achieved.

Owner:江苏龙胜机床制造有限公司

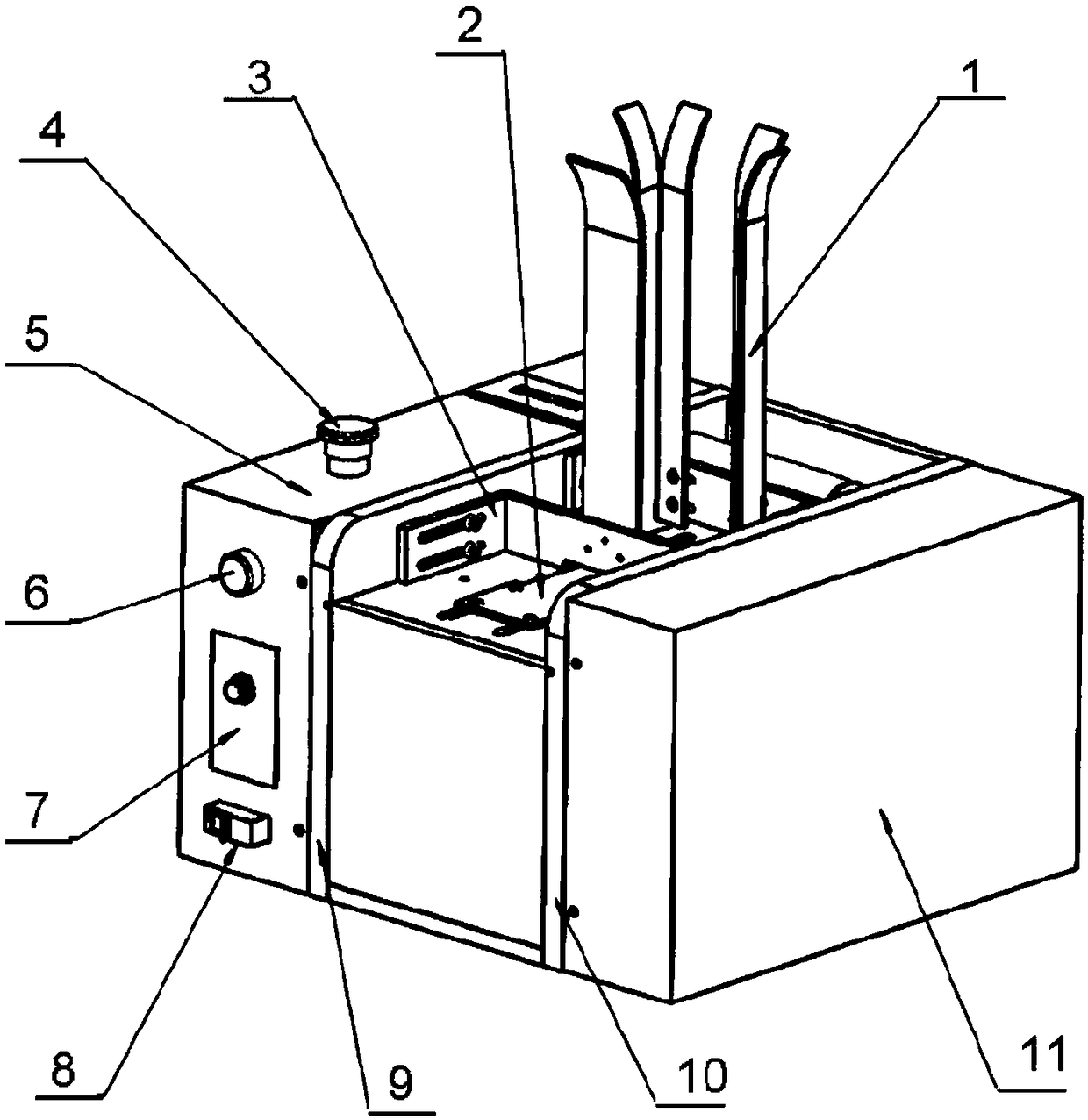

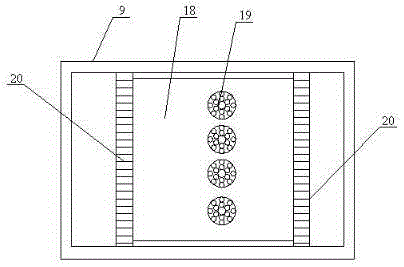

Multi-specification bubble cap drug plate automatic pill peeling machine and application thereof

InactiveCN109178517AStatistically accurateUniform extrusion pointArticle unpackingEngineeringAutomation

The invention provides a multi-specification bubble cap drug plate automatic pill peeling machine. The multi-specification bubble cap drug plate automatic pill peering machine comprises a panel, a material bin, an automatic feeding mechanism, a transmission mechanism, an extrusion mechanism, a safe protective cover, a rack mounting plate, a drug discharge guide plate, a bubble cap drug plate discharging guide plate, a speed controller and a counting system. According to the multi-specification bubble cap drug plate automatic pill peeling machine, manual work can be replaced, the removal of plate loading lines and automatic pill peeling are achieved, automation separation of a pill and a drug plate is realized, manual direct contact with drug is avoided, and the drug after pill peeling is prevented from being contaminated or damaged; the size is small, transportation is convenient, and peeled drug plates can be accurately and automatically counted, the efficiency of pill peeling is high, operation is easy, the labor intensity is low, the production quantity is increased, the loss cost is lowered, and the multi-specification bubble cap drug plate automatic pill peeling machine is suitable for drug plates with different specifications.

Owner:YUNNAN BAIYAO GROUP

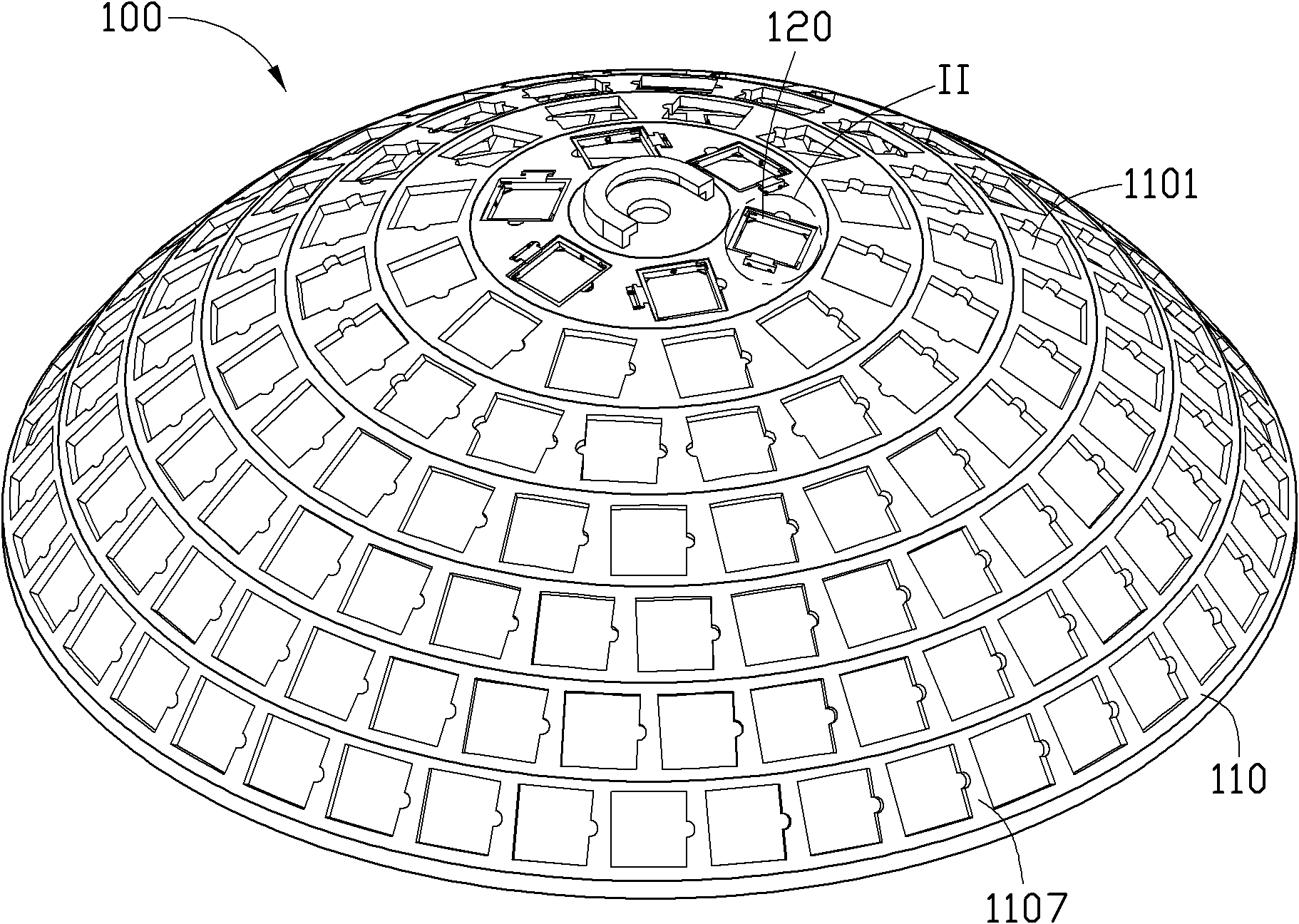

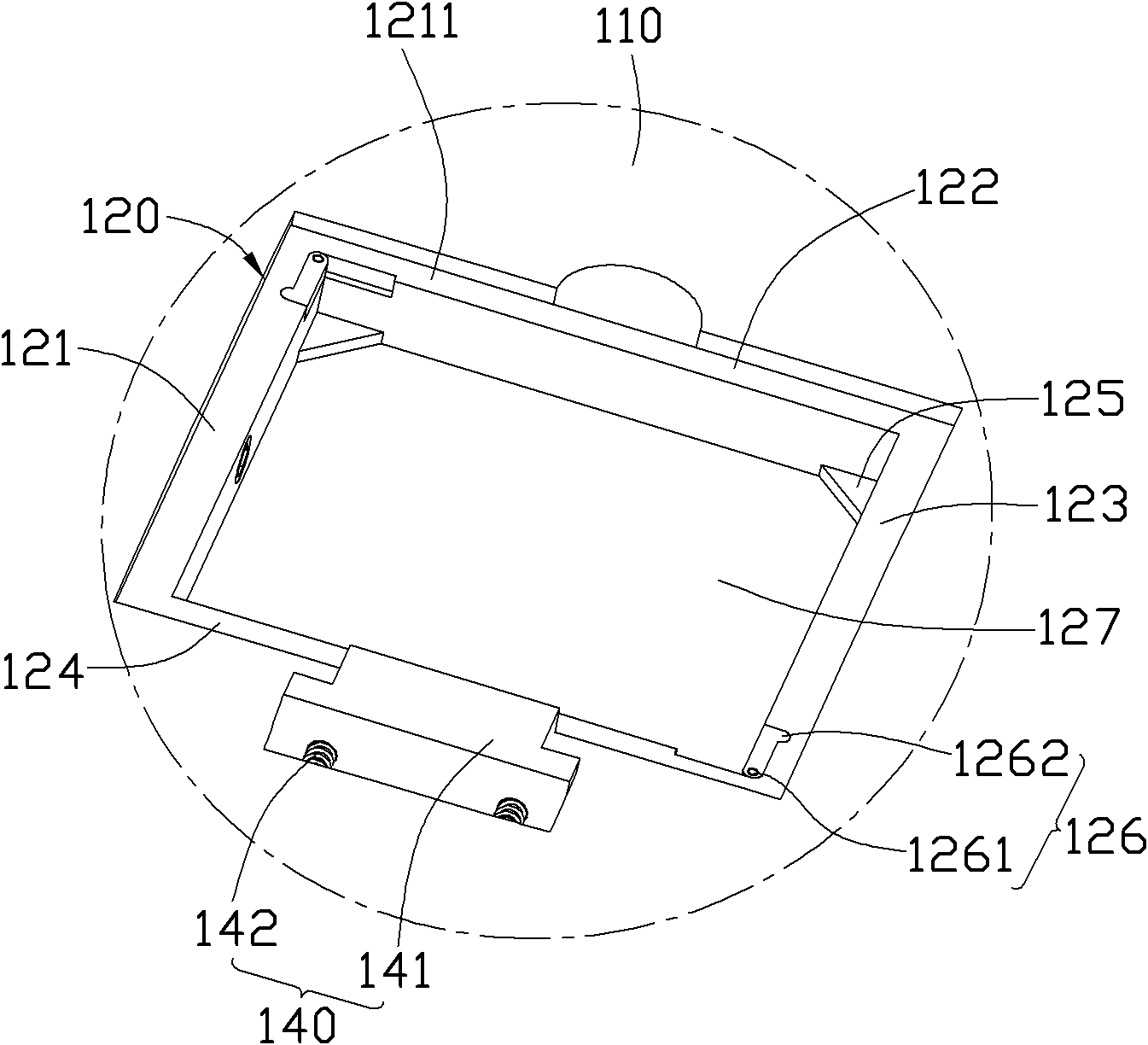

Coating support and coating machine

InactiveCN102212783AAvoid direct human contactReduce pollutionVacuum evaporation coatingSputtering coatingBiochemical engineeringCoating

The invention relates to a coating support. The coating support comprises a support body provided with a plurality of through holes, a plurality of turnover frames for bearing lens disks, a plurality of fixed shafts and a plurality of blocking devices, wherein each through hole is internally provided with one turnover frame; each turnover frame is connected with the support body via at least one fixed shaft and can turn over around at least one fixed shaft; and each blocking device is connected with the support body and is used for clamping the turnover frame before or after turning over and the support body. The invention also relates to a coating machine comprising the coating support. The coating machine has the following beneficial effects: optical components in the same lens disk can be simultaneously turned over once by directly turning over the turnover frames, thus improving the coating efficiency, preventing persons from directly contacting the optical components and reducing pollution of the optical components.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

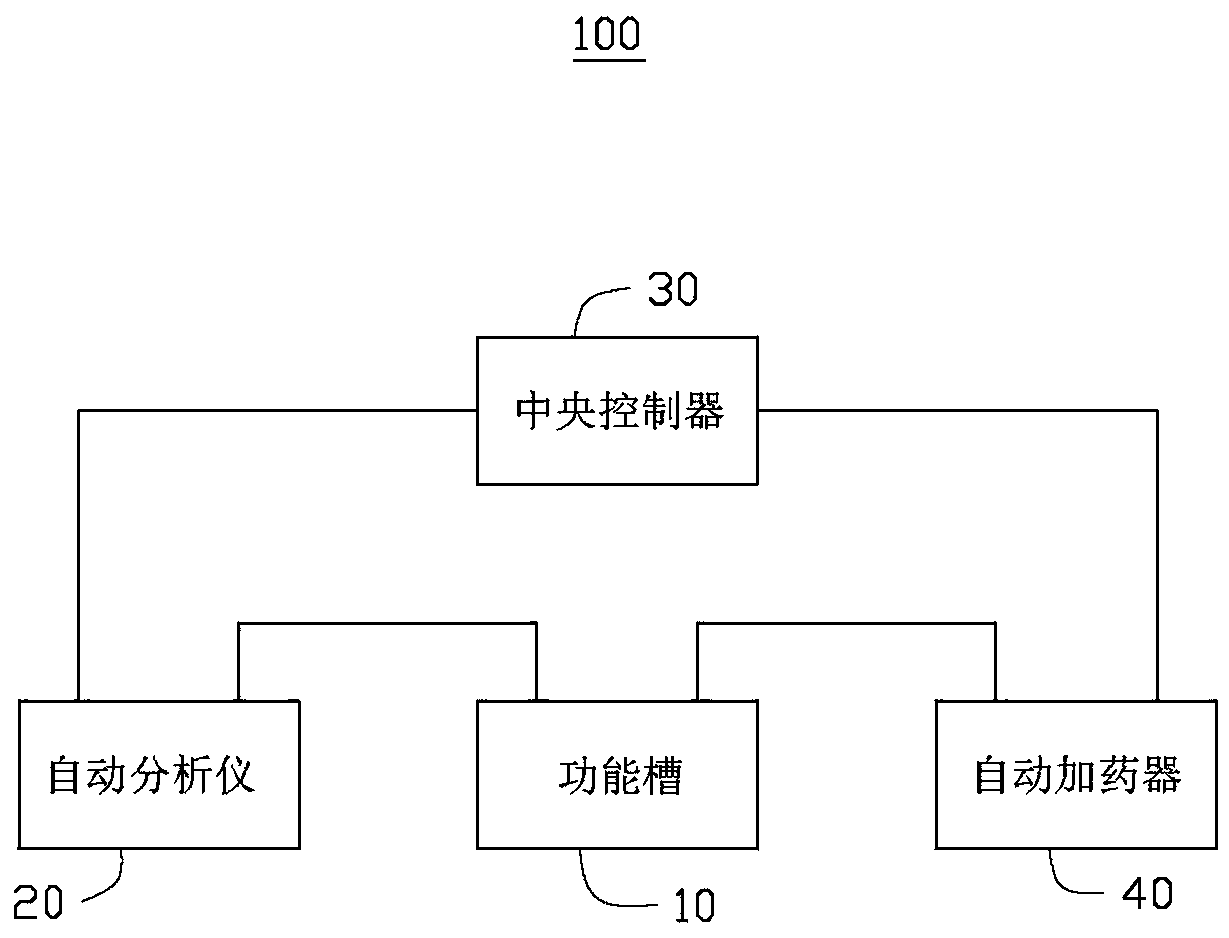

Automatic dosing system and application method thereof

ActiveCN107694473AAvoid direct human contactImprove efficiencyTransportation and packagingMixer accessoriesAutomotive engineeringReagent

Provided is an automatic dosing system. The automatic dosing system includes a functional tank, an automatic analyzer, a central controller and an automatic doser, wherein the functional tank is usedfor containing liquid required for chemical processing, the automatic analyzer is connected with the functional tank and used for automatically collecting the liquid from the functional tank and automatically detecting the concentration of the liquid, and the central controller is electrically connected with the automatic analyzer; the automatic analyzer is also used for sending detected concentration information of the liquid to the central controller, the central controller is used for calculating the required amount of a regulating reagent which is added into the functional tank according to the concentration information of the liquid, and the automatic doser is electrically connected to the central controller and with the functional tank; the central controller can control the automatic doser to add the required regulating reagent into the functional tank automatically and quantitatively. In addition, the invention also provides an application method of the automatic dosing system.

Owner:富联科技(济源)有限公司

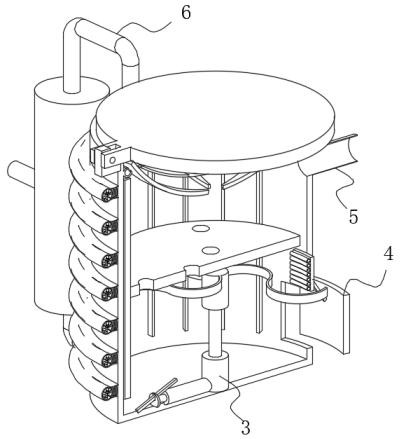

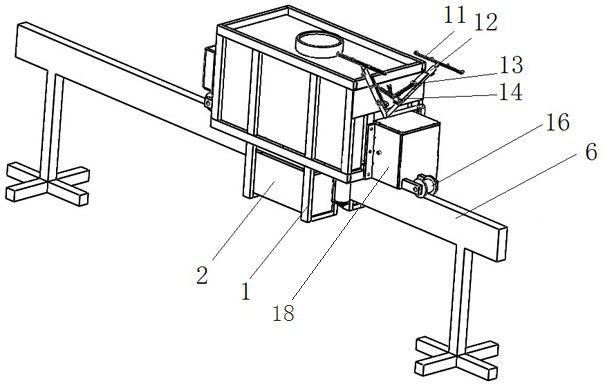

Efficient mashed garlic production device

The invention discloses an efficient mashed garlic production device which comprises a garlic pressing device. One side of the garlic pressing device is provided with a cleaning device, the other side of the garlic pressing device is provided with a conveying device, and a peeling device is arranged above the conveying device. The garlic pressing device comprises a column, the column is connected with a first beam, the first beam is connected with a first oil cylinder, the first oil cylinder is connected with a pressing plate, a garlic placing table is placed below the pressing plate, a garlic placing box is placed on the garlic placing table and connected with a second oil cylinder, the column is further connected with a second beam, a supporting frame of the cleaning device is connected with the second beam, a guide rail on the inner wall of the second beam is connected with walking wheels, the walking wheels are connected through a shaft, the shaft is connected with a driven gear, the driven gear is meshed with a driving gear, the driving gear is connected with a speed reducer, the speed reducer is connected with motors, the walking wheels are further provided with walking grooves, the motors are fixed to the bottom surfaces of the walking grooves, and the walking grooves are provided with spraying pipes. The efficient mashed garlic production device is high in working efficiency, and mashed garlic residue adhering to the pressing plate can be cleaned away easily.

Owner:GUIZHOU WEIYUAN FOOD DEV CO LTD

Fastener forming device for hardware manufacturing

A fastener forming device for hardware manufacturing is disclosed in the invention, and comprises a sealing device, a machine body is arranged at the bottom of the sealing device, a feeding device is movably connected to the inner surface of the machine body, an opening and closing device is arranged on the right side of the feeding device, the outer surface of the opening and closing device is movably connected with the inner surface of the right side of the machine body, and an air inlet pipe is arranged at the top of the opening and closing device. The invention relates to the technical field of hardware fastener manufacturing. According to the fastener forming device for hardware manufacturing, by arranging a cooling device, after a workpiece enters the machine body, a heat conducting piece transmits heat to a heat exchange device, in the heat exchange device, fluid completes heat exchange work, hot water floats upwards and flows upwards to the interior of a water tank along the bottom end of a circulating pipe, cold water in the water tank sinks, flows upwards to the interior of the heat exchange device along the bottom end of the circulating pipe, and heat circulation and water circulation are completed by the equipment, so the problems of high heat loss and energy consumption of a traditional fastener are solved.

Owner:JIANGSU SANPU HARDWARE CO LTD

Full-process atomization cleaning and disinfection device for gynecological nursing

ActiveCN113369228AAvoid direct human contactEasy to operateLavatory sanitoryFiltration separationUltravioletDistilled water

The invention provides a full-process atomization cleaning and disinfecting device for gynecological nursing, and belongs to the technical field of medical instruments. The full-process atomization cleaning and disinfecting device comprises a mounting shell assembly, a workpiece containing assembly, a distilled water cleaning assembly, an ozone sterilization assembly, a wastewater treatment assembly and an ultraviolet lamp drying module, and the workpiece containing assembly, the distilled water cleaning assembly, the ozone sterilization assembly, the wastewater treatment assembly and the ultraviolet lamp drying module are arranged in the mounting shell assembly; the workpiece containing assembly is arranged at the lower part of a lower shell, and a hanging disc and a lower containing disc are arranged in the workpiece containing assembly; the distilled water cleaning assembly and the ozone sterilization assembly are respectively arranged at the upper part of the mounting shell assembly, the distilled water cleaning assembly can be used for firstly flushing dirt of a to-be-cleaned instrument, then the to-be-cleaned instrument is sterilized by the ozone sterilization assembly after being flushed, and the to-be-cleaned instrument is is sterilized and dried by the ultraviolet lamp drying module after being sterilized through the ozone sterilization assembly; and the waste water treatment assembly is located at the bottom of the lower containing disc, waste water after flushing can be discharged after being filtered by the waste water treatment assembly, and pollution caused by medical waste is avoided. The full-process atomization cleaning and disinfecting device has the advantages of being high in automation degree, thorough in cleaning, environmentally friendly and harmless.

Owner:张艳

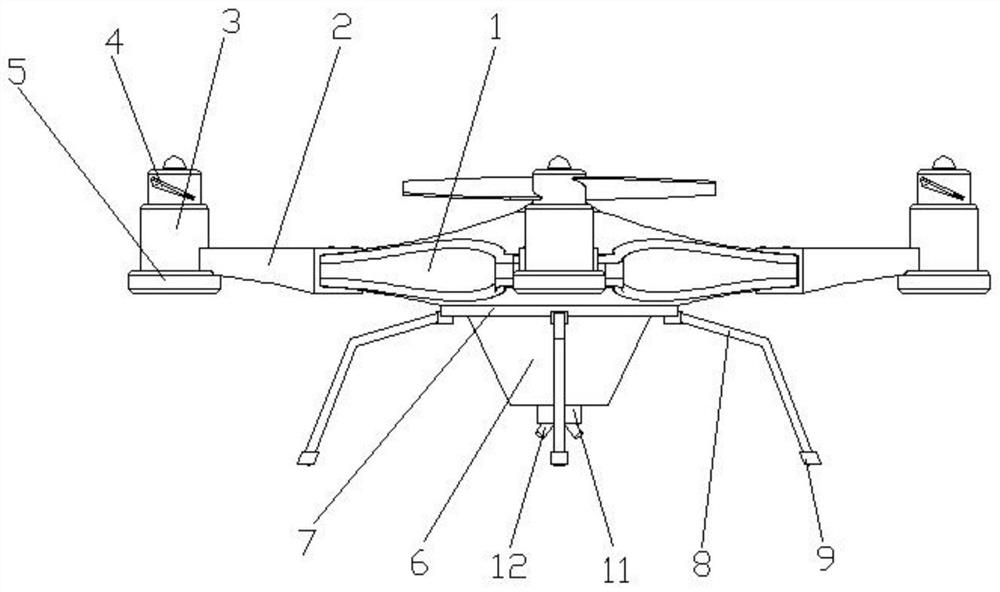

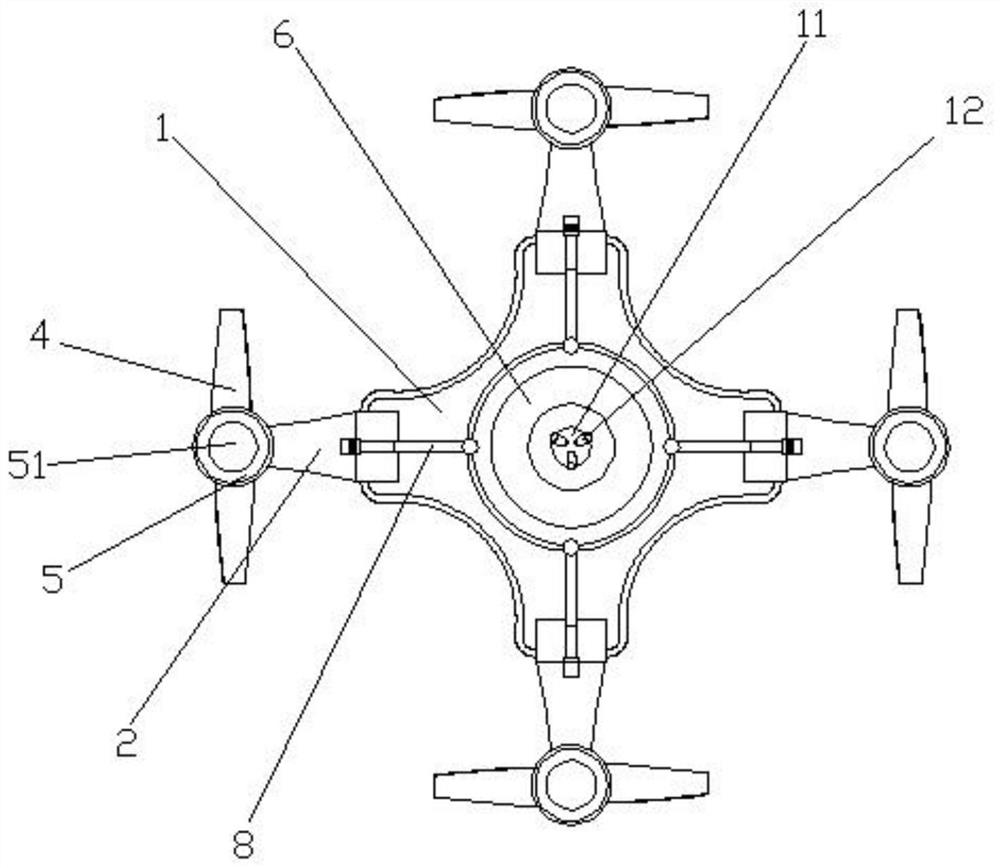

Agricultural spraying unmanned aerial vehicle with rotary spraying function

InactiveCN112335632AAvoid damageAvoid direct human contactAircraft componentsInsect catchers and killersAgricultural sciencePharmacy medicine

The invention relates to the technical field of agricultural production, in particular to an agricultural spraying unmanned aerial vehicle with a rotary spraying function. The agricultural spraying unmanned aerial vehicle comprises a vehicle body and a base, a group of mounting plates are fixedly connected to the vehicle body, the mounting plates are arranged in a circumferential array by taking the central point of the vehicle body as a circle center, and a brushless unmanned aerial vehicle motor is fixed on each mounting plate. According to the agricultural spraying unmanned aerial vehicle,pesticide is sprayed through the vehicle body, in the spraying process, a spraying head can rotate due to the counter-acting force of a spraying pipe, pesticide liquid is supplemented to a pesticide box on the vehicle body through the base, it is avoided that workers make direct contact with the pesticide liquid of the pesticide, safety is improved, and working efficiency is improved; and medicinecrushing operation is completed through a medicine powder box, during use, tablet-shaped medicine is crushed through crushing blades and mixed with powder medicine in a tablet box, and the medicine effect existence time of the tablet-shaped medicine is prolonged.

Owner:安徽军松现代农业科技有限公司

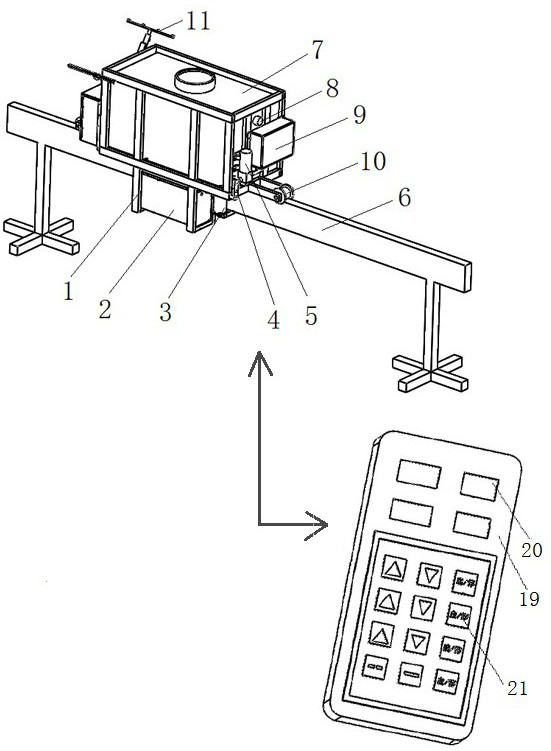

High-efficiency mashed garlic preparation equipment

InactiveCN106690231AAvoid getting wetEasy to wearCleaning using toolsCleaning using liquidsGear wheelEngineering

The invention discloses high-efficiency mashed garlic preparation equipment. The high-efficiency mashed garlic preparation equipment comprises a garlic pressing device; a cleaning device is arranged on one side of the garlic pressing device; the top of an upright post of the garlic pressing device is connected with a first cross beam; the first cross beam is connected with a first oil cylinder; the first oil cylinder is connected with a pressing plate; a garlic placement table is placed below the pressing plate; a garlic placement box is placed on the garlic placement table; the upright post is also connected with a second cross beam; the cleaning device comprises a supporting frame; the supporting frame is connected with the second cross beam; guide rails are arranged on the inner wall of the second cross beam; the guide rails are connected with travelling wheels; the travelling wheels are connected with each other through a shaft; the shaft is connected with a first driven gear; the first driven gear is engaged with a first driving gear; the first driving gear is connected with a speed reducer; the speed reducer is connected with a motor; a travelling trough is further arranged on the travelling wheels; the motor is fixed to the bottom surface of the travelling trough; a spraying pipe is arranged on the travelling trough; cleaning brushes are arranged on two side plates of the travelling trough. The high-efficiency mashed garlic preparation equipment is high in work efficiency; mashed garlic residues which are adhered to the pressing plate are easily cleaned. The hygiene is guaranteed.

Owner:GUIZHOU WEIYUAN FOOD DEV CO LTD

Cooling method for hot-pressing cast electronic ceramic blank

InactiveCN107813419AAvoid worker injury and defacementReduce impactCeramic shaping apparatusCooling methodsHot pressing

The invention discloses a cooling method for a hot-pressing cast electronic ceramic blank. The cooling method comprises the following steps: arranging a conveying belt below a blank die outlet of a hot-pressing casting molding machine; putting a storage box which is good in leakproofness and provided with a top cover at one side, far away from the hot-pressing casting molding machine, of the conveying belt; making the hot-pressing cast electronic ceramic blank fall on the conveying belt and conveying the electronic ceramic blank to the upper portion of the storage box through the conveying belt; connecting an elastic rubber film between the outer walls of the two sides of the storage box; making the electronic ceramic blank fall on the elastic rubber film from the conveying belt; filling the storage box with cooling water which is at the temperature of 15 to 25 DEG C; and submerging the electronic ceramic blank into the liquid level of the cooling water. The cooling method disclosed bythe invention has the advantages of preventing the electronic ceramic blank from damages and stains caused by workers, protecting the electronic ceramic blank, accelerating evaporation and circulation of the cooling water, increasing the heat exchange speed of the electronic ceramic blank and the cooling water and shortening the cooling time of the electronic ceramic blank.

Owner:HUNAN JIAYEDA ELECTRONICS

Heatable lens cleaning device

InactiveCN105057260AGuaranteed cleanlinessPrevent proliferationDirt cleaningCleaning using liquidsSprayerWater storage tank

The invention discloses a heatable lens cleaning device. The heatable lens cleaning device is characterized in that the heatable lens cleaning device comprises a cleaning tank which is connected with a pure water spraying device, and the pure water spraying device comprises a lifting platform, supports, sprayers and a water storage tank; the lifting platform is disposed in the cleaning tank and detachably connected with lens frames; a plurality of fixing brackets are arranged on the lens frames and provided with a plurality of lens clamps; the supports are arranged on the left side and the right side of the cleaning tank; the sprayers are fixedly arranged on the supports and connected with the water storage tank through water pipes; a water pump is arranged in the water storage tank; a heating device is further arranged in the cleaning tank, and a controller is connected with the heating device and the pure water spraying device. According to the heatable lens cleaning device, by the adoption of the pure water spraying device, solution on the surfaces of lenses can be directly removed and directly cleaned through pure water, and therefore cleaning efficiency is higher; the heating effect of the heatable lens cleaning device is good through the adoption of the heating device.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

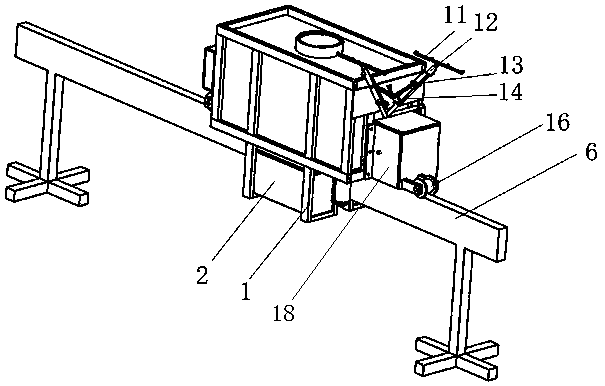

Intelligent pesticide spraying robot

ActiveCN111264506AImprove work efficiencySimple structureInsect catchers and killersElectric machineryPesticide

The invention relates to an intelligent pesticide spraying robot. The intelligent pesticide spraying robot comprises a rack and a guide rail, wherein a pesticide box is arranged in the rack; guide wheels walking on the guide rail are arranged at the bottom of the rack; storage batteries are installed on the two sides of the bottom of the rack respectively; a main control box and a power motor areinstalled on the side part of the rack; a pesticide spraying motor is arranged on the rack on one side of the main control box; the pesticide spraying motor is connected with a water pump; a water inlet pipe of the water pump is connected with the pesticide box through a pipeline; a water outlet pipe is connected with water inlets of row-type nozzles; the lower ends of the row-type nozzles are connected with the upper end of a nozzle swing arm respectively; a swing arm motor is arranged on the rack; a power wheel is fixed to power output shaft of the power motor and is arranged on the front side of the rack to enable the robot to walk on the guide rail; the pesticide spraying motor, the swing arm motor and the power motor are all in control connection with the main control box; and the main control box is in signal transmission connection with a remote controller. According to the intelligent pesticide spraying robot, dangerous and heavy work of manual pesticide spraying is avoided, intelligent spraying is carried out, the cost is reduced, and the efficiency is improved.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

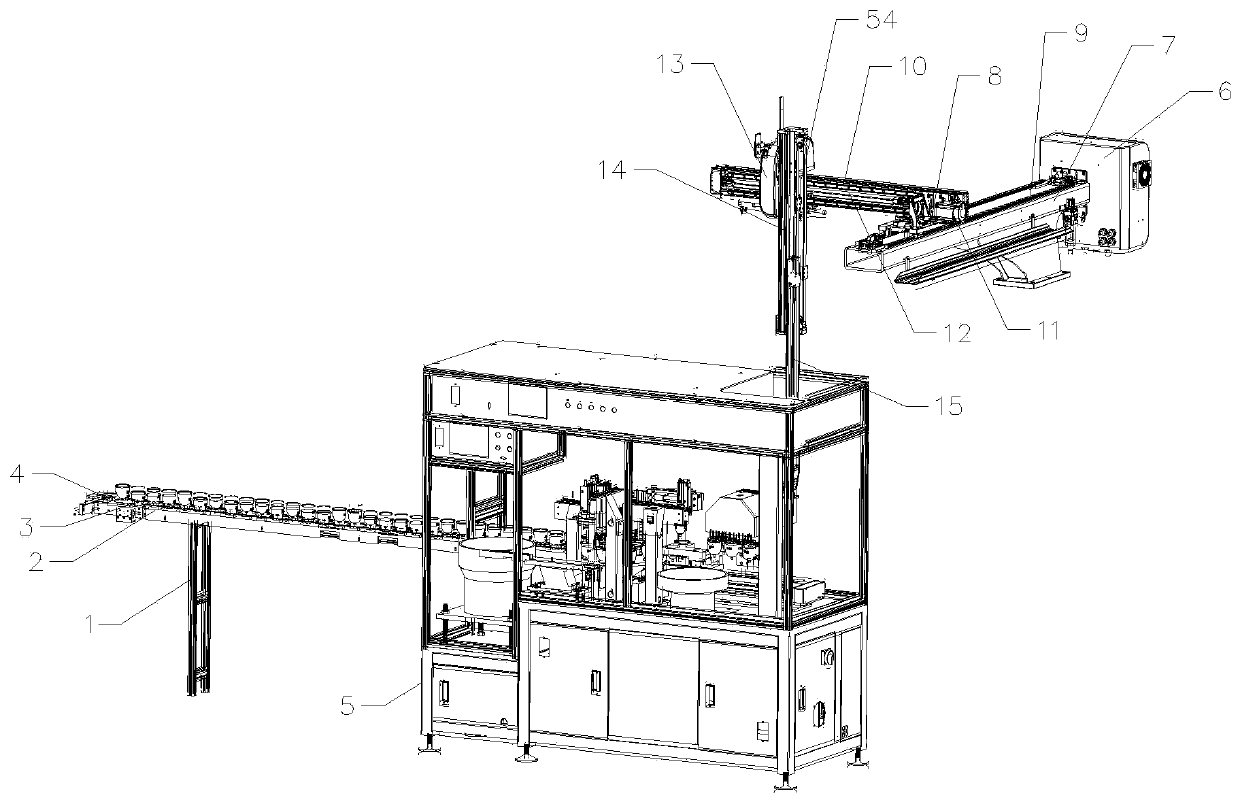

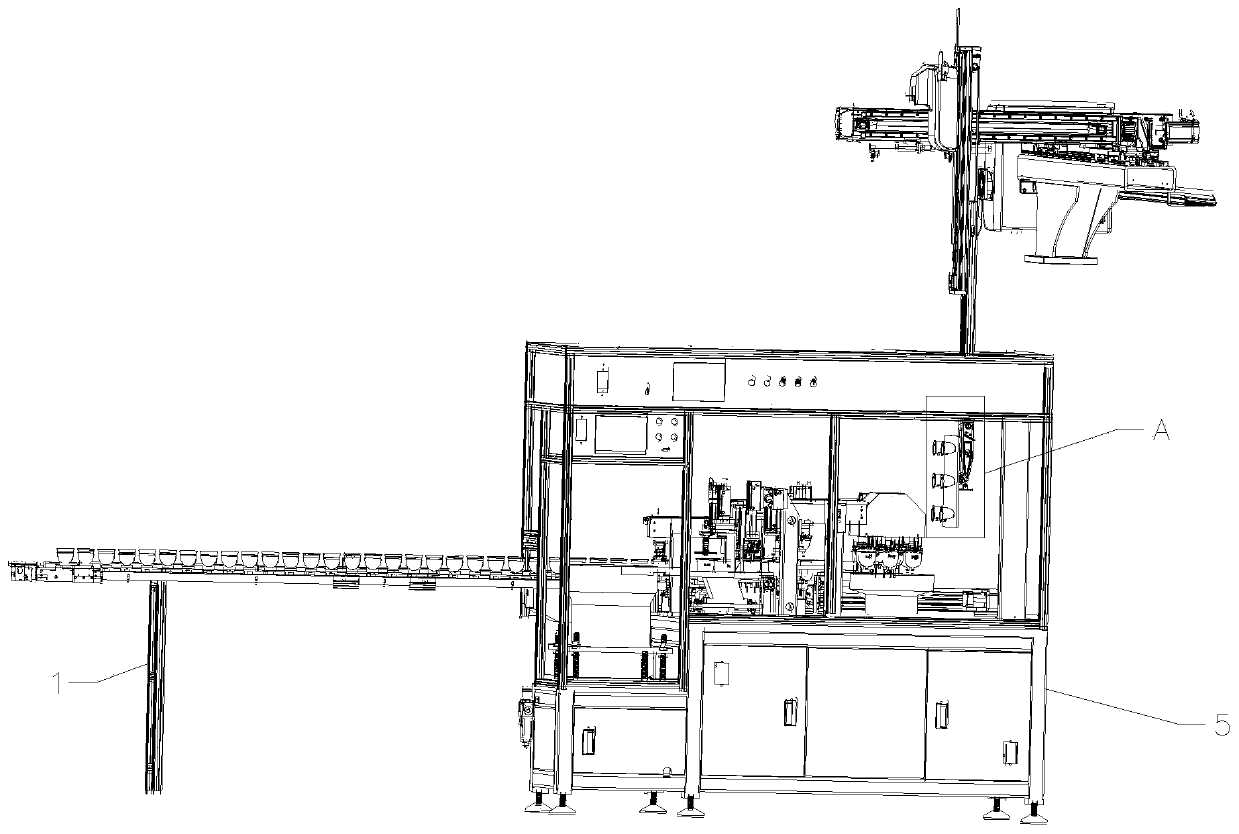

Automatic Die Casting Machine

The invention discloses a full-automatic die-casting machine. The full-automatic die-casting machine comprises a machine frame, a vibration disc loading machine and a melting furnace, wherein a die-casting station is arranged on the machine frame; an automatic rotation grabbing mechanism, an automatic soup-feeding mechanism, an upper and lower die mechanism, a station-inlet / outlet mechanism, a material-receiving disc mechanism and a waste material pushing mechanism are arranged on the machine frame; the upper and lower die mechanism and the waste material pushing mechanism are arranged at the die-casting station; the automatic soup-feeding mechanism is arranged between the die-casting station and the melting furnace; the automatic rotation grabbing mechanism is arranged between the vibration disc loading machine and the material-receiving disc mechanism; the station-inlet / outlet mechanism is arranged below the automatic rotation grabbing mechanism. In such a way, feeding of a melted liquid, taking and placing of a workpiece, and die casting of the workpiece can be automatically finished, and waste materials can also be automatically discharged; a workpiece taking position and a workpiece placing position are precise, the feeding amount is precise, operation is convenient to perform, the efficiency is high, a worker is prevented from being directly contacted with a high-temperature material, and the safety of the worker is guaranteed.

Owner:JIANGSU NIDE AUTOMATION TECH

Full-automatic receiving and feeding mechanism

PendingCN111169999AAvoid product turnoverLabor savingMetal working apparatusConveyor partsElectric machineryPiston

The invention discloses a full-automatic receiving and feeding mechanism. A rotary table is installed on the periphery of a second motor, a plurality of fourth sucking cups are arranged on the circumference of the rotary table, a fourth air cylinder is further installed on the periphery of a main frame, a second hydraulic piston is installed on the fourth air cylinder, a connecting plate is installed on the second hydraulic piston, a fifth air cylinder is installed on the connecting plate, and a second claw hand is installed on the fifth air cylinder. An eighth air cylinder is installed at theposition, located on one side of the rotary table, at the upper end of a second bracket, a third sucking cup is installed on one side of the eighth air cylinder, a sixth installation plate is installed on one side of the main frame, a fourth guide rail is arranged on the sixth installation plate in the length direction, a ninth air cylinder is installed on the sixth installation plate, a third hydraulic piston is arranged on one side of the ninth air cylinder, a third sliding block is installed on the third hydraulic piston, the third sliding block slides on the fourth guide rail, a sixth aircylinder is installed at the lower end of the third sliding block, and a third claw hand is installed on the sixth air cylinder. According to the full-automatic receiving and feeding mechanism, manual direct contact with products is avoided, product turnover is avoided, and labor is reduced.

Owner:JINHUA CALET AUTOMATION TECH

Full-automatic safety dustbin

InactiveCN101503138BAvoid direct contactReduce the Possibility of Exposure to ContaminantsRefuse receptaclesElectric machineryEngineering

The invention discloses an automatic security garbage can. An opening is arranged on a temporary storage storehouse, the middle part is provided with a rack, and the rack is meshed with the gear on electric machinery; one side of the opening is provided with a fixed heat seal, the movable heat seal is connected with a sleeve by a connecting rod and rotates around a central axis, and the upper part of the temporary storage storehouse is an I-shaped neck which remains an aperture for pulling and taking plastic bags; the lower part of the temporary storage storehouse is connected with a storage storehouse, and the whole deice is arranged in the garbage can; the inner wall of a can body is provided with a collision block at the position near the electric machinery; a stop button and a start button are arranged on a can cover; three travel switches are fixed on the surface of the temporary storage storehouse: a first switch is positioned at the contact point of the collision block when theelectrical machinery commutes, a second switch is positioned at the contact point of the collision block after the temporary storage storehouse returns, a third switch is positioned at the contact point of the collision block when the heat seal is electrified, and an electric circuit box is respectively connected with two second buttons, three switches and the electrical machinery. The invention uses common electric circuit to realize automatic continues execution, reduces the time that the cleanup crew directly contact the garbage, and protects indoor environment.

Owner:ZHEJIANG UNIV

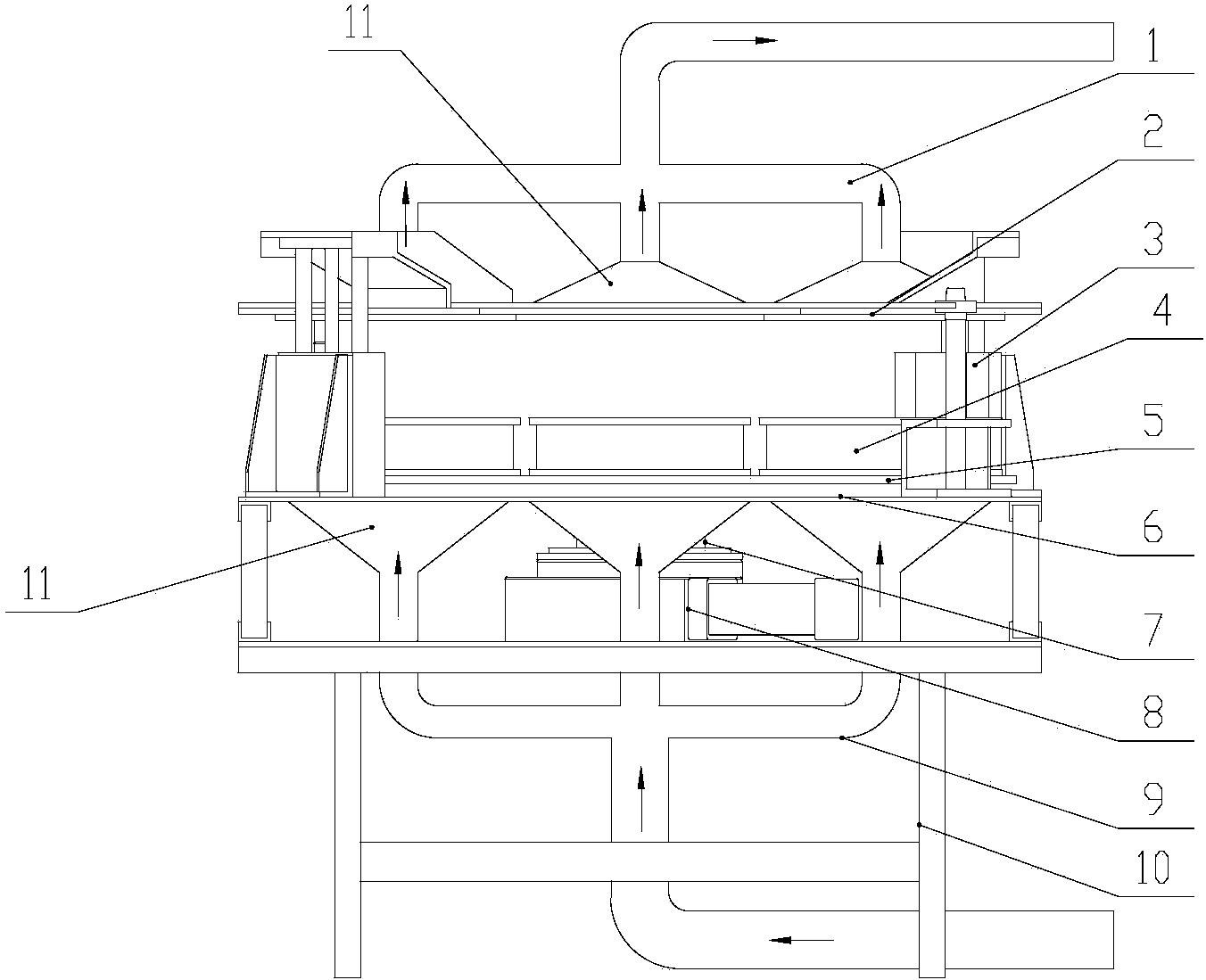

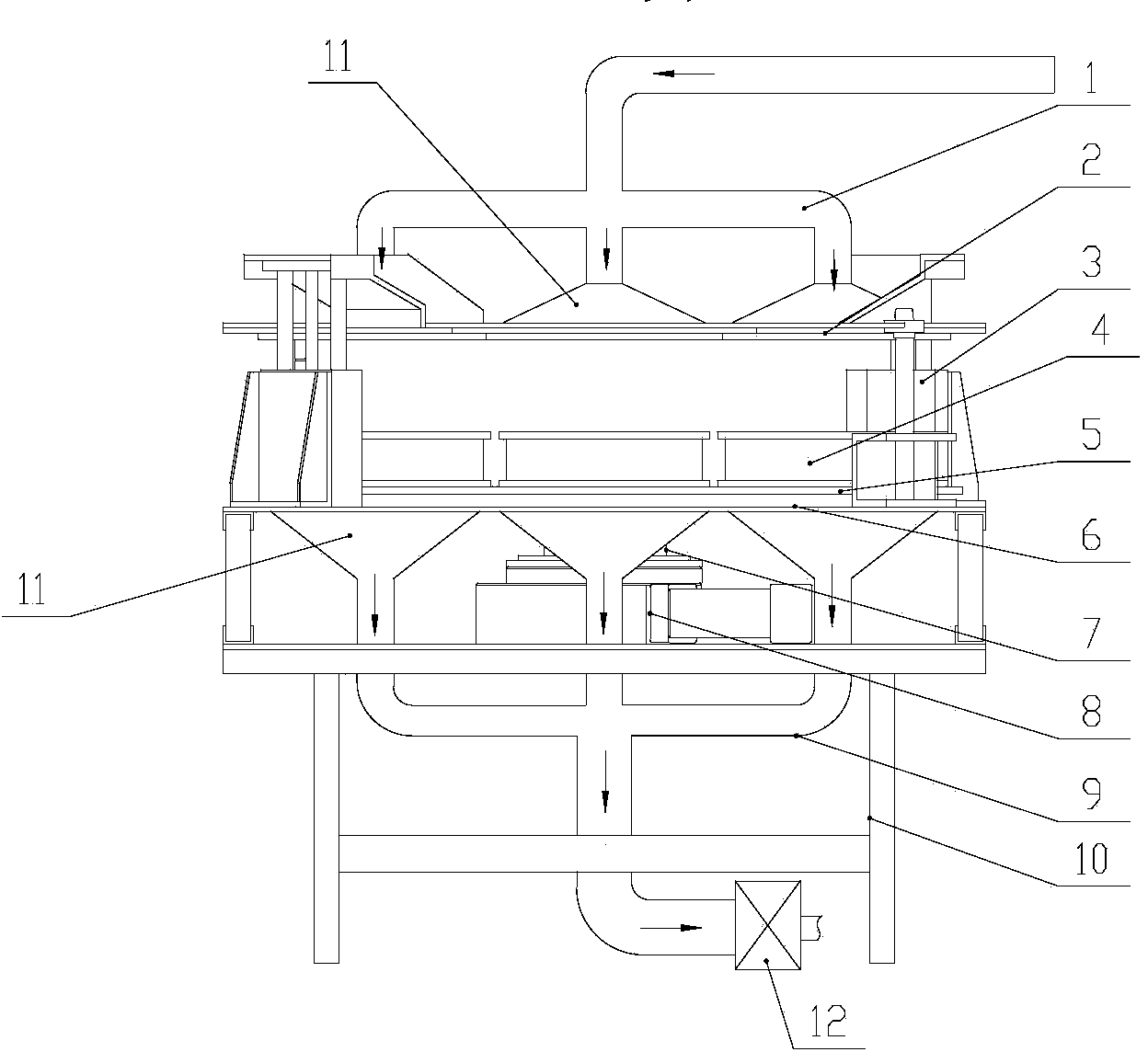

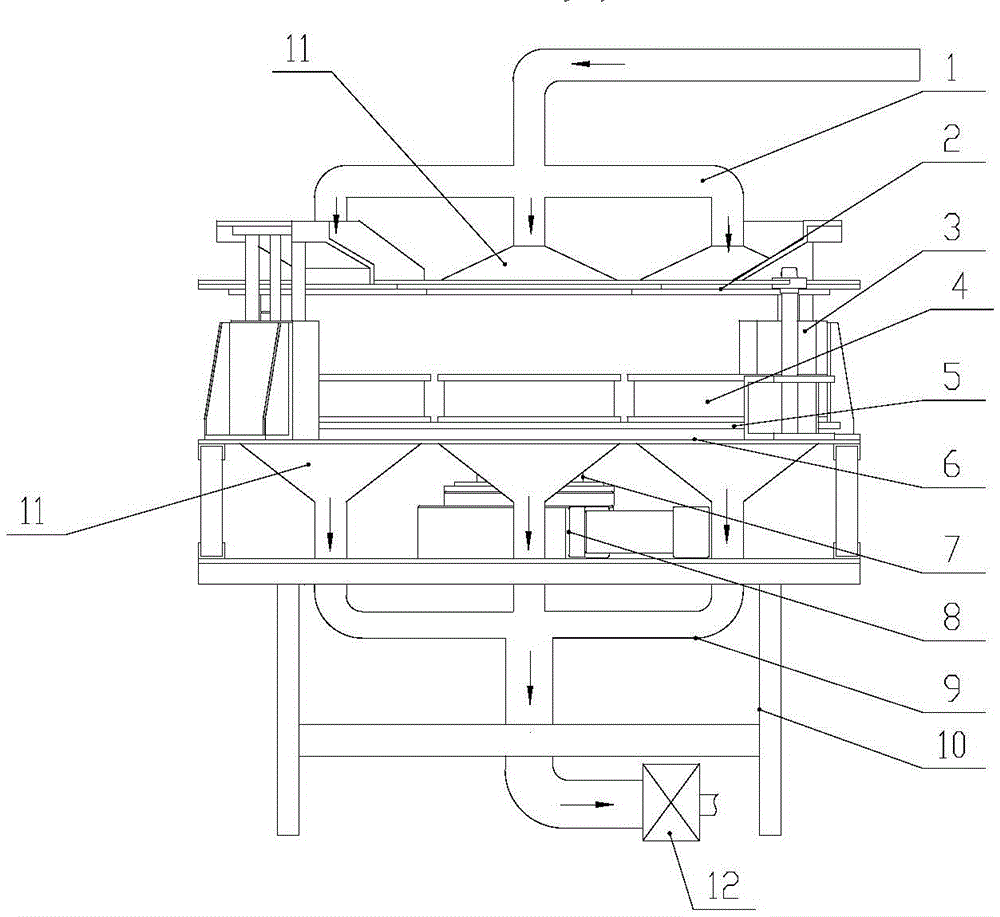

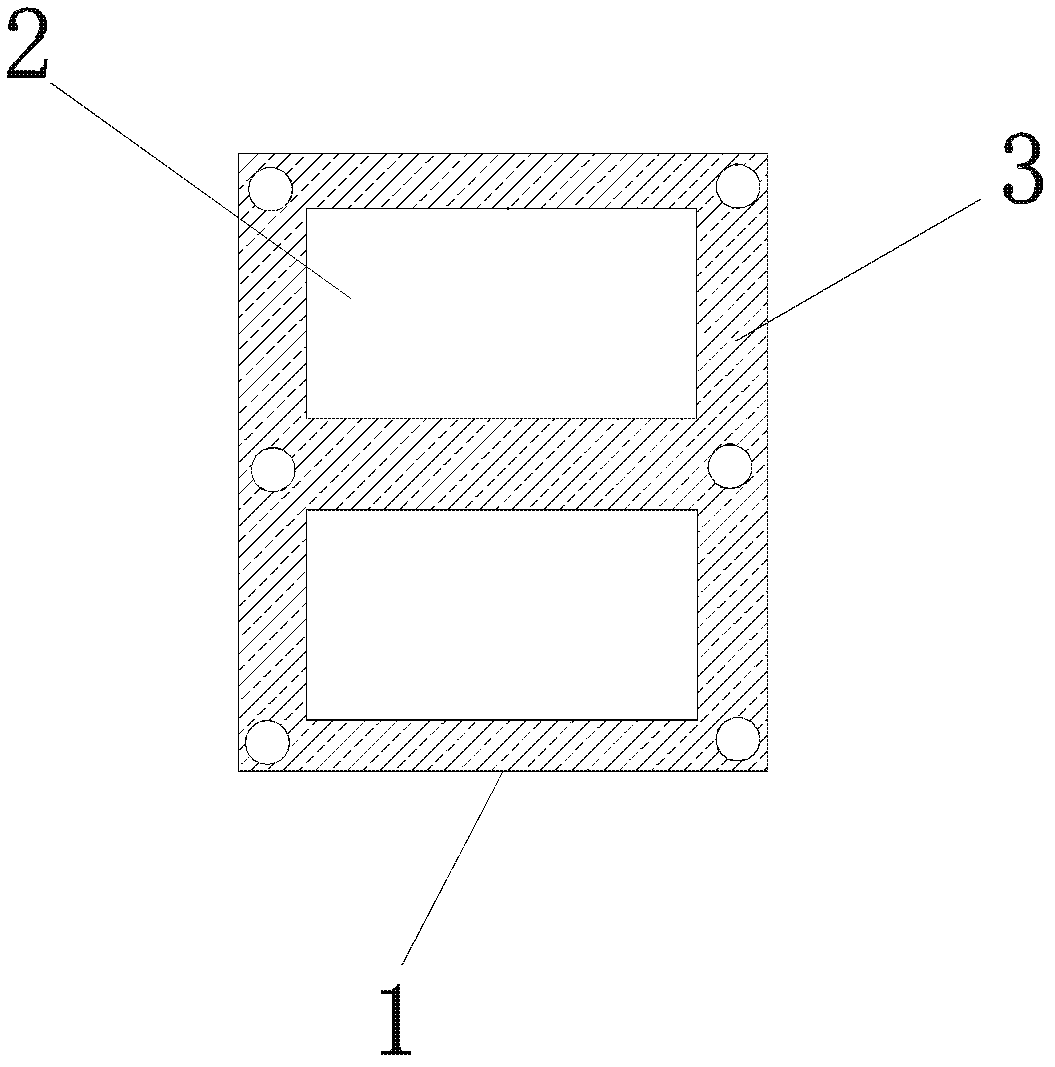

Initiating explosive drying device

ActiveCN104045493AAvoid direct human contactShorten drying timeExplosive working-up apparatusDrying timePallet

The invention provides an drying device drying device, comprising a first pipeline, an upper fan housing fixing plate, a first cylinder, drug boxes, a drug box pallet, a lower fan housing fixing plate, a second cylinder, a second pipeline and a controller. The drug box tray is arranged on a base, and is provided with a plurality of drug boxes; the lower fan housing fixing plate is arranged on the top of the second cylinder and is located below the in the drug box pallet; the upper fan housing fixing plate is arranged on the top of the first cylinder and located right above the drug box pallet; the upper fan housing fixing plate and the lower fan housing fixing plate are provided with air holes; the first pipeline and the upper fan housing fixing plate, and the second pipeline and the lower fan housing fixing plate are in a flexible connection mode; the air holes on the upper fan housing fixing plate are communicated with the inside of the first pipe, and the air holes on the lower fan housing fixing plate are communicated with the inside of the second pipeline; and the first cylinder and the second cylinder are all connected with the controller. The invention adopts automatic production, avoids direct artificial contact with the explosive, greatly shortens the drying time and improves production efficiency.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

A detonator drying device

ActiveCN104045493BAvoid direct human contactShorten drying timeExplosive working-up apparatusDrying timeComputer engineering

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

Method for manufacturing solder mask of unit plate by using electrostatic spray coating machine

InactiveCN102625591BAvoid direct human contactAvoid wastingNon-metallic protective coating applicationState of artElectricity

The invention discloses a method for manufacturing a solder mask of a unit plate by using an electrostatic spray coating machine. A frame is manufactured, an inner frame with same shape and size of the unit plate is arranged on the frame and is used for fixing the unit plate, and a clamping force to the frame is formed by the electrostatic spray coating machine, so that the problems of easily scratched plate surface and ink tightness caused by the direct contact between a clamp and the unit plate are avoided. Compared with the prior art, the method provided by the invention has the advantages: printing ink cannot enter into a hole because the printing ink of the electrostatic spray coating machine has negative electricity and achieves an electrostatic shielding effect while acting on the hole, the production quality is ensured, the operation in such a manner is convenient, the complex operations, such as manual net filling, 'hand pushing' silk printing, are omitted, and the production efficiency is increased. The frame is used for preventing labor from directly contacting the surface of the unit plate, so that the quality of product is ensured and the unnecessary material waste is avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Laser pen indication and luminescent spot track recognizing method

InactiveCN101251784BTeaching continuity and freedomProduce wear and tearReadingCharacter and pattern recognitionLight spotComputer vision

The present invention discloses a laser pen indicating and light spot trajectory identification method which belongs to the interactive reorganization technical field. Step 1, according to laser pen indicating information, a user obtains video information of a display screen from a video input device; step 2, an embedded device extracts light spots from the acquired video information, and determines the positions of the light spots after a de-noising process; step 3, the position coordinates of the light spots are transmitted to a computer which controls a target screen; step 4, according to the position coordinates of the light spots, the computer which controls the target screen recognizes the light spot trajectory; with the specific light spot information, the trajectory information indicated by the user is obtained; when the recognition is succeeded, step 5 is carried out; step 5, after the trajectory recognition is succeeded, the trajectory of the recognition result of the original trajectory is optimized, so that a new trajectory is obtained; the optimized result is displayed with visually optimized effect on the target screen to replace the indication effect of the step 3. The method can be applied in various interactive recognition display circumstances so as to carry out highly effective light spot analysis and trajectory recognition.

Owner:SHANGHAI JIAOTONG UNIV

A cleaning device for surgical gowns for medical care

InactiveCN108425209BProtection securityAvoid secondary infectionWashing machine with receptaclesTextiles and paperSurgical GownsNursing care

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

An intelligent spraying robot

ActiveCN111264506BEasy to useControl swing frequencyInsect catchers and killersRemote controlControl engineering

The invention relates to an intelligent spraying robot, which comprises a frame and a guide rail. The inside of the frame is provided with a medicine box, and the bottom is provided with guide wheels walking on the guide rail. Both sides of the bottom of the frame are equipped with batteries. A main control box and a power motor are installed on the top of the main control box. A spraying motor is installed on the frame on one side of the main control box. The spraying motor is connected to a water pump. The water inlet of the nozzle, the lower end of the row type nozzle is respectively connected to the upper end of the nozzle swing arm, the swing arm motor is arranged on the frame, the power output shaft of the power motor is fixed with the power wheel, and the power wheel is arranged on the front side of the frame To make the robot walk on the guide rail, the spraying motor, swing arm motor, and power motor are all connected to the main control box, and the main control box is connected to the remote controller for signal transmission. The intelligent spraying robot of the present invention solves the danger and heavy work of manual spraying, performs intelligent spraying, reduces costs, and improves efficiency.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com