Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about How to "Avoid affecting processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction waste crushing and reusing device with iron recovery function

InactiveCN107737631AImprove crushing efficiencyImprove the fineness of crushingMagnetic separationGrain treatmentsMotor shaftScrap

The invention discloses a construction waste crushing and reusing device with an iron recovery function. The construction waste crushing and reusing device comprises a base. A working box is fixedly arranged on the top of the base through a bracket. A left second rotary shaft and a right second rotary shaft are arranged on the top in the working box. Second crushing rollers which are matched witheach other are correspondingly and fixedly mounted in the middle parts of the left second rotary shaft and the right second rotary shaft. Gears which are engaged with each other are correspondingly mounted on the left second rotary shaft and the right second rotary shaft. A gear motor is fixedly arranged on the rear side wall of the working box. A motor shaft at the front end of the gear motor isconnected with the rear end of the second rotary shaft on the right side. An opening is formed in the right side wall of the working box. A receiving tank is hinged to the opening position through a hinge. The receiving tank is located below a first crushing roller. The receiving tank is inclined to the lower left corner. An electromagnet is fixedly arranged at the bottom of the receiving tank andlocated in the working box. According to the construction waste crushing and reusing device with the iron recovery function, iron is attracted by the electromagnet at the bottom of the receiving tankand accordingly recovered; and when the receiving tank is inclined to the lower right corner, the electromagnet is de-energized, and the iron can slide into the iron recovery box.

Owner:徐得强

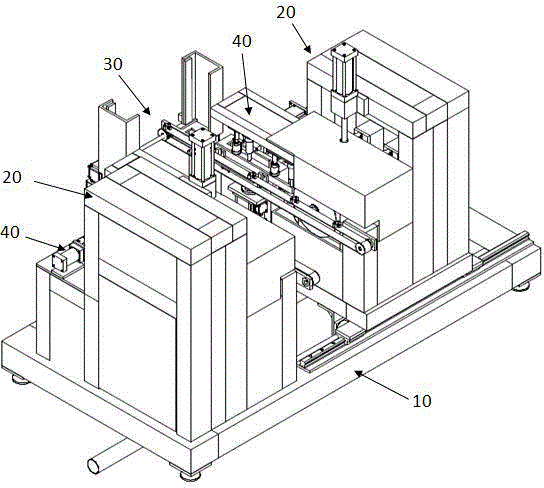

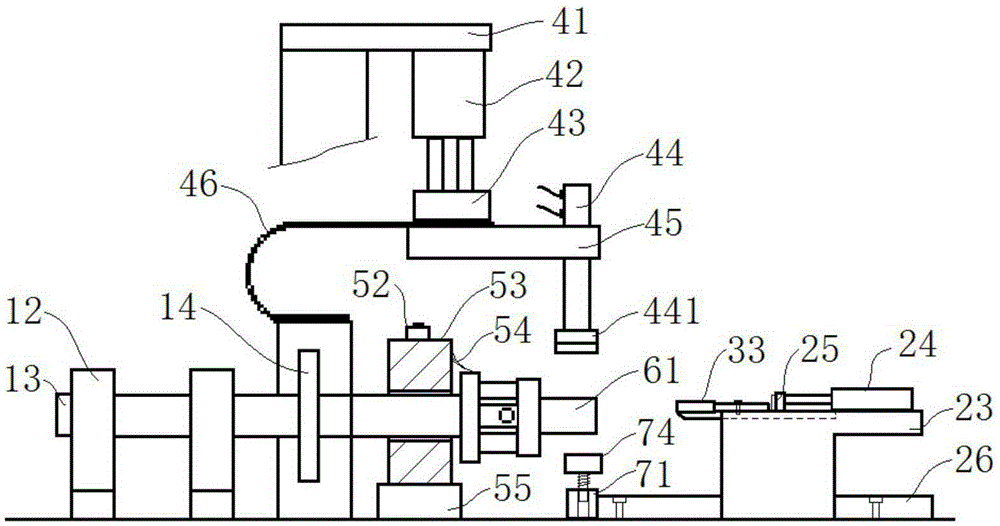

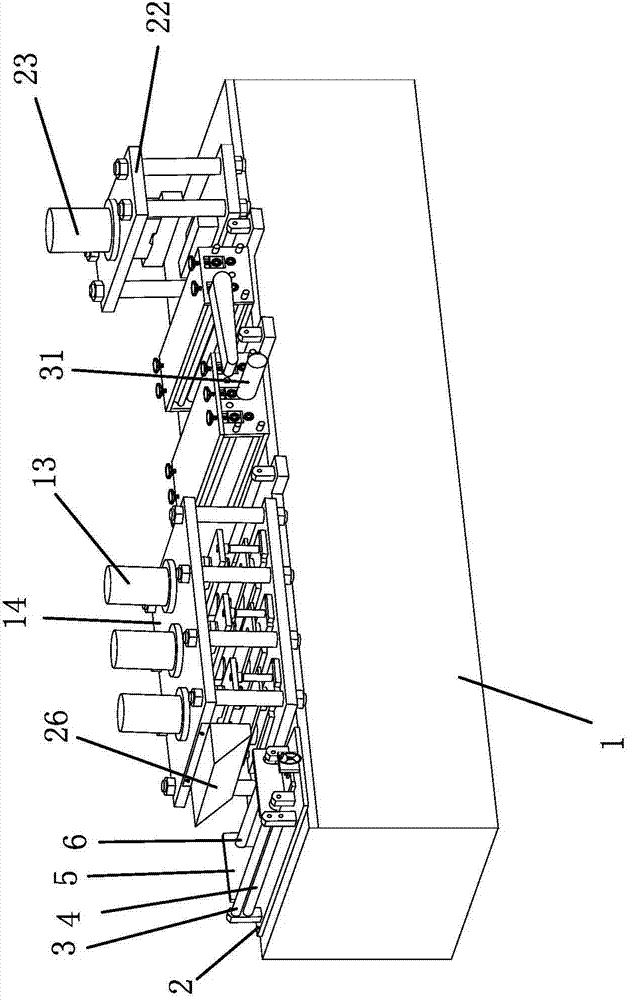

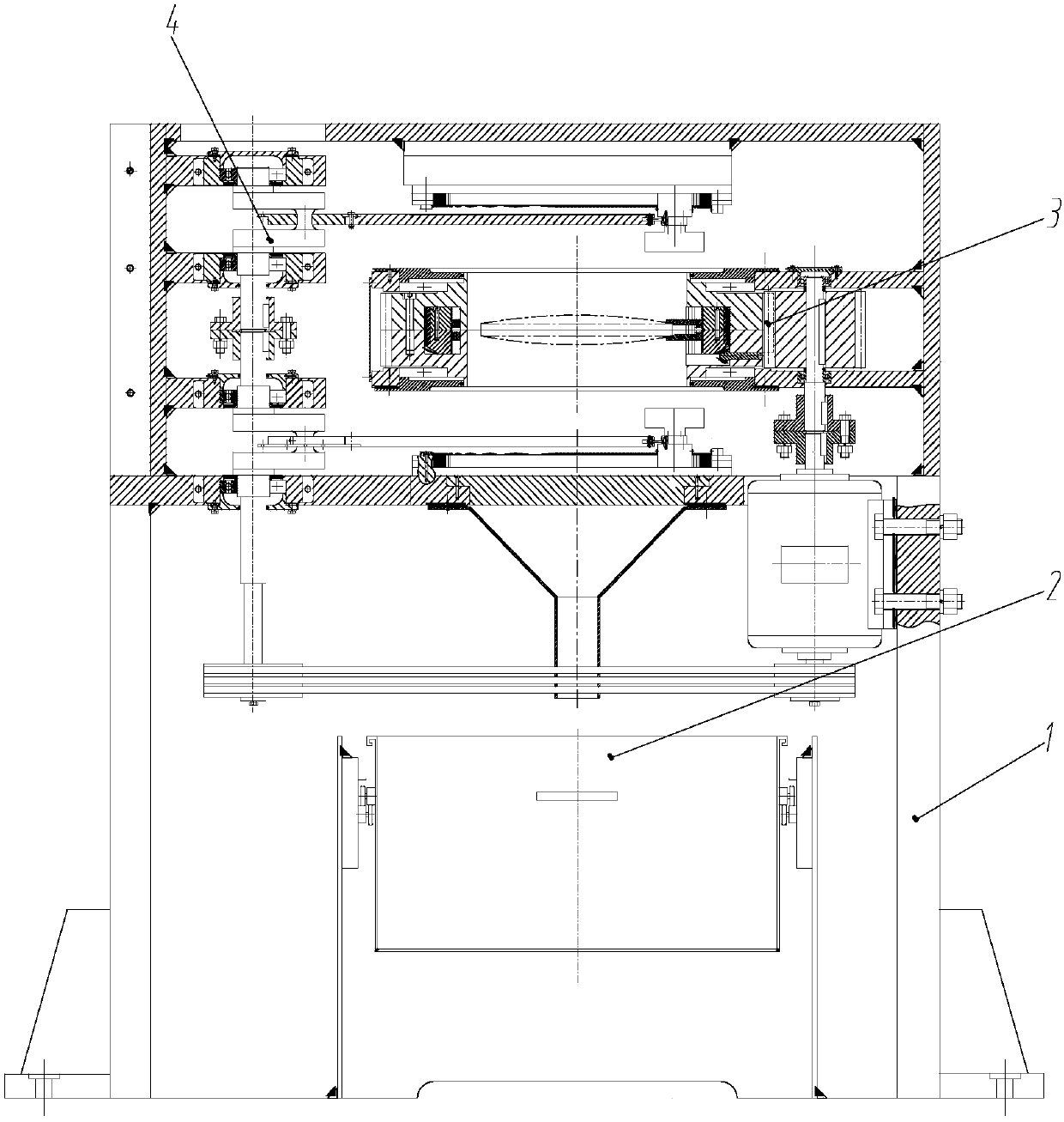

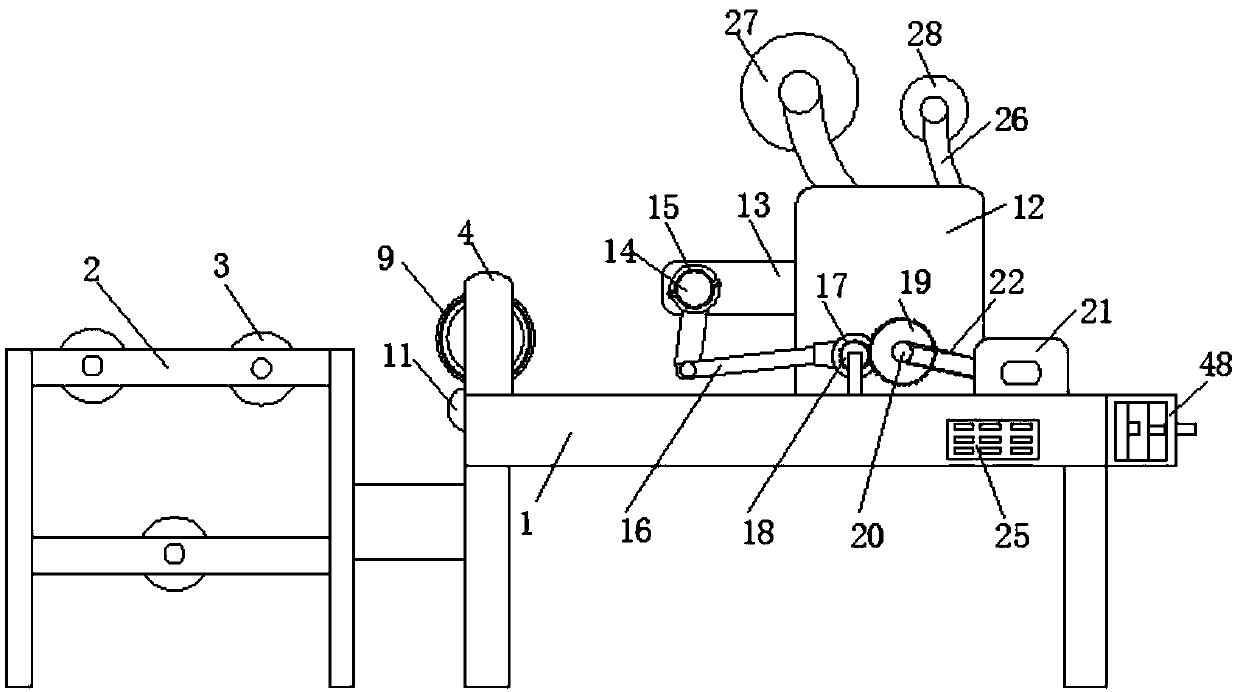

Cutting-off and perforating machine

InactiveCN105690472AAvoid affecting processing qualityAchieve reductionMetal working apparatusEngineeringAutomation

The invention relates to a cutting-off and perforating machine which comprises a machine frame. Opposite cutting devices are arranged at the two sides of the machine frame correspondingly. A conveying device is arranged between the cutting devices. Perforating devices are arranged on the machine frame and located beside the cutting devices and on the two sides of the conveying device correspondingly, and the perforating devices are oppositely arranged. The conveying device is used for automatic conveying, the perforating devices are used for automatic perforation, and the cutting devices are used for automatic cutting. The cutting-off and perforating machine achieves cutting and perforating, is high in automation degree, prevents the machining quality from being affected by man-made factors, and reduces labor cost.

Owner:WUXI FORMEN TECHN

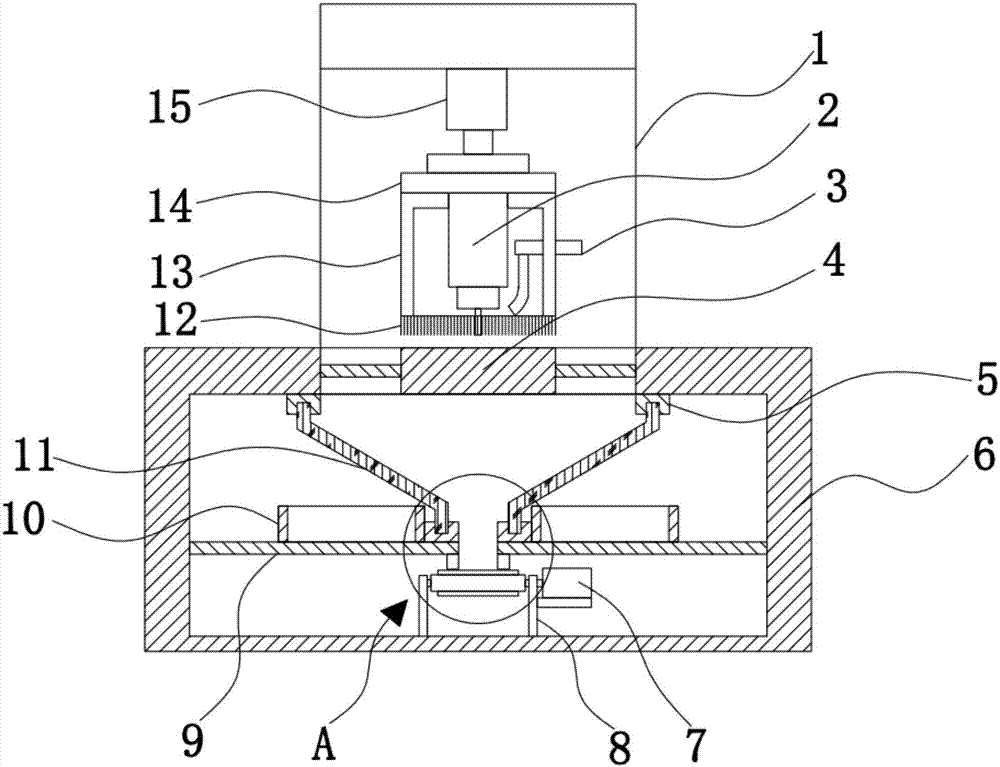

Wafer transfer device

PendingCN106783710AHigh degree of automationEasy transferSemiconductor/solid-state device manufacturingConveyor partsElectrical and Electronics engineeringEngineering

The invention discloses a wafer transfer device which comprises a supporting table, a tray, a first mechanical arm and a second mechanical arm, wherein a through hole is formed in the supporting table, and the supporting table is arranged in a lifting manner; the tray is fixedly arranged under the supporting table, and runs through the through hole when the supporting table is lifted; the first mechanical arm and the second mechanical arm are arranged close to each other or far away from each other for commonly clamping a wafer; and the first mechanical arm and the second mechanical arm are arranged above the supporting table, can be lifted and are arranged in a horizontally moving manner. Since the wafer is taken and placed by utilizing fixing of the tray and lifting of the supporting table, the wafer transfer device has a high degree of automation, can be used for replacing manual wafer transfer, has small labor intensity and high efficiency, and can adapt to the requirement of large-scale production. The wafer transfer device can ensure stable operation of each part and protect the wafer from being damaged by utilizing a guiding device.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

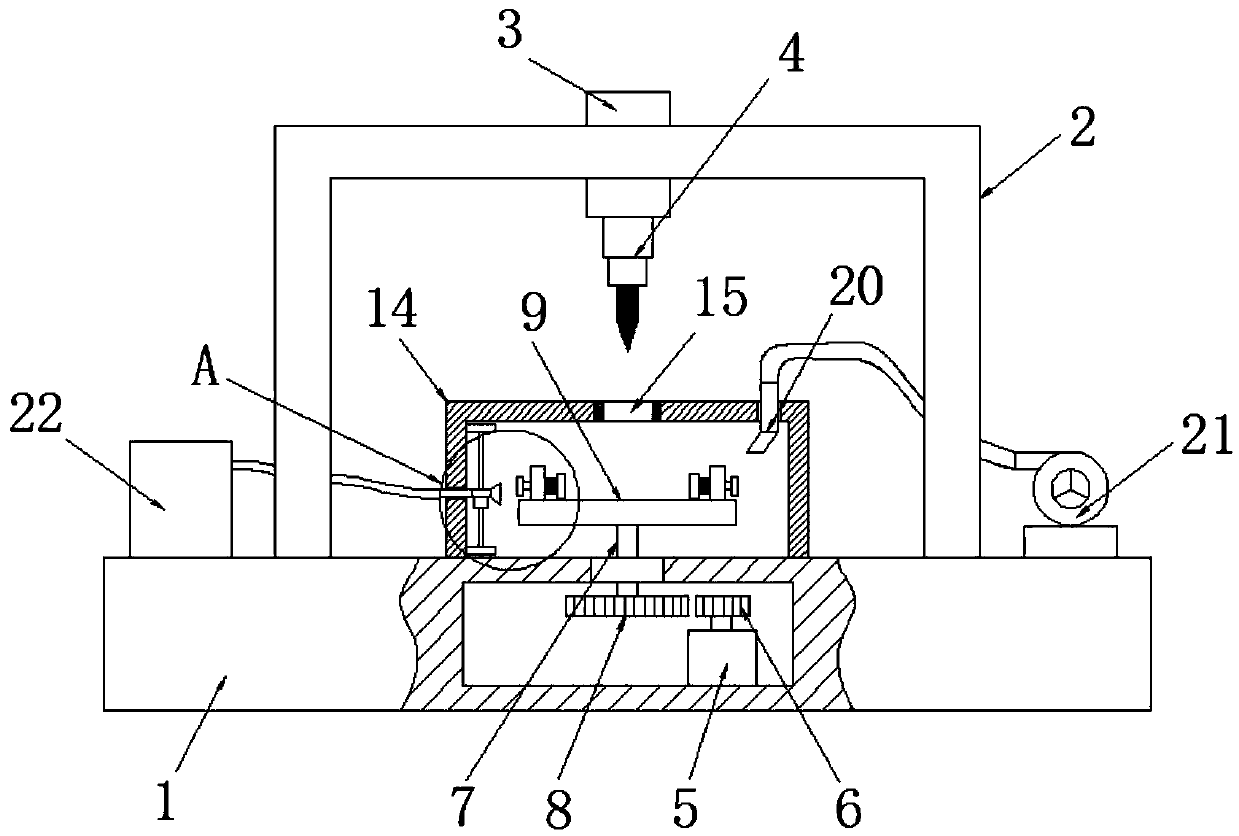

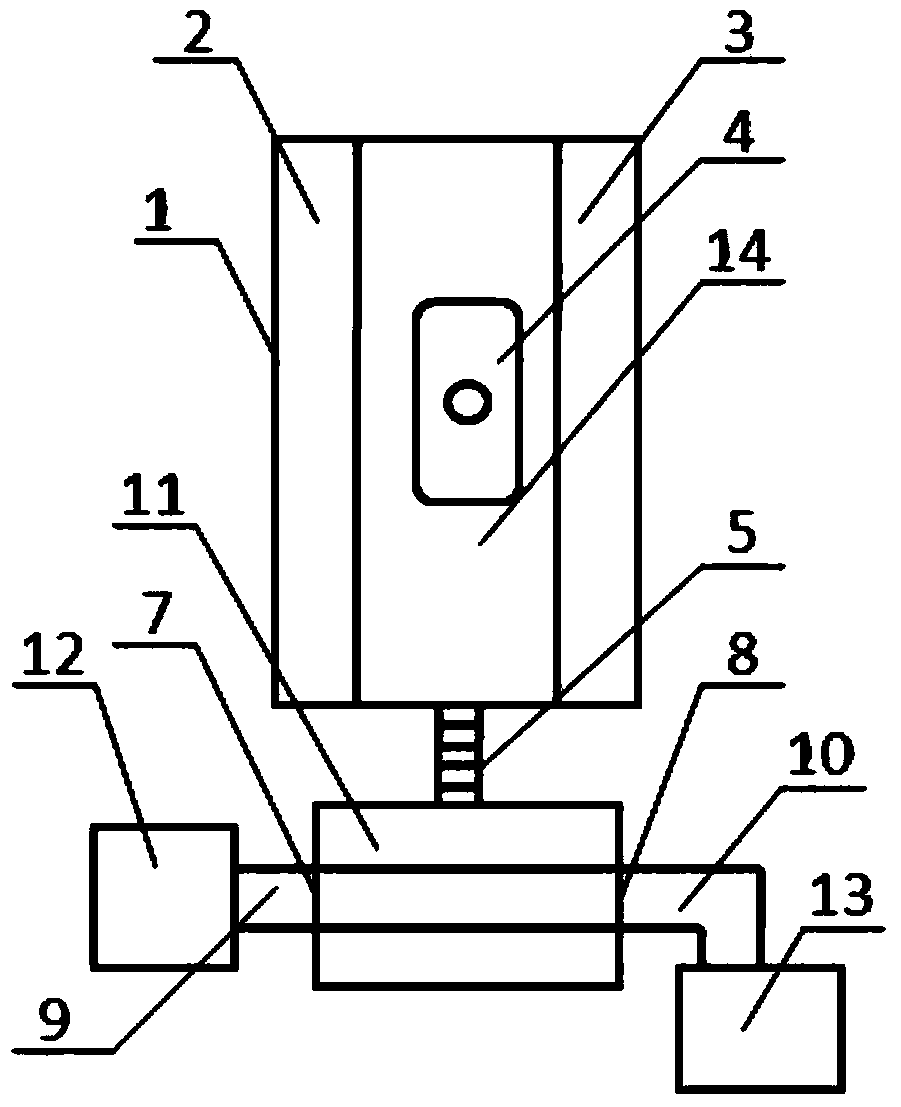

Numerically controlled beveling machine for mechanical manufacturing

ActiveCN107984290AAvoid affecting processing qualityAvoid accumulationMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses a numerically controlled beveling machine for mechanical manufacturing. The numerically controlled beveling machine for mechanical manufacturing comprises a machine table and afiltering hood, wherein a mounting back plate is fixed to the machine table, an electric sliding rail module is connected to the top end of the mounting back plate through a hydraulic cylinder, a machining spindle is fixed to the electric sliding rail module, and a machining platform is fixed to the machine table through a fixing rod; the upper end of the filtering hood is clamped to an upper clamping ring, the lower end of the filtering hood is clamped to a lower clamping ring, and the lower clamping ring is fixed to the machine table through a supporting plate; the machine table is furtherfixedly provided with a bracket; a guide roller is rotationally connected to the bracket and connected with the output end of a motor; a conveying belt is arranged on the guide roller; and a recoverybin is arranged below one end of the conveying belt. The numerically controlled beveling machine for mechanical manufacturing can clean up impurities on the surfaces of workpieces in the machining process, thereby ensuring the machining quality of the workpieces; and by means of the filtering hood, cutting fluid mixed with scrap iron, iron wires and other impurities can be filtered, solid and liquid can be separated and recovered separately, resources are saved, and the impurity removal efficiency is high.

Owner:泰州市银利标准件制造有限公司

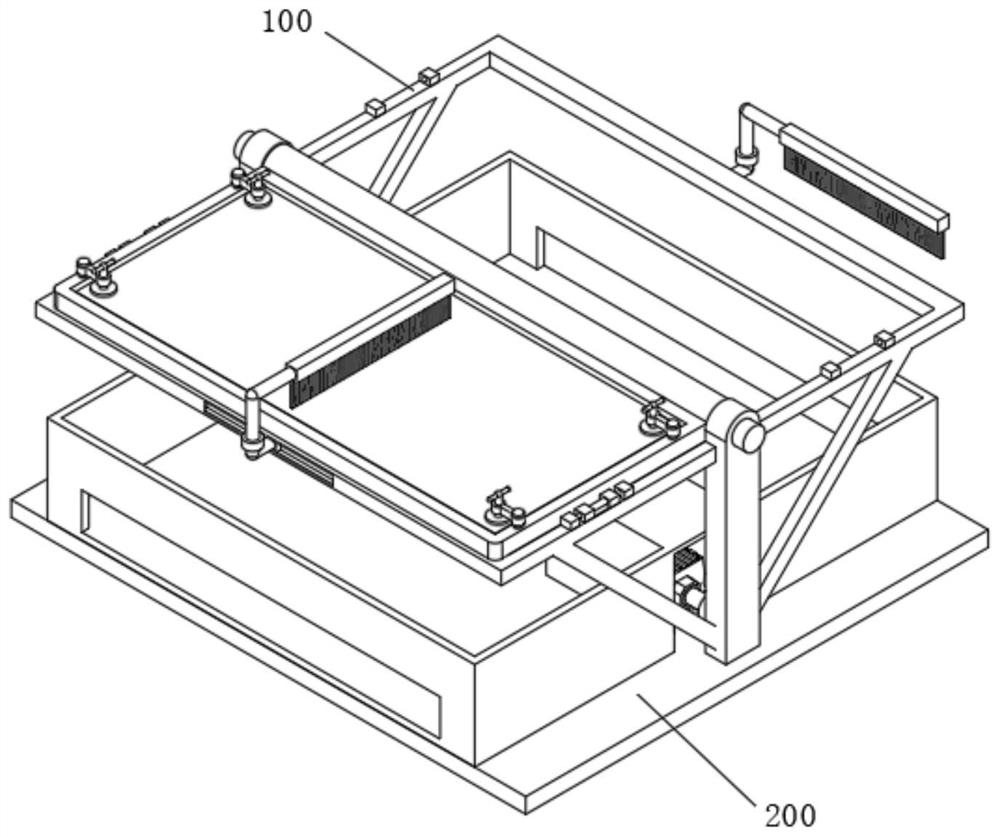

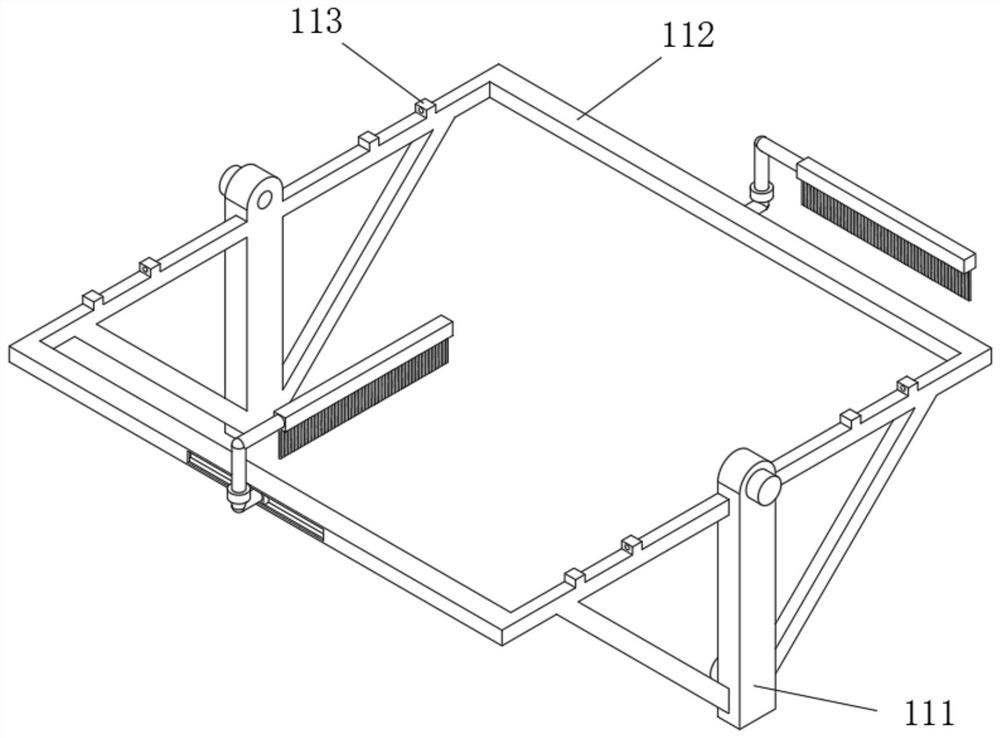

Printing device and printing method for packaging bag production

ActiveCN109484048AFit tightlyAvoid affecting processing qualityOther printing apparatusStampingEngineeringAnnular array

The invention discloses a printing device for packaging bag production in the technical field of packaging bags. The printing device comprises a workbench. A groove is formed in the outer wall of themiddle of the top of the workbench. Buffer devices are evenly arranged on the outer wall of a conveying belt and are arranged in an annular array manner. A supporting plate is arranged at the end, away from the conveying belt, of each buffer device. Rotating shafts are arranged at the left end and the right end of the outer wall of the side, away from the corresponding buffer device, of each supporting plate. Pressing devices are arranged at the close ends of the rotating shafts of the left set and the right set of each supporting plate. In the device, the pressing devices are moved to the positions above packaging bags, the packaging bags are fixed to the supporting plates, and the situation that the packaging bags move during printing, consequently, printing positions deviate, or part ofpatterns are not printed onto the packaging bags is avoided; and a mold plate is blocked by a sponge layer, the situation that the mold plate is directly inserted into ink, and consequently a large amount of ink is attached to the outer wall of the mold plate is avoided, the situation that the ink drops off from the mold plate to contaminate the workbench and the packaging bags is avoided, and the processing quality of the packaging bags is guaranteed.

Owner:上海柏连艾广告有限公司

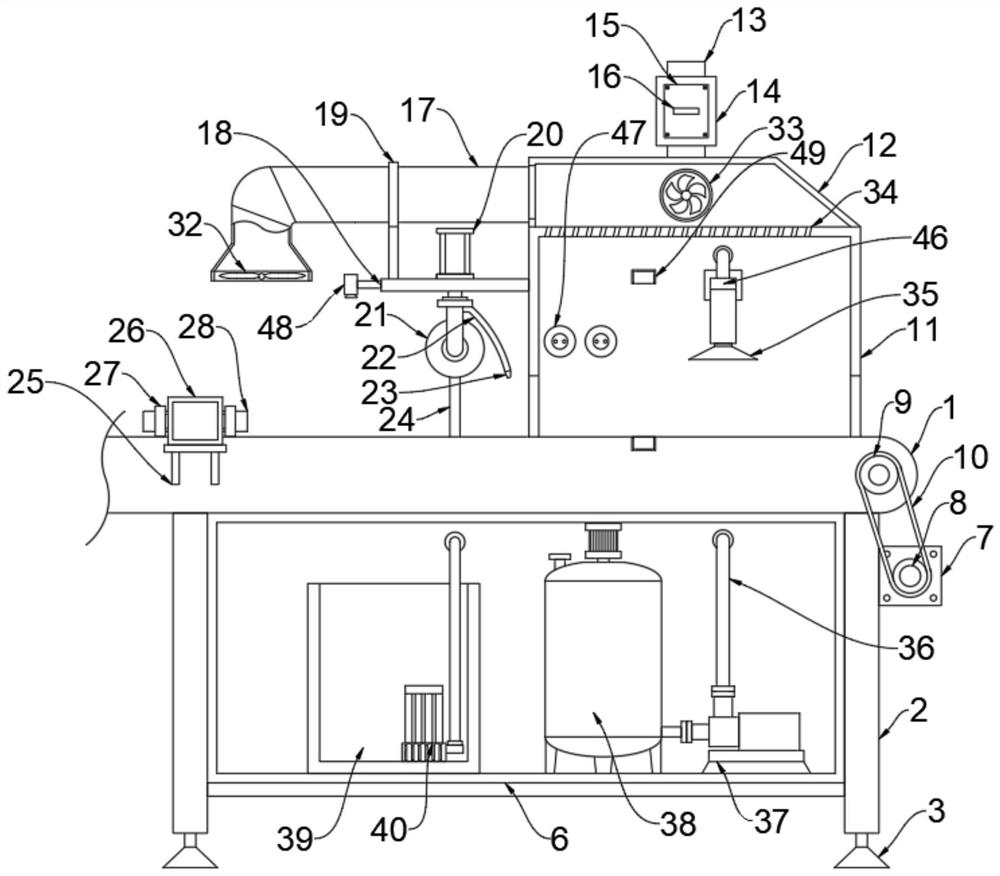

Brake pad machining grinding machine convenient for chipping cleaning

InactiveCN108326688AEnsure safetyAvoid affecting processing qualityGrinding machinesGrinding/polishing safety devicesEngineeringAir blower

The invention discloses a brake pad machining grinding machine convenient for chipping cleaning, and belongs to the technical field of grinding machine chipping cleaning. A chipping cleaning pipe is arranged on the left portion of a workpiece chuck, and an air blower is arranged behind a chipping removal box. An air inlet pipeline is arranged in an inner cavity of the chipping removal box. Two sets of exhaust pipelines extend to the front side wall and the rear side wall of the chipping removal box correspondingly, and a discharging pipeline is arranged at the left end of an air inlet pipelineand exactly faces the air blower. The other ends of two sets of air conveying pipelines are connected with the exhaust pipelines, and filtering screens are arranged in inner cavities of the exhaust pipelines. A supporting plate is arranged at the other end of a connecting baffle, and a compressed spring is arranged on the side, away from the axis of an air inlet pipeline, of the supporting plate.The other end of the compressed spring is connected to the side wall of an inner cavity of the air inlet pipeline. The brake pad machining grinding machine is reasonable in structural design, chippings and dust generated in the workpiece machining process can be cleared away synchronously, the situation that the chippings are accumulated to influence the machining quality is avoided, and safety of an operator is guaranteed.

Owner:郑余龙

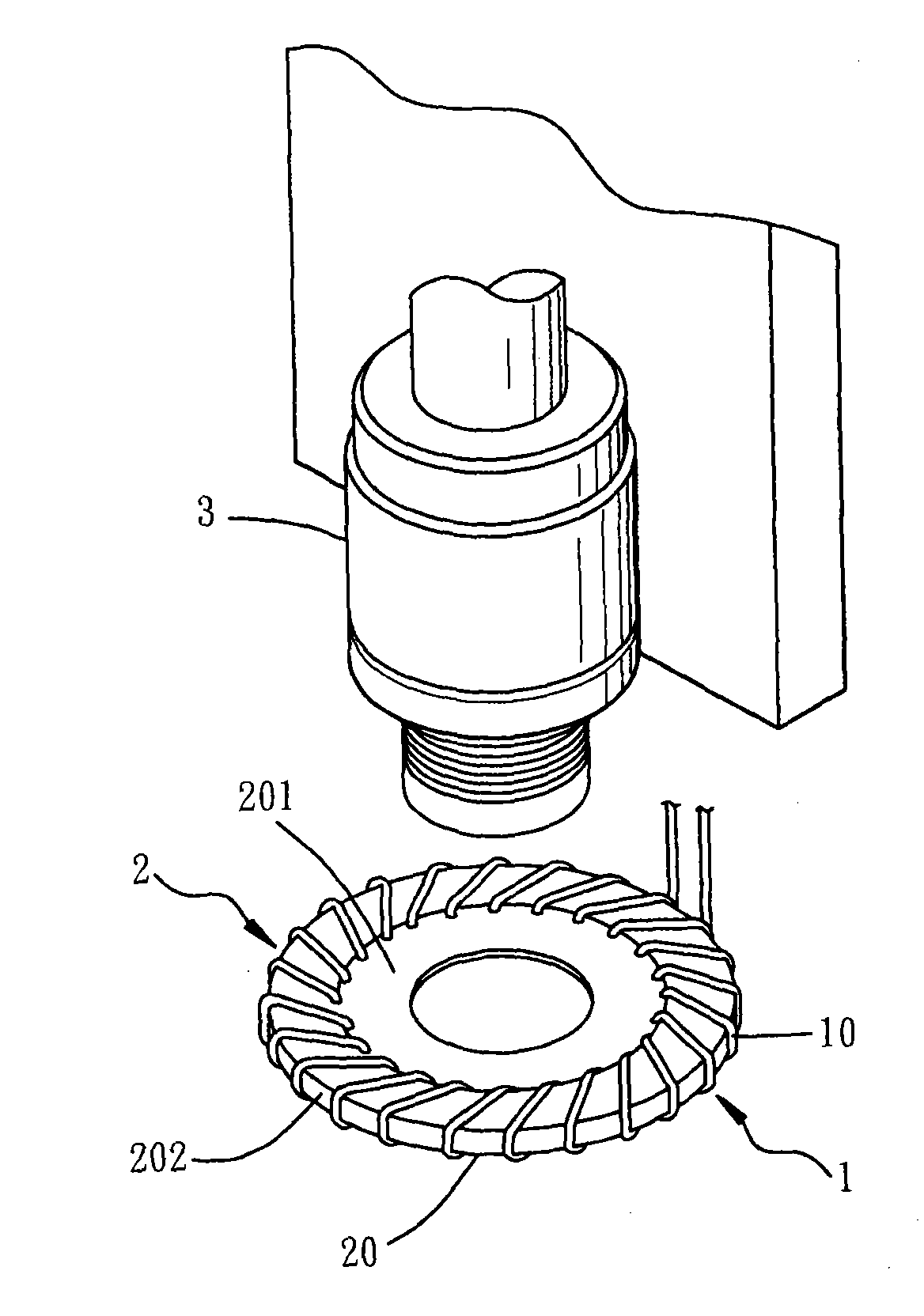

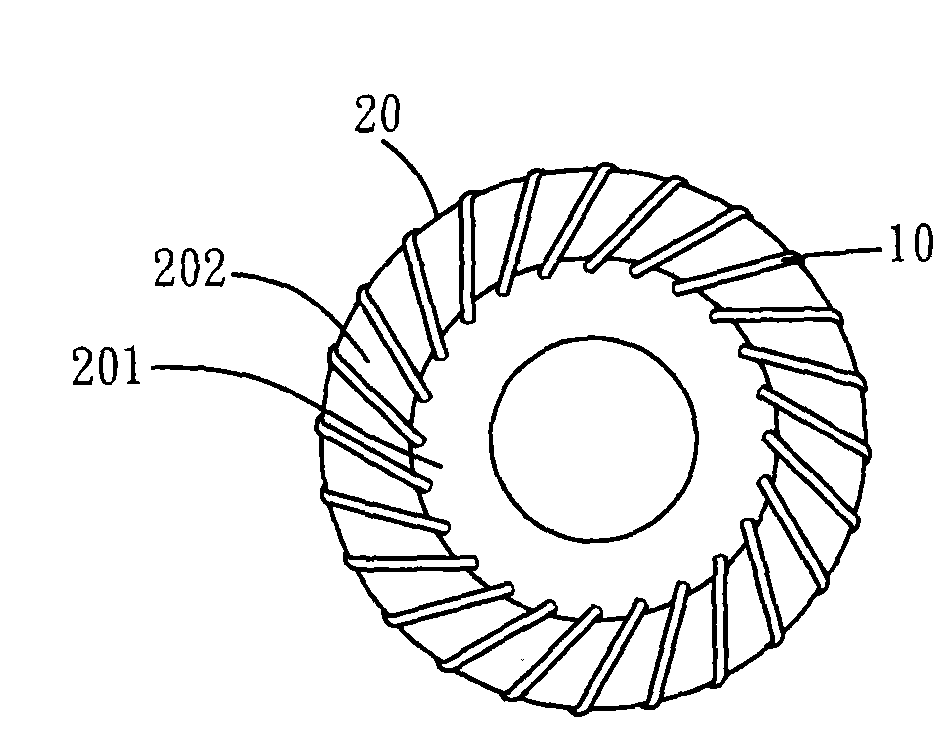

Automatic welding machine for stator casings

ActiveCN105252157AEasy to useImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesControl systemMotor processing

The invention discloses an automatic welding machine for stator casings, and belongs to the field of motor processing. The automatic welding machine disclosed by the invention comprises a control system, a driving mechanism, an element supporting mechanism, a welding mechanism and an advancing and positioning mechanism, wherein in the driving mechanism, a motor controls a main shaft to rotate through belt transmission; a chassis in the element supporting mechanism is mounted at the outer end of the main shaft; the end part of the chassis is a magnetic conductive strip supporting shaft which is coaxial with the chassis; a stator casing sleeve disc is mounted at the inner end of the magnetic conductive strip supporting shaft in a sleeving manner; the welding mechanism is arranged on the element supporting mechanism; the advancing and positioning mechanism and the main shaft are in corresponding arrangement; during welding, the control system controls the middle part of the advancing and positioning mechanism to slide towards the magnetic conductive strip supporting shaft so as to position the magnetic conductive strip, and the welding mechanism is controlled to perform fixed-point welding. According to the automatic welding machine disclosed by the invention, through the cooperation of the welding mechanism, the advancing and positioning mechanism, and a pressing mechanism, the welding processing of a stator casing is automatically completed, so that the labor strength of workers is reduced, and the welding quality and the processing efficiency are greatly improved.

Owner:MAANSHAN HETENG AUTO PARTS

Multi-taper deep hole processing detecting device

InactiveCN102679855ASimple structureImprove detection accuracyUsing electrical meansUsing optical meansData processing systemData treatment

The invention discloses a multi-taper deep hole processing detecting device, which consists of a guide post, a lead screw, a fixing mechanism, a crawler, a motive power mechanism and a data processing system, wherein the lead screw is arranged on the fixing mechanism, the crawler is fixedly connected with the middle position of the lead screw, the guide post is arranged at the front part of the lead screw, the motive power mechanism is fixedly connected with the back part of the lead screw, the crawler with a sensor moves along the lead screw and collects data, the data is transmitted to the data processing system through a data wire, and the guide post, the lead screw and the fixing mechanism form a simple support beam structure. The detecting device is mainly used for detecting the dimension precision and the surface quality of multi-taper deep holes during precise processing. For the multi-taper deep holes, the detecting device can realize the self guide, various parameters of the multi-taper deep holes can also be simultaneously detected, and the function of detecting multiple data in one step is realized. The detecting device has the advantages that the structure is simple and practical, the advancing and the retreating of the detecting device are realized through mechanical transmission, the detection function is realized through a sensor, and the detection process is stable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

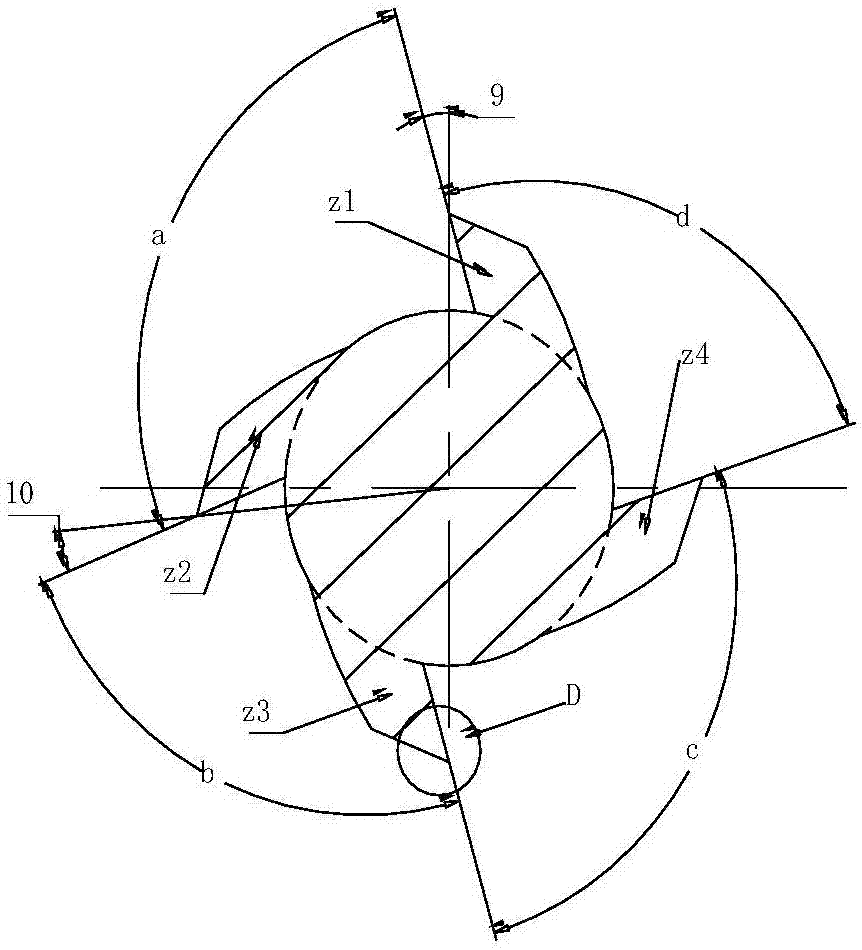

Dedicated compound tool suitable for helical hole milling of industrial robot lamination component

InactiveCN107262796AReduce cutting forceReduce machining chatterMilling cuttersEngineeringMilling cutter

The invention discloses a special composite tool suitable for helical milling holes of laminated components of industrial robots, which includes a second blade part connected to the front end and the rear end of the first blade part. The core thickness of the first blade part is smaller than the core thickness of the second blade part, and the core body of the first blade part and the core body of the second blade part are connected by a tapered smooth transition. A spiral cutting edge with unequal spacing, the second blade part includes four unequal distances which are arranged in the peripheral direction of the outer edge of the cutter and are smoothly connected with the helical cutting edge of the first blade part through a circular arc transition bottom edge. Helical cutting edge. Adopting this structure can reduce robot machining chatter.

Owner:TIANJIN UNIV

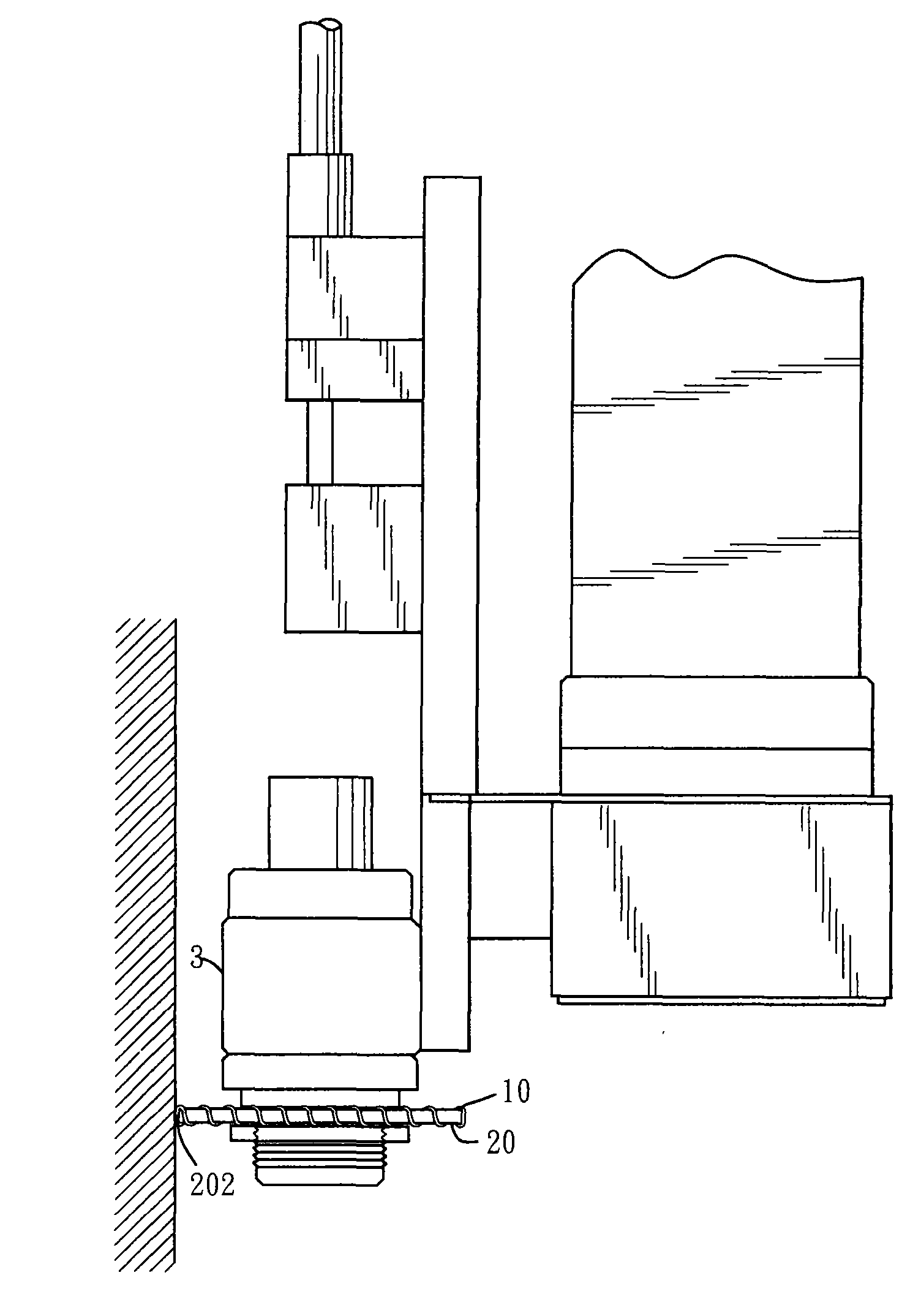

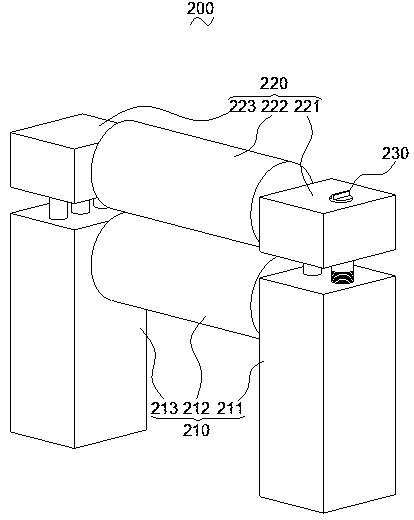

Signal device of error action anti-collision detector for machine table or equipment working head

InactiveCN102032434AAvoid damageAvoid affecting processing qualityOptical detectionEngineering emergency devicesDisplacement - actionEngineering

The invention discloses a signal device of an error action anti-collision detector for a machine table or an equipment working head. The signal device comprises a control mechanism and an induction mechanism, wherein the induction mechanism is annularly arranged on the working head; an elastic buffer mechanism is arranged between the induction mechanism and the control mechanism; the control mechanism and the induction mechanism are assembled and matched with each other to form a normal state; when the induction mechanism contacts a foreign object because of the displacement action of the working head, the normal state turns into a variable state; the state change serves as a signal for prompting the error action anti-collision detector; meanwhile, the induction mechanism is prevented from colliding with the working head by elastic buffer caused by the contact with the foreign object, and the response time that the error action anti-collision detector commands the working head to correct error action is provided by the elastic buffer process. The signal device of the error action anti-collision detector for the machine table or equipment working head avoids the precision offset of the machine table or working head, or avoids influencing machining quality or damaging the working head and articles to be machined.

Owner:唐毅机械有限公司

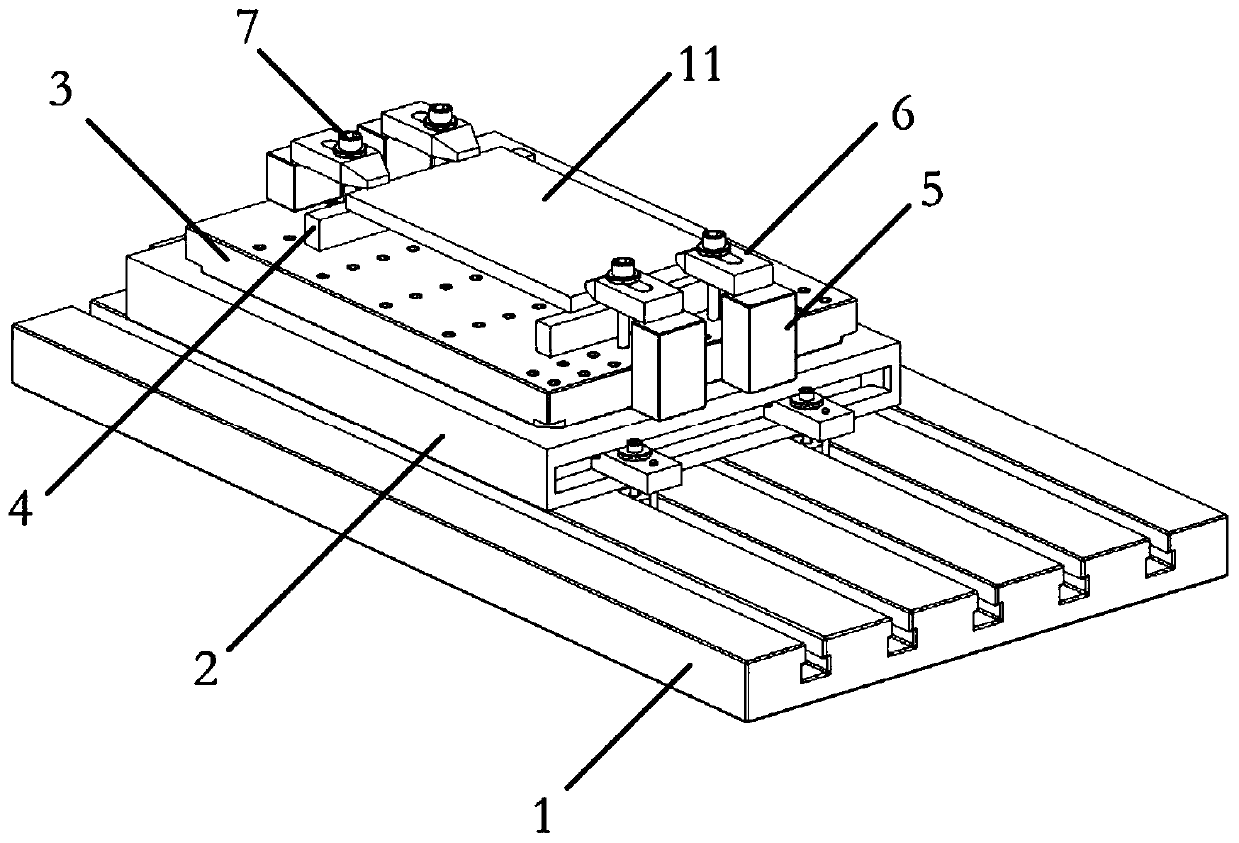

Header processing device

ActiveCN104759550AImprove processing efficiencyAvoid affecting processing qualityMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention provides a header processing device, and belongs to the technical field of solar header processing. The header processing device comprises a frame, an adjusting mechanism, a punching mechanism, a feeding rib-rolling mechanism and a cutter mechanism; the adjusting mechanism comprises an adjusting plate arranged on the frame and an upper roller wheel and a lower roller wheel on the adjusting plate; the vertical plates capable of translating in parallel are arranged on the adjusting block; the outsides of the vertical plates are provided with driving pieces for driving the vertical plates to close towards a thin plate; the punching mechanism is located on the frame, and the punching mechanism comprises several oil cylinders, a punching die and an oil cylinder bracket; the punching die is situated between the oil cylinder bracket and the frame, and the feeding rib-rolling mechanism comprises a feeding machine and a rib-rolling machine; the cutter mechanism comprises a cutter frame, a hydraulic cylinder, and a fixing cutter and a moving cutter which can perform the opening and closing movements to each other; the moving cutter is interlinked to the lower end of the hydraulic cylinder, and the fixing cutter is located at the upper end of the frame. The header processing device is wide in suitability, and also can greatly improve the processing efficiency and quality of the processed product.

Owner:浙江瑞翔新能源科技有限公司

Machine tool for producing shaft parts

InactiveCN114800068AFull multi-point supportAffect machining accuracyEdge grinding machinesGrinding carriagesRatchetMachine tool

The invention is applicable to the technical field of shaft part production equipment, and provides a machining tool for shaft part production, which comprises a rack, a workbench and a clamp unit, and further comprises a supporting unit mounted on the workbench, the supporting unit comprises a mounting plate, a plurality of supporting pieces, an adjusting assembly and a moving assembly, the clamp unit comprises a chuck assembly and a tip assembly, and each supporting piece comprises an inner sleeve, an outer sleeve, a mounting rod, a supporting roller, a spherical protrusion, a first spring, a first hemispherical protrusion, a ratchet ring, a pawl and a second spring. Multi-point supporting can be fully carried out on the shaft, the situation that the machining precision is affected due to deformation of the shaft is reduced, and the distance between the adjacent supporting pieces is adjusted through the adjusting assemblies to adapt to shafts of different lengths; the clamp unit is arranged, so that shafts with different lengths can be clamped and fixed; and the supporting piece can support shafts with different diameters.

Owner:葛恒伟

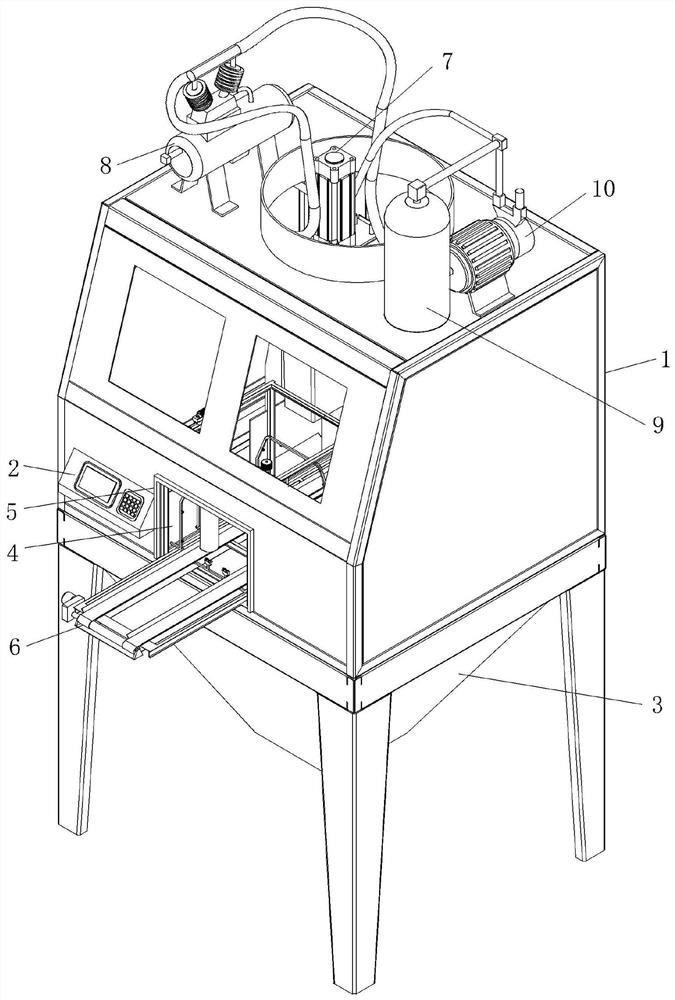

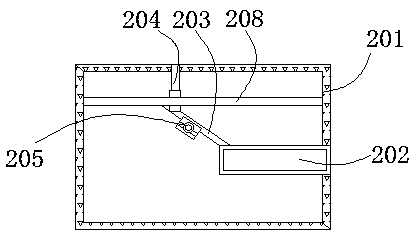

Die cleaning device of stamping equipment

InactiveCN111940353APrevent crushingAvoid affecting processing qualityDirt cleaningCleaning using toolsEngineeringAir pump

The invention discloses a die cleaning device of stamping equipment. The die cleaning device comprises a shell, a controller, a waste collecting hopper, a feeding port, an infrared raster scanner, a cleaning mechanism and a brushing mechanism; the controller is installed at the lower left corner of the front side of the shell along the left and right directions; the waste collecting hopper is installed at the bottom end of the inner cavity of the shell; the feeding port is formed at the center of the front side of the inner cavity of the shell; the infrared raster scanner is installed on the front side of the shell and located on the outer side of the waste collecting hopper; the cleaning mechanism is arranged at the bottom end of the inner cavity of the shell along the front and back directions, and the front side of the cleaning mechanism penetrates through the inner cavity of the feeding port; the brushing mechanism is arranged at the top end of the inner cavity of the shell along the the up and down directions and located on the rear side above an air pump. According to the die cleaning device of the stamping equipment provided by the invention, accumulated chips in a die cavity of a die can be cleaned, a produced product is prevented from being crushed, engine oil attached to the outer wall of the die can be cleaned, and the machining quality of the product is prevented from being affected.

Owner:路荞瑀

Auxiliary fixing device for electric permanent-magnet workbench

PendingCN110757215AAvoid damageAvoid direct contactPositioning apparatusMaintainance and safety accessoriesMilling cutterEngineering

The invention relates to the technical field of machining, in particular to an auxiliary fixing device for an electric permanent-magnet workbench. The auxiliary fixing device for the electric permanent-magnet workbench comprises a protective shell and at least one pair of clamping assemblies, wherein a cavity groove is formed in the bottom surface of the protective shell, the protective shell is cooperatively fixed to the electric permanent-magnet workbench through the cavity groove, and a plurality of through holes are formed in the top surface of the protective shell; and the paired clampingassemblies are separately installed at the two opposite ends of the protective shell to form an installation space of a to-be-machined workpiece, and each clamping assembly at least comprises a firstfastener which is inserted into one through hole to fixedly install the to-be-machined workpiece in the installation space above the protective shell. The protective shell is cooperatively fixed to the electric permanent-magnet workbench through the cavity groove, and meanwhile, the to-be-machined workpiece is fixedly installed by means of the clamping assemblies; and when the workpiece is machined through a machine tool, the protective shell can protect the electric permanent-magnet workbench, and the situation that a milling cutter penetrates through the workpiece and consequentially damages the electric permanent-magnet workbench is prevented.

Owner:浙江合兴电工有限公司

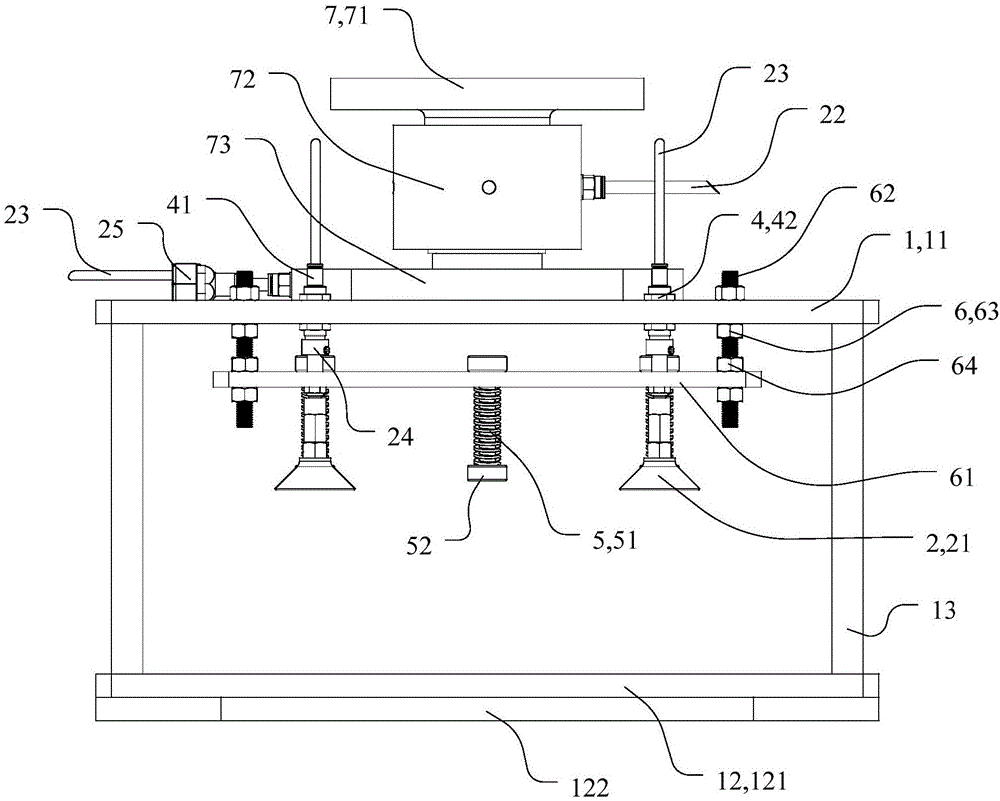

Fixture for workpiece

ActiveCN106737304ANot easy to moveAvoid affecting processing qualityWork holdersMachining processIndustrial engineering

The invention discloses a fixture for a workpiece. A limiting part is arranged on the workpiece. The fixture comprises an adsorbing device used for adsorbing the workpiece and a limiting structure. When the adsorbing device adsorbs the workpiece, the limiting part of the workpiece abuts against the limiting structure, the limiting structure applies limiting force opposite to the adsorption force of the adsorbing device to the workpiece, and the workpiece is located under the effects of the adsorption force and the limiting force. According to the provided fixture for the workpiece, the workpiece is adsorbed by the adsorbing device, and the limiting structure abuts against a limiting part of the workpiece to limit the workpiece, so that locating of the workpiece is reliable, and displacement is not liable to occur under the effect of external force. The fixture for the workpiece can be applied to the location of a water tank, the situation that the machining quality is affected by the displacement of the water tank in the machining process is avoided, and the labor cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC +1

Cutting apparatus for bearing pedestal cutting

The present invention discloses a cutting apparatus for bearing pedestal cutting. The device comprises a base and a gantry arranged at an upper end of the base, wherein the upper end of the cross beamof the gantry is fixedly connected with an electric push rod through a first through hole, a lower end of the electric push rod extends into the gantry, and the lower end of the electric push rod isfixedly provided with a cutting gun; a cavity is arranged at the center of the inner part of the base, the right side of the lower end of the cavity is fixedly provided with a motor, and the output shaft of the motor is rotationally connected with a small gear; a rotating shaft is rotationally connected to the center of the upper end of the cavity through a rolling bearing, the lower end of the rotating shaft is fixedly provided with a large gear, the large gear and the small gear are meshed; the upper end of the rotating shaft penetrates through the rolling bearing and extends outwards, and the upper end of the rotating shaft is fixedly provided with a rotating disc. According to the cutting apparatus for bearing pedestal cutting, the operation is convenient, the shaft hole of the bearingpedestal can be quickly cut out, the production efficiency is improved, and the dust generated in the cutting process can be prevented from polluting the environment.

Owner:响水星火传动件有限公司

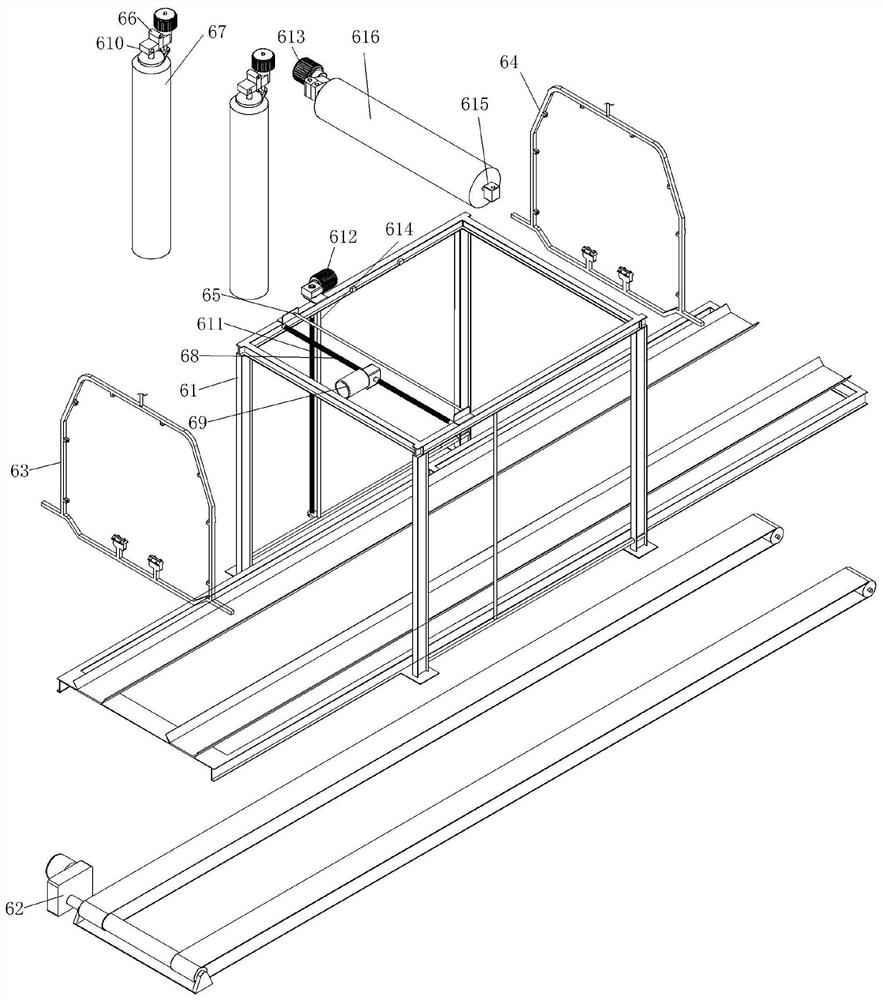

Chip removing device for metal processing lathe

ActiveCN104369050AEnsure safetyAvoid affecting processing qualityWire toolsMaintainance and safety accessoriesMetal machiningEngineering

The invention discloses a chip removing device for a metal processing lathe. The chip removing device comprises a groove bin room formed in a lathe body, the groove bin room is of a cuboid structure, the bottom of the groove bin room is provided with a suction disc in a fixed mode, the suction disc is connected with a negative pressure generator through a chip removing tube, an air inlet is formed in one end of the negative pressure generator, an air outlet is formed in the other end of the negative pressure generator, the air inlet of the negative pressure generator is connected with a steel cylinder for storing air through an air inlet tube, a shell of the negative pressure generator is provided with a tube hole matched with the chip removing tube, a baffle is arranged at the bottom of the later wall, close to the air inlet, of the tube hole and rotates with a rotating shaft of the baffle as a circle center, an air exhausting hole is formed in the bottom of the lateral wall, close to the air outlet, of the tube hole and connected with an air exhausting device through an air exhausting tube, and a filtering net is arranged at the position of the air exhausting hole. Chips can be synchronously removed in the metal processing process, the processing quality is prevented from being influenced by chip accumulation, and meanwhile the safety of an operator is guaranteed.

Owner:苏州微米光电子科技有限公司

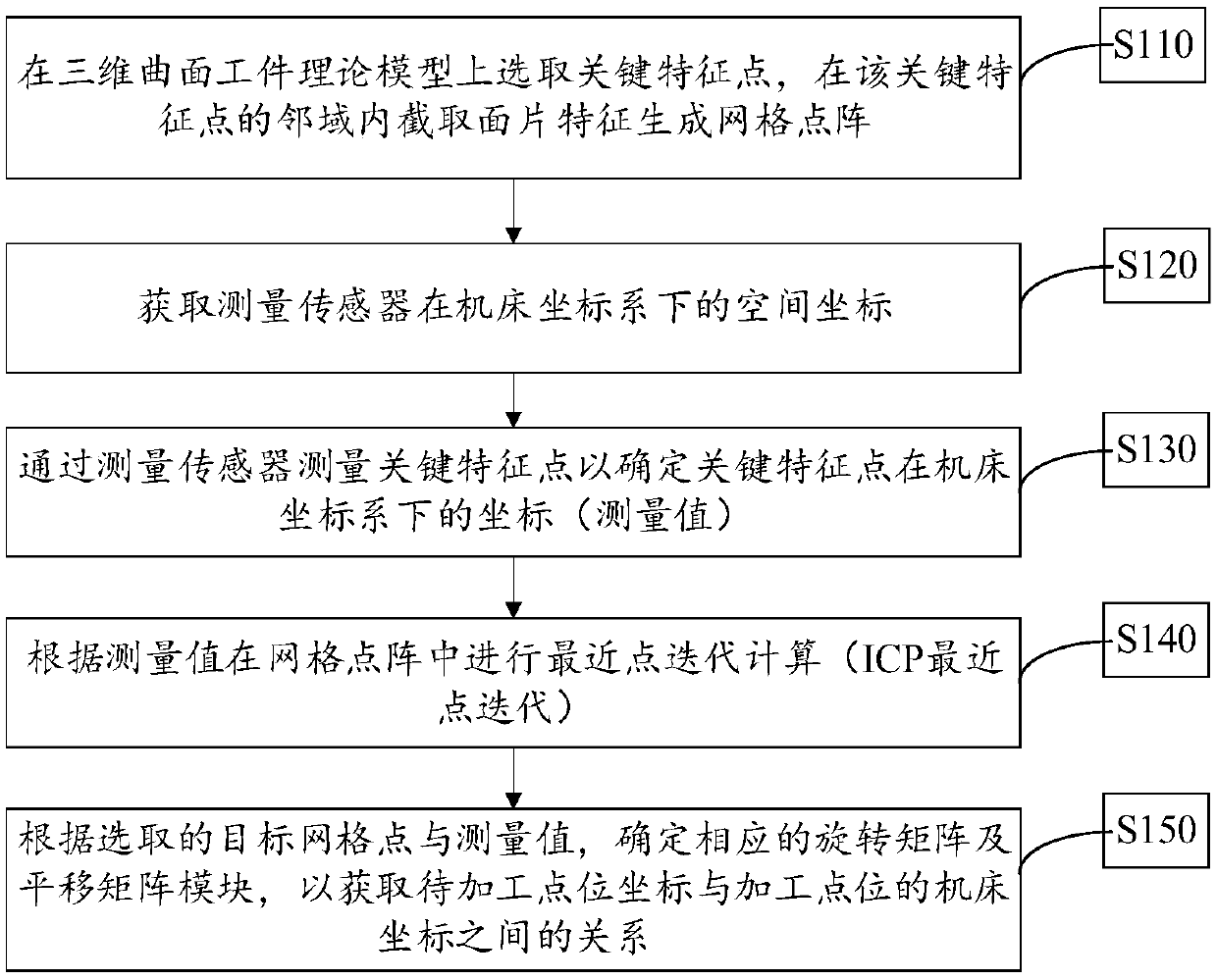

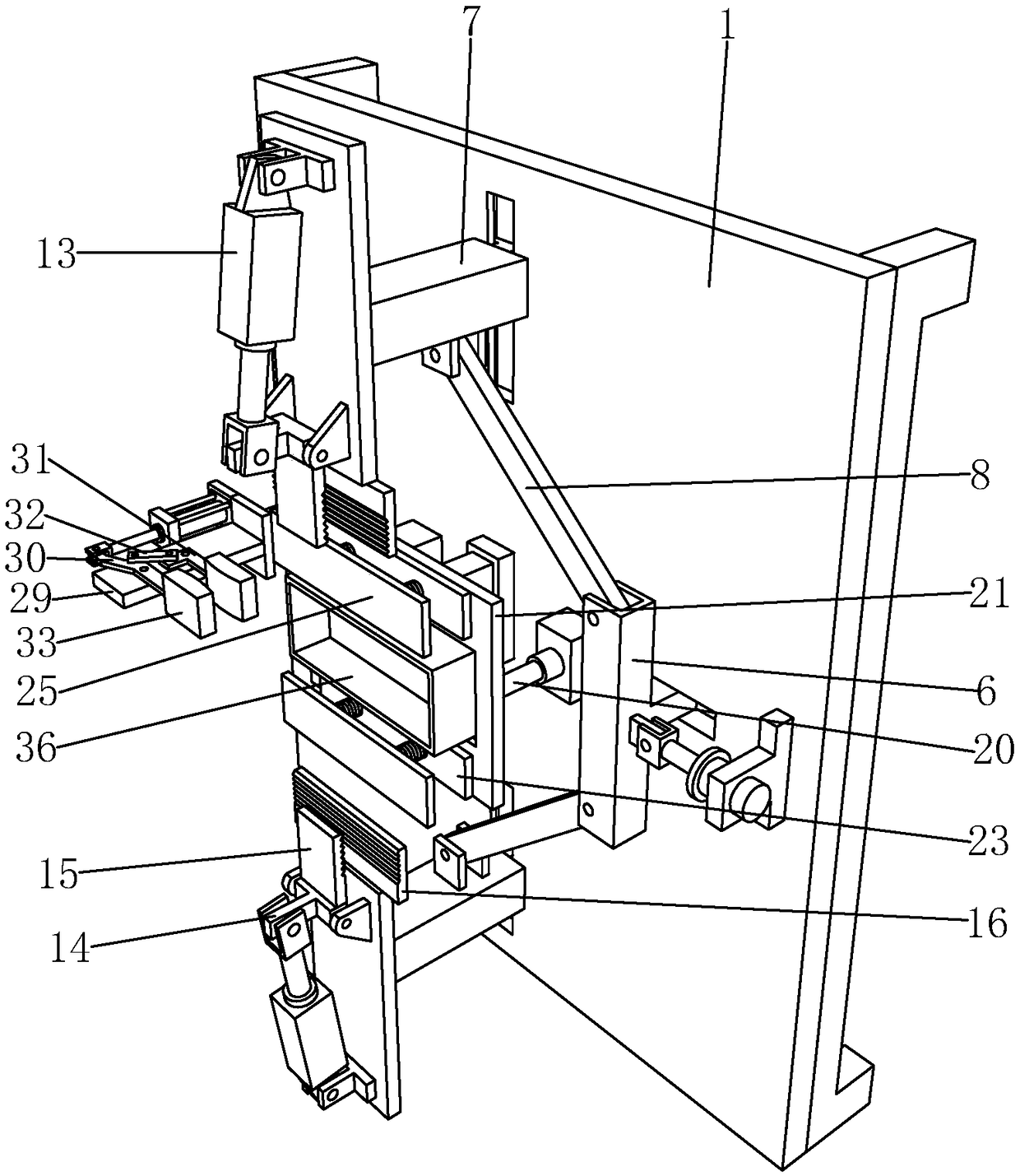

Positioning method, device and system for three-dimensional curved surface workpiece

ActiveCN110686655AHigh positioning accuracyAvoid affecting processing qualitySurveying instrumentsDot matrixEngineering

The invention belongs to the field of curved surface workpiece positioning, and provides a positioning method, a positioning device and a positioning system for a three-dimensional curved surface workpiece. The method comprises the steps of: intercepting patch features from the three-dimensional curved surface workpiece to generate a grid dot matrix according to theoretical parameters of key feature points; acquiring coordinates of a measurement sensor under a machine tool coordinate system; measuring the key feature points by means of the measurement sensor so as to determine coordinates of the key feature points under the machine tool coordinate system; carrying out iterative computation in the grid dot matrix according to measured values; determining a corresponding rotation matrix anda corresponding translation matrix according to a selected target grid point and the measured values; and calculating machine tool coordinates of a machining point position according to coordinates ofa point position to be machined, the rotation matrix and the translation matrix. Therefore, the finally obtained machining point is close to the actual machining position, and the positioning precision in the three-dimensional curved surface workpiece is greatly improved.

Owner:XIAN MICROMACH TECH CO LTD

Operation platform for cooker panel machining

The invention discloses an operation platform for cooker panel machining. The operation platform comprises a workbench, and a pushing mechanism, supporting bases and a stroke air cylinder are arrangedon the workbench; a U-shaped sliding plate is connected to one end of the pushing mechanism, vertical frames are slidably connected to the workbench, and transmission rods are arranged between the vertical frames and the U-shaped sliding plate; a clamping air cylinder and a T-shaped swinging base are connected to each vertical frame, each clamping air cylinder is connected with the top end of thecorresponding T-shaped swinging base, and an upper pressing plate is arranged on each T-shaped swinging base; a supporting clamping plate is arranged on one side of each vertical frame; a pushing plate is connected to the stroke air cylinder; and a supporting rod is arranged on each supporting base in a penetrating mode, a supporting flat plate is arranged between the supporting rods, and elasticsupporting bases are symmetrically distributed on the supporting flat plate. According to the operation platform for cooker panel machining, the structure is novel, adjustment is flexible, the operation platform can be suitable for machining operation of cooker panels with different sizes, the application range is wide, arrangement is steady, clamping and fixing are reliable, and machining operation is convenient.

Owner:绍兴阿利卡电器有限公司

Machining machinery for grooving and drilling

InactiveCN108247415AEasy to installReduce installation difficultyPositioning apparatusMaintainance and safety accessoriesStopped workCoupling

The invention disclose machining machinery for grooving and drilling, and relates to the technical field of machining machinery. The machinery comprises a box body, a supporting table is fixedly connected to the bottom of the inner cavity of the box body, a machining groove is formed in the middle of the top of the supporting table, rolling wheels are arranged at the bottom of the inner cavity ofthe machining groove, a rotating disc is arranged in the inner cavity of a transverse plate, a horizontal moving device is fixedly connected to one side of the bottom of the rotating disc, and the side, far away from the transverse plate, of the horizontal moving device is fixedly connected with a grooving and drilling device; and the output end of a first motor is rotationally connected with a connecting rod through a coupler, the end, far away from the first motor, of the connecting rod is fixedly connected with a supporting rod, and the end, far away from the connecting rod, of the supporting rod is fixedly connected with the rotating disc. When a machining part is replaced for the machinery or when the machinery stops working, a cutter retracts into a machining box, so that the problemthat the cutter collides with the machining part, then the cutter and the machining part are damaged, so that the machining quality is influenced is solved, the workpiece is convenient and easy to install, the difficulty is lowered, the time is saved, and the machining efficiency is improved.

Owner:HUZHOU JINGHENG MACHINERY CO LTD

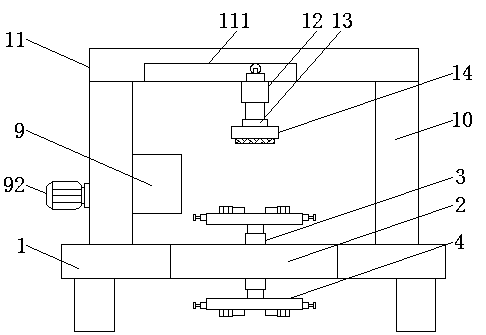

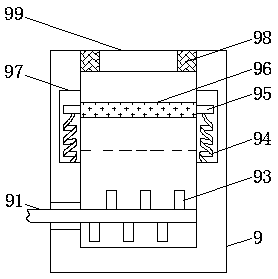

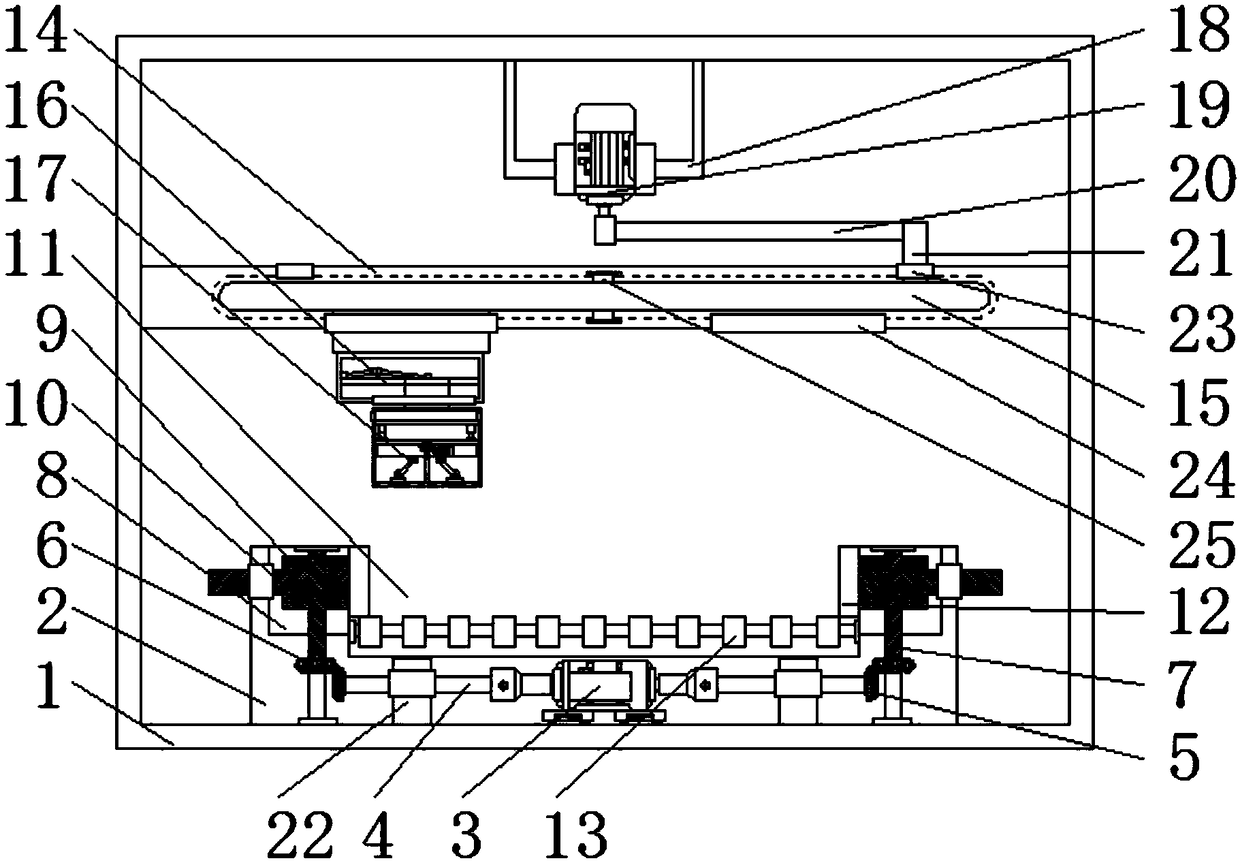

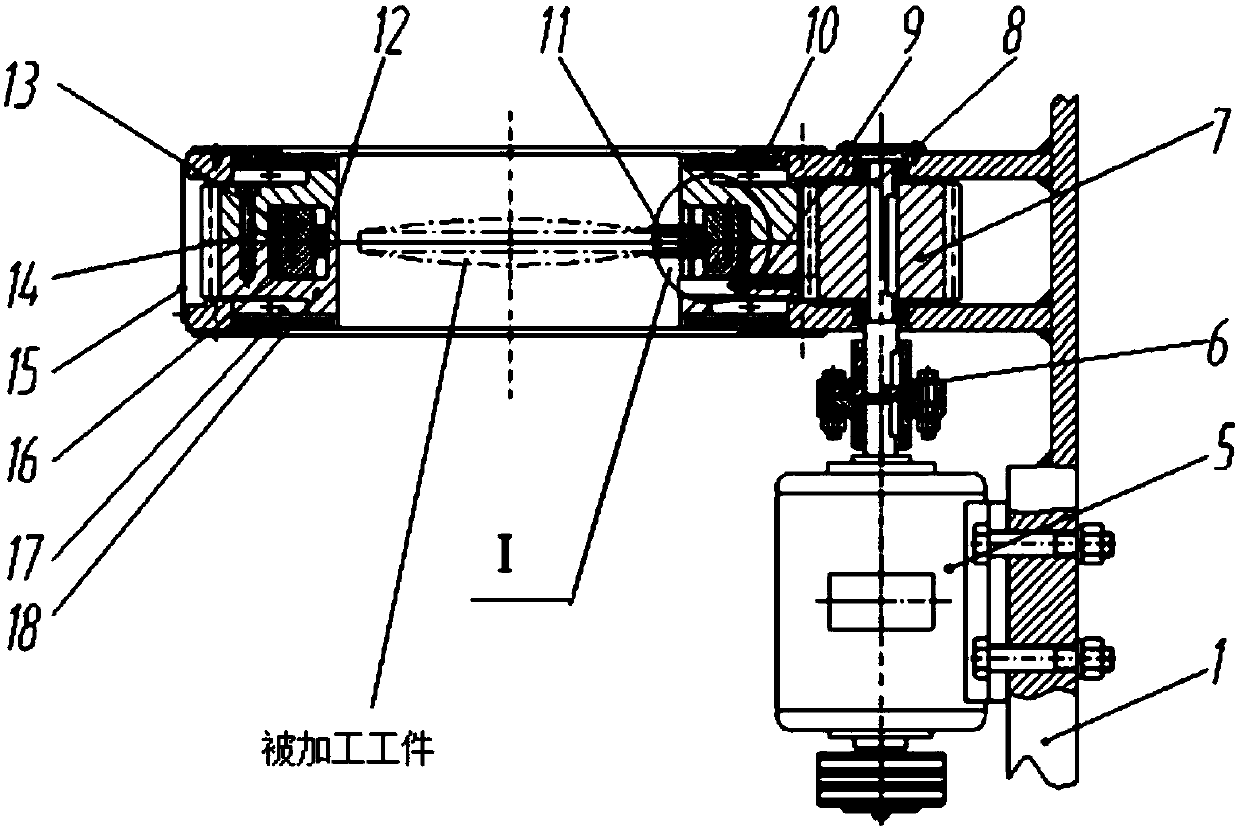

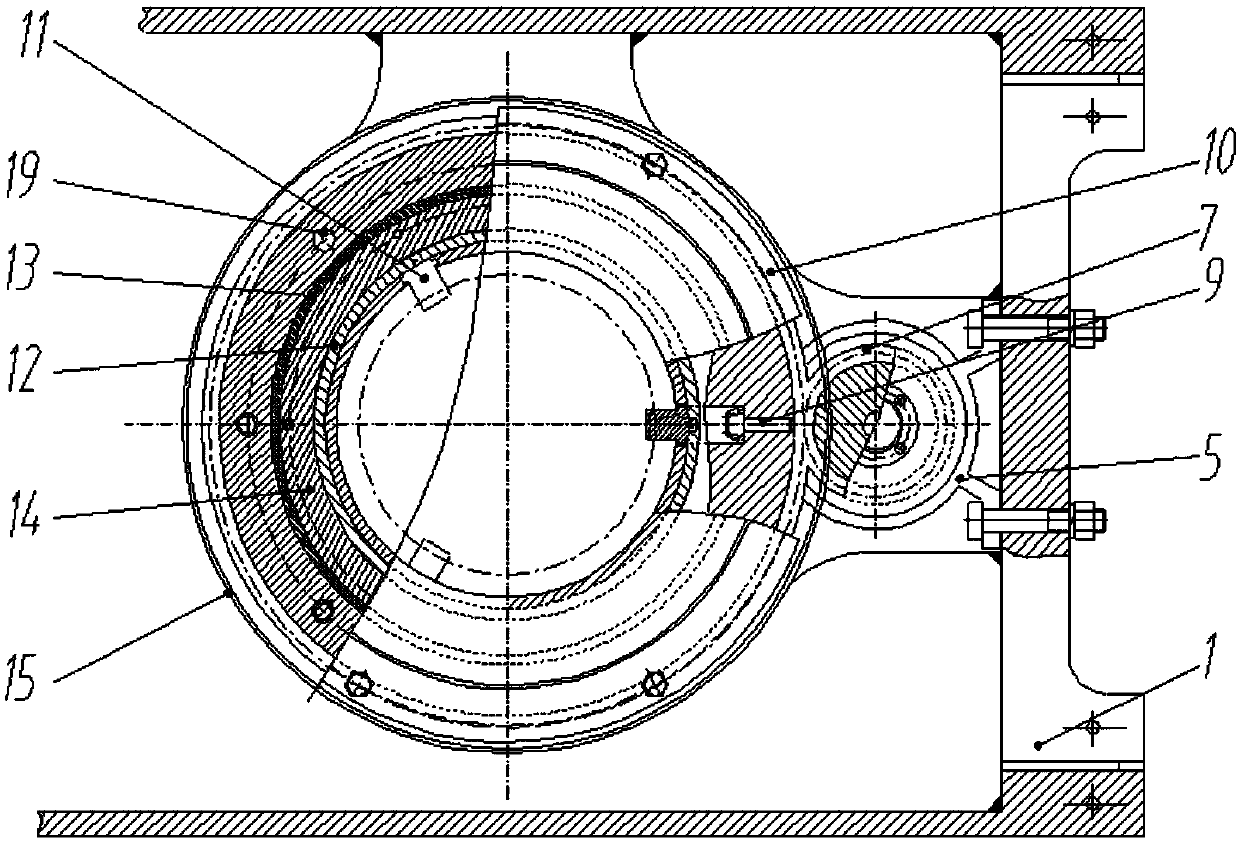

Magnetic grinder for two-sided disc small-curvature-surface component

PendingCN107617932AImprove processing qualityImprove processing efficiencyGrinding work supportsLinear motionEngineering

The invention discloses a magnetic grinder for a two-sided disc small-curvature-surface component. The magnetic grinder comprises a workpiece rotating mechanism, a workpiece clamping mechanism, a magnetic grinding head reciprocating linear motion mechanism and a magnetic grinding material collecting device. When the whole magnetic grinder is driven by a double-shaft output motor, a workpiece can rotate through gear transmission, and double-eccentric-crankshaft sliding blocks can be driven through belt transmission to assist a magnetic grinding head in reciprocating linear motion; the transmission ratio of the gear transmission to the belt transmission is 1:1, that is, the magnetic grinding head performs the reciprocating linear motion once when the workpiece rotates in a circle; under theaction of a magnetic brush, machining tracks on the workpiece can be uniformly distributed on the whole machining surface through the matching between the rotating motion and the reciprocating linearmotion; in the above process, the grinding material is collected by the magnetic grinding material collecting device, thereby improving the workpiece machining quality and efficiency; and accordingly,the magnetic grinder can be utilized for the finishing grinding of a high-precision large-diameter lens, and has an extensive application prospect in the field of high-precision machining.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

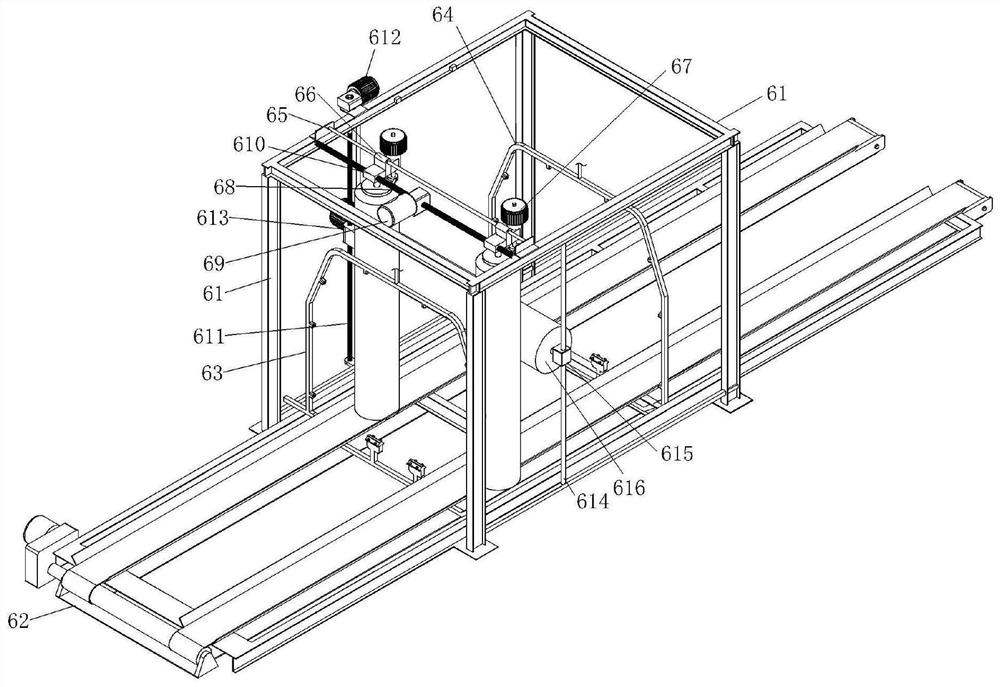

Surface treatment equipment for plastic products and use method of surface treatment equipment

ActiveCN112743408AImprove continuityImprove processing efficiencyGrinding carriagesPretreated surfacesStructural engineeringMechanical engineering

The invention discloses surface treatment equipment for plastic products and a use method of the surface treatment equipment, relates to the technical field of surface treatment equipment, and aims to solve the problems that various equipment needs to be used during surface treatment of the existing plastic products, but the continuity among the equipment is poor, so that the production and processing efficiency is seriously influenced. Six supporting legs are arranged at the lower end of a roller type conveying belt, and damping foot bases are arranged at the lower ends of the supporting legs. A storage cabinet is arranged among the supporting legs, a power distribution box is arranged on one side of the storage cabinet, and a power cabinet is arranged on one side of the power distribution box. Push rod bases are arranged on the two sides of the roller type conveying belt, the number of the push rod bases is six, and the six push rod bases are evenly distributed on the two sides of the roller type conveying belt in a pairwise alignment mode. Electric push rods are arranged at the upper ends of the push rod bases.

Owner:苏州锦坤模塑有限公司

Fully automatic table skirt machine

The invention provides a fully automatic table skirt machine, and relates to the field of table skirt machines. The machine comprises a working table, a side of the working table is provided with a bracket, the inside of the bracket is movably provided with a feeding roller, side plates are clamped to the two ends of one side, near the bracket, of the top of the working table, and a fixing shaft is movably mounted between the two side plates. According to the fully automatic table skirt machine, a motor drives a reciprocating plate to rotate through a belt, the reciprocating plate rotates to drive an interlocking shaft to swing in a reciprocating manner through a movable shaft, the principle of a crank arm connecting rod is formed, so that a rotating rod drives a rubber pleated shovel to swing back and forth, a material is shoveled into a plated shape to formed a skirt, the rubber pleated shovel is used, thereby avoiding the hard contact between the pleated shovel and the material, theexcessive contact is prevented from damaging the material, and a set pressure bar can be expanded and contracted inside a pressure cylinder to prevent the excessive contact from damaging the materialand affecting the processing quality.

Owner:廖其明

Auxiliary overturn mechanism for panel processing

InactiveCN112518691AEasy flipEasy to flip workCleaning using toolsWork benchesStructural engineeringMechanical engineering

The invention relates to the technical field of water purification equipment, in particular to an auxiliary overturn mechanism for panel processing. The auxiliary overturn mechanism for panel processing comprises a bottom plate and an overturn mechanism mounted above the bottom plate. According to the auxiliary overturn mechanism for panel processing, by arranging the overturn mechanism, it is convenient to overturn a frame by means of rotation between a rotating rod and a rotating block, so that timbers are overturned conveniently. By arranging a hairbrush, it is convenient to clean dust on the surfaces of the timbers. It is convenient to expand a sweeping range of the hairbrush by means of rotation between the sweeping rod and the rotating block, so that a role of improving the sweepingefficiency is exerted. By arranging a clamping device, it is convenient to drive a clamping rod to move up and down according to a threaded connection relationship between the clamping rod and a threaded through hole, so that it is convenient to contact and attach the clamping rod to a common panel to play a role of stabilizing the common panel, and therefore, a condition that the timbers are separated from placing grooves during overturning is avoided.

Owner:王永琦

Finished automobile pipeline connecting tool and working method thereof

PendingCN110480382AAvoid shakingEasy to processPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a finished automobile pipeline connecting tool. The finished automobile pipeline connecting tool comprises a pedestal, a base plate and a supporting rod; the base plate is arranged at the top of the pedestal; the edges of the two sides of the base plate are symmetrically provided with two rows of clamping slots; the part, positioned below each clamping slot, of the sidewallof the pedestal is provided with two clamping blocks; between every two clamping blocks is provided with a rotating shaft; the two ends of each rotating shaft are correspondingly arranged on the twocorresponding clamping blocks and are rotationally connected with the two clamping blocks; a first hydraulic cylinder is used for controlling a first hydraulic rod therein to move toward the outer side of the cylinder body so that the first hydraulic rod can push the top end of a supporting plate to move, thus a pressing disc moves down to tightly press the opening of a pipeline and fix the position of the pipeline; when the opening of the pipeline is warped, the first hydraulic cylinder is used for controlling the first hydraulic rod therein to move toward the inner side of the cylinder bodyso that the pressing disc moves upwards to make sure that the pipeline makes contact with the pressing disc and the position of the pipeline is fixed; shake of the pipeline is prevented when the pipeline is processed; and thus the processing quality is not affected.

Owner:ANHUI ANKAI AUTOMOBILE

Drilling machine and method for detecting abrasion loss of pressure foot on drilling machine

ActiveCN106514773AEasy to replaceAvoid affecting processing qualityMetal working apparatusEngineeringPRESSURE FEET

The invention discloses a drilling machine and a method for detecting the abrasion loss of a pressure foot on the drilling machine. The drilling machine comprises a workbench, a drilling mechanism located above the workbench, a dust suction cover and a detection mechanism for detecting the abrasion loss of the pressure foot mounted at the bottom of the dust suction cover; the drilling mechanism comprises a spindle and a cutter mounted on the spindle; a cutter yielding hole is formed in the workbench; the detection mechanism comprises a photoelectric sensor, a telescoping mechanism, a photoelectric sensor sensing seat for shielding the photoelectric sensor and a positon measuring device for measuring the positon of the spindle or the photoelectric sensor; and the dust suction cover is mounted on the telescoping mechanism and is located between the spindle and the workbench. Compared with the prior art, the drilling machine has the advantages that the detection mechanism for detecting the abrasion loss of the pressure foot is arranged, so that an alarm can be made for the pressure foot with the excessively large abrasion loss, an operator can change the pressure foot conveniently, and the machining quality is prevented from being affected.

Owner:SUZHOU VEGA TECH CO LTD

Steel bar bending device for circumferential fastening of crystallization tank

ActiveCN109604474AEasy to compressEasy to roll smoothMetal-working apparatusArchitectural engineeringWork in process

The invention discloses a steel bar bending device for circumferential fastening of a crystallization tank. The steel bar bending device for circumferential fastening of the crystallization tank comprises a workbench, wherein an inner mold plate, an outer mold plate and pressing plate mechanisms are arranged at the top of the workbench; the outer mold plate is arranged on the front side of the inner mold plate; the pressing plate mechanisms are arranged on two sides of the inner mold plate; an annular groove is formed in the outer side wall of the inner mold plate; a positive and negative motor is embedded on the inner mold plate; and the top of the positive and negative motor is connected with a first lifting mechanism through a rotating shaft. According to the steel bar bending device for circumferential fastening of the crystallization tank, the inner mold plate and the outer mold plate are used in combination, a steel bar is firstly subjected to press-fit to become a U-shaped semi-finished product, and then the pressing plate mechanisms and a rolling material pressing mechanism are matched to gradually perform press-fit on the two sides of the U-shaped semi-finished product andthe outer wall of the inner mold plate twice to form a steel ring finished product, while an outer circular plate and an inner cylinder are matched with the steel bar, so that the outer circular plate conveniently bends the outer side wall of the steel bar in a butting mode, and the inner cylinder conveniently presses the upper surface of the steel bar, and the inner cylinder conveniently rolls the upper and lower surfaces of the steel rod smoothly to avoid edge warping.

Owner:MAANSHAN WANXIN CASTING

Screw cap processing equipment with clamping structure capable of removing chips

InactiveCN110369813AAchieving the purpose of clearingImprove cleanlinessThread cutting machinesPositioning apparatusMechanical engineering

The invention discloses screw cap processing equipment with a clamping structure capable of removing chips and relates to the technical field of screw cap processing. The screw cap processing equipment comprises a bearing mechanism and a protecting mechanism. A storage mechanism is arranged on the inner side of the bearing mechanism, a limiting mechanism is placed above the storage mechanism, theprotecting mechanism is arranged above the limiting mechanism, and the top of the protecting mechanism is connected to the bearing mechanism. The screw cap processing equipment has the beneficial effects that according to the screw cap processing equipment with the clamping structure capable of removing chips, by arranging the limiting mechanism, the storage mechanism and the bearing mechanism andforming a sliding structure by a storage groove in the inner side of the storage mechanism with a box body through a slide bar and a chute, when a second electric push rod presses down the top of a screw cap and a device is started to process the screw cap, a tapping rod rotates to dive a joining ring and a rod body, so that a first pipeline drives the second electric push rod and a hairbrush padat the bottom of the second electric push rod to clean a gap between the screw cap and a fixed groove.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

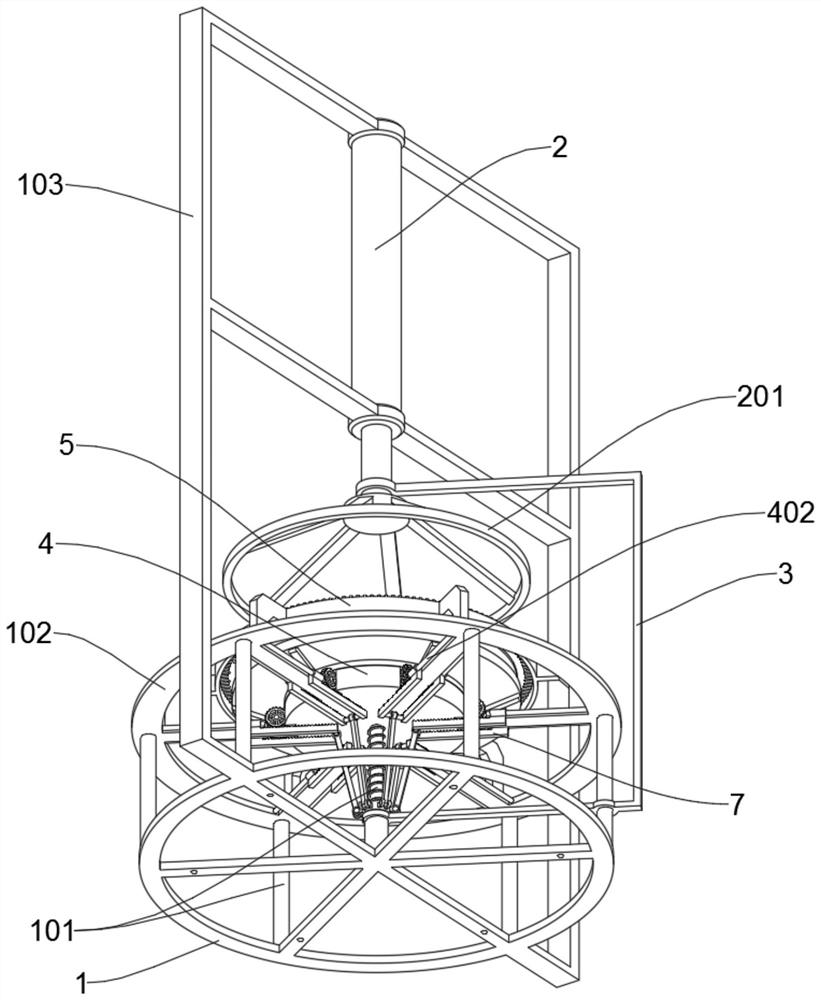

Gear ring and flywheel thermocompression bonding device

The invention discloses a gear ring and flywheel thermocompression bonding device, and relates to the technical field of thermocompression bonding processing equipment. The device includes a circular base; six vertical supporting shaft rods are welded to the top end of the circular base in a surrounding mode, where a force transmission piece is slidably installed on the vertical supporting shaft rod in the middle of the rear side, and a horizontal installation ring is welded to the top ends of the six vertical supporting shaft rods in a supporting mode. Six horizontal supporting rods are welded to the interior of the horizontal mounting ring in an annular array mode, a tray is welded and fixed to the centers of the six horizontal supporting rods and used for supporting and placing a flywheel, and a positioning lantern ring is welded and supported to the upper portion of the top end of the horizontal mounting ring and used for surrounding and sleeving a limiting gear ring; a vertical supporting frame is further welded to the top end of the circular base. According to the positioning lantern ring, the gear ring inserting fence can be kept in the horizontal state through the four clamping jaws in the positioning lantern ring, and the problems that the gear ring cannot be in horizontal butt joint with the outer ring of the flywheel, deflection is likely to happen in the press-fit machining process, and the machining quality is affected are solved.

Owner:王刚

Machining equipment for nickel-plated copper strip

ActiveCN111571357AUniform thicknessAchieve secondary molding operationsEdge grinding machinesGrinding carriagesMolding machineDust control

The invention provides machining equipment for a nickel-plated copper strip. The machining equipment for the nickel-plated copper strip comprises a fixing mechanism, a thickness forming mechanism, a width shaping mechanism, a burr removing mechanism, three dust removing mechanisms, a winding mechanism and a workbench; the fixing mechanism, the thickness forming mechanism, the width shaping mechanism, the burr removing mechanism and the winding mechanism are sequentially arranged on the workbench; one dust removing mechanism is located between the fixing mechanism and the thickness forming mechanism, the other dust removing mechanism is located between the width shaping mechanism and the burr removing mechanism, and the other dust removing mechanism is located between the burr removing mechanism and the winding mechanism. According to the machining equipment for the nickel-plated copper strip, secondary machining operation on the nickel-plated copper strip is achieved, and the nickel-plated copper strip which is uniform in thickness, consistent in width, smooth in edge and free of burrs can be conveniently and efficiently machined by a user at low cost.

Owner:惠州市岩邦科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com