Chip removing device for metal processing lathe

A metal processing and cleaning device technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of easily scratching the operator's skin, affecting the quality of metal processing, etc., to avoid processing quality and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

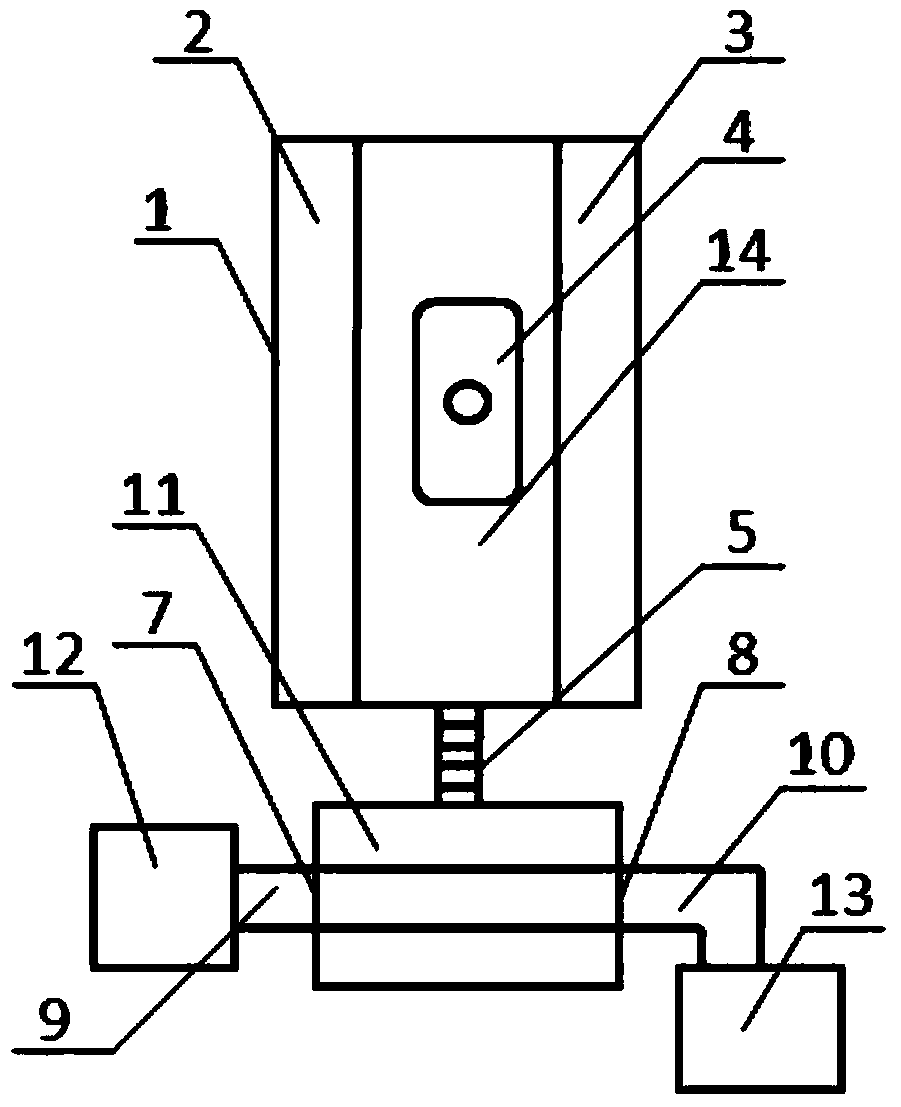

[0018] In order for examiners to better understand the technical features, technical contents and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments. However, the drawings shown are only for better illustration of the technical solutions of the present invention, not the true scale and optimal configuration of the present invention, so the examiner is requested not to limit the scope of the present invention with respect to the ratio and configuration of the drawings Scope of claims.

[0019] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

[0020] Such as Figure 1-3 As shown, the present invention includes a groove chamber 14 arranged on the lathe bed 1, the groove chamber 14 is a cuboid structure, and a suction cup 4 is fixedly installed at the bottom of the groove chamber 14, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com