Positioning method, device and system for three-dimensional curved surface workpiece

A technology of three-dimensional curved surfaces and workpieces, which is used in measuring devices, instruments, surveying and navigation, etc., and can solve the problems of deviation between the processing position and direction and the target processing position and direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

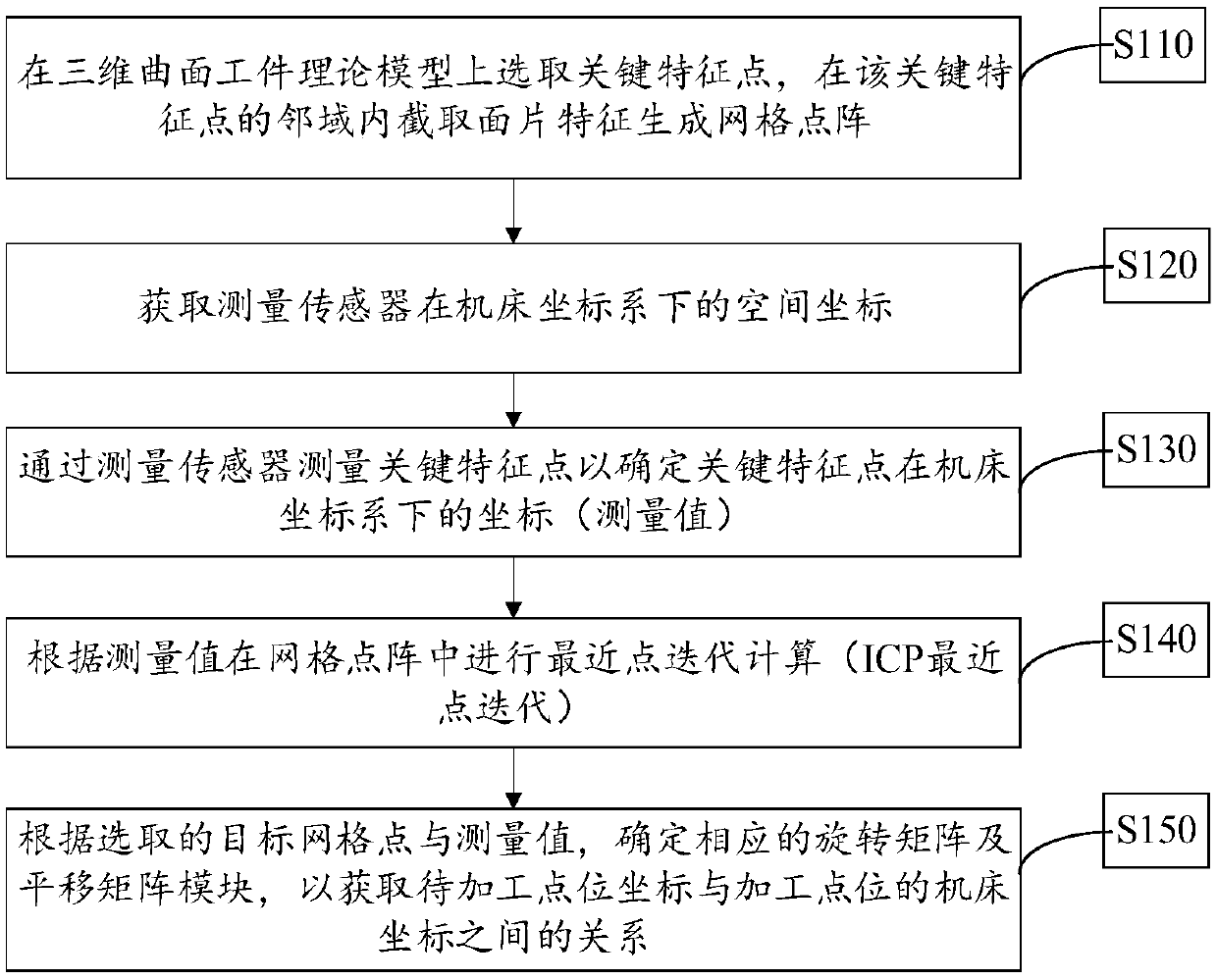

[0029] figure 1 It shows the implementation process of the positioning method of the three-dimensional curved surface workpiece provided by the first embodiment of the present invention. For the convenience of explanation, only the parts related to the embodiment of the present invention are shown. The details are as follows, which may include step S110, step S120, step S130, step S140, step S150:

[0030] In step S110, key feature points are selected on the theoretical model of the three-dimensional curved surface workpiece, and surface patch features are intercepted in the neighborhood of the key feature points to generate grid lattices.

[0031] The embodiments of the present invention are applicable to laser processing machine tools or traditional mechanical processing machine tools for positioning and processing three-dimensional curved surface workpieces.

[0032] In the embodiment of the present invention, a positioning system for a three-dimensional curved surface wor...

Embodiment 2

[0084] Figure 5 It shows the structural diagram of the positioning device for the three-dimensional curved surface workpiece provided by the second embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown, including:

[0085] The grid lattice generation module 110 is used to select key feature points on the theoretical model of the three-dimensional curved surface workpiece, and intercept surface features in the neighborhood of the key feature points to generate a grid lattice;

[0086] A sensor coordinate acquisition module 120, configured to acquire the spatial coordinates of the measurement sensor in the machine tool coordinate system;

[0087] The measurement value determination module 130 is used to measure the key feature point by the measurement sensor, and determine the coordinates of the key feature point in the machine tool coordinate system as the measurement value;

[0088...

Embodiment 3

[0104] Figure 6 The structure of the positioning system for a three-dimensional curved surface workpiece provided by the third embodiment of the present invention is shown, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0105] An embodiment of the present invention provides a positioning system 4 for a three-dimensional curved surface workpiece. The positioning system 4 for a three-dimensional curved surface workpiece includes a numerical control machine tool 61 , a measurement sensor 62 , a fixture 63 and a controller 64 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com