Auxiliary overturn mechanism for panel processing

A technology of turning over mechanism and plate processing, which is applied to wood processing appliances, workbenches, manufacturing tools, etc., can solve the problems of plate damage, labor consumption, affecting work efficiency, etc., so as to avoid shaking, expand the cleaning range, and stabilize ordinary plates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

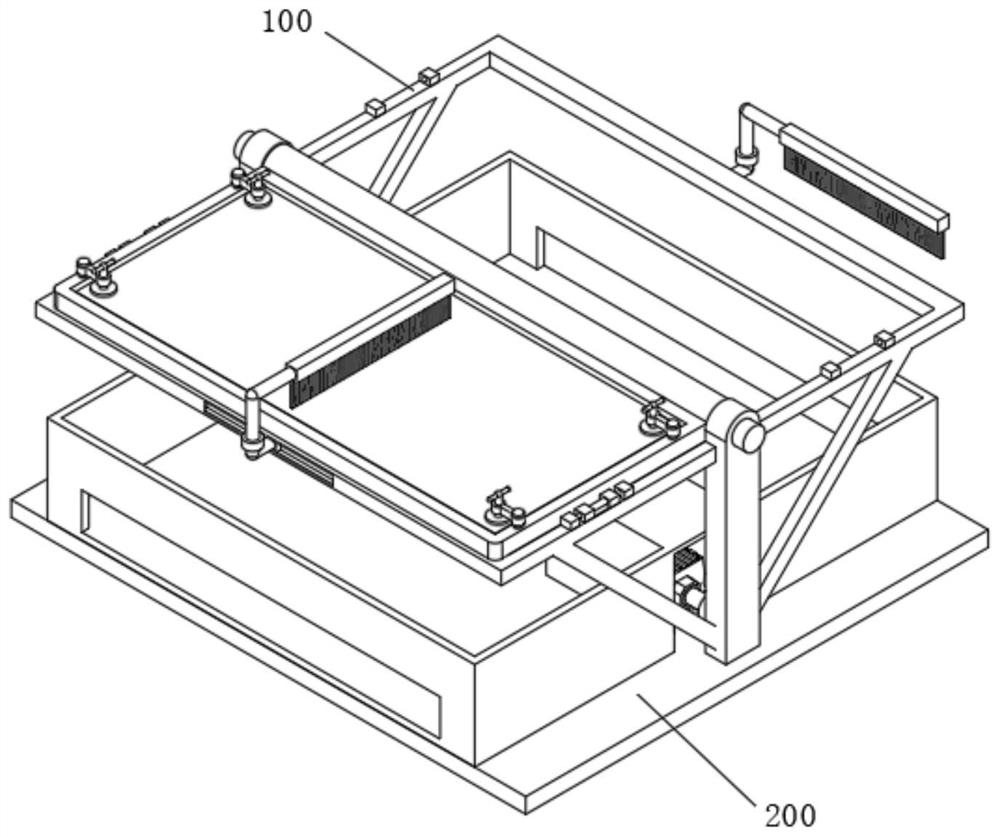

[0061] see Figure 1-Figure 13 As shown, this embodiment provides an auxiliary turning mechanism for plate processing, including a bottom plate 200 and a turning mechanism 100 installed above the bottom plate 200, and the turning mechanism 100 includes at least;

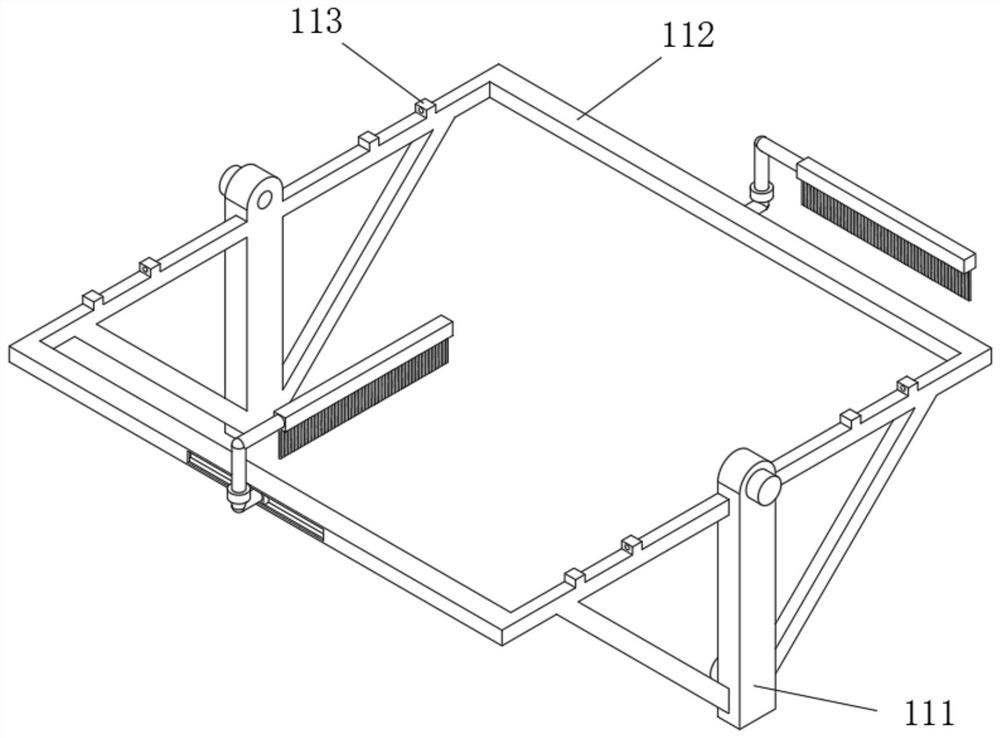

[0062] Supporting device 110, supporting device 110 comprises supporting leg 111, and supporting leg 111 is provided with two, two supporting legs 111 are respectively positioned at the left and right ends of base plate 200, and the bottom end of supporting leg 111 is fixedly connected with the upper surface of base plate 200, is convenient to The overturning mechanism 100 and the bottom plate 200 are fixed, and at the same time play a fixed role. Both sides of the top of the support leg 111 are fixed with a support frame 112. The support frame 112 is a frame structure, which is convenient for the discharge of sawdust during wood processing. The bottom end of 112 is provided with connecting leg 1121, and connecting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com