Dedicated compound tool suitable for helical hole milling of industrial robot lamination component

An industrial robot and helical milling technology, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of no special tools, etc., and achieve the effect of reducing machining chatter, reducing cutting force, and reducing delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

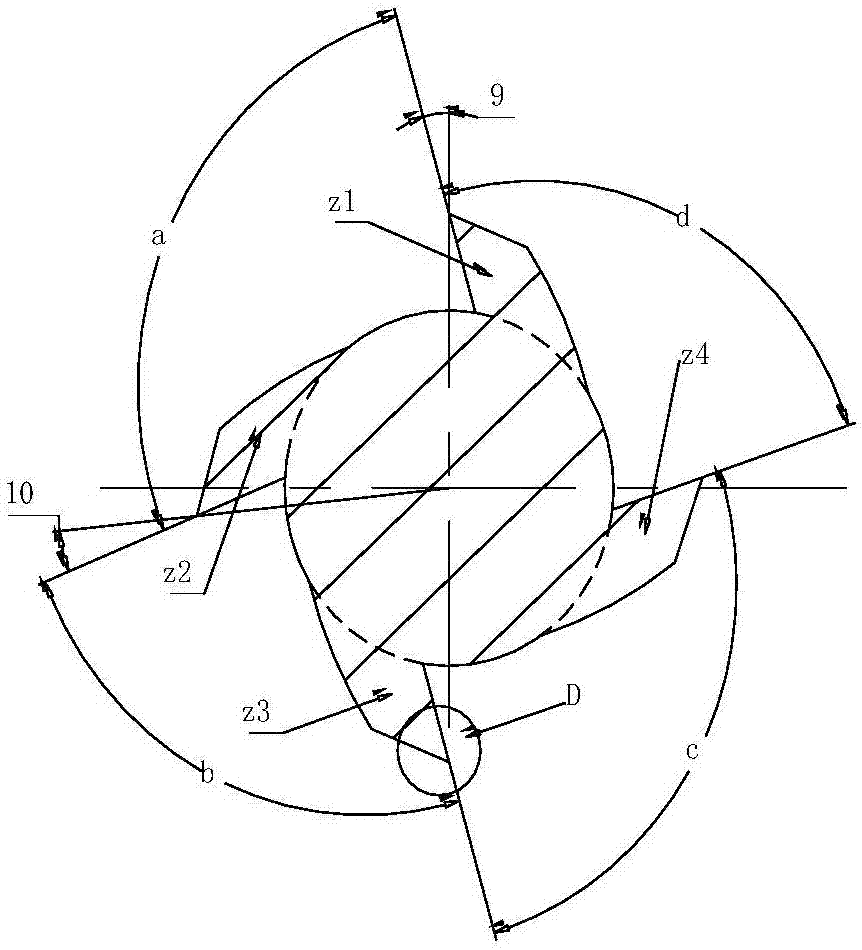

[0024] As an embodiment of the present invention, the angle a between the first helical cutting edge z1 and the second helical cutting edge z2 is 93°, and the angle b between the second helical cutting edge z2 and the third helical cutting edge z3 is 85°. °, the angle c between the third helical cutting edge z3 and the fourth helical cutting edge z4 is 87°, and the angle d between the fourth helical cutting edge z4 and the first helical cutting edge z1 is 95°. The rake angle 9 of the first helical cutting edge z1 and the third helical cutting edge z3 is 7°, and the rake angle 10 of the second helical cutting edge z2 and the fourth helical cutting edge z4 is 9°; The first relief angle 13 of the side edge of the four helical cutting edges of a blade part 2 is 15°, and the second relief angle 14 of the side edge is 19°; the length 11 of the first relief angle of the side edge is 0.7mm, so The total length 12 of the first rear angle of the side edge and the second rear angle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com