Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

274results about "Rotation direction control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

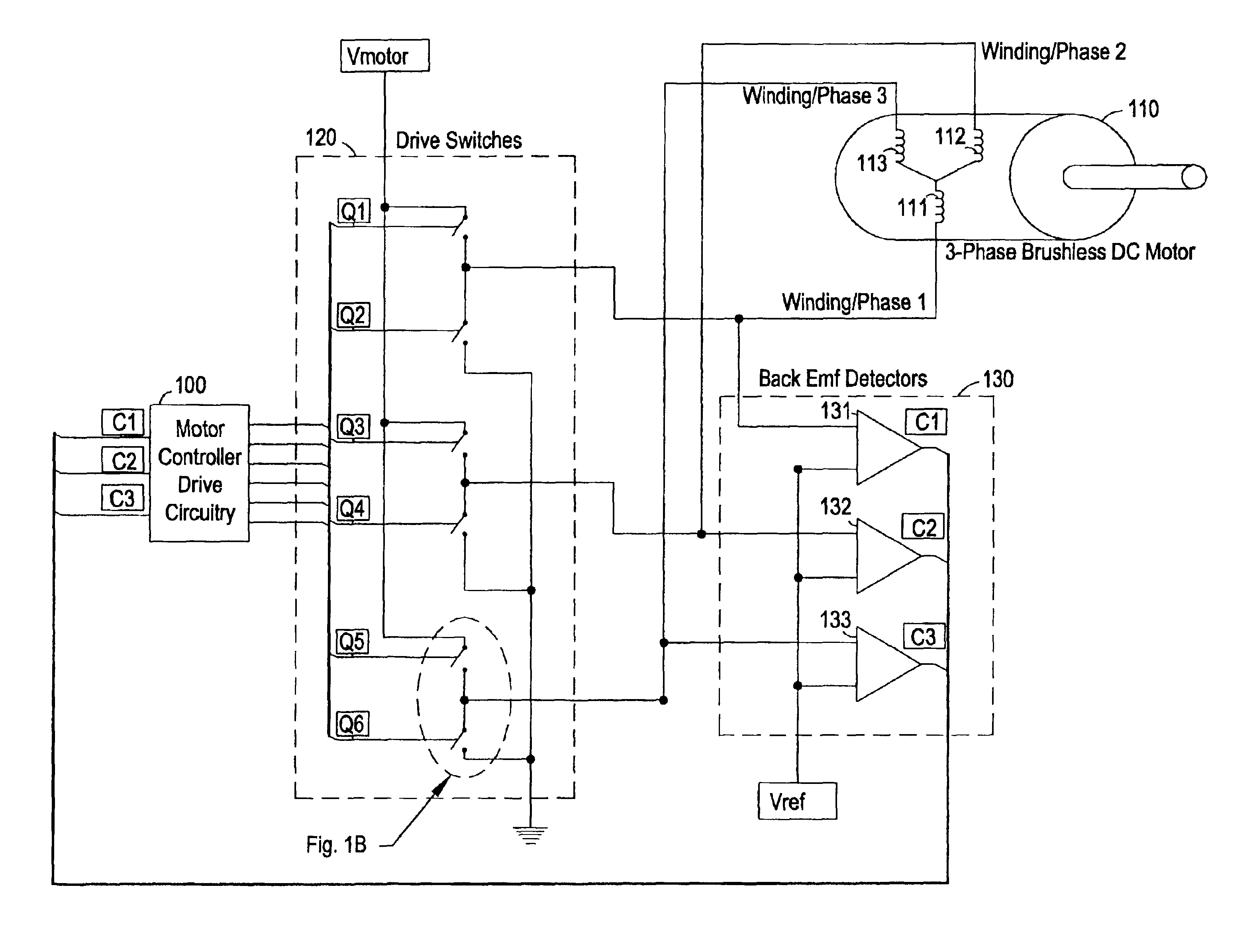

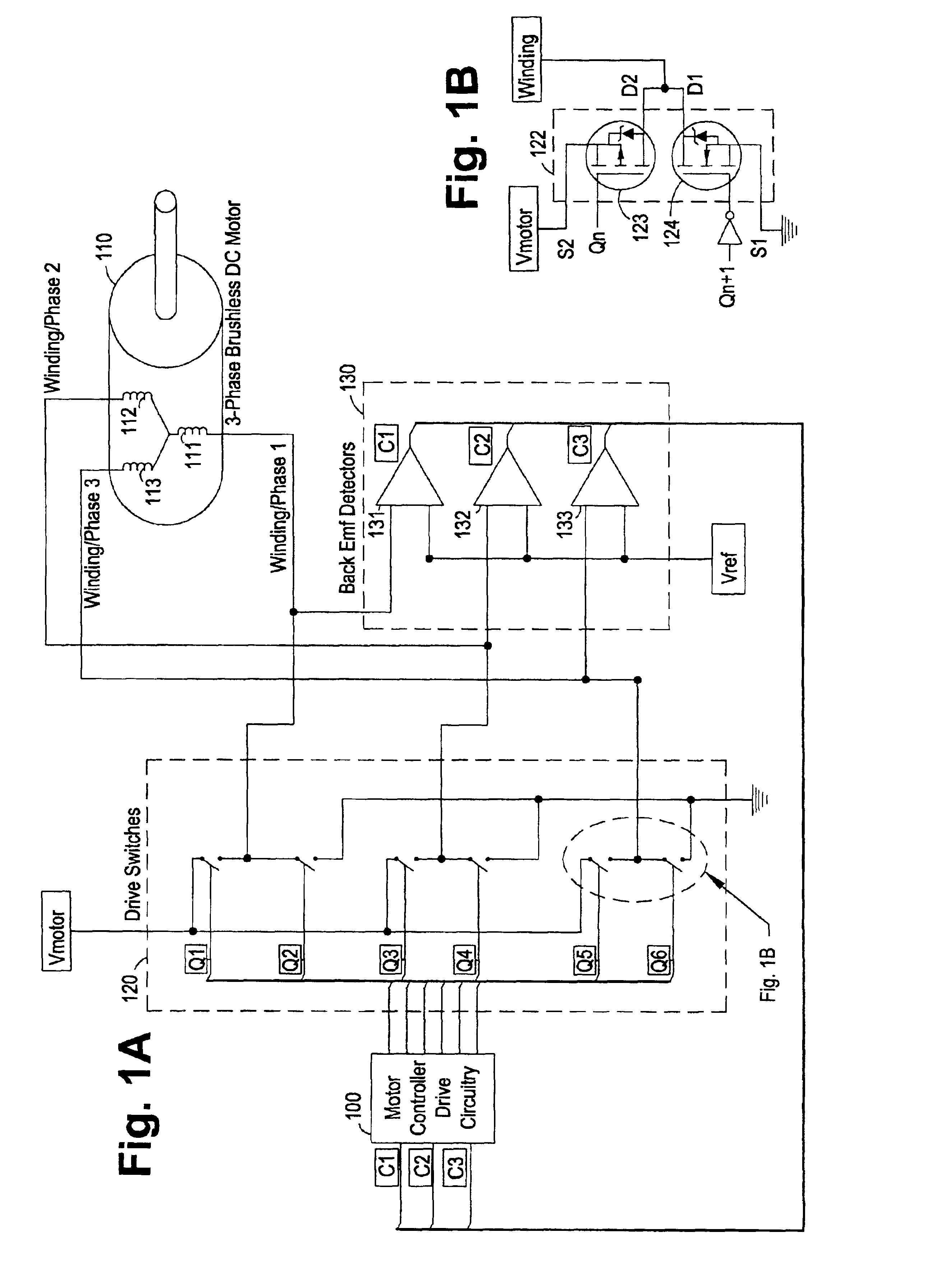

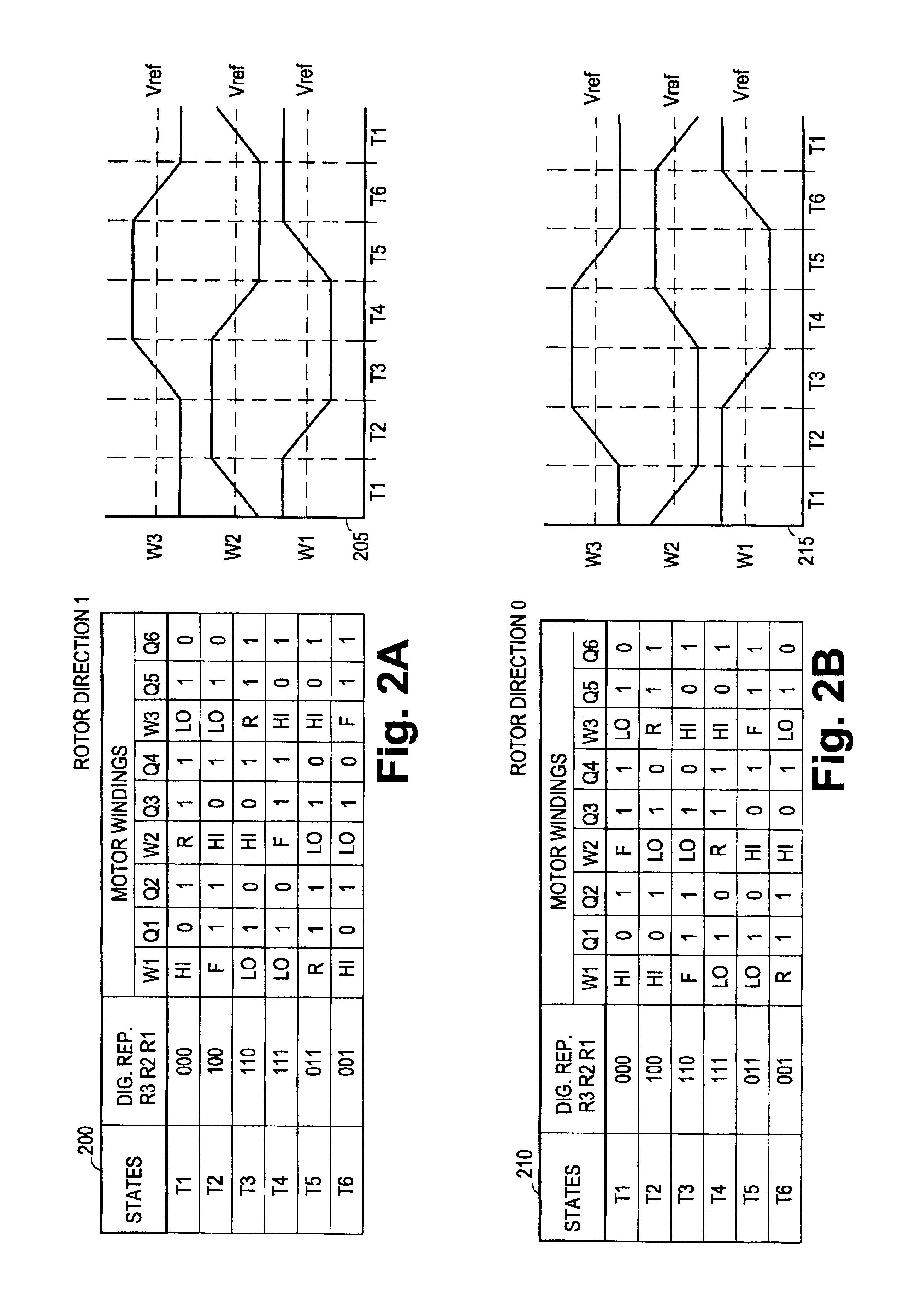

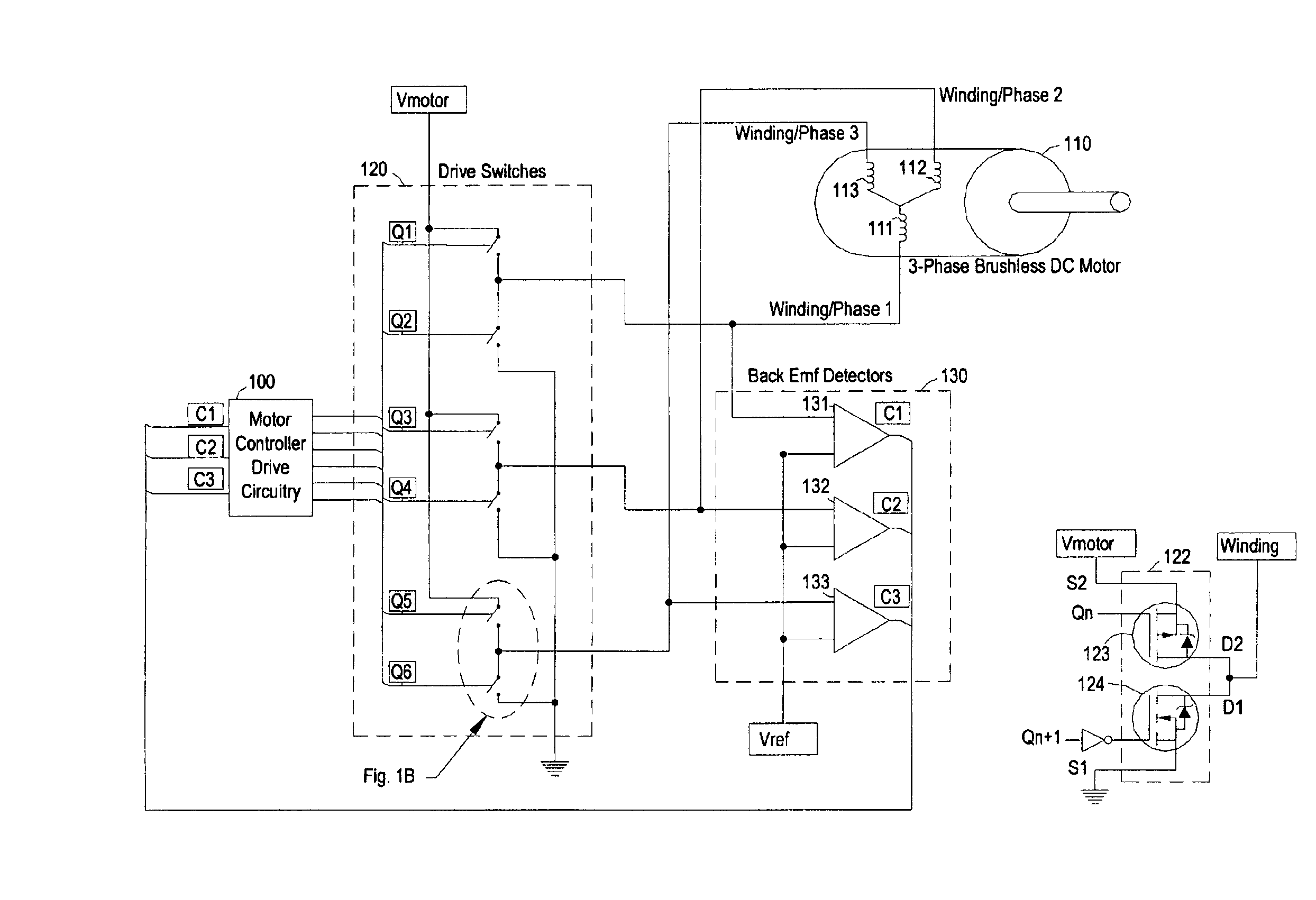

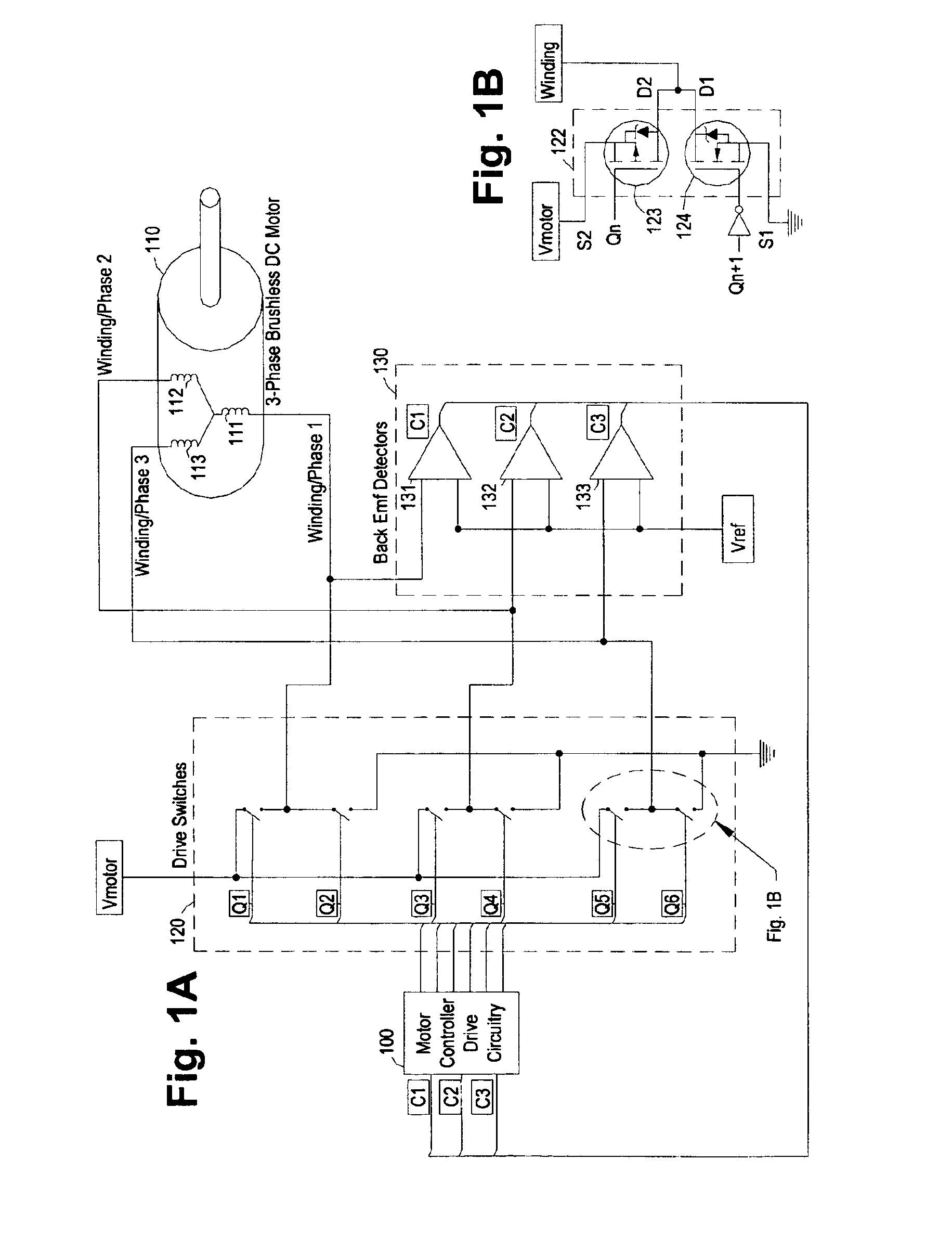

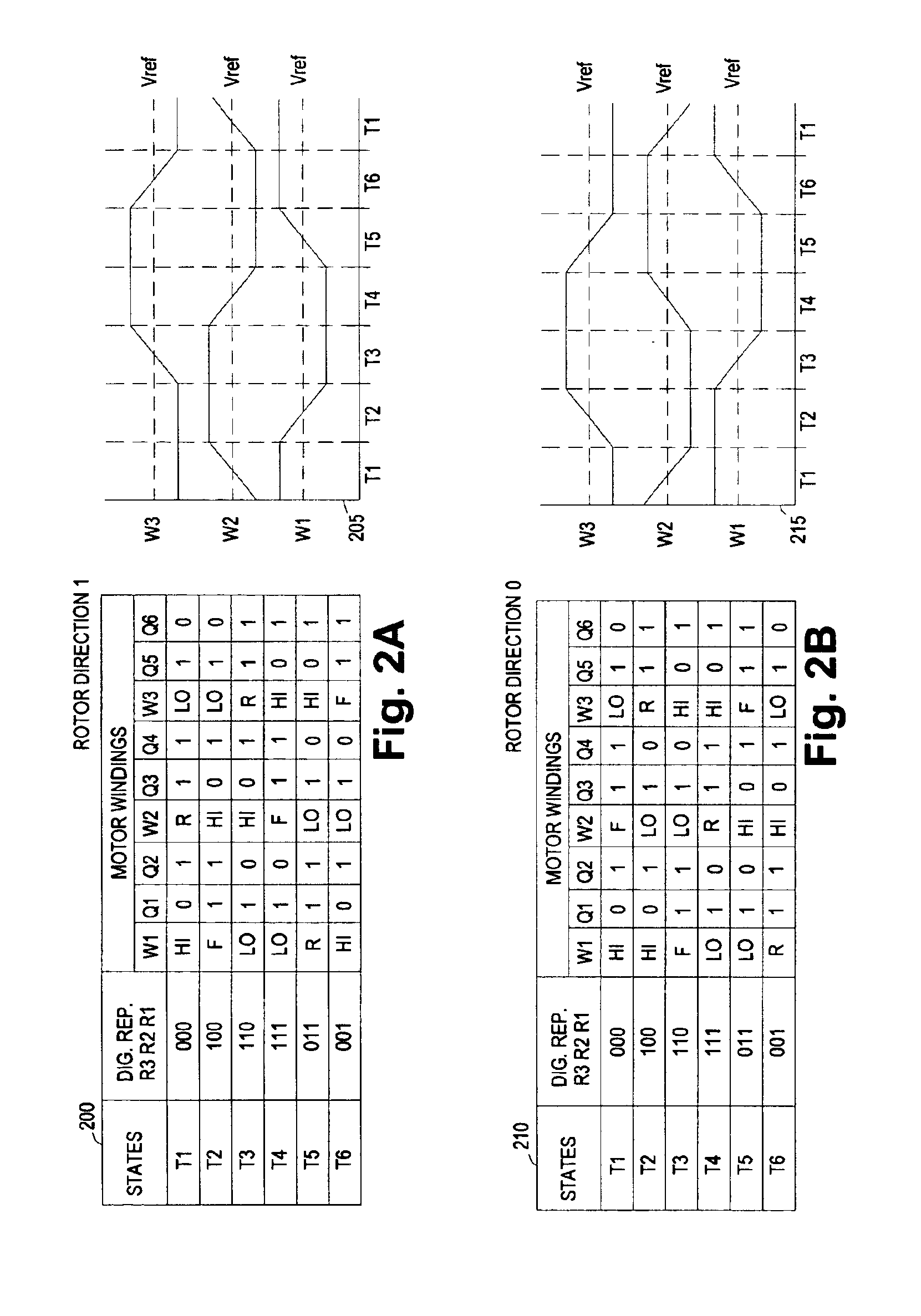

Digital adaptive sensorless commutational drive controller for a brushless DC motor

InactiveUS6901212B2Efficient startMotor/generator/converter stoppersCommutation monitoringControl signalProgrammable logic device

A digitally adaptive controller circuit for commutating a brushless, sensorless, DC motor in either of two directions adapted to receive digital back electromotive force (BEMF) detector signals. The digital circuit is driven by an input clock that is adjustable to configure the motor controller for use with a broad range of DC motors. The circuit includes commutational logic that decodes a current commutational state and a user-definable binary direction input into logic levels for digital control signals for controlling motor drive switches. The circuit also includes a signature analyzer to compare logic levels in the BEMF detector signals with expected logic levels based on an expected rotor position and direction of rotation. The digital circuit commutates the motor if the logic levels in the BEMF detector signals are at the expected logic levels. The digital circuit is compact and simple enough to be deployed onto a single programmable logic device.

Owner:HALLIBURTON ENERGY SERVICES INC

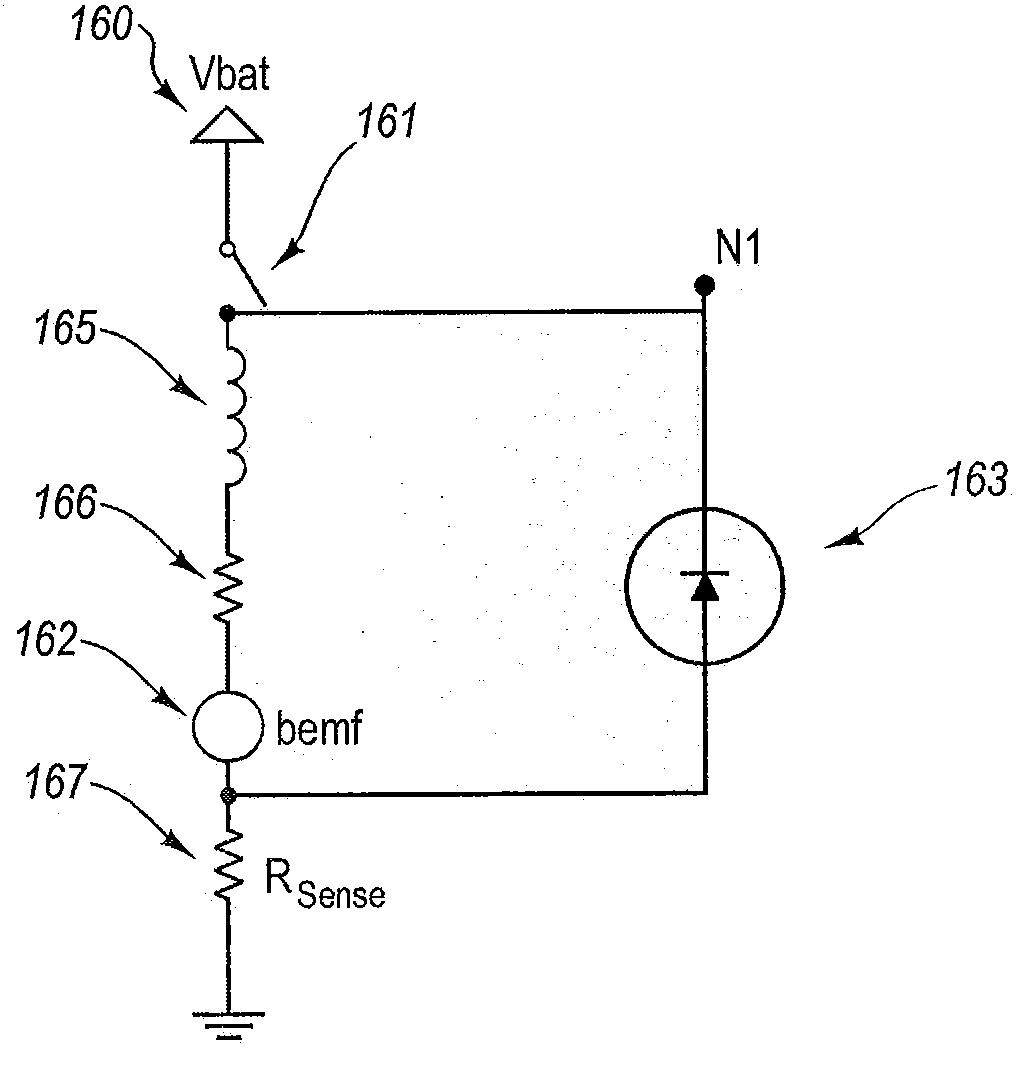

Digital adaptive sensorless commutational drive controller for a brushless DC motor

InactiveUS7030582B2Commutation monitoringSynchronous motors startersVoltage polarityElectrical polarity

Devices and methods for controlling brushless, sensorless DC motors are disclosed. In one embodiment, an electrical motor is provided with a rotor, a stator, and a semiconductor on insulator (SOI) application-specific integrated circuit (ASIC). The ASIC is configured to energize stator windings in a commutational sequence to drive the rotor. A motor controller embodiment is provided with a set of comparators and a clocked digital circuit. Each comparator determines a voltage polarity on a respective stator winding. The clocked digital circuit receives polarity signals from the comparators and detects zero crossings having an expected crossing direction, which are then used to determine a commutational sequence for energizing stator windings. A method embodiment is provided for driving DC motor windings. One method embodiment includes: receiving polarity signals, measuring intervals, and advancing a commutation state.

Owner:HALLIBURTON ENERGY SERVICES INC

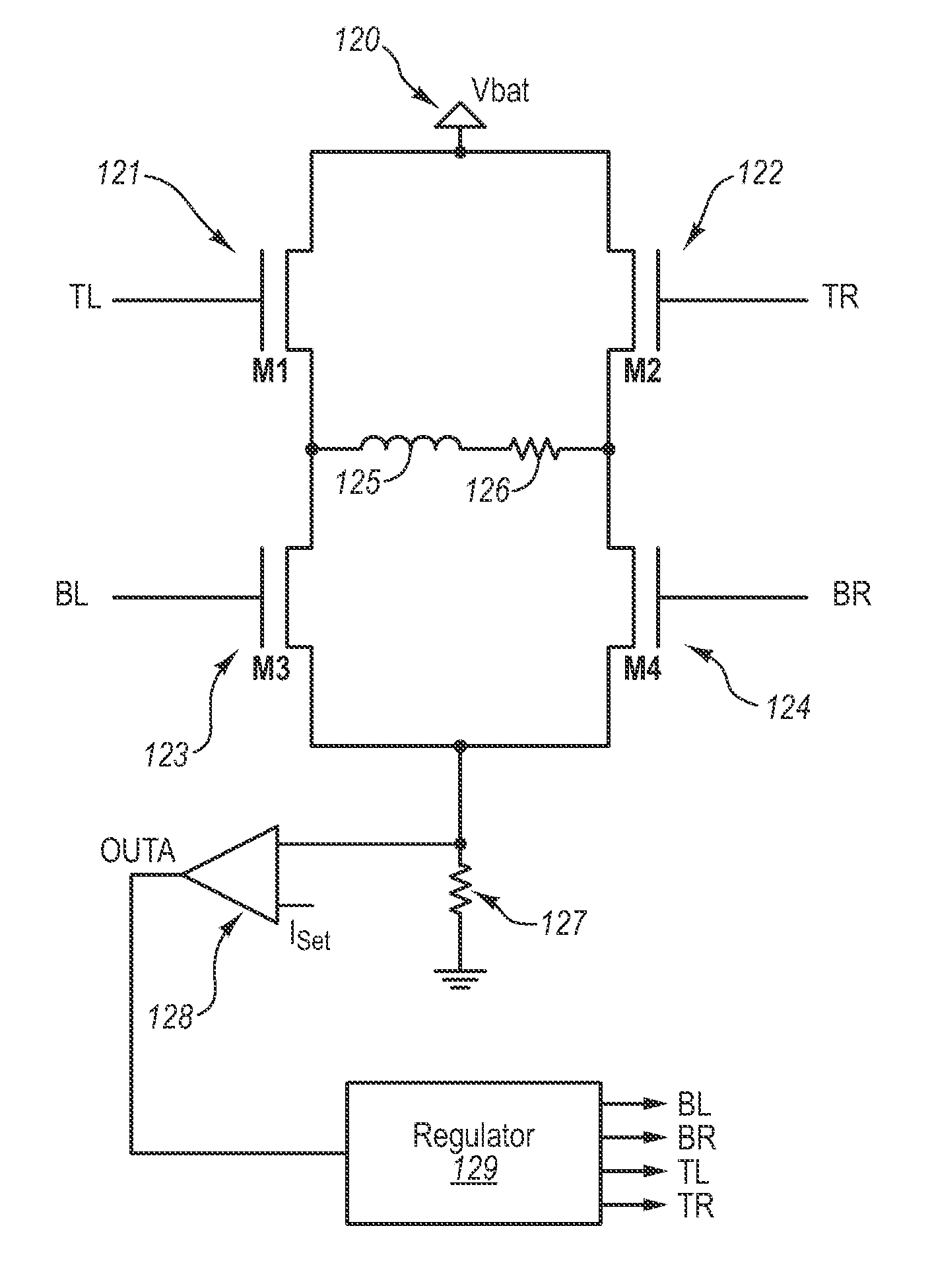

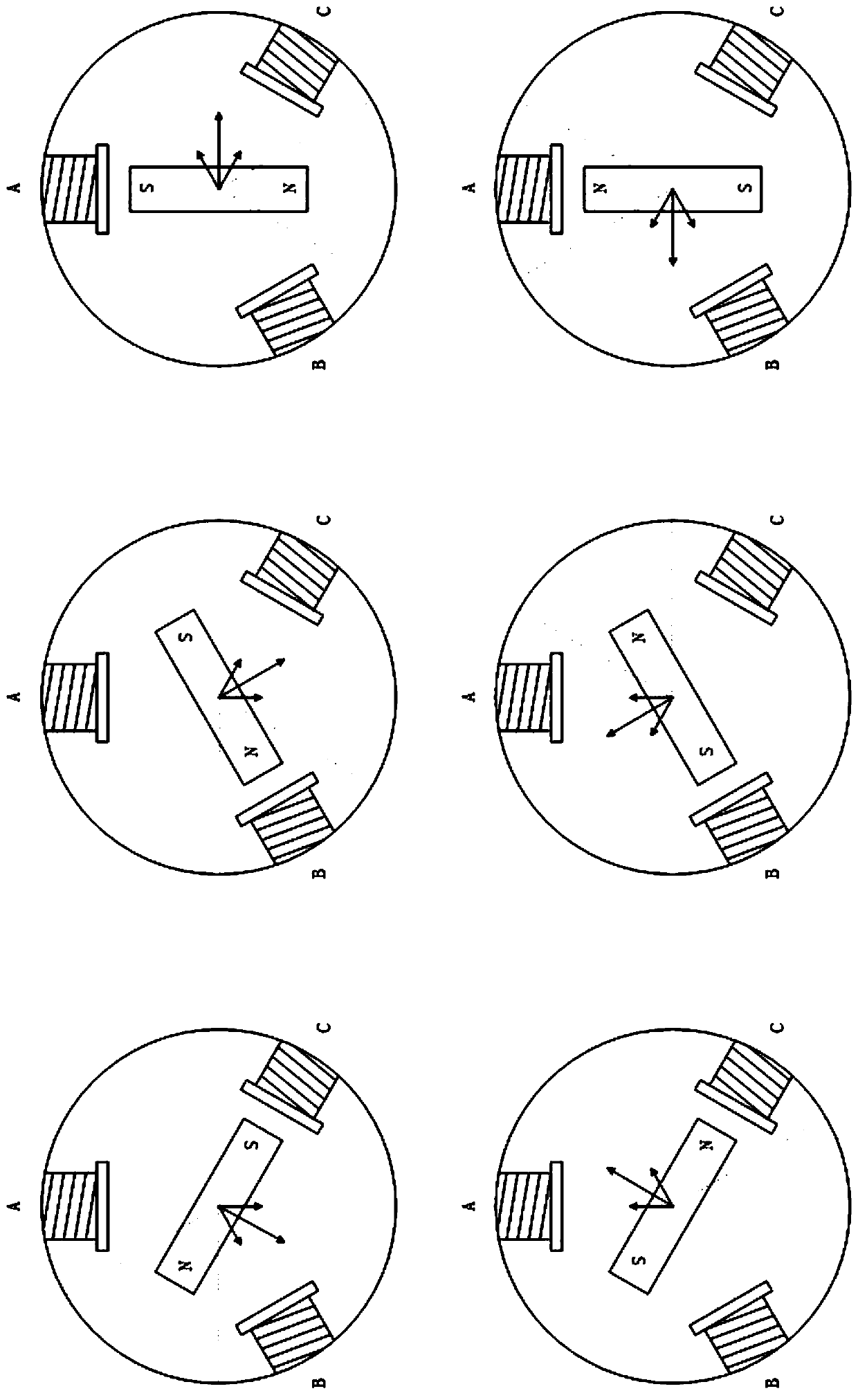

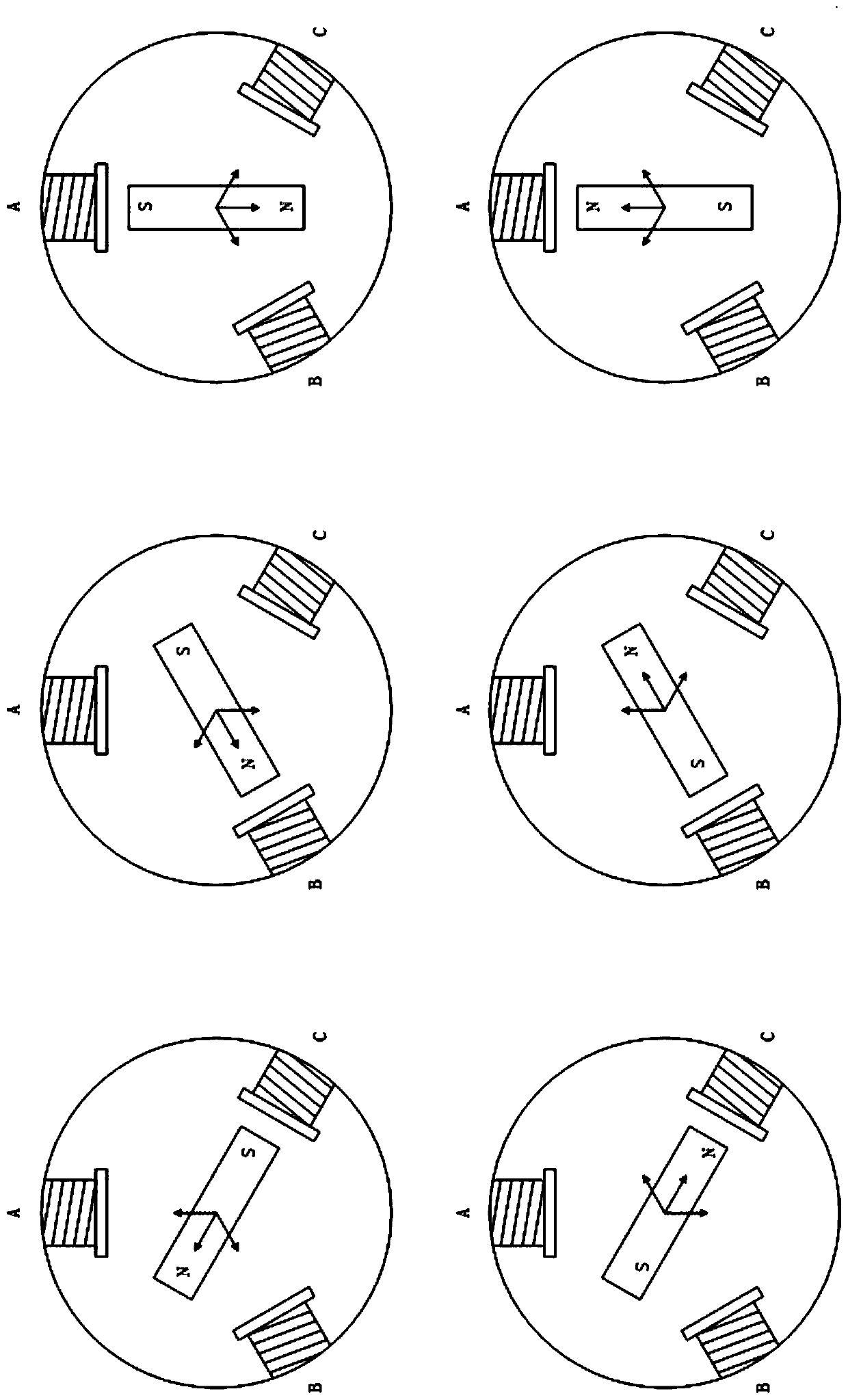

Method and apparatus for driving a DC motor

ActiveUS20080197794A1Synchronous motors startersDC motor speed/torque controlControl signalEngineering

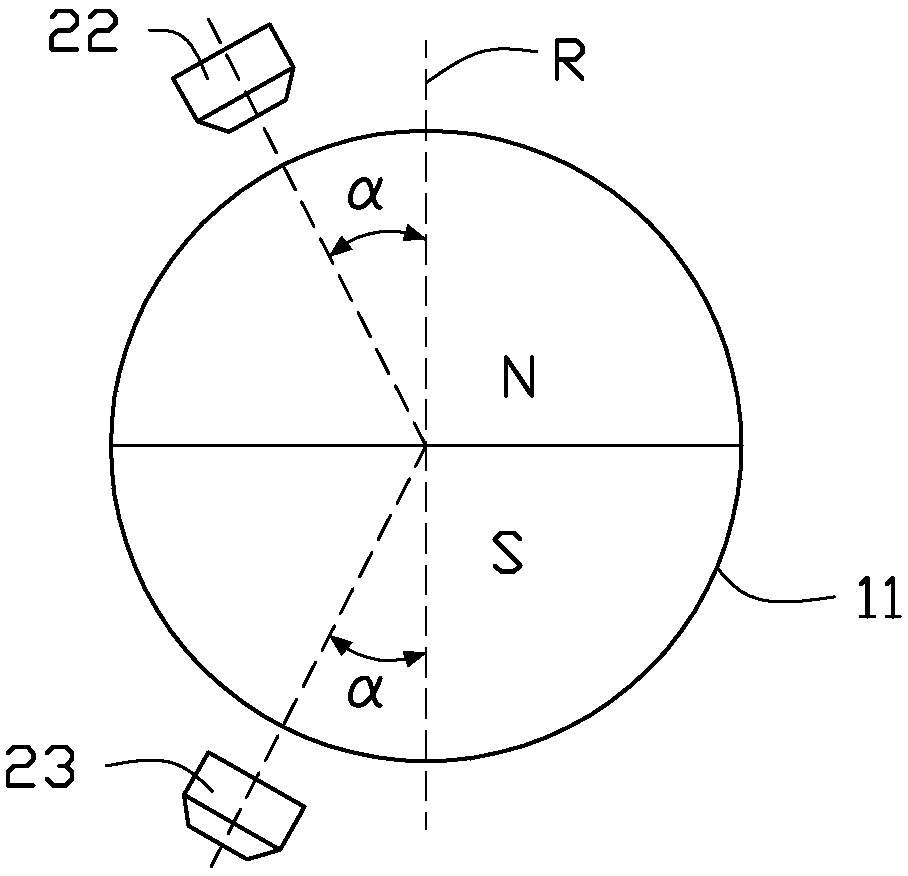

A circuit for determining a direction of rotation of an electric motor, the motor having asymmetry and / or eccentricity in a profile of back electromotive force as a function of angular position of a rotor with respect to a stator, the circuit receiving a signal representing the BEMF, and use the corresponding asymmetry and / or eccentricity in the signal to derive the direction of rotation. The signal representing the back emf can be generated by a control circuit. The control circuit can have a feedback loop regulator to generate a control signal (TL or TR) to control a current drive circuit (11,12) to control an amplitude of current (iw) in the windings, the feedback loop regulator being arranged to compare the amplitude of the current (iw) in the windings with a reference value (iset), and use the control signal to provide the signal representing the back electromotive force.

Owner:AMI SEMICON BELGIUM

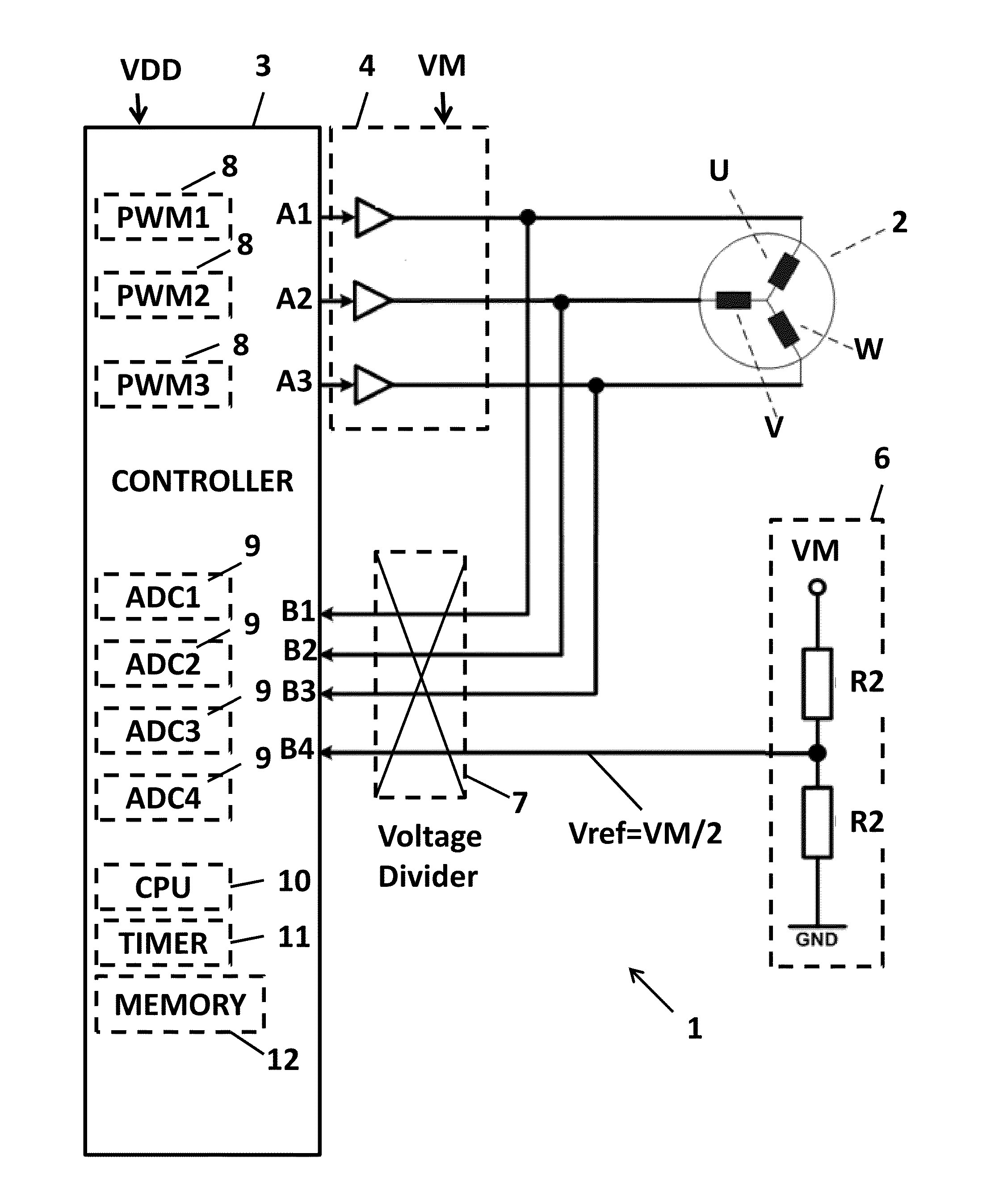

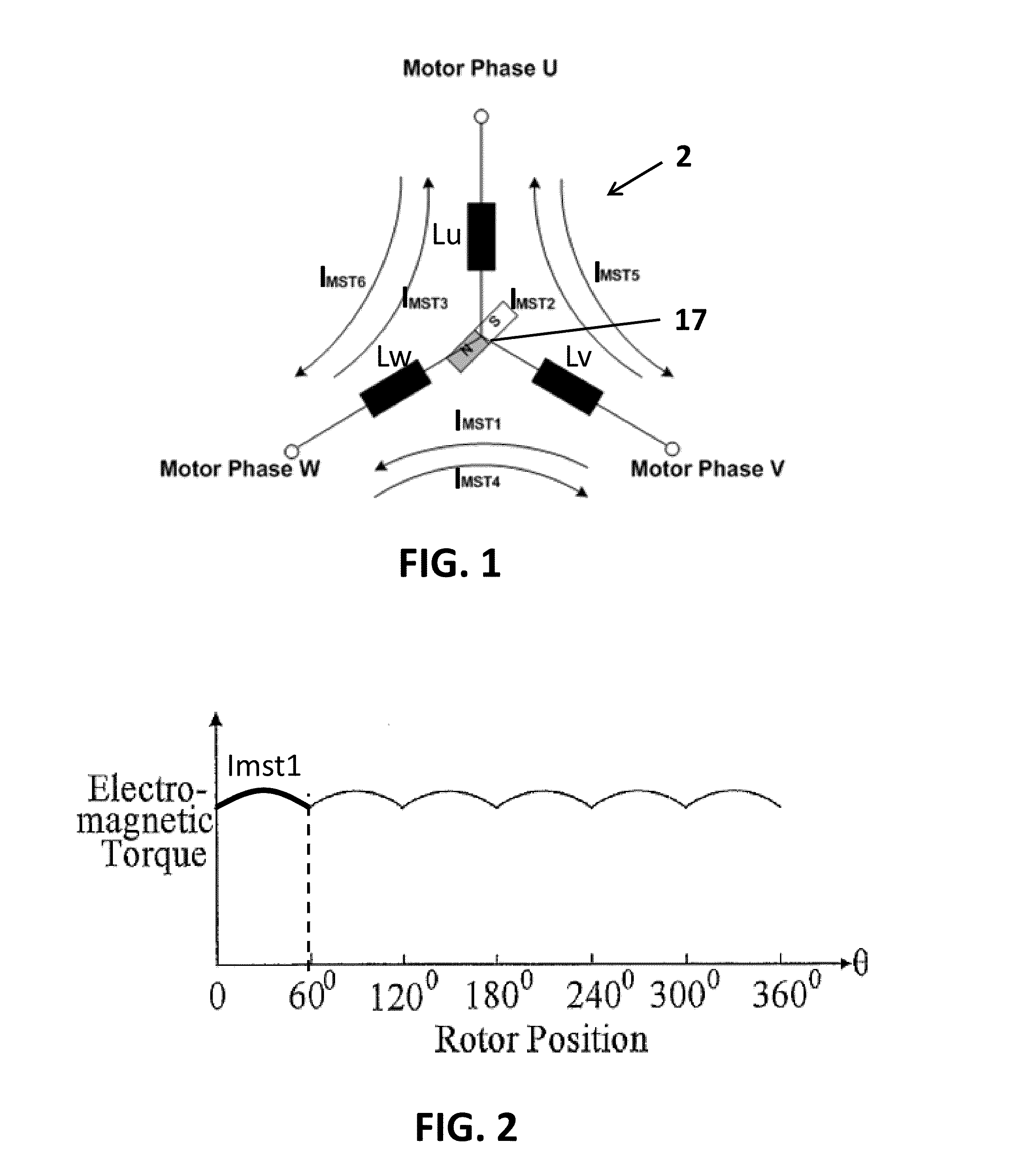

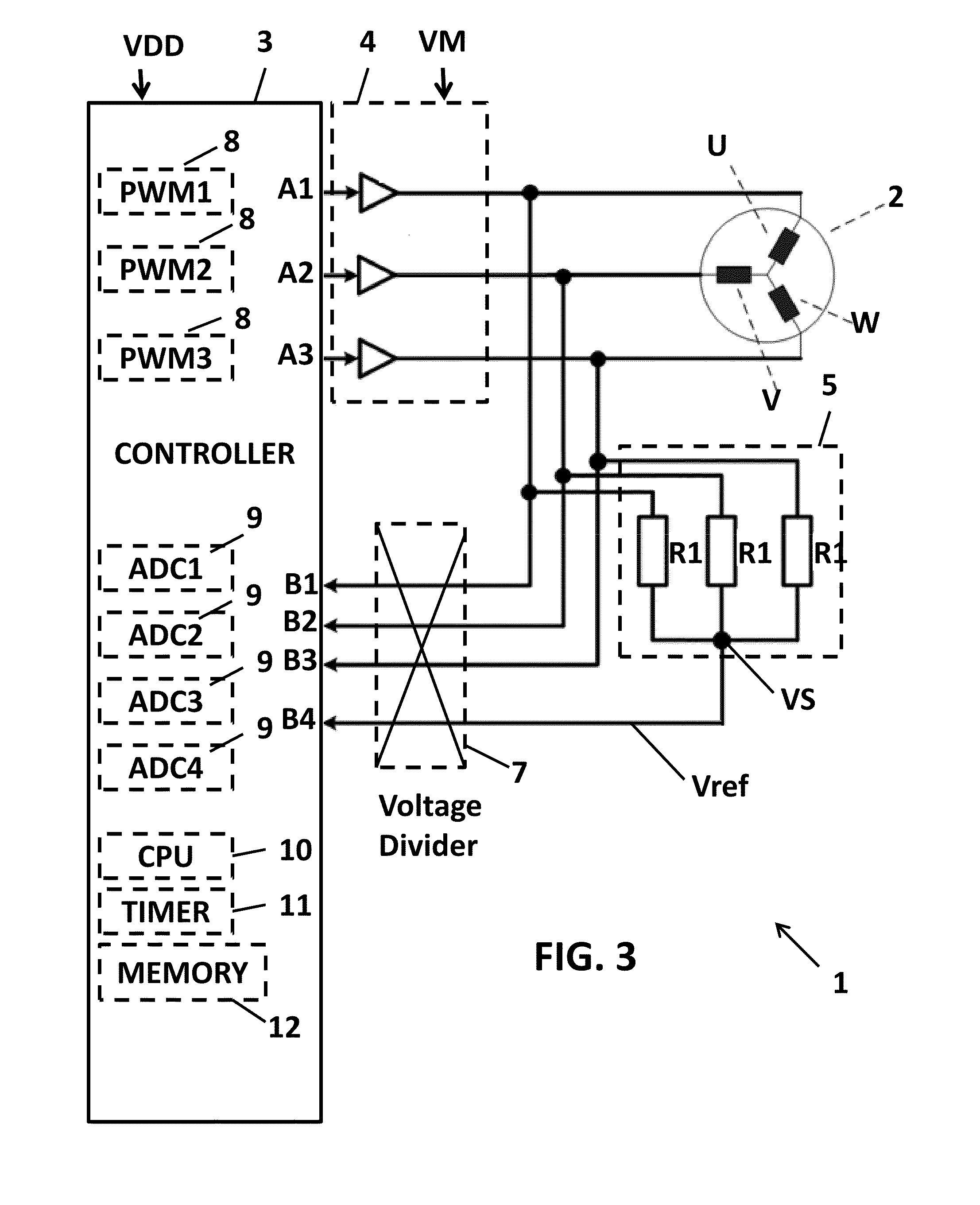

Method and apparatus for driving a sensorless bldc/pmsm motor

ActiveUS20140062364A1Reduce complexityMotor/generator/converter stoppersSynchronous motors startersElectric machineTime segment

A method for driving a BLDC motor comprising at least three stator windings, comprising: a) determining a time period, and energizing during the time period two of the windings and leaving a third winding un-energized, based on a first motor state; b) measuring a first voltage representative for the back-EMF generated in the un-energized winding shortly before expiry of the time period; c) applying a commutation at expiry of the current time period; d) measuring a second voltage shortly after the commutation, and calculating a subsequent time period; e) repeating steps b) and c). An electrical circuit and a controller are provided for performing these methods.

Owner:MELEXIS TECH NV

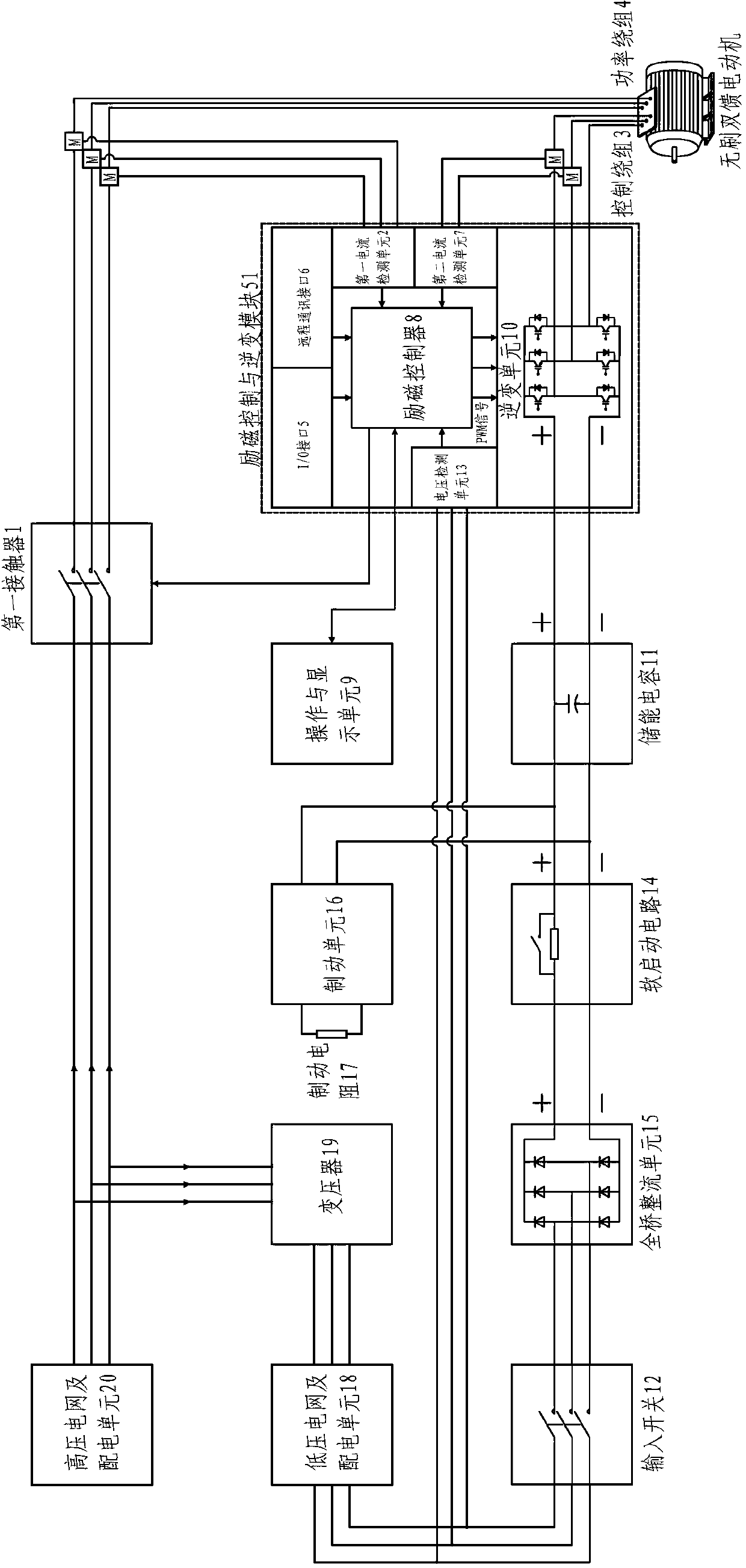

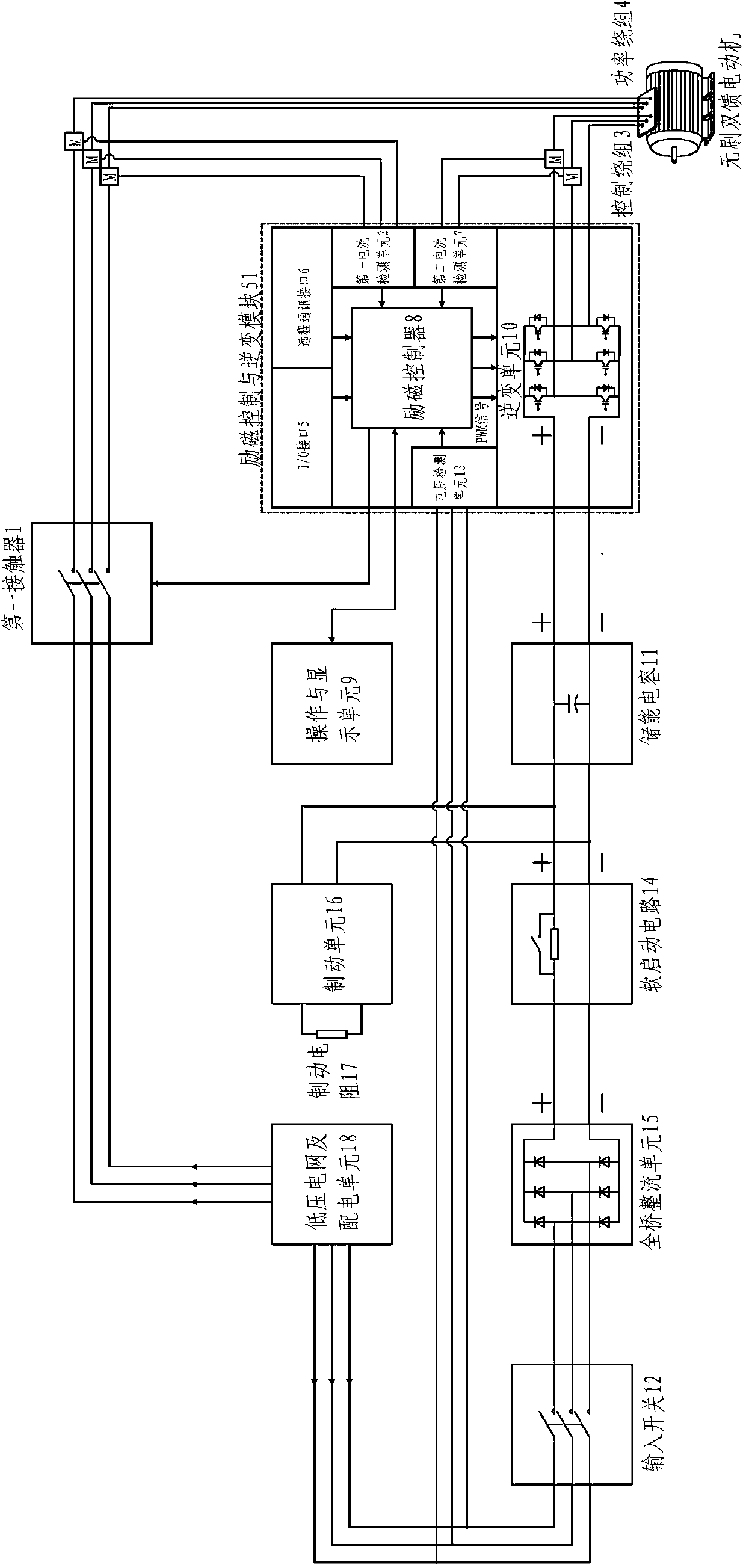

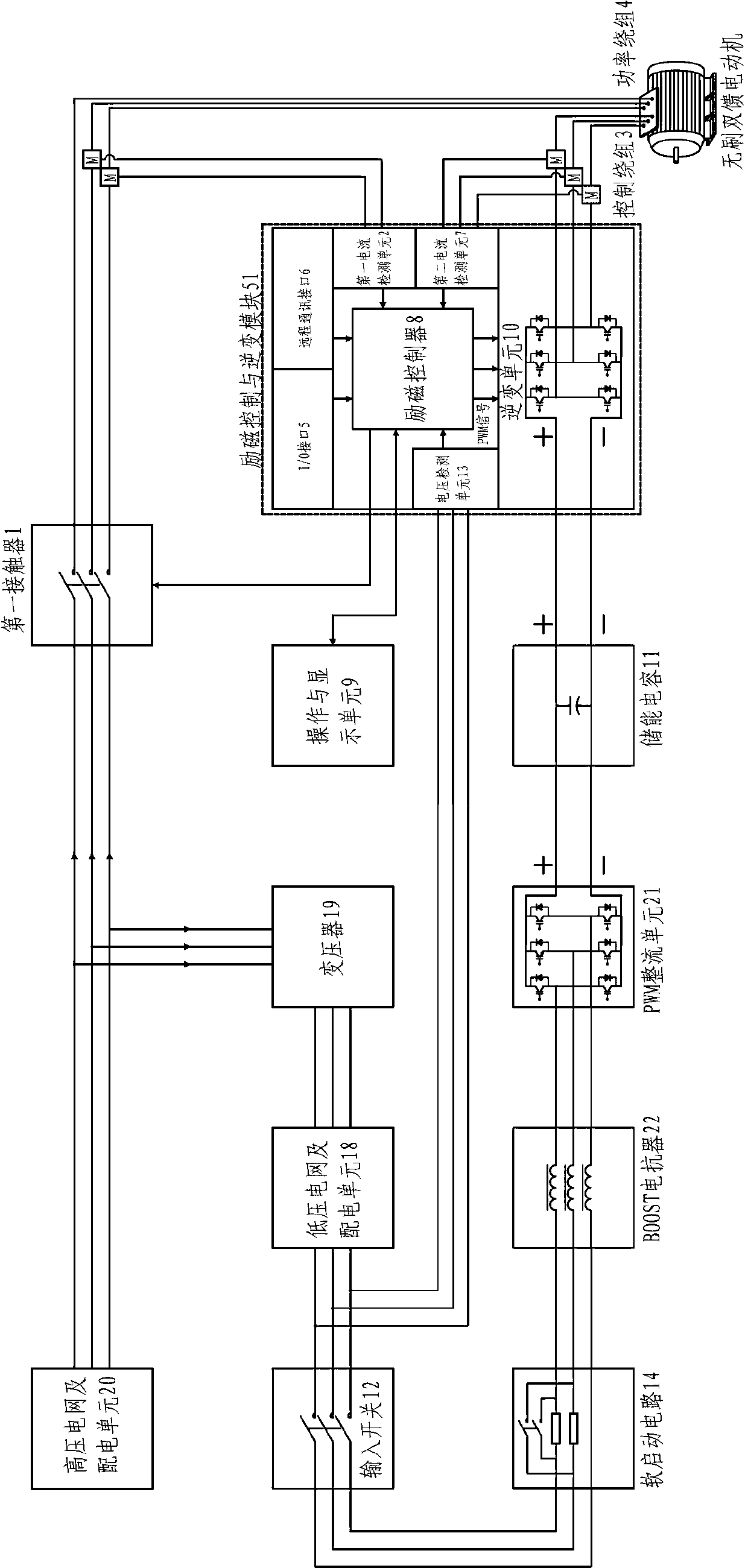

High-power brushless double fed motor variable frequency speed regulation system and control method

ActiveCN103138674AImprove reliabilityReduce manufacturing costAC motor controlSingle motor speed/torque controlCapacitanceEngineering

A high-power brushless double fed motor variable frequency speed regulation system comprises a power winding of the high-power brushless double fed motor and a control winding, a first contactor, an input power distribution unit, an entry switch, a soft start circuit, a alternating current or direct current rectifying unit, a energy-storage capacitor, an operation and display unit, and an excitation control and inverter module which is composed of a excitation controller, an inverter unit, a first current detection unit, a second current detection unit and a voltage detection unit. After the power winding is connected with the first contactor in series, the power winding is connected with the input power distribution unit, the entry switch, the alternating current or direct current rectifying unit, the energy-storage capacitor, and the inverter module, then the power winding is connected with the control winding. The soft start circuit is connected with a circuit between the alternating current or direct current rectifying unit and a three-phase output end of the entry switch in series or the soft start circuit is connected with a circuit between the alternating current or direct current rectifying unit and the energy-storage capacitor. Whole course frequency speed regulation of the brushless double fed motor can be achieved. The invention further comprises a fundamental control timing sequence and a method.

Owner:BEIJING SWORD ELECTRIC IND

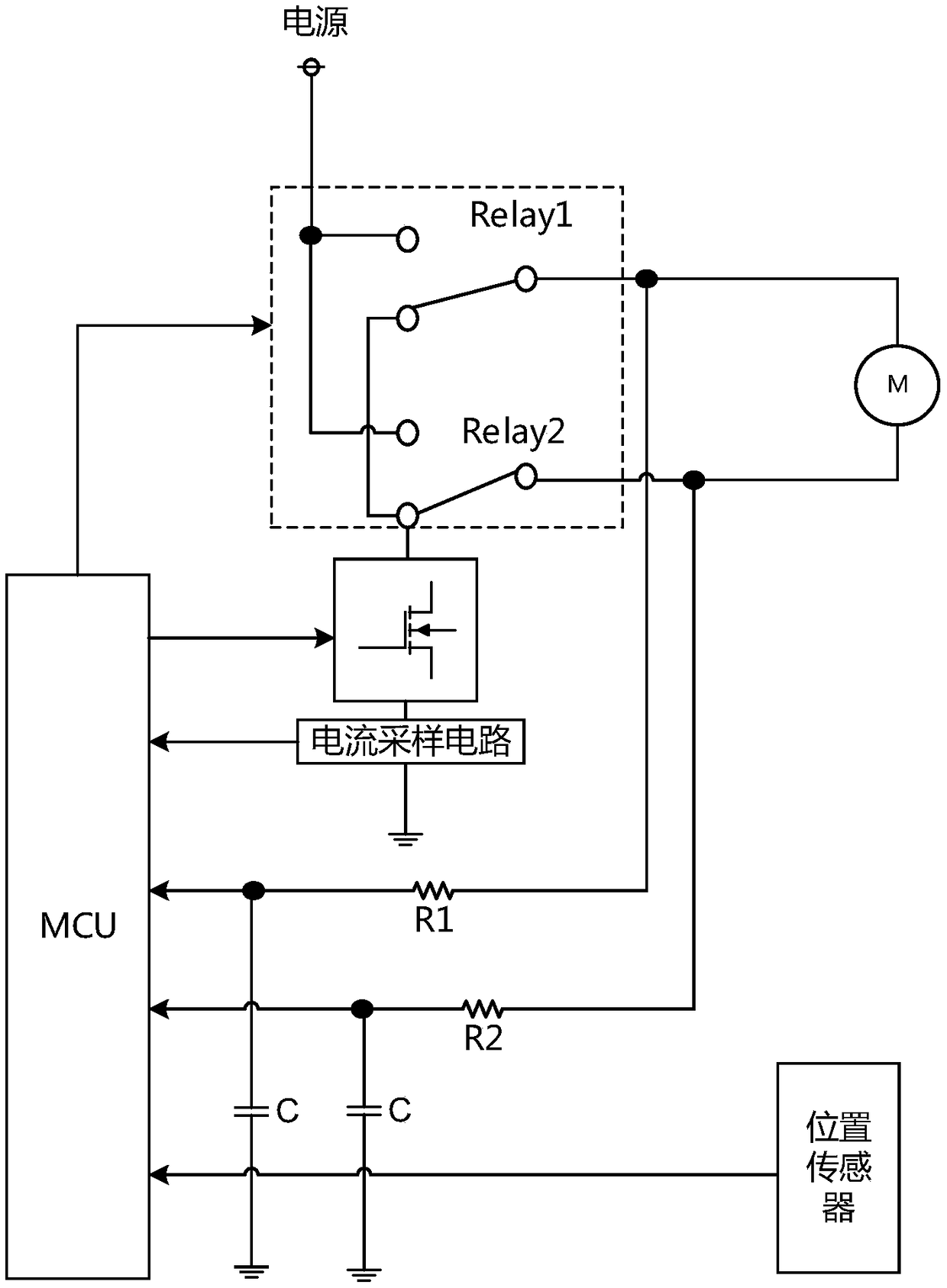

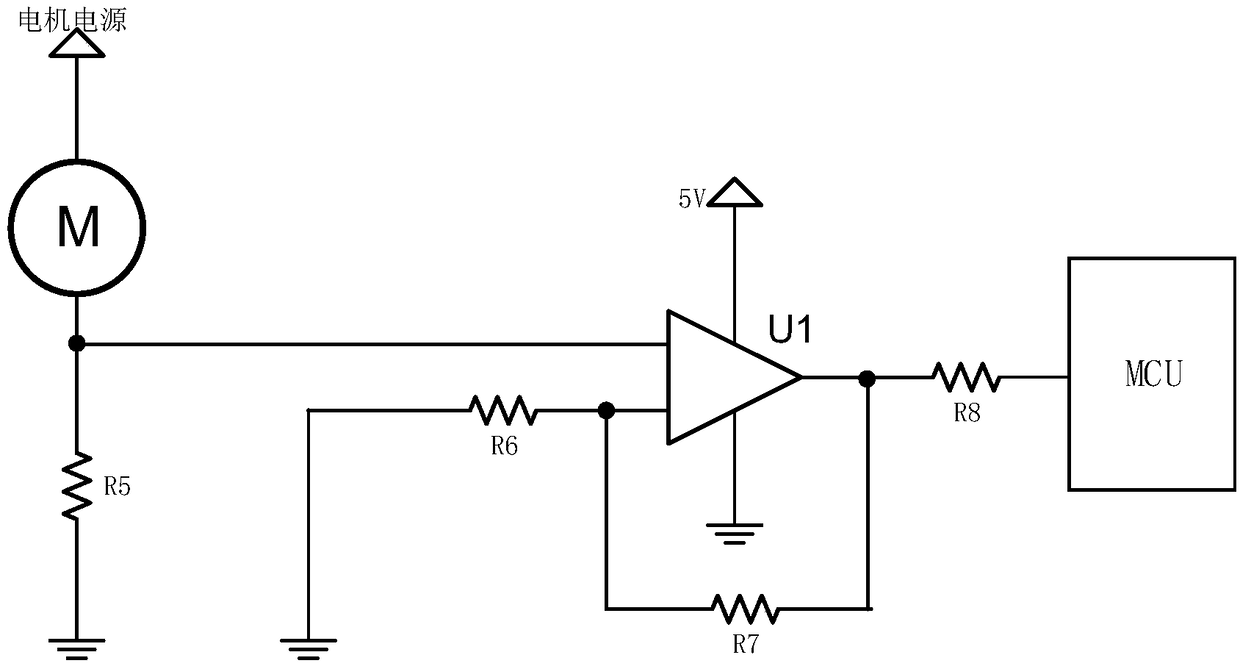

Car window motor control circuit and method

InactiveCN108798350AAvoid lax closuresSlow downPower-operated mechanismRotation direction controlControl theorySlow speed

The invention discloses a car window motor control circuit and method. When an MCU obtains that a vehicle window does not run to the position near the full-opening or full-closed position through a position sensor, the MCU is used for controlling the average voltage at the two ends of an car window motor to not change, so that the car window motor is kept at a set relatively high speed; when the MCU obtains the car window through the position sensor and reaches the full-opening or full-closed position, the MCU controls the average voltage at the two ends of the car window motor, so that the running speed of the car window motor is reduced, and the MCU controls the car window motor to run at a set relatively slow speed until the full-opening or full-closed position is completely closed andis blocked; and the MCU controls the car window motor to stop running when the MCU obtains a full-open or full-closed position through the position sensor. According to the car window motor control circuit and method, the impact sound of the car window glass and a car body metal plate is reduced when the car window glass runs to a fully-opened or fully-closed position, and the current is reduced when the car window glass runs to the full-opening or full-closed position.

Owner:CHONGQING HI LEX CABLE SYST GRP CO LTD

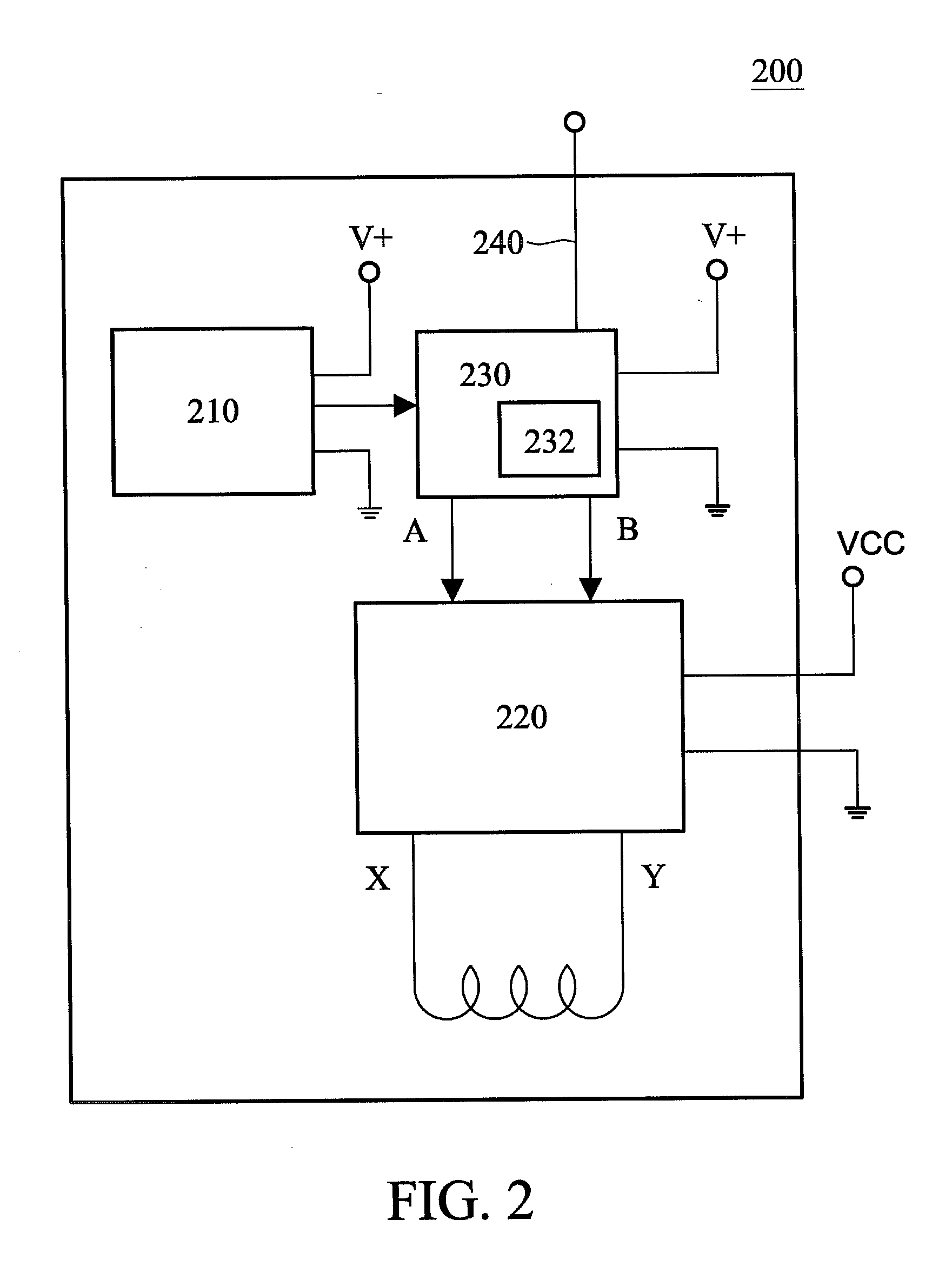

Single phase DC brushless motor controller and method for controlling rotation speed and direction of single phase DC brushless motor

A single phase DC brushless motor controller, including: a micro control unit including: a Pulse Width Modulation (PWM) pin for receiving a PWM signal from a system; and a commutation logic unit for controlling the speed and rotation of a single phase DC brushless motor according to the PWM signal.

Owner:DELTA ELECTRONICS INC

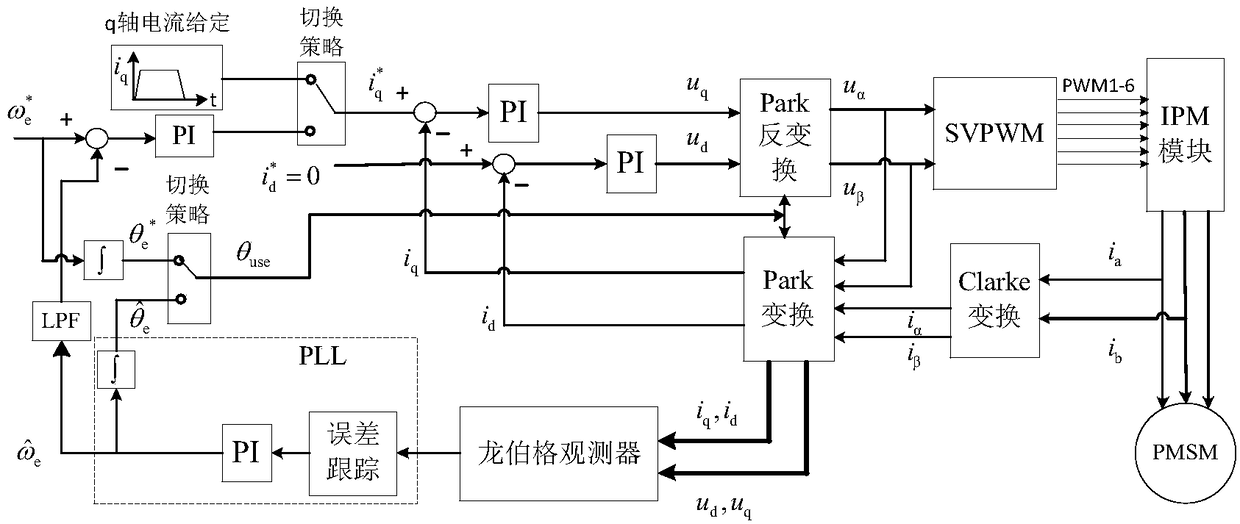

A position sensorless control method for permanent magnet synchronous motor (PMSM) with forward and reverse speed regulation

ActiveCN109167543AQuick switchSmall amount of calculationVector control systemsDynamo-electric converter controlElectric machineState observer

A position sensorless control method of permanent magnet synchronous motor with forward and reverse speed regulation is disclosed. includes I / F start-up strategy, switching control strategy, positionestimation strategy and deceleration and inversion strategy. Firstly, the motor current is closed-loop preset to zero, then I / F semi-closed-loop start-up is carried out, and when the motor runs to a certain speed, the motor can be switched to sensorless closed-loop control quickly and smoothly. When receiving the inversion command, decelerate, decelerate to a certain speed and then switch to I / F semi-closed loop control. After continuing to decelerate to zero speed and accelerating to a certain speed in the opposite direction, switch to the closed loop inversion process smoothly without position sensor. During I / F operation, the position signal is obtained by integrating the given velocity. When the speed reaches a certain value, the rotor position of the motor can be estimated accuratelyby the Romberg state observer, and then it is switched to the closed-loop control without position sensor. The invention can realize full-range sensorless control of a permanent magnet synchronous motor rotating in both positive and negative directions.

Owner:ZHEJIANG UNIV OF TECH

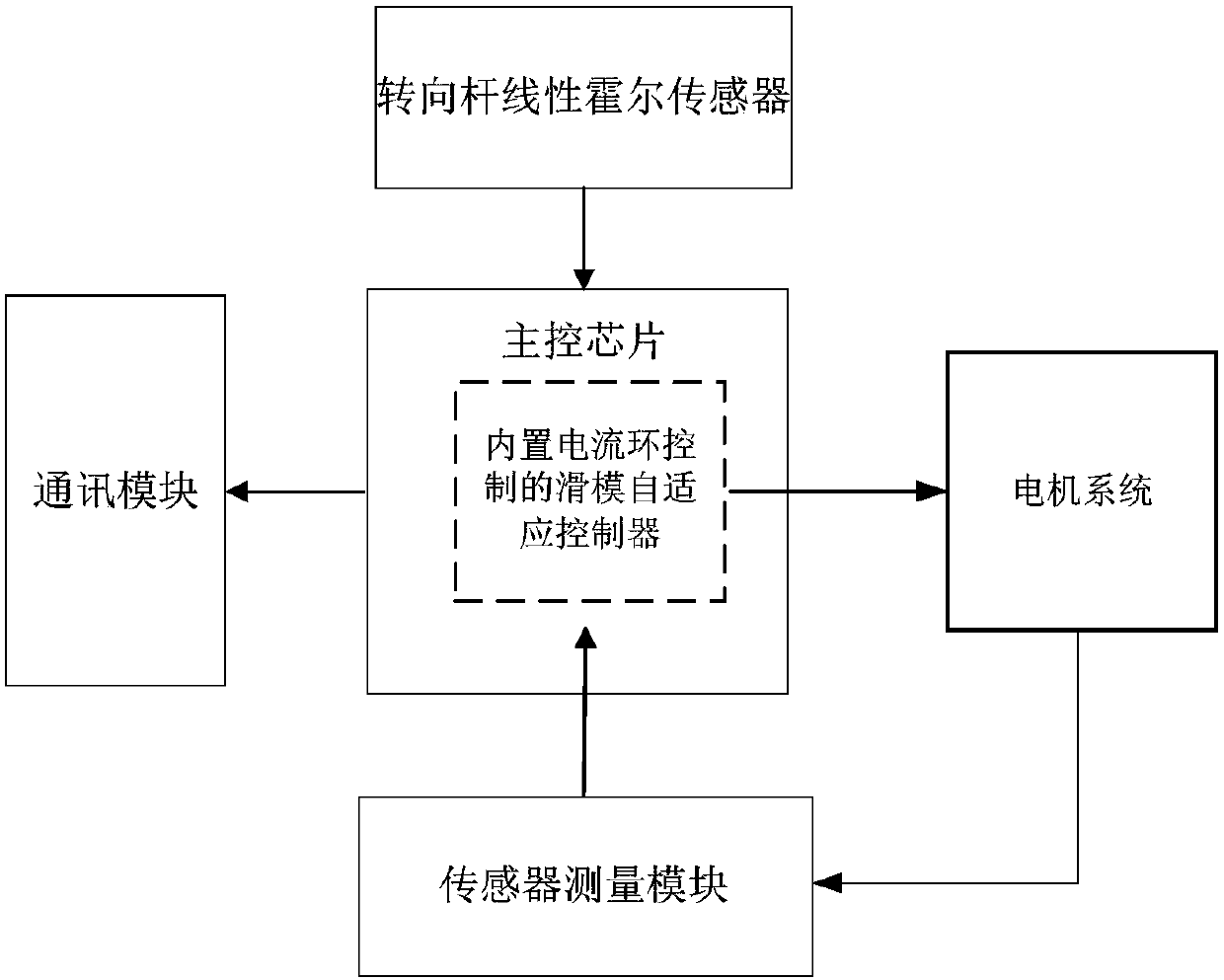

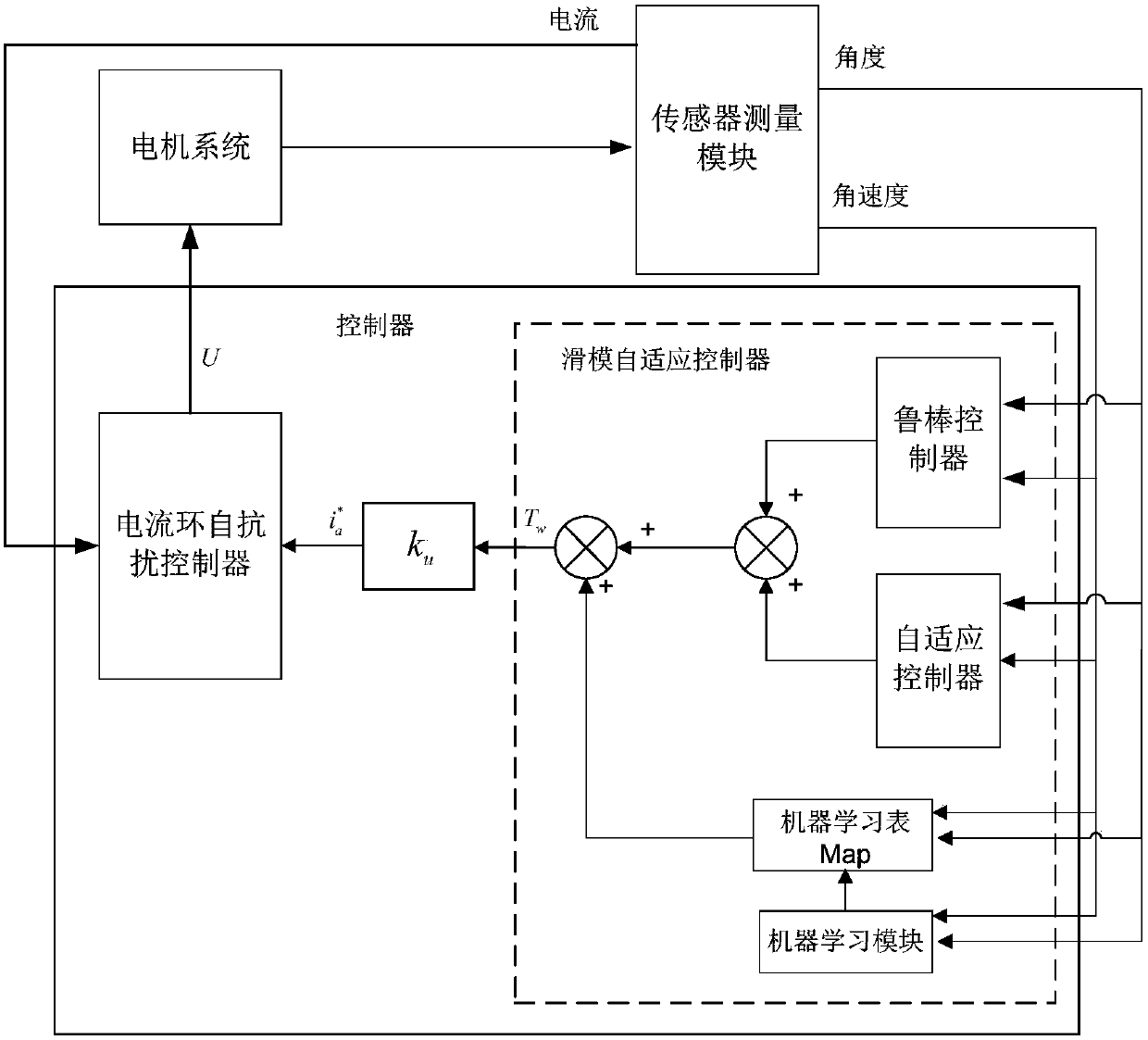

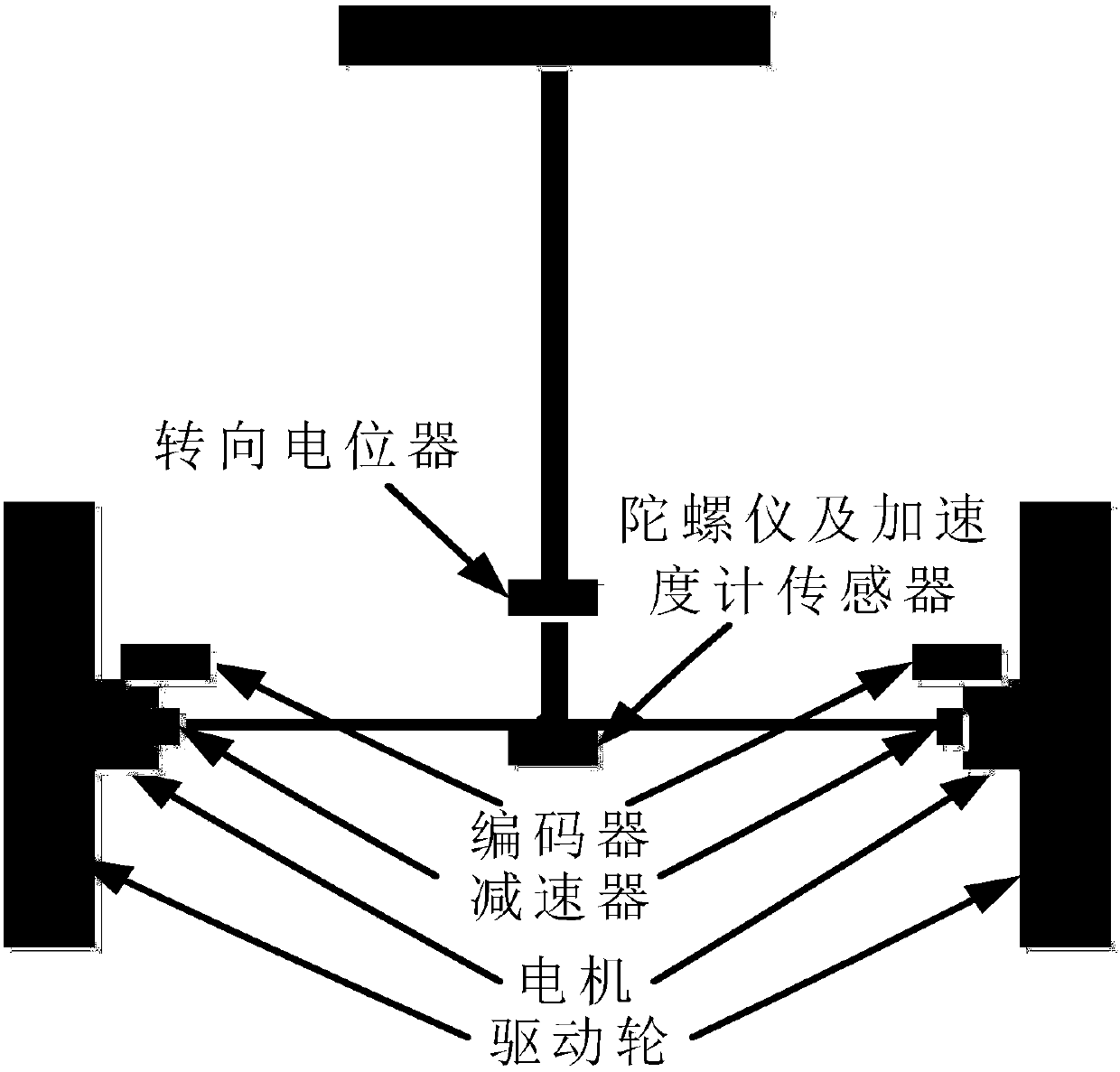

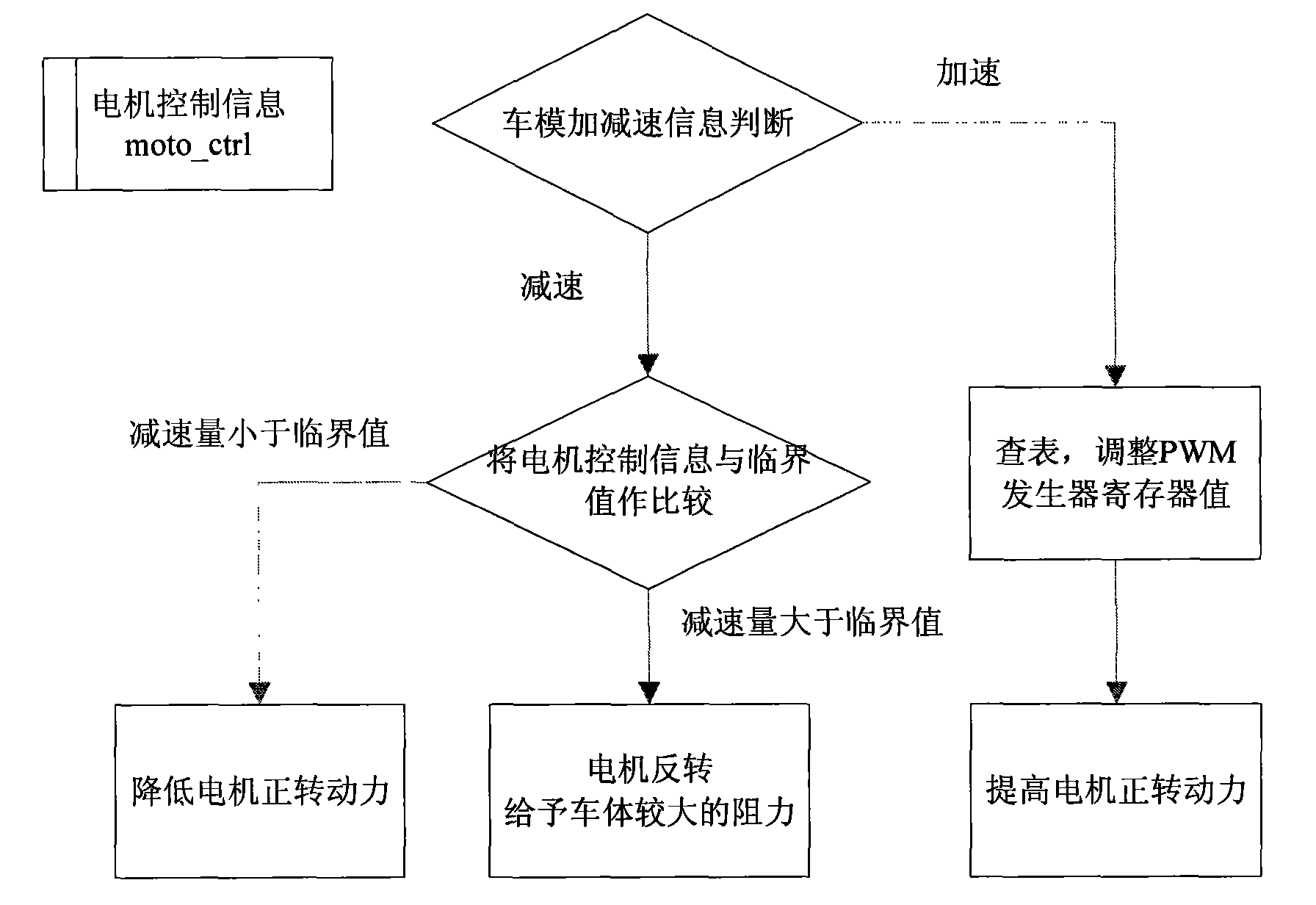

Sliding mode adaptive controller with built-in brushless DC motor current loop control for two-wheeled self-balancing robot

ActiveCN106452206AReduce the impactImprove performanceProgramme-controlled manipulatorCurrent controllersBrushless motorsDriving current

The invention discloses a sliding mode adaptive controller with built-in brushless DC motor current loop control for a two-wheeled self-balancing robot. The controller at least comprises a sliding mode adaptive controller and a current loop active-disturbance-rejection controller, wherein the sliding mode adaptive controller is used for controlling an output motor torque T<w> according to an angle parameter Theta and an angular speed Theta-bar and converting the motor torque T<w> to a current i<*>, and the current loop active-disturbance-rejection controller is used for controlling an output voltage U<*><a0>(t) to drive a motor system to move according to the current i<*> and a motor current i detected by a sensor measurement module. With the adoption of the technical scheme disclosed by the invention, current loop control is added into the controller, thus, the size of the driving current is effectively controlled, a large current cannot be generated, the driving of a brushless motor is protected, the lifetime of a balance car is greatly prolonged, and the application safety of the balance car is greatly improved.

Owner:HANGZHOU DIANZI UNIV

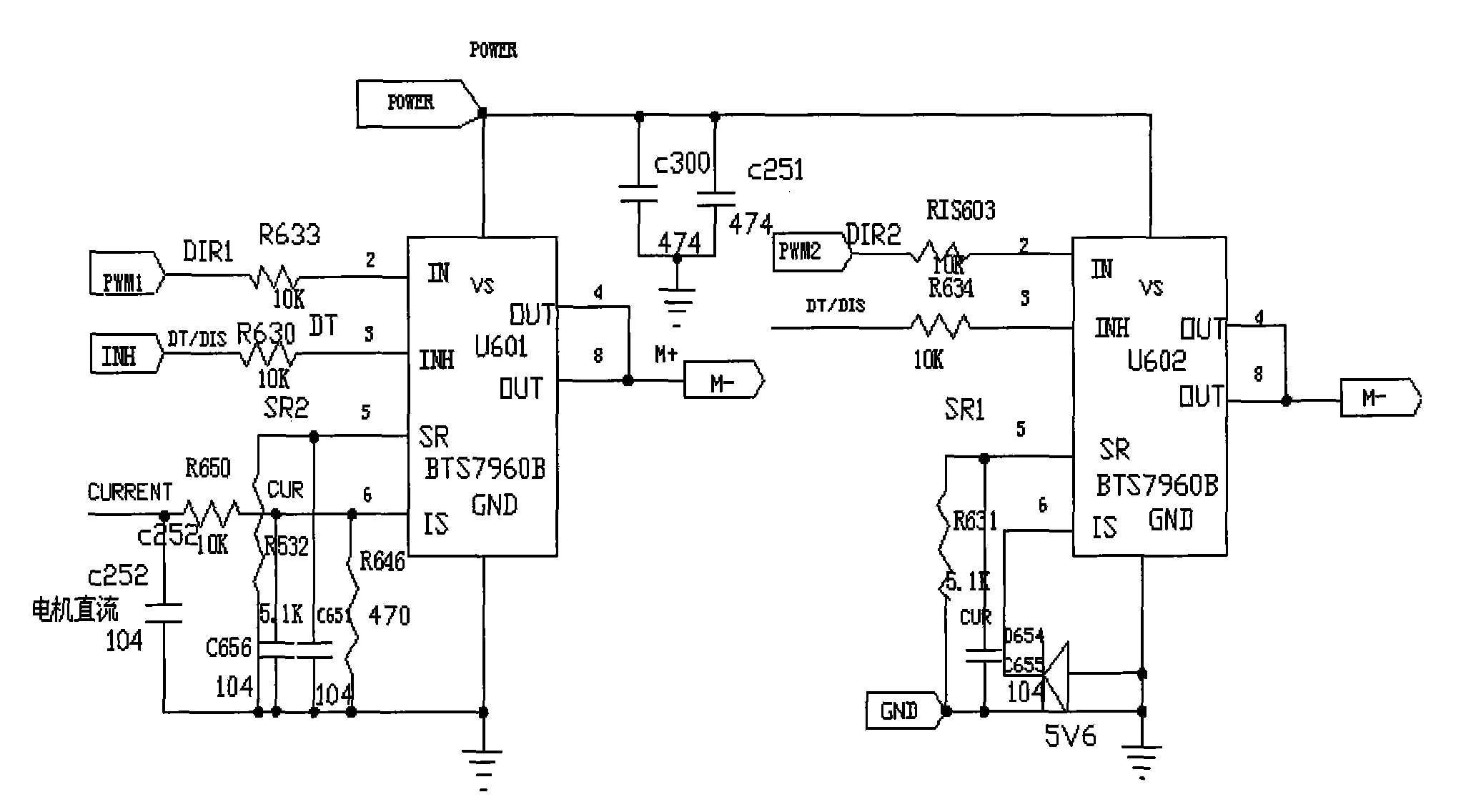

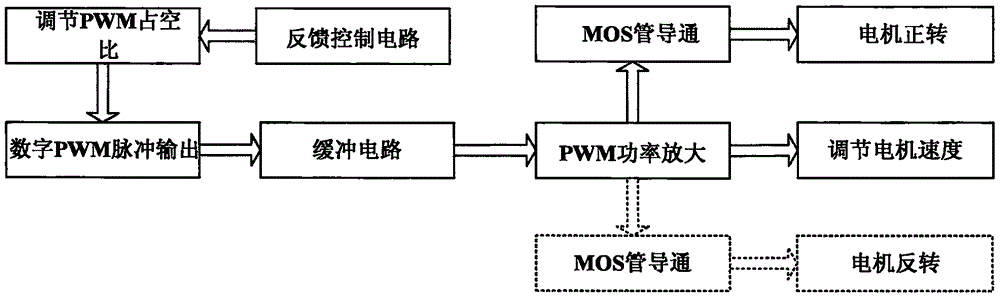

System and method for controlling motor of wire-controlled braking system

ActiveCN101594106AEasy to controlSimple designSingle motor speed/torque controlRotation direction controlMotor driveControl system

The invention discloses a system and a method for controlling a motor of a wire-controlled braking system. The system comprises a control chip for outputting two circuits of complementary PWM signals, controlling the positive rotation and reverse rotation of the motor and controlling speed regulation, and two motor drive chips for driving the motor to positively rotate and reversely rotate, wherein the motor drive chips adopt a special chip BTS7960B. The system and the method are based on wire-controlled technology, change various complicated equipment devices into electronic elements and control the motor by software technology so that a circuit has simple design, convenient control, good real-time and high precision; and the system has the advantages of simple structure, economic construction cost, high safety coefficient and the like.

Owner:CHERY AUTOMOBILE CO LTD

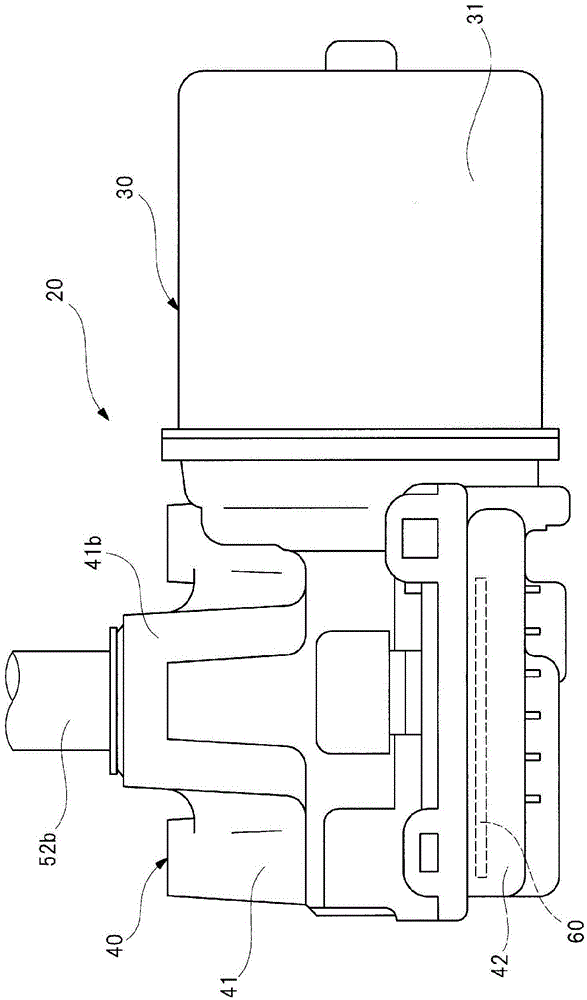

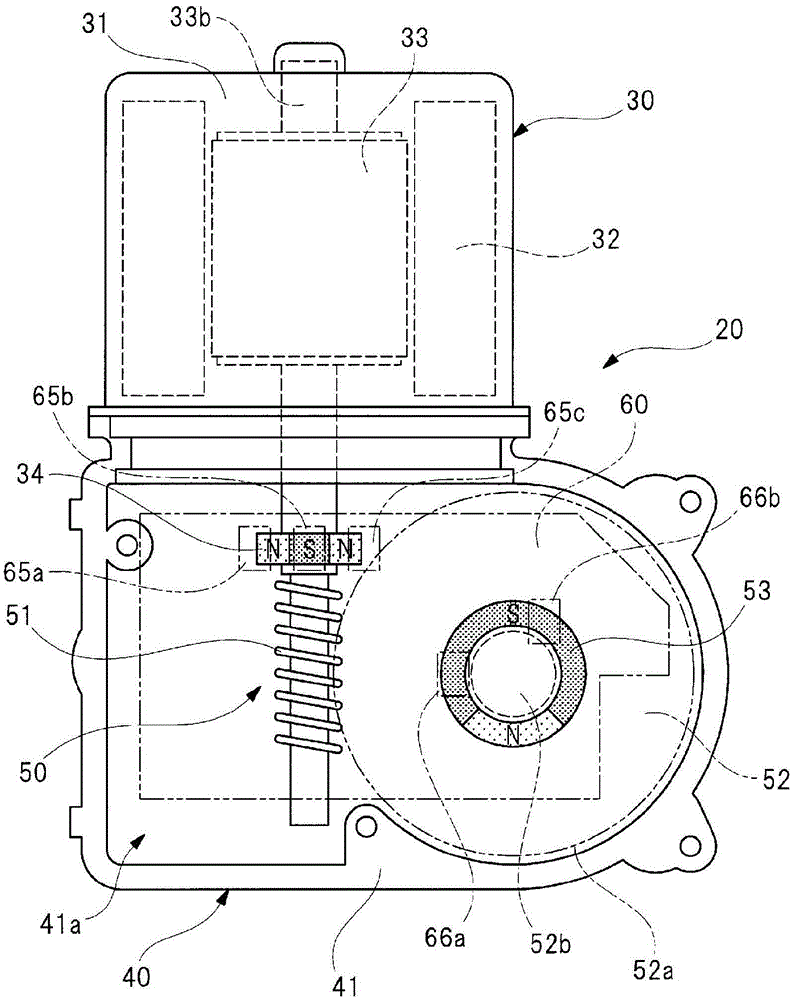

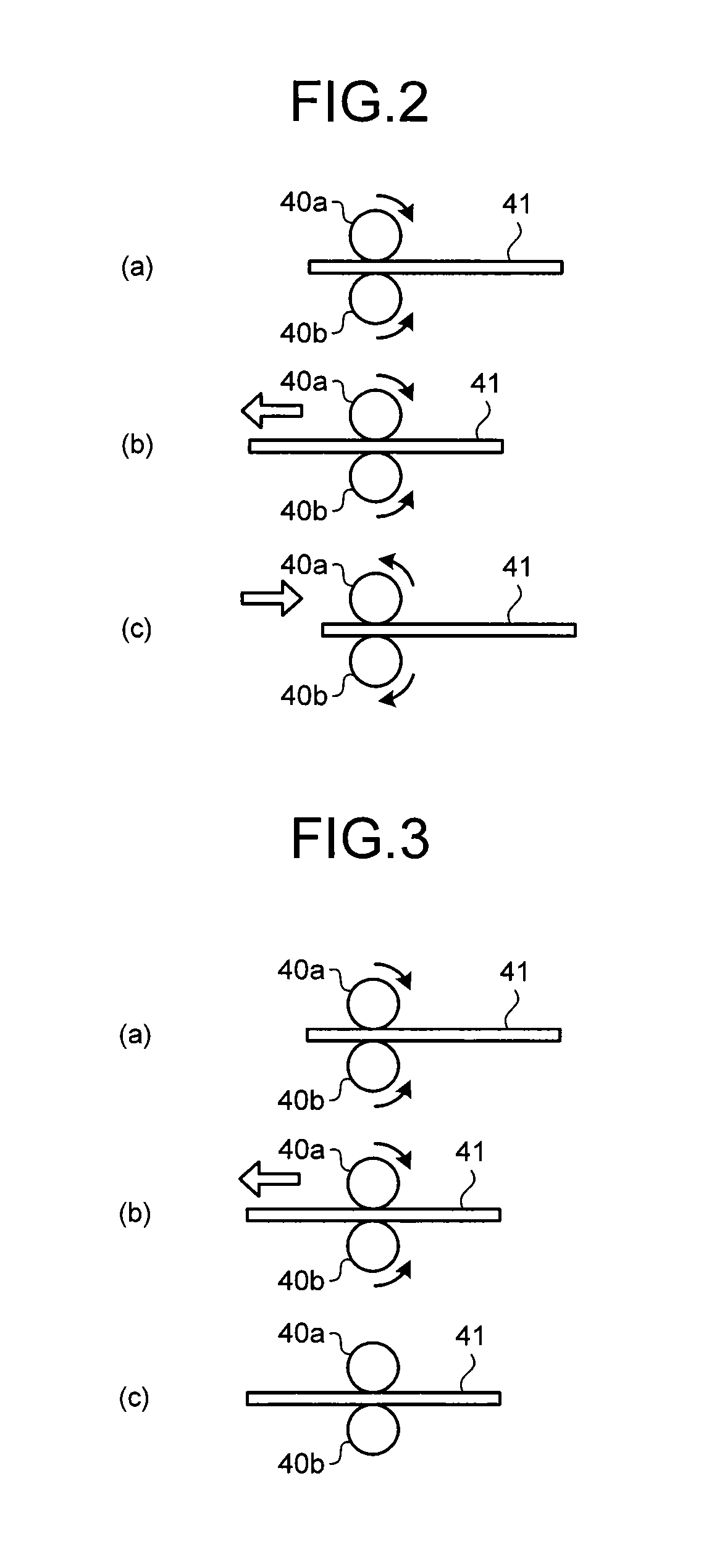

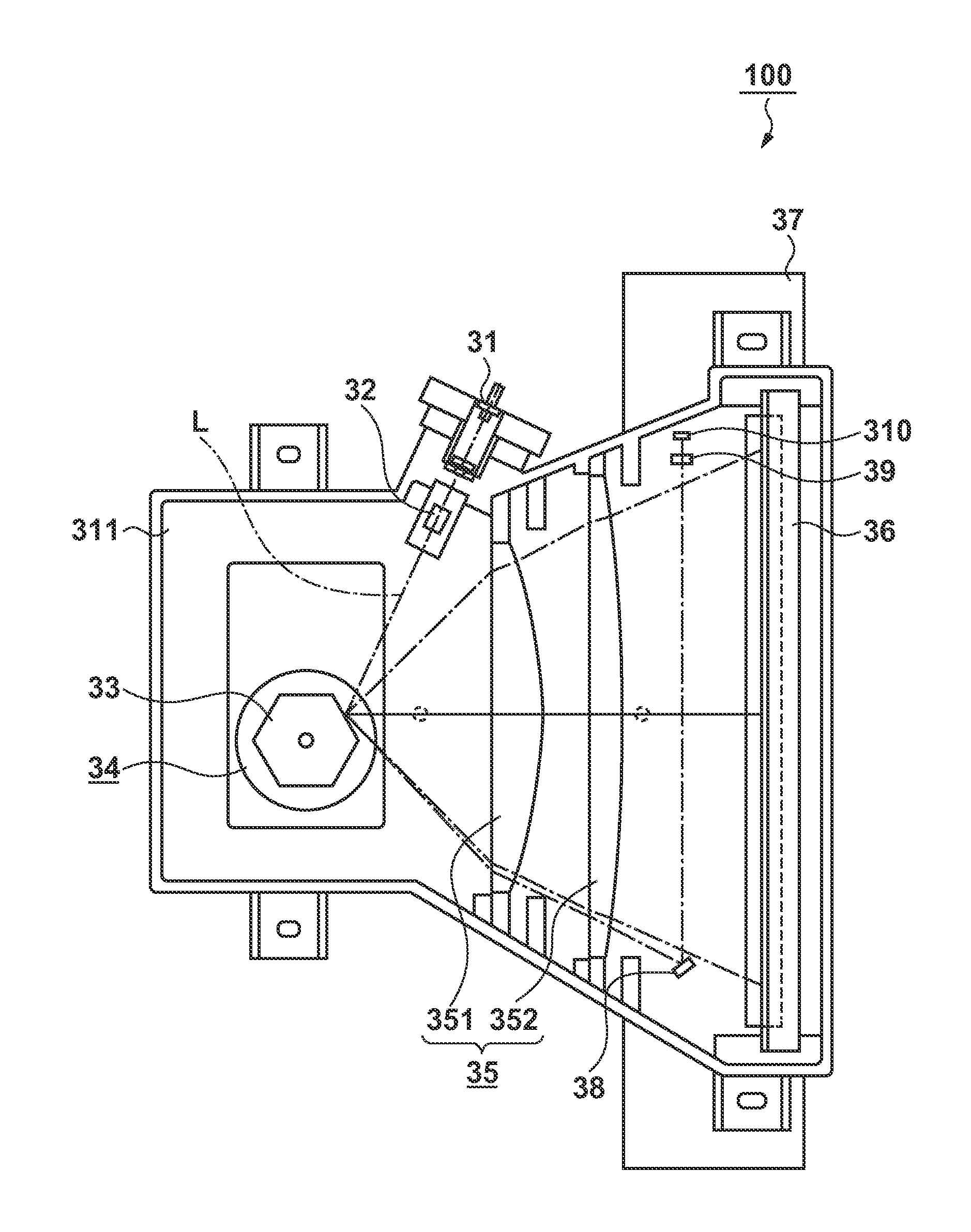

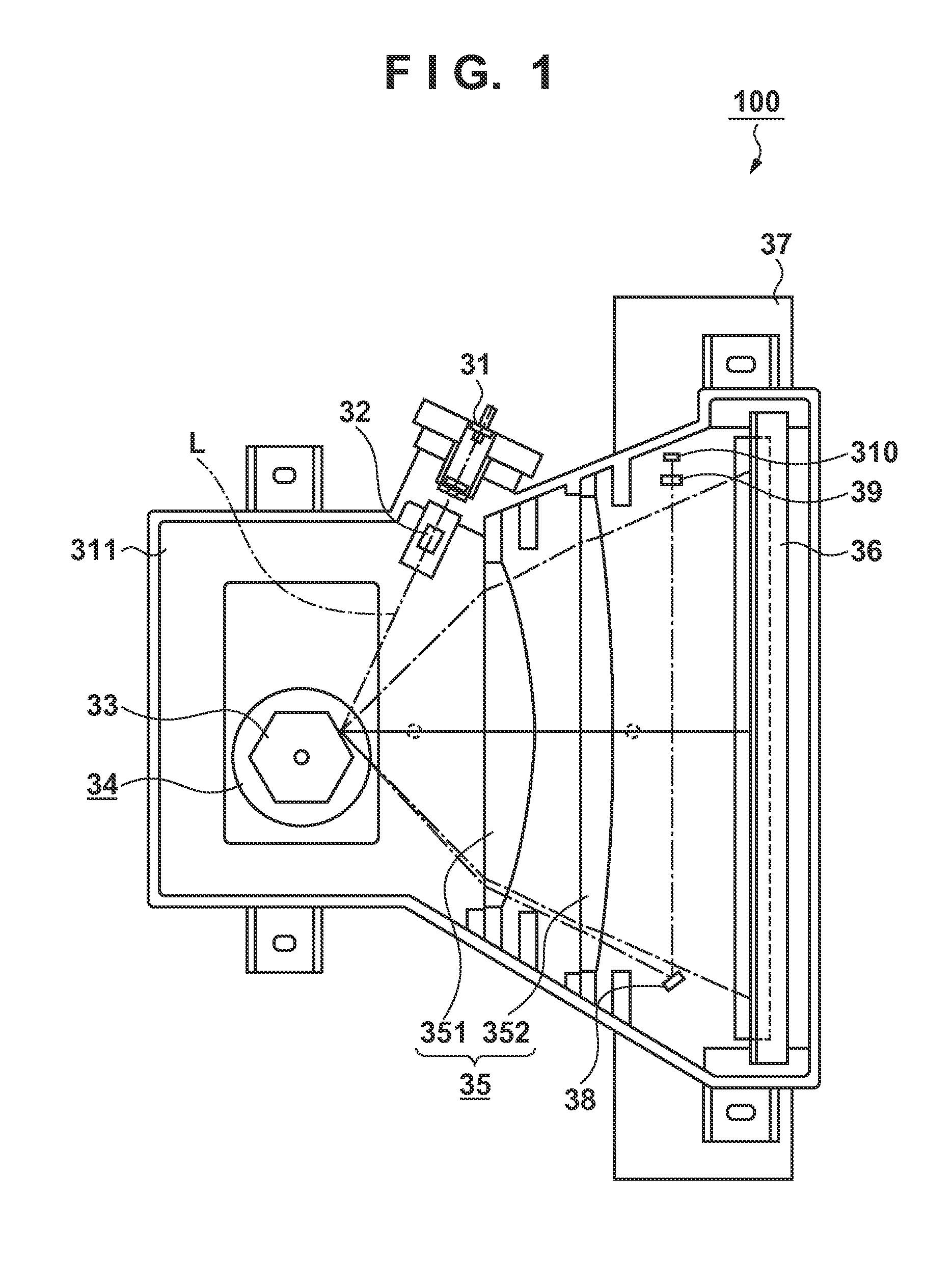

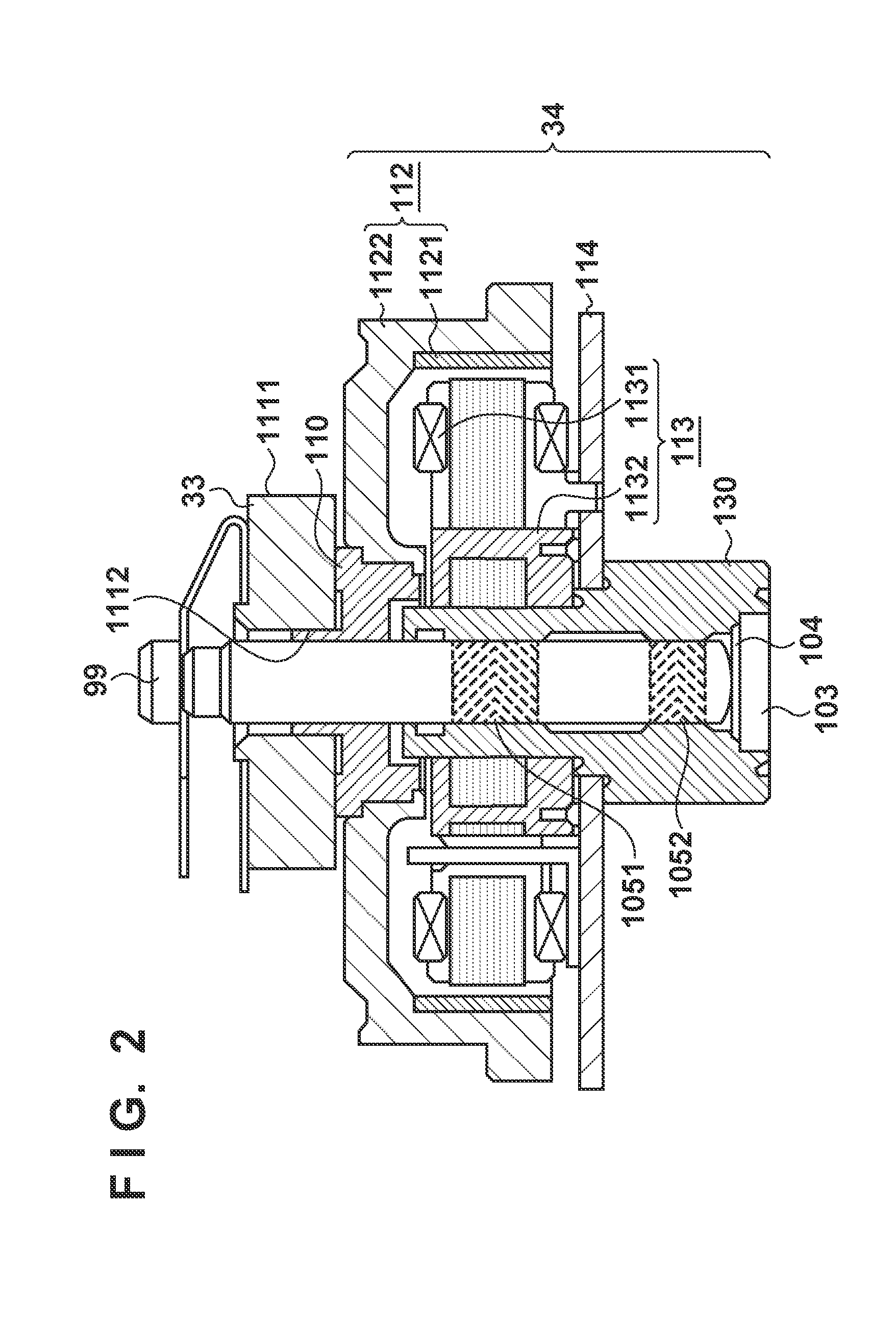

Brushless wiper motor

InactiveCN105556812ASmall sizeMiniaturizationAC motor controlMagnetic circuit rotating partsElectric machineEngineering

Rotary shaft magnets (first magnet, second magnet) (34) are provided on a section of a rotary shaft (33b), said section extending into a gear housing (41), and rotary shaft Hall ICs (first sensor, second sensor) (65a-65c) are arranged on a control board (60) inside the gear housing (41) so as to respectively face the rotary shaft magnets (34). A rotational position of the rotary shaft (33b) with respect to a stator (32), that is, a rotational position of a rotor (33) with respect to the stator (32), is detected by the respective rotary shaft Hall ICs (65a-65c), and a rotating speed of the rotary shaft (33b) is also detected by the respective rotary shaft Hall ICs (65a-65c).

Owner:MITSUBA CORP

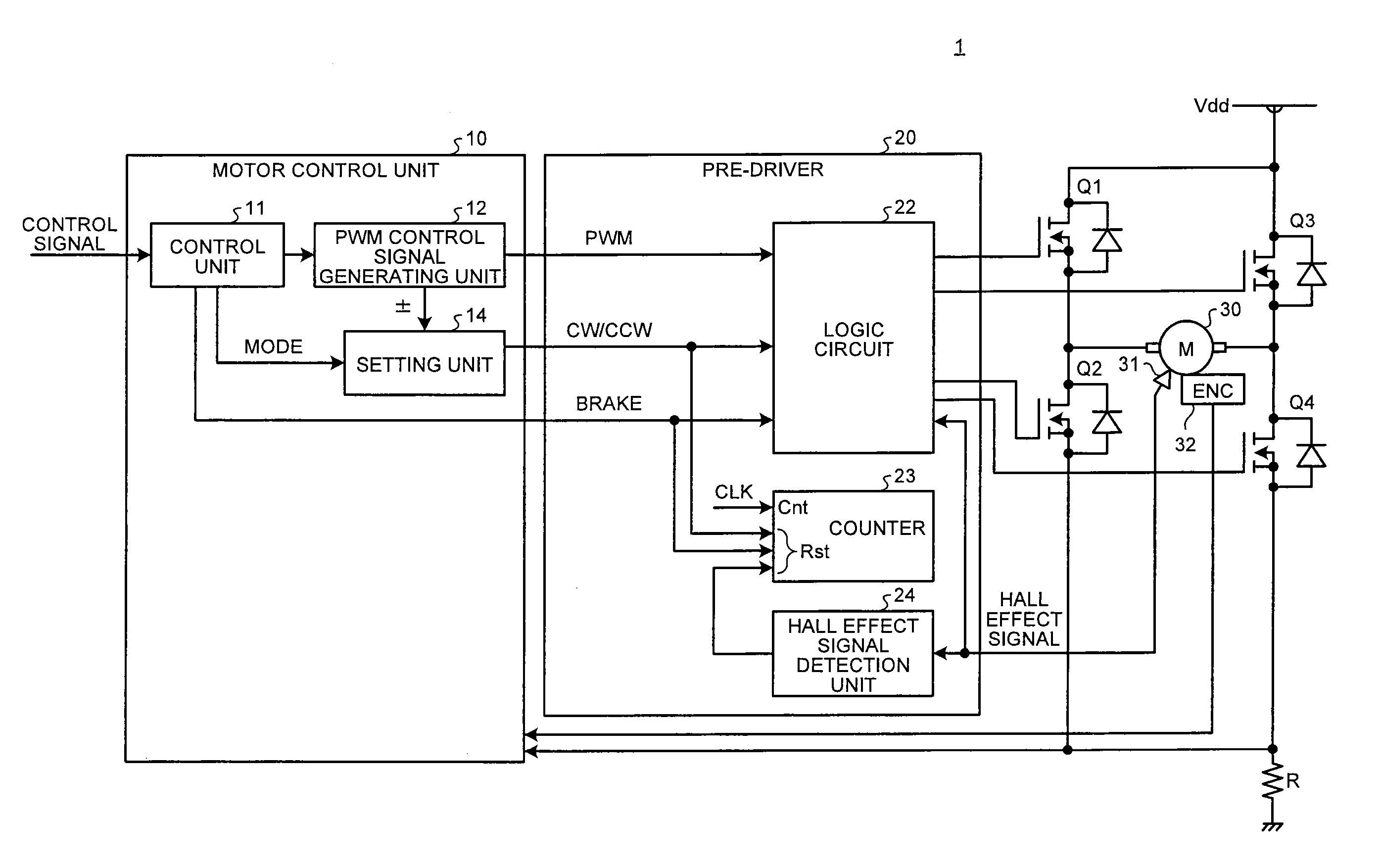

Motor control device, motor control method, and image forming apparatus

ActiveUS20140049199A1Motor/generator/converter stoppersCommutation monitoringMotor driveControl signal

A motor control device supplies a drive control signal to a drive circuit that drives a motor at a constant period using a motor drive signal based on the drive control signal, and shuts off the motor drive signal when a count value counted by a counter that reset the count value if a state of the motor changes exceeds a threshold corresponding to a plurality of driving periods of the motor. The motor control device includes: a control unit that controls a setting unit to set a rotational direction of the motor to a first rotational direction and a second rotational direction reverse to the first rotational direction at the constant period alternately, when a drive mode of the motor is a position holding mode to drive the motor so as to hold a rotational position of the motor.

Owner:RICOH KK

Motor controller, image processing apparatus including the motor controller, and motor control method

A motor controller, operatively connected to a motor having an output shaft, includes a rotary detector to detect a rotation direction and a rotation amount of the output shaft of the motor to generate an actual rotary signal, a drive controller to generate a control signal based on the actual rotary signal and a target rotary signal indicating a target rotary direction and a target rotary amount, and a driver to supply a driving power to the motor based on the control signal. When the motor is in a hold state, the control signal is reversed periodically for a predetermined reverse time period T2 per a predetermined one reverse cycle T1. When the control signal is not reversed for a certain lock detection time period Tr that is longer than the revere cycle T1 of the control signal, supply of the driving power to the motor is blocked.

Owner:RICOH KK

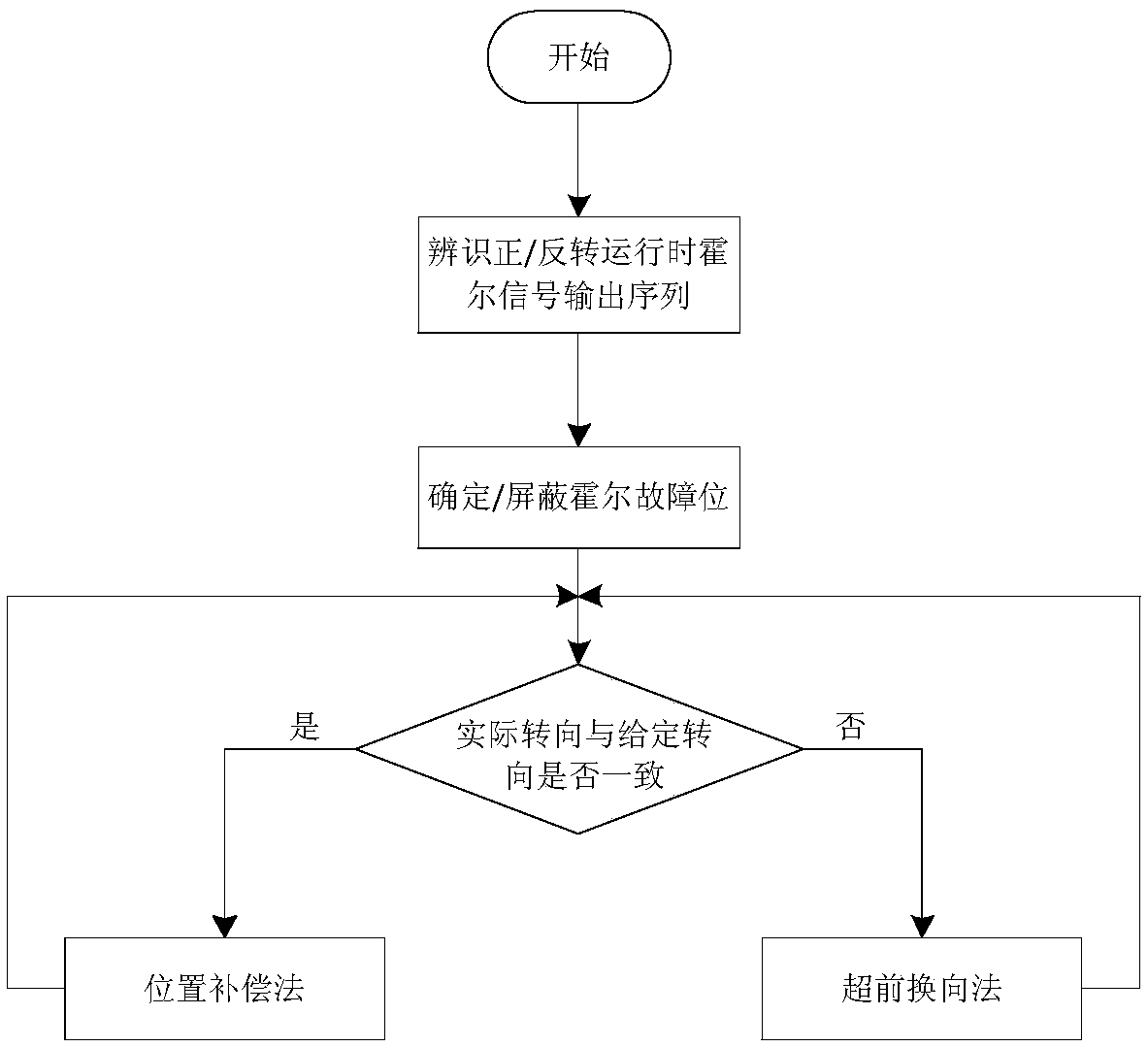

Fault-tolerant control method for Hall position sensor of permanent-magnet brushless motor

InactiveCN108900120AImprove reliabilityImplement fault-tolerant controlElectric motor controlRotation direction controlBrushless motorsElectric machine

The invention discloses a fault-tolerant control method for a Hall position sensor of a permanent-magnet brushless motor, aiming to solve the technical problem of low practicality of existing fault-tolerant control methods for Hall position sensors of permanent-magnet brushless motors. The technical scheme of the fault-tolerant control method includes the steps of identifying three Hall position sensor output sequences during forward and backward rotation of the permanent-magnet brushless motor firstly; outputting signals to the Hall position sensor to determine fault positions and shield fault signals; if the actual rotation direction of the permanent-magnet brushless motor is identical to a given rotation direction, performing fault-tolerant control on the Hall position sensor of the permanent-magnet brushless motor according to a position compensation method; if the actual rotation direction of the permanent-magnet brushless motor is different from the given rotation direction, restarting the motor according to an advanced phase change method to keep the actual rotation direction identical to the given rotation direction. The fault-tolerant control method has the advantages thatfault-tolerant control is realized by the position compensation method, torque ripples are reduced, normal working of the permanent-magnet brushless motor is guaranteed, the reliability of a full-electric braking system of an airplane is improved, and the practicality is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

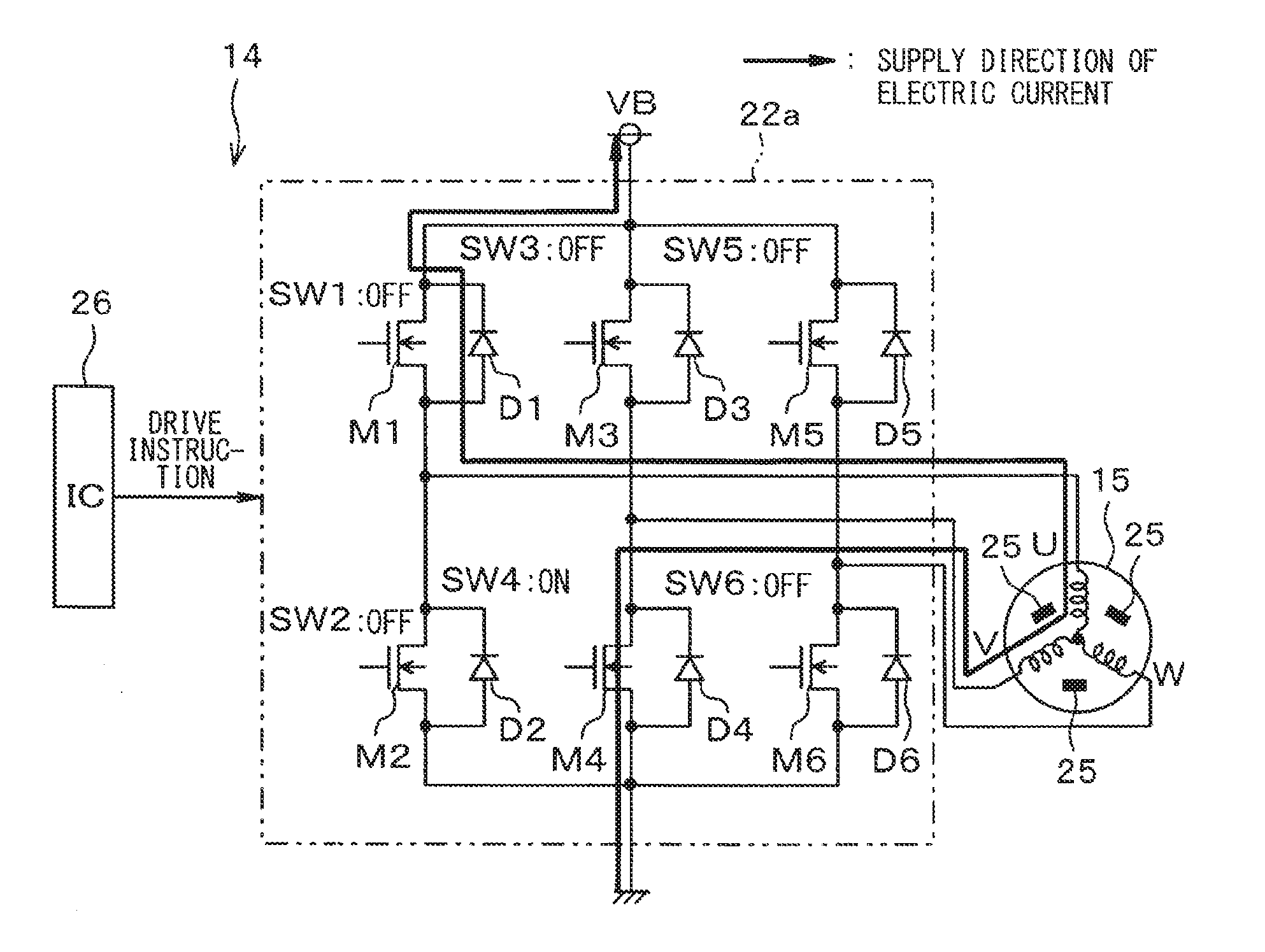

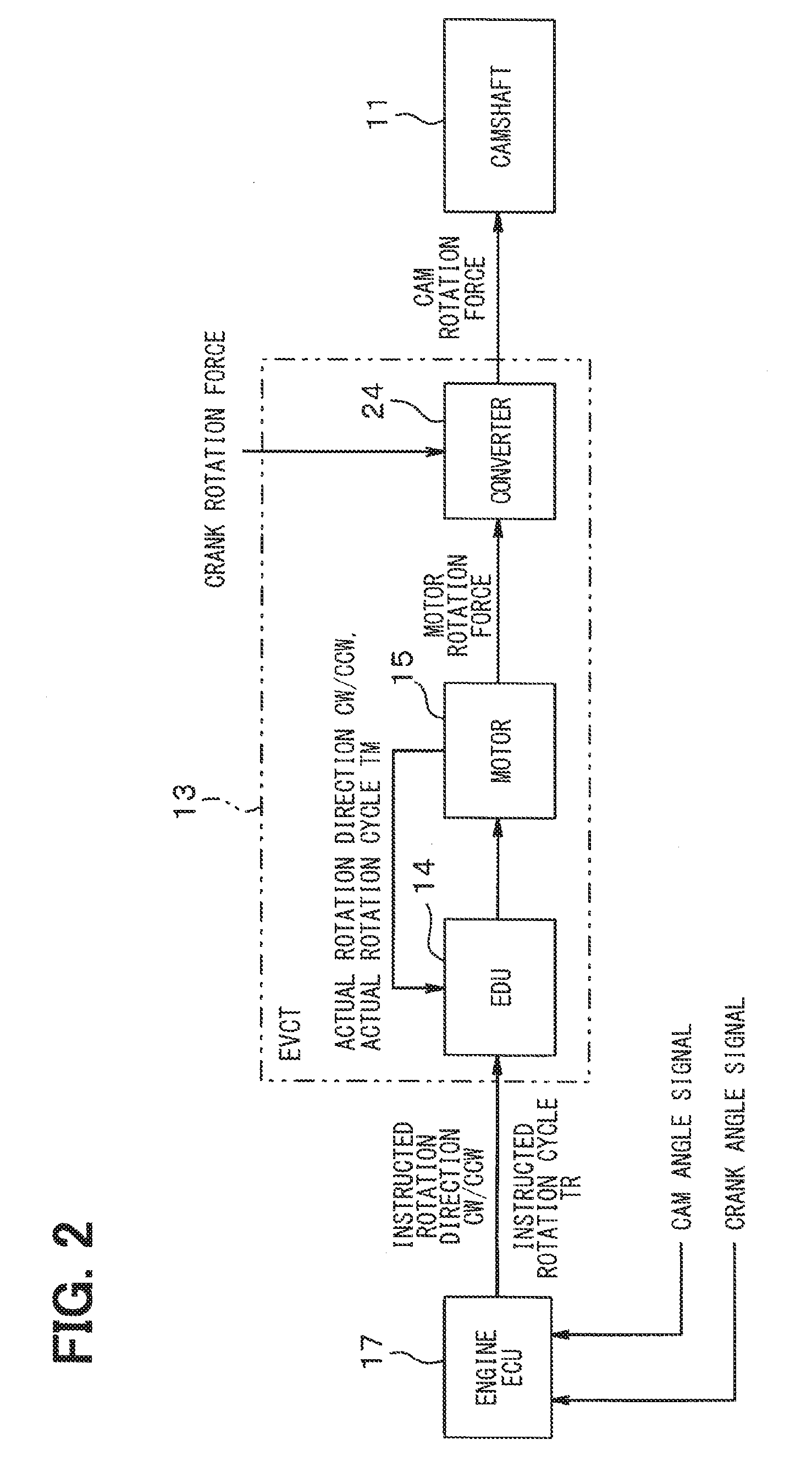

Motor driver of motor for valve timing control of internal combustion engine

ActiveUS20160359434A1Accurate motor rotation speed controlImprove responsivenessAC motor controlElectrical controlMotor driveInternal combustion engine

A motor driver for driving a motor in a valve timing controller of an internal combustion engine, including an Electronic Driver Unit (EDU) that, upon receiving a target rotation cycle as the instructed rotation cycle, instructs a rotation controller to (i) calculate a duty value of a Pulse Width Modulation (PWM) signal for driving the motor based on an instructed rotation cycle and an actual rotation cycle and (ii) output a calculation result of the duty value to a motor drive unit, with the rotation controller outputting, to the motor drive unit, an instruction signal that rotates the motor forward along an actual rotation direction, when the calculation result takes a positive value as a duty ratio of the PWM signal, establishing an accurate motor rotation speed control together with an improved responsiveness.

Owner:DENSO CORP

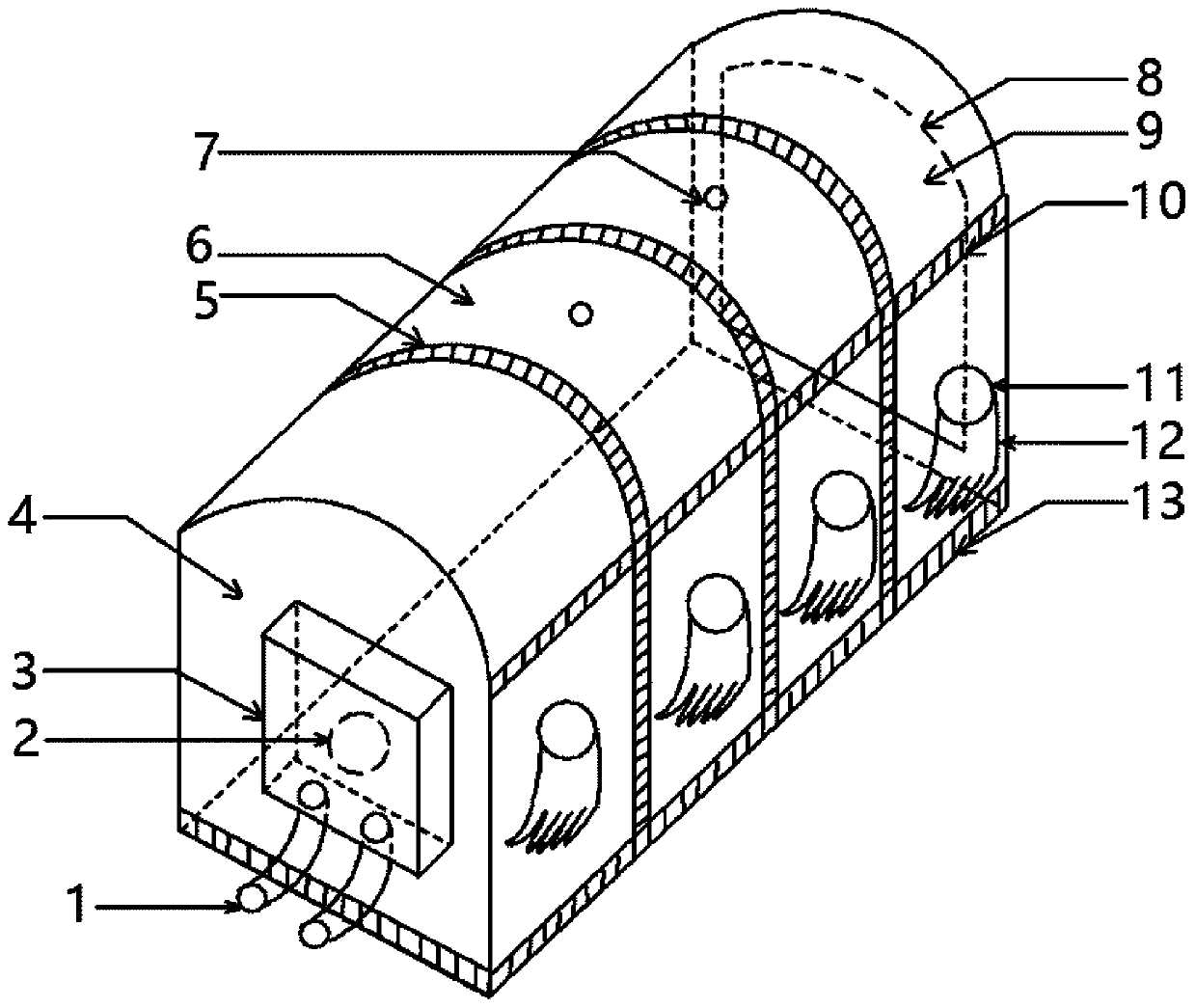

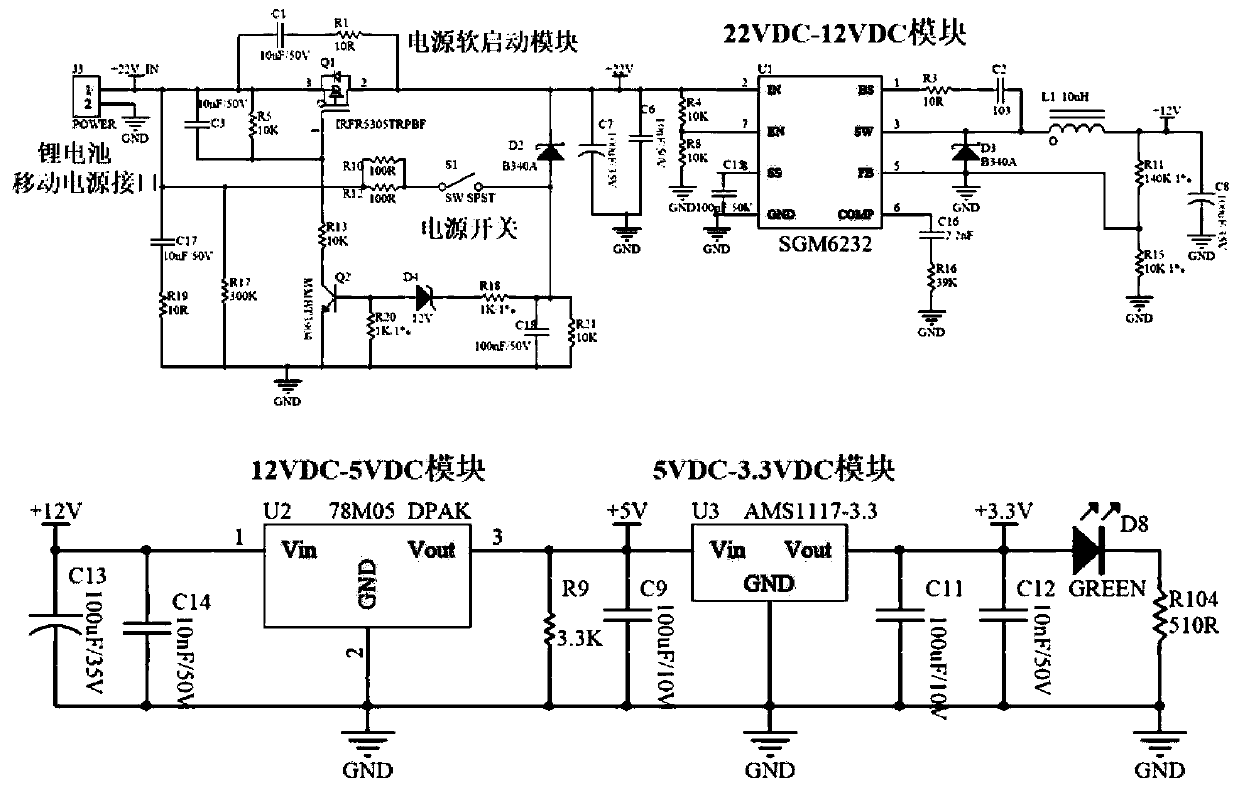

Inflatable negative pressure isolated transferring cabin and use method thereof

The invention relates to the field of clinical medical equipment and discloses an inflatable negative pressure isolated transferring cabin which comprises a cabin body and function modules, wherein the cabin body is provided with an air inlet and an exhaust hole; an exhaust tube is connected with the exhaust hole; the function modules comprise a circuit control board, a negative pressure sensor and an inflation exhaust motor driving circuit; the circuit control board, the negative pressure sensor and the inflation exhaust motor driving circuit form a control loop; the negative pressure sensoris arranged in the cabin body; and the inflation exhaust motor driving circuit controls on / off of the exhaust tube. Air introduced into the cabin body can be efficiently filtered through an air filtering and sterilization module, and air discharged outside the cabin body can be efficiently filtered and sterilized with ultraviolet rays, so that related emission standards can be met. The cabin can be compressed and folded into a small size in volume, is controlled within 25Kg in weight, is convenient to configure in ambulances, outpatient emergency treatments, ICUs (intensive care units), and the like, is particularly used for transferring acute infectious patients, and is particularly applicable to large-scale rapid transferring of infected people with biochemical protection in battlefieldoperation situations.

Owner:GUANGAN PEOPLES HOSPITAL

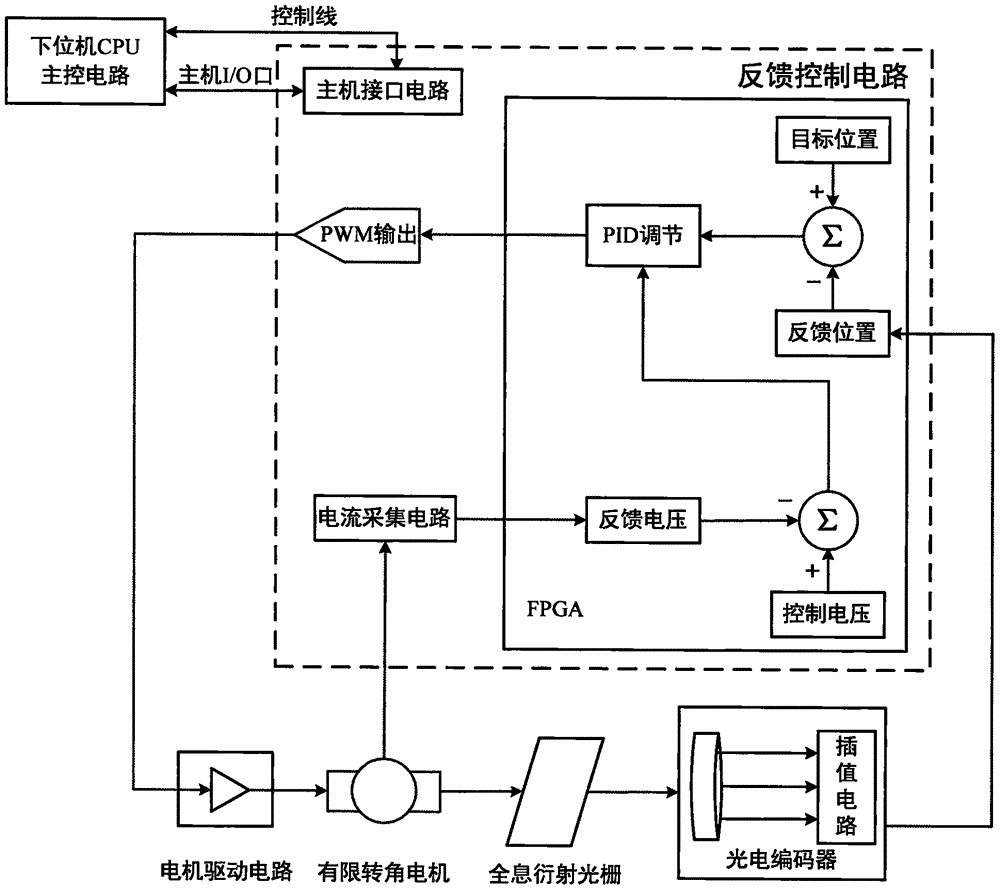

High-precision grating positioning device directly driven by a limited angle motor

InactiveCN106352980AEliminate transmission errorsEliminate transmission lossesSpectrum investigationStructural associationClosed loopOpto electronic

The invention provides a high-precision grating positioning device directly driven by a limited angle motor, which comprises a motor drive circuit, a limited angle motor, a holographic diffraction grating, a photoelectric encoder, an interpolation circuit and a feedback control circuit. The rotor on one side of the limited angle motor passes directly through the bottom of the diffraction grating, while ensuring the center of the grating is located on the shaft, the stator is fixed on the outer heat dissipation frame, the motor is connected with the load through rigid coupling and directly drives the grating to rotate; the photoelectric encoder detects the angular position of the diffraction grating, and the output terminal of the photoelectric encoder is connected with the interpolation circuit. The interpolation circuit amplifies the sine and cosine signals outputted by the photoelectric encoder, doubles the frequency and interpolates after conversion, and connects the feedback control circuit through the interpolated output signal; the feedback control circuit achieves double closed-loop control of current feedback and position feedback, and the motor drives the circuit to generate the drive voltage to control the motor rotation. The high-precision grating positioning device has strong anti-interference ability, high resolution precision, and strong practicability and versatility.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

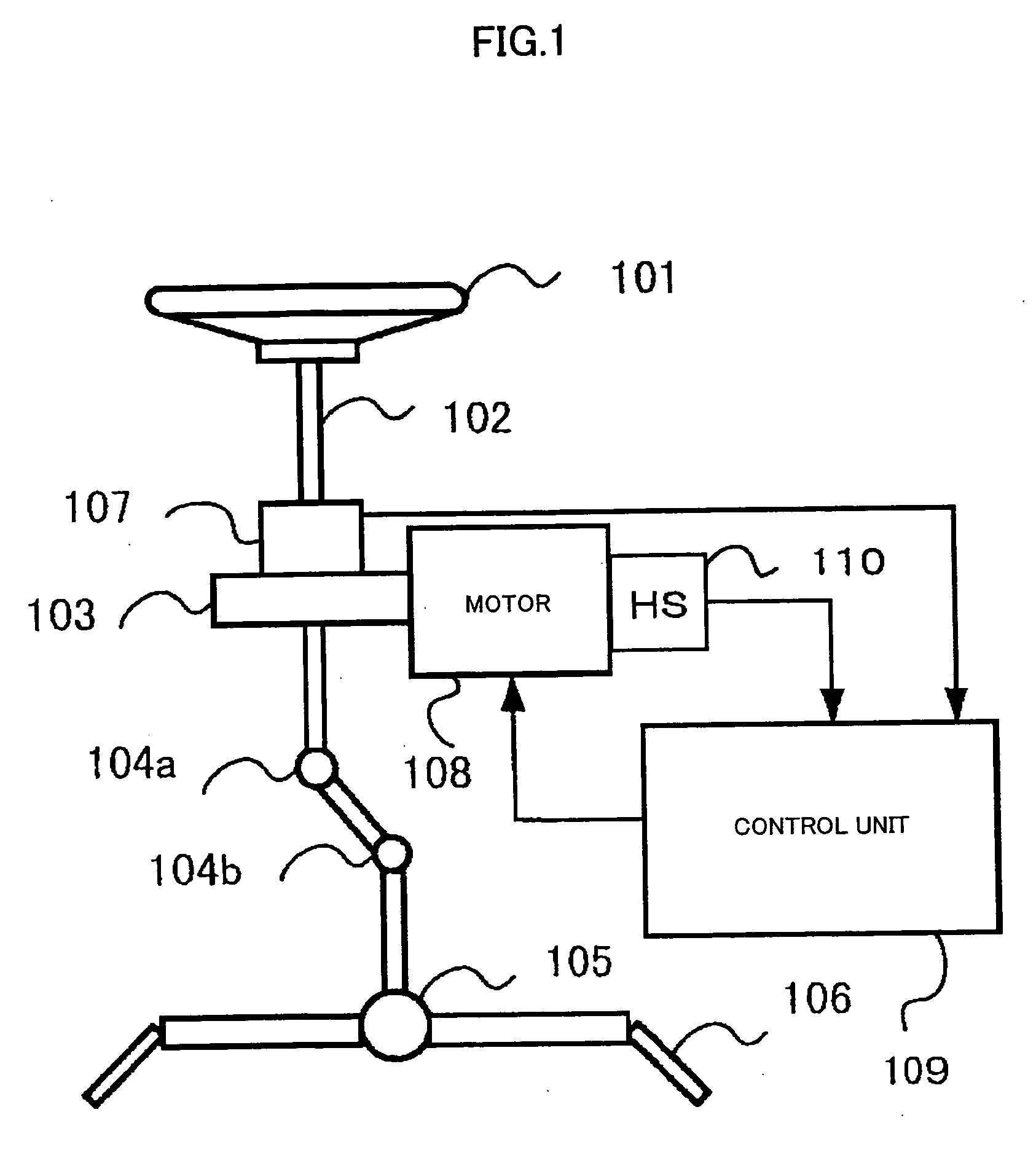

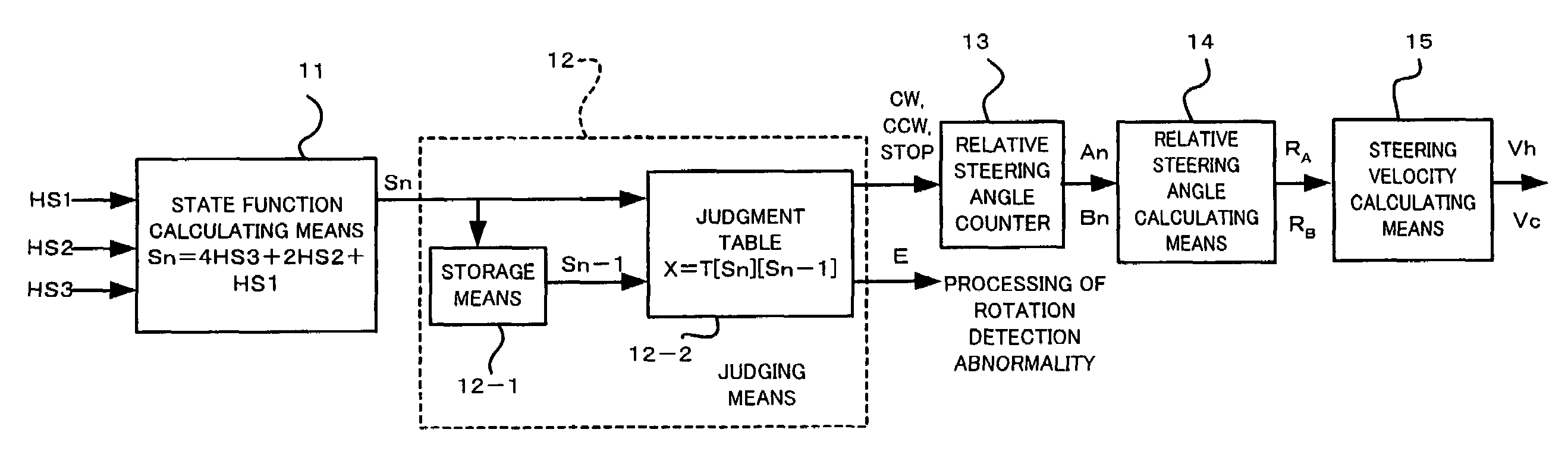

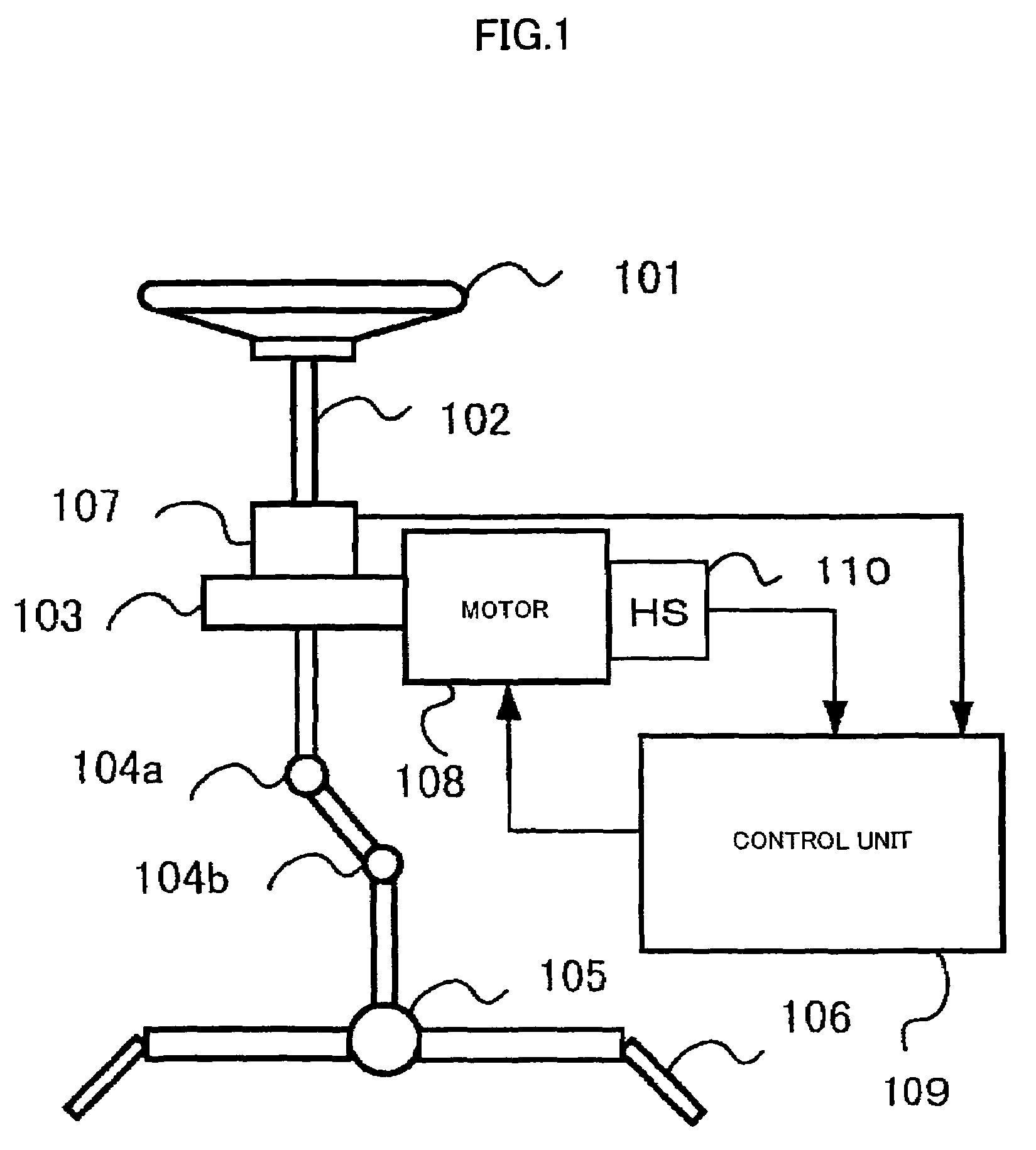

Control unit for electric power steering apparatus

InactiveUS20070132414A1DC motor speed/torque controlVector control systemsElectric power steeringElectric machine

In the present invention, only an abnormality of detection of a rotating direction of a motor is detected and therefore, with simple processing and by using a table for judging the abnormality of the detection of a rotating direction of a motor and the rotating direction of the motor, the abnormality of the detection of a rotating direction and the rotating direction of the motor are judged at one time.

Owner:NSK LTD +1

Method and apparatus for driving a DC motor

A circuit for determining a direction of rotation of an electric motor, the motor having asymmetry and / or eccentricity in a profile of back electromotive force as a function of angular position of a rotor with respect to a stator, the circuit receiving a signal representing the BEMF, and use the corresponding asymmetry and / or eccentricity in the signal to derive the direction of rotation. The signal representing the back emf can be generated by a control circuit. The control circuit can have a feedback loop regulator to generate a control signal (TL or TR) to control a current drive circuit (11,12) to control an amplitude of current (iw) in the windings, the feedback loop regulator being arranged to compare the amplitude of the current (iw) in the windings with a reference value (iset), and use the control signal to provide the signal representing the back electromotive force.

Owner:AMI SEMICON BELGIUM

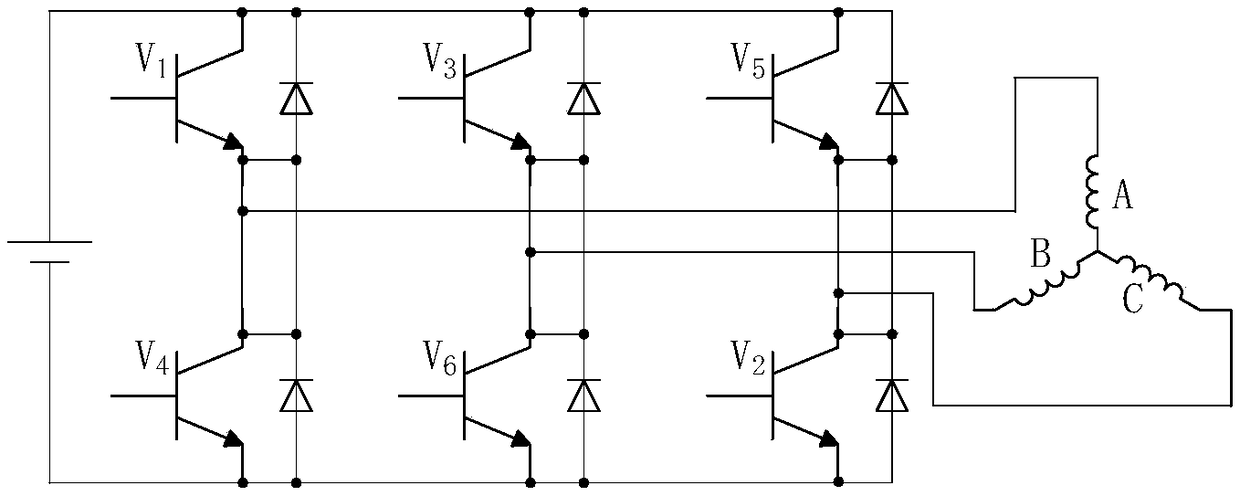

Hall line sequence adaptive learning method of brushless motor

InactiveCN111245307AHelps identify the type of installationMeet control requirementsRotation direction controlElectronic commutatorsBrushless motorsAdaptive learning

The invention discloses a Hall line sequence adaptive learning method of a brushless motor. The method comprises the steps of targeting to a first sector, opening a C-phase upper bridge arm, an A-phase lower bridge arm and a B-phase lower bridge arm; enabling the current to flow in from the C phase and flow out from the phase A and the phase B; enabling the rotor of the motor to stop at a positionafter being dragged by a magnetic field, storing the Hall signal of the position , and establishing a mapping relation : when the Hall signal appears, if the motor needs to be controlled to rotate forwards, controlling the current direction of the coil to be A phase to B phase, and if the motor needs to be controlled to rotate reversely, controlling the current direction of the coil to be B phaseto A phase; and sequentially processing the second sector, the third sector, the fourth sector, the fifth sector and the sixth sector in the same way. According to the invention, by establishing themapping relation between the Hall signal and the brushless motor energized coil, the motor power line and the Hall signal line can be connected according to any sequence; the installation type of theHall sensor can be recognized, and various Hall sensor installation modes can be supported.

Owner:SHENZHEN VMMORE CONTROL TECH

Control unit for electric power steering apparatus

InactiveUS7397210B2DC motor speed/torque controlVector control systemsElectric power steeringIndustrial engineering

In the present invention, only an abnormality of detection of a rotating direction of a motor is detected and therefore, with simple processing and by using a table for judging the abnormality of the detection of a rotating direction of a motor and the rotating direction of the motor, the abnormality of the detection of a rotating direction and the rotating direction of the motor are judged at one time.

Owner:NSK LTD +1

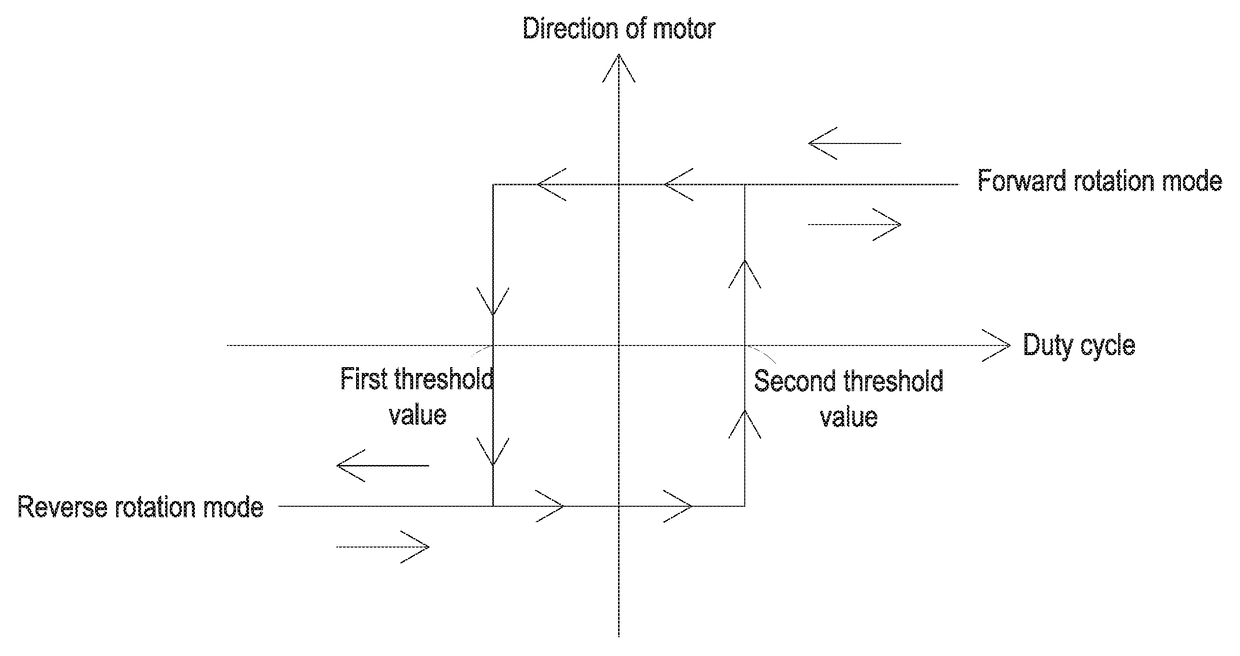

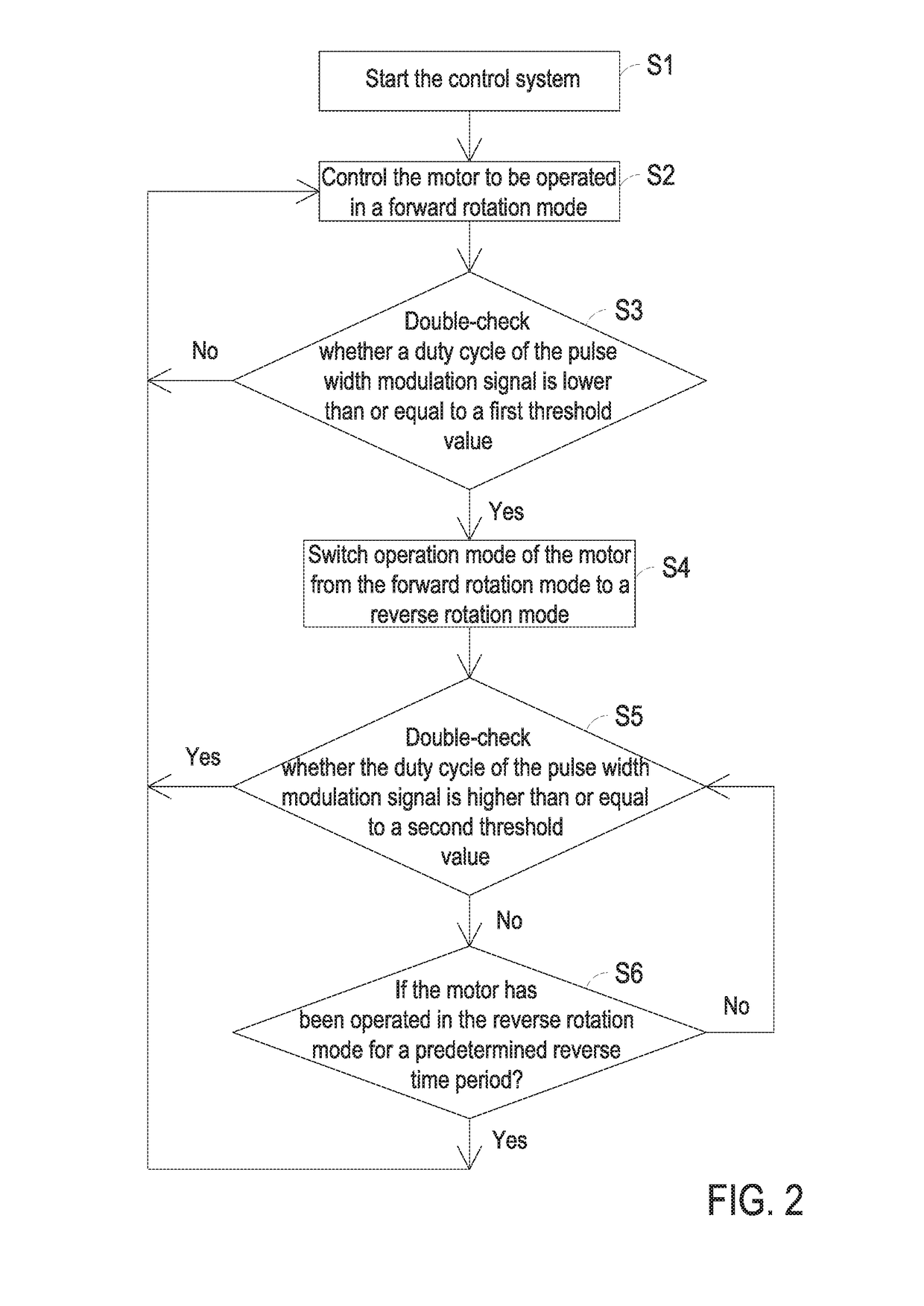

System and method for controlling forward/reverse rotation of fan

ActiveUS9903381B2Heat dissipationMinimize the possibilityEfficient regulation technologiesPump controlControl systemOperation mode

A control system includes a motor, an interface circuit, a motor controller and a detection control circuit. The interface circuit receives and converts a pulse width modulation signal. The fan dissipates heat when the motor is operated in a forward rotation mode and eliminates dust when the motor is operated in a reverse rotation mode. The detection control circuit reads a duty cycle of the converted pulse width modulation signal in real time. When the motor is operated in the forward rotation mode, the detection control circuit drives the motor controller to control the rotation speed of the fan according to the duty cycle. If the duty cycle is lower than or equal to a first threshold value, the detection control circuit drives the motor controller to switch operation mode of the motor from the forward rotation mode to the reverse rotation mode.

Owner:DELTA ELECTRONICS INC

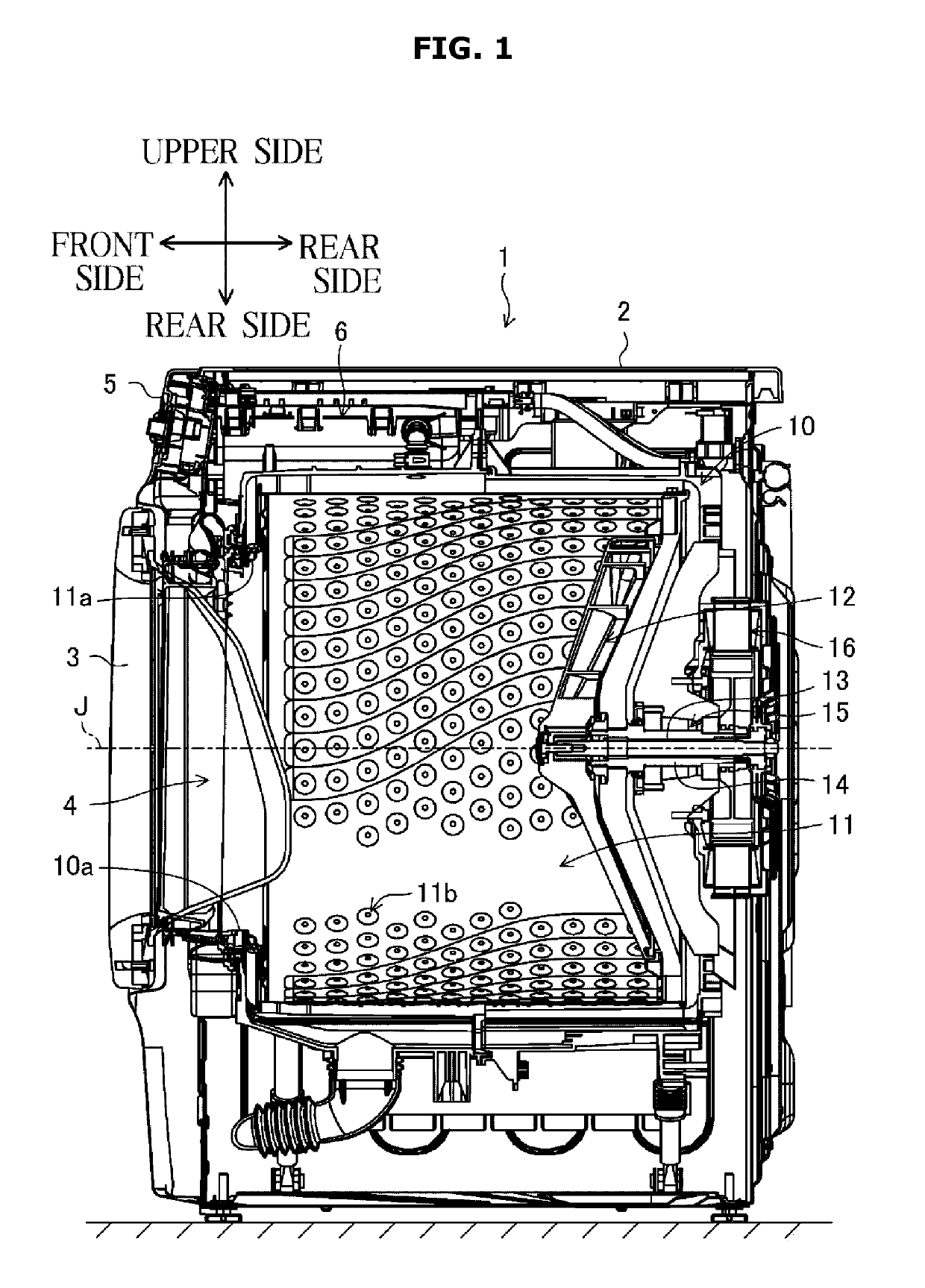

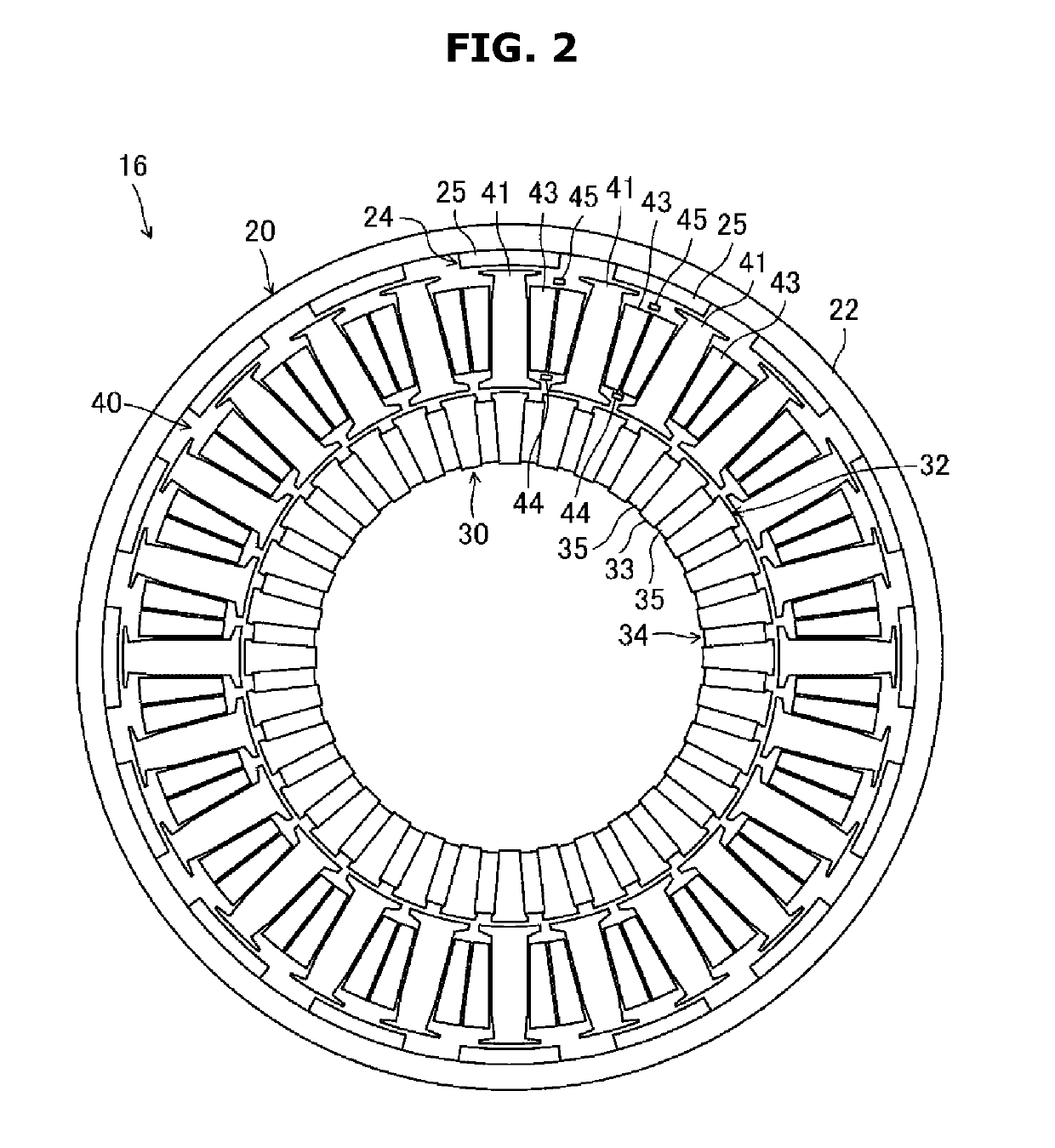

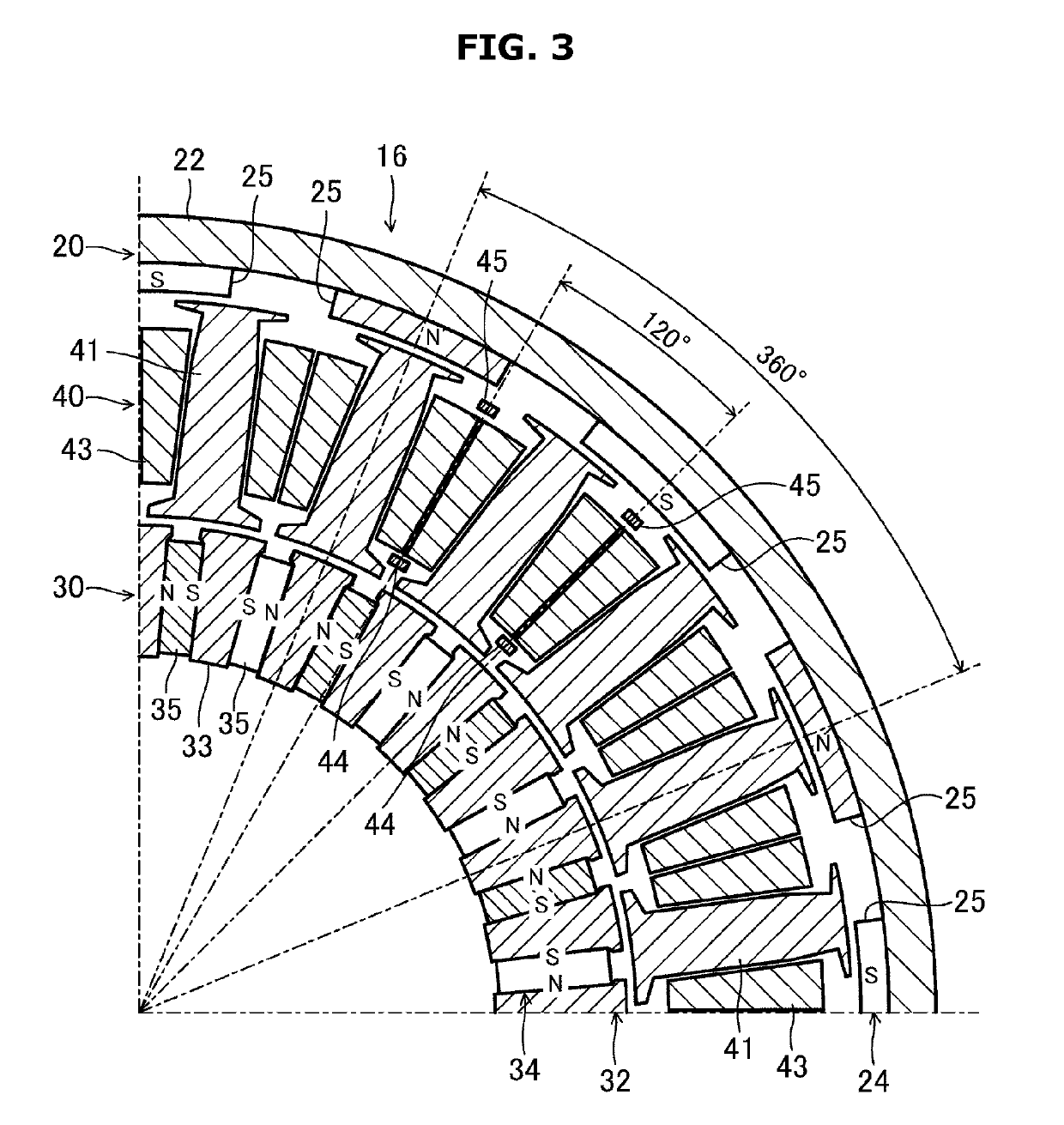

Motor and washing machine having the same

ActiveUS20190190413A1The detection position is accurateAssociation with control/drive circuitsMagnetic circuitMagnetic fluxPosition sensor

Provided is a washing machine including: a stator including a coil; a rotor including a plurality of variable magnets each having a magnetic force variable, and rotatable with respect to the stator; a controller configured to control an energizing of the coil to increase or decrease a magnetic force of the variable magnet; and a plurality of position sensors each having a output voltage changed according to a magnetic flux of the variable magnet.

Owner:SAMSUNG ELECTRONICS CO LTD

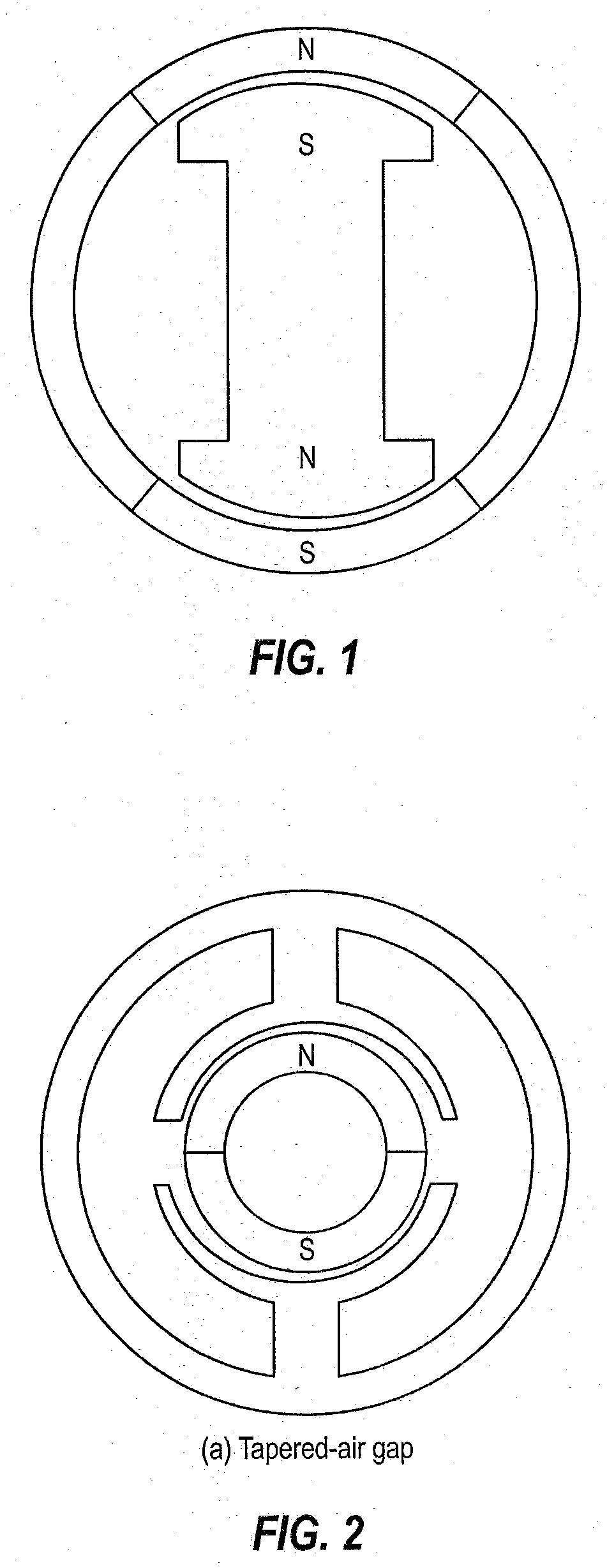

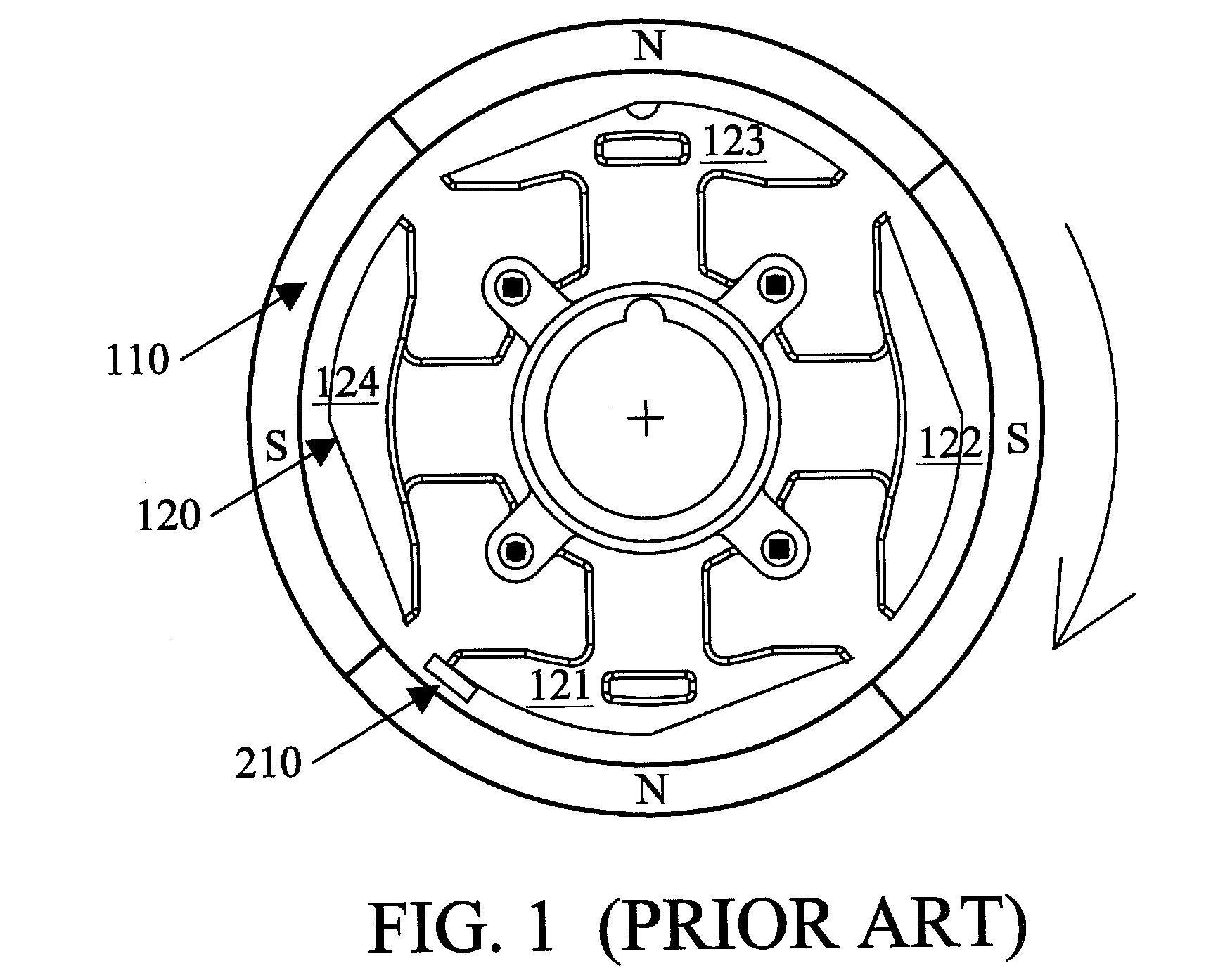

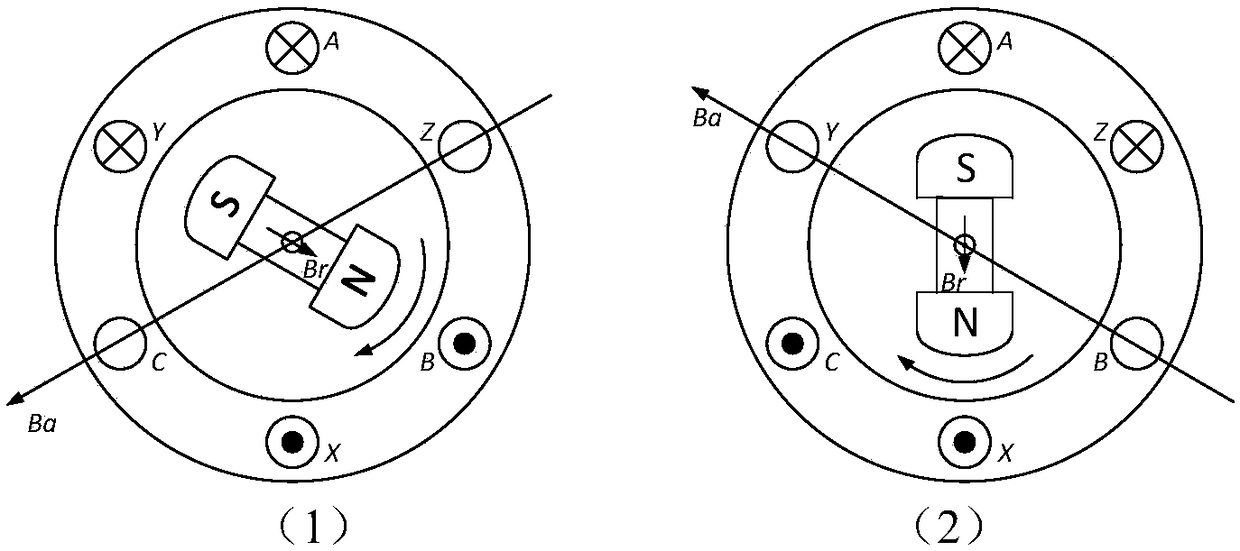

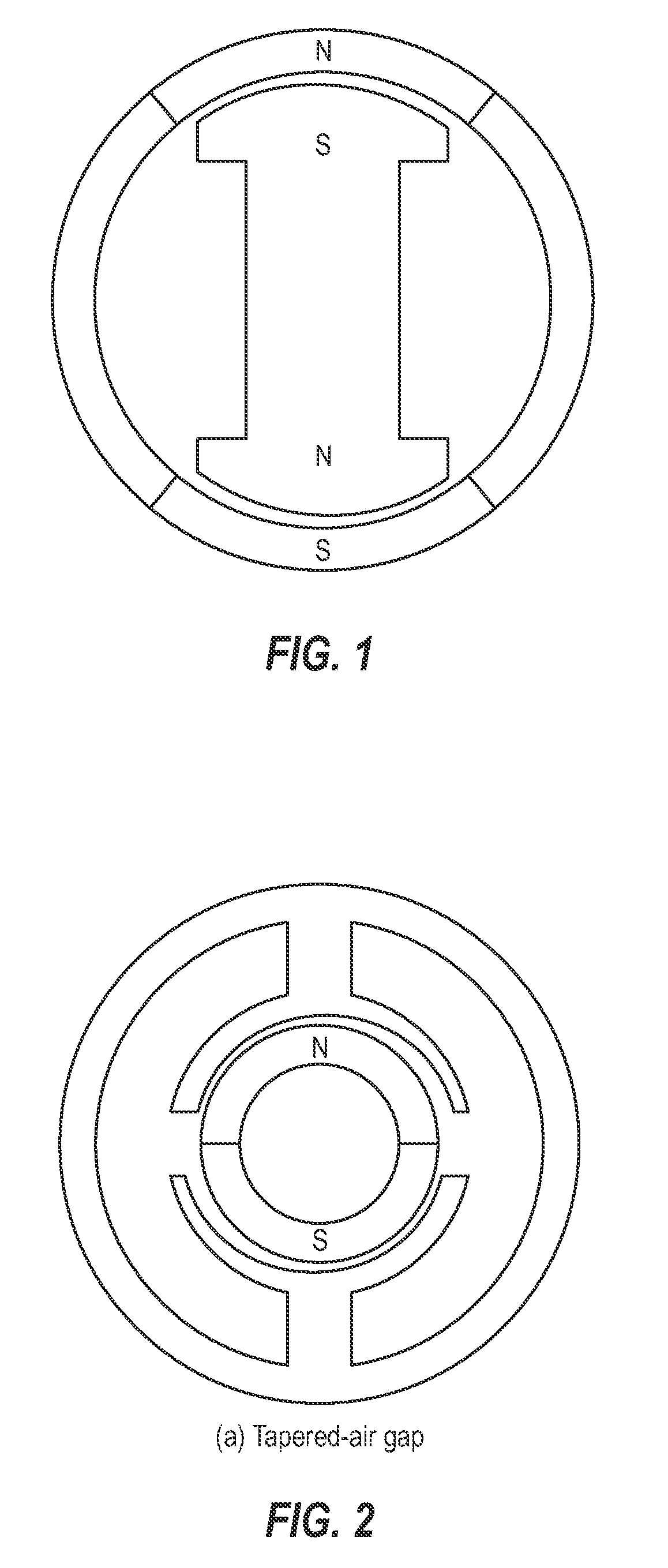

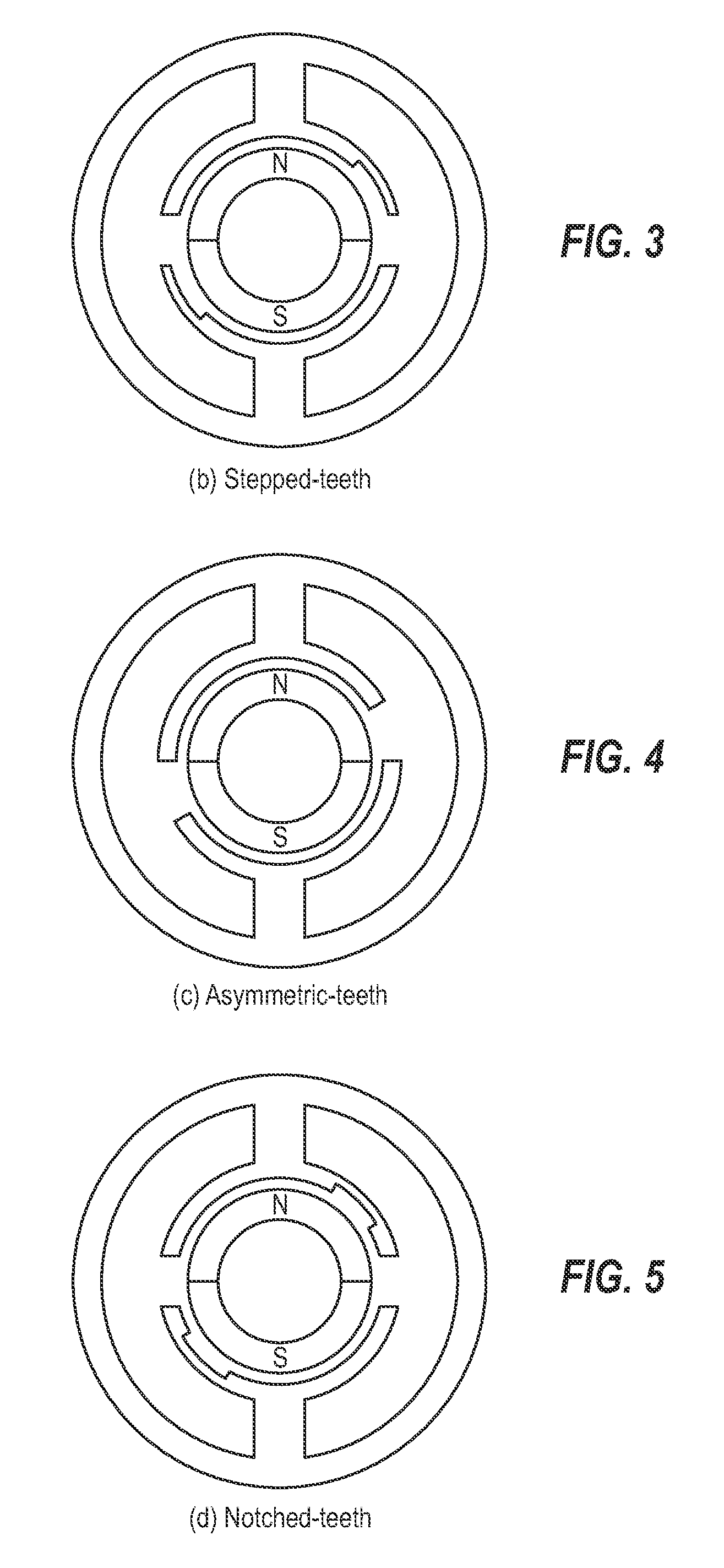

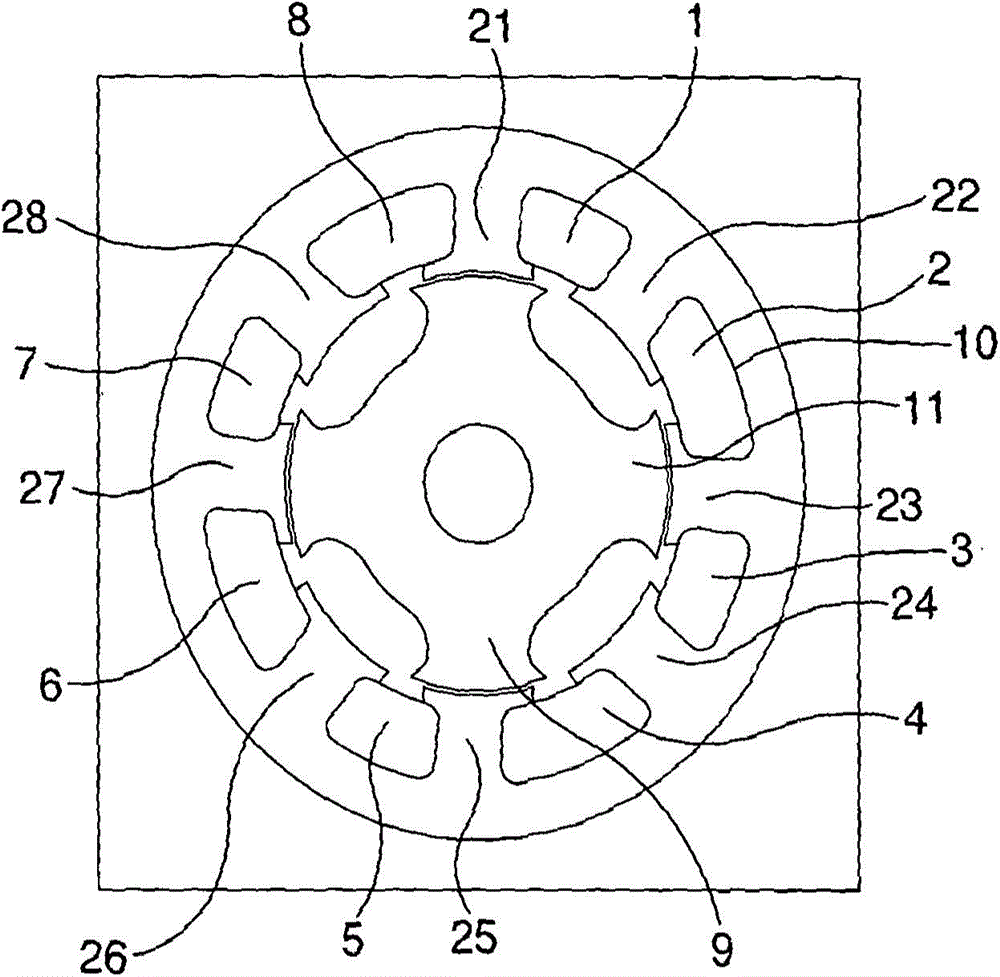

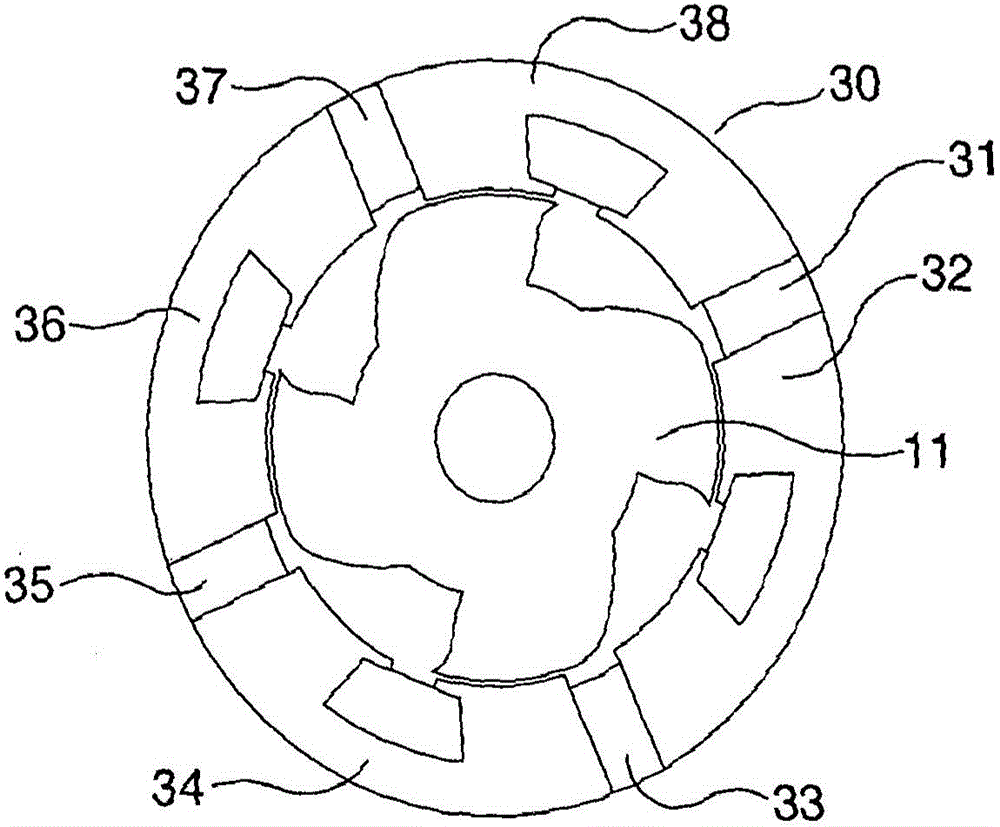

Design improvements for flux switching machines

InactiveCN103563239ATorque ripple controlAssociation with control/drive circuitsHigh torqueControl theory

It is the object of this invention to provide a design for flux switching machines with a one or more armature windings which can deliver controlled torque, in either selected direction on start up, without the use of a mechanical position sensor. Rotor slotting 210 is introduced to create a path of low permeability across a rotor tooth with minimal impact on the normal torque producing flux paths, bridges 211 retaining the portions of the laminations together.. Asymmetry of stator slots e.g. 207, 208 is used to further create a stable rotor position when energised by predominantly field means or armature means. The method is suitable for starting permanent magnet flux switching motors. The invention discloses design features for such machines which improves the torque profile of the motor with angle. In three phase machines this delivers higher torque and lower ripple torque. In single phase flux switching machines the invention allows the rotor to be placed in a position where maximum torque can be delivered in either direction by selection of either positive or negative armature current.

Owner:TECHNELEC

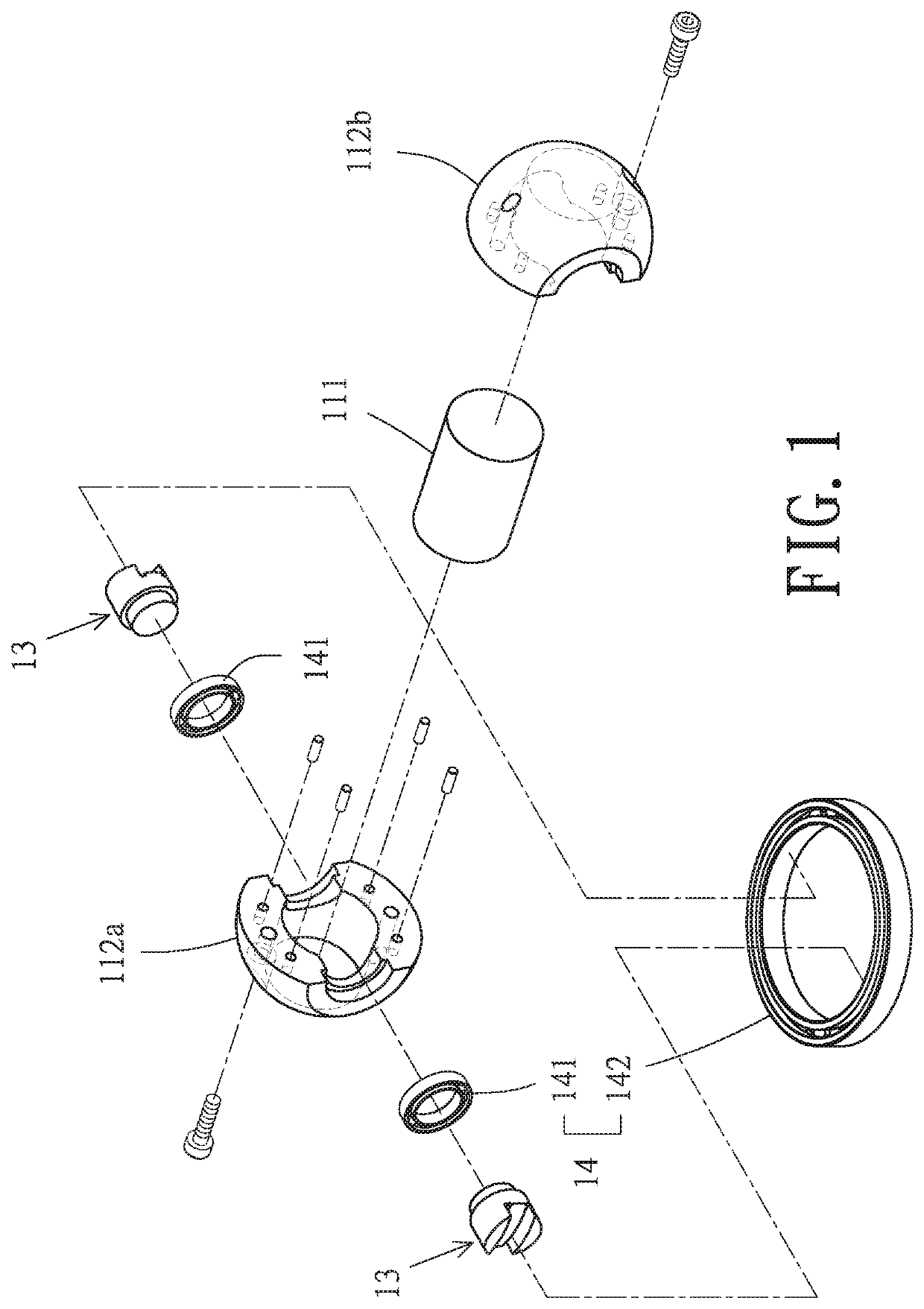

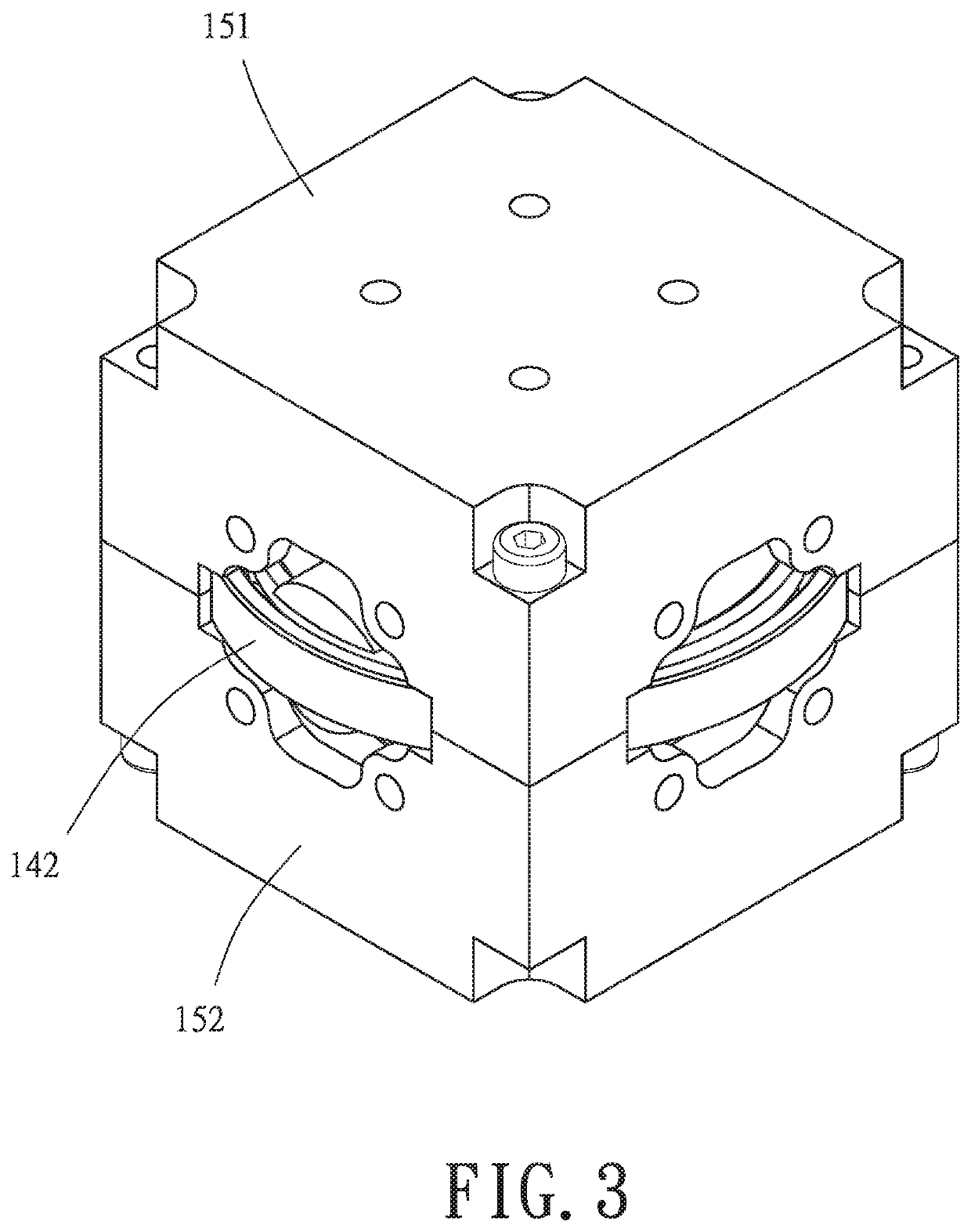

Motor and Drive Circuit and Driving Method the Same

ActiveUS20210050767A1Reduce the burden onReduce weightAssociation with control/drive circuitsMagnetic circuitElectric machineStator coil

A motor comprising a stator and a rotor; the stator includes a first stator, a second stator, and a third stator; the stators each include at least one stator coil; the rotor includes a magnetic element, a first bearing, a second bearing, and a shaft; the stators generating a superimposed magnetic field together causes the magnetic element to rotate; when the magnetic element rotates in the first plane, the outer ring of the first bearing rotates; the center of the first bearing is located in a plane where the second bearing is located, and when the magnetic element rotates in the second plane, the inner ring of the second bearing rotates; the central axis of the shaft passes through the center of the first bearing; wherein the shaft is rotatably fixed to the first bearing and connected to the second bearing; the magnetic element located in where the central axis of the first bearing meets the central axis of the second bearing, the normal vector of the first plane is parallel to the axial direction of the shaft; the normal vector of the second plane is perpendicular to the axial direction of the shaft.

Owner:TENSOR TECH CO LTD

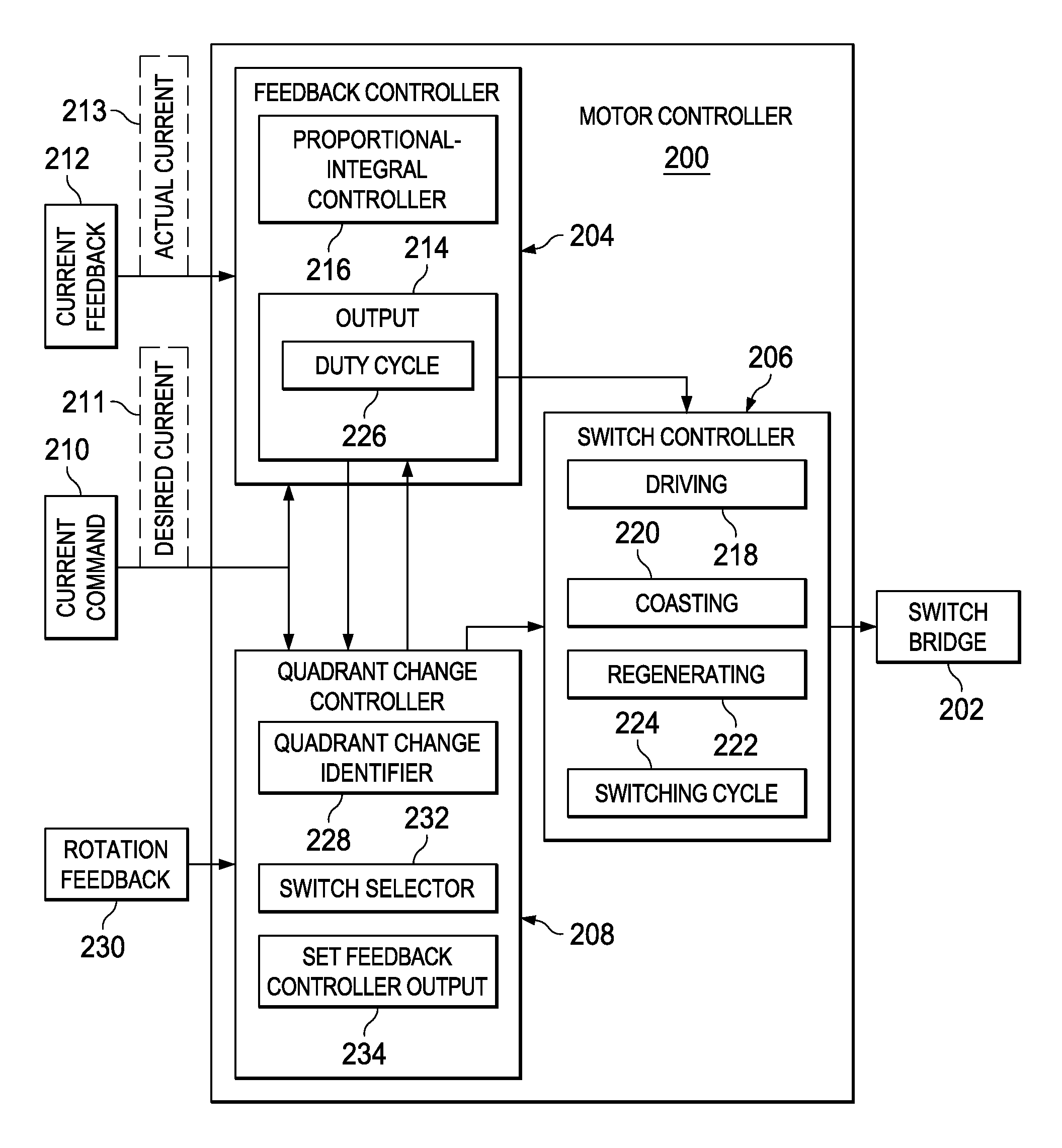

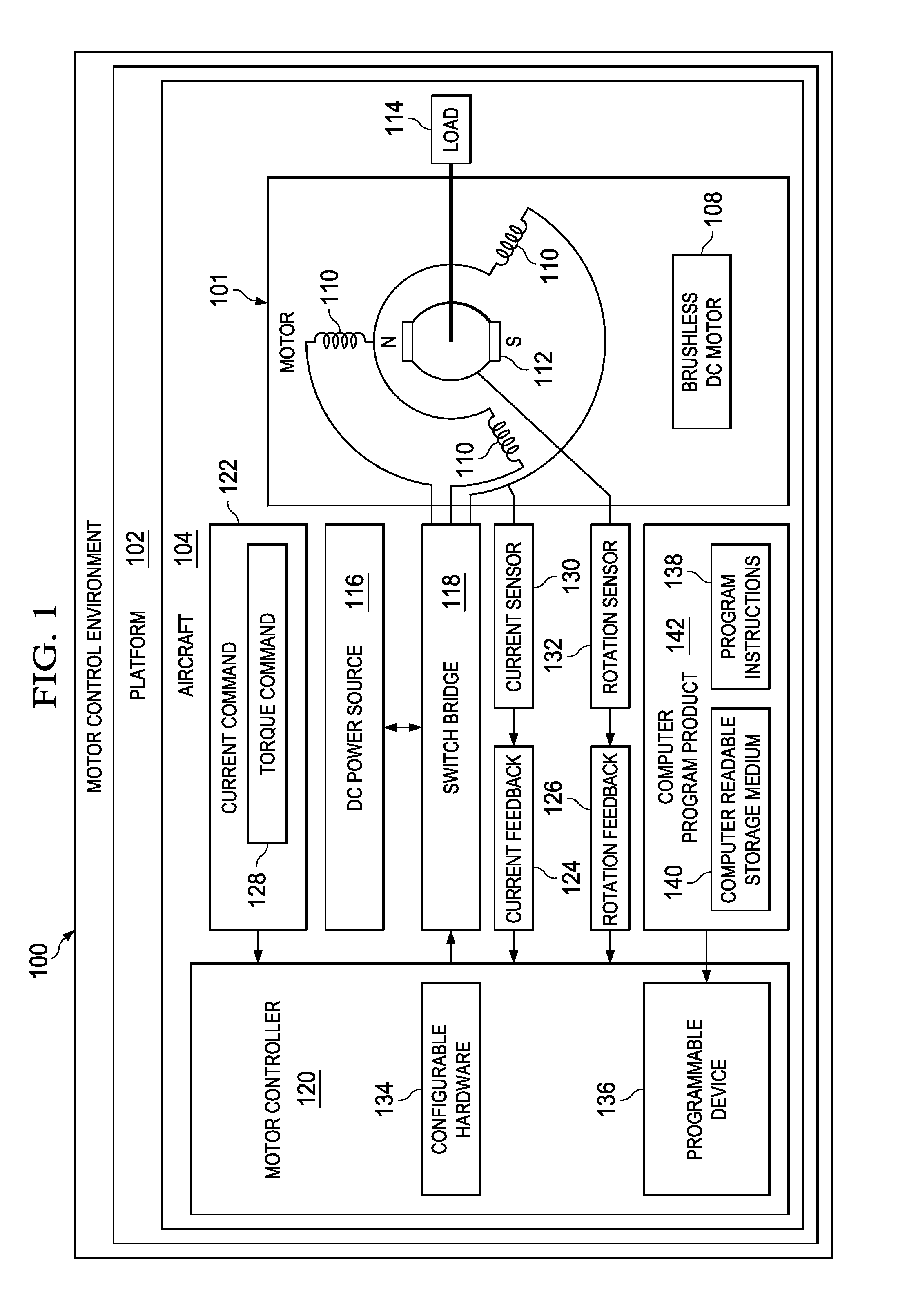

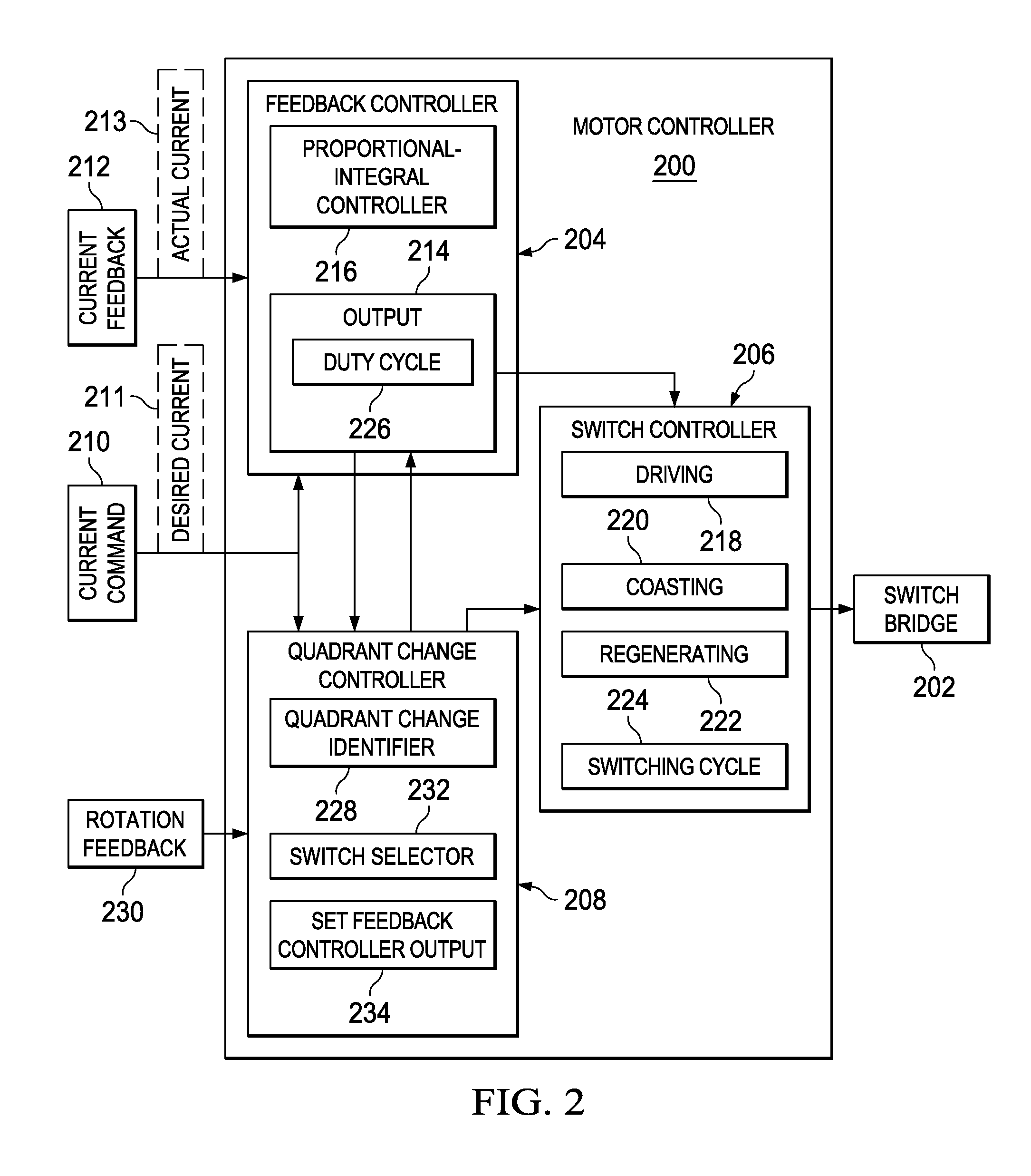

Quadrant change control in brushless DC motors

A method and apparatus for controlling a change in a quadrant of operation of a brushless direct current motor. A quadrant change in an operation of a motor is identified. In response to identifying the quadrant change, selected ones of a plurality of switches in a switch bridge are selected to be controlled to couple a direct current power source to the windings of the motor to change a direction of an actual current in the windings.

Owner:THE BOEING CO

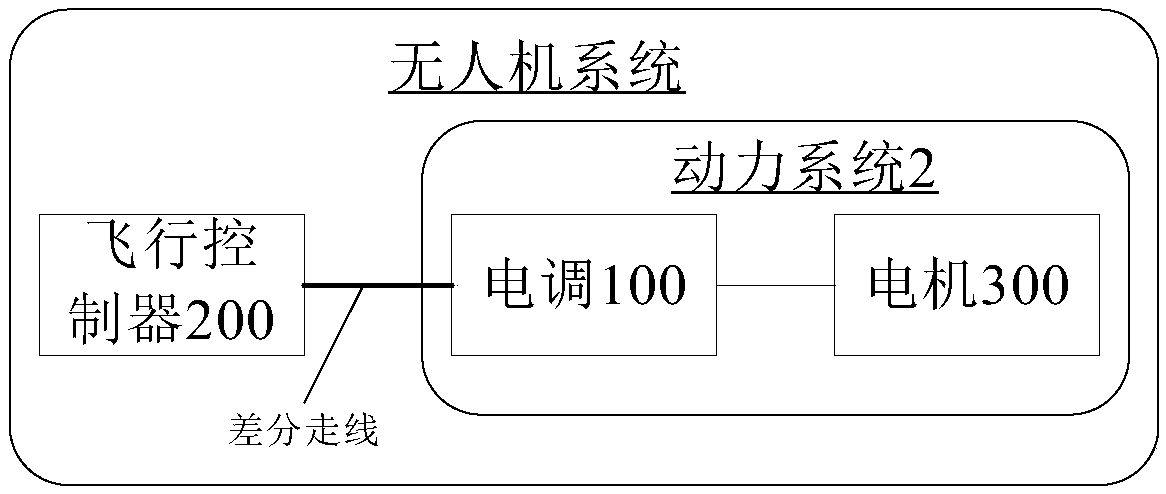

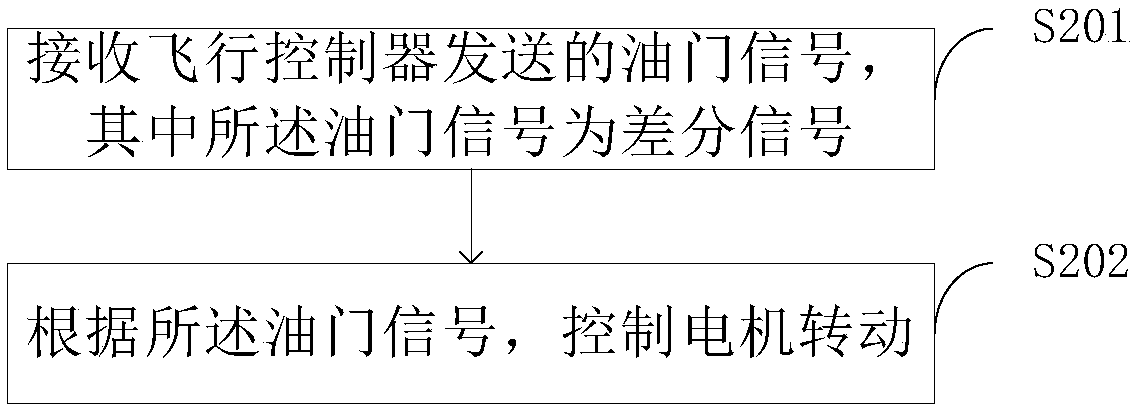

Motor drive and flight control method, ESC, power system and UAV system

PendingCN108513639AEasy to controlStrong anti-interference (mainly refers to noise interference) abilityAircraft componentsSpeed controllerFlight control modesDifferential signaling

The invention provides a motor drive and flight control method, an ESC, a power system and a UAV system, wherein the UAV system comprises a rack (1), a plurality of power systems (2) respectively arranged on the rack, and Flight controller (200), the power system includes ESC (100) and motor (300), ESC is connected with motor for controlling the working state of the motor; E-communication connection between flight controller and power system; Flight control The device sends the throttle signal to the ESC, and the ESC controls the corresponding motor rotation according to the throttle signal toprovide flight power for the drone, wherein the throttle signal is a differential signal. The invention sends the differential throttle signal to the electric adjustment by the flight controller to drive the motor to rotate, the differential throttle signal has strong anti-interference ability, effectively suppresses electromagnetic interference, and the timing positioning is accurate, so that the ESC can obtain a more accurate throttle signal and realize the motor. The precise control for the precise control of the drone is realized.

Owner:SZ DJI TECH CO LTD

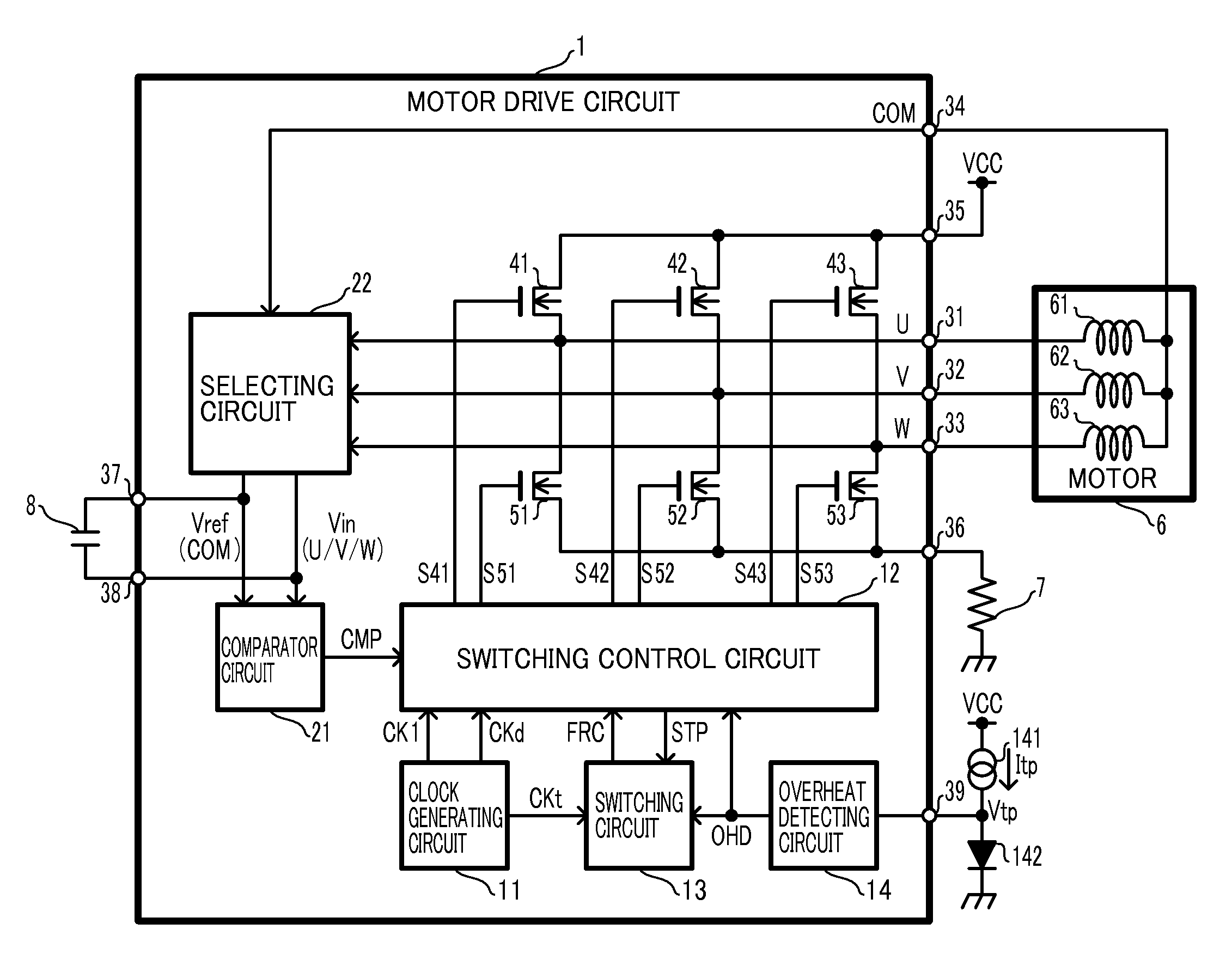

Motor Drive Circuit and Illumination Apparatus

InactiveUS20120068605A1Low heat generationLow efficiencySingle motor speed/torque controlTemperatue controlDriver circuitDriving current

A motor-drive circuit includes: an output transistor configured to supply a drive current to a motor for a cooling fan; a switching-control circuit configured to control switching of the output transistor so that the motor rotates in a first direction, or rotates in a second direction opposite to the first direction; and a switching circuit configured to, when a first time has elapsed since start of rotation of the motor in the first direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the first direction and thereafter rotates in the second direction, and configured to, when a second time has elapsed since start of rotation of the motor in the second direction, cause the switching-control circuit to start switching control so that the motor stops rotating in the second direction and thereafter rotates in the first direction.

Owner:SEMICON COMPONENTS IND LLC

Motor control device, and optical scanning device, image forming device and printed circuit board including the same

InactiveUS20140204431A1Low costReduce cost and amount of time necessaryCommutation monitoringDC motor speed/torque controlLight beamImage formation

A CPU determines that a motor is undergoing a forward rotation when a time difference between a detection timing of a light beam deflected by a rotating polygonal mirror and an output timing of a detection signal from a magnetic detector element falls within a predetermined range, and that the motor is undergoing a reverse rotation when the time difference does not fall within the predetermined range. With this configuration, a detection circuit for detecting voltage induced in three phases is unnecessary, and therefore the cost can be reduced. Furthermore, there is no need to detect voltage induced in each of the three phases. As it suffices to simply detect the time difference, the amount of time required to detect a rotation direction can be reduced.

Owner:CANON KK

Motor and motor driving circuit

InactiveCN108075696ASimple structureImprove general performanceCurrent controllersStructural associationDriver circuitPermanent magnet rotor

The invention provides a motor and a driving circuit thereof. The driving circuit comprises a controllable bidirectional AC switch, a first detection circuit, a second detection circuit, a steering control circuit and an on-off control circuit, wherein the controllable bidirectional AC switch is connected with a stator winding at two ends of an AC power supply; the first detection circuit and thesecond detection circuit are used for detecting the magnetic pole position of a permanent magnet rotor and outputting a magnetic pole position signal at the respective output end; the steering controlcircuit selectively outputs the magnetic pole position signal outputted by the first detection circuit or the second detection circuit to the on-off control circuit according to steering setting of the motor; and the on-off control circuit controls the conducting state of the controllable bidirectional AC switch according to a signal outputted by the steering control circuit and polarity information of the AC power supply so as to control the motor to rotate positively or negatively. The motor driving circuit is simple in structure and good in universality.

Owner:JOHNSON ELECTRIC SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com