Fault-tolerant control method for Hall position sensor of permanent-magnet brushless motor

A permanent magnet brushless motor, Hall position technology, applied in the direction of motor control, control system, electronic commutator, etc., can solve problems such as poor practicability, achieve the effect of good practicability, ensure normal operation, and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

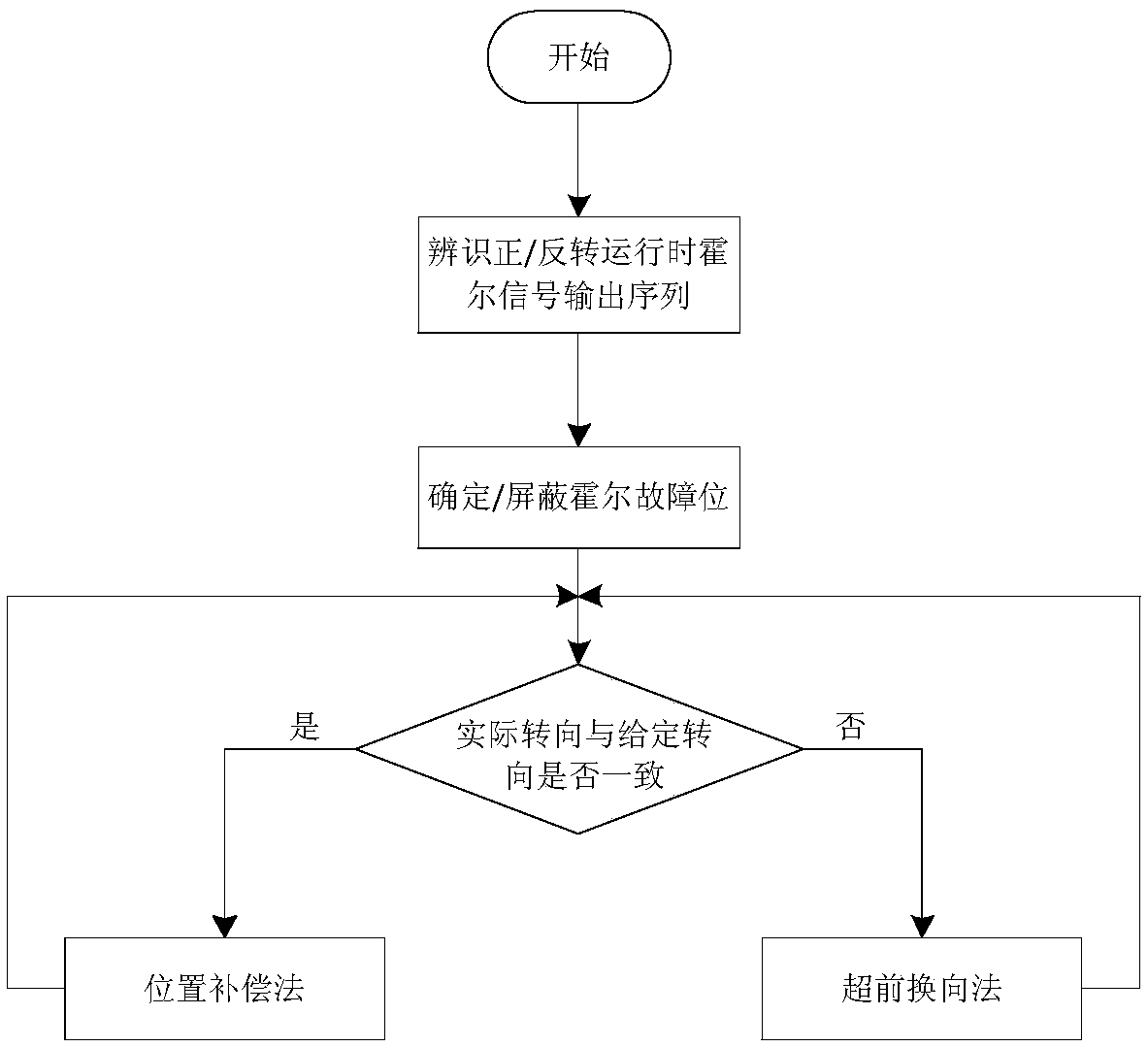

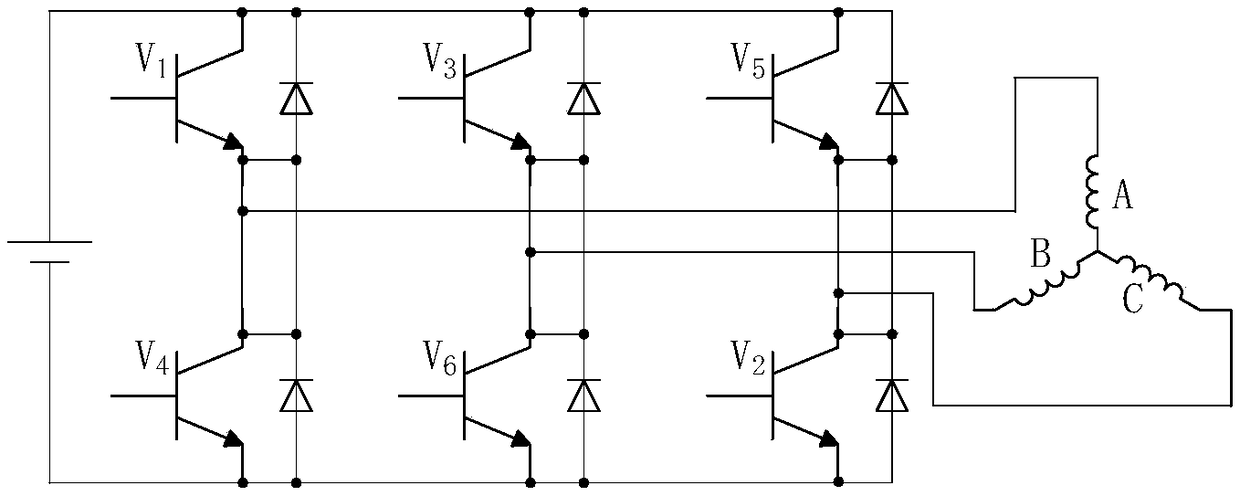

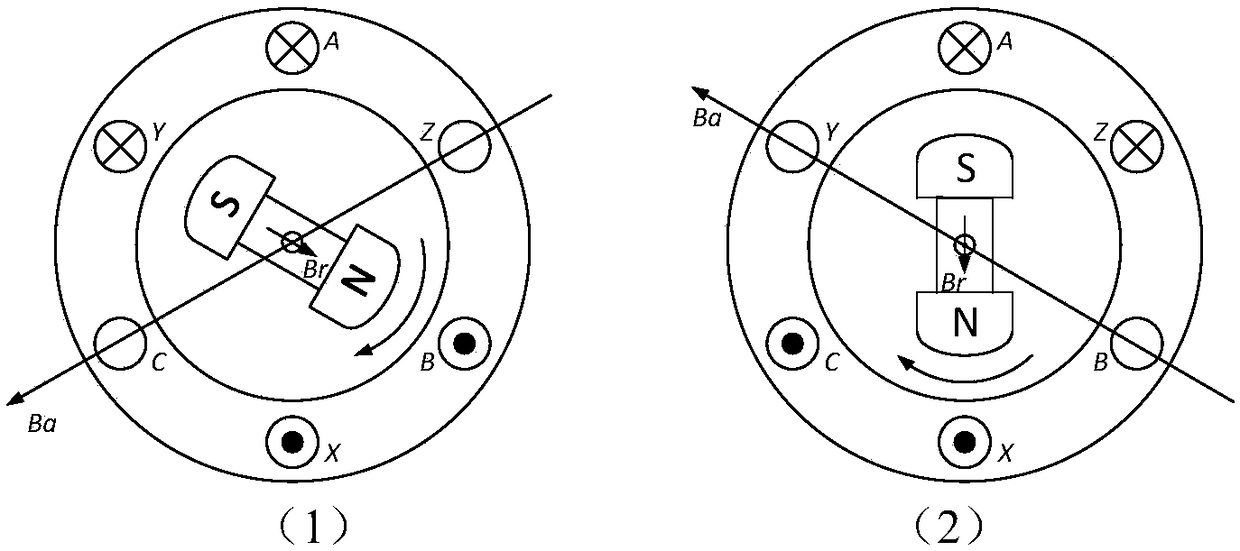

[0024] The following examples refer to Figure 1-5 .

[0025] The present invention aims at the failure of the hall sensor of the permanent magnet brushless motor under the condition of low speed and frequent positive and negative rotation of the permanent magnet brushless motor used in the servo of the aircraft all-electric brake system, and proposes a combination of position compensation method and advanced commutation method A fault-tolerant control method for Hall position sensors of permanent magnet brushless motors. In this method, when the Hall position sensor fails, the rotor position information is obtained through the position compensation method, and the reverse operation of the motor is realized through the advanced commutation method, so that the permanent magnet brushless motor with low speed and frequent forward and reverse operation is at the Hall position. When the sensor fails, it works normally to ensure the reliable operation of the aircraft's all-electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com