Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about "Insulating resist/coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for planarizing substrates and encapsulating printable electronic features

InactiveUS20060160373A1Printed electric component incorporationPrinted circuit aspectsEngineeringMechanical engineering

Owner:CABOT CORP

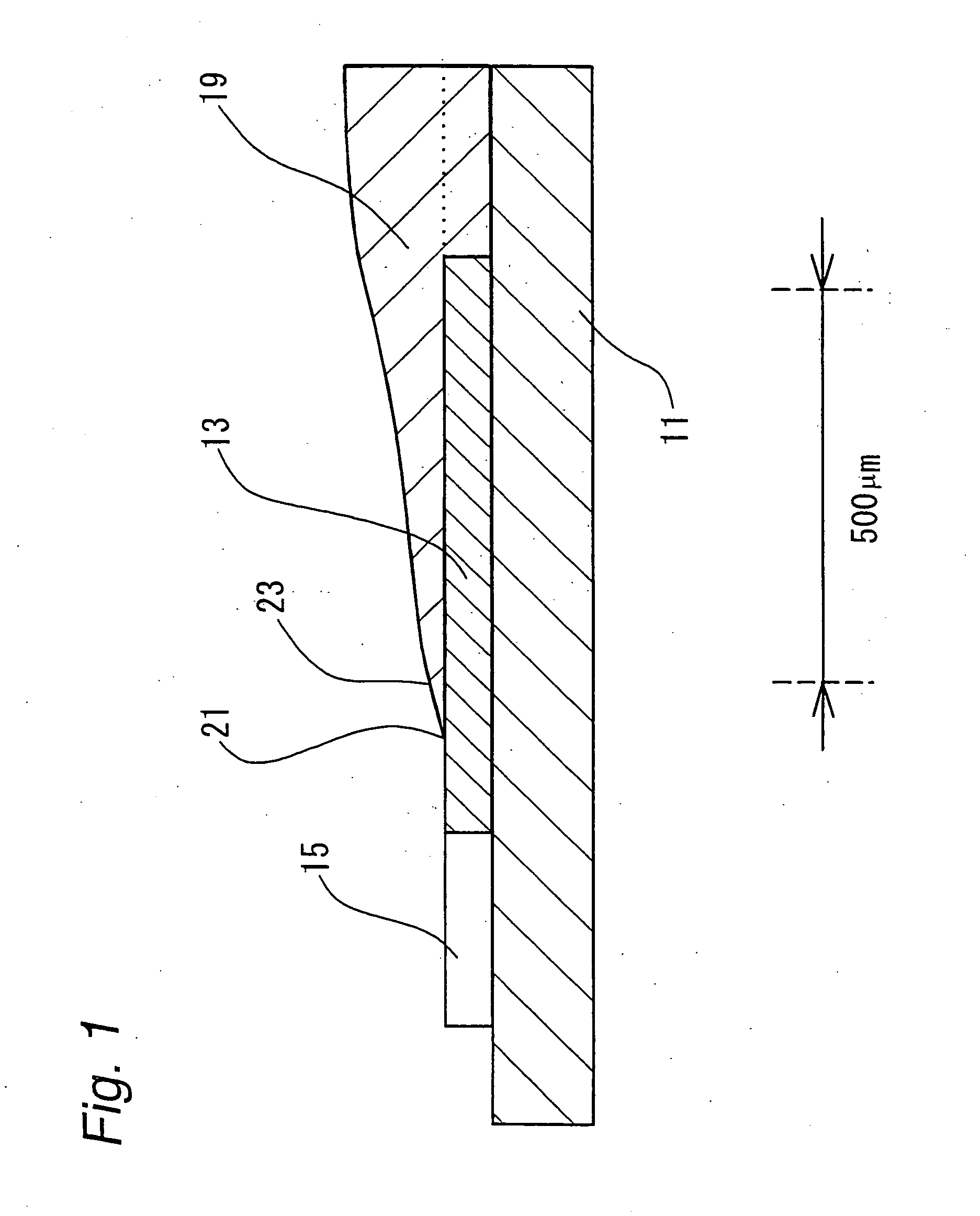

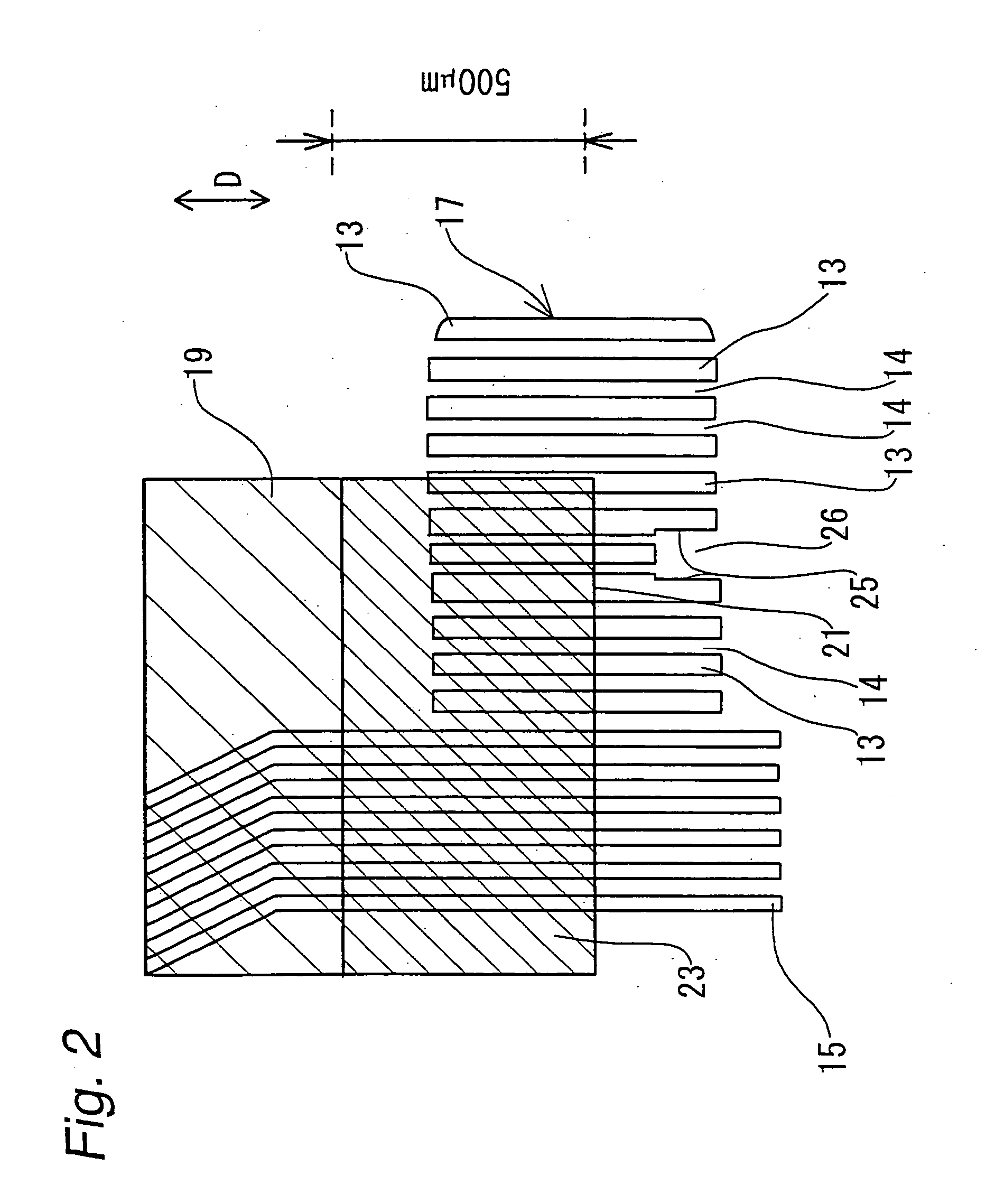

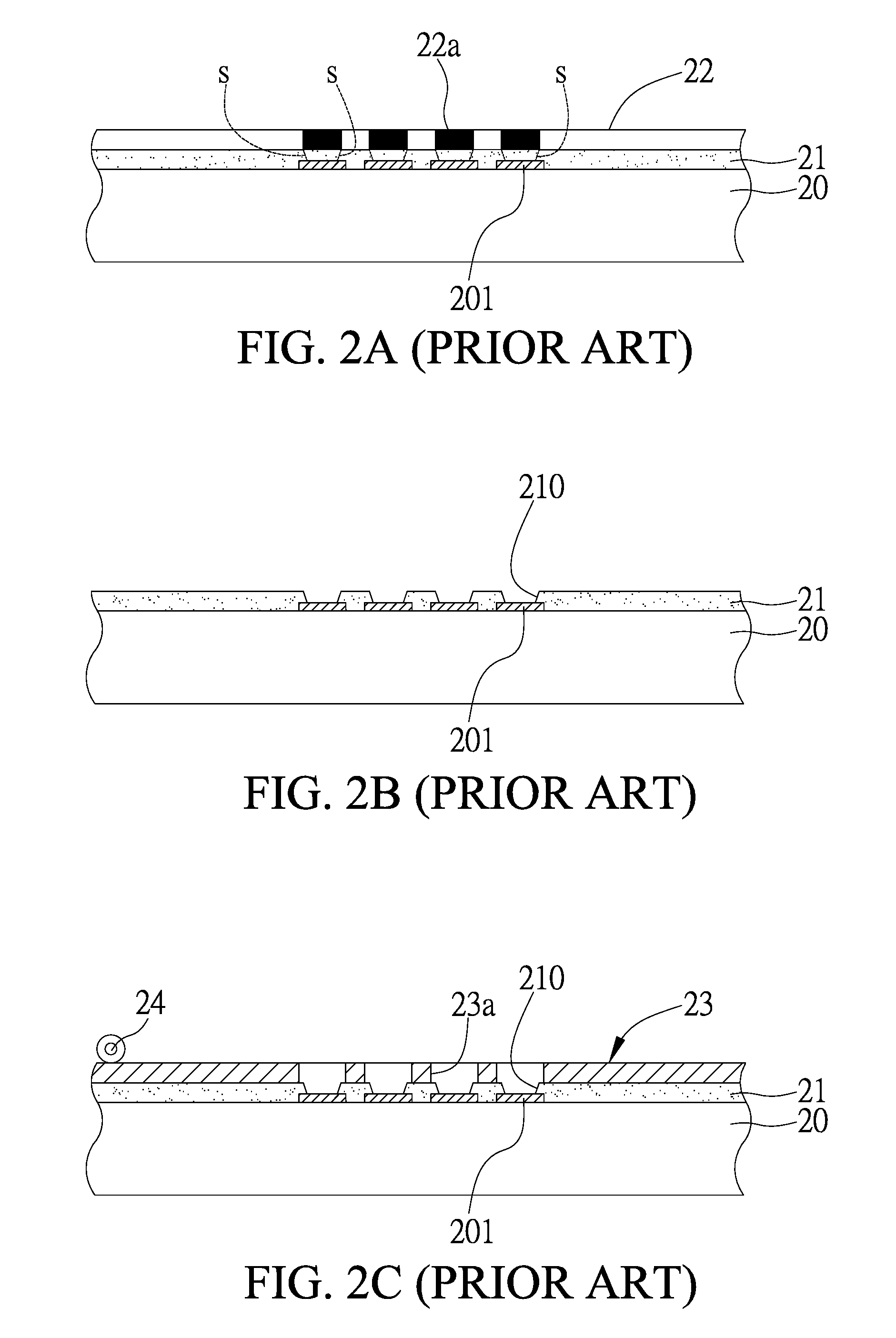

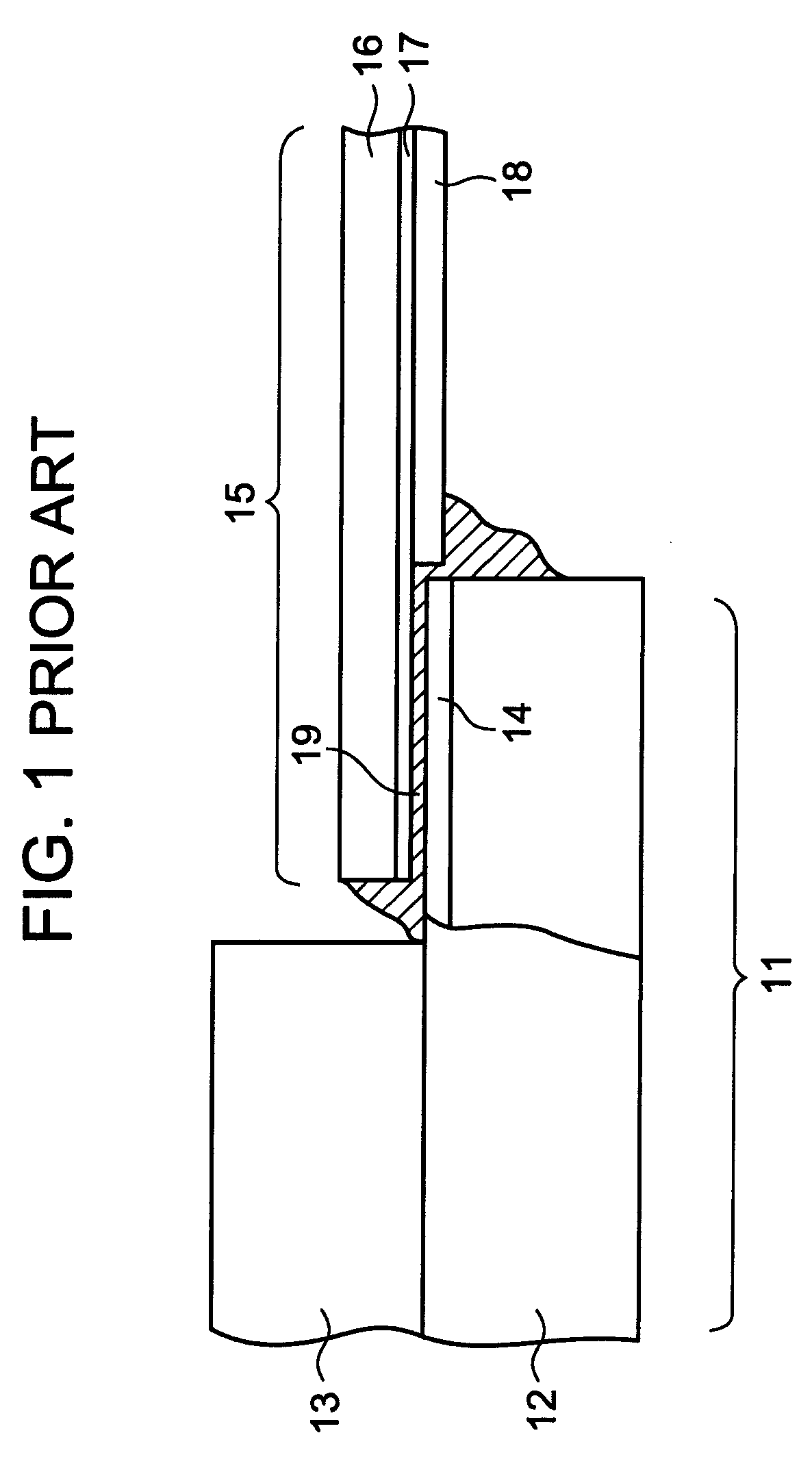

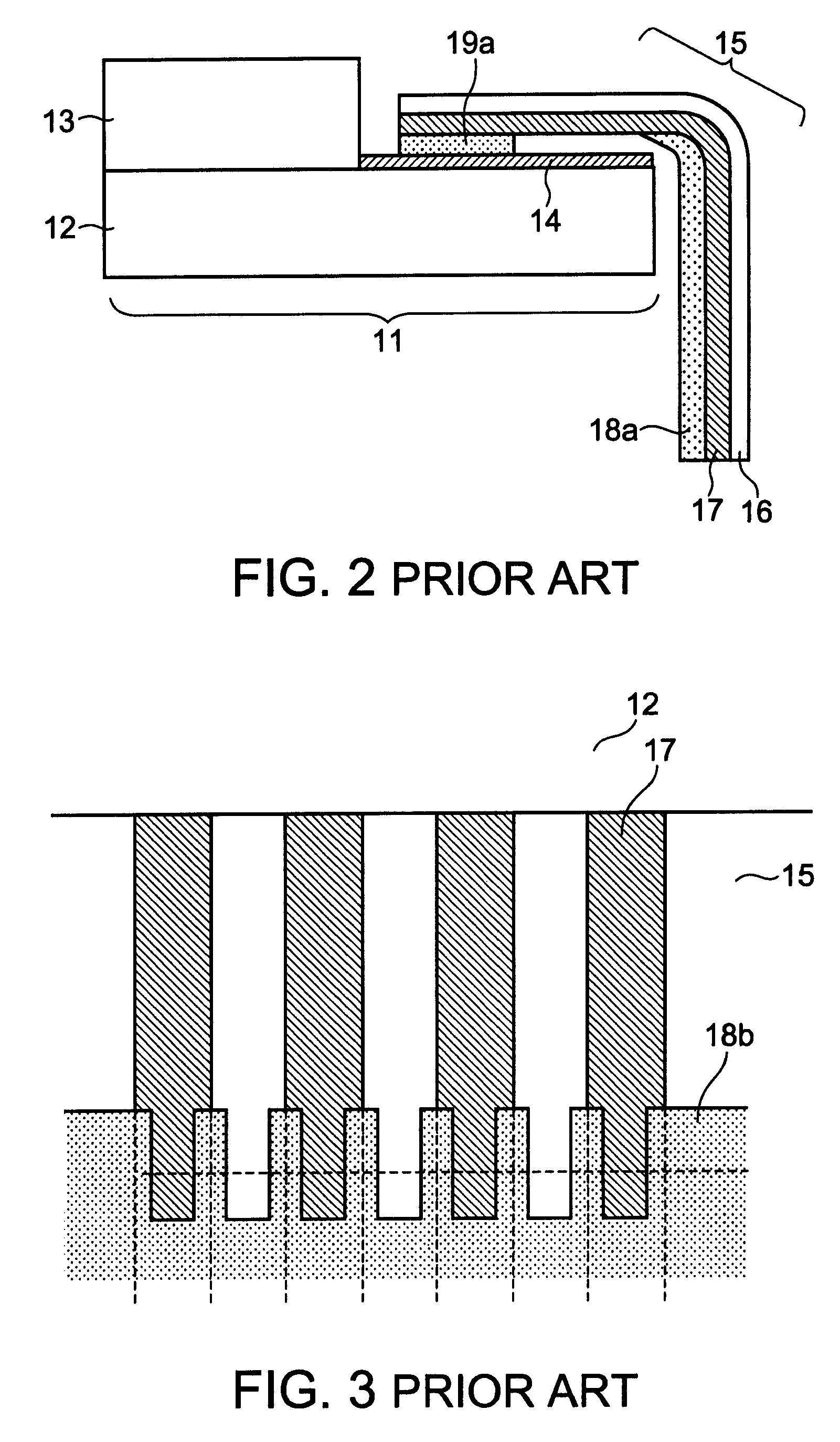

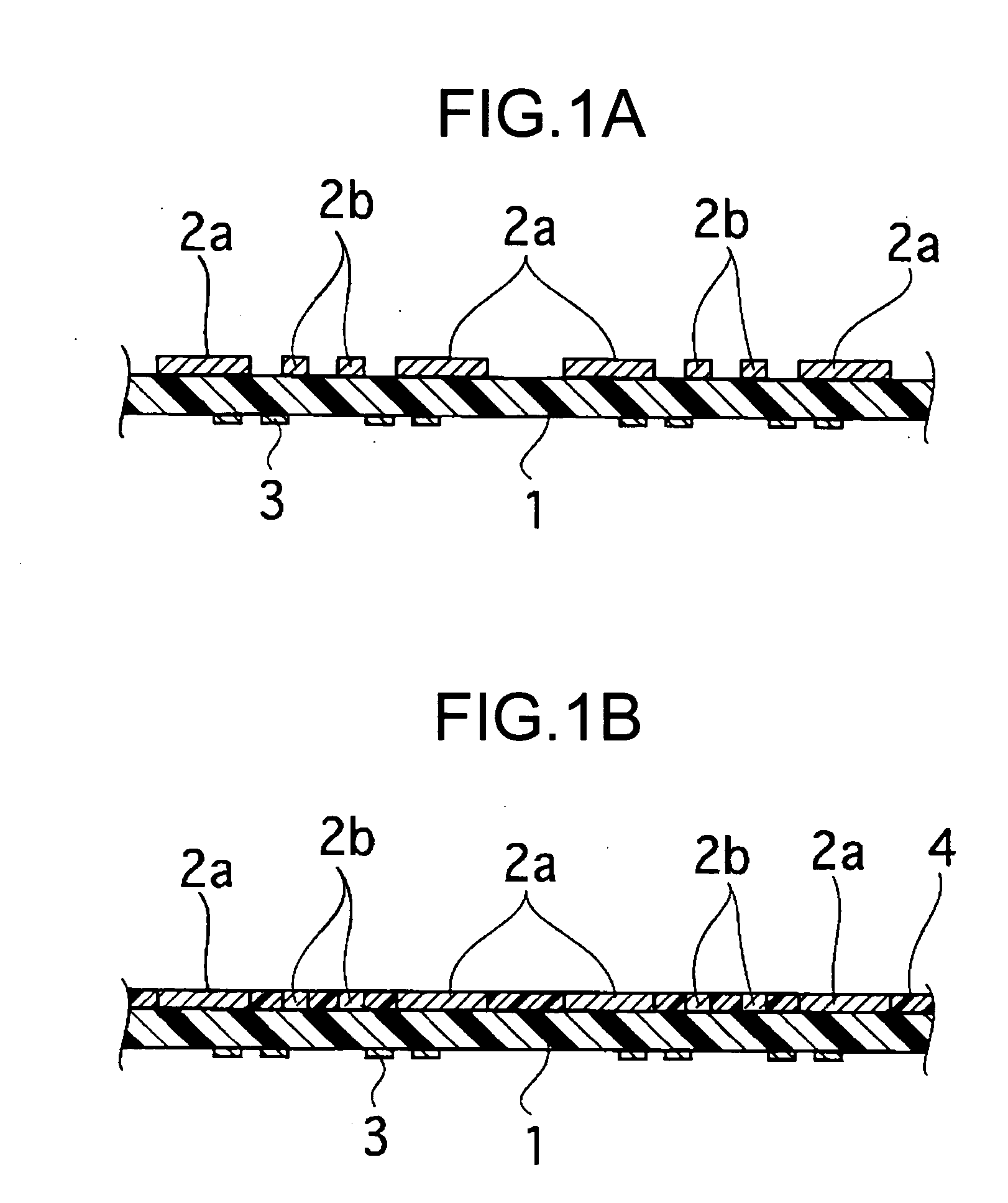

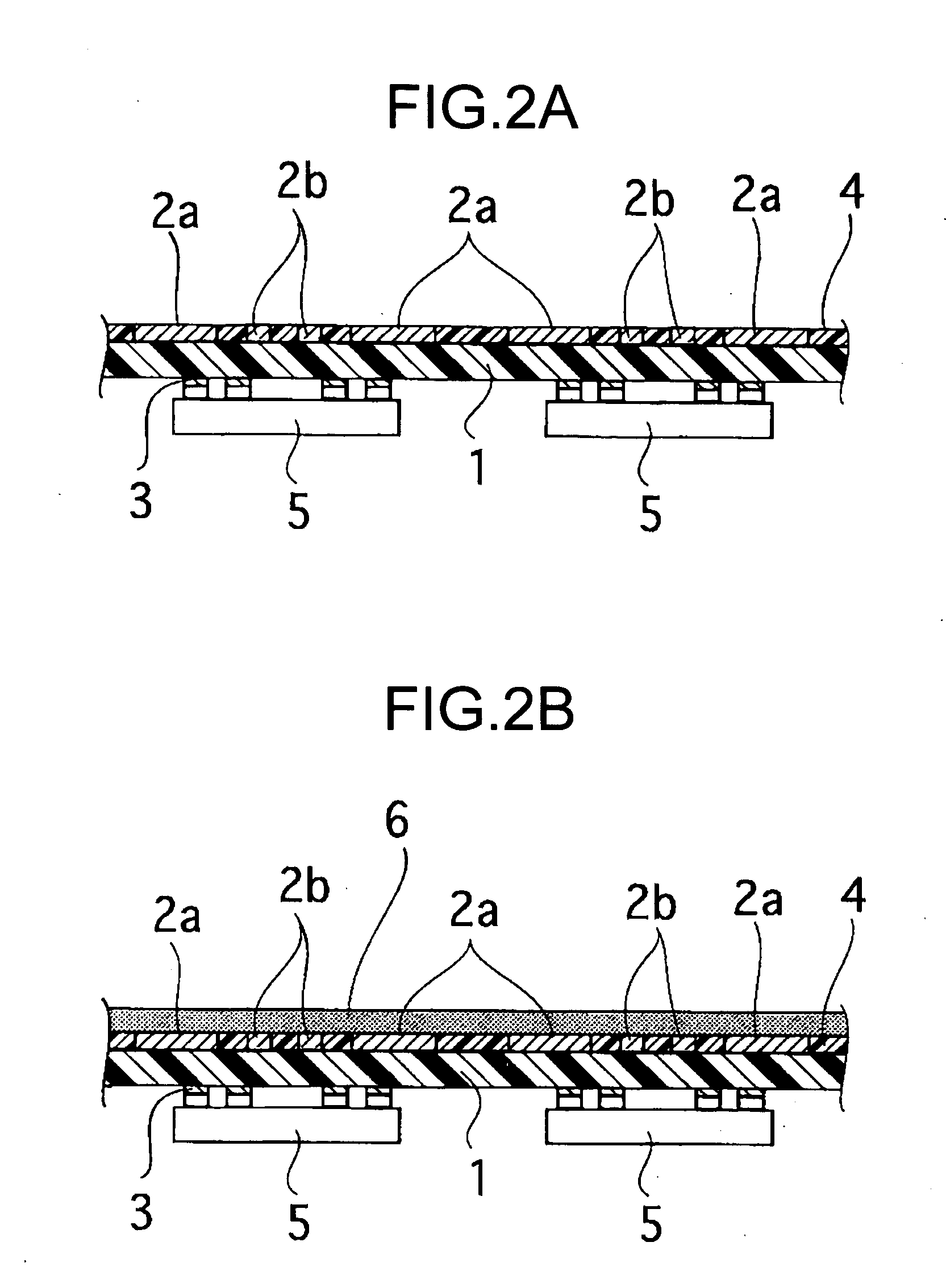

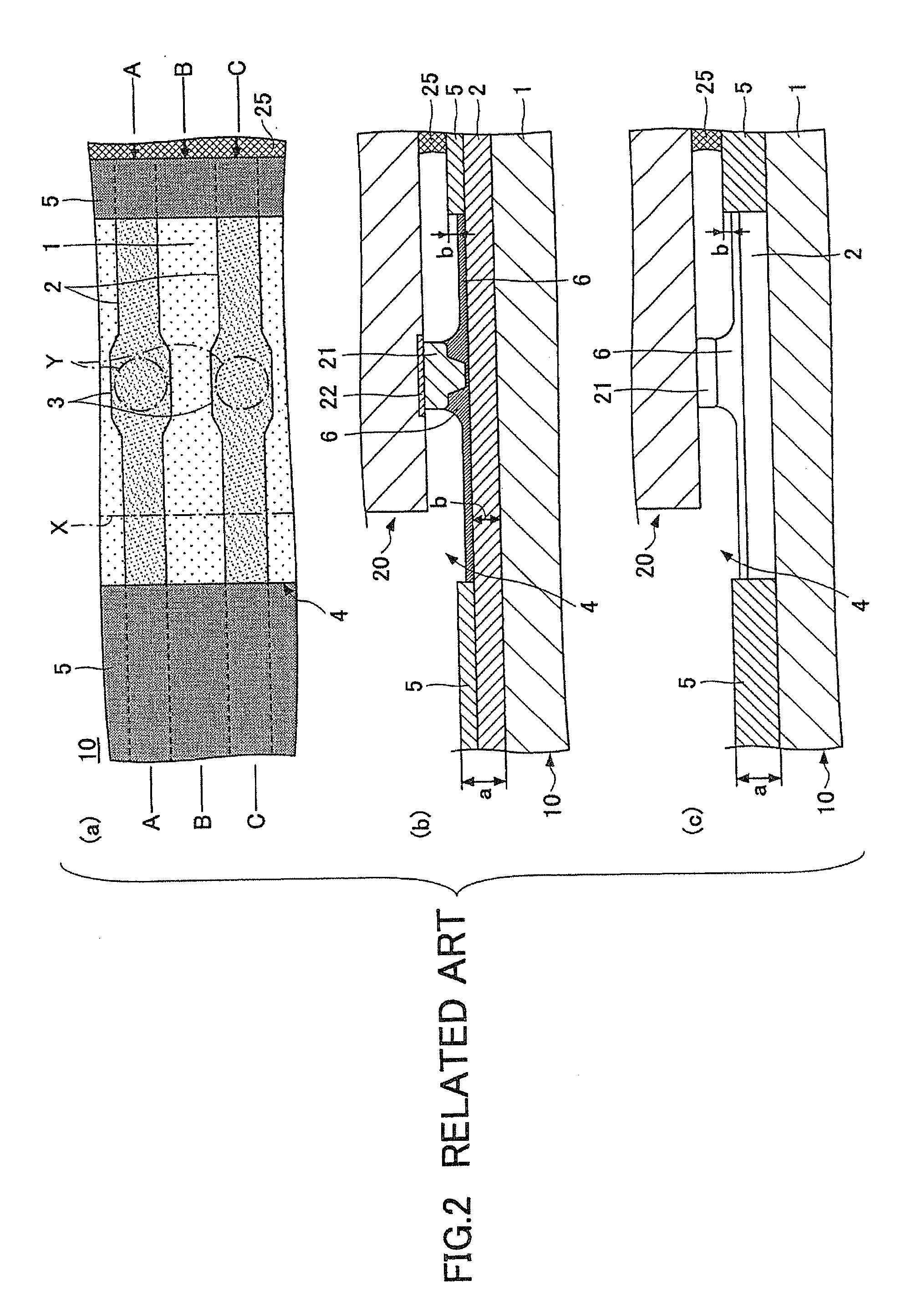

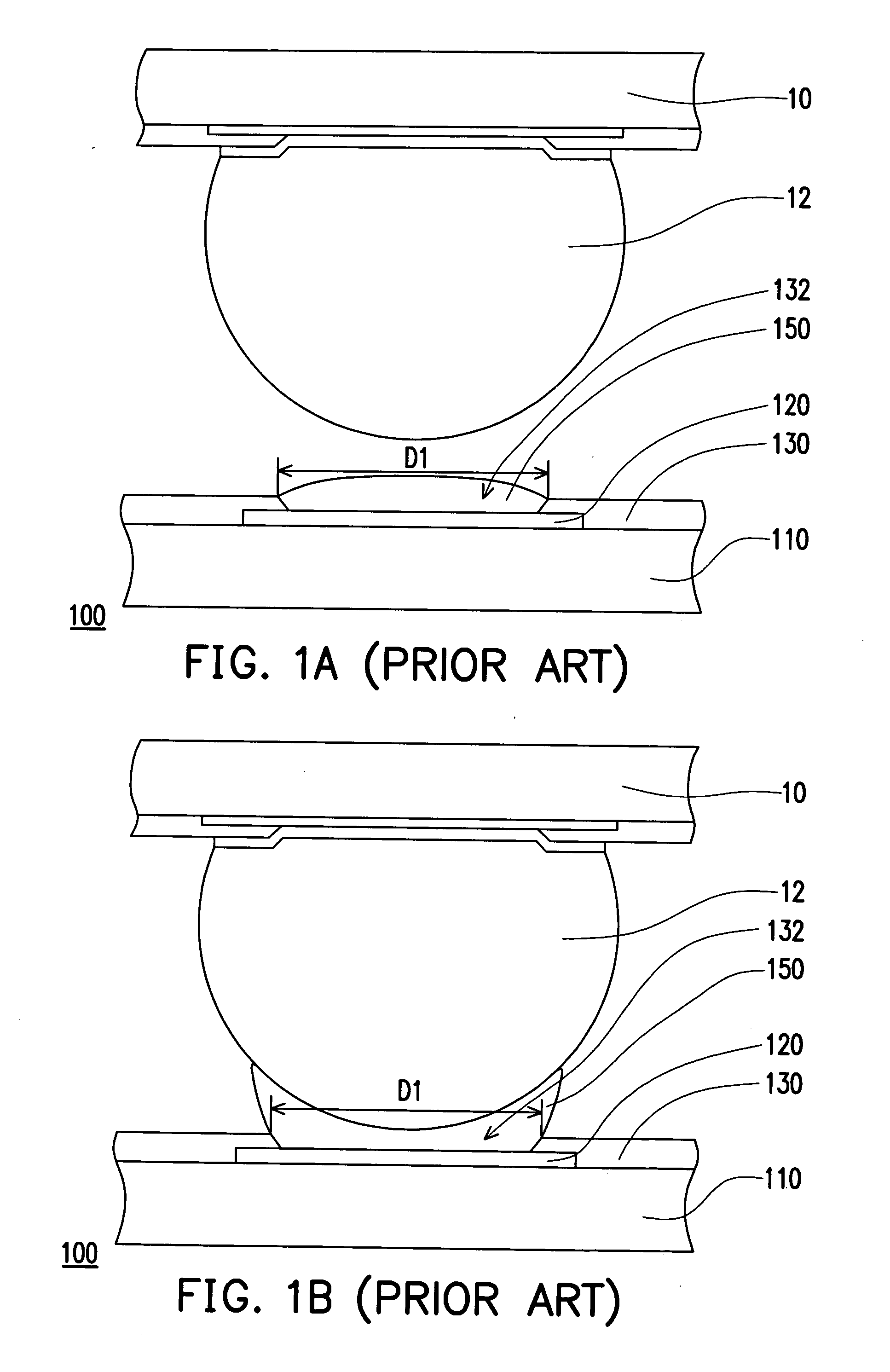

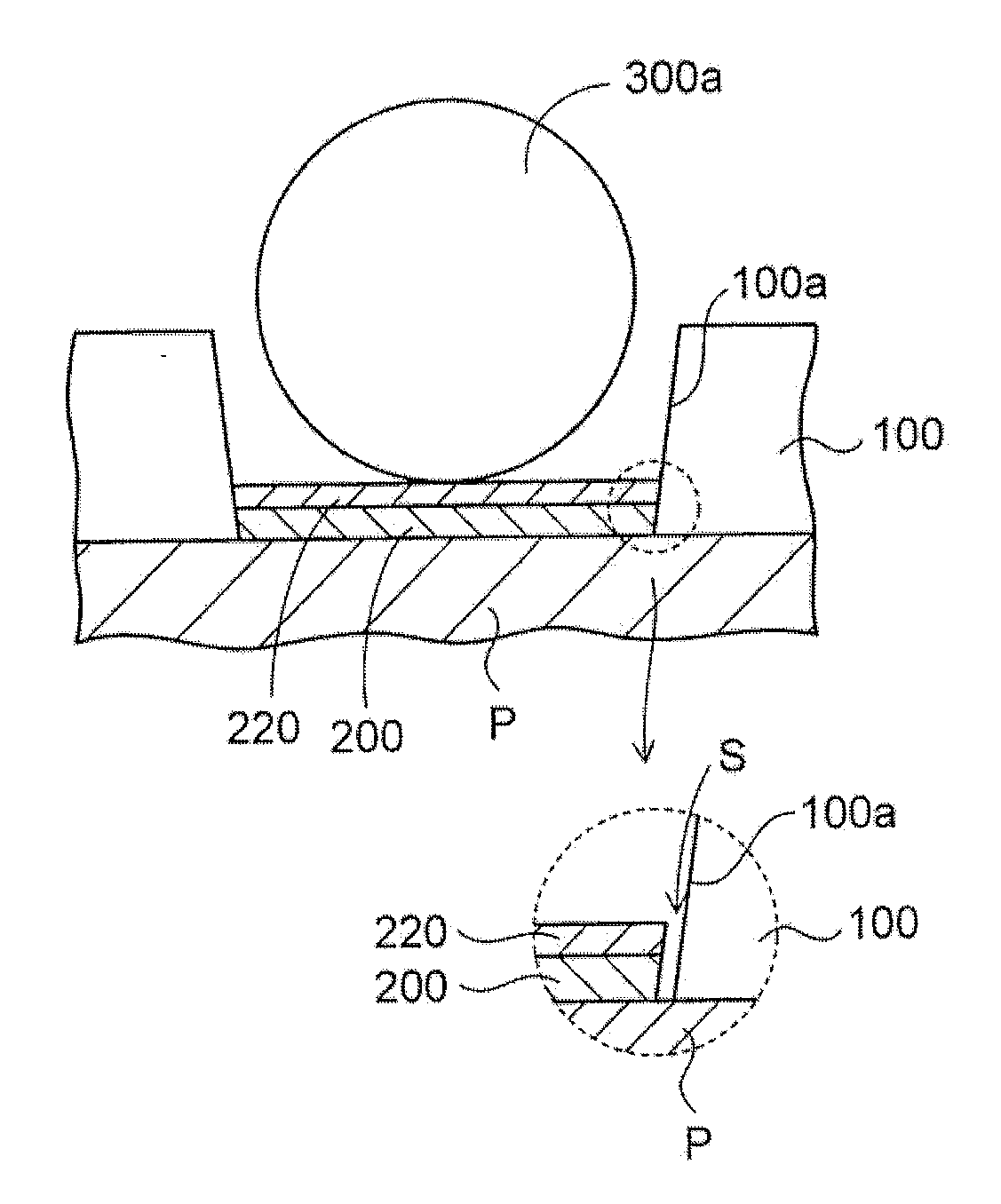

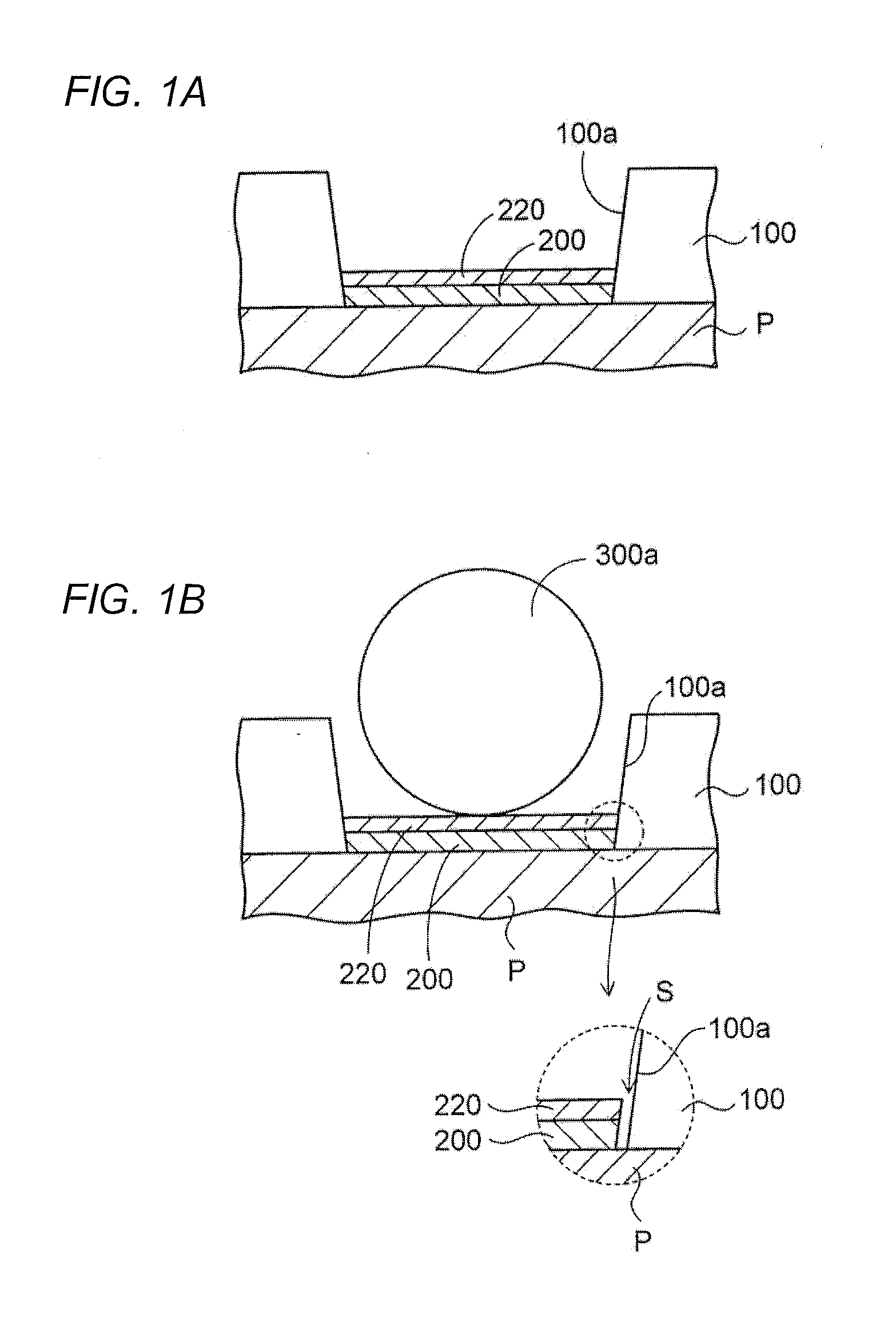

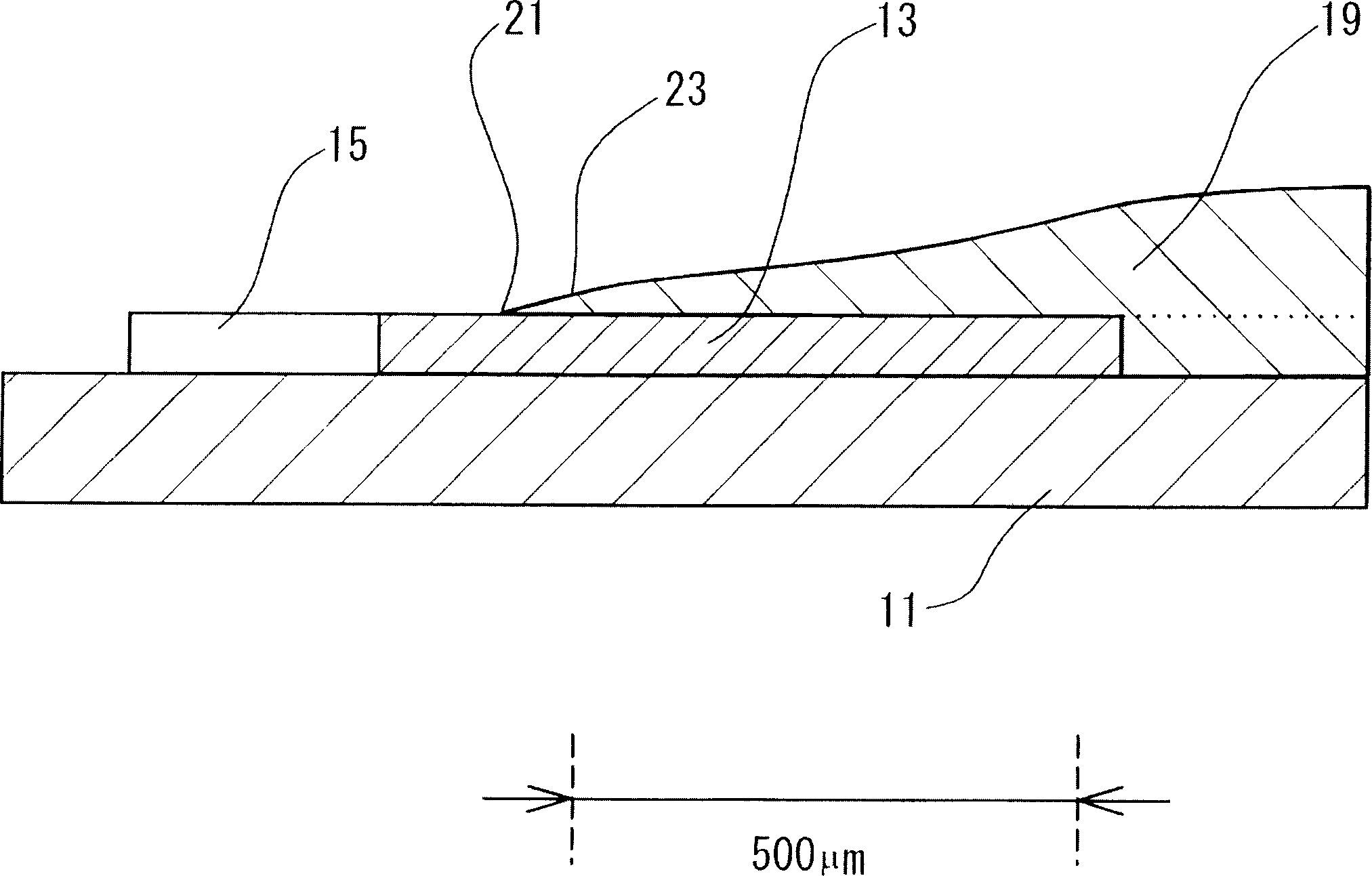

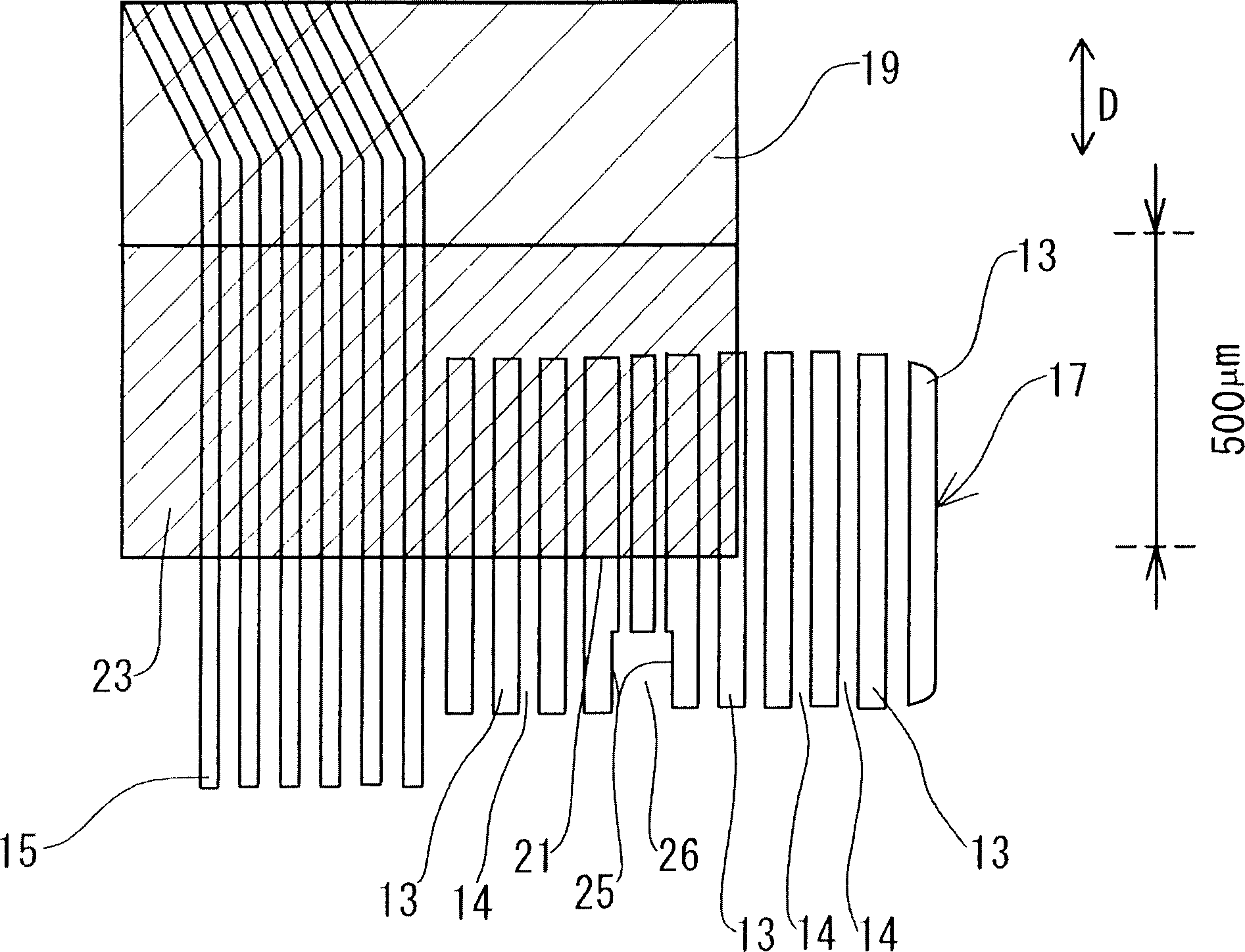

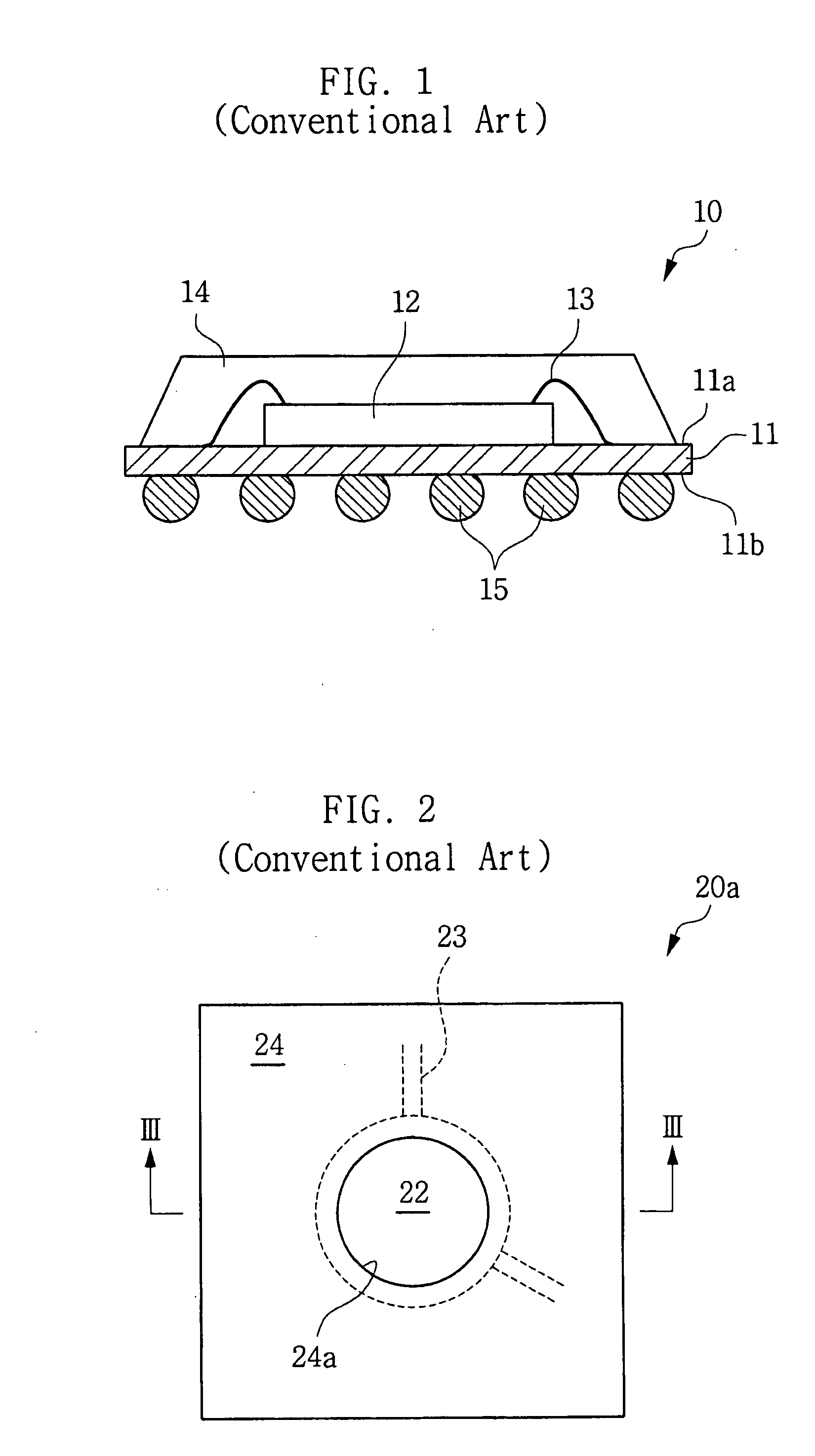

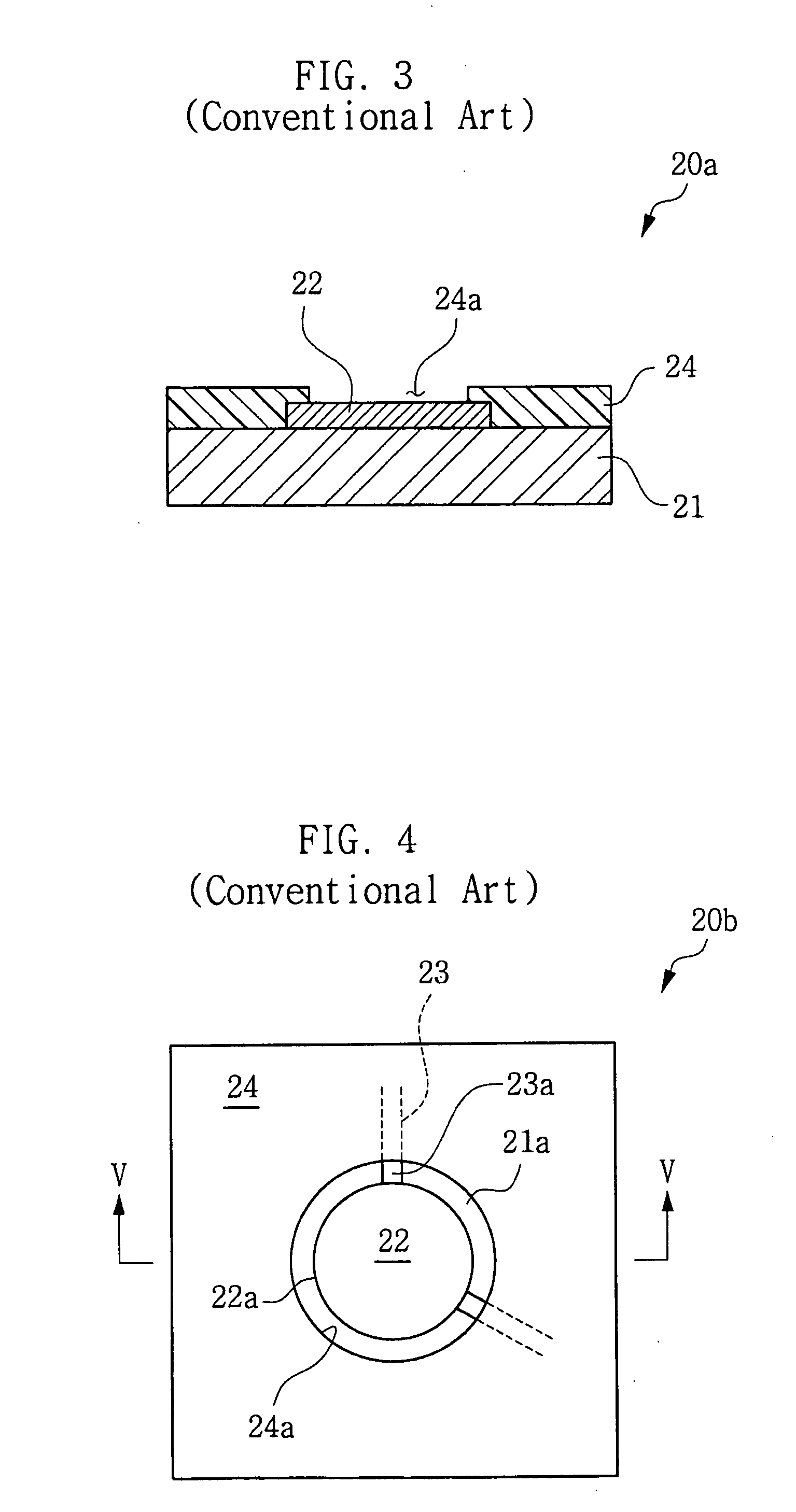

Printed wiring board and semiconductor device

InactiveUS20050133249A1Reduce coating thicknessAvoid deformationPrinted circuit assemblingPrinted circuit aspectsResistSolder mask

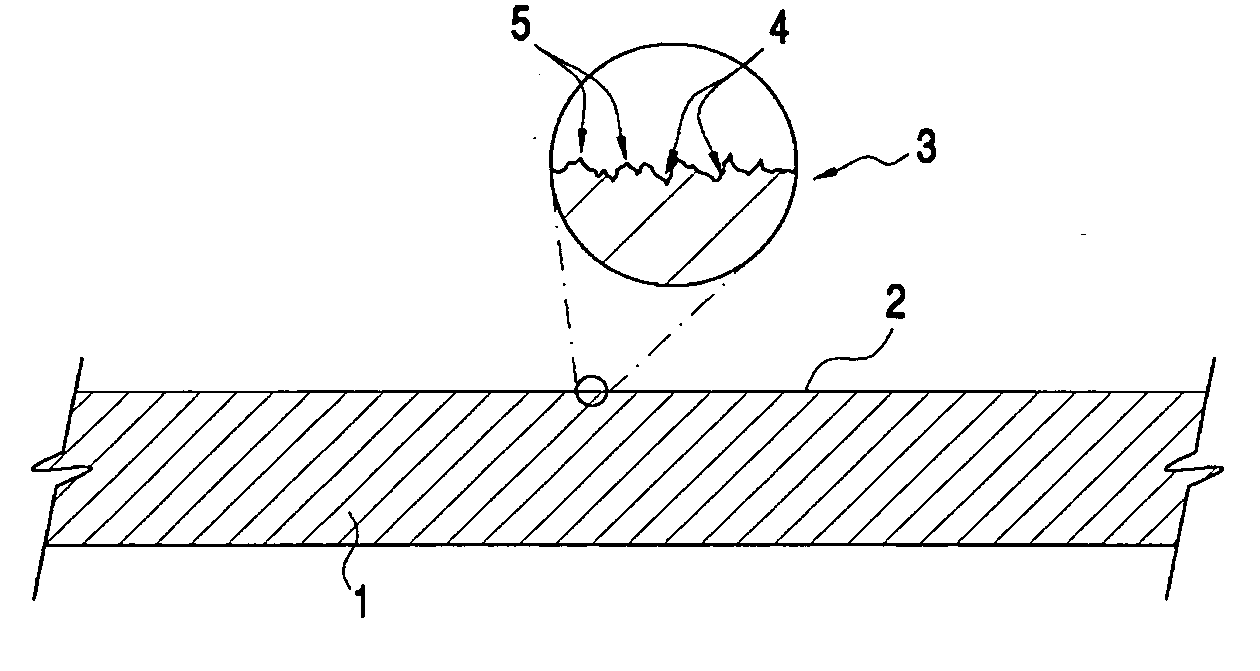

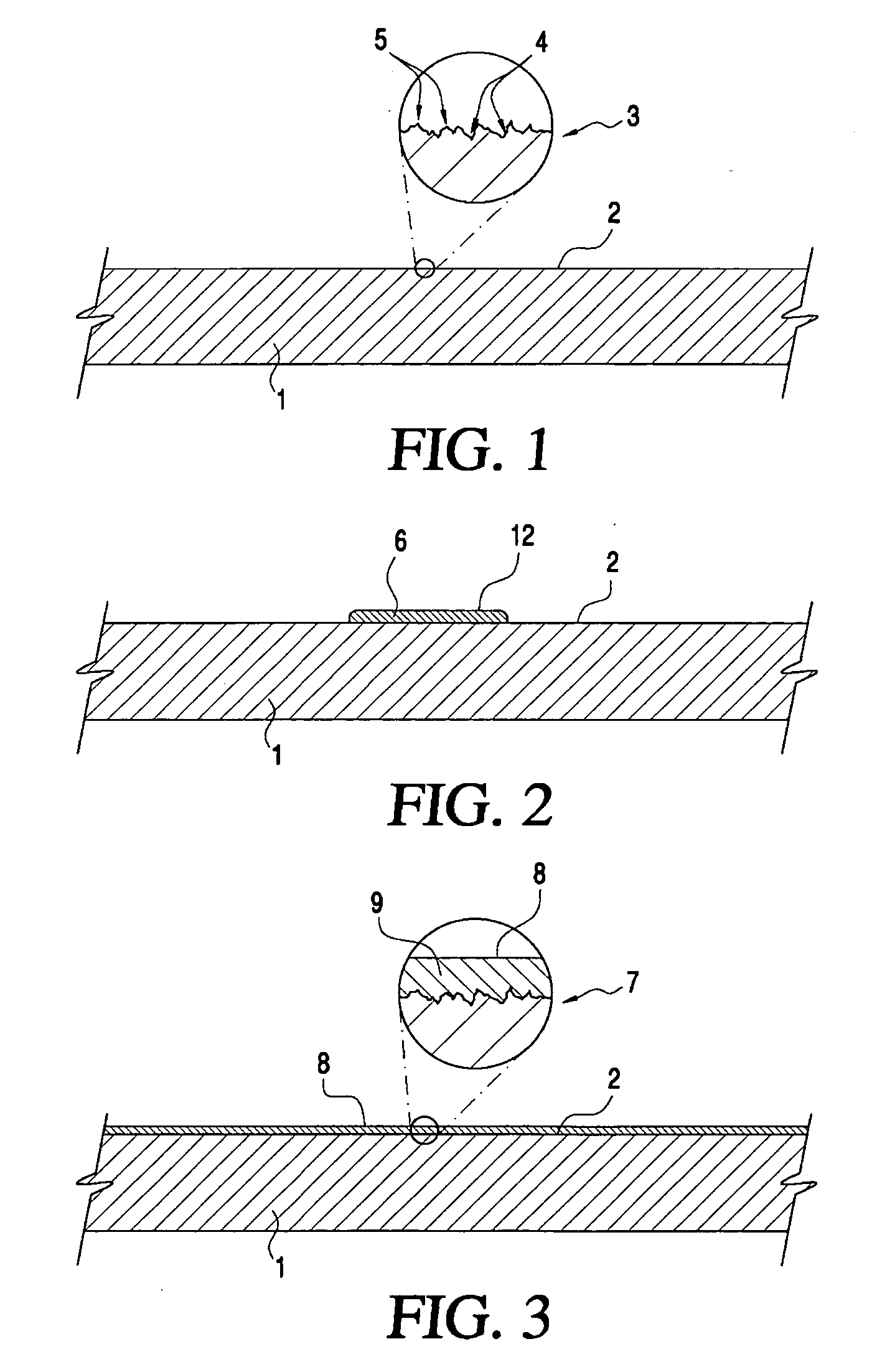

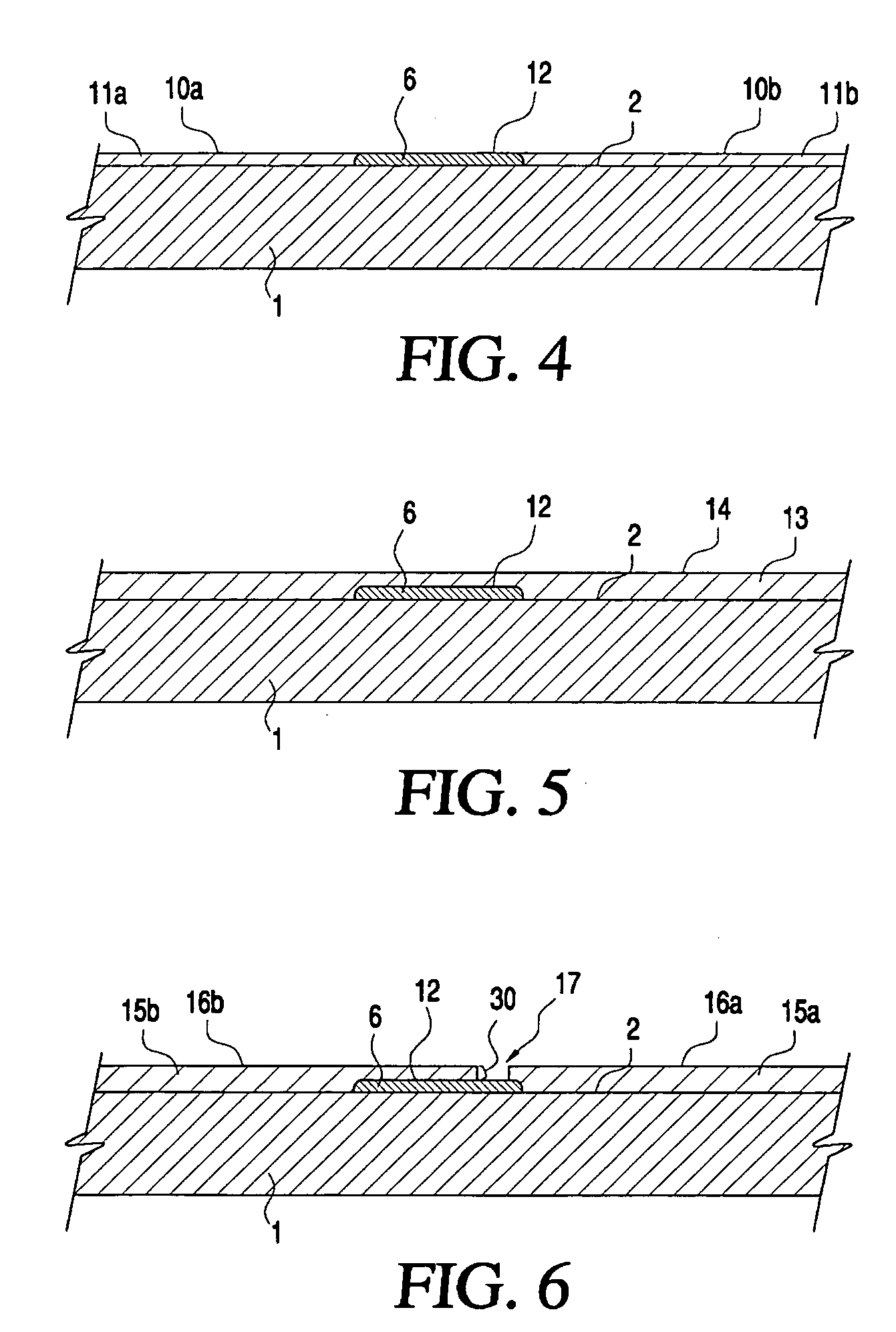

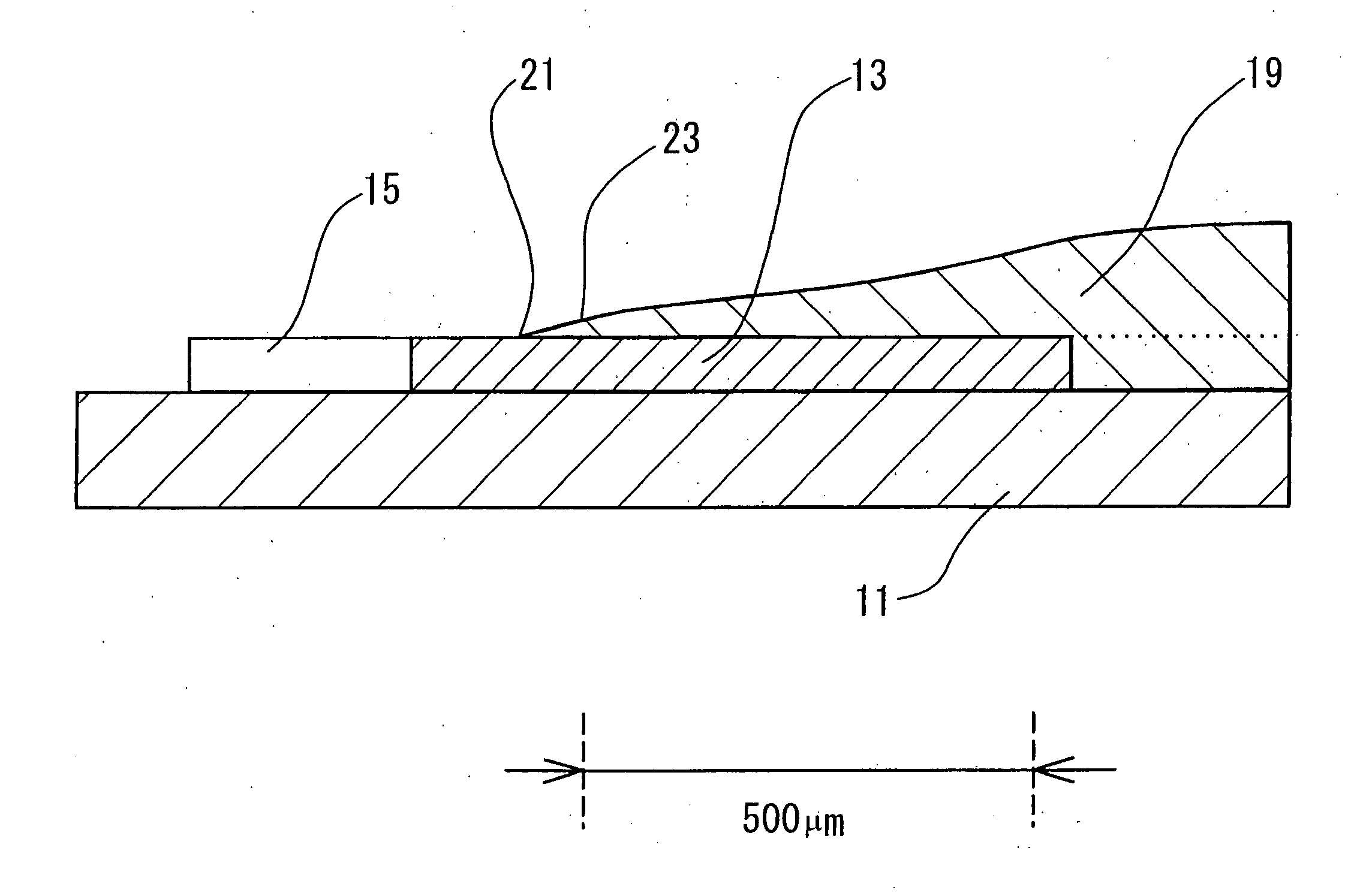

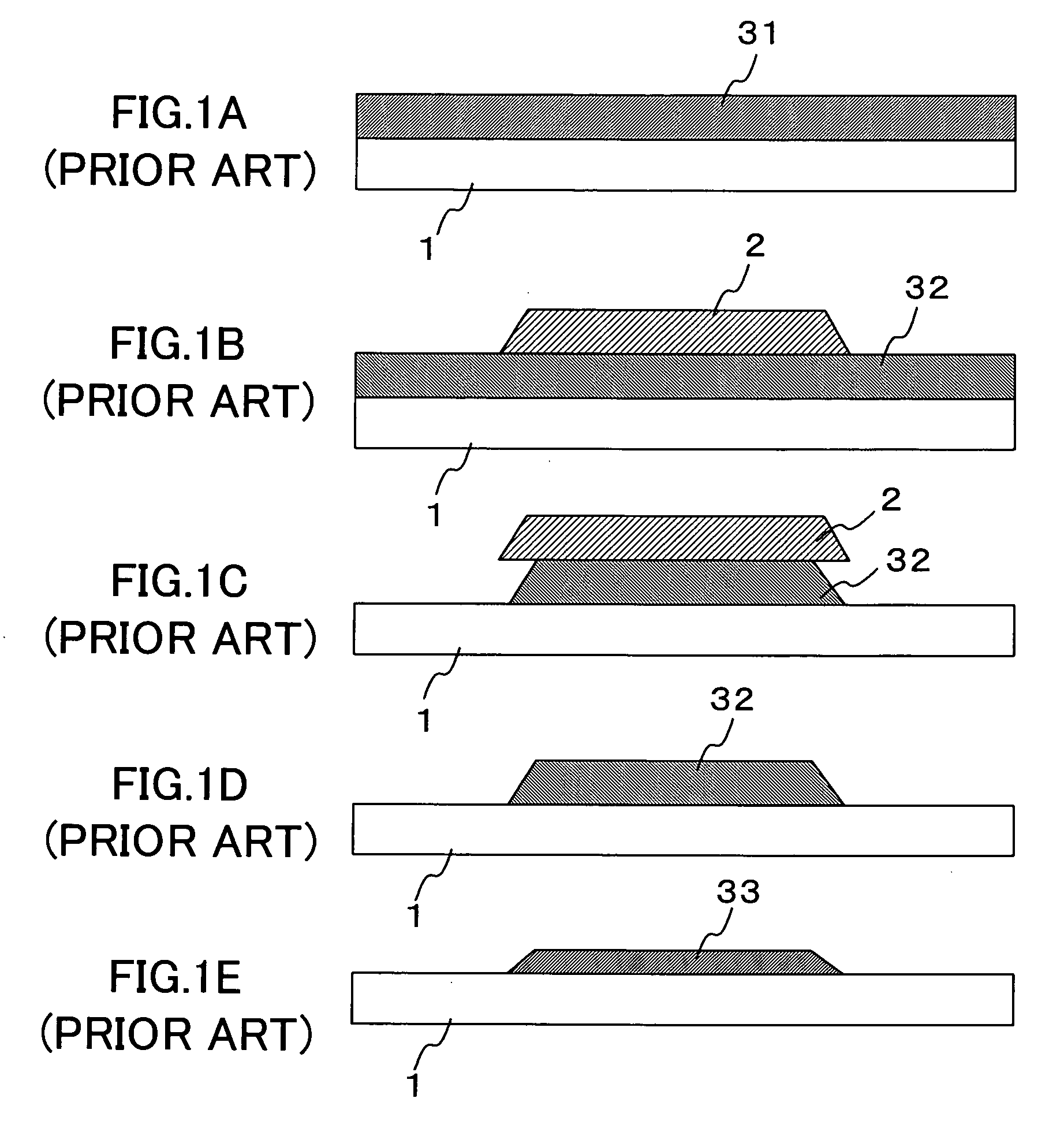

A printed wiring board has a large number of wirings formed substantially parallel to one another, a dummy pattern is formed along the wirings and a solder resist layer is formed by coating the wirings and the dummy pattern with a solder resist. The coating thickness of said solder resist gradually decreases toward the edge, wherein the dummy pattern has a solder resist coating thickness control area. A semiconductor device includes the above-mentioned printed wiring board with an electronic part mounted thereon. Accordingly, a slope uniformly extending over the whole width of the solder resist layer is formed at the edge portion of the solder resist layer to improve electrical connectivity.

Owner:MITSUI MINING & SMELTING CO LTD

Printed circuit board and manufacturing method thereof

InactiveUS20090027864A1Improve adhesionSufficient amountPrinted circuit detailsPrinted circuit aspectsResistInsulation layer

A printed circuit board and a method of manufacturing the printed circuit board are disclosed. A printed circuit board, which includes an insulation layer, a circuit pattern formed on a surface of the insulation layer that includes at least one pad, and a solder resist which covers the circuit pattern, and in which an opening is formed that exposes a portion of a side and a surface of the pad, can ensure a sufficient amount of attachment area for the pads and the solder resist, to strengthen the adhesion of the pads. Also, the adhesion can be increased between the electronic components and the printed circuit board, and heat release characteristics can be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

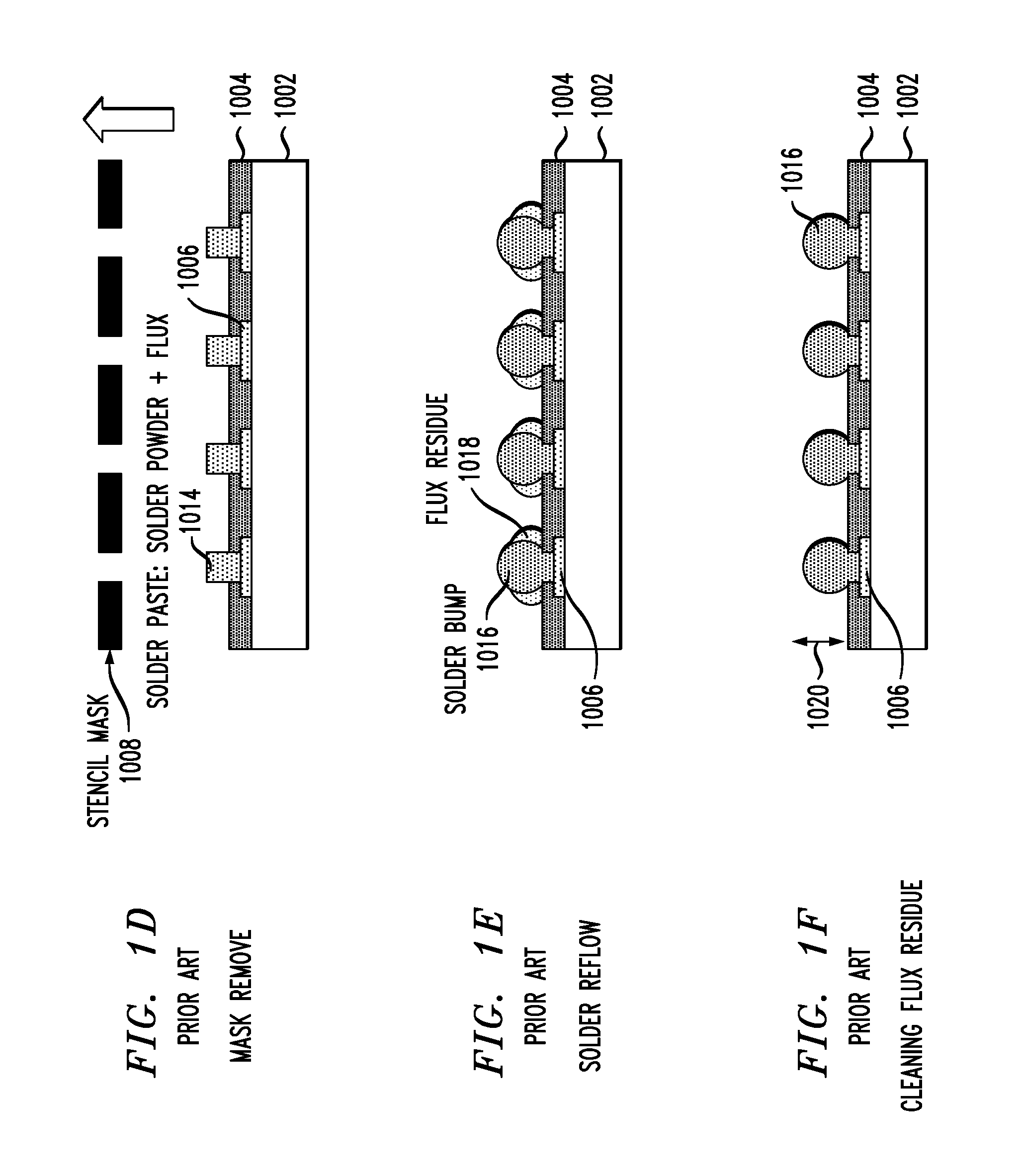

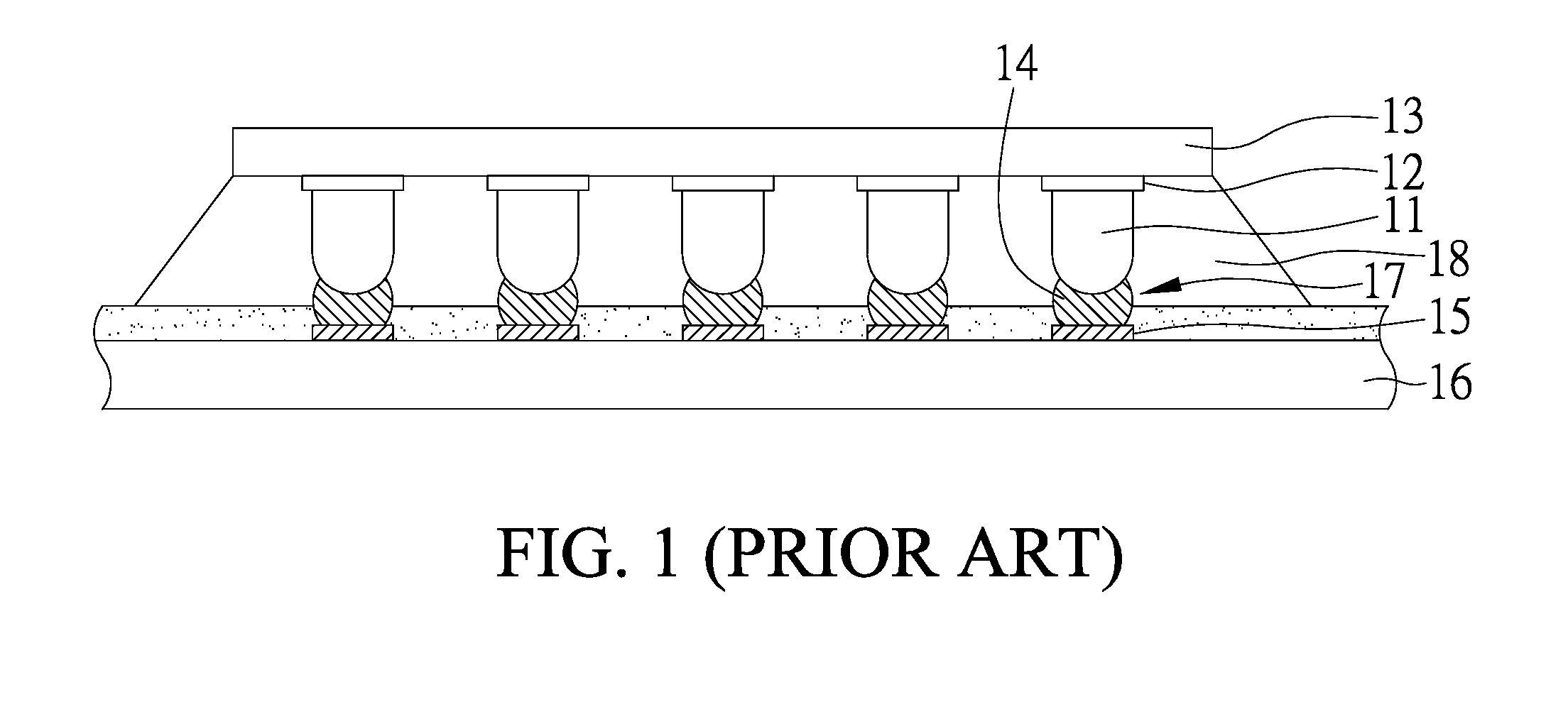

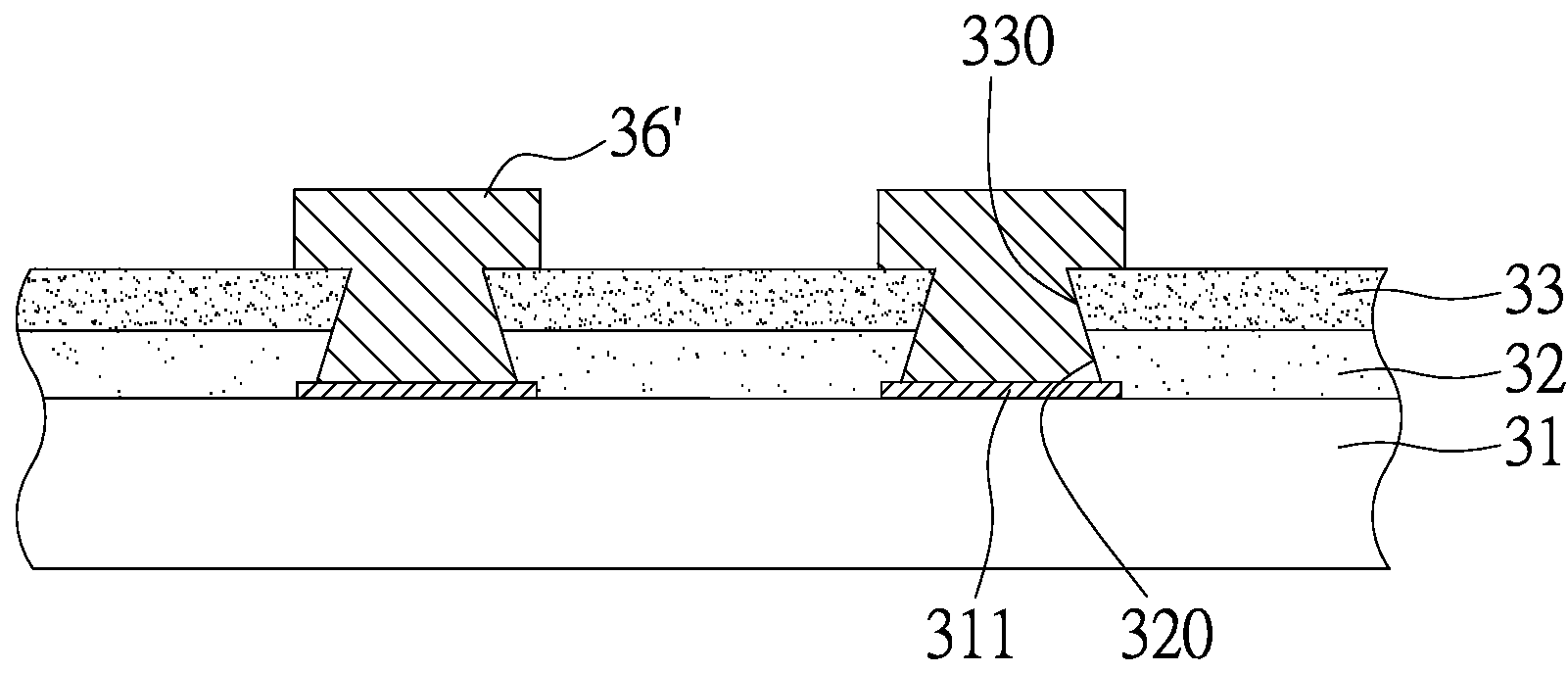

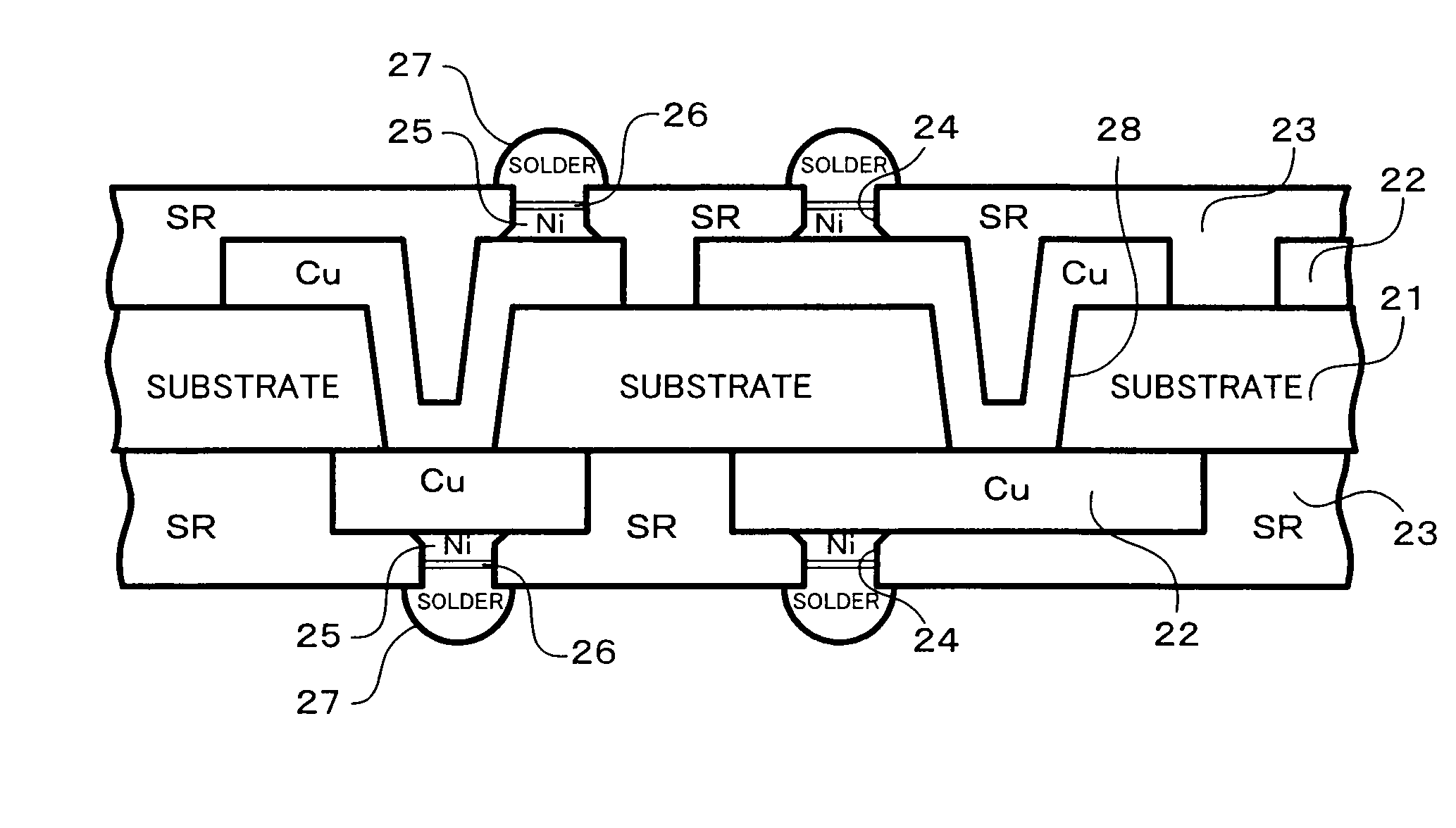

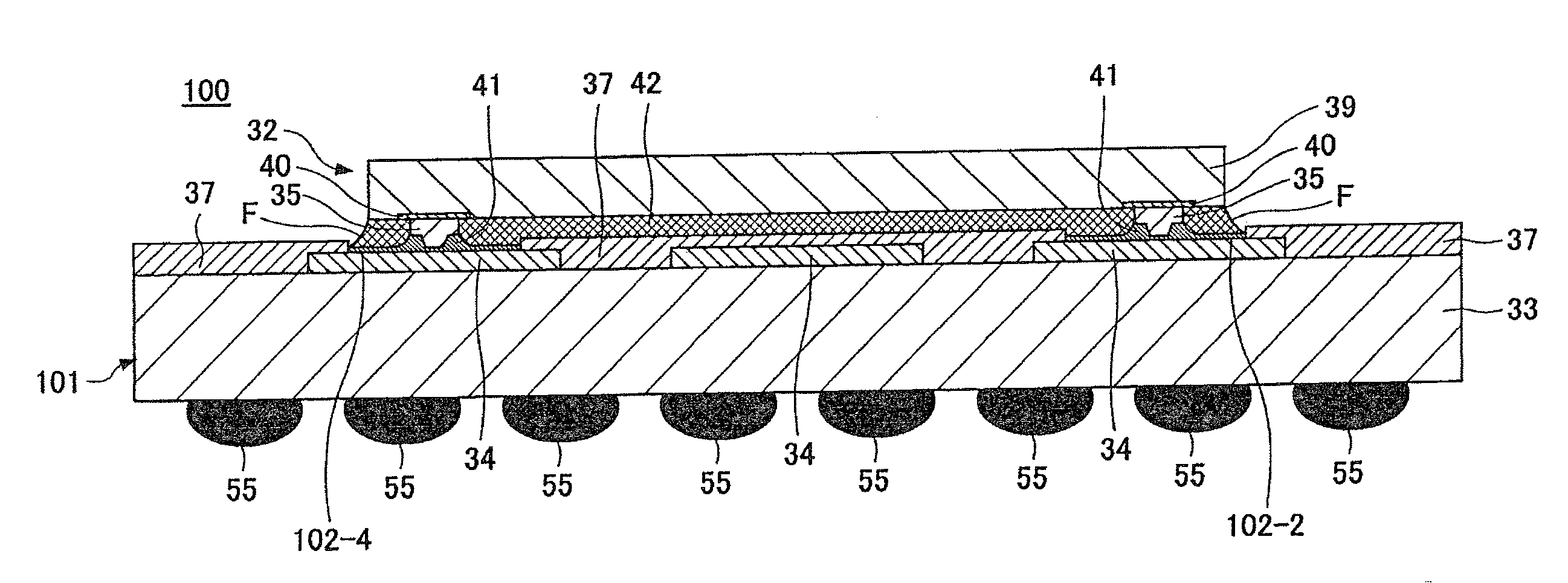

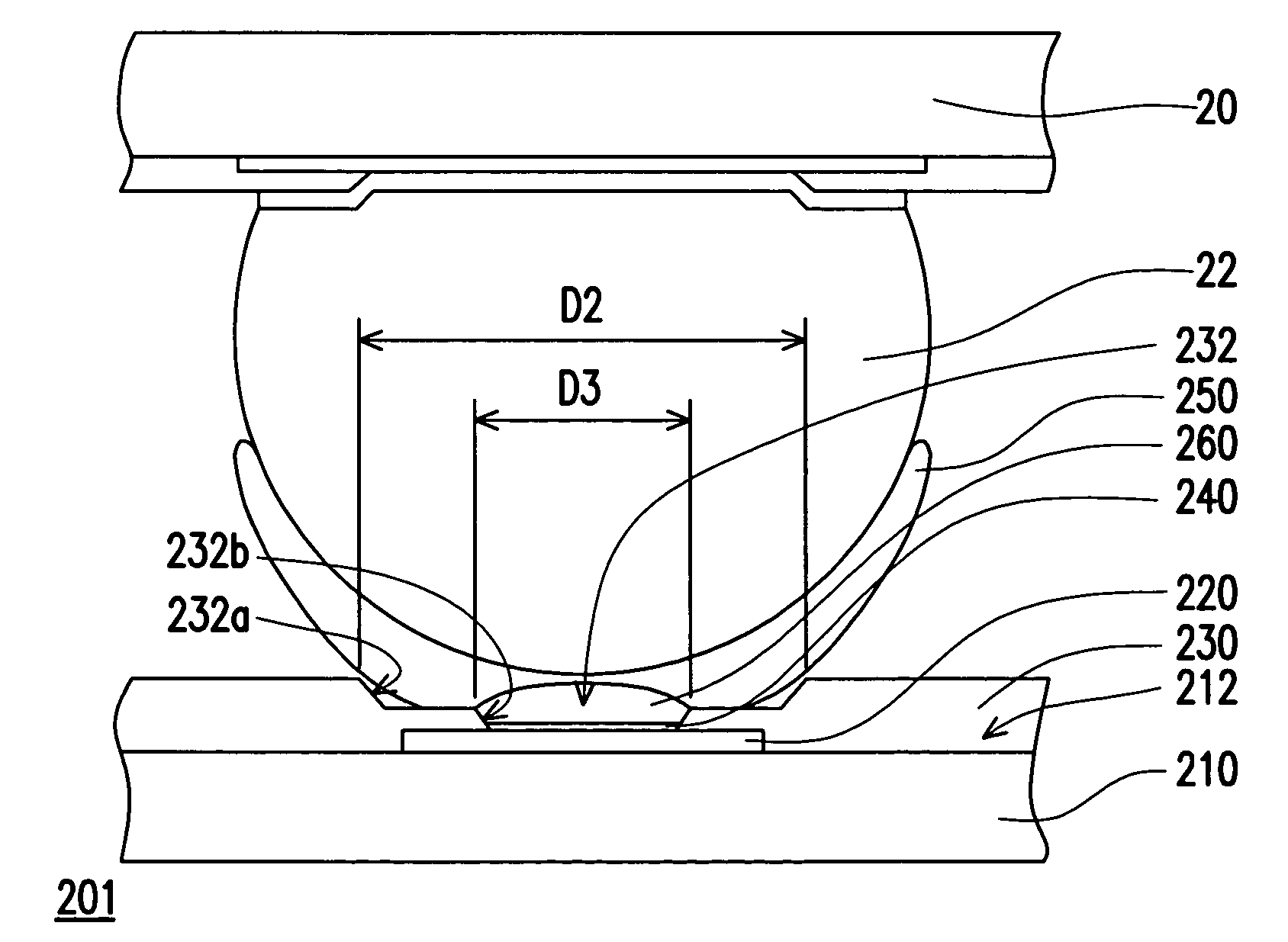

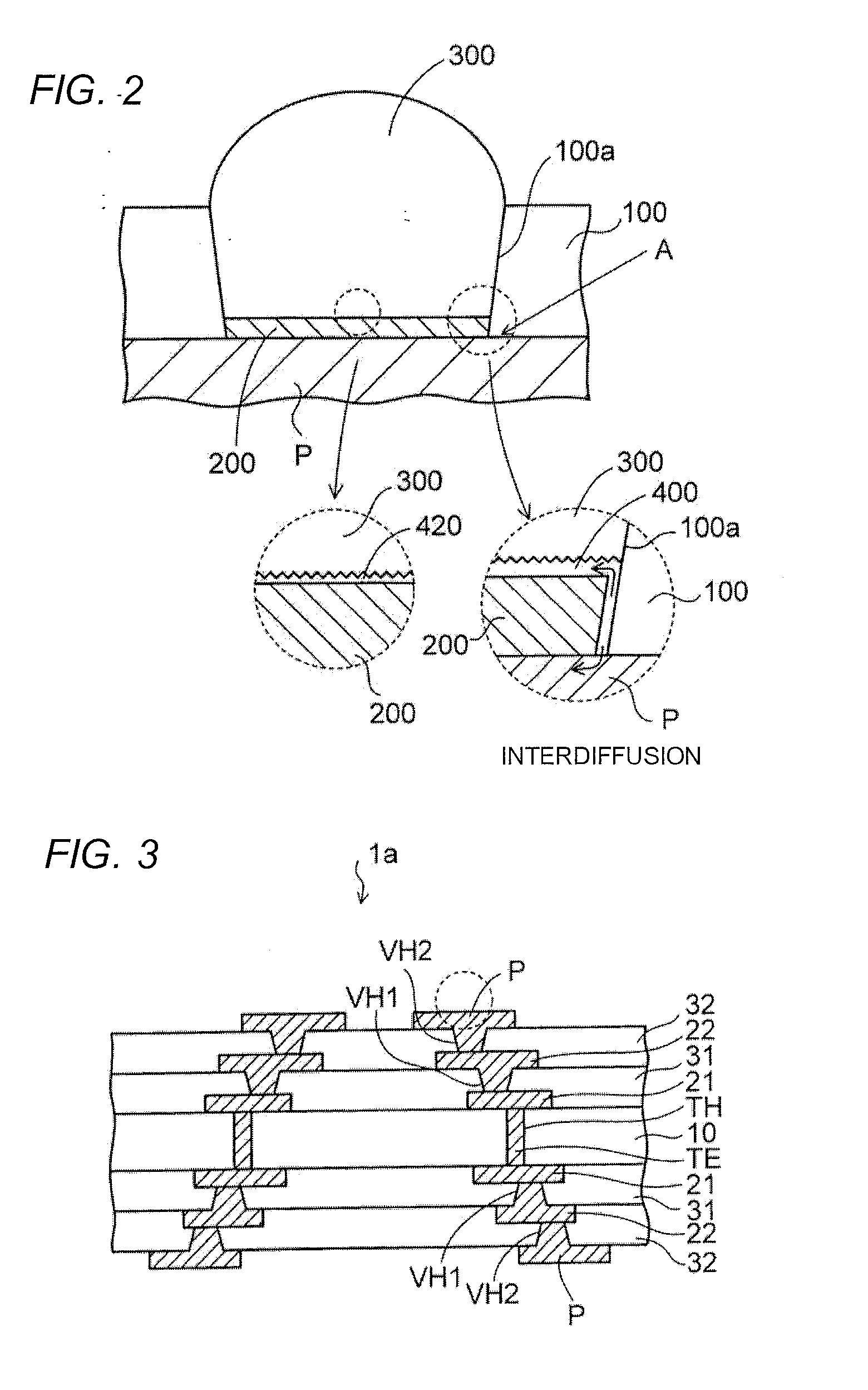

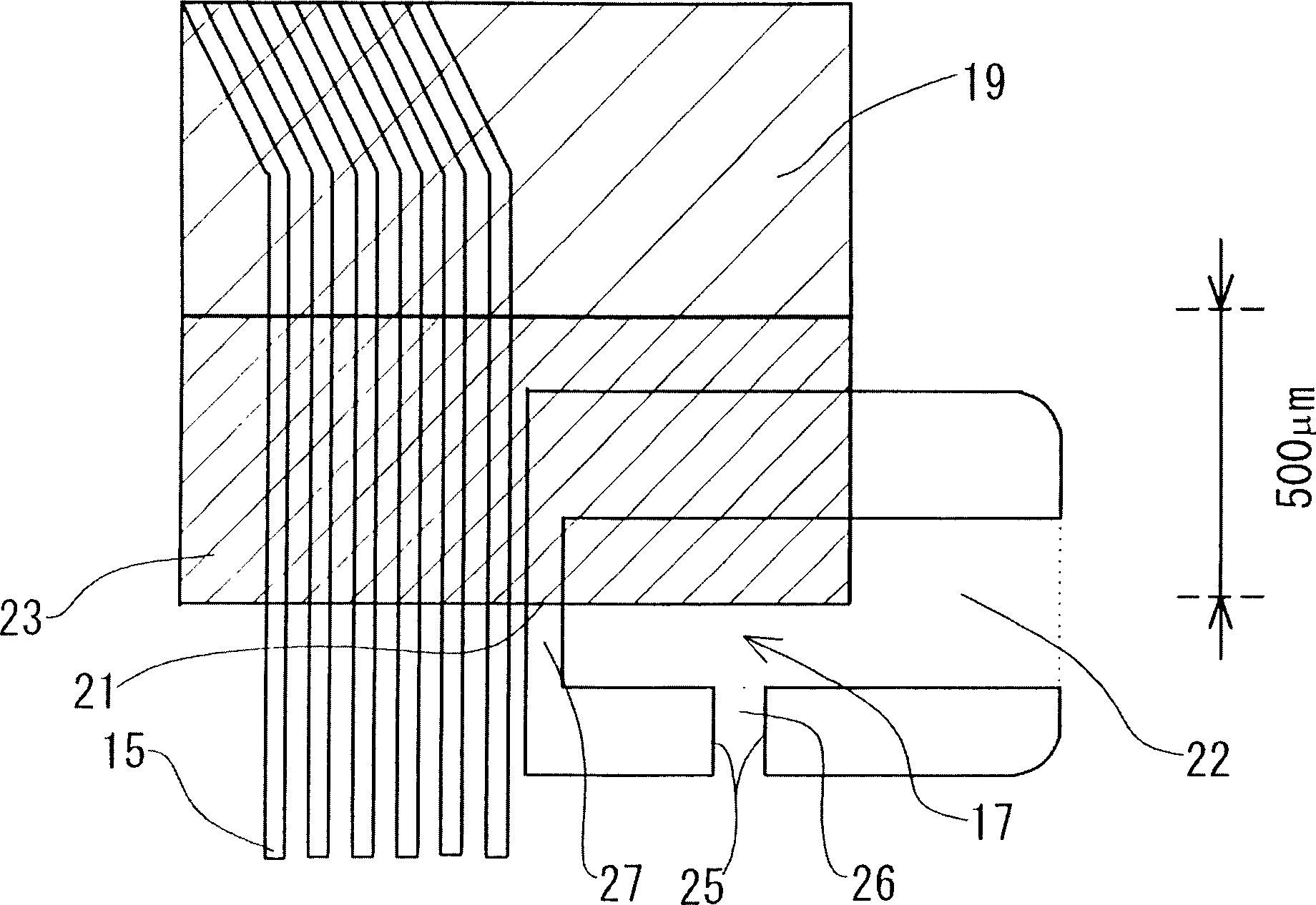

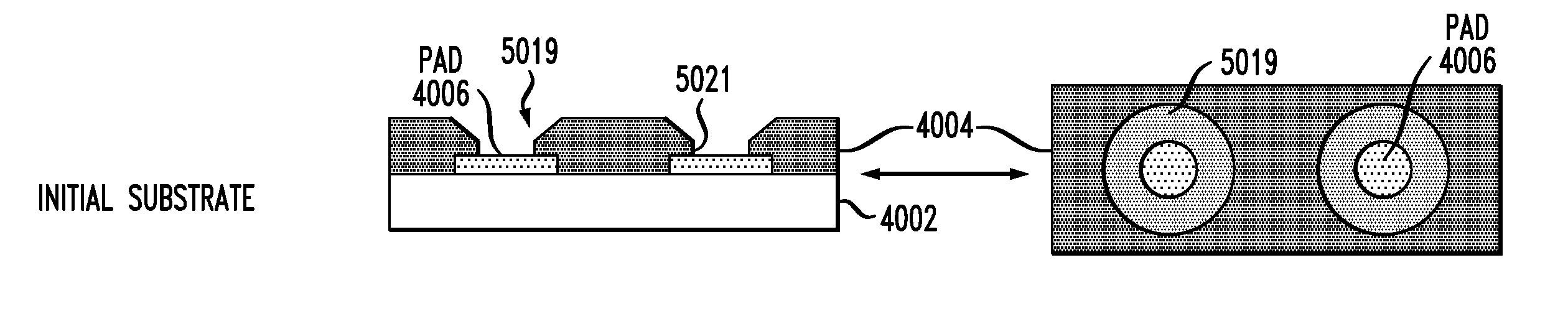

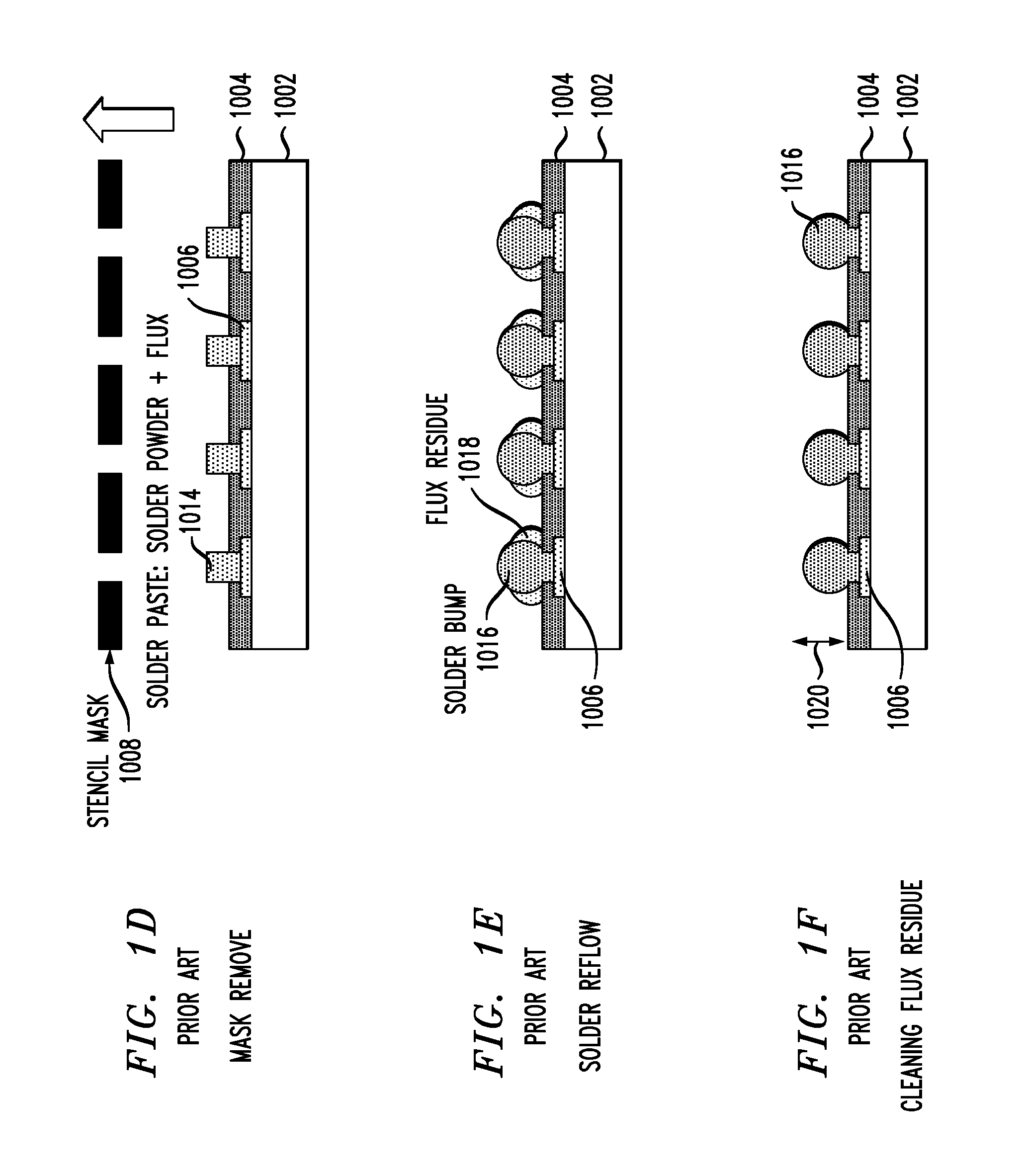

Direct IMS (Injection Molded Solder) Without a Mask for Forming Solder Bumps on Substrates

ActiveUS20110201194A1Avoid confusionSemiconductor/solid-state device detailsPrinted circuit aspectsResistForming gas

An assembly is obtained; it includes a substrate; a plurality of wet-able pads formed on a surface of the substrate; and a solder resist layer deposited on the surface of the substrate and having an outer surface. At least the solder resist layer is formed with recessed regions defining volumes adjacent the wet-able pads. Molten solder is directly injected into the volumes adjacent the wet-able pads, such that the volumes adjacent the wet-able pads are filled with solder. The solder is allowed to solidify. It forms a plurality of solder structures adhered to the wet-able pads. The substrate and the solder are re-heated after the solidification, to re-flow the solder into generally spherical balls extending above the outer surface of the solder resist layer. The volumes adjacent the wet-able pads are configured and dimensioned to receive sufficient solder in the injecting step such that the generally spherical balls extend above the outer surface of the solder resist layer as a result of the re-heating step. In an alternative approach, solder injection and solidification are carried out in a nitrogen environment or a forming gas environment, and the reflow step may be omitted.

Owner:GLOBALFOUNDRIES US INC

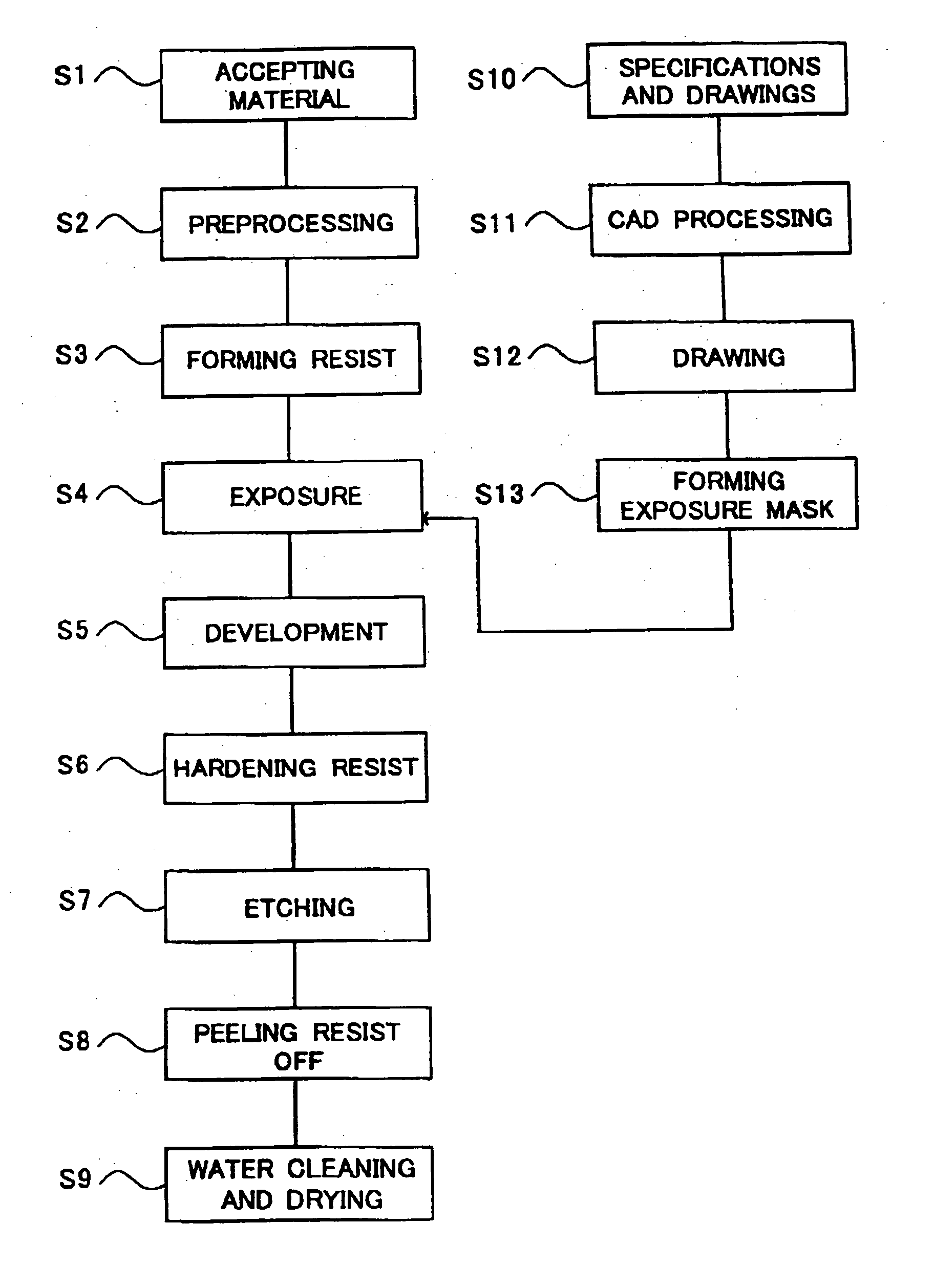

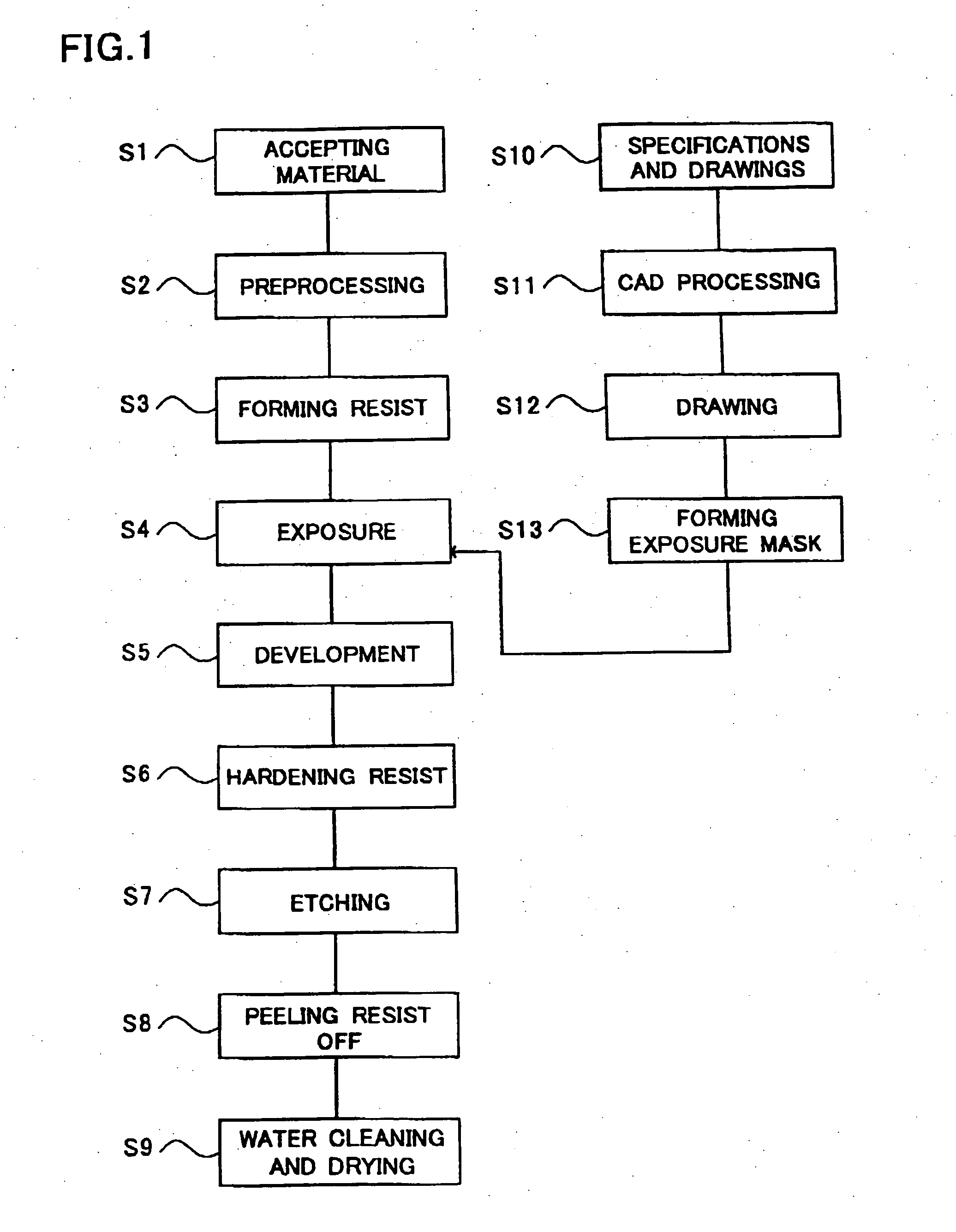

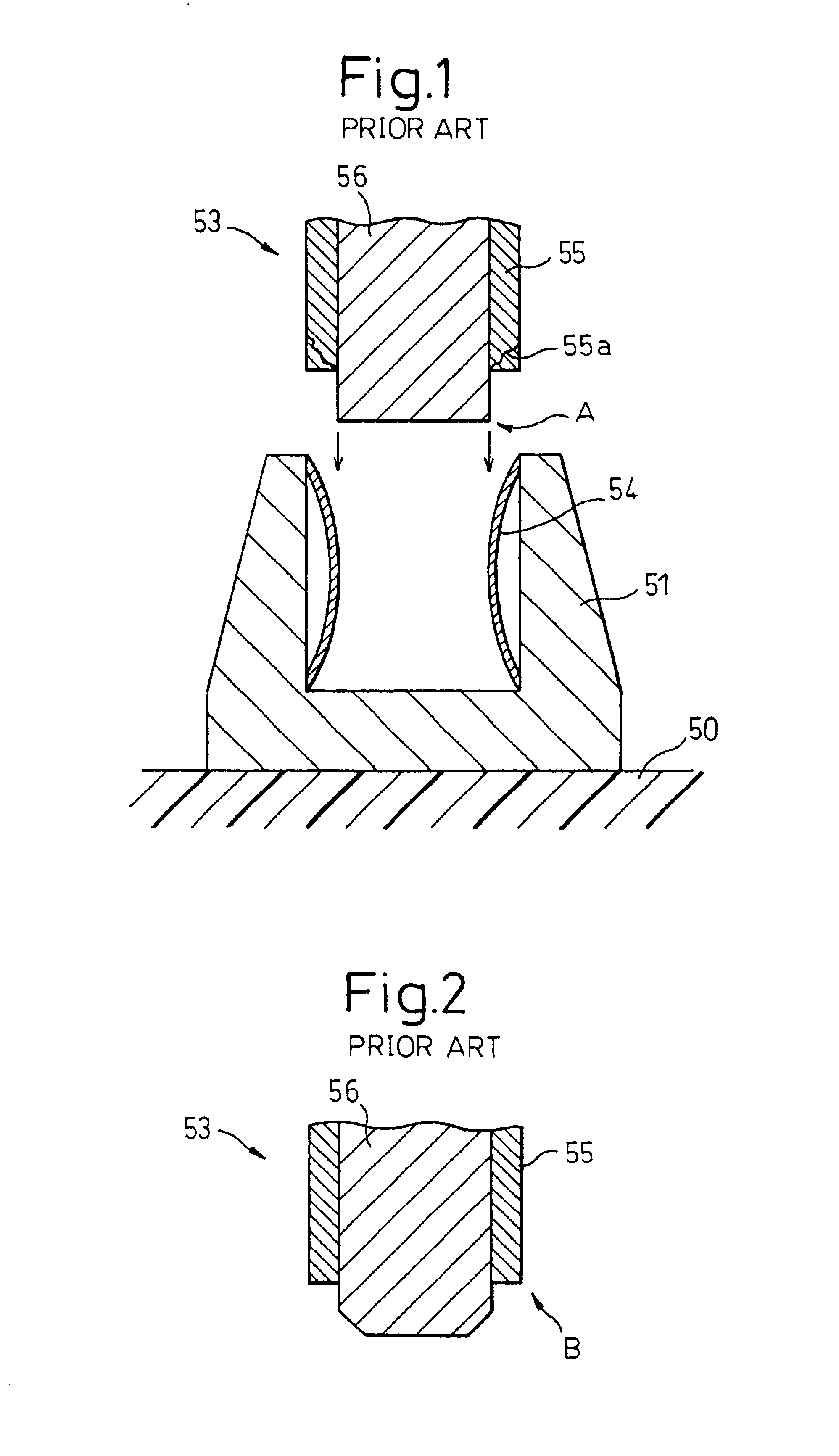

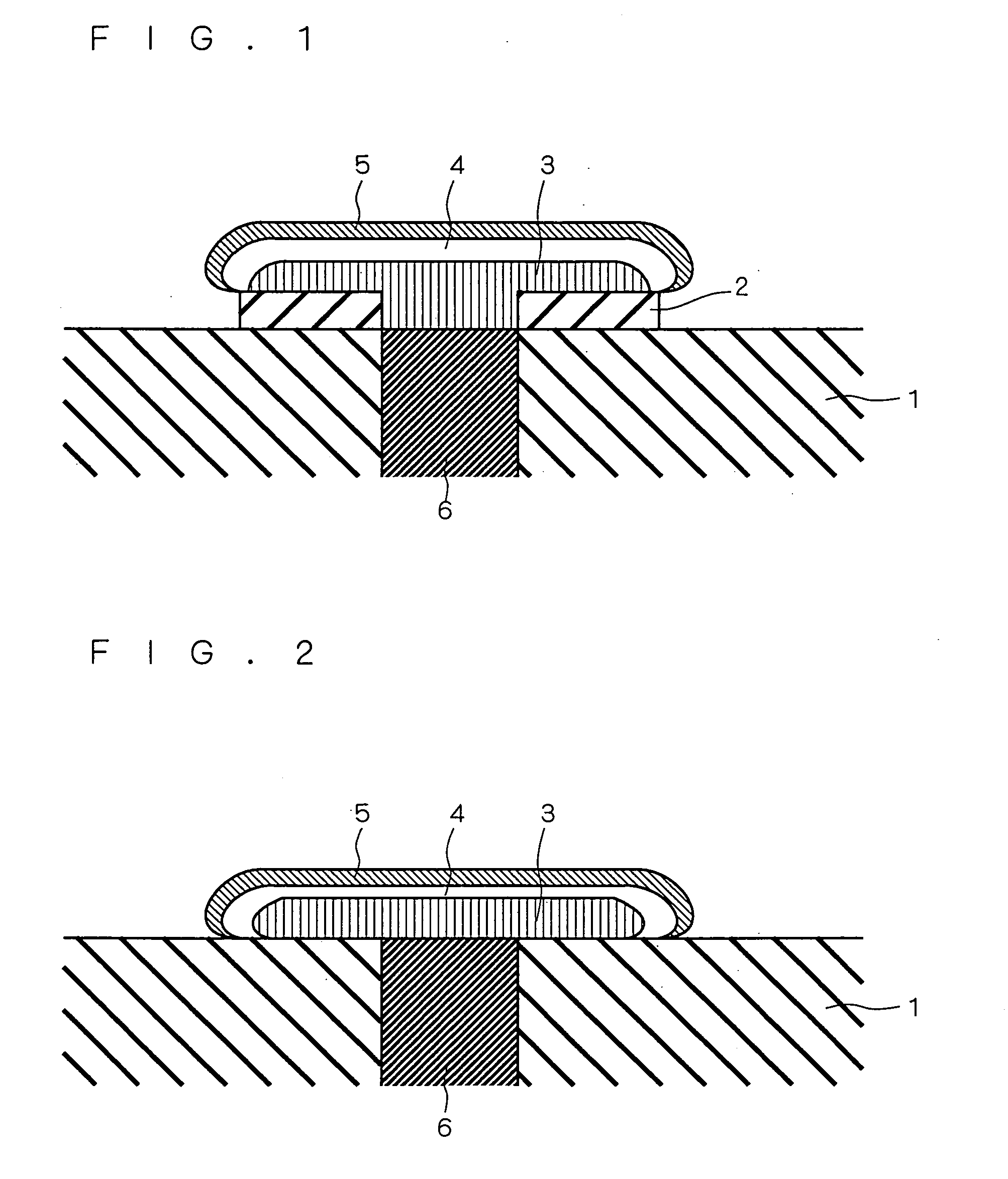

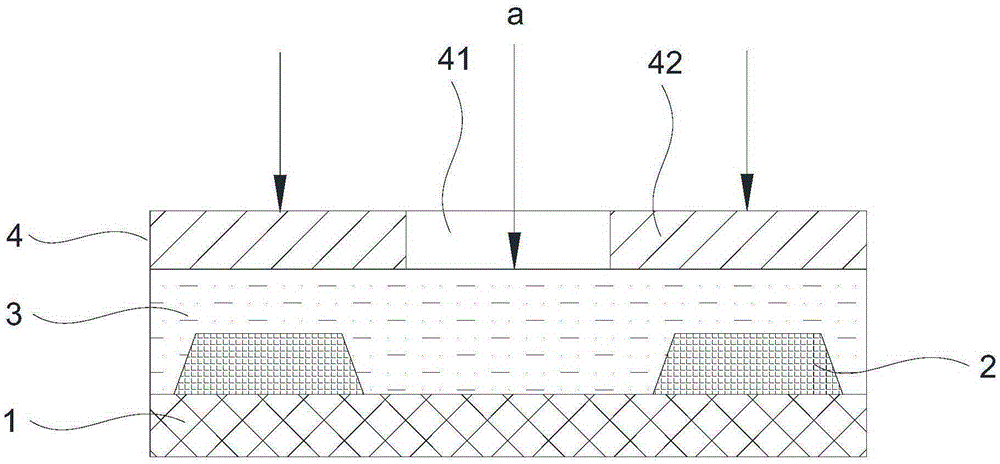

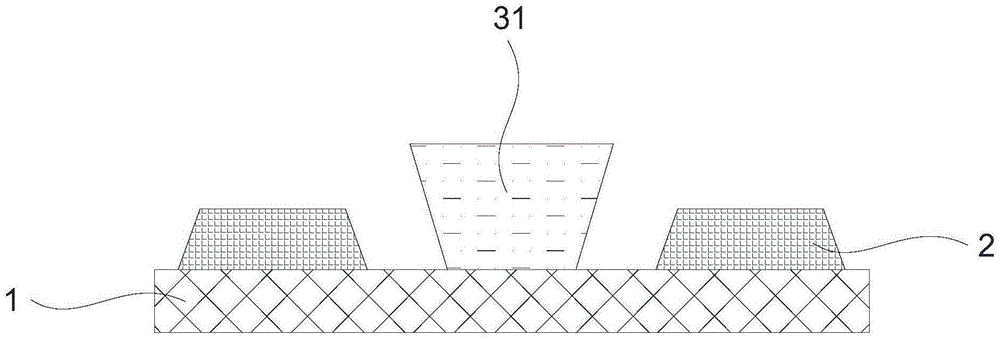

Etching method and method of manufacturing circuit device using the same

Provided are an etching method capable of improving an etching factor, and a method of manufacturing a circuit device using the etching method. In the etching method, an etching resist is firstly coated on a surface of a conductive foil as an etching target material. Then, the etching resist is subjected to selective exposure by use of an exposure mask, thereby selectively transforming the etching resist. In this way, a non-exposed region is formed as a remaining region having a cross section, in which a lower part thereof is greater than an upper part thereof. Thereafter, the etching resist in a region other than the remaining region is removed by use of a solution, and the conductive foil is subjected to etching by use of the remaining region as a mask.

Owner:SANYO ELECTRIC CO LTD

Circuit board surface structure

InactiveUS20080217047A1High bonding strengthIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringSurface structure

A circuit board surface structure includes a circuit board having at least one surface provided with a plurality of electrically connecting pads, an insulating protective layer characterized by photosensitivity and solder resisting and formed on the circuit board, and a plurality of openings formed in the insulating protective layer to expose the electrical connecting pads on the circuit board and tapered upward; and a conductive element formed in the opening, so as to increase the contact area and reinforce bonding between the electrically connecting pads and the conductive element.

Owner:UNIMICRON TECH CORP

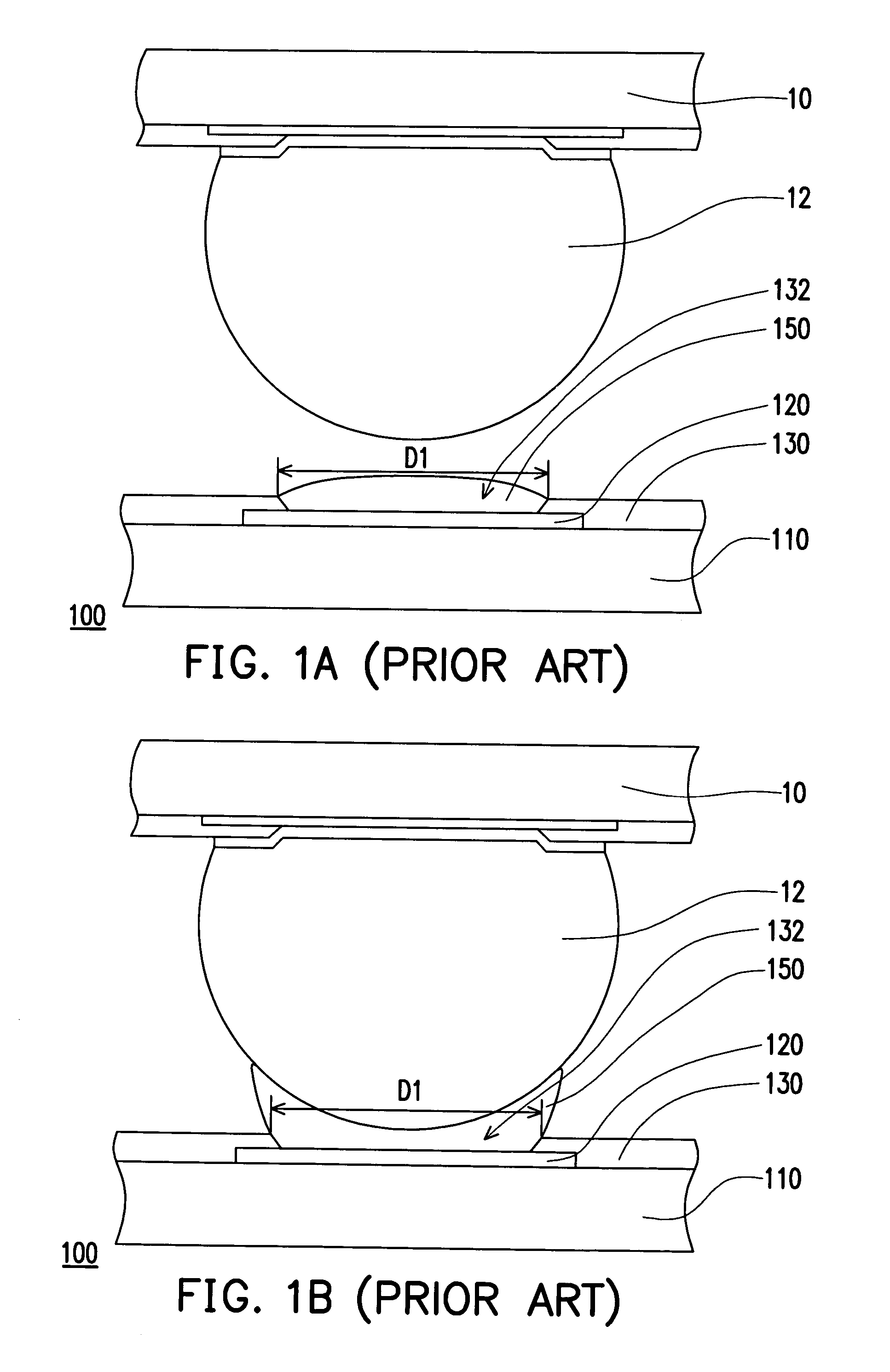

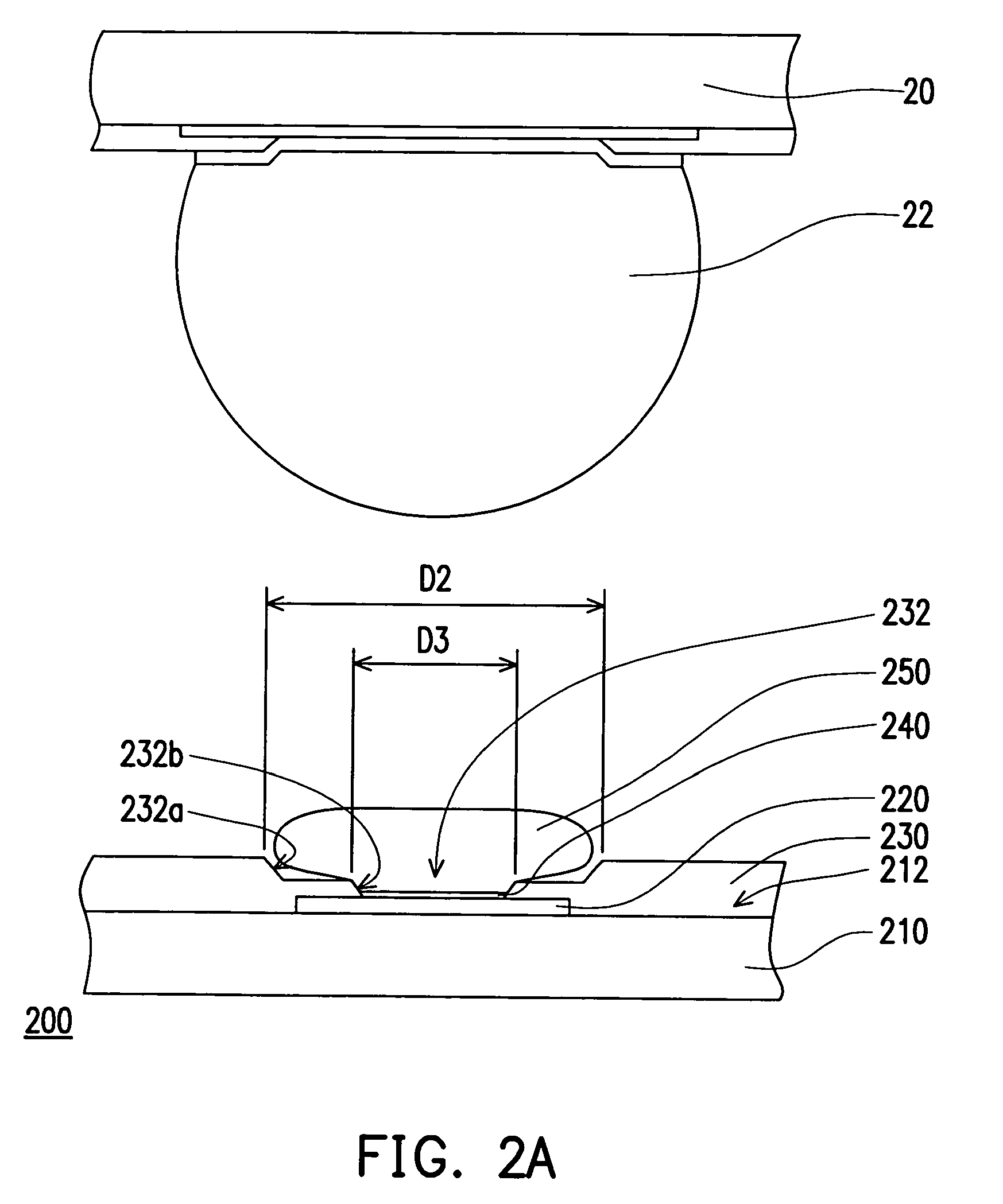

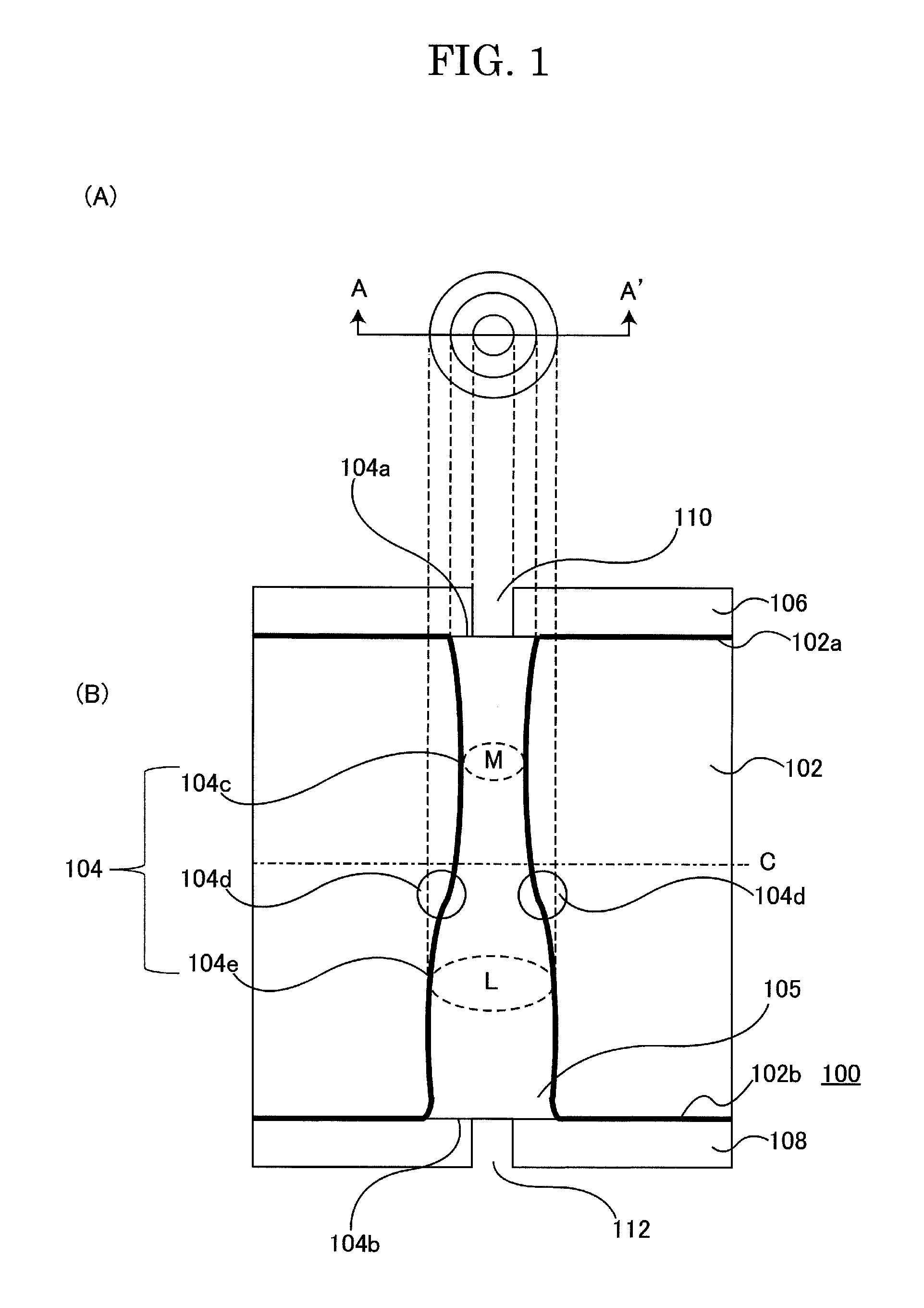

Wiring board with semiconductor component

InactiveUS7488896B2Avoid crackingHigh melting pointFinal product manufacturePrinted electric component incorporationResistSolder mask

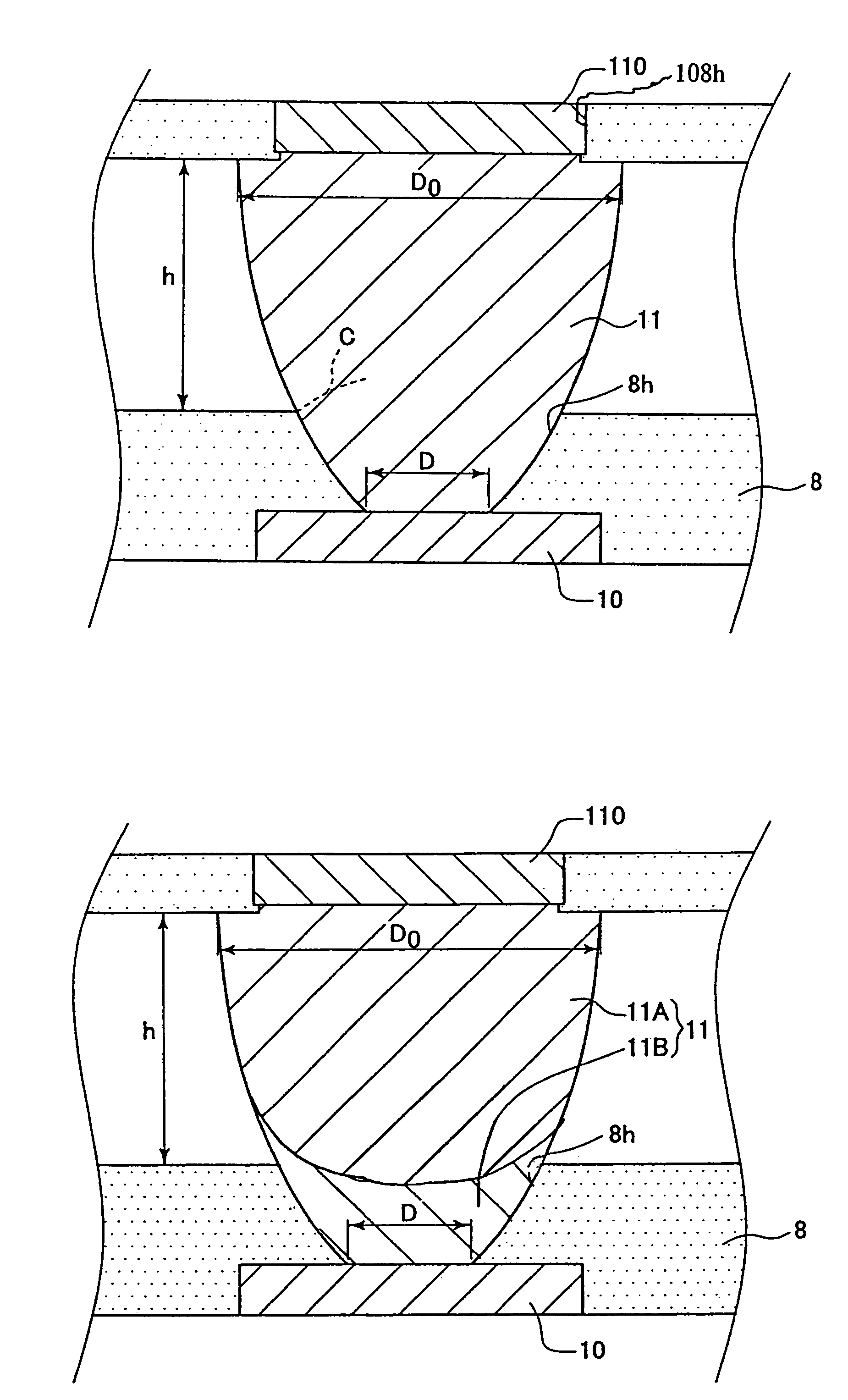

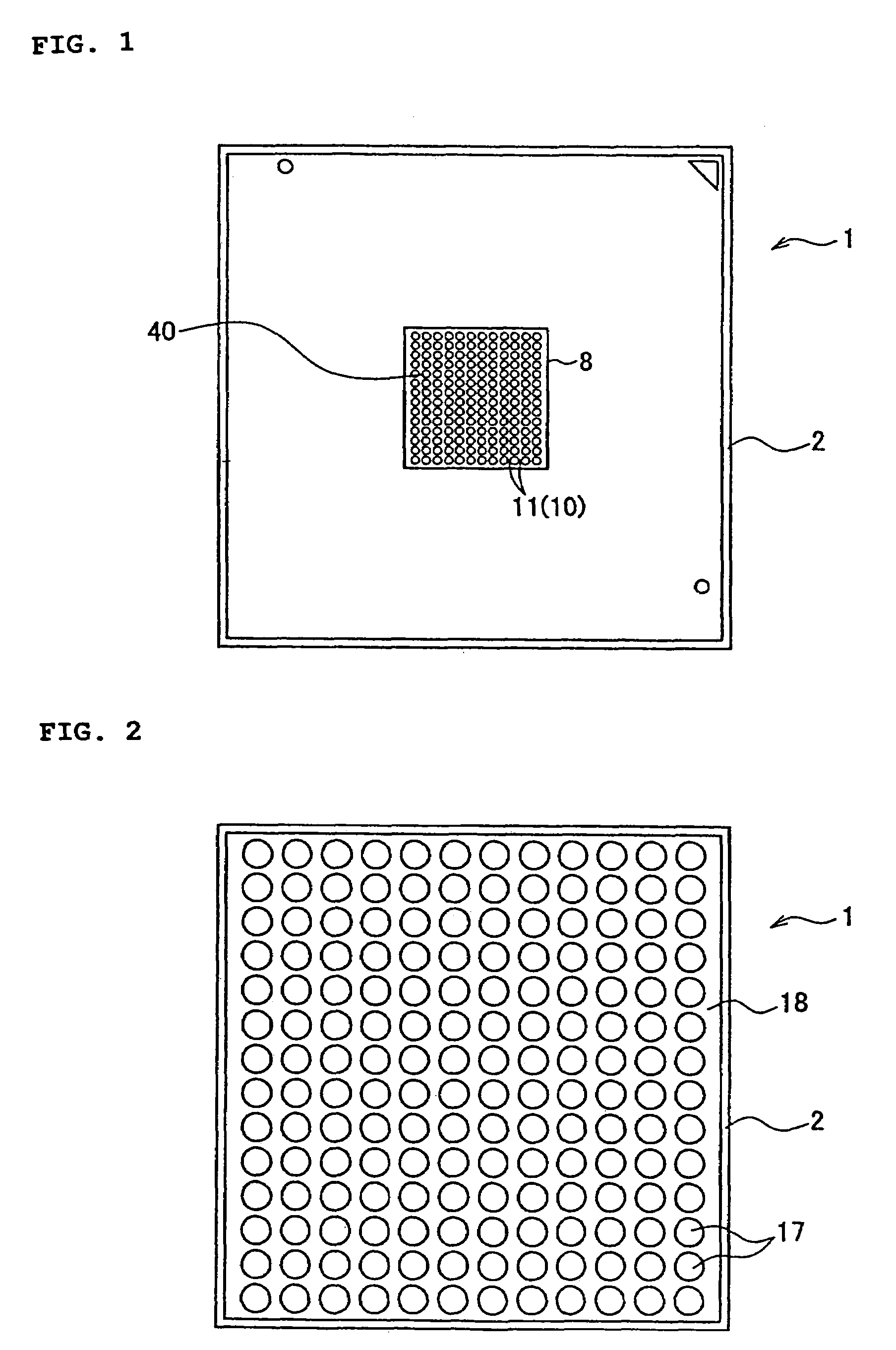

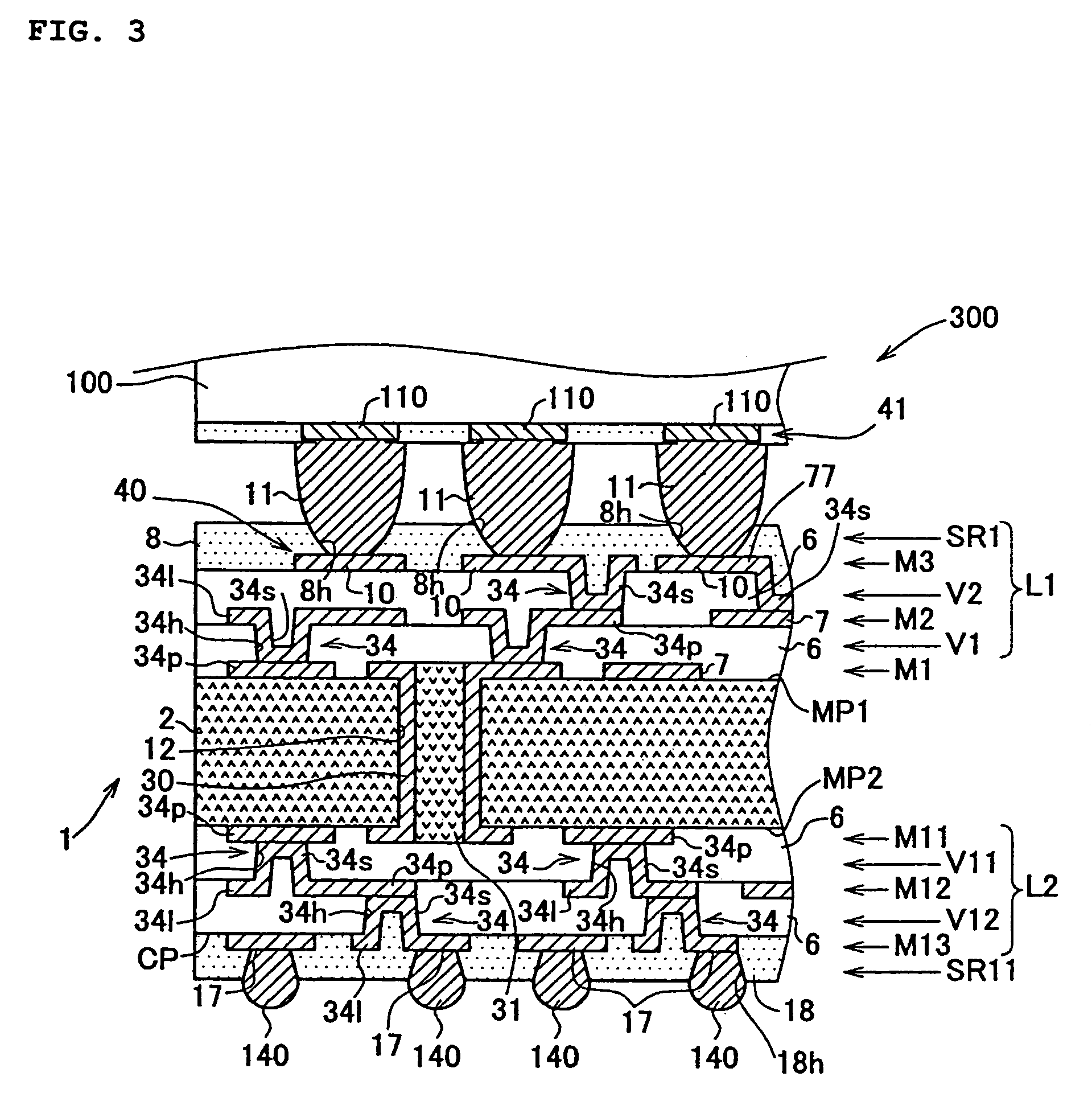

An electronic device comprised of a wiring board with a semiconductor component. The device is unlikely to have any defects, such as cracks to a solder joint portion during a reflow process of a flip-chip connection. The semiconductor component is flip-chip bonded at a pad array at a component side thereof to a pad array at a board side by way of an individual solder joint portion. In a solder resist layer at a semiconductor component side and a solder resist layer at a board side, D / D0 is prepared to be in a range of 0.70 to 0.99, where D is a bottom inner diameter of an opening at the board side and D0 is a bottom inner diameter of an opening at the component side.

Owner:NGK SPARK PLUG CO LTD

Card edge connector, method of manufacturing same, electronic card and electronic equipment

InactiveUS6855891B2Avoid it happening againEasy extractionPrinted circuit assemblingLine/current collector detailsEngineeringEdge connector

A card edge connector comprises a connector body and a conductive pad, and is constructed such that the conductive pad terminates at a predetermined distance from the end of the tip portion of the connector body, and that there is further provided a protective pad, adjacent to the terminating portion of the conductive pad, which is formed at the same time with the formation of a wiring pattern in a post-fabrication step of the wiring pattern. Using the card edge connector, an electric card and an electric equipment are also provided.

Owner:FUJITSU LTD

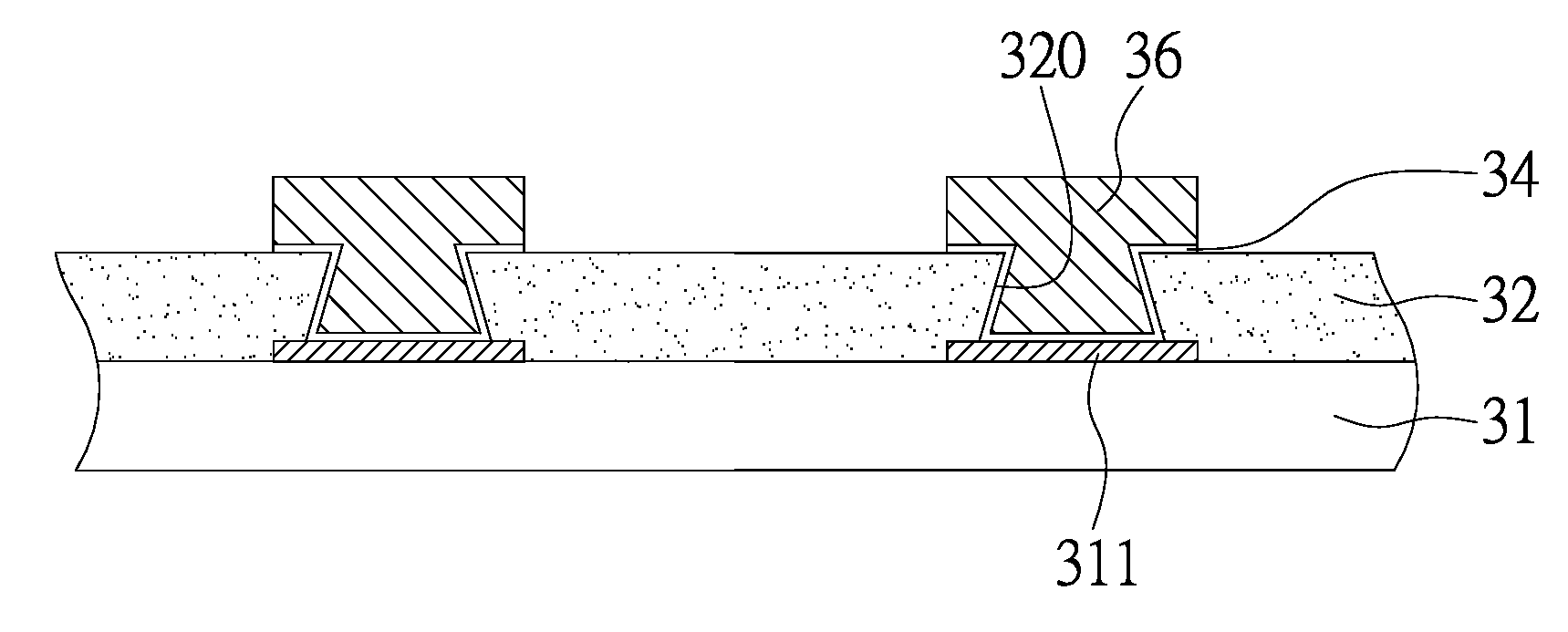

Circuit board surface structure and fabrication method thereof

ActiveUS20080217046A1Improve bindingGood adhesionSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringSurface structure

A circuit board surface structure and a fabrication method thereof are proposed. The circuit board surface structure includes: a circuit board having a plurality of electrically connecting pads formed on at least one surface thereof; a first and a second insulating protective layers formed on the surface of the circuit board in sequence; first and a second openings respectively formed in the first and second insulating protective layers to expose the electrically connecting pads on the surface of the circuit board, wherein the first and second openings have narrow top and wide bottom and the diameter of the first openings is bigger than that of the second openings; and conductive elements formed in the first and second openings on surfaces of the electrically connecting pads. The present structure facilitates to strengthen the bonding between the conductive elements and the corresponding electrically connecting pads.

Owner:UNIMICRON TECH CORP

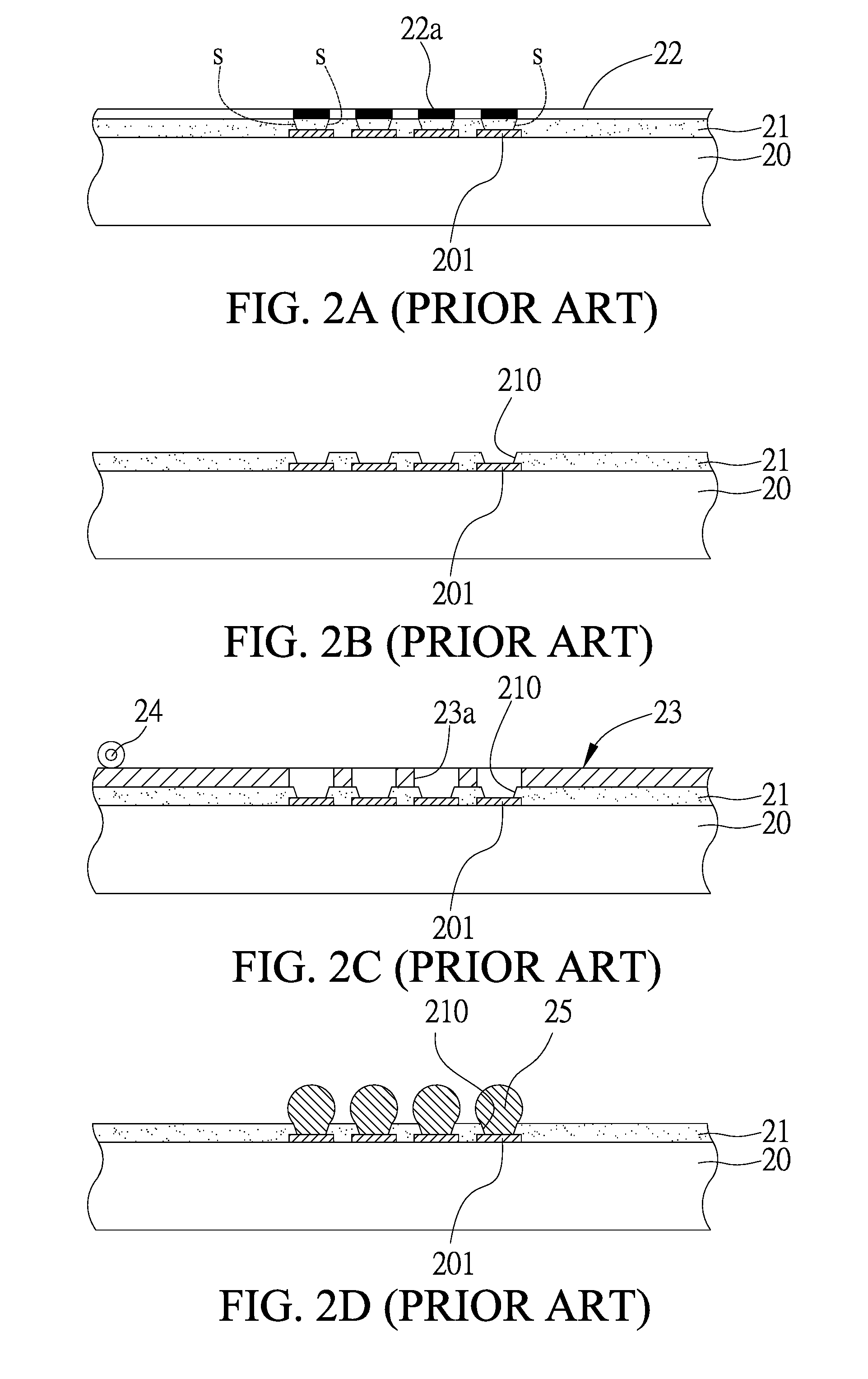

Printed circuit board, method of producing the same, and electronic unit

InactiveUS20070187136A1Easy to makePrevent outflowSecond resist masksSecond resist patternAcute anglePrinted circuit board

A printed circuit board is disclosed that is able to prevent outflow of a potting resin out of a sealing region. The printed circuit board includes a conductive pattern formed on an insulating substrate, an electrode for connecting an electronic part to the conductive pattern, and a stripe-like resin-outflow-prevention dam arranged in a periphery of a resin-sealing region covering the electronic part. An outer side surface and an upper surface of the resin-outflow-prevention dam subtend an acute angle.

Owner:RICOH KK

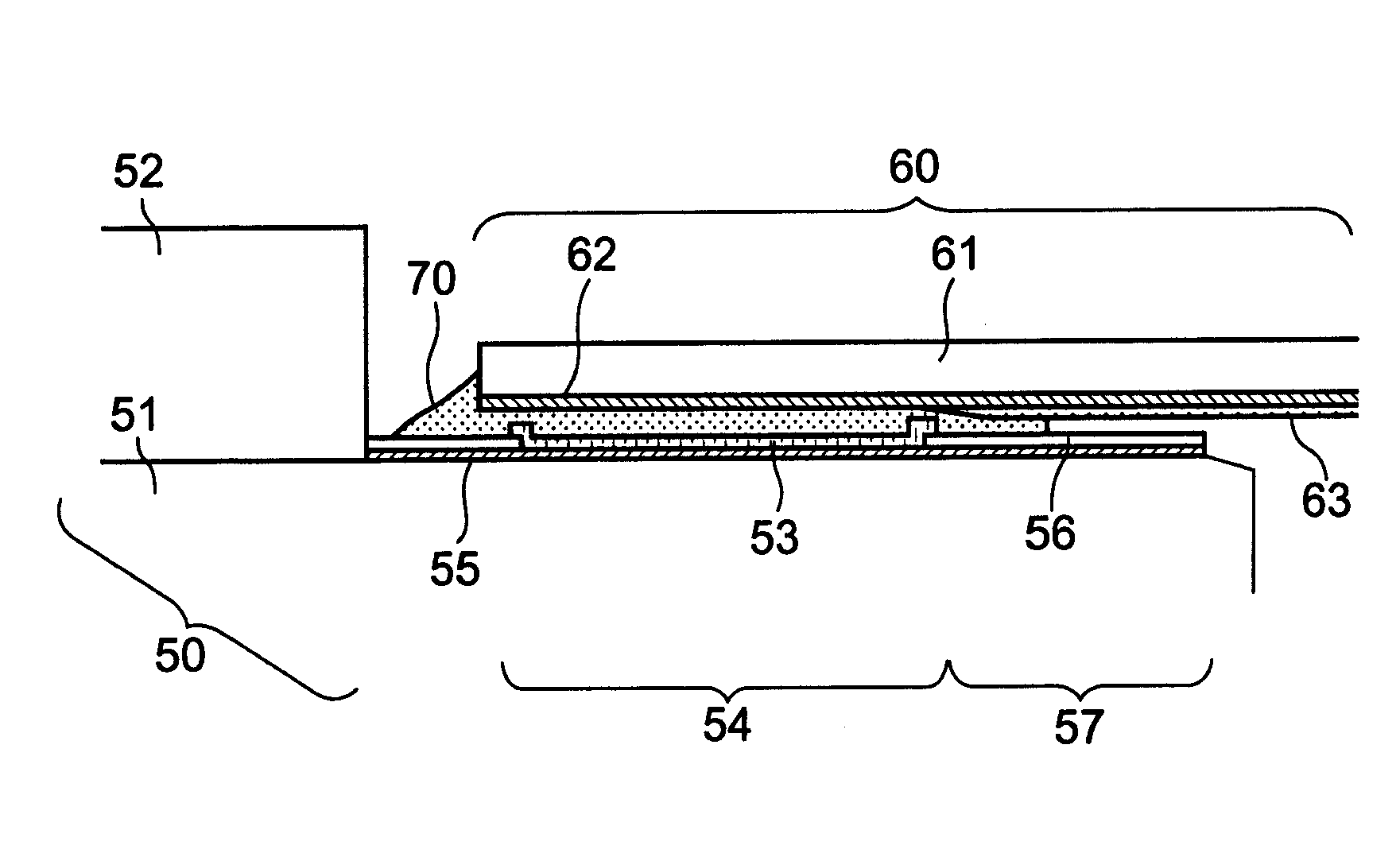

Flat display panel and connection structure

InactiveUS20070242207A1Avoid problemsCoupling device connectionsPrinted circuit aspectsResistAnisotropic conductive film

In a flat display panel having a panel and a flexible board connected and fixed to each other through an anisotropic conductive film, a surface end of a solder resist formed on the flexible board is located to face a surface end of an insulating film layer formed on the panel. Conductive particles contained in the anisotropic conductive film flowing out during a compression bonding process aggregate in a non-connection region due to the thickness of the insulating resin layer. This makes it possible to substantially completely prevent the short-circuit problem due to the aggregation of the conductive particles.

Owner:NEC LCD TECH CORP

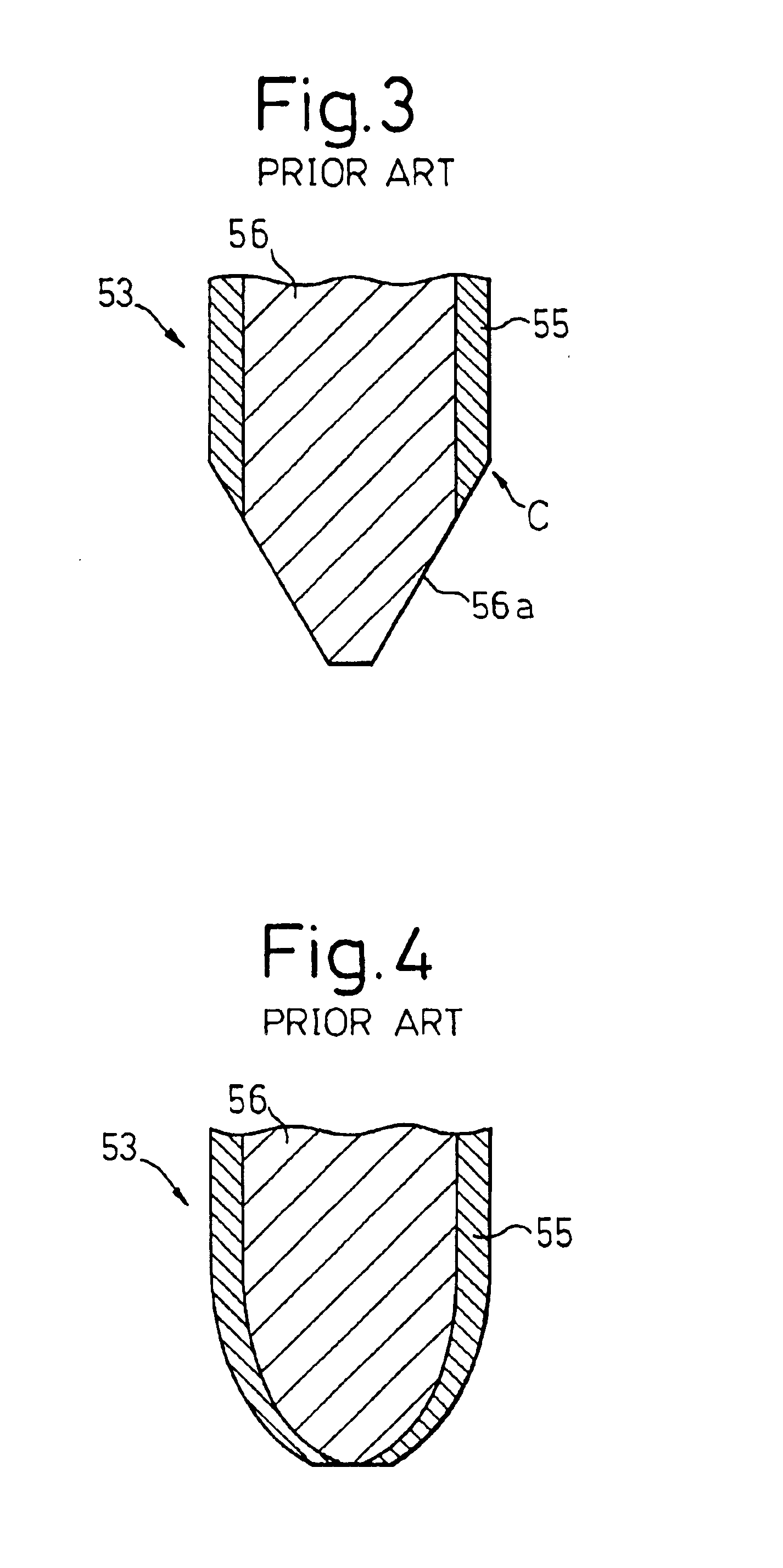

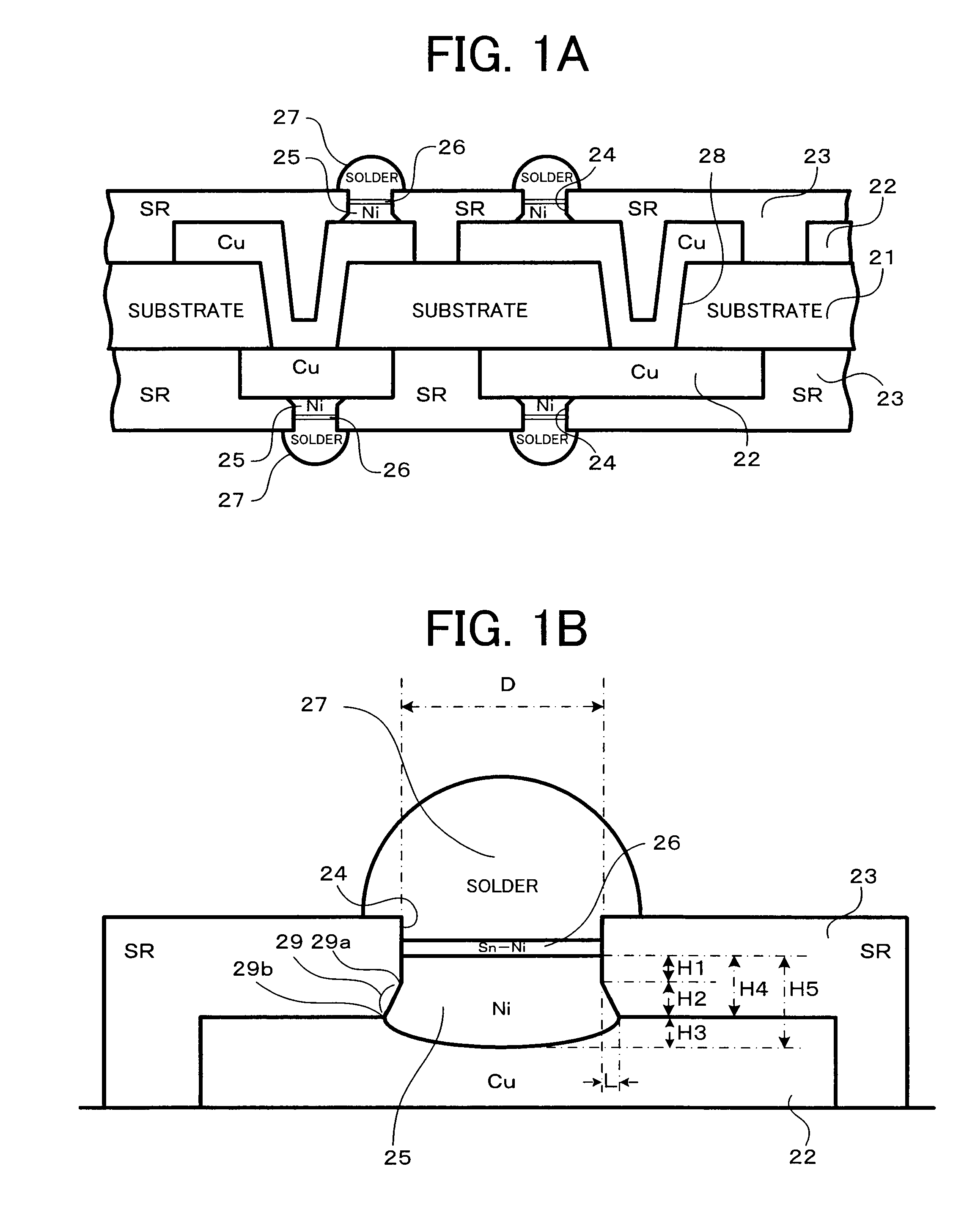

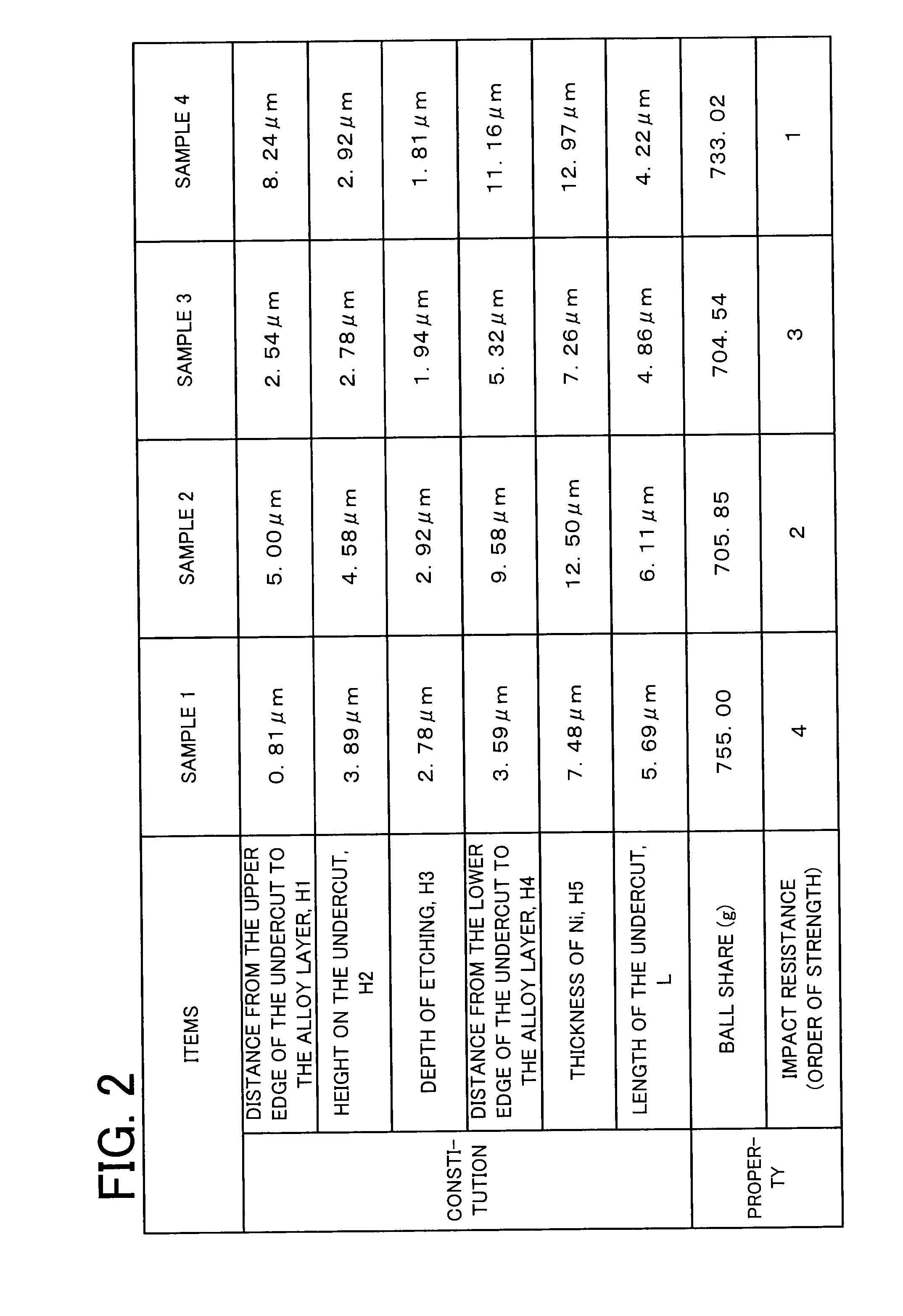

Circuit board and manufacturing method thereof

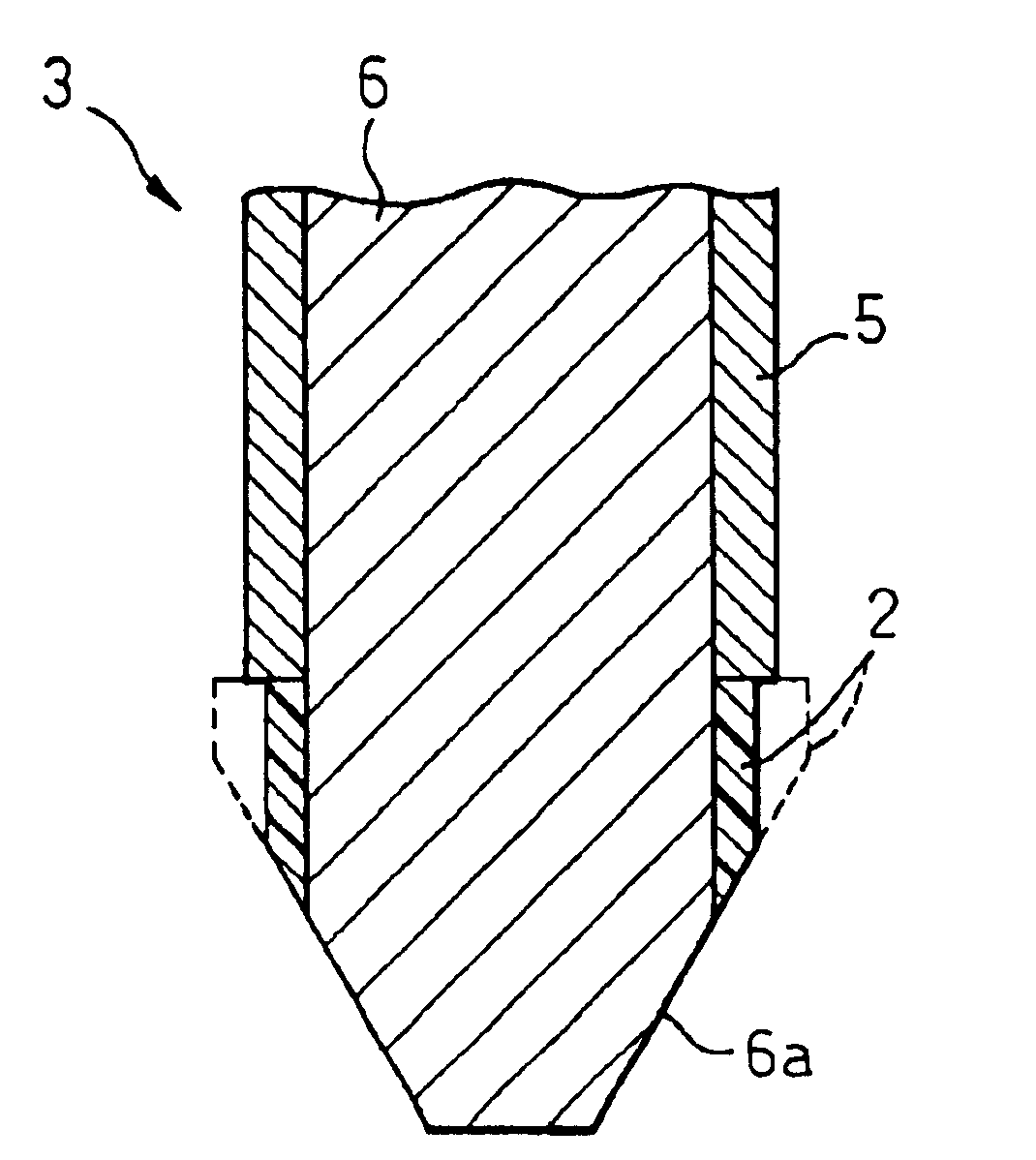

ActiveUS20090114431A1Semiconductor/solid-state device detailsSolid-state devicesInsulation layerElectrical conductor

A circuit board and method of manufacturing a circuit board. The circuit board includes a substrate, a conductor layer formed on the substrate, and an insulation layer formed on the substrate and the conductor layer, the insulating layer having an opening with an undercut therein, the opening reaching the conductor layer. A metal layer is formed in the opening of the insulation layer and connected to the conductor layer, a solder layer formed in the opening of the insulation layer and outside of the opening; and an alloy layer formed in a boundary region between the metal layer and the solder layer in the opening. The alloy layer includes a metal of the metal layer and a composition of the solder layer, the alloy layer being more fragile than the metal layer and being formed in a position misaligned from an edge of the undercut of the opening formed on the insulation layer.

Owner:IBIDEN CO LTD

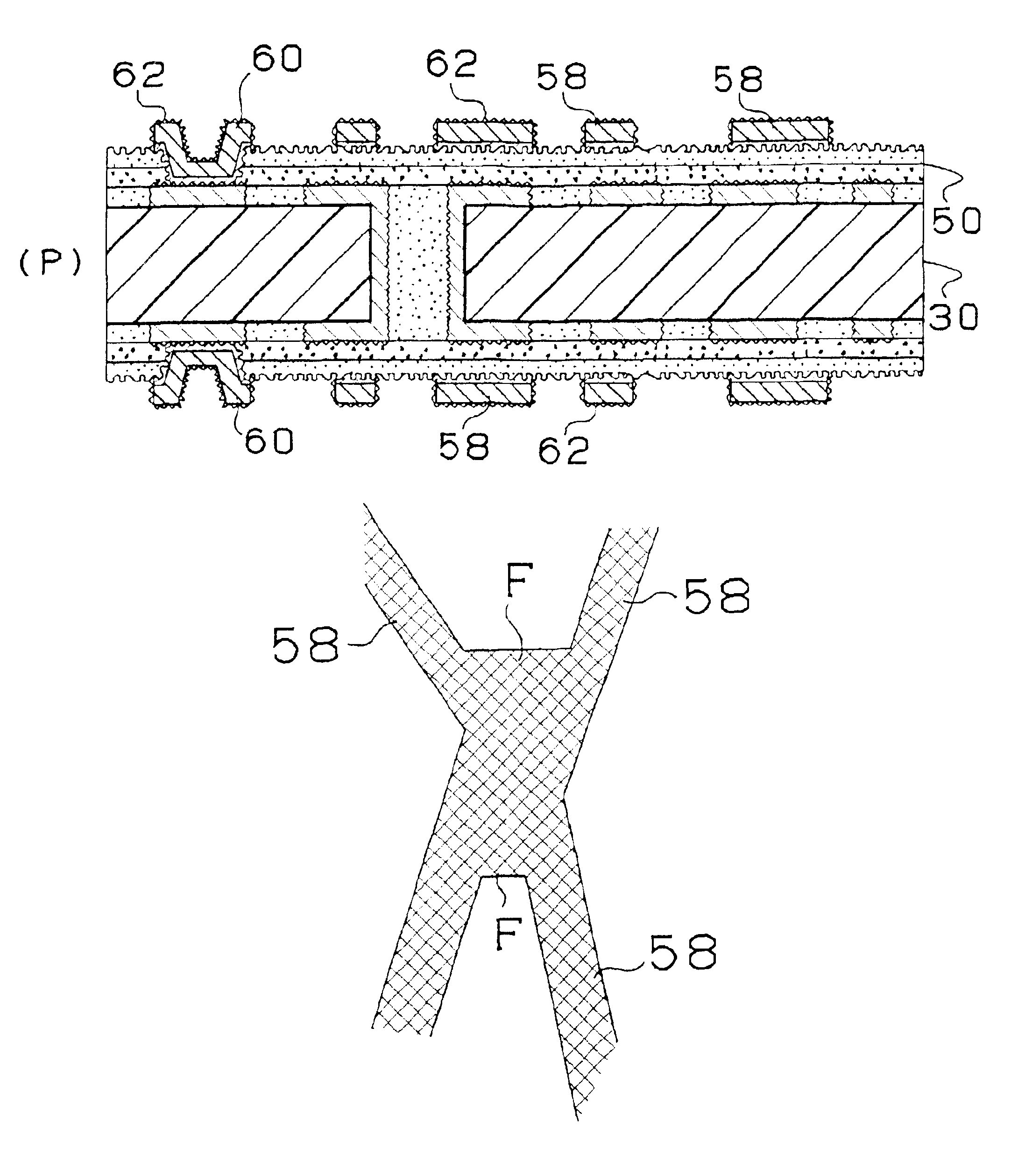

Method of fabricating crossing wiring pattern on a printed circuit board

InactiveUS7332816B2Improve reliabilityImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesAir bubbleElectrical and Electronics engineering

Owner:IBIDEN CO LTD

Junction structure and junction method for conductive projection

InactiveUS20050056445A1Large heightImprove reliabilityPrinted circuit assemblingElectrically conductive connectionsElectrical conductorUltraviolet lights

To provide a junction structure and a junction method for conductive projection advantageous in that a required reinforcement strength can be obtained while suppressing the amount of a reinforcing resin material supplied to prevent warpage due to curing shrinkage. A conductive projection is joined to the surface of a conductor portion formed at the same level as that of the surface of the insulating layer so that a root portion of the projection is surrounded by a fillet-form resin material. The resin material contains an activator which assists in the junction between the conductive projection and the conductor portion when the resin material is in an uncured state, and is fused by heating to wet and rise the root portion of the conductive projection so as to be in a fillet form. The resin material is cured by an ultraviolet light while excluding the resin material on the conductor portion.

Owner:SONY CORP

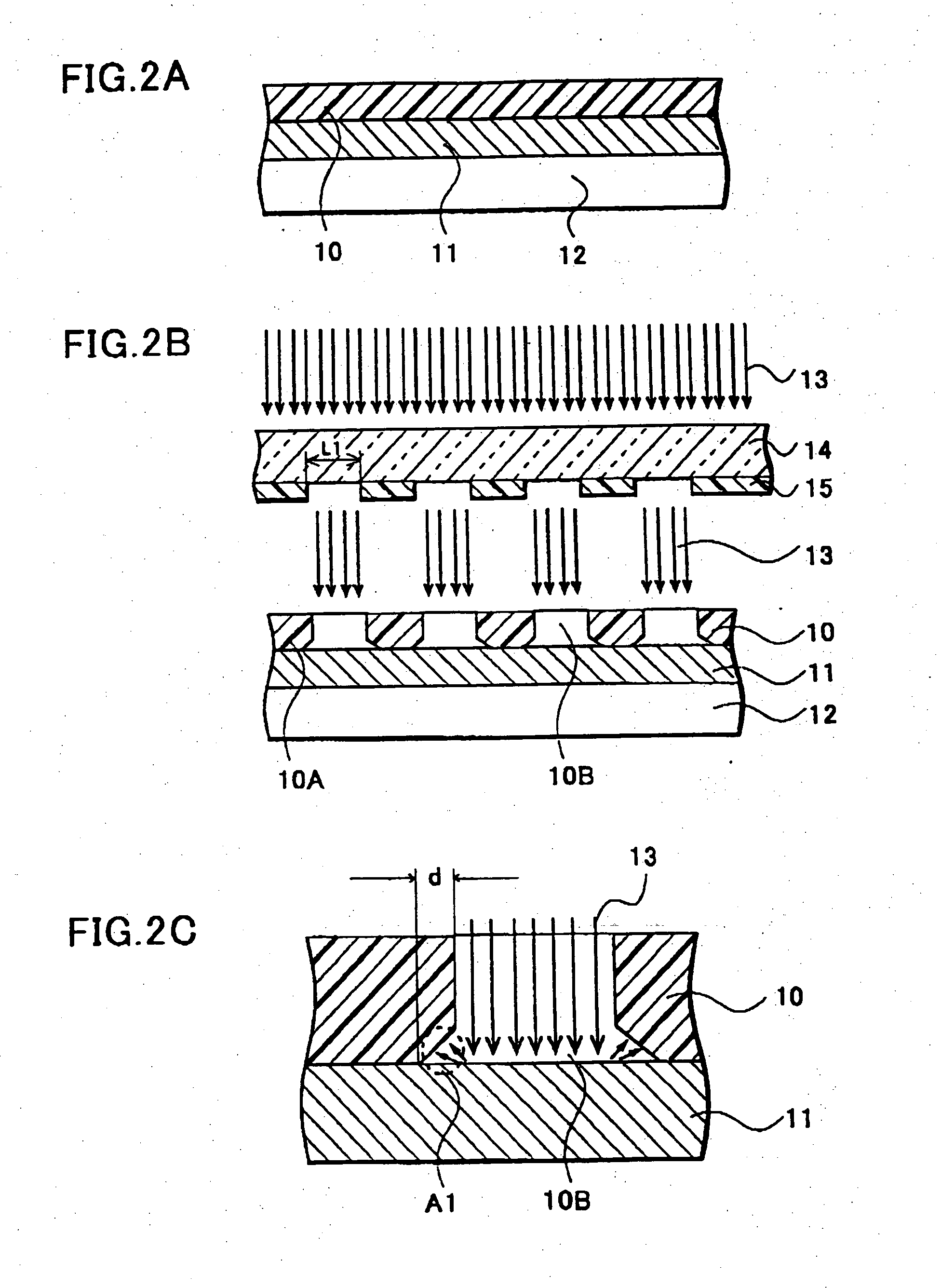

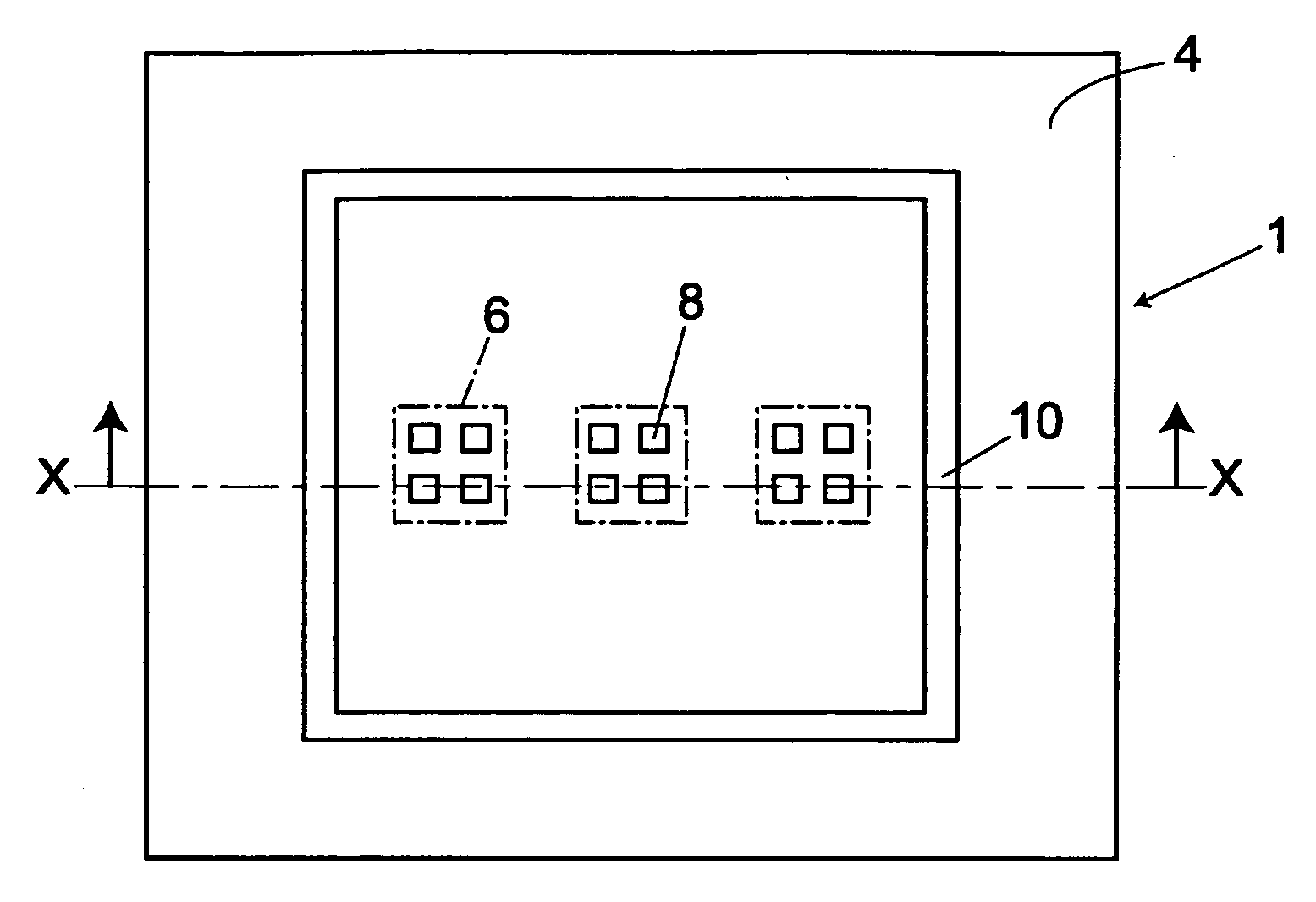

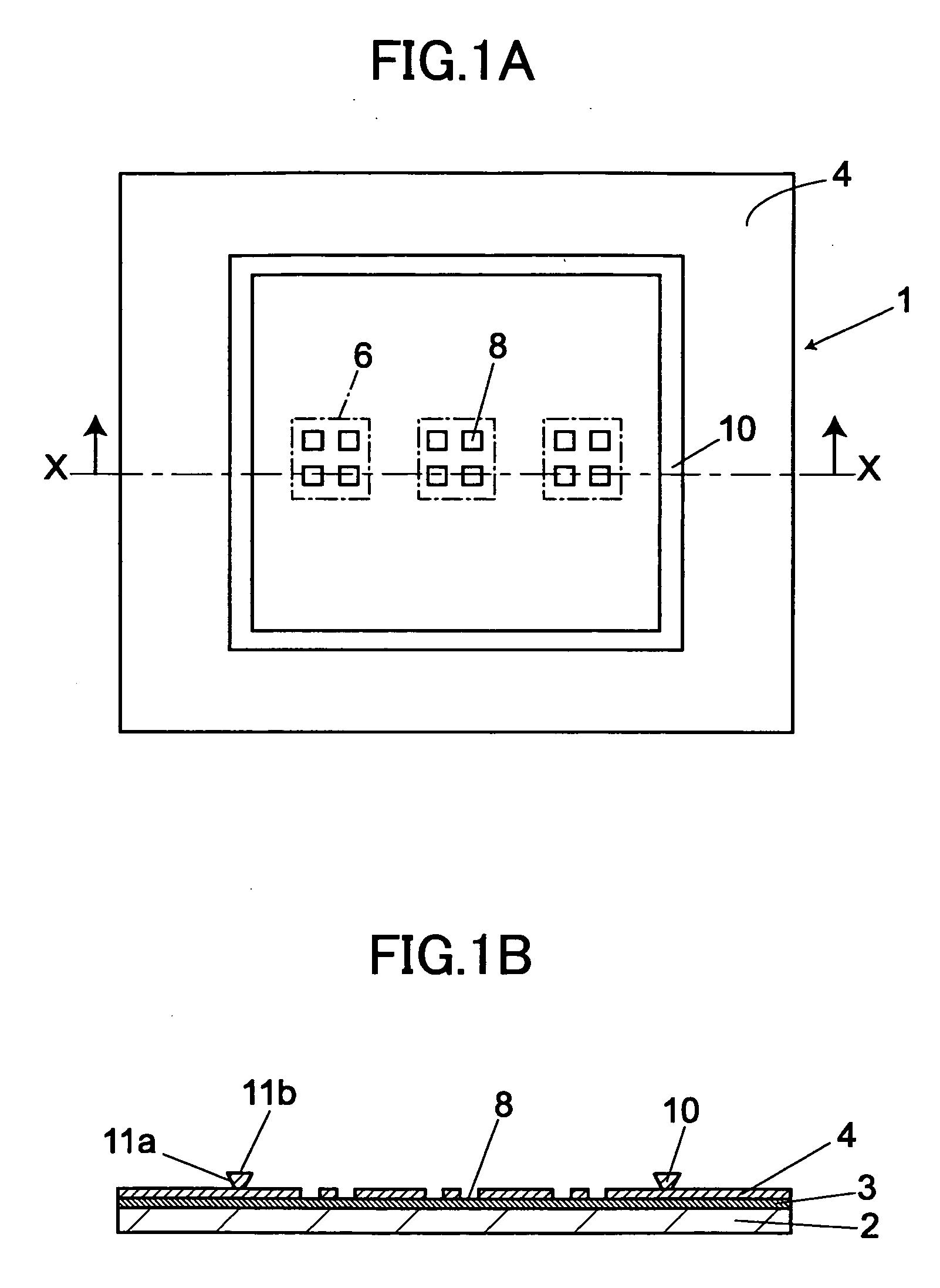

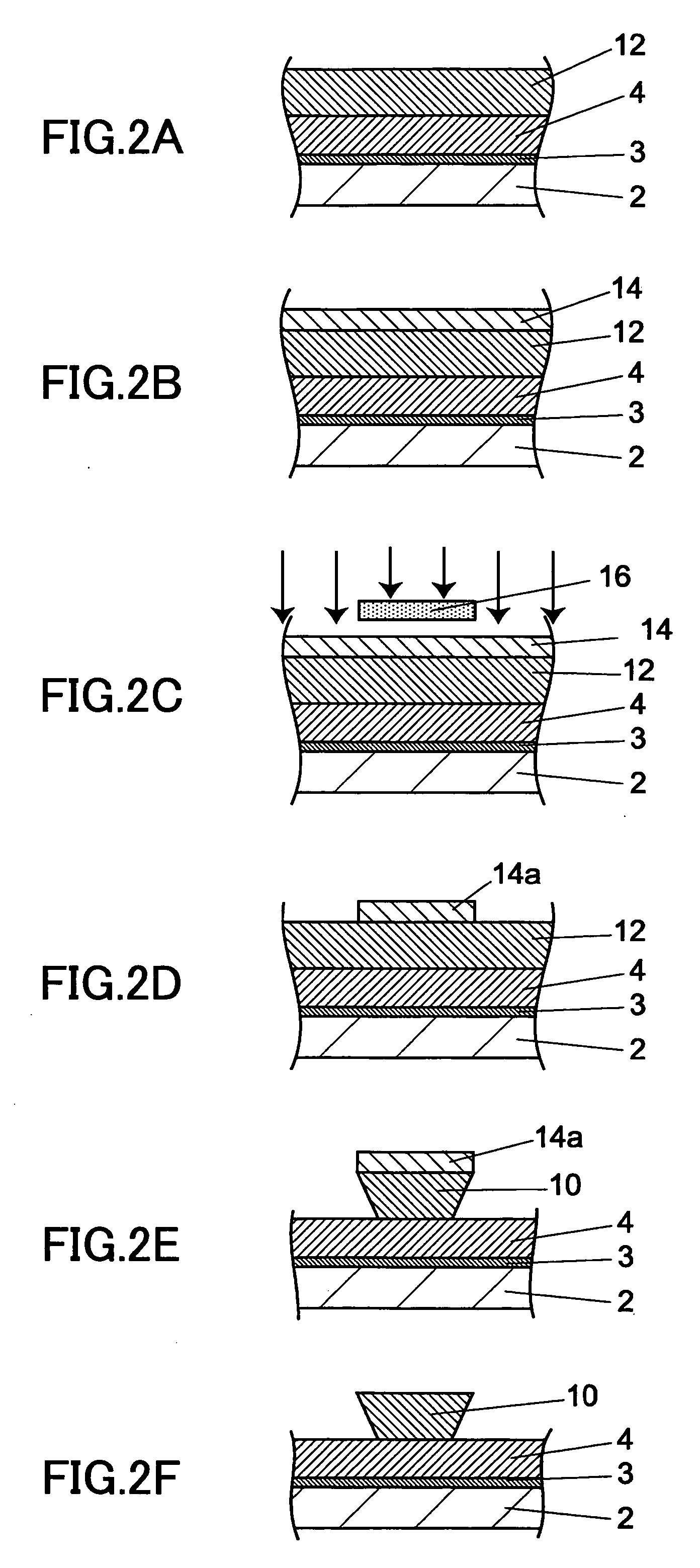

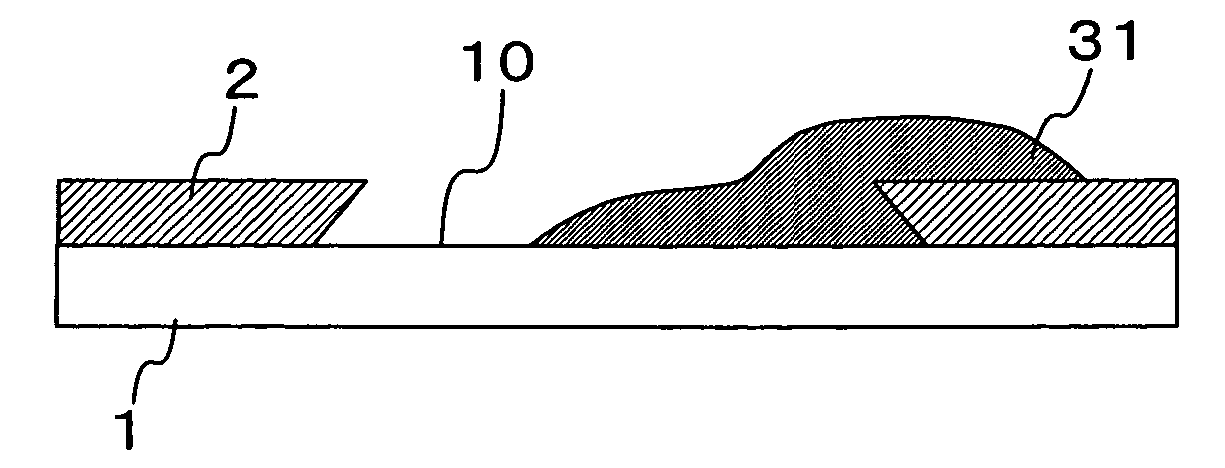

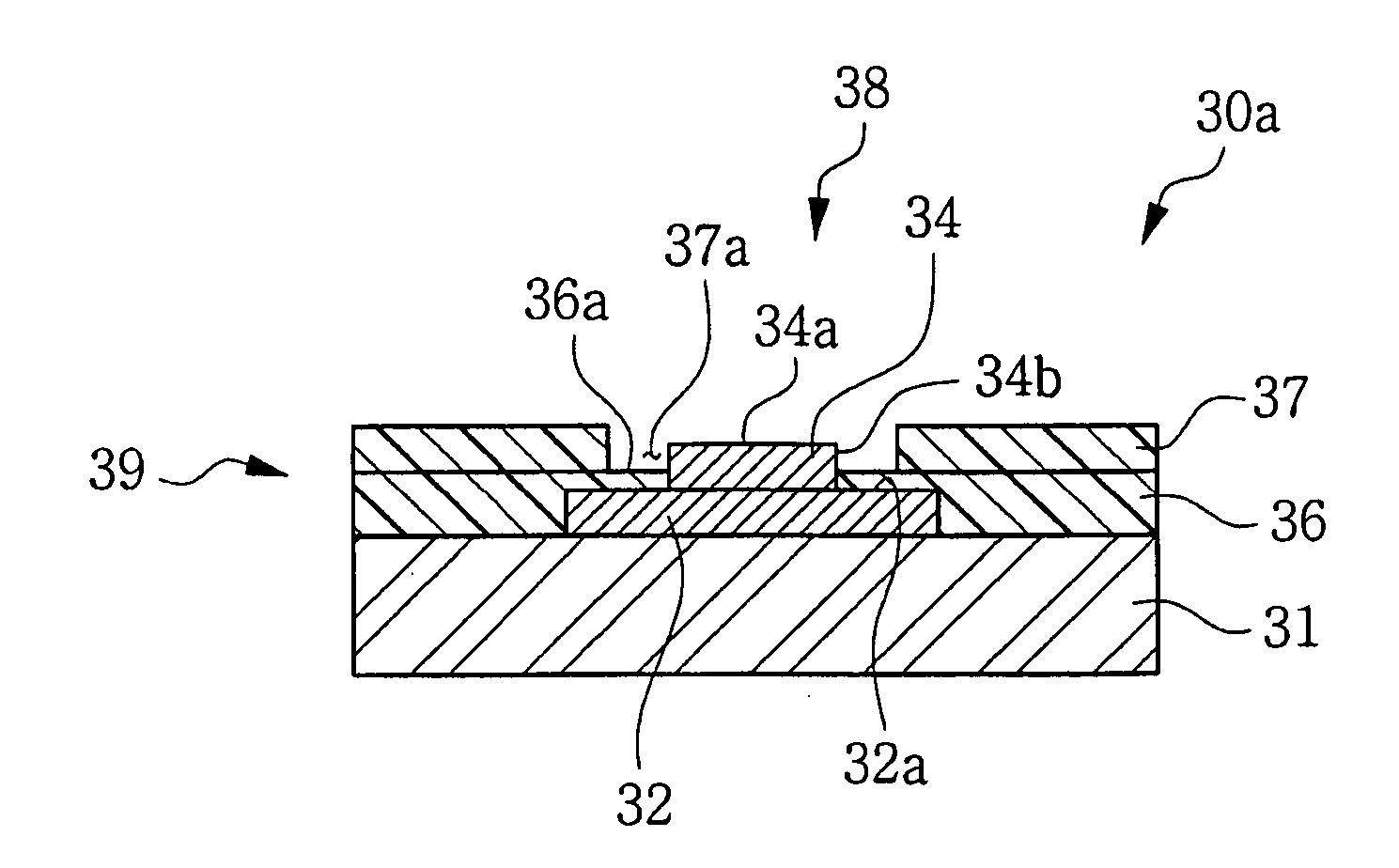

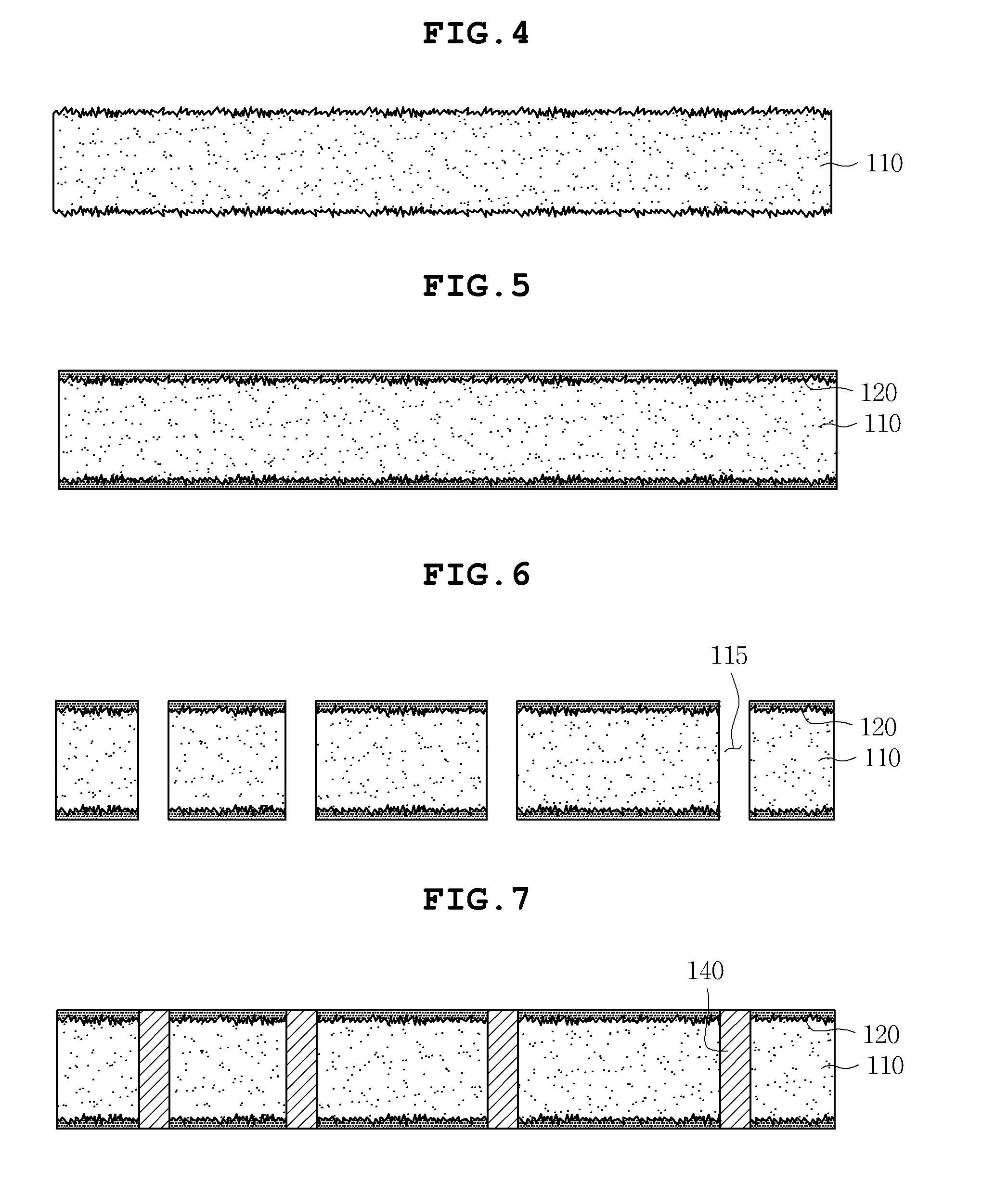

Method of forming wiring pattern

ActiveUS20060009020A1Reduce the impactMaterial efficiencyMaterial nanotechnologySemiconductor/solid-state device manufacturingResistCooking & baking

A photoresist pattern is formed on an insulating substrate so that it has a reverse tapered cross section and a reverse pattern of a wiring pattern to be formed. Next, a nanoparticles-containing ink is injected on a wiring region using an inkjet system, followed by a leveling process, a drying process, a resist separation process and a baking process. Thus a wiring pattern is formed.

Owner:HANNSTAR DISPLAY CORPORATION

Heat-resistant synthetic fiber sheet

InactiveCN1522326ASolve the above-mentioned problems that haveImprove heat resistancePrinted circuit aspectsReinforcing agents additionPolymer sciencePolymer chemistry

Owner:TEIJIN LTD

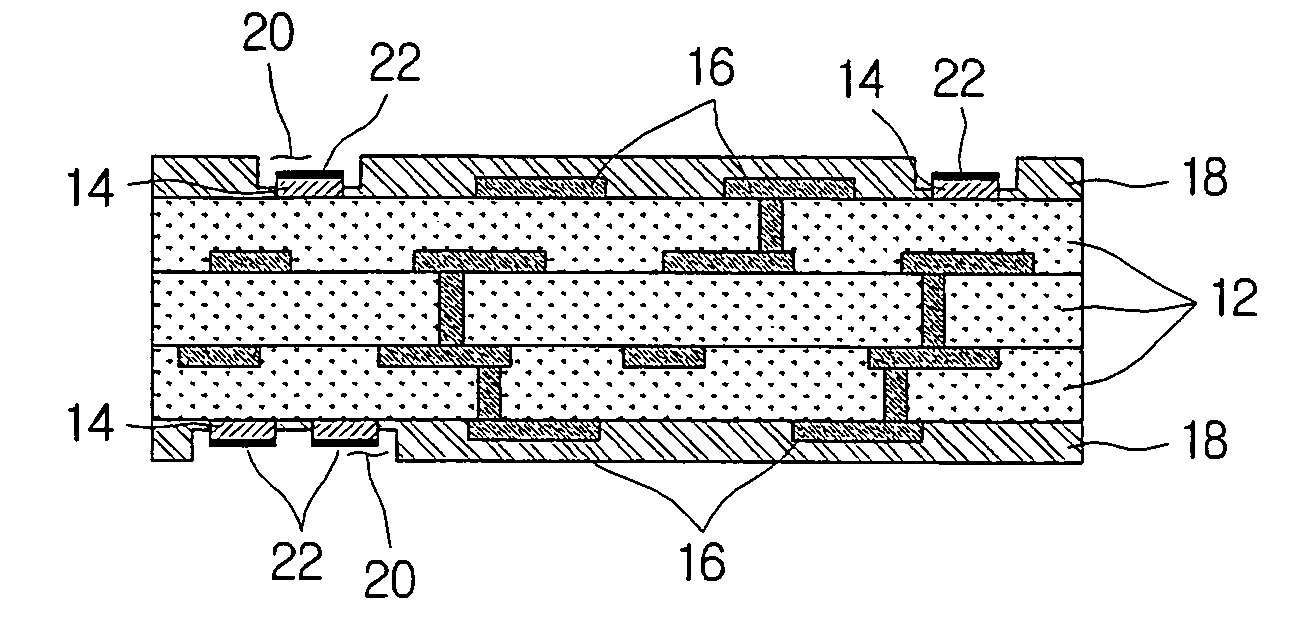

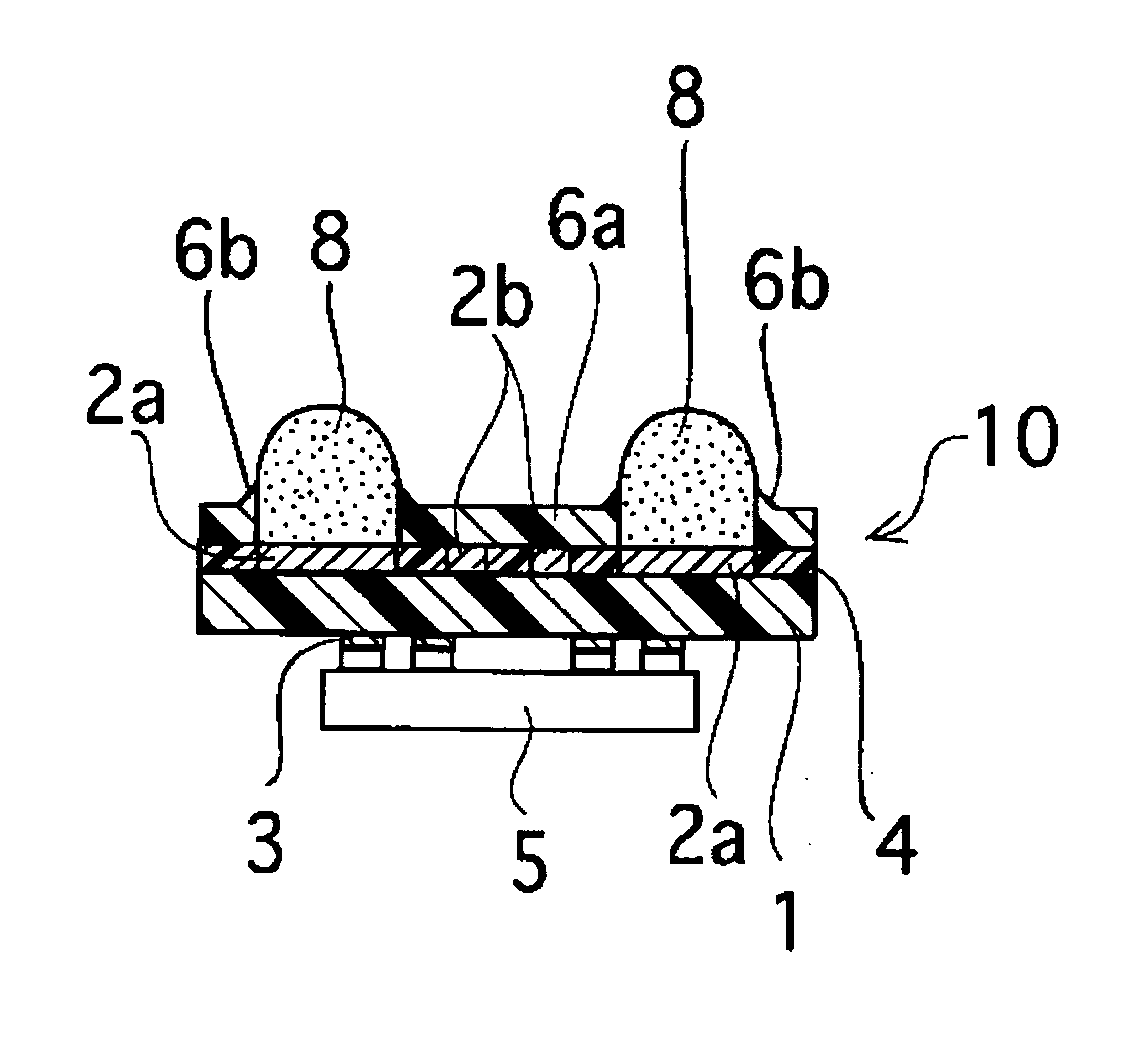

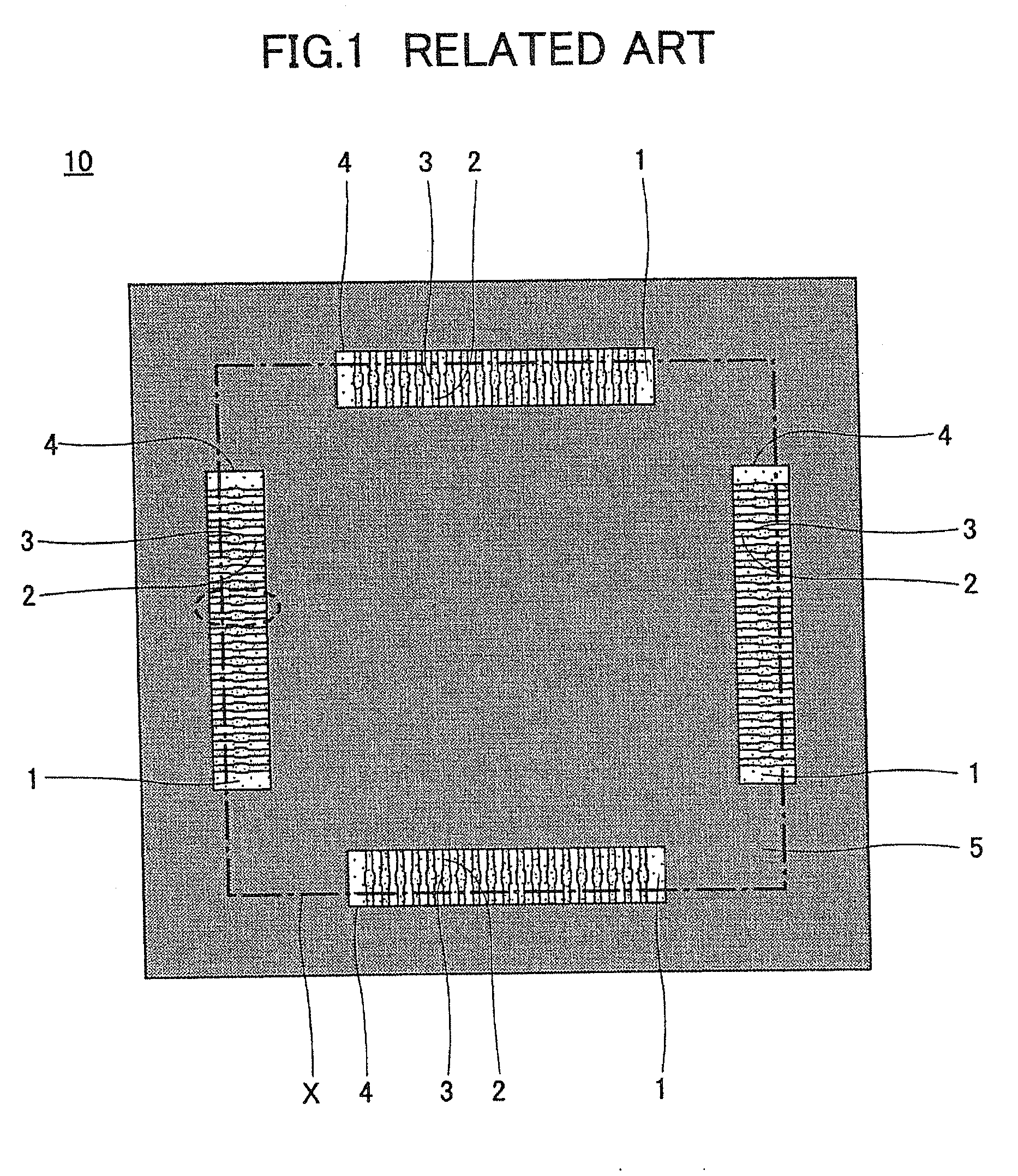

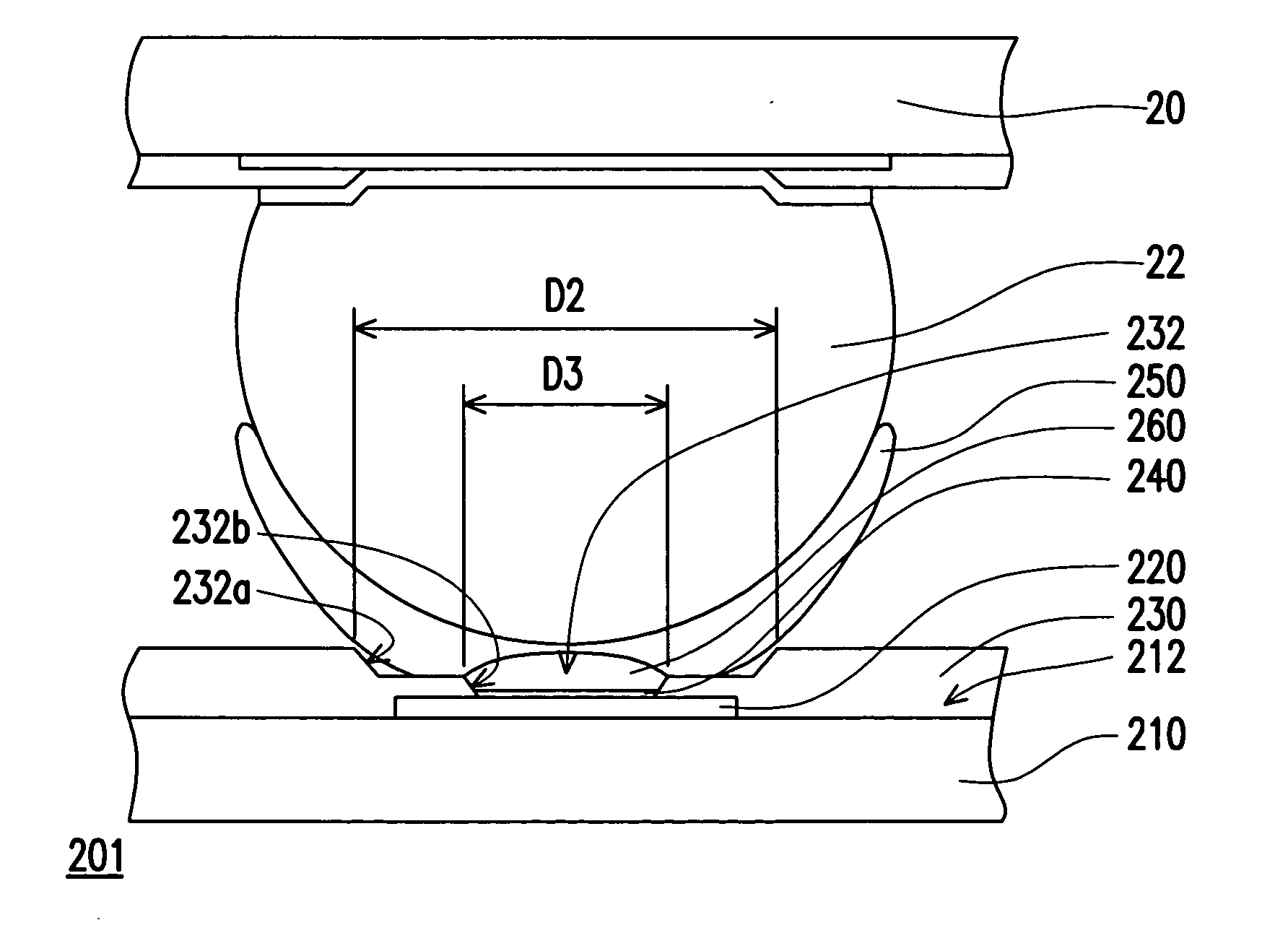

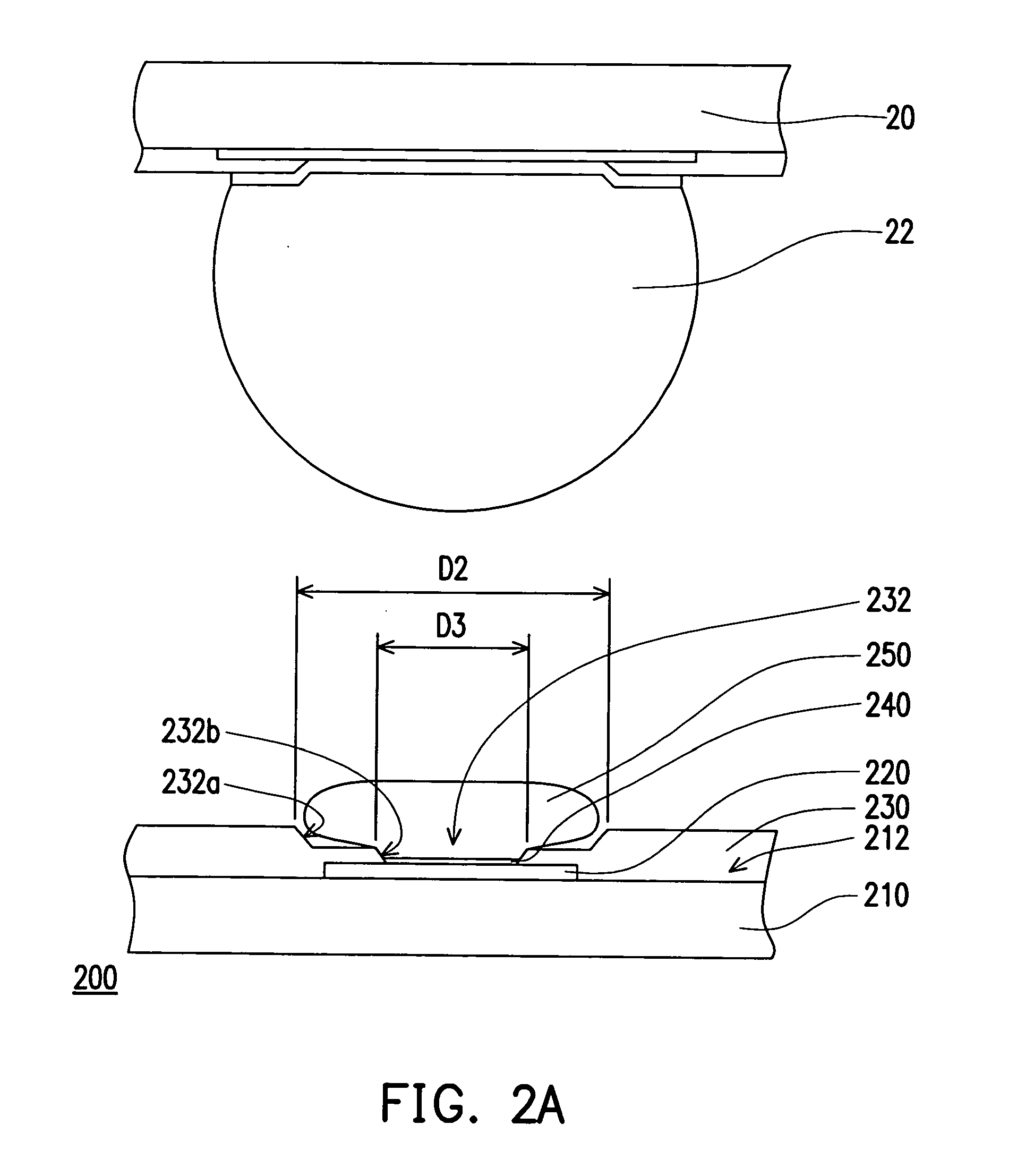

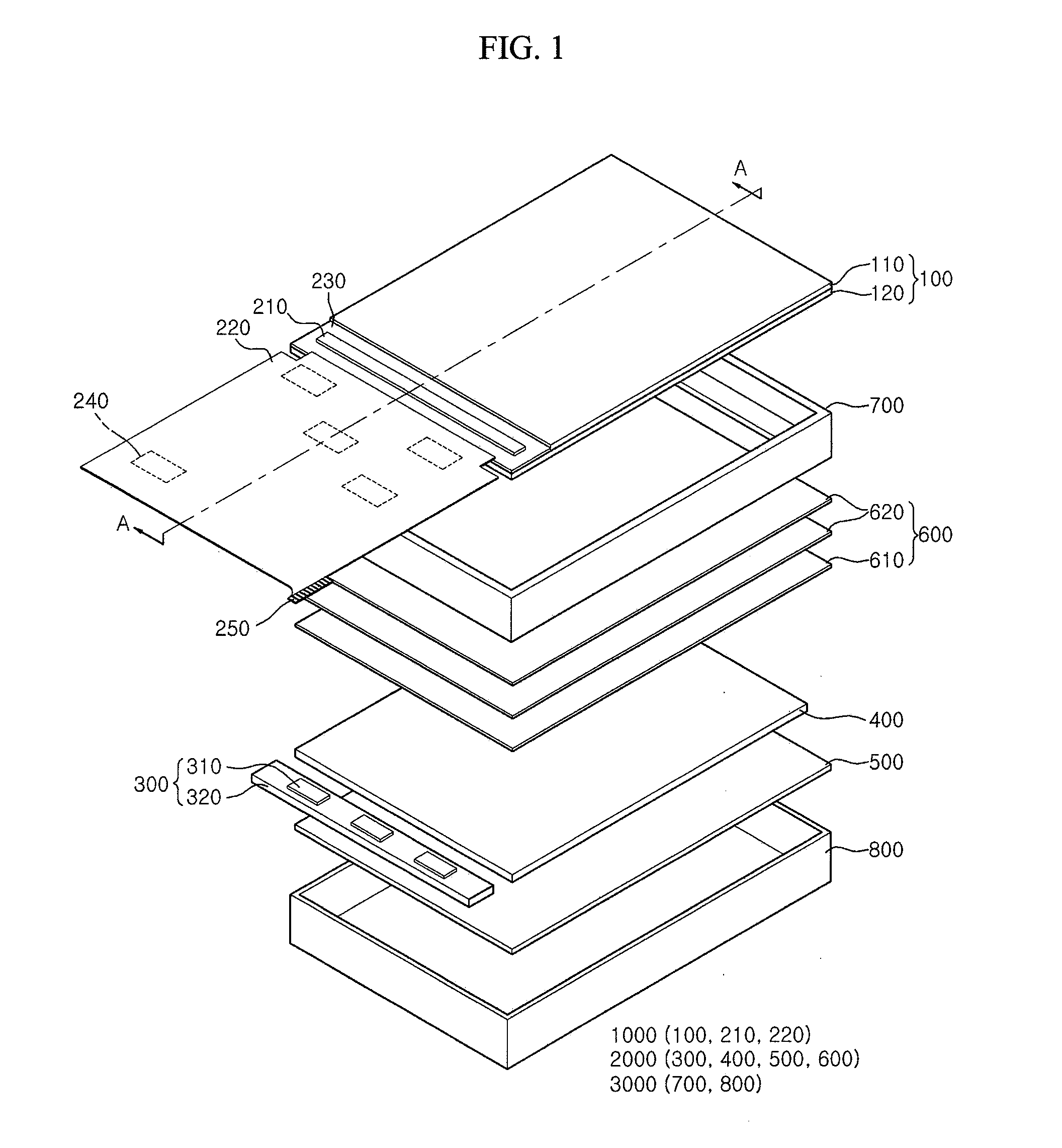

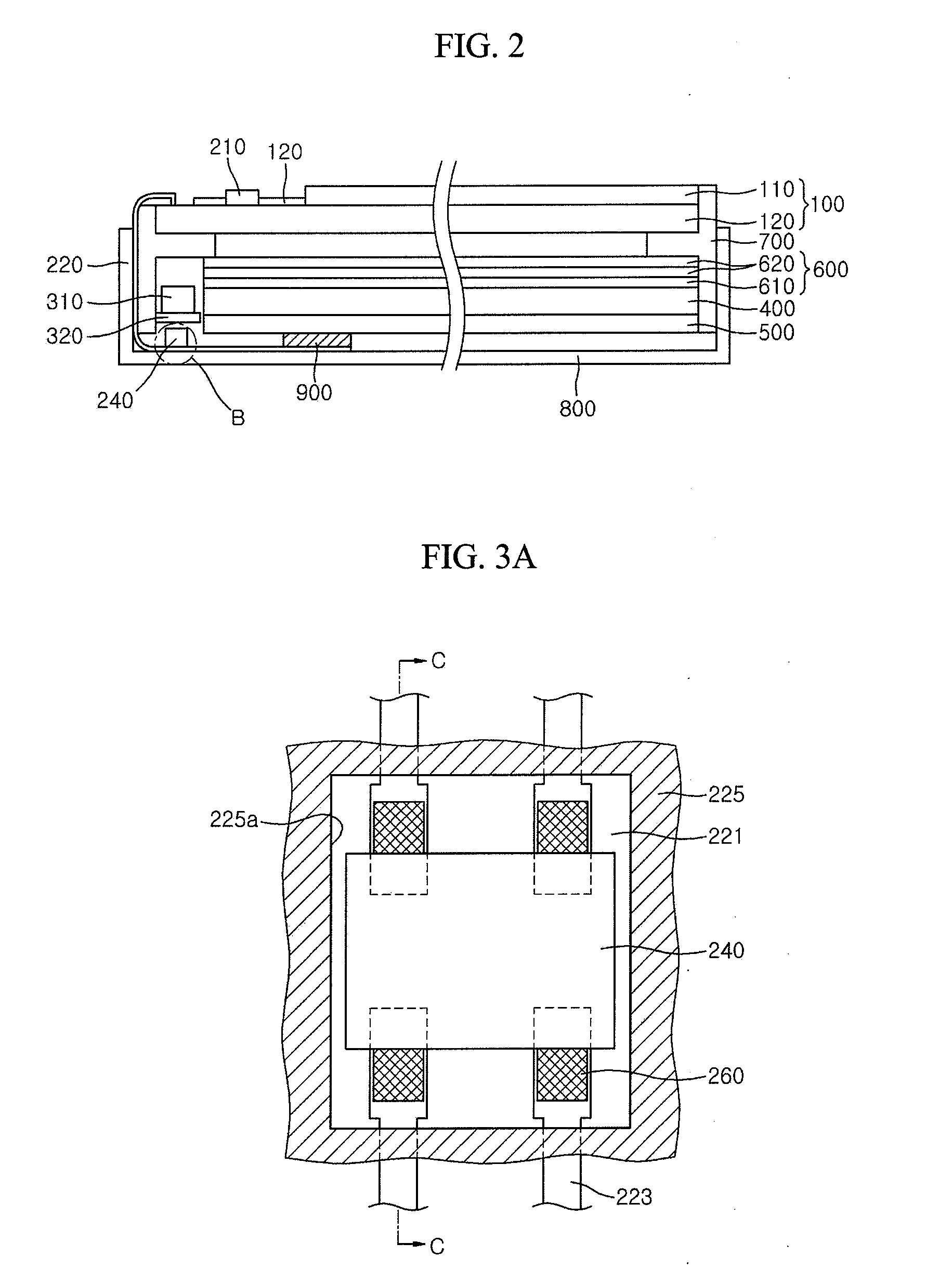

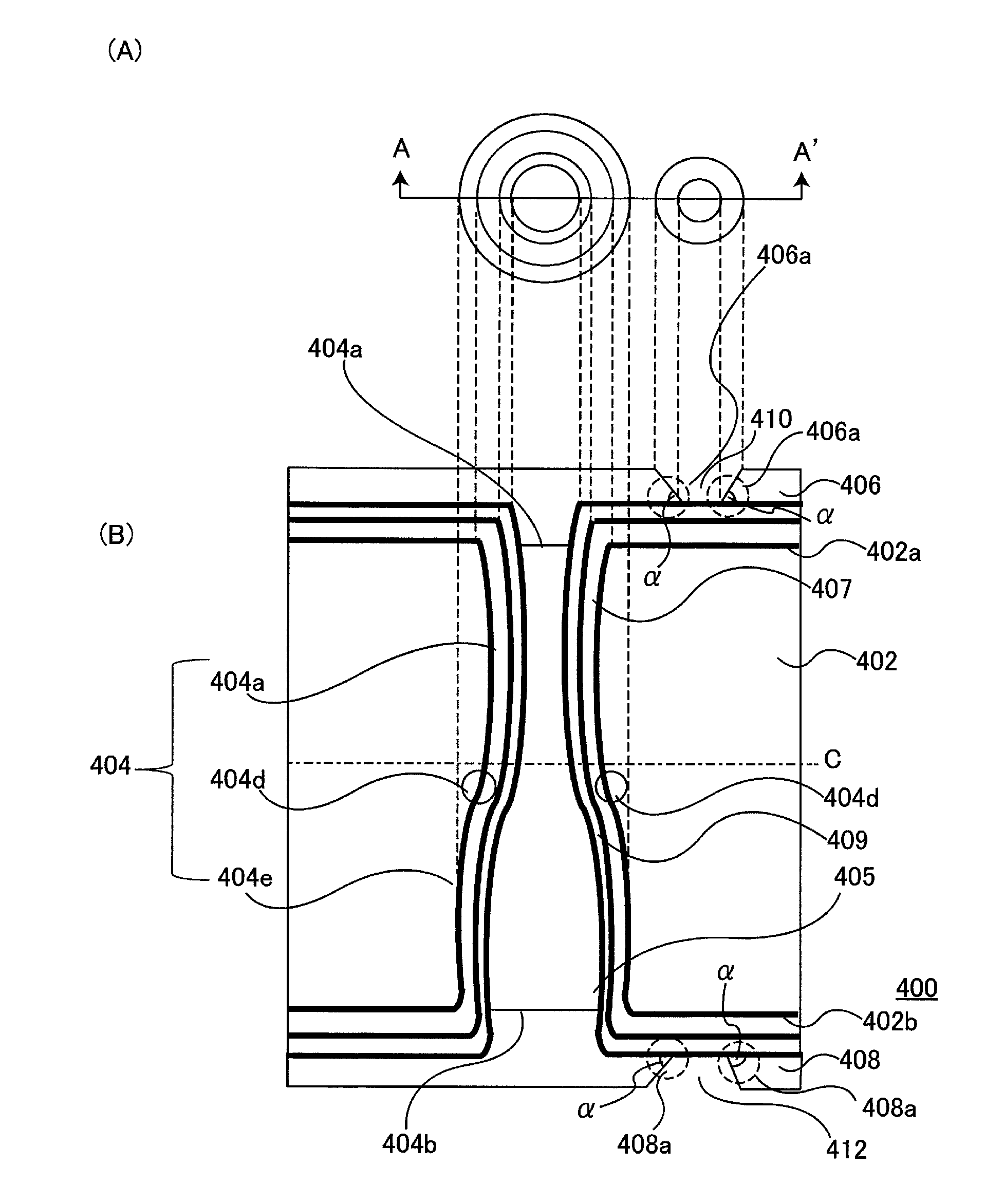

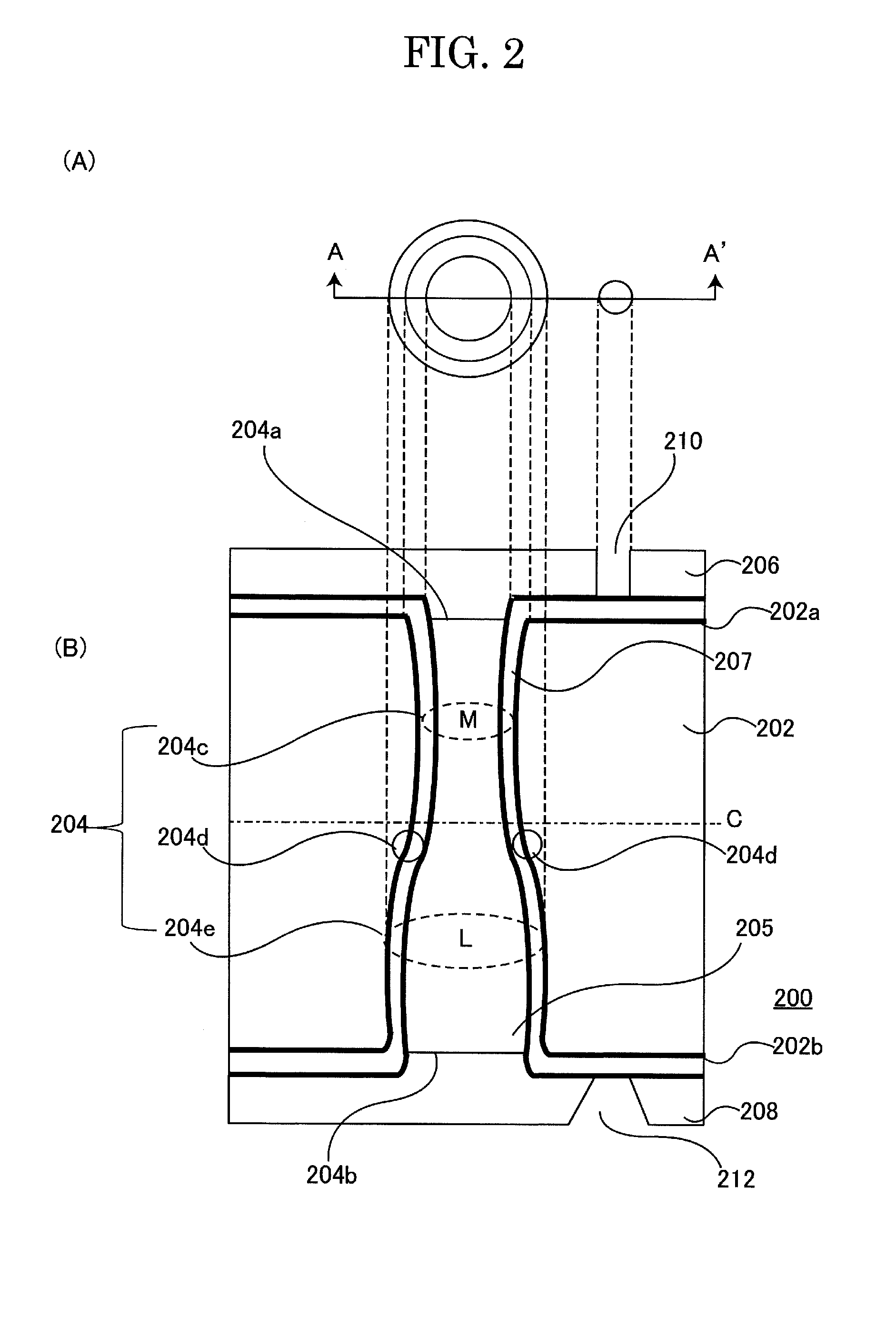

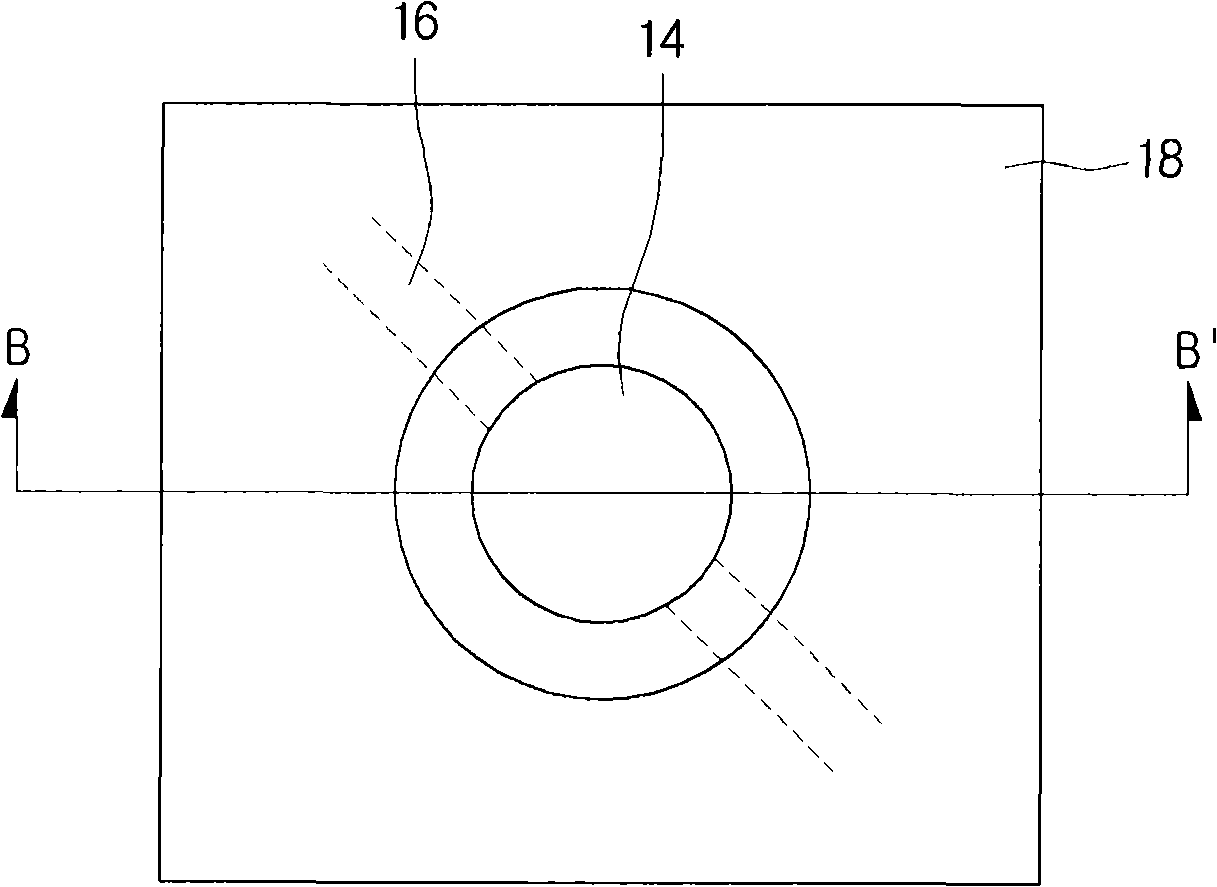

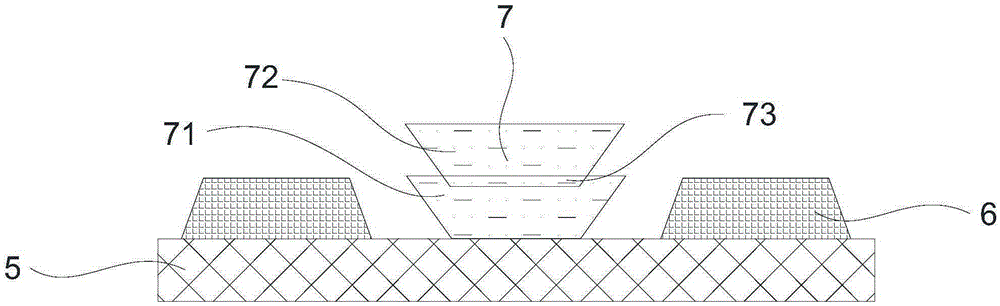

Wiring board, mounting structure for electronic components, and semiconductor device

ActiveUS20080224325A1Semiconductor/solid-state device detailsPrinted circuit aspectsAdhesiveEngineering

A wiring board includes a main surface where an electronic component is mounted in a face-down manner so that a surface of the electronic component having plurality of external connecting terminals faces the main surface of the wiring board, the electronic component being fixed to the wiring board by an adhesive; an insulating layer formed on the main surface where the electronic component is mounted; an opening part formed in the insulating layer so that a plurality of adjacent wiring patterns are commonly and partially opened, the adjacent wiring patterns having electrodes where electrodes of the electronic component are connected; wherein an outer periphery of the opening part situated at a center side of the wiring board is formed in an oblique direction against extending directions of the wiring patters.

Owner:SOCIONEXT INC

Circuit carrier

ActiveUS7126211B2Improve connection strengthIncreasing reliability and qualityPrinted circuit assemblingFinal product manufactureContact padSolder mask

The present invention provides a circuit carrier for connecting to at least a bump. The circuit carrier comprises a substrate, at least a contact pad on a surface of the substrate and a solder mask layer covering the substrate. The solder mask has at least a stepped opening that exposes a portion of the contact pad. The stepped opening includes at least a first opening and a second opening and the size of the first opening is larger than that of the second opening. The stepped opening of the solder mask layer can contain more pre-solder paste, thus increasing the bonding strength between the bump and the contact pad.

Owner:VIA TECH INC

Circuit carrier

ActiveUS20050184371A1Improve connection strengthIncreasing reliability and qualityPrinted circuit assemblingFinal product manufactureSolder maskContact pad

The present invention provides a circuit carrier for connecting to at least a bump. The circuit carrier comprises a substrate, at least a contact pad on a surface of the substrate and a solder mask layer covering the substrate. The solder mask has at least a stepped opening that exposes a portion of the contact pad. The stepped opening includes at least a first opening and a second opening and the size of the first opening is larger than that of the second opening. The stepped opening of the solder mask layer can contain more pre-solder paste, thus increasing the bonding strength between the bump and the contact pad.

Owner:VIA TECH INC

Substrate

InactiveUS20050205293A1Inhibit the generation of cracksImprove productivitySemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsCeramic insulators

A substrate has a base, an intermediate layer a conductive layer, and conductive films. The base is a ceramic insulator. The intermediate layer on a main surface of the base. The conductive layer is on the intermediate layer The conductive films are on the conductive layer, covering an exposed portion of the conductive layer.

Owner:MITSUBISHI ELECTRIC CORP

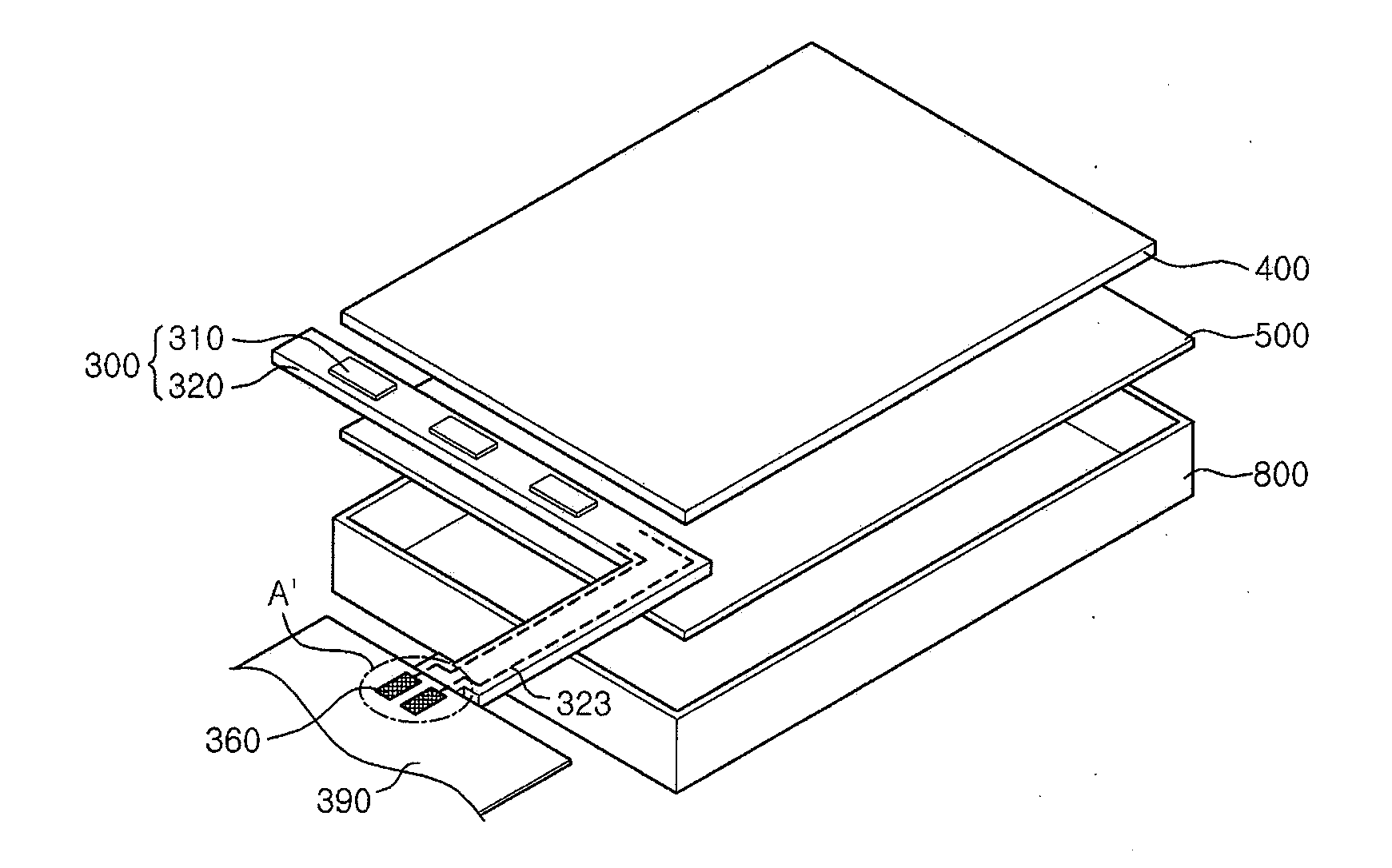

Printed circuit board assembly and display having the same

InactiveUS20080123335A1Preventing flex crackIncrease the conductive areaElectric circuit arrangementsPrinted circuit aspectsDisplay devicePrinted circuit board

A PCB assembly includes a base, a conductive pattern disposed on the base, a pad provided on a portion of the conductive pattern, a mounting unit disposed on the pad for electrically connecting the conductive pattern and a coverlay having an opening that exposes the mounting unit

Owner:SAMSUNG ELECTRONICS CO LTD

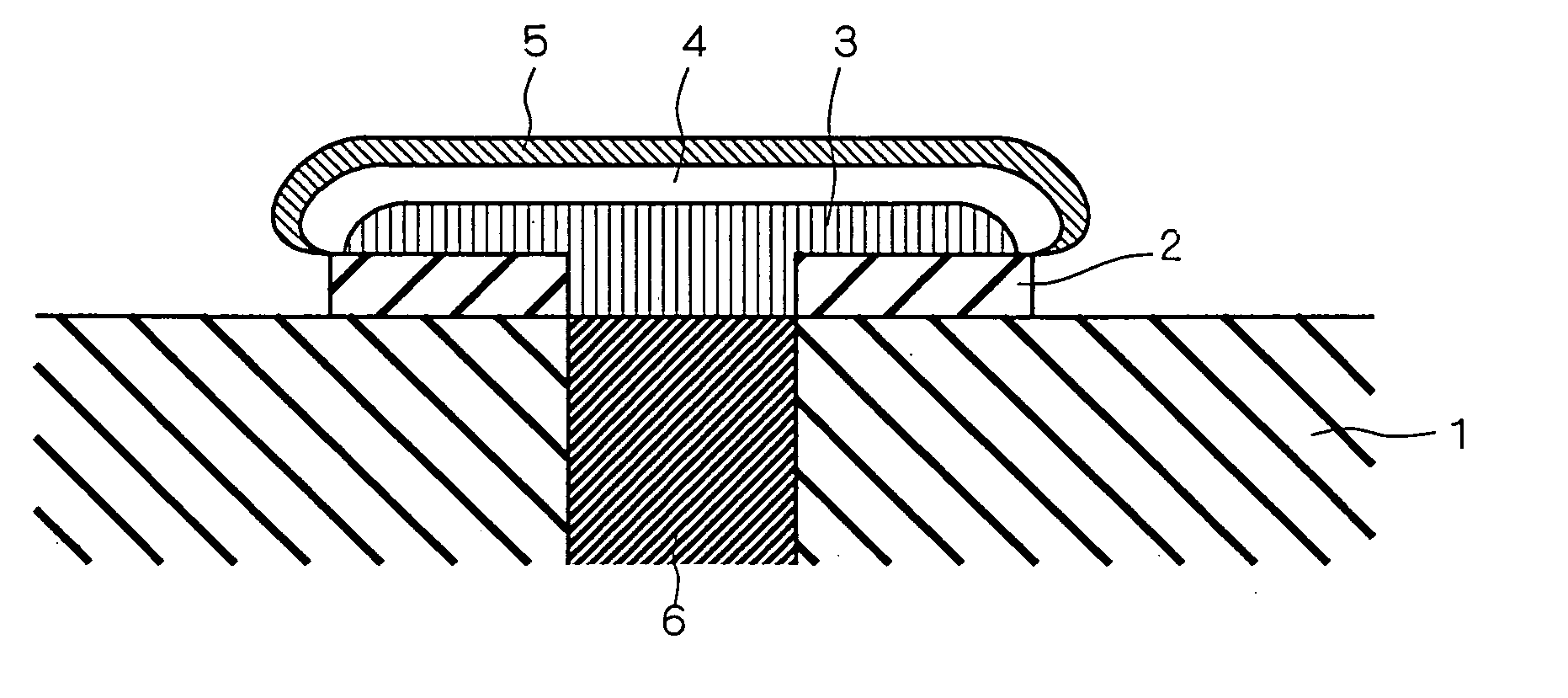

Wiring substrate

A wiring substrate includes: a connection pad having a first surface; a protective insulation layer formed on the first surface of the connection pad and having an opening portion therein, wherein a portion of the first surface of the connection pad is exposed from the opening portion; a metal layer having a lower surface facing the first surface of the connection pad and an upper surface opposite to the lower surface and formed on the first surface of the connection pad which is exposed from the opening portion, the metal layer including a raised portion that extends upward from the upper surface of the metal layer in a peripheral portion thereof; and a bump electrode formed on the upper surface of the metal layer.

Owner:SHINKO ELECTRIC IND CO LTD

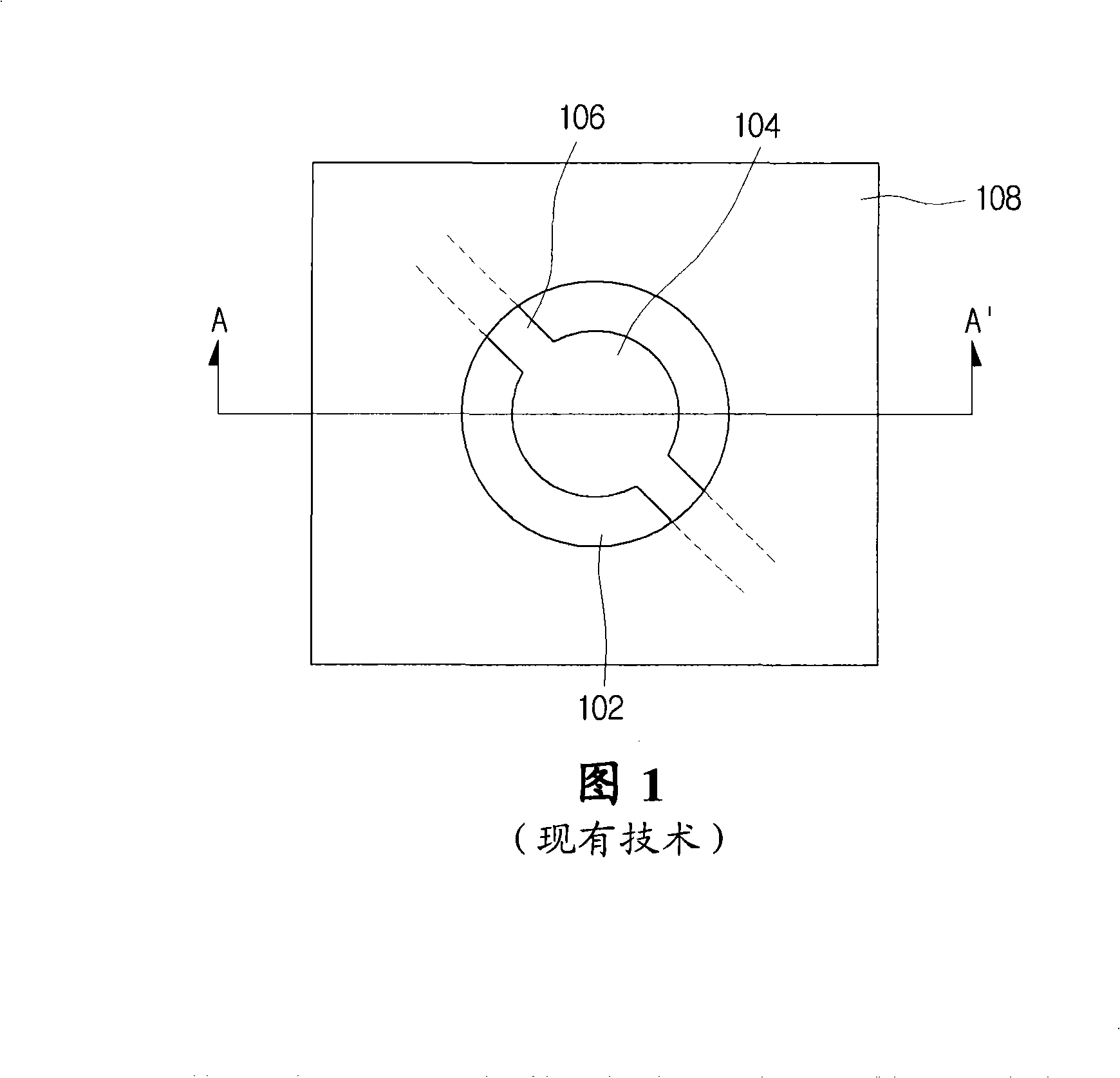

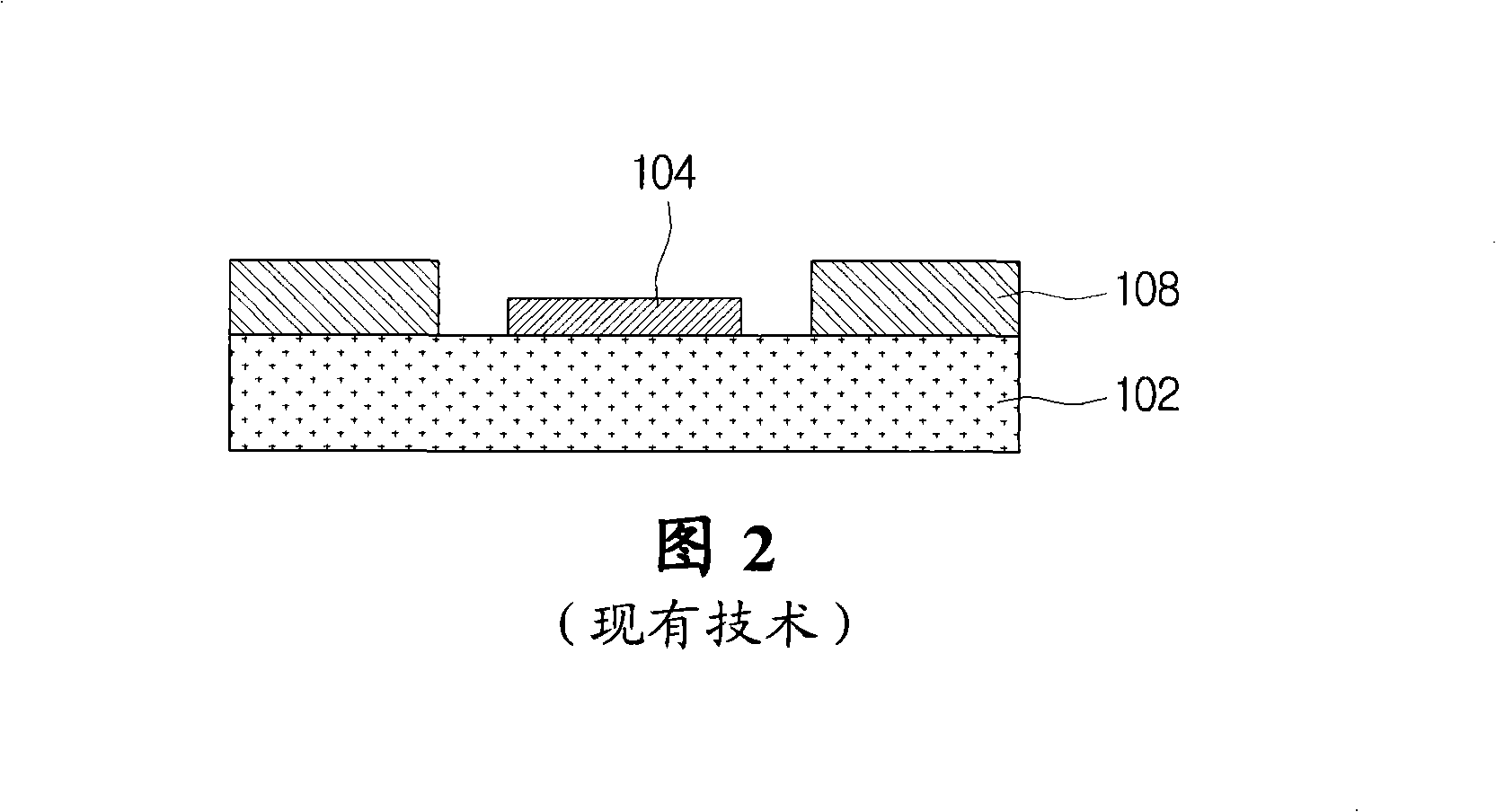

Printed wiring board and semiconductor device

InactiveCN1630454AAvoid deformationPrinted circuit assemblingPrinted circuit aspectsResistEngineering

The invention discloses a printed wiring board which has a large number of wirings formed approximately parallel to each other, dummy patterns formed along the wirings, and a solder resist layer formed by coating the wirings and dummy patterns with a solder resist, the resist The solder coating thickness decreases toward the edge, wherein the dummy pattern has a solder resist coating thickness control area. The present invention also discloses a semiconductor device, which includes the above-mentioned printed circuit board and electronic components mounted on it. According to the present invention, the slope extending uniformly over the entire width of the solder resist can be formed at the edge portion of the solder resist.

Owner:MITSUI MINING & SMELTING CO LTD

Direct IMS (injection molded solder) without a mask for forming solder bumps on substrates

An assembly is obtained; it includes a substrate; a plurality of wet-able pads formed on a surface of the substrate; and a solder resist layer deposited on the surface of the substrate and having an outer surface. At least the solder resist layer is formed with recessed regions defining volumes adjacent the wet-able pads. Molten solder is directly injected into the volumes adjacent the wet-able pads, such that the volumes adjacent the wet-able pads are filled with solder. The solder is allowed to solidify. It forms a plurality of solder structures adhered to the wet-able pads. The substrate and the solder are re-heated after the solidification, to re-flow the solder into generally spherical balls extending above the outer surface of the solder resist layer. The volumes adjacent the wet-able pads are configured and dimensioned to receive sufficient solder in the injecting step such that the generally spherical balls extend above the outer surface of the solder resist layer as a result of the re-heating step. In an alternative approach, solder injection and solidification are carried out in a nitrogen environment or a forming gas environment, and the reflow step may be omitted.

Owner:GLOBALFOUNDRIES U S INC

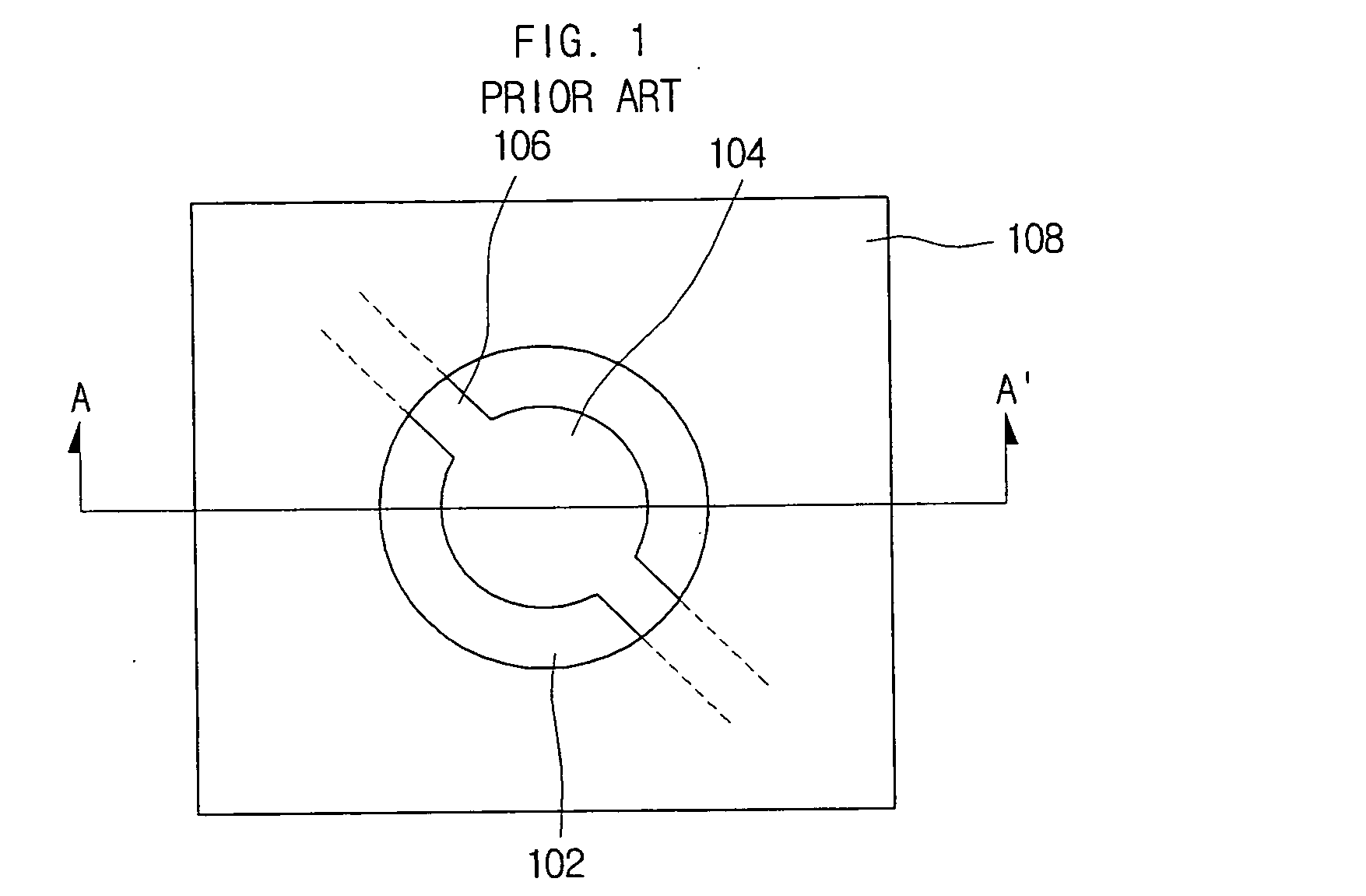

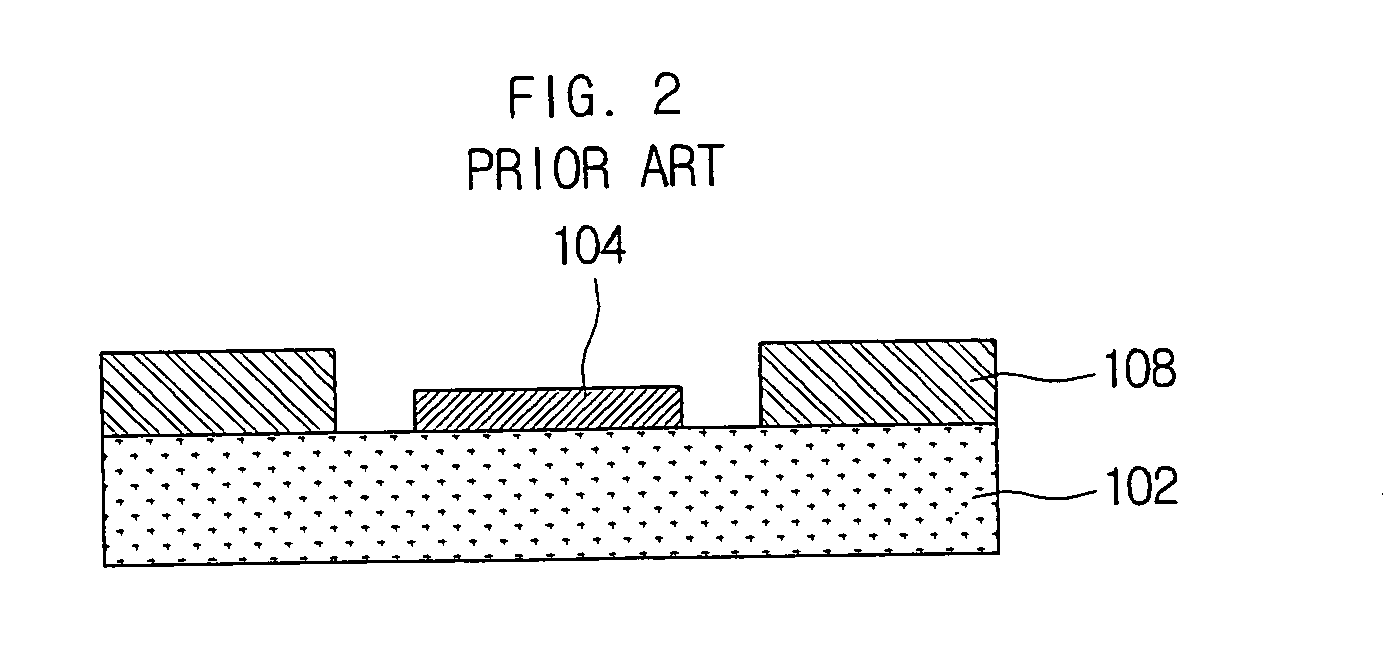

Bump land structure of circuit substrate for semiconductor package

InactiveUS20060220246A1Semiconductor/solid-state device detailsPrinted circuit aspectsSolder maskSemiconductor package

A bump land structure of a circuit substrate for a semiconductor package may have a combination of an SMD type bump land structure and an NSMD type bump land structure. A lower portion of a solder mask and a lower layer of a bump land may form the SMD type bump land structure. An upper portion of a solder mask and an upper layer of a bump land may form the NSMD type bump land structure.

Owner:SAMSUNG ELECTRONICS CO LTD

Through electrode substrate and semiconductor device using through electrode substrate

ActiveUS20160276257A1Increase in sizeRemove defectSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductorSemiconductor device

A through-hole electrode substrate includes a substrate including a through-hole extending from a first aperture of a first surface to a second aperture of a second surface, an area of the second aperture being larger than that of the first aperture, the through-hole having a minimum aperture part between the first aperture and the second aperture, wherein an area of the minimum aperture part in a planer view is smallest among a plurality of areas of the through-hole in a planer view, a filler arranged within the through-hole, and at least one gas discharge member contacting the filler exposed to one of the first surface and the second surface.

Owner:DAI NIPPON PRINTING CO LTD

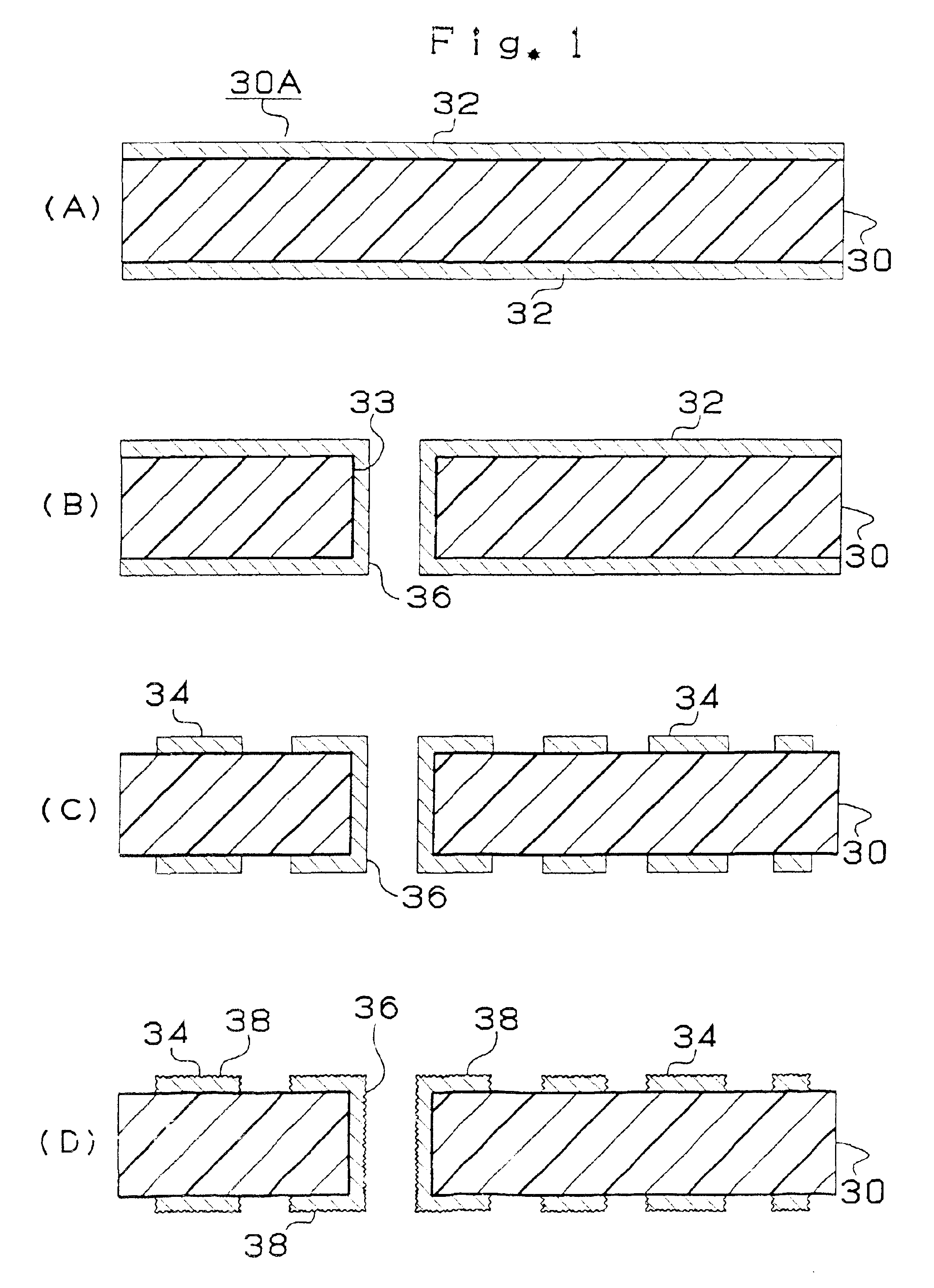

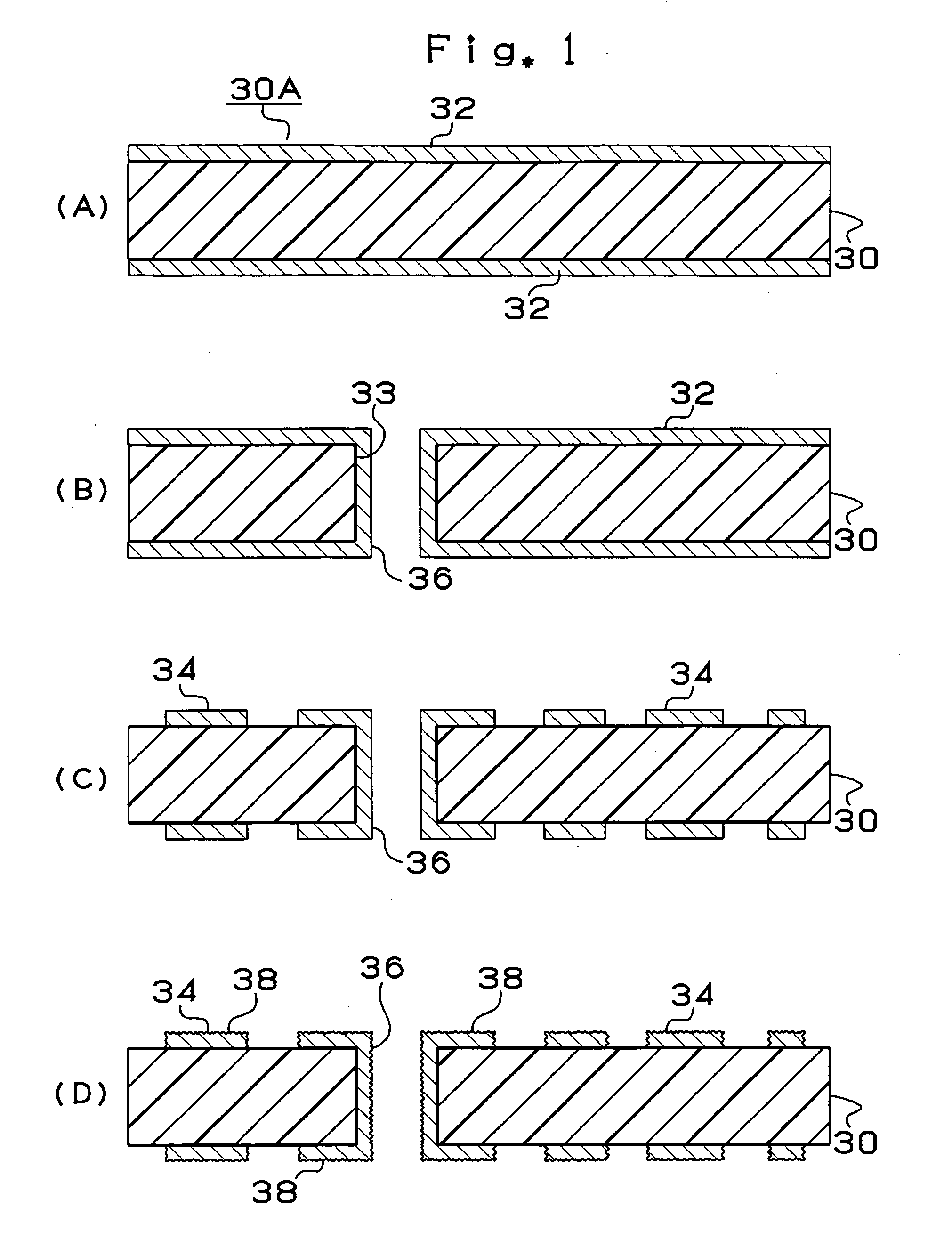

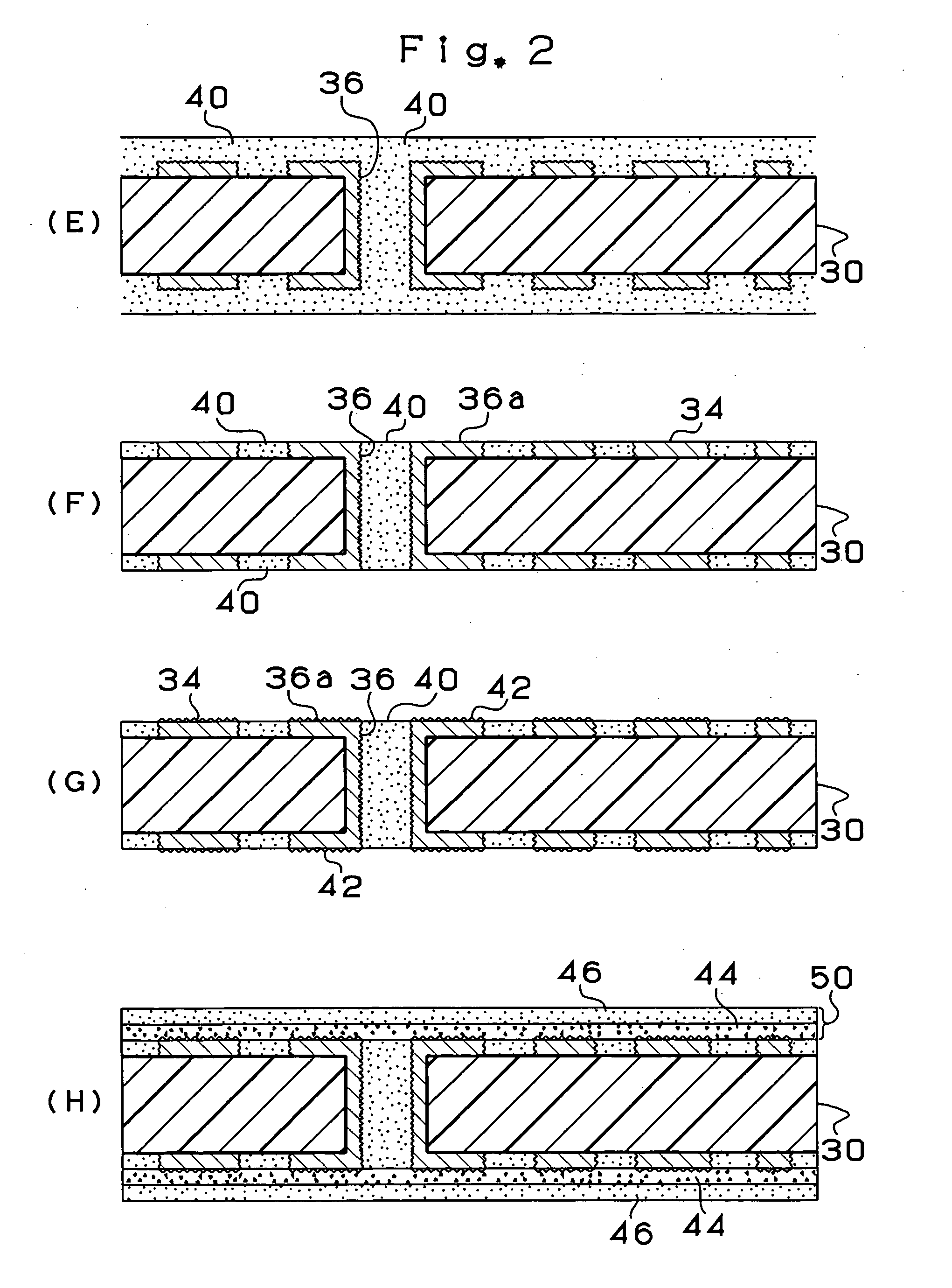

Printed wiring board and manufacturing method of printed wiring board

InactiveUS20050158553A1Improve featuresImprove reliabilityLayered productsSemiconductor/solid-state device detailsStress concentrationEngineering

Owner:IBIDEN CO LTD

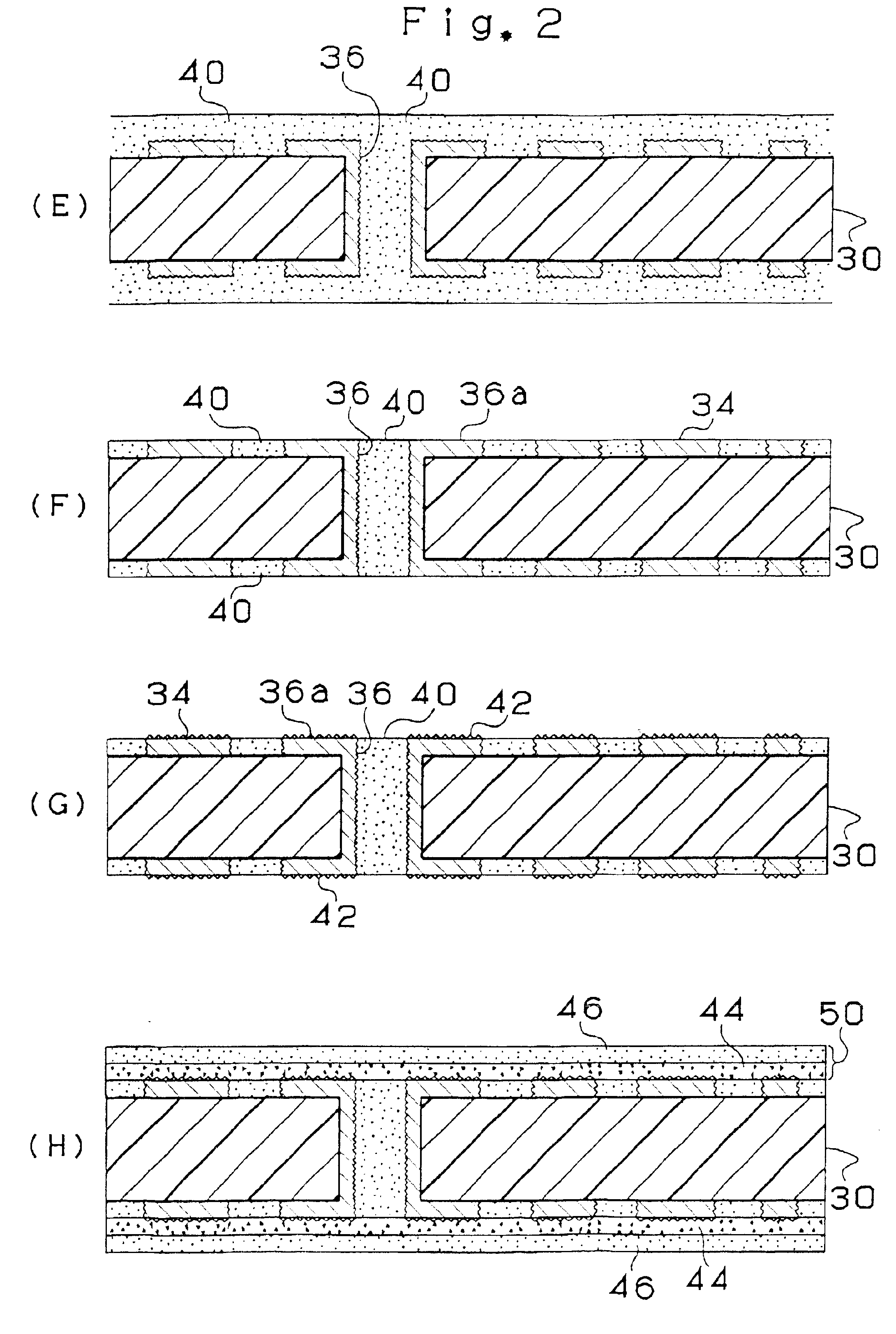

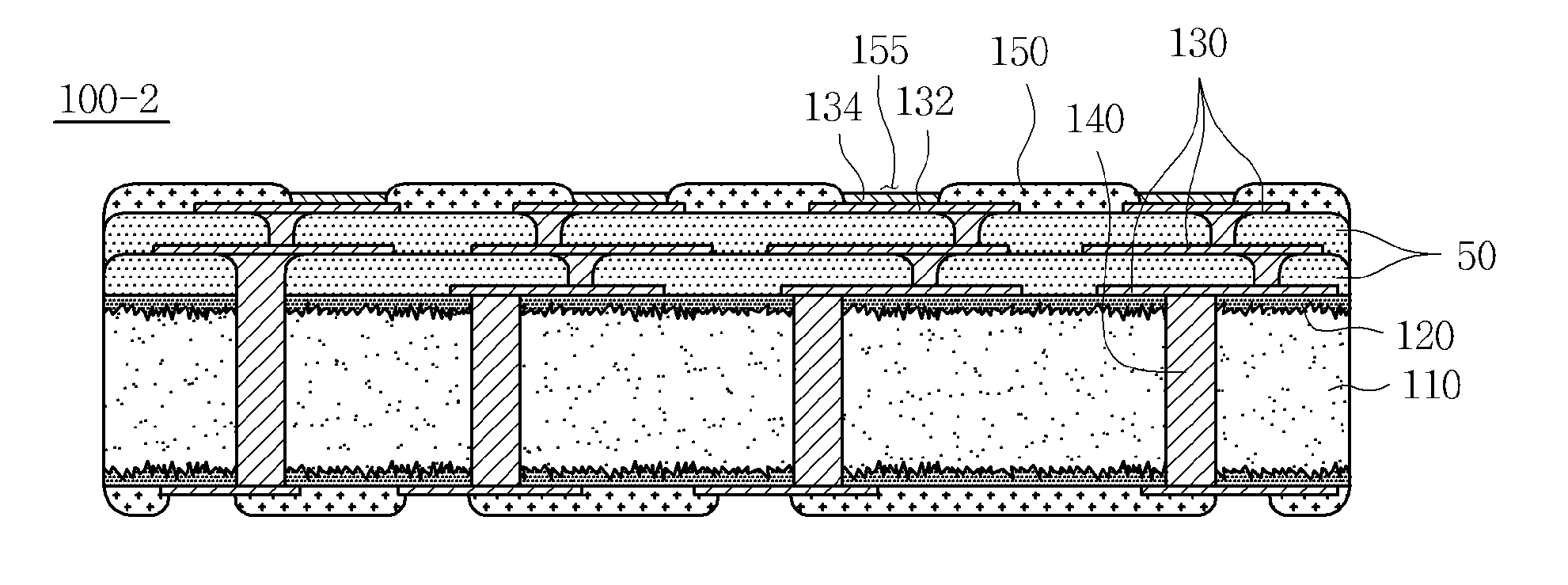

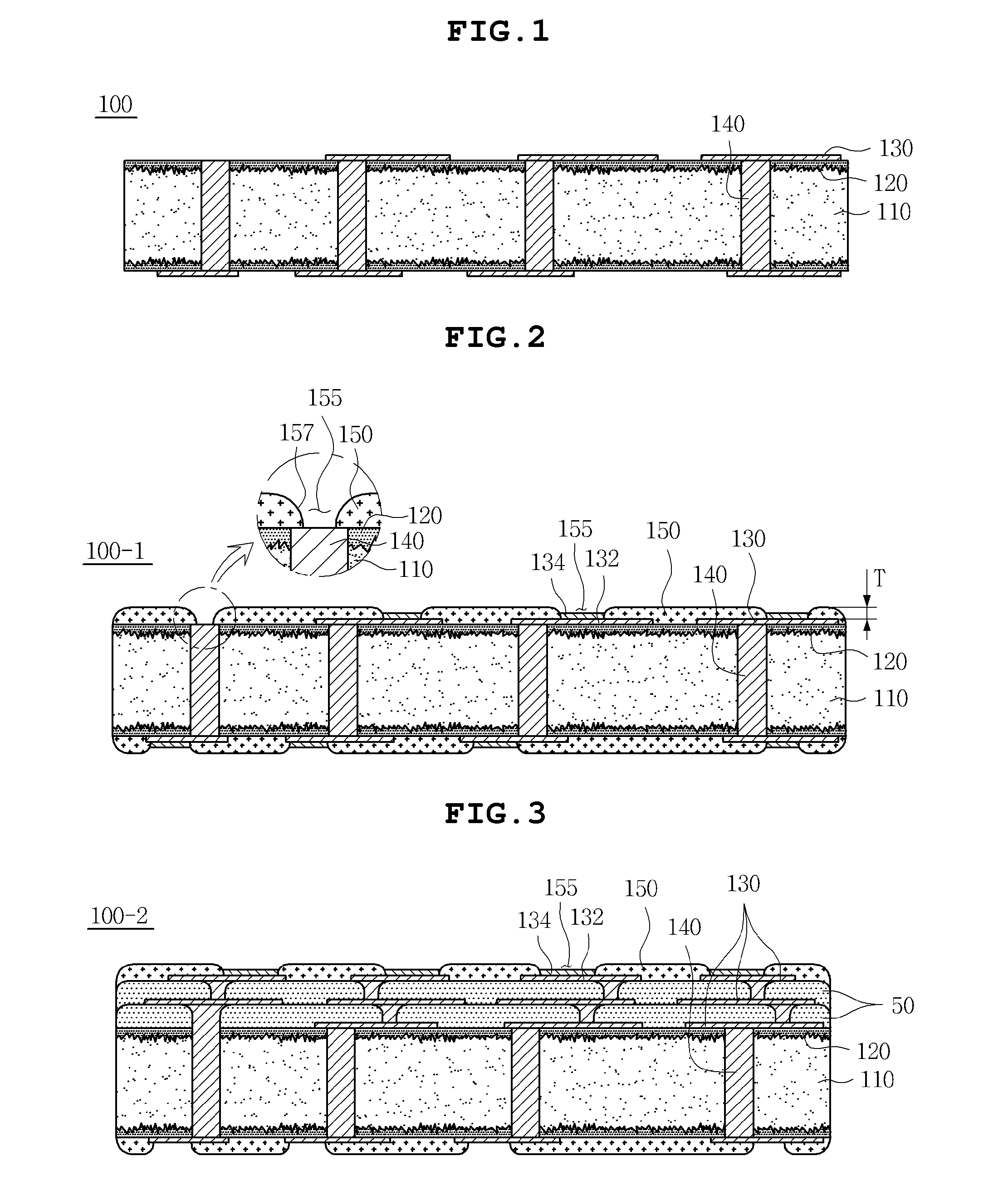

Printed circuit board and method of manufacturing the same

ActiveUS20120073870A1Easy to identifySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringPrinted circuit board

Disclosed is a printed circuit board, including a base member, an insulating layer formed on each of both surfaces of the base member so that the surfaces of the base member are flattened, a circuit layer formed on the insulating layer, and a via for connecting the circuit layer formed on one surface of the base member with the circuit layer formed on the other surface of the base member. A method of manufacturing the printed circuit board is also provided.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Printed circuit board and manufacturing method thereof

ActiveCN101355847AExcellent adhesionFirmly connectedPrinted circuit detailsPrinted circuit aspectsResistInsulation layer

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Fabrication method of circuit board solder mask layer

InactiveCN105338755AImprove bindingImprove firmnessInsulating resist/coatingNon-metallic protective coating applicationResistSolder mask

The invention discloses a fabrication method of a circuit board solder mask layer, and relates to the technical field of producing and manufacturing of circuit boards. The fabrication method of the circuit board solder mask layer sequentially comprises the following steps: covering the surface of the circuit board with solder resist ink and pre-baking and curing the solder resist ink; coating the cured solder resist ink on the surface of the circuit board with a film for carrying out first exposure; enabling the circuit board which is exposed once to pass through a spray developer line, and rinsing out the solder resist ink in the unexposed region with a photograph potion; drying the developed circuit board, and then coating with the film which is the same as that in the first exposure for carrying out second exposure; enabling the circuit board which is exposed for the second time to pass through the spray developer line, and rinsing out the solder resist ink in the unexposed region with the photograph potion. According to the method, the binding force of the solder resist ink and the surface of the circuit board can be reinforced; the problems of bridge drop and bridge cutoff of the solder resist ink are overcome; and the capability of the manufacture procedure of a solder mask bridge site is improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com