Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about "Electrode screen printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

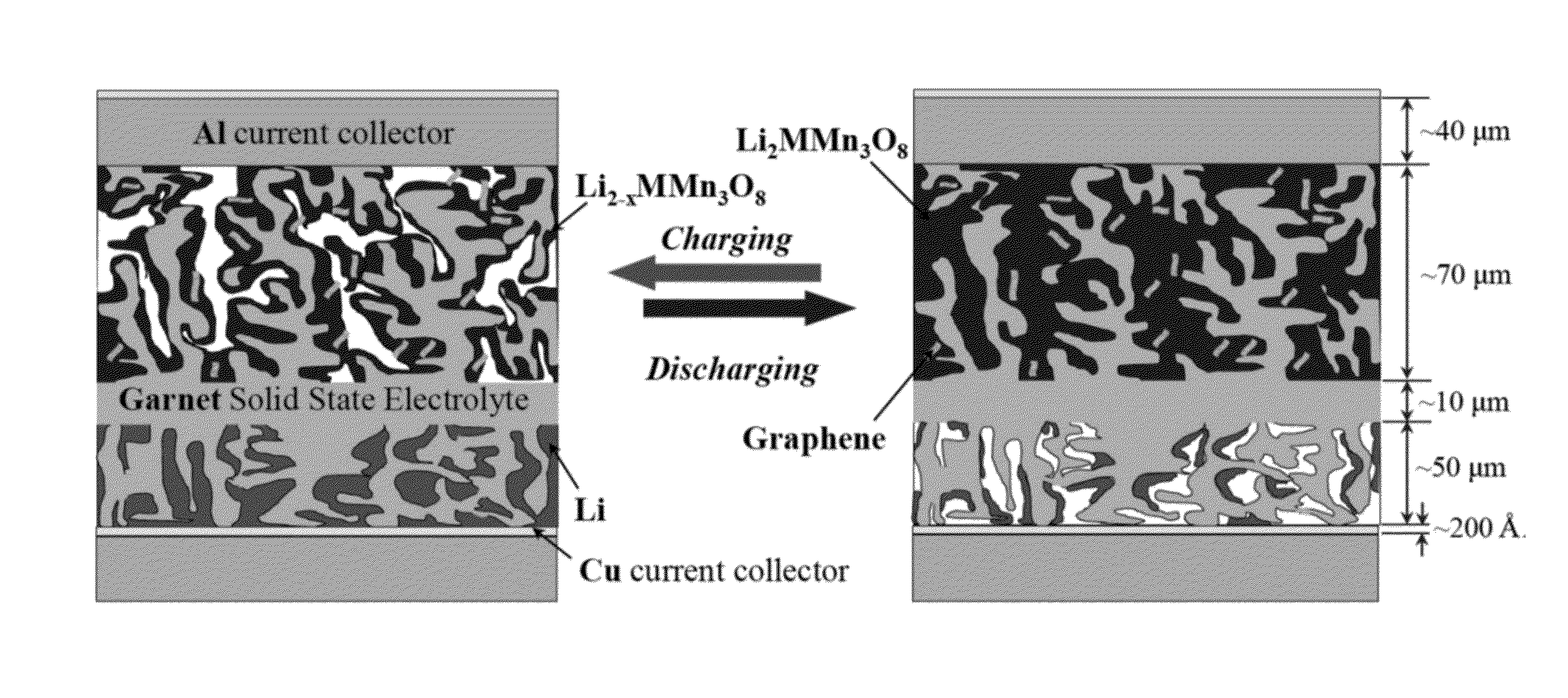

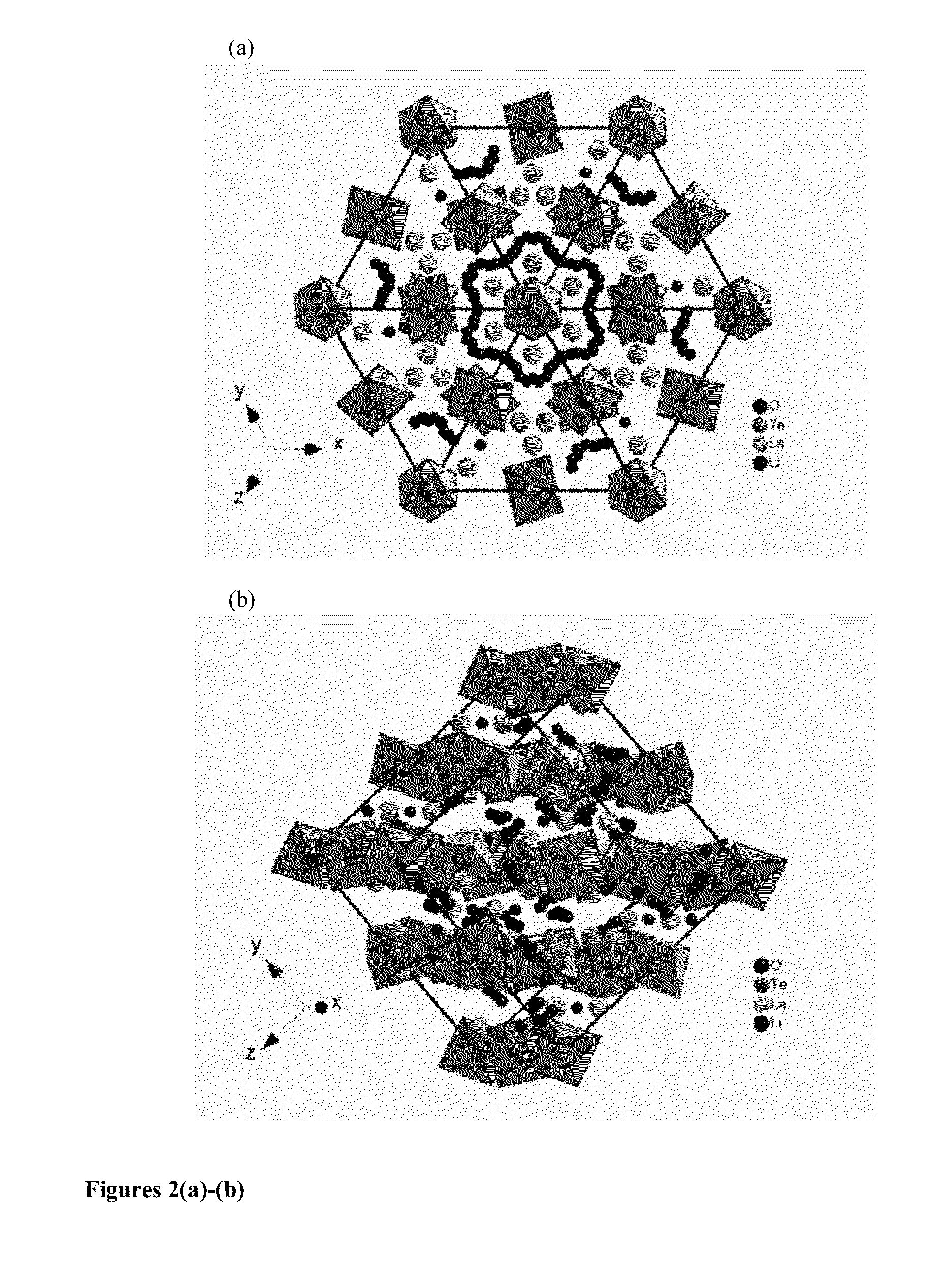

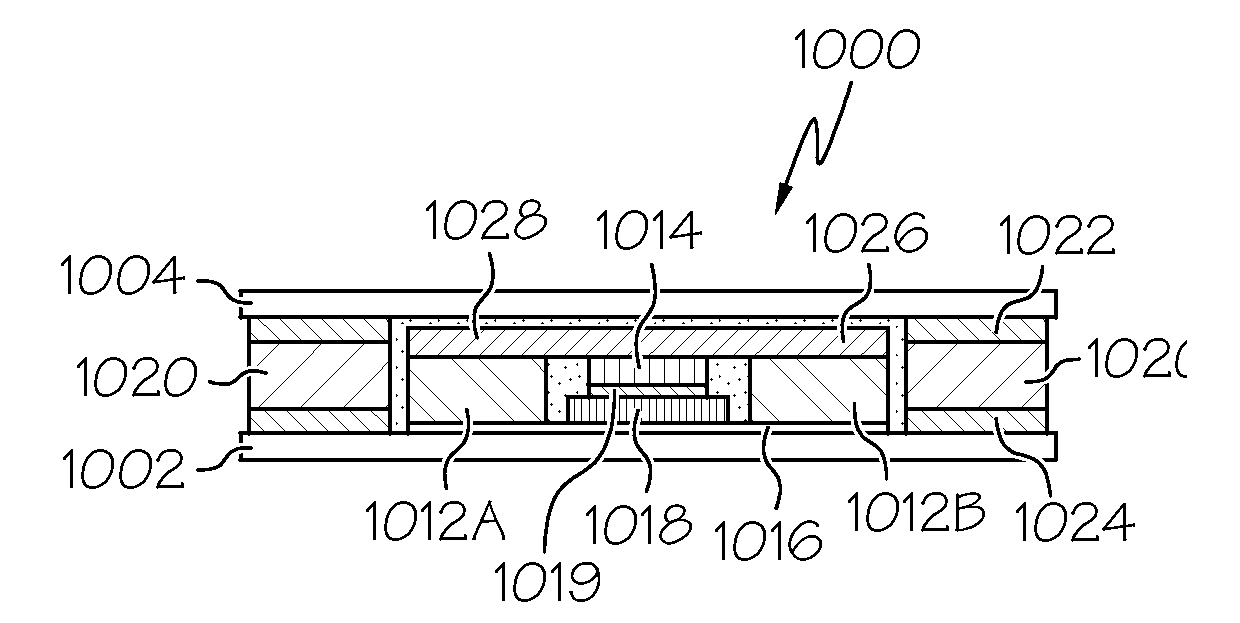

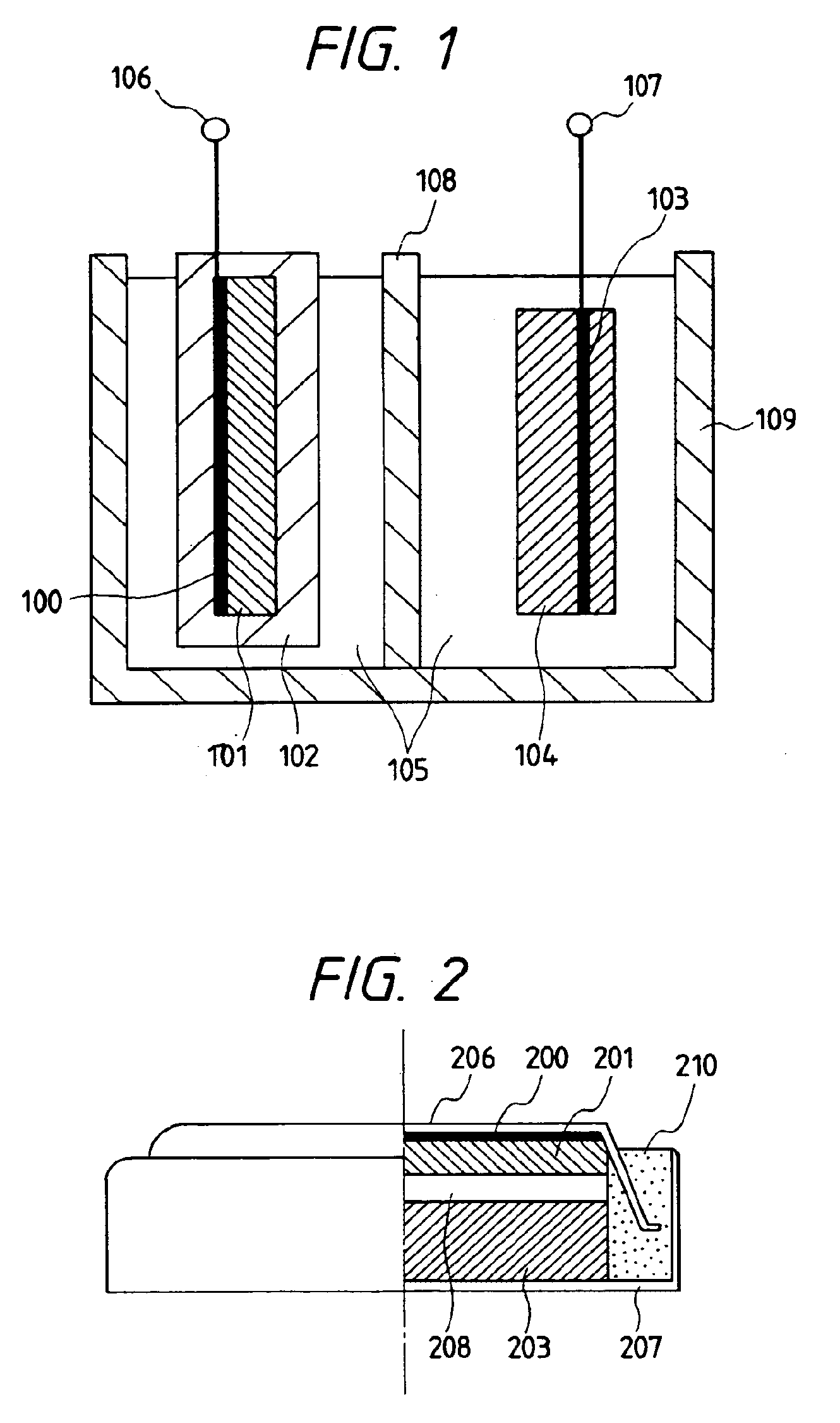

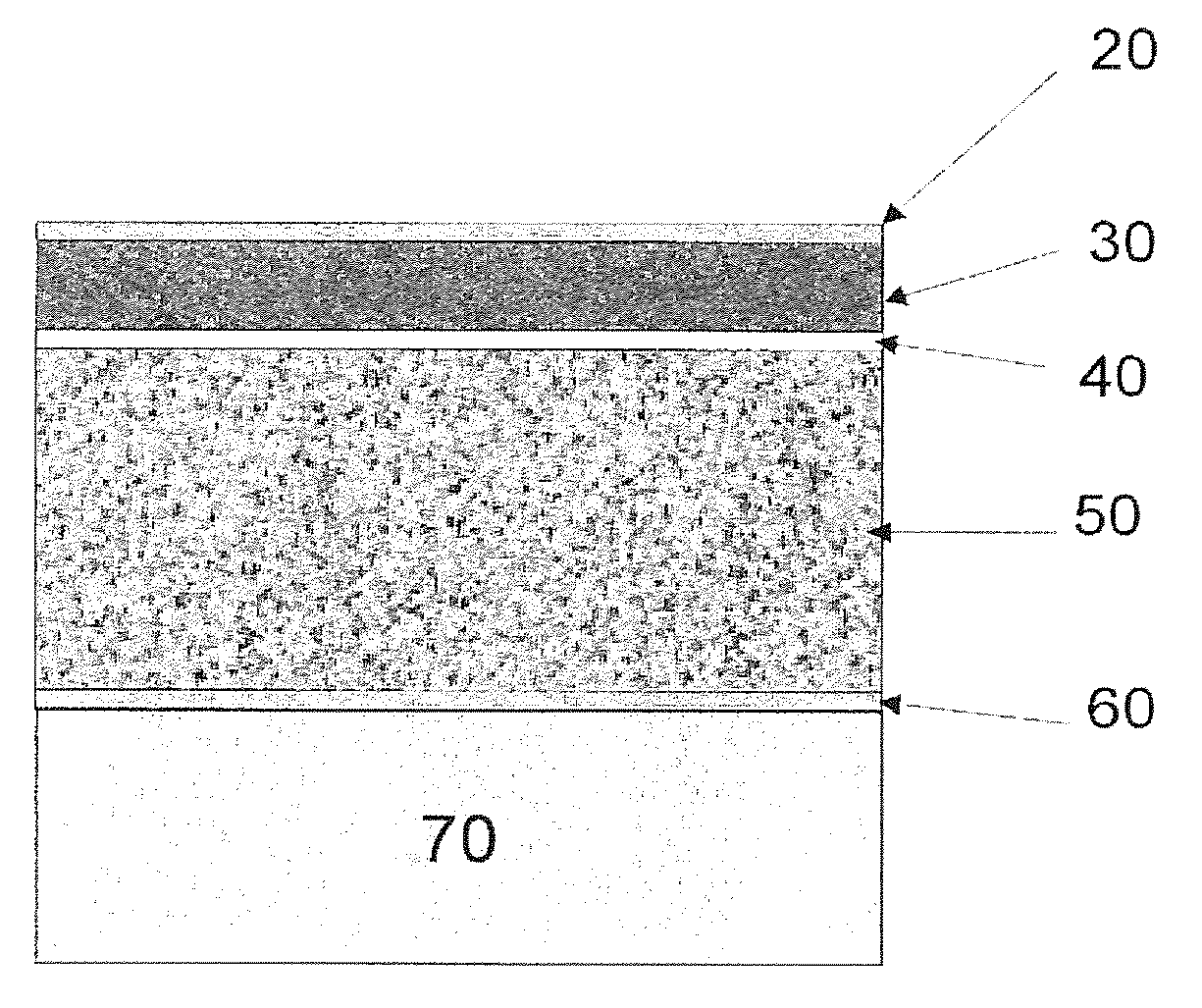

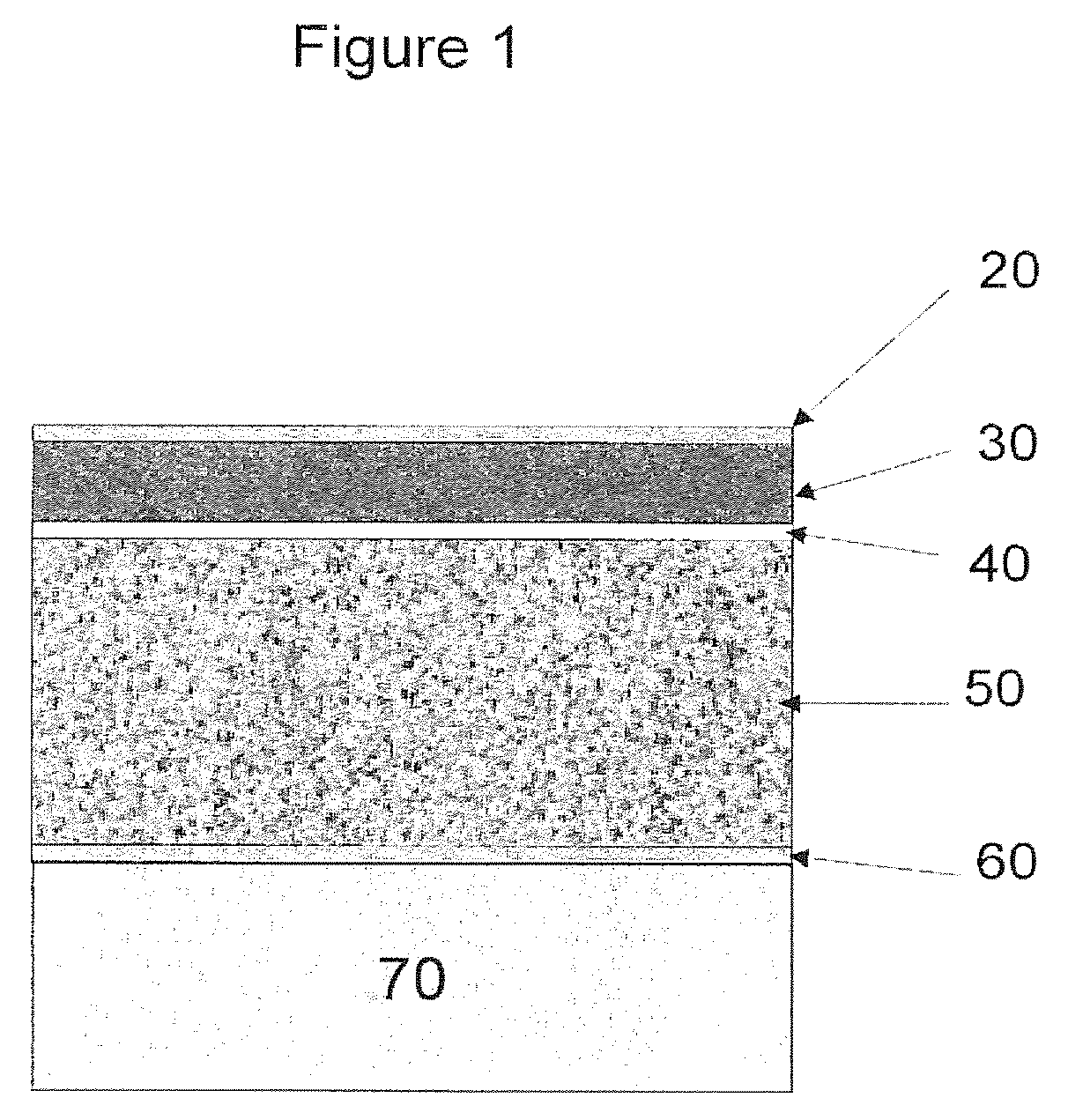

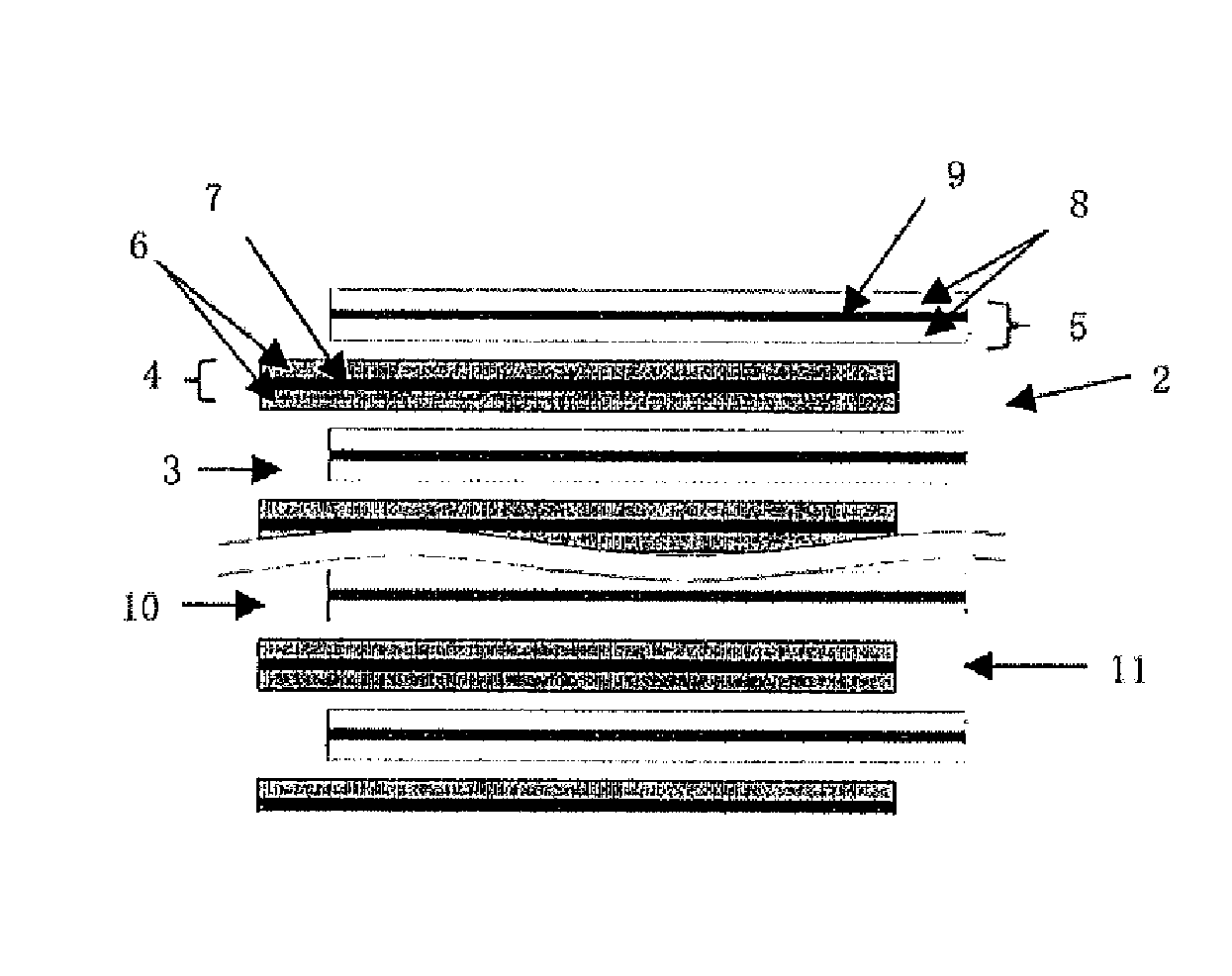

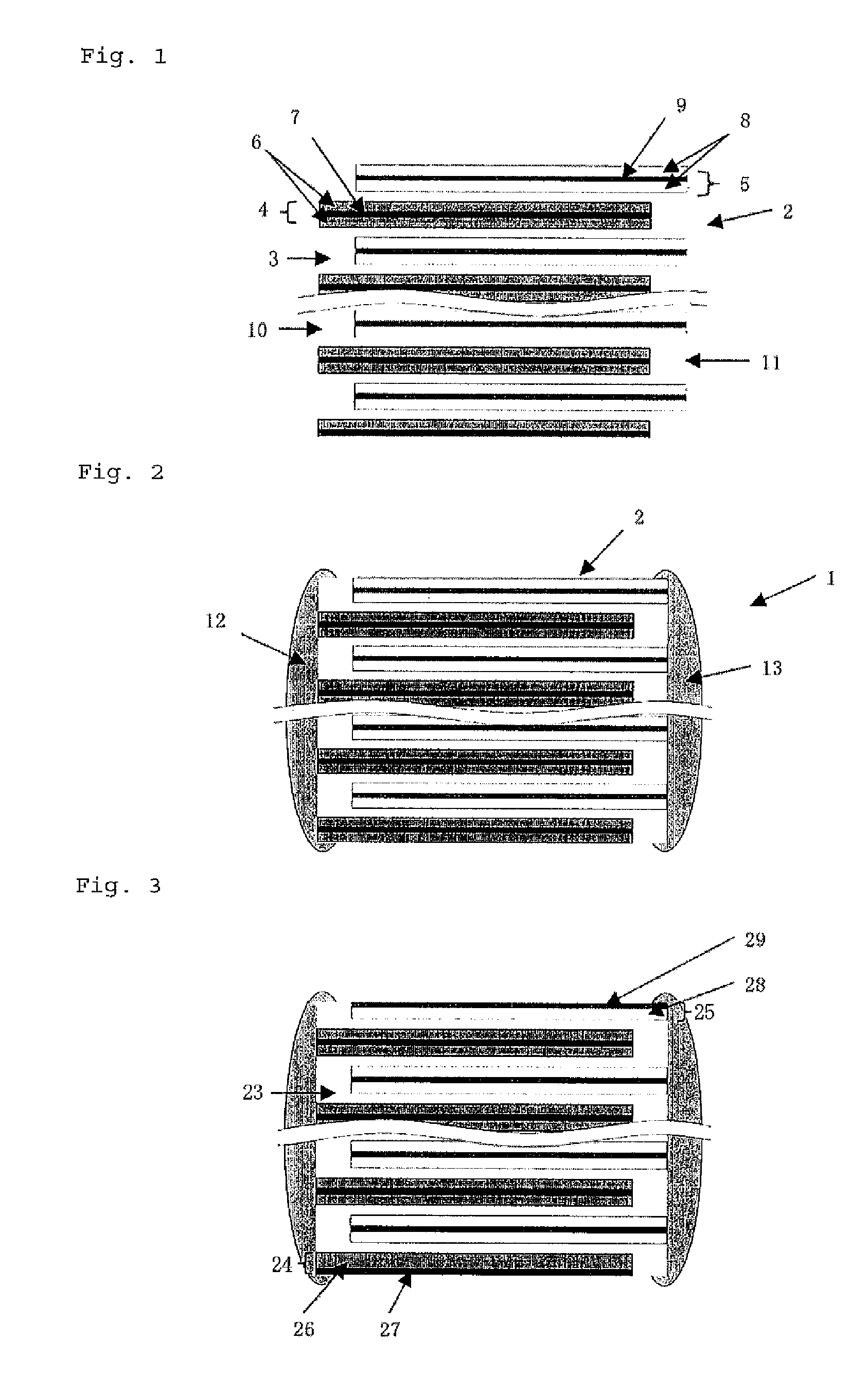

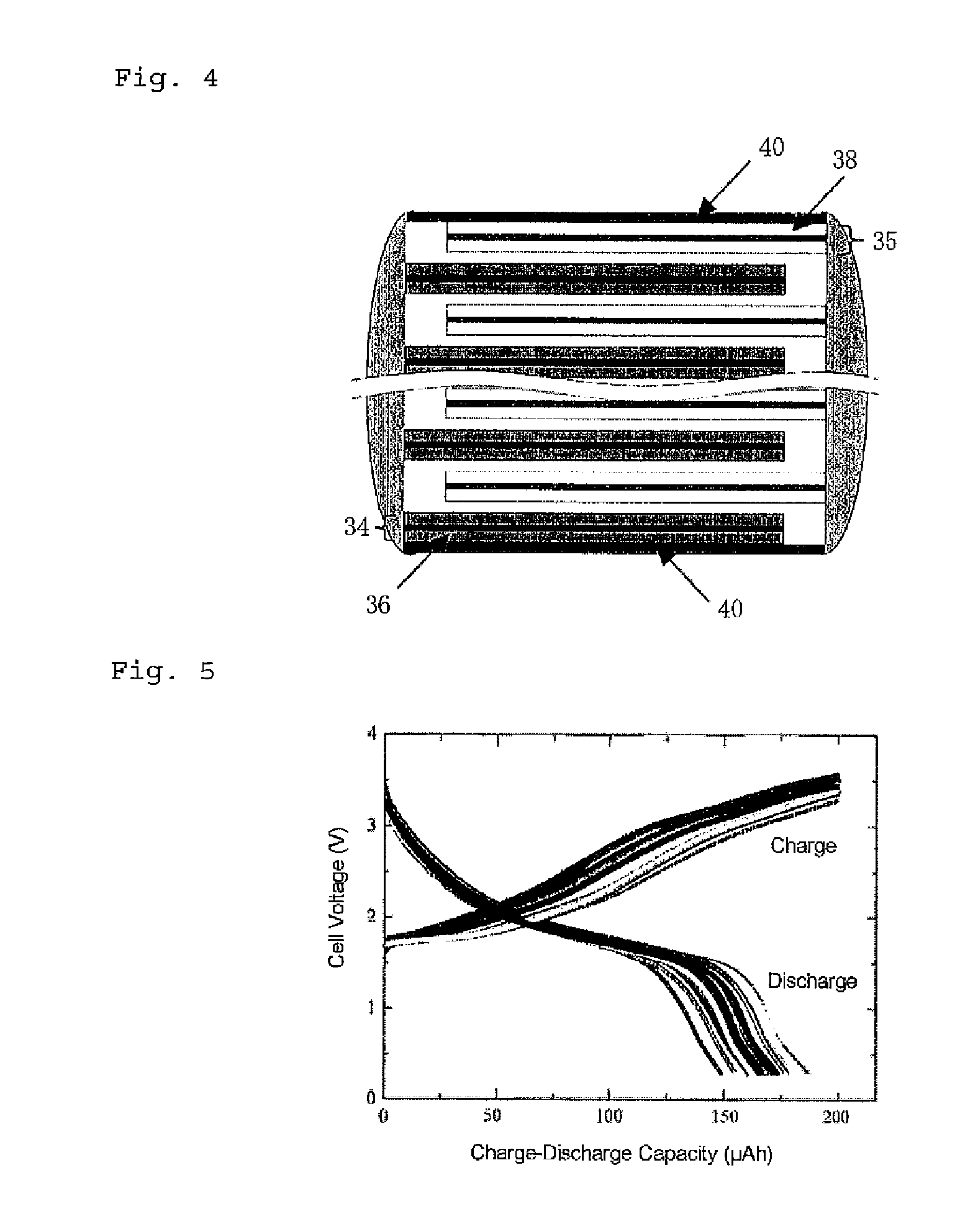

Ion conducting batteries with solid state electrolyte materials

ActiveUS20140287305A1Final product manufactureActive material electrodesSolid state electrolytePorous layer

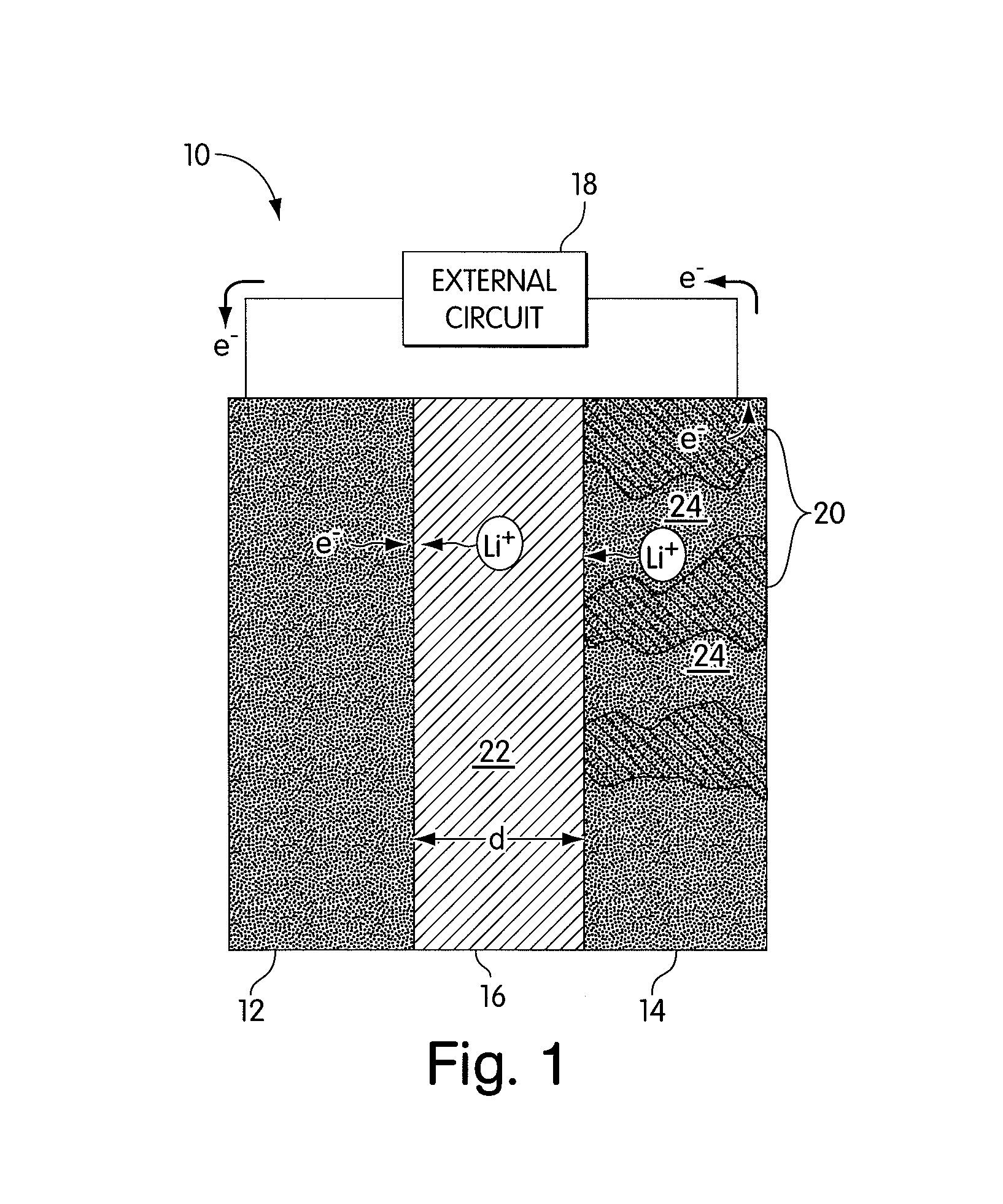

Solid-state, ion-conducting batteries with an ion-conducting, solid-state electrolyte. The solid-state electrolyte has at least one porous region (e.g., porous layer) and a dense region (e.g., dense layer). The batteries are, for example, lithium-ion, sodium-ion, or magnesium-ion conducting solid-state batteries. The ion-conducting, solid-state electrolyte is, for example, a lithium-garnet material.

Owner:UNIV OF MARYLAND

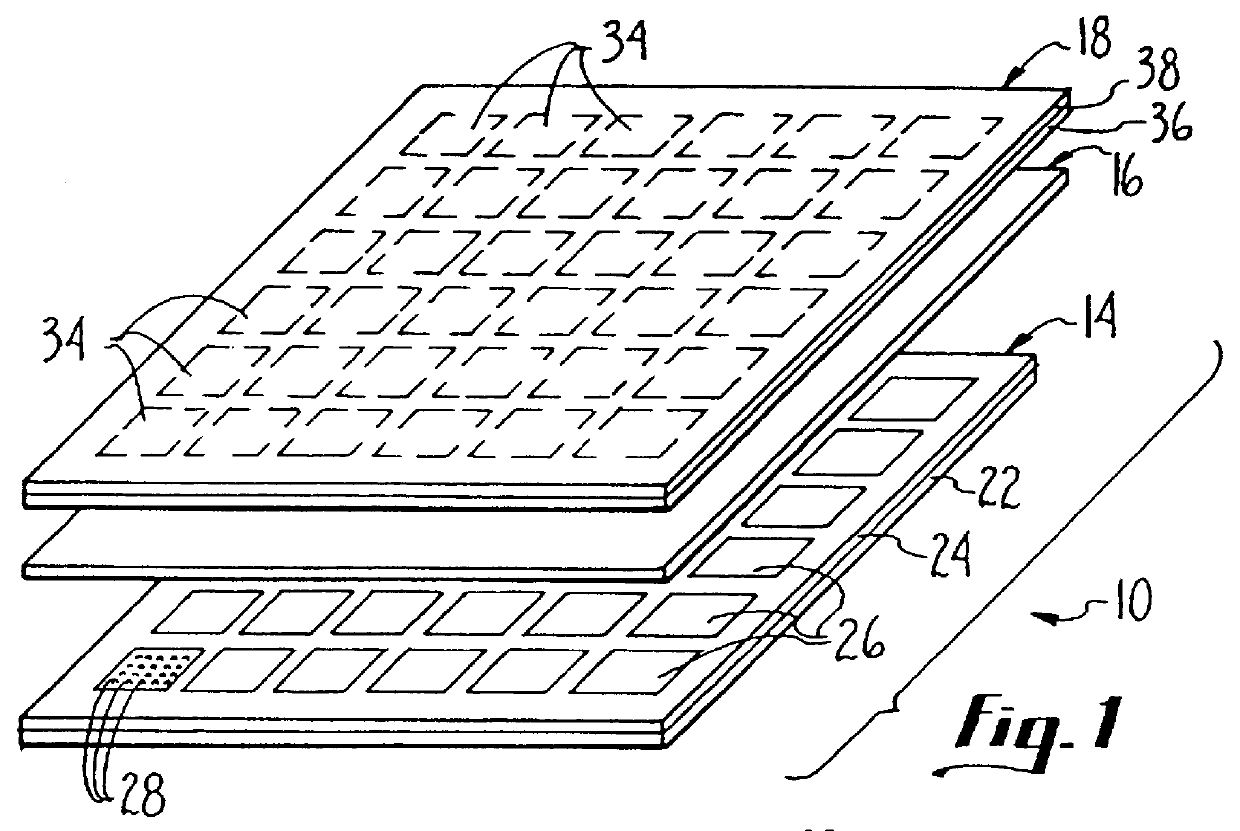

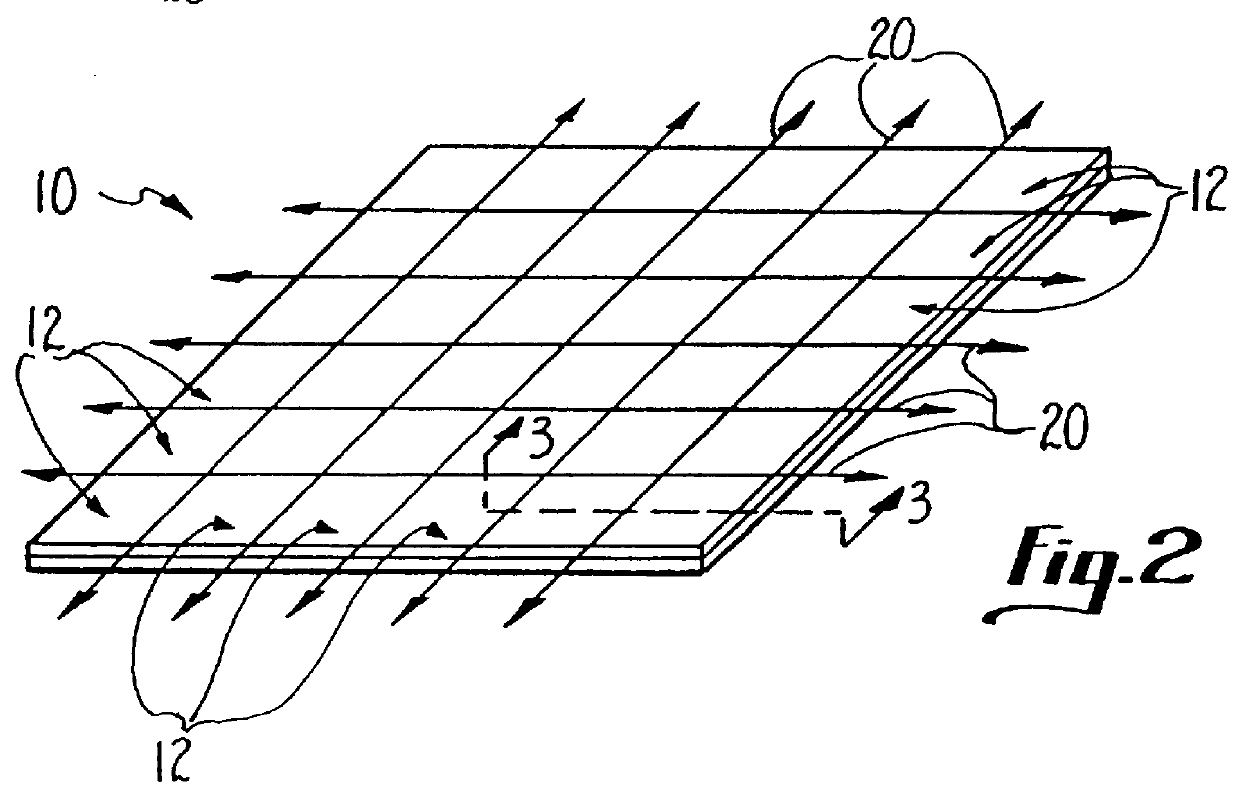

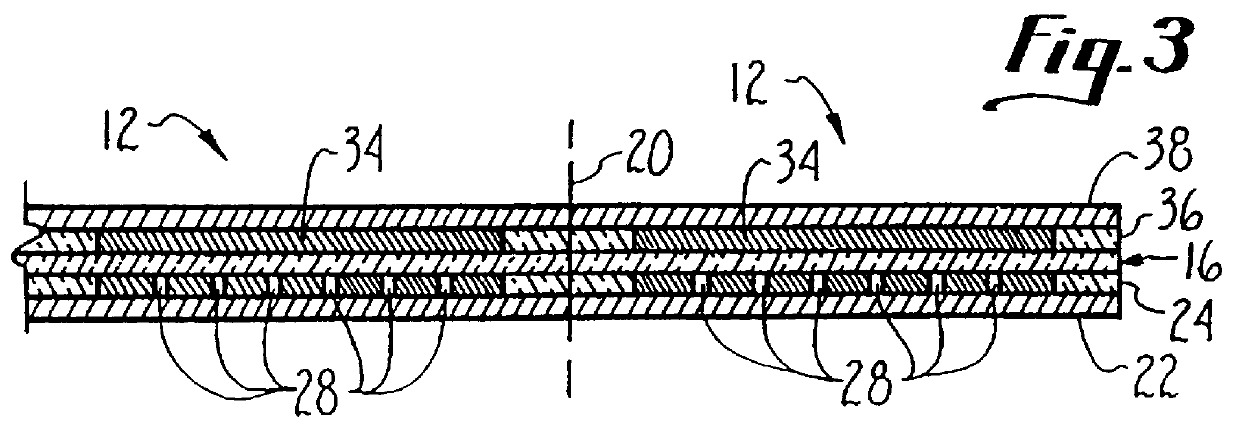

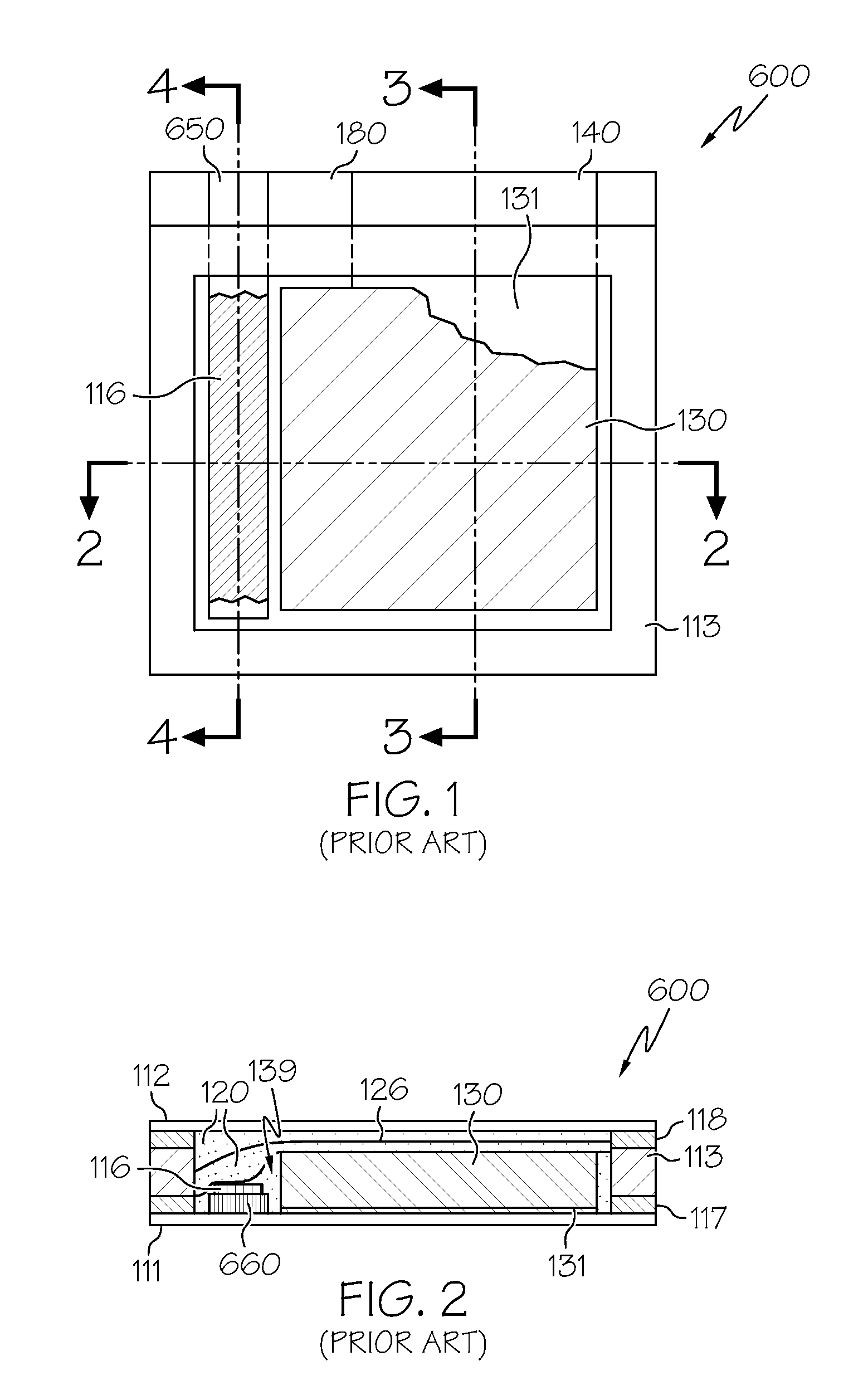

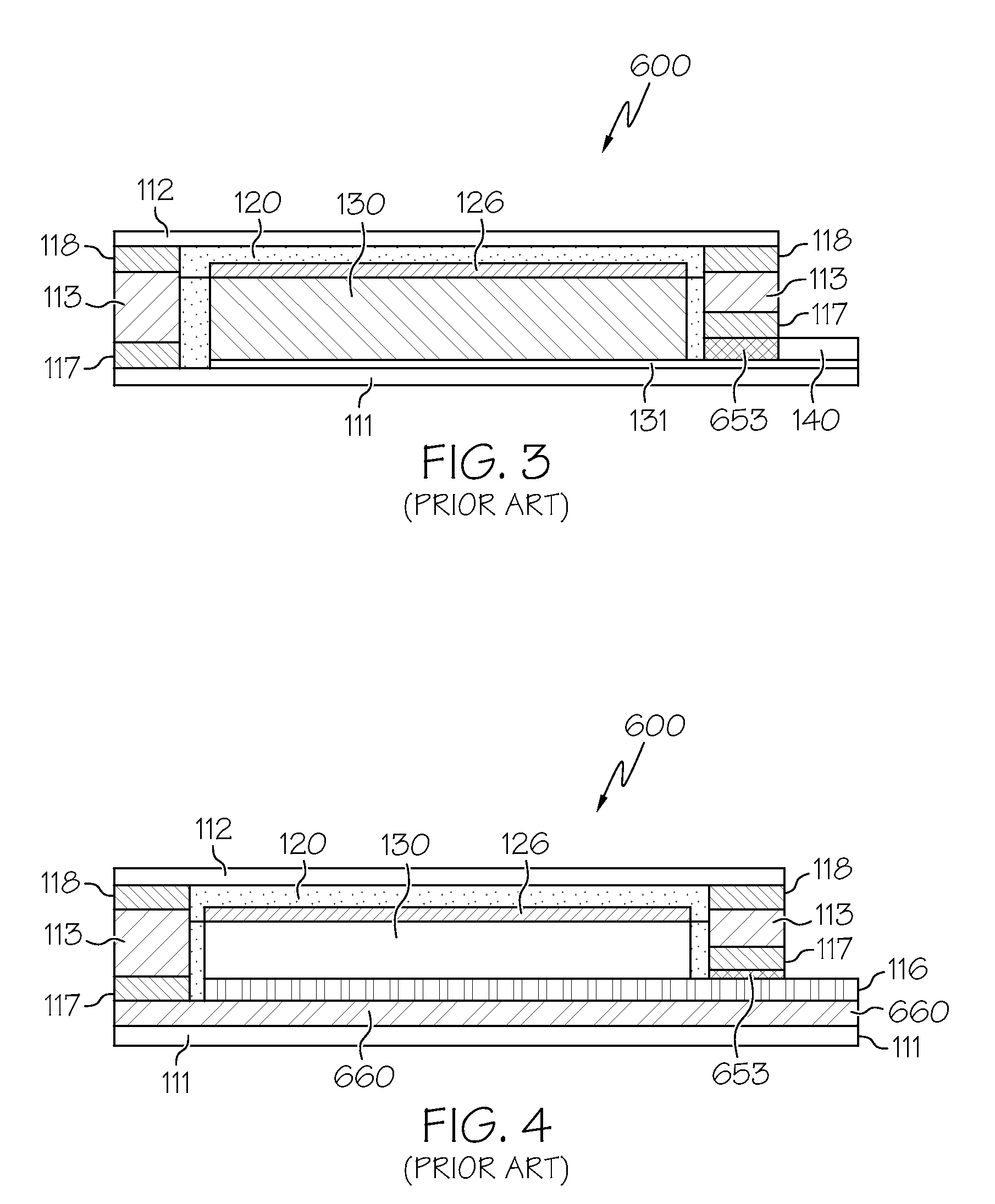

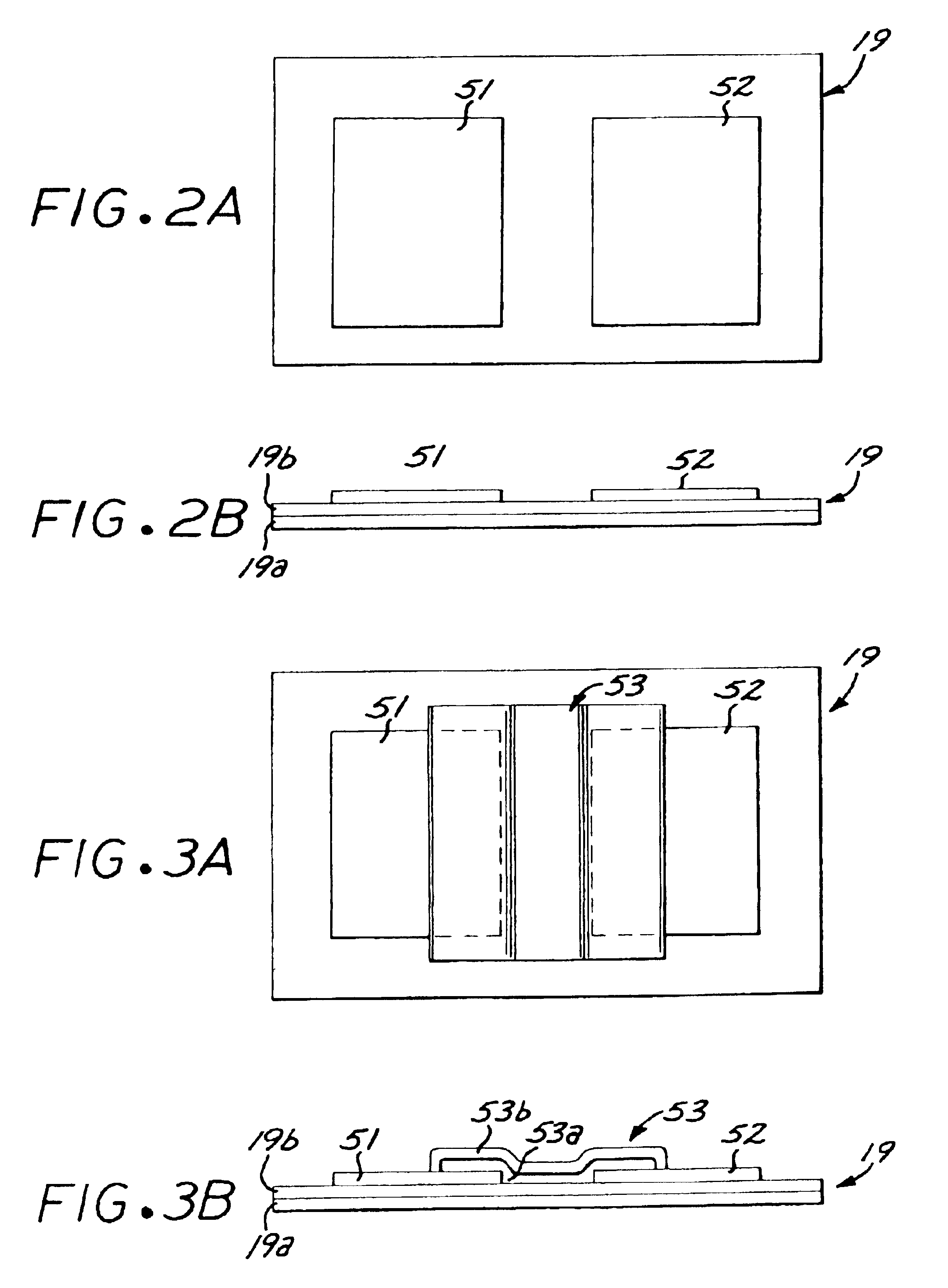

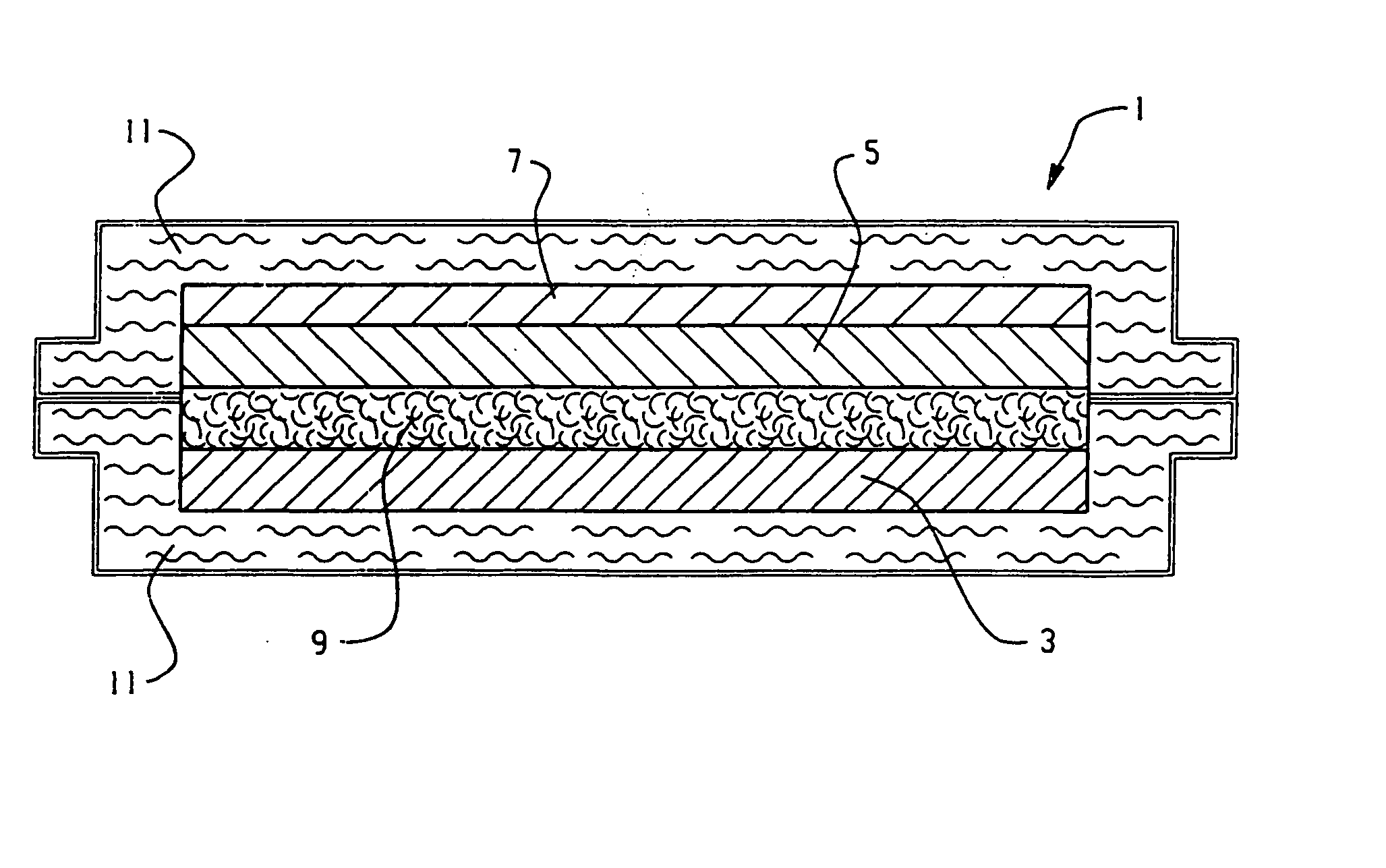

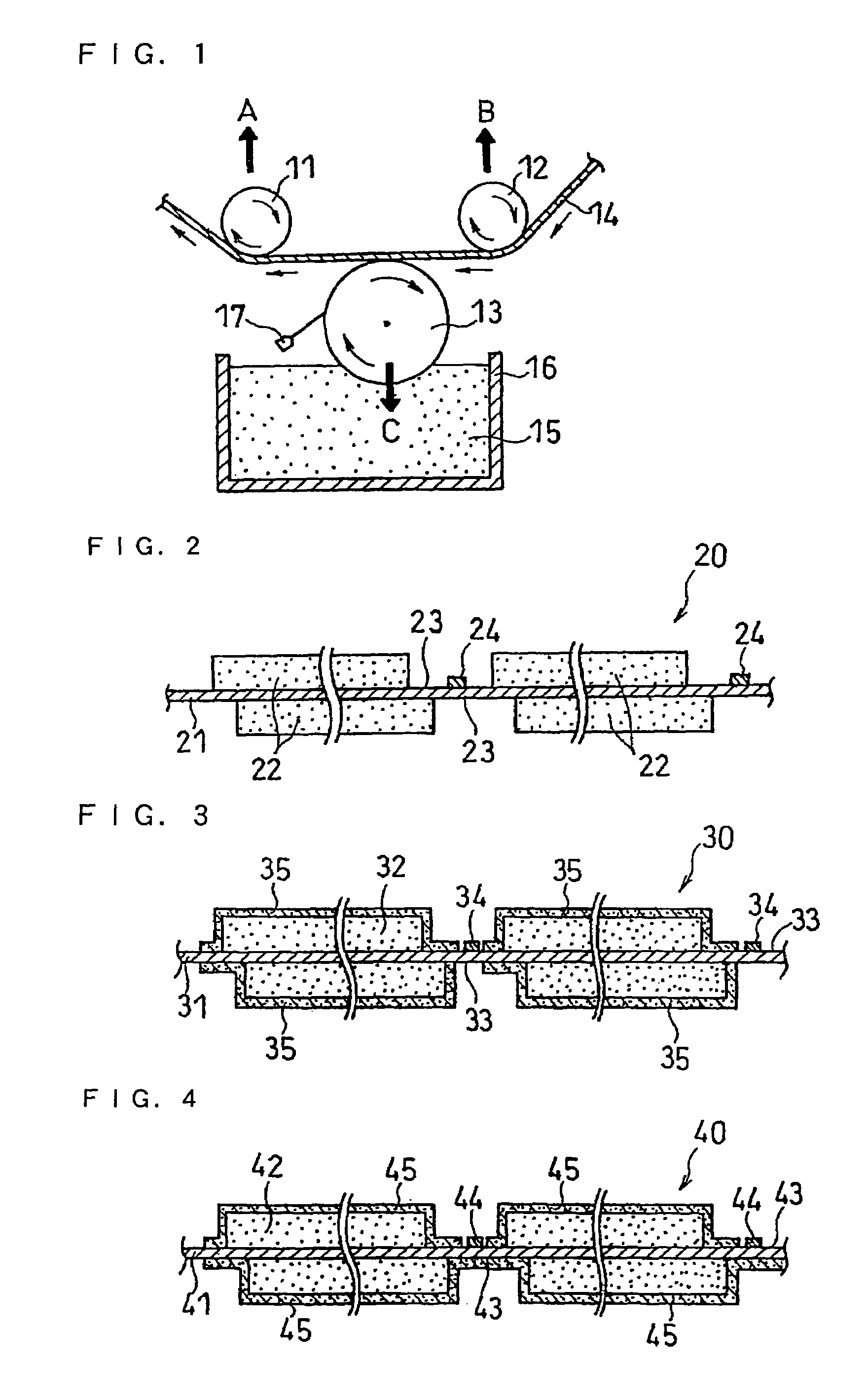

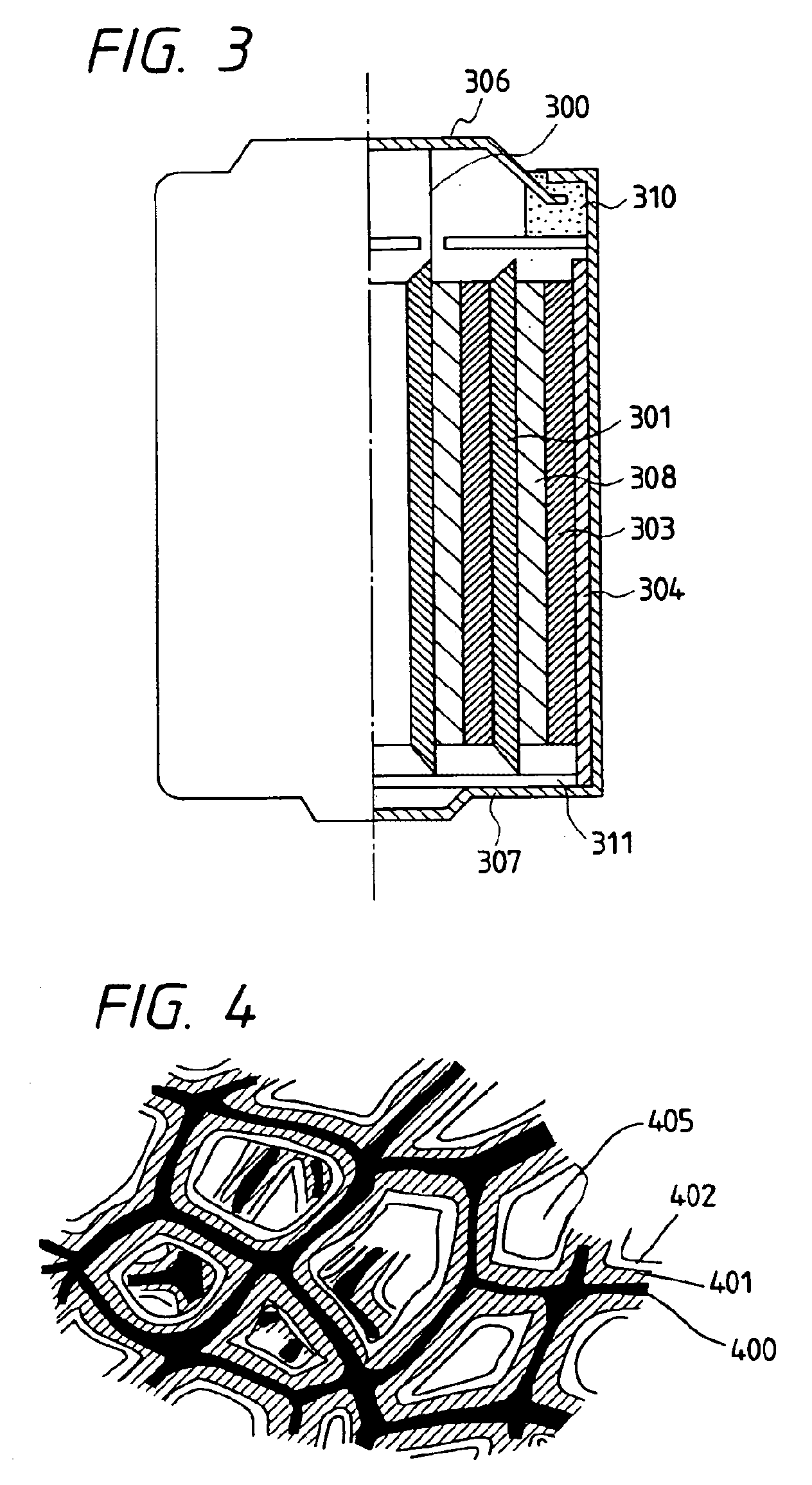

Reticulated and controlled porosity battery structures

InactiveUS7553584B2Boost energyHigh porosityElectrode thermal treatmentElectrolytic capacitorsEngineeringTortuous retinal vessels

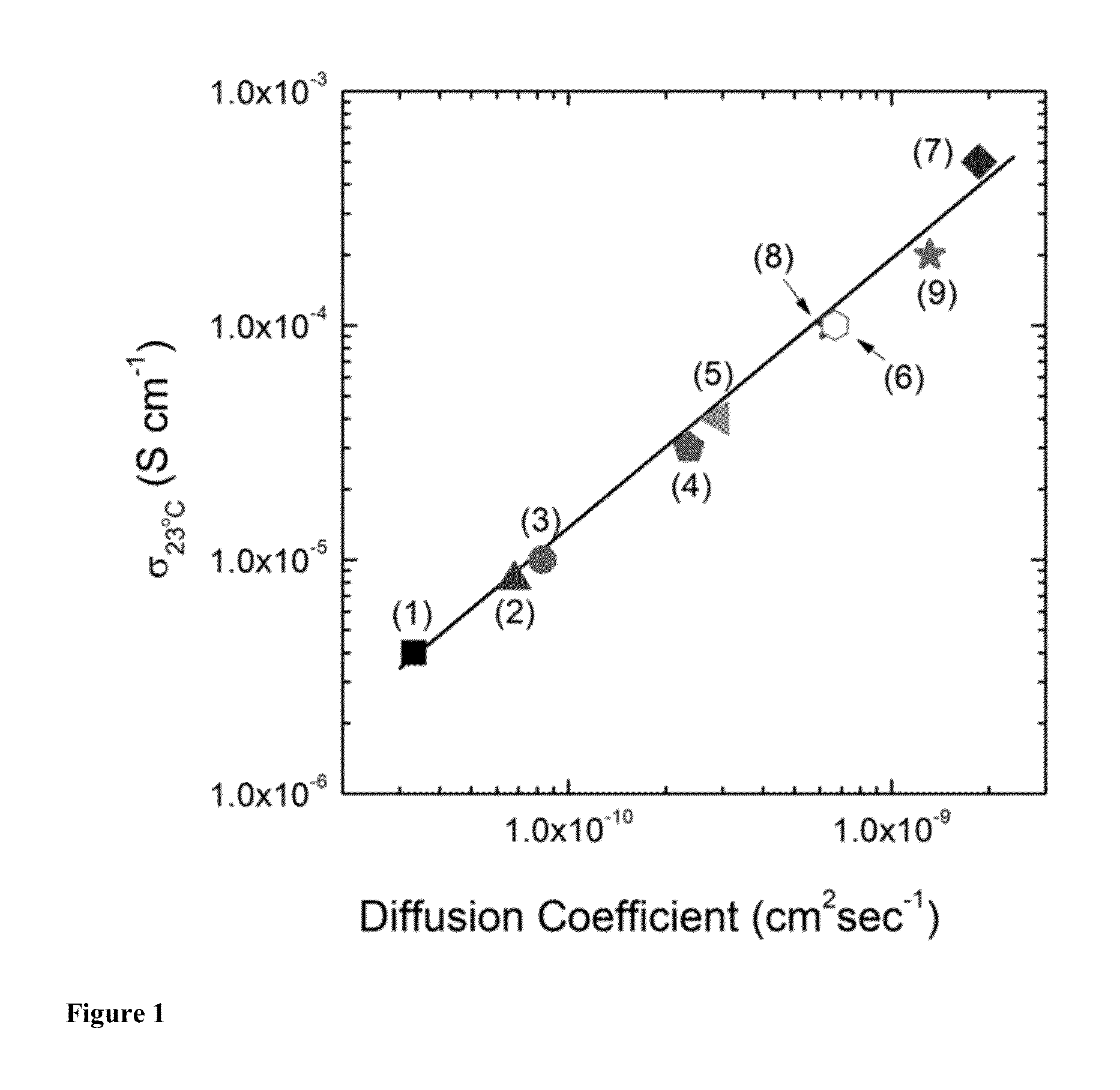

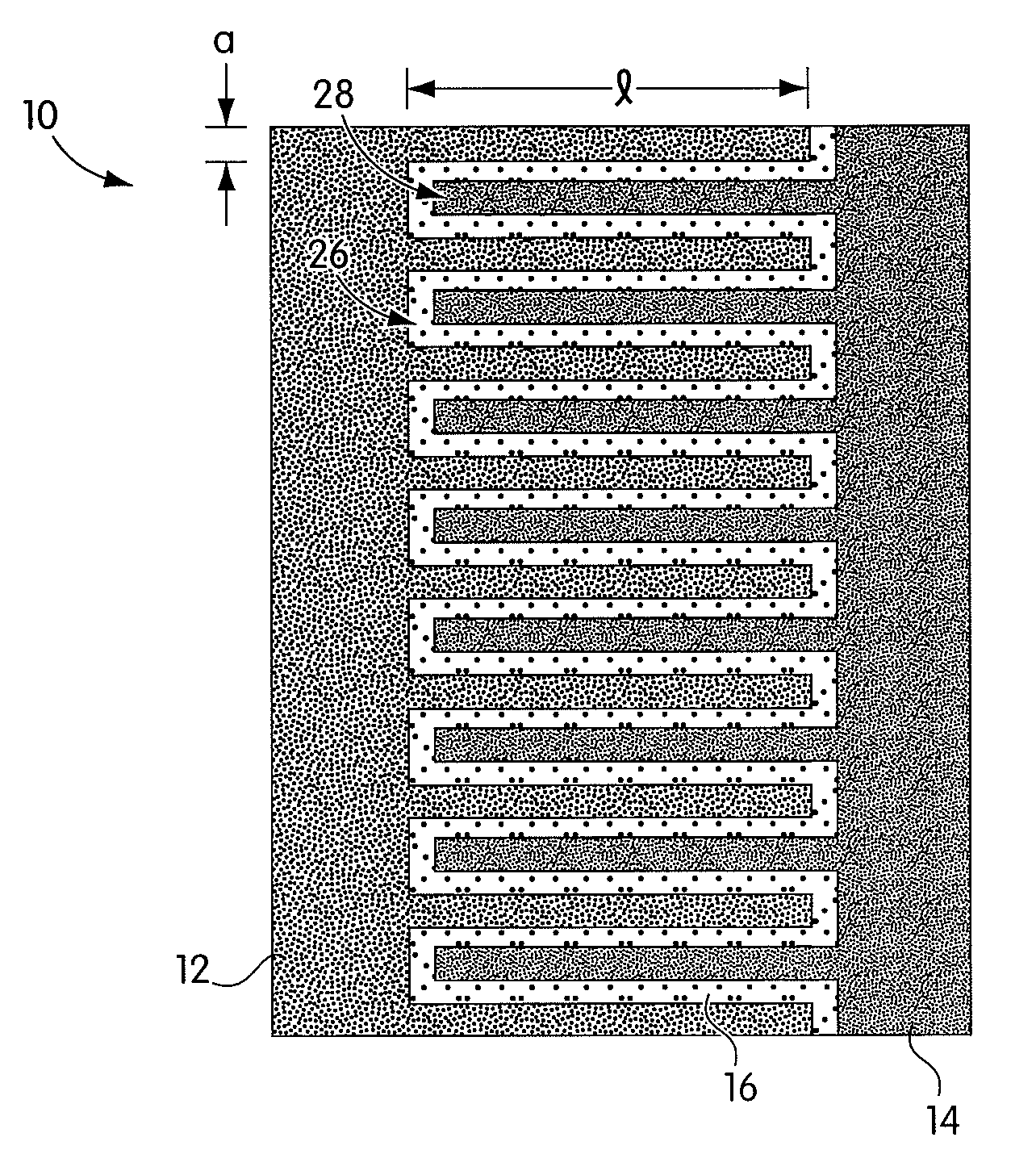

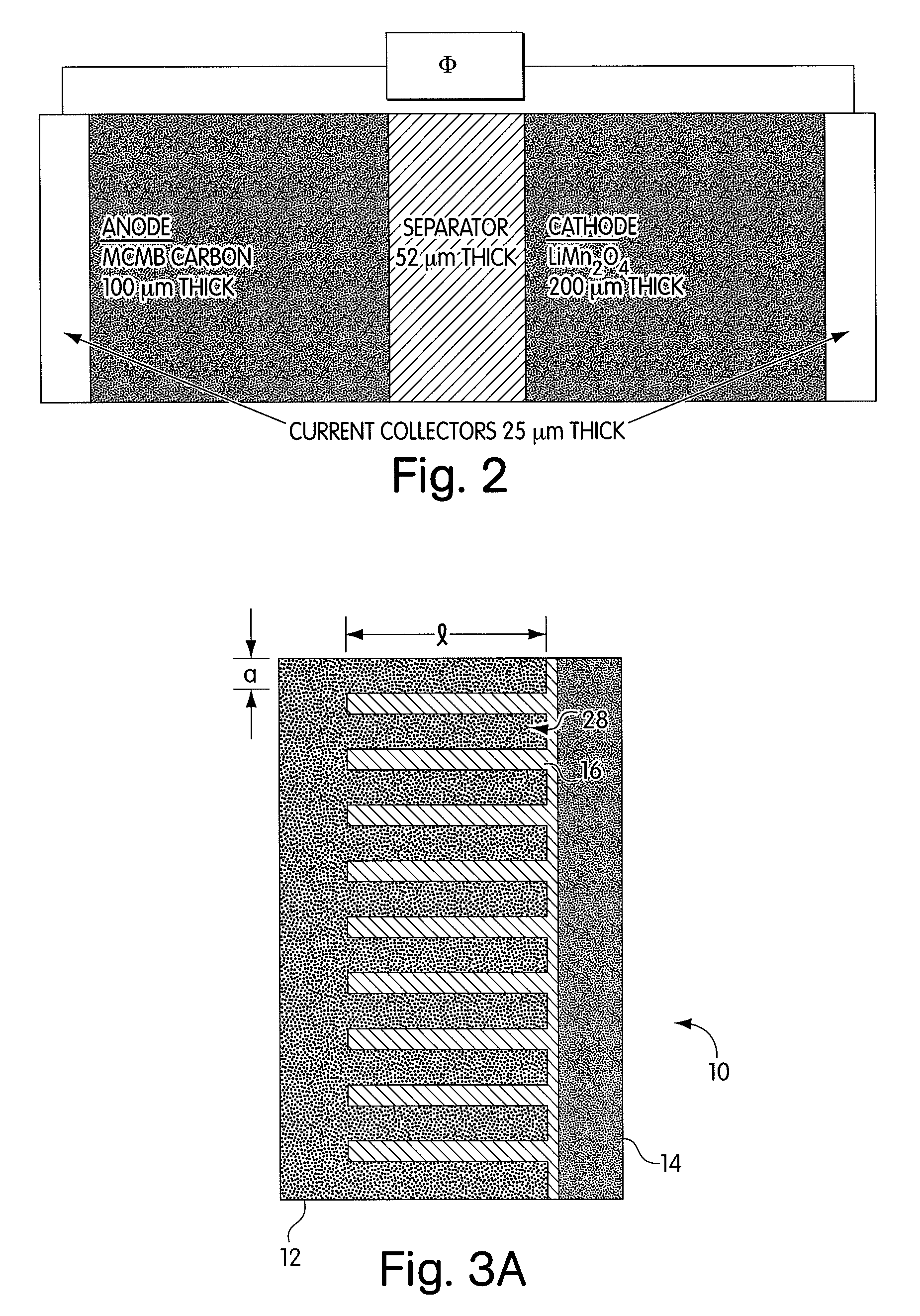

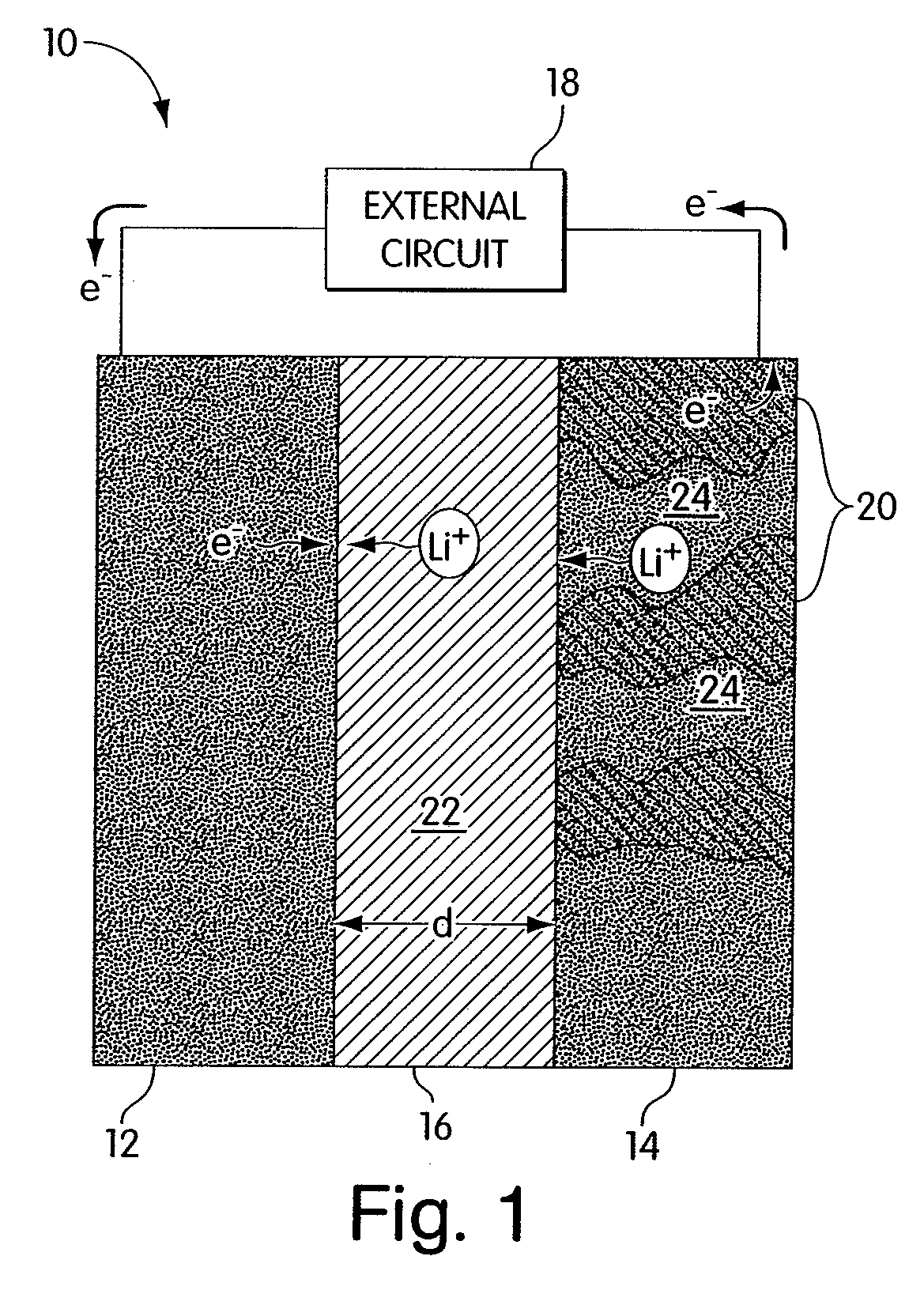

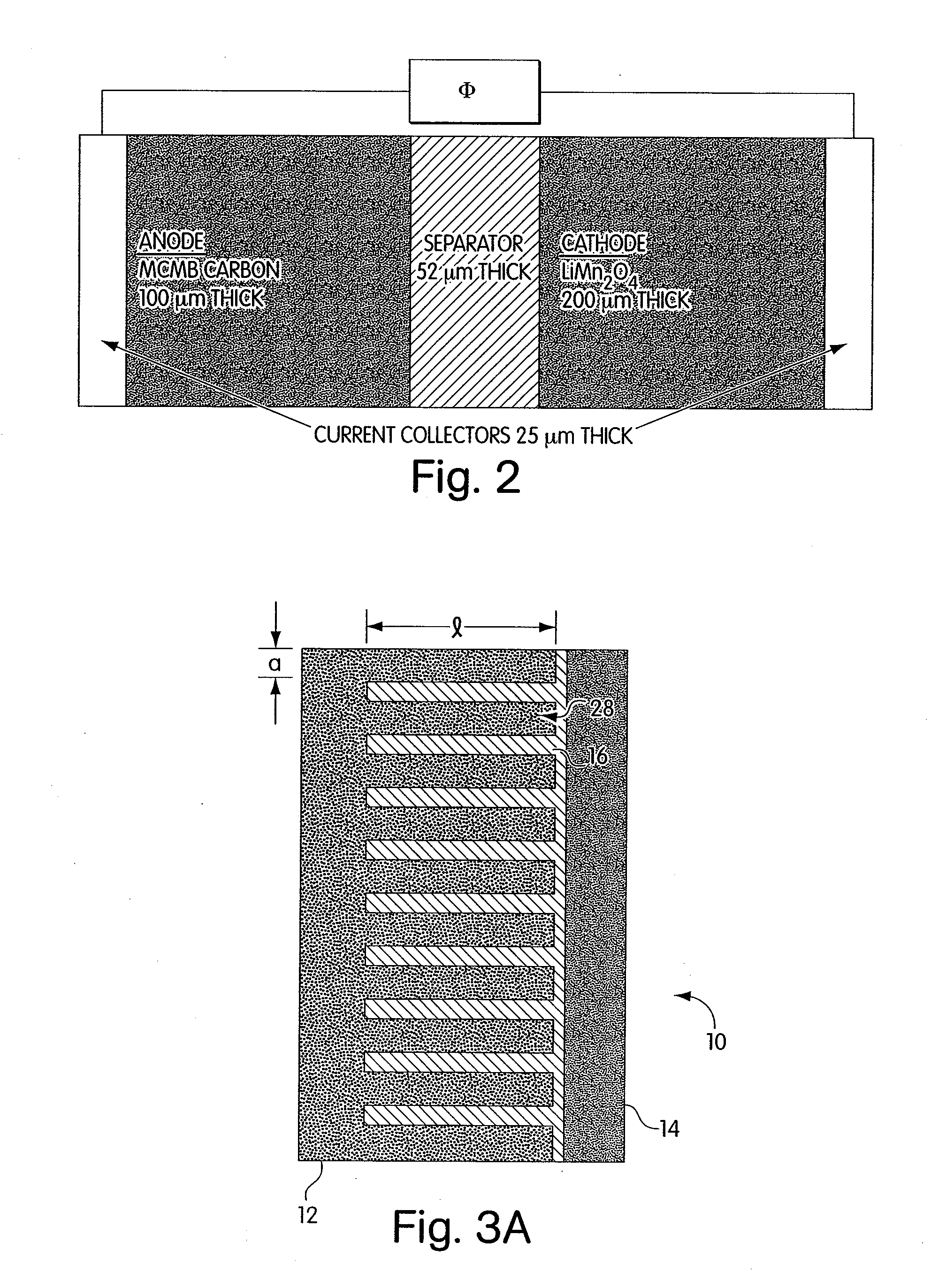

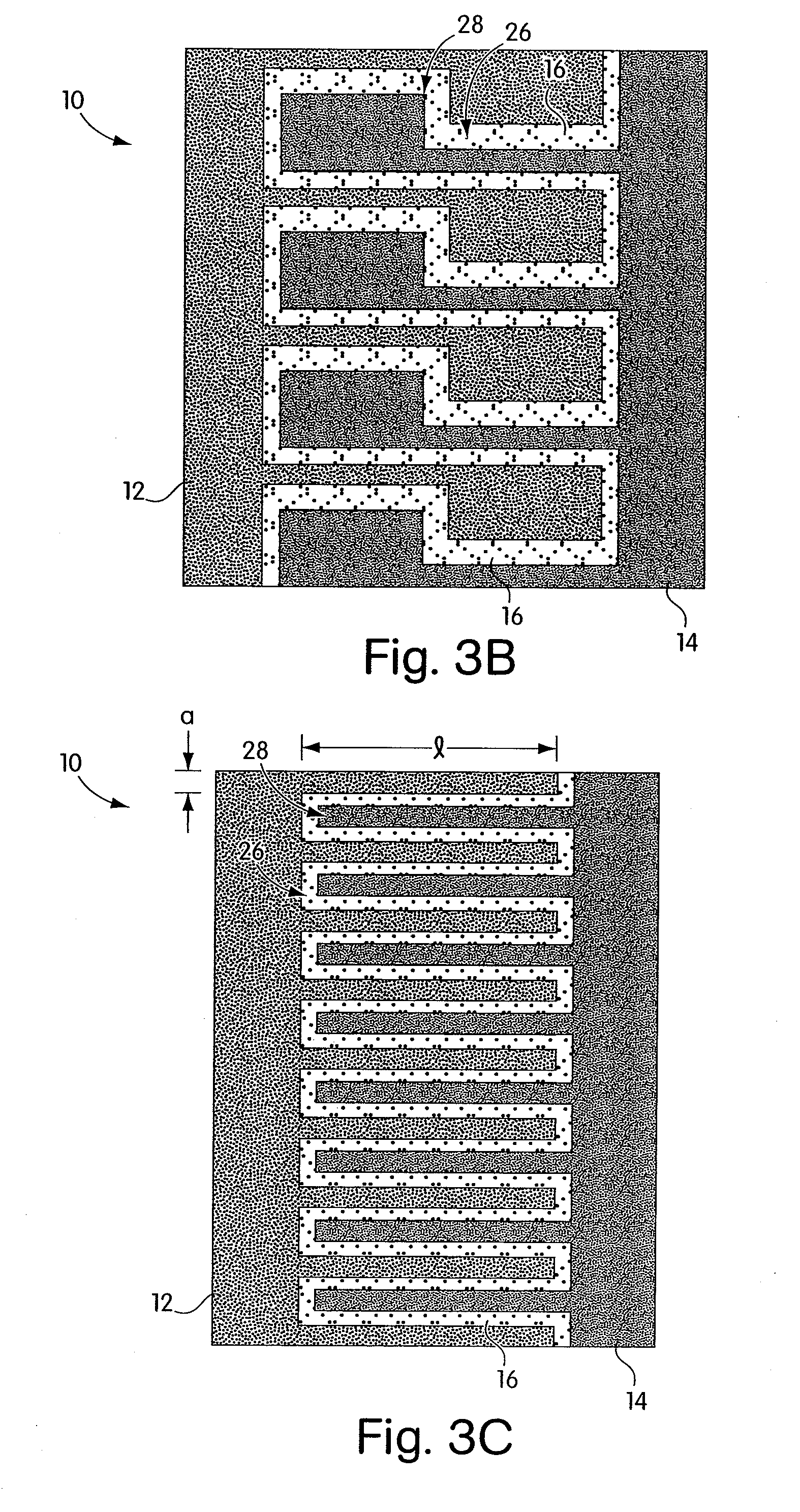

The effective ionic conductivity in a composite structure is believed to decrease rapidly with volume fraction. A system, such as a bipolar device or energy storage device, has structures or components in which the diffusion length or path that electrodes or ions must traverse is minimized and the interfacial area exposed to the ions or electrons is maximized. The device includes components that can be reticulated or has a reticulated interface so that an interface area can be increased. The increased interfacial perimeter increases the available sites for reaction of ionic species. Many different reticulation patterns can be used. The aspect ratio of the reticulated features can be varied. Such bipolar devices can be fabricated by a variety of methods or procedures. A bipolar device having structures of reticulated interface can be tailored for the purposes of controlling and optimizing charge and discharge kinetics. A bipolar device having graded porosity structures can have improved transport properties because the diffusion controlling reaction kinetics can be modified. Graded porosity electrodes can be linearly or nonlinearly graded. A bipolar device having perforated structures also provides improved transport properties by removing tortuosity and reducing diffusion distance.

Owner:MASSACHUSETTS INST OF TECH

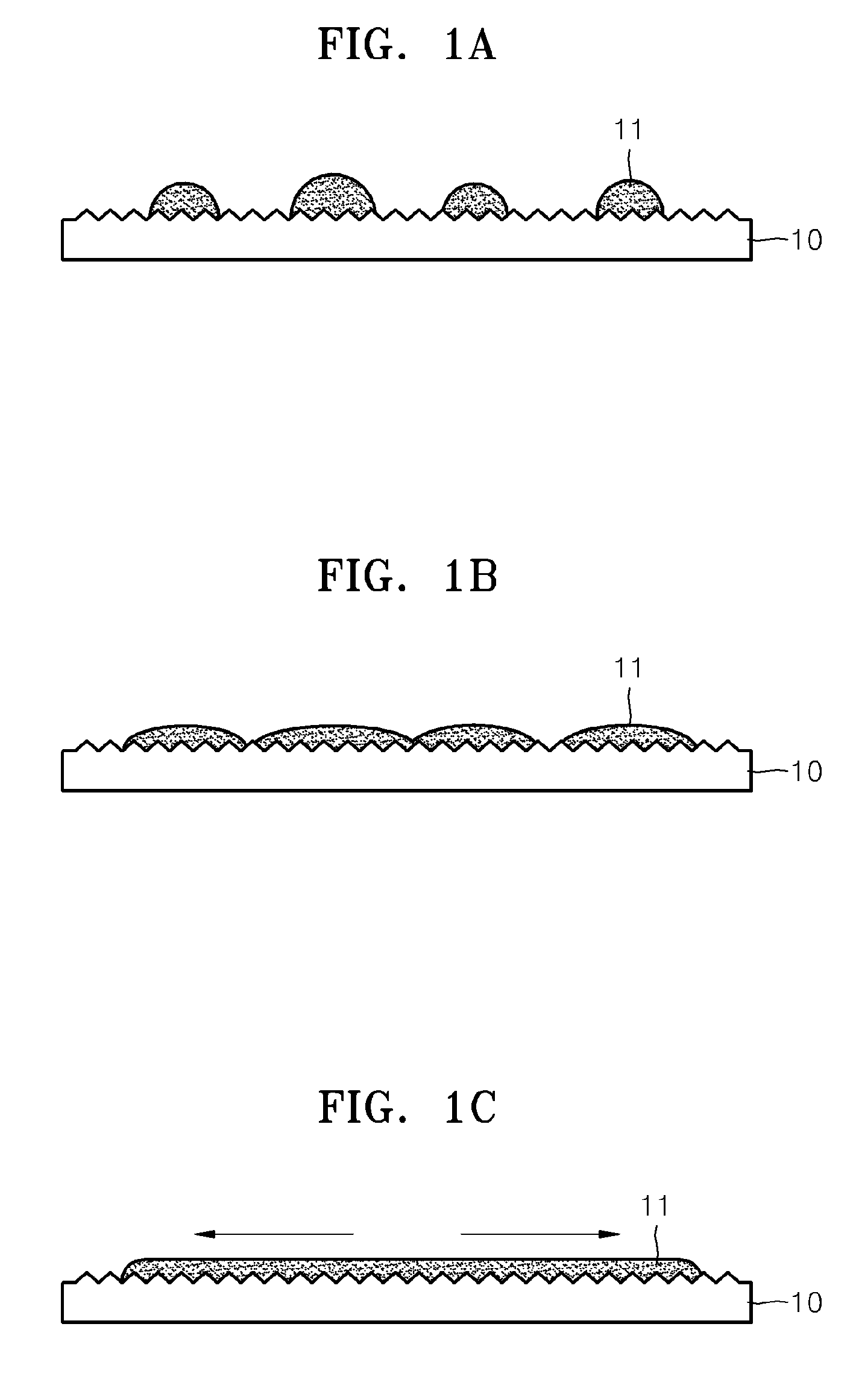

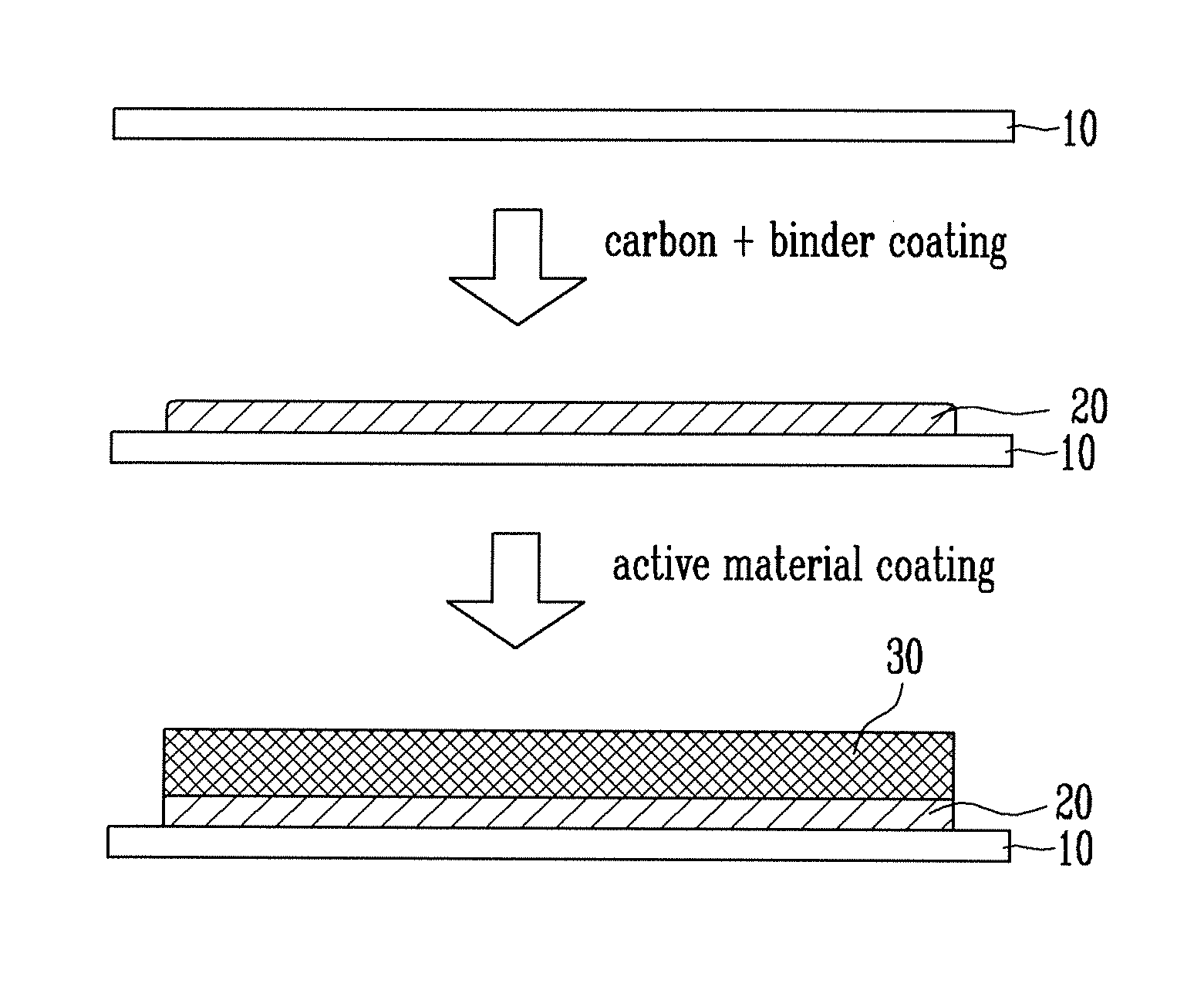

Electrode for secondary battery, manufacturing method thereof and secondary battery employing the same

InactiveUS20090098457A1Improve thickness uniformityIncrease electrode capacityCylinder pressesPlaten pressesElectrical batterySurface roughness

Provided are an electrode for a secondary battery employing an active material layer having improved thickness uniformity by printing low-viscosity ink on the active material layer, a manufacturing method of the electrode, and a secondary battery having improved electrode capacity due to the employing of the electrode. The electrode includes a current collector, and an active material layer formed by printing ink having a viscosity not exceeding 500 mPa·s on the current collector and drying the current collector, wherein the current collector has a surface roughness (Ra) in a range from about 0.025 to 1.0 μm.

Owner:SAMSUNG ELECTRONICS CO LTD

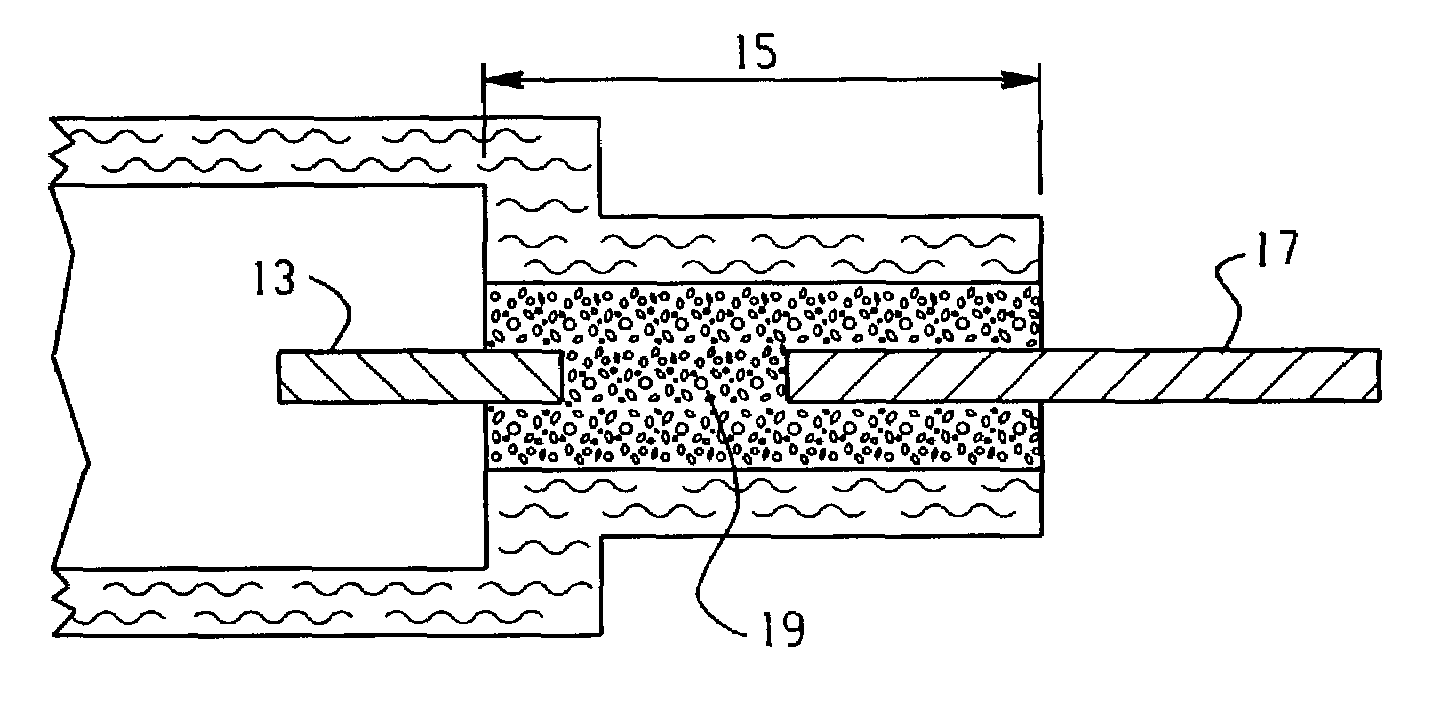

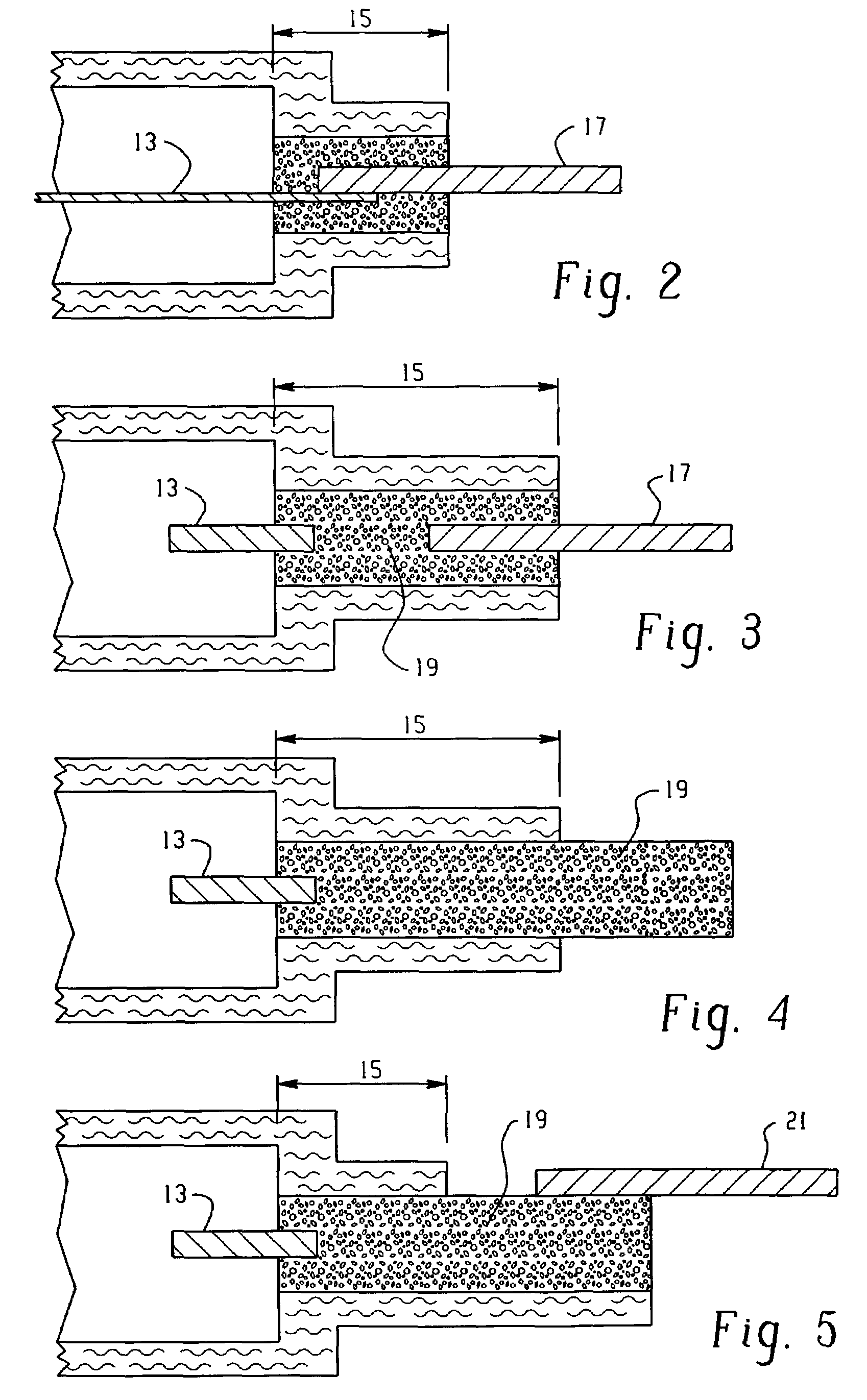

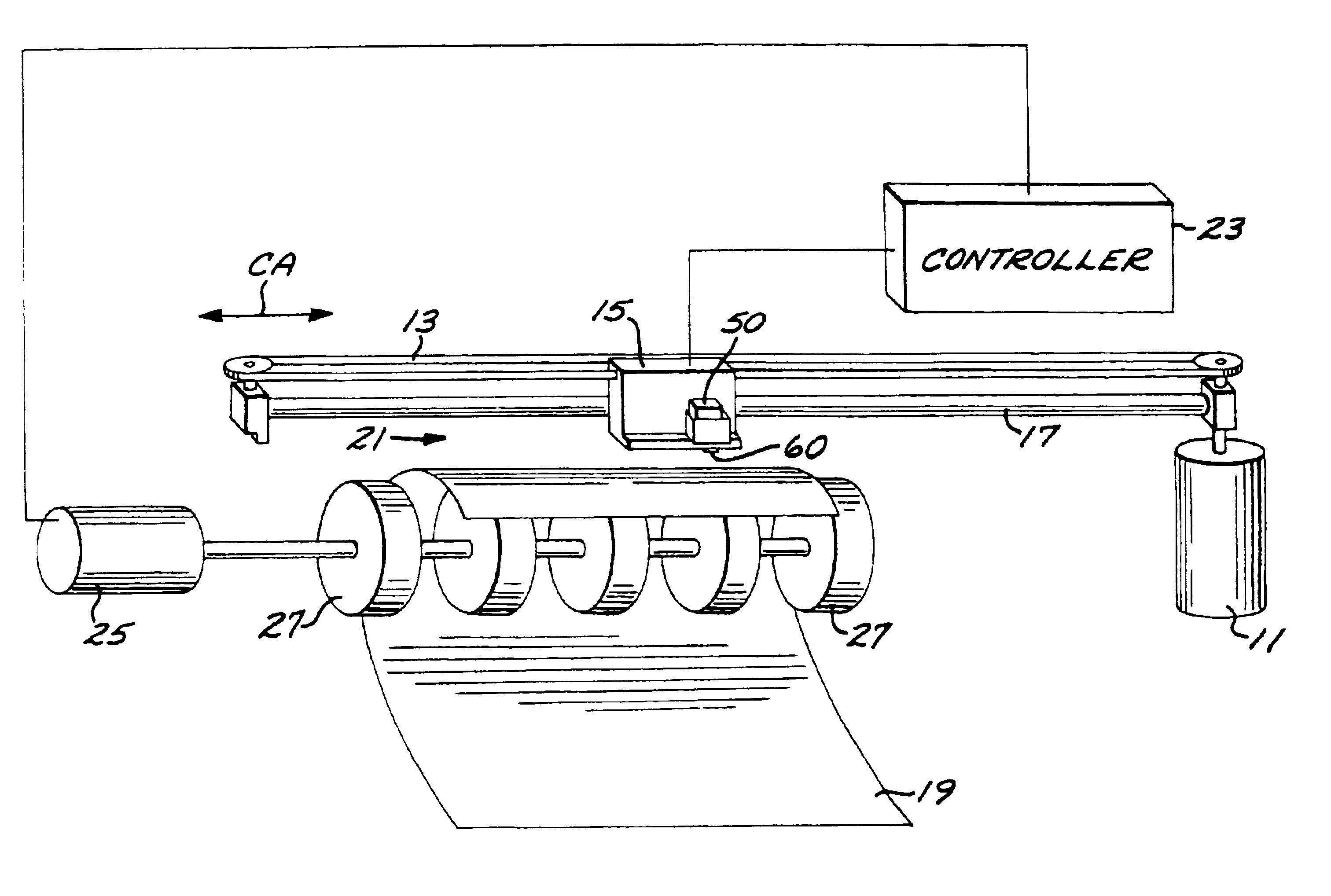

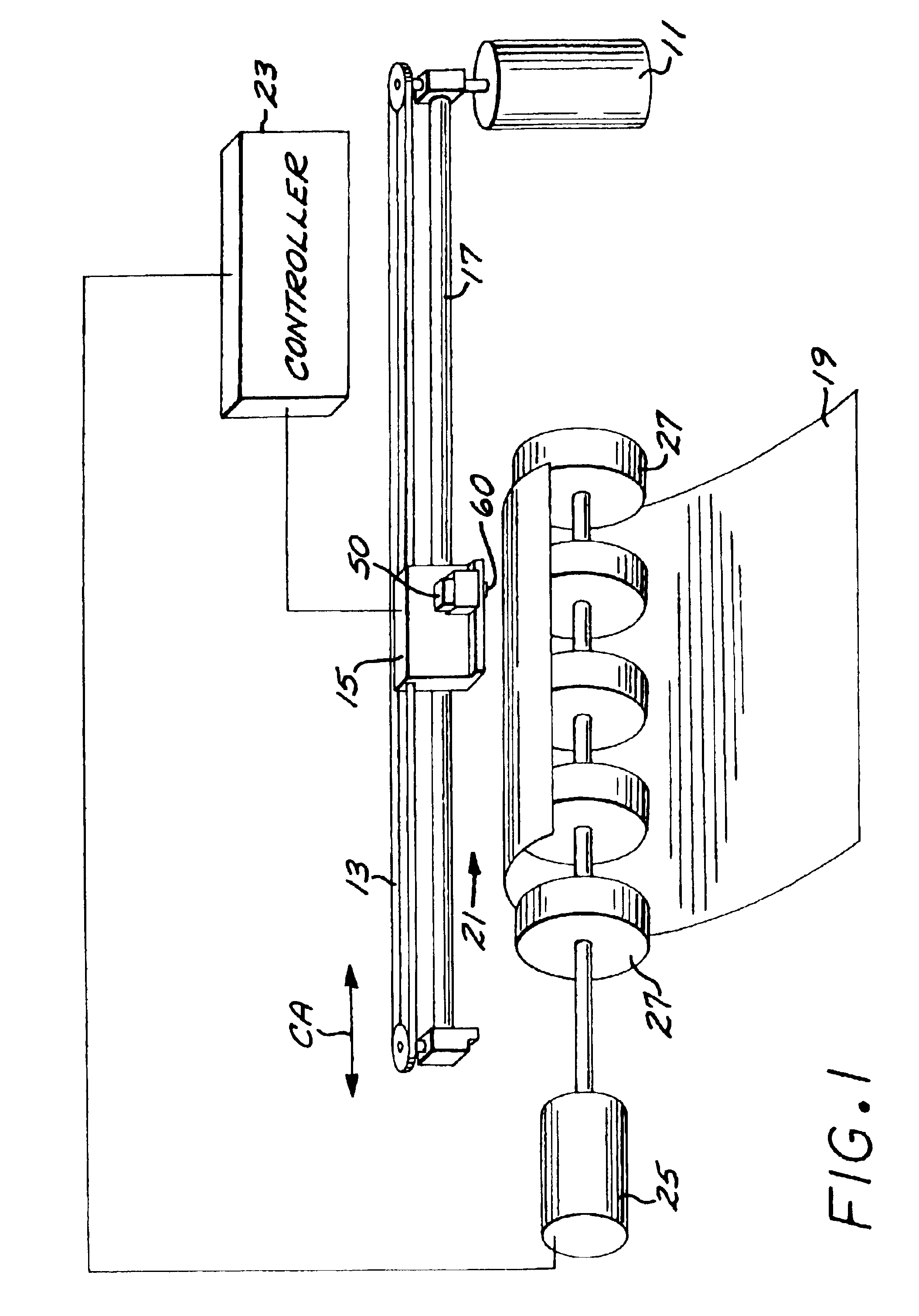

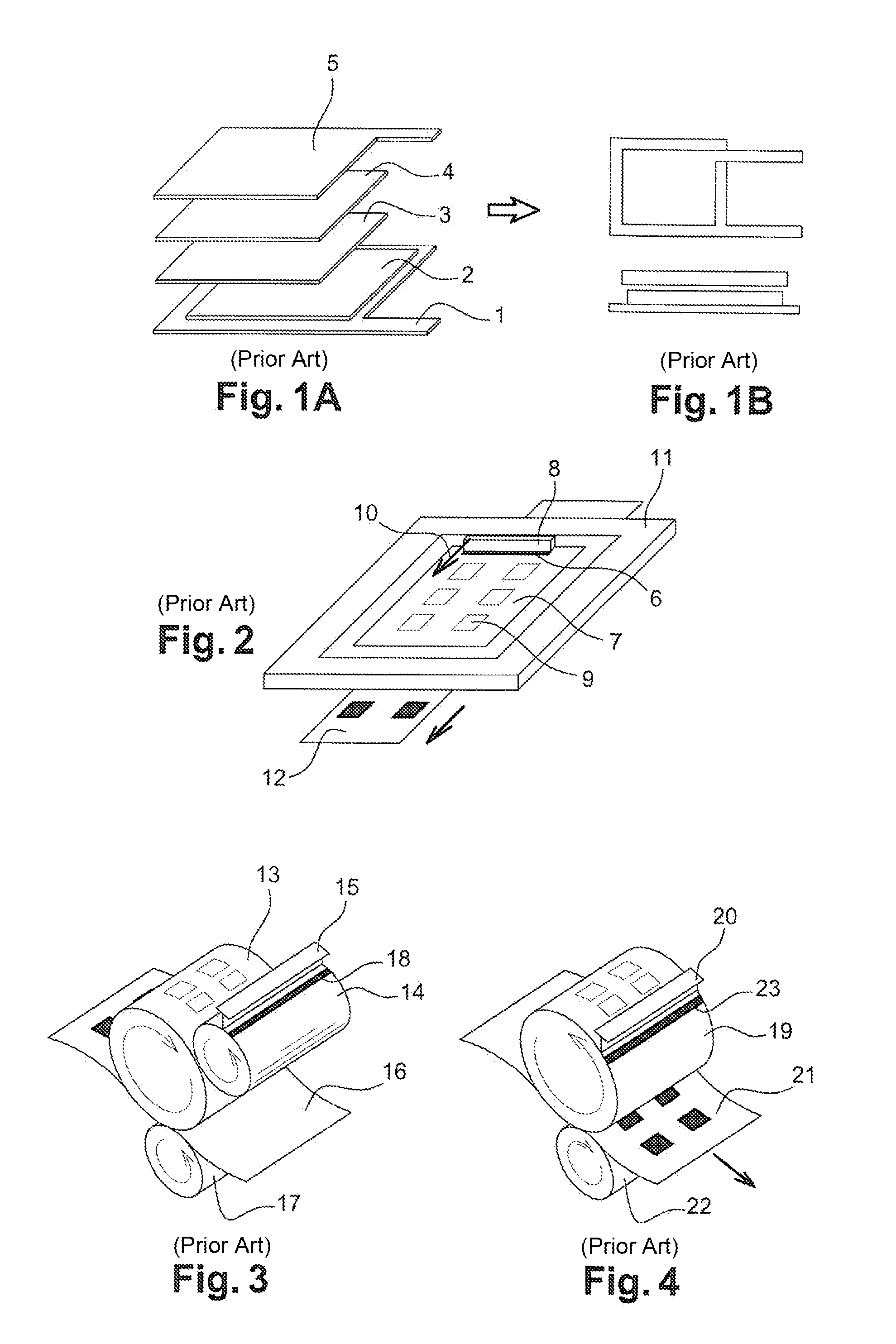

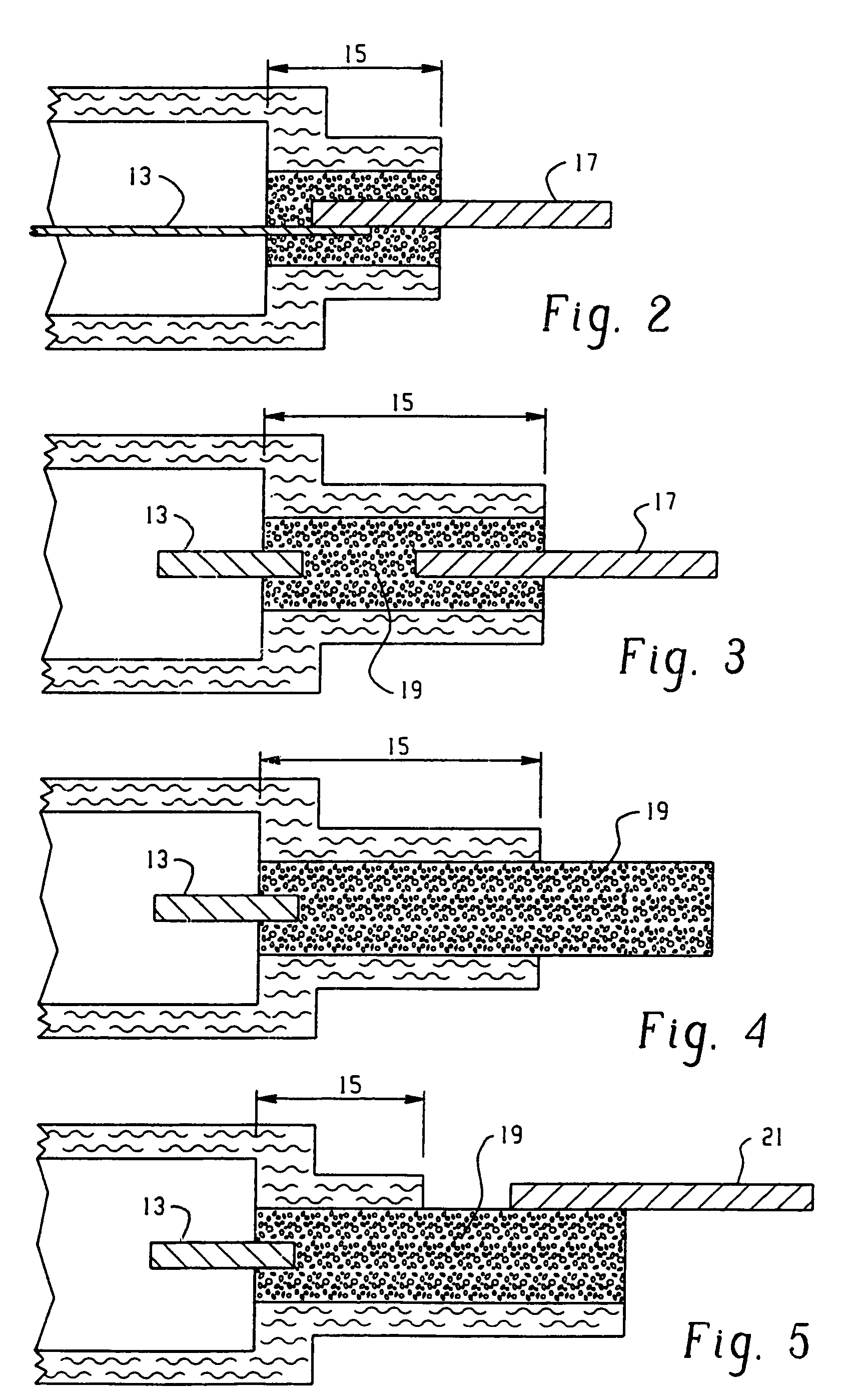

Polymer-lithium batteries and improved methods for manufacturing batteries

InactiveUSRE36843E1Prevent and minimize electrical shortingHigh voltageElectrode rolling/calenderingFinal product manufactureEngineeringDeposition process

Improved polymer batteries and improved methods of manufacturing such polymer batteries are provided. One improved method of manufacture involves the formation of a laminated array structure that includes a number of individual battery cells. After formation of the laminated array the individual batteries are singulated from the array by cutting, shearing or stamping. Other manufacturing improvements include the use of a printing process (e.g. stenciling) to form the cathodes, the use of permanent mask layers to contain and insulate the cathodes and anodes, and the use of a molten lithium deposition process for forming the anodes.

Owner:ROUND ROCK RES LLC

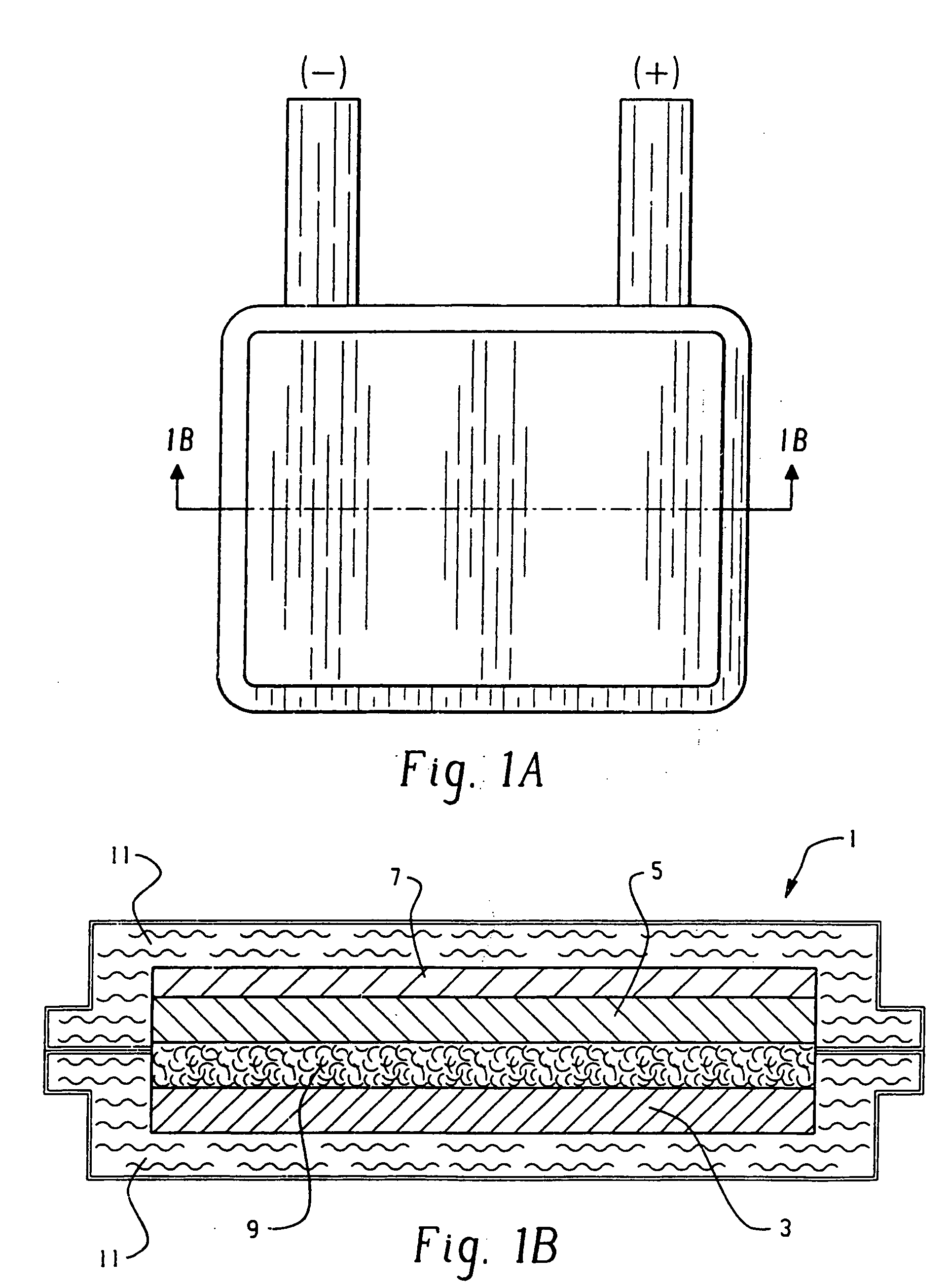

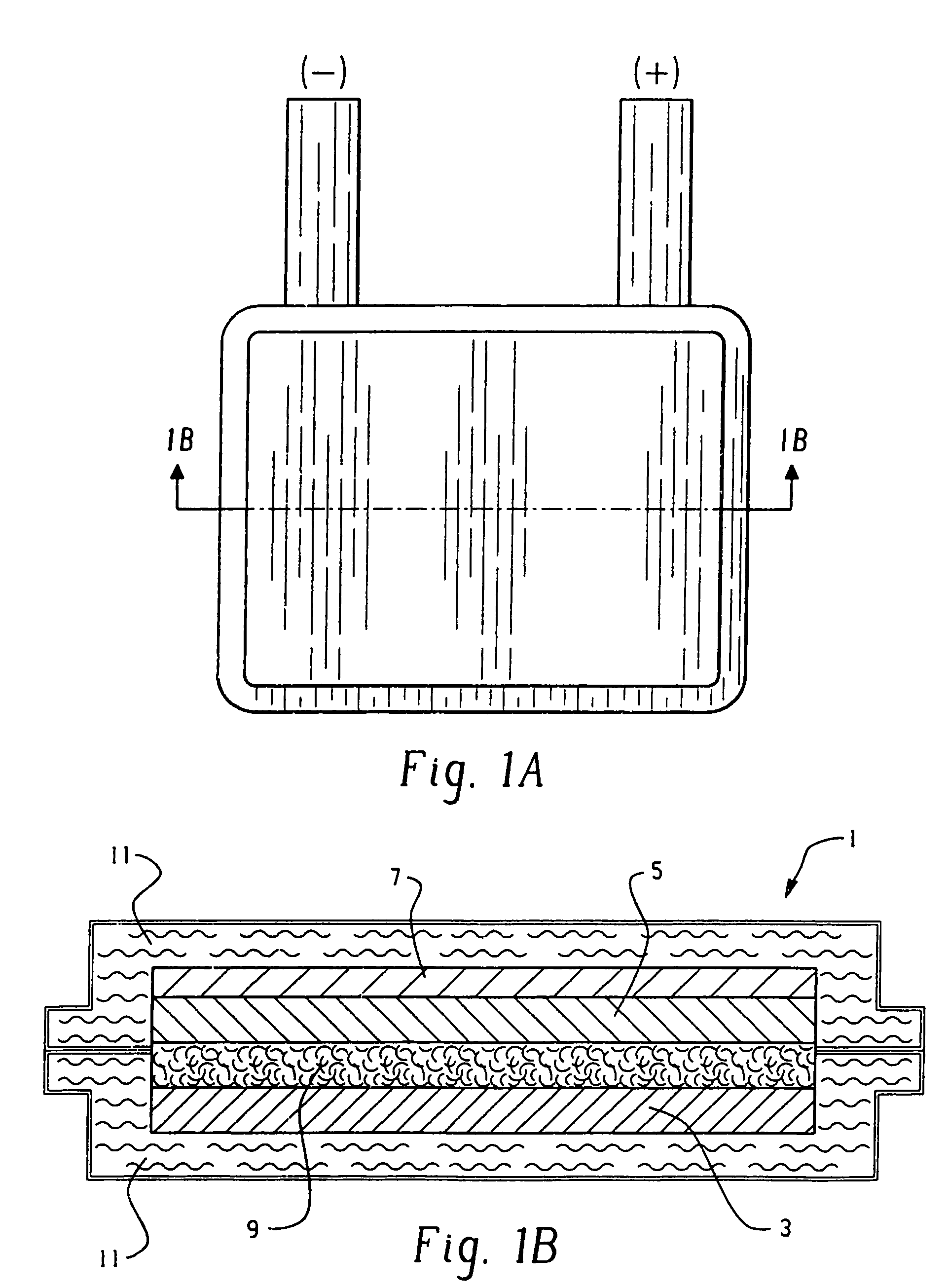

High current thin electrochemical cell and methods of making the same

ActiveUS20100266895A1Well formedPrimary cell manufactureElectrode carriers/collectorsEngineeringPrinting press

A battery including at least one electrochemical cell for generating an electrical current is provided, along with its method of manufacture. In one example, the electrochemical cell is provided on a first substrate and includes an anode and a plurality of cathodes. At least a portion of said anode is located between an adjacent two of said plurality of cathodes. In one example method of manufacture, the electrochemical cell is made via a printing press process.

Owner:BLUE SPARK INNOVATIONS LLC

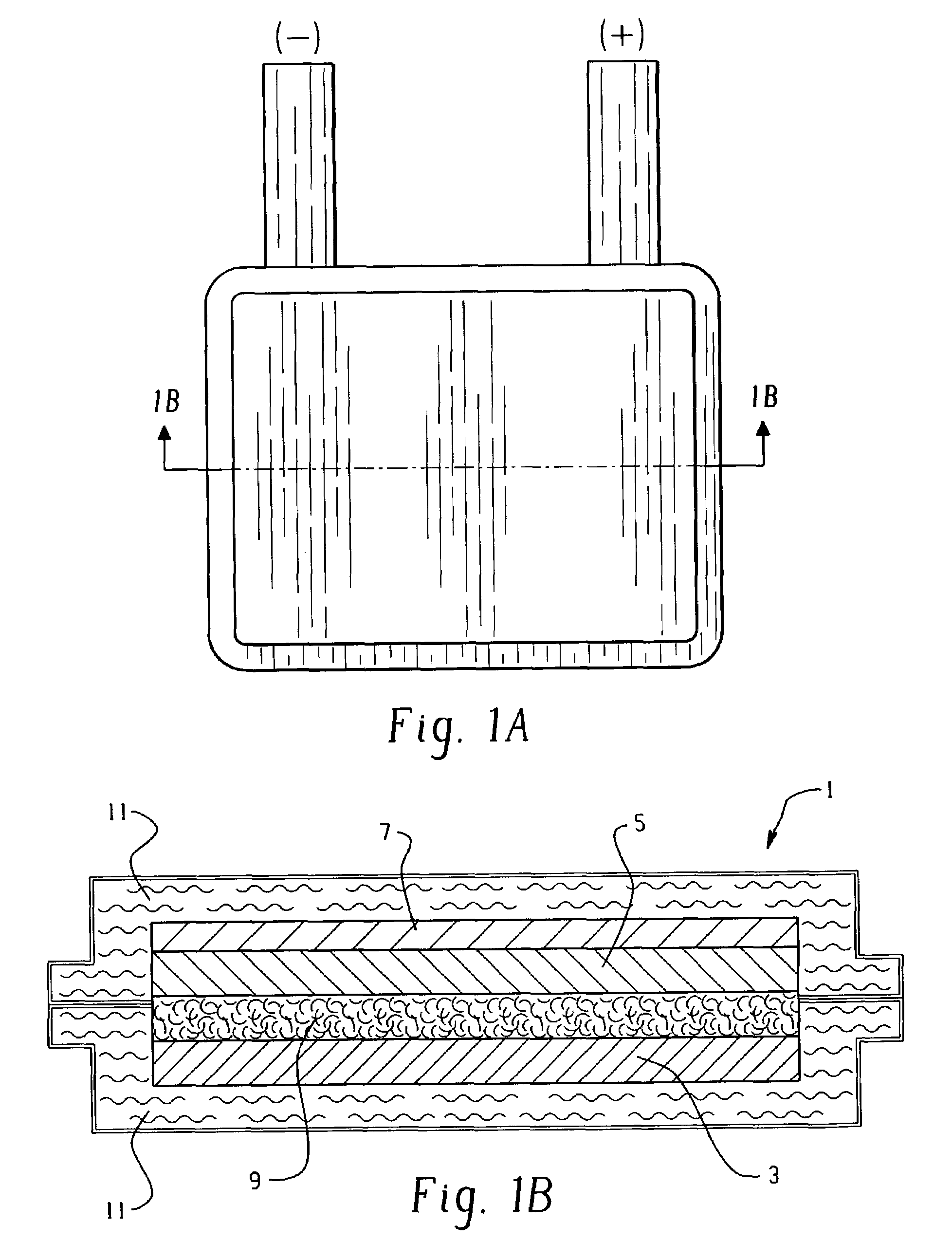

Flexible thin printed battery and device and method of manufacturing same

ActiveUS7348096B2Eliminate needFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

A flat, flexible electrochemical cell is provided. The within invention describes various aspects of the flat, flexible electrochemical cell. A printed anode is provided that obviates the need for a discrete anode current collector, thereby reducing the size of the battery. An advantageous electrolyte is provided that enables the use of a metallic cathode current collector, thereby improving the performance of the battery. Printable gelled electrolytes and separators are provided, enabling the construction of both co-facial and co-planar batteries. Cell contacts are provided that reduce the potential for electrolyte creepage in the flat, flexible electrochemical cells of the within invention.

Owner:ENERGIZER BRANDS

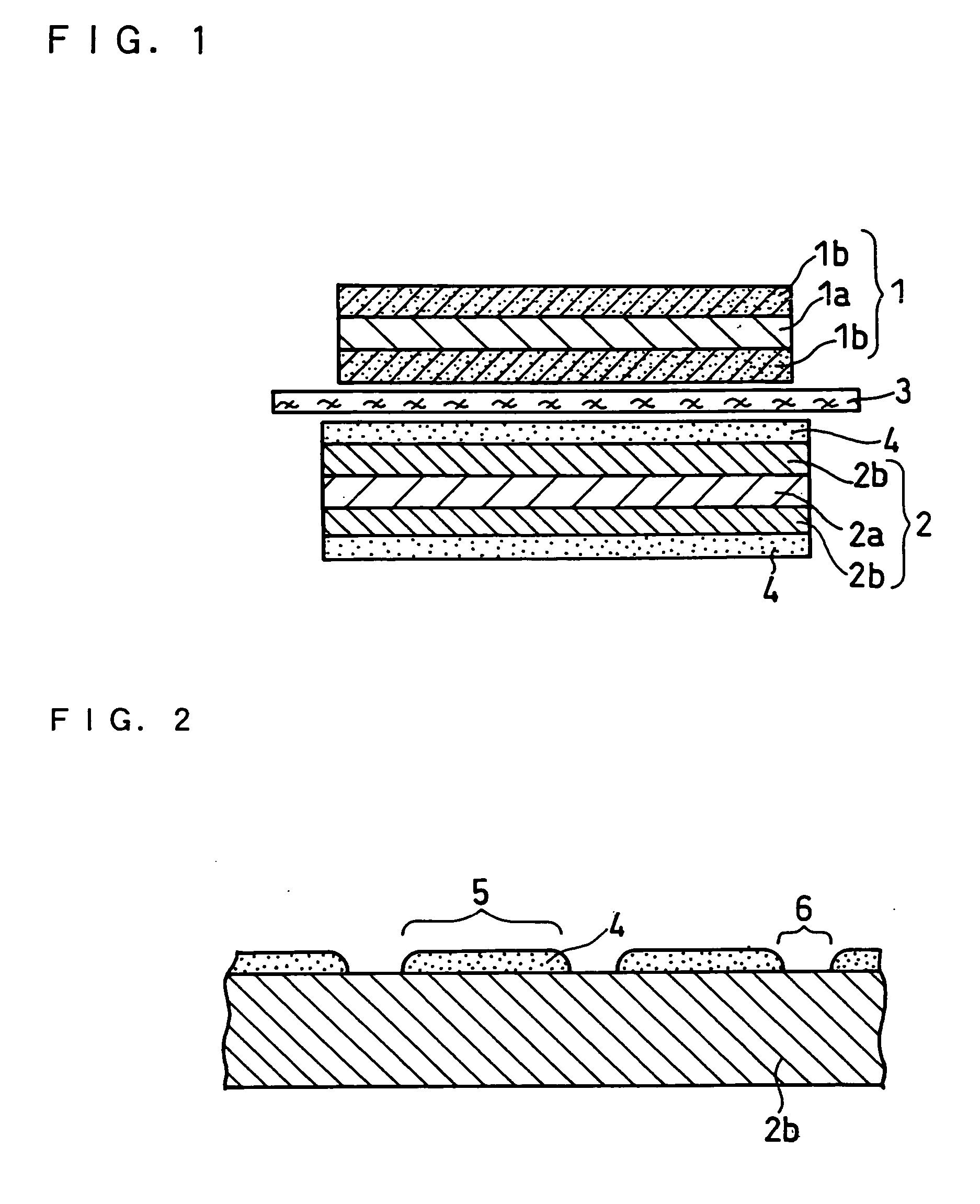

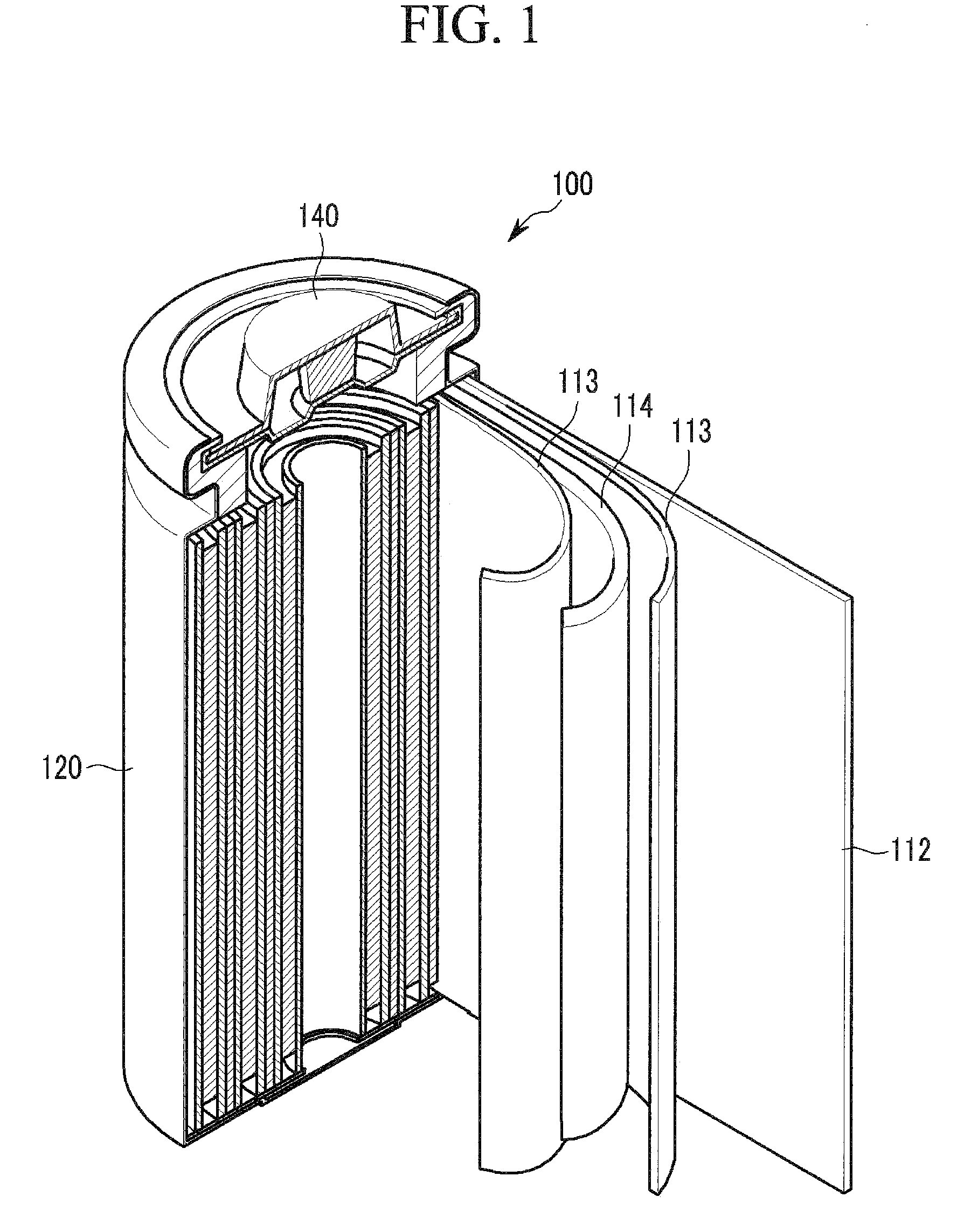

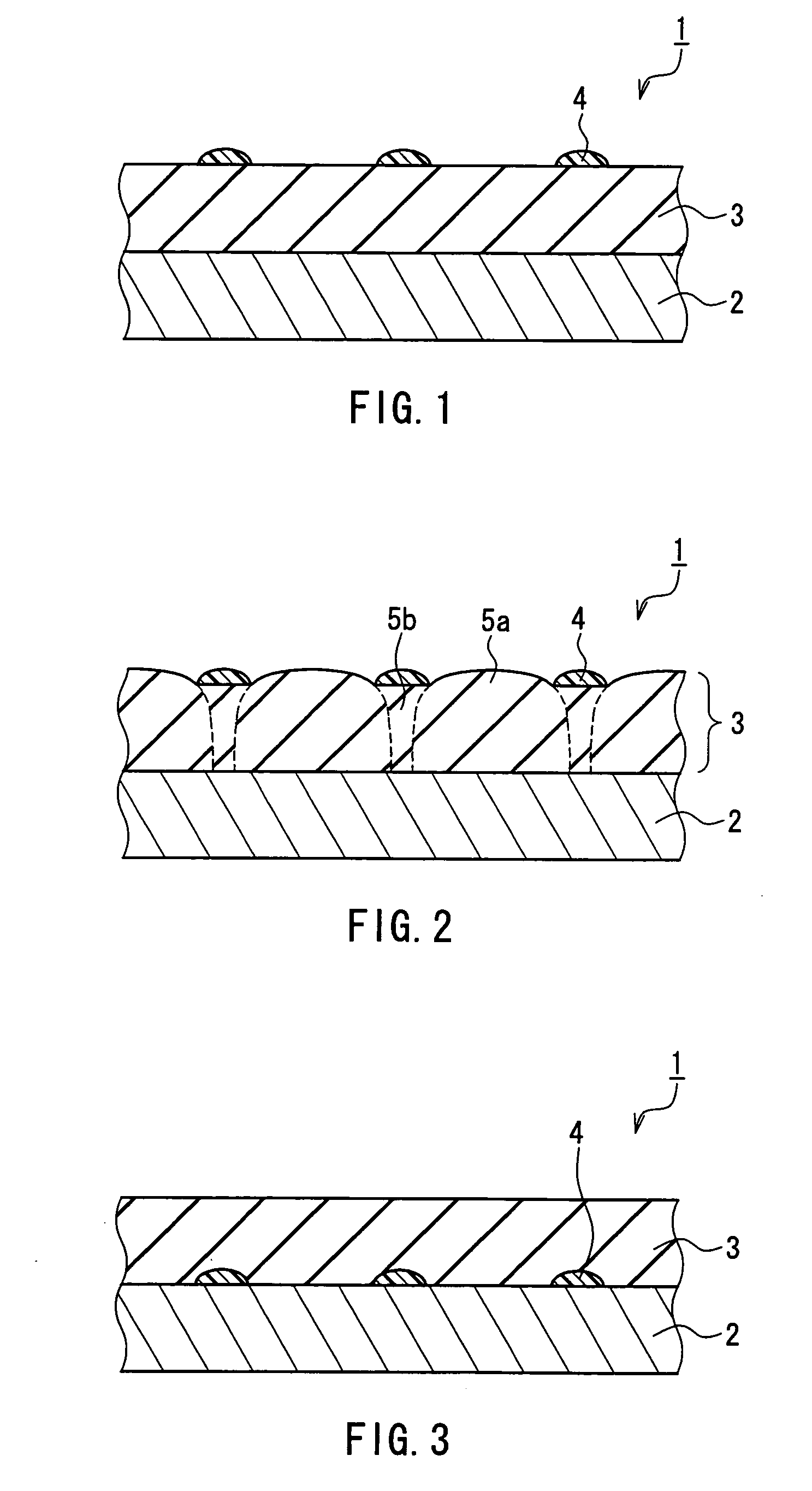

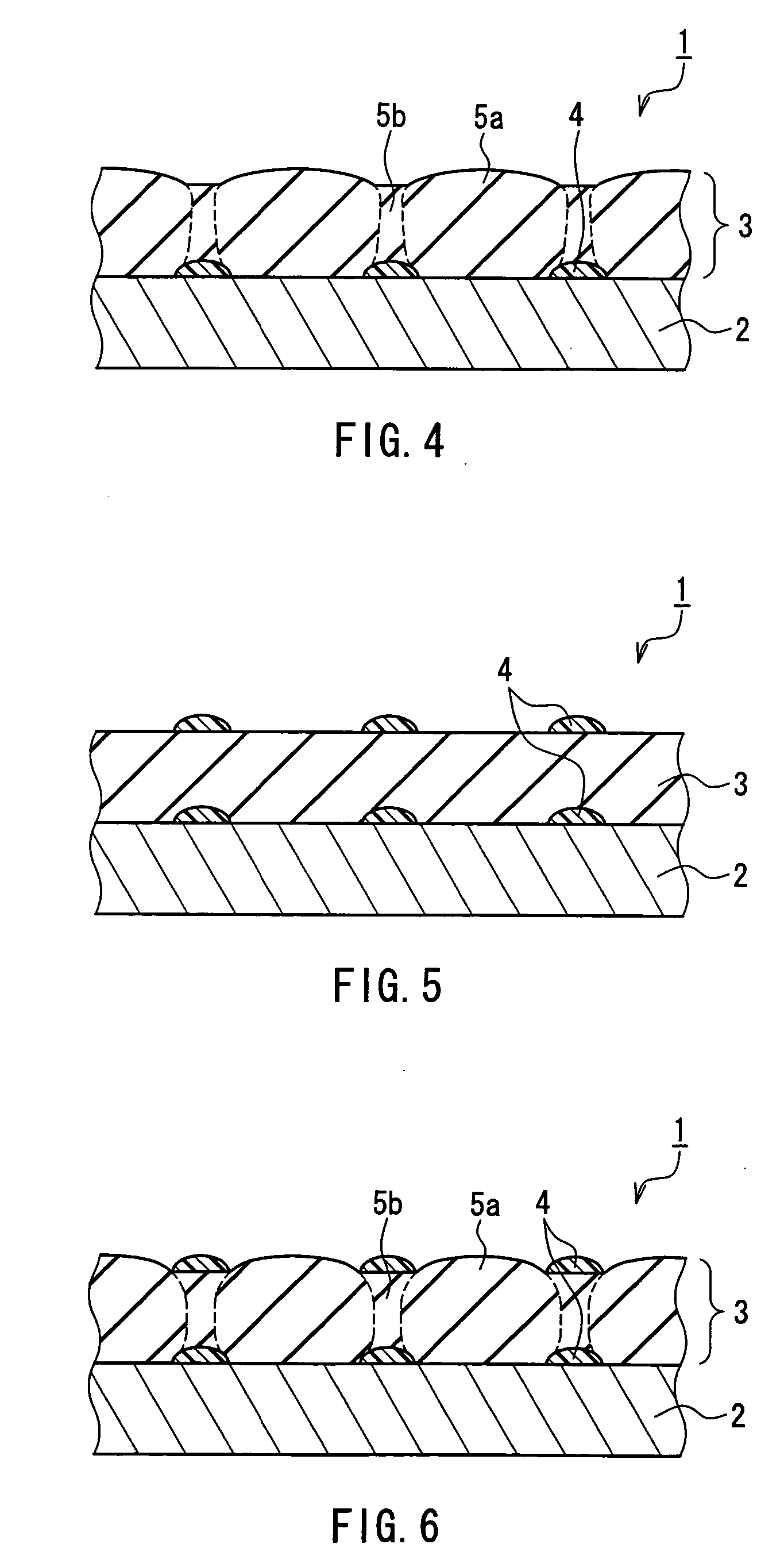

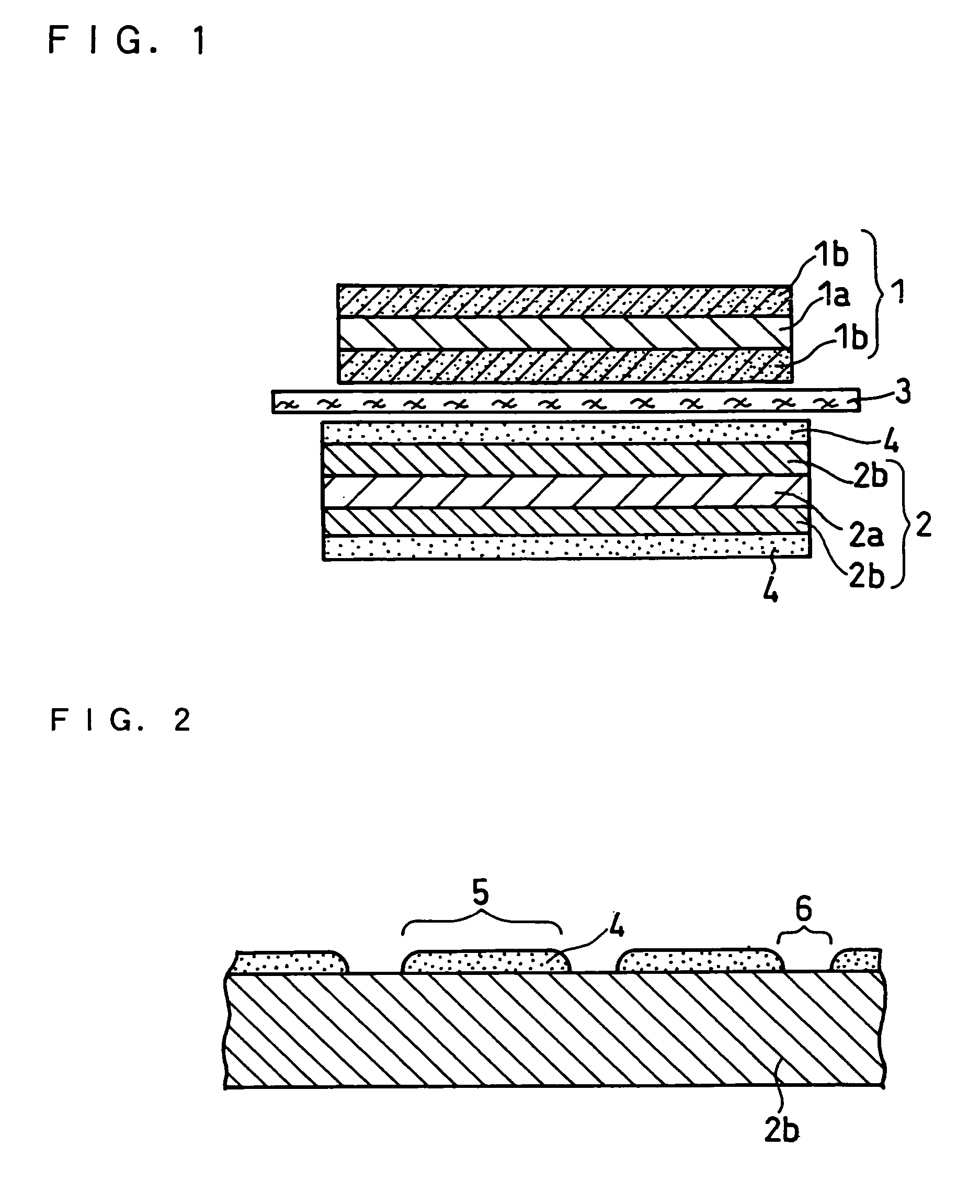

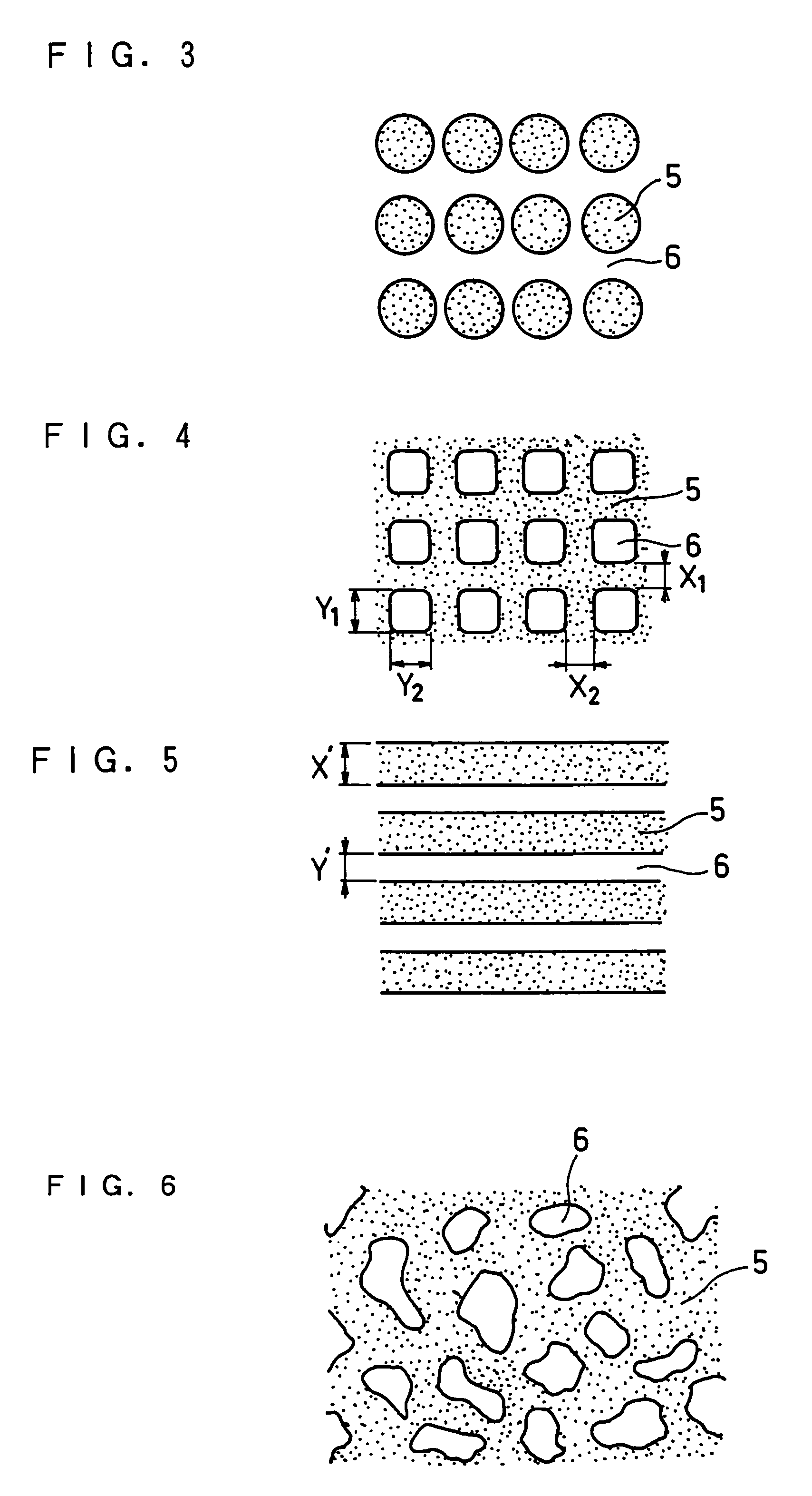

Electrode for lithium ion secondary batteries, lithium ion secondary battery using the same, and method for manufacturing the battery

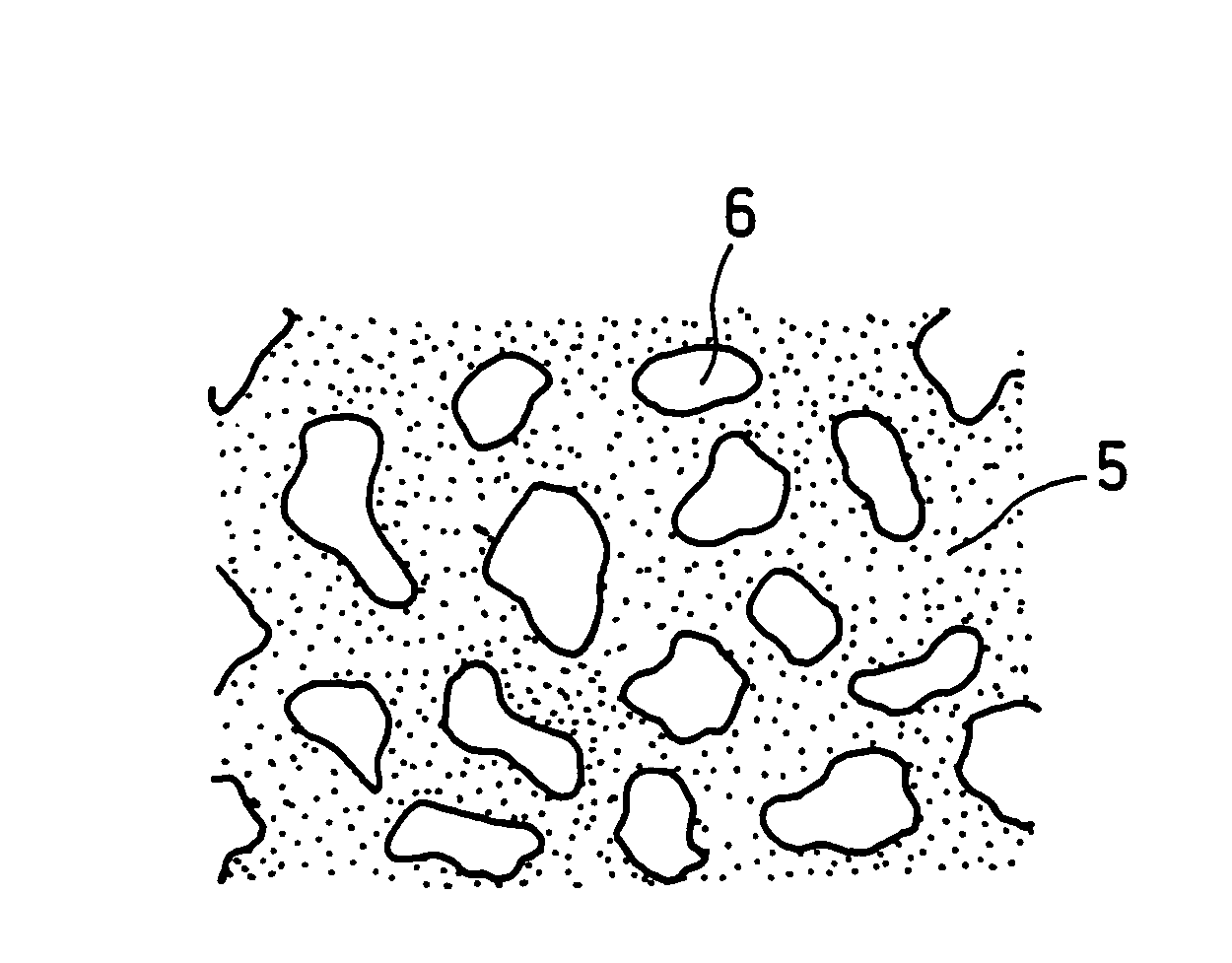

ActiveUS20070072083A1Increase capacityExcellent characteristicsHybrid capacitor electrodesFinal product manufactureLithiumMaterials science

Disclosed is an electrode for lithium ion secondary batteries which includes an active material layer containing active material particles and a porous insulating layer formed on the surface of the active material layer. The porous insulating layer includes an inorganic filler and a resin binder, and the surface of the active material layer has a first region on which the porous insulating layer is formed, and a second region on which the porous insulating layer is not formed. By using such an electrode, a lithium ion secondary battery can have a high capacity, excellent characteristics and improved safety.

Owner:PANASONIC CORP

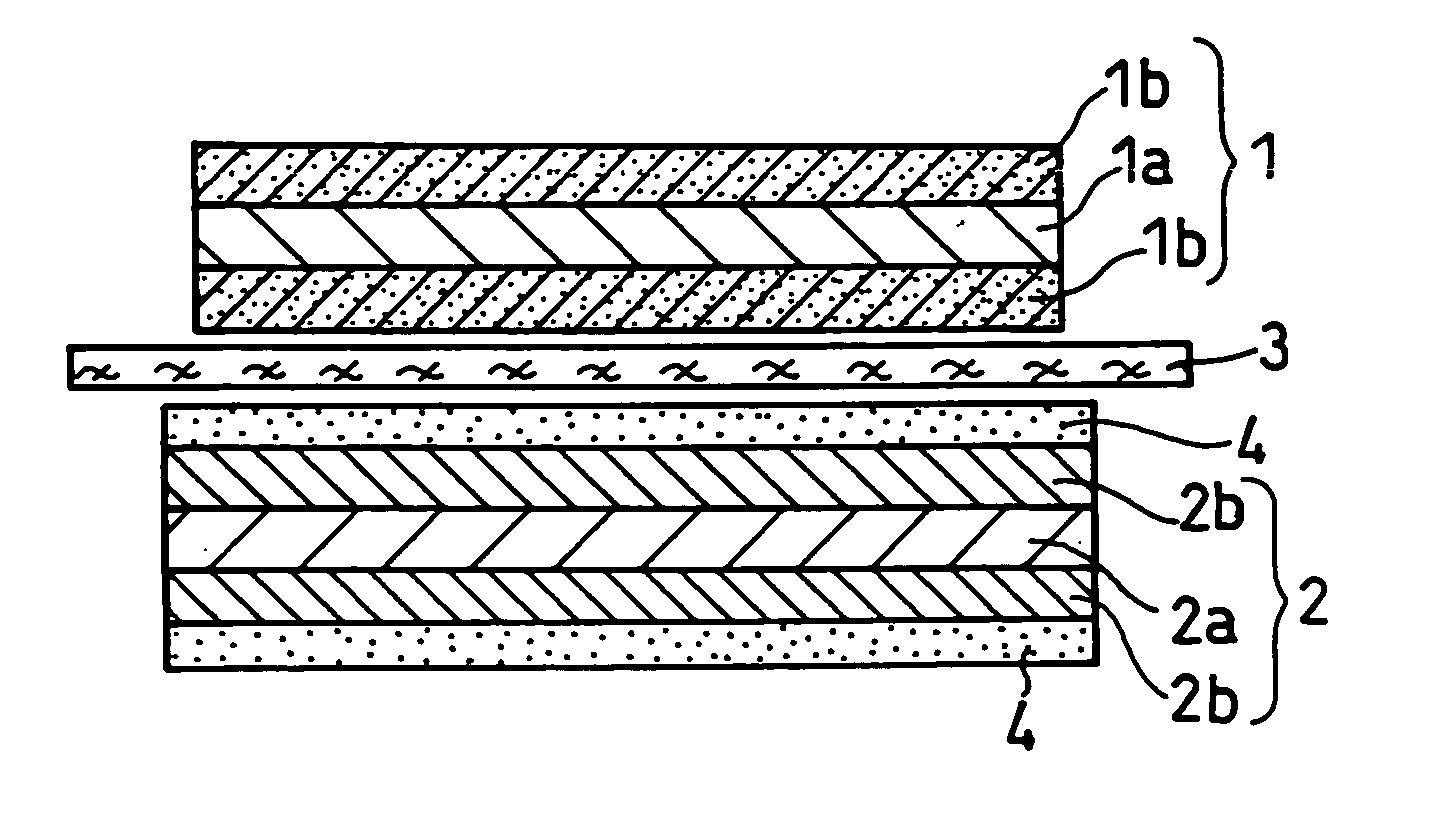

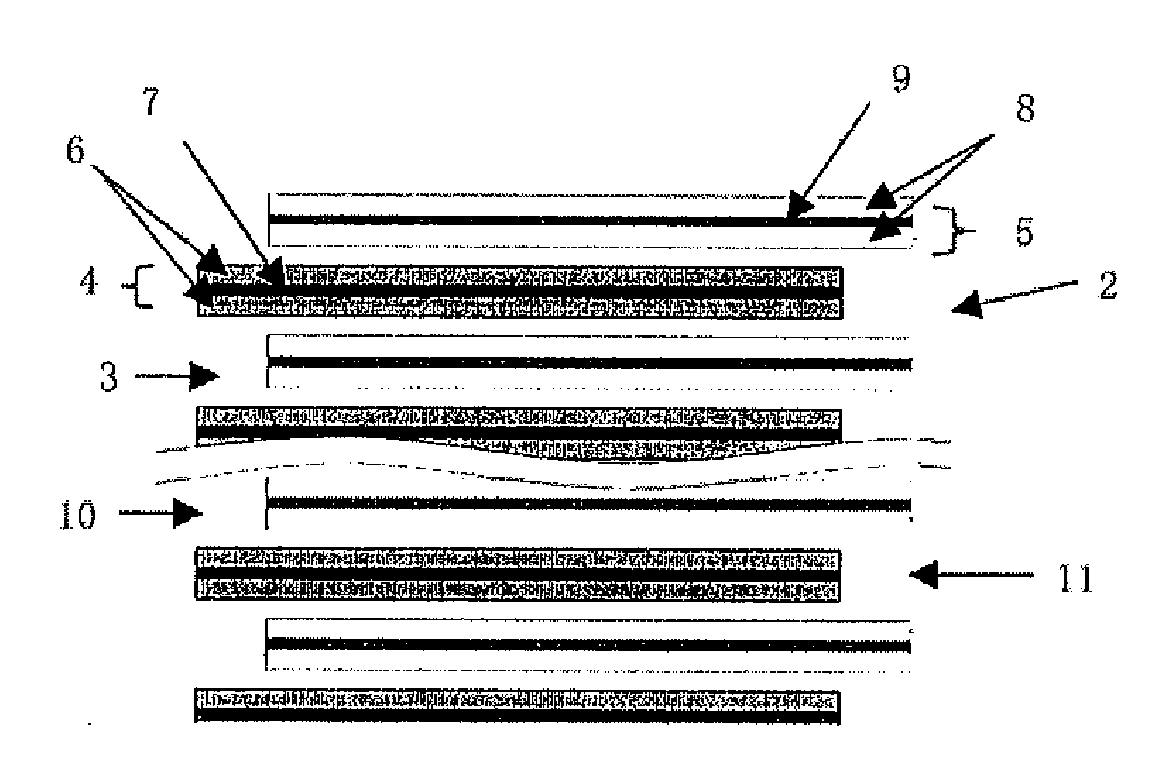

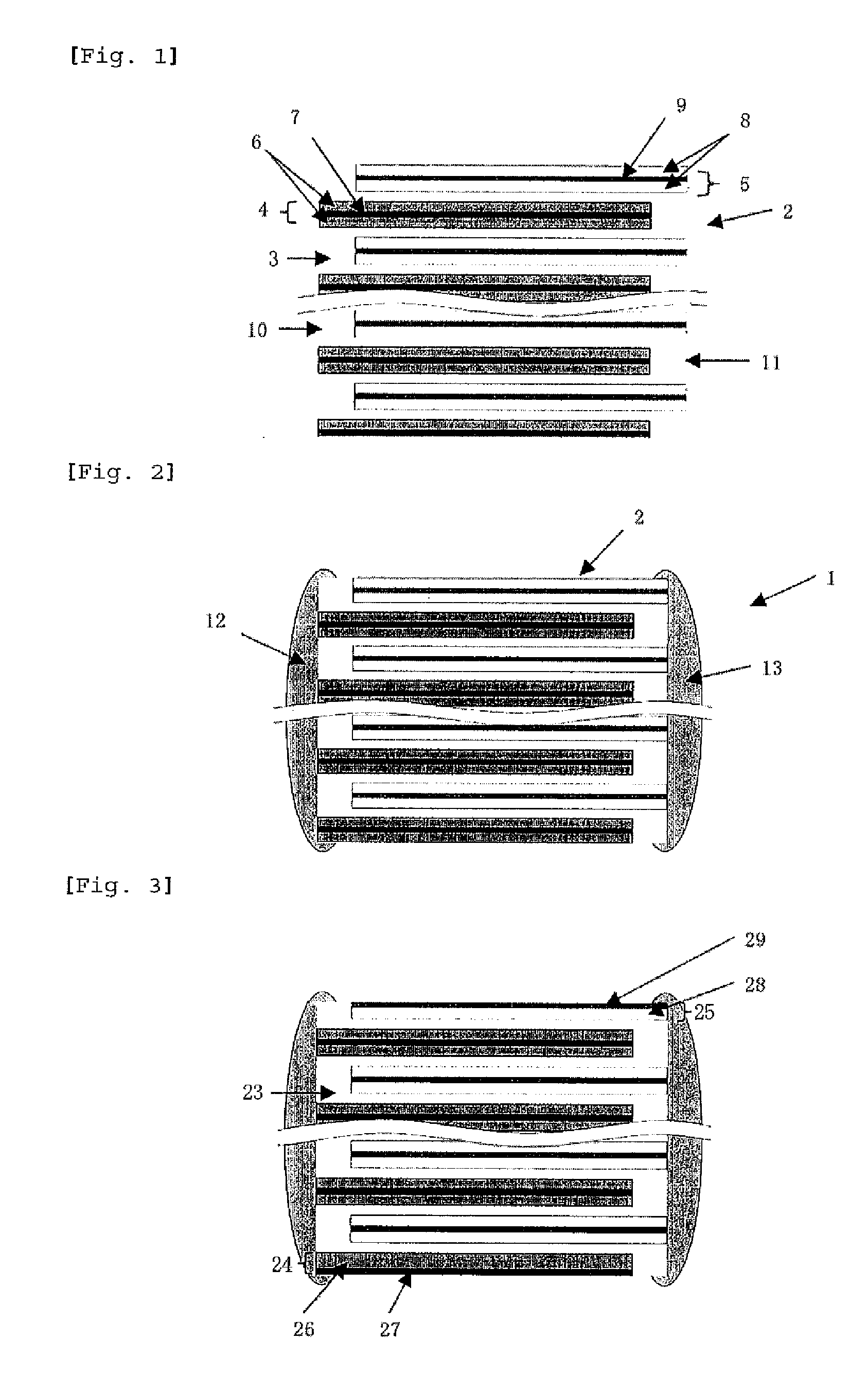

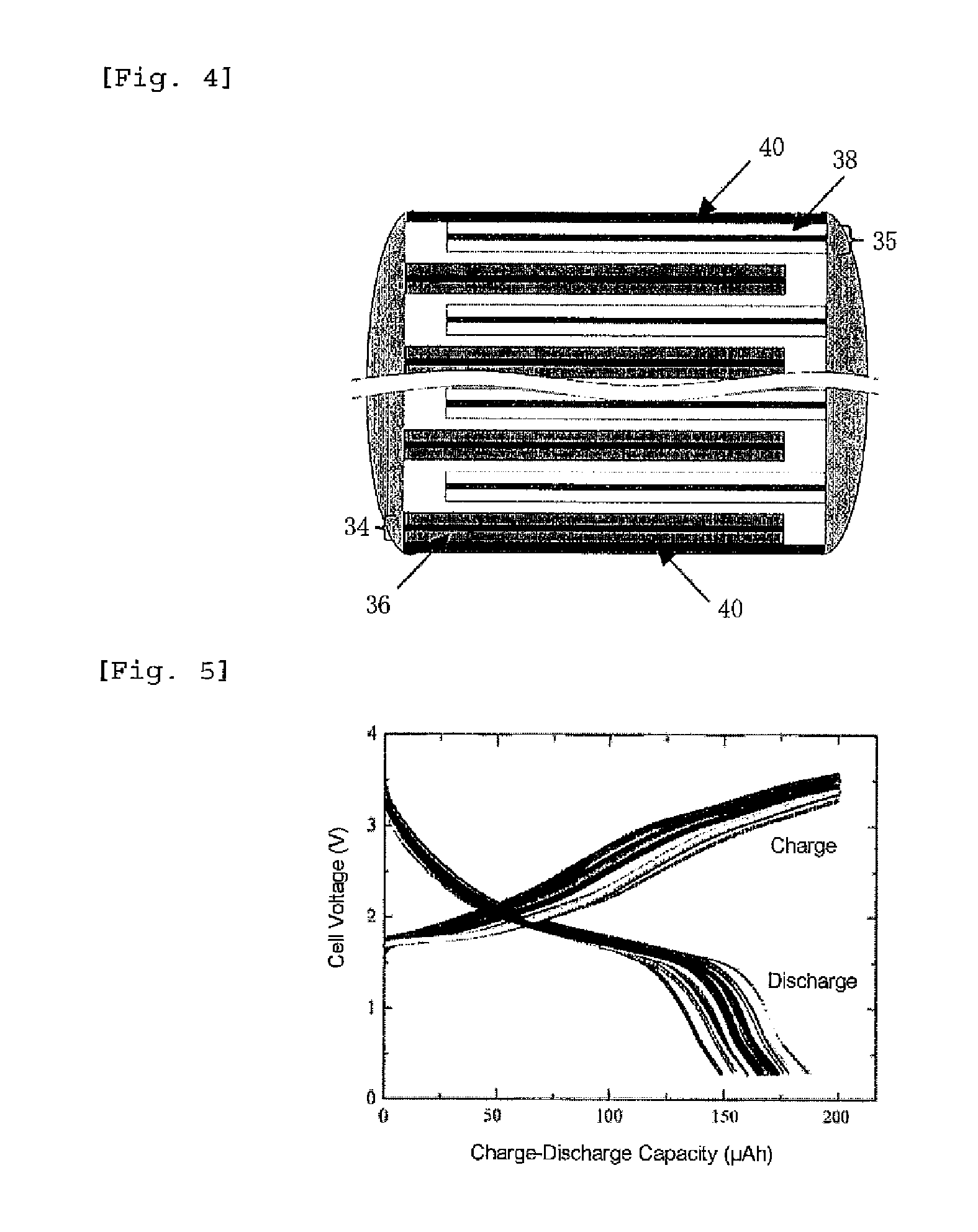

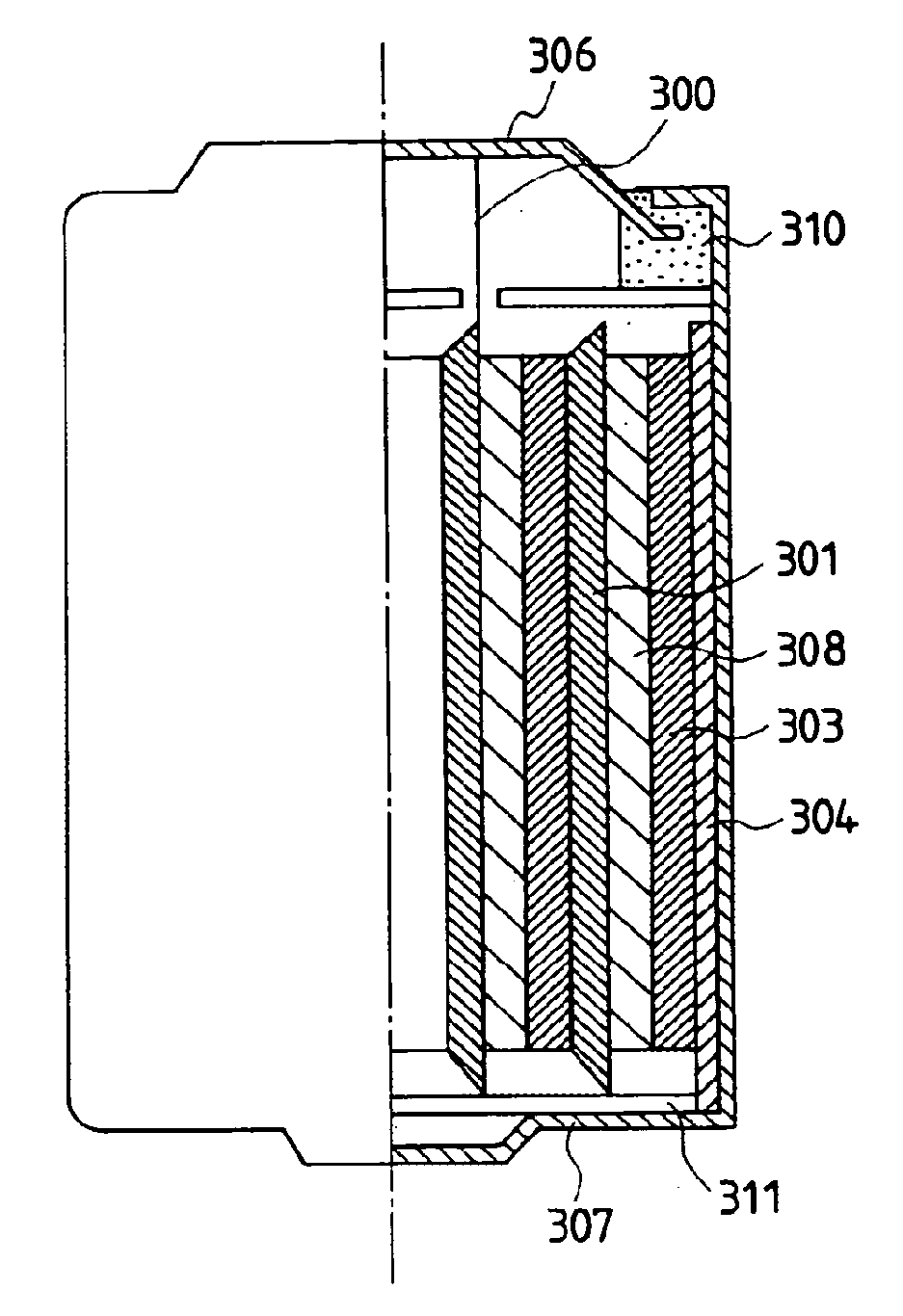

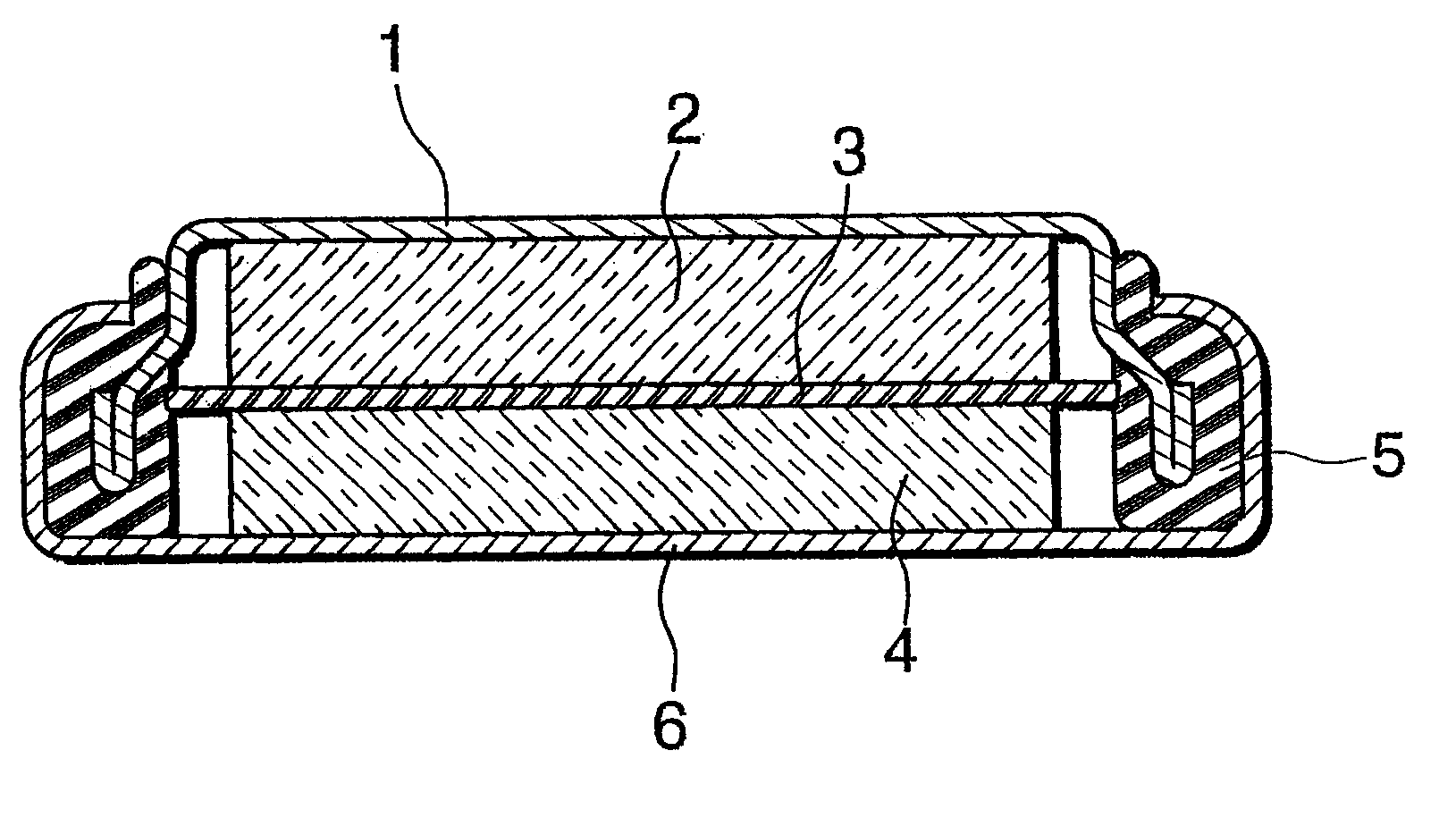

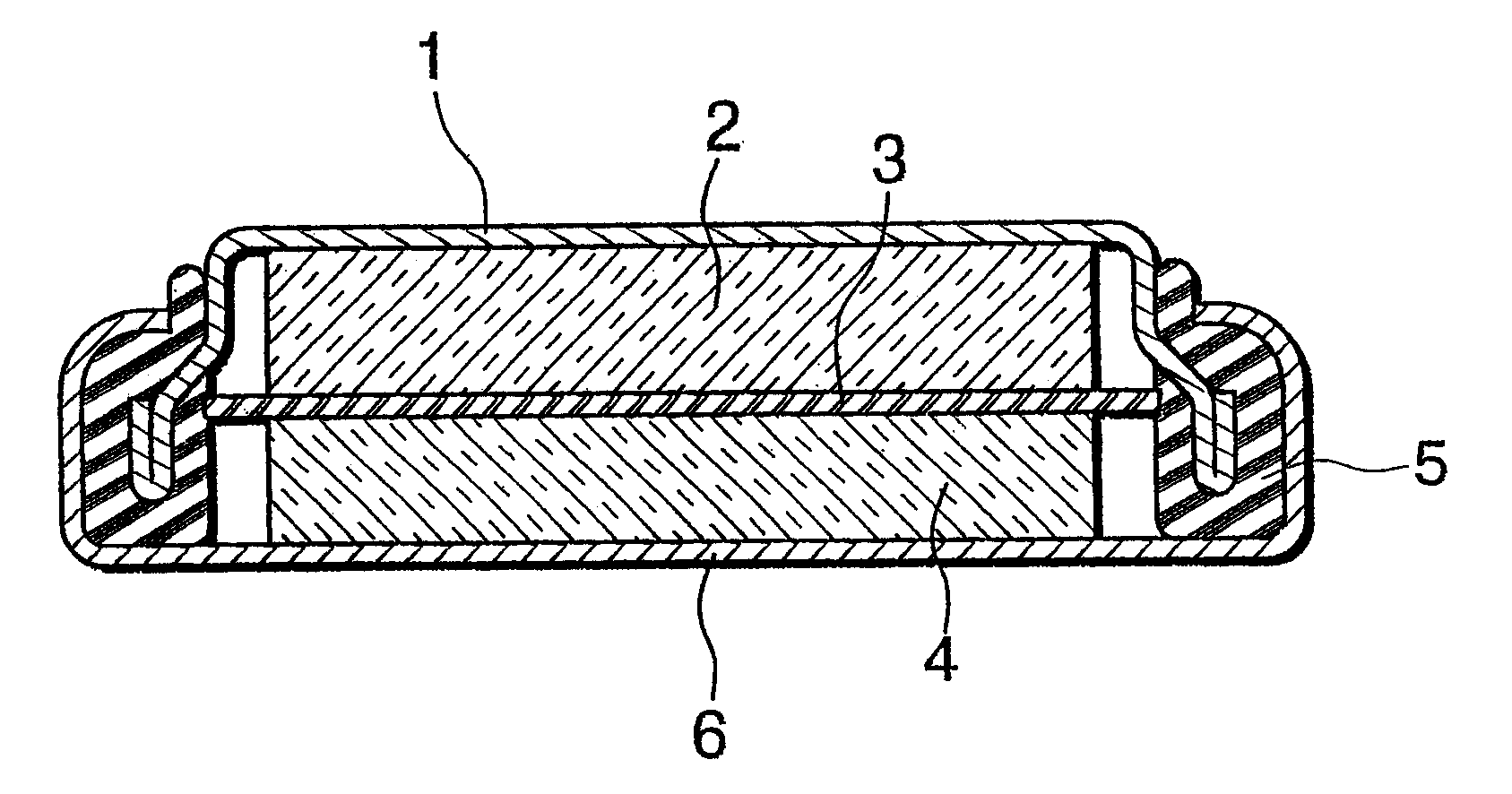

All solid state secondary battery

ActiveUS20090202912A1Keep for a long timeSuperior in pointElectrode thermal treatmentFinal product manufactureAll solid stateEngineering

This is to provide an all solid state secondary battery which can be produced by an industrially employable method capable of mass-production and has excellent secondary battery characteristics.This is an all solid state secondary battery containing a laminated material in which a positive-electrode unit and a negative-electrode unit are laminated alternately through an ion conductive inorganic-material layer, the positive-electrode unit has positive active material layers on both surfaces of a positive-electrode collector layer, the above-mentioned negative-electrode unit has negative active material layers on both surfaces of a negative-electrode collector layer, (A) at least one of the positive-electrode collector layer and the negative-electrode collector layer comprises a metal of either of Ag, Pd, Au and Pt, or an alloy containing either of Ag, Pd, Au and Pt, or a mixture containing two or more kinds selected from the metals and alloys, (B) each layer is in a sintered state, or (C) at least the starting material for the ion conductive inorganic material of the ion conductive inorganic-material layer is a calcined powder.

Owner:NAMICS CORPORATION

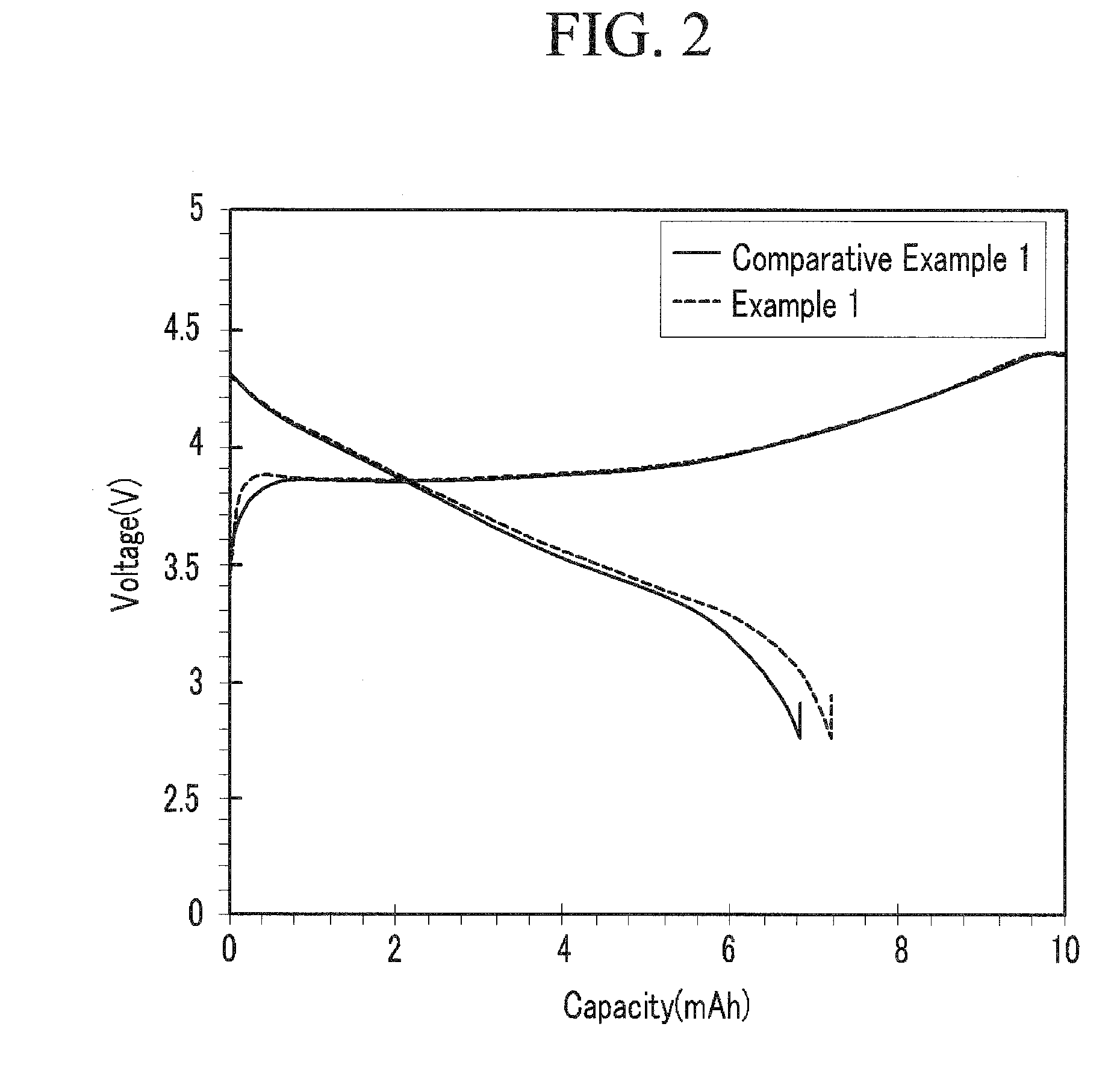

Negative electrode for rechargeable lithium battery, and rechargeable lithium battery including the same

ActiveUS20090136845A1Improved initial formation efficiency and cycle-life characteristicImproved cycle life characteristicsNon-fibrous pulp additionElectrode thermal treatmentCross-linkEngineering

A negative electrode for a rechargeable lithium battery and a rechargeable lithium battery including the same are provided. The negative electrode for a rechargeable lithium battery includes a current collector, and a negative active material layer on the current collector. The negative active material layer includes an interpenetrating network network, and a negative active material in the interpenetrating network network. The interpenetrating network is formed by cross-linking a first polymer having a hydroxyl or amine group and a second polymer having a carboxylic acid group. The negative electrode for a rechargeable lithium battery minimizes volume expansion and imparts good cycle-life characteristics and initial formation efficiency.

Owner:SAMSUNG SDI CO LTD

Method of making printed battery structures

A battery is made by drop on demand printing a first electrode pattern and a second electrode pattern, and applying an electrolyte region over a portion of the first electrode pattern and a portion of the second electrode pattern.

Owner:HEWLETT PACKARD DEV CO LP

Negative electrode for lithium secondary battery, method for manufacturing the same and lithium secondary battery

InactiveUS20050142447A1Avoid deformationFinal product manufactureNegative electrodesOptoelectronicsLithium-ion battery

A negative electrode for a lithium secondary battery capable of storing and releasing lithium reversibly includes a collector, and a negative electrode material layer arranged on the collector. The negative electrode material layer contains a thin-film negative electrode material capable of storing and releasing lithium reversibly, and lithium non-storing portions containing a lithium non-storing material are arranged on at least one selected from the group consisting of a surface and an inside of the negative electrode material layer. In this way, a negative electrode for a lithium secondary battery capable of suppressing the deformation accompanying charging and discharging is provided.

Owner:PANASONIC CORP

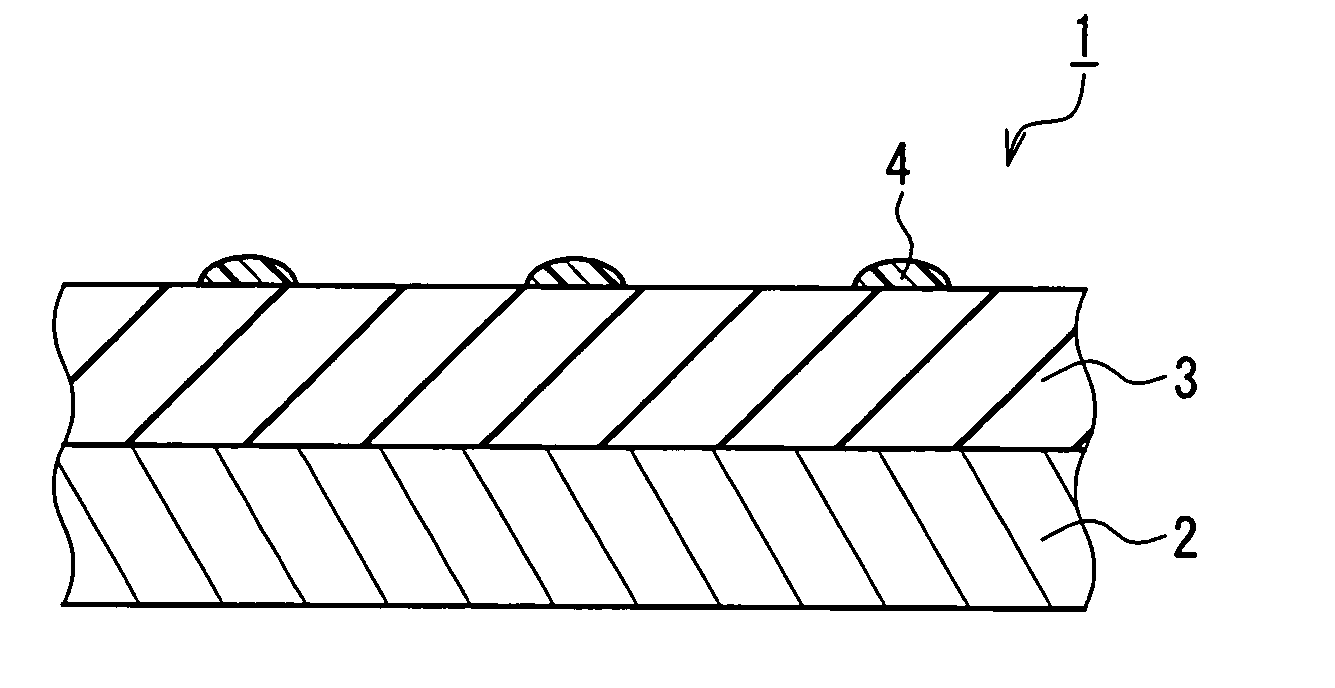

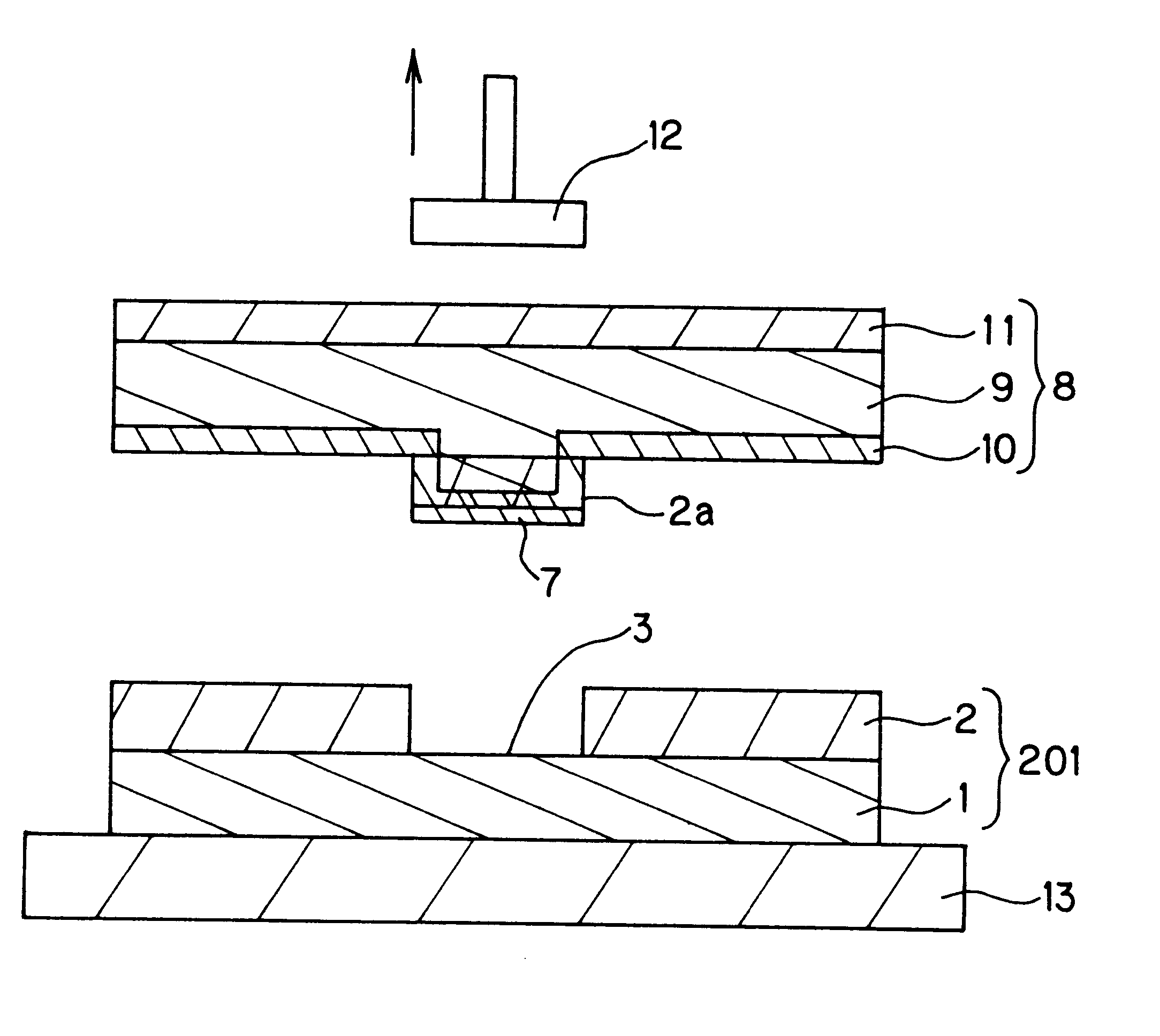

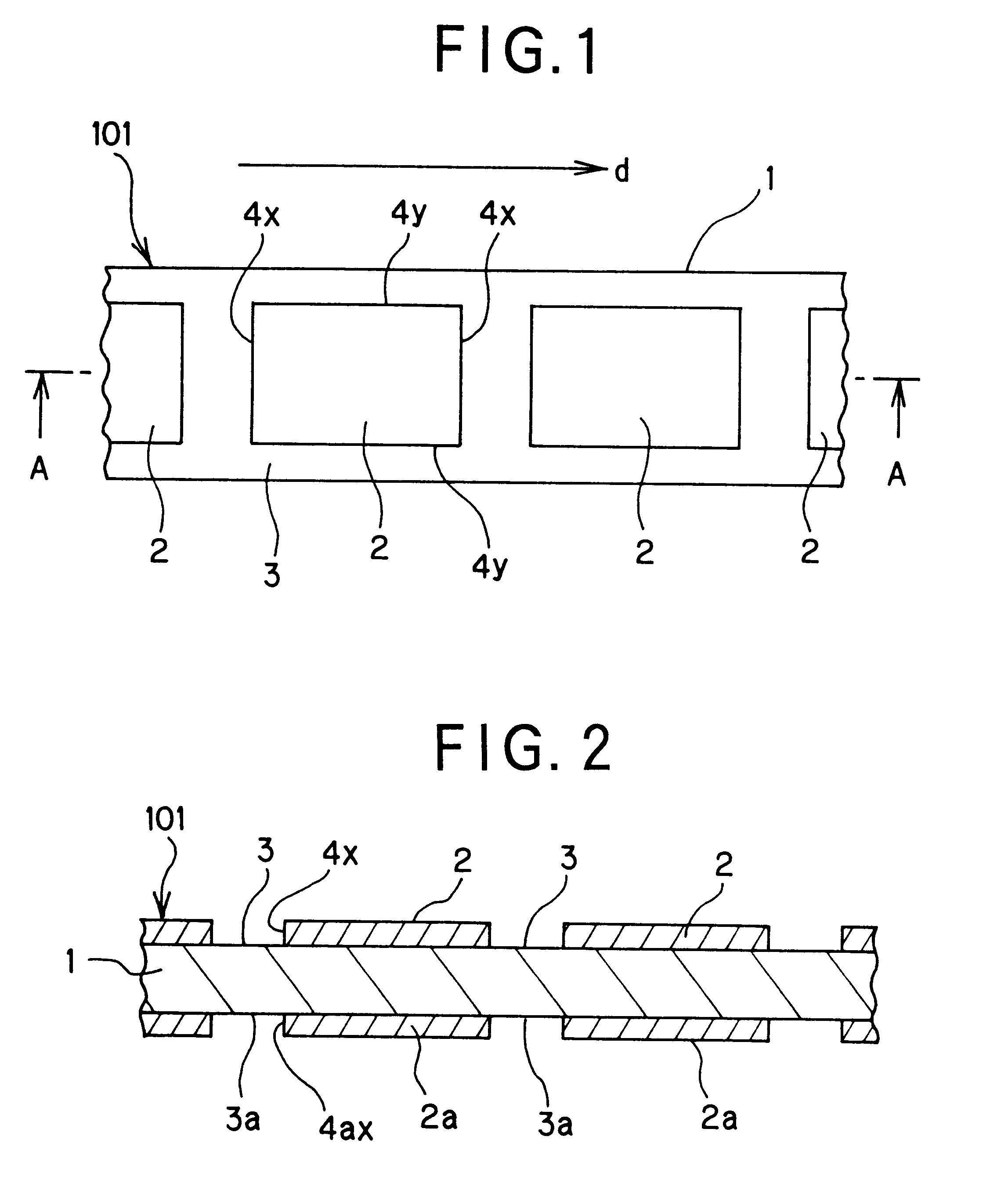

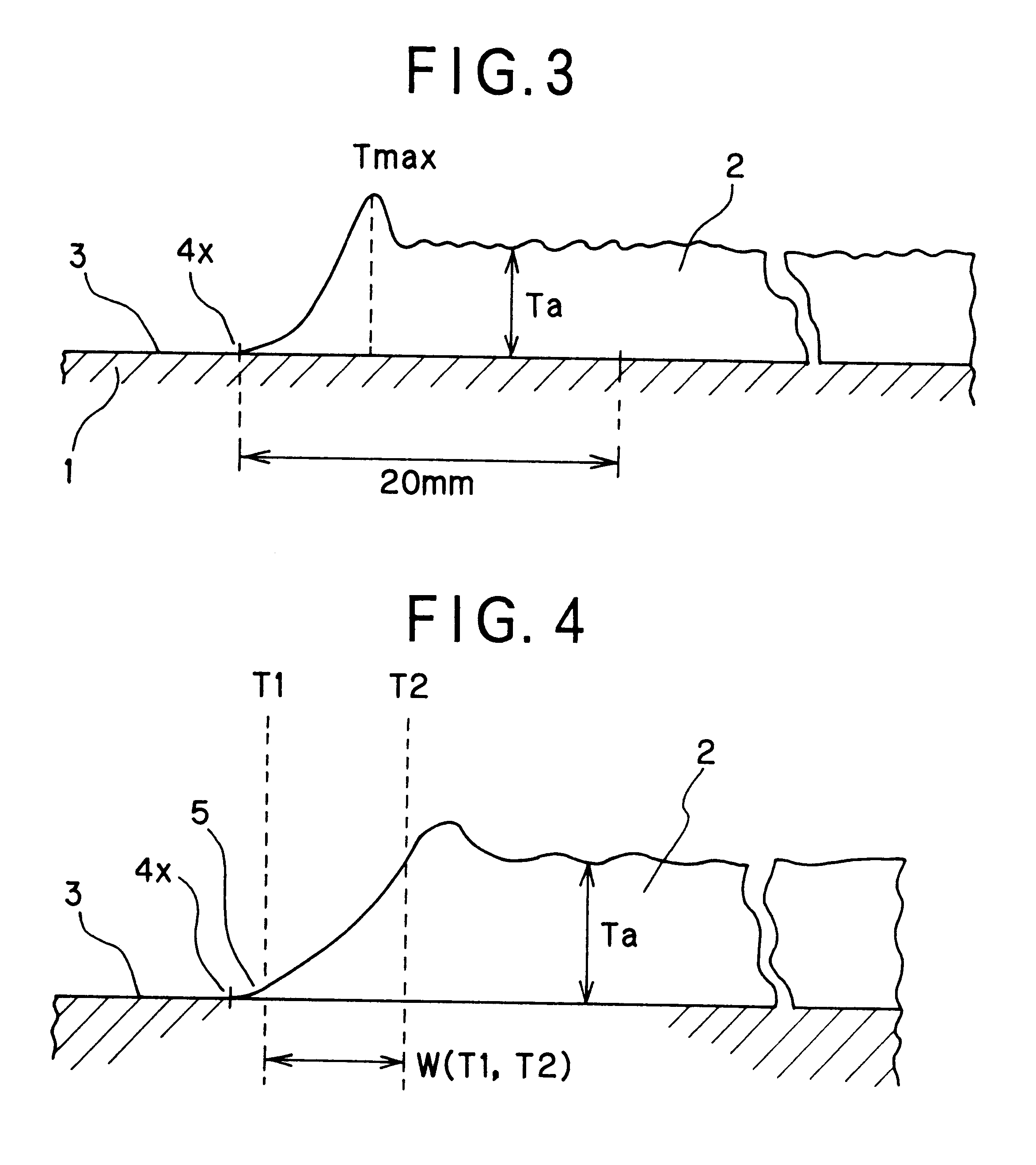

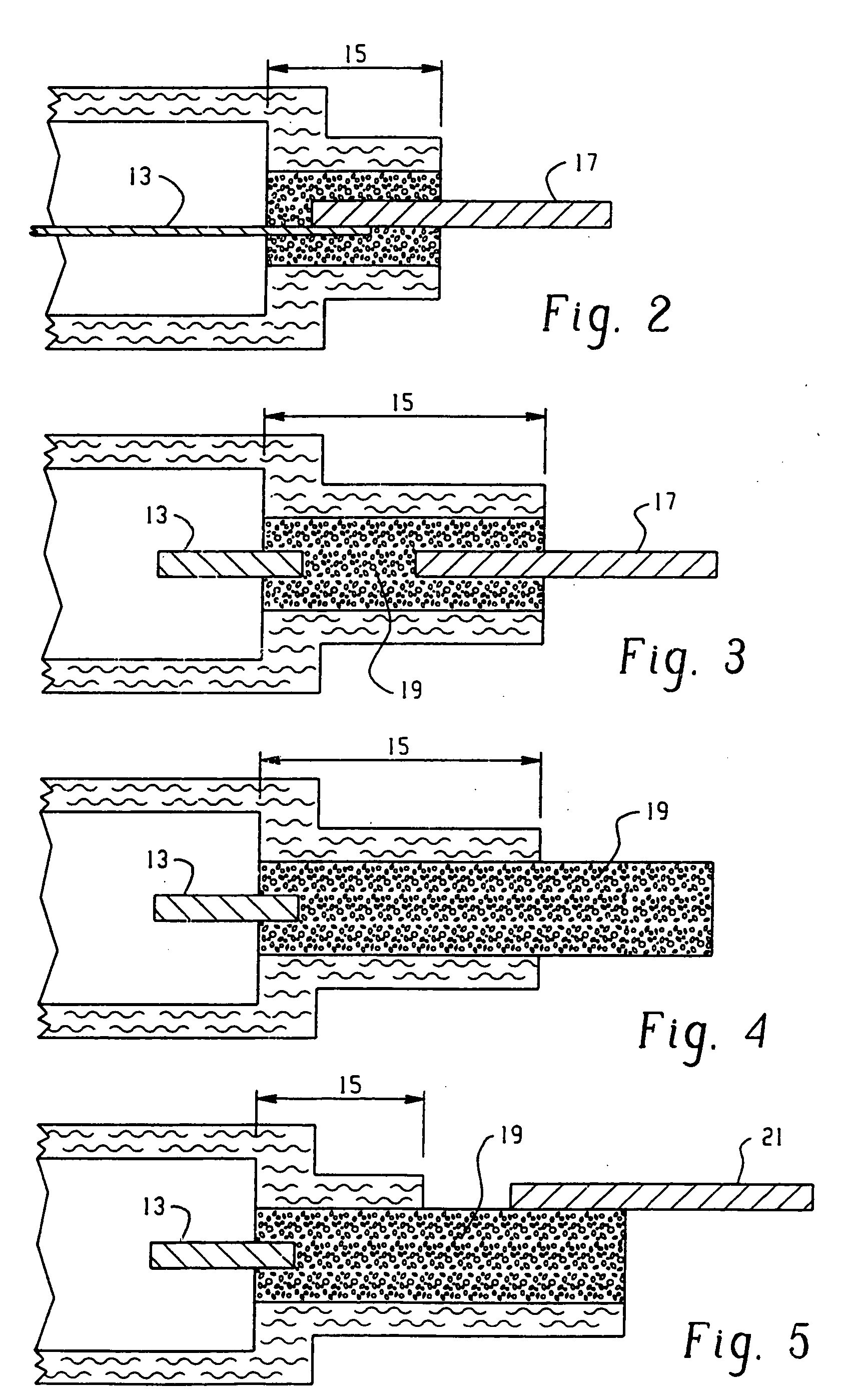

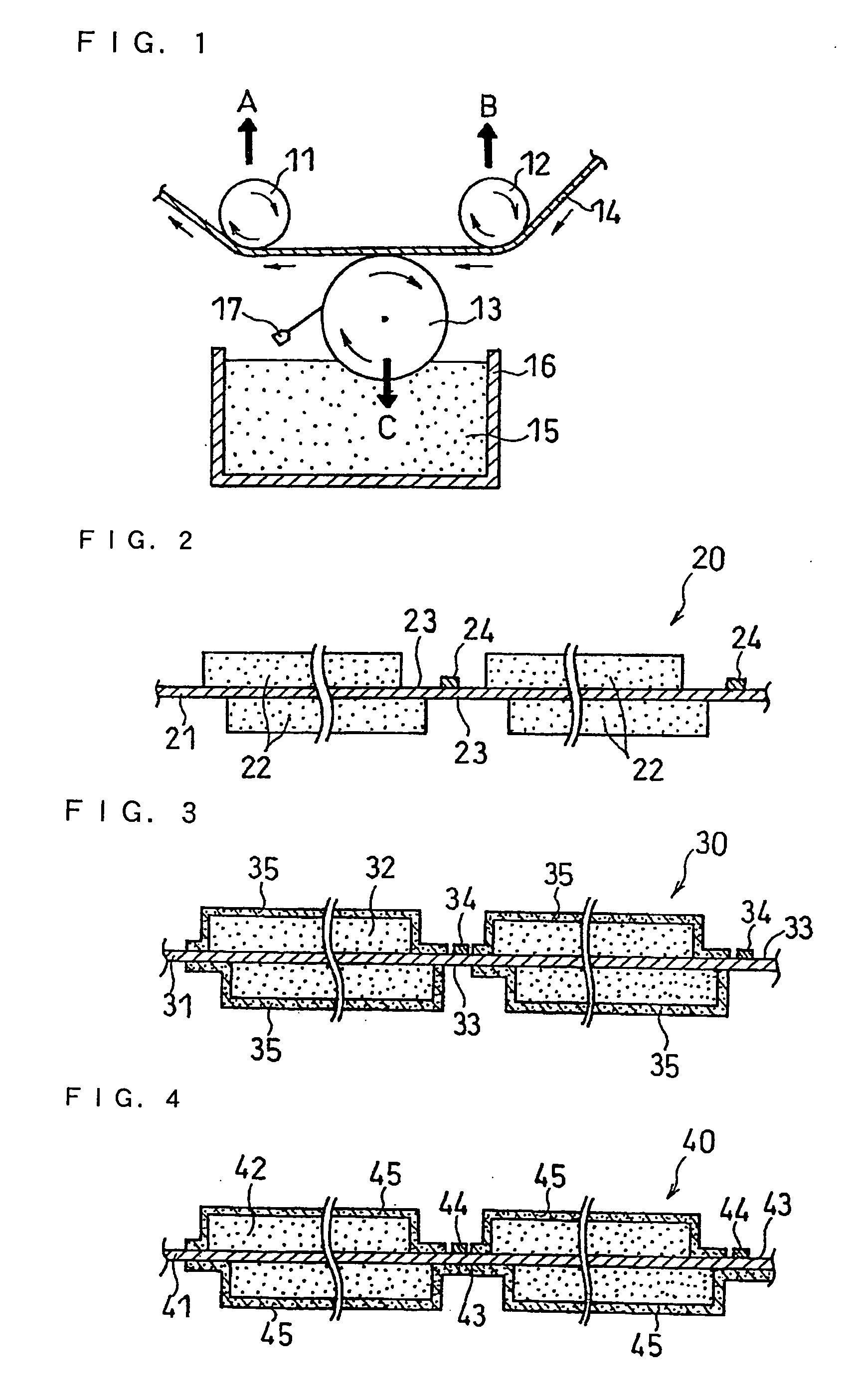

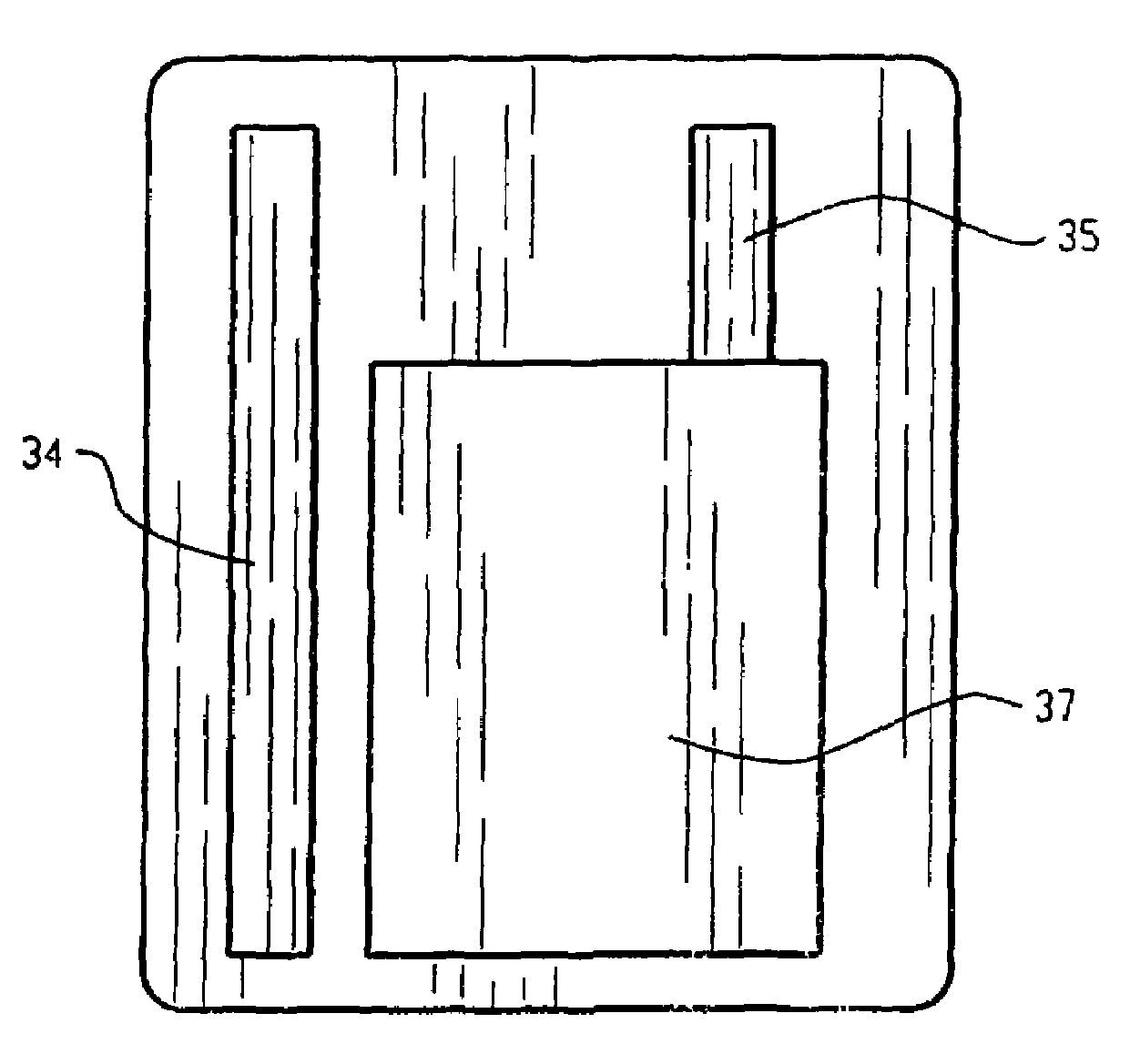

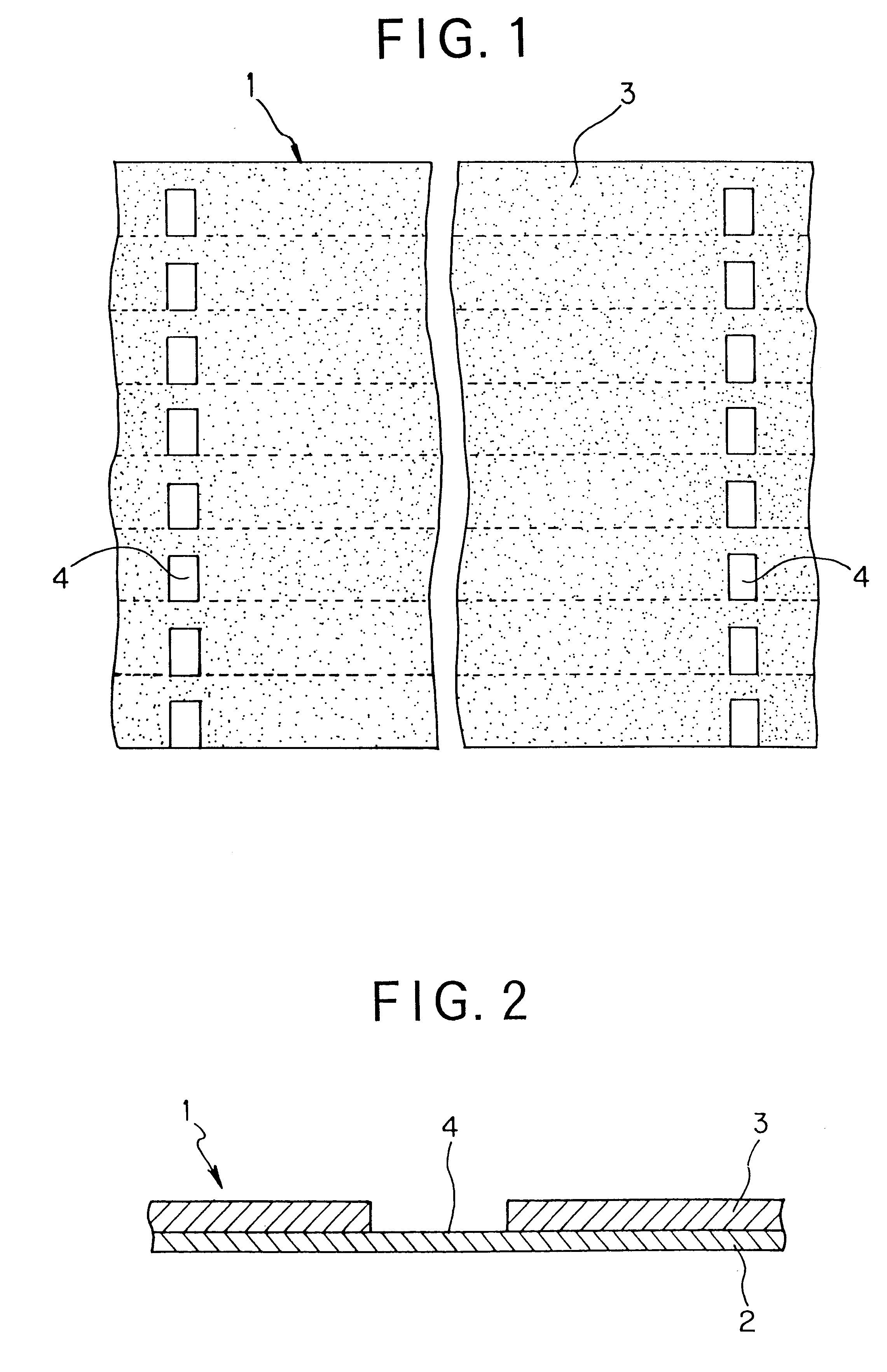

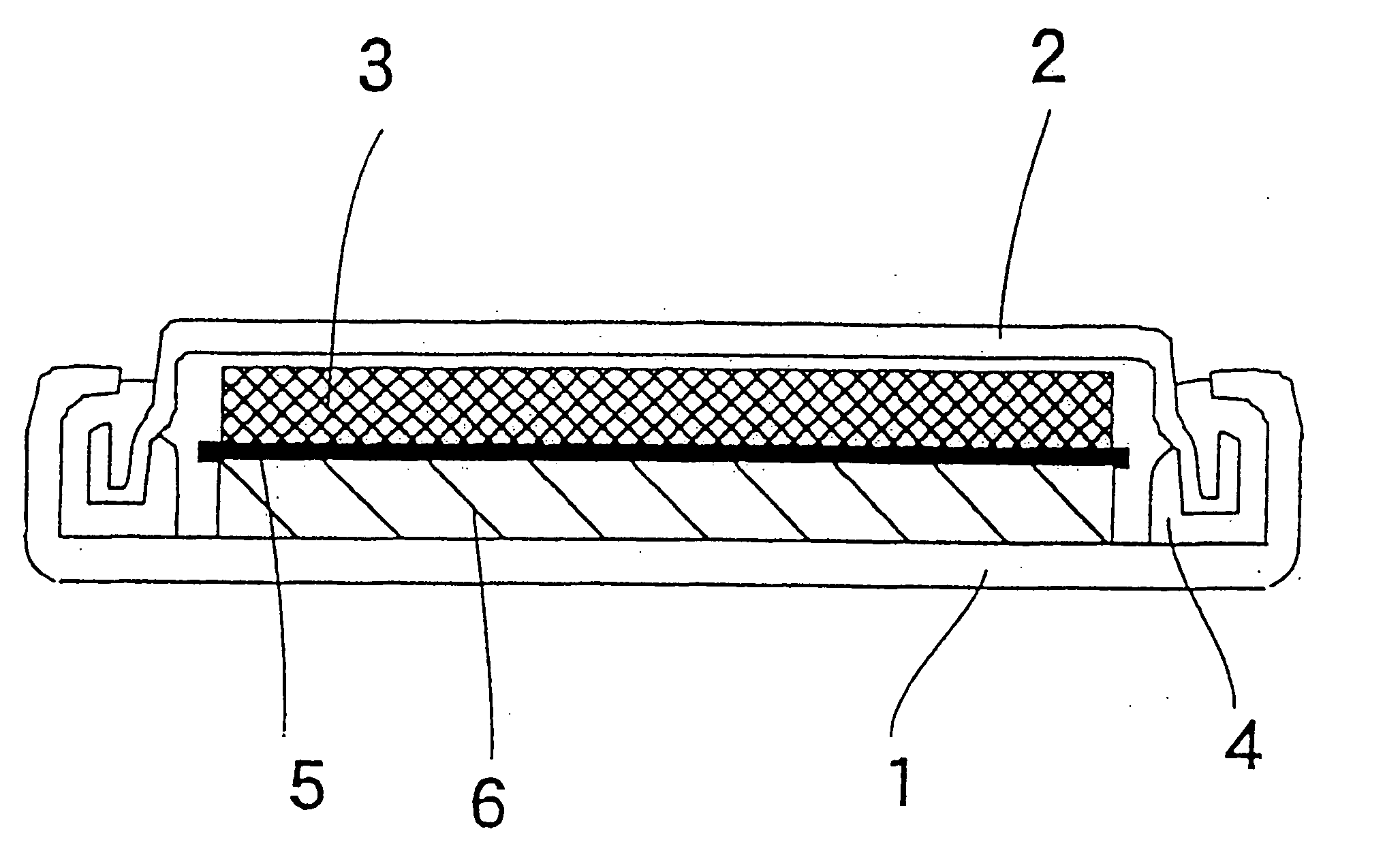

Electrode plate for secondary battery with nonaqueous electrolyte and process for producing same

InactiveUS6423446B1High dimensionalHigh thickness accuracyElectrode rolling/calenderingElectrode melt handlingEngineeringElectrolyte

The present invention provides an electrode plate having a collector 1, an active material layer 2 and a non-coated portion 3 and satisfies at least one of the following conditions. (1) The maximum thickness in an area inside by 20 mm from an edge portion of the active material layer is not more than the sum of an average thickness of the active material layer and 10 mum. (2) In an inclined portion of the peripheral edge portion of the active material layer, an area in which the thickness of the active material layer is not less than 1 mum and less than an average thickness of the active material layer has a width of not more than 1 mm. (3) An absolute value of a positional shifting of an actually formed pattern with respect to a true boundary line of a predetermined pattern is not more than 1 mm. (4) The active material layers are formed in a plane symmetry to front and back surfaces of the collector, and an absolute value in the positional shifting between the patterns formed on front and back side surfaces of the collector is not more than 1 mm.

Owner:DAI NIPPON PRINTING CO LTD

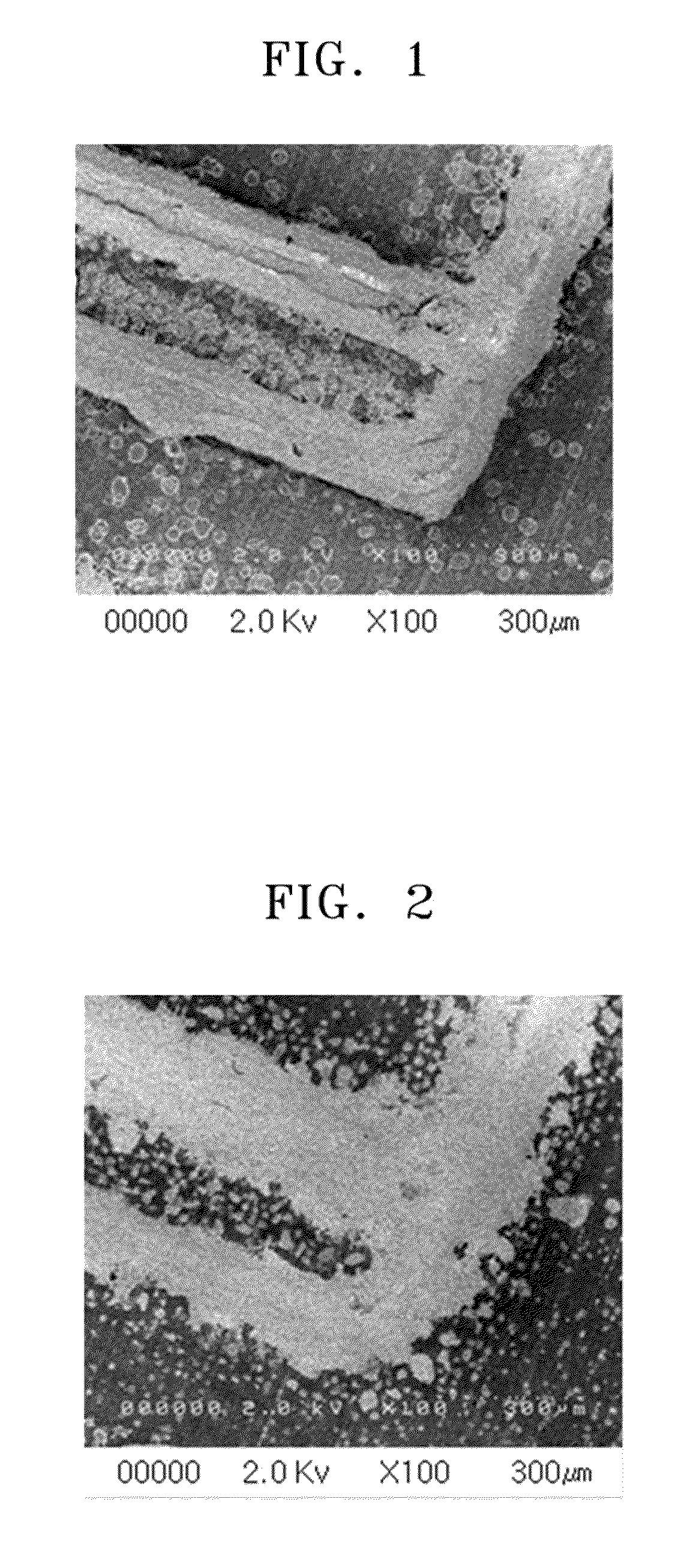

Electrode for lithium ion secondary batteries, lithium ion secondary battery using the same, and method for manufacturing the battery

ActiveUS7759004B2Increase capacityExcellent characteristicsHybrid capacitor electrodesFinal product manufactureLithiumMaterials science

Disclosed is an electrode for lithium ion secondary batteries which includes an active material layer containing active material particles and a porous insulating layer formed on the surface of the active material layer. The porous insulating layer includes an inorganic filler and a resin binder, and the surface of the active material layer has a first region on which the porous insulating layer is formed, and a second region on which the porous insulating layer is not formed. By using such an electrode, a lithium ion secondary battery can have a high capacity, excellent characteristics and improved safety.

Owner:PANASONIC CORP

Flexible thin printed battery and device and method of manufacturing same

InactiveUS20060115717A1Sufficiently conductiveEliminate needFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

A flat, flexible electrochemical cell is provided. The within invention describes various aspects of the flat, flexible electrochemical cell. A printed anode is provided that obviates the need for a discrete anode current collector, thereby reducing the size of the battery. An advantageous electrolyte is provided that enables the use of a metallic cathode current collector, thereby improving the performance of the battery. Printable gelled electrolytes and separators are provided, enabling the construction of both co-facial and co-planar batteries. Cell contacts are provided that reduce the potential for electrolyte creepage in the flat, flexible electrochemical cells of the within invention.

Owner:ENERGIZER BRANDS

Electrode composition for inkjet printing, and electrode and secondary battery prepared using the electrode composition

InactiveUS20110111292A1Improve cycle lifeConductive materialActive material electrodesSolventSpreadability

An electrode composition for inkjet printing includes an electrode active material, a binder resin, and a solvent. An electrode and a secondary battery prepared by using the electrode use the printed electrode composition. A precise electrode pattern is formed by using an inkjet printing method since spreadability of the electrode composition is excellent. The secondary battery is a micro-thin type having increased electrode capacity and increased cycle lifespan which is prepared since coherence between the electrode composition and a current collector is excellent.

Owner:SAMSUNG ELECTRONICS CO LTD

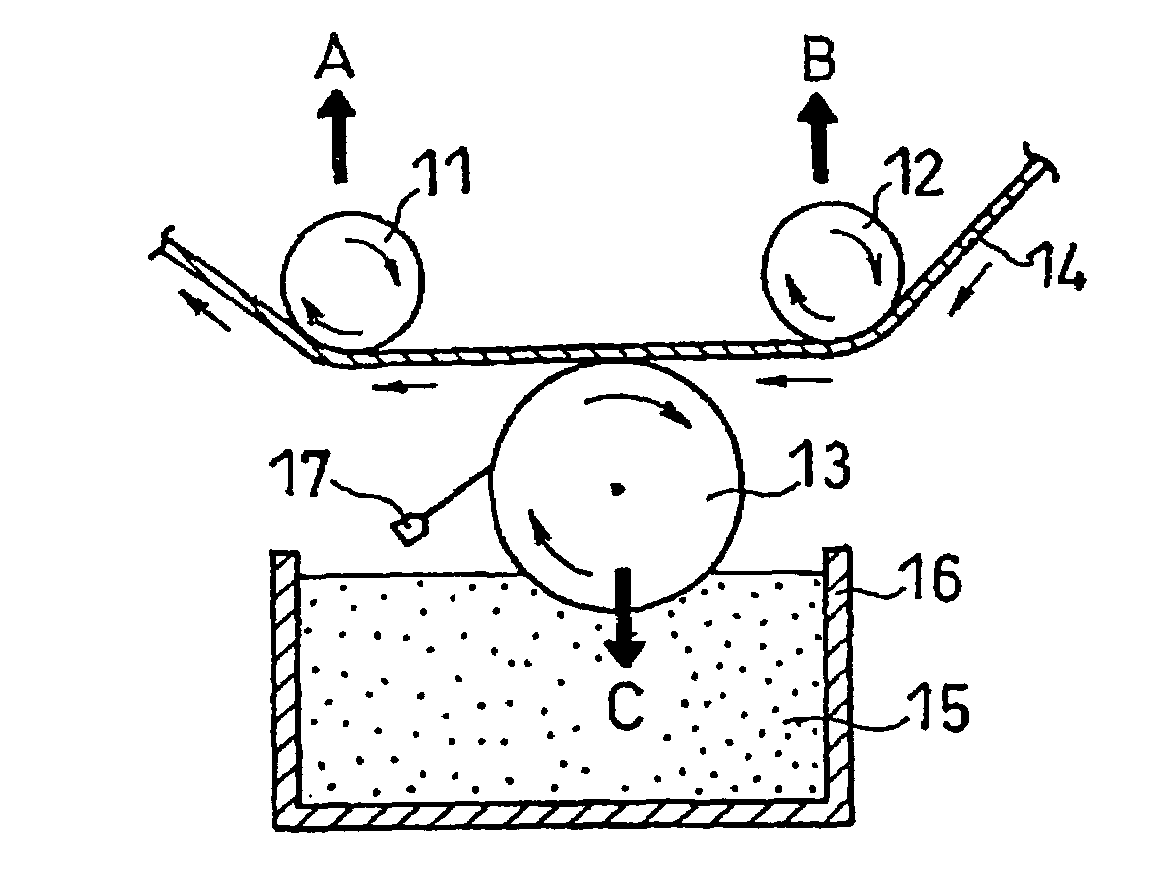

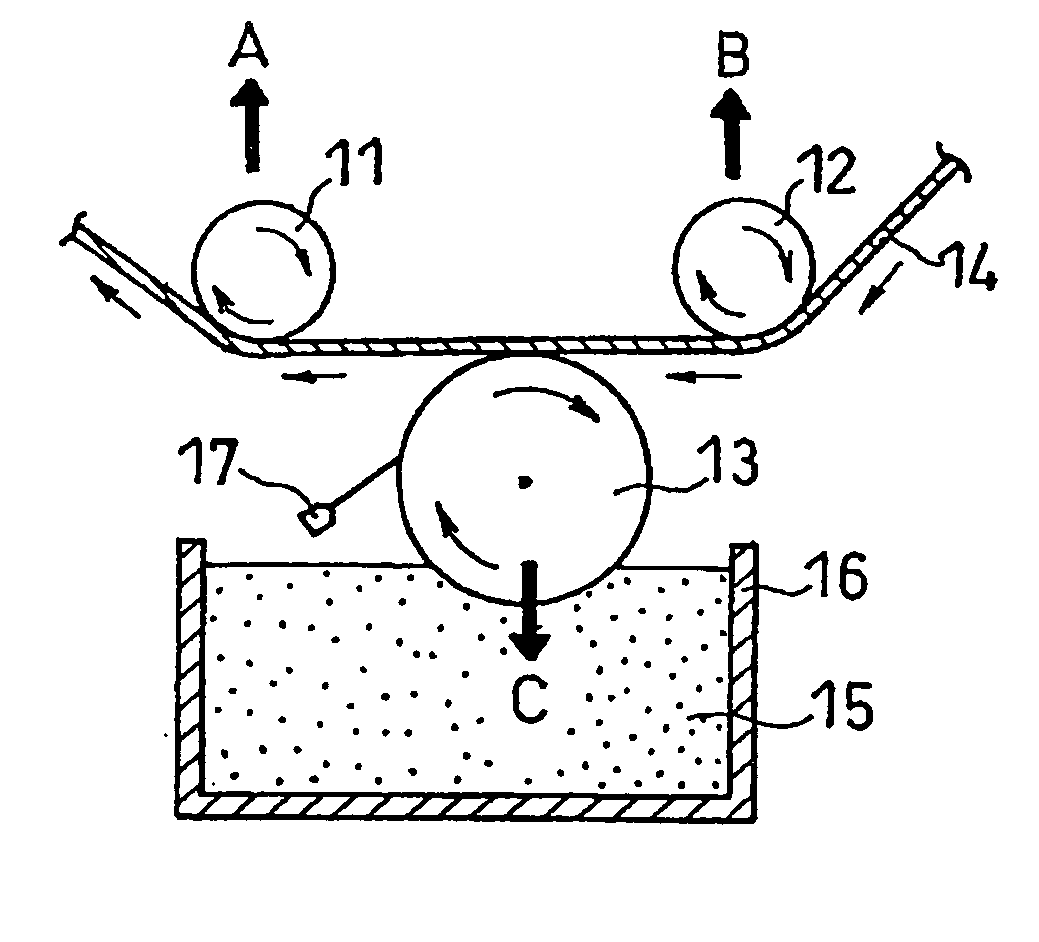

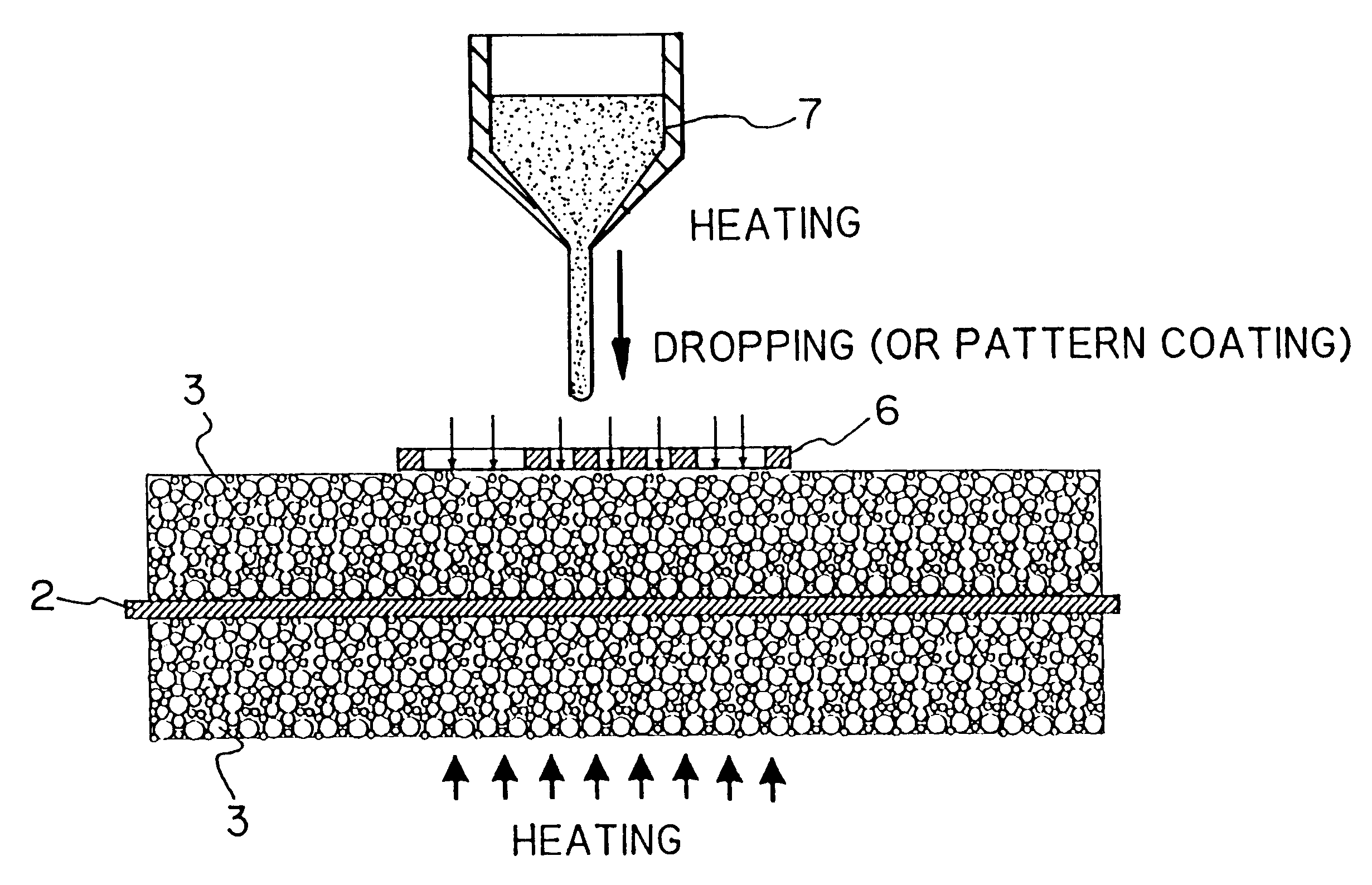

Method for producing lithium ion secondary battery

ActiveUS7575606B2Uniform thicknessExcellent cycle characteristicsLiquid surface applicatorsFinal product manufactureLithiumSlurry

A method for producing lithium ion secondary batteries includes the steps of: (A) preparing an electrode sheet with lead-forming parts, (B) intermittently forming porous insulating layers containing an inorganic oxide filler and a binder on a surface of the electrode sheet excluding the lead-forming parts, (C) connecting a lead to each of the lead-forming parts, and (D) fabricating batteries by using the electrode sheet to which the leads are connected. The step B includes: the step of applying a slurry containing the inorganic oxide filler and the binder to the outer surface of a gravure roll, and transferring the slurry applied to the outer surface of the gravure roll on a surface of the electrode sheet that is being transported by a plurality of guide rolls excluding the lead-forming part; and the step of moving at least one selected from the gravure roll and the guide rolls to make the electrode sheet away from the gravure roll in the lead-forming part.

Owner:PANASONIC CORP

Method for producing a lithium secondary battery

InactiveUS20070180688A1Improve cycle lifeAvoid it happening againElectrode rolling/calenderingElectrochemical processing of electrodesPhysical chemistryEngineering

A secondary battery exhibiting a long cycle life and comprising a negative pole activating material made of lithium or zinc is provided. The battery at least having a negative pole made of lithium or zinc serving as the negative pole activating material, an electrolyte (electrolytic solution), a separator, a positive pole made of a positive pole activating material, a collecting electrode and a battery case, wherein at least the surface of the negative pole is covered with a film having a structure which allows ions relating to the battery reactions to pass through. Since growth of dendrites of lithium or zinc at the time of charge can be prevented, short circuiting between the negative pole and the positive pole can be prevented. Therefore, the charge / discharge cycle life can significantly be lengthened. As a result, a lithium secondary battery, a nickel-zinc secondary battery, an air-zinc secondary battery, a bromine-zinc secondary battery and a silver oxide-zinc secondary battery of long cycle life can be manufactured.

Owner:CANON KK

Method for producing lithium ion secondary battery

ActiveUS20060248710A1Uniform thicknessExcellent cycle characteristicsLiquid surface applicatorsFinal product manufactureLithiumSlurry

A method for producing lithium ion secondary batteries includes the steps of: (A) preparing an electrode sheet with lead-forming parts, (B) intermittently forming porous insulating layers containing an inorganic oxide filler and a binder on a surface of the electrode sheet excluding the lead-forming parts, (C) connecting a lead to each of the lead-forming parts, and (D) fabricating batteries by using the electrode sheet to which the leads are connected. The step B includes: the step of applying a slurry containing the inorganic oxide filler and the binder to the outer surface of a gravure roll, and transferring the slurry applied to the outer surface of the gravure roll on a surface of the electrode sheet that is being transported by a plurality of guide rolls excluding the lead-forming part; and the step of moving at least one selected from the gravure roll and the guide rolls to make the electrode sheet away from the gravure roll in the lead-forming part.

Owner:PANASONIC CORP

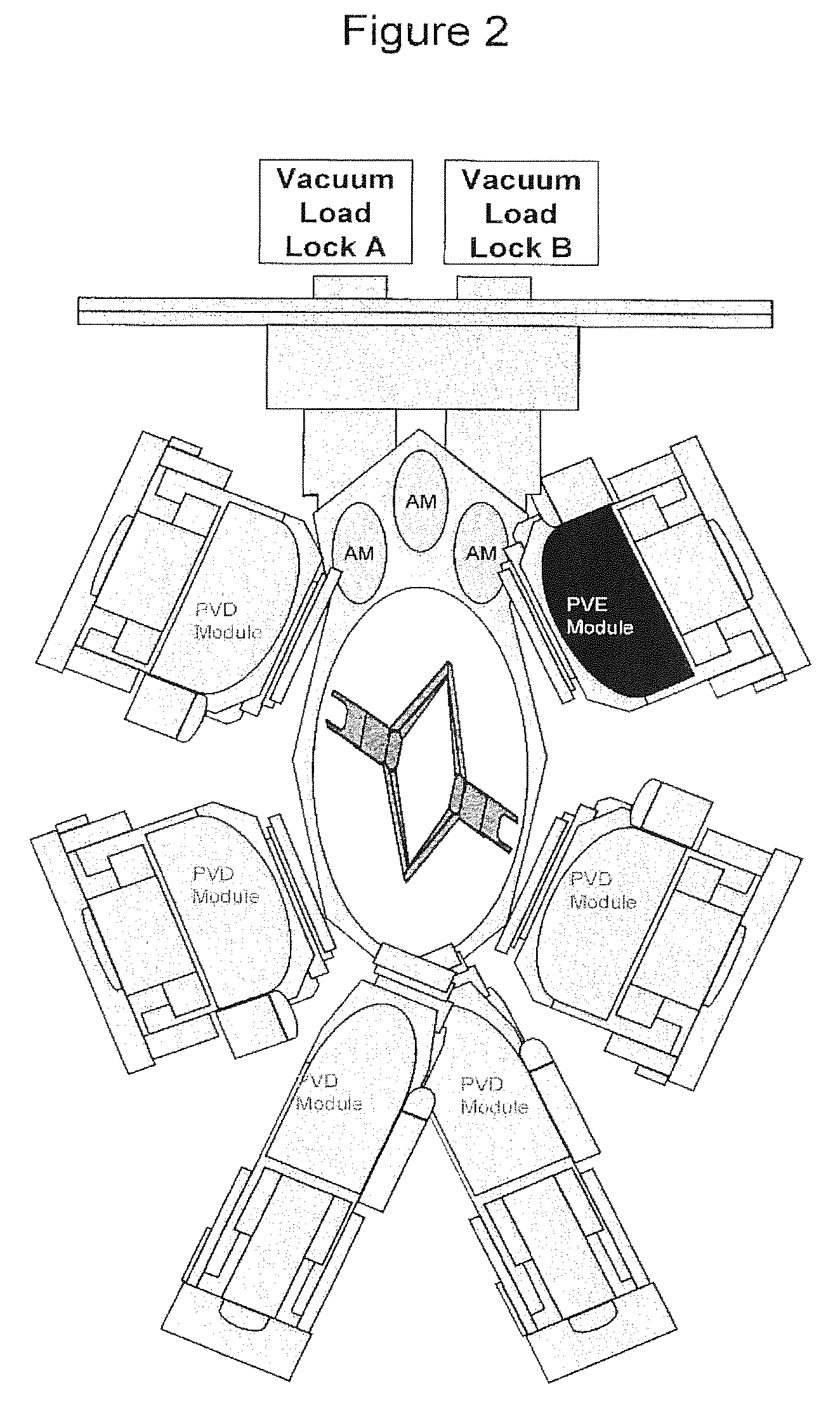

Reticulated and controlled porosity battery structures

InactiveUS20080213662A1Facilitating providing energyHigh porosityElectrode thermal treatmentFuel cell auxillariesEngineeringTortuosity

The effective ionic conductivity in a composite structure is believed to decrease rapidly with volume fraction. A system, such as a bipolar device or energy storage device, has structures or components in which the diffusion length or path that electrodes or ions must traverse is minimized and the interfacial area exposed to the ions or electrons is maximized. The device includes components that can be reticulated or has a reticulated interface so that an interface area can be increased. The increased interfacial perimeter increases the available sites for reaction of ionic species. Many different reticulation patterns can be used. The aspect ratio of the reticulated features can be varied. Such bipolar devices can be fabricated by a variety of methods or procedures. A bipolar device having structures of reticulated interface can be tailored for the purposes of controlling and optimizing charge and discharge kinetics. A bipolar device having graded porosity structures can have improved transport properties because the diffusion controlling reaction kinetics can be modified. Graded porosity electrodes can be linearly or nonlinearly graded. A bipolar device having perforated structures also provides improved transport properties by removing tortuosity and reducing diffusion distance.

Owner:MASSACHUSETTS INST OF TECH

Electrode plate for secondary battery with nonaqueous electrolyte

InactiveUS6051338AElectrode rolling/calenderingElectrode melt handlingEngineeringElectrical and Electronics engineering

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and said electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

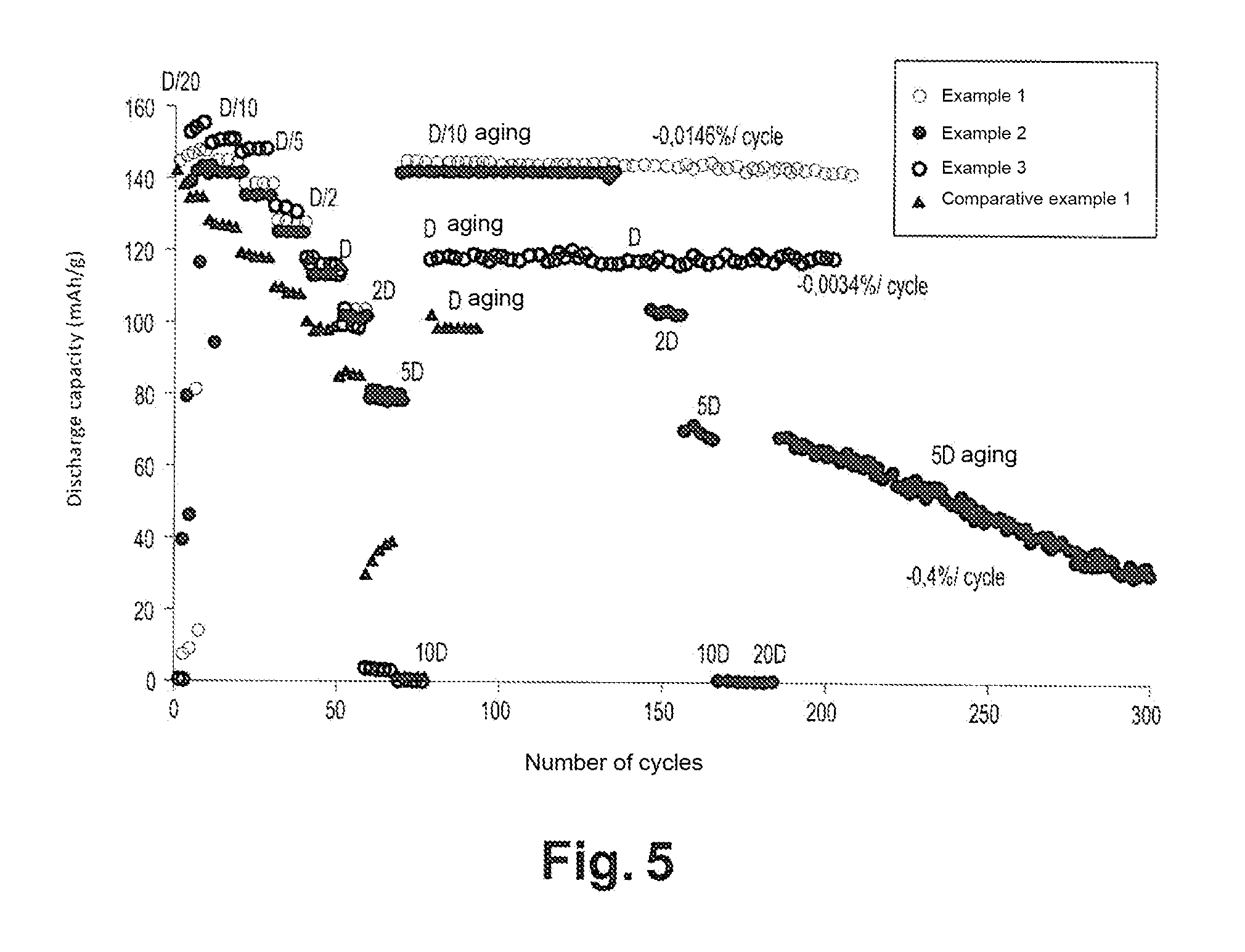

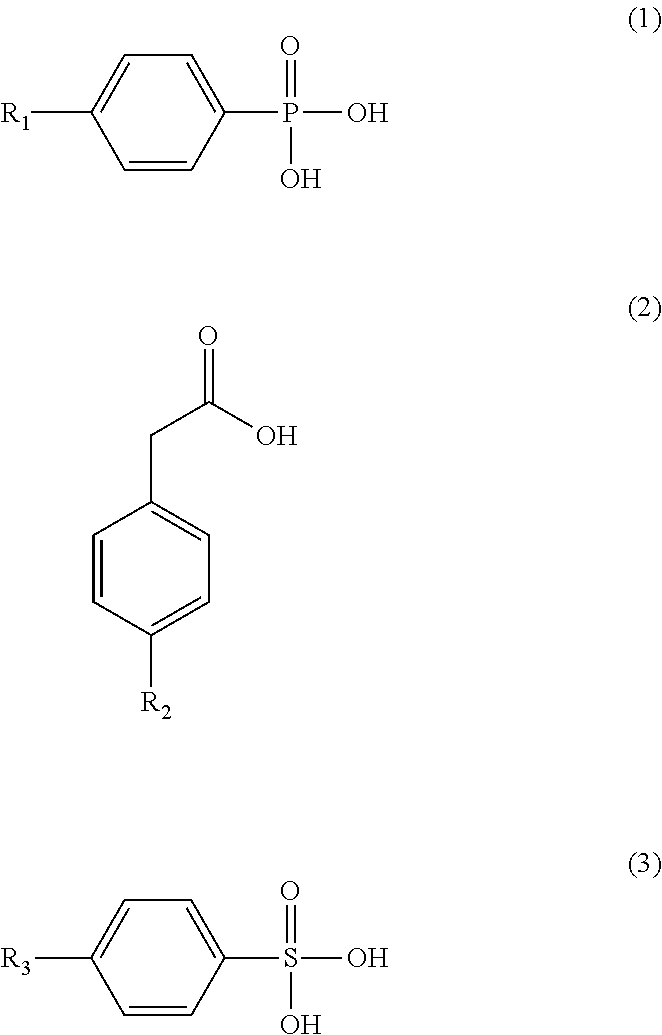

Aqueous ink for the printing of electrodes for lithium batteries

InactiveUS20130157105A1Increase surface tensionImprove different transferElectrode rolling/calenderingFinal product manufactureConductive polymerWater soluble

It comprises at least one active electrode material and at least one water-soluble or water-dispersible conductive polymer, advantageously PEDOT / PSS.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Flexible thin printed battery and device and method of manufacturing same

InactiveUS7625664B2Eliminate needFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

A flat, flexible electrochemical cell is provided. The within invention describes various aspects of the flat, flexible electrochemical cell. A printed anode is provided that obviates the need for a discrete anode current collector, thereby reducing the size of the battery. An advantageous electrolyte is provided that enables the use of a metallic cathode current collector, thereby improving the performance of the battery. Printable gelled electrolytes and separators are provided, enabling the construction of both co-facial and co-planar batteries. Cell contacts are provided that reduce the potential for electrolyte creepage in the flat, flexible electrochemical cells of the within invention.

Owner:ENERGIZER BRANDS

Lithium ion battery and method for manufacturing of such battery

InactiveUS8956761B2Overcomes inherent cycle life and safety issueFinal product manufactureElectrode carriers/collectorsEngineeringLithium-ion battery

The present invention provides an electrochemical cell comprising an anodic current collector in contact with an anode. A cathodic current collector is in contact with a cathode. A solid electrolyte thin-film separates the anode and the cathode.

Owner:OERLIKON ADVANCED TECH

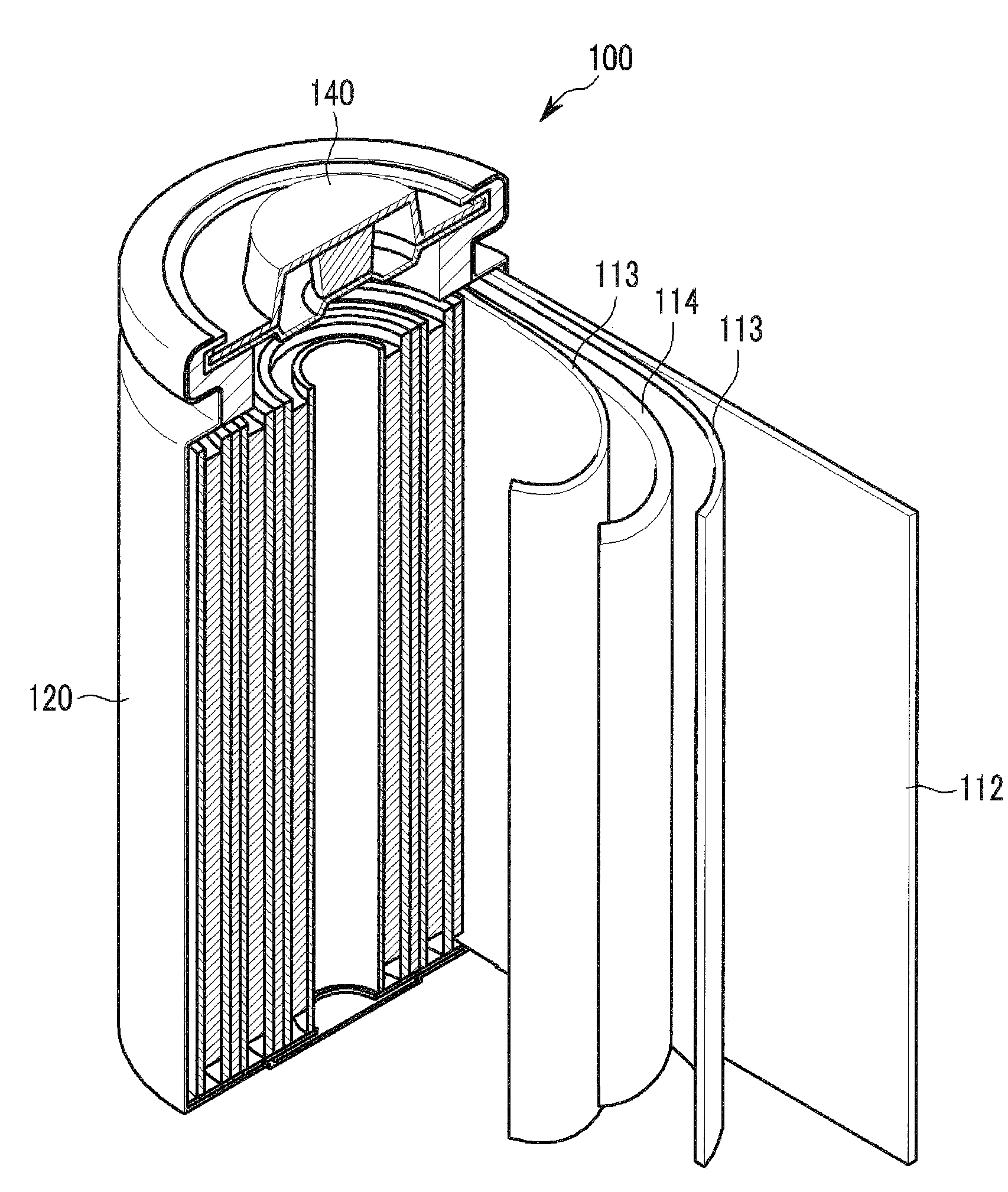

Secondary battery

ActiveUS20130011732A1Improve reliabilityImproving lifetimeMaterial nanotechnologyElectrode carriers/collectorsElectrical batteryElectrical and Electronics engineering

Owner:SAMSUNG SDI CO LTD

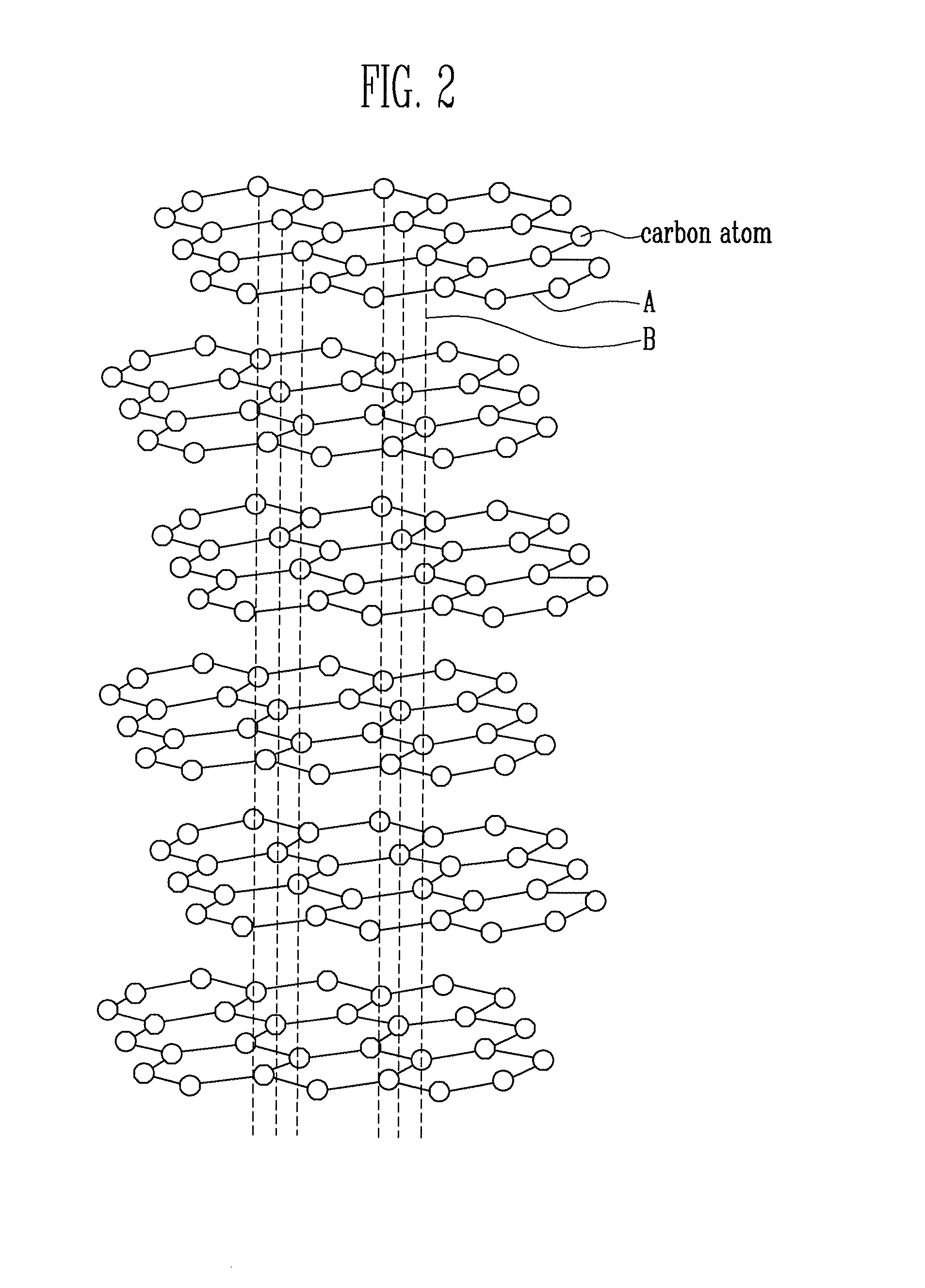

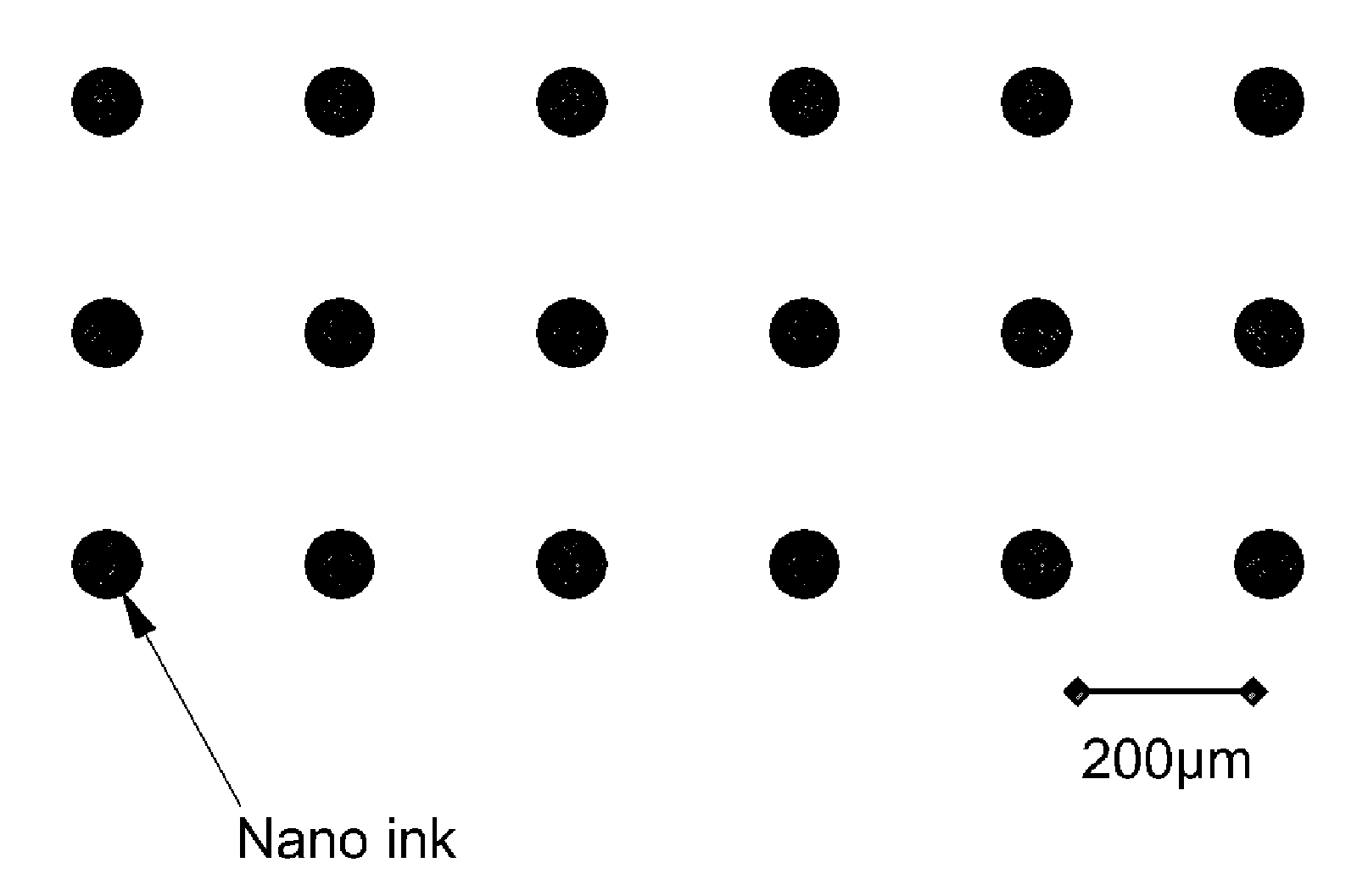

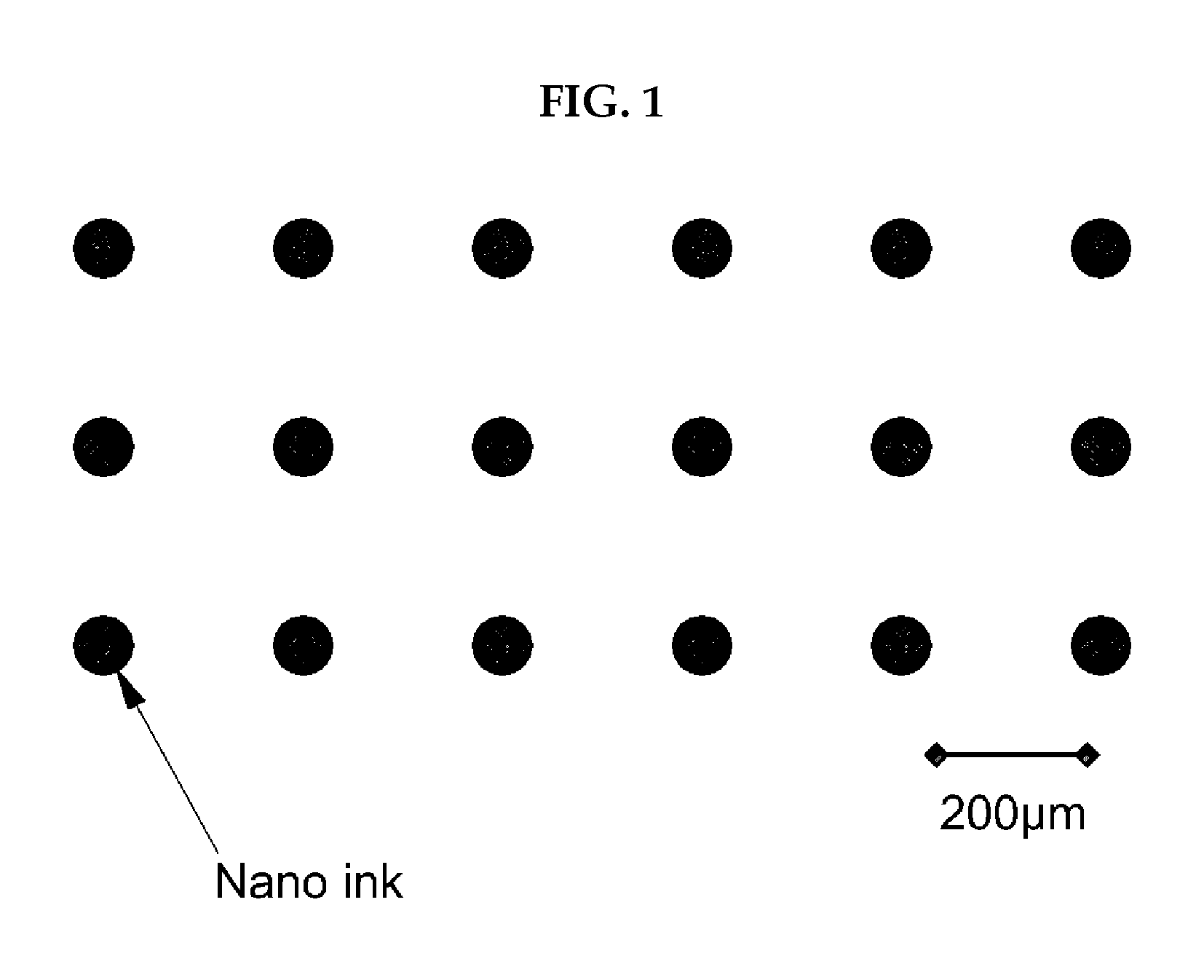

Titanium dioxide NANO particle modified by surface stabilizer, titanium dioxide NANO ink comprising the same, solar cell employing the same, and producing method of the same

ActiveUS20110226321A1Minimized cohesionMaximized diffusionMaterial nanotechnologyPigmenting treatmentSolar cellNanometre

Disclosed are a titanium dioxide nano ink having such a strong dispersibility as to be applicable by inkjet printing and having adequate viscosity without requiring printing several times, and a titanium dioxide nano particle modified by a surface stabilizer included therein. Inkjet printing of the titanium dioxide nano ink enables printing of a minute electrode. In addition, efficiency of a solar cell may be maximized since occurrence of pattern cracking is minimized.

Owner:HYUNDAI MOTOR CO LTD

Method of producing an electrode for non-aqueous electrolyte battery

InactiveUS6361822B1Eliminate effect produced by moistureReduce capacityElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsMetallurgyMoisture

Owner:TDK CORPARATION

Electrode ink composition for ink-jet printing, and electrode and secondary battery manufactured by using the same

An electrode ink composition for ink-jet printing and an electrode and secondary battery manufactured by ink-jet printing the electrode ink composition. The electrode ink composition includes an electrode active material and a solvent. A fine electrode pattern is formed by ink-jet printing the electrode ink composition, and thus a thin micro secondary battery can be manufactured.

Owner:SAMSUNG ELECTRONICS CO LTD +1

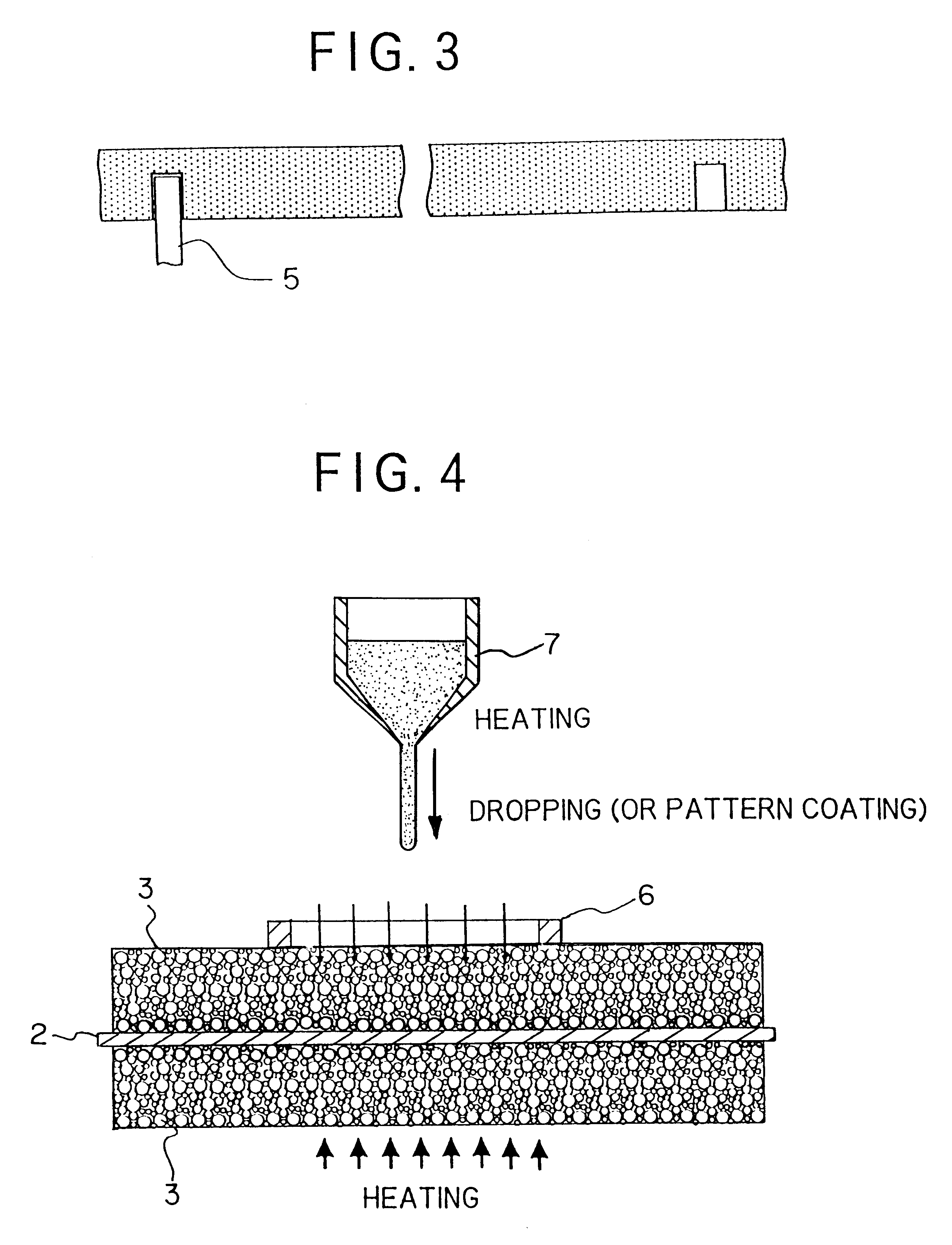

Process for producing an electrode plate with a terminal mounting portion and/or an identification mark

InactiveUS6315801B1Electrode rolling/calenderingPrimary cellsElectrical and Electronics engineeringCurrent collector

An electrode plate for a secondary battery with a nonaqueous electrolyte composed of a collector and an active material layer which is formed of at least an active material and a binder disposed on the collector, and the electrode plate is provided with a terminal mounting portion provided with a collector surface exposed to mount a terminal. In such electrode plate, the exposed collector surface of the terminal mounting portion has the same shape and size substantially as those of an area to which the terminal is actually mounted. The electrode plate may further be provided with an identification mark made by forming the active material layer in shape of pattern on an area at which the collector surface is exposed or by exposing the collector surface in the shape of pattern on an area at which the collector is covered with the active material layer.

Owner:DAI NIPPON PRINTING CO LTD

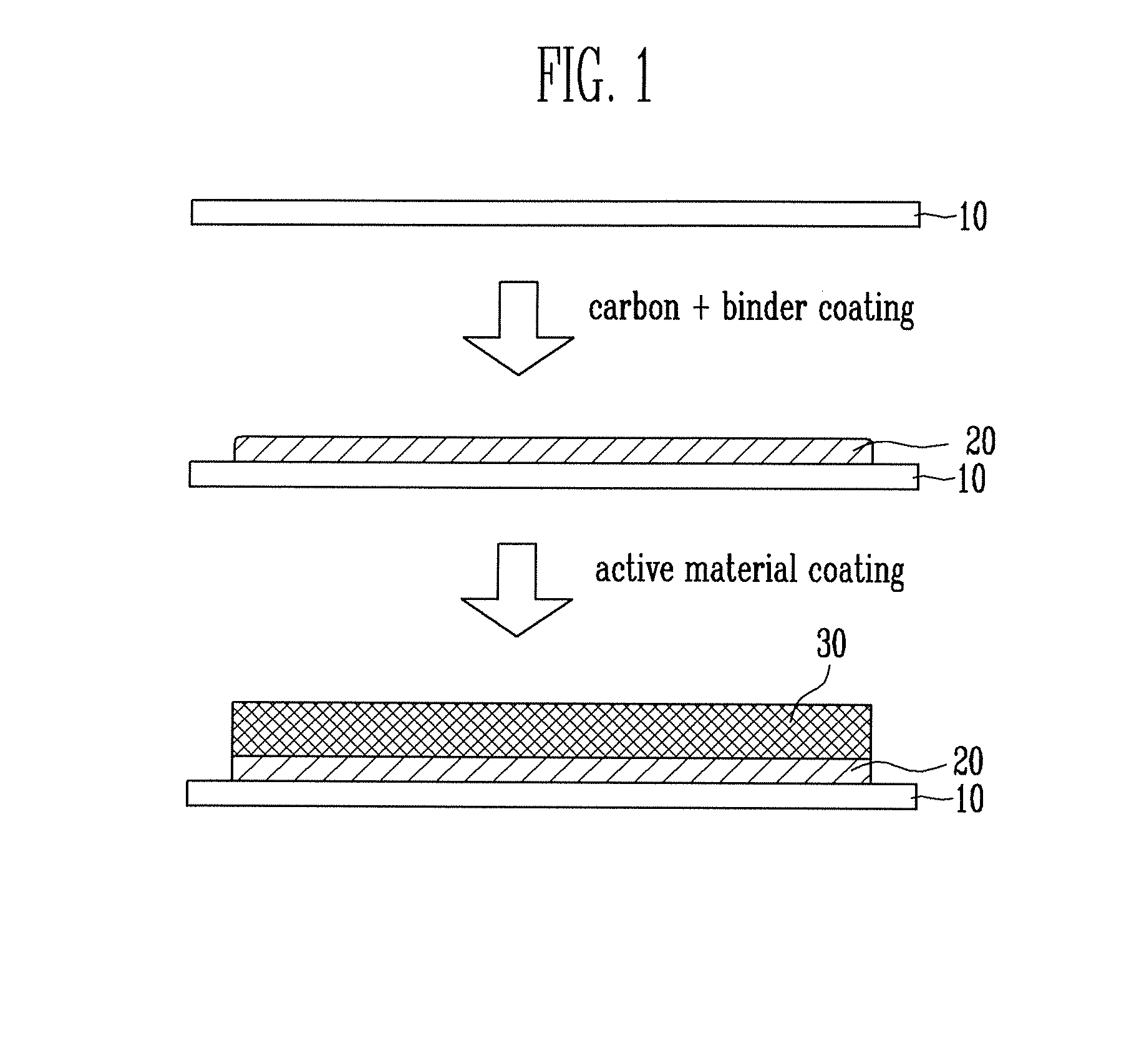

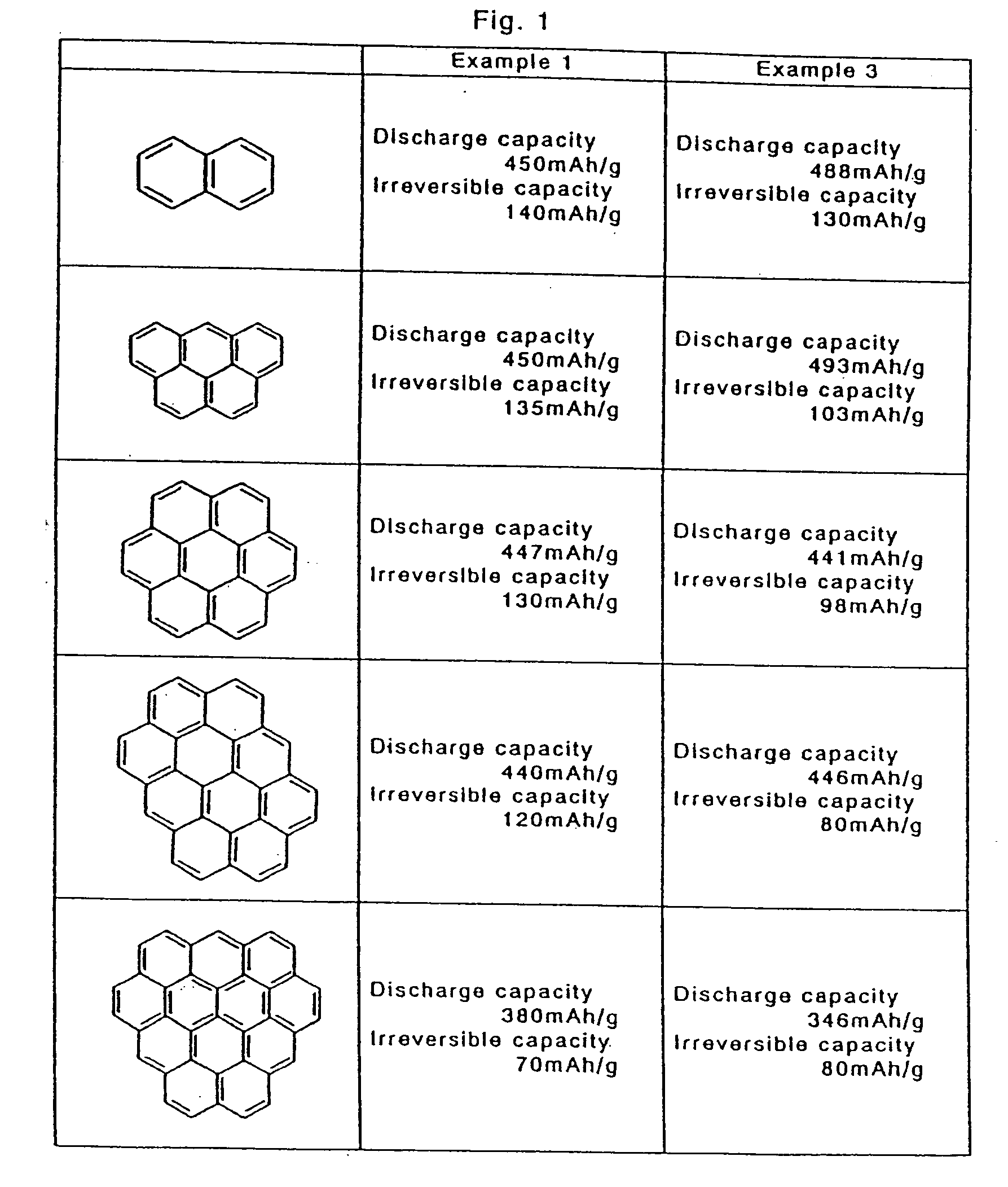

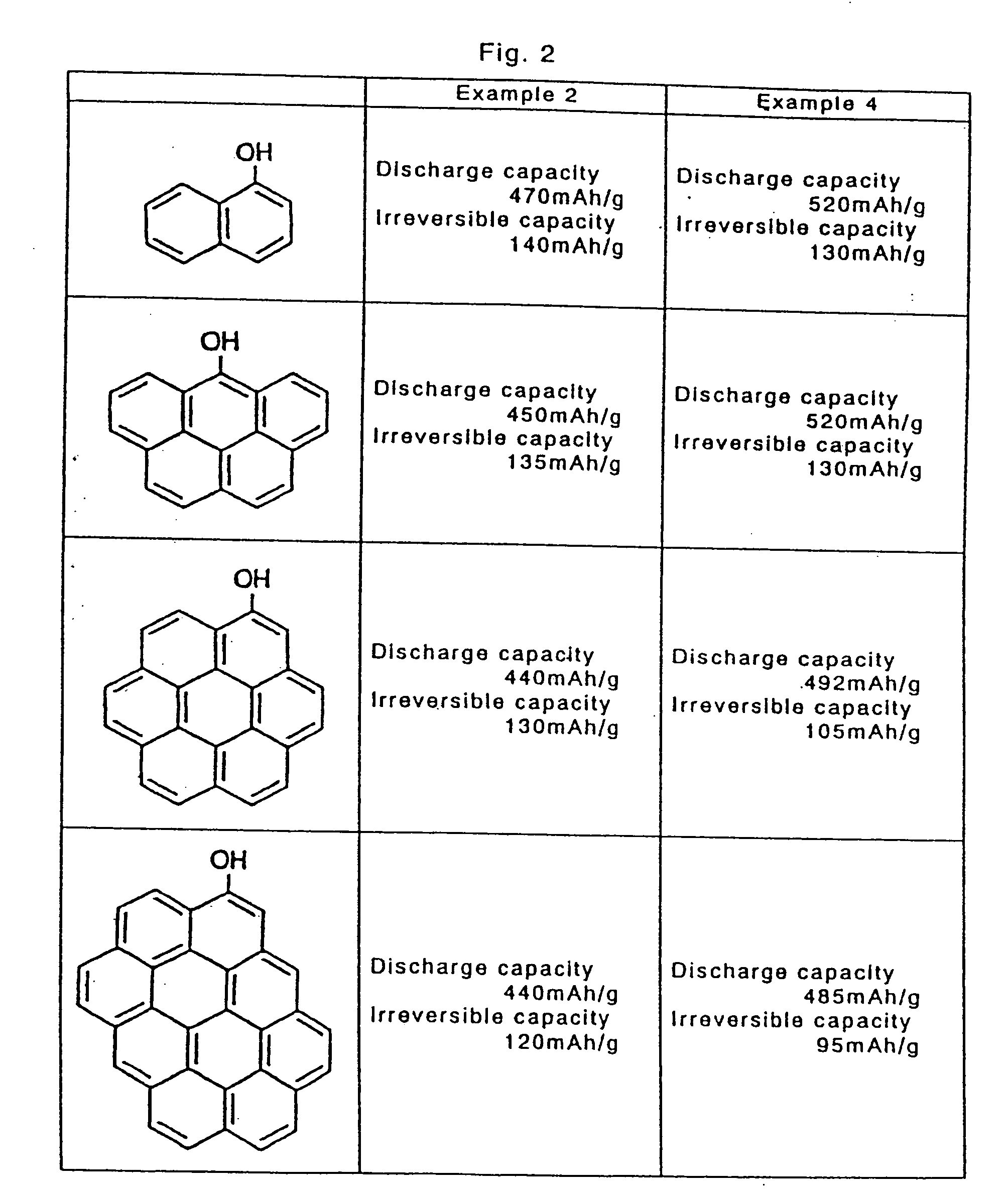

Nonaqueous secondary battery, constituent elements of battery, and materials thereof

InactiveUS20060078799A1Increase energy densityImprove stabilitySolid electrolytesGraphiteElectrical conductorHigh energy

To realize constituent elements for realizing a nonaqueous secondary battery having high energy density and high repeating stability, and a nonaqueous secondary battery using the same. To present also a lithium ion secondary battery of light weight and high energy density to be used in various electronic appliances and power source of electric vehicle or the like. By using vanadium oxide expressed as M2+xV4O11, where x is 0 or more to 1 or less, and M is a monovalent metal ion such as Cu and Li, as positive electrode, a nonaqueous secondary battery having high energy density and high repeating stability is obtained. Moreover, by using the carbon obtained by heating a cured resin by adding an aromatic compound of 2 to 10 rings to a high polymer before curing, as negative electrode, a nonaqueous secondary battery of high energy density is obtained. By composing an electrochemical element by using a gel or solid ion conductor having an iron containing an organic cationic structure including quaternary nitrogen or its derivative and different cations at least as coexistent ions, a nonaqueous secondary battery of high energy density is obtained. As the current collector of the battery, by using a graphite sheet obtained by baking a high polymer film, a lithium ion secondary battery of light weight, excellent cycle characteristics and high energy density is presented.

Owner:WATANABE KAZUHIRO +4

All solid state secondary battery

ActiveUS8883347B2Keep for a long timeImprove featuresElectrode thermal treatmentFinal product manufactureAll solid stateAlloy

This is to provide an all solid state secondary battery which can be produced by an industrially employable method capable of mass-production and has excellent secondary battery characteristics.This is an all solid state secondary battery containing a laminated material in which a positive-electrode unit and a negative-electrode unit are laminated alternately through an ion conductive inorganic-material layer, the positive-electrode unit has positive active material layers on both surfaces of a positive-electrode collector layer, the above-mentioned negative-electrode unit has negative active material layers on both surfaces of a negative-electrode collector layer, (A) at least one of the positive-electrode collector layer and the negative-electrode collector layer comprises a metal of either of Ag, Pd, Au and Pt, or an alloy containing either of Ag, Pd, Au and Pt, or a mixture containing two or more kinds selected from the metals and alloys, (B) each layer is in a sintered state, or (C) at least the starting material for the ion conductive inorganic material of the ion conductive inorganic-material layer is a calcined powder.

Owner:NAMICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com