Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about "Carcasses disinfection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

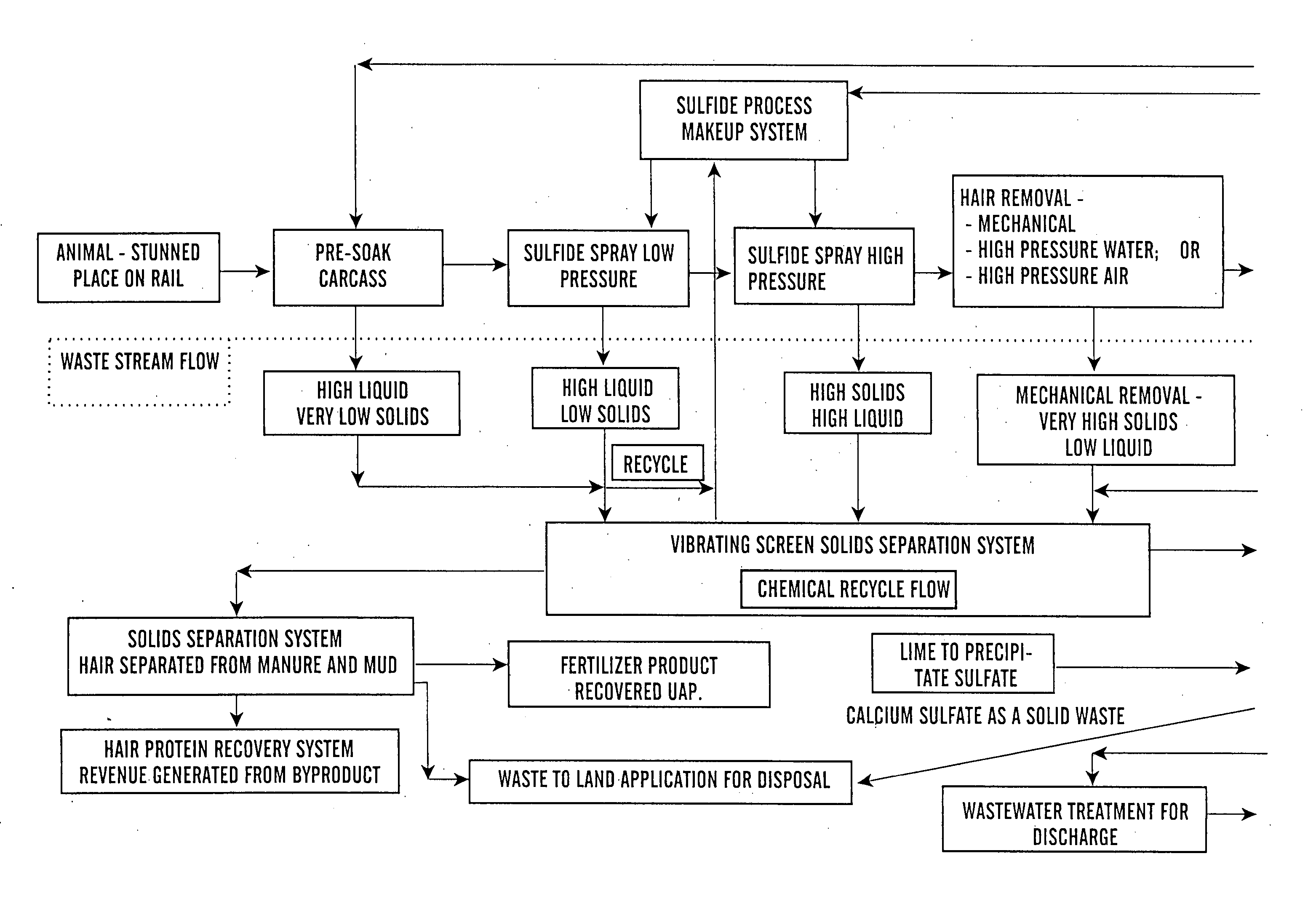

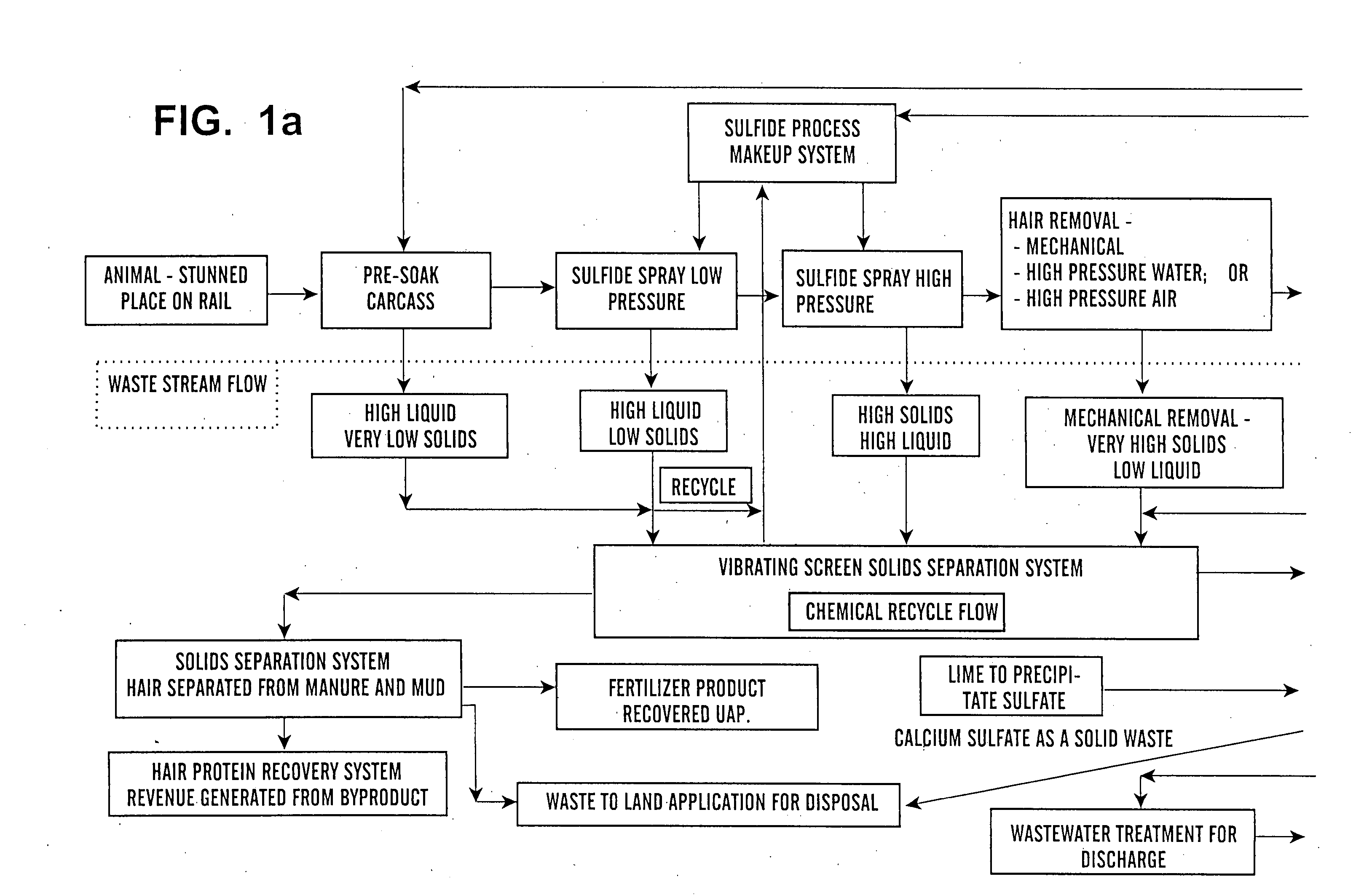

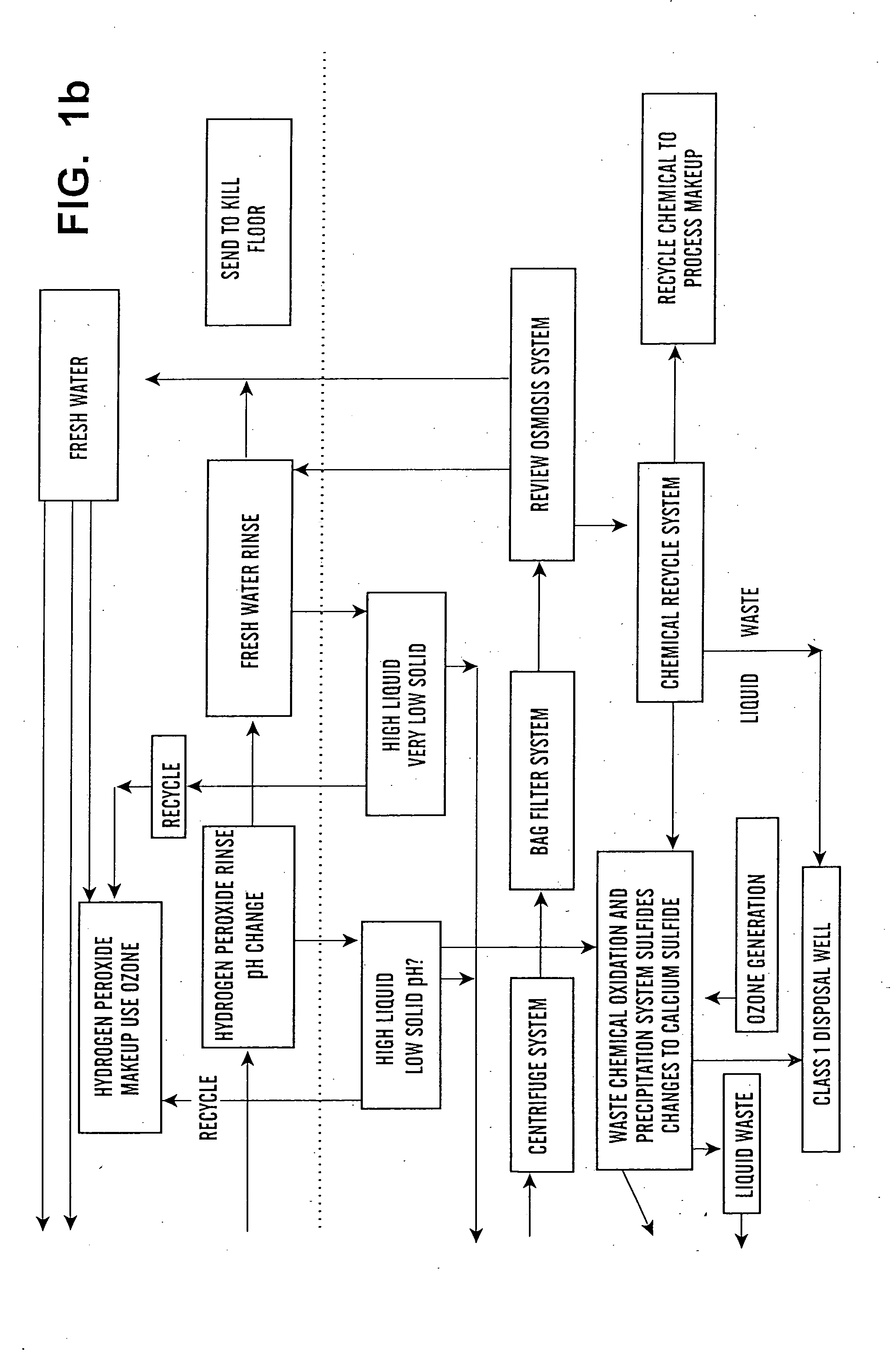

Method and system for processing waste streams derived from the dehairing of animals

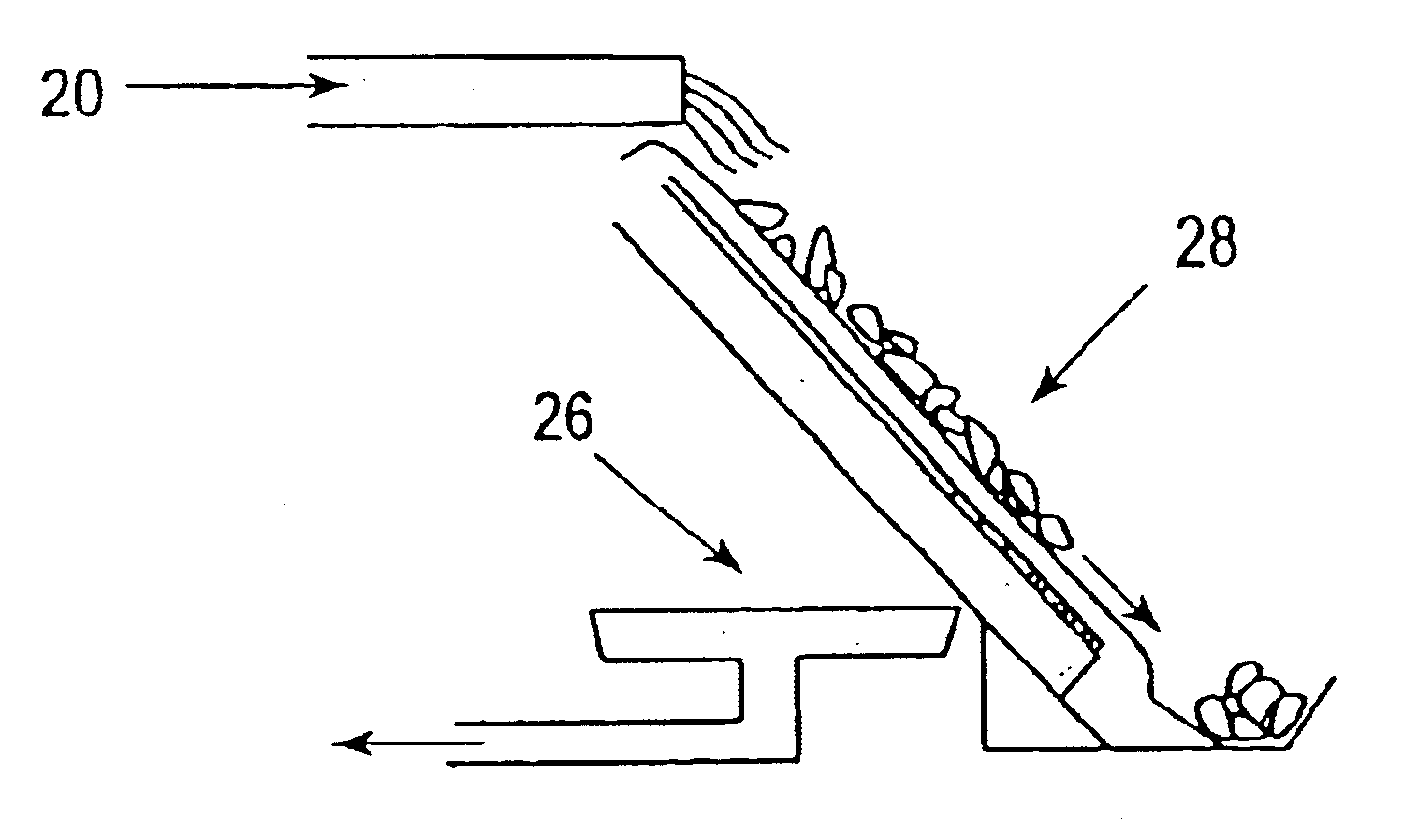

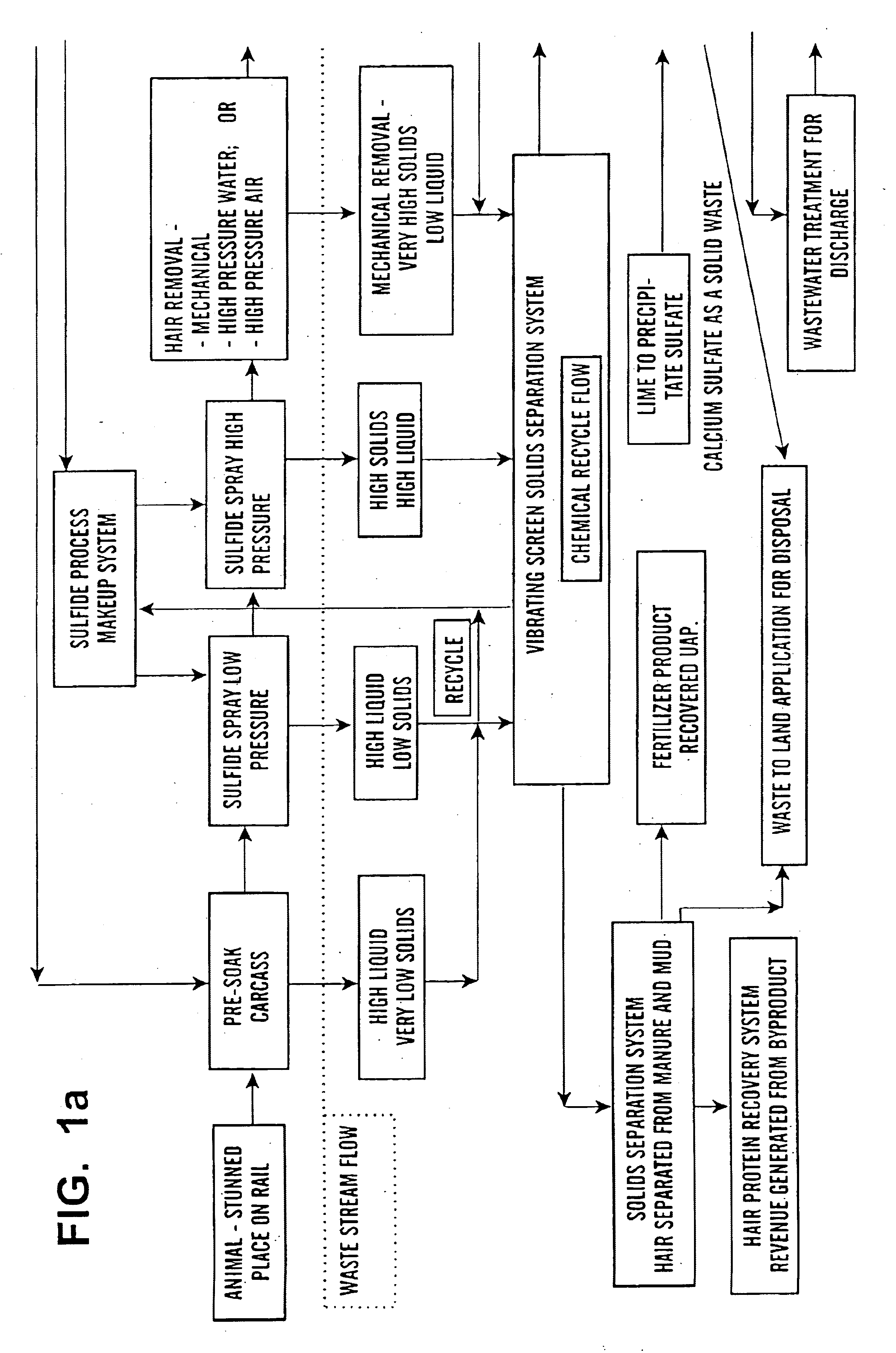

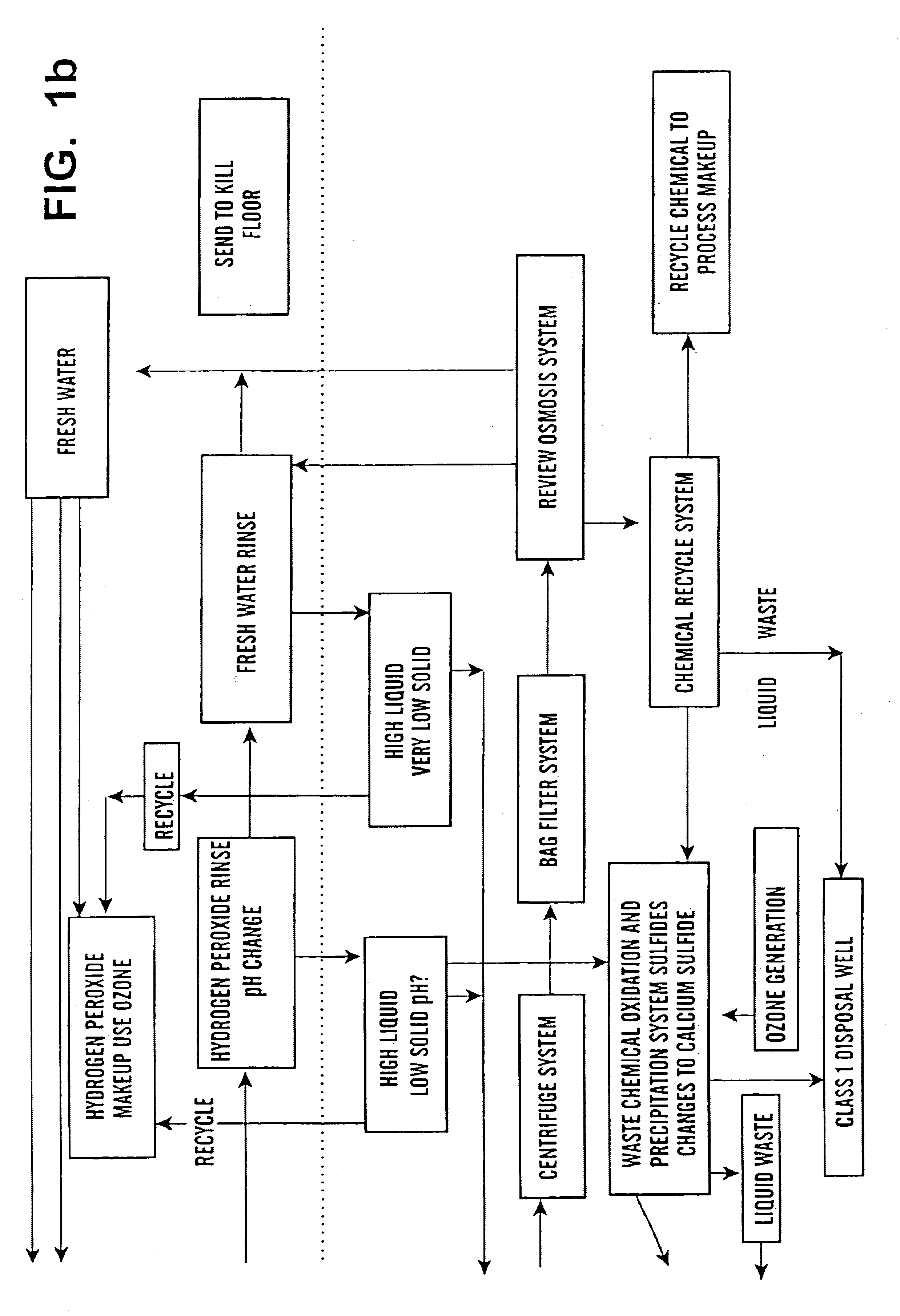

InactiveUS6896607B2Fish washing/descalingPoultry plucking mechanismsWaste streamEnvironmental engineering

Disclosed is a novel method and system for dehairing an animal, providing a system for recycling and safely disposing of chemical and biological wastes produced during such dehairing method. Included in such method are processes for handling sodium production in waste materials, reducing and handling production of H2S, removing sulfides from animal hides, safely disposing of sulfide waste, removing solids from the waste materials, and reducing water and reagent use and disposal.

Owner:SWIFT BEEF +1

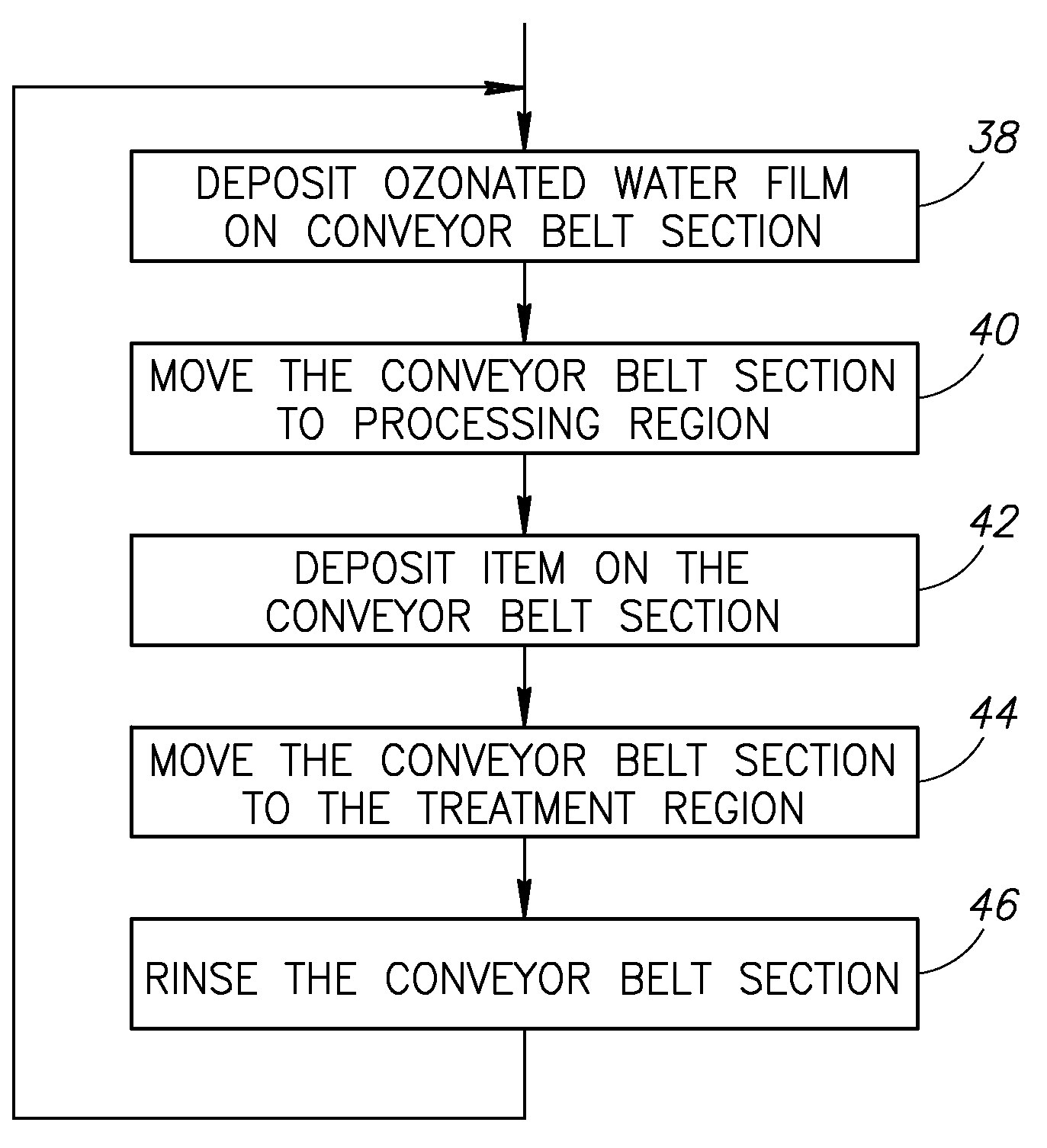

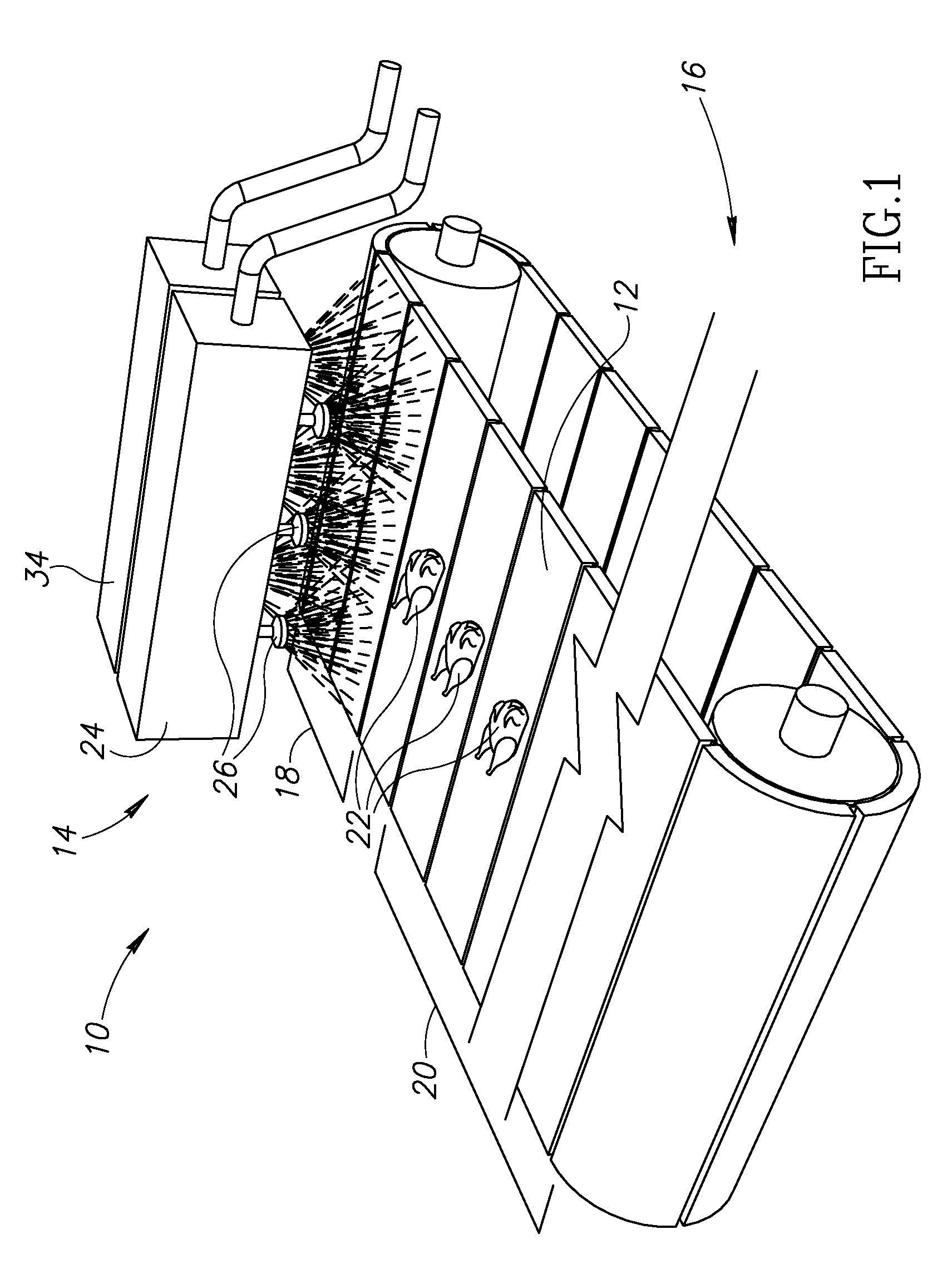

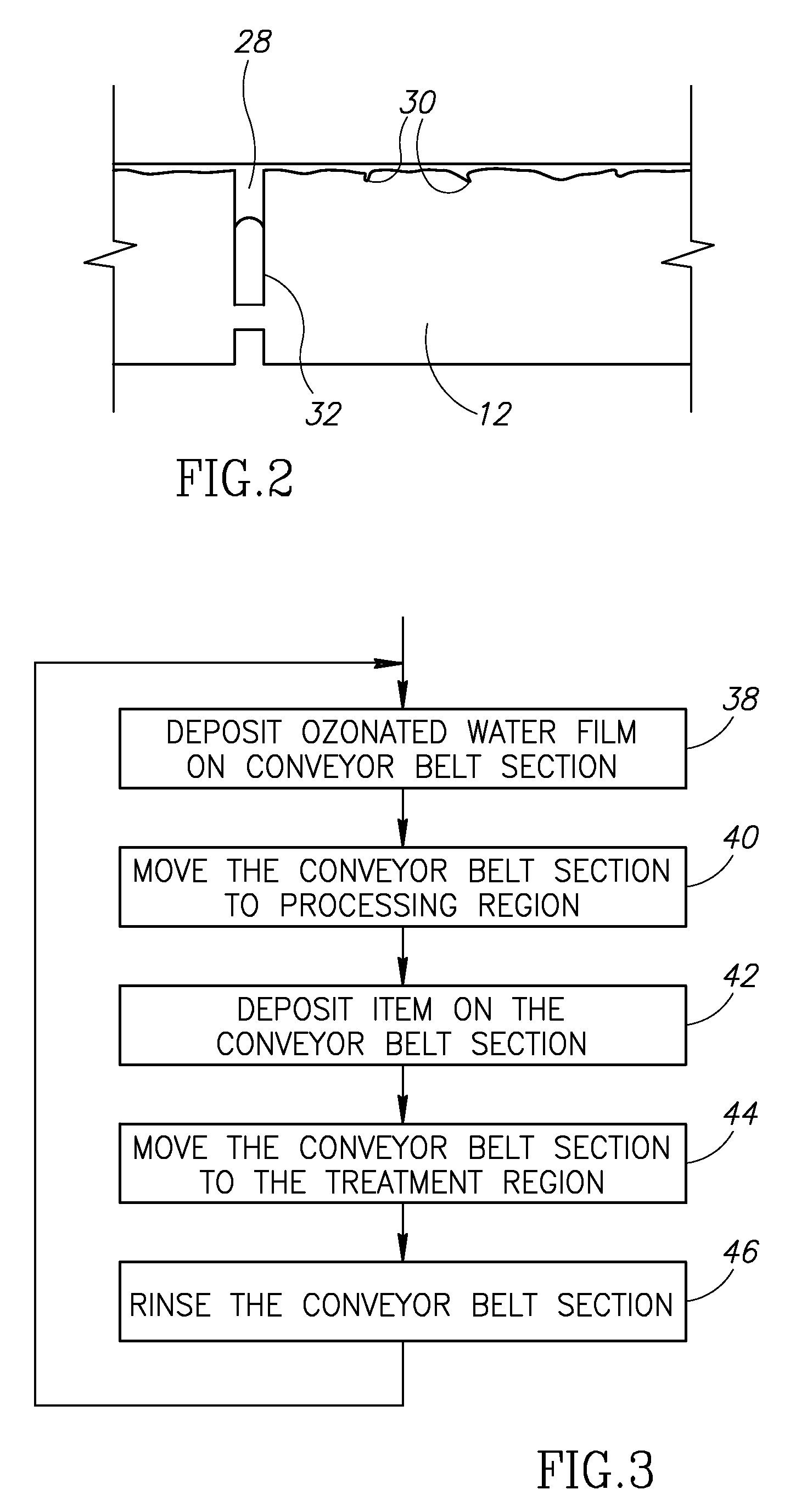

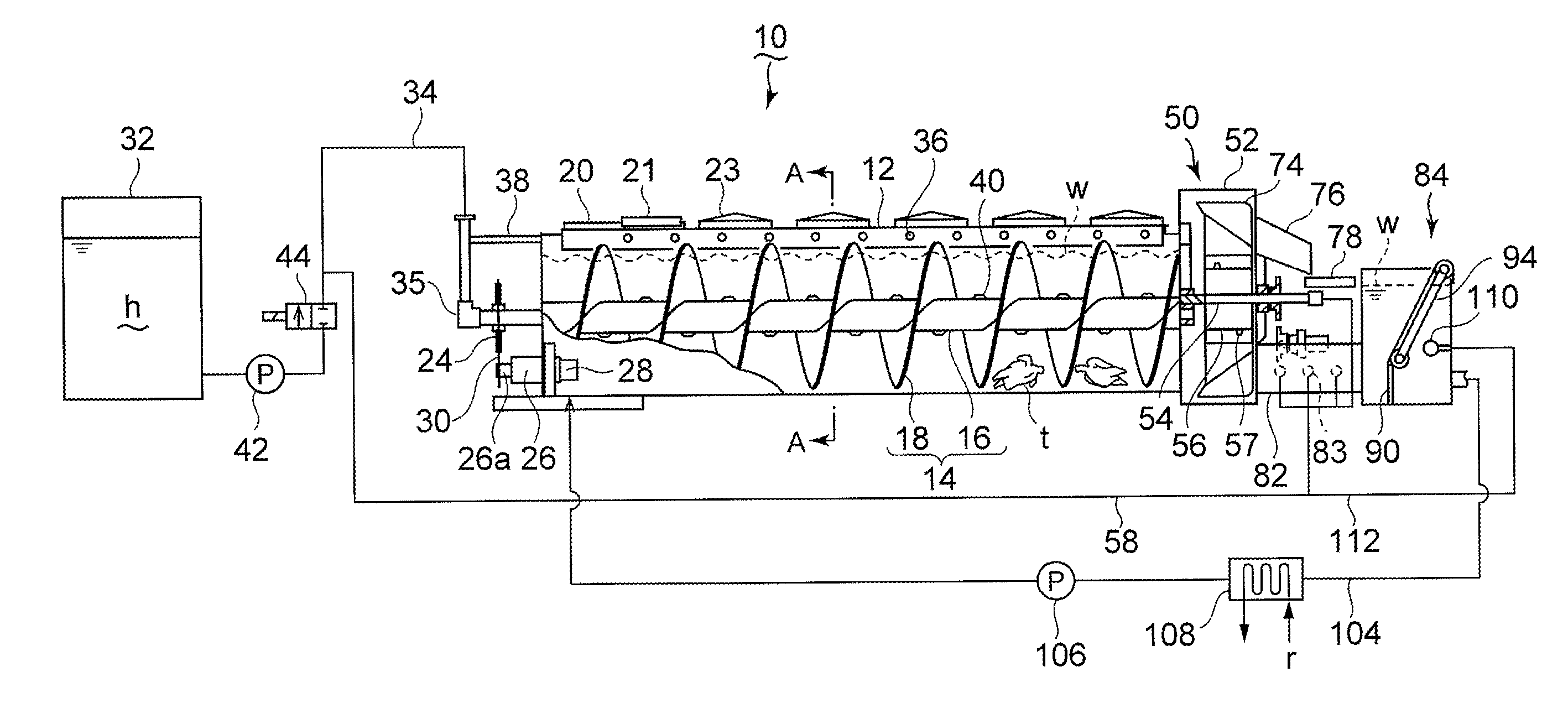

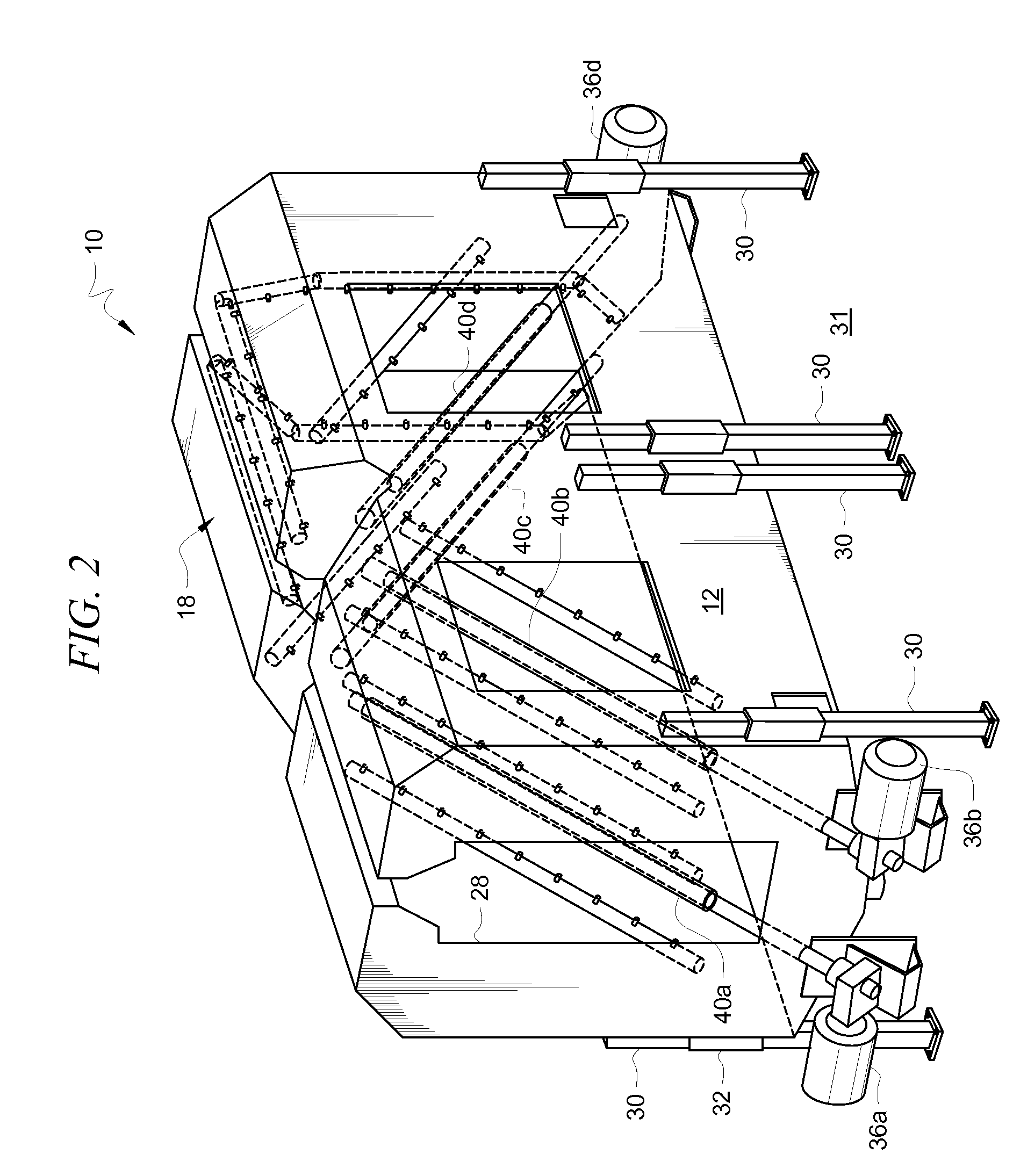

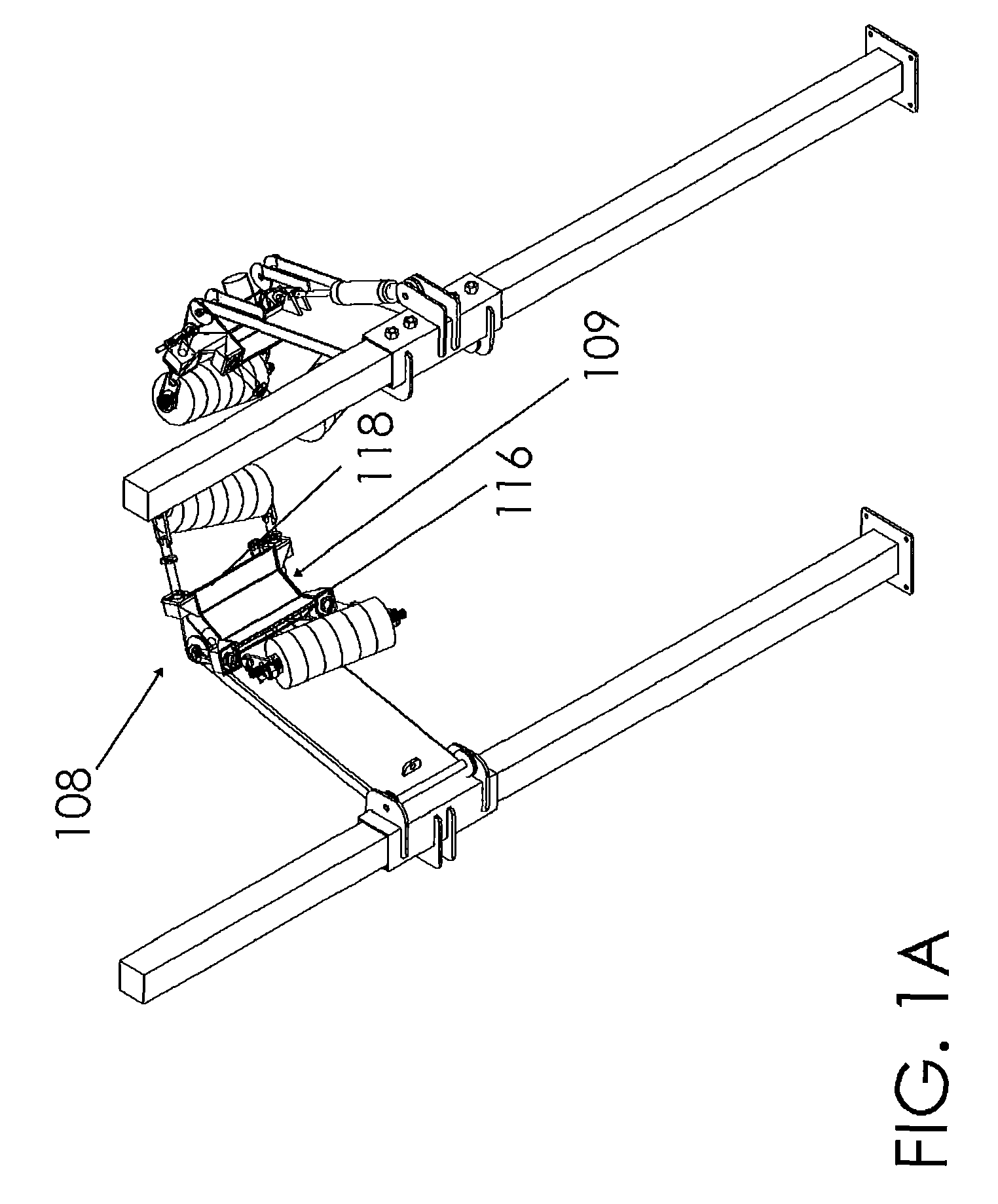

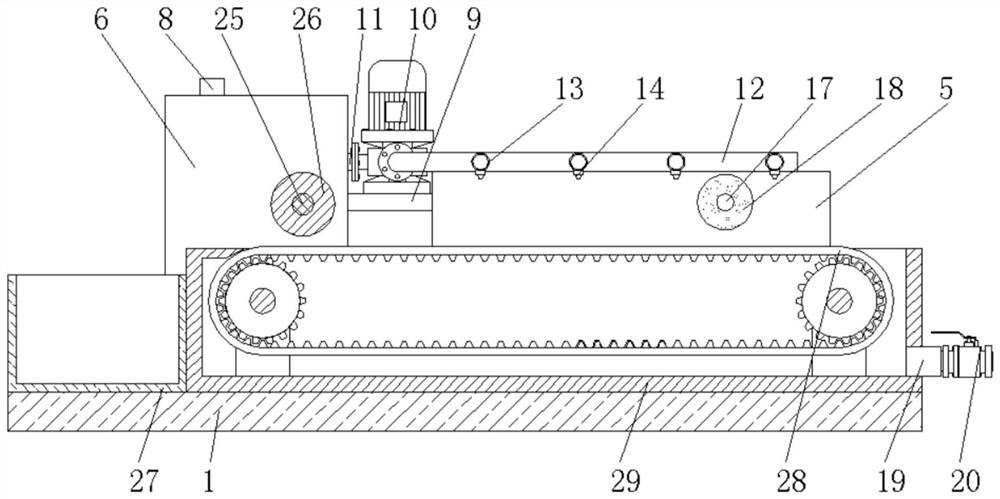

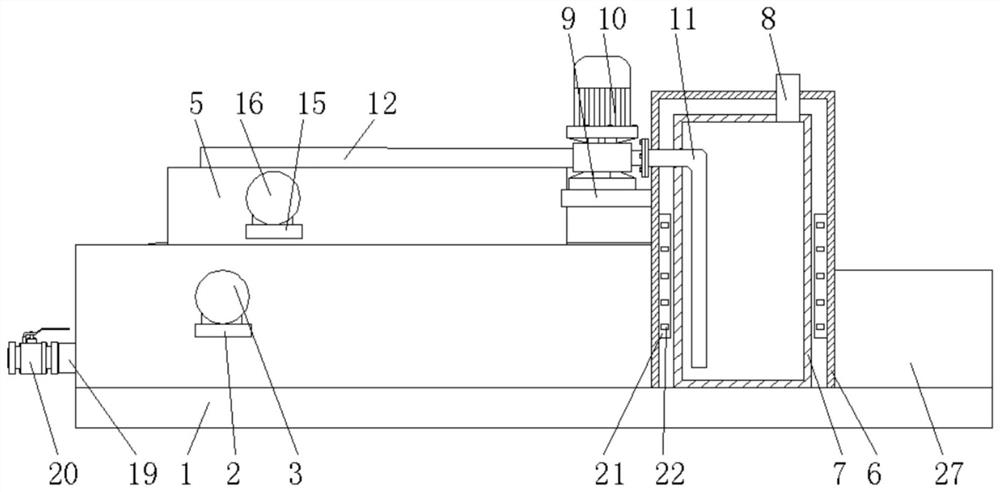

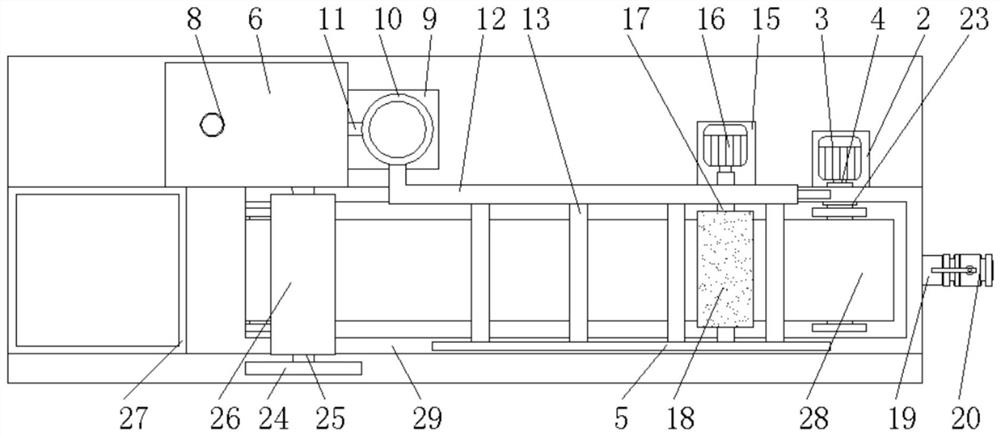

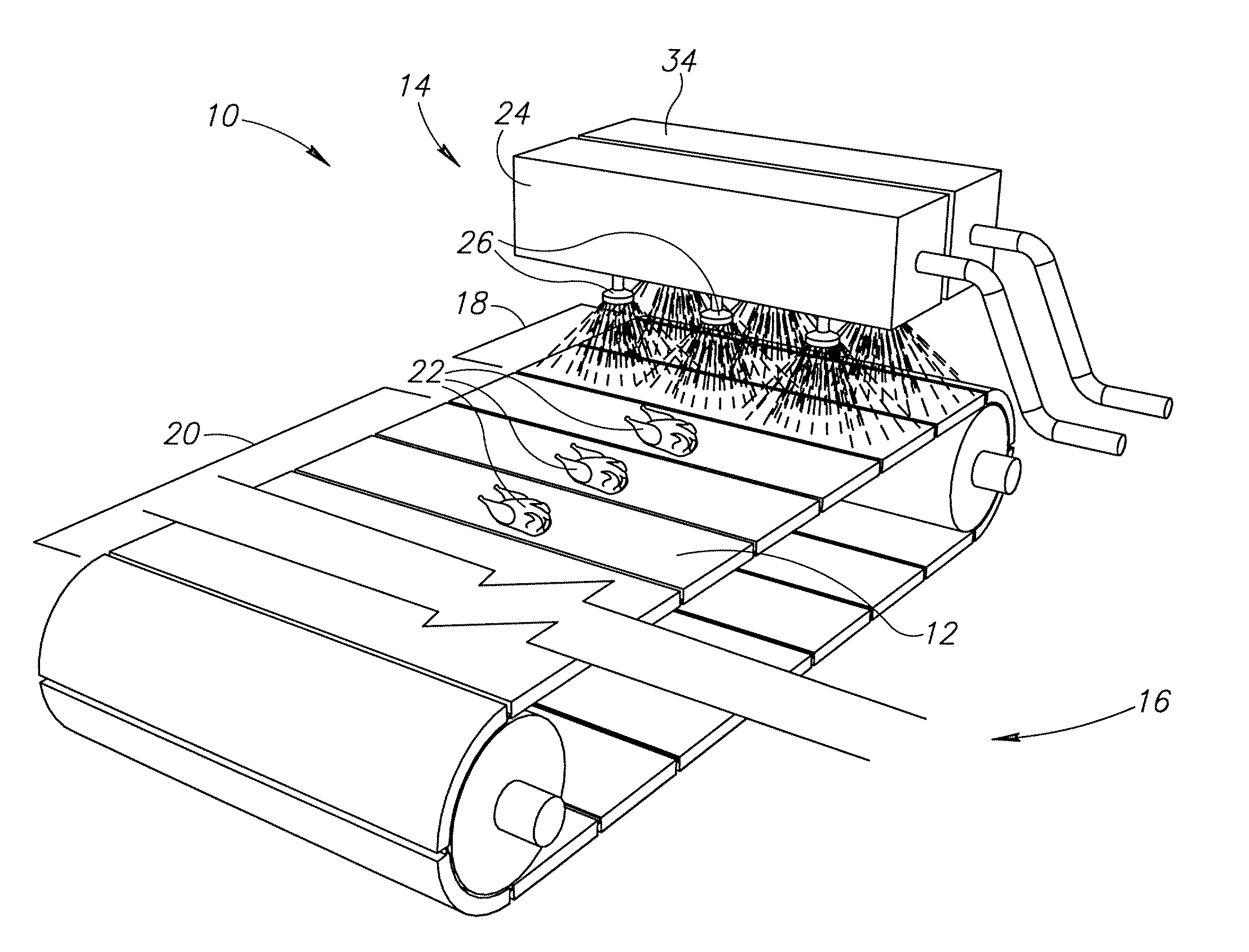

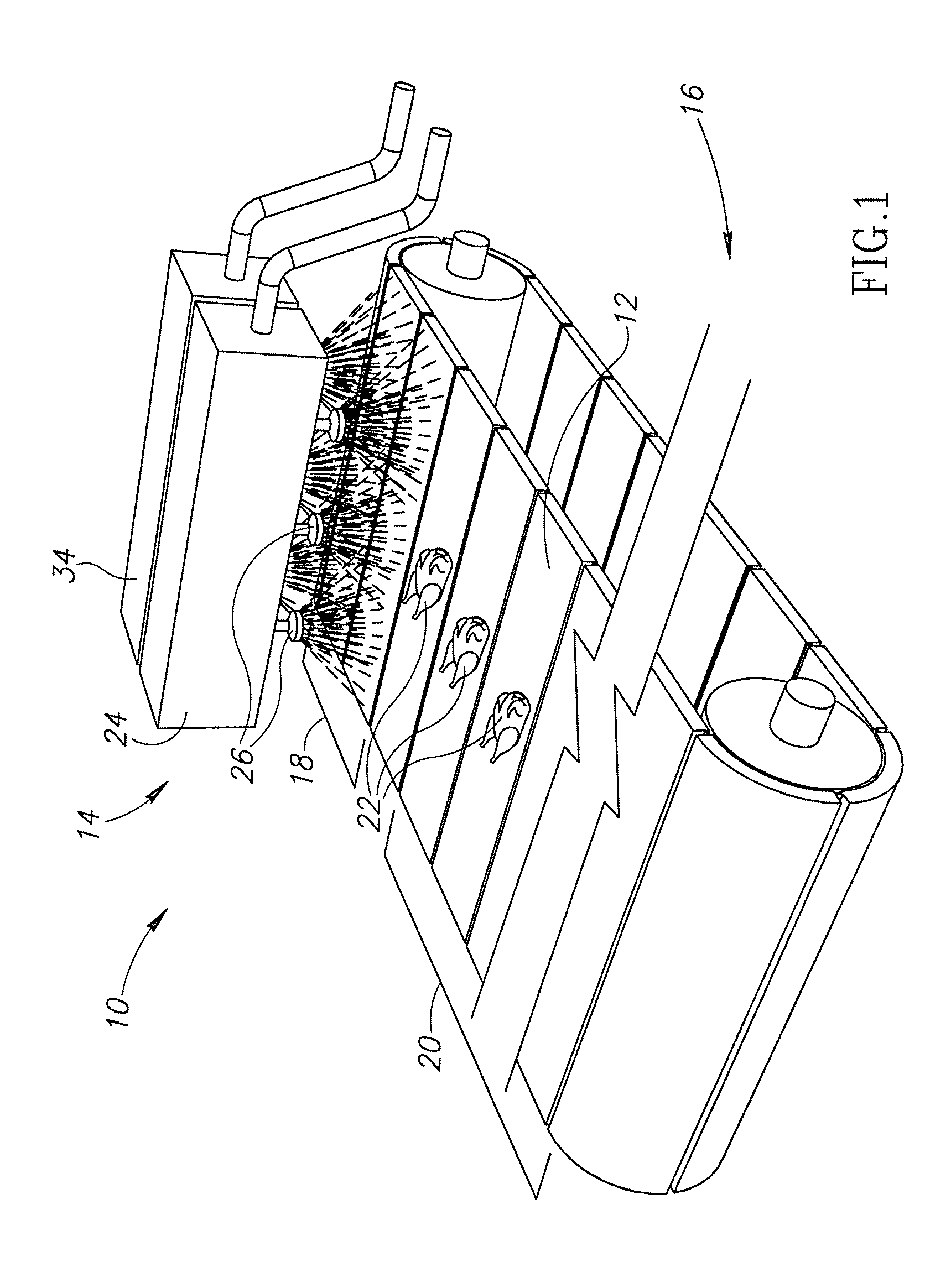

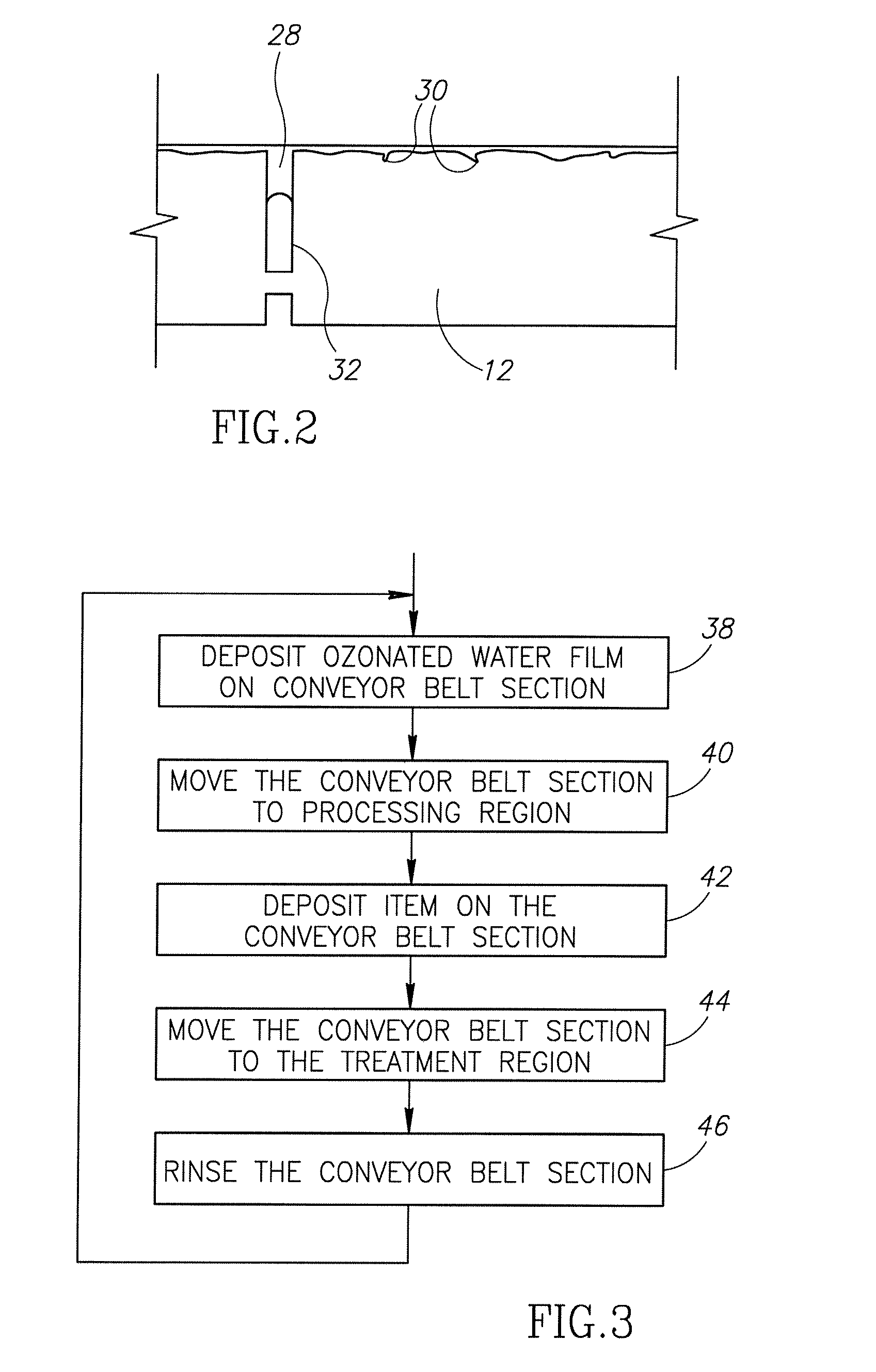

Ozone-based conveyor cleaning system

A conveyor cleaning system includes a treating region, a processing region, and a conveyor belt traveling from the treating region to the processing region. A distributor positioned across the treating region deposits a film of ozonated water on the conveyor belt. In the processing region, the conveyor belt is exposed to soiling agents such as grease and other animal matter. A high-pressure rinser may be positioned over the treating section such that the distributor is positioned between the high-pressure rinser and the processing region. Ozonated water may be generated by a system including first and second tanks. The first tank is filled with ozone gas and water. After a predetermined time, undissolved ozone gas is released. The contents of the first tank are then transferred to a second tank along with more ozone gas. After waiting a predetermined time period, undissolved ozone gas is released from the second tank.

Owner:OZONE INT +1

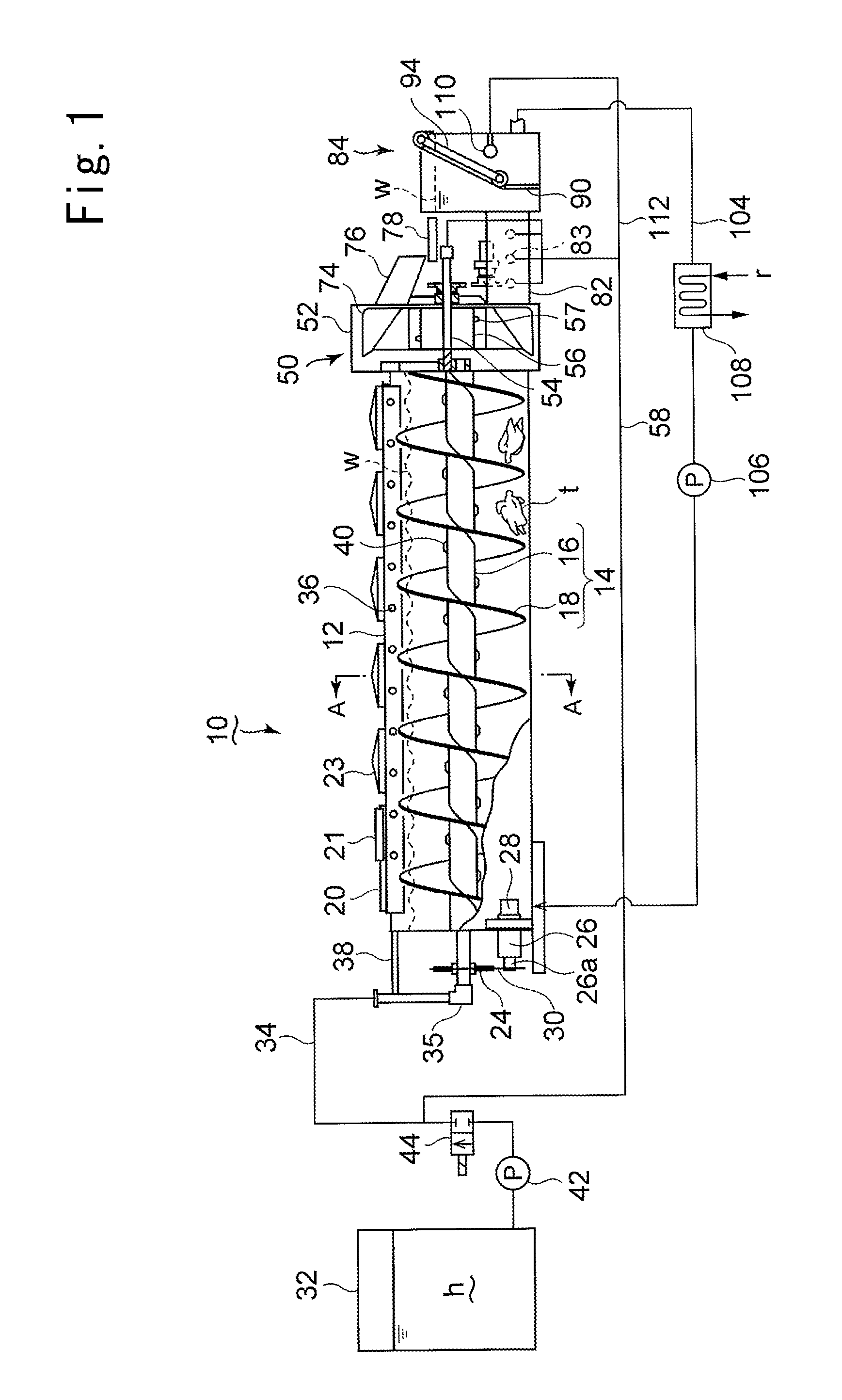

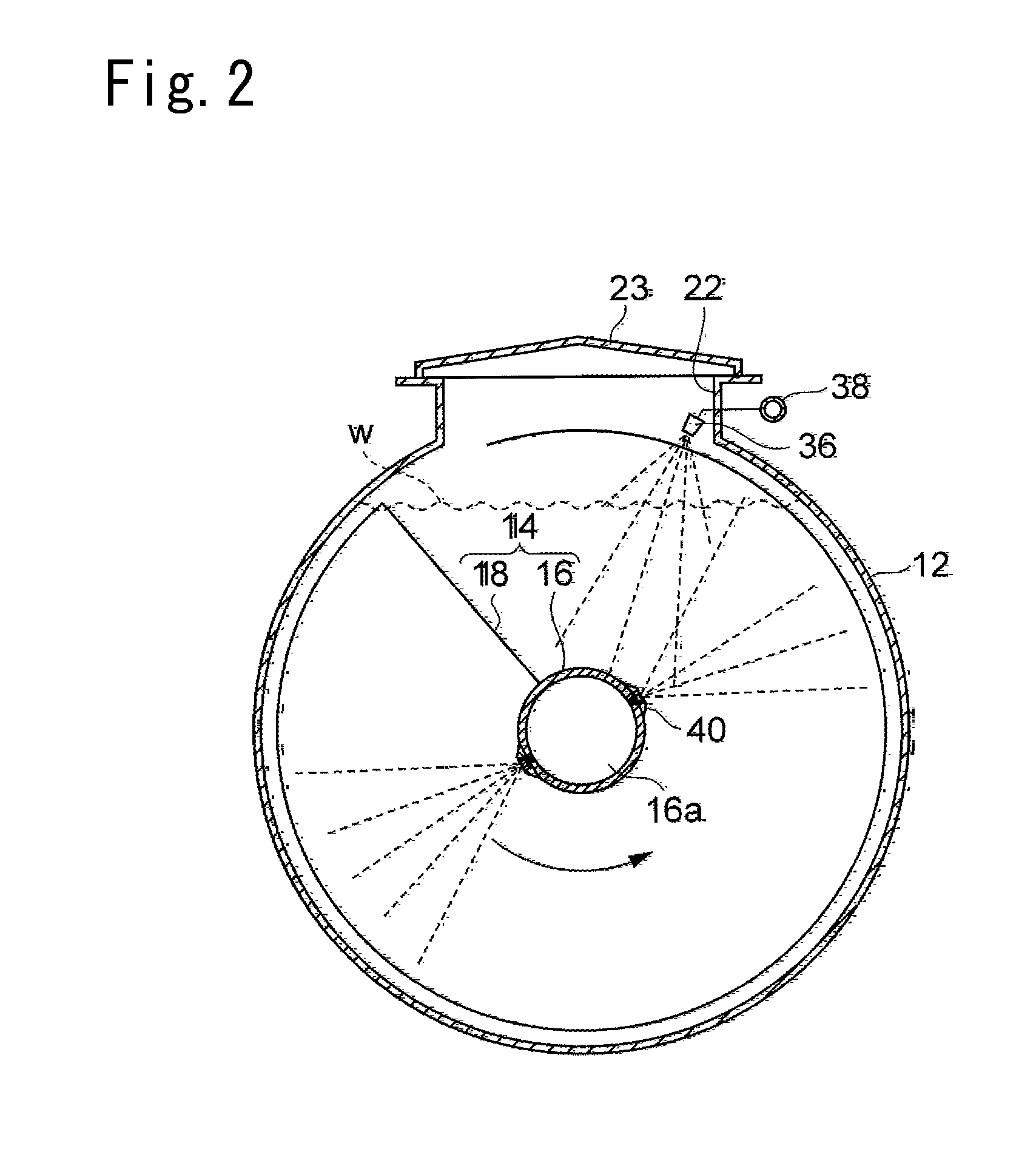

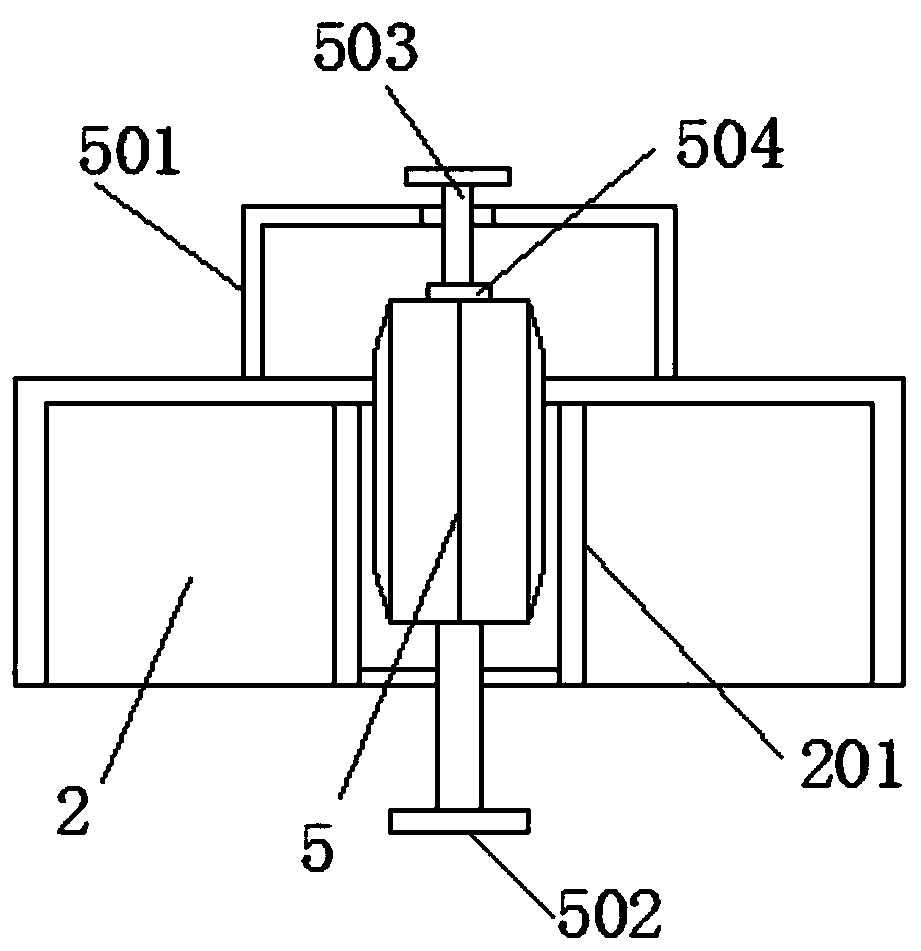

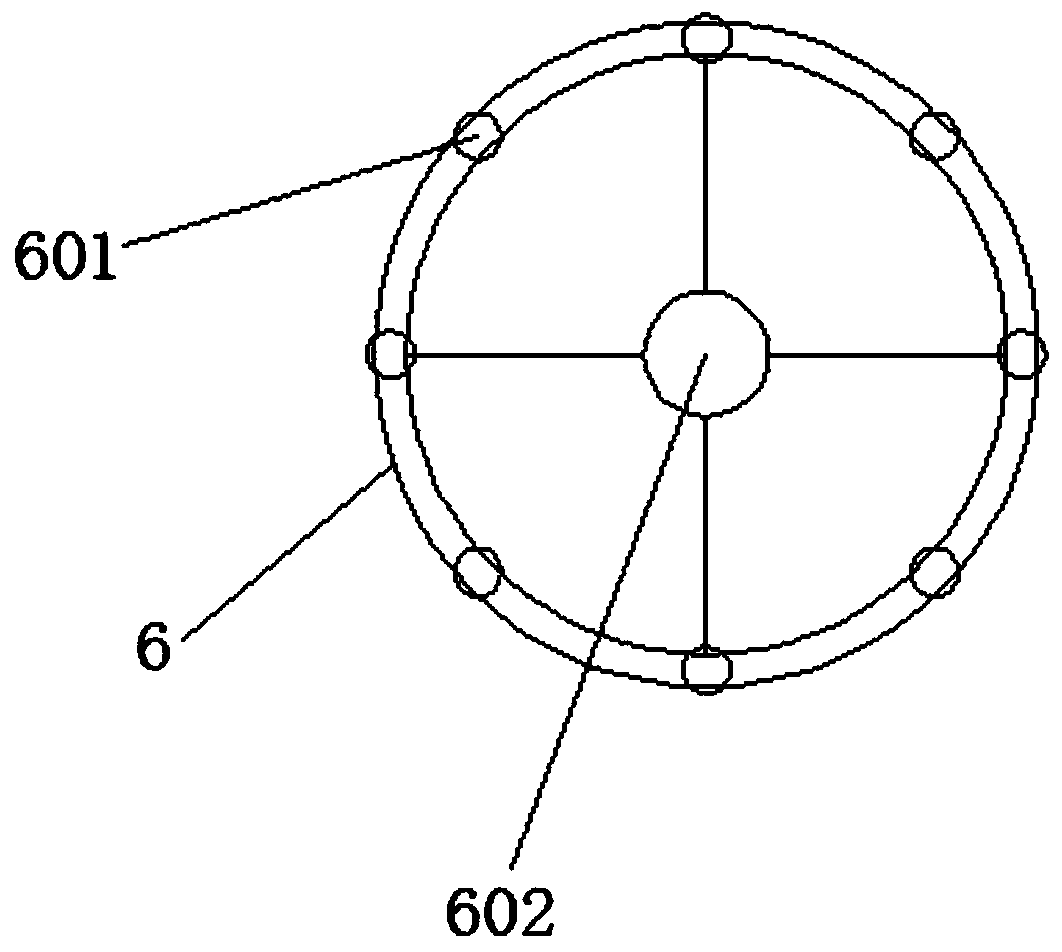

Poultry carcass cooling and conveying system

ActiveUS20140202659A1Increase the areaReduce areaMeat/fish preservationStationary refrigeration devicesWash waterEngineering

In a hollow cylindrical housing which stores a coolant, a feeding device having a rotating shaft and spiral screw vanes fixedly installed on the periphery of the rotating shaft is provided. At least one first diffusion nozzle is provided in each pitch of the screw vanes on the inner wall of the housing. A pair of second diffusion nozzles are provided for every pitch of the screw vanes on the outer periphery of the rotating shaft respectively at different positions in the axial direction of the rotating shaft and at mutually opposite positions in the circumferential direction of the rotating shaft. The first diffusion nozzles are supplied with wash water through a high-temperature water piping provided on the upper outside of the housing, while the second diffusion nozzles are supplied with wash water through a channel formed in the interior of the rotating shaft.

Owner:MAYEKAWA MFG CO LTD

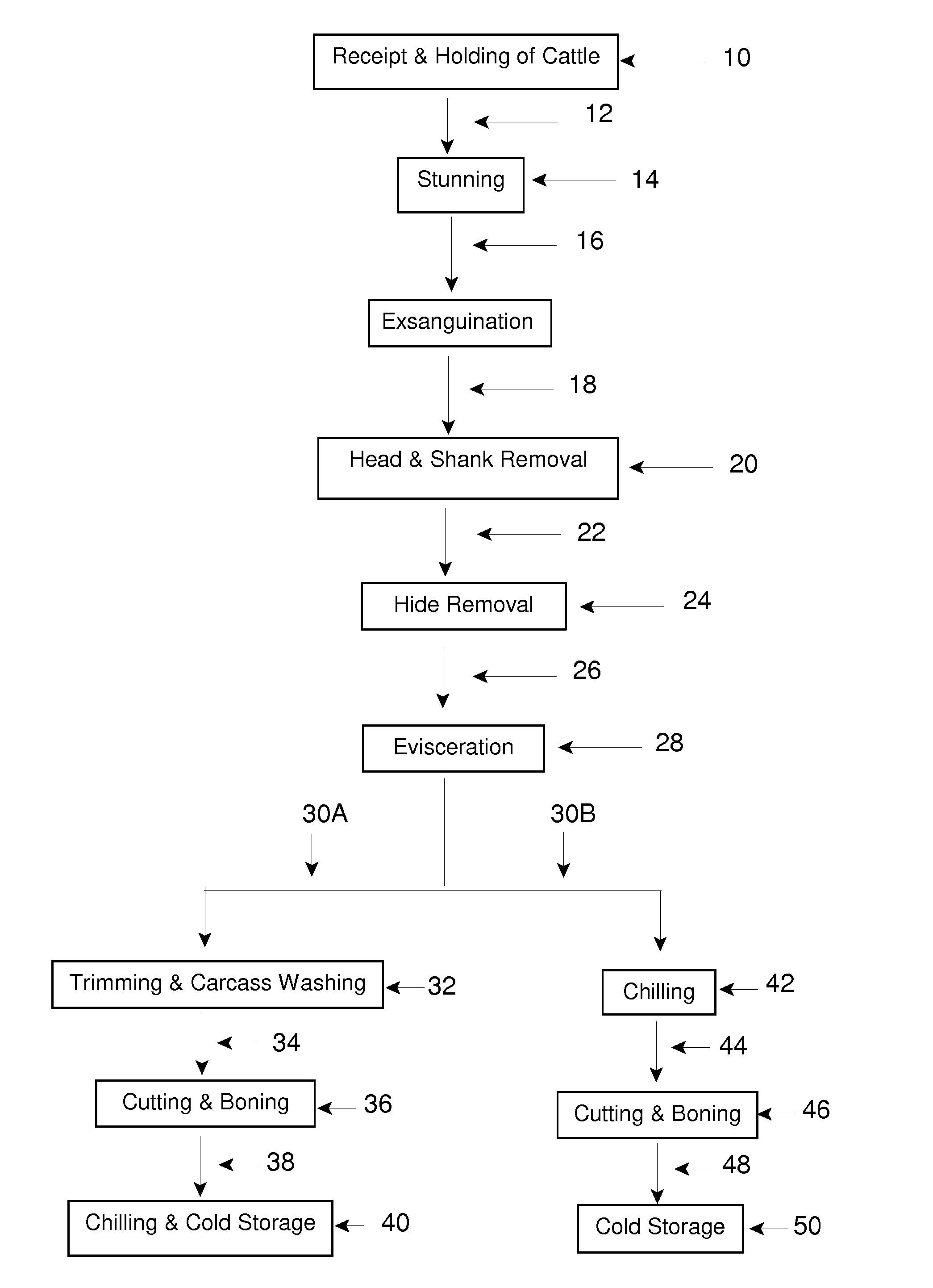

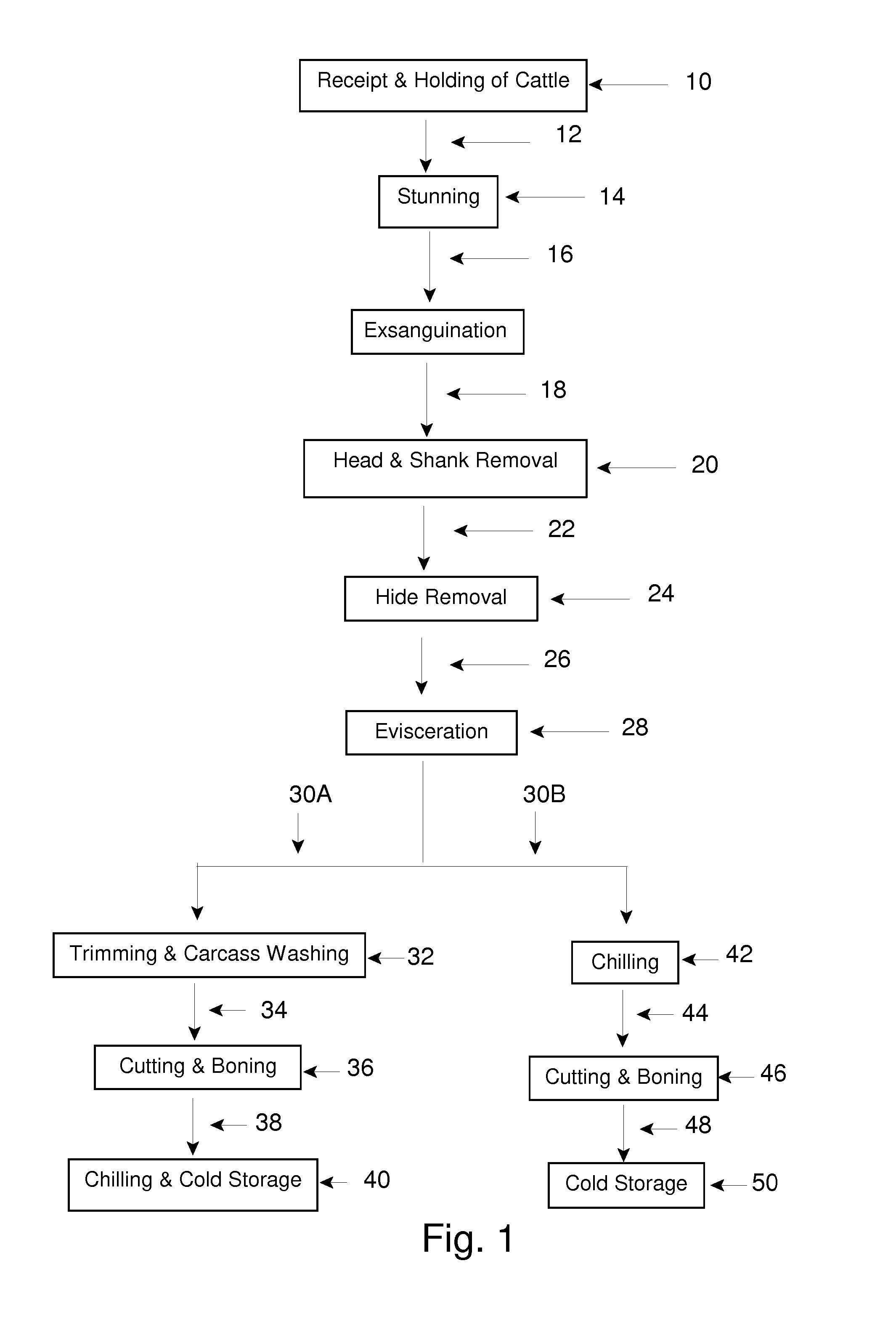

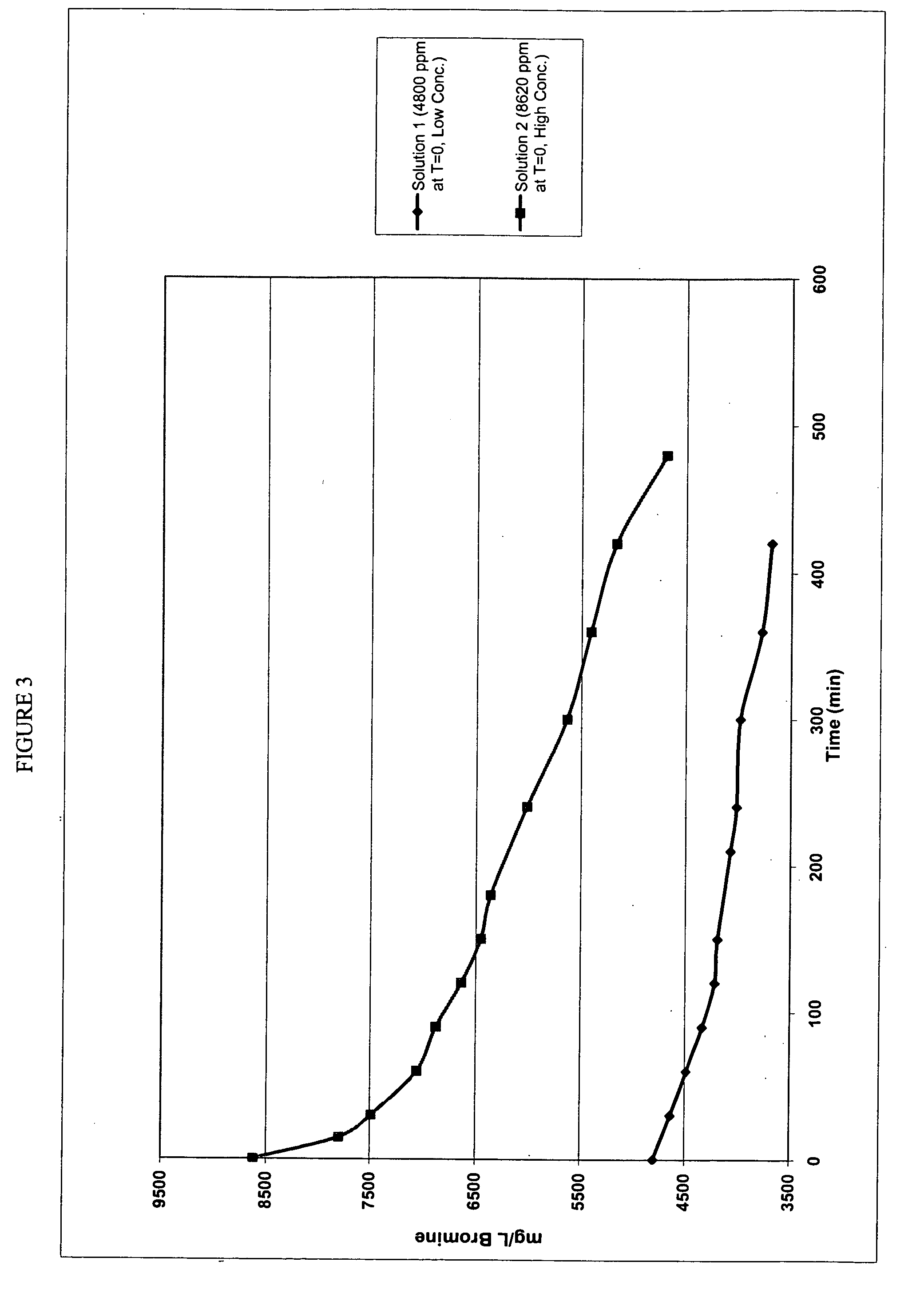

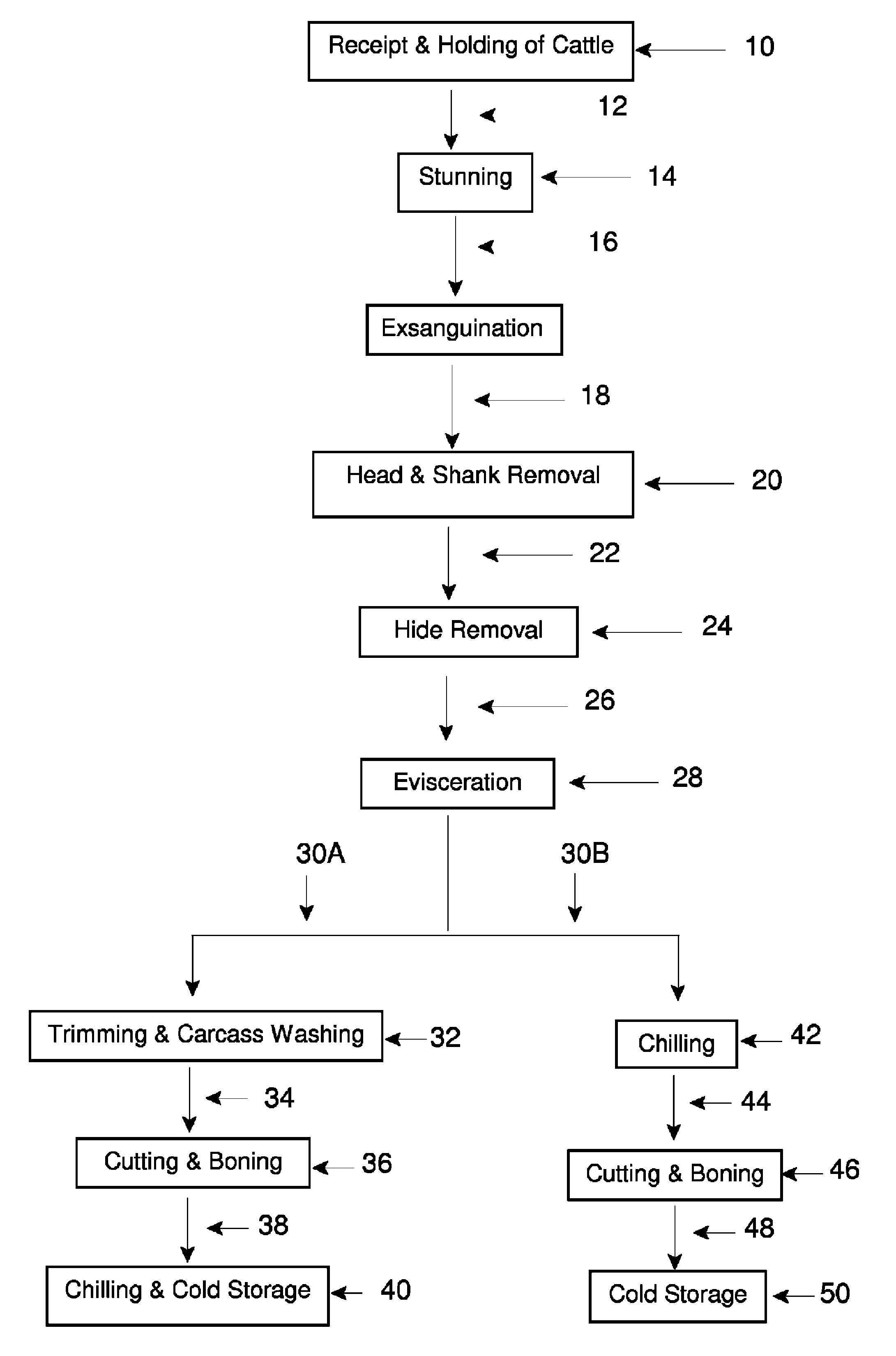

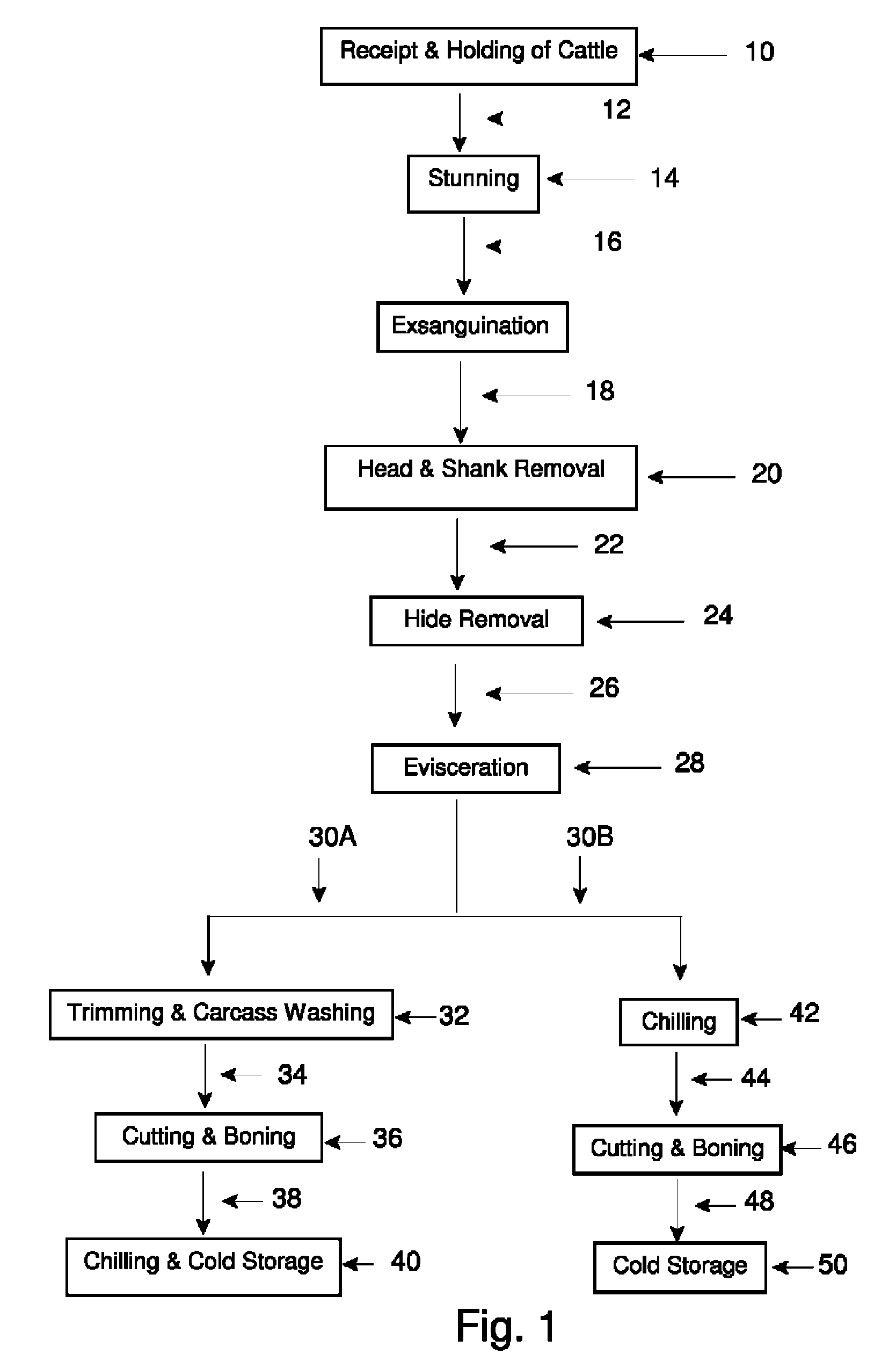

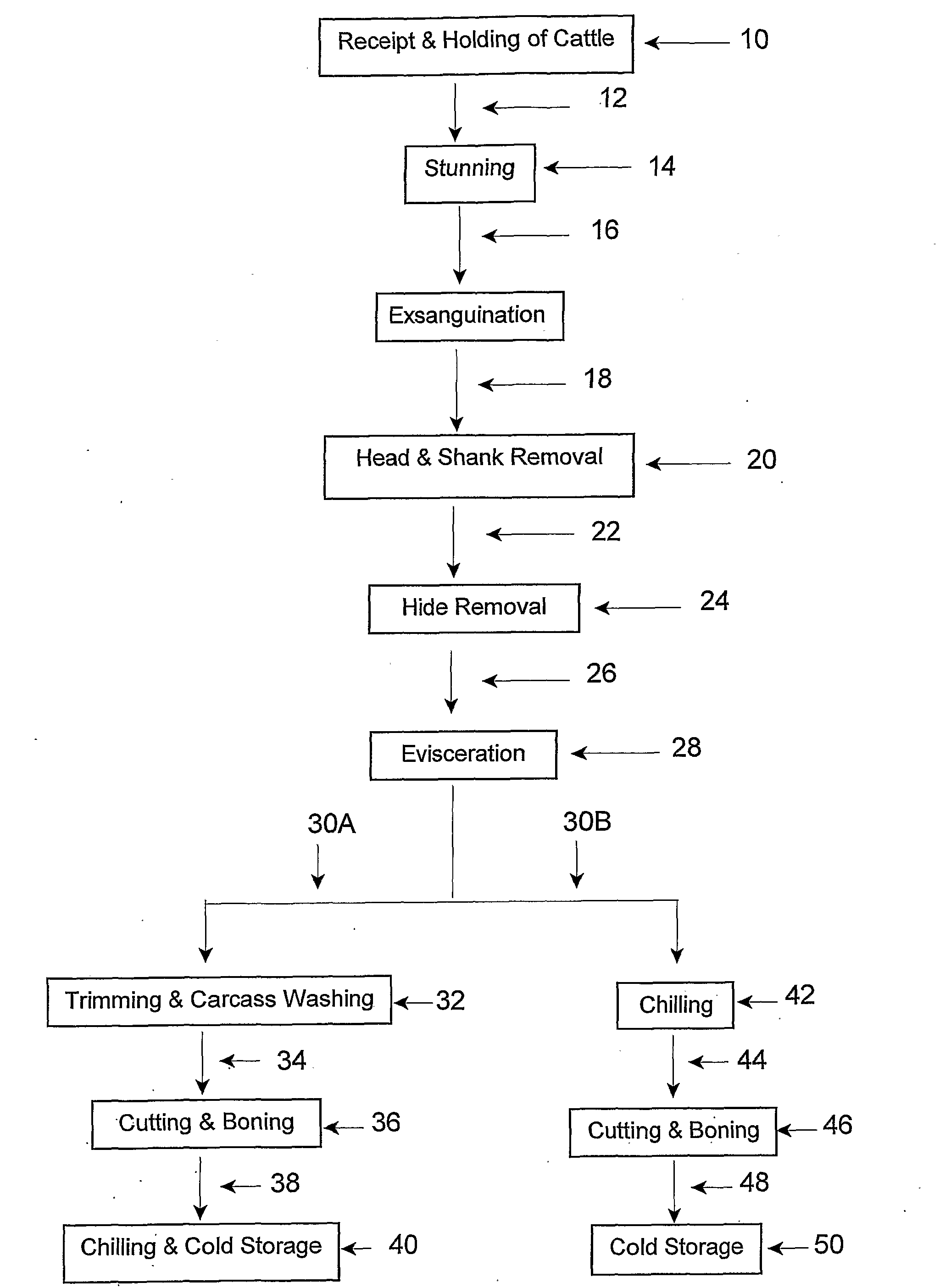

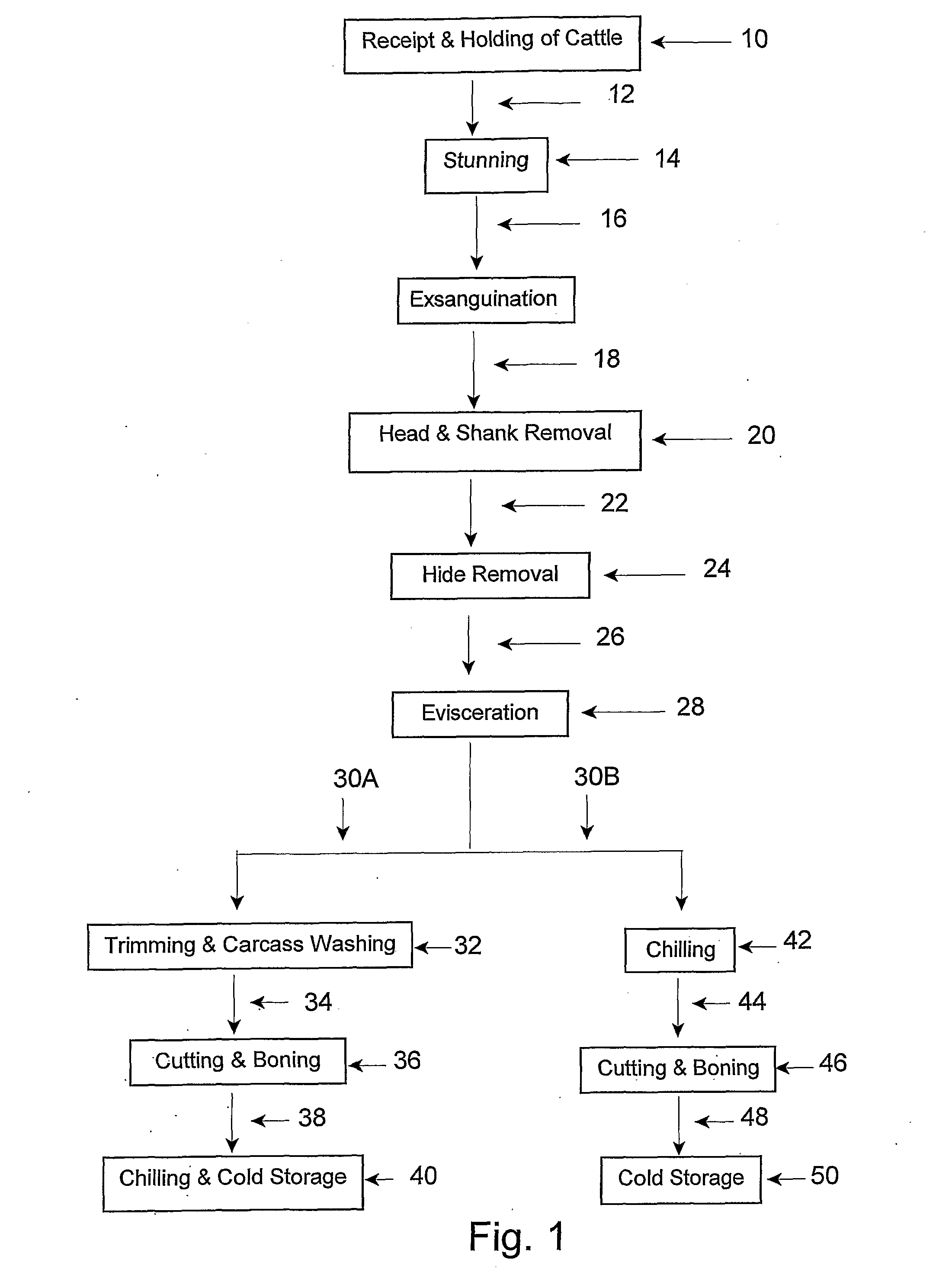

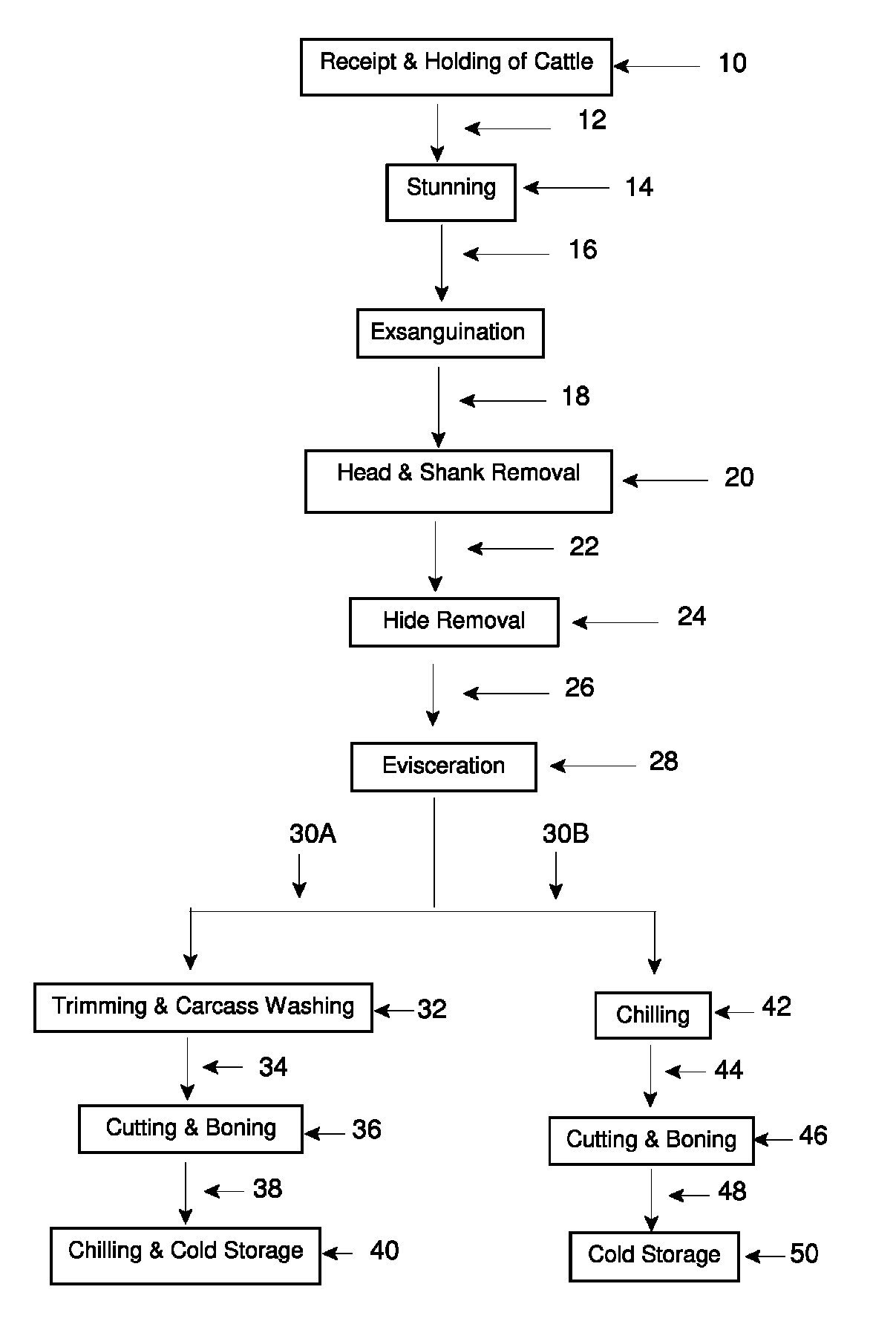

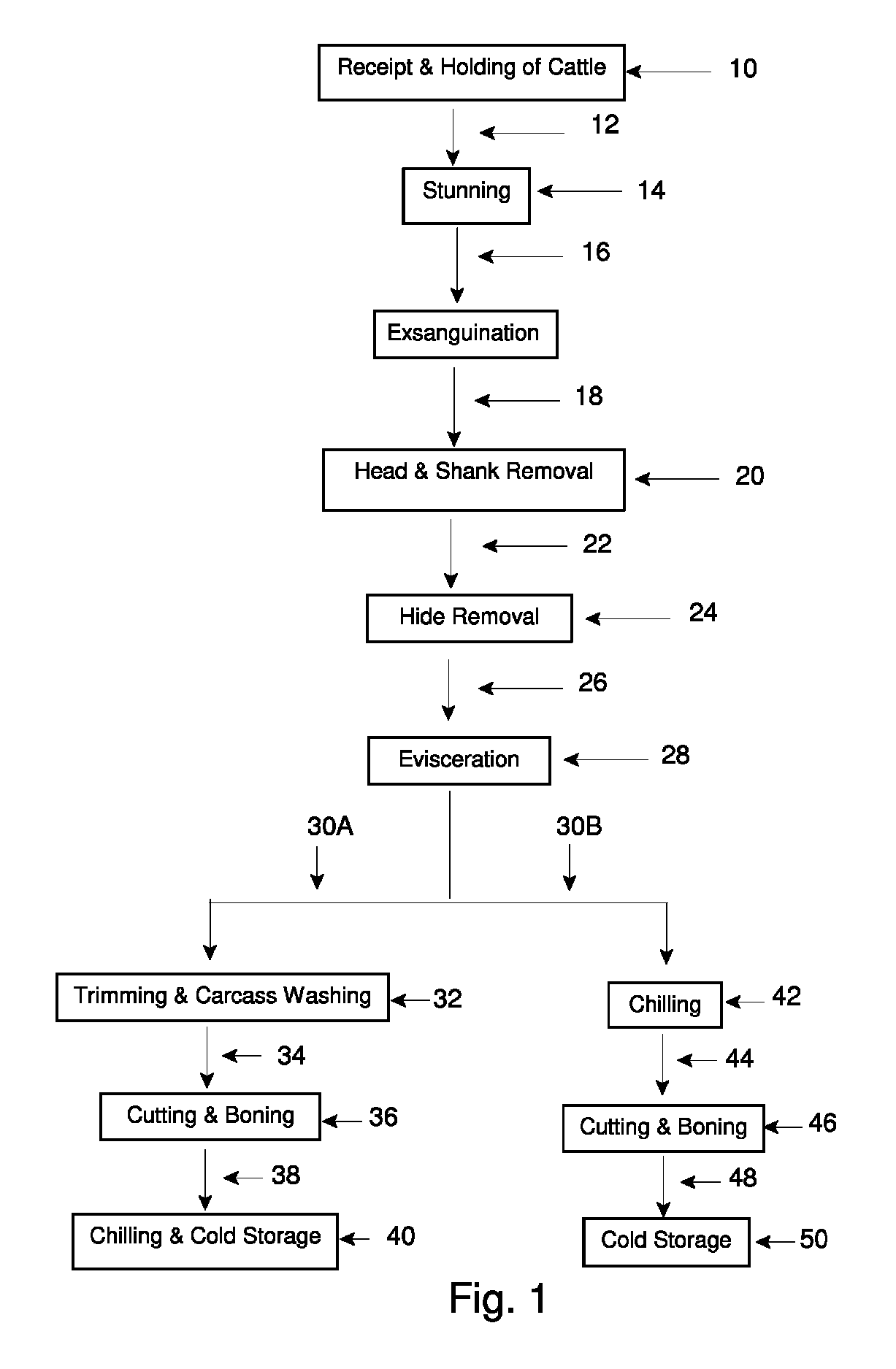

Microbiocidal Control in the Processing of Meat-Producing Four-Legged Animals

ActiveUS20070141974A1Reduce Microbial ContaminationImprove the bactericidal effectBiocideAntiinfectivesBiotechnologyMicroorganism

Methods of processing four-legged slaughter animals for consumption as meat and / or meat product(s) are described. The methods comprise I) contacting exterior surfaces of the live animal at least once with a microbiocidal solution formed from mixing together at least (i) water and (ii) at least one N,N′-bromochloro-5,5-dialkylhydantoin, such contacting occurring at least once when the animal is en route to being slaughtered but before it is killed by exsanguination; or II) contacting the carcass of the animal, after exsanguination, with a microbiocidal solution formed from mixing together at least (i) water and (ii) at least one N,N′-bromochloro-5,5-dialkylhydantoin or III) contacting at least one raw meat product and / or at least one processed meat product derived from the carcass. The contacting can be done one or more times in each of I), II), and III). Considerable advantages, which are described, are realized when using such methods.

Owner:ALBEMARLE CORP

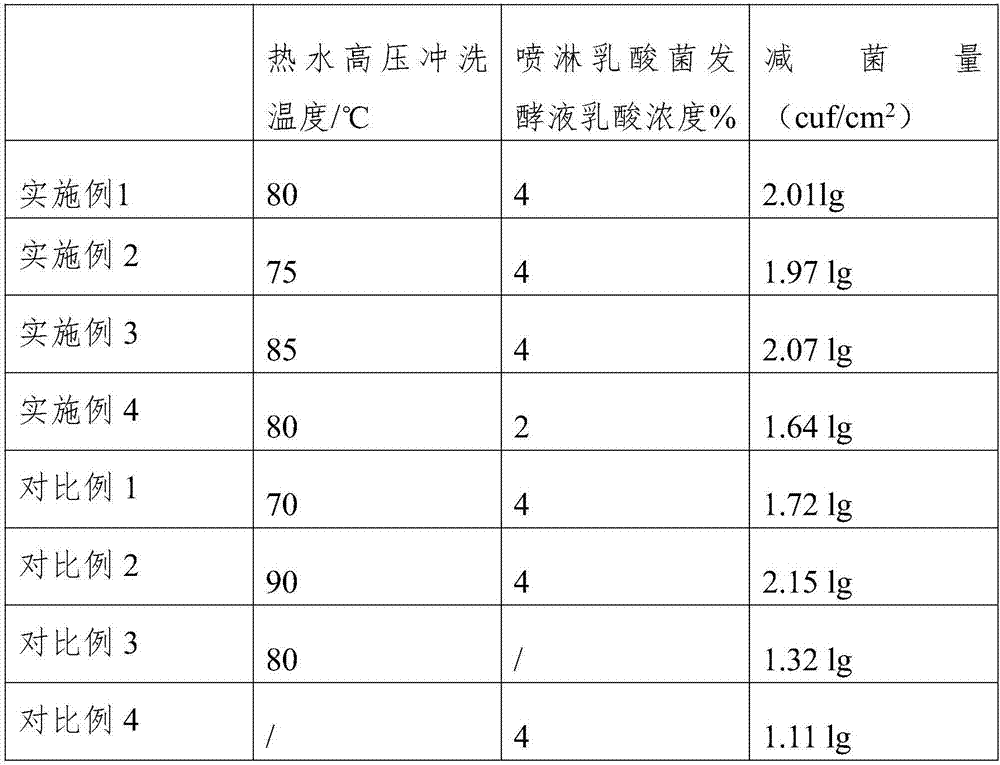

Beef cattle slaughtering method

InactiveCN107087665AExtended shelf lifeHigh Bacteria ReductionElectric current slaughtering/stunningCarcasses disinfectionAgricultural scienceHigh pressure

The invention relates to the field of breeding of livestock, in particular to a beef cattle slaughtering method. According to the method, firstly beef cattle are slaughtered, hot water high-pressure rinsing is performed in the process of treating carcasses, and then sprinkling with lactic acid bacteria fermentation liquor is performed, so that disinfection and bacterium resistance are performed on beef, the total quantity of bacterial colonies of the whole carcasses of the beef is reduced, and the fresh-keeping period of the beef is prolonged.

Owner:广西山水牛畜牧业有限责任公司

Variable size carcass contaminant removal

ActiveUS7467994B2Reduce consumptionIncrease in sizeMeat/fish preservation using liquidsSlaughtering/stunningDead bodyEngineering

A washer cabinet has a bottom floor, a top wall, and a pair of upstanding sidewalls to define a channel that extends the length of the cabinet. The channel has an entry end and an exit end. An overhead track suspends animal carcasses in alignment with the channel. A plurality of rotating appendages and a plurality of fluid nozzles are positioned within the cabinet. An animal carcass suspended from the overhead track is moved into the cabinet through the entry end. The carcass comes into contact with the rotating appendages and is washed by fluid emitted from the fluid nozzles as it traverses the length of the cabinet before exiting at the exit end.

Owner:SANITATION CHEM DISPENSING

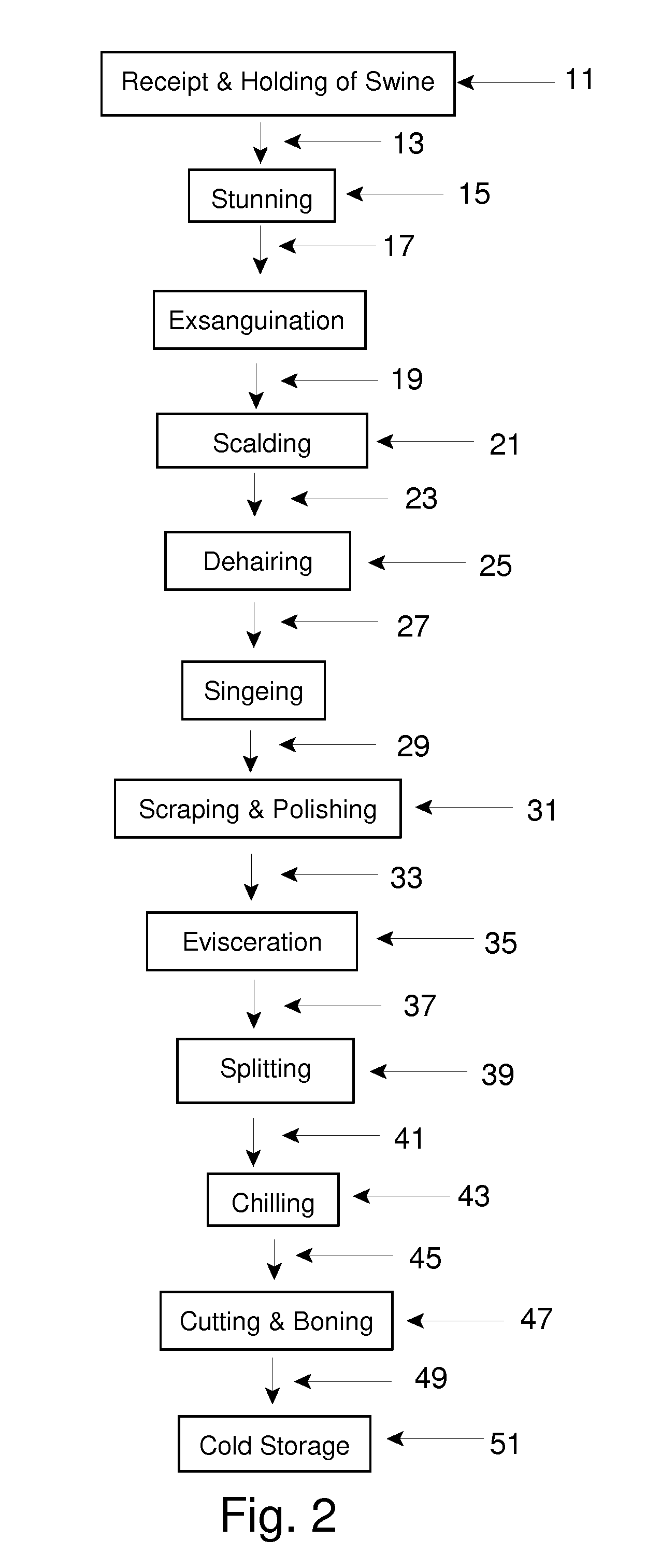

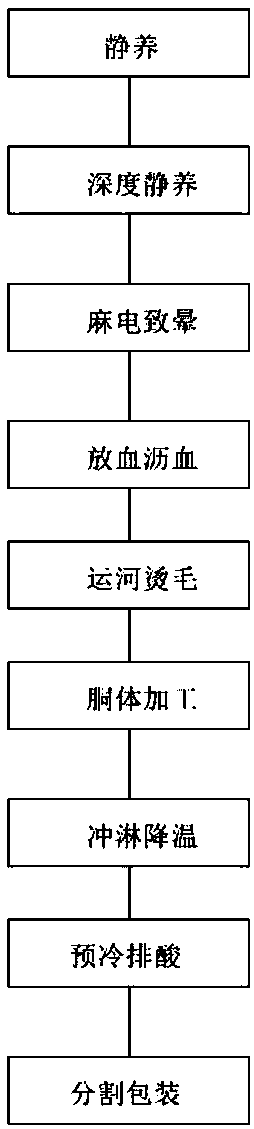

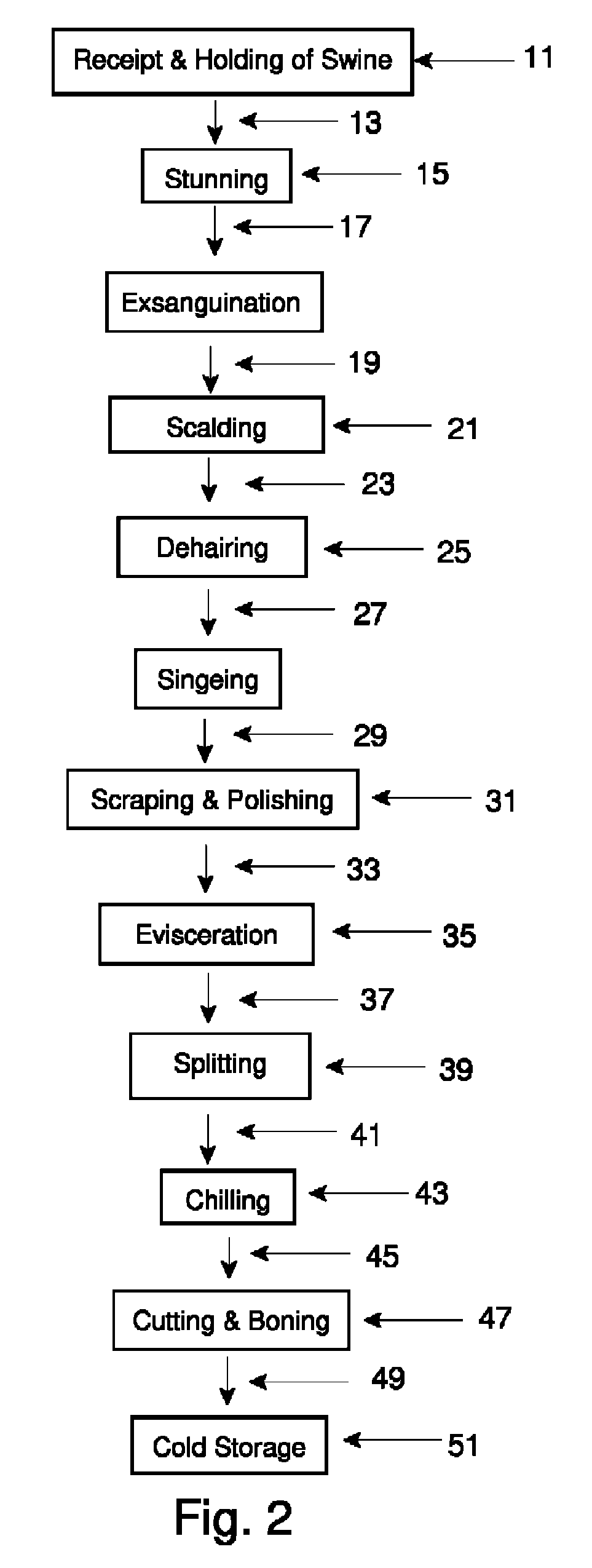

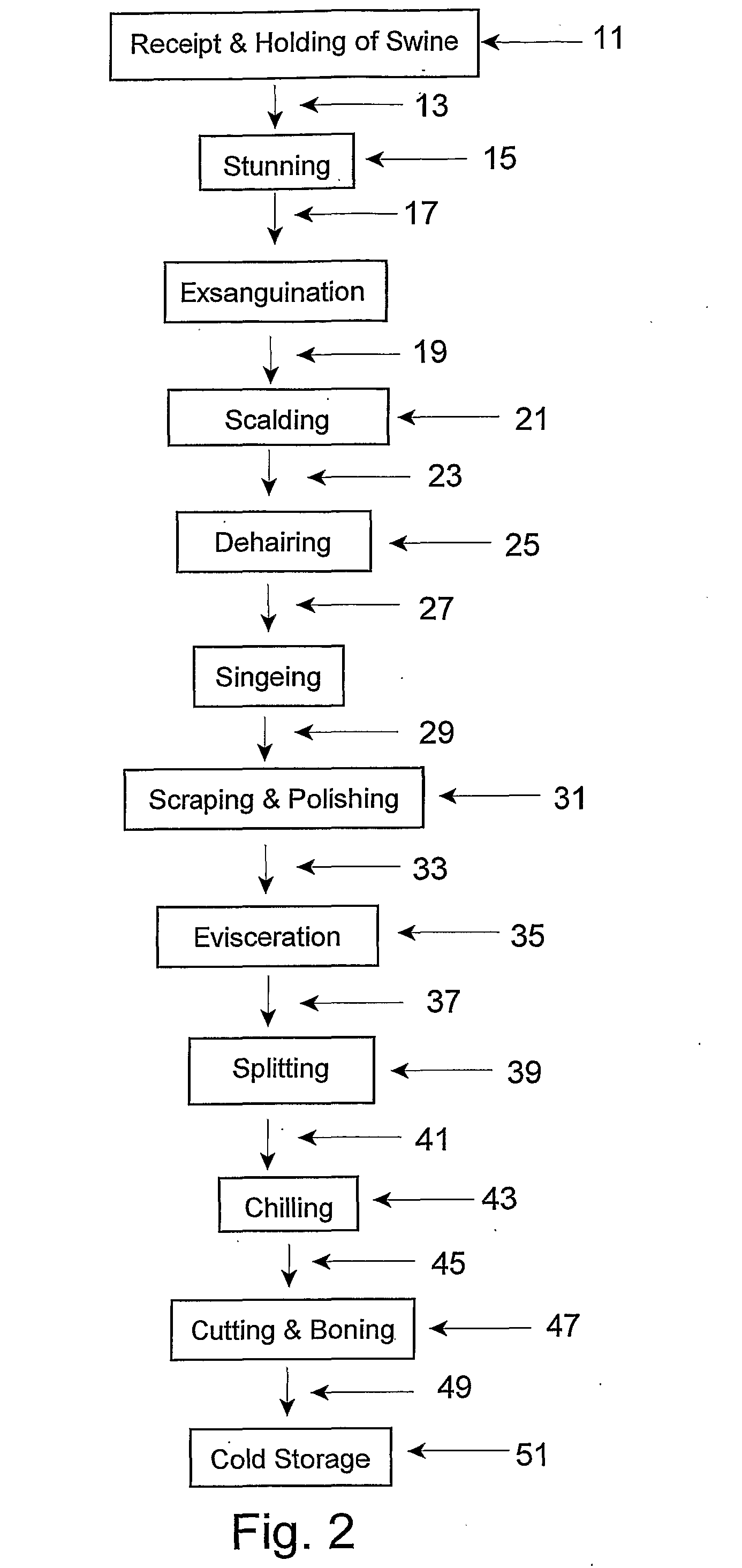

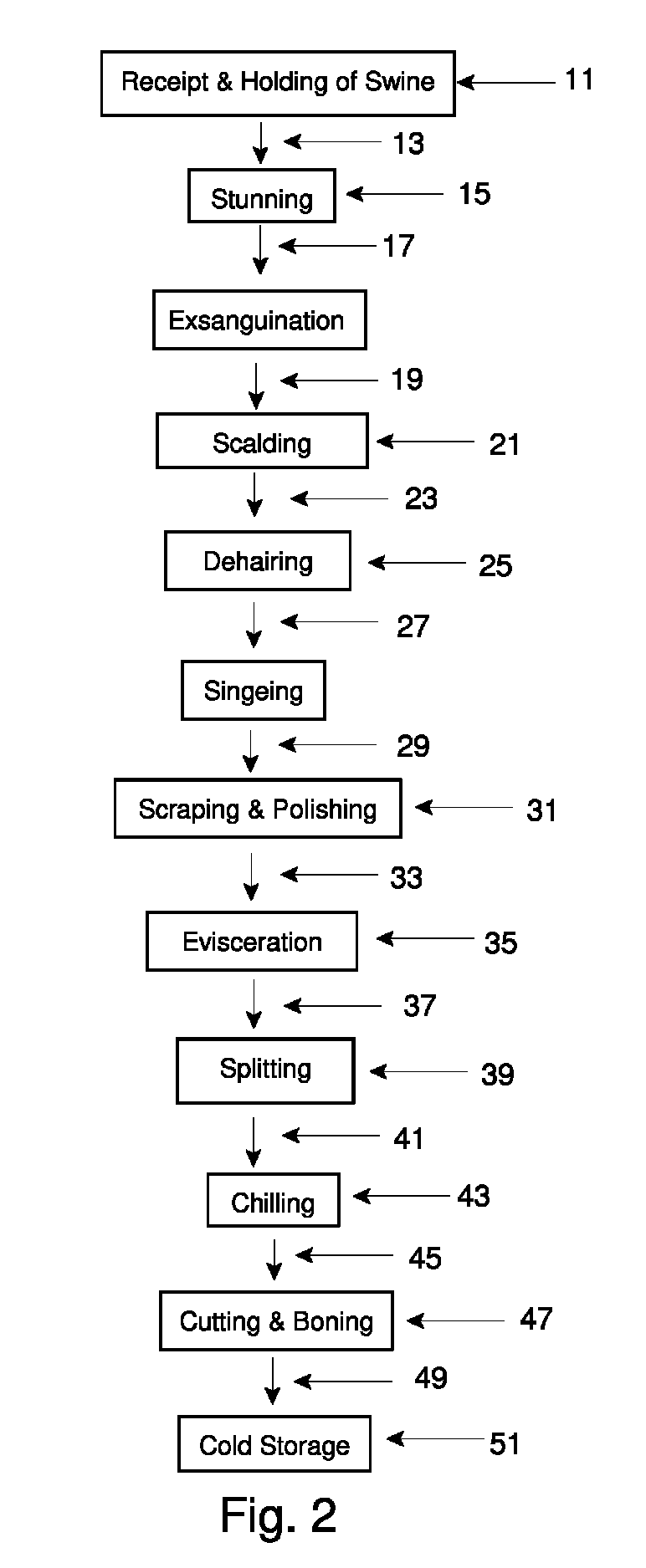

Slaughtering and producing technology of safety pigs

InactiveCN107668151AReduce formationBright colorPackaging meatElectric current slaughtering/stunningElectricityLean meat

The invention discloses a slaughtering and producing technology of safety pigs. The slaughtering and producing technology comprises the following steps of: a. performing relaxation; b. performing deeprelaxation: after the pigs to be slaughtered are in relaxation, showering the pigs with water for 3-5 minutes, wherein when the season for deep relaxation is summer, the water temperature is 20 DEG C, and when the season for deep relaxation is winter, the water temperature is 38 DEG C; c. performing electric-shock for stunning; d. performing bloodletting and bleeding; e. performing transferring and scalding; f. performing carcass processing; g. performing showering for cooling; h. performing pre-cooling and acid discharge; and i. performing segmentation and packaging: wherein in the whole segmentation process of chilled meat, the temperature of a segmentation workshop is less than or equal to 12 DEG C, the temperature of a packaging workshop is less than or equal to 10 DEG C, and the segmented chilled meat is safety pork, putting the safety pork on a tray with absorbent paper being spread, then transferring the safety pork into a packaging machine, performing overlay film packaging, and in the packaging process, charging mixed gas consisting of oxygen and carbon dioxide in the ratio of the oxygen to the carbon dioxide being 1 to 4 into an overlay film. According to the slaughtering and producing technology disclosed by the invention, the residual heat inside the product is reduced by water gradient, the product loss is smaller, and the lean meat of the product in the market isbrighter in color.

Owner:成都春源食品有限公司

Methods and compositions for the reduction of pathogenic microorganisms from meat and poultry carcasses, trim and offal

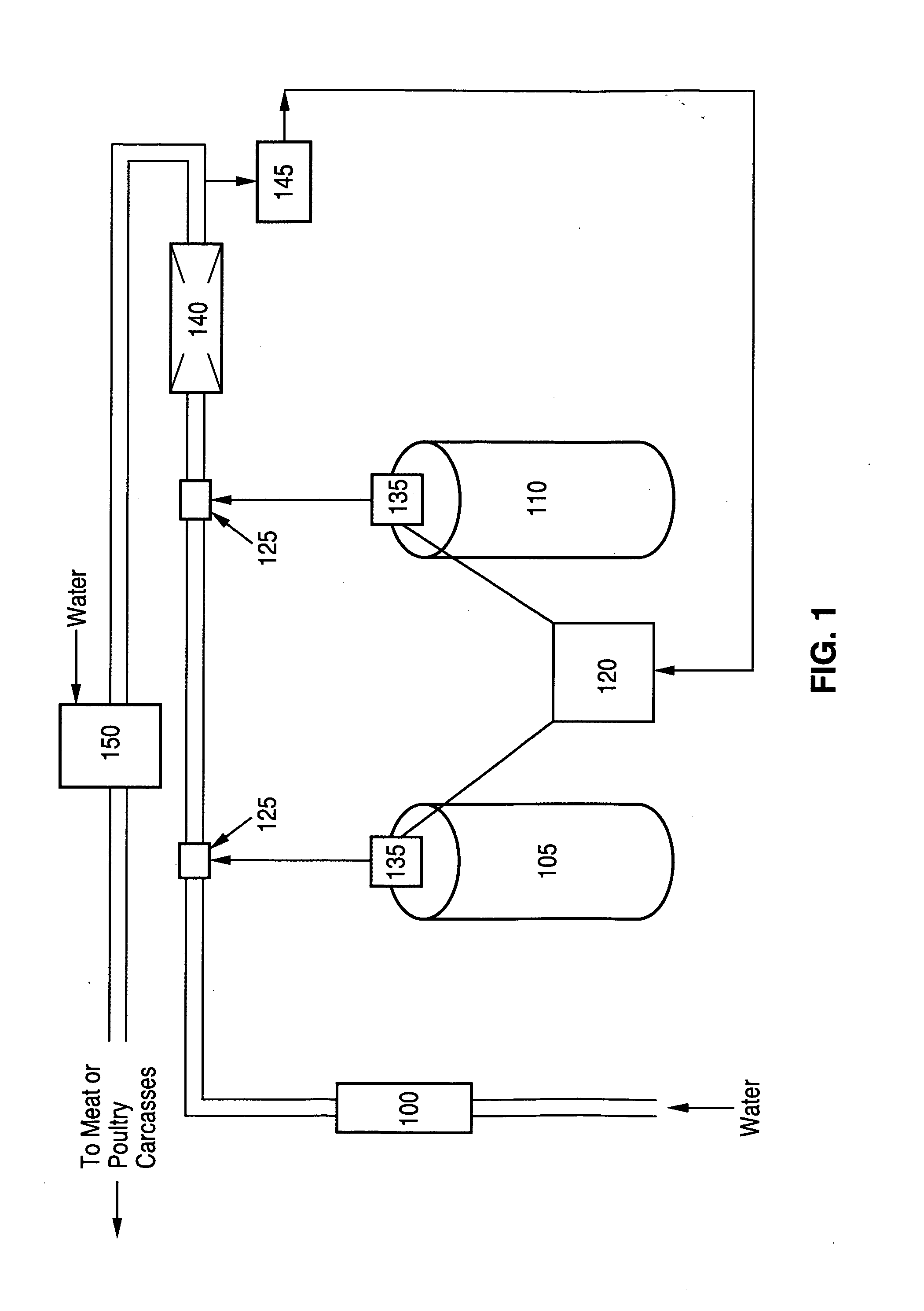

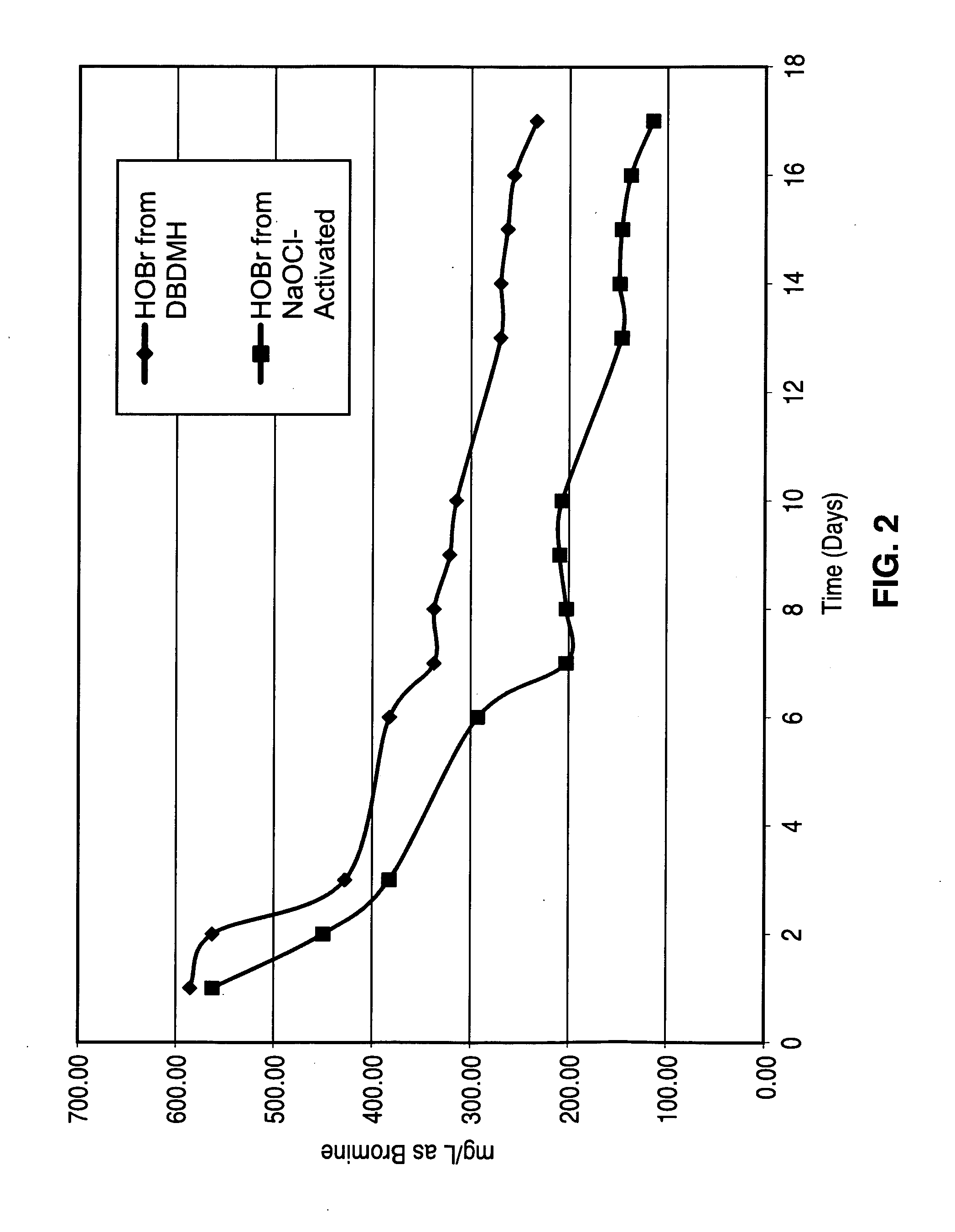

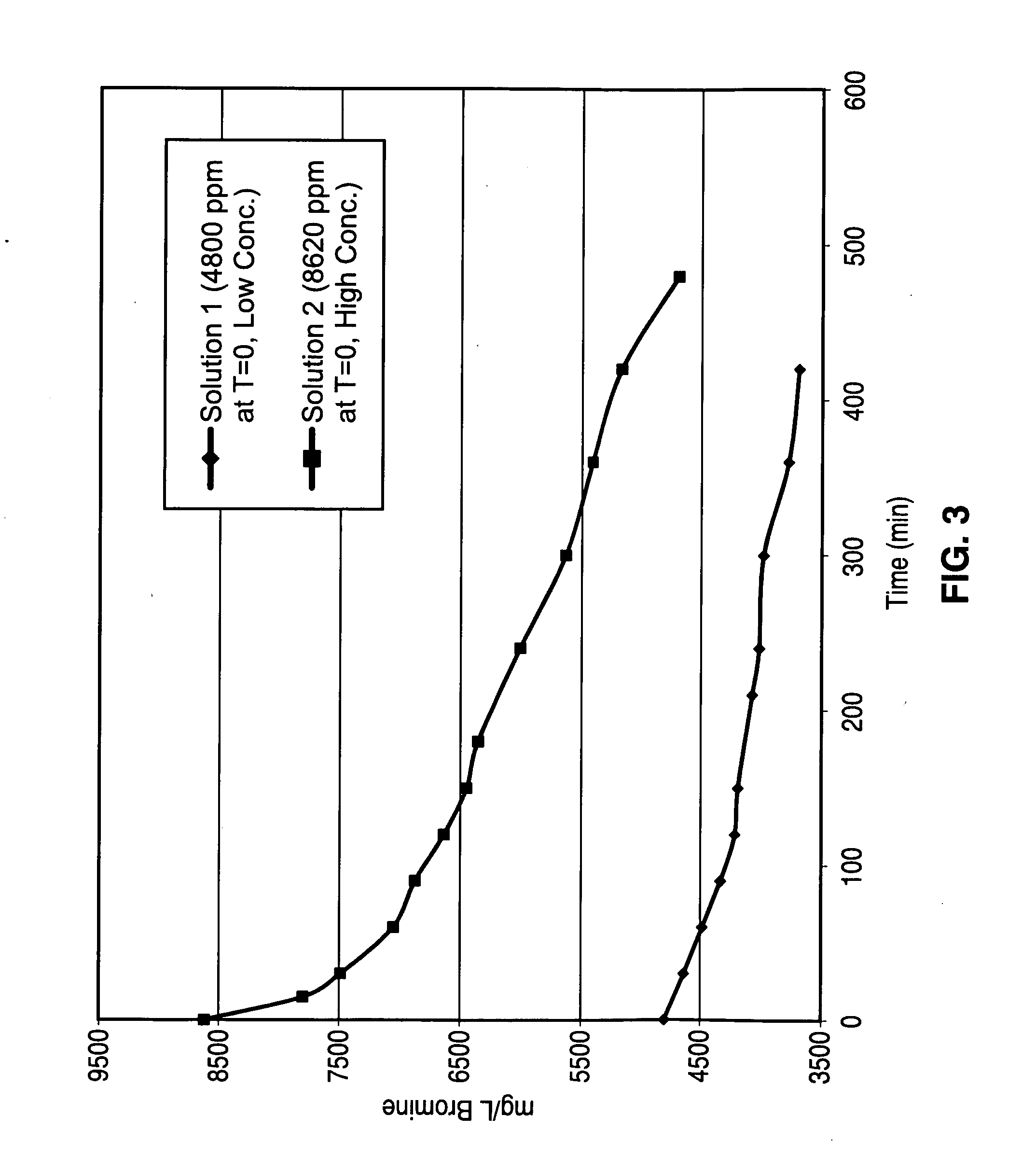

InactiveUS20110200688A1Reducing cleaning chemicalReduce cleanup timeInorganic/elemental detergent compounding agentsBiocideMicroorganismHypobromous acid

The invention includes a method of preparing hypobromous acid by mixing an aqueous solution of hydrogen bromide and a source of hypochlorite with water. The invention also includes a method of using the hypobromous acid prepared by this method to wash animal carcasses, trim, and offal to reduce microorganisms, in particular, human pathogenic bacteria, on and in the carcasses, trim, or offal. Compositions of hypobromous acid are also described. The hypobromous acid of the invention may also be used to reduce fat, oil, and grease build-up on equipment and hard surfaces used in the processing of animal carcasses, trim, and offal.

Owner:ENVIRO TECH CHEM SERVICES

Microbiocidal control in the processing of meat-producing four-legged animals

InactiveUS8033898B2Reduce Microbial ContaminationSignificant comprehensive benefitsBiocidePoultry cleaning/disinfectionBiotechnologyMicroorganism

Owner:ALBEMARLE CORP

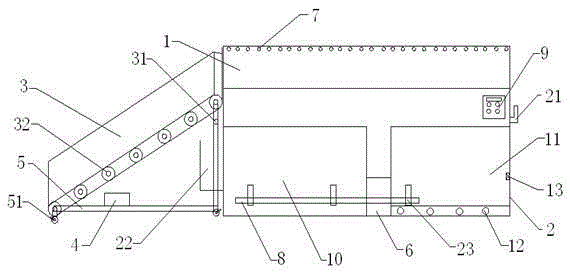

Live pig slaughter operating platform

InactiveCN105285038ASave human effortClean upElectric current slaughtering/stunningSlaughterhouse arrangementsMicrocontrollerAgricultural engineering

The present invention discloses a live pig slaughter operating platform which includes a hollow base, a cold water tank is arranged inside the left side of the hollow base, a water pump is arranged on the right side of the cold water tank, a boiling water tank is arranged on the right side of the water pump, a spraying device is arranged on one end of a table-board, the spraying device is electrically connected with the water pump, the water pump is electrically connected with a controller, the spraying device is connected with the cold water tank and the boiling water tank through water pipes, heating pipes are arranged at the bottom of the boiling water tank, a temperature sensor is arranged on the right side of the inner wall of the boiling water tank, the heating pipes and the temperature sensor are electrically connected with the controller, a conveyer belt is arranged on the left side of the base, brackets are arranged on both ends of the conveyer belt, a motor is arranged on the bracket, and the controller is electrically connected with the water pump, a temperature detecting module, a spraying module and a heating module through a single chip micyoco. The live pig slaughter operating platform is labor-saving, easy to wash and clean pig hair and less in water consumption, is health and safety, and can be operated by one person.

Owner:CHONGQING MINGGAO FOOD CO LTD

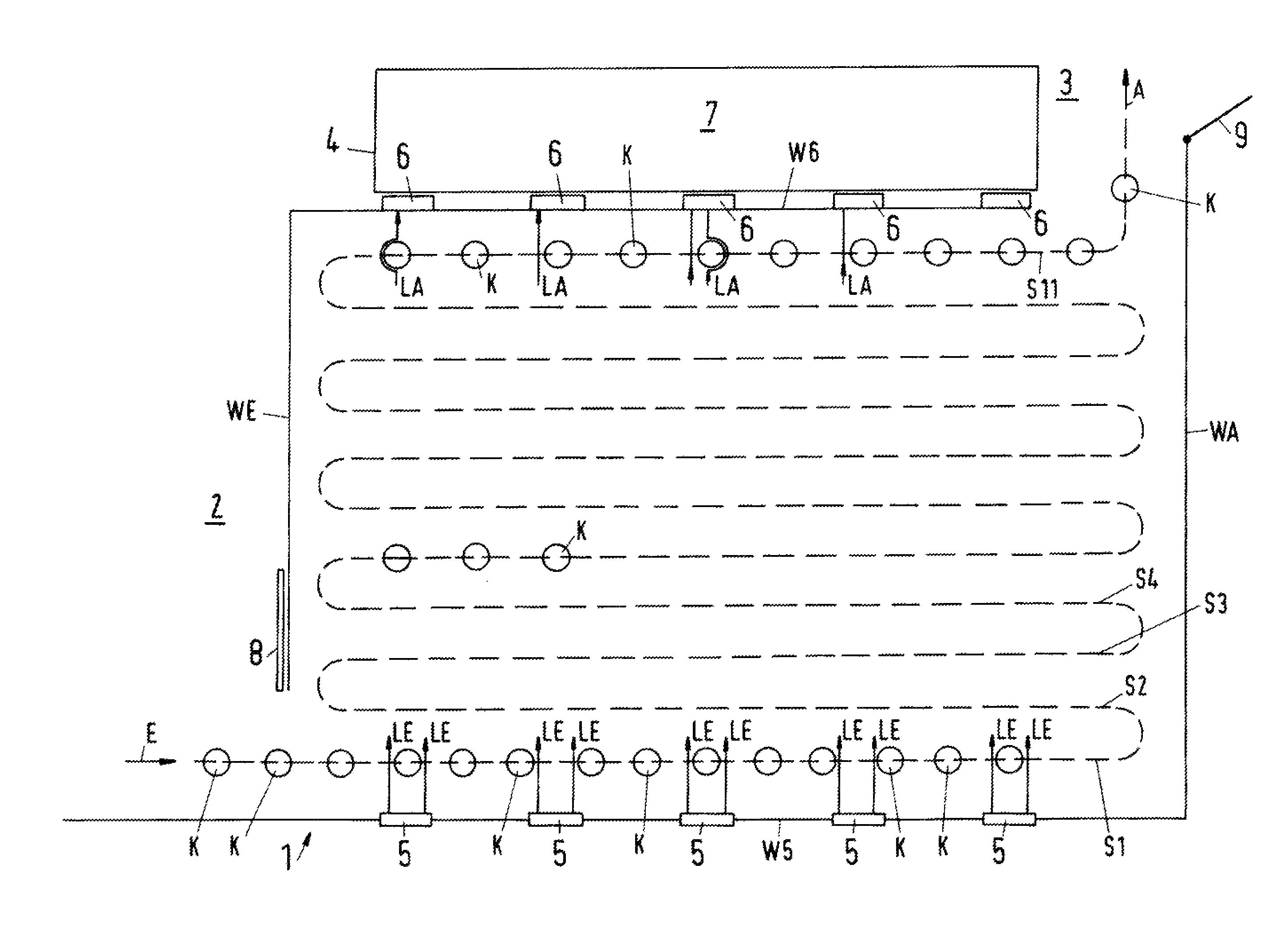

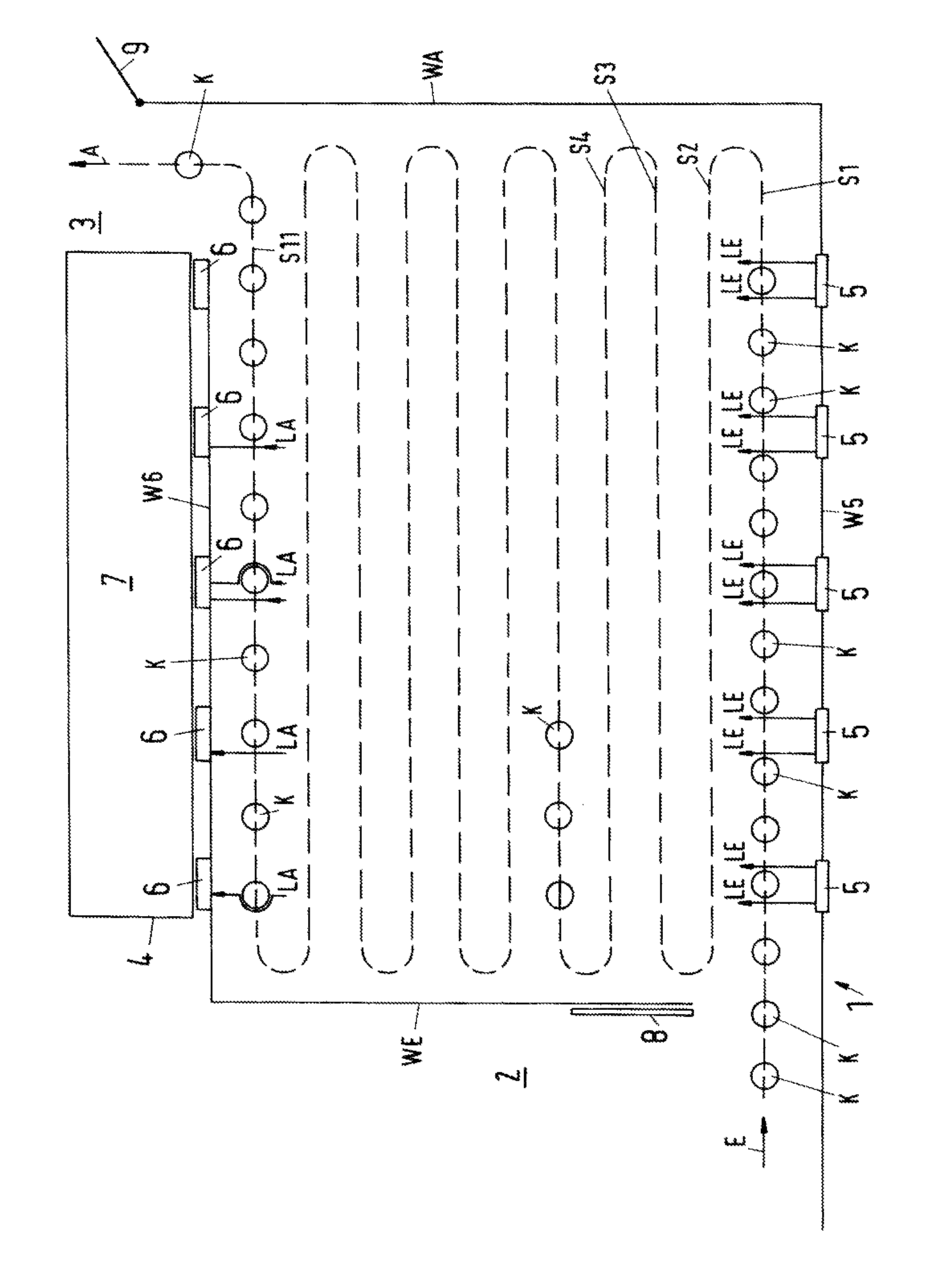

Hygienic dehumidification of animal carcasses warm from slaughter

ActiveUS8572864B2Reduce lossesImproved acquisition real weightDrying using combination processesDrying solid materials with heatAbdominal eviscerationAir conditioning

The invention relates to a method and a device for handling carcasses of slaughtered animals during suspended transport after evisceration and before weighing in an abattoir by means of an air stream, in which a horizontally directed stream of conditioned air is made to flow around the carcasses at speeds of 1.5 to 6 m / s with a suction effect. Suspension conveyors are set up in a separate room in a meandering arrangement along parallel tracks transversely to the horizontally aligned extraction openings and inlet openings for air, and the inlet openings and extraction openings are connected through an air-conditioning plant, arranged outside the room, for dehumidifying and cooling the air extracted from the room. When a room designed as a dripping zone in an abattoir is used for the purposes according to the invention, the room is prepared by installing or fitting inlet openings and extraction openings on two enclosing walls lying opposite one another and is connected to a separate air-conditioning plant for conditioning the air.

Owner:PROMETHON

Microbiocidal Control in the Processing of Meat-Producing Four-Legged Animals

InactiveUS20090081317A1Reduce Microbial ContaminationSignificant comprehensive benefitsBiocideMilk preservationMicroorganismAlkaline earth metal

Methods of processing four-legged slaughter animals for consumption as meat and / or meat product(s) are described. The methods comprise (I) contacting exterior surfaces of the live animal at least once when the animal is en route to being slaughtered but before it is killed by exsanguination, with a microbiocidal solution, or (II) contacting a carcass of the animal, after exsanguination, with a microbiocidal solution, or (III) contacting at least one raw meat product and / or at least one processed meat product derived from the carcass at least once with a microbiocidal solution, or (IV) conducting any two or all three of (I), (II), and (III). In each case the microbiocidal solution is, independently, comprised of: (a) water having a bromine residual derived from (i) at least one bromine source, (ii) at least one alkali metal base, and / or at least one alkaline earth metal base, and (iii) at least one halogen stabilizer; or (b) water having a bromine residual derived from (i) ammonium bromide, and / or at least one alkali metal bromide, and / or at least one alkaline earth metal bromide, and (ii) at least one alkali metal hypohalite and / or at least one alkaline earth metal hypohalite; or (c) water having a bromine residual derived from a mixture or combination of any one or more of (a) and any one or more of (b); the bromine residual in each of (a), (b), and (c) being sufficient to provide microbiocidal activity.

Owner:ALBEMARLE CORP

Method and apparatus for processing animals

ActiveUS7591718B2Significant processing efficiencyImprove efficiencyBlood collection/stirring apparatusSlaughtering/stunningEngineeringCirculatory system

Owner:MPSC INC

Method and apparatus for removing water from hide of cattle

InactiveUS8176652B2Solve the lack of tensionLeather manufacturingDrying solid materials with heatHydraulic cylinderHeifer calf

An apparatus and method for a water removing roller device for removing excess water from the hide of a cattle, which uses pliable urethane roller stacks that can be attached by an arm structure. The roller structure can be mounted on a hinge to an arm thereby allowing the structure to swivel. The arm can be attached to a stationery device with a hinge, which is also allowed to swivel. A tension device, for example, a spring or a hydraulic cylinder can be attached to the back of the arm and connected to the stationery device to provide enough tension on the structure to keep the rollers in contact with the cattle hide, thereby pressing out the water allowing it to run off prior the blood plasma saving section.

Owner:TYSON FRESH MEATS

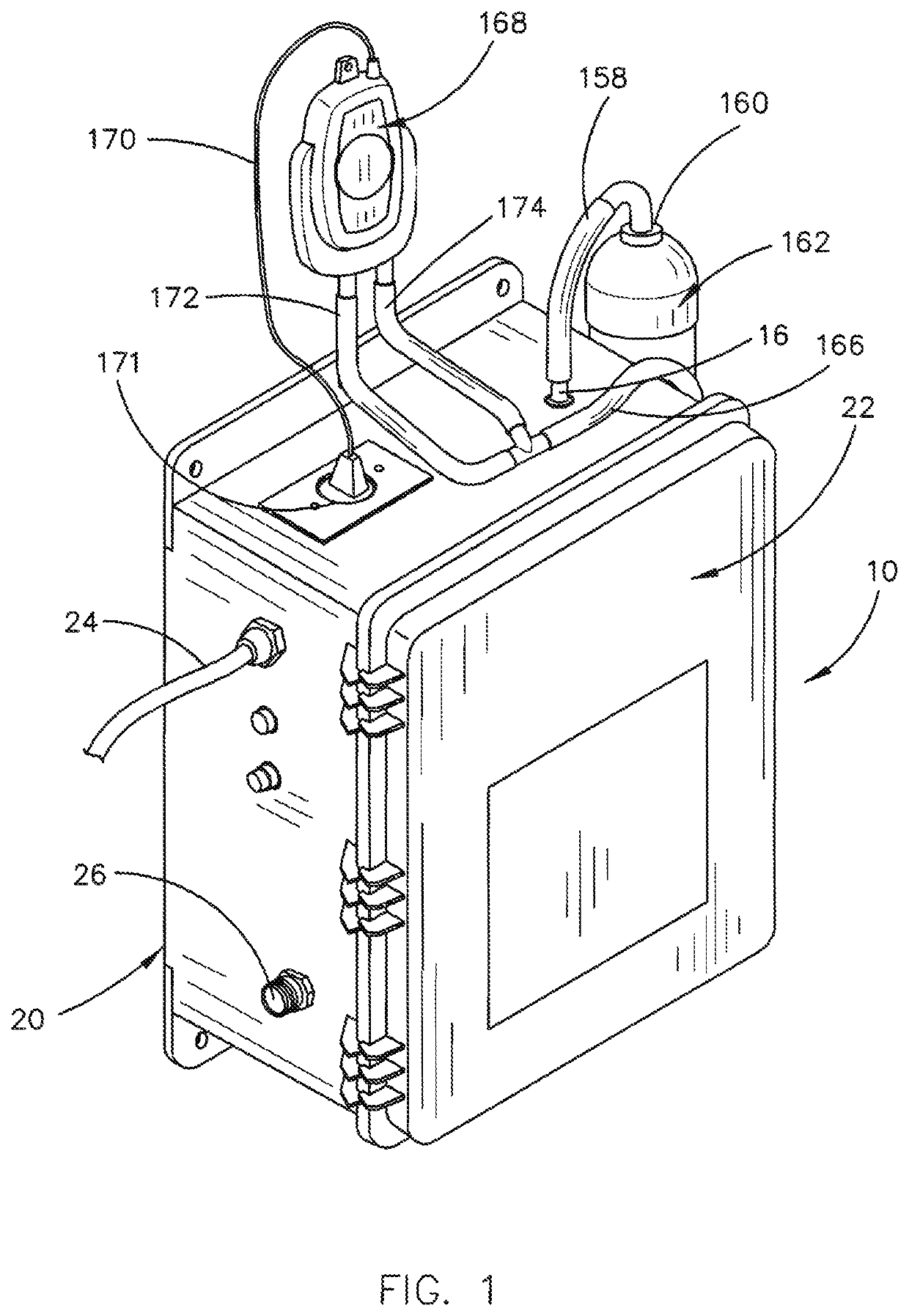

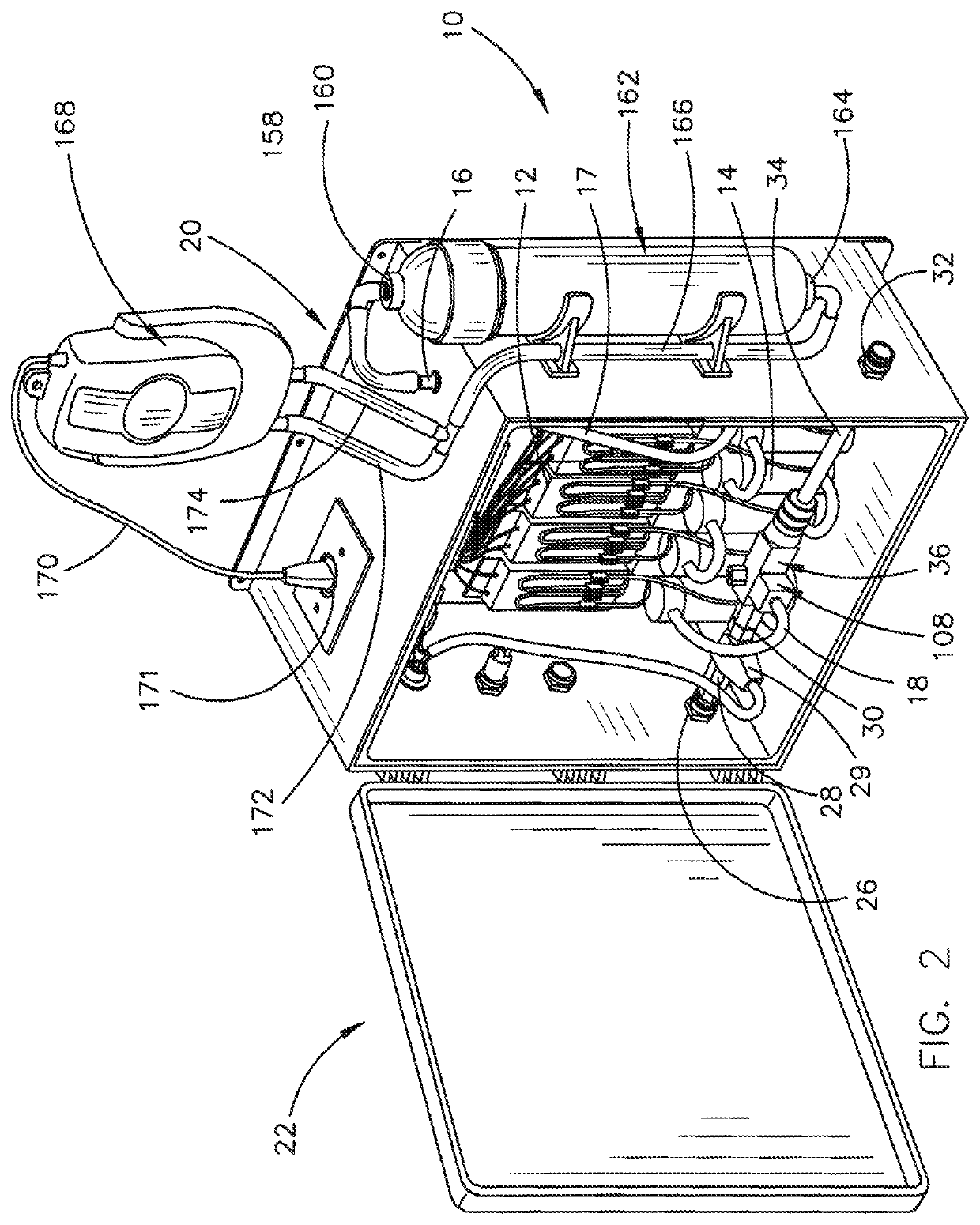

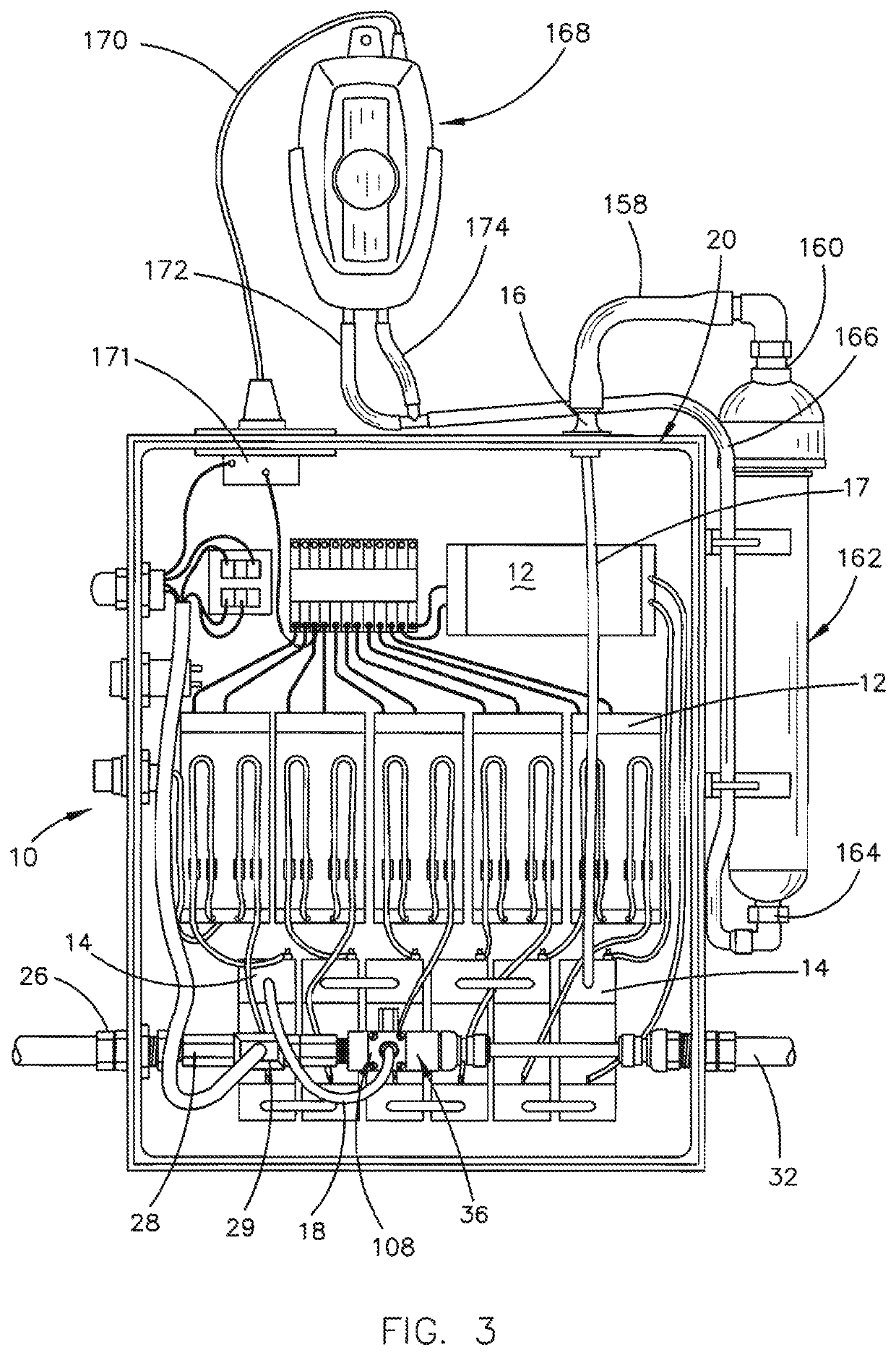

System for creating an oxidation reduction potential (ORP) in water for decontamination of a food animal carcass

ActiveUS11019827B1Reduce surface tensionReduce impactWater treatment parameter controlFlow mixersMicroorganismEnvironmental engineering

A system and method for creating an oxidation reduction potential (ORP) in water and for reducing the surface tension of the water for the microbiological decontamination of food animal carcasses. A method is also described for the microbiological decontamination of beef trimmings.

Owner:BIOSECURITY TECH

Blood draining device special for livestock and poultry

InactiveCN107432309AImprove practicalityEnsure stabilityBlood collection/stirring apparatusPoultry cleaning/disinfectionCrop livestockEngineering

The invention relates to a blood draining device special for livestock and poultry. The blood draining device comprises a fixing base, support rods, moving guide rails, a first blood draining frame and blood draining hooks. Anti-slip plates are fixed at left and right ends of the fixing base. Buffering frames are arranged on the inner walls of the anti-slip plates. The support rods are mounted at the top end of the fixing base. A recording plate is fixed to the outer walls of the bottom sides of the support rods. The moving guide rails are arranged on the outer walls of the middles of the support rods. The top ends of the support rods are connected with the top plate. The first blood draining frame is arranged on the right sides of the moving guide rails. A second blood draining frame is arranged on the left sides of the moving guide rails. The top end of the second blood draining frame is connected with the top plate through a limiting rod. The blood draining hooks are embedded at the bottom end of the second blood draining frame. The blood draining device has the advantages that pressure generated during blood draining of the livestock and poultry can be dispersed through the buffering frames during use, stability of the blood draining device is guaranteed, and the practicability of the blood draining device is improved greatly.

Owner:微微(杭州)信息技术有限公司

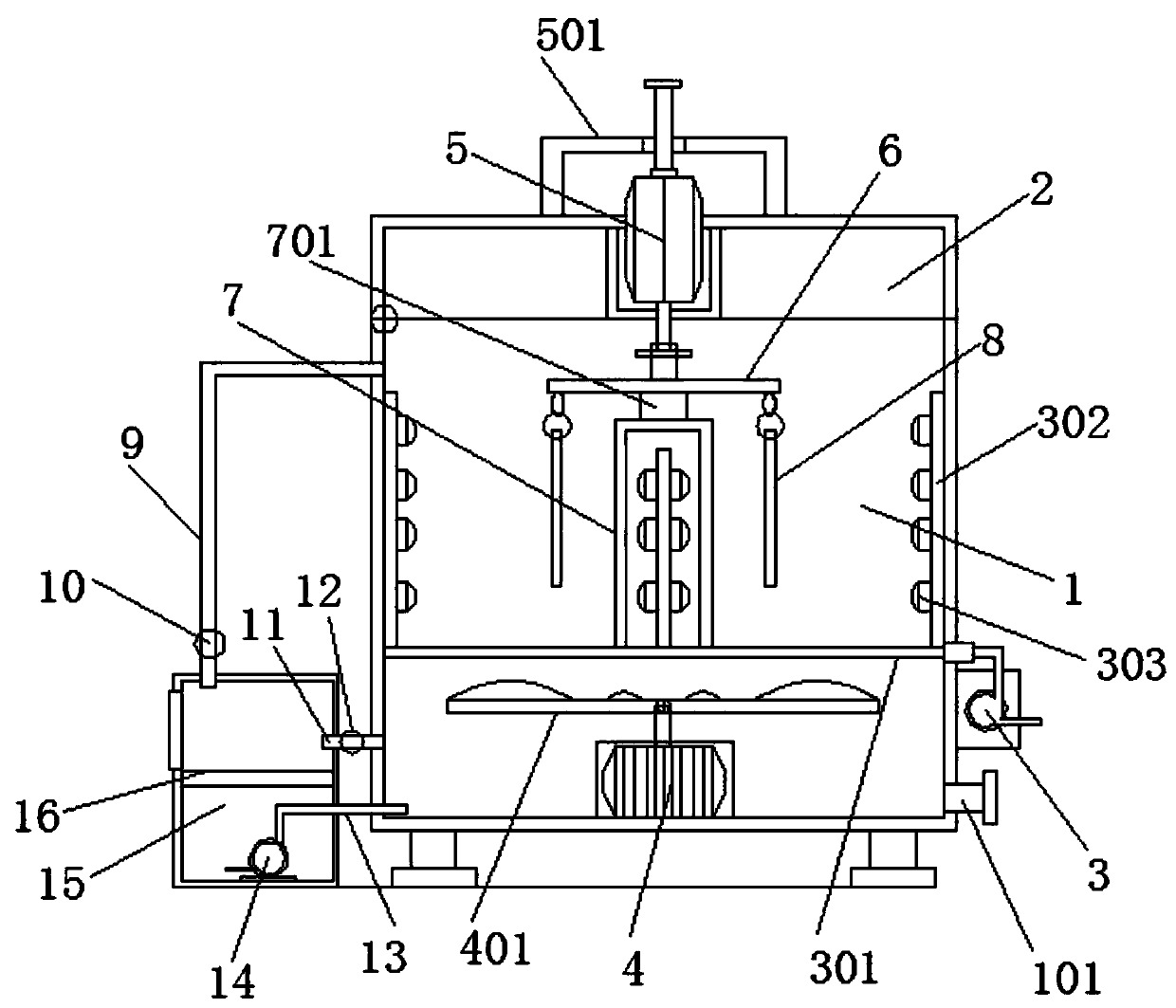

Cleaning device for beef processing

InactiveCN111771943AQuick washEasy to cleanCarcasses disinfectionMeat processing devicesElectric machineryProcess engineering

The invention discloses a cleaning device for beef processing. The cleaning device comprises a bottom plate, wherein a cleaning tank is fixedly connected to the top of the bottom plate, a belt conveyor body is fixedly connected to the interior of the cleaning tank, a supporting plate is fixedly connected to the back of the cleaning tank, and a first motor is fixedly connected to the top of the supporting plate. According to the cleaning device for beef processing, the first motor drives the belt conveyor body to move, the belt conveyor body drives beef to move, meanwhile, clear water is injected into a water tank, a water pump pumps the clear water out of the water tank through a water pumping pipe, and the clear water is injected into a spraying pipe through a water outlet pipe and then sprayed out through a spraying head to clean the beef. The cleaning device for beef processing solves the problems that an existing meat cleaning method carries out cleaning manually, and thus is low in operation efficiency, not suitable for large-batch meat cleaning, and wastes a large amount of manpower and material resources, and has the advantages of being capable of rapidly cleaning the beef and the like.

Owner:广州上仕船务有限公司

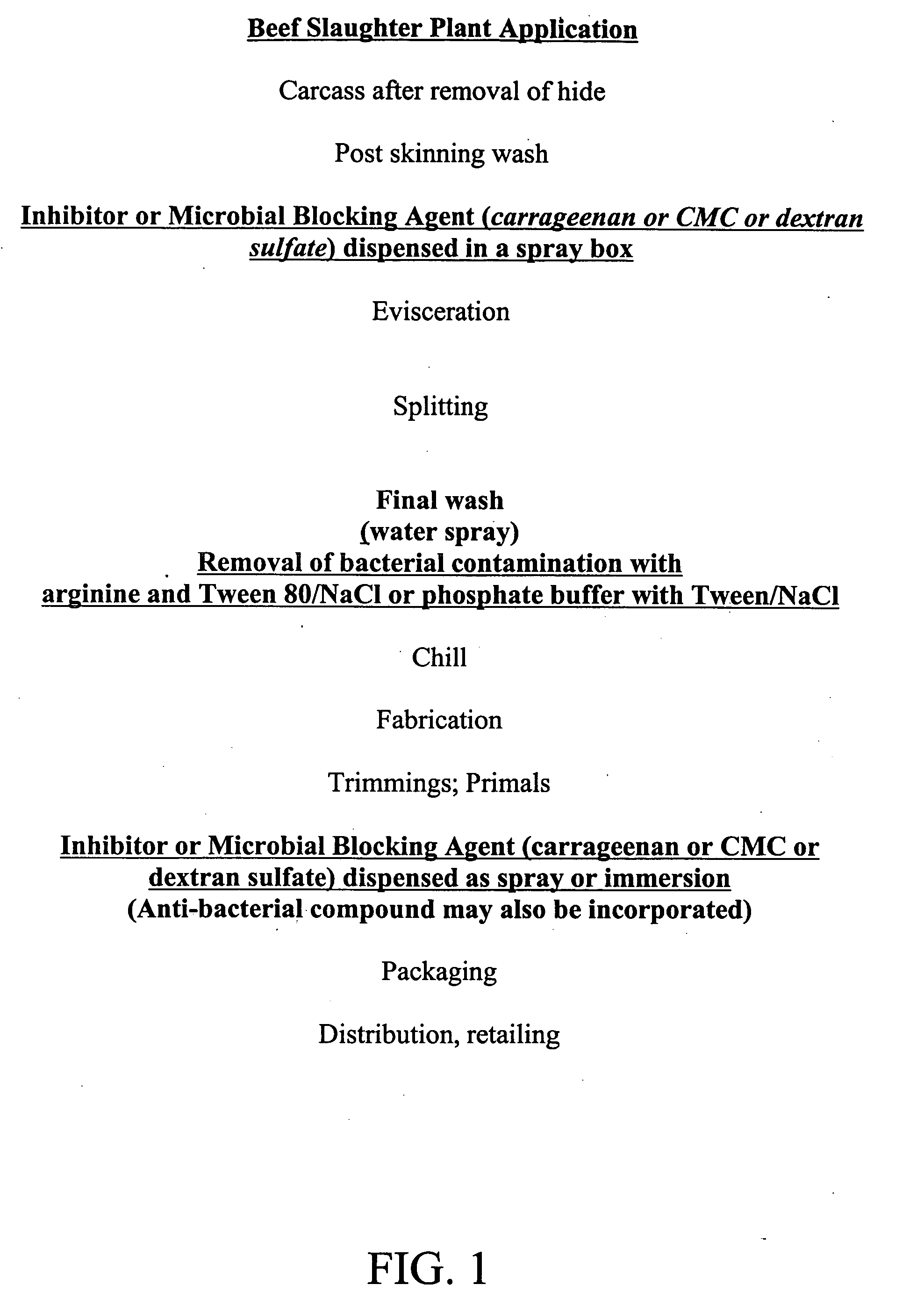

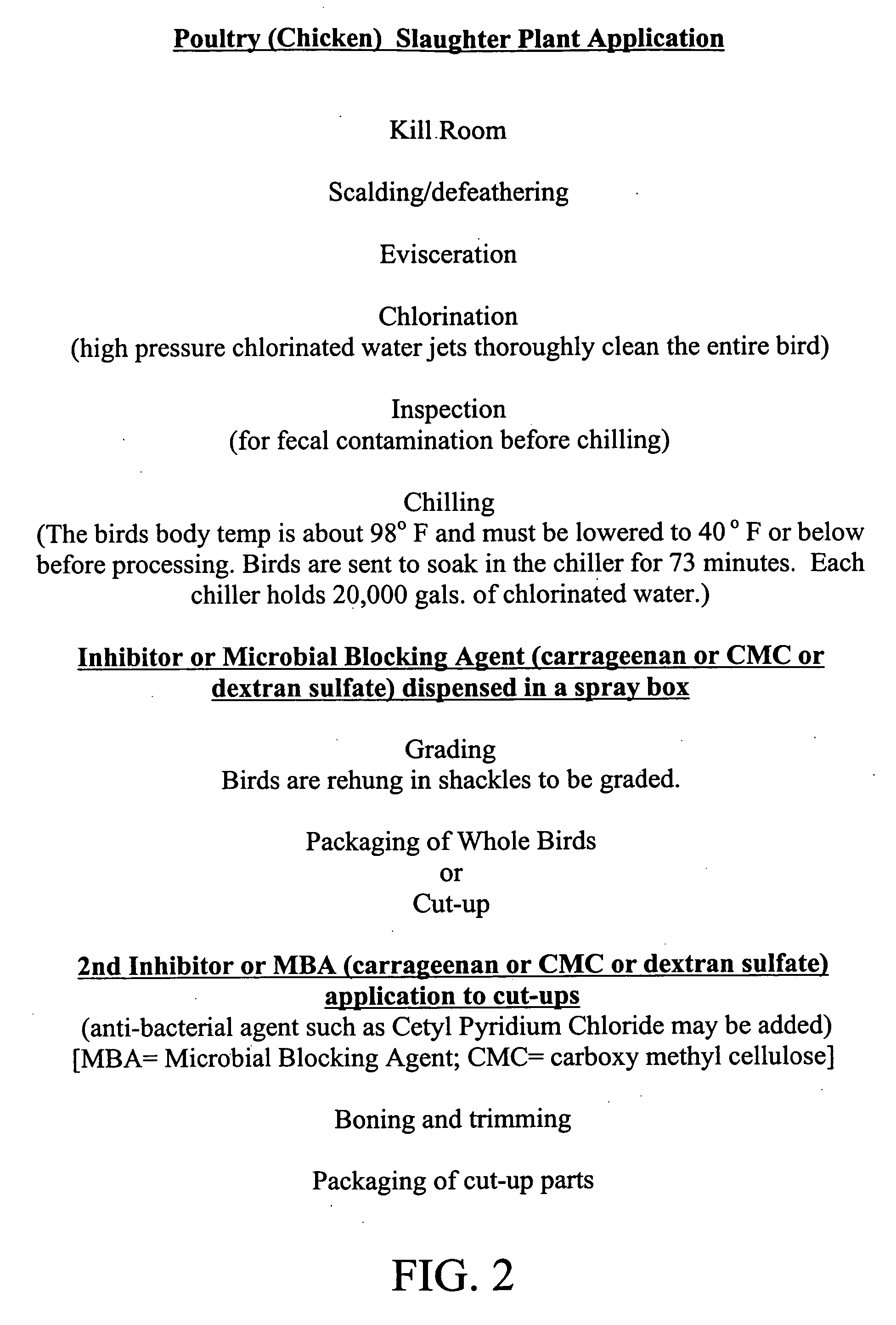

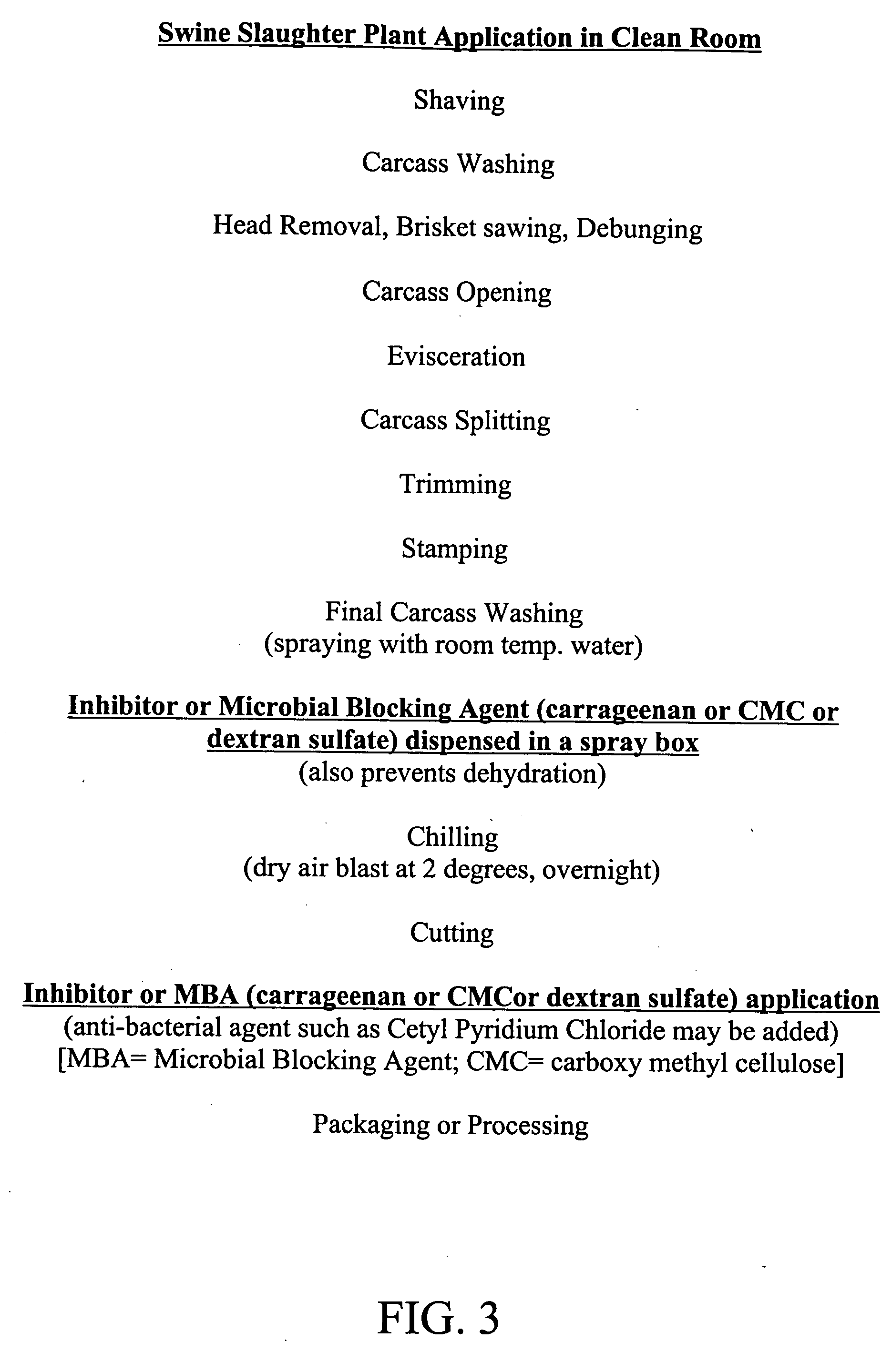

Methods of detaching microorganisms from, or of inhibiting microbial attachment to, animal or poultry carcasses or seafood or parts thereof

InactiveUS20050224097A1Organic active ingredientsFatty acid chemical modificationCarboxymethyl celluloseArginine

Methods of detaching microorganisms (e.g., bacteria) from, or of inhibiting microbial (e.g., bacterial) attachment to, animal or poultry carcasses or seafood or parts thereof, wherein the method involves contacting animal or poultry carcasses or seafood or parts thereof at least once with at least one of the following: (i) a polysulfated polysaccharide, (ii) carboxymethyl cellulose, or (iii) guanidine or arginine, optionally together with sodium chloride and at least one non-ionic surfactant, or (iv) mixtures thereof, in an amount effective to detach microorganisms (e.g., bacteria) from, or inhibit microbial (e.g., bacterial) attachment to, animal or poultry carcasses or seafood or parts thereof.

Owner:US SEC AGRI

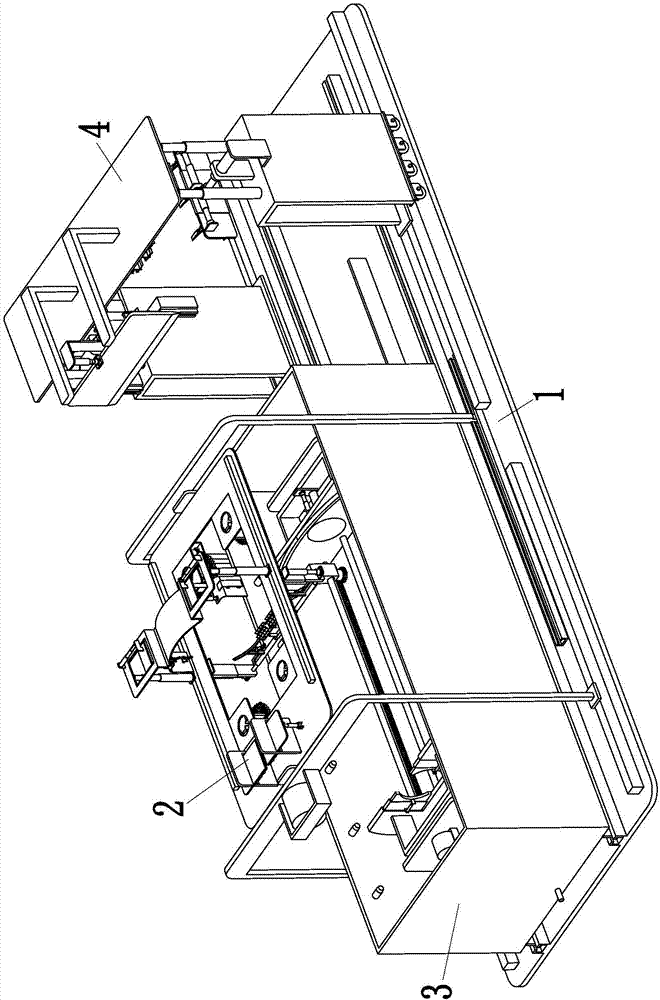

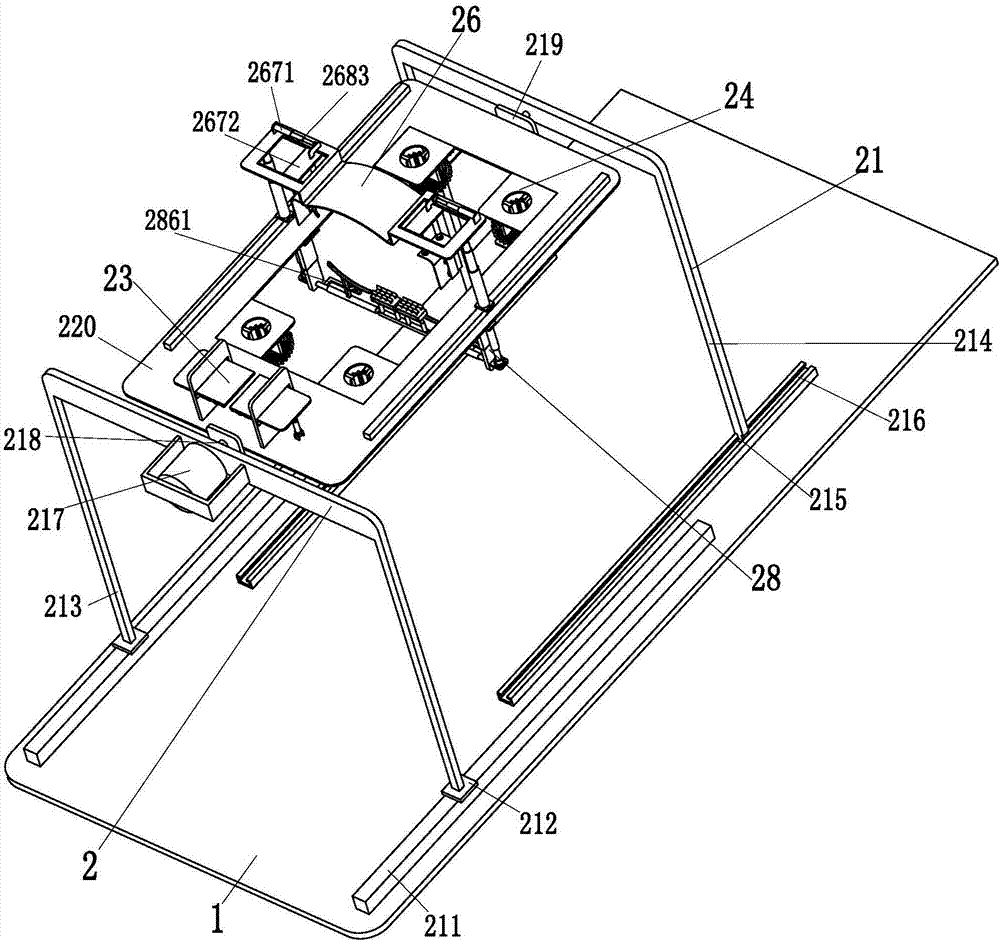

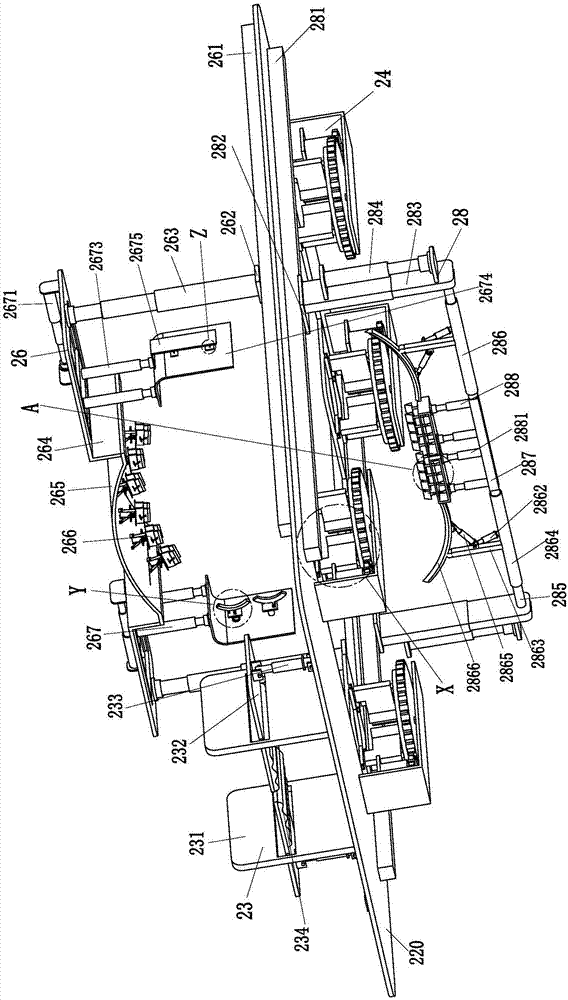

Pork processing robot capable of automatically shaving, cleaning and removing head and trotters of pig

The invention relates to a pork processing robot capable of automatically shaving, cleaning and removing head and trotters of a pig. The robot comprises a bottom plate, a shaving device, a cleaning device and a head and trotter removal device, wherein the shaving device is mounted on the upper side of the front end of the bottom plate, the cleaning device is mounted on the upper side of the frontend of the bottom plate and located in the shaving device, and the head and trotter removal device is mounted on the upper side of the rear end of the bottom plate. The problems that the pig is required to be manually shaved, manually carried to be cleaned and subjected to manually head and trotter removal during conventional processing of pork, a pig body is required to be turned by workers for shaving, the pig body is required to be turned and cleaned manually in water during cleaning of the pig body because residual hair is left on the pig body after shaving, besides, turning is difficult,the pig is required to be cut manually by a cutter when the head and the trotters are removed, the trotters of the pig are required to be held stably for cutting, repeated cutting is required when thepig head is cut manually and the like can be solved, and the functions of automatic shaving, cleaning and head and trotter removal during pork processing can be realized.

Owner:黄远明

Microbiocidal control in the processing of meat-producing four-legged animals

ActiveUS7914365B2Reduce Microbial ContaminationImprove the bactericidal effectBiocideAntiinfectivesRaw meatEngineering

Methods of processing four-legged slaughter animals for consumption as meat and / or meat product(s) are described. The methods comprise I) contacting exterior surfaces of the live animal at least once with a microbiocidal solution formed from mixing together at least (i) water and (ii) at least one N,N′-bromochloro-5,5-dialkylhydantoin, such contacting occurring at least once when the animal is en route to being slaughtered but before it is killed by exsanguination; or II) contacting the carcass of the animal, after exsanguination, with a microbiocidal solution formed from mixing together at least (i) water and (ii) at least one N,N′-bromochloro-5,5-dialkylhydantoin or III) contacting at least one raw meat product and / or at least one processed meat product derived from the carcass. The contacting can be done one or more times in each of I), II), and III). Considerable advantages, which are described, are realized when using such methods.

Owner:ALBEMARLE CORP

Antimicrobial treatment of animal carcasses and food products

PendingUS20180360060A1Reduce Microbial ContaminationImprove sensory propertiesBiocideFruit and vegetables preservationFowlMicroorganism

Provided herein are methods and compositions for the reduction of microbial contamination of animal carcasses, including fowl, and food products with carbonic acid-based compositions.

Owner:EVONIK OPERATIONS GMBH

Method and system for processing waste streams derived from the dehairing of animals

InactiveUS20050048887A1Fish washing/descalingPoultry plucking mechanismsWaste streamEnvironmental engineering

Disclosed is a novel method and system for dehairing an animal, providing a system for recycling and safely disposing of chemical and biological wastes produced during such dehairing method. Included in such method are processes for handling sodium production in waste materials, reducing and handling production of H2S, removing sulfides from animal hides, safely disposing of sulfide waste, removing solids from the waste materials, and reducing water and reagent use and disposal.

Owner:MONFORT INC

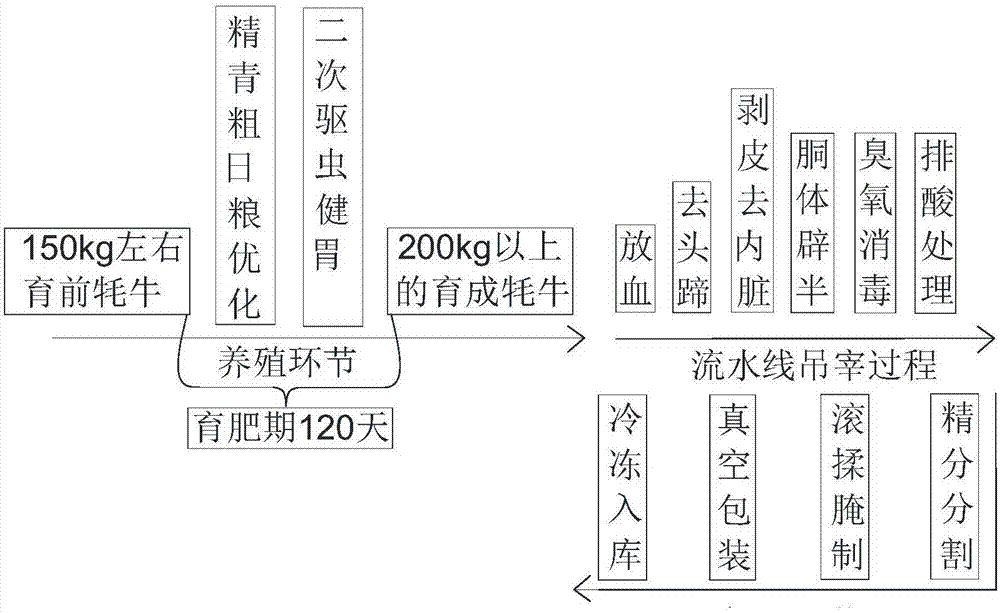

Yak steak meat production method

InactiveCN107980719AShorten the breeding cycleReduce secondary pollutionFodderElectric current slaughtering/stunningAnimal scienceFood material

The invention provides a yak steak meat production method which includes a breeding link, a slaughtering link and a processing link. In the breeding link, yaks at the age of 36-48 months before breeding are selected and bred, feed is firstly replaced to perform adaptive culture, strict refined, green and coarse daily ration schemes are formulated to perform optimal culture after the yaks before breeding adapt to the feed, and three parasite expelling and stomach invigorating processes are performed. In the slaughtering link, the yaks are slaughtered by an assembly line lifting and slaughteringprocess to obtain beef carcasses. In the processing link, the beef carcasses are sequentially finely segmented, rolled, rubbed, pickled, subjected to vacuum packaging, frozen and put in storage. Yakbreeding technology is optimized and matched with the slaughtering link and the processing link, produced yak meat is tender in meat quality and silky in taste, fillets of the yak meat can be used formaking high-end steak, and leg meat of the yak meat can also be used for making high-end steak, so that food materials of the high-end steak are richer.

Owner:李志鹏

Cleaning device for beef processing

InactiveCN110947674AEasy to cleanImprove water qualityCleaning using liquidsCarcasses disinfectionElectric machineryEnvironmental engineering

The invention discloses a cleaning device for beef processing. The cleaning device comprises a cleaning box, a sewage discharge pipe and a box cover, the sewage discharge pipe is inserted into the position, close to the bottom end, of the side wall of the cleaning box, and the box cover is connected to the top end of the cleaning box through hinges. The inner bottom end of the cleaning box is in transmission connection with a stirring shaft through a first motor, a flow guide pipe and water spraying straight pipes are installed in the cleaning box, the interior of the cleaning box is detachably connected with hanging rods through a circular ring, a second motor is slidably inserted into the surface of the box cover, and a filter box is arranged on one side of the cleaning box. According tothe device, cut beef is suspended and fixed, the second motor is started to drive the circular ring to move circularly, meanwhile, a clear water pump is started, water is sprayed along the water spraying straight pipes and high-pressure nozzles from the interior and exterior of the beef, spraying cleaning is carried out, and blood and hair are removed. Water is added into the cleaning box, the beef is soaked and cleaned through the first motor and the stirring shaft, and the cleaning effect is improved. The filter box filters out the hair in the cleaning process, and the cleanliness of cleaning liquid is improved.

Owner:安徽匠桥财务咨询服务有限公司

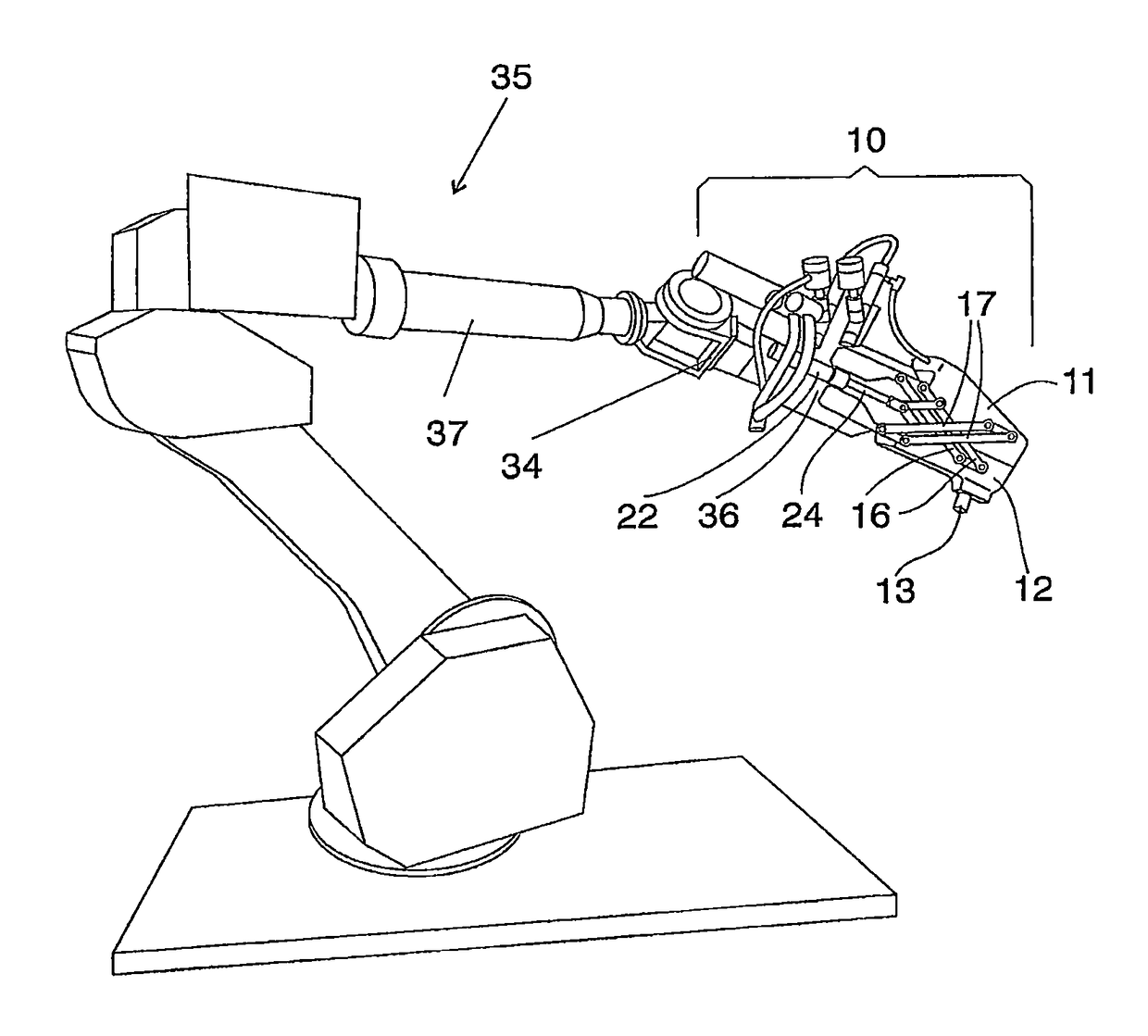

Device for cleaning and for processing the rectum and pelvis of slaughtered pigs and operating method of said device

The invention relates to a device for cleaning and processing the rectum and pelvis of slaughtered pigs, that is mainly mechanical in nature, and its operating method and that it solves the problem of the cleaning and disinfection operations of these devices, basically of the blades and the mandrel which are inserted into the animal's rectum, this invention carries out these operations in a single operation, which allows it to successively in about 2 to 3 seconds enter the animal's rectum, cut it out and make an incision in the animal's pelvis and then simultaneously clean and sterilize by incorporating into the device a semi-enclosed chamber in which this cleaning takes place.

Owner:INNOVATIVE FOOD ROBOTICS BANSS & AIRA

Highly bacteriocidal chlorine dioxide, formulation, preparation and use thereof

InactiveUS20100003910A1Easy to controlEfficient ConcentrationFish washing/descalingMeat processing plantsChlorine dioxideBiocide

When used as a biocide on newly butchered chickens, chlorine dioxide at concentrations of 12 to 50 ppm is effective at temperatures of 35° C. to 90° C. with 15 ppm being very effective at temperatures of 45° C. to 60° C. Chlorine dioxide in about 50° C. water did not off gas chlorine dioxide at a concentration of 50 ppm.

Owner:BALLINGER KENNETH E

Methods and compositions for the reduction of pathogenic microorganisms from meat and poultry carcasses, trim and offal

InactiveUS20110200685A1Maximize activationBiocidePoultry cleaning/disinfectionMicroorganismHypochlorite

The invention includes a method of preparing hypochlorite-activated solutions of hypobromous acid and / or hypobromite ion. The method includes the steps of mixing a solution of a source of bromide ion with a solution of a source of hypochlorite ion to activate the bromide ion, allowing sufficient time to maximize the activation of the bromide ion, and storing the solution before use. The invention also includes a method of using the solution to wash meat and poultry carcasses, trim, and offal to reduce pathogenic microorganisms. The solutions may also be used to reduce pathogenic microorganisms in industrial cooling water and on food contact hard surfaces and equipment. The solutions may be stored for up to about three hours before use and are stable for that period of time.

Owner:HARVEY MICHAEL S +2

Ozone-based conveyor cleaning system

A conveyor cleaning system includes a treating region, a processing region, and a conveyor belt traveling from the treating region to the processing region. A distributor positioned across the treating region deposits a film of ozonated water on the conveyor belt. In the processing region, the conveyor belt is exposed to soiling agents such as grease and other animal matter. A high-pressure rinser may be positioned over the treating section such that the distributor is positioned between the high-pressure rinser and the processing region. Ozonated water may be generated by a system including first and second tanks. The first tank is filled with ozone gas and water. After a predetermined time, undissolved ozone gas is released. The contents of the first tank are then transferred to a second tank along with more ozone gas. After waiting a predetermined time period, undissolved ozone gas is released from the second tank.

Owner:OZONE INT

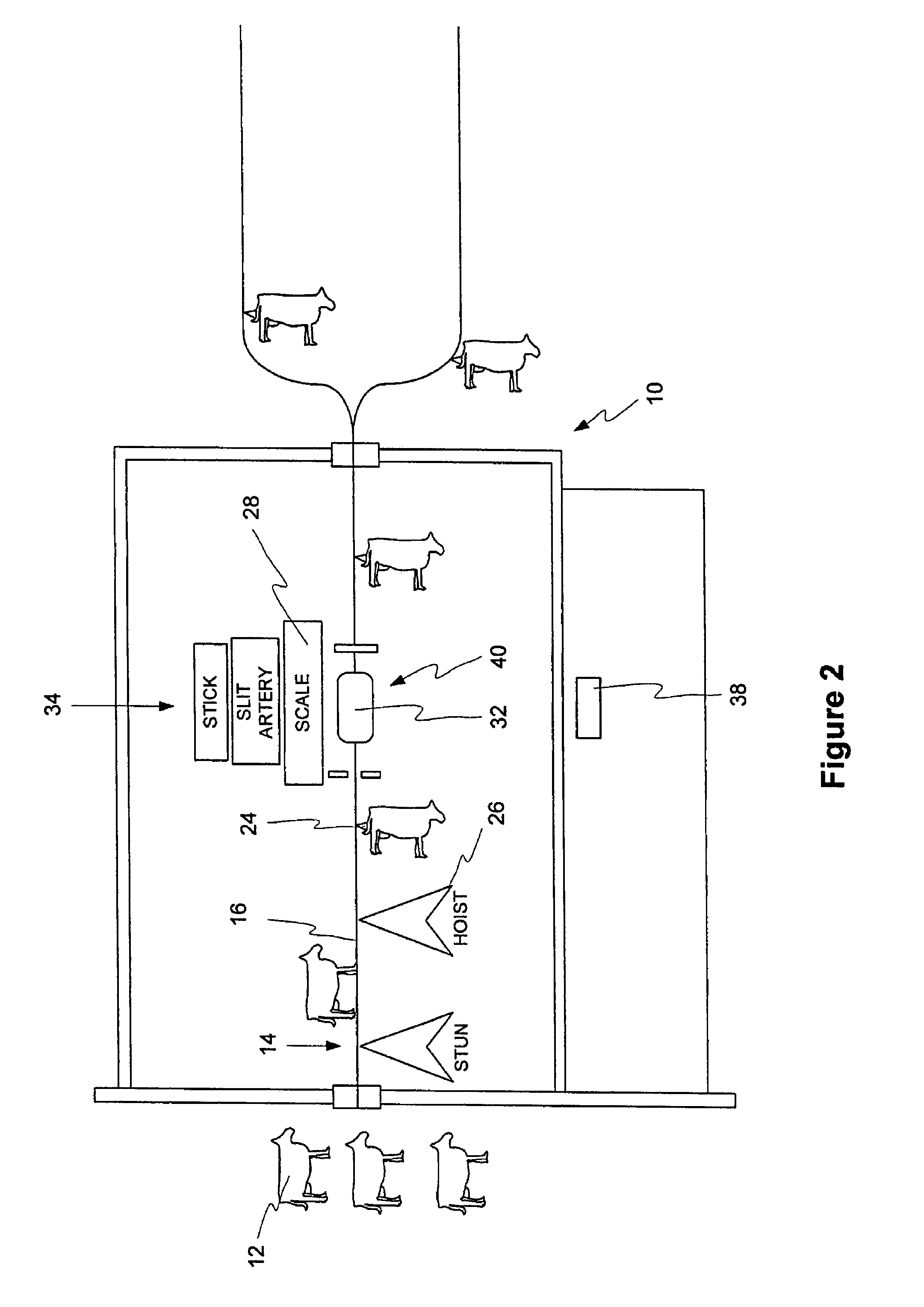

Method and apparatus for processing animals

ActiveUS20070197154A1Significant processing efficiencyImprove efficiencyBlood collection/stirring apparatusSlaughtering/stunningEngineeringWorkstation

The present invention provides a method for processing animals. The method includes providing a carrier for holding a plurality of animals; providing a multi-task station; locating an animal on at least part of the carrier at the multi-task station; weighing the animal at the multi-task station; providing a volume of rinse solution for introduction into the circulatory system of the animal, wherein the volume of rinse solution is based on the weight of the animal; and initiating a rinse of the animal prior to weighing a subsequent animal at the multi-task station. The invention also provides an animal processing system and a multi-task Station suitable for use in accordance with the method.

Owner:MPSC INC

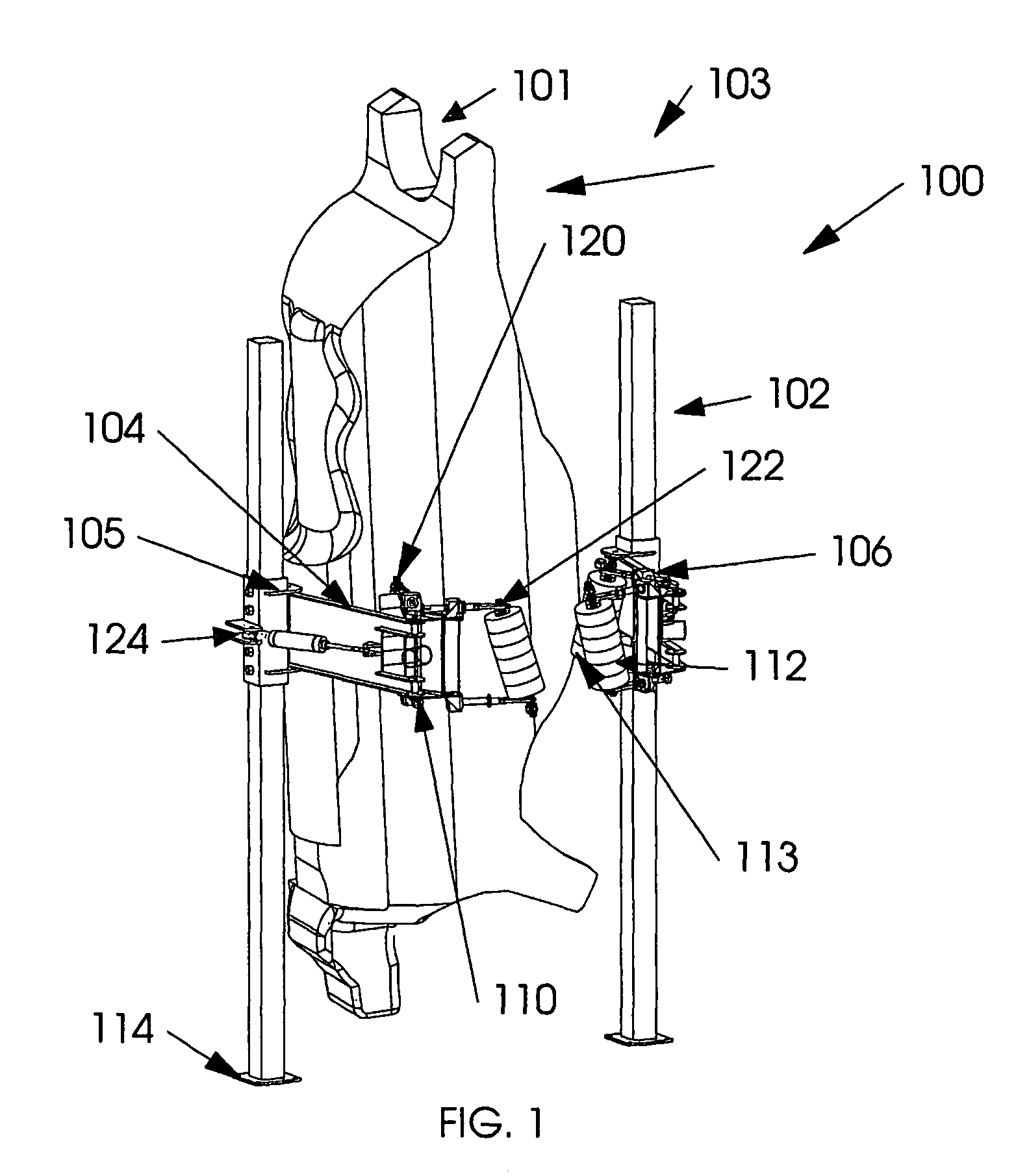

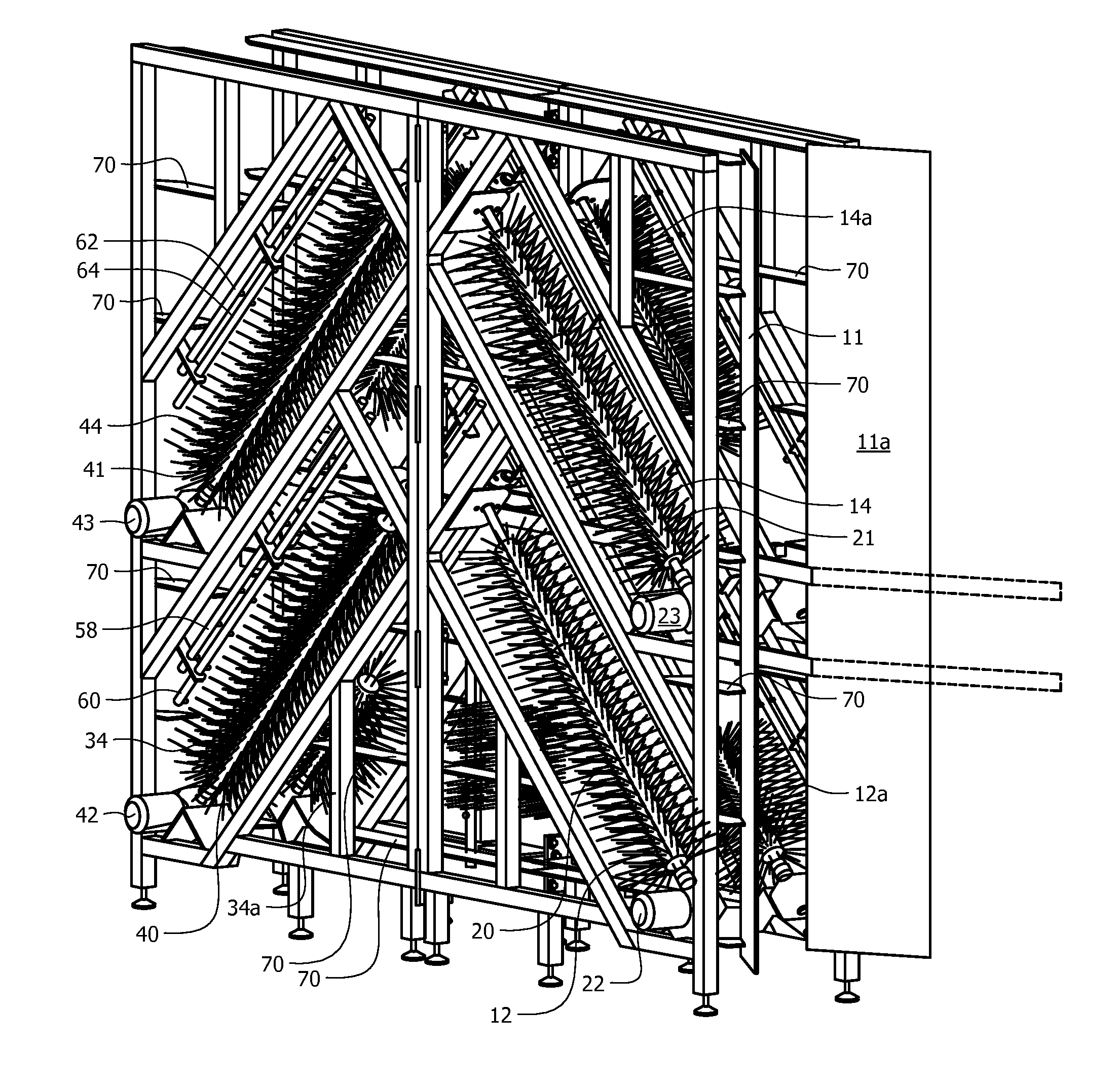

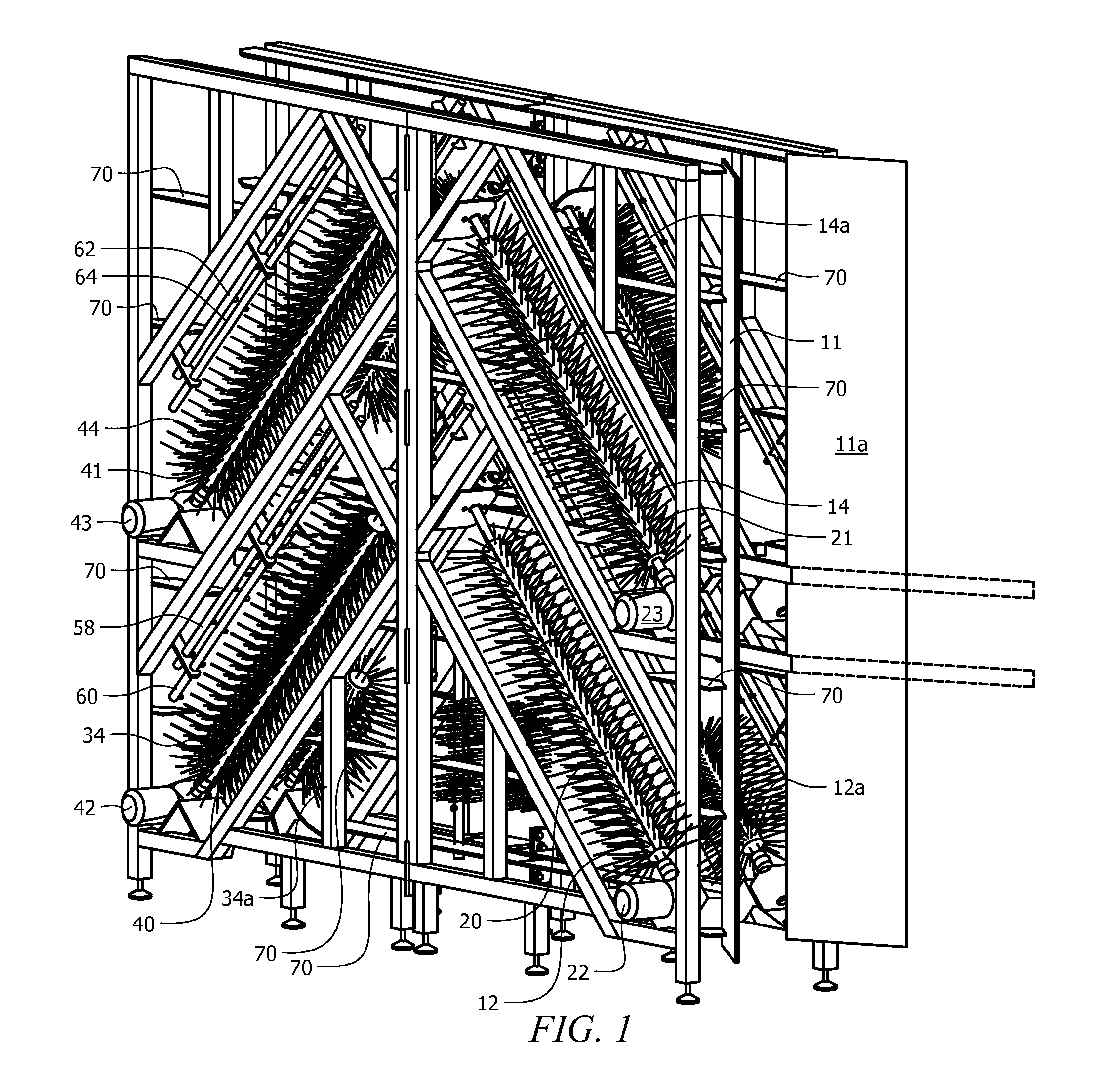

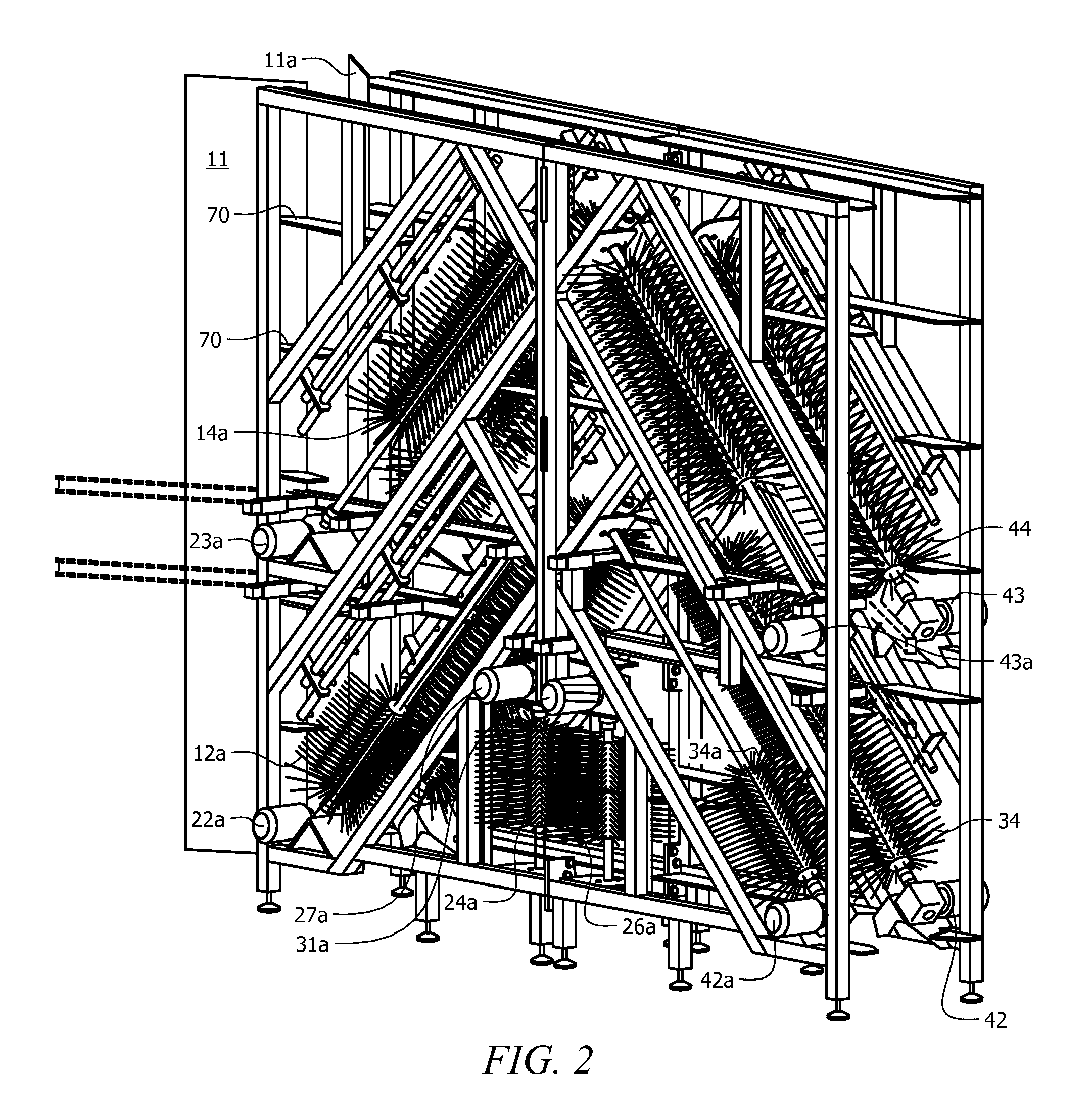

Split carcass washer

An apparatus for washing a split animal carcass includes upper and lower pairs of upwardly inclined brushes, leading and trailing vertical brushes, and upper and lower pairs of downwardly inclined brushes. The upwardly inclined brushes are transversely spaced apart from one another to accommodate an animal carcass between them, as are the downwardly inclined brushes. First and second fluid headers are positioned in parallel relation to each inclined brush and three fluid headers are associated with the vertical brushes. The first inclined fluid headers have nozzles aimed at the carcass and the second inclined fluid headers have nozzles aimed at the brushes. Two of the vertical brush fluid headers are aimed at the vertical brushes and the third fluid header is aimed at the carcass.

Owner:SANITATION CHEM DISPENSING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com